Patents

Literature

226 results about "Dry storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of treating glutaraldehyde-fixed pericardial tissue with a non-aqueous mixture of glycerol and a C1-C3 alcohol

A method of treating a biological tissue that enables dry storage of said tissue is disclosed. In one embodiment, the method comprises contacting the biological tissue with a non-aqueous treatment solution comprising a polyhydric alcohol and a C1-C3 alcohol and removing a portion of the treatment solution from the solution-treated biological tissue. Also disclosed is biological tissue prepared using the above process and prosthetic devices made with such tissue.

Owner:EDWARDS LIFESCIENCES CORP

Biological tissue for surgical implantation

ActiveUS20080102439A1Rigid enoughPrevent eversionHeart valvesDead animal preservationAlcoholDry storage

A method of treating a biological tissue that enables dry storage of said tissue is disclosed. In one embodiment, the method comprises contacting the biological tissue with a non-aqueous treatment solution comprising a polyhydric alcohol and a C1-C3 alcohol and removing a portion of the treatment solution from the solution-treated biological tissue. Also disclosed is biological tissue prepared using the above process and prosthetic devices made with such tissue.

Owner:EDWARDS LIFESCIENCES CORP

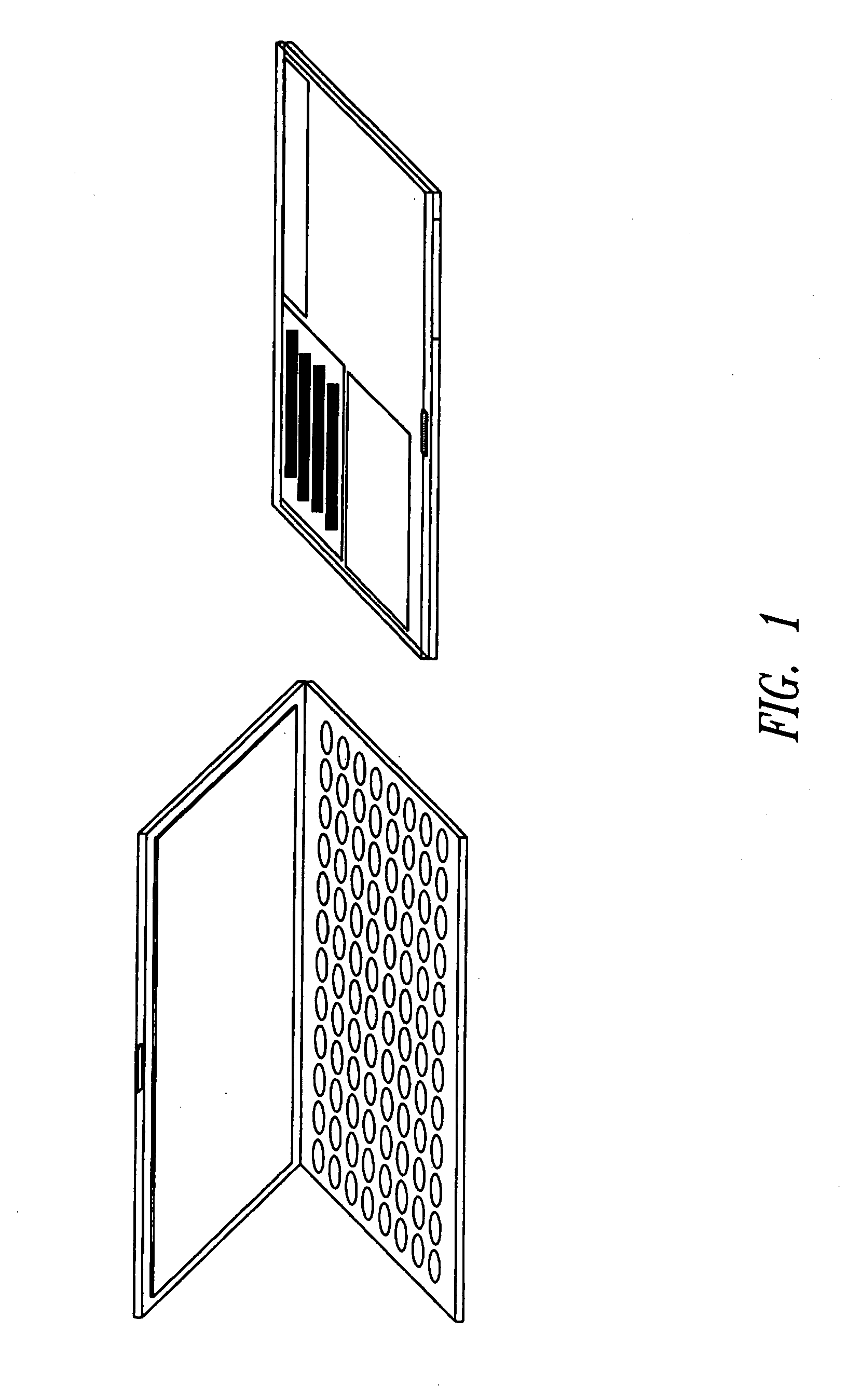

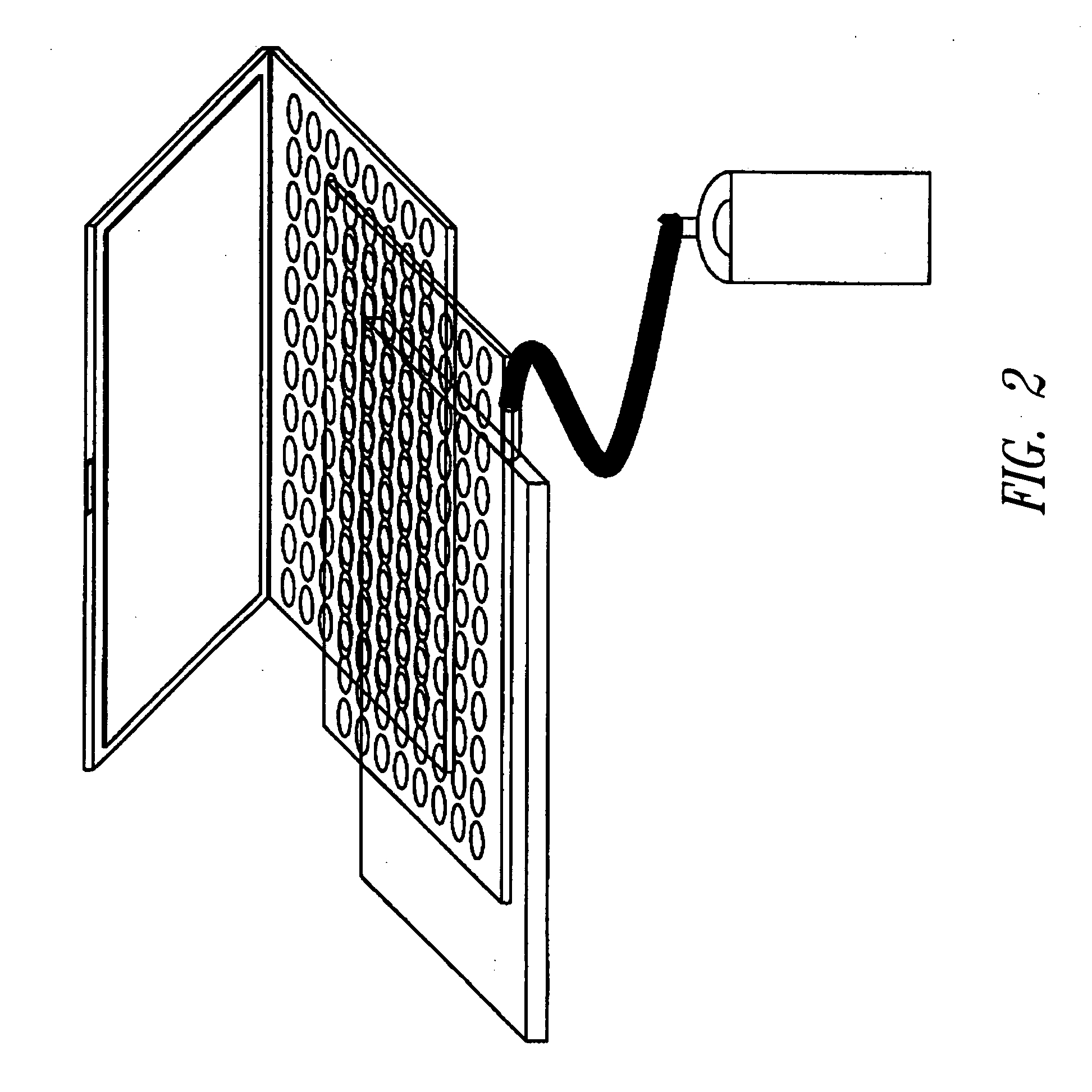

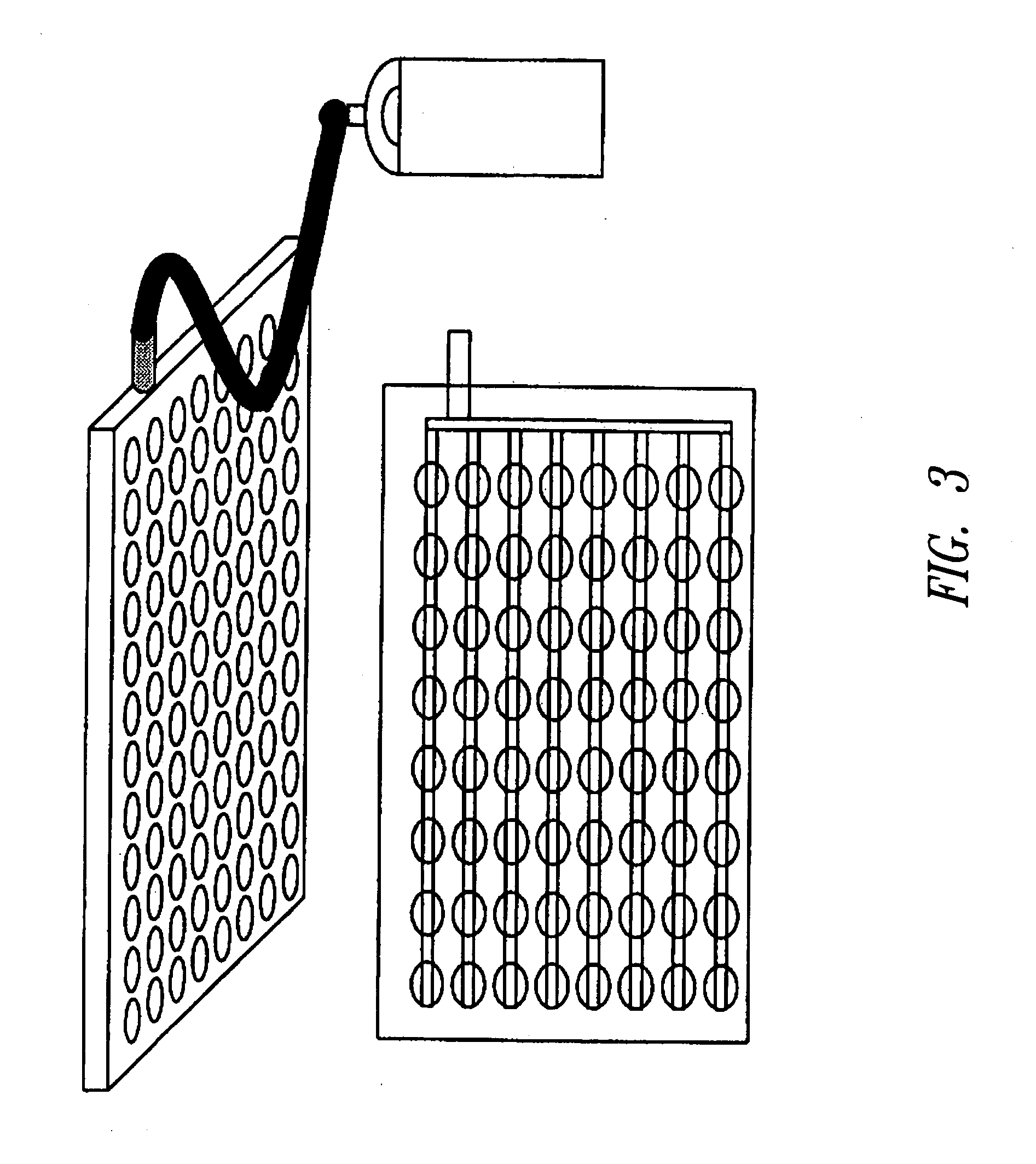

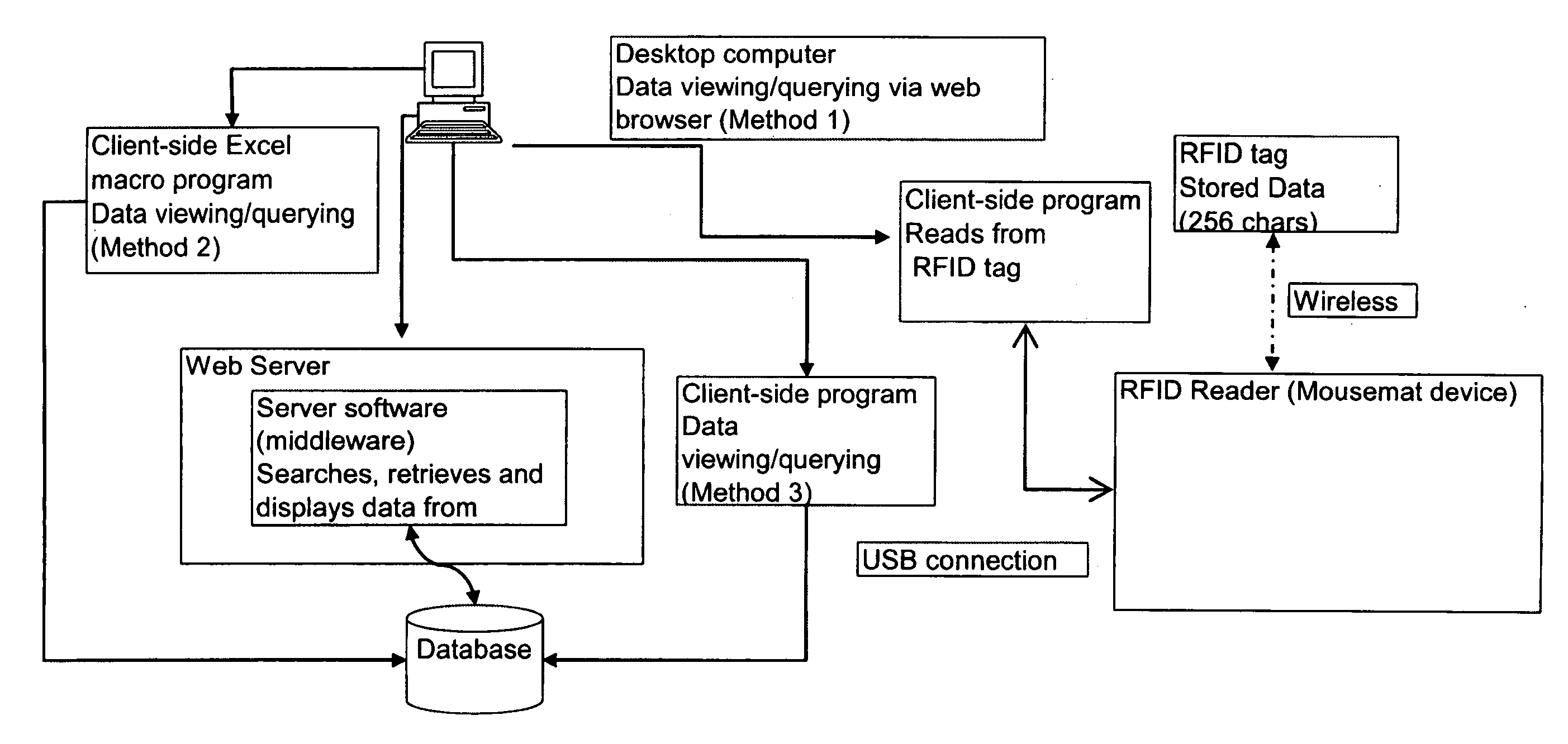

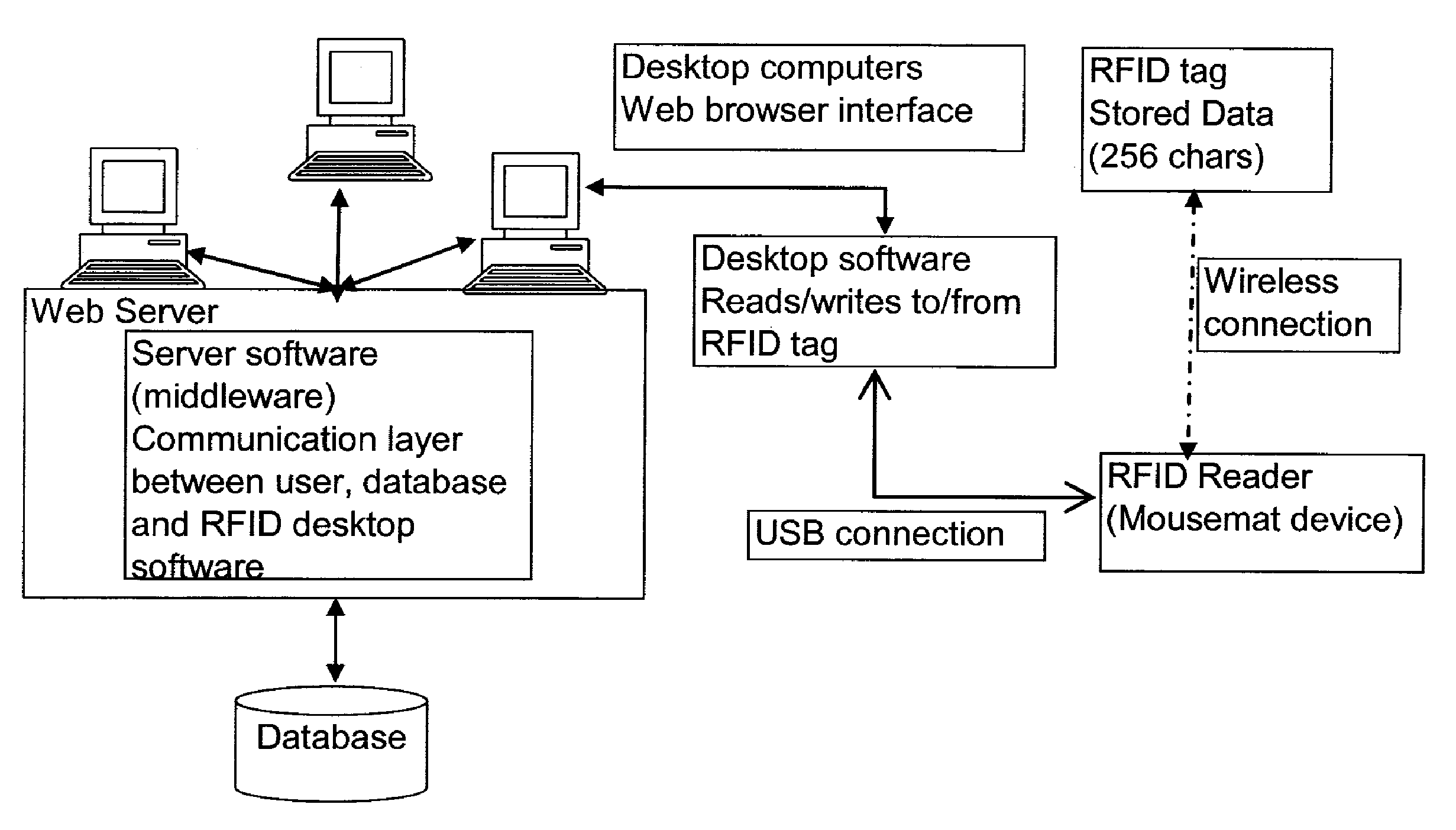

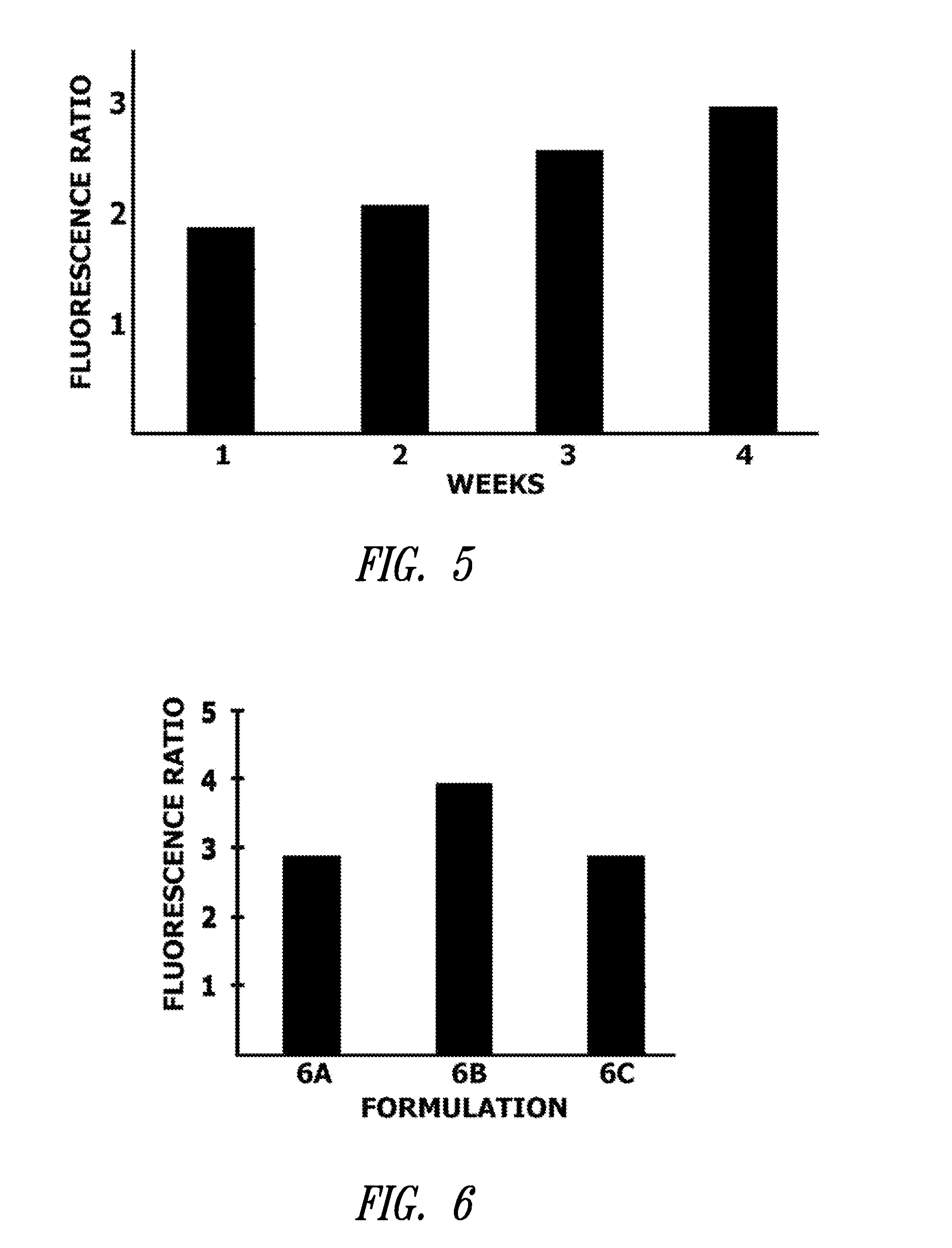

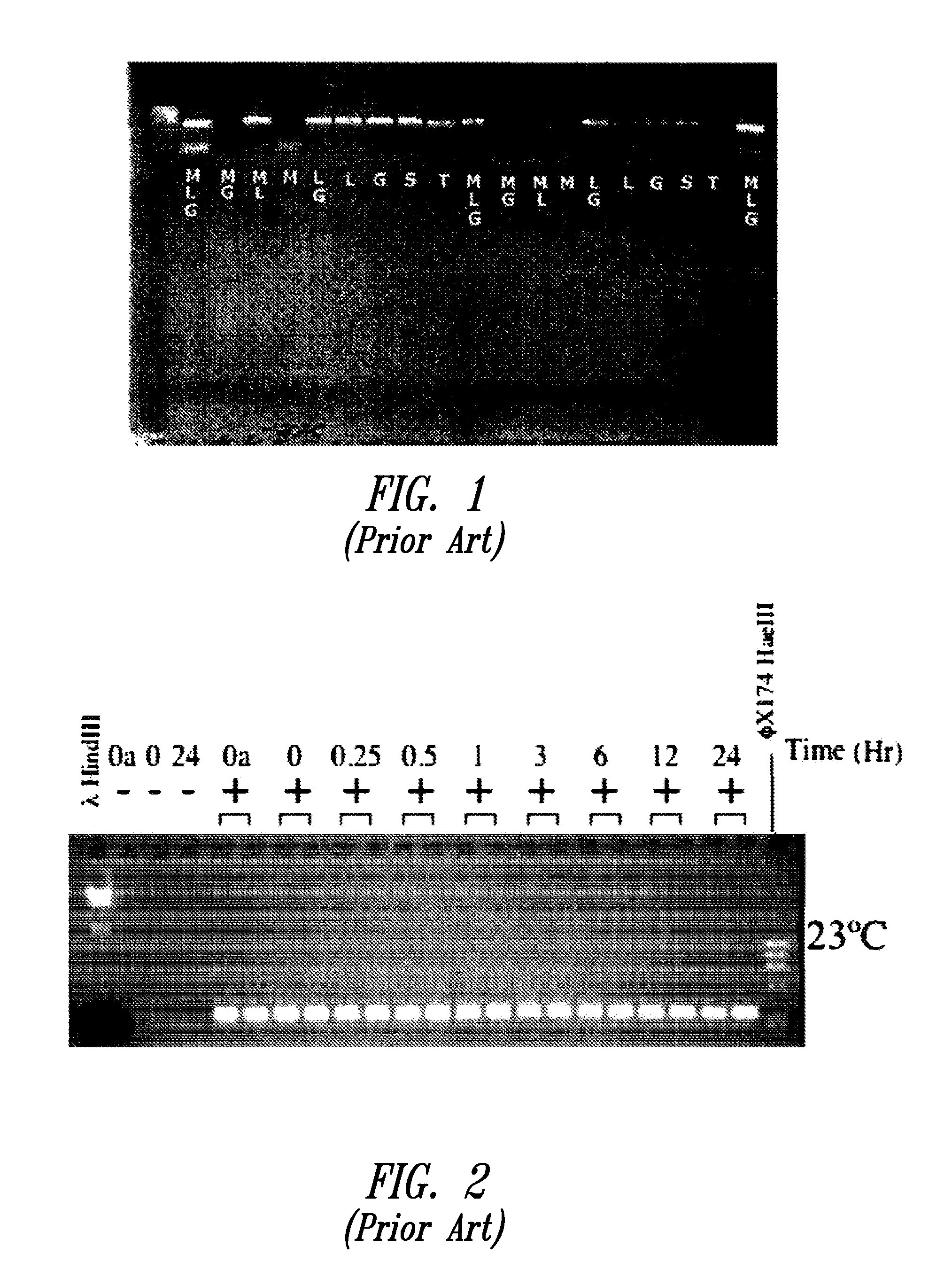

Integration of sample storage and sample management for life science

InactiveUS20060099567A1Reduce degradationImmobilised enzymesMaterial nanotechnologyEnzymeDry storage

Compositions and methods are disclosed for automated storing, tracking, retrieving and analyzing biological samples, including dry storage at ambient temperatures of nucleic acids, proteins (including enzymes), and cells using a dissolvable dry storage matrix that permits recovery of biologically active materials. RFID-tagged biological sample storage devices featuring dissolvable or dissociable matrices are described for use as supports of biological samples, which matrices can be dried and subsequently rehydrated for sample recovery. Also disclosed are computer-implemented systems and methods for managing sample data.

Owner:BIOMATRICA INC

Integration of sample storage and sample management for life science

Compositions and methods are disclosed for substantially dry storage at ambient temperatures of biological samples such as nucleic acids and cells in a form from which nucleic acids can be recovered, using a dissolvable or dissociable dry storage matrix that permits recovery of biologically active materials. Compositions and methods are also disclosed for automated storing, tracking retrieving and analyzing of nucleic acid samples. RFID-tagged biological sample storage devices featuring dissolvable or dissociable matrices are described for use as supports of biological samples, which matrices can be dried and subsequently rehydrated for sample recovery. Also disclosed are computer-implemented systems and methods for managing sample data.

