Patents

Literature

131results about "Dissolving using flow mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

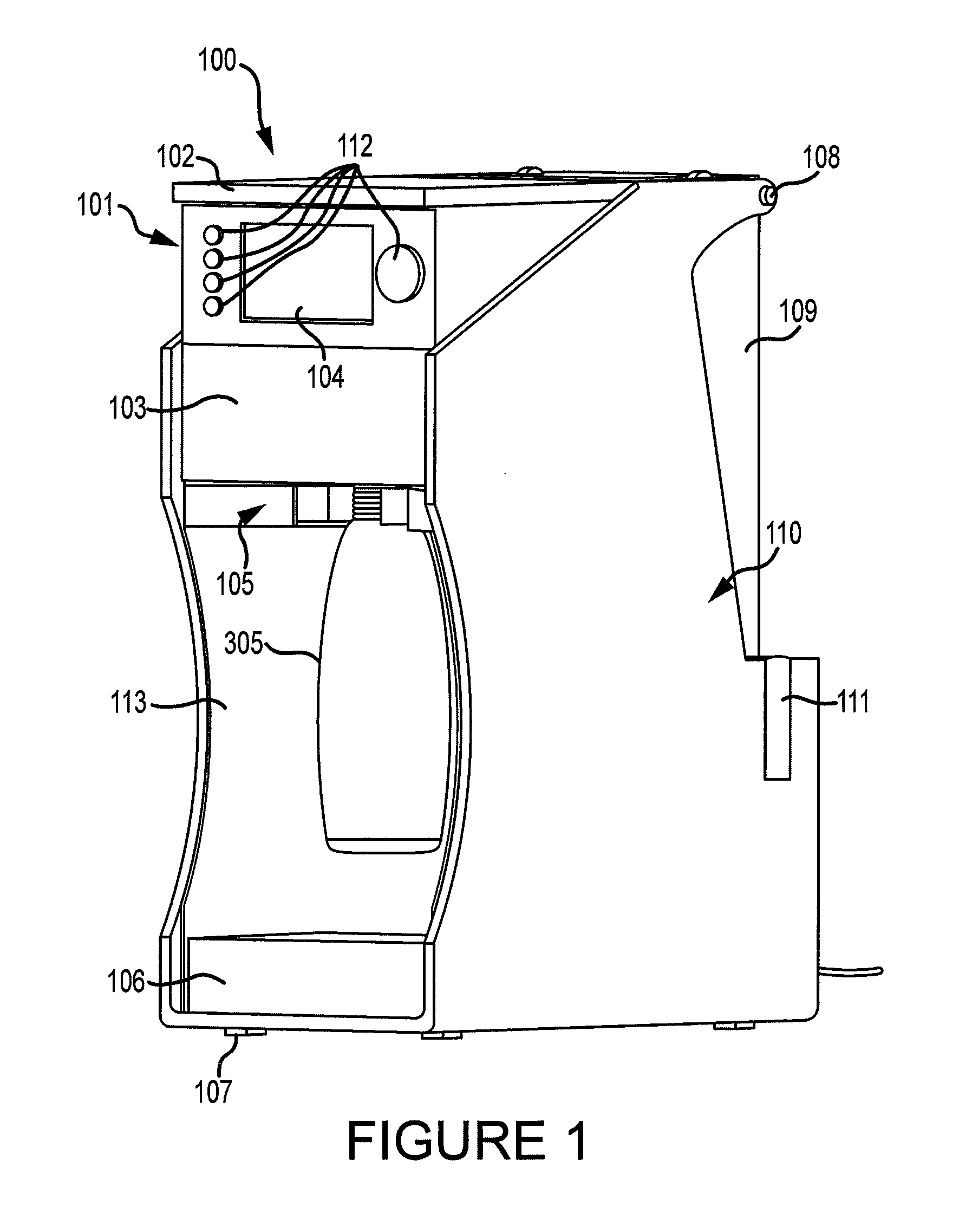

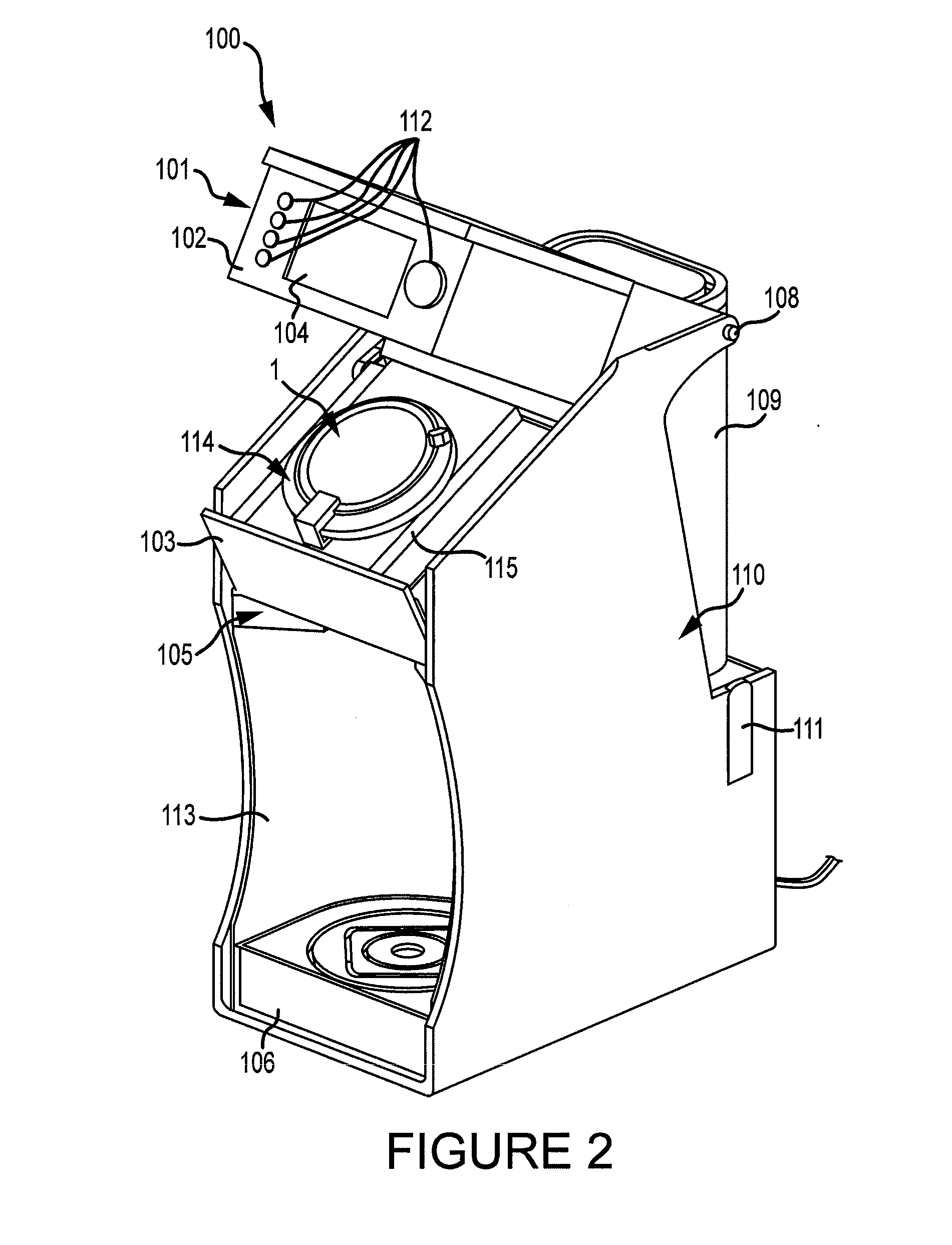

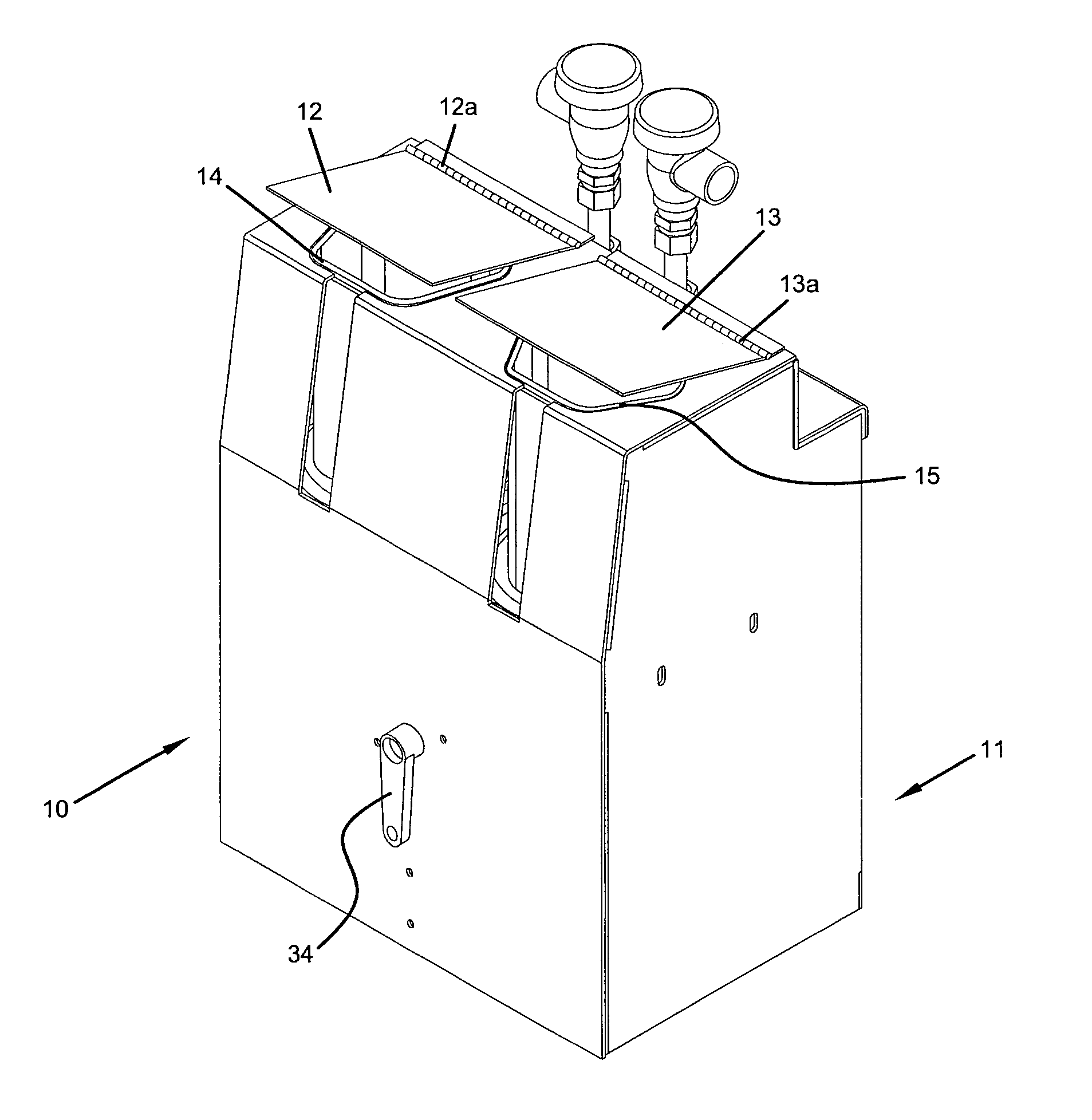

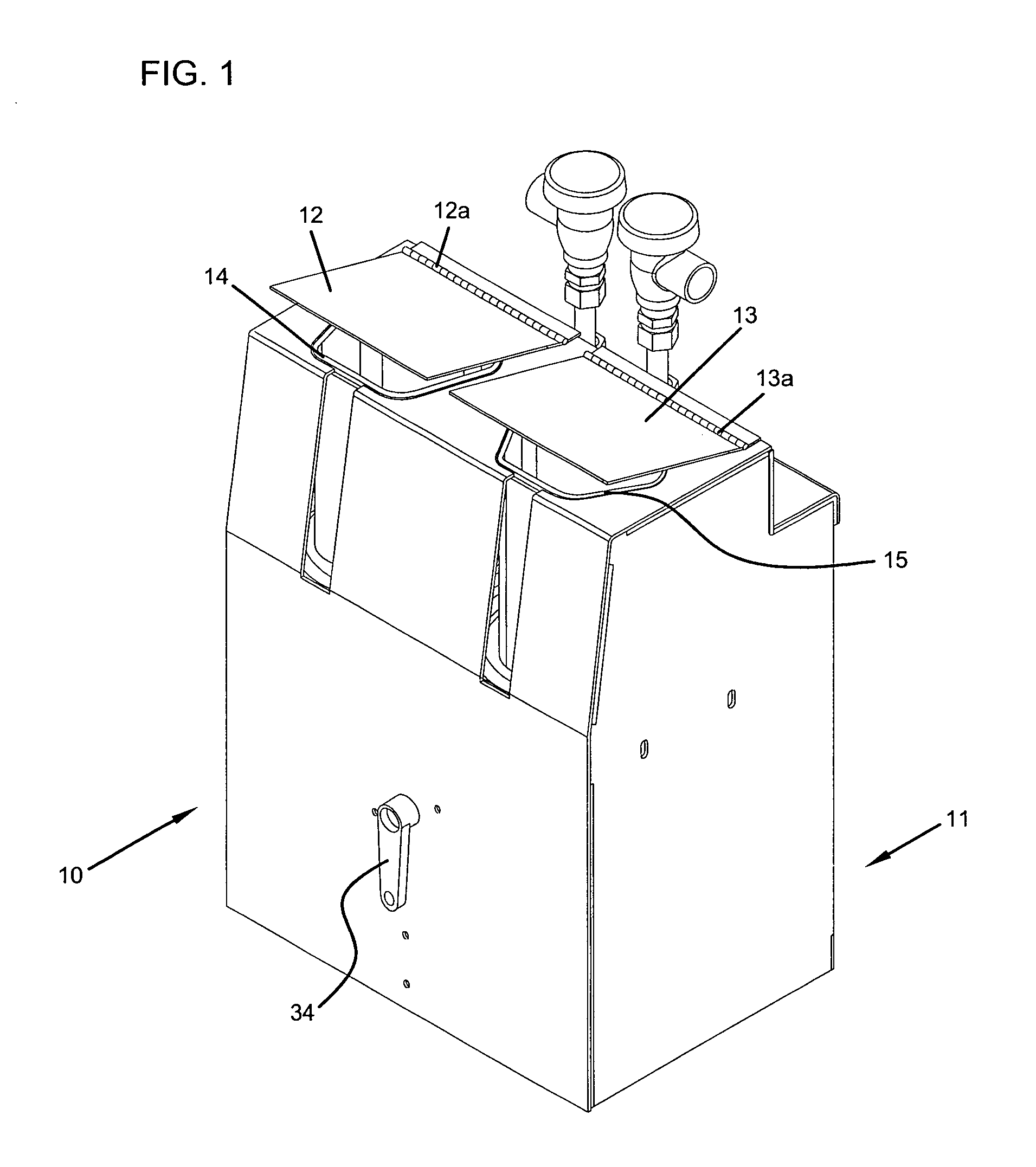

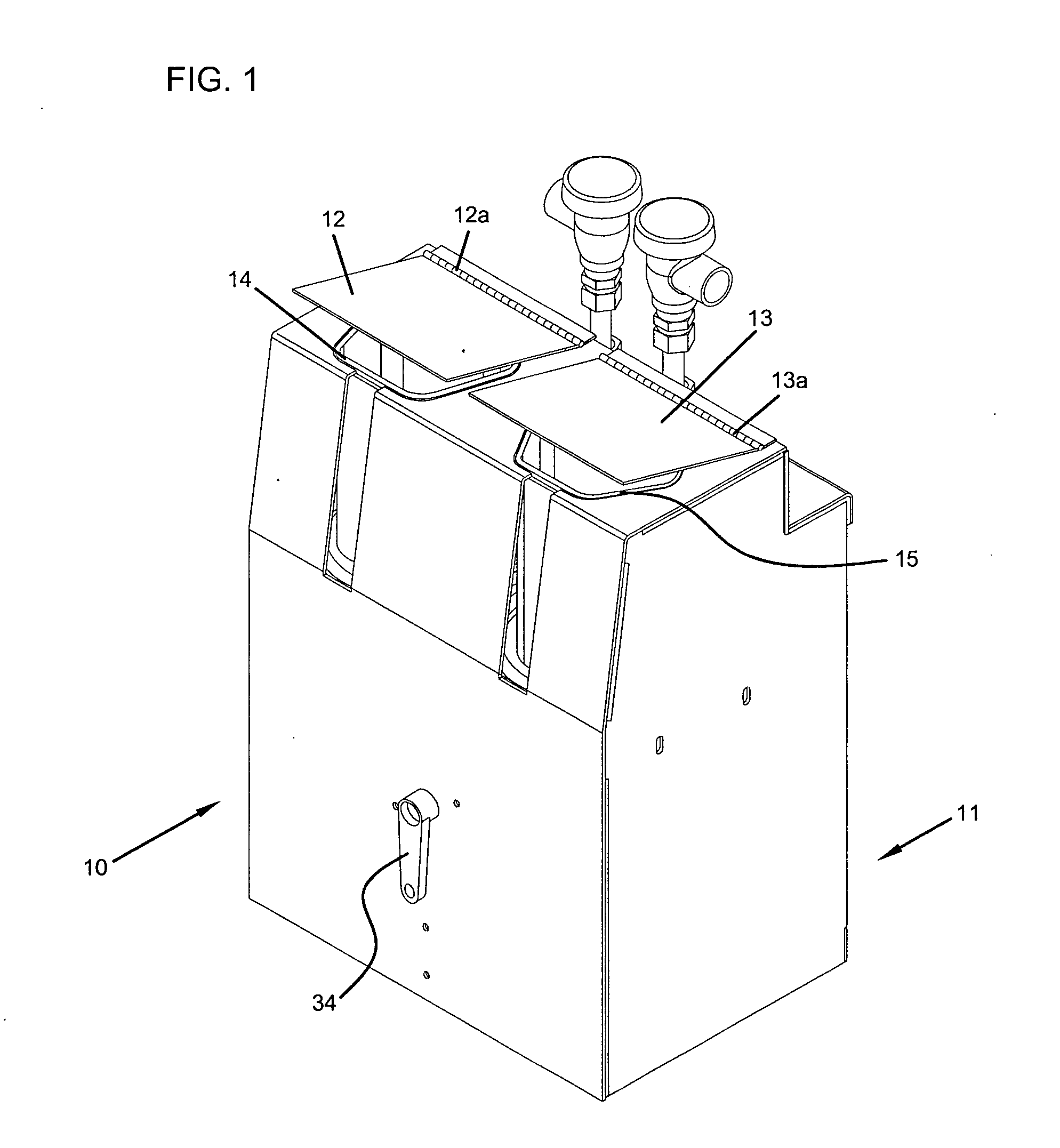

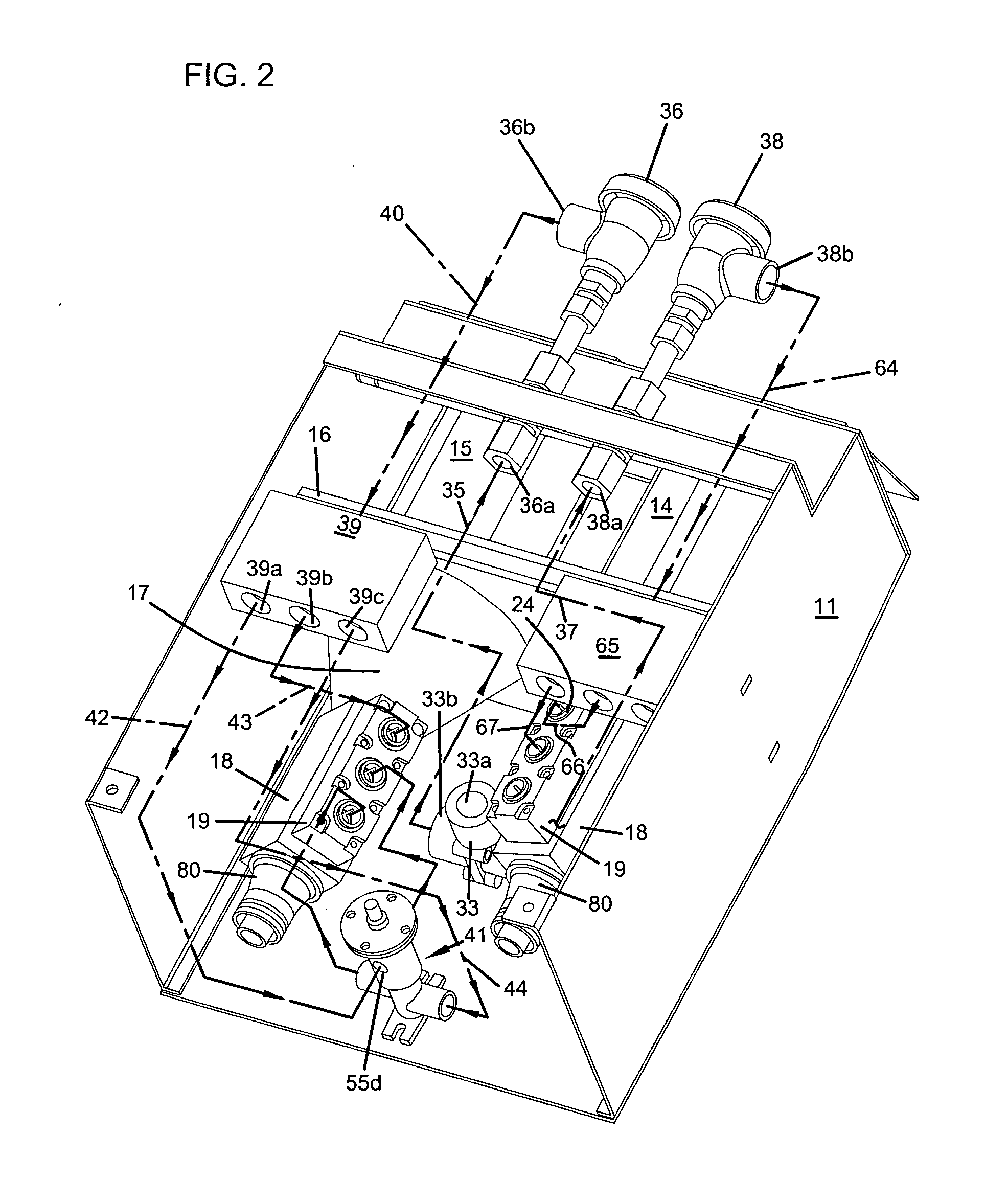

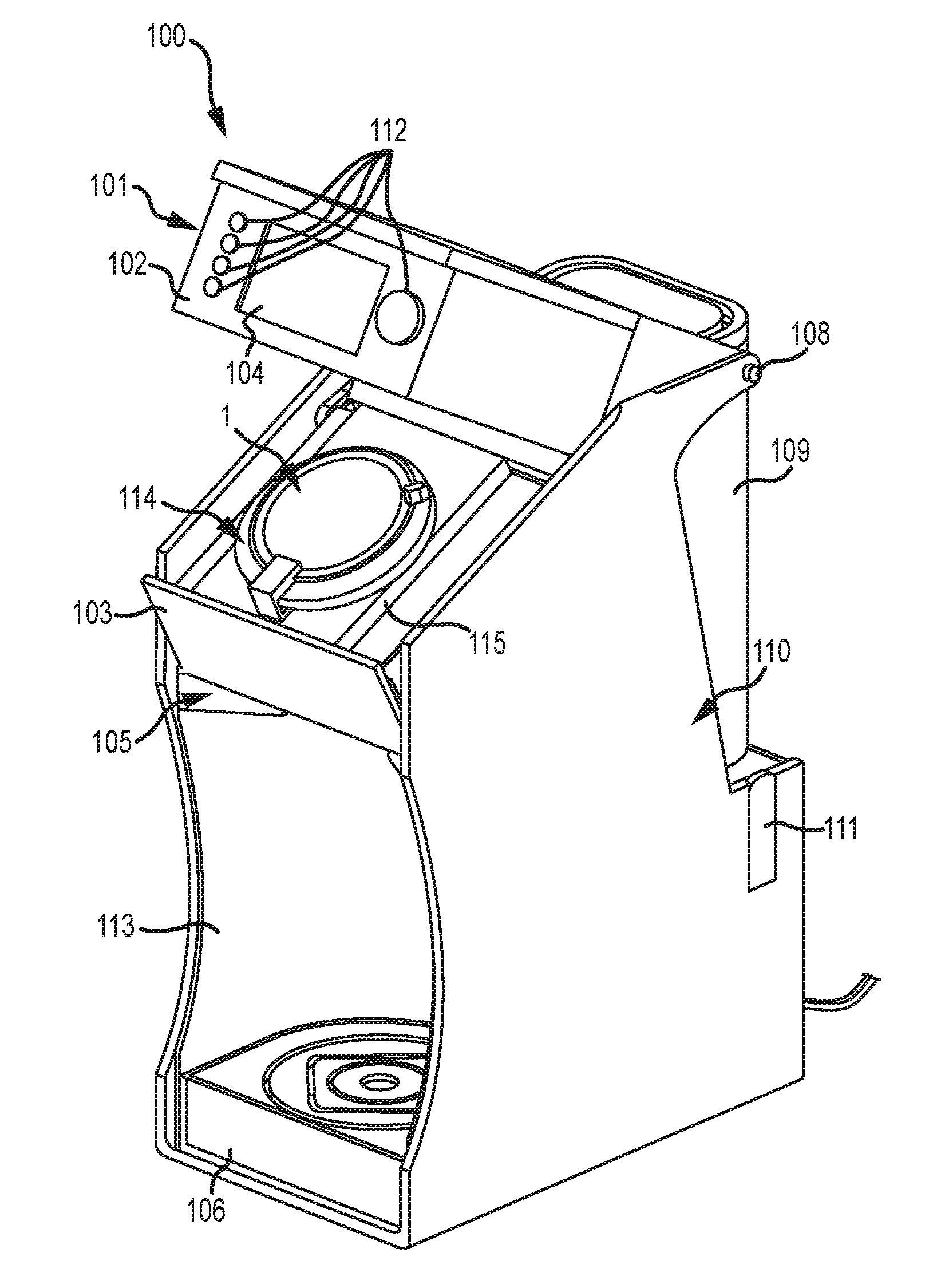

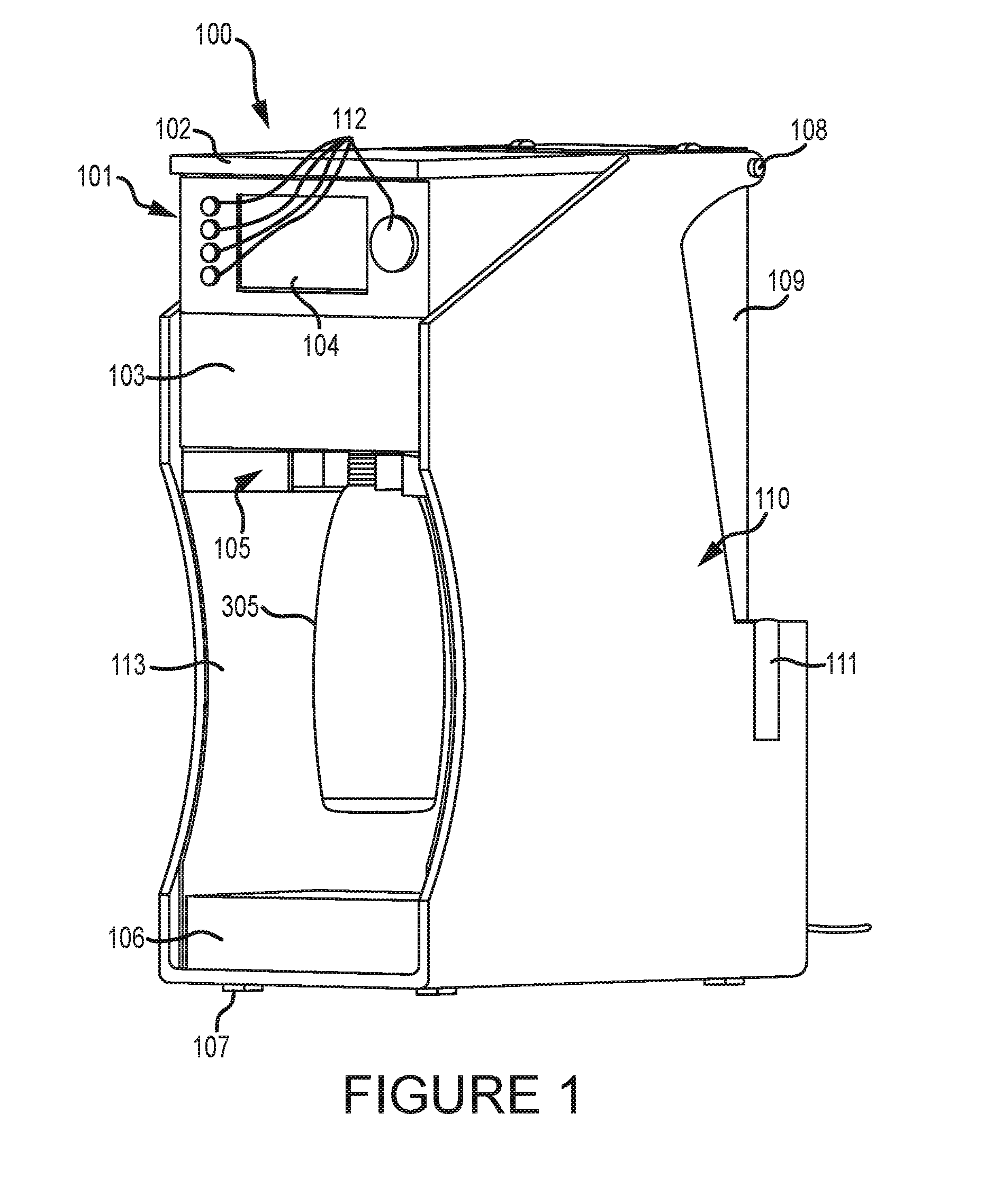

Apparatus and method for preparing a liquid mixture

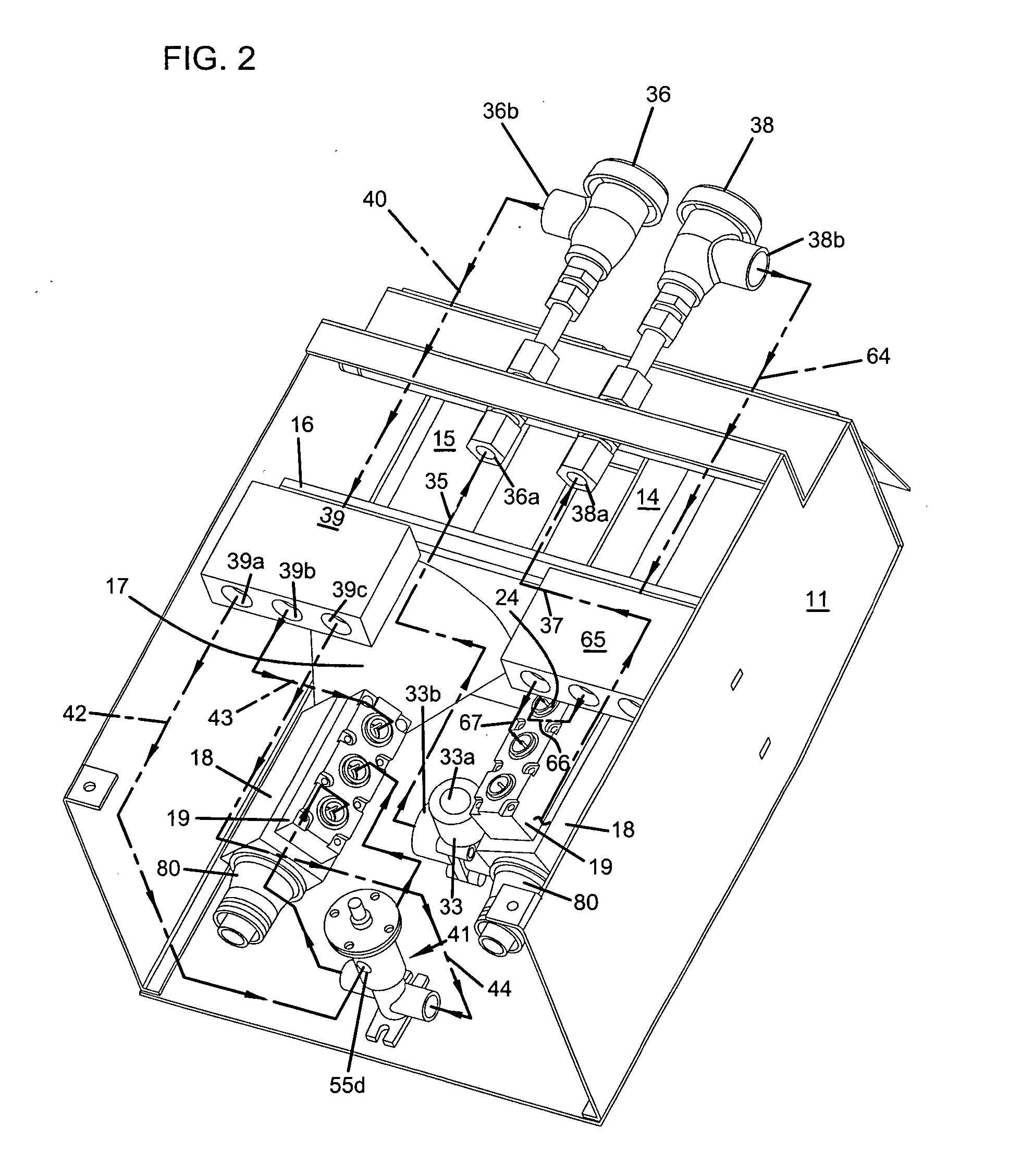

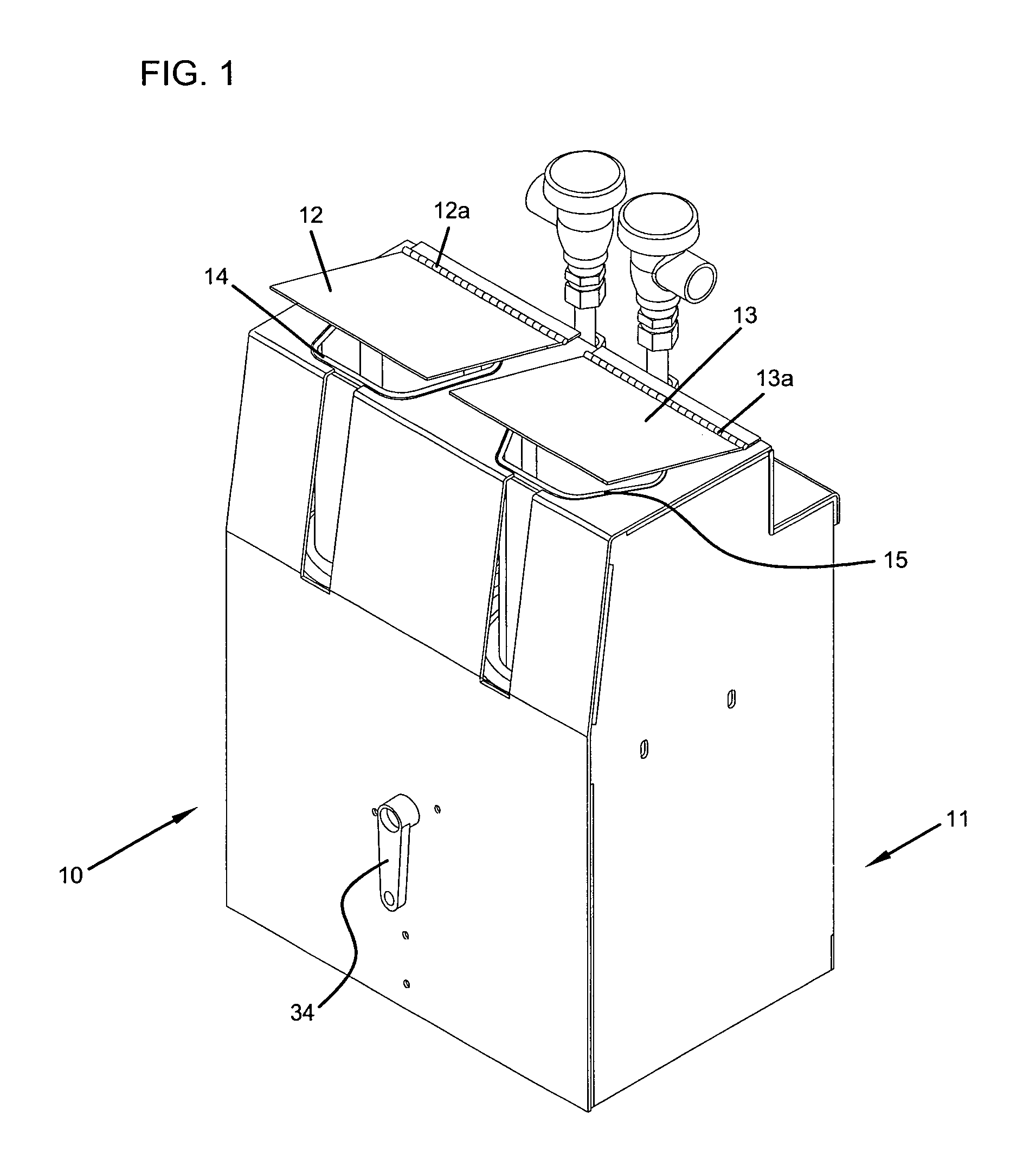

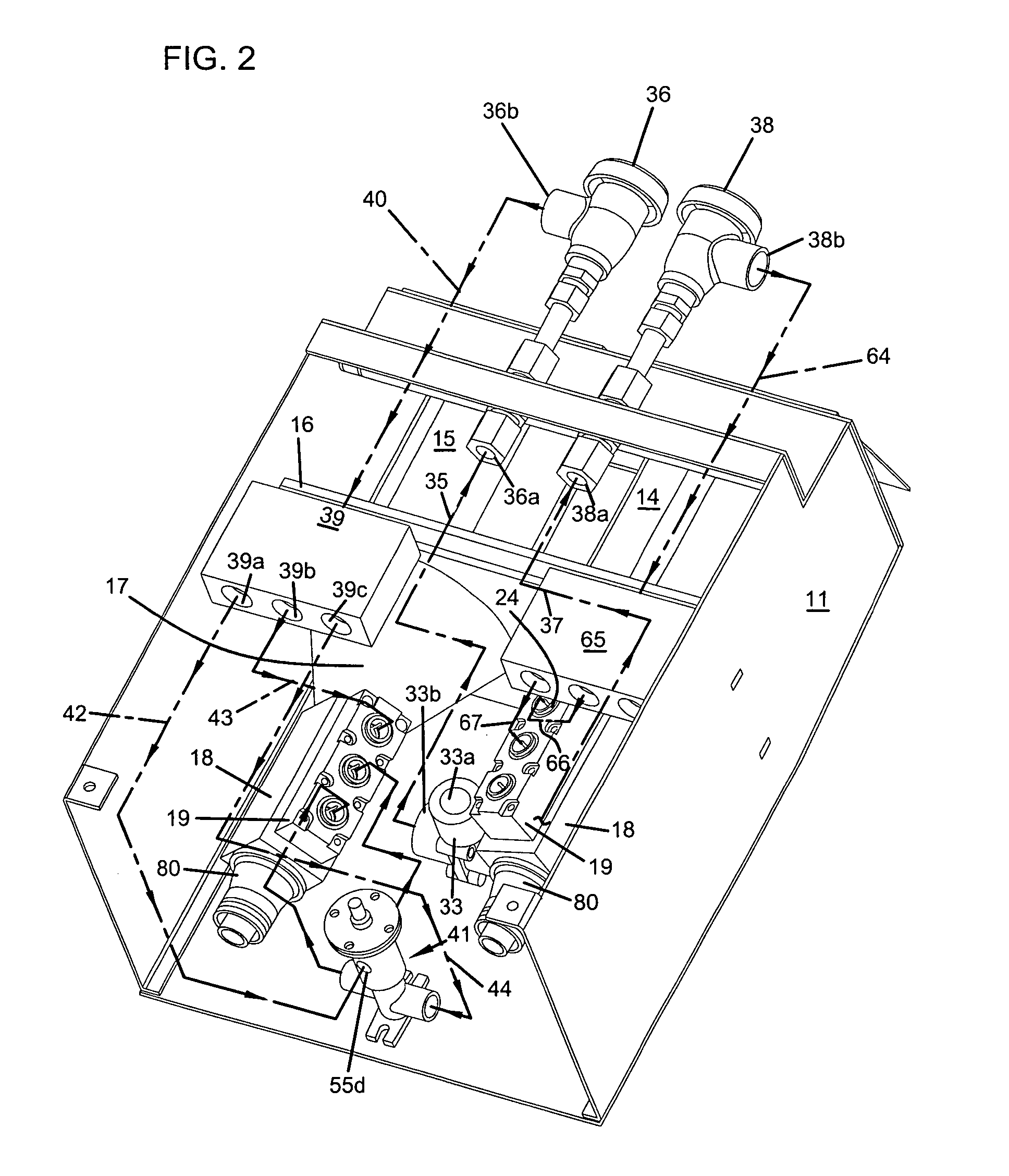

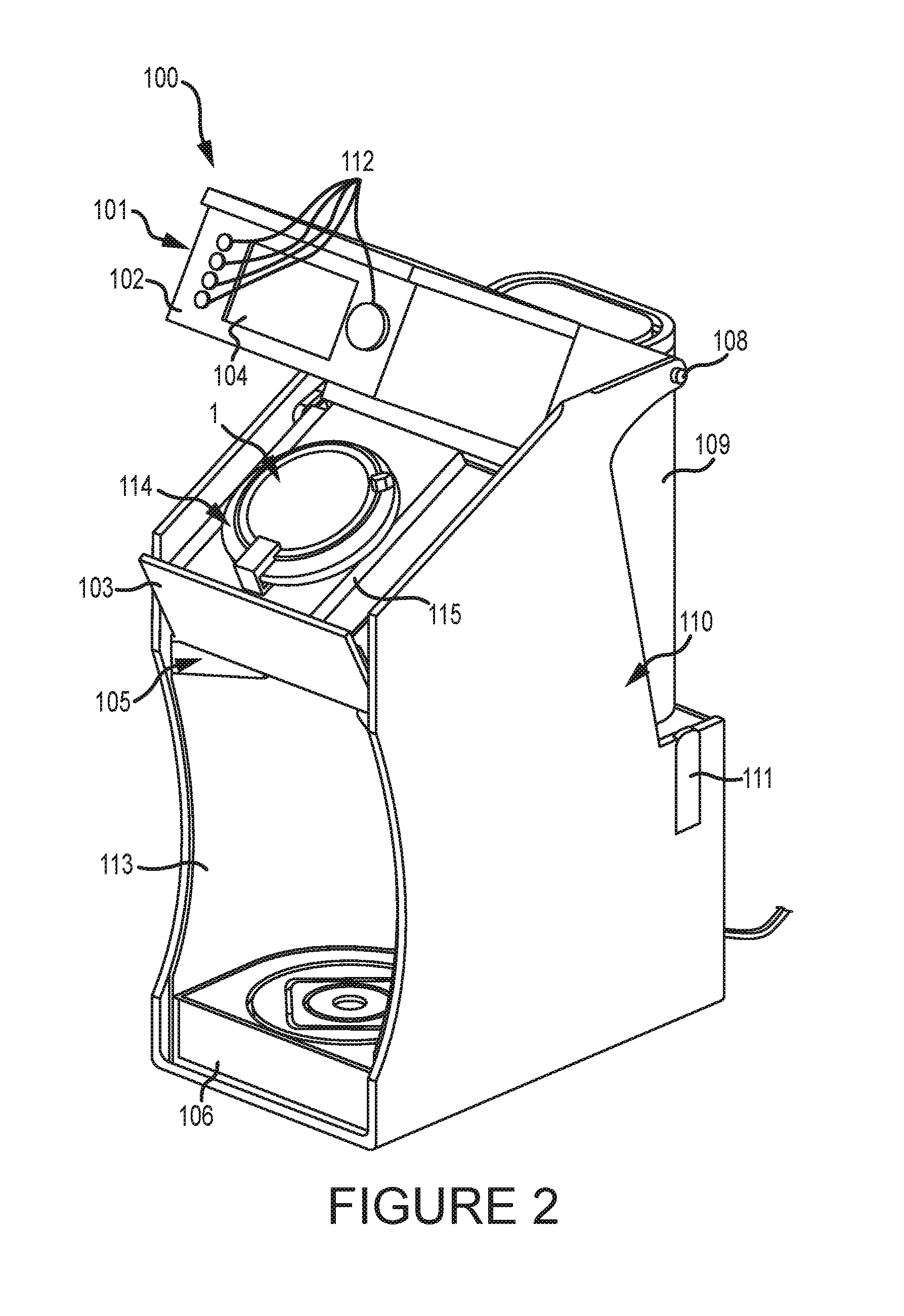

A mixing apparatus, puncturing mechanism, and cartridge are disclosed. The mixing apparatus has a housing and a drawer with a recess. Corresponding cartridges may be inserted into the drawer and slid into the housing to facilitate mixing a liquid with contents of the cartridge. The liquid may originate from a reservoir in the mixing apparatus or a direct line. Also inside the housing of the mixing apparatus is the puncturing mechanism. The puncturing mechanism has a nozzle configured to puncture a lid of a cartridge and inject liquid to mix with the contents of the cartridge. The puncturing mechanism is further configured to drive an internal puncturing unit inside of the cartridge through a lower portion of the cartridge to allow liquid from the nozzle and contents of the cartridge to be dispensed into a receptacle.

