Quick dissolution impurity-removal device for white latex production

A white latex, fast technology, applied in the direction of dissolution, dissolution, fluid mixing and dissolving, etc., can solve the problems of slow filtration speed, slow filtration speed of melting and filtration, affecting the production speed of white latex, and achieve the effect of increasing the dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

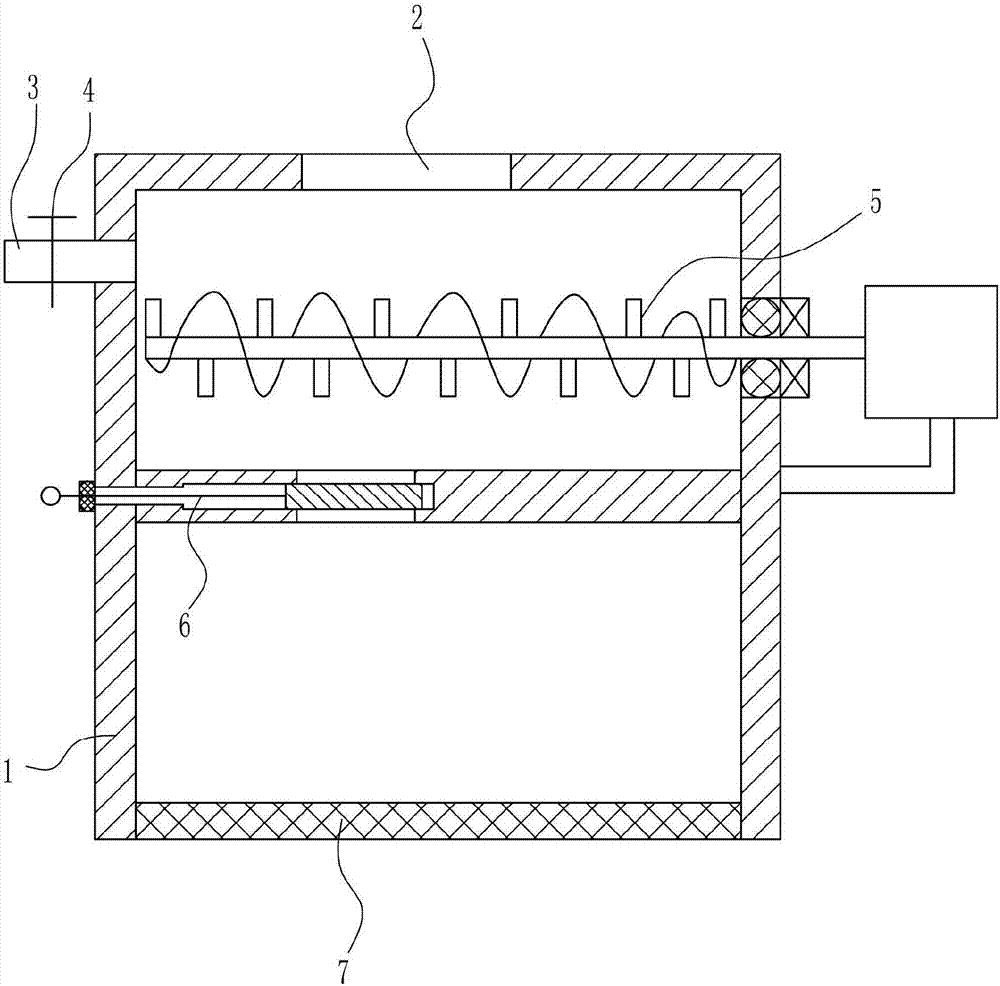

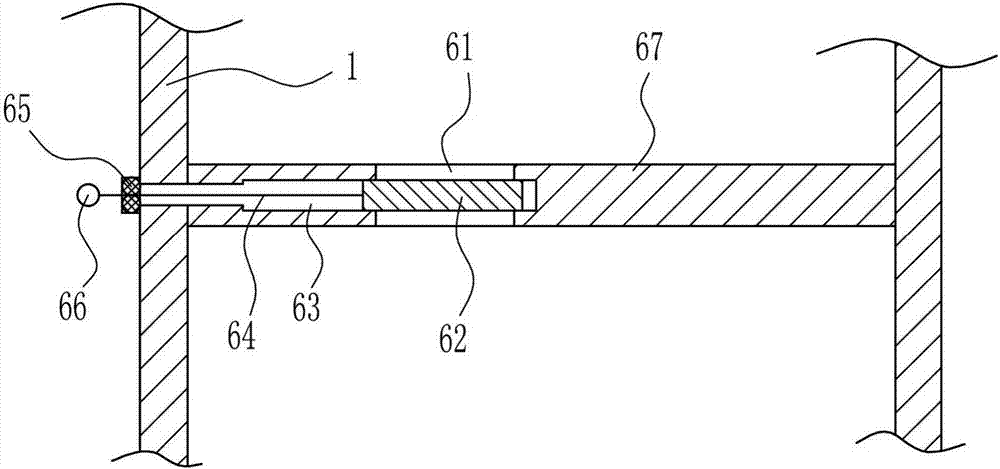

[0037] A kind of fast dissolving impurity removal device for white latex production, such as Figure 1-7 As shown, it includes a treatment box 1, a water inlet pipe 3, a valve 4, a stirring mechanism 5, a discharge mechanism 6 and a filter screen 7. The top middle part of the treatment box 1 has a first through hole 2, and the upper left side of the treatment box 1 is provided with The water inlet pipe 3 is provided with a valve 4 on the water inlet pipe 3, the upper part of the treatment box 1 is provided with a stirring mechanism 5, the middle part of the treatment box 1 is provided with a discharge mechanism 6, and the bottom of the treatment box 1 is provided with a filter screen 7.

Embodiment 2

[0039] A kind of fast dissolving impurity removal device for white latex production, such as Figure 1-7 As shown, it includes a treatment box 1, a water inlet pipe 3, a valve 4, a stirring mechanism 5, a discharge mechanism 6 and a filter screen 7. The top middle part of the treatment box 1 has a first through hole 2, and the upper left side of the treatment box 1 is provided with The water inlet pipe 3 is provided with a valve 