Owner:BIOMATRICA INC

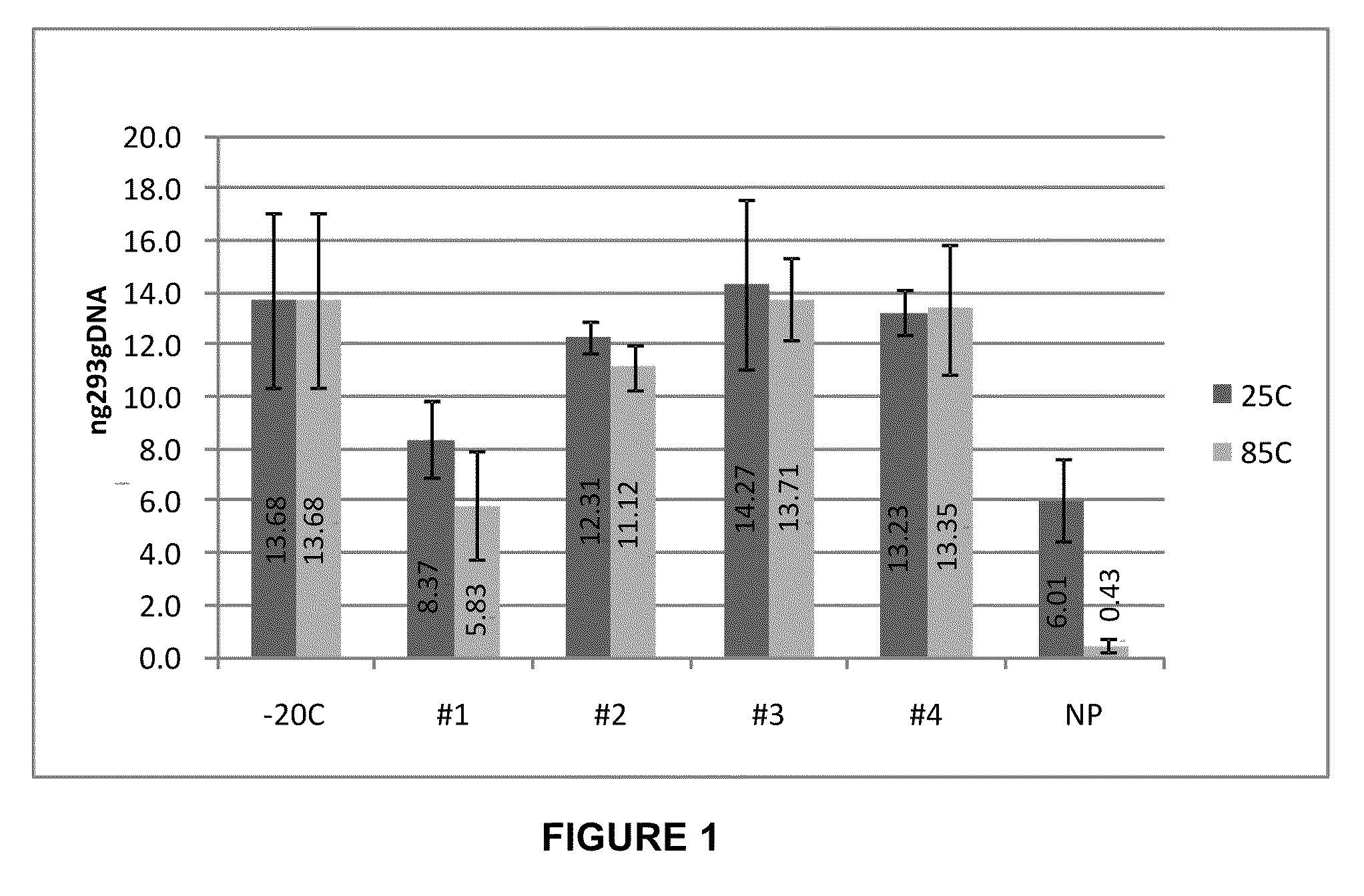

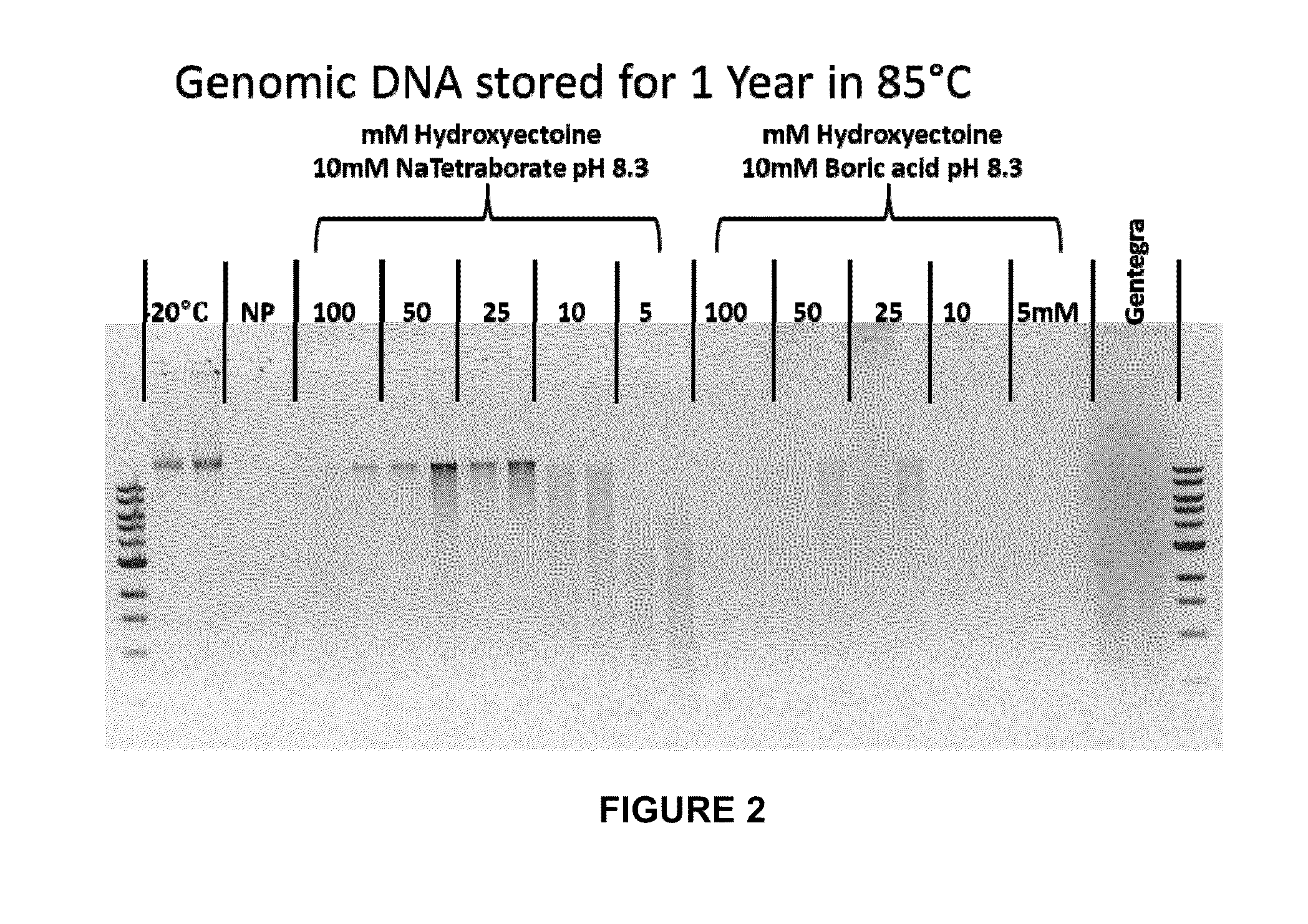

Compositions and methods for biological sample storage

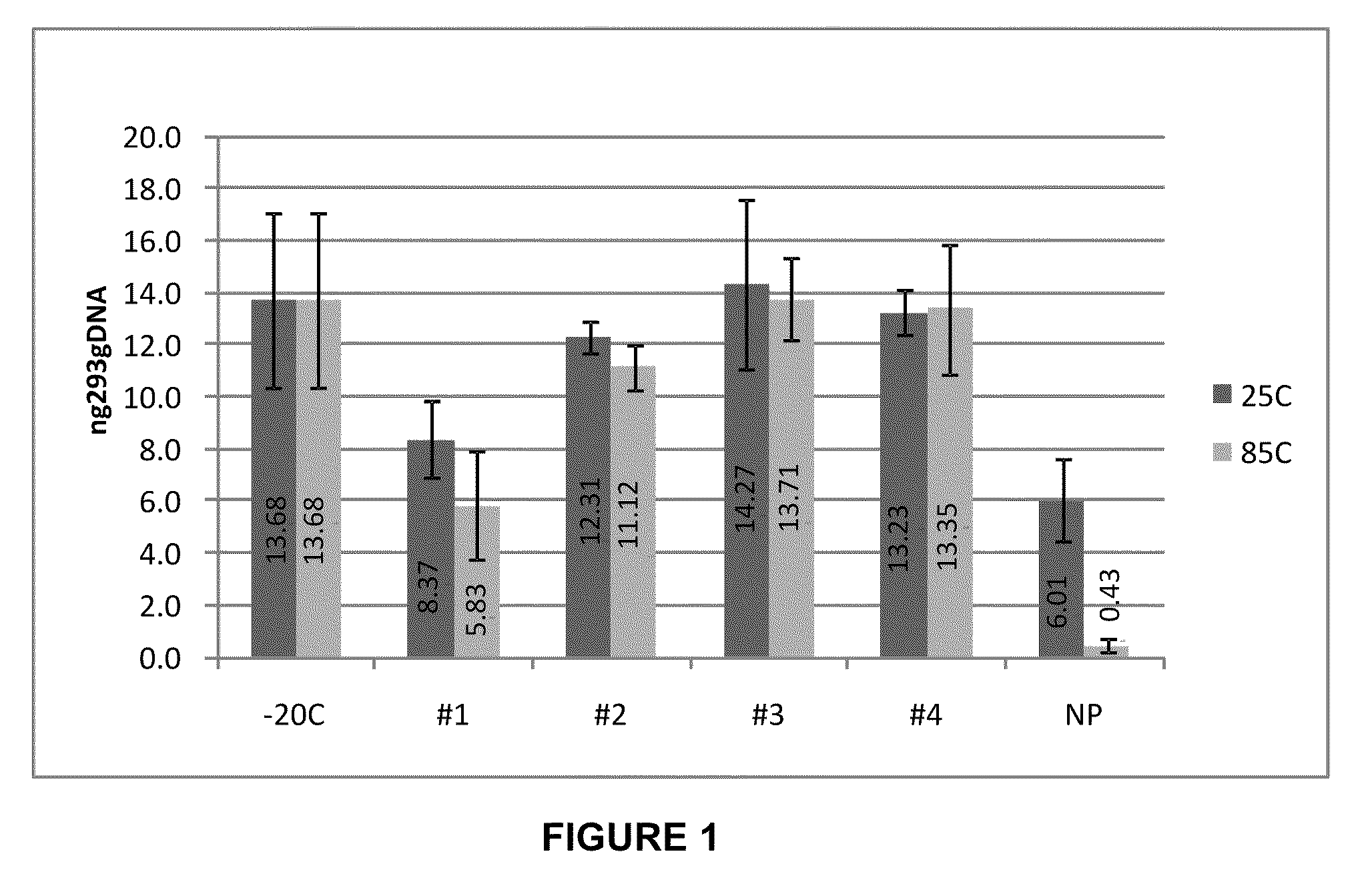

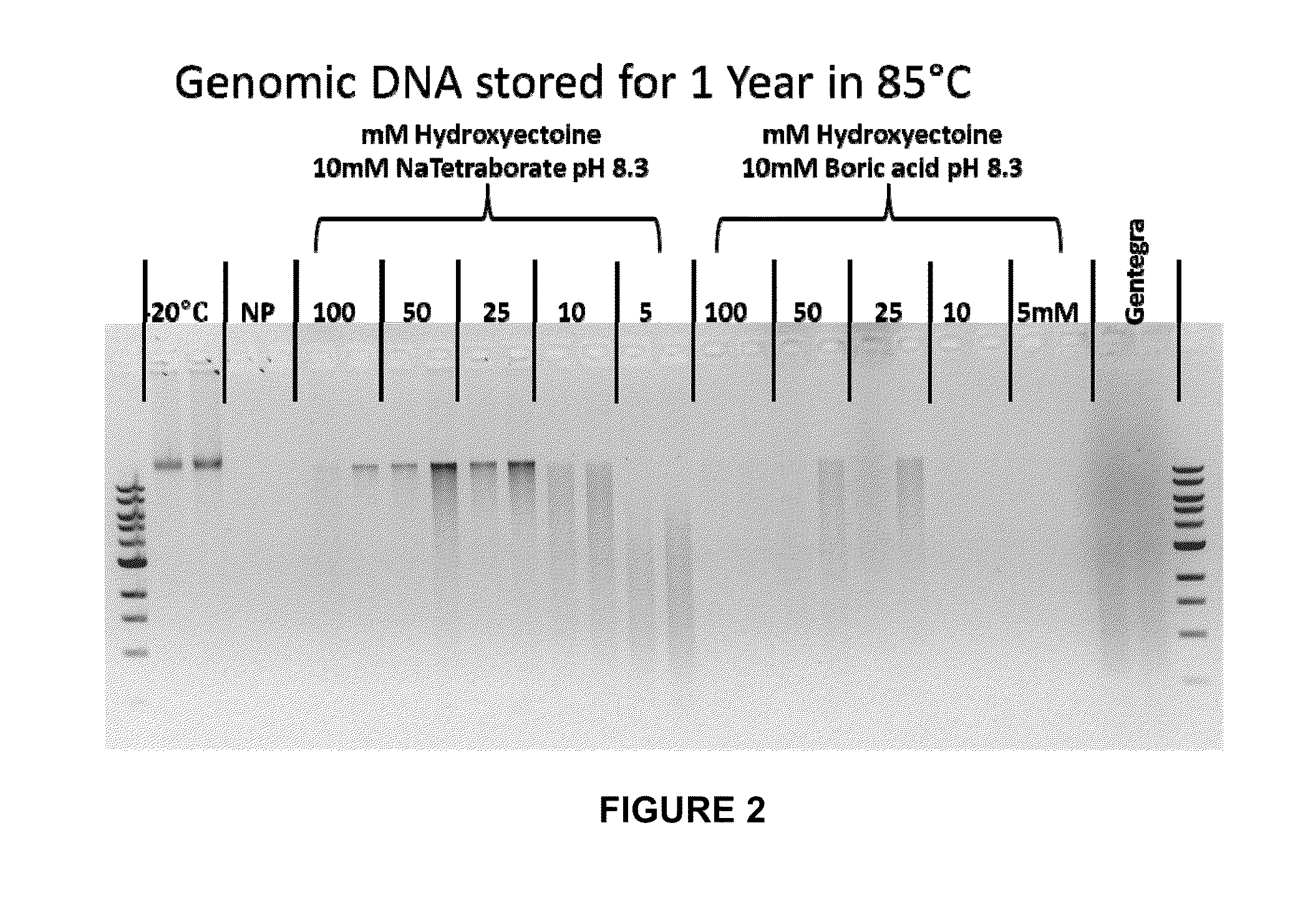

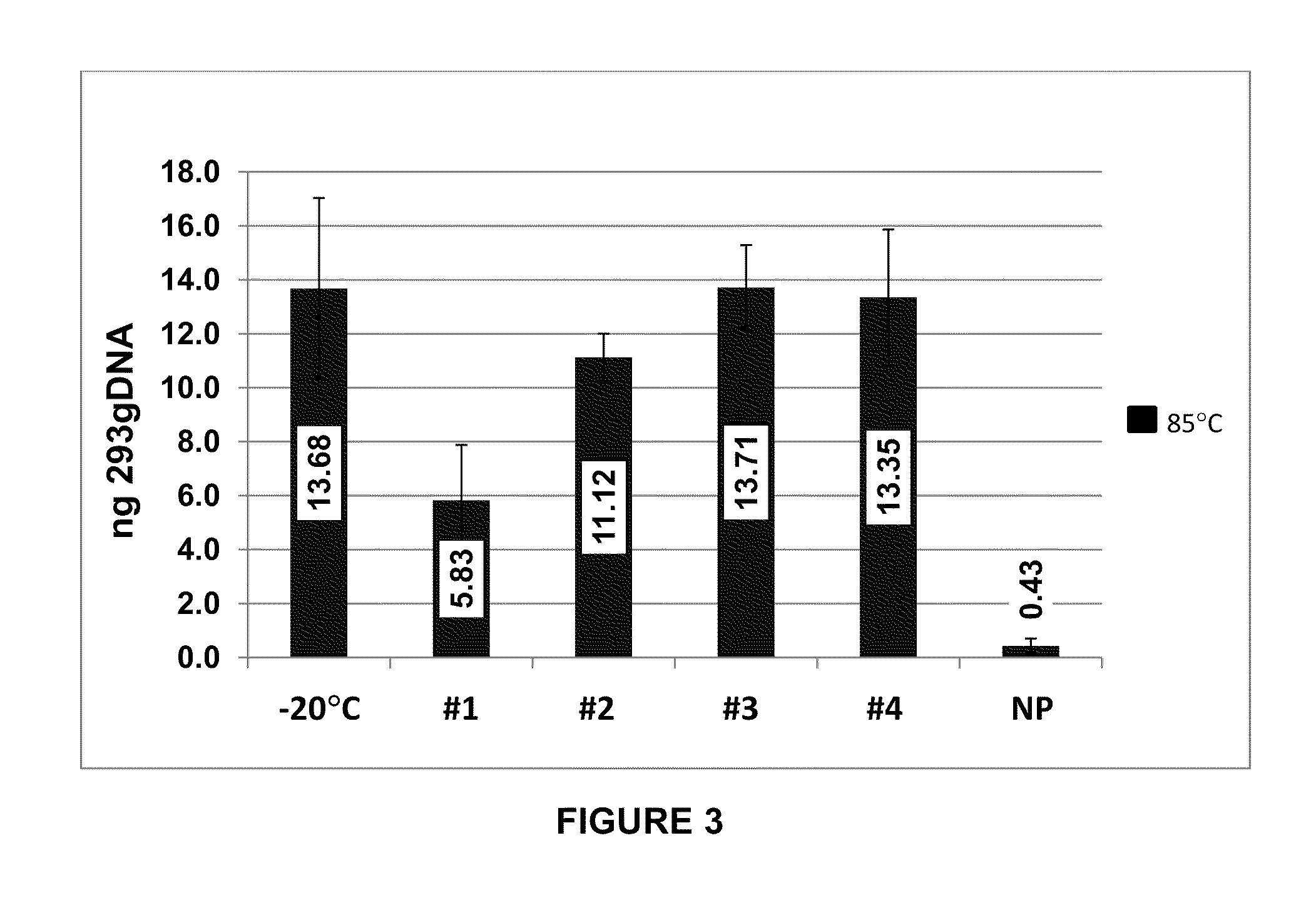

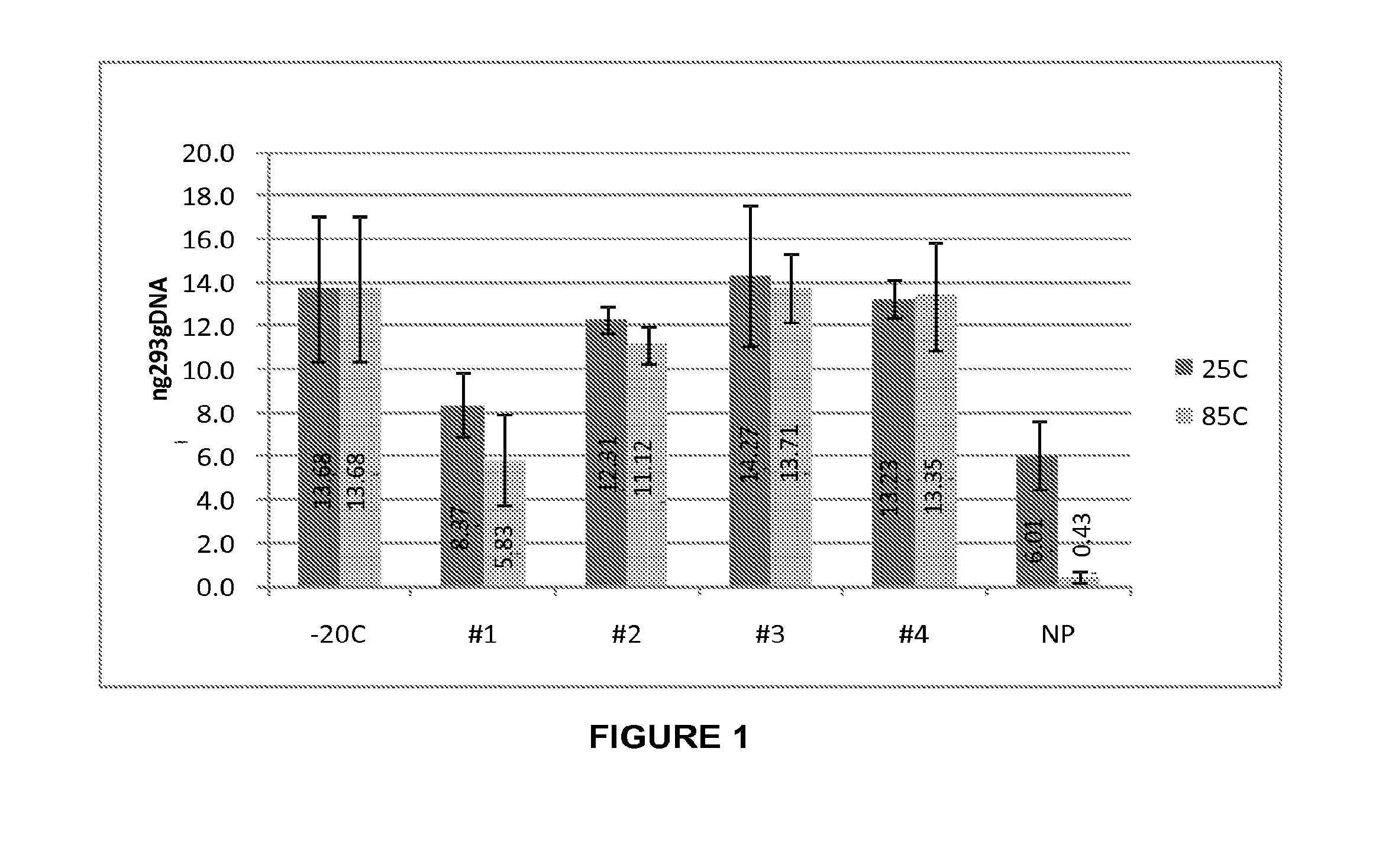

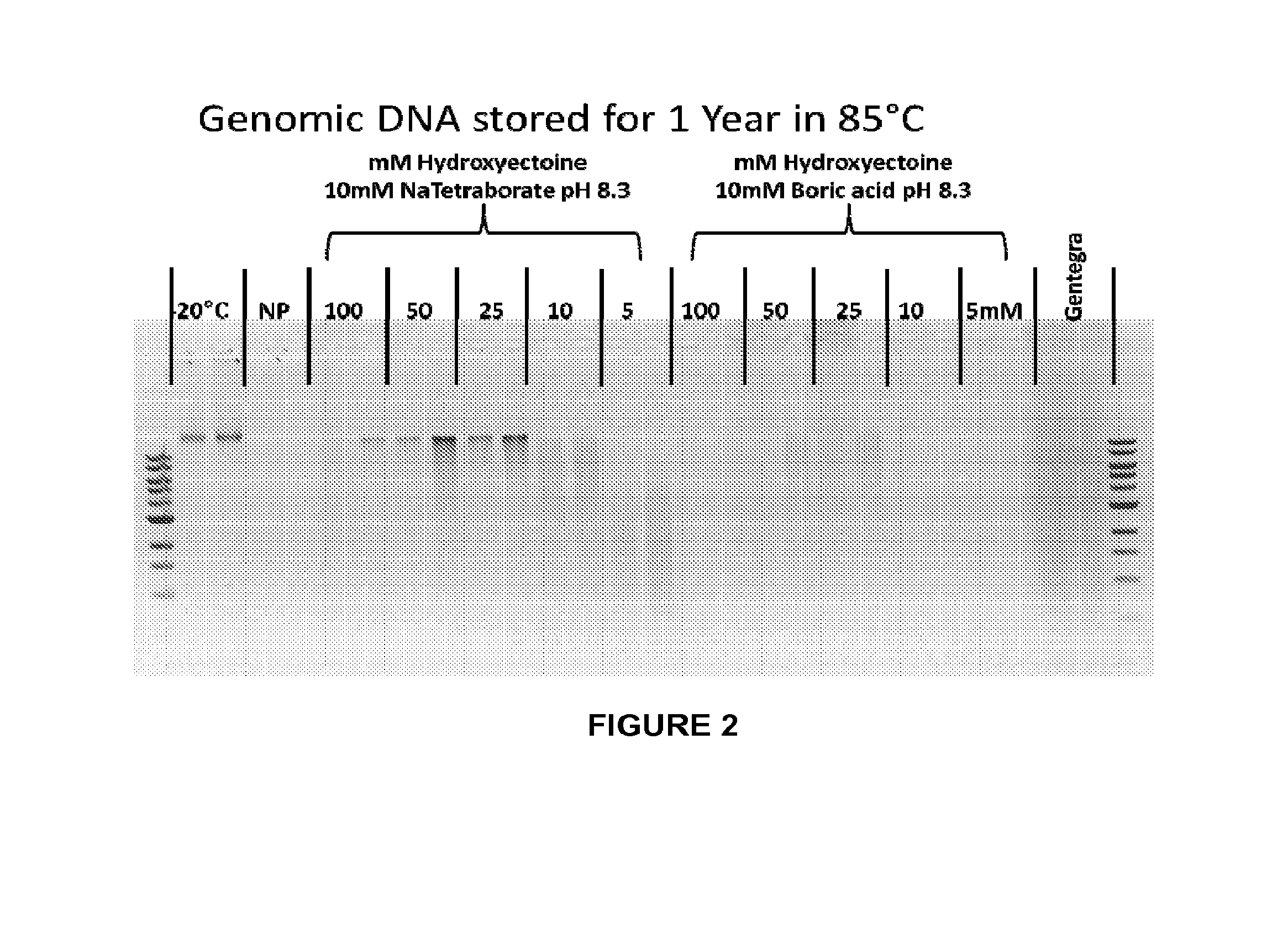

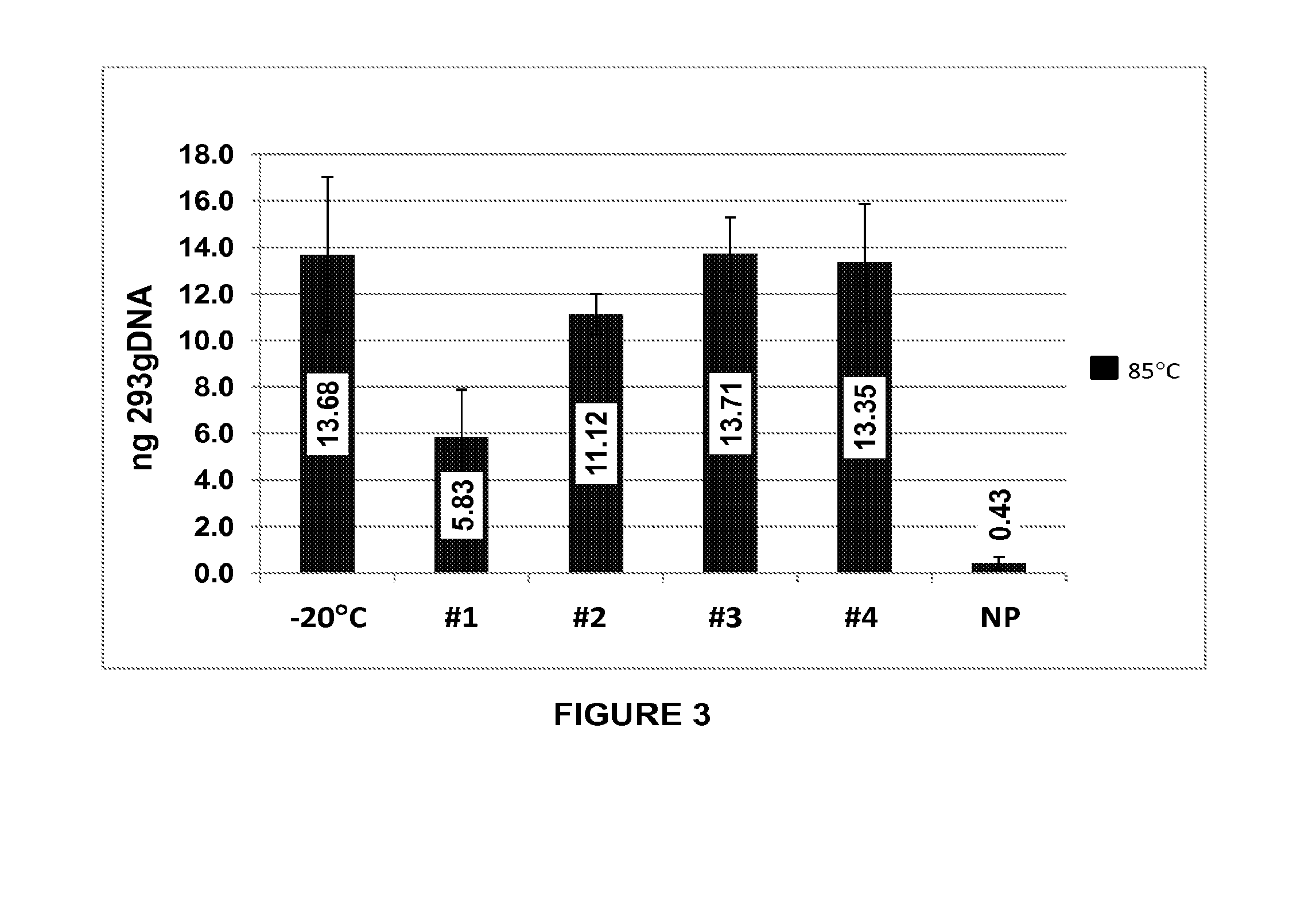

Compositions and methods are disclosed for substantially dry storage at ambient or elevated temperatures of biological samples such as nucleic acids, proteins and cells in a form from which the samples can be substantially recovered, using a dissolvable or dissociable dry storage matrix comprising a borate composition and a stabilizer as disclosed, such as any of a number of zwitterionic stabilizers.