Owner:FORMULANOW

Method and basket apparatus for transporting biological samples

InactiveUS6899850B2Effective treatmentPromote recoveryBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

A container assembly for storing and stabilizing a biological sample includes a container, a closure cap and a sample holder coupled to the closure cap and removably received in the container. The sample holder can be a basket-like device coupled to an inner face of the cap and includes a central cavity for receiving the sample and immersing the sample in the reagent in the container. The closure cap includes a body member with a dimension to displace a volume of air and reduce the head space to ensure that the sample holder is completely immersed in the reagent. The sample holder has a closure member for closing the open top end of the cavity.

Owner:BECTON DICKINSON & CO

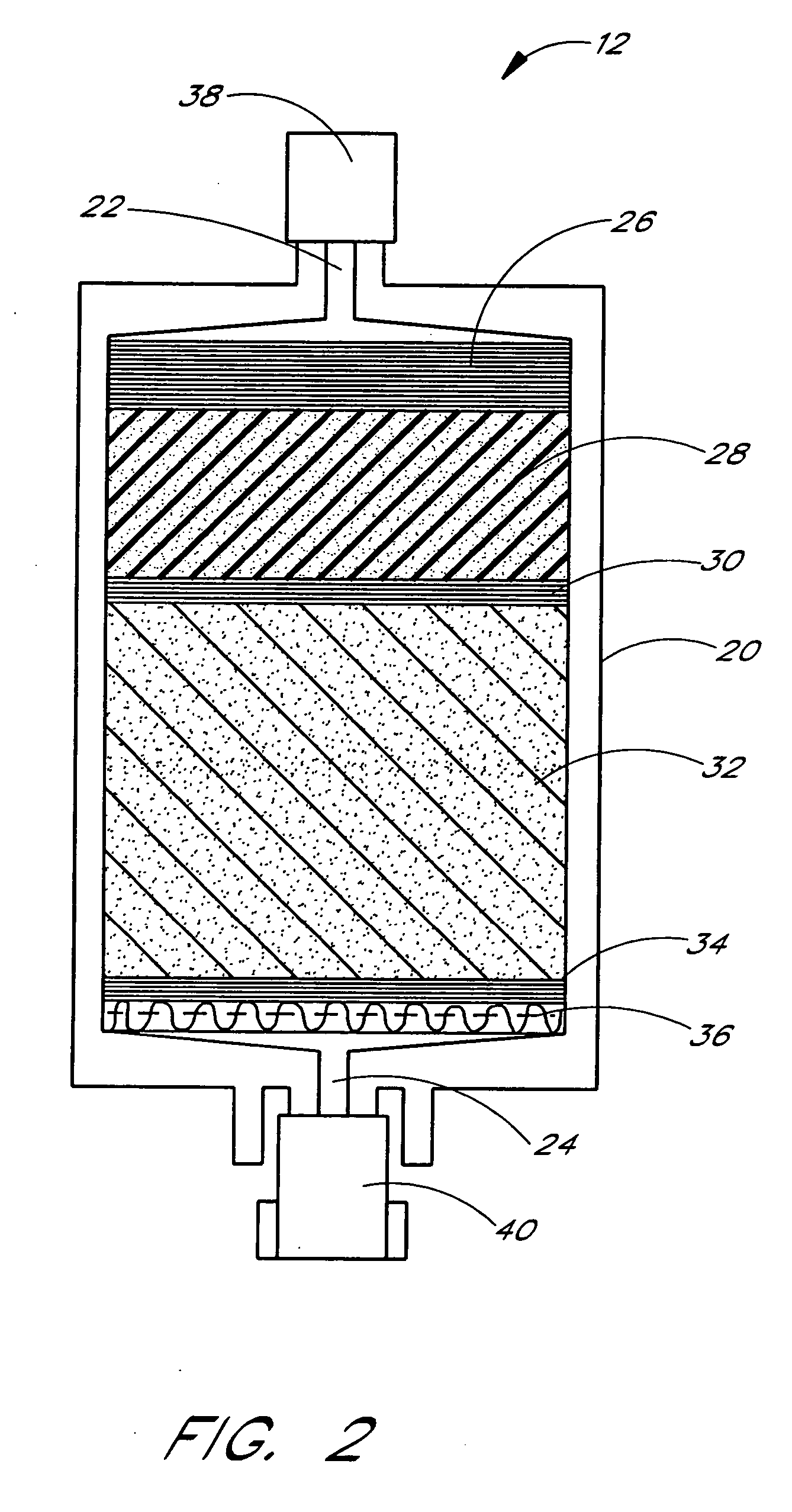

Water purification pack

InactiveUS20050113796A1General water supply conservationTransportation and packagingHuman bodyQuality level

An apparatus and methods are disclosed for purifying fluid, such as potable water, to quality levels suitable for medical application, particularly to applications involving injection of the fluid into a human body. The apparatus comprises a portable purification pack constructed for a single use. The pack houses depth filtration, activated carbon, mixed bed ion exchange resins and terminal filtration stages in series. The terminal filter comprises a fine (microfiltration or ultrafiltration), permeable membrane, treated with an endotoxin-binding chemistry. In contrast with semi-permeable osmotic membranes, the permeable membrane produces high flow rates at relatively low pressures, while still safely purifying fluid to injection quality.

Owner:TAYLOR MICHAEL A

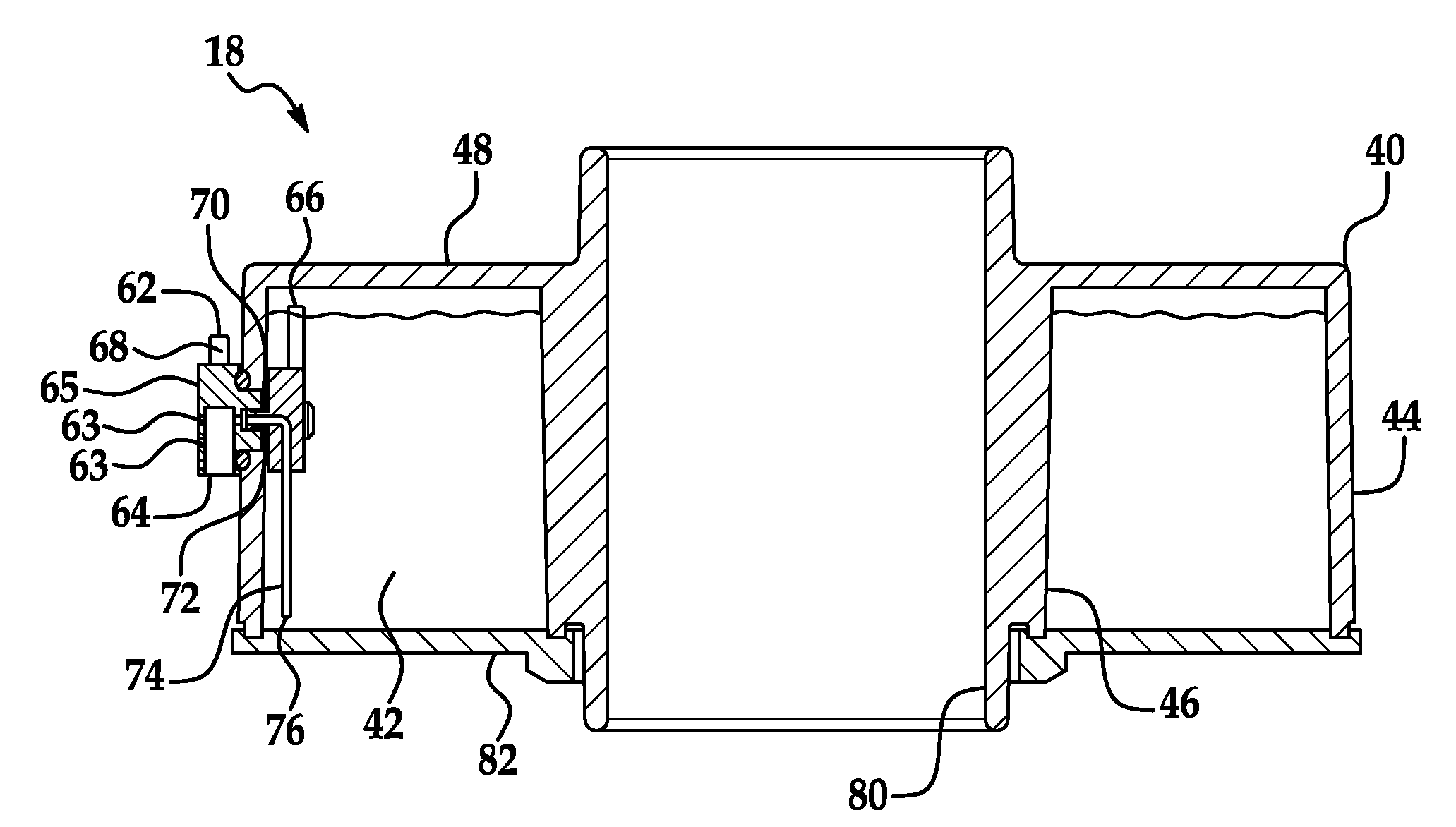

Slow release coolant filter

InactiveUSRE37369E1Transportation and packagingSolid sorbent liquid separationEngineeringCooling fluid

A coolant filter for use in filtering a coolant solution which flows through the coolant filter includes a filter housing assembly which is made up of an outer housing which is crimped to a nutplate which defines an internally threaded flow outlet. A generally cylindrical filter element is positioned inside of the filter housing assembly and a first endplate is bonded to the end of the filter element which is adjacent to the nutplate. An endplate member is provided for attachment to the opposite end of the filter element and is configured in such a way so as to define an interior chamber where supplemental coolant additive pellets are stored. A closing plate is applied across the open end of the interior chamber so as to create an enclosed chamber for the supplemental coolant additive pellets. A slow release mechanism is provided for controlling the rate of release of the supplemental coolant additive from the enclosed chamber into the coolant solution. In one embodiment of the present invention, the slow release mechanism includes a diffusion tube which defines a diffusion orifice. In another embodiment of the present invention, the slow release mechanism includes a semipermeable (or osmotic) membrane wafer. In both instances, the slow release mechanism is positioned between the source of supplemental coolant additive and the flow outlet in the nutplate.

Owner:FLEETGUARD INC

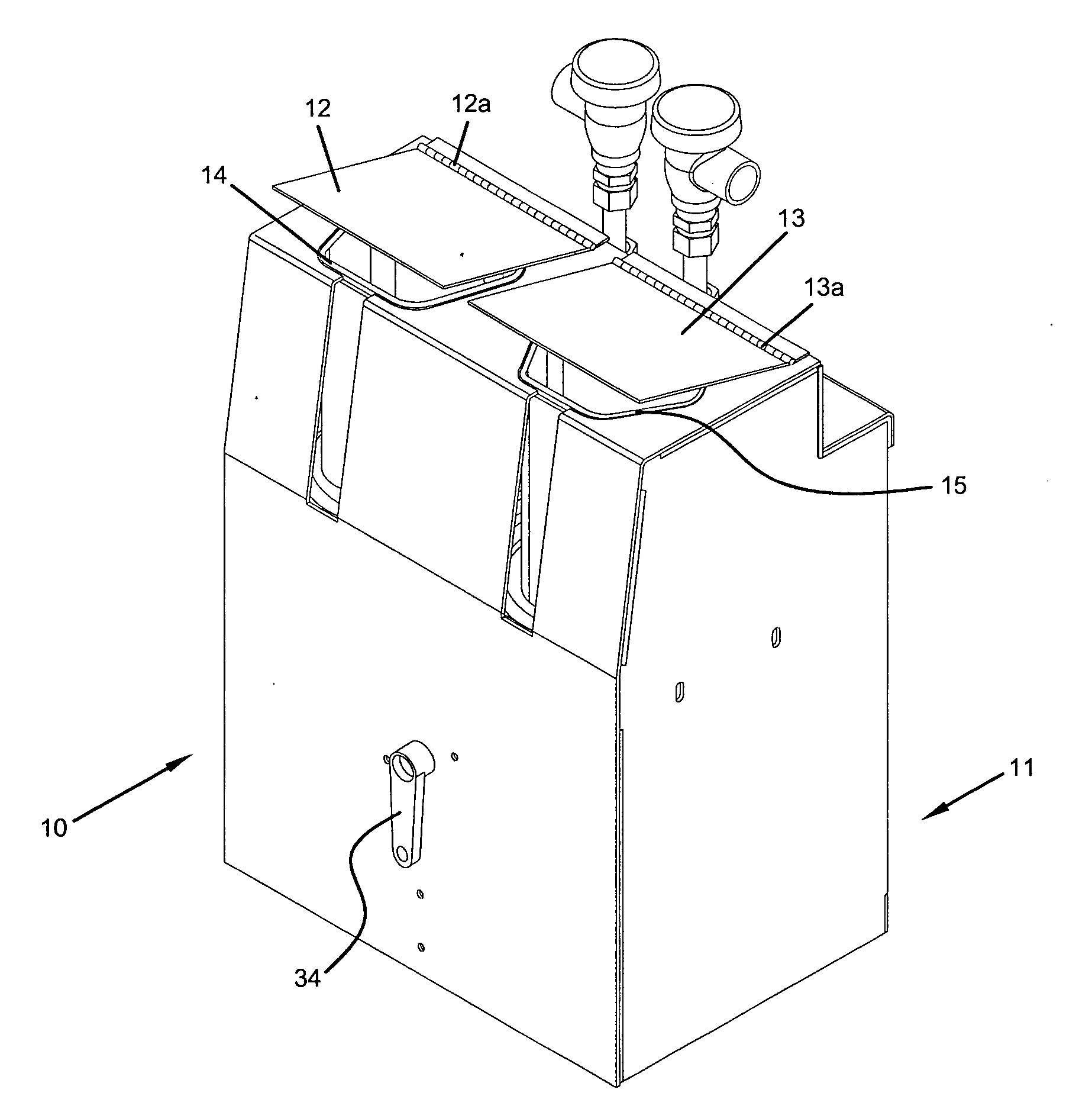

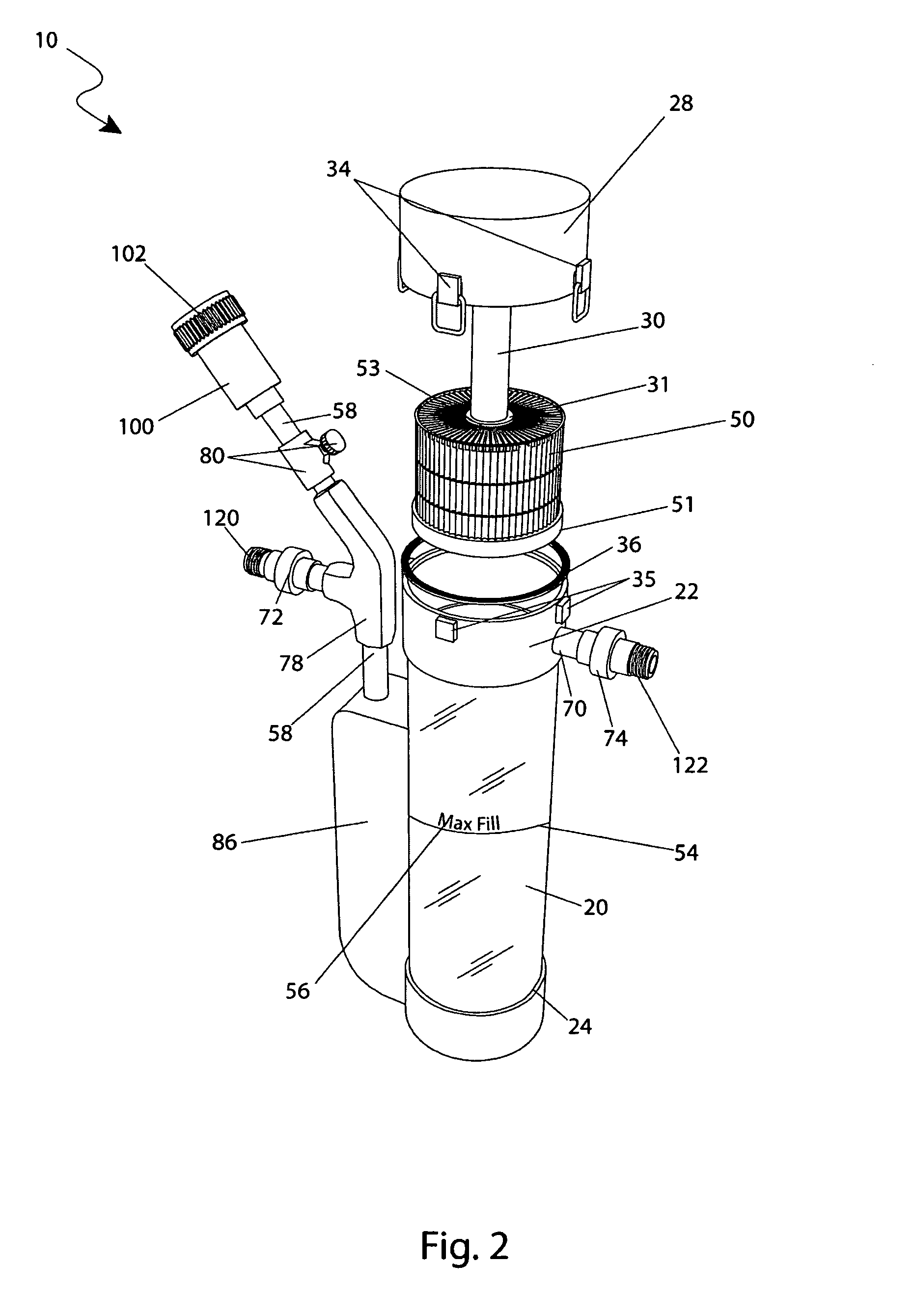

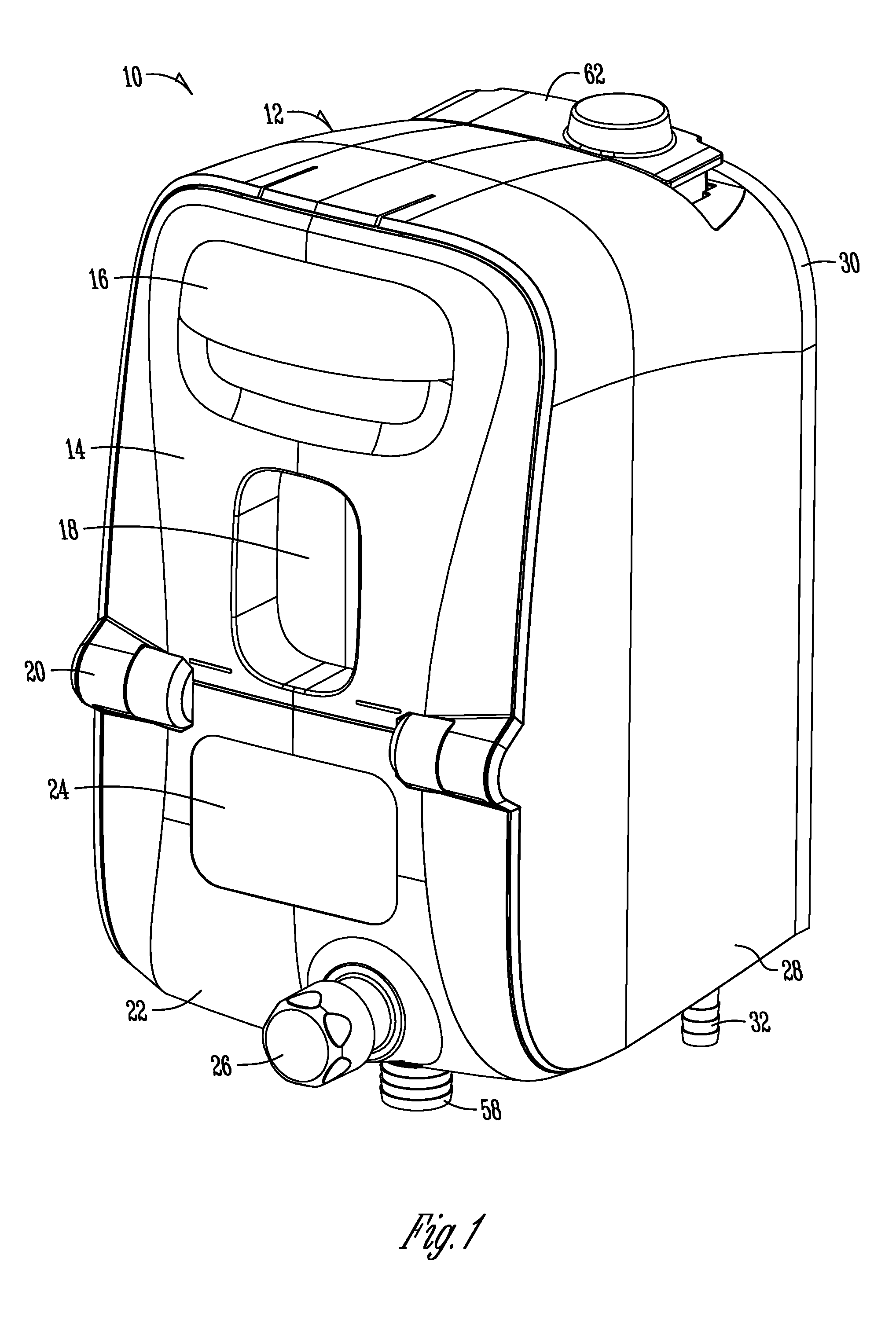

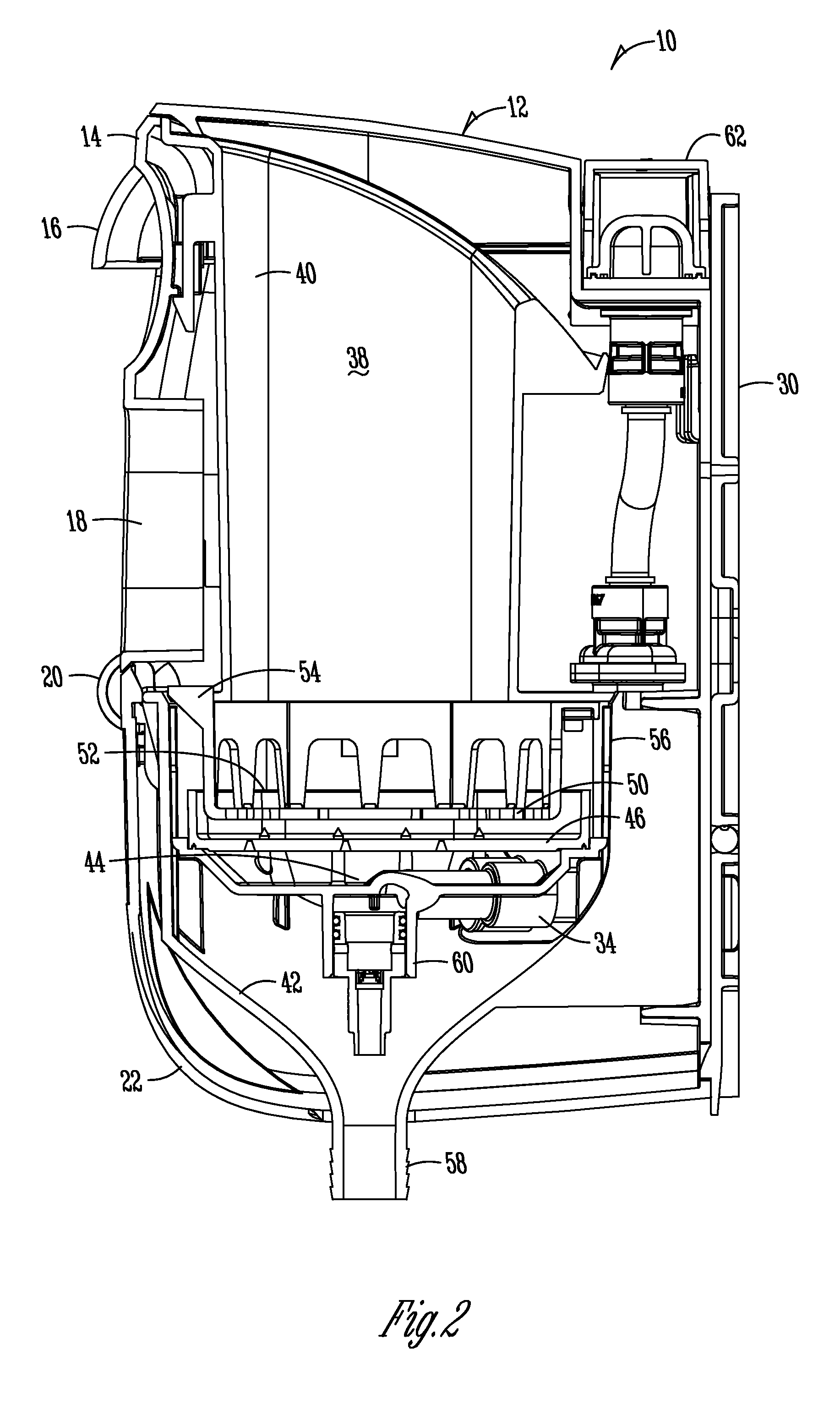

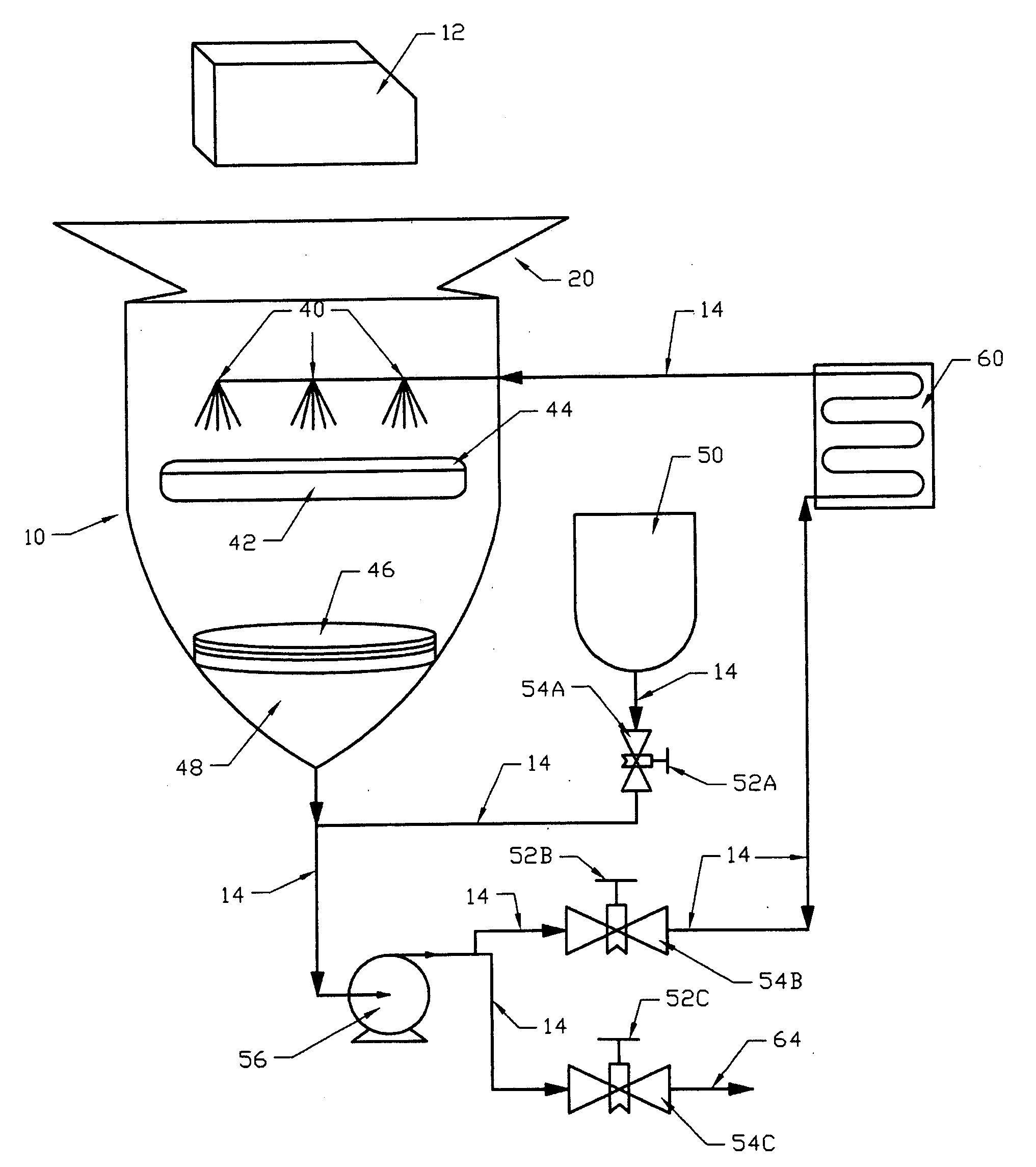

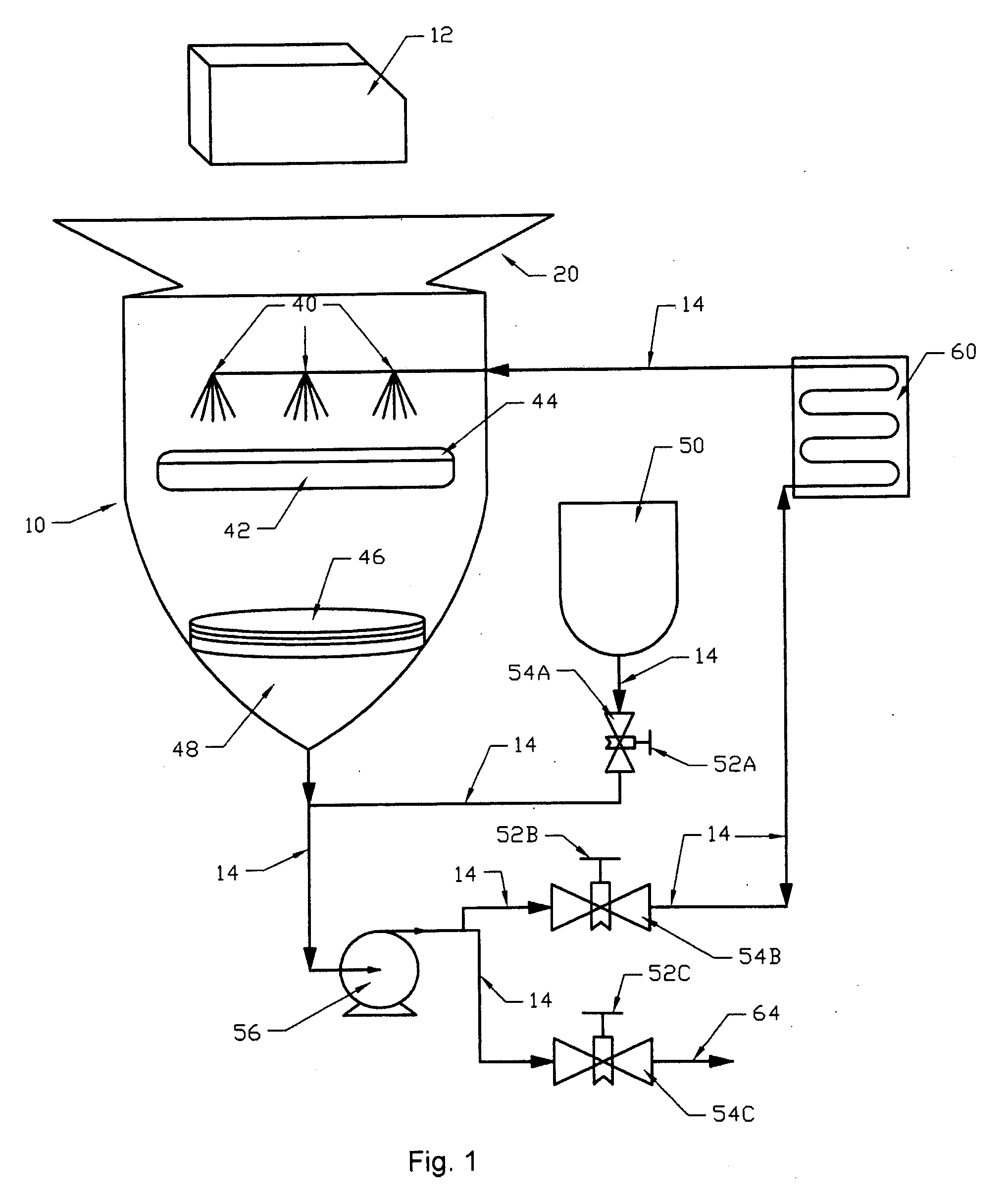

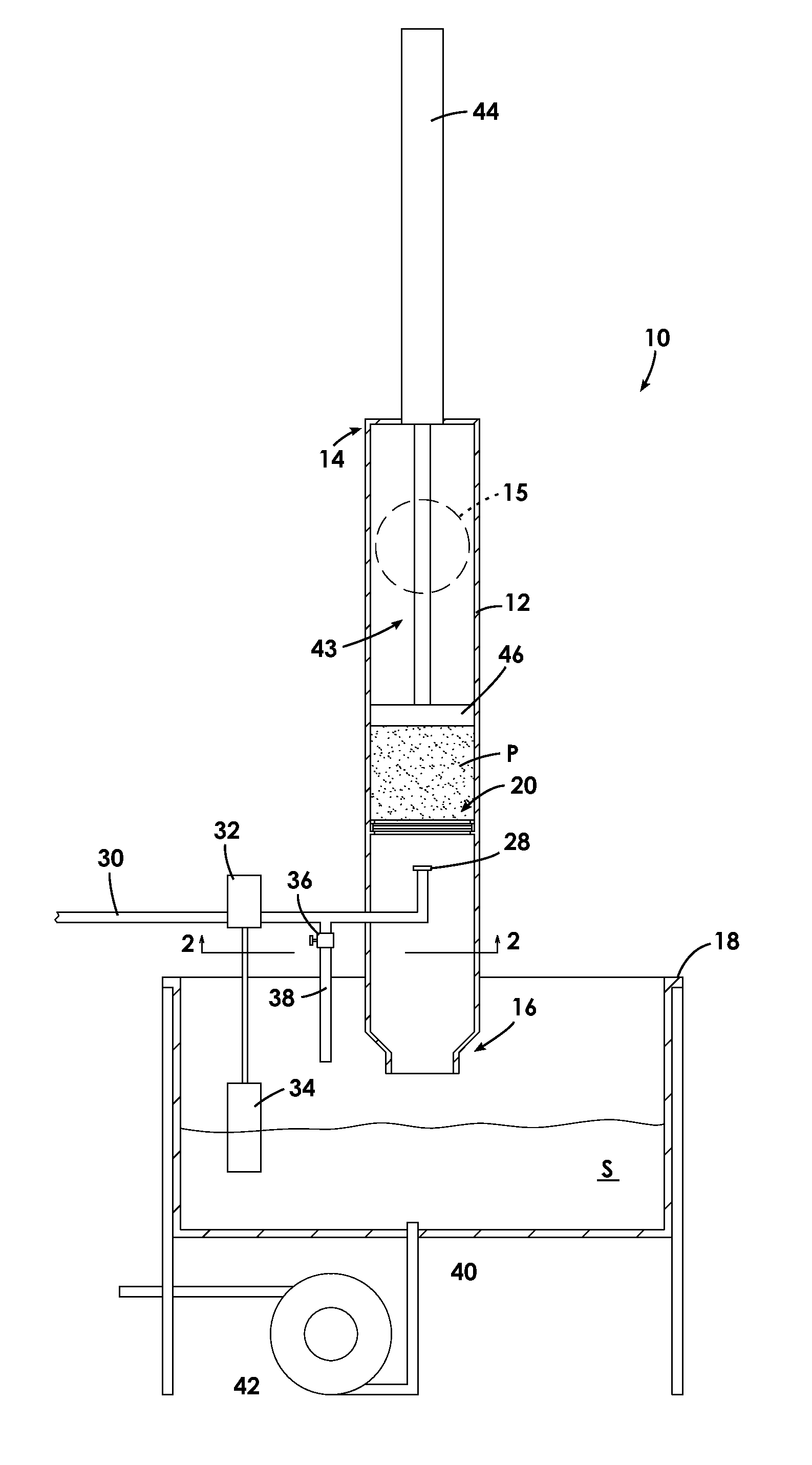

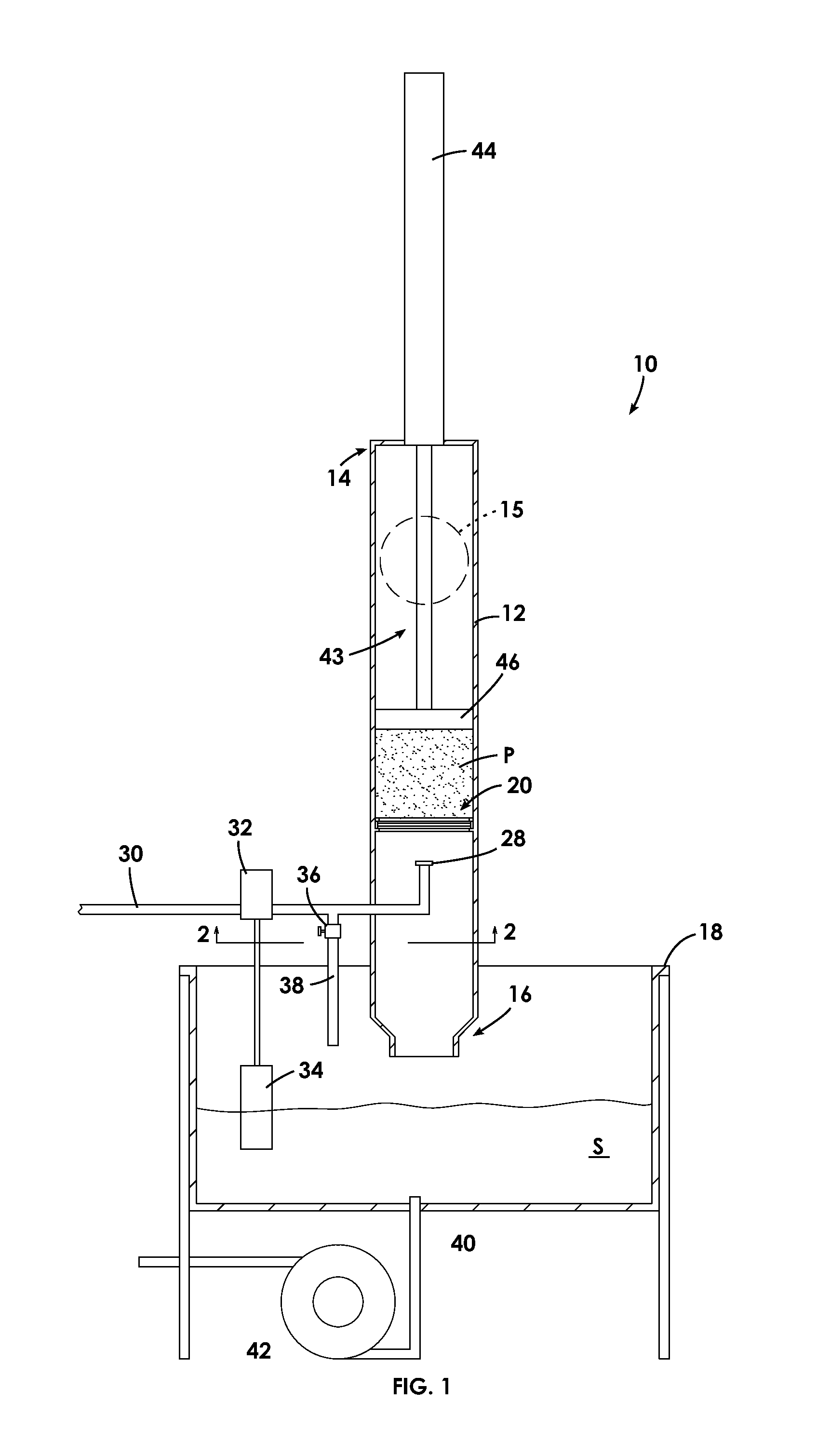

Solid product dissolver and method of use thereof

InactiveUS20050244315A1Easy to transportEasy to assembleWater treatment parameter controlDissolving using flow mixingIndustrial waterWater treatment

The present invention provides a device for producing a water treatment solution from a solid chemical block for distribution into a water system selected from the group comprising an institutional water system and an industrial water system. The device includes a housing to contain the solid chemical block. A fluid, preferably water at ambient temperature, is introduced into the housing to dissolve the block and form a liquid solution that may then be dispensed into either an institutional water system or an industrial water system. A method of dispensing the liquid solution with the device is also provided.