4 on the water inlet pipe 3, the upper part of the treatment box 1 is provided with a stirring mechanism 5, the middle part of the treatment box 1 is provided with a discharge mechanism 6, and the bottom of the treatment box 1 is provided with a filter screen 7.

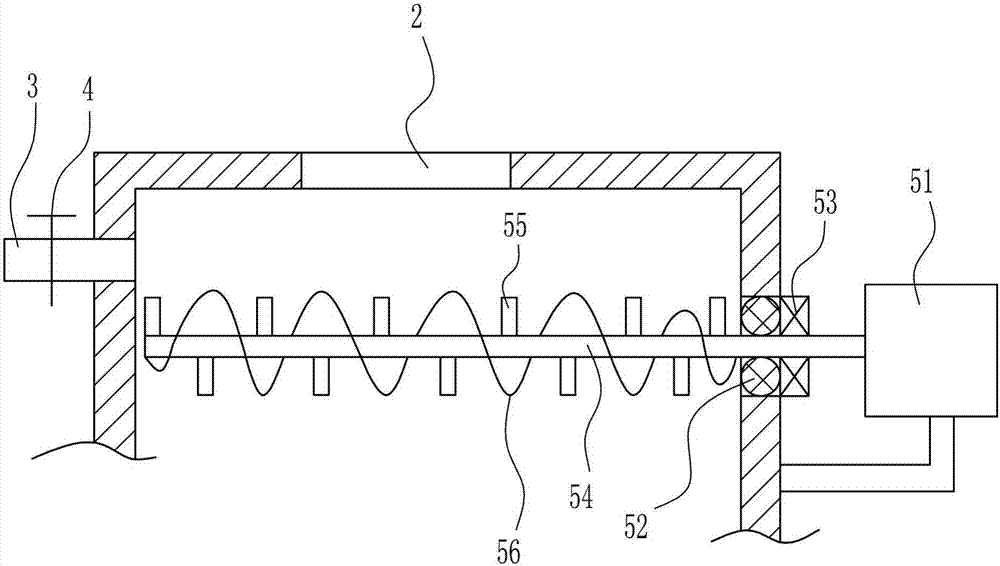

[0040] The stirring mechanism 5 includes a motor 51, a first sealing ring 52, a first bearing seat 53, a first rotating rod 54, a first stirring rod 55 and a screw rod 56, and the upper right side of the processing box 1 is provided with a first bearing seat 53, Process case 1 right side uppe...

Embodiment 3

[0042] A kind of fast dissolving impurity removal device for white latex production, such as Figure 1-7 As shown, it includes a treatment box 1, a water inlet pipe 3, a valve 4, a stirring mechanism 5, a discharge mechanism 6 and a filter screen 7. The top middle part of the treatment box 1 has a first through hole 2, and the upper left side of the treatment box 1 is provided with The water inlet pipe 3 is provided with a valve 4 on the water inlet pipe 3, the upper part of the treatment box 1 is provided with a stirring mechanism 5, the middle part of the treatment box 1 is provided with a discharge mechanism 6, and the bottom of the treatment box 1 is provided with a filter screen 7.

[0043] The stirring mechanism 5 includes a motor 51, a first sealing ring 52, a first bearing seat 53, a first rotating rod 54, a first stirring rod 55 and a screw rod 56, and the upper right side of the processing box 1 is provided with a first bearing seat 53, Process case 1 right side uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com