Owner:MXCGLOBAL INC +2

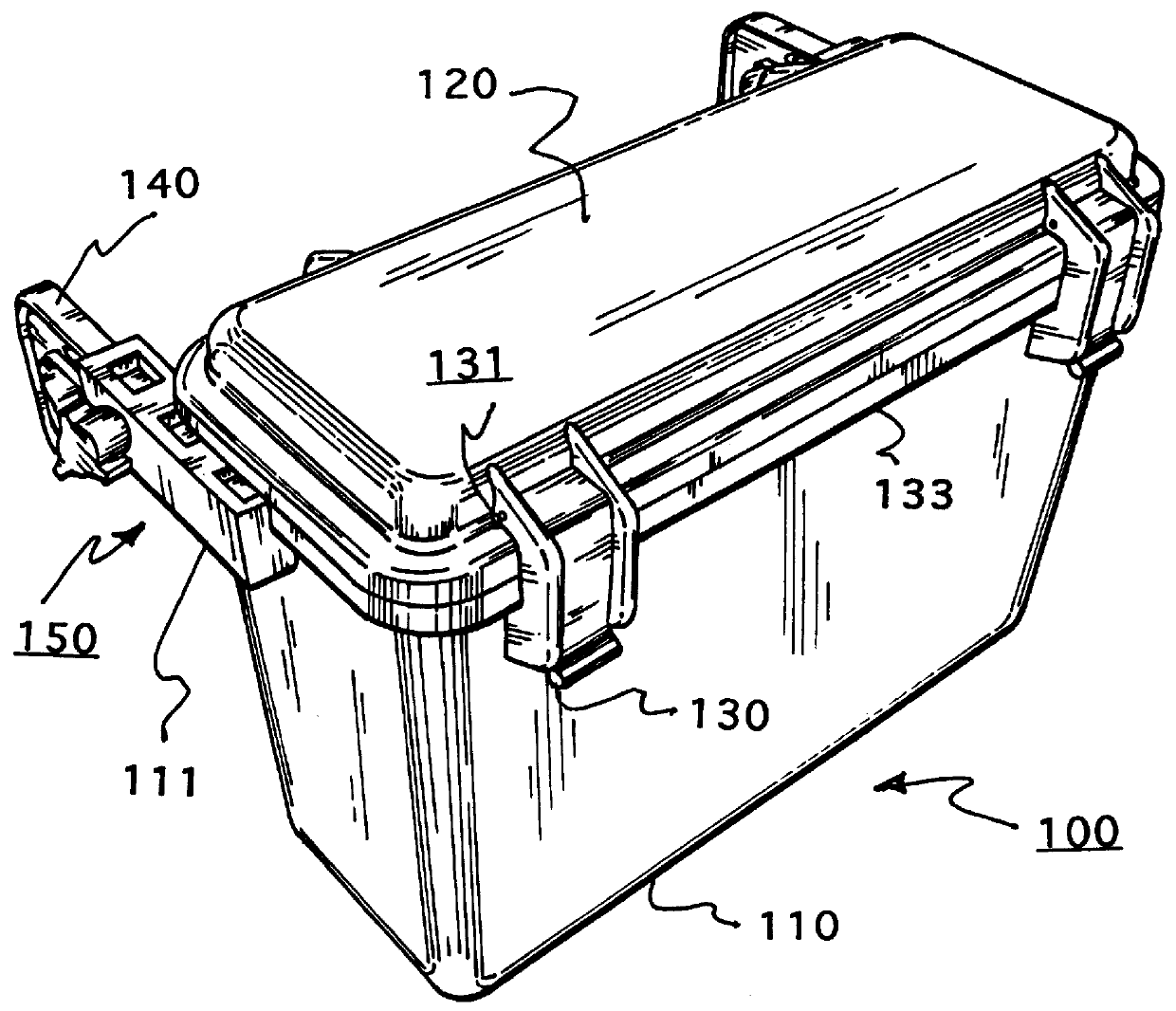

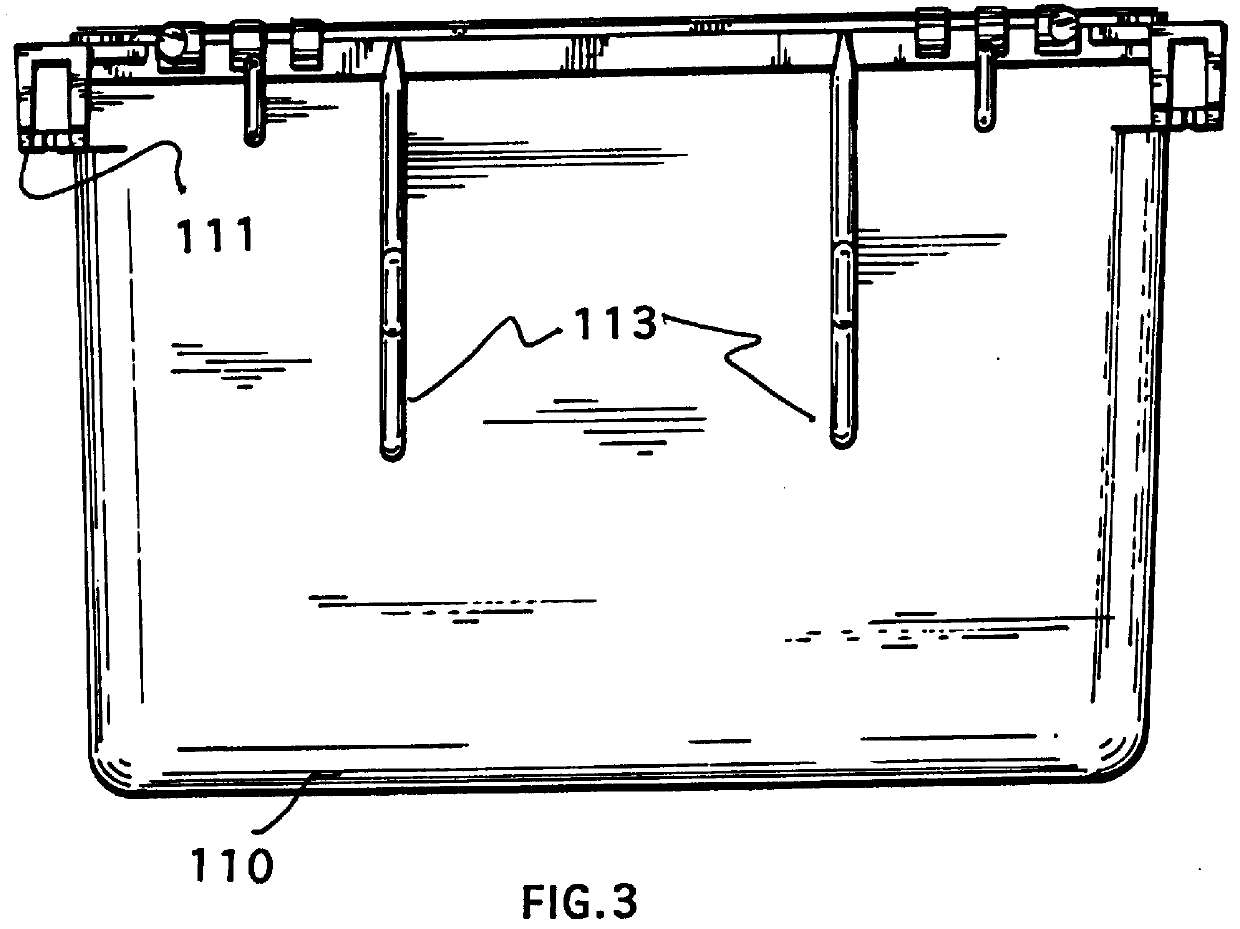

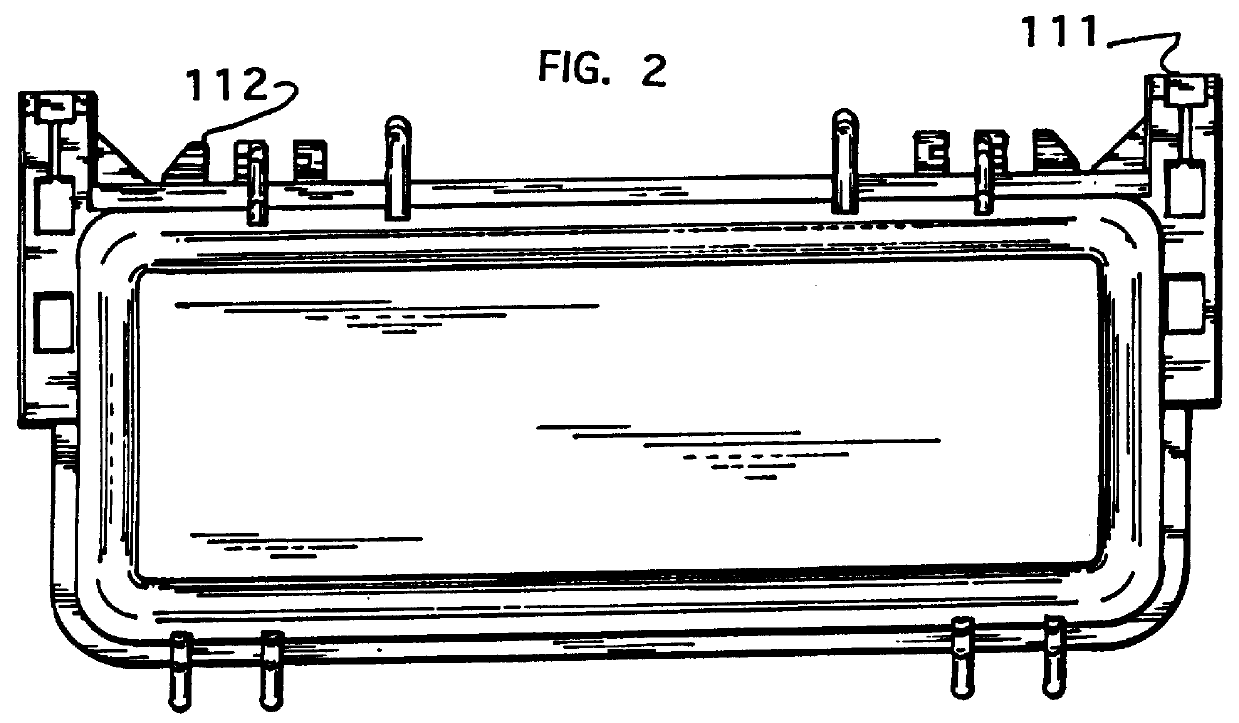

Gunwale attachable dry box for small watercraft

A dry storage box is held by a clamping device at a longitudinal location along the length of the small watercraft. Dry box provides water tight storage compartment with a hinged lid and latches for storing miscellaneous personal valuables and belongings. The clamped water tight box, in the event of capsize, remains secured to the gunwale, and thus valuables and belongings remain safe, dry and in one location. Incidentally provided are added buoyancy to the vessel in the event of a capsized condition, and when box is in normal use the longitudinal location allows free movement of the occupants about the small watercraft.

Owner:CLIFFORD PETER A

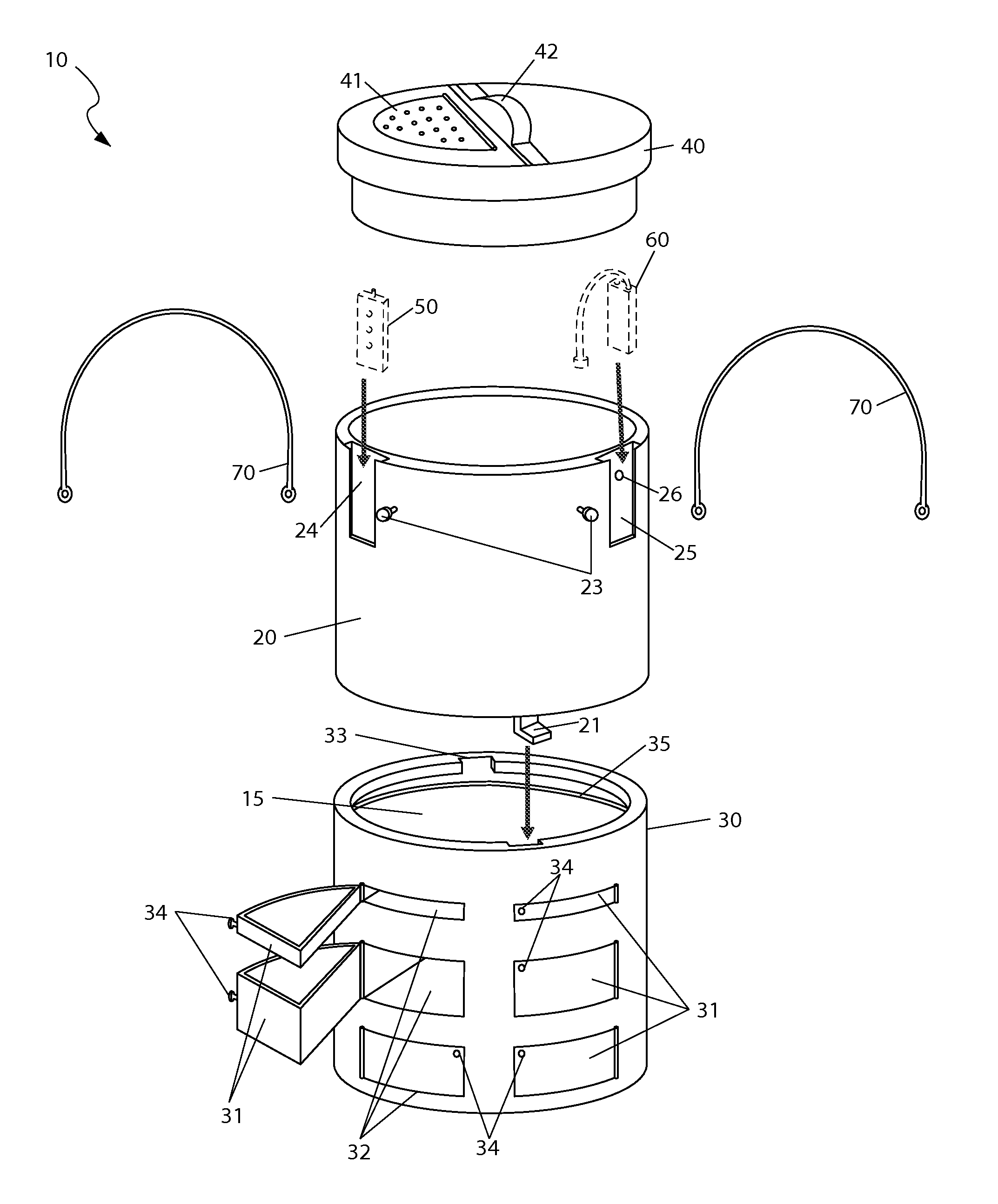

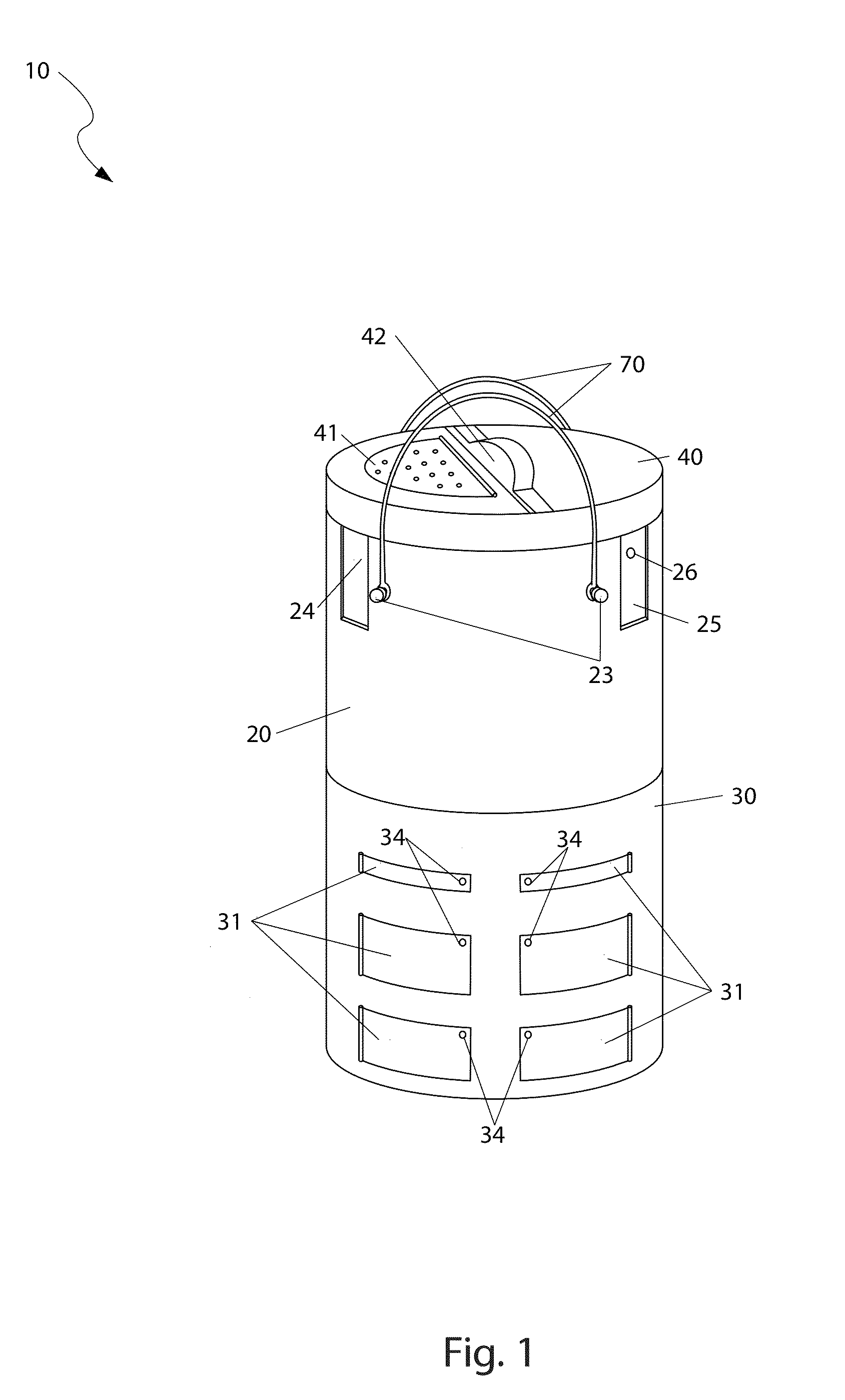

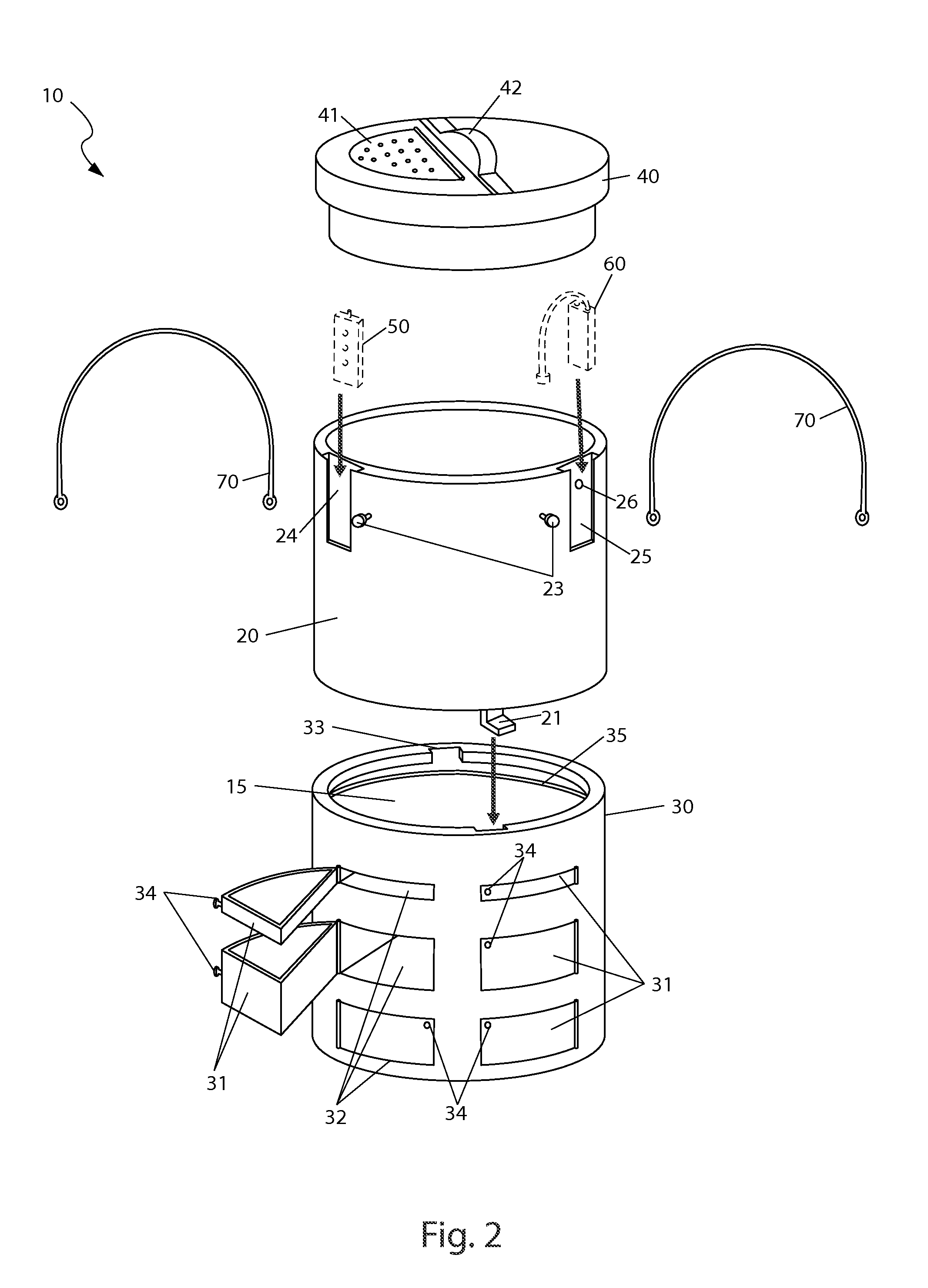

Combination bait bucket and tackle box

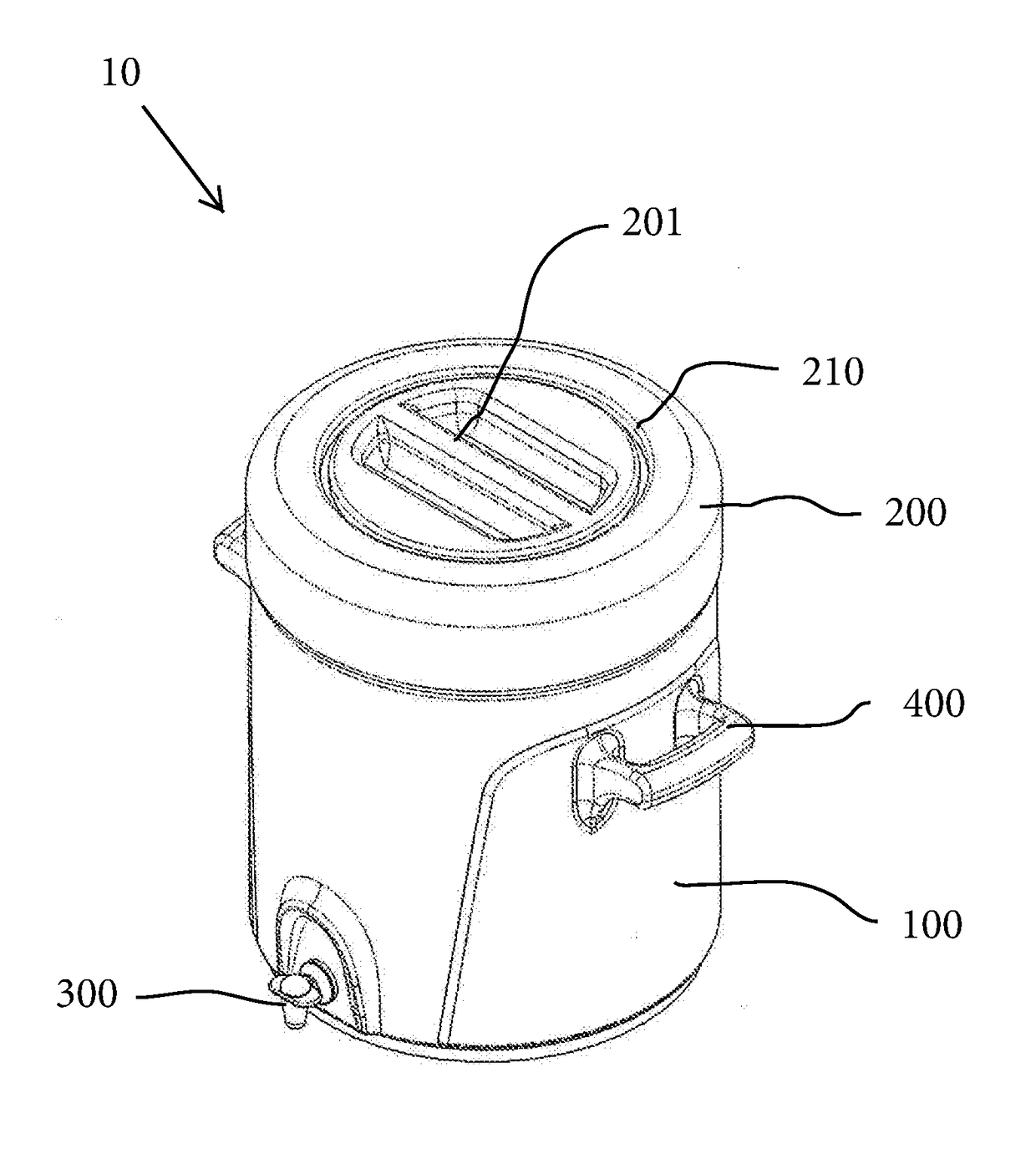

InactiveUS8806803B1Convenient manual transportationQuick connectionOther accessoriesOther angling devicesEngineeringLantern