Owner:ECOLAB USA INC

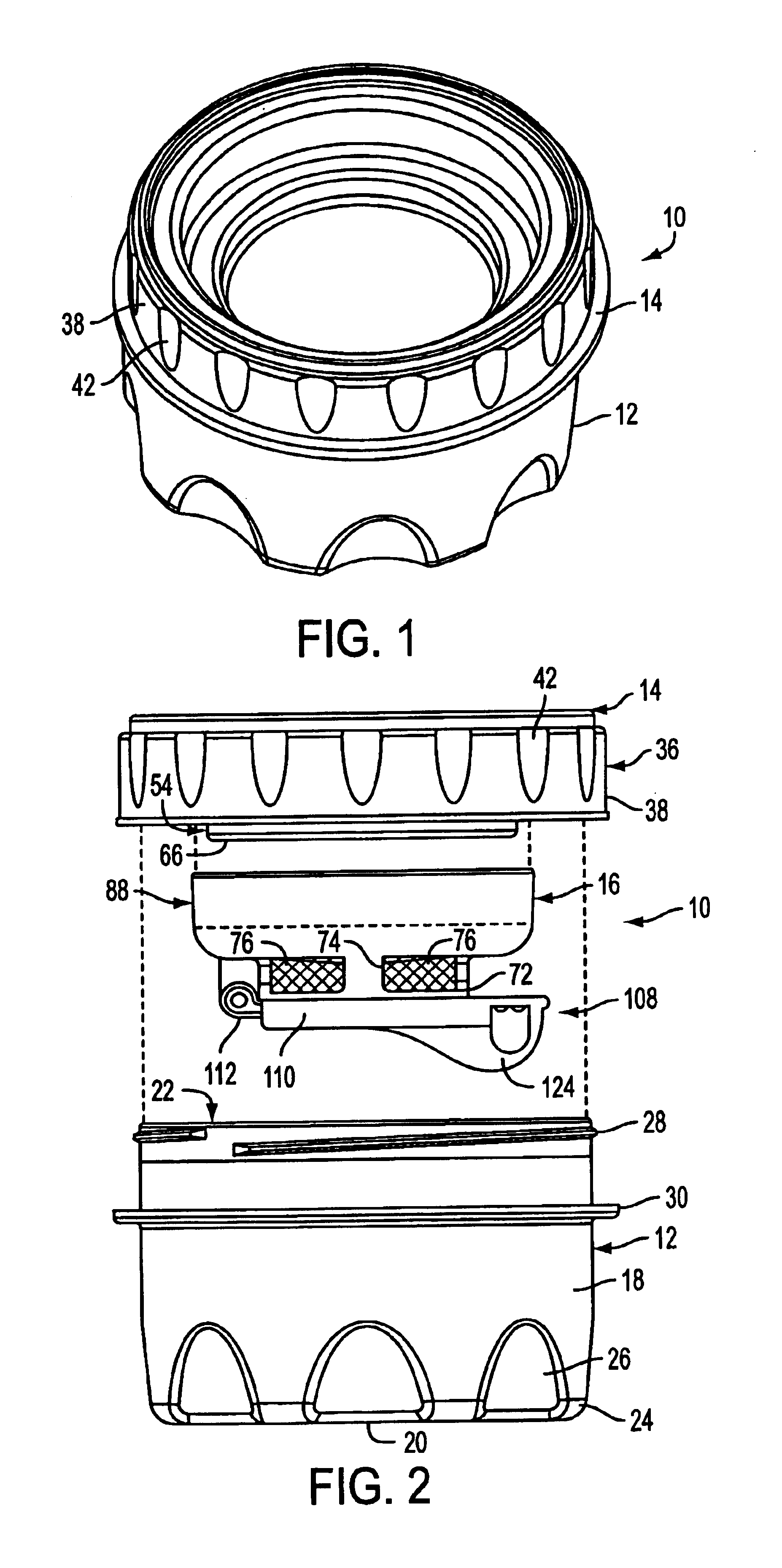

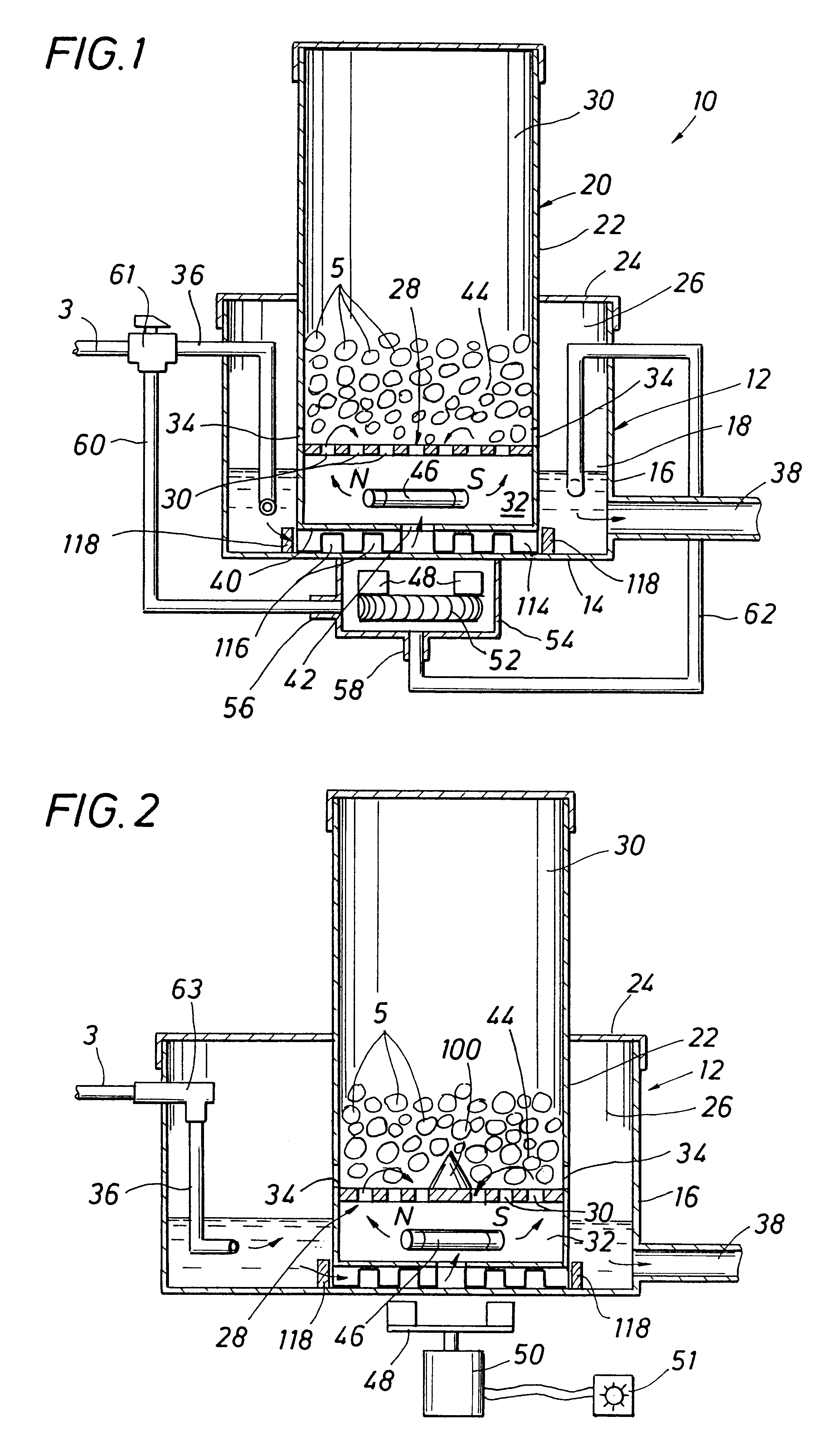

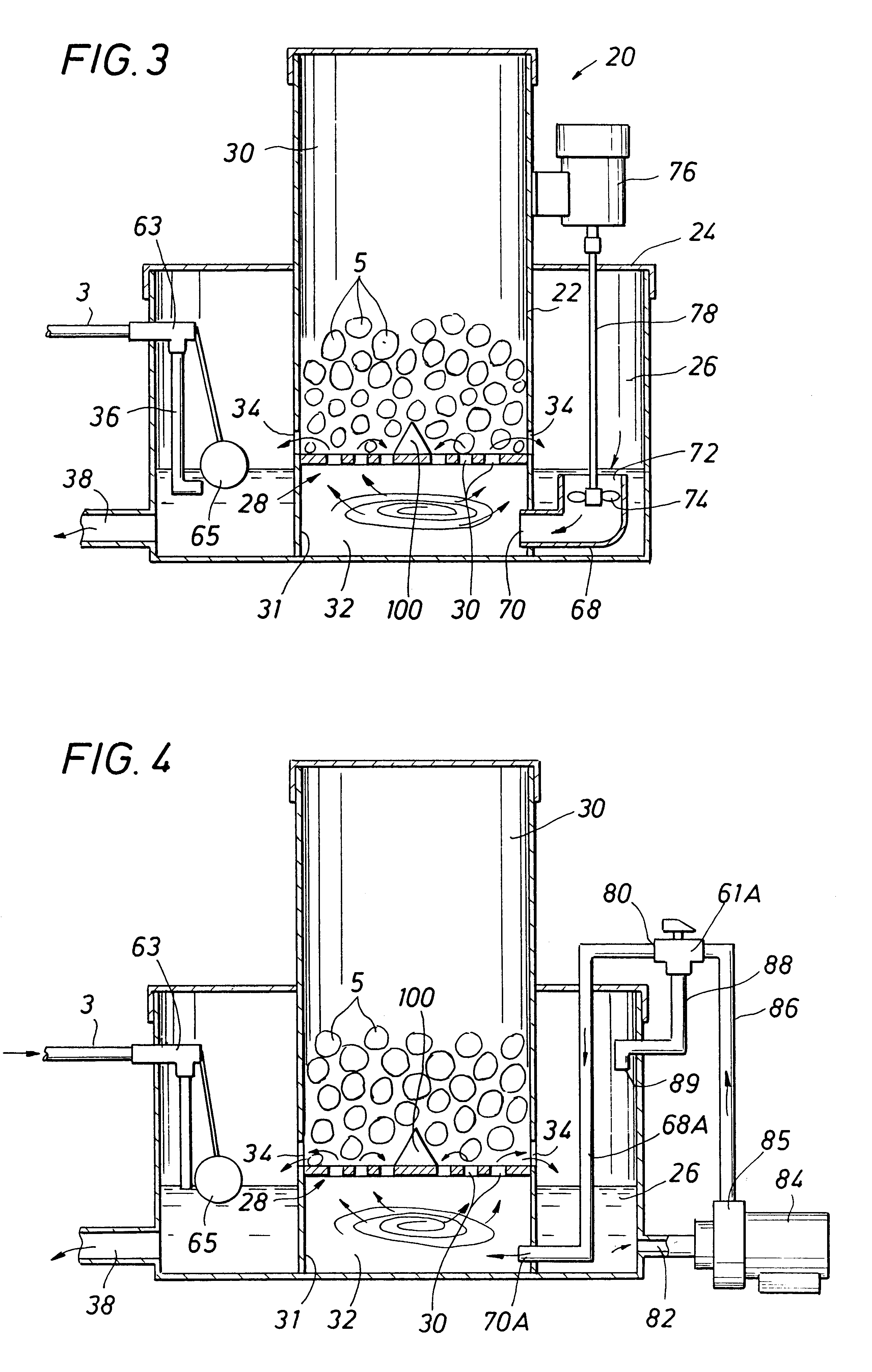

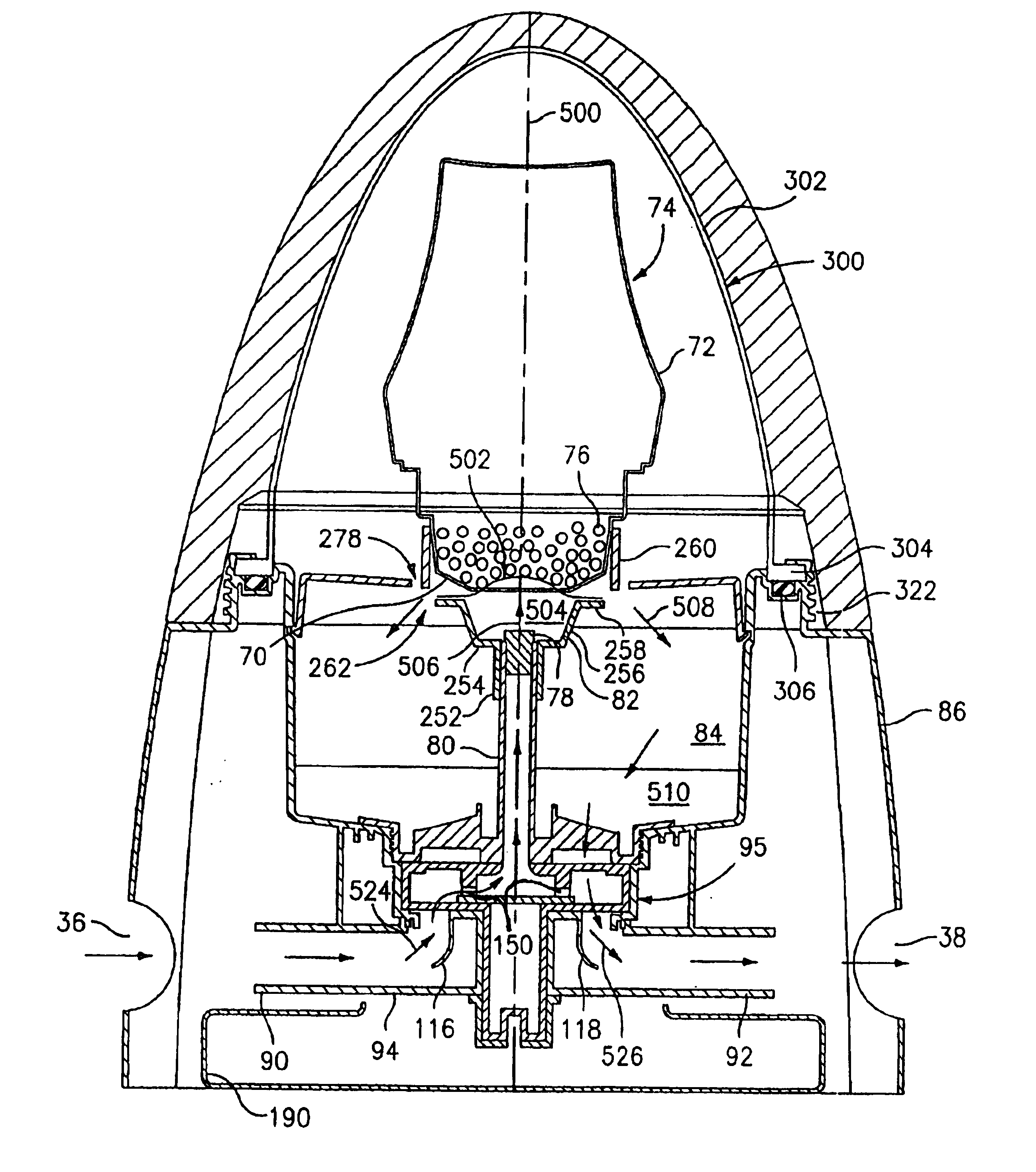

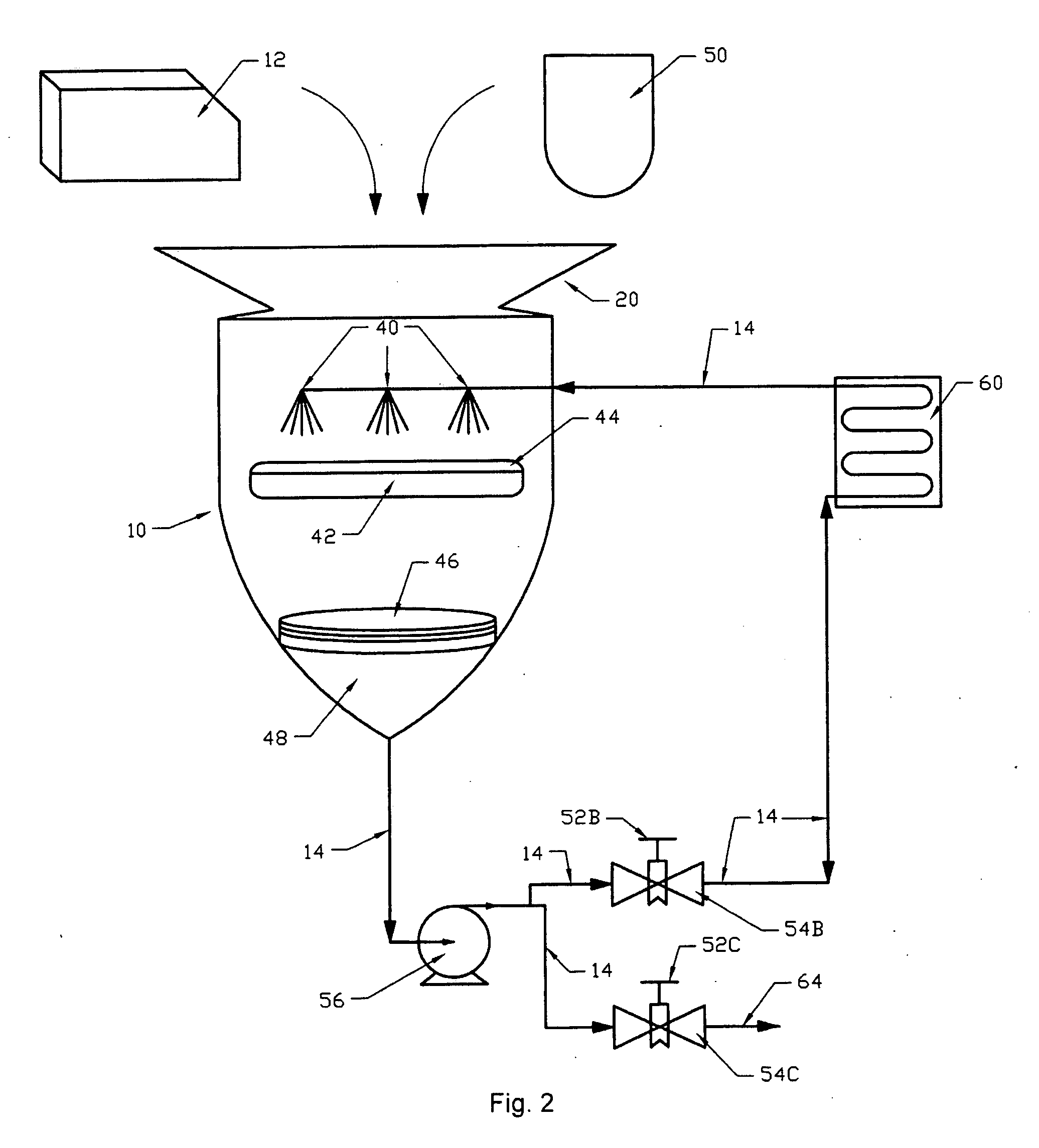

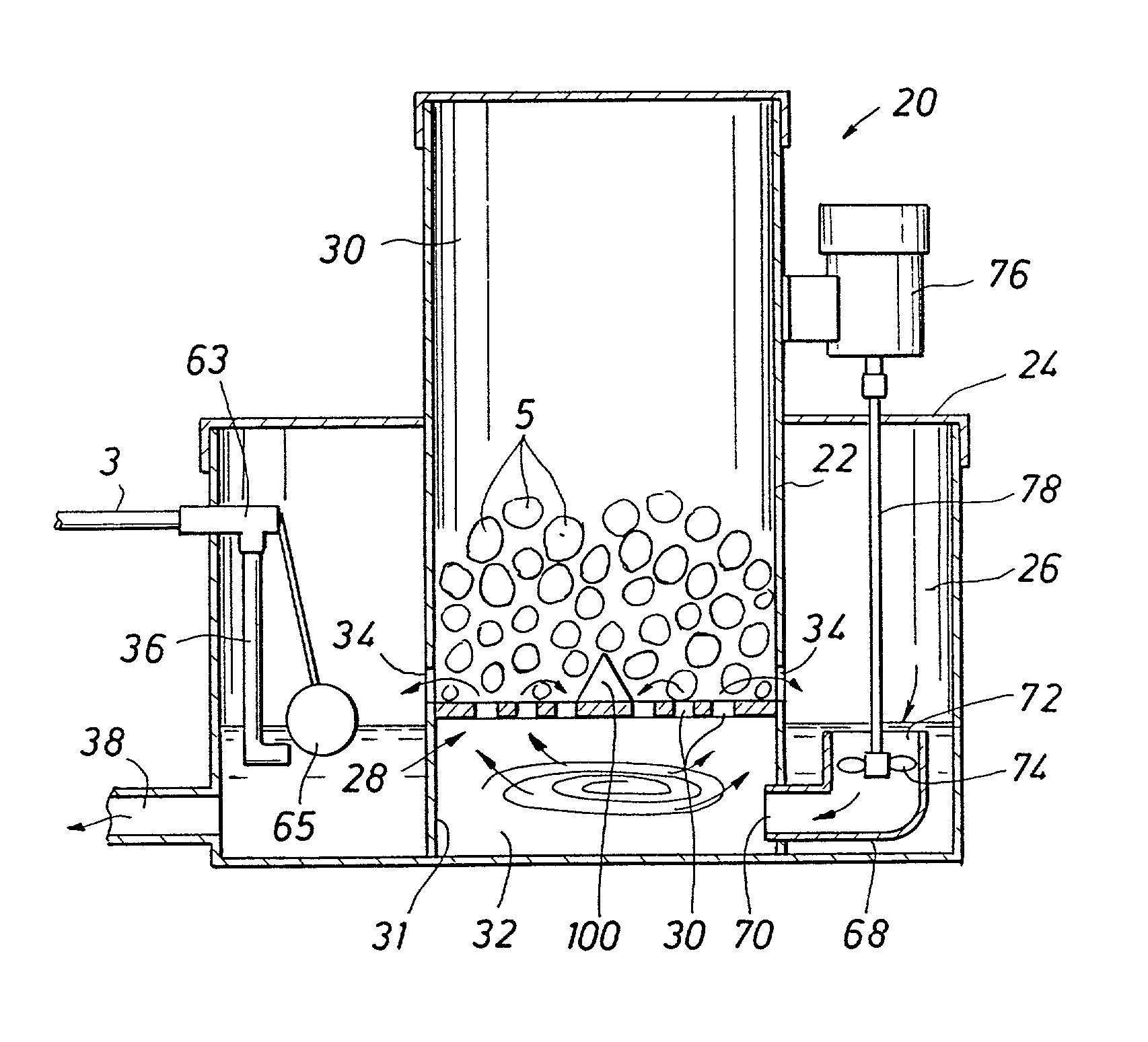

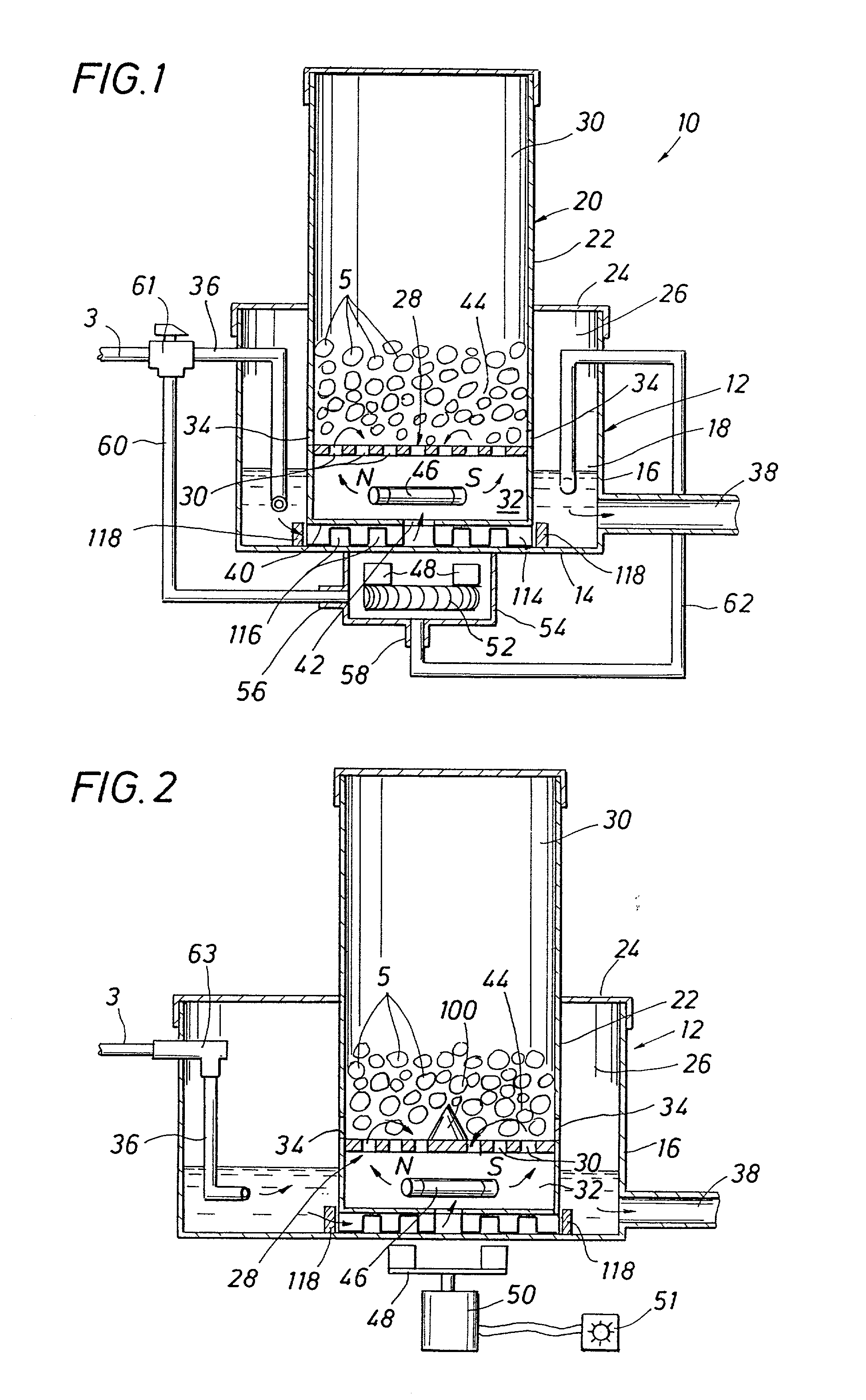

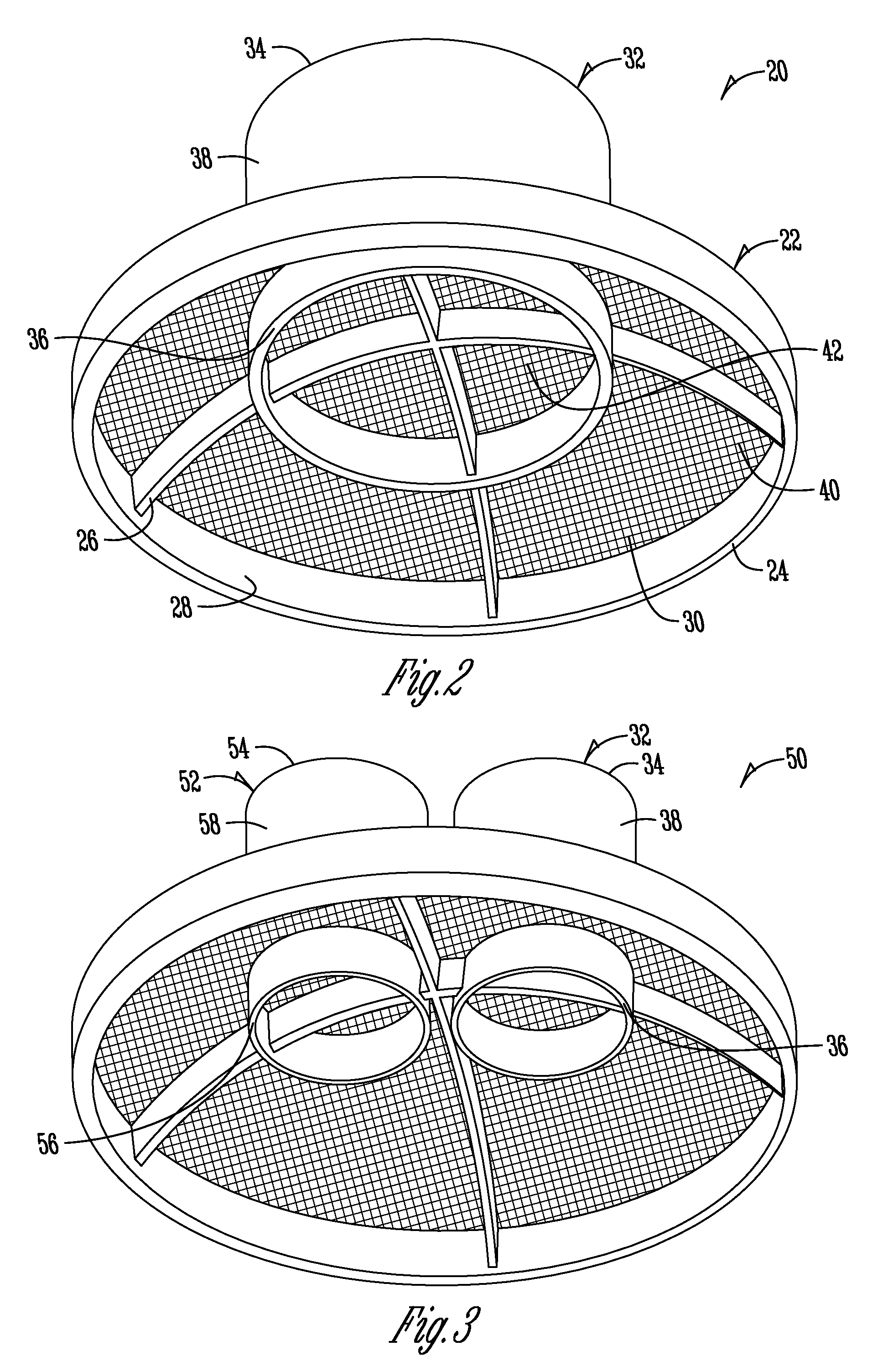

Chlorination apparatus and method

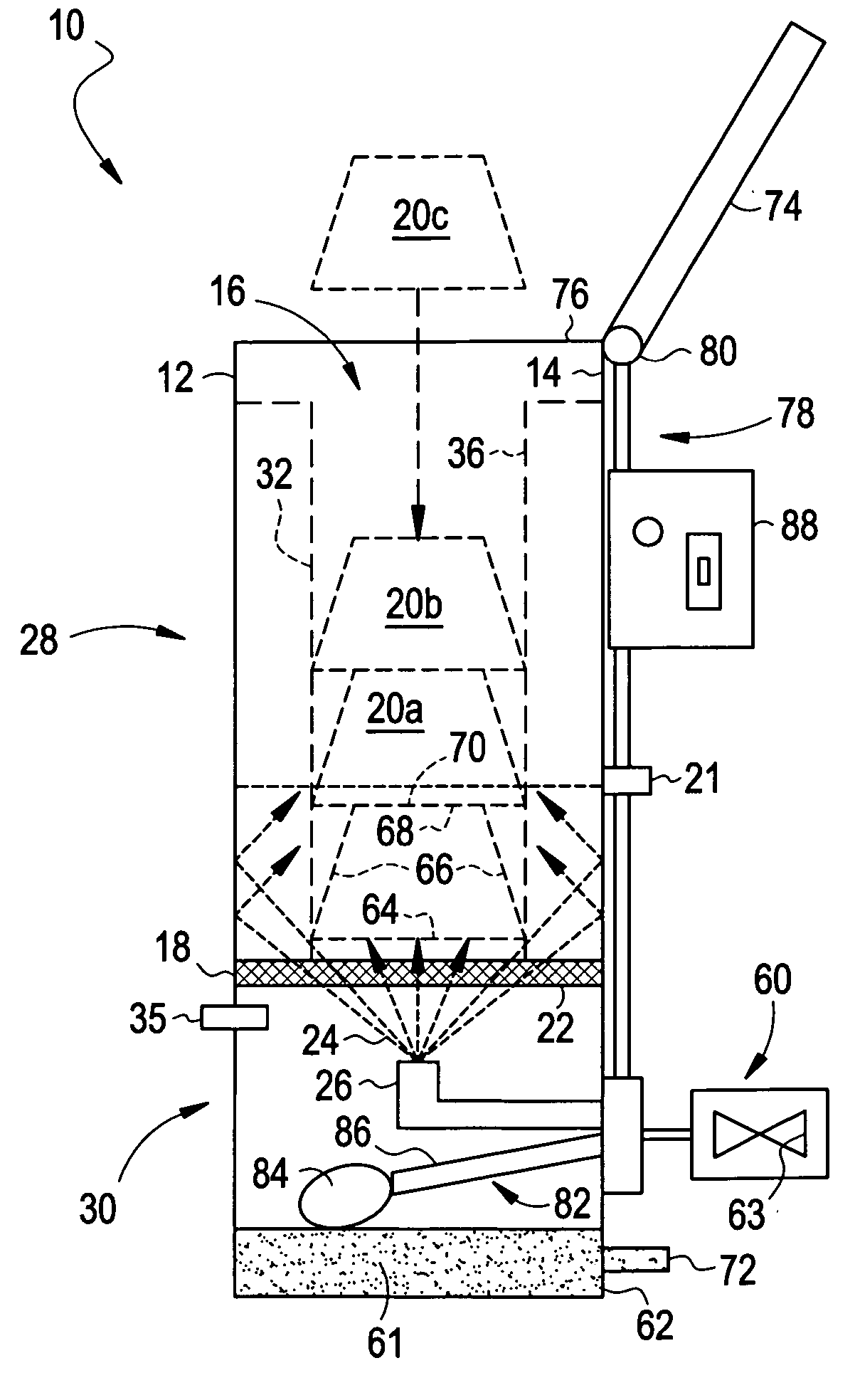

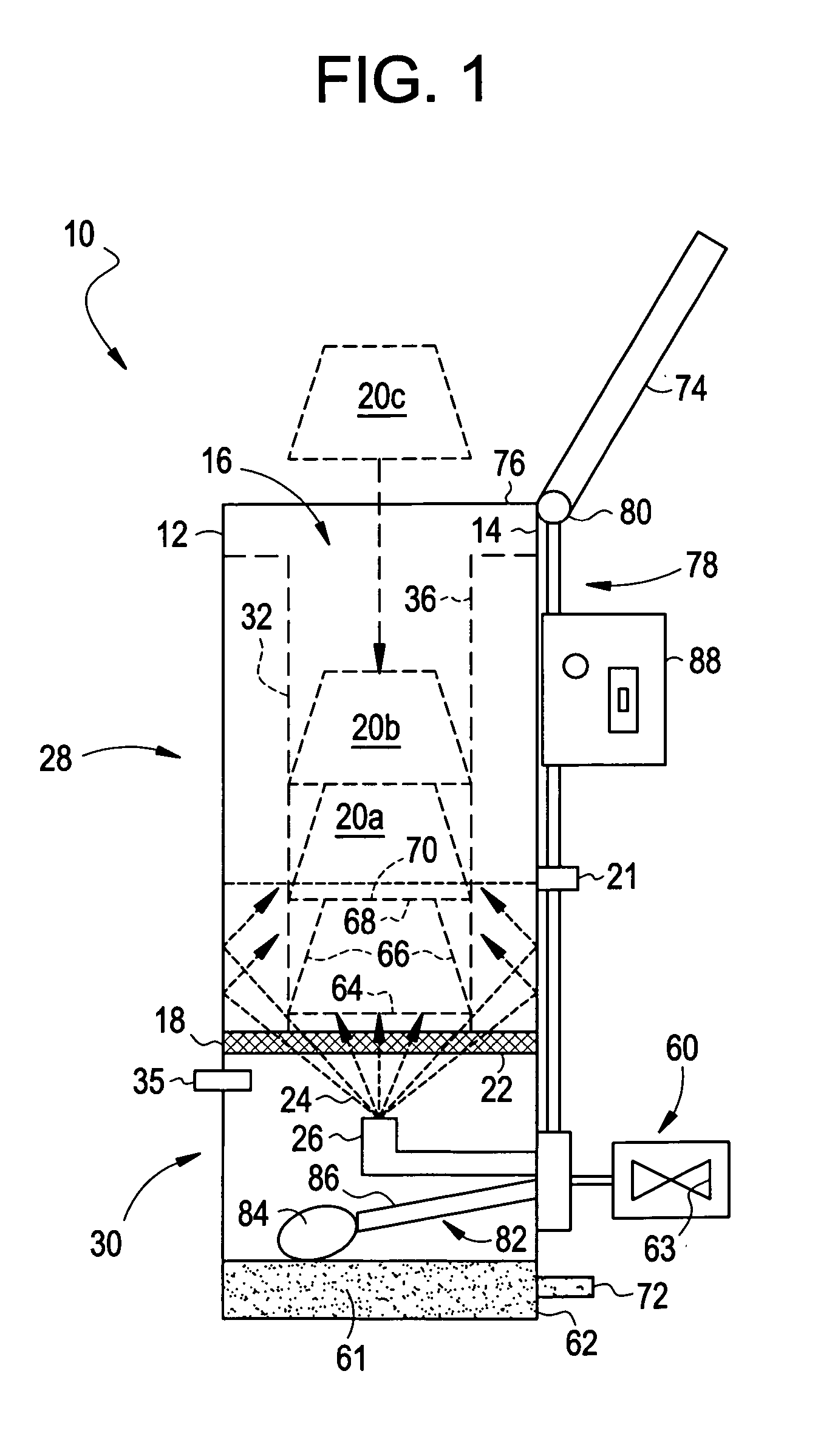

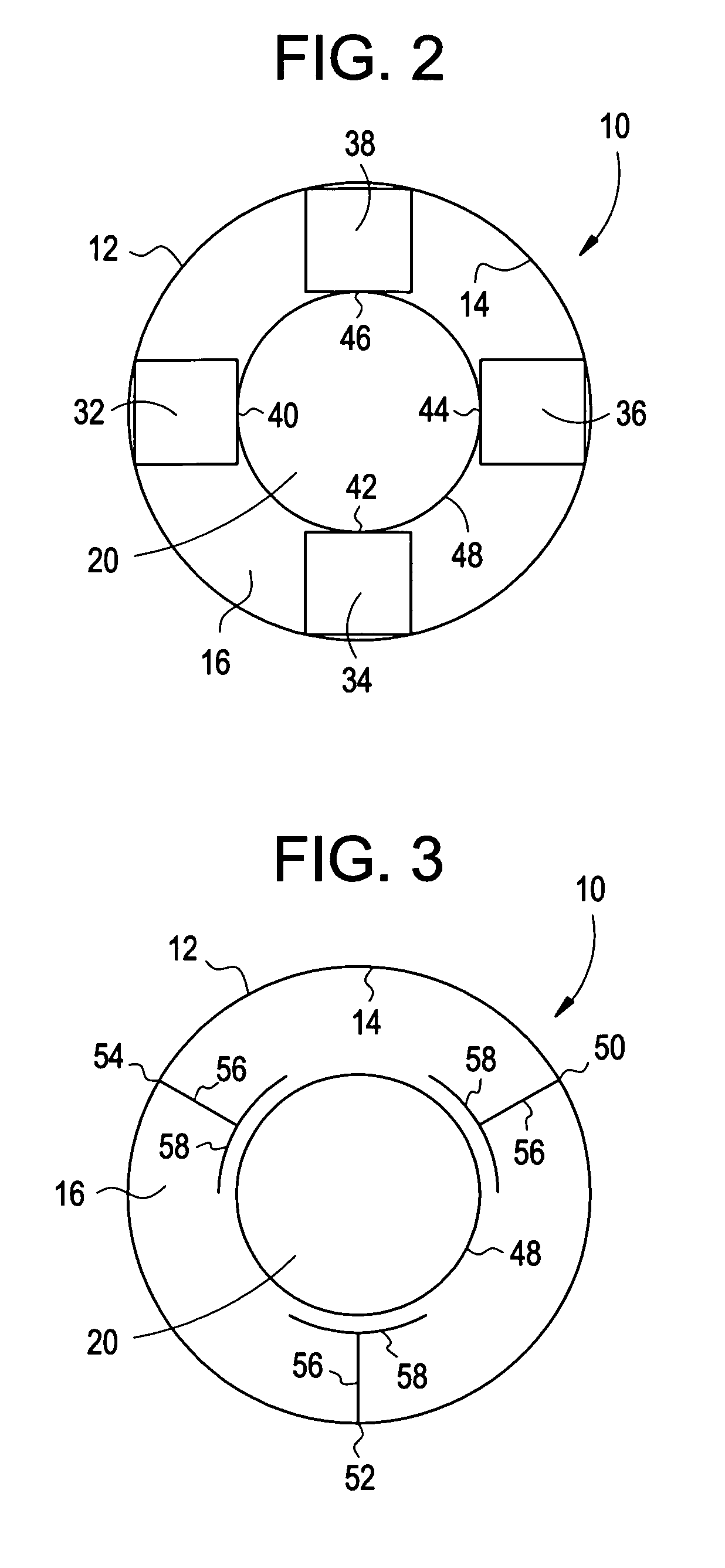

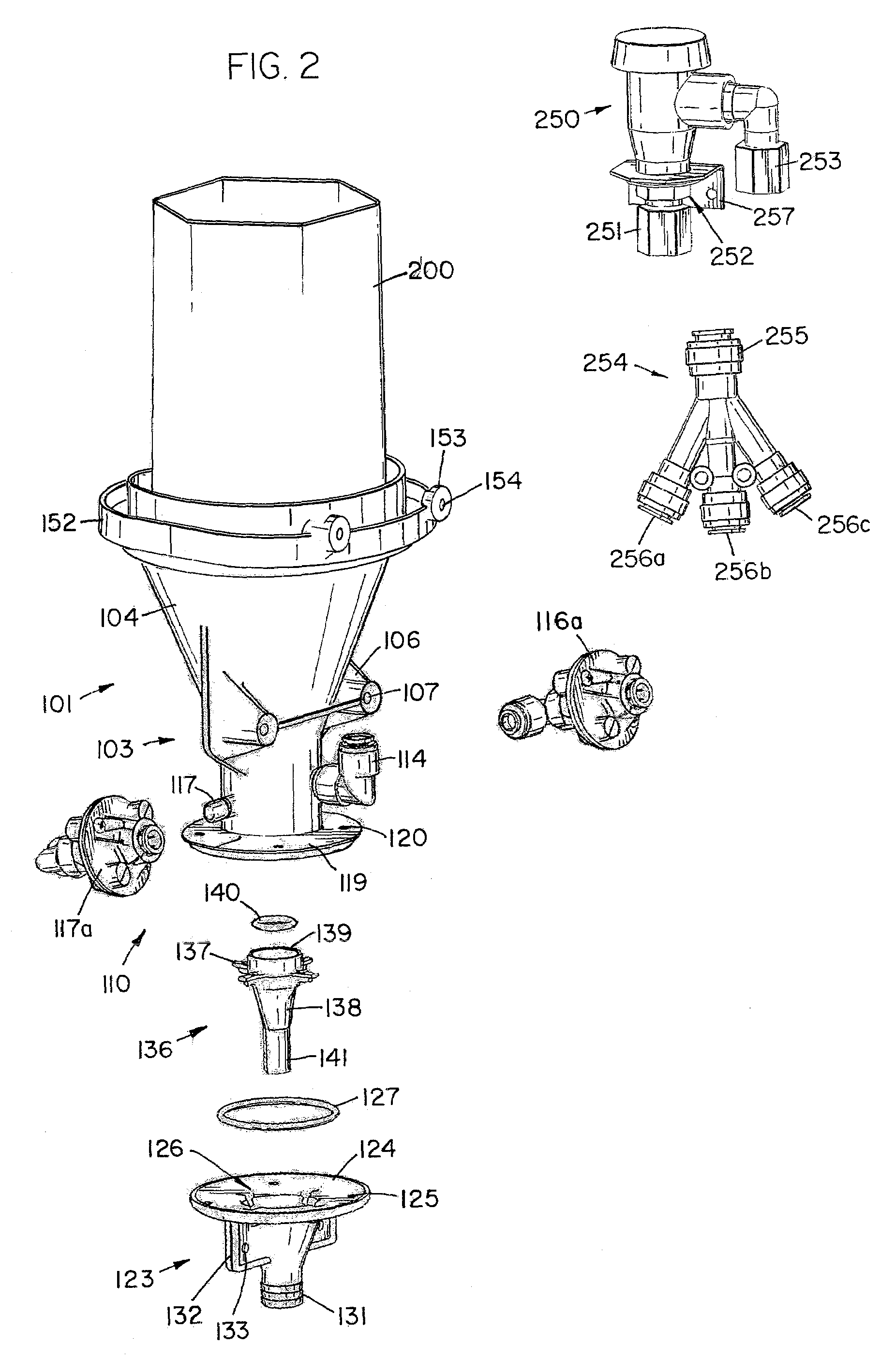

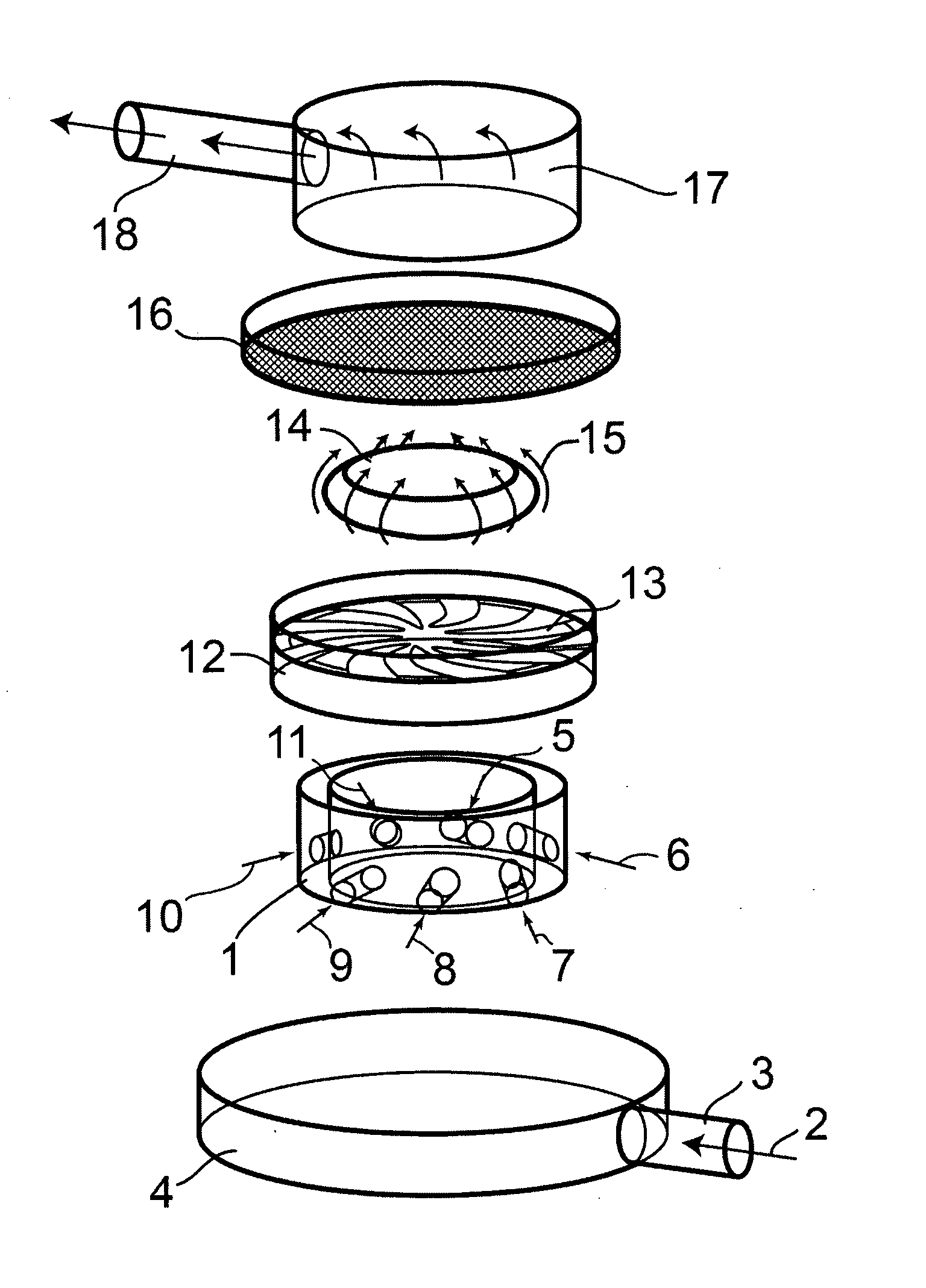

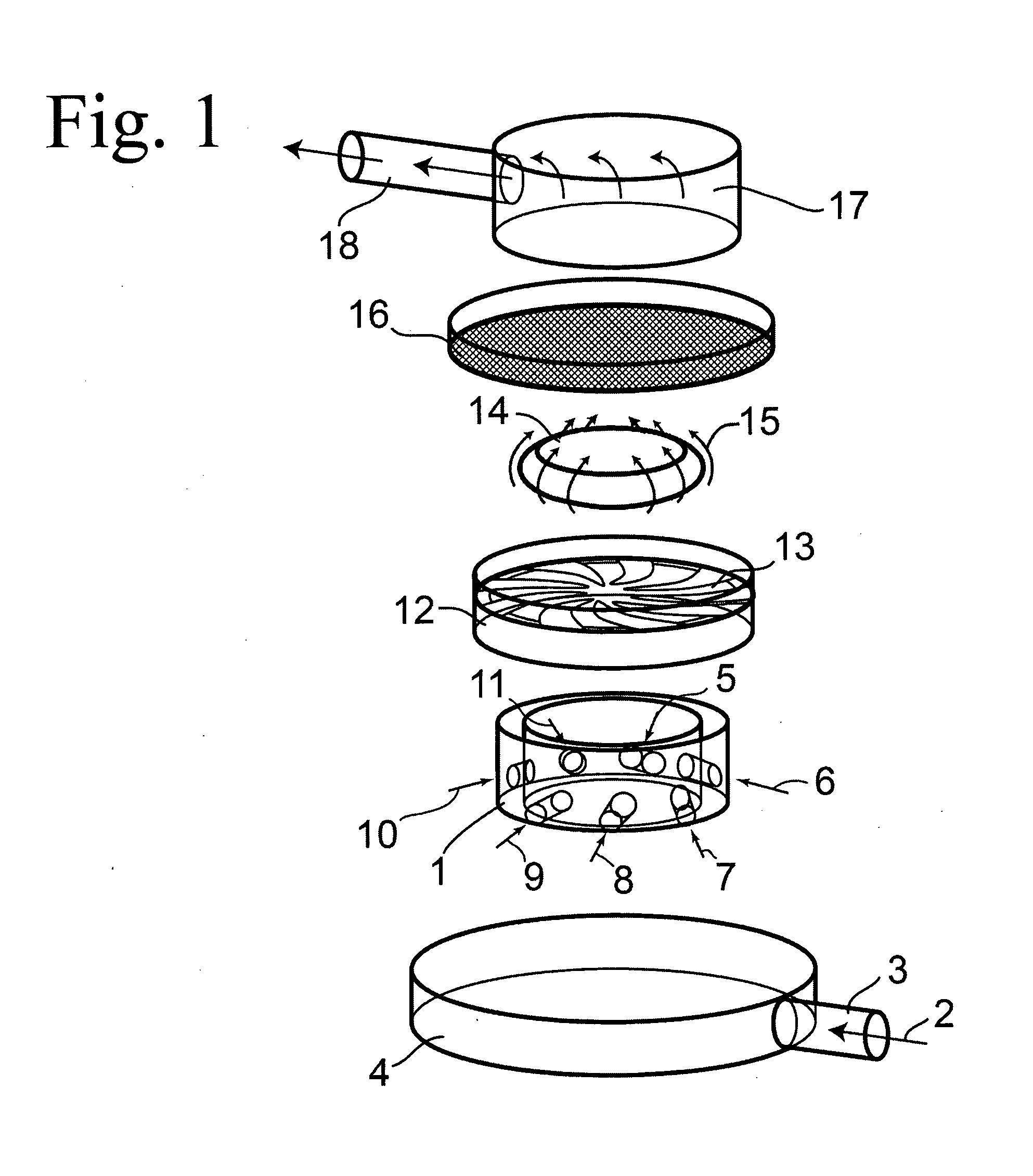

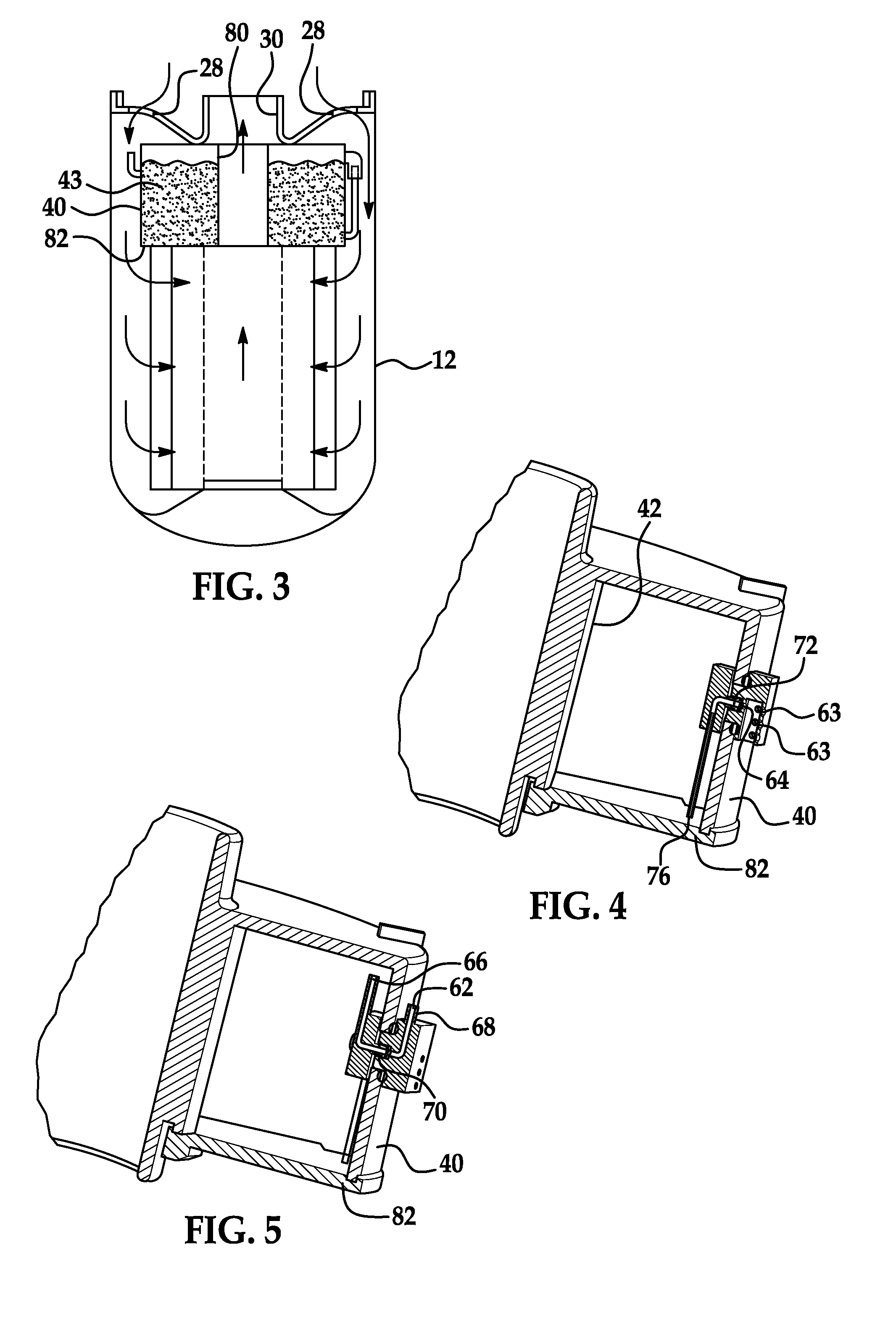

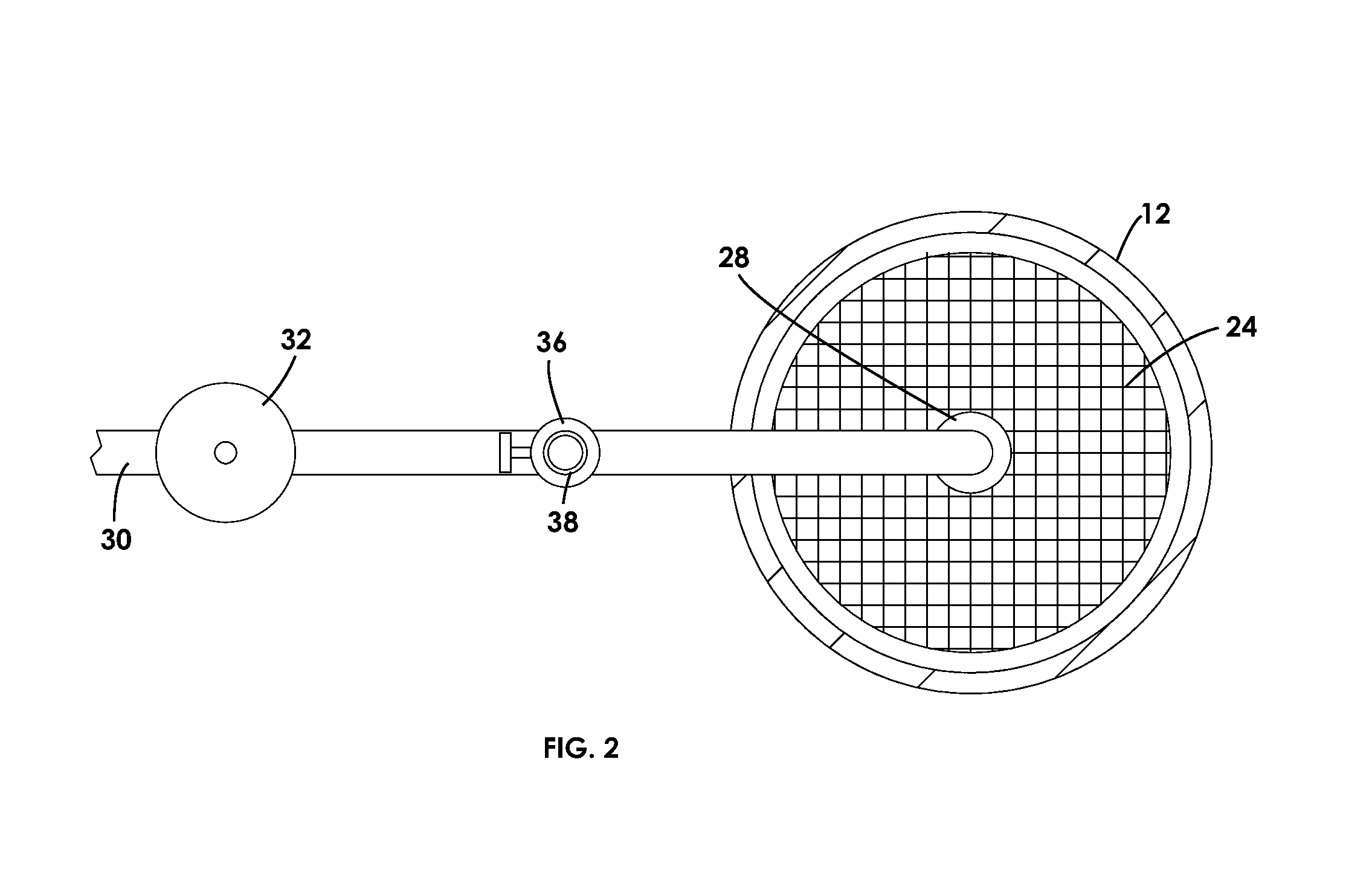

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

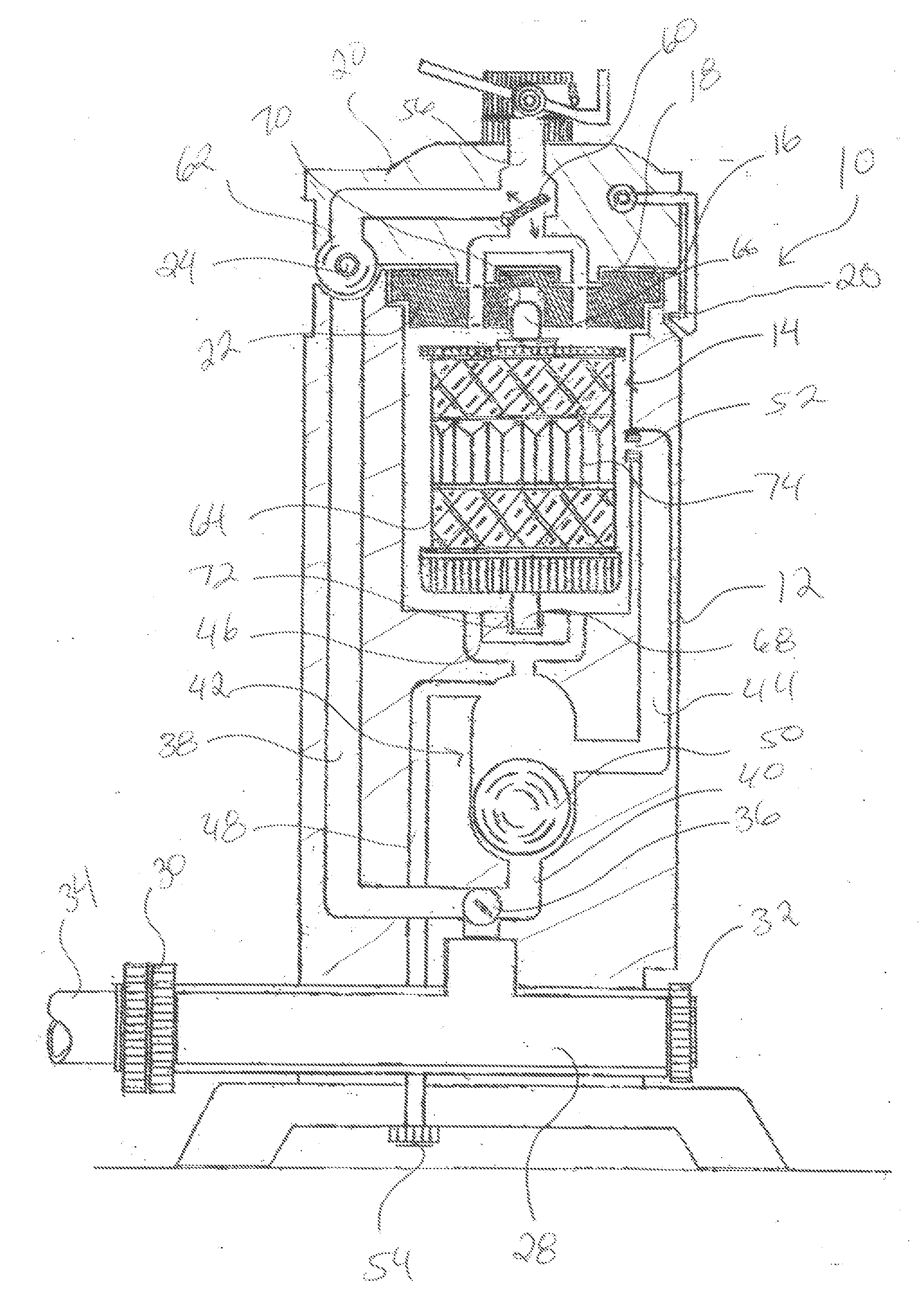

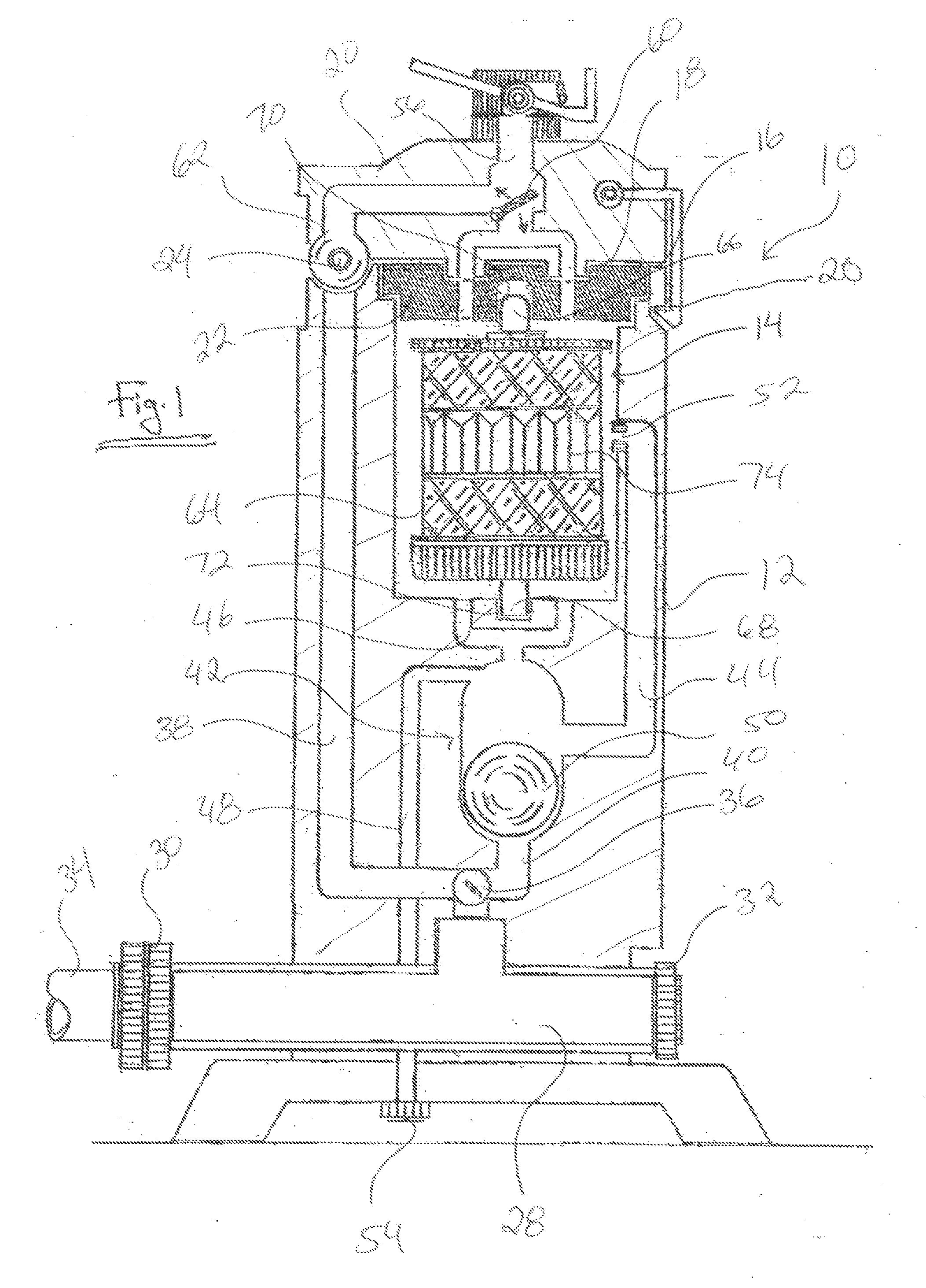

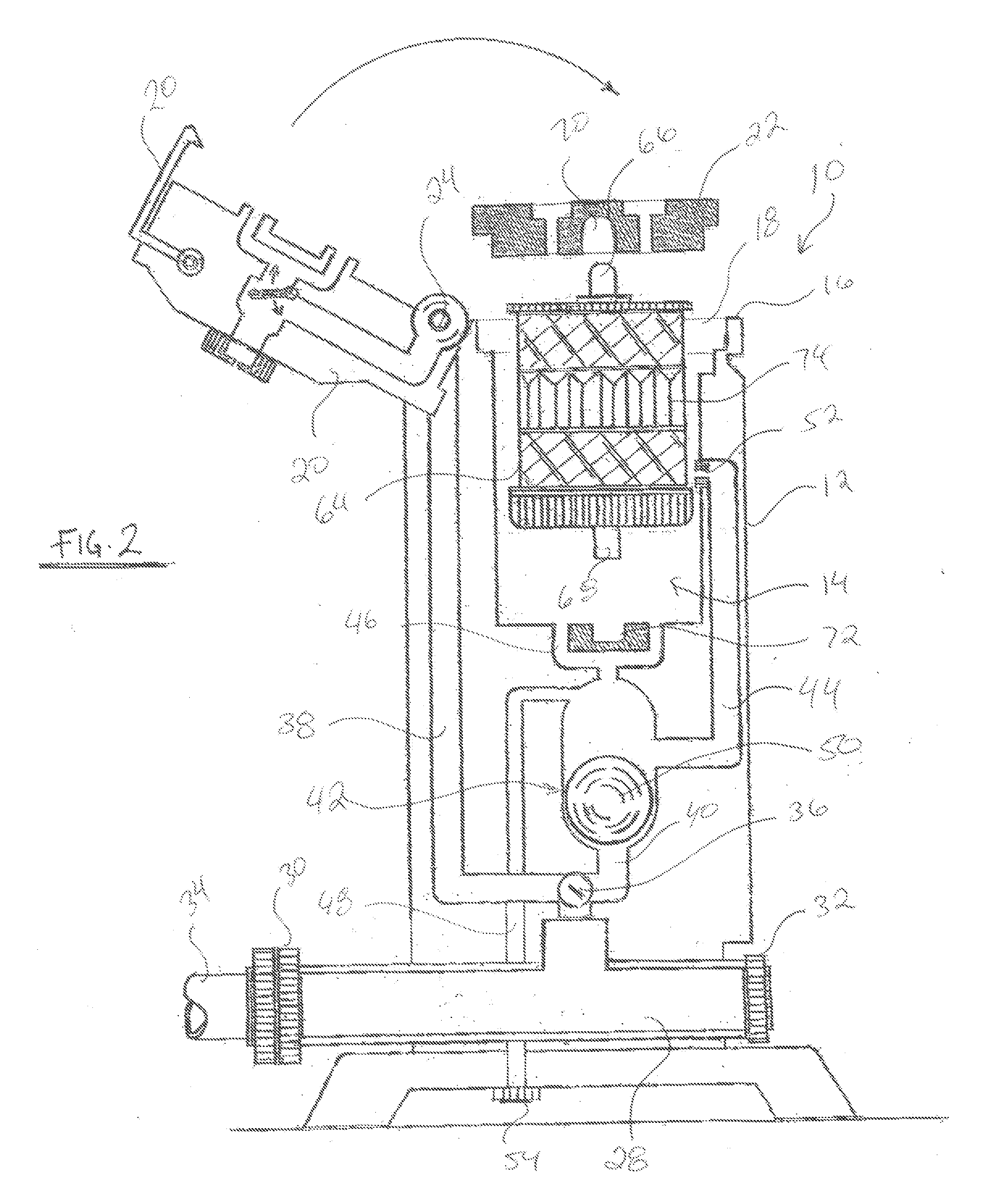

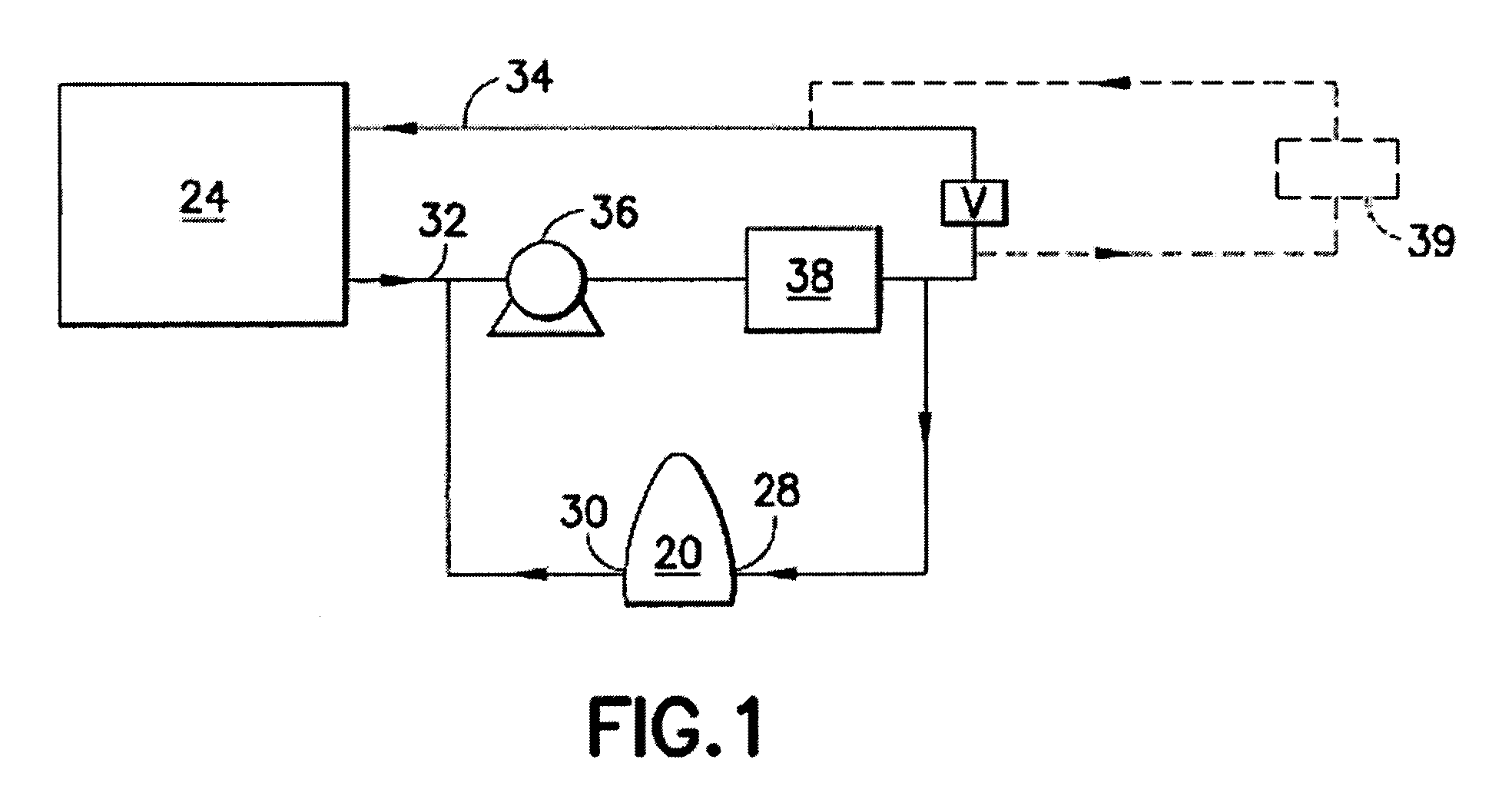

Solid product dispenser

A dispenser (10) uses first and second flow controls (70, 73). The flow controls maintain first and second flow ranges independent of diluent pressure within a pressure range, wherein the use solution's concentration is maintained over the pressure range. A third flow control (75) may also be utilized in a third diluent passageway for maintaining a third flow range independent of the diluent pressure within the pressure range. A bypass valve assembly (41) is operatively connected to the third incoming diluent passageway. The bypass valve has a temperature control valve. The temperature control valve having a bypass passageway, wherein additional diluent is added to the use solution, thereby controlling the use solution's concentration.