A combination bait bucket and tackle box comprises a cylindrical container providing a means for dry storage of fishing supplies and also live bait. The bait container comprises a top portion of the device. The container further comprises a hinged access lid, a carrying handle, and a pair of slots adapted for securely receiving an aerator pump and a lantern. A bottom portion of the bait container lockably engages a top portion of the tackle box in order to allow the entire apparatus to be carried as unitary device. The tackle box comprises a round bottom portion of the apparatus which includes a plurality of drawers for storage of fishing supplies.

Owner:MITCHELL MICHAEL S +1

Integration of sample storage and sample management for life science

ActiveUS20080307117A1Reduce degradationMaterial nanotechnologyAnalysis using chemical indicatorsDrug biological activityEnzyme

Compositions and methods are disclosed for automated storing, tracking, retrieving and analyzing biological samples, including dry storage at ambient temperatures of nucleic acids, proteins (including enzymes), and cells using a dry storage matrix that permits recovery of biologically active materials. RFID-tagged biological sample storage devices featuring dissolvable or dissociable matrices are described for use as supports of biological samples, which matrices can be dried and subsequently rehydrated for sample recovery. Also disclosed are computer-implemented systems and methods for managing sample data.

Owner:BIOMATRICA INC

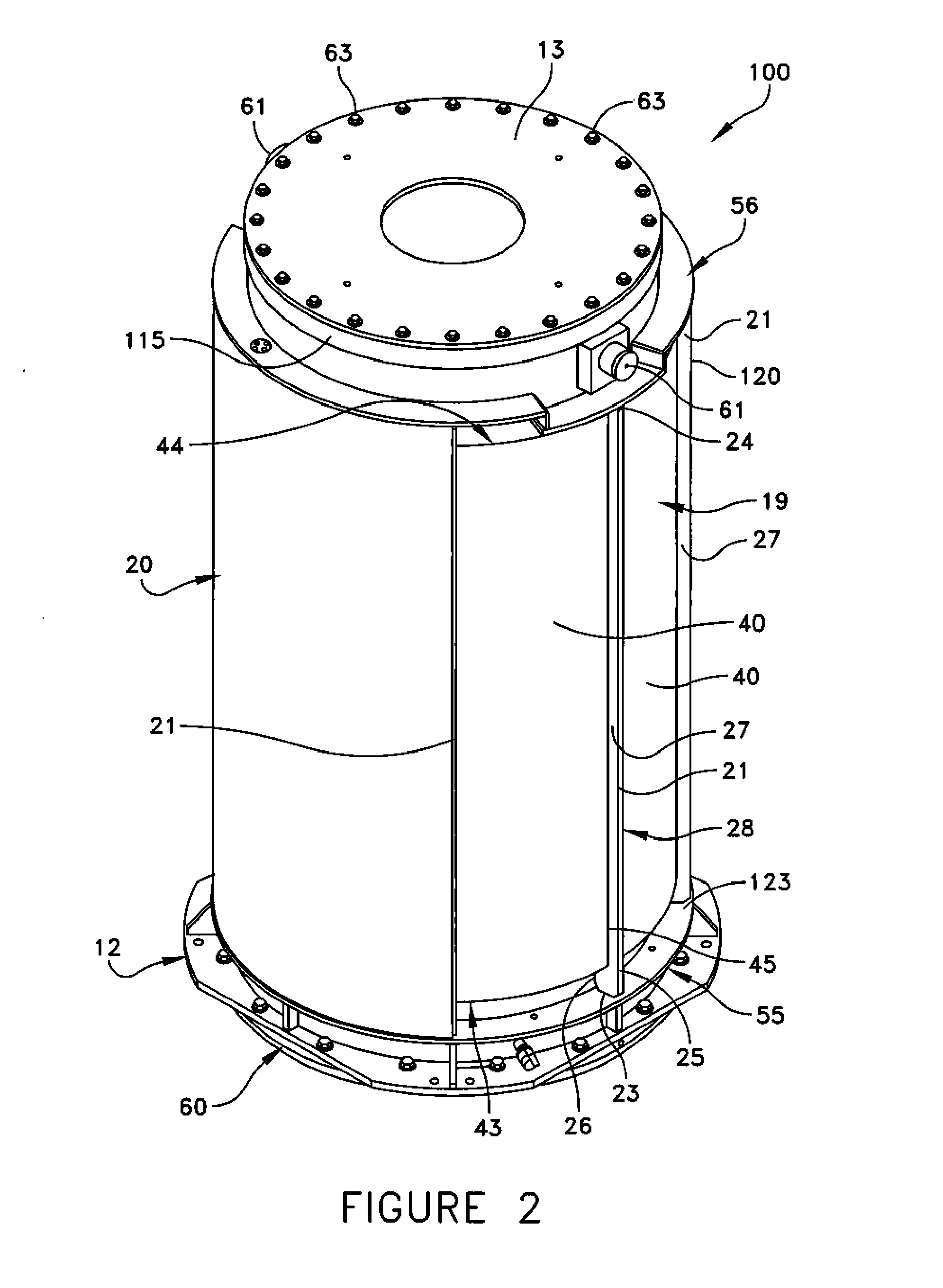

Method of removing radioactive materials from a submerged state and/or preparing spent nuclear fuel for dry storage

ActiveUS20090069621A1Quantity maximizationIncreasing transfer procedure cycleNuclear engineering problemsNuclear engineering solutionsRadioactive agentRadioactive waste

A system, apparatus and method of processing and / or removing radioactive materials from a body of water that utilizes the buoyancy of the water itself to minimize the load experienced by a crane and / or other lifting equipment. In one aspect, the invention is a method comprising: a) submerging a container having a top, a bottom, and a cavity in a body of water having a surface level, the cavity filling with water; b) positioning radioactive material within the cavity of the submerged container; c) raising the submerged container until the top of the containment apparatus is above the surface level of the body of water while a major portion of the container remains below the surface level of the body of water; and d) removing bulk water from the cavity while the top of the container remains above the surface level of the body of water and a portion of the container remains submerged. The bulk water can be added back into the cavity to add neutron shielding after the container is placed in a staging area and prior to personnel performing the desired operations to the container. As a result, gamma radiation and neutron shielding of the container can be maximized for any crane capacity.

Owner:HOLTEC INT

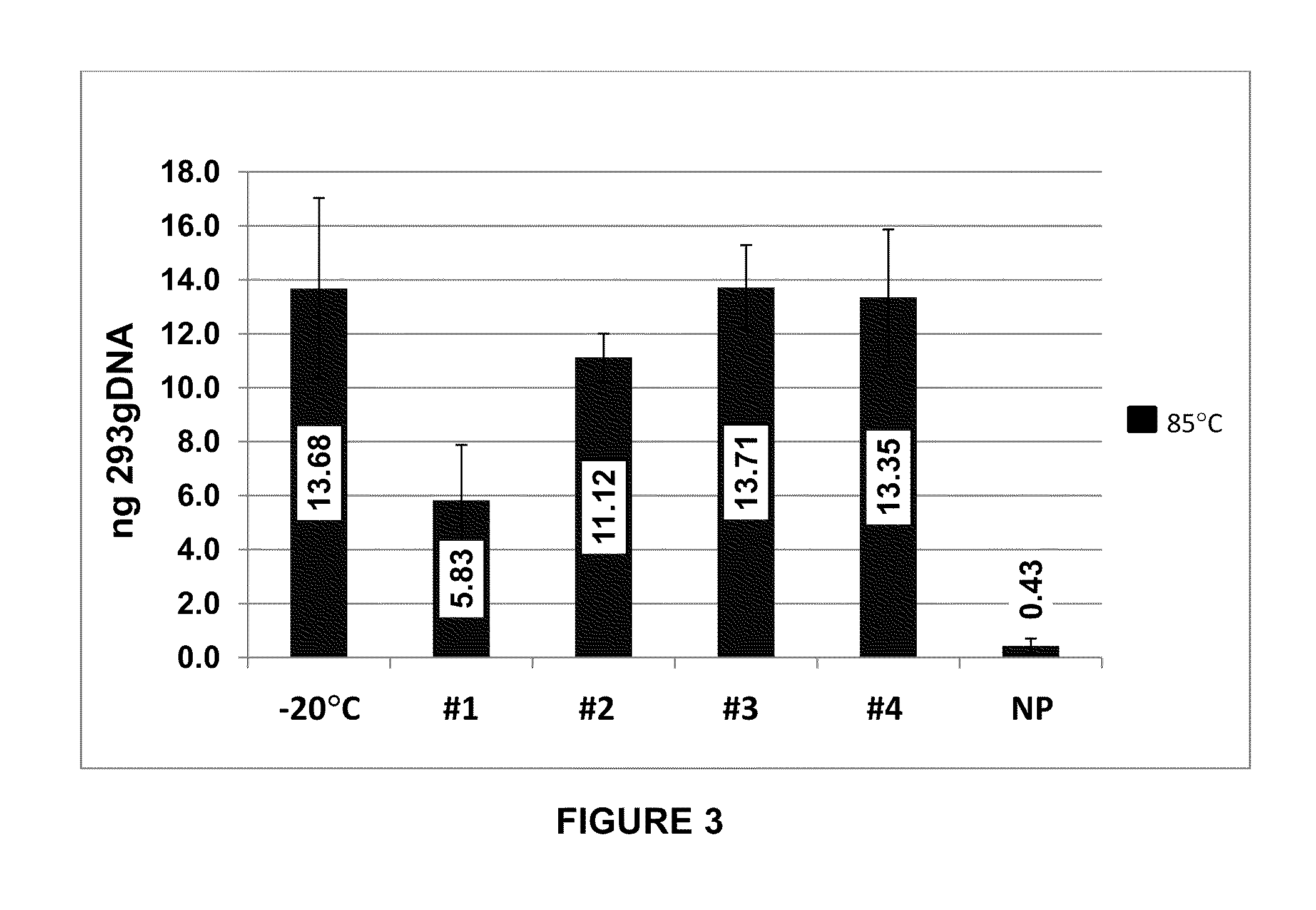

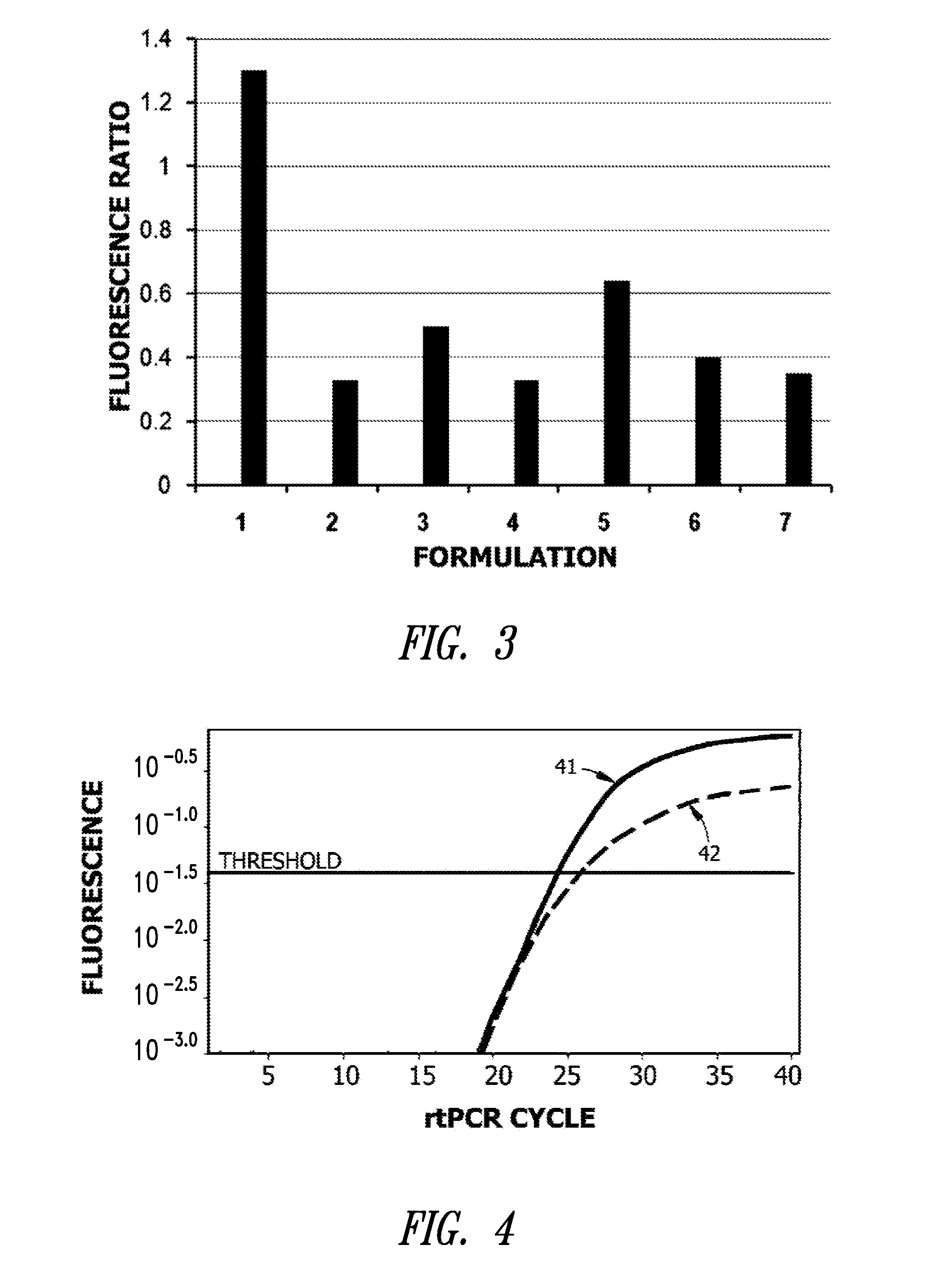

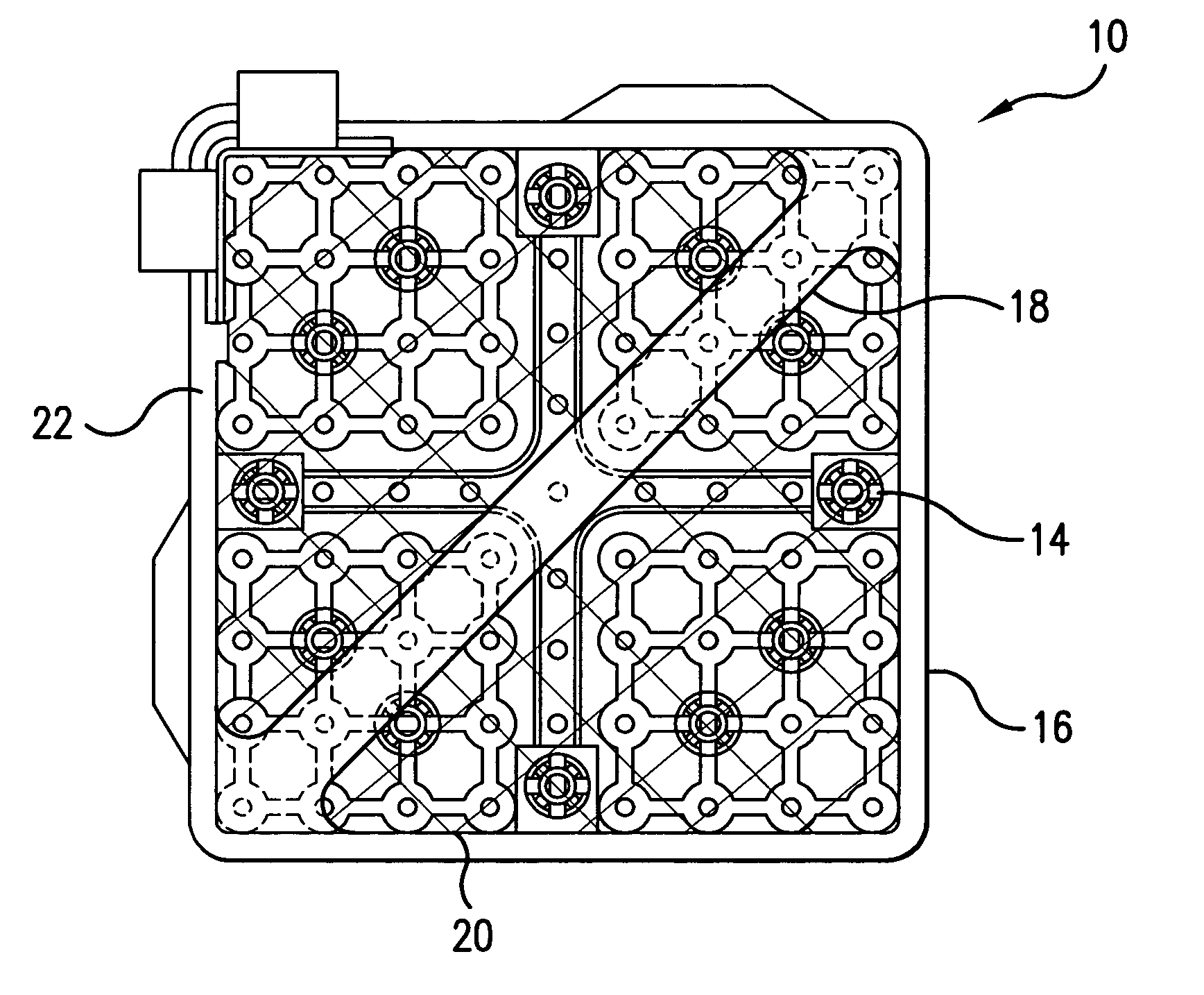

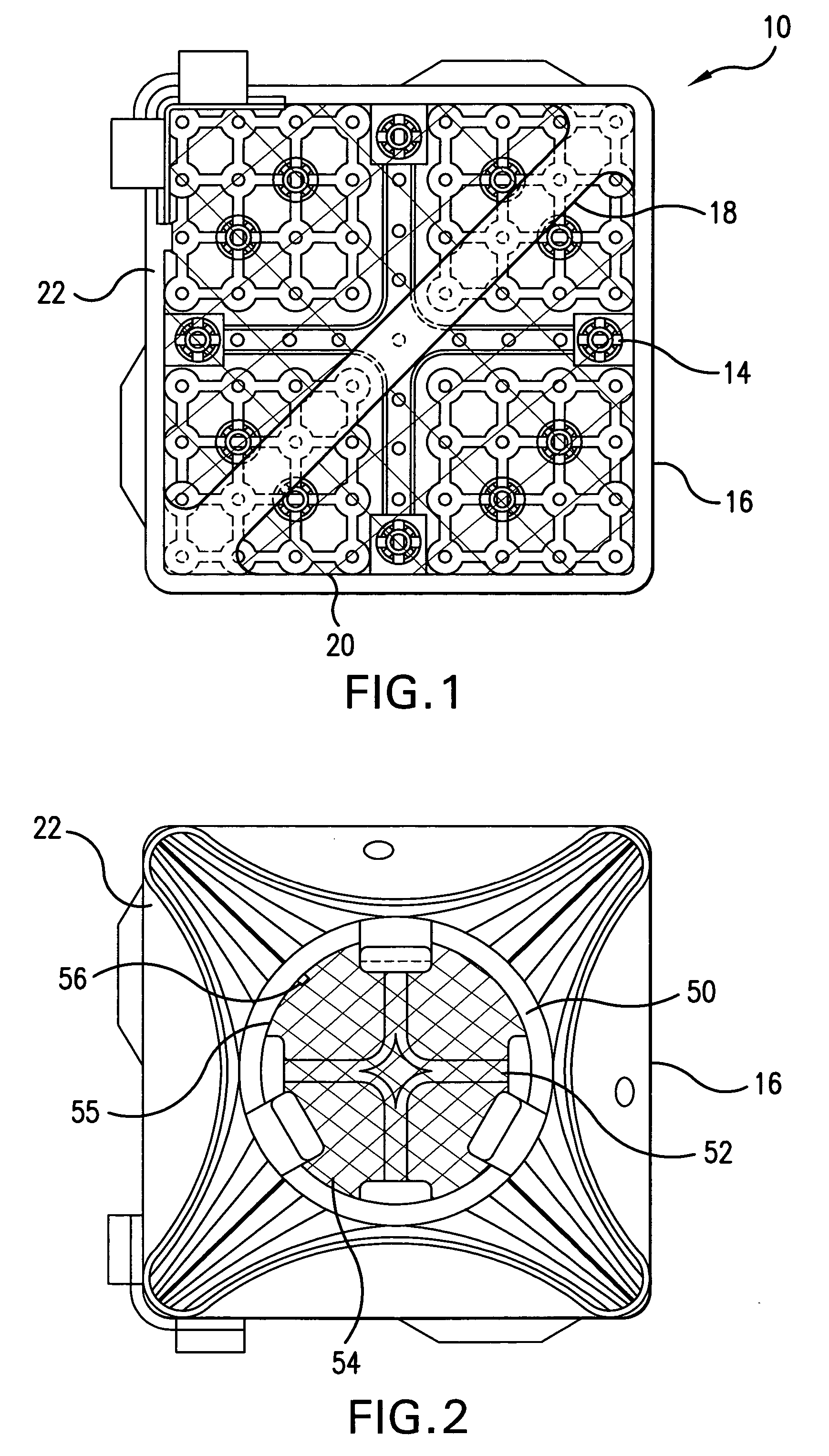

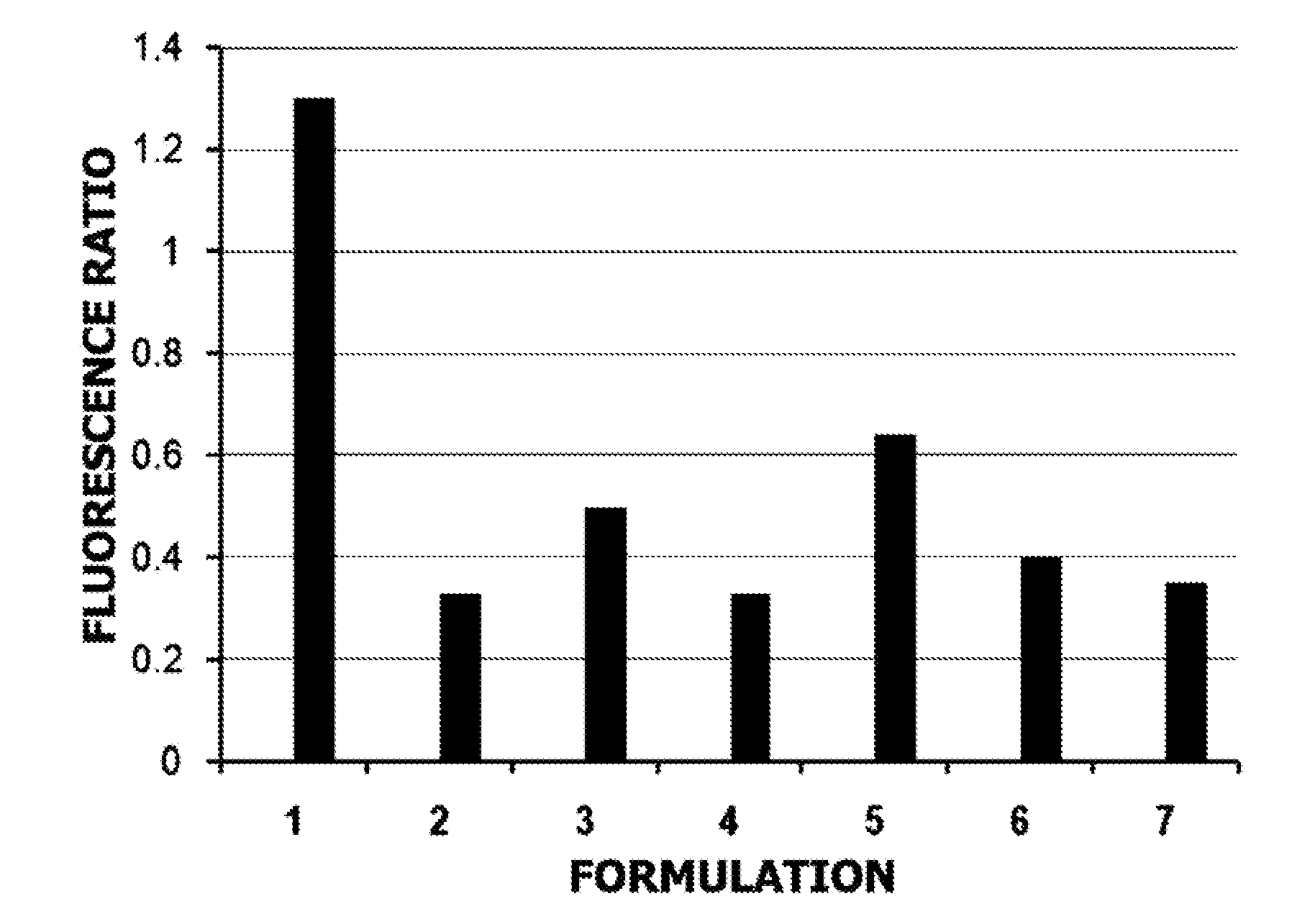

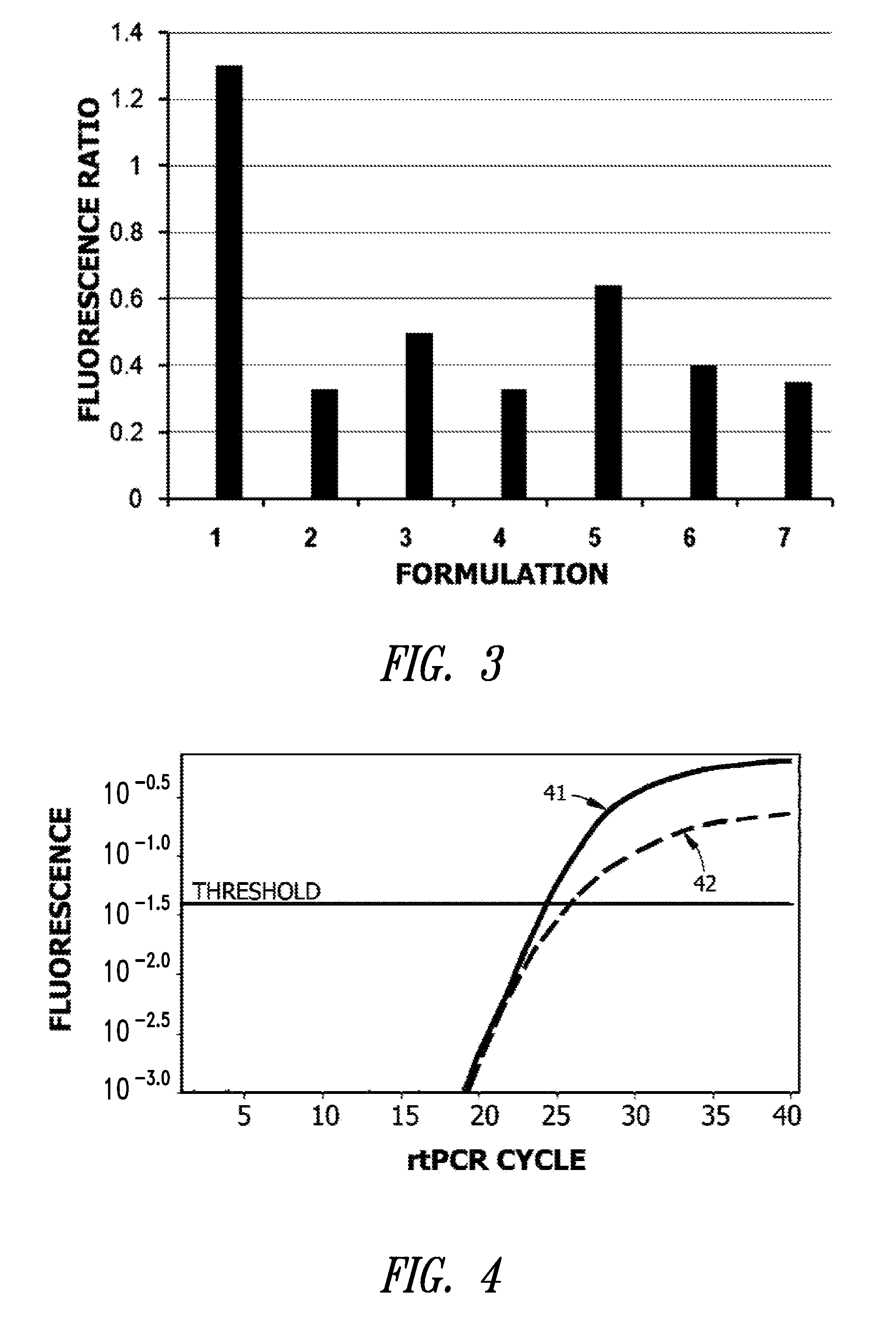

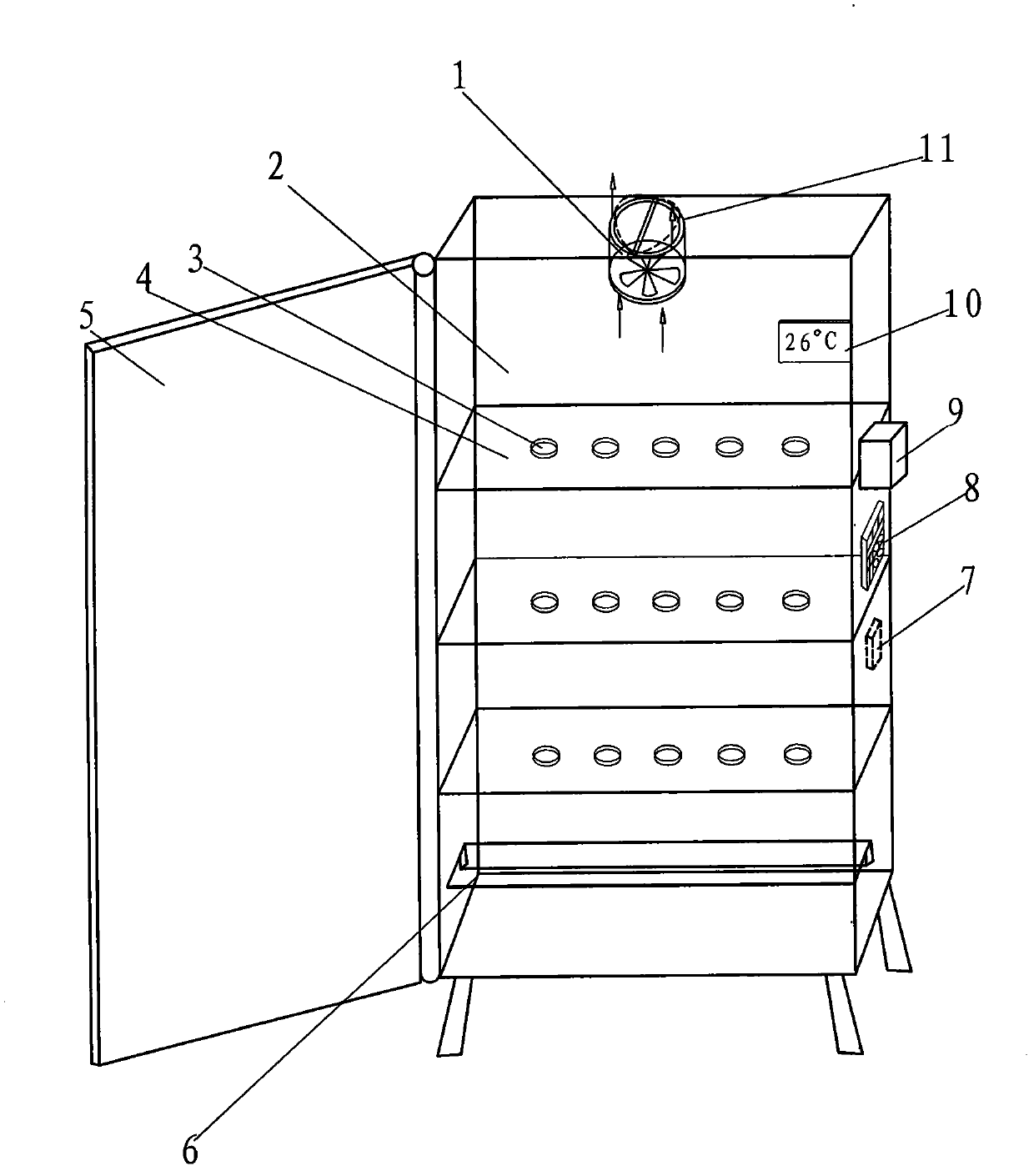

Rehydratable matrices for dry storage of TAQ polymerase in a microfluidic device

Formulations for dry storage of PCR reagents are described. These formulations find use in manufacture of self-contained microfluidic card devices for PCR clinical testing in which the reagents are reconstituted at the point of testing. In these cards, TAQ polymerase is stored “on-board” in vitrified dry form without lyophilization or freezing, and is reconstituted by either the sample or a sample eluate during the assay.

Owner:PERKINELMER HEALTH SCIENCES INC

Compositions and methods for biological sample storage

Compositions and methods are disclosed for substantially dry storage at ambient or elevated temperatures of biological samples such as nucleic acids, proteins and cells in a form from which the samples can be substantially recovered, using a dissolvable or dissociable dry storage matrix comprising a borate composition and a stabilizer as disclosed, such as any of a number of zwitterionic stabilizers.