Owner:ECOLAB USA INC

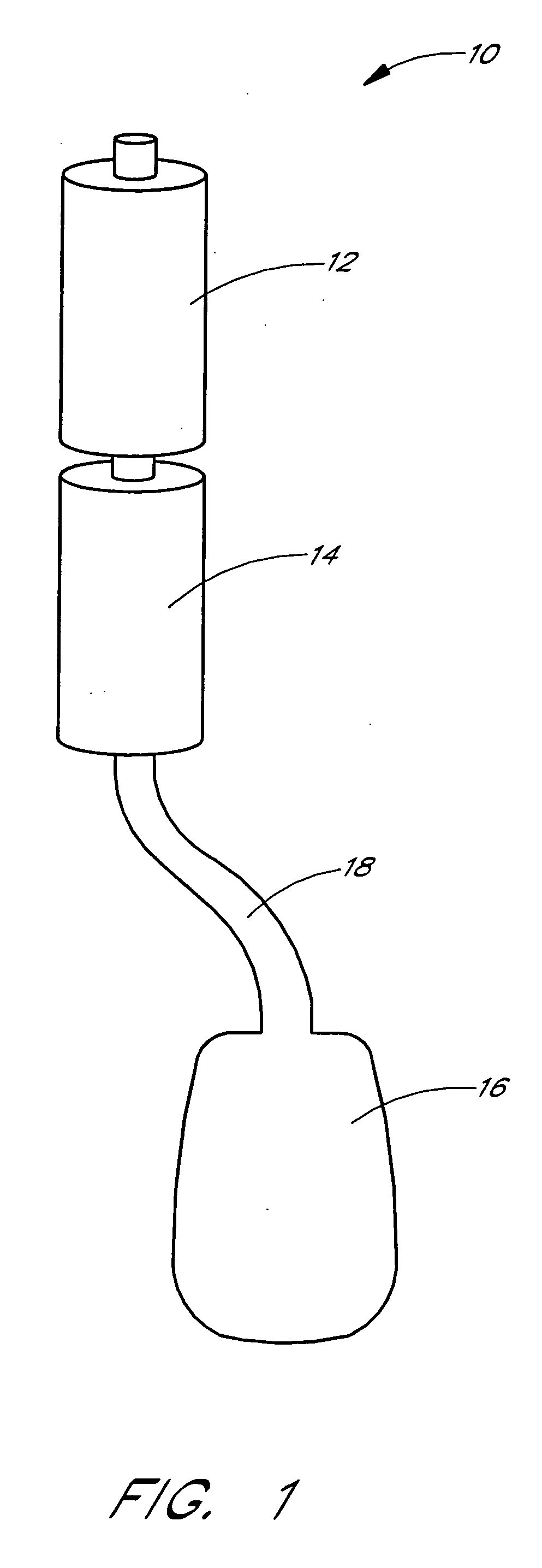

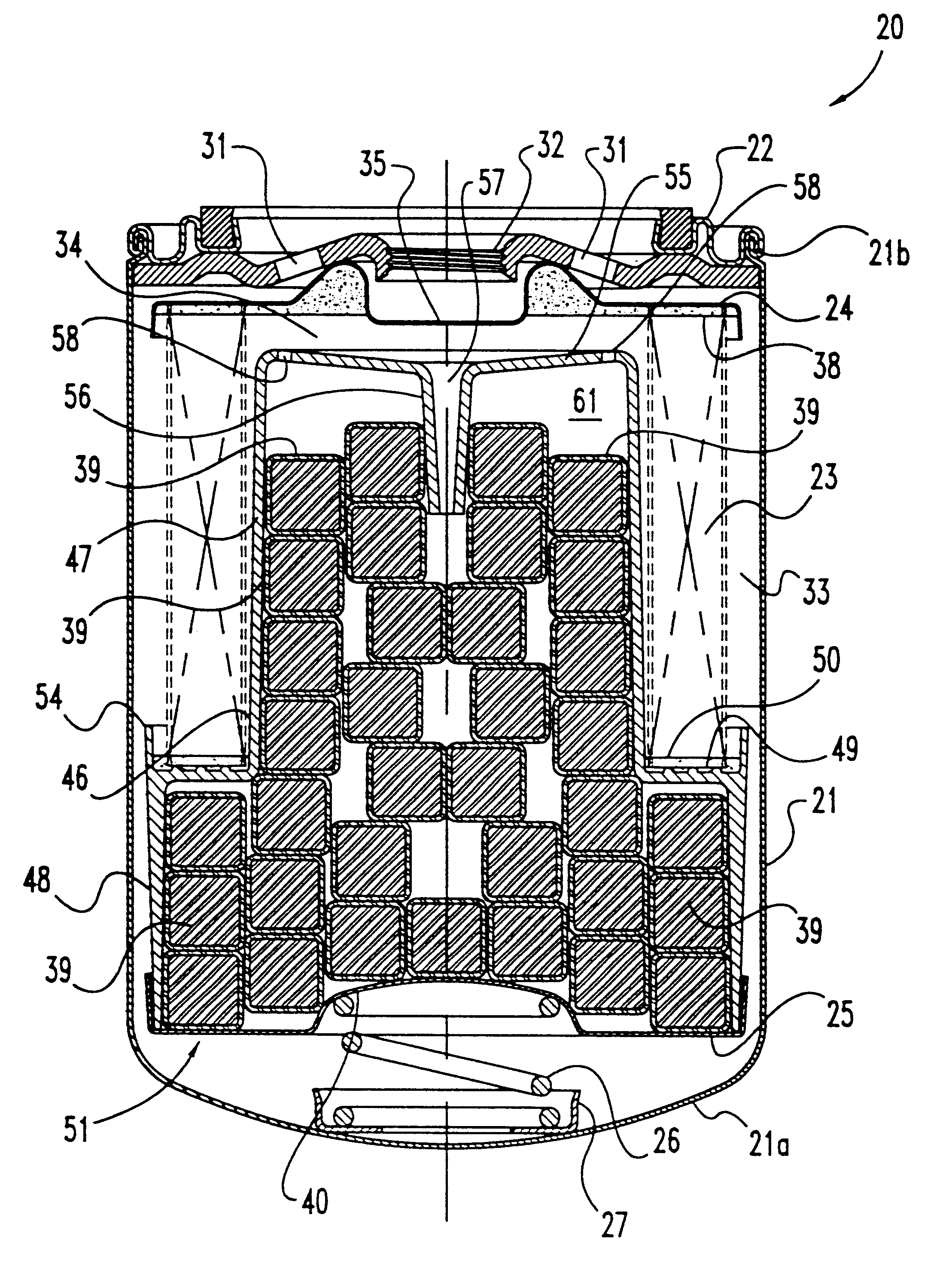

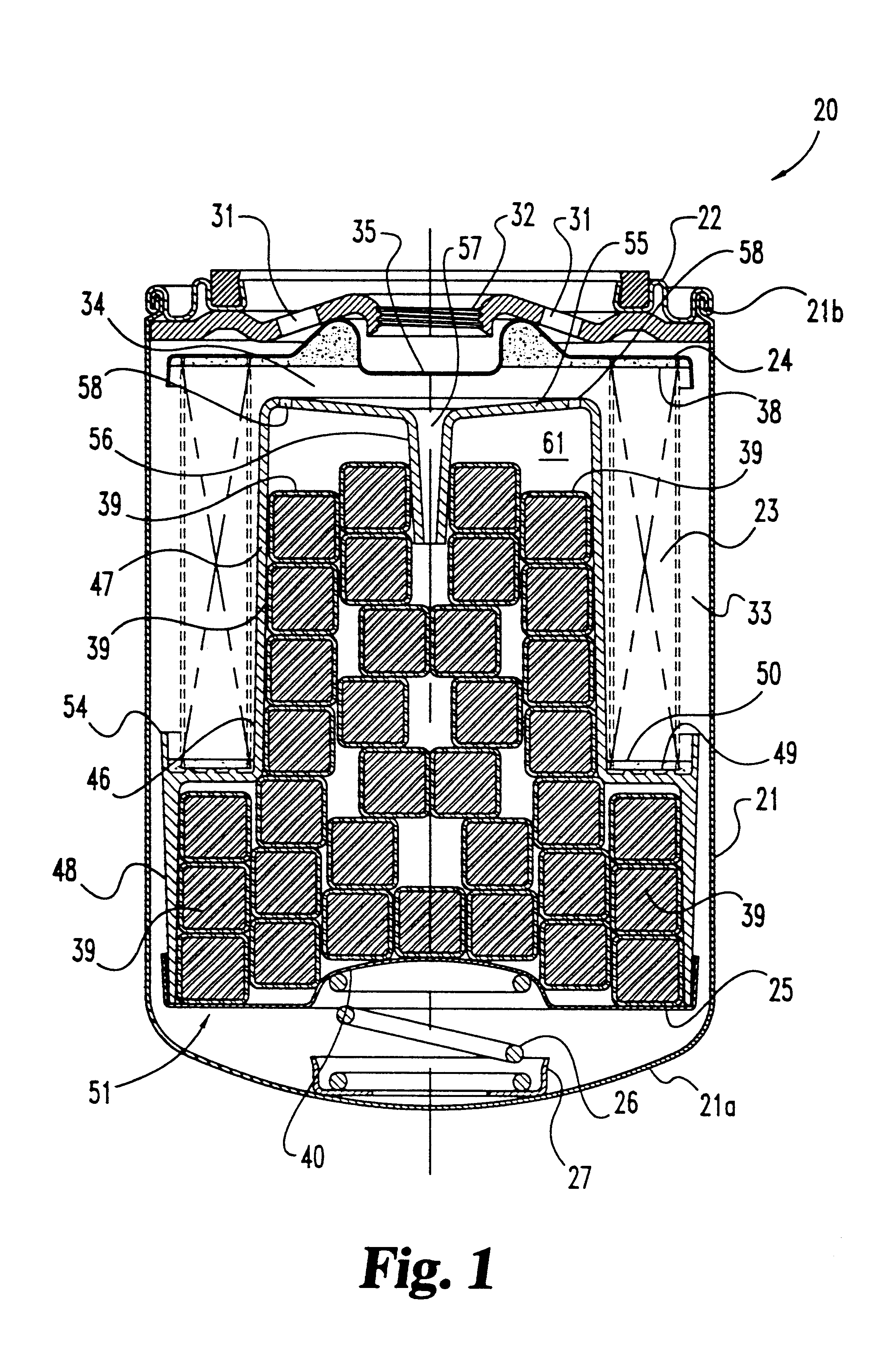

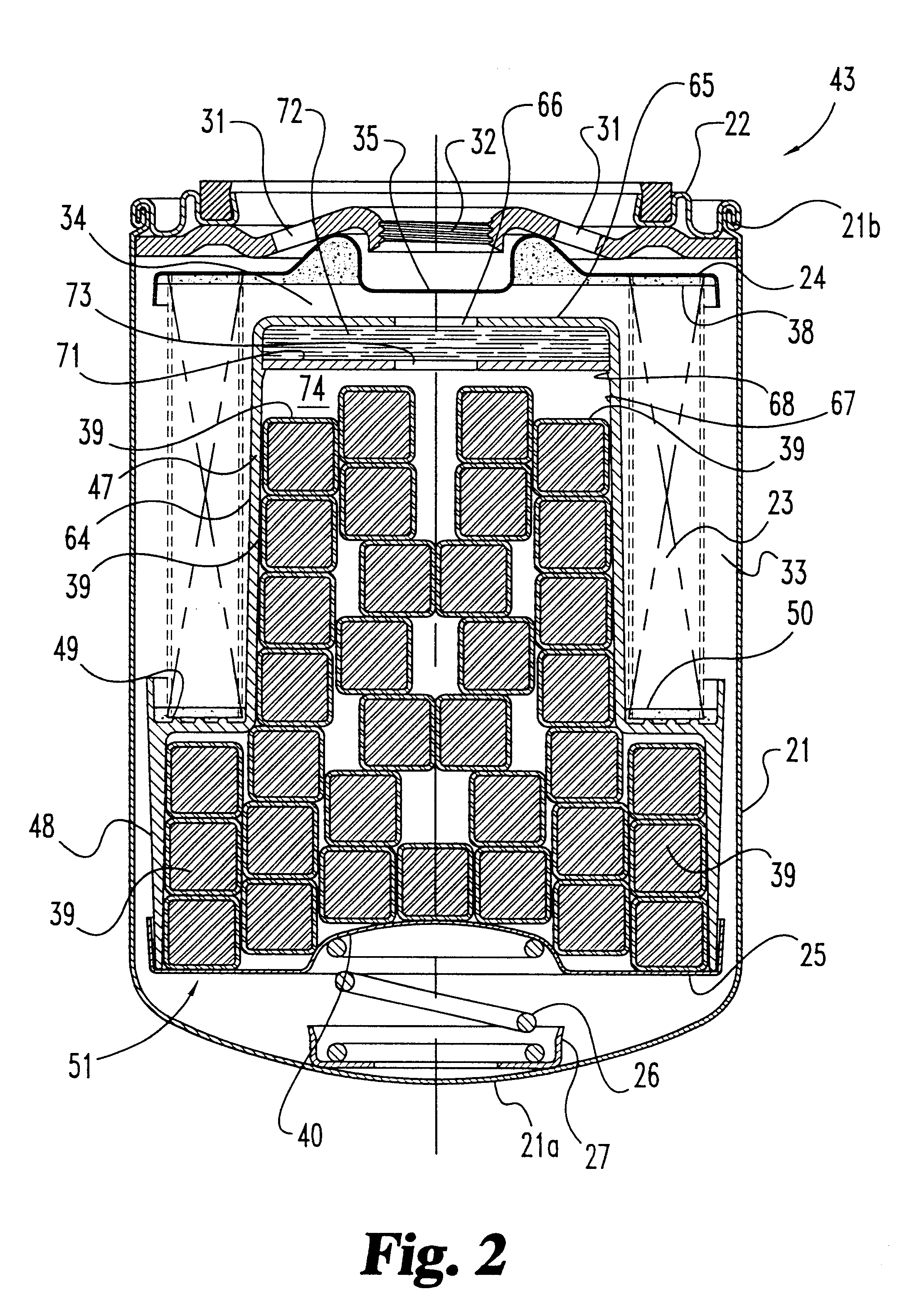

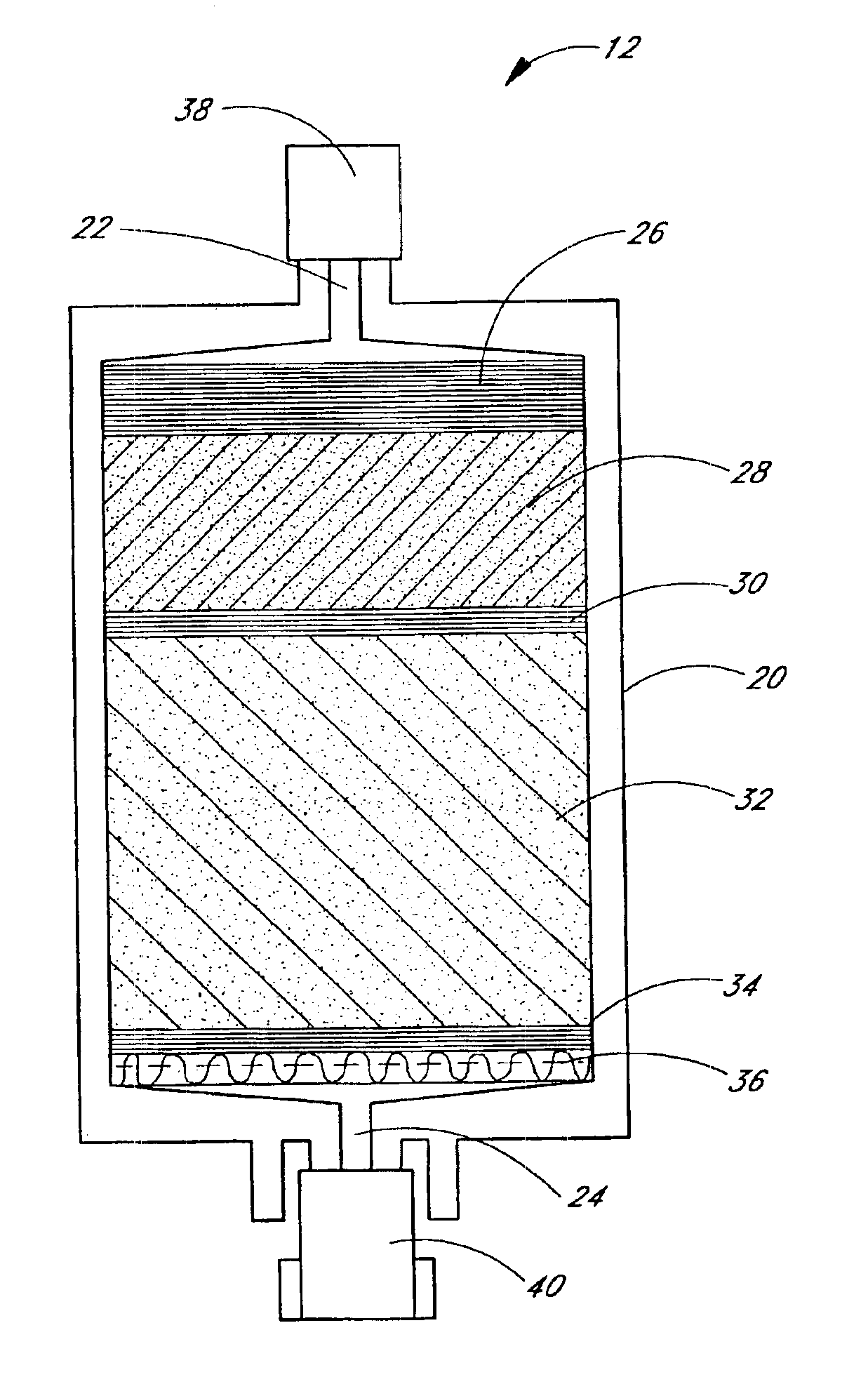

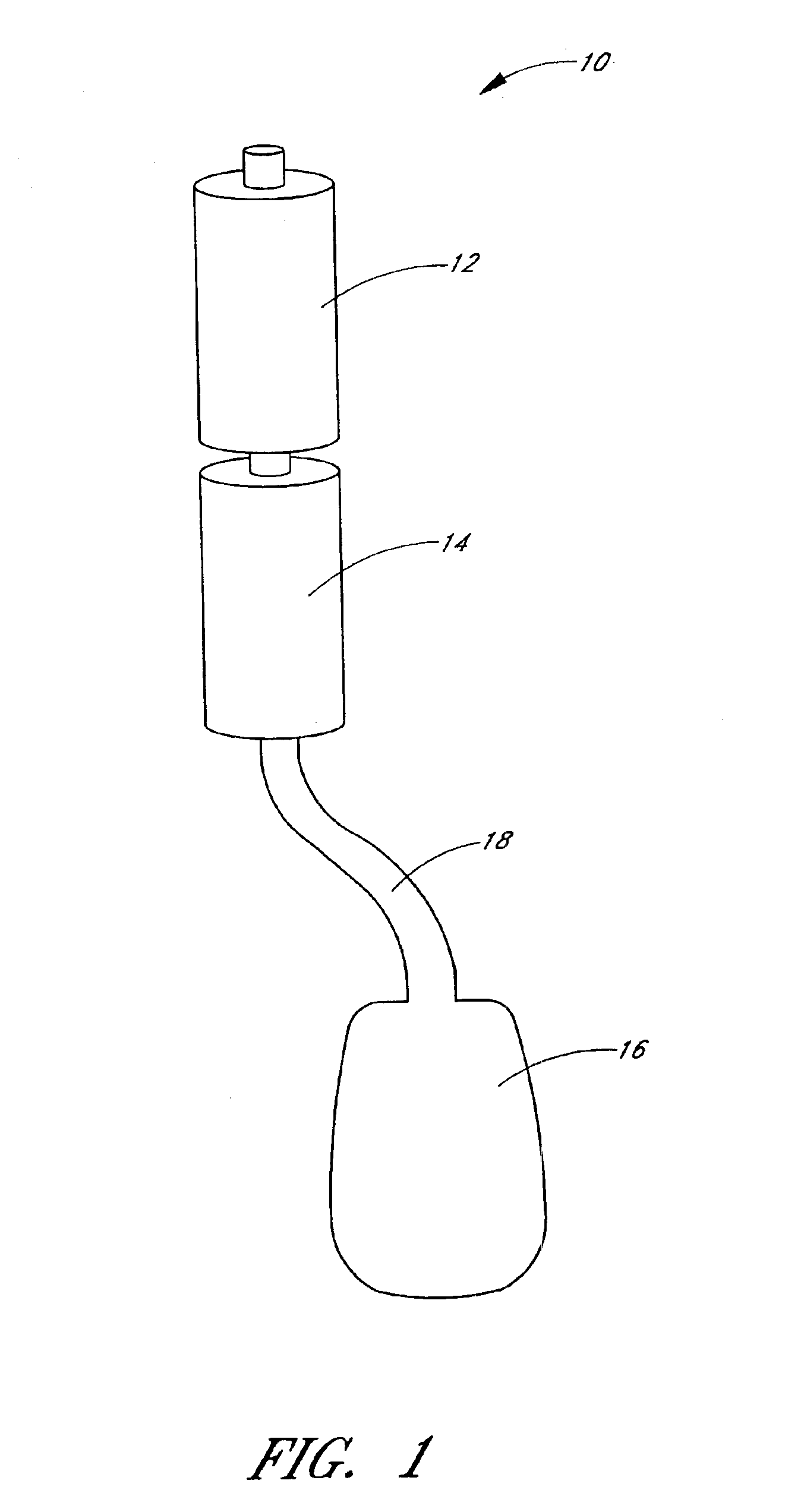

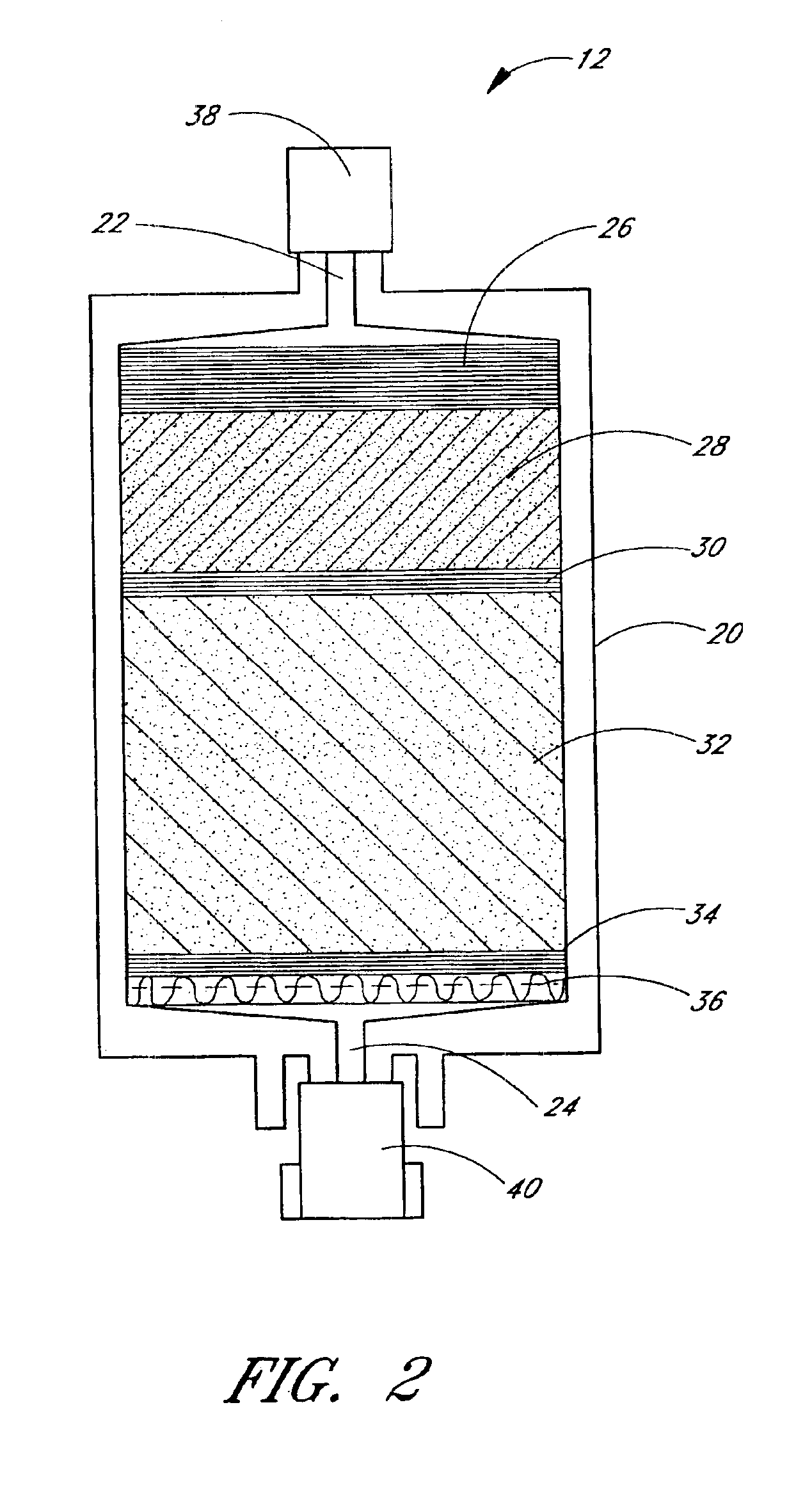

Apparatus and method for preparation of a peritoneal dialysis solution

InactiveUS6986872B2Minimize the possibilityEasy to separateGeneral water supply conservationDiagnosticsPeritoneal dialysateMagnesium salt

The invention provides an apparatus and method for storing and transporting peritoneal dialysate in dry or lyophilized form, and for forming a deliverable peritoneal dialysis solution therefrom. In one embodiment, a dry reagent bed, including reagents sufficient to produce a dialysis solution, is suspended in a diluent flow path through the apparatus housing. Continuous pressure on the reagent bed causes the bed to compact as it erodes when purified water is passed through the housing. The pressure ensures complete and even dissolution of the reagents. Through dry storage and simple dissolution, even in a home, the invention enables a wider variety of solution constituents, including reduced acid content and the use of bicarbonate as a stable buffer component. The latter is illustrated in a double-bed embodiment, where bicarbonate is stored separately from calcium or magnesium salts within a single housing.

Owner:PRISMEDICAL CORP

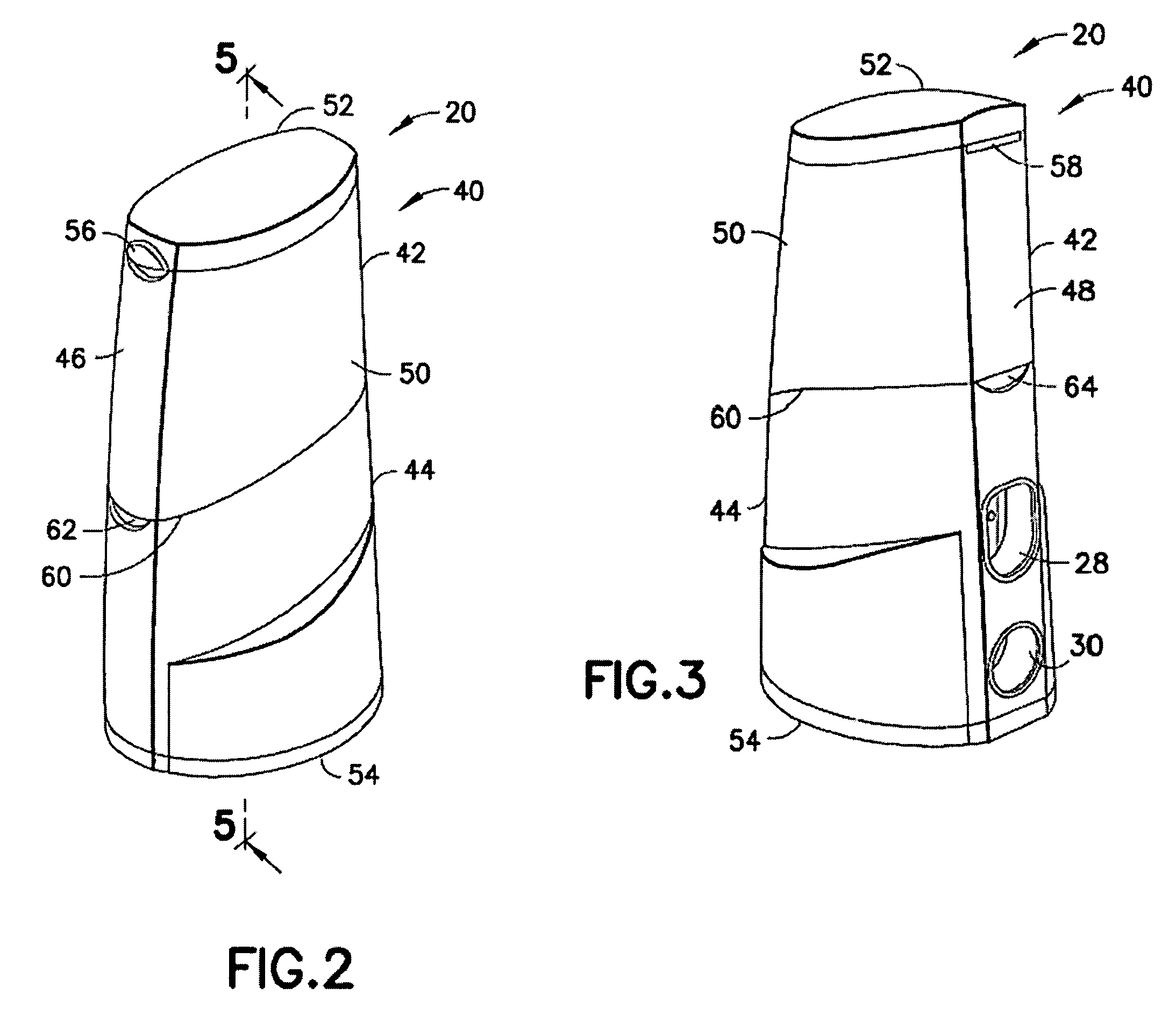

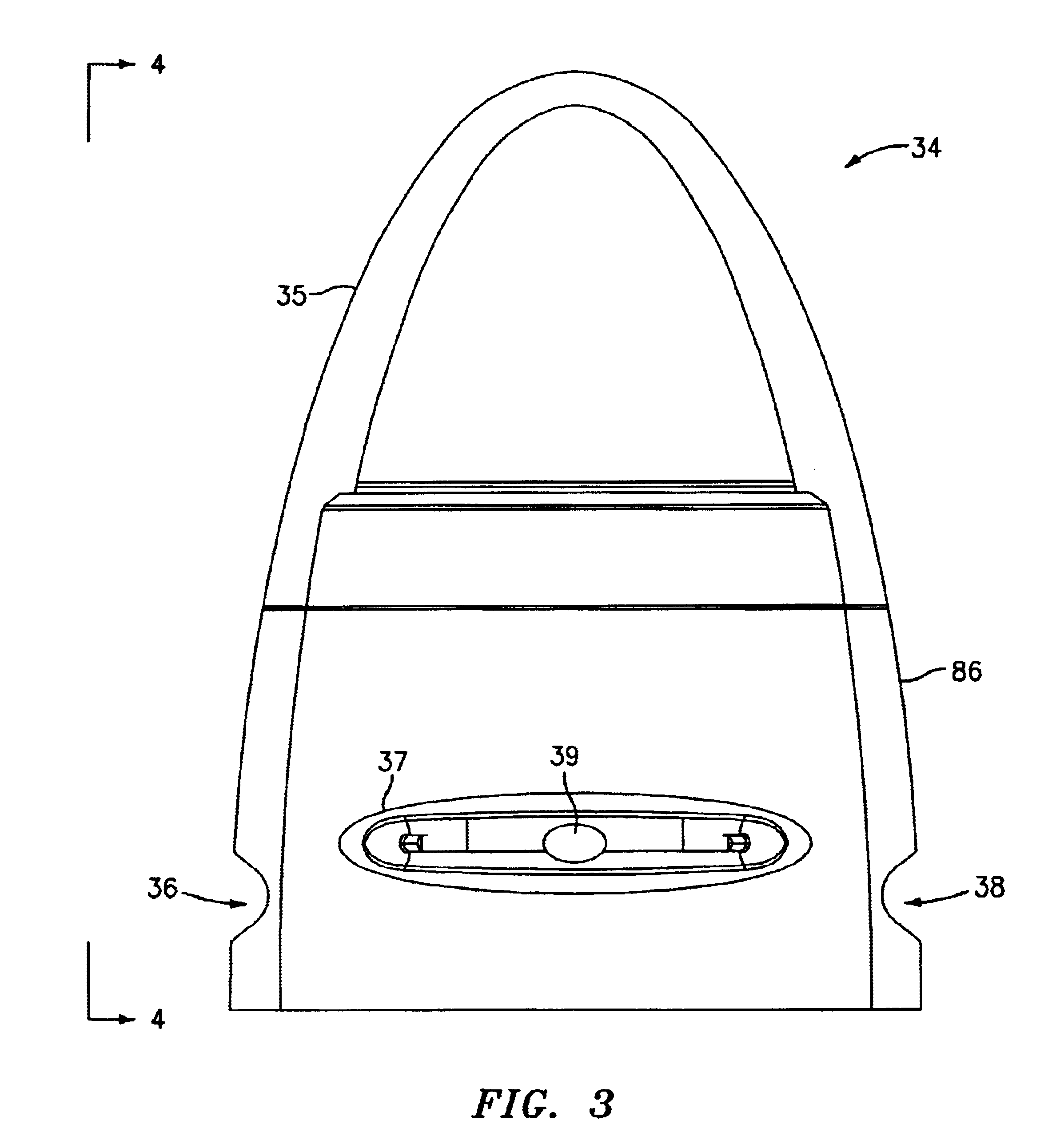

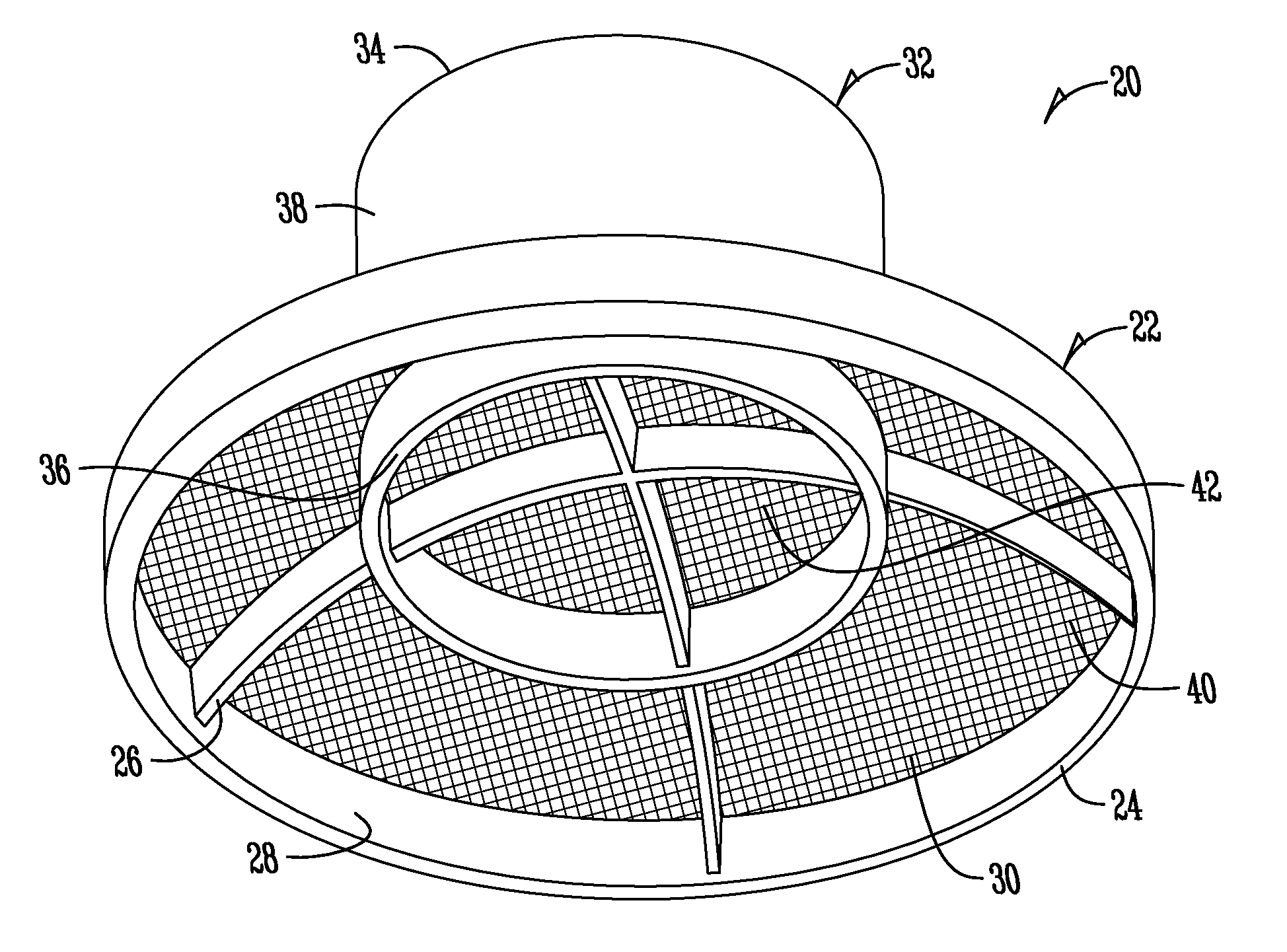

Yard and garden chemical dispenser

InactiveUS20110315790A1Dissolving using flow mixingTransportation and packagingInterior spaceAtomizer nozzle

A chemical dispensing apparatus includes a housing that is connectable to a source of water, such as a standard garden house, and an internal space in which is disposed a rotatable container containing a quantity of chemical concentrate to be mixed with the source of water as it flows through the housing and is dispensed from the housing from a sprinkler head or misting nozzle. The flow of water through the housing is directed to imping vanes on the rotatable container, such that the container is rotated as water flows through the housing. In an alternative embodiment, the vanes are replaced with an electric motor. Rotation of the container cause the chemical concentrate to dissolve which is then mixed with the water before it is dispensed through the sprinkler or mister.

Owner:ORUBOR LAWRENCE

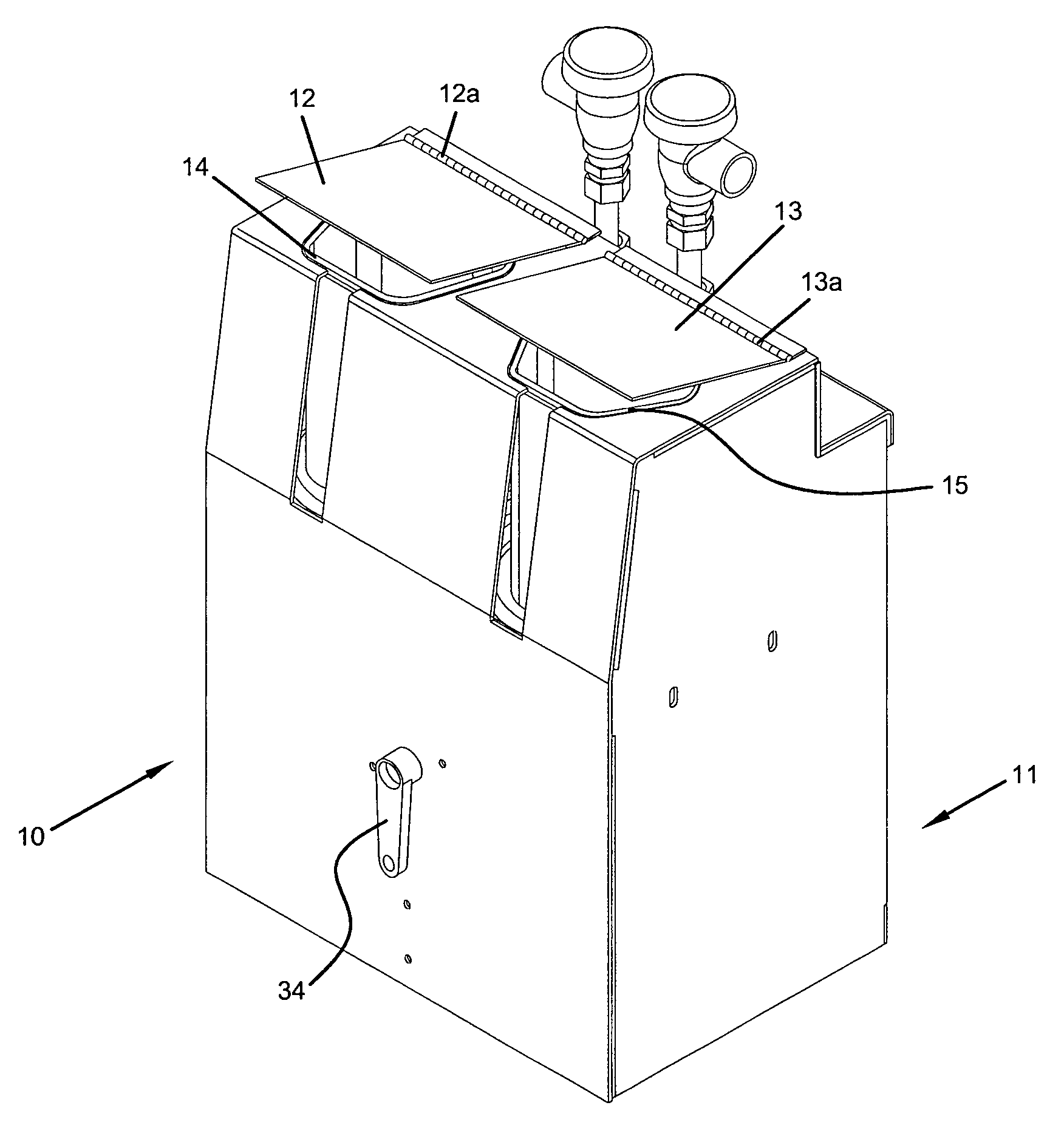

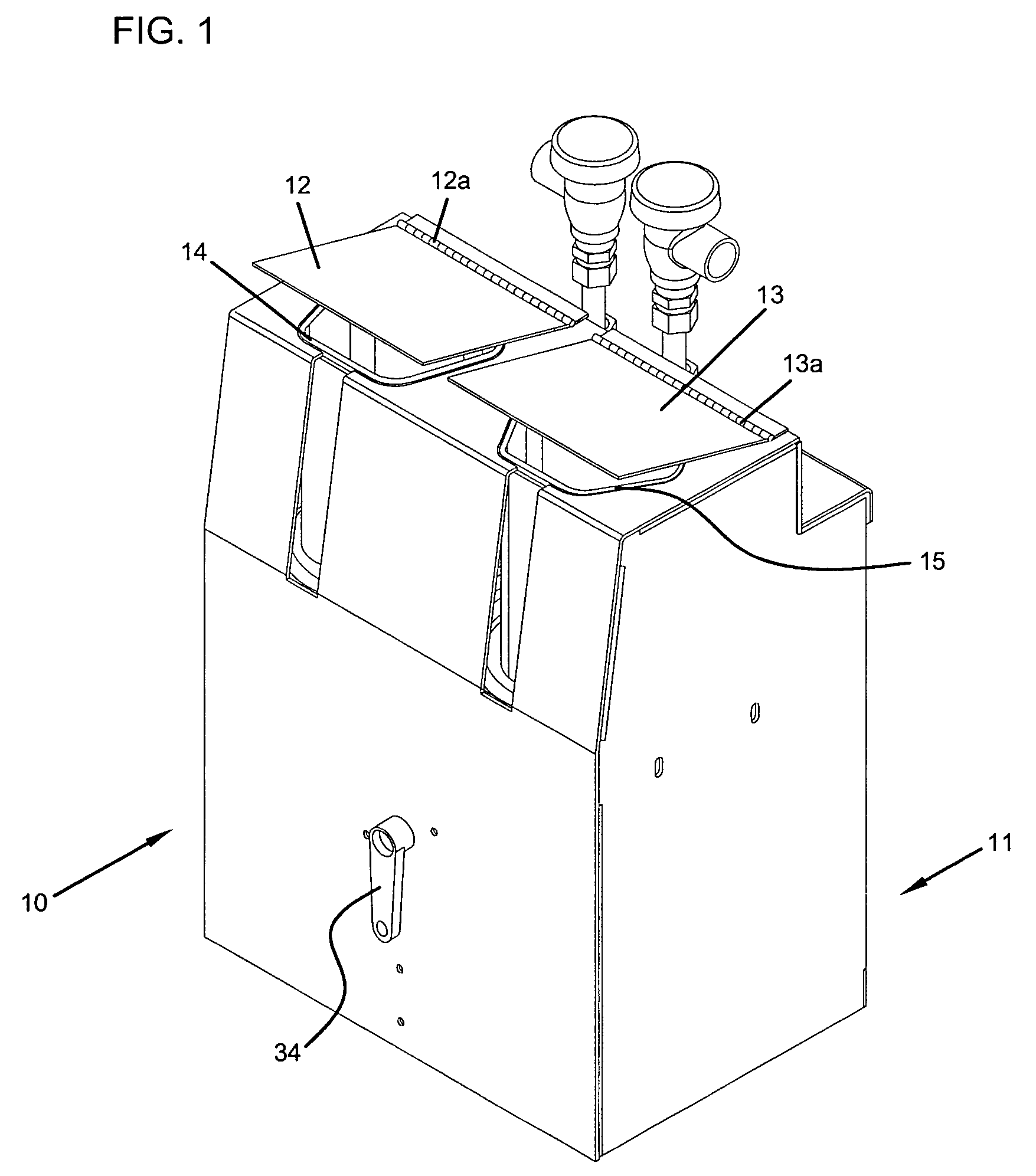

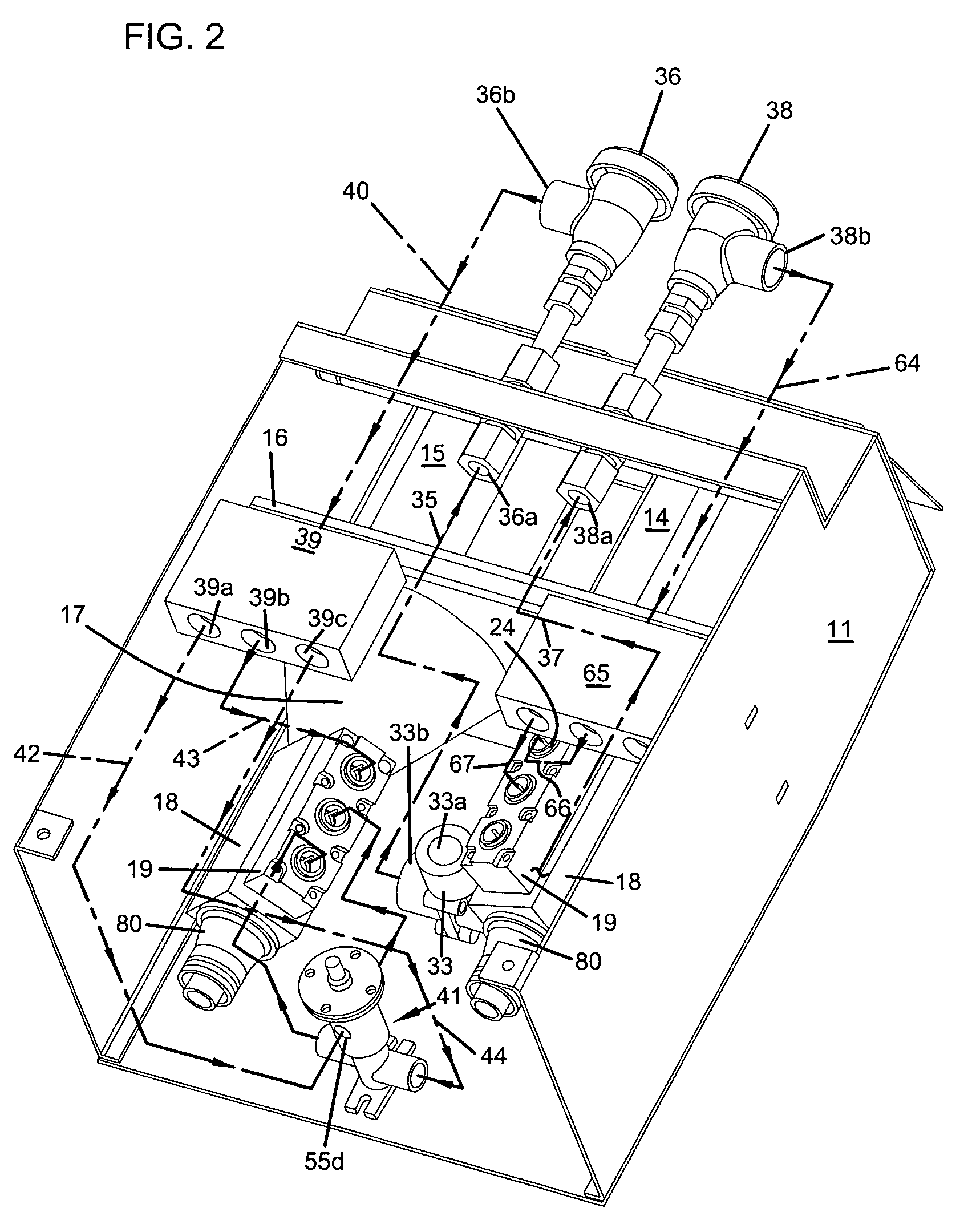

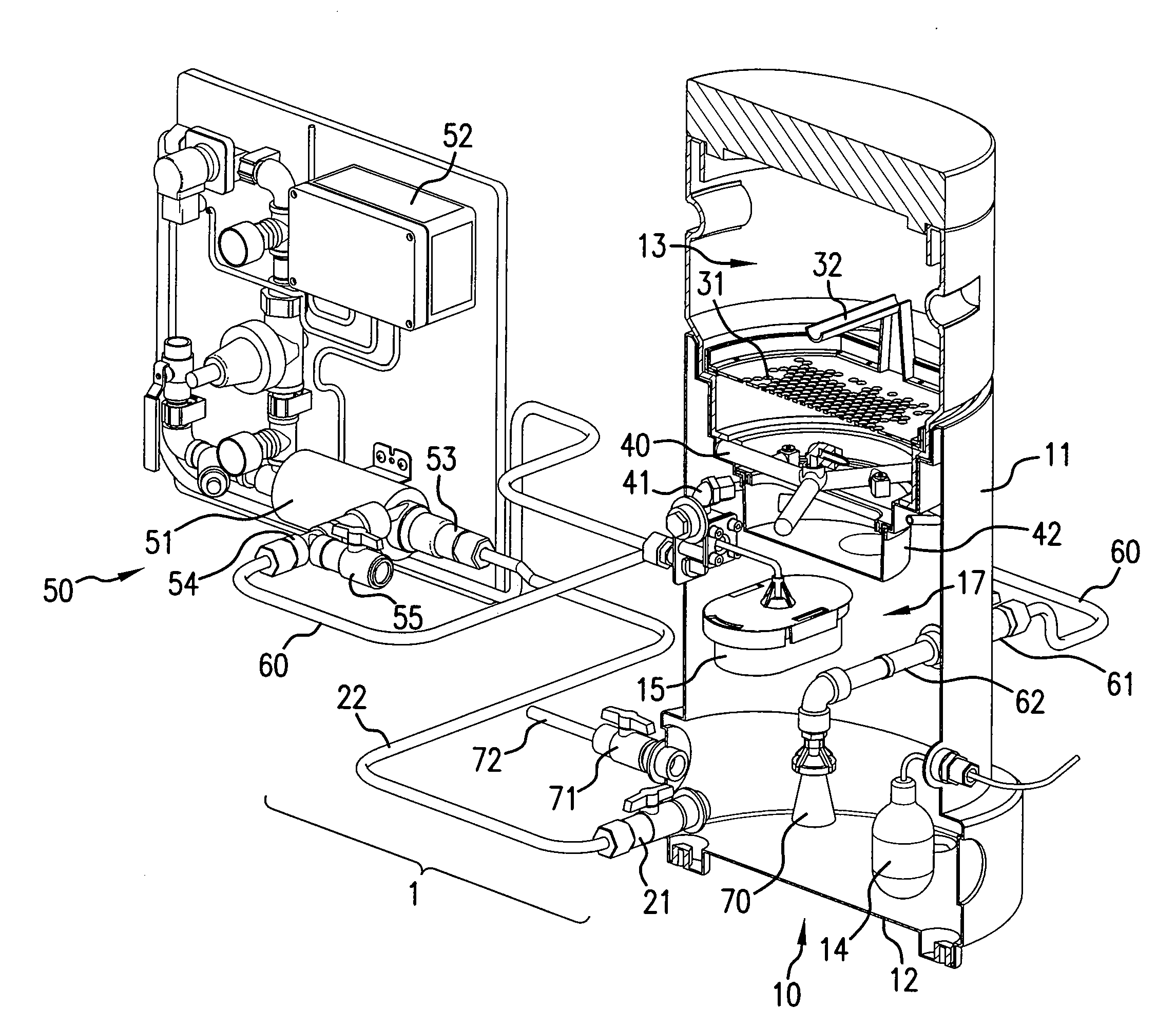

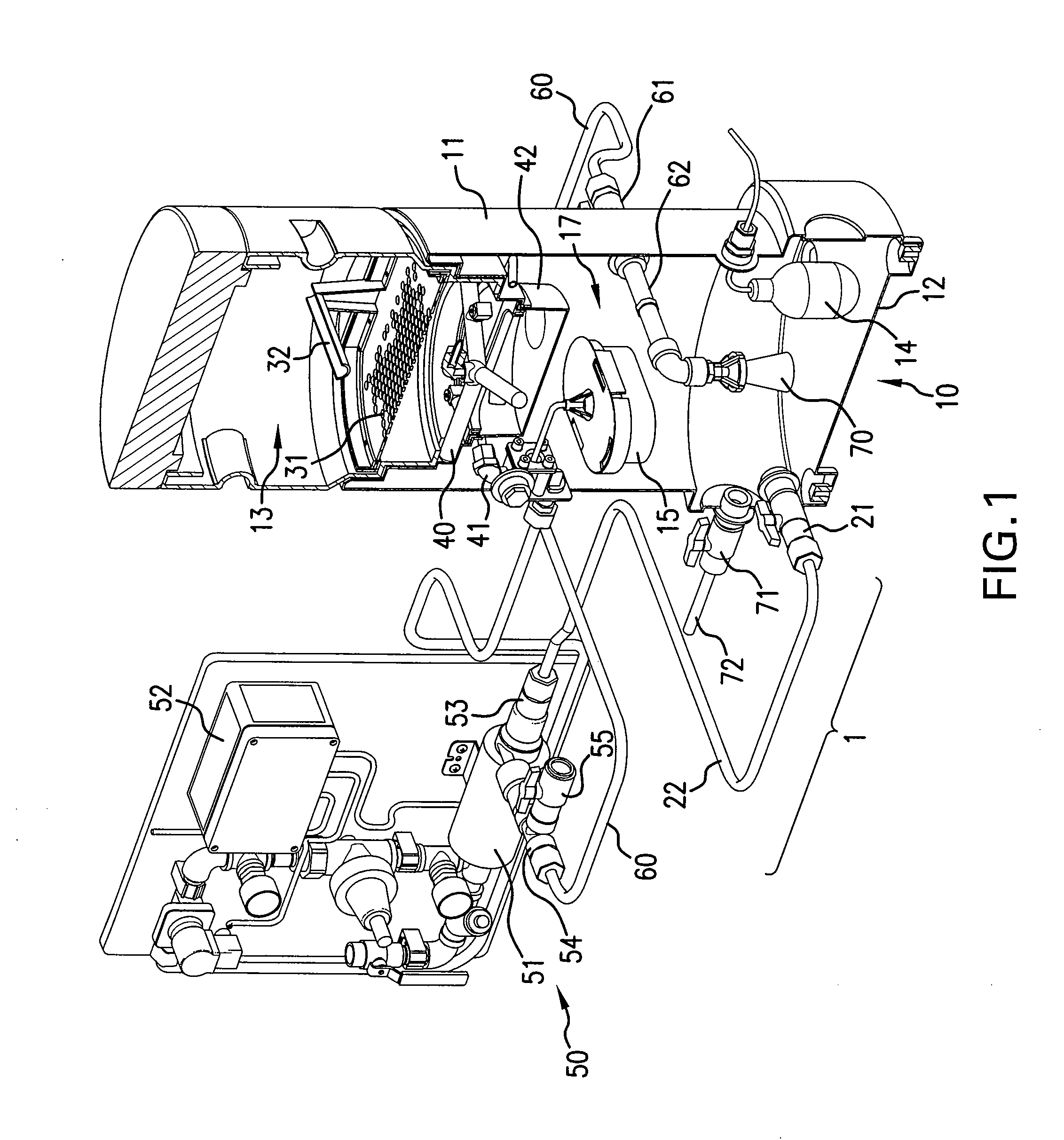

Method and apparatus to control dispensing rate of a solid product with changing temperature

InactiveUS20060083669A1Stay focusedAvoid prolonged usePower operated devicesSolid sorbent liquid separationTemperature controlDiluent

A dispenser (10) uses first and second flow controls (70, 73). The flow controls maintain first and second flow ranges independent of diluent pressure within a pressure range, wherein the use solution's concentration is maintained over the pressure range. A third flow control (75) may also be utilized in a third diluent passageway for maintaining a third flow range independent of the diluent pressure within the pressure range. A bypass valve assembly (41) is operatively connected to the third incoming diluent passageway. The bypass valve has a temperature control valve. The temperature control valve having a bypass passageway, wherein additional diluent is added to the use solution, thereby controlling the use solution's concentration.