Owner:MXCGLOBAL INC +2

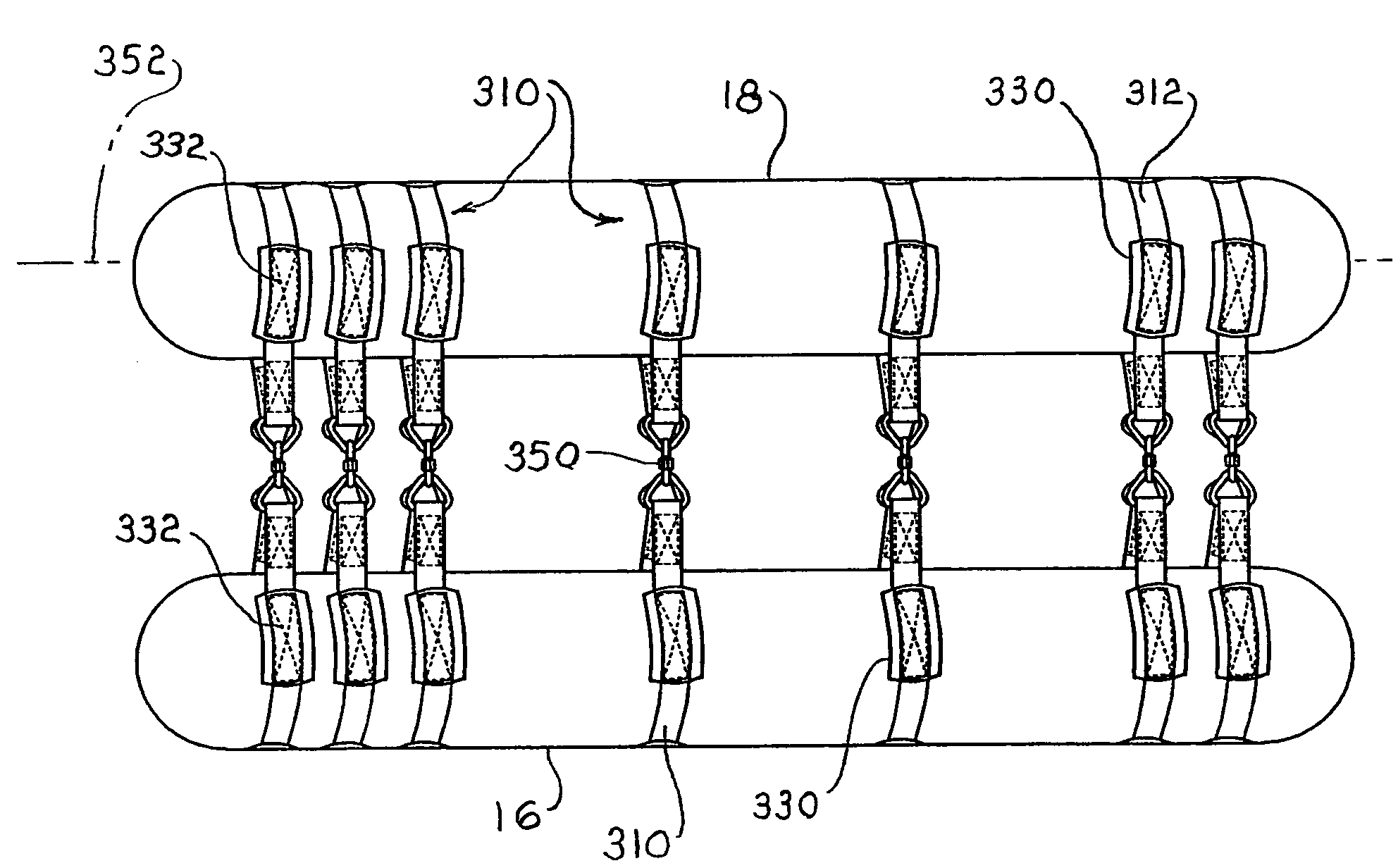

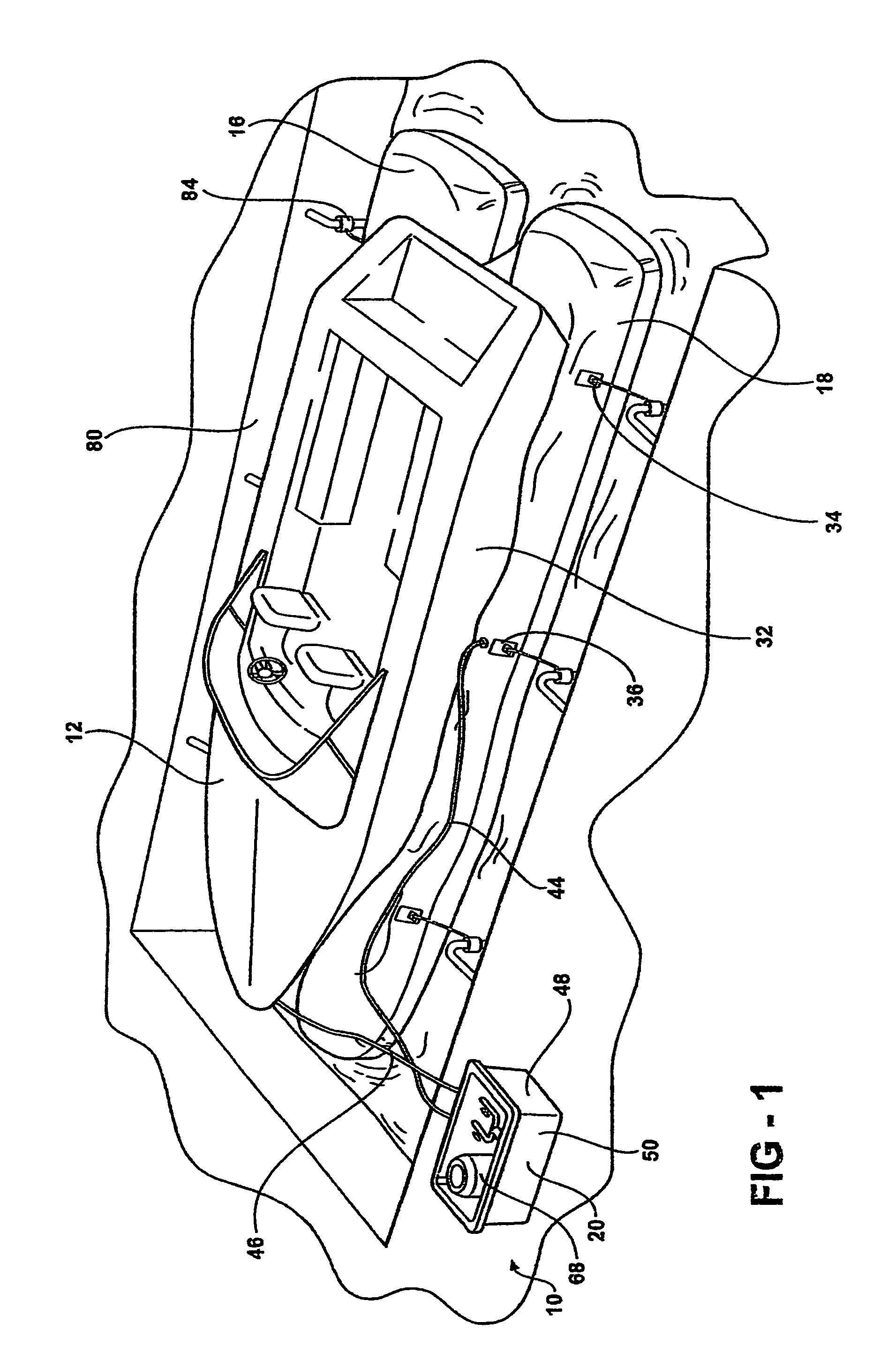

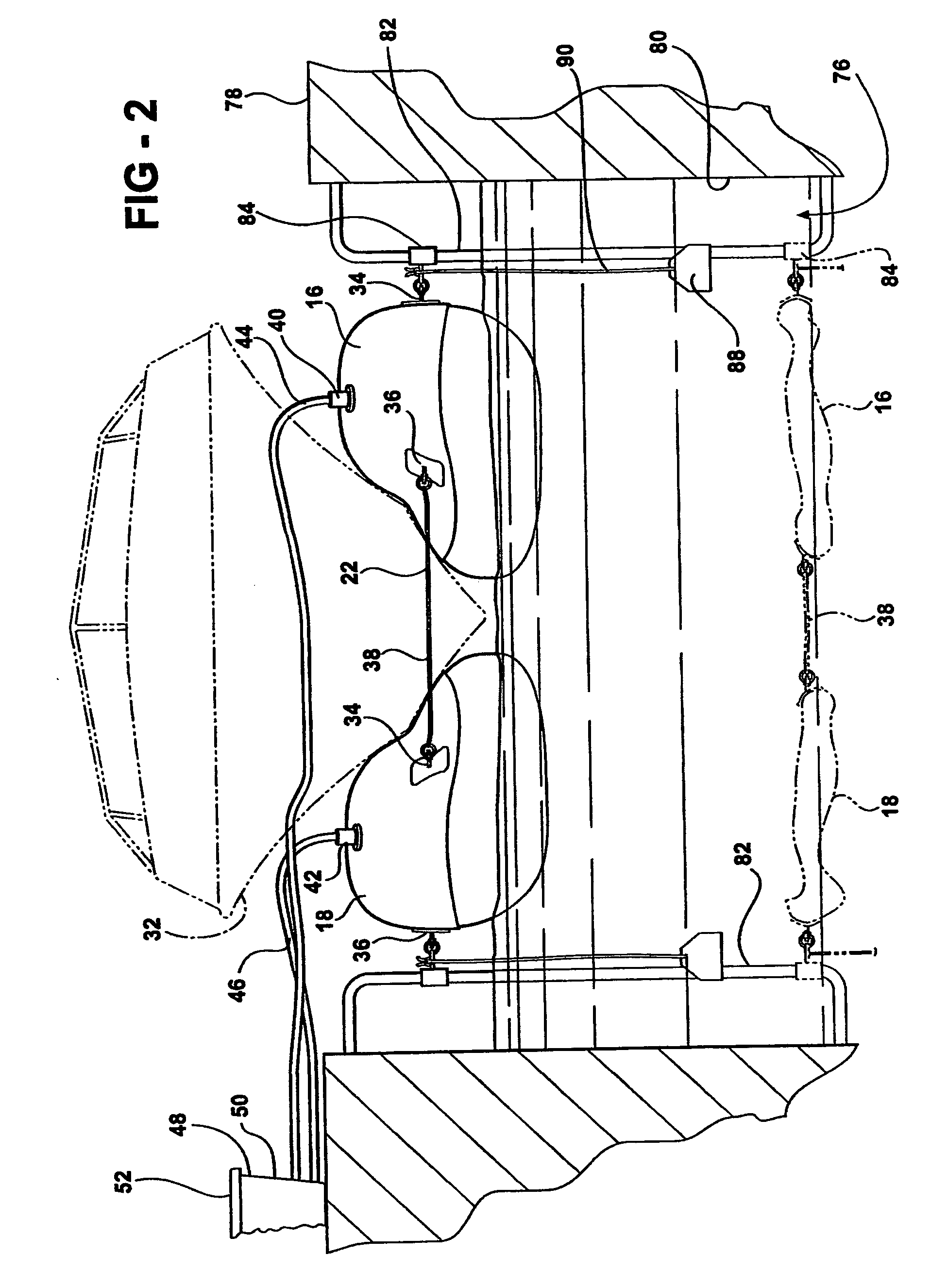

Watercraft dry storage and storage method

The watercraft dry storage assembly includes two generally cylindrical bladders that are inflated to lift a boat from the water and hold the hull in a raised position. Each bladder is made from a scrim encased in a flexible plastic. The scrim is substantially non-stretchable. Air fills the bladders until each inch of bladder material is tensioned in a direction parallel to a long axis of the bladder by a force of at least 5 pounds and in a transverse direction by a force of at least 10 pounds. A plurality of straps encircle each bladder. Rings on the ends of each strap are connected by coupler assemblies to secure both bladders together. The straps are attached to the bladders in selected positions along the length of the bladders.

Owner:VICTOR REMI L

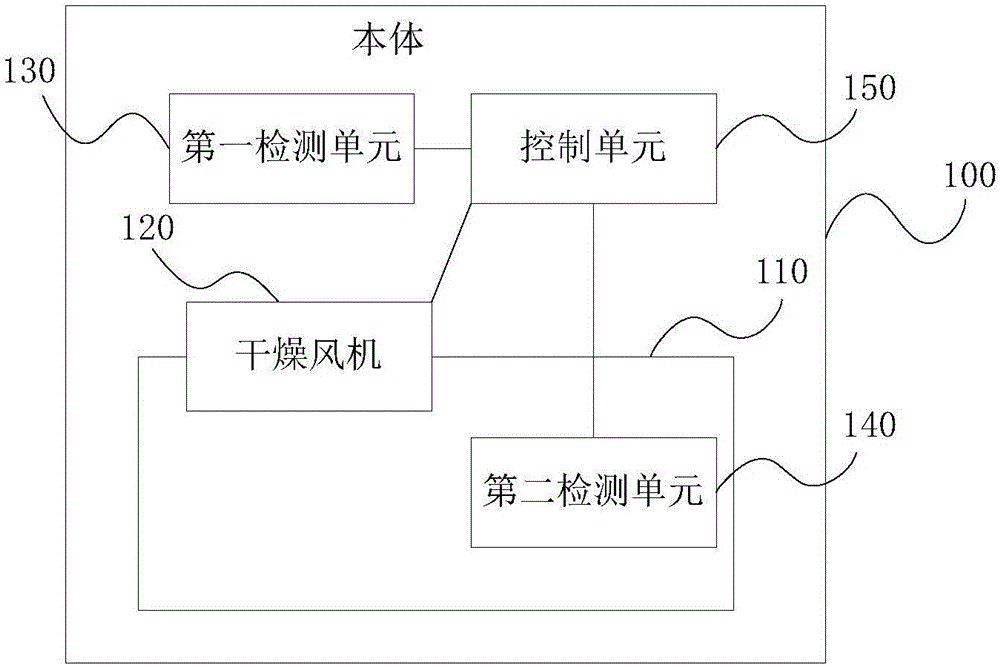

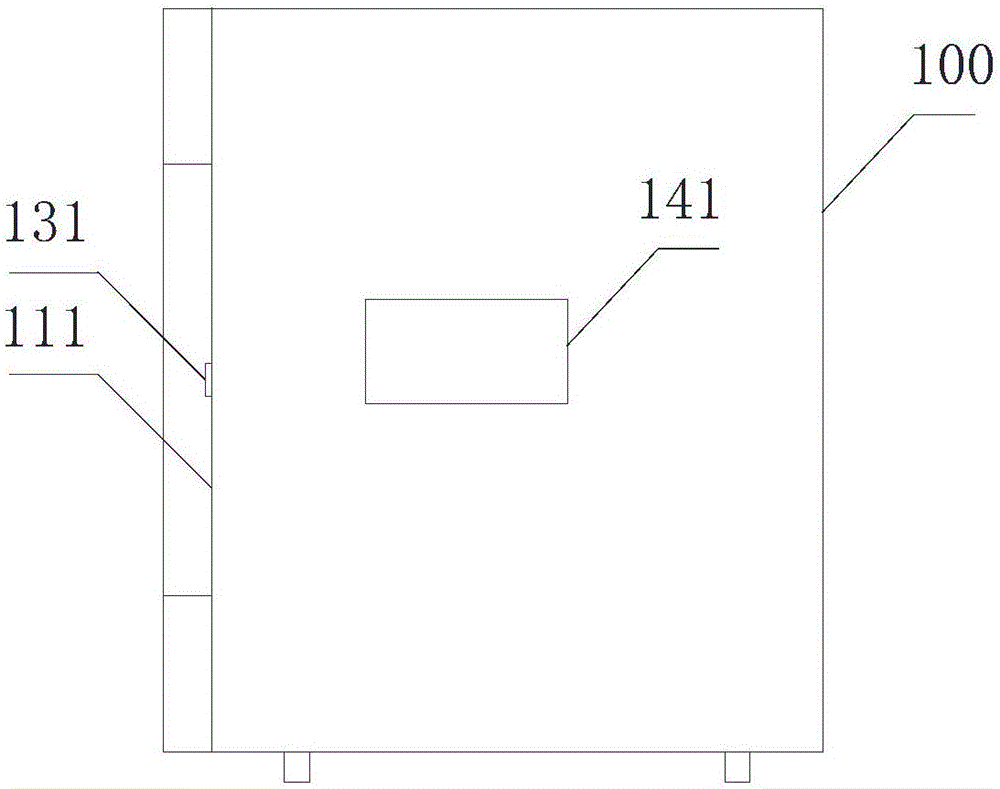

Dish washing machine and control method thereof

ActiveCN106725184ASolve the problem of re-contaminationShorten washing timeTableware washing/rinsing machine detailsProcess engineeringContamination

The invention discloses a dish washing machine and a control method thereof. The dish washing machine comprises a body, an inner container arranged in the body, a drying fan arranged in the body, a first detection unit used for detecting the environment temperature outside the inner container, a second detection unit for detecting the temperature and humidity of space of the inner container, and a control unit used for calculating the dew point temperature of the space of the inner container according to the temperature and humidity of the space of the inner container and controlling the drying fan according to the dew point temperature and the environment temperature outside the inner container when the dish washing machine gets into a dish drying storage stage. Thus, after washing is completed, the drying fan is controlled according to the environment temperature outside the inner container and the dew point temperature of the space of the inner container to carry out drying storage on dishes. The problem of re-contamination caused by the fact that the dishes are not taken out in time is effectively solved, and meanwhile the whole washing time of the dishes can be effectively shortened.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Tailgating system

InactiveUS8672200B2Lower the motorized hitch assemblySupplementary fittingsTowing devicesCouplingEngineering

A tailgating system for attachment to a transport vehicle includes a cabinet configured to include at least one of a refrigerator, a grill, a draft system, and a dry storage cabinet. A movable hitch assembly includes a hitch coupling configured to be coupled to a hitch ball connectable to the transport vehicle. The movable hitch assembly is configured to move the hitch coupling up and down relative to the cabinet to raise and lower the cabinet when the movable hitch assembly is coupled to the transport vehicle.

Owner:OHARE MATTHEW J

Apparatus and method for preparation of a peritoneal dialysis solution

InactiveUS6986872B2Minimize the possibilityEasy to separateGeneral water supply conservationDiagnosticsPeritoneal dialysateMagnesium salt

The invention provides an apparatus and method for storing and transporting peritoneal dialysate in dry or lyophilized form, and for forming a deliverable peritoneal dialysis solution therefrom. In one embodiment, a dry reagent bed, including reagents sufficient to produce a dialysis solution, is suspended in a diluent flow path through the apparatus housing. Continuous pressure on the reagent bed causes the bed to compact as it erodes when purified water is passed through the housing. The pressure ensures complete and even dissolution of the reagents. Through dry storage and simple dissolution, even in a home, the invention enables a wider variety of solution constituents, including reduced acid content and the use of bicarbonate as a stable buffer component. The latter is illustrated in a double-bed embodiment, where bicarbonate is stored separately from calcium or magnesium salts within a single housing.