Owner:ECOLAB USA INC

Solid product dispenser

ActiveUS20070253876A1Increase rate increaseSmall diameterFlow mixersSolid sorbent liquid separationDiluentProcess engineering

A solid product dispenser includes a housing and a product holder. The housing includes a concentrated solution outlet, a diluent outlet, and an outlet tube in which concentrated solution from the concentrated solution outlet and diluent from the diluent outlet are mixed to form a use solution. Proximate the housing and the product holder is an overflow outlet from which a vacuum breaker is at least 3.50 inches.

Owner:ECOLAB USA INC

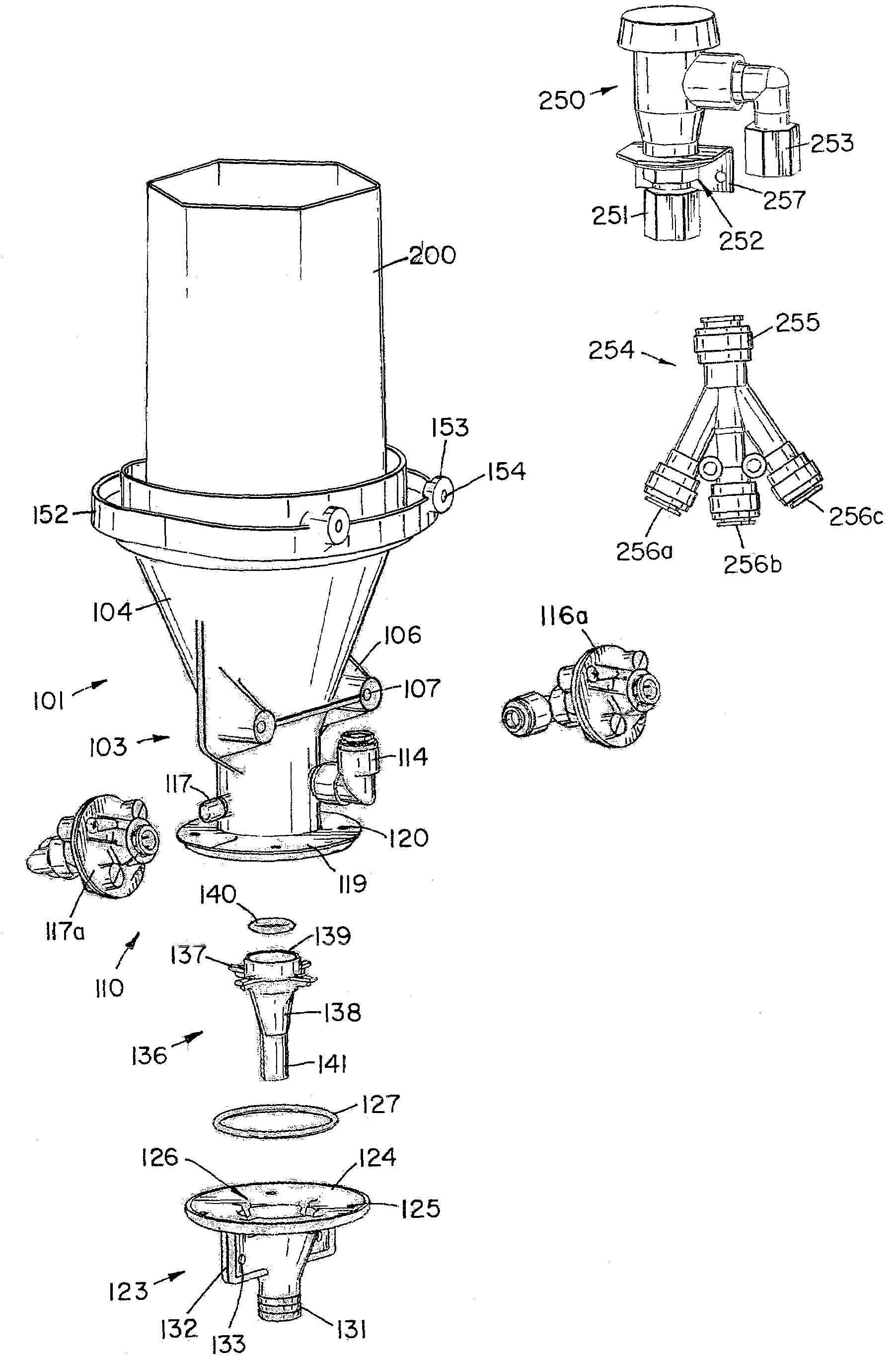

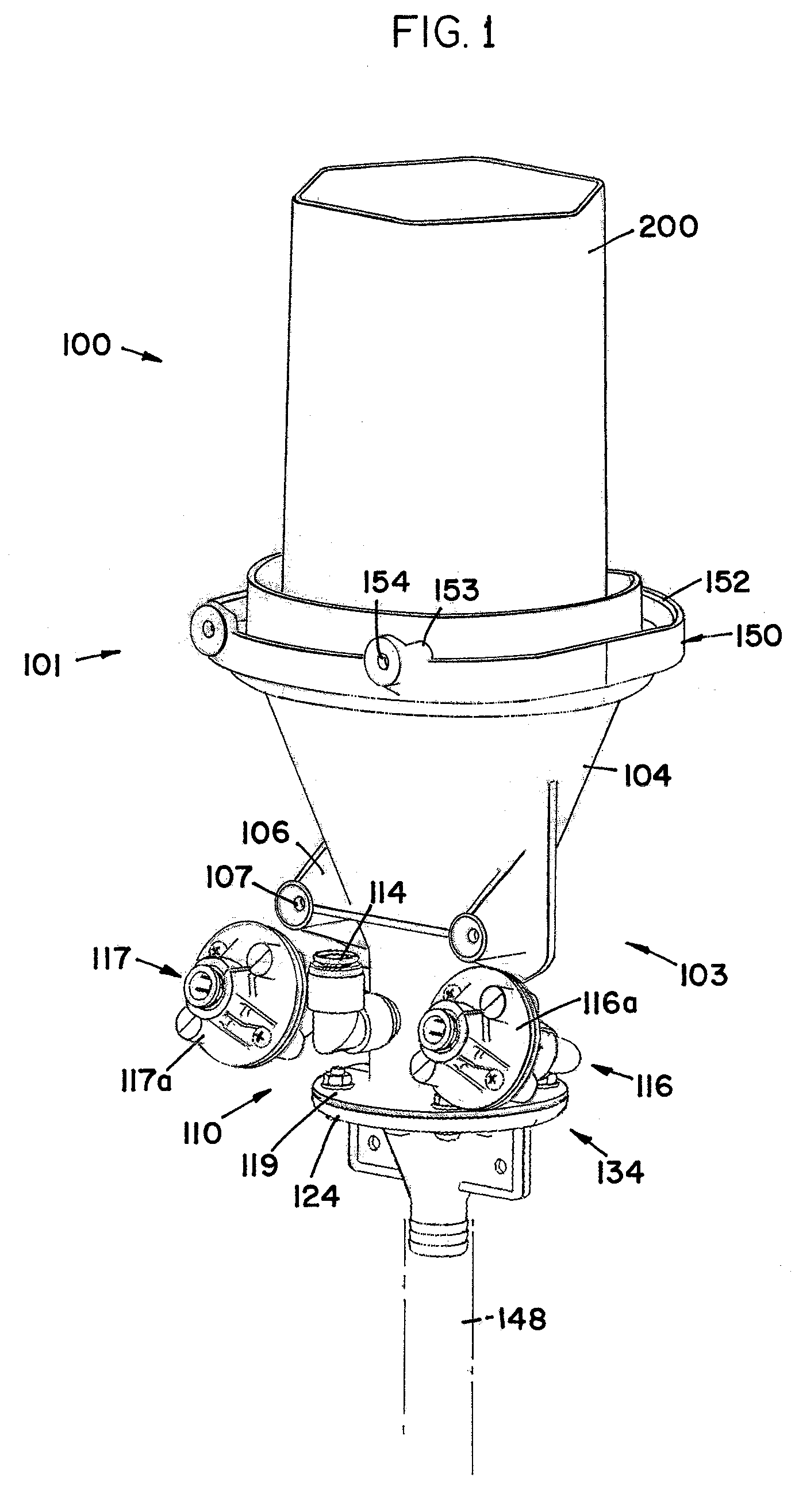

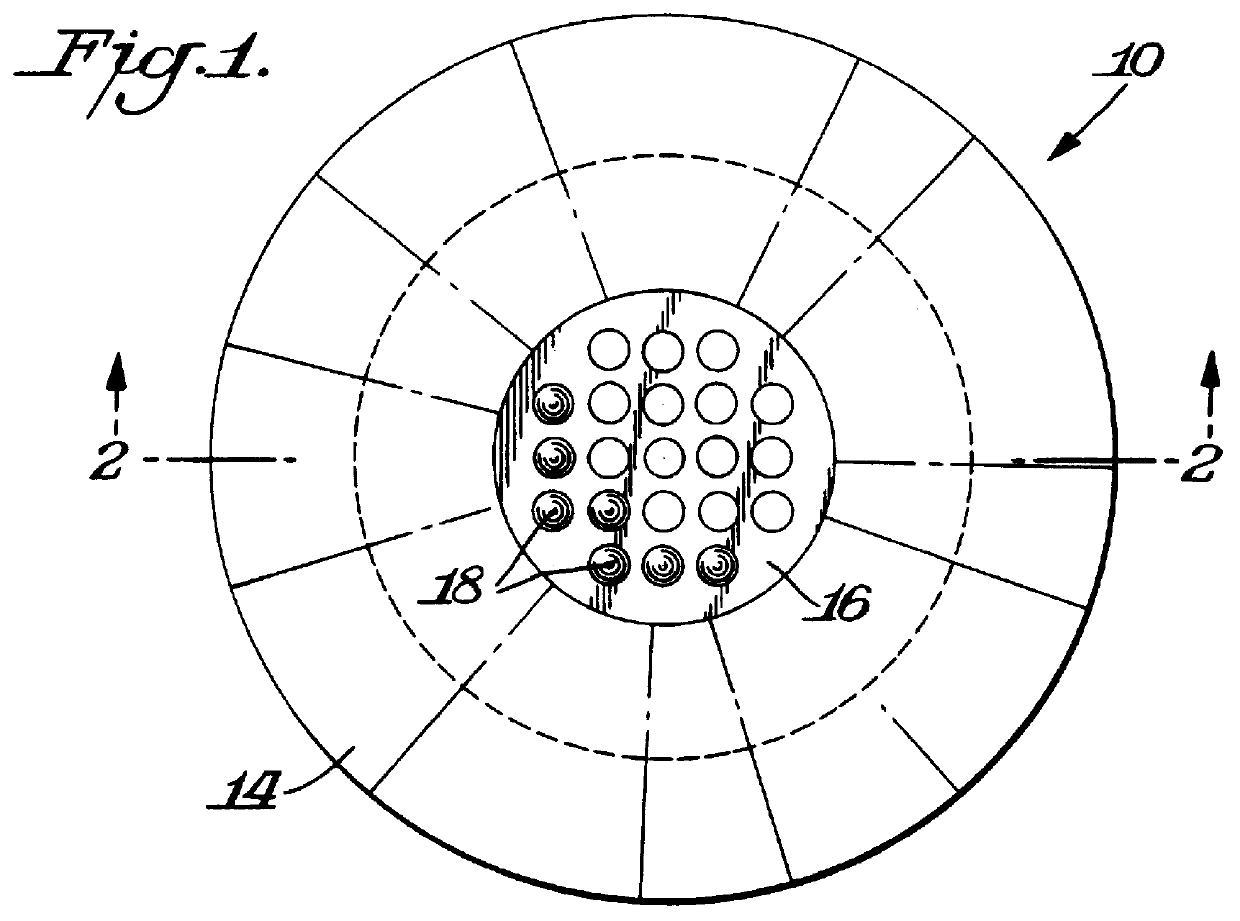

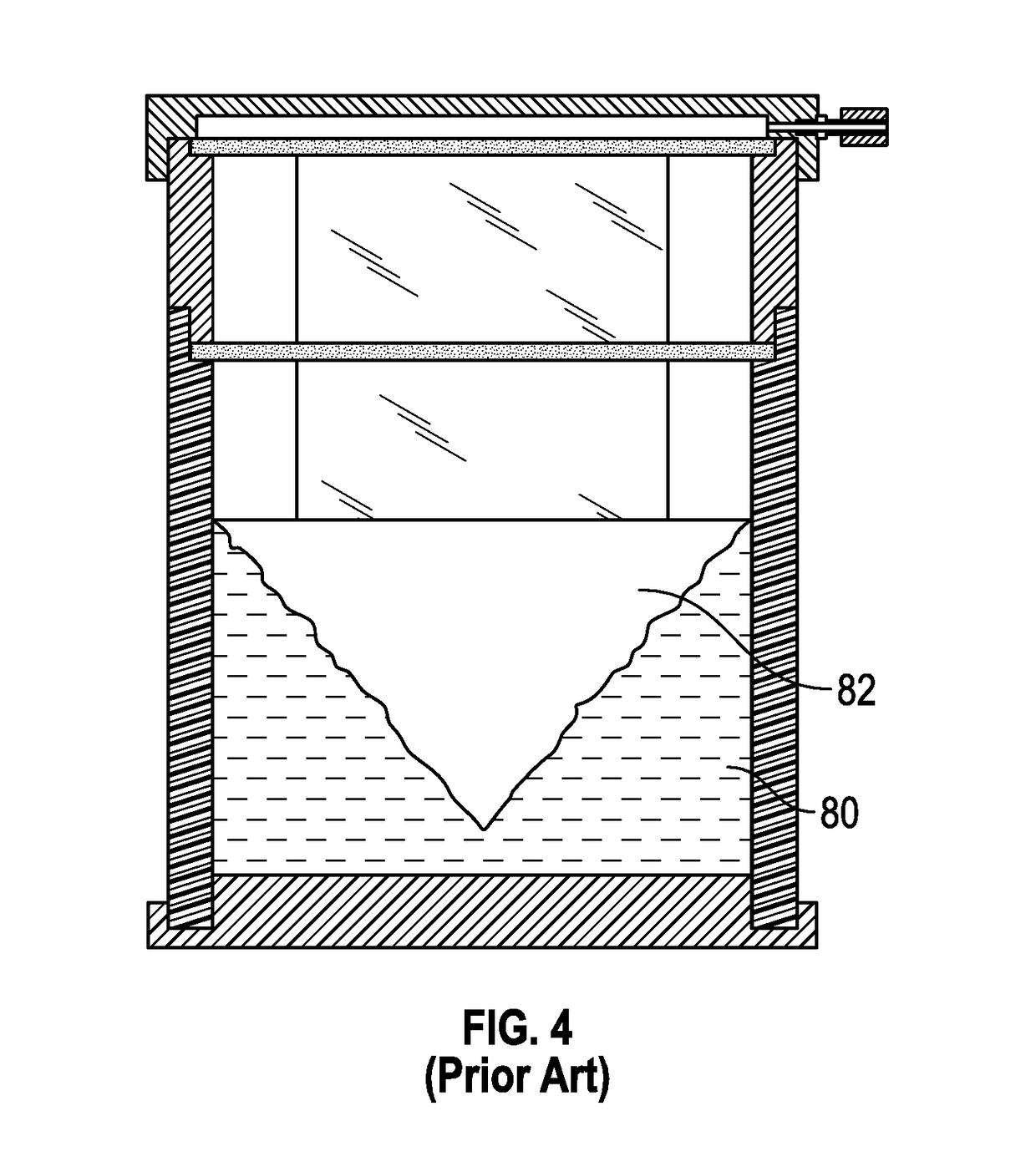

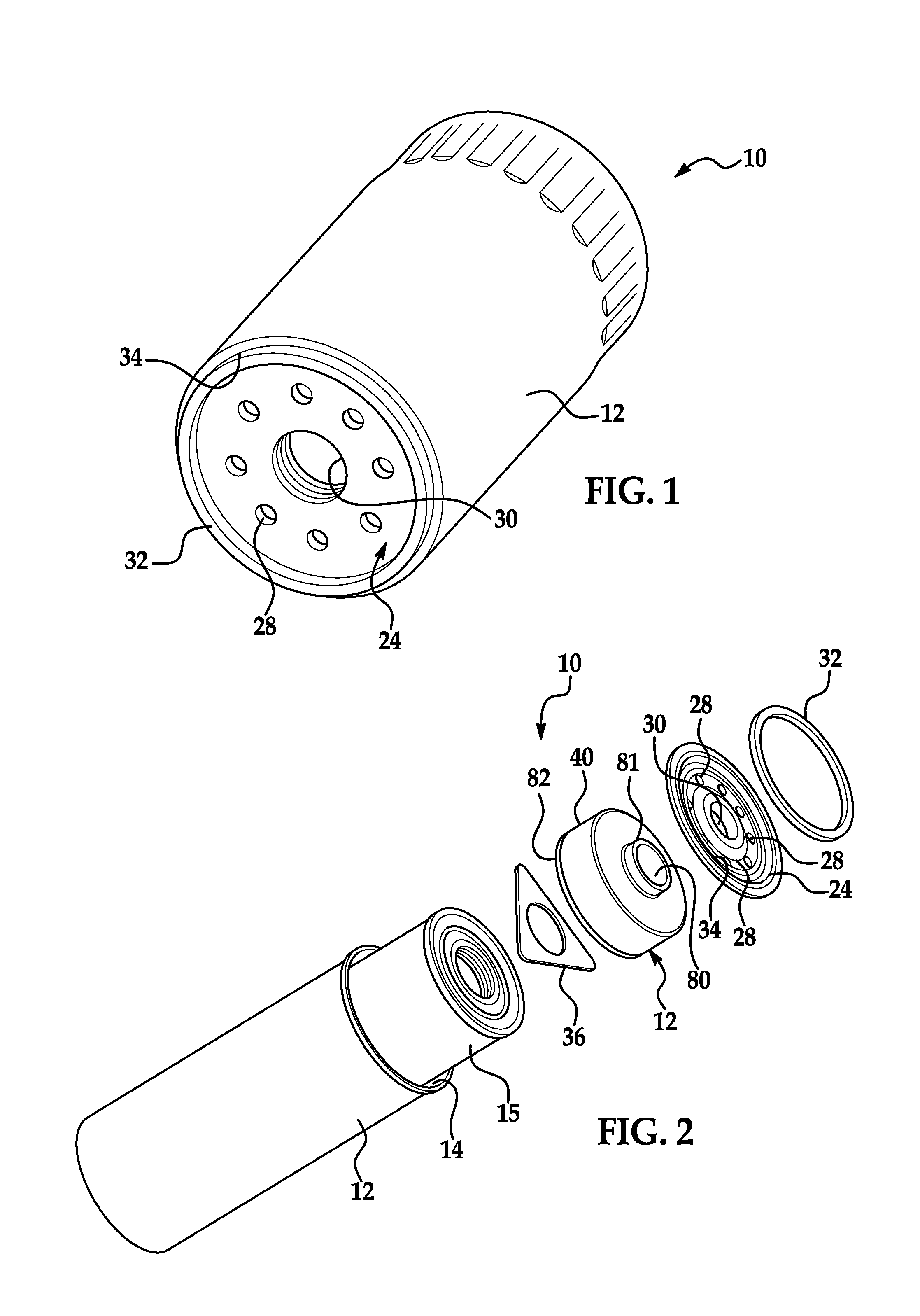

Chemical feeder

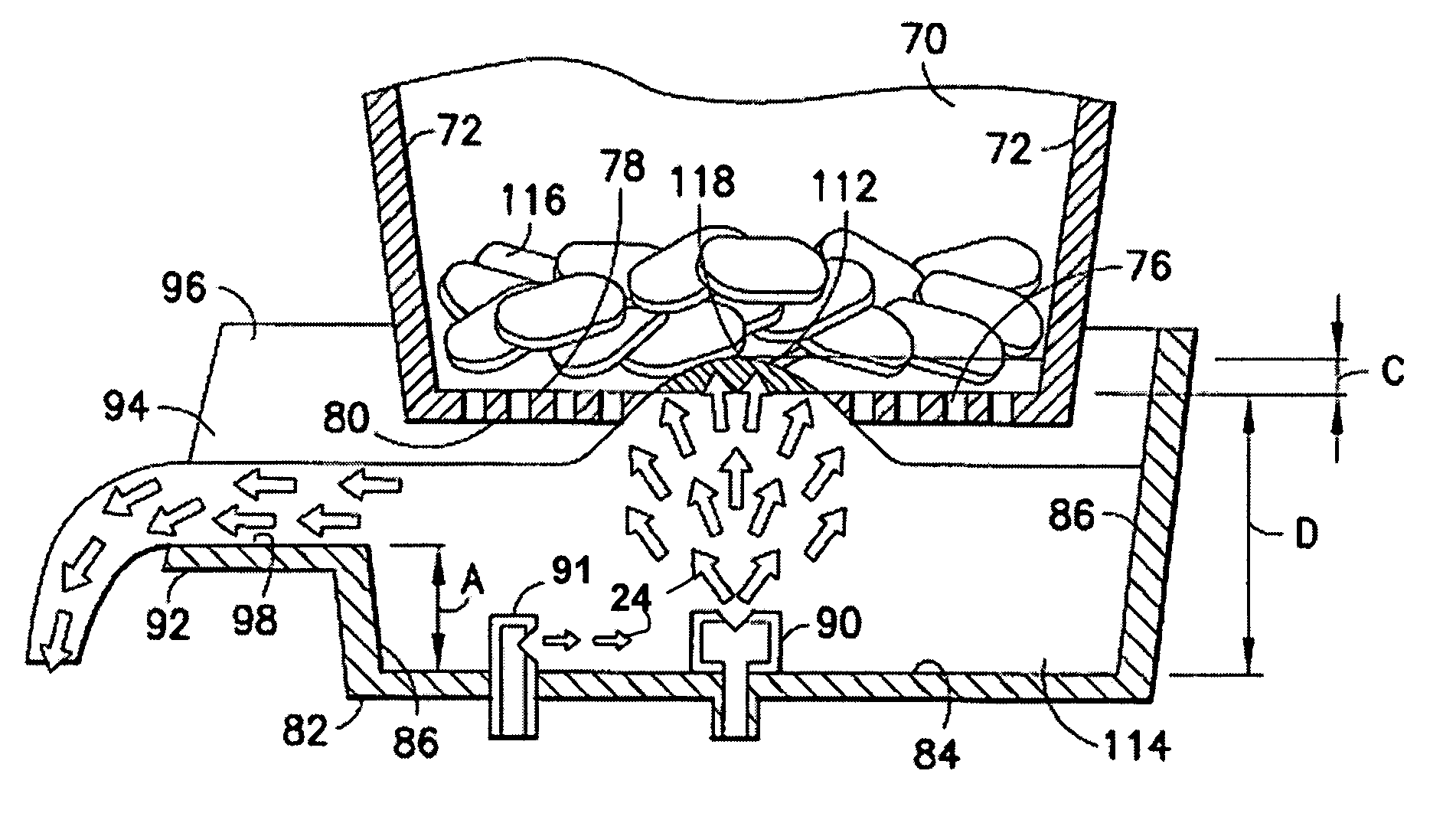

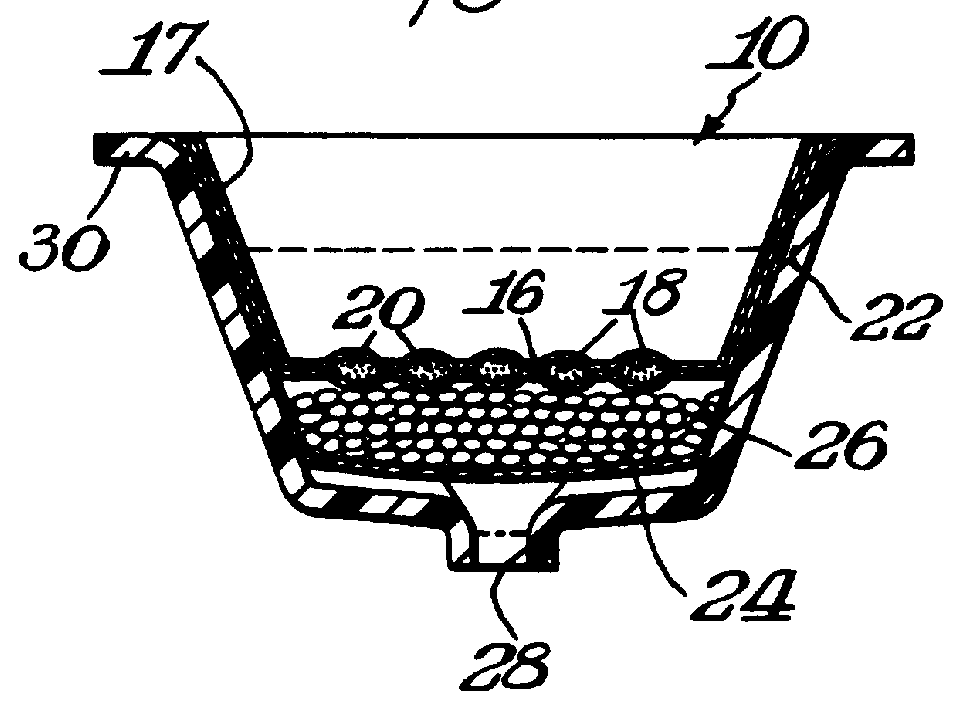

InactiveUS7143778B2Quality improvementMore tolerant to manufacturing toleranceSolid sorbent liquid separationMixer accessoriesWater flowCompound (substance)

A feeder device for introducing treatment chemicals into a recirculating water stream from a swimming pool. The feeder device includes a housing having a top and bottom portions. A funnel-like hopper having sidewalls and an open bottom forms the inside of the top portion. A grid at least partially closes the open bottom of the hopper. The grid includes a top surface and a bottom surface. One or more chemicals such as chlorine are contained within the sidewalls of the hopper and supported by the top surface of the grid. A dissolving cup having a bottom surface and sidewalls is positioned within the bottom portion. The sidewalls include an opening or notch of a predetermined cross-sectional area formed therein. The bottom surface includes a center nozzle oriented vertically toward the bottom surface of the grid and an off-center nozzle adapted to direct the fluid horizontally in the dissolving cup.

Owner:INNOVATIVE WATER CARE LLC

Dissolution Chamber for Cleaning Tablets

ActiveUS20130215705A1Reduce erosionDissolving using flow mixingFlow mixersTablet dissolutionEngineering

Owner:DENTAL CARE INNOVATION

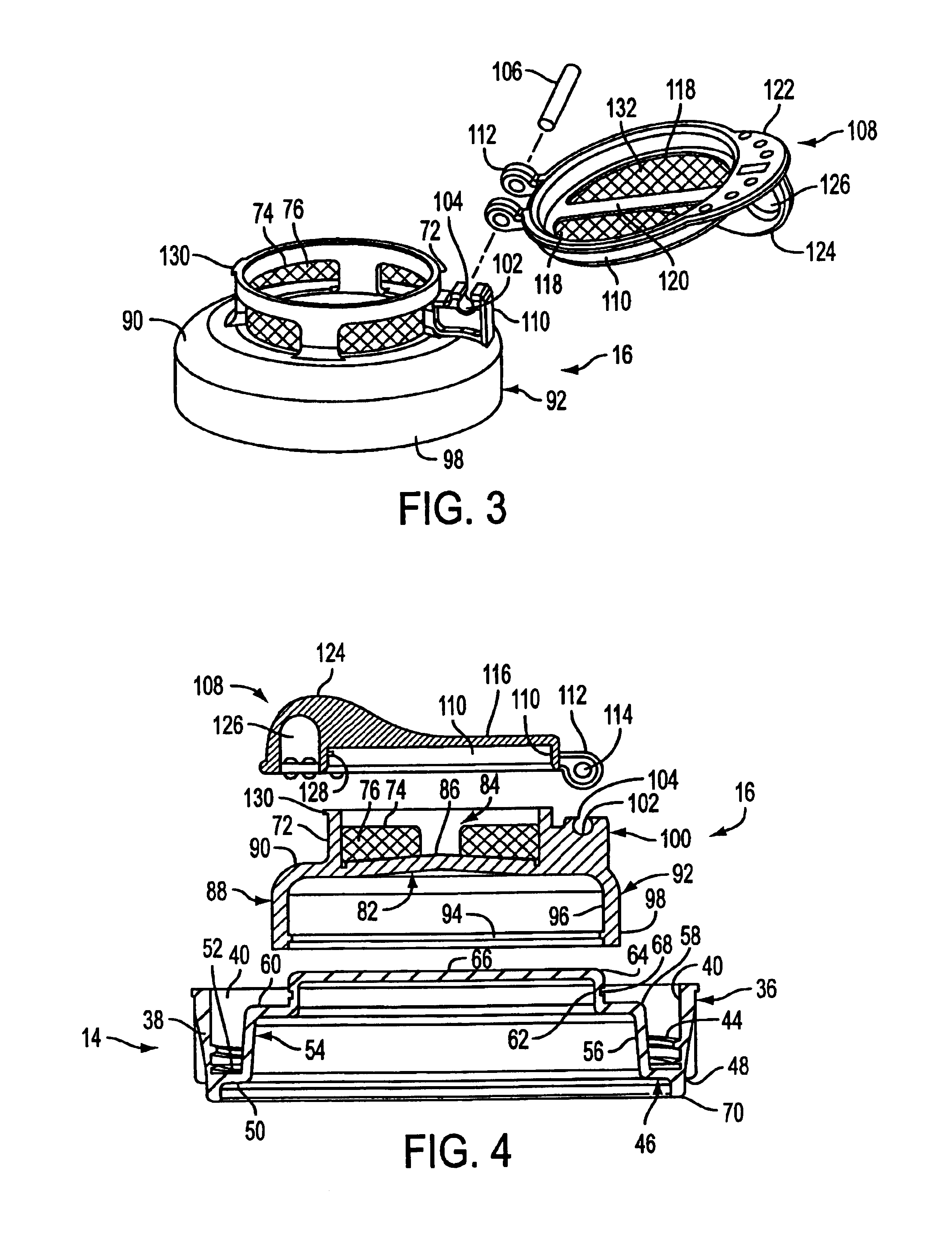

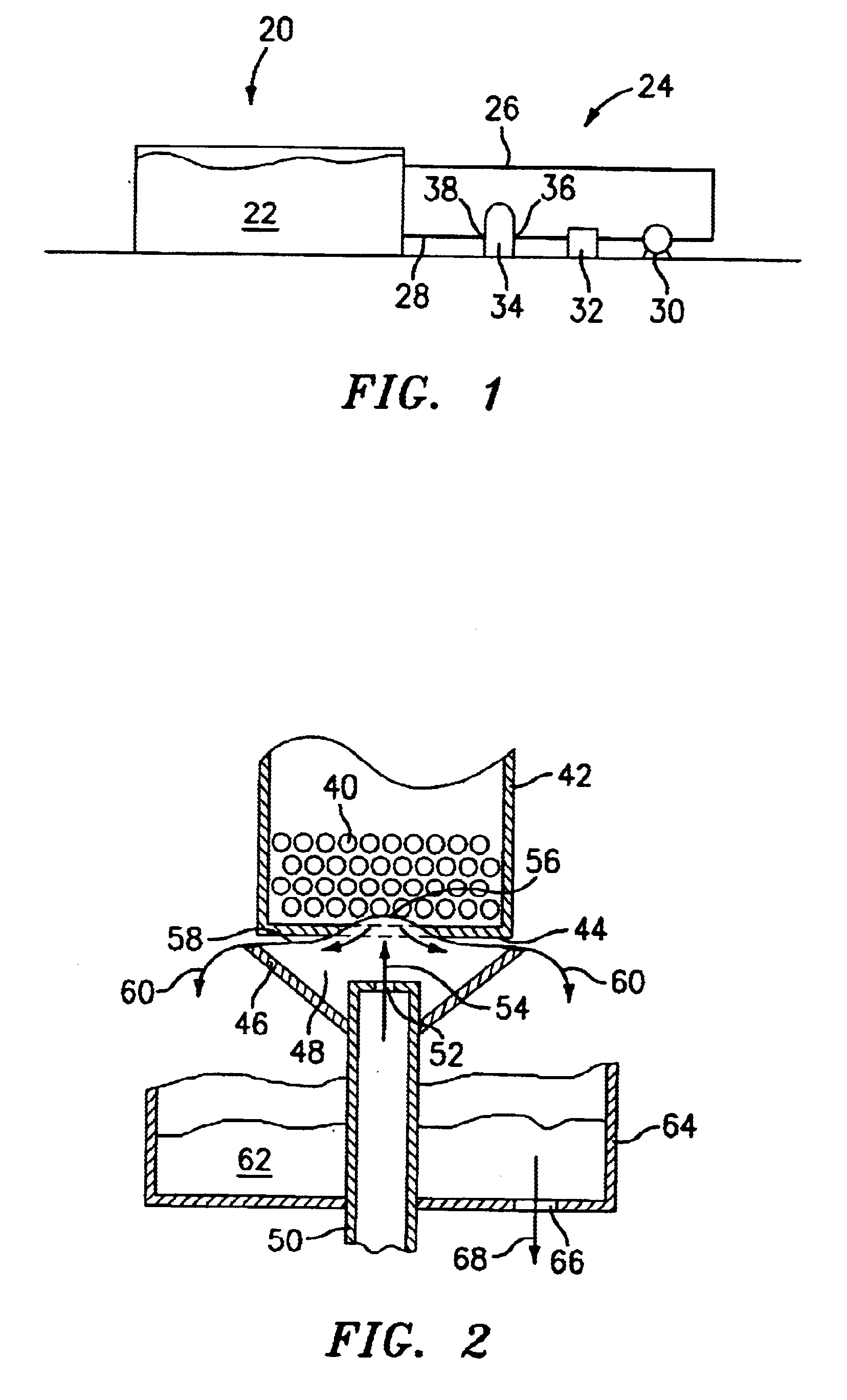

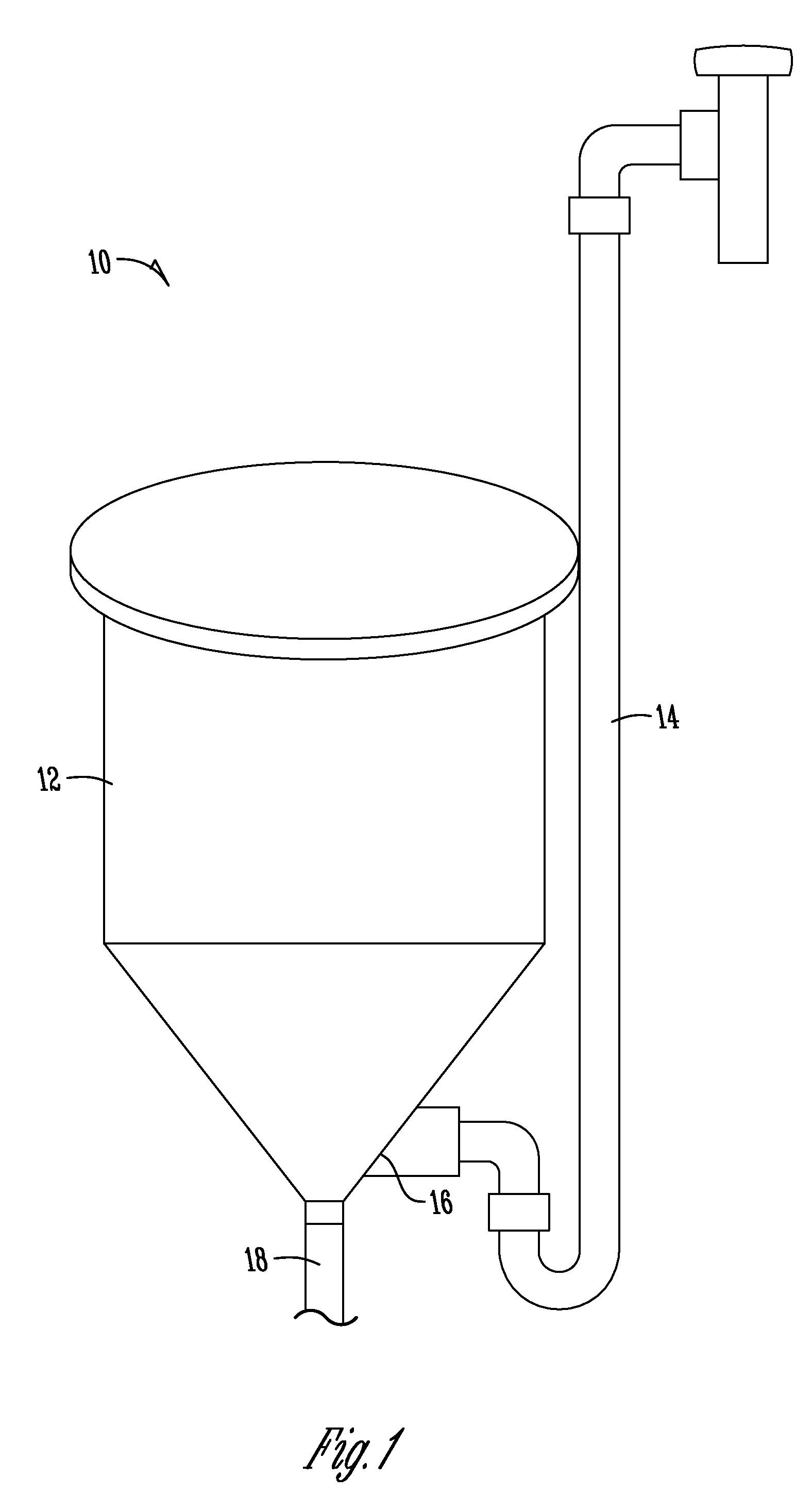

In-line fertilizing and lawn care dispensing system

InactiveUS8297535B1Firmly connectedDissolving using flow mixingLiquid fertiliser distributionParticulatesSprinkler system