Owner:PRISMEDICAL CORP

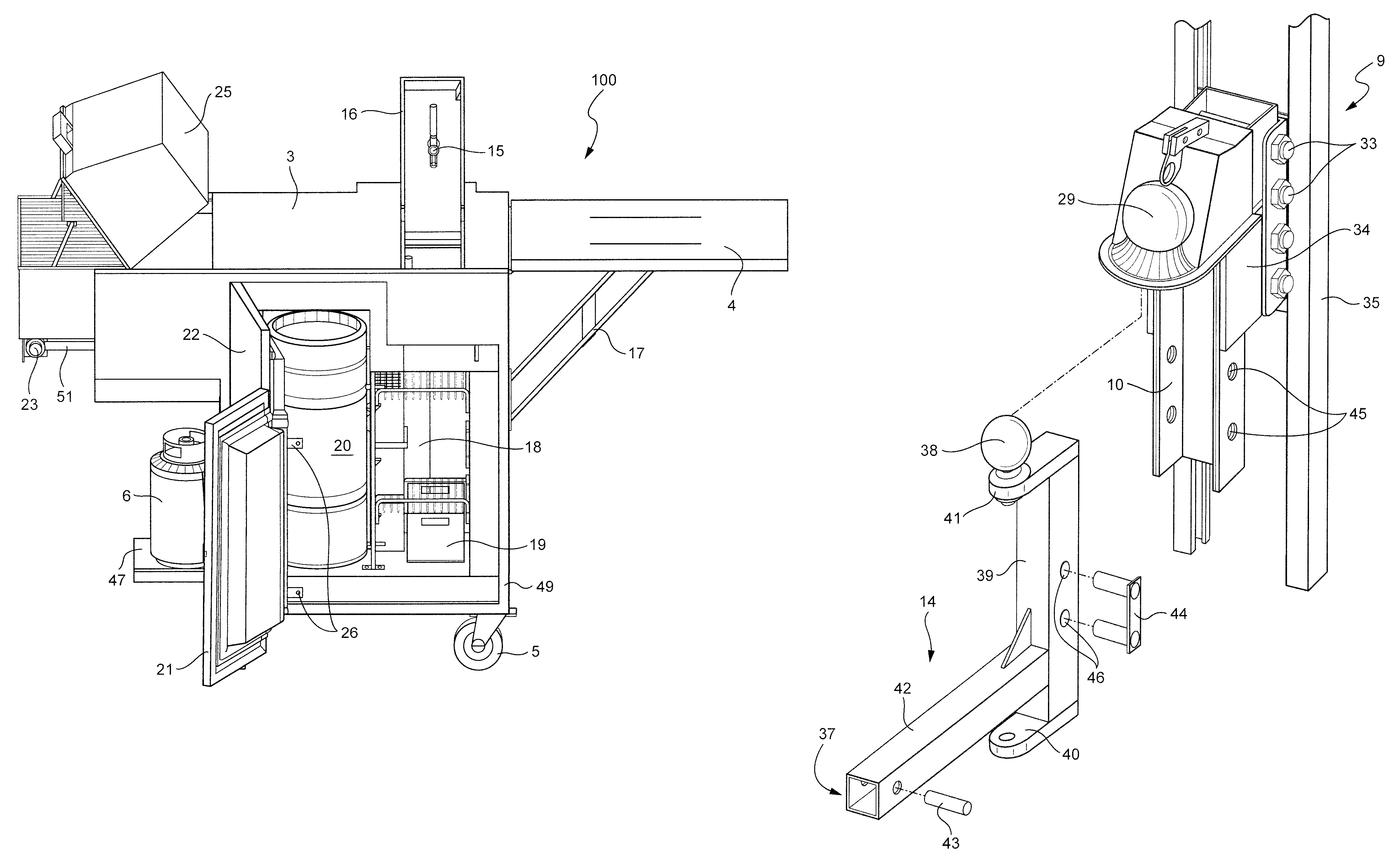

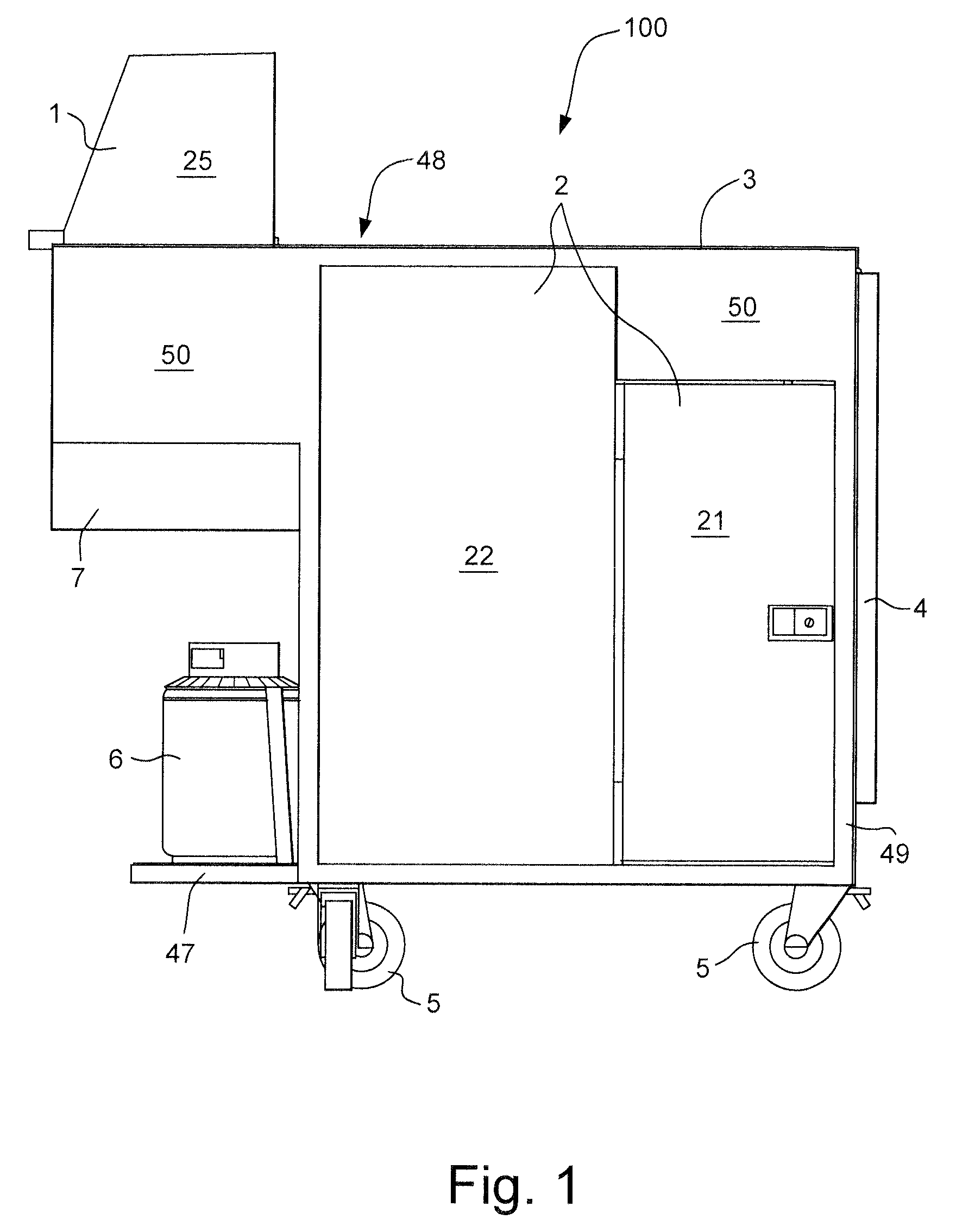

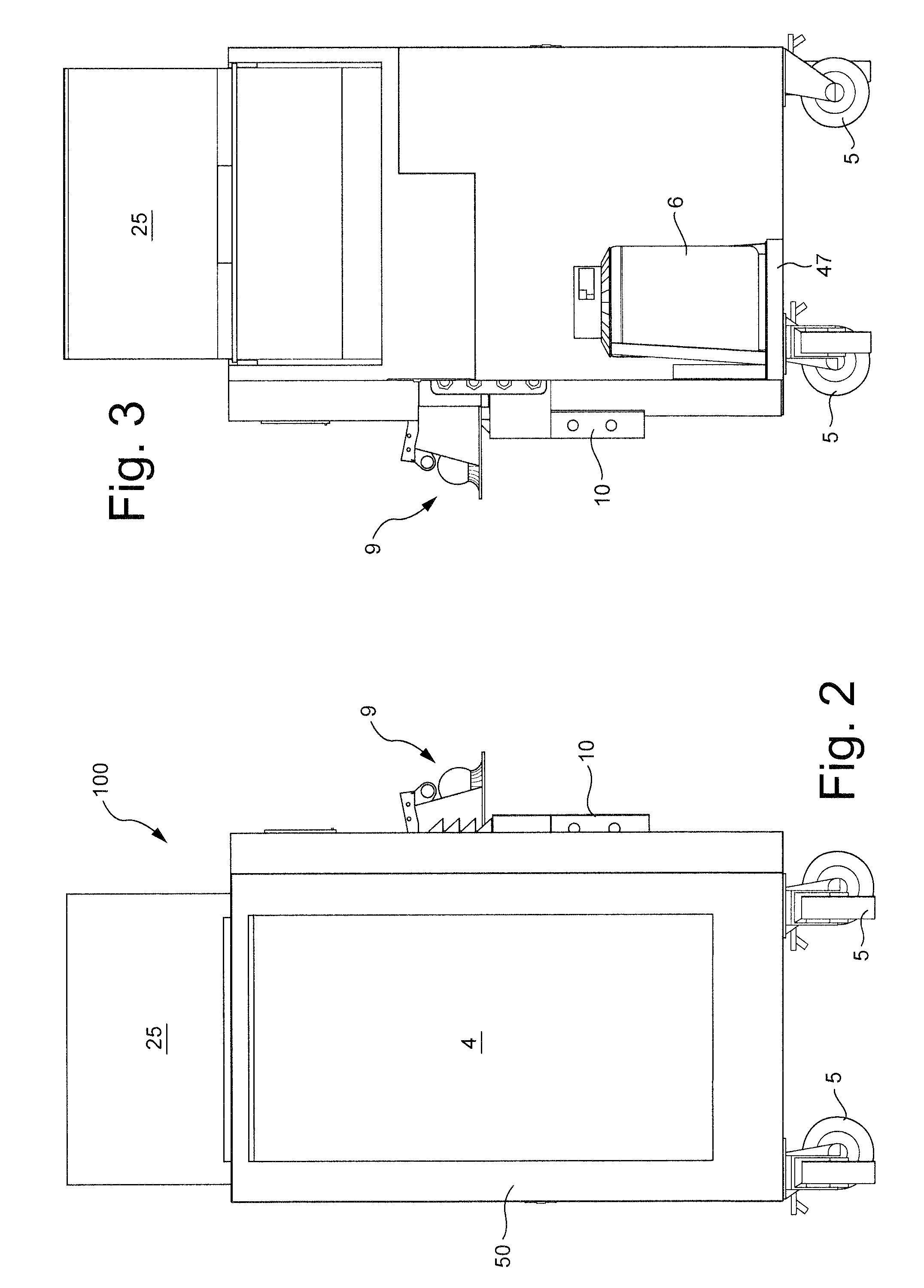

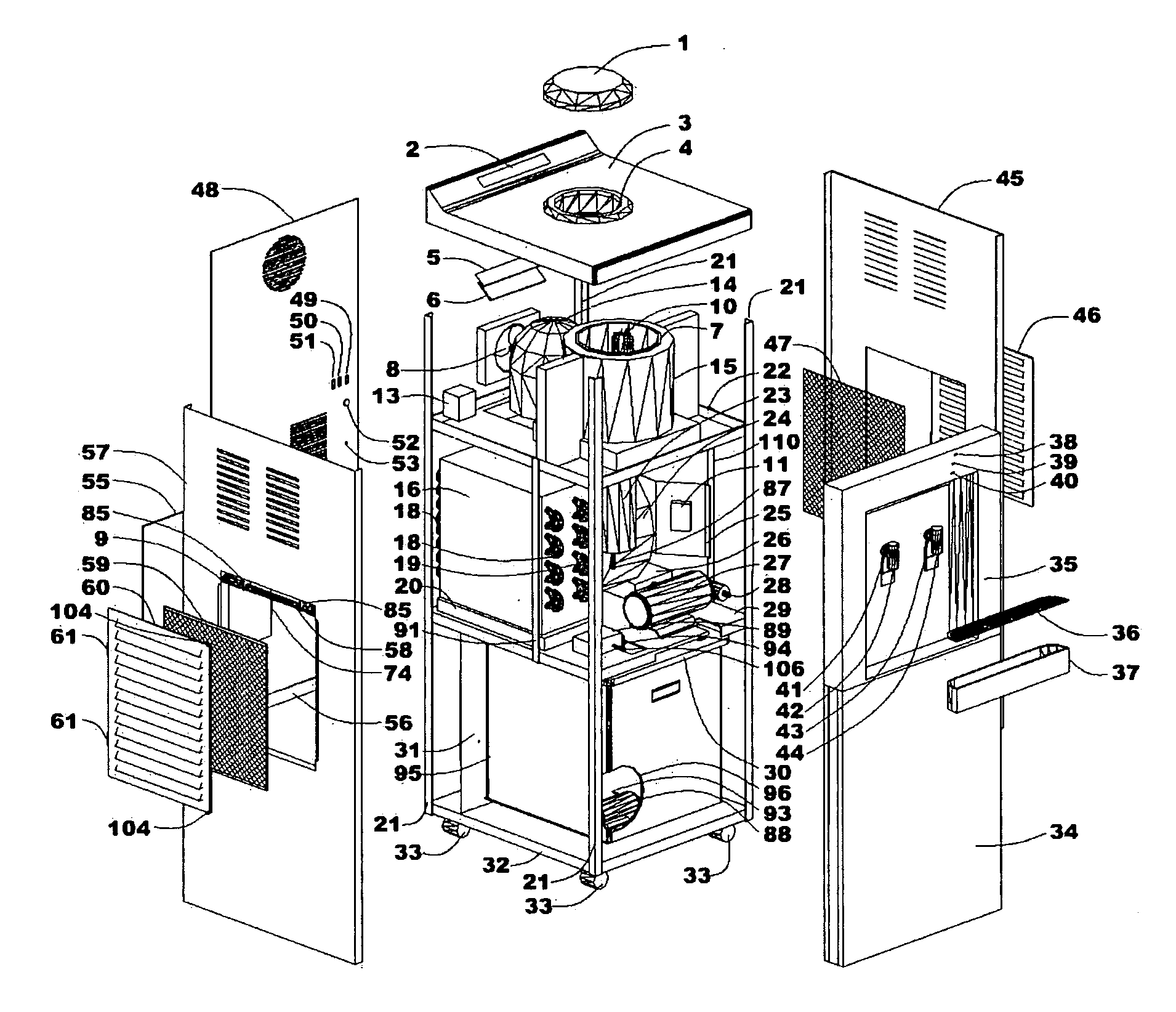

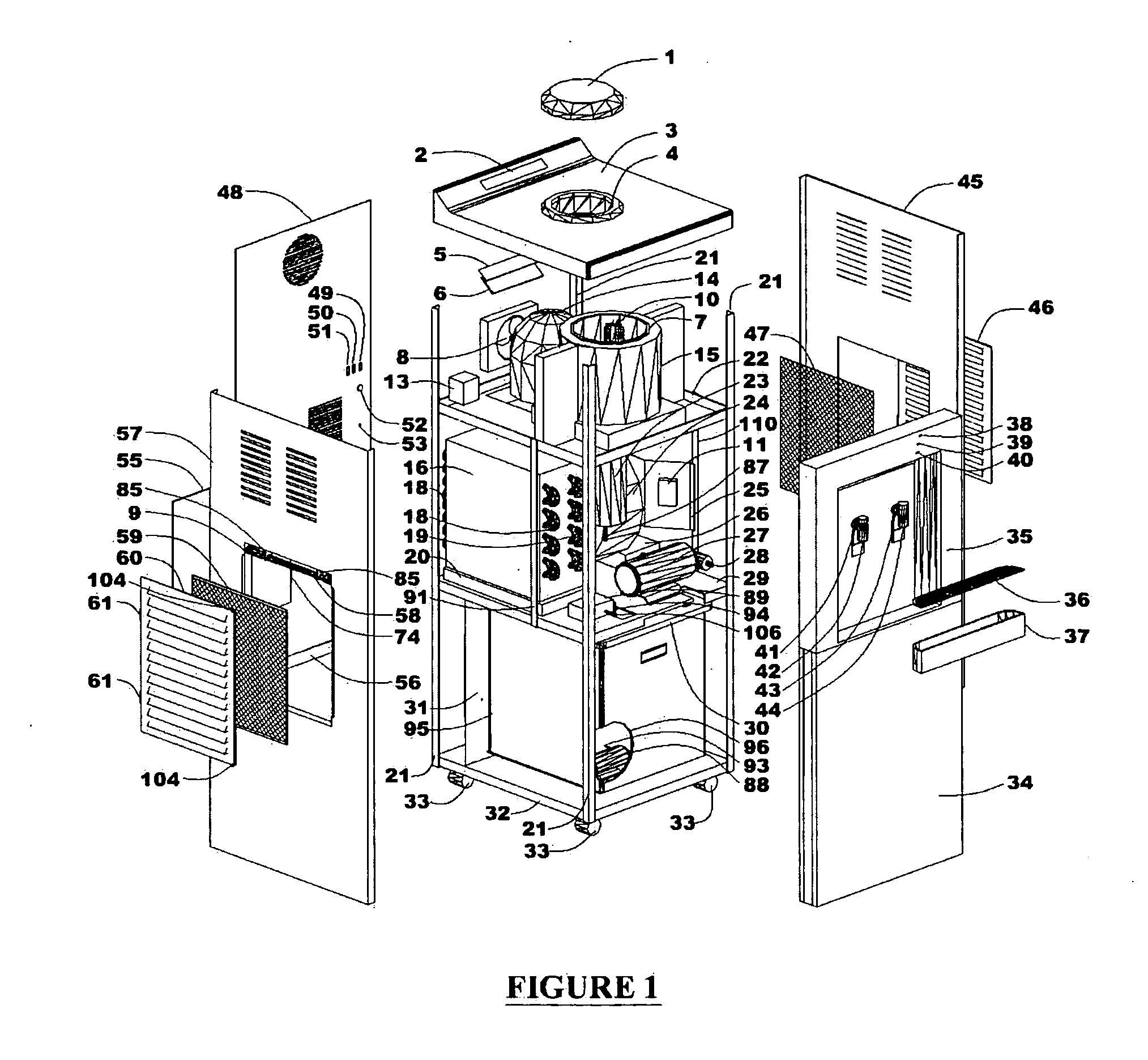

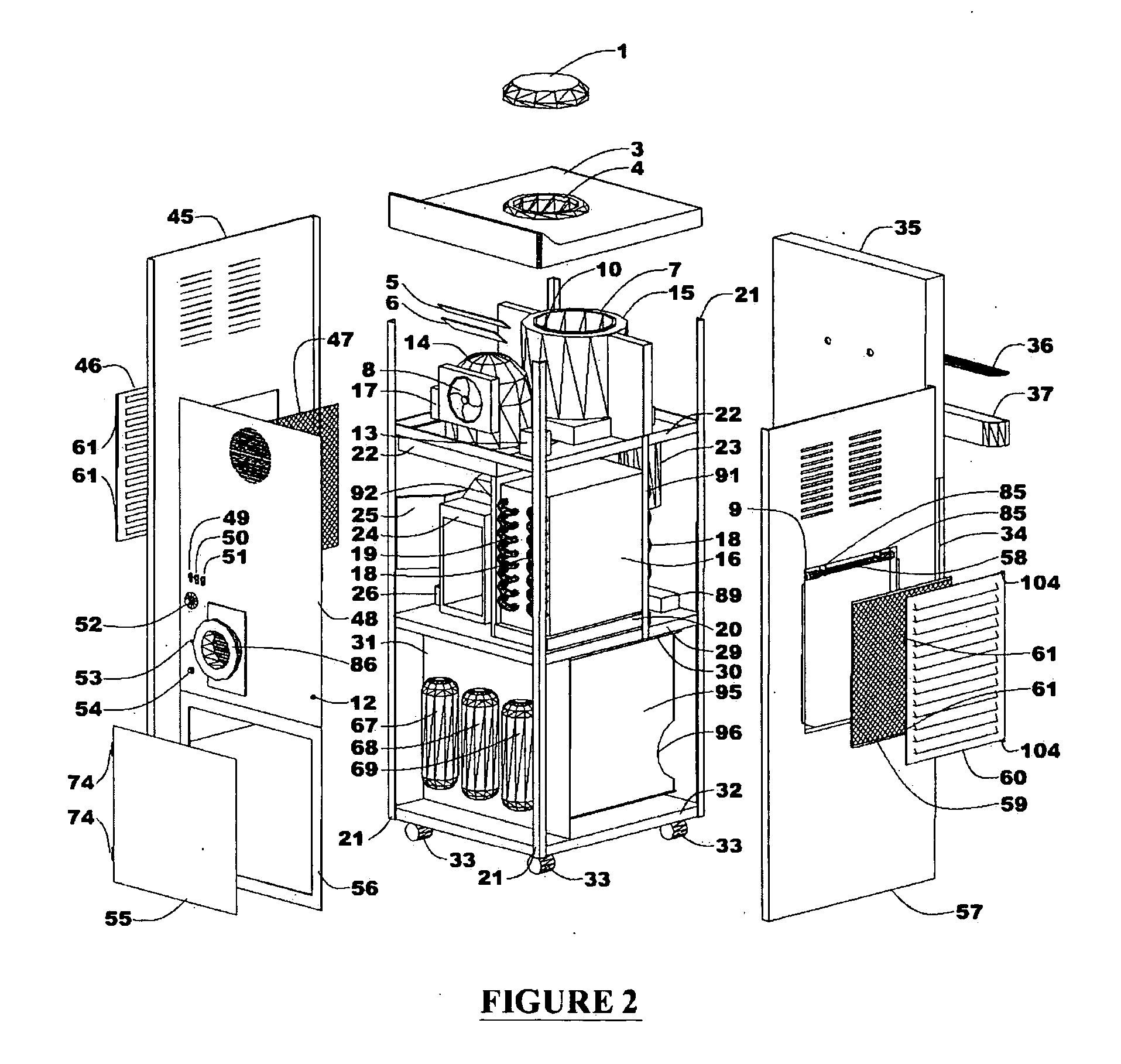

Combination dehydrator, dry return air and condensed water generator/dispenser

InactiveUS20070175063A1Drying solid materials with heatDrying gas arrangementsEngineeringBelow threshold level

A portable, combination dehydrator, dry return air and condensed water generator / dispenser configured to reduce the humidity in a dry storage unit. In one embodiment, a system draws intake air from the dry storage unit across the condenser of a heat exchanger and condenses water from the air, collecting the water in a storage tank. The dried return air is ducted into the dry storage unit. In one embodiment, the source of the intake air may be selected from either the dry storage unit or an alternative source (e.g., outside air.) The selection of the intake air source may be based on the humidity of the air (e.g., if the humidity of the air in the dry storage unit is above a threshold, the dry storage unit is selected.) If both of the alternate sources of intake air have humidities below a threshold level, operation of the system may be suspended.

Owner:MORGAN MICHAEL +1

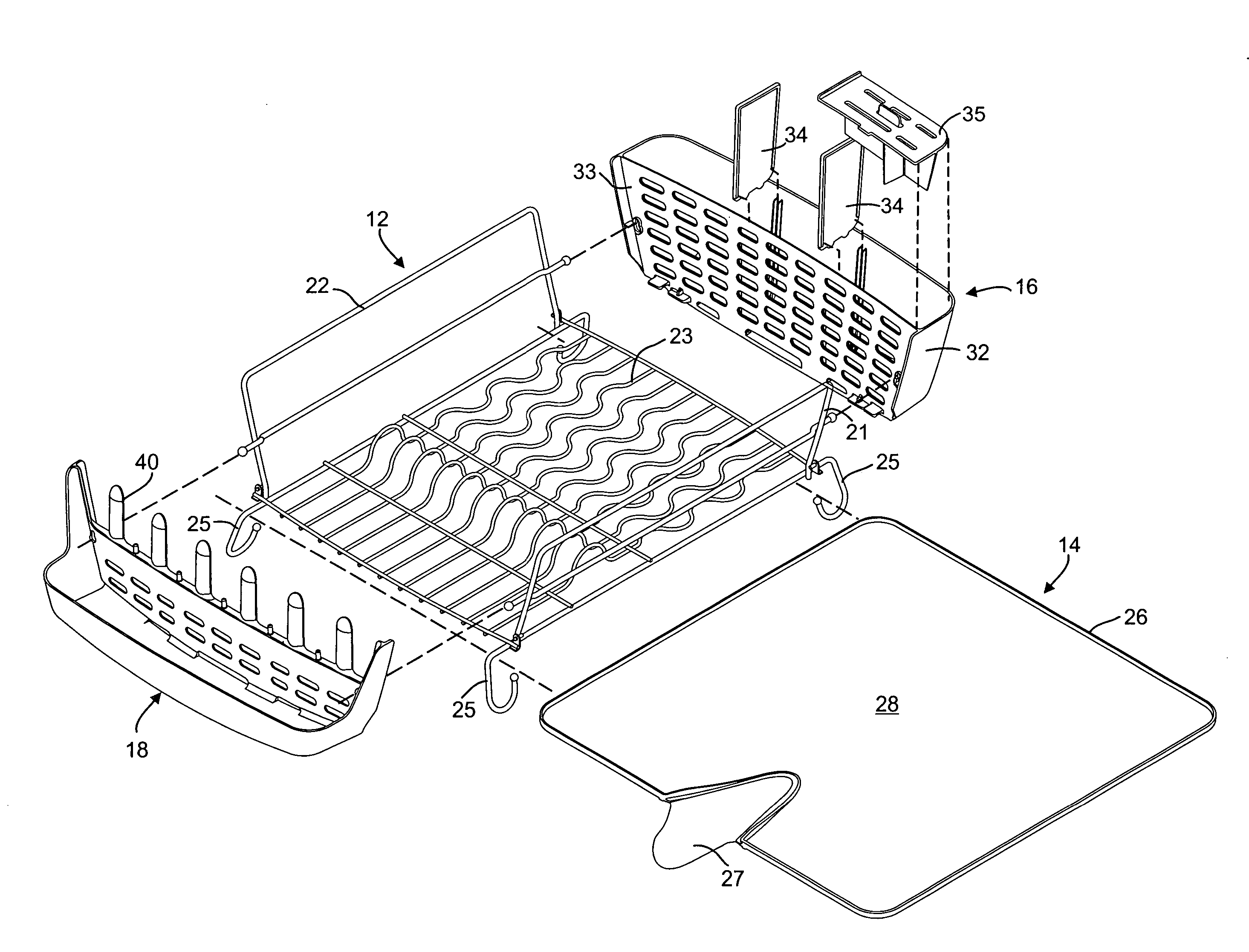