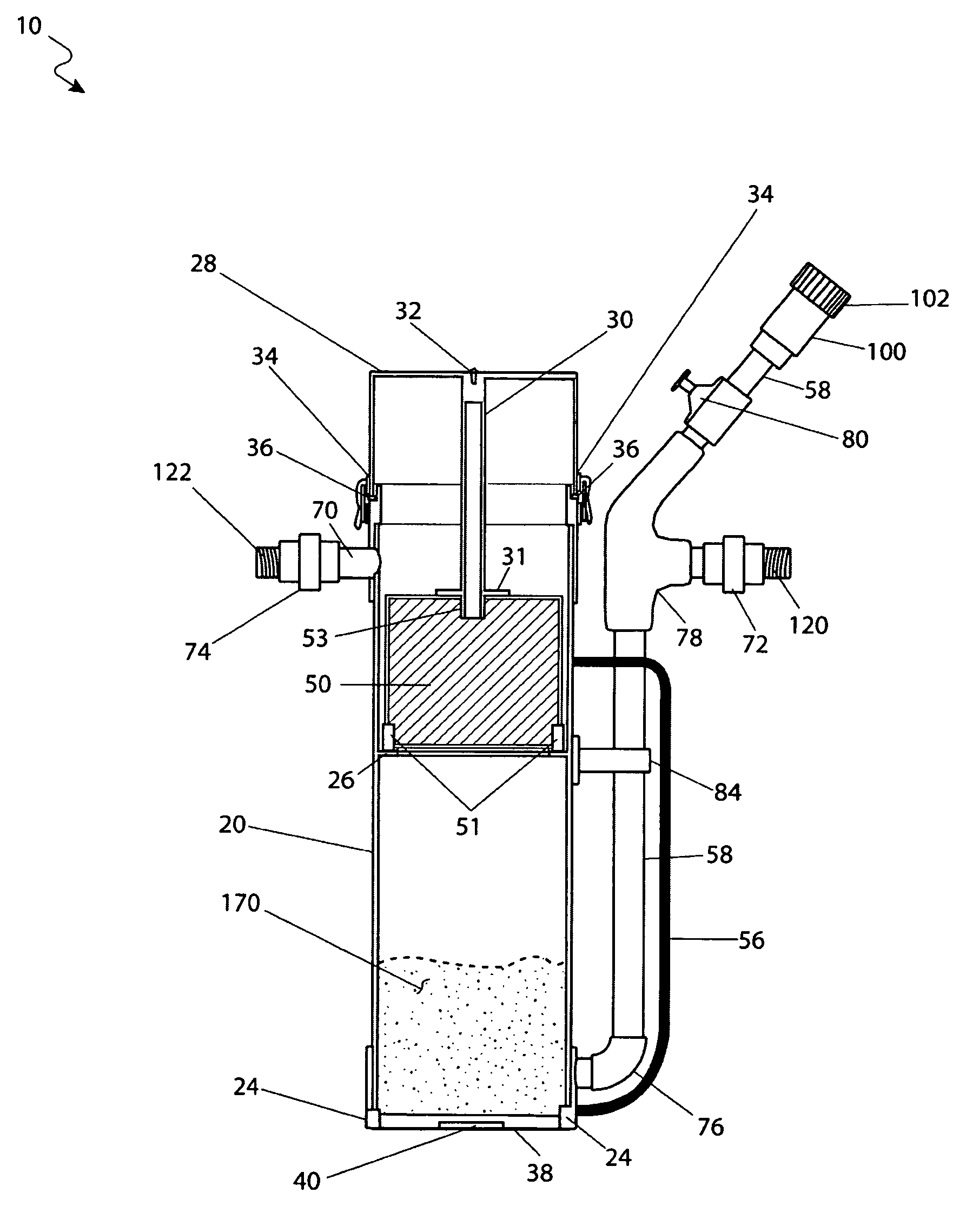

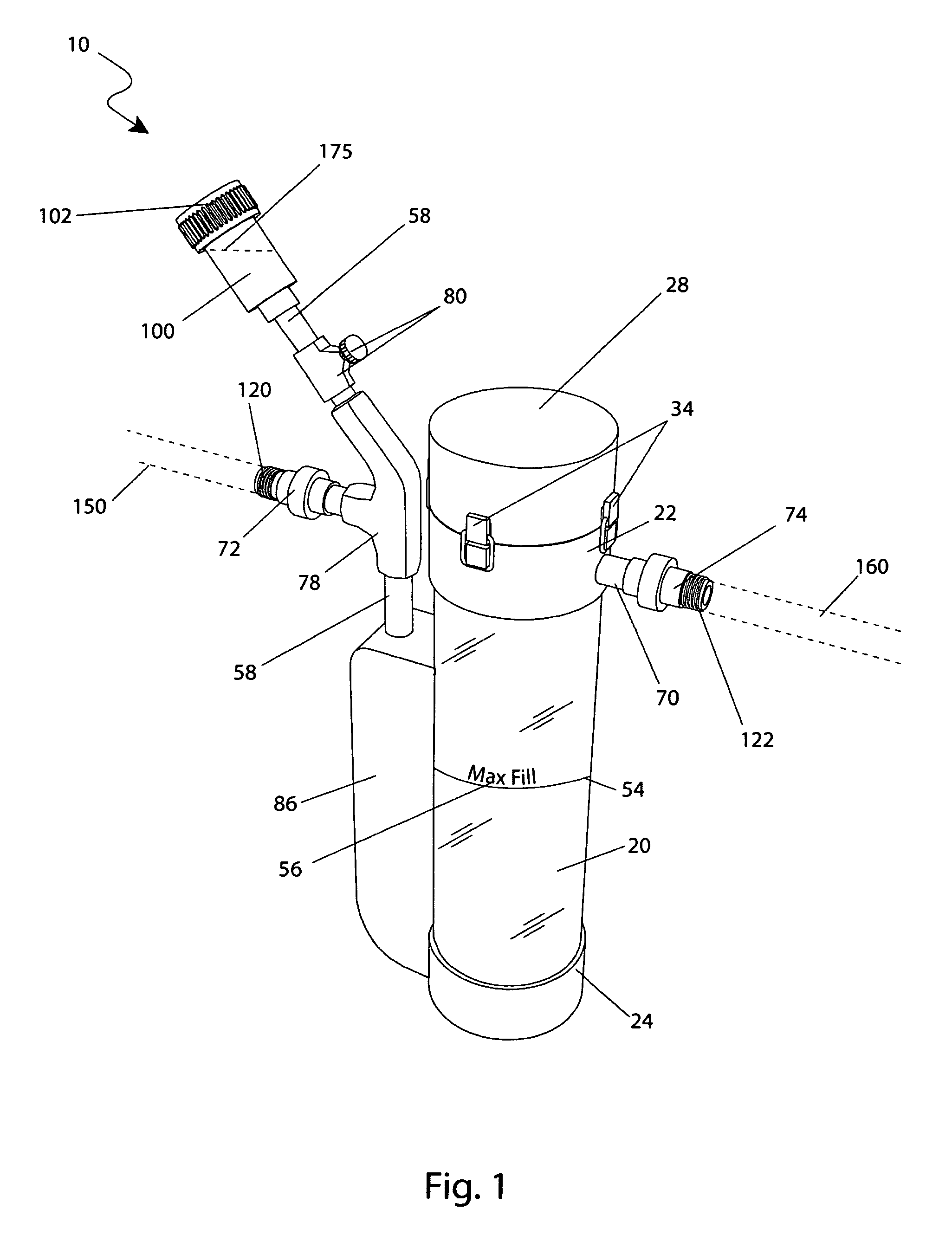

An apparatus that provides automatic mixing and distribution of granular or liquid fertilizers through an underground or portable sprinkler system, comprising a mixing container connected in-line with the sprinkler system's water delivery line or a regular garden hose connected to a portable or movable sprinkler, is herein disclosed. This mixing container provides a large lower portion which is accessed through a sealed and latched cover portion, through which granular-based lawn care chemicals are added. Incoming water then dissolves and mixes the chemicals, passes through removable filter media and exits the apparatus. This outgoing water is then routed to an underground sprinkler system or a portable hose-based sprinkler. A bottom valve can be opened to drain the apparatus and allow for cleaning. Additionally, the apparatus comprises an integral liquid fertilizer receptacle to automatically mix the incoming water with various liquid lawn care chemicals. Finally, the apparatus provides internal filtration to remove particulate matter therefrom the created fertilizer solution. The apparatus may be utilized at a header supply portion of a sprinkler system, part of an underground system, or connected inline between two garden hoses or a spigot.

Owner:REID EZEKIEL T

Chemical feeder

InactiveUS6915811B2Treatment involving filtrationSolid sorbent liquid separationCompound (substance)Water treatment

A feeder that uses a local elevation or stationary wave of a body of water to facilitate the dissolving of a chlorine-containing water treatment chemical.

Owner:INNOVATIVE WATER CARE LLC

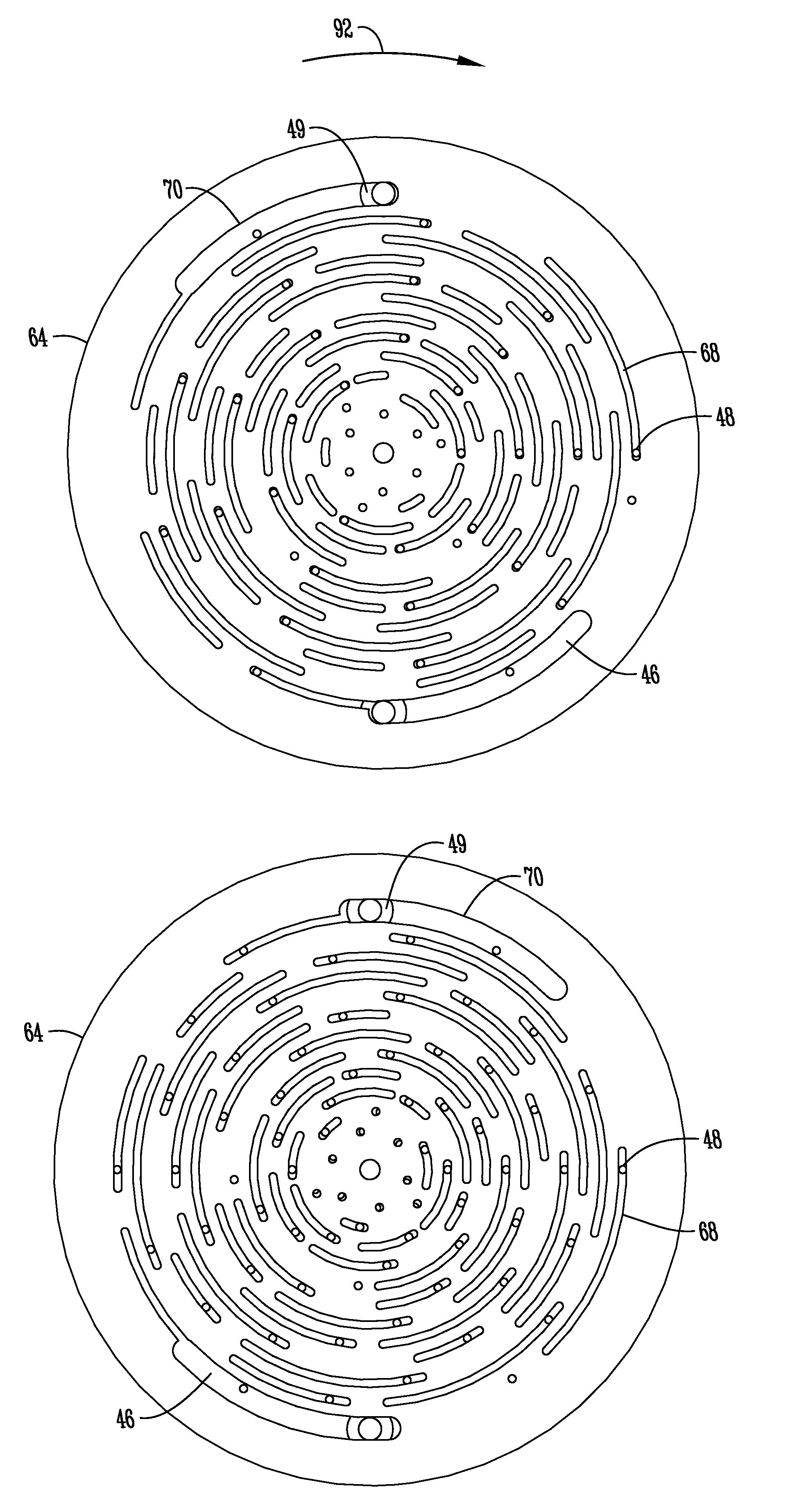

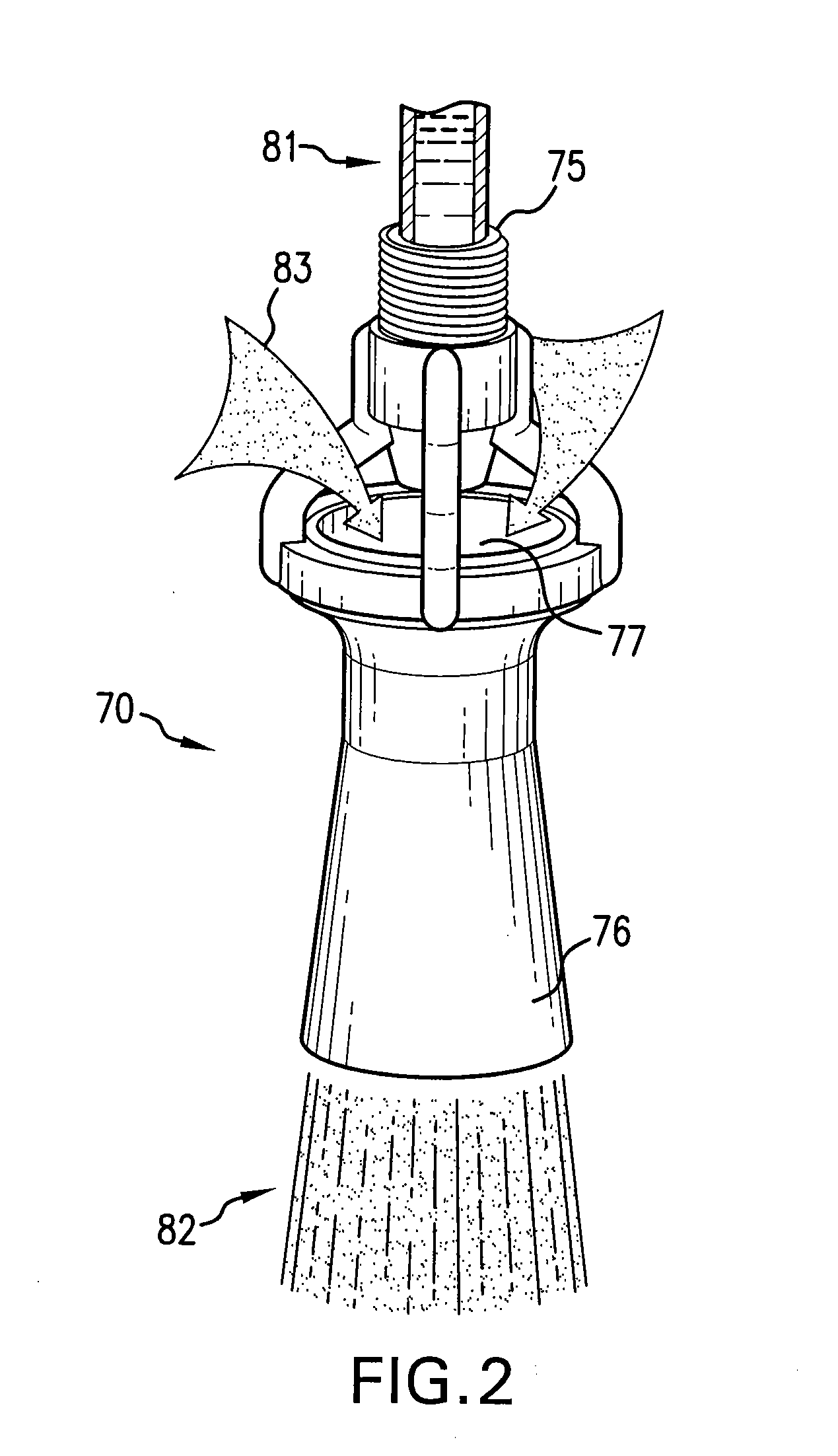

Method and apparatus for variation of flow to erode solid chemistry

ActiveUS20140233346A1Flow adjustableUniform erosionControlling ratio of multiple fluid flowsDissolving using flow mixingSolid-state chemistryWaste management

A method and apparatus for obtaining a product chemistry from a product and a fluid is provided. A product is housed within a dispenser. A fluid is introduced through a manifold diffuse member having a plurality of ports. A cover is positioned adjacent the manifold diffuse member and includes a plurality of ports. The cover is able to be adjusted, for example, by rotating the cover, to align and un-align the manifold diffuse ports and the cover ports. This adjustment controls the flow characteristics of the fluid through the manifold diffuse member and cover to control the characteristics of the fluid in contact with the product. The adjustment of the cover to control the flow will provide a generally consistent concentration and erosion rate based upon known relationships between a characteristic of the fluid and the flow of the fluid in relation to the product.

Owner:ECOLAB USA INC

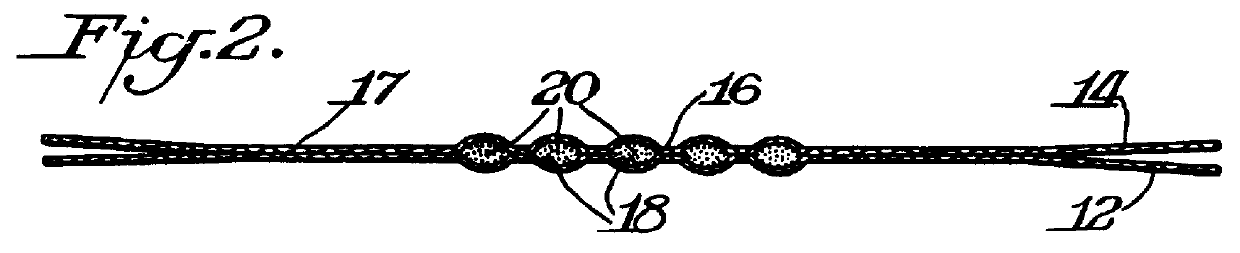

Method of treating fluids with a filter

InactiveUSRE36516E1Easy to manufactureEasy to useSolid sorbent liquid separationWater/sewage treatment using germicide/oligodynamic-processEngineeringBiomedical engineering

A filter for fluids includes a pair of layers or multiple layers or pairs of material joined together to form a laminate having a fluid contacting surface. A plurality of spaced pockets is formed between the layers of material in the contacting surface. The layers of material are fluid permeable at the pockets whereby fluid may flow through the laminate at the pockets. The fluid contacting surface is fluid impermeable except for the pockets to require the fluid passing through the laminate to be confined to flowing through the pockets. Filter members are in the pockets for removing any contaminants from the fluid. Alternatively, additive materials such as powdered cream or sugar in the pockets dissolve in the fluid passing through the pockets to enhance the fluid.

Owner:DVC INC

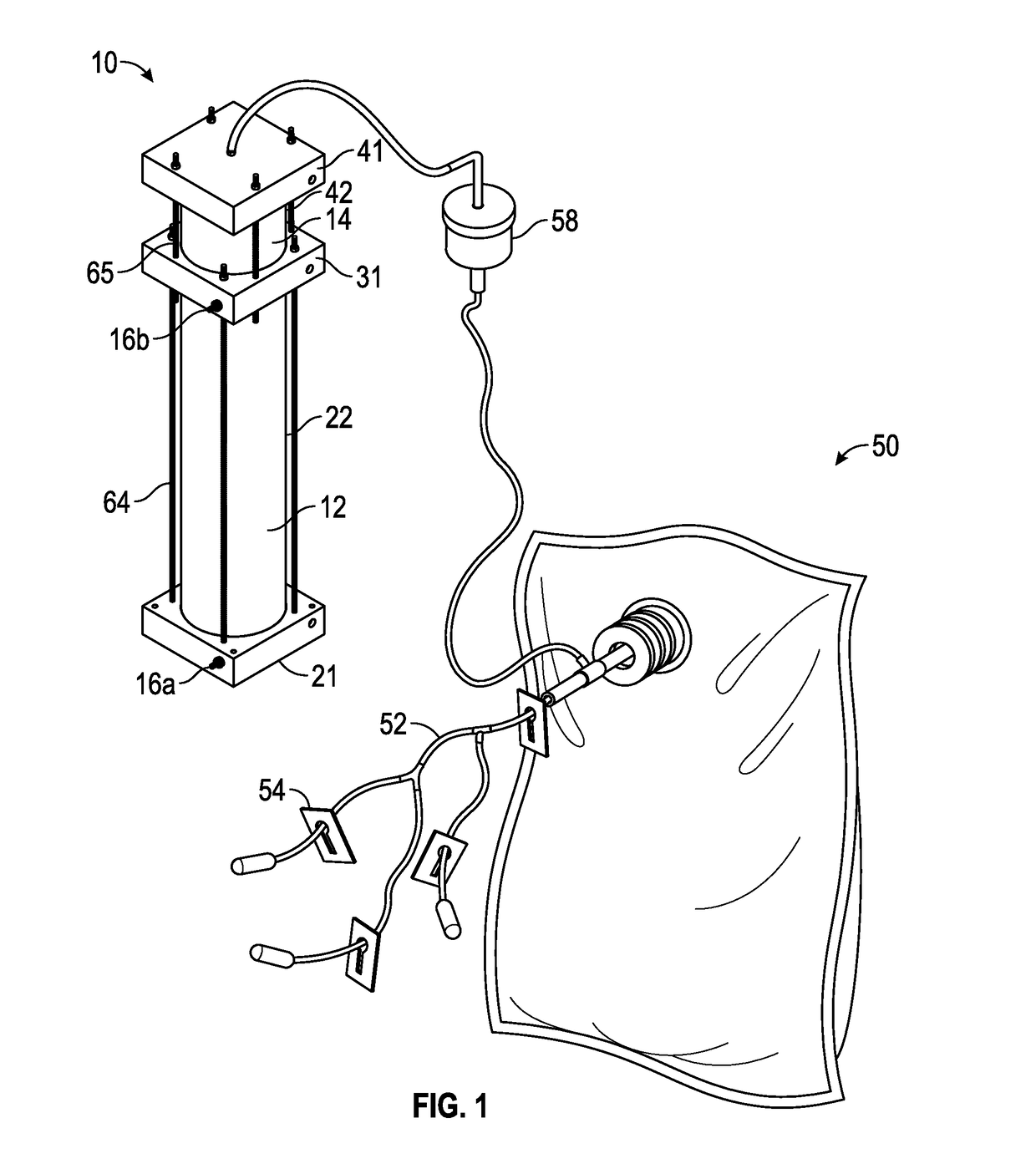

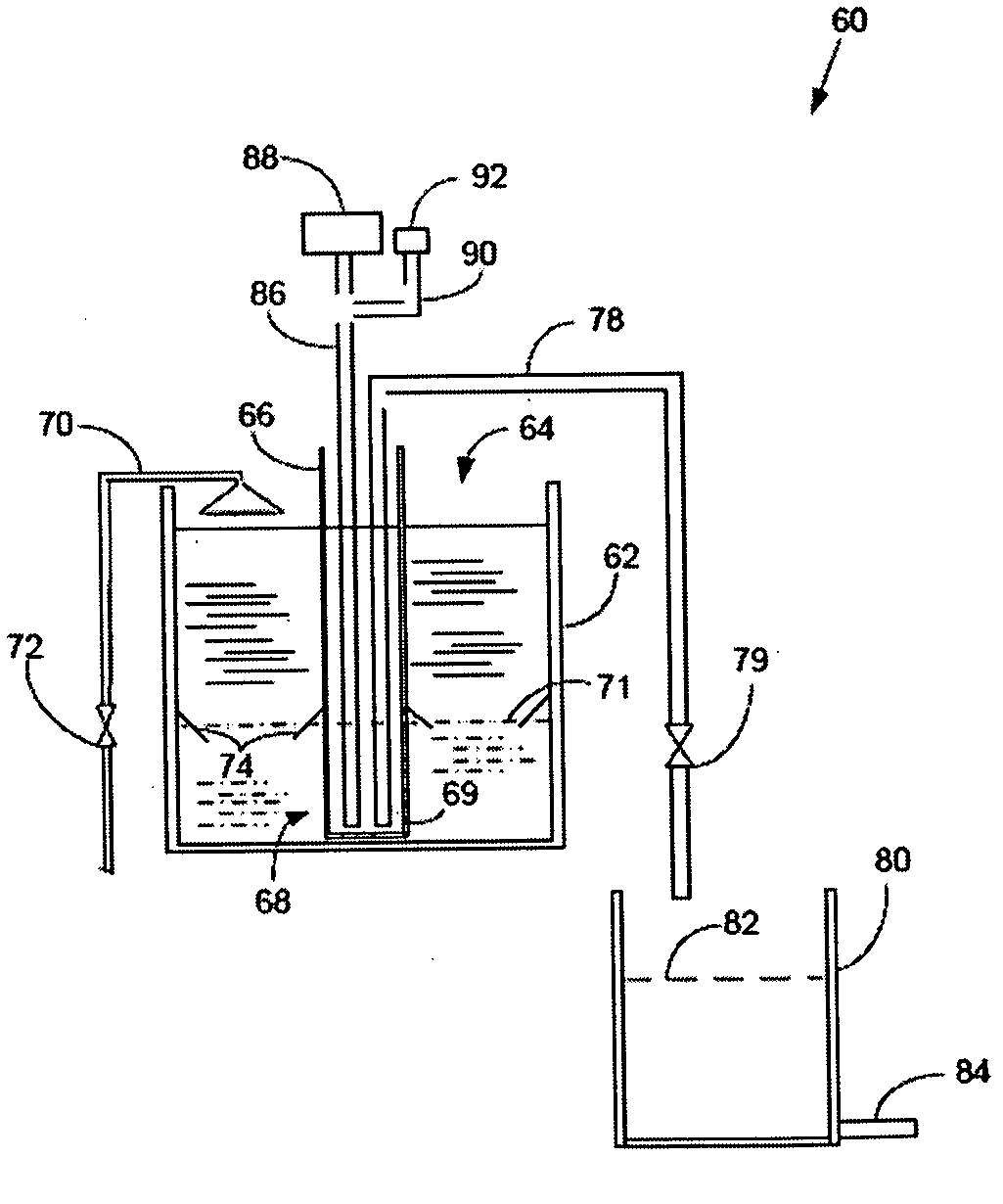

Media mixing chamber

ActiveUS20170145368A1Reduced shelf lifeAggressive agitationBioreactor/fermenter combinationsBiological substance pretreatmentsAid positionsCell culture media

A mixing apparatus for reconstituting a powdered cell culture media. The apparatus includes at least one fluid chamber, an influent port at a lower portion of the fluid chamber. The apparatus further includes a geometric fluid flow aid positioned in the fluid chamber and an effluent port at the top of the fluid chamber. A powdered cell culture media is provided in the fluid to be mixed with a fluid provided by the influent port. The effluent port is configured to allow reconstituted media to exit the fluid chamber.

Owner:FUJIFILM IRVINE SCI INC

Method and apparatus to control dispensing rate of a solid product with changing temperature

InactiveUS7597861B2Avoid prolonged usePower operated devicesSolid sorbent liquid separationTemperature controlDiluent

A dispenser (10) uses first and second flow controls (70, 73). The flow controls maintain first and second flow ranges independent of diluent pressure within a pressure range, wherein the use solution's concentration is maintained over the pressure range. A third flow control (75) may also be utilized in a third diluent passageway for maintaining a third flow range independent of the diluent pressure within the pressure range. A bypass valve assembly (41) is operatively connected to the third incoming diluent passageway. The bypass valve has a temperature control valve. The temperature control valve having a bypass passageway, wherein additional diluent is added to the use solution, thereby controlling the use solution's concentration.

Owner:ECOLAB USA INC

Preparing Formulations for Treating Agricultural Products

InactiveUS20090203527A1Reducing thermal fogging temperatureGood aerosol characteristicBiocideFlow mixersFoggerTime of use

The invention provides an improved method for creating a formulation using a solid chemical agent in solution within a reservoir, and treating crops within a storage facility with an aerosol of the solution substantially at the time of use. The method includes having a premixing section for formulating the solution and mixing solid with a solvent in a premixing section. Further the solution may be heated by circulating it through a substantially instantaneous heater then channeling the solution into a commercial fogger, generating an aerosol of the CIPC solution, and providing said storage facility with said aerosol.

Owner:NELSON DALE E

Chlorination apparatus and method

InactiveUS20020030004A1Other chemical processesDissolving using flow mixingRadial positionEngineering

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

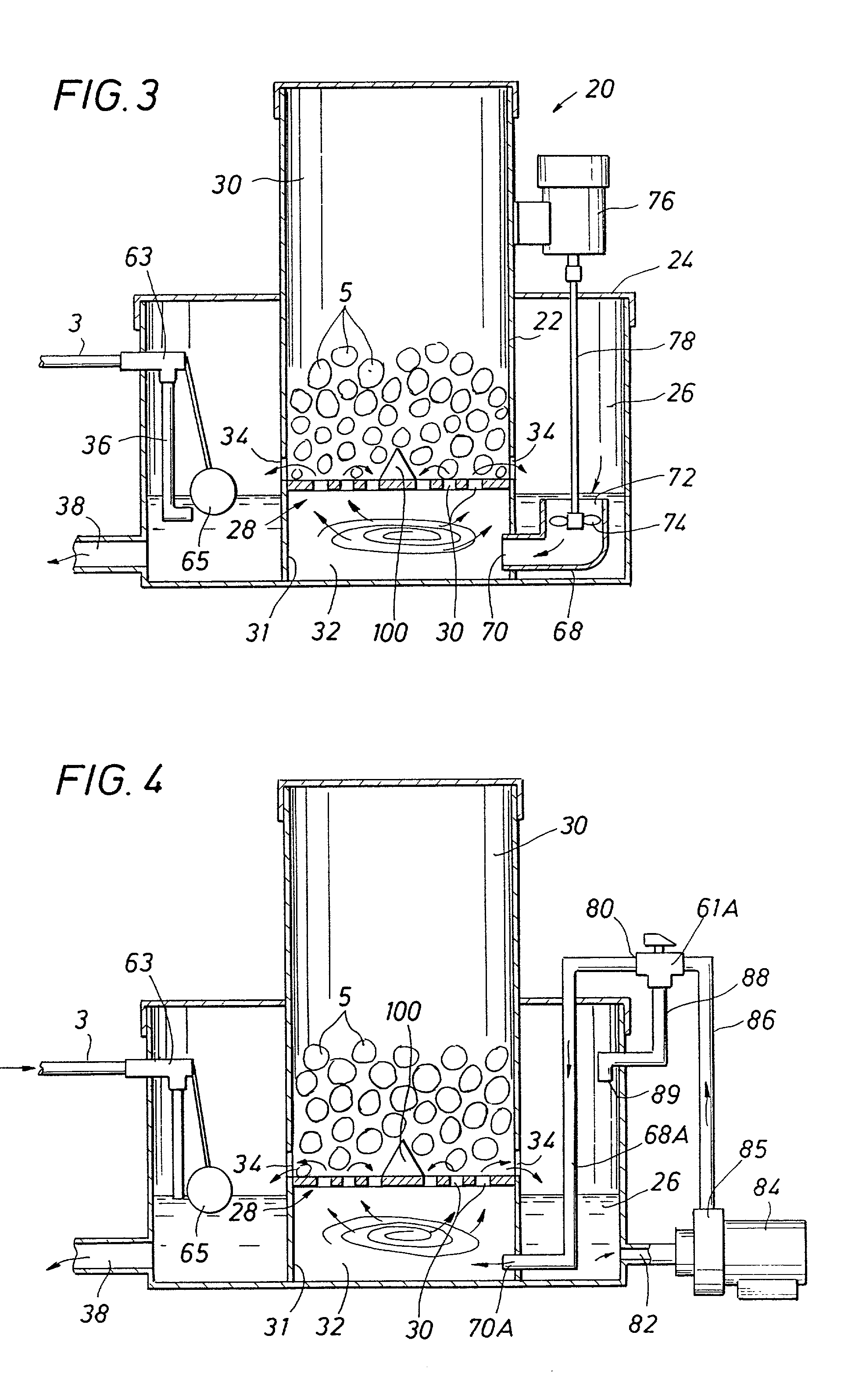

Additive dispersing filter and method of making

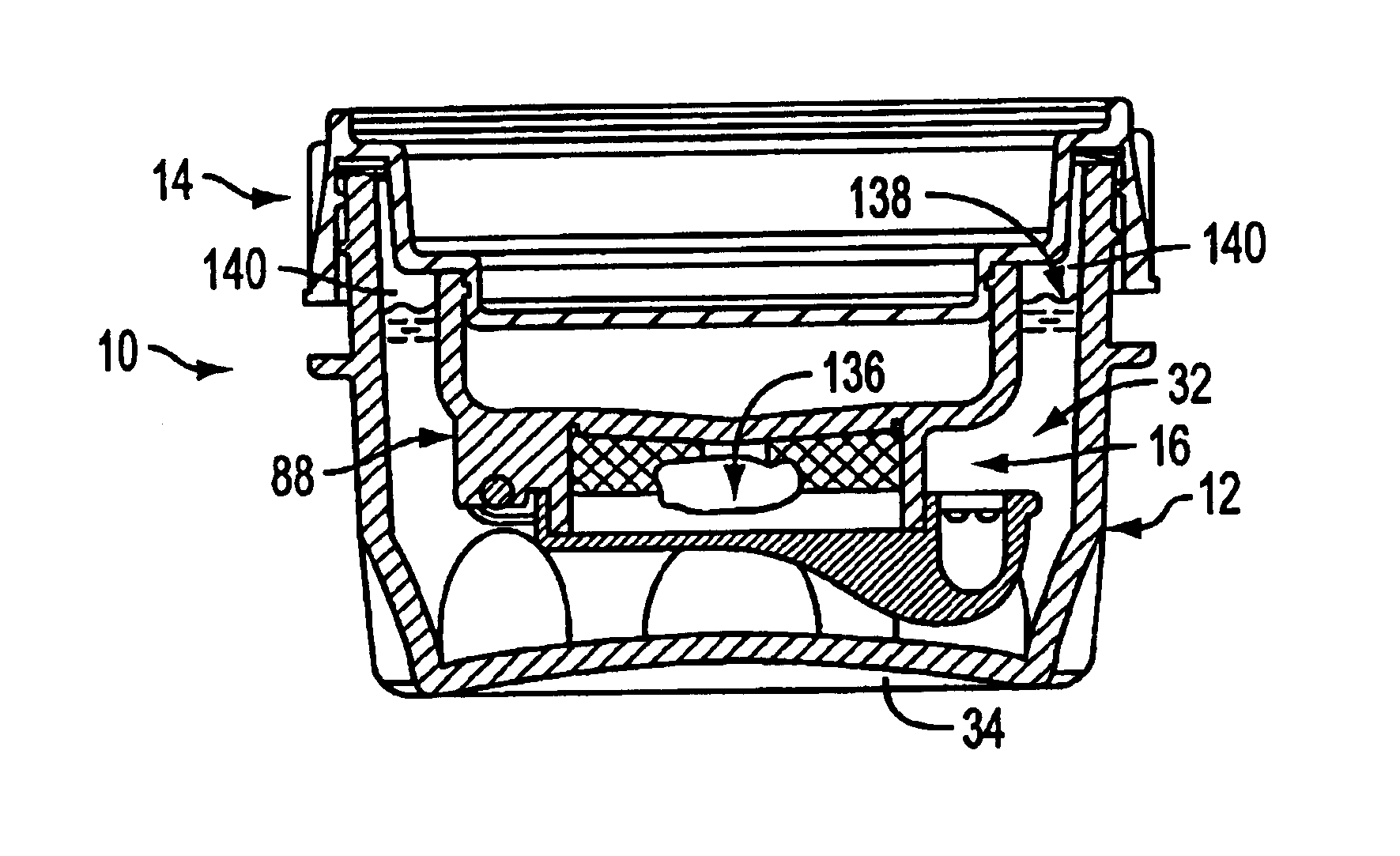

ActiveUS20080190504A1Extend life of engine oilExtended time intervalDissolving using flow mixingFlow mixersEngineeringMechanical engineering

A method for dispersing an additive from an additive cartridge disposed in a housing of an oil filter is provided herein, the method includes using stagnation pressure to disperse the additive from the additive cartridge; and regulating a flow rate of the additive from the additive cartridge by restricting an inlet opening of an outlet tube of the additive cartridge. Also provide herein is an additive cartridge for dispersing an additive within a filter housing, the additive cartridge having a housing defining a receiving area for receipt of the additive; a fluid inlet path through a wall of the housing, the fluid inlet path providing a means for increasing a pressure within the receiving area, the fluid inlet path having an inlet opening disposed adjacent to an outer wall portion of the housing; and a fluid outlet path through the wall of the housing, the fluid outlet path providing a means for dispersing the additive from the receiving area when the pressure within the receiving area exceeds a predetermined value, the fluid outlet path having an outlet opening disposed adjacent to the outer wall portion of the housing, the outlet opening being covered by a shroud configured to deflect fluid flowing in a first direction away from the outlet opening and the inlet opening of the fluid inlet path is positioned to receive fluid flowing in the first direction; and fluid flow of the additive through the fluid outlet path is controlled by varying an inlet opening of the fluid outlet path.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

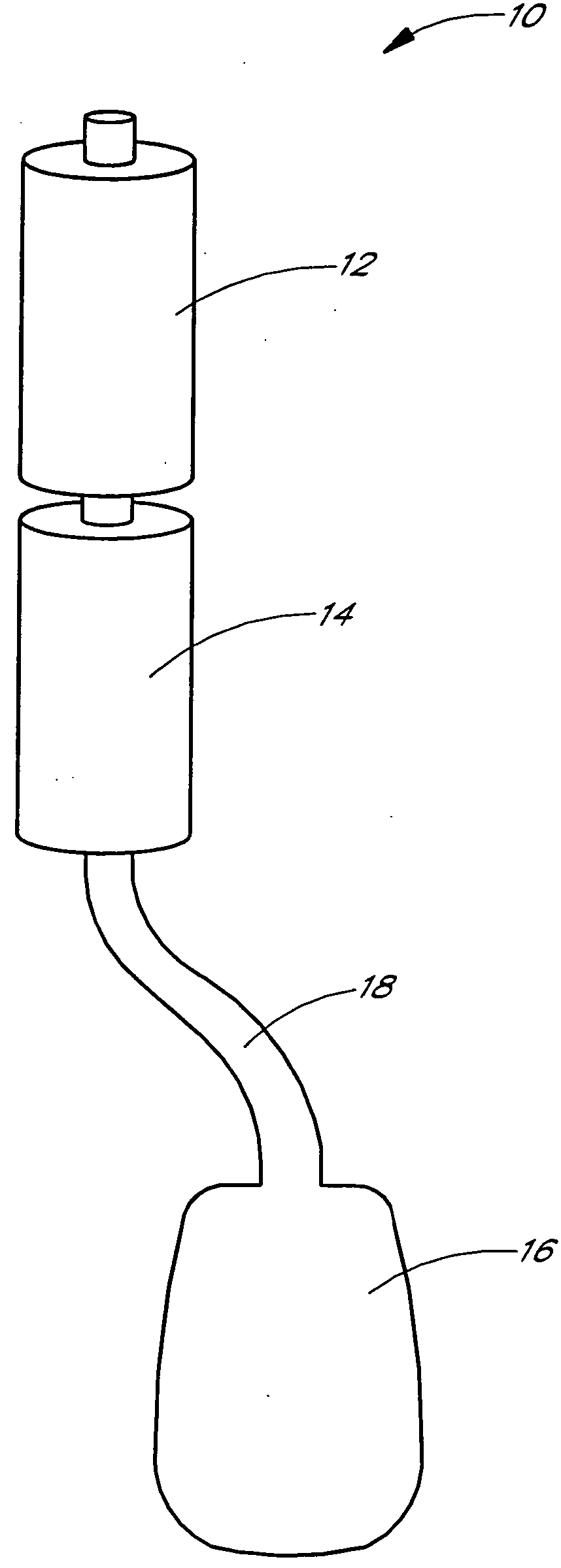

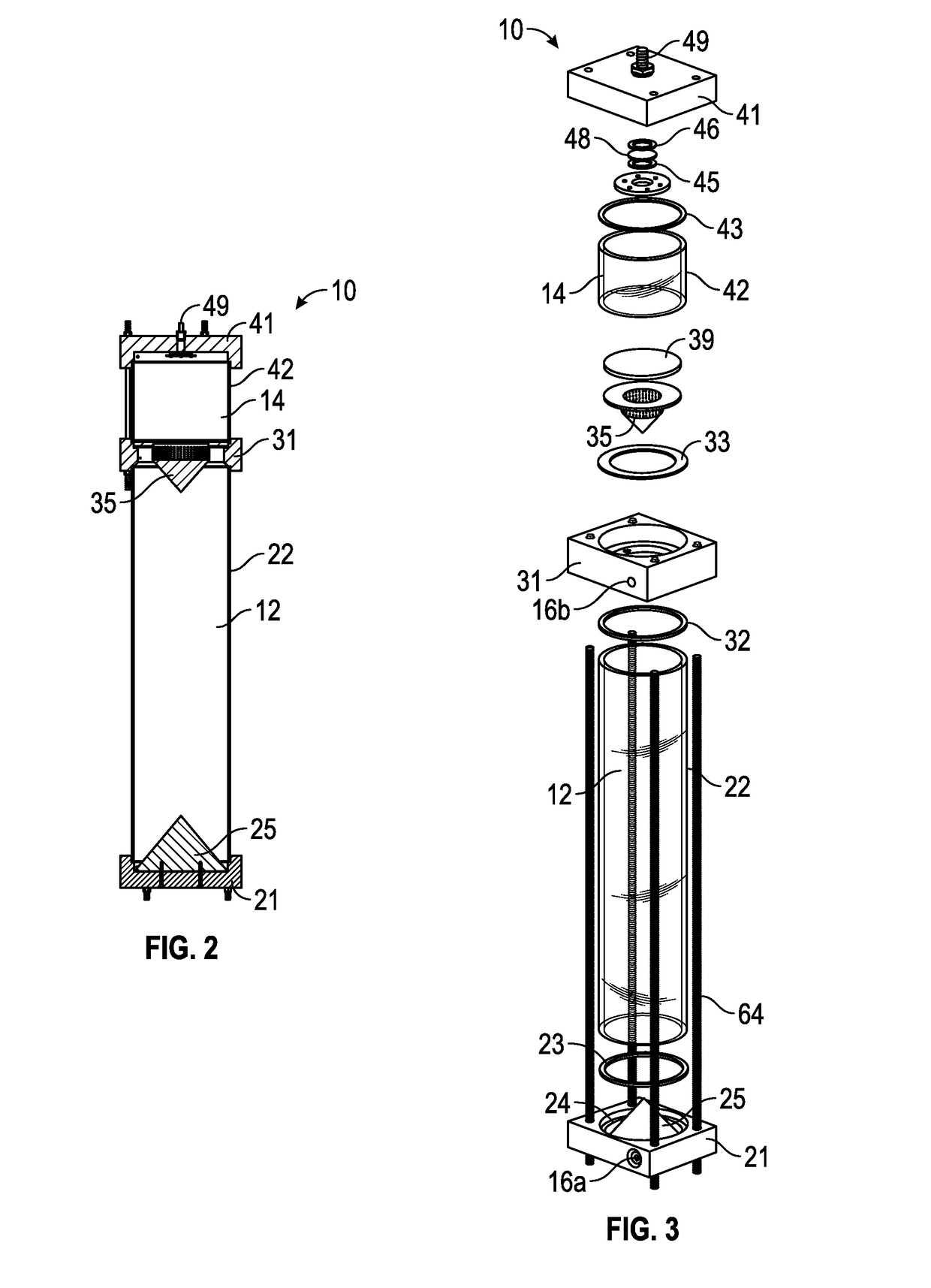

Dissolution generator, method of dissoving powder, and mixing system

ActiveUS20120273585A1Dissolving using flow mixingTransportation and packagingSpray nozzleEngineering

A dissolution generator includes: an upright housing; a screen assembly extending across an interior of the housing, and configured to support a column of powder thereabove; a spray nozzle disposed below the screen assembly and directed towards the screen assembly; and a pressure mechanism disposed above the screen assembly, and configured to apply a substantially constant downward pressure.

Owner:BROOME HUBERT RAY

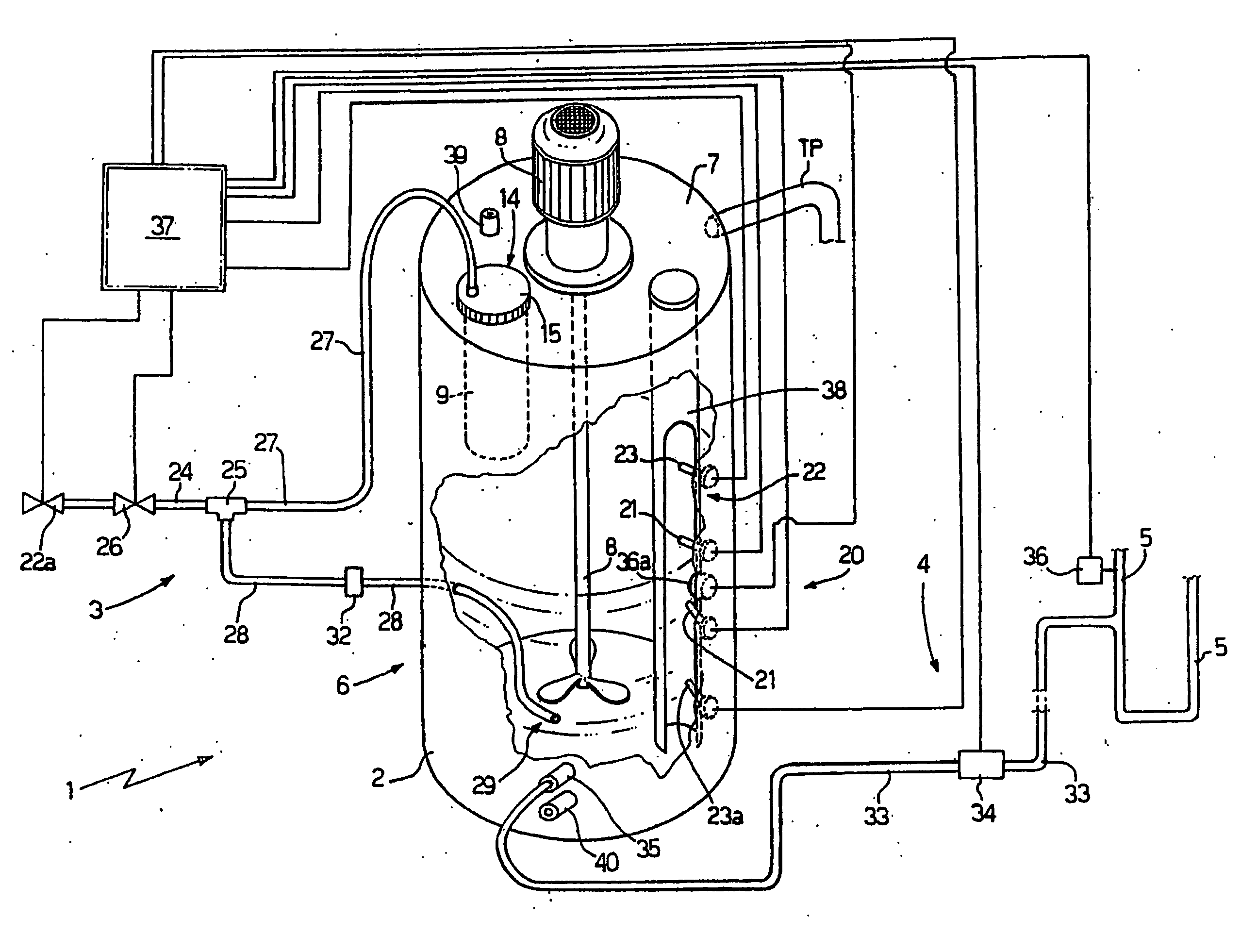

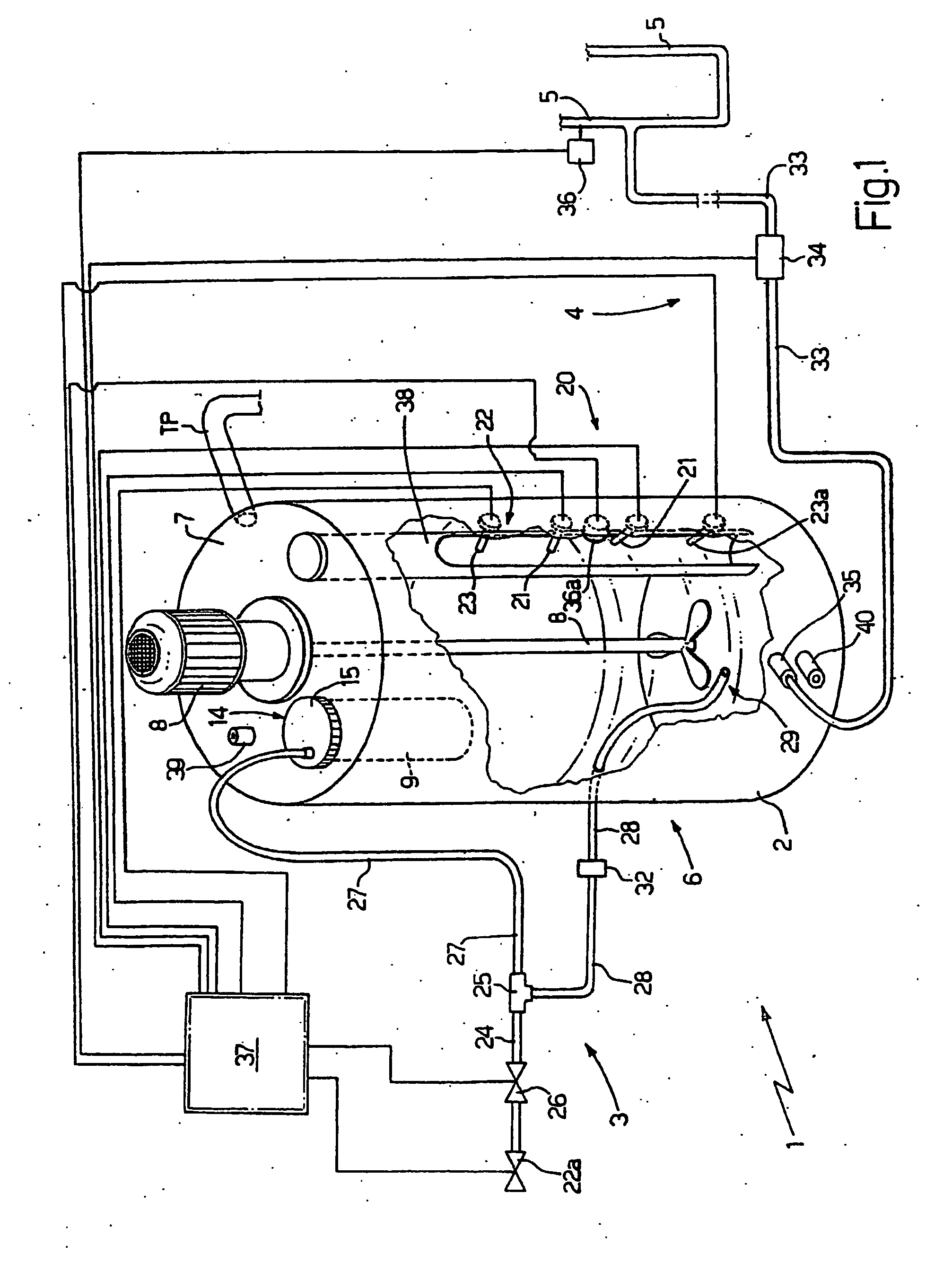

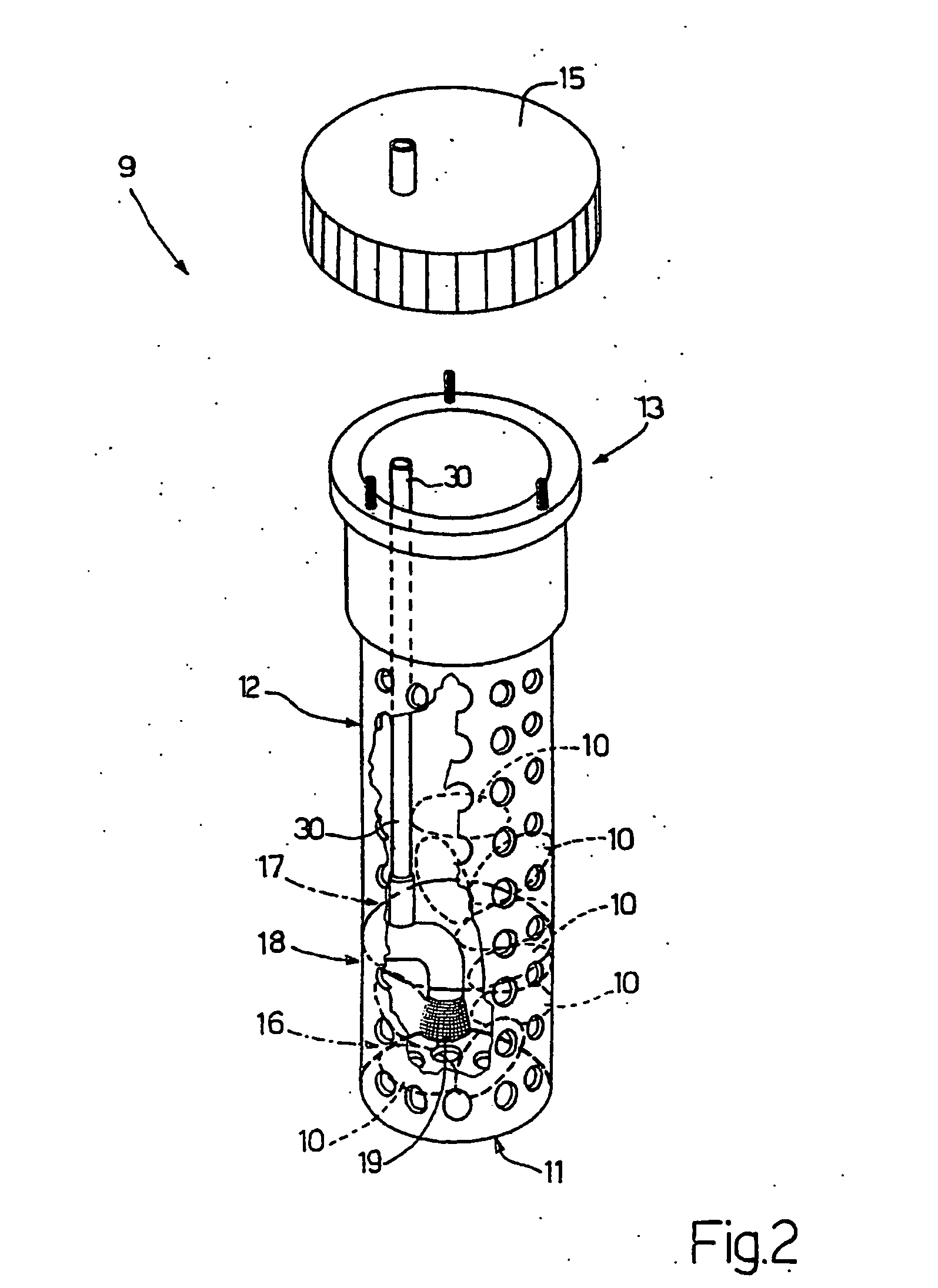

Device for dissolving solid substances in water

A device (1) for dissolving solid chemical substances in water is provided with: a container (2), which has a bottom portion (6) designed to contain an aqueous solution; a perforated loading chamber (9), which is set at the top of the bottom portion (6) and is designed to contain a solid chemical substance (10); and a spraying device (18) set within the loading chamber (9) for directing at least one jet of water onto the solid chemical substance (10). In use, the solid chemical substance (10) is set around the spraying device (18), and the jet of water is directed downwards and / or laterally so as not to wet the solid chemical substance (10) set above the spraying device (18). In this way, there is obtained a relatively gradual dissolution of the solid chemical substance (10) and a lower development of gaseous substances having an unpleasant smell.

Owner:MARCHI & BREVETTI INTERPRISE +1

Solid product dispenser

A dispenser (10) uses first and second flow controls (70, 73). The flow controls maintain first and second flow ranges independent of diluent pressure within a pressure range, wherein the use solution's concentration is maintained over the pressure range. A third flow control (75) may also be utilized in a third diluent passageway for maintaining a third flow range independent of the diluent pressure within the pressure range. A bypass valve assembly (41) is operatively connected to the third incoming diluent passageway. The bypass valve has a temperature control valve. The temperature control valve having a bypass passageway, wherein additional diluent is added to the use solution, thereby controlling the use solution's concentration.

Owner:ECOLAB USA INC

Apparatus for control of on site mixing of solid peroxide source and catalyst

An apparatus for controlling on site generation and mixing of a two or more part chemistry, such as a peroxide source and a catalyst. In particular, the invention discloses an apparatus and dispensing method for separating solid surfaces that undergo an uncontrolled, continuous reaction when contacted with water and allows for delivery of solid reactive chemistries at the same time in a standard spray from the bottom dispensing configuration while preventing continued reaction after the dosing is complete.

Owner:ECOLAB USA INC

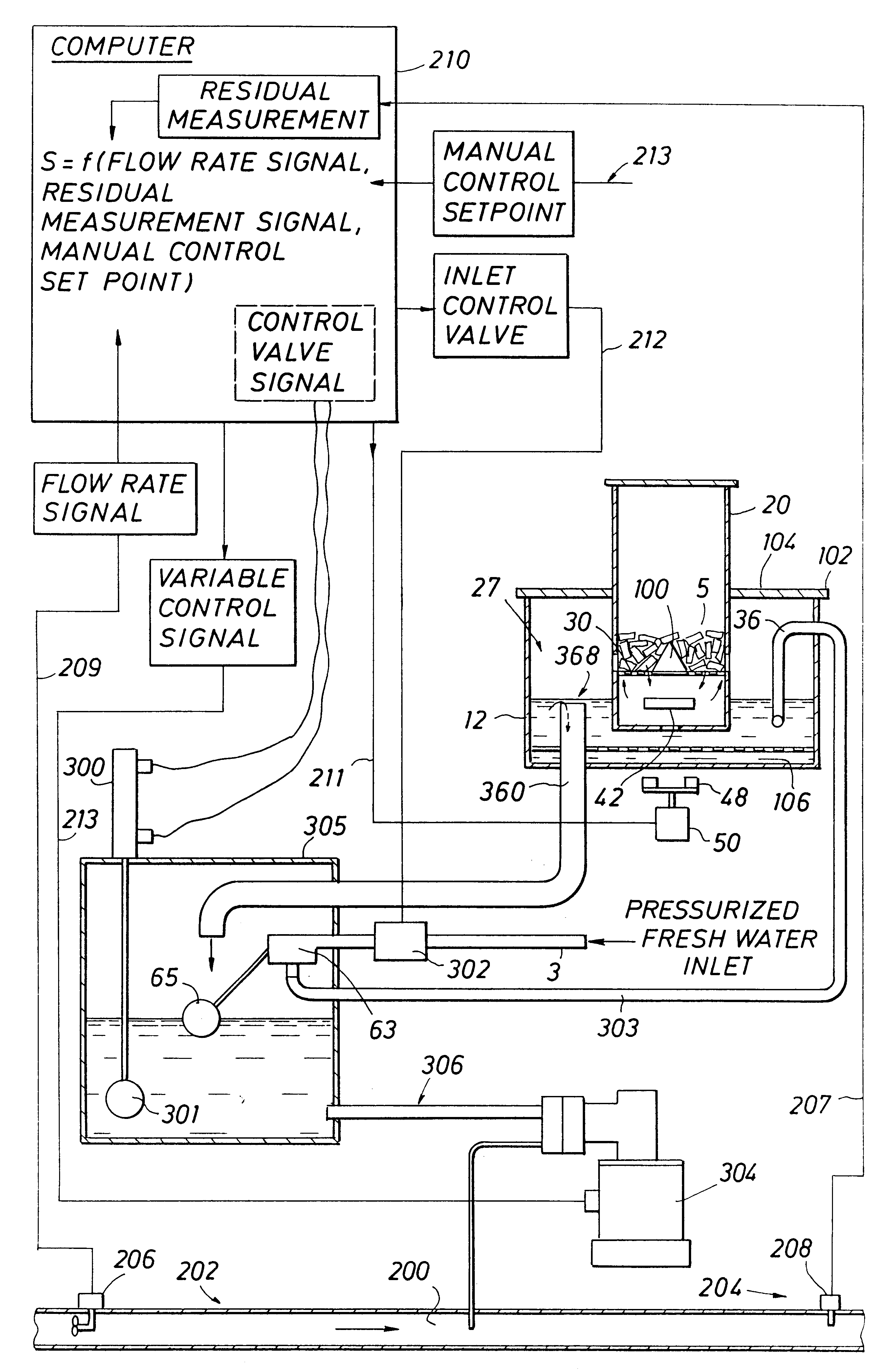

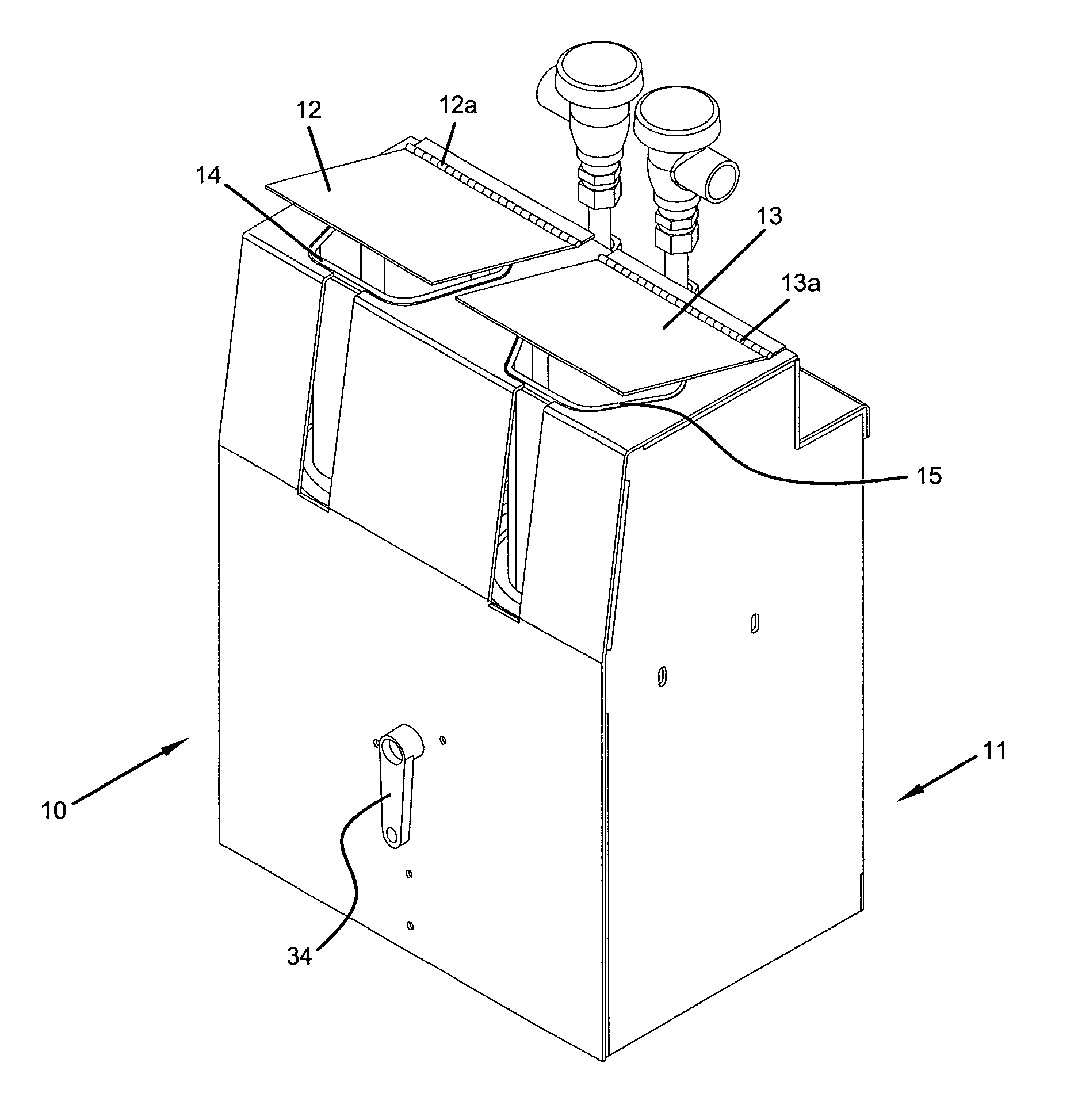

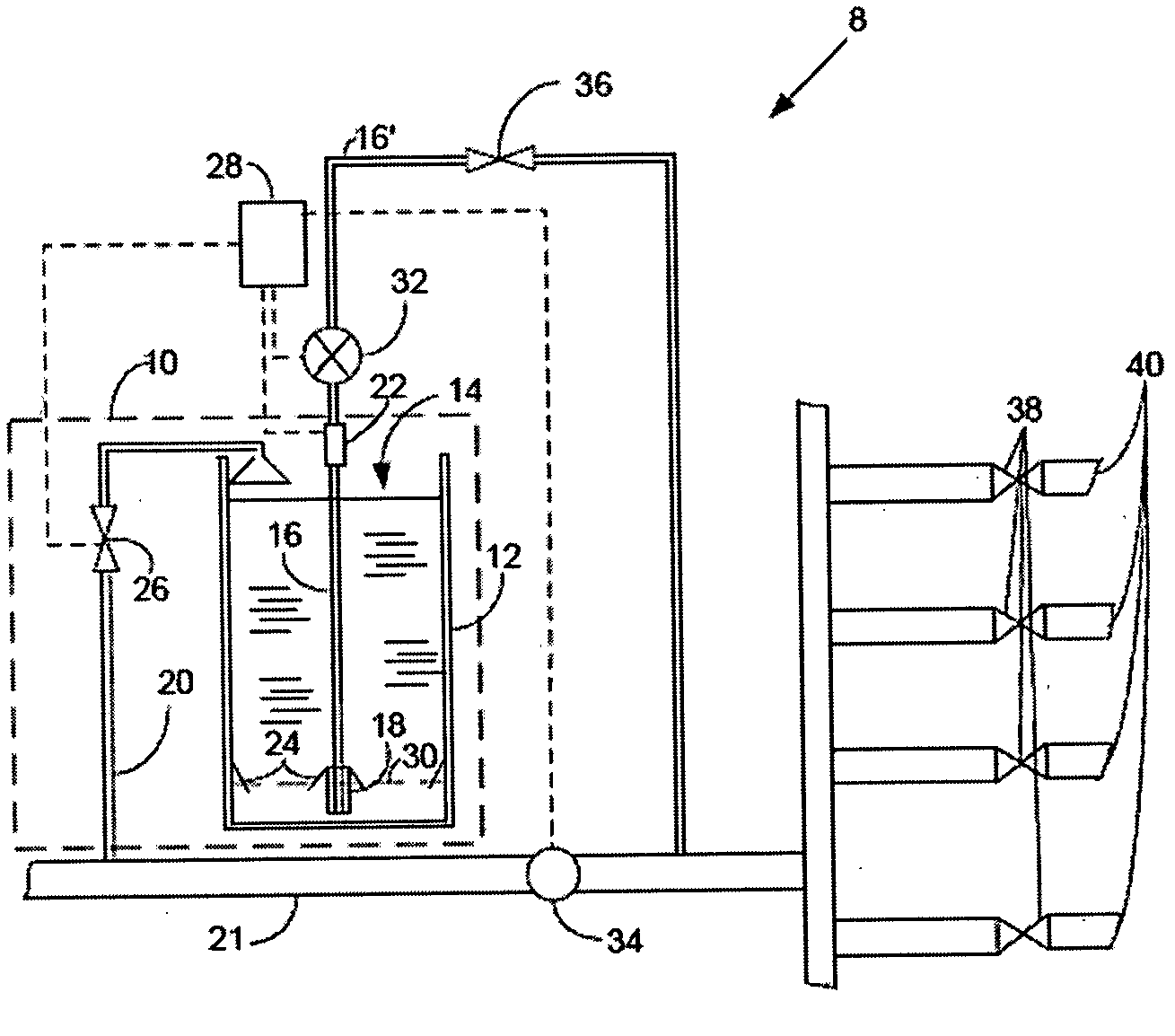

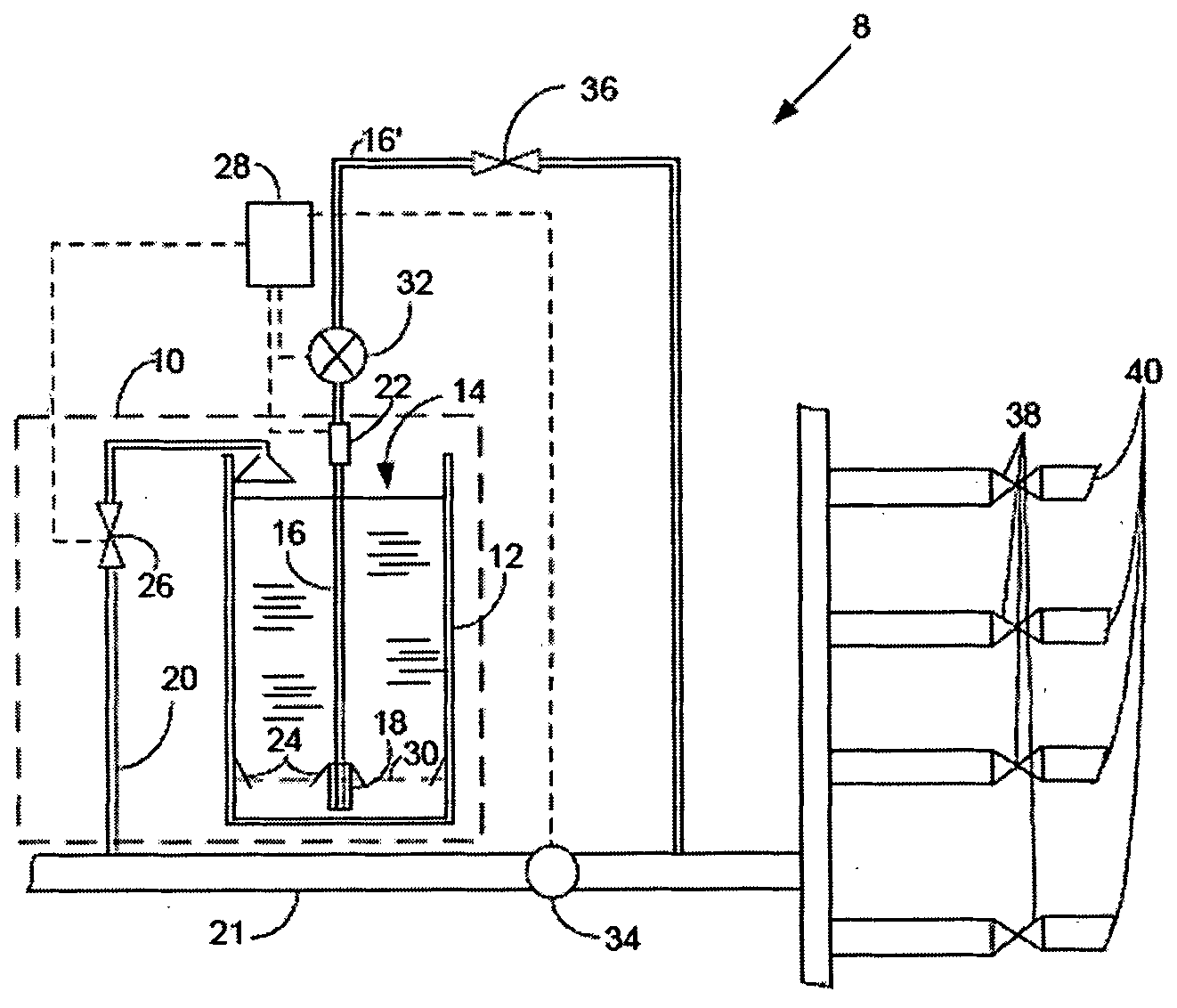

Apparatus and method for mixing a concentrated water treatment solution

An apparatus includes a reservoir for holding a chemical solution, a pump and a discharge nozzle. The pump has an inlet and an outlet connected to the reservoir by inlet and discharge lines. The nozzle is disposed in a lower portion of the reservoir and discharges the solution toward the bottom of the reservoir; the nozzle has an inlet port connected to the pump discharge line through the sidewall of the reservoir. The pump inlet line is connected to a sidewall of the reservoir at a location below a normal surface level of the solution, and the pump discharge line is connected to the sidewall of the reservoir above that location. The reservoir, pump, pump inlet line, pump discharge line, nozzle inlet line and nozzle form a closed loop recirculation system effective to suspend insoluble material in the chemical solution.

Owner:INNOVATIVE WATER CARE LLC

Feeder for dispensing a solution of a solid matter dissolved therein

InactiveCN102549220ADissolving using flow mixingLiquid fertiliser distributionEngineeringSolid matter

Owner:ECOFER FERTIGATION TECH 2010

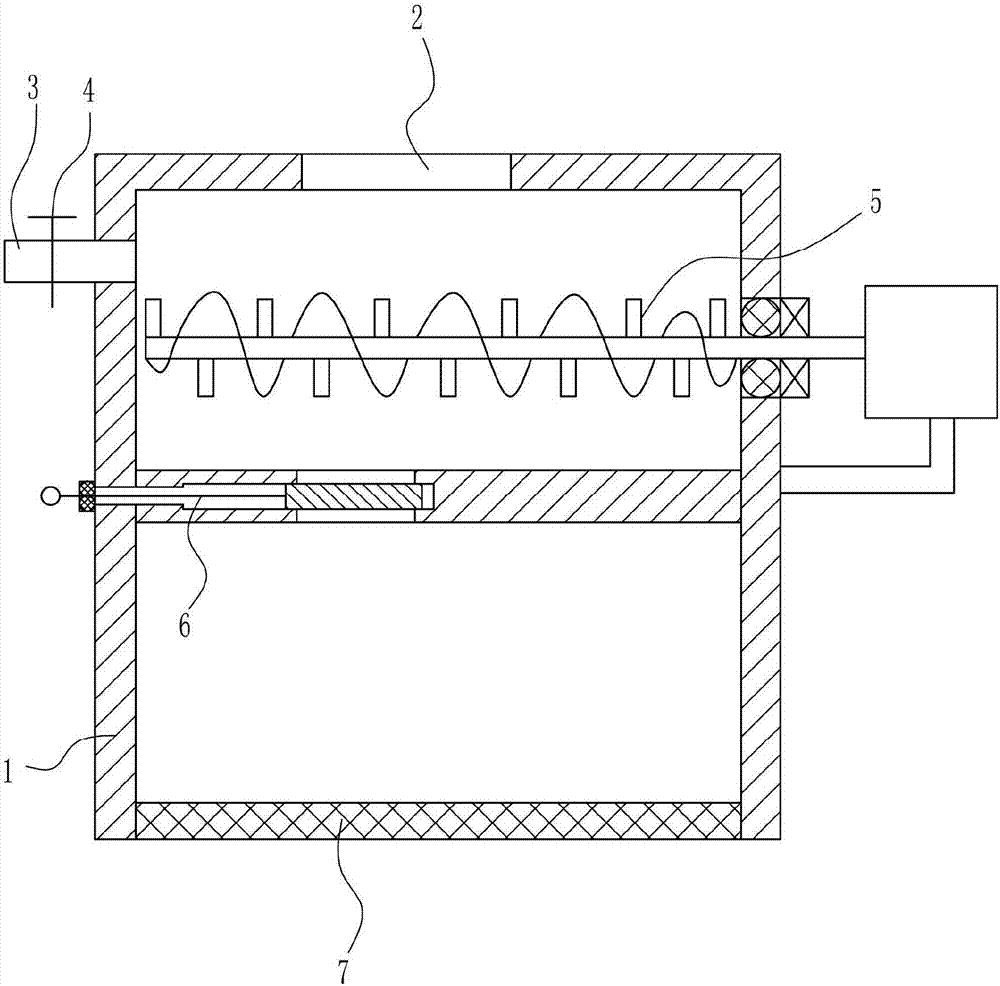

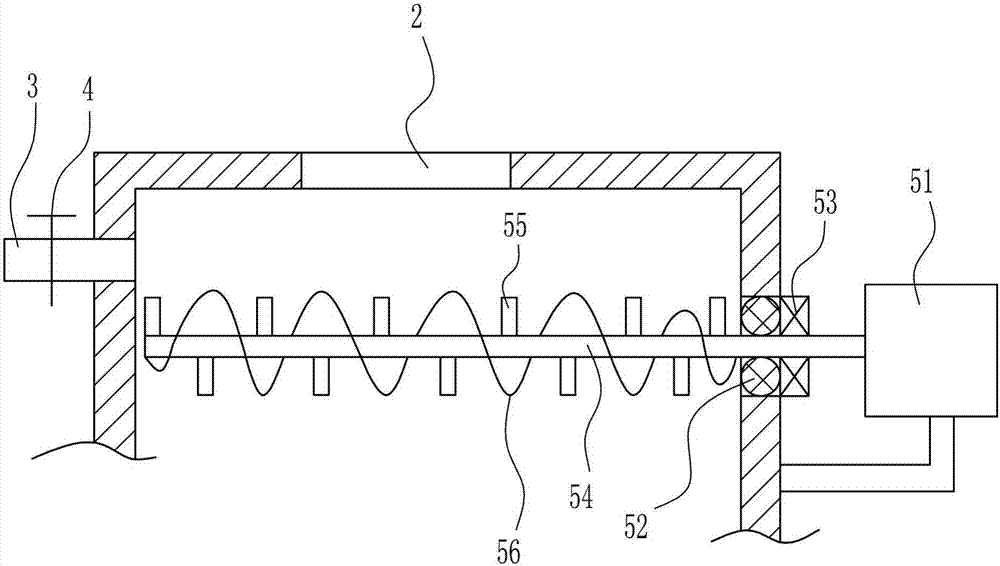

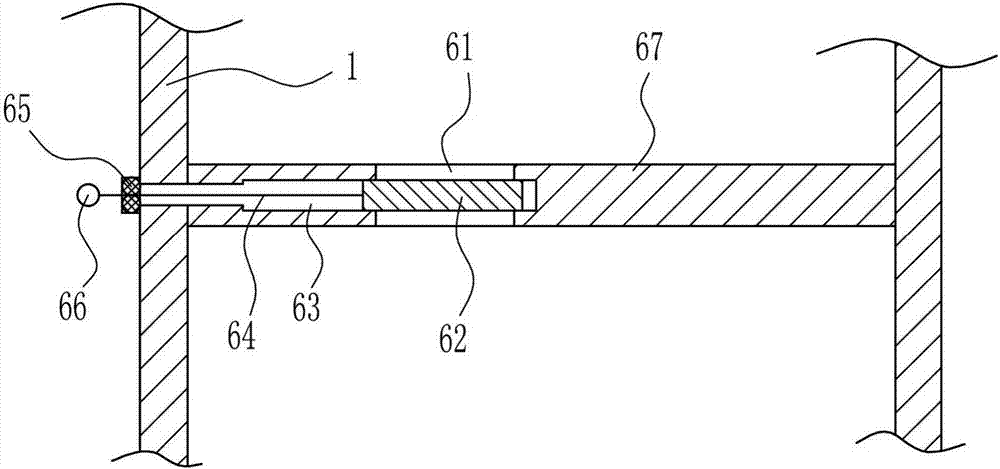

Quick dissolution impurity-removal device for white latex production

InactiveCN106890579AQuality improvementIncrease removal speedDissolving using flow mixingRotary stirring mixersPolyvinyl alcoholDissolution

The invention relates to a dissolution impurity-removal device, in particular to a quick dissolution impurity-removal device for white latex production. The technical problem to be solved herein is to provide a quick dissolution impurity-removal device for white latex production which may fully filter impurities while fully dissolving polyvinyl alcohol powder. In order to solve the above technical scheme, the invention provides such a quick dissolution impurity-removal device for white latex production, comprising a treatment box and the like; the top center of the treatment box is provided with a first through hole, the upper left of the treatment box is provided with a water incoming pipe which is provided with a valve, a stirring mechanism is arranged in the inner upper portion of the treatment box, a discharge mechanism is arranged in the center of the treatment box, and a filter mesh is arranged at the bottom of the treatment box. The invention designs the quick dissolution impurity-removal device for white latex production, the stirring mechanism and the discharge mechanism enable non-dissolved impurities to be removed while dissolving the polyvinyl alcohol powder, and the quality of white latex is improved.

Owner:林建武

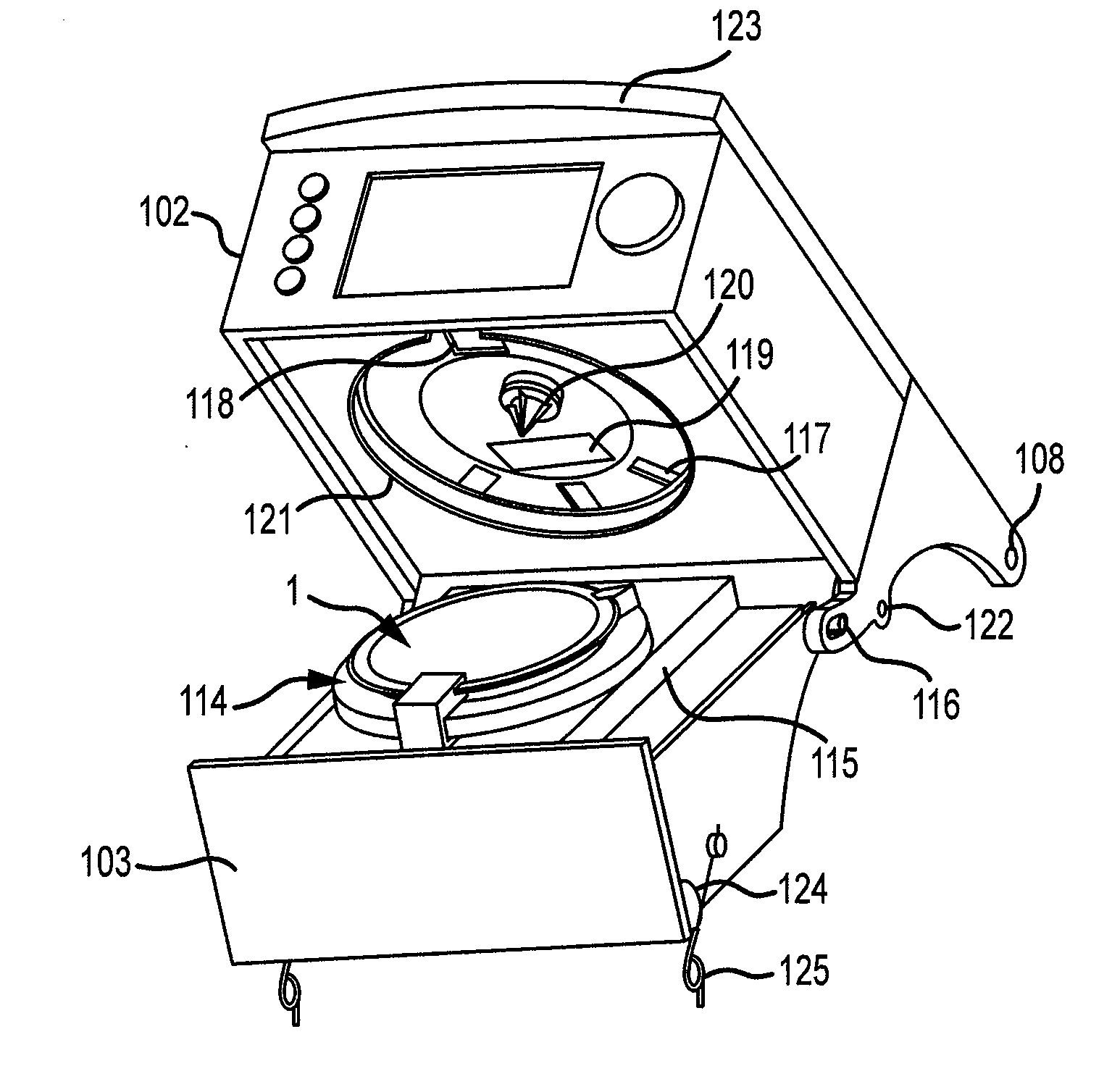

Apparatus and method for preparing a liquid mixture

A mixing apparatus, puncturing mechanism, and cartridge are disclosed. The mixing apparatus has a housing and a drawer with a recess. Corresponding cartridges may be inserted into the drawer and slid into the housing to facilitate mixing a liquid with contents of the cartridge. The liquid may originate from a reservoir in the mixing apparatus or a direct line. Also inside the housing of the mixing apparatus is the puncturing mechanism. The puncturing mechanism has a nozzle configured to puncture a lid of a cartridge and inject liquid to mix with the contents of the cartridge. The puncturing mechanism is further configured to drive an internal puncturing unit inside of the cartridge through a lower portion of the cartridge to allow liquid from the nozzle and contents of the cartridge to be dispensed into a receptacle.

Owner:FORMULANOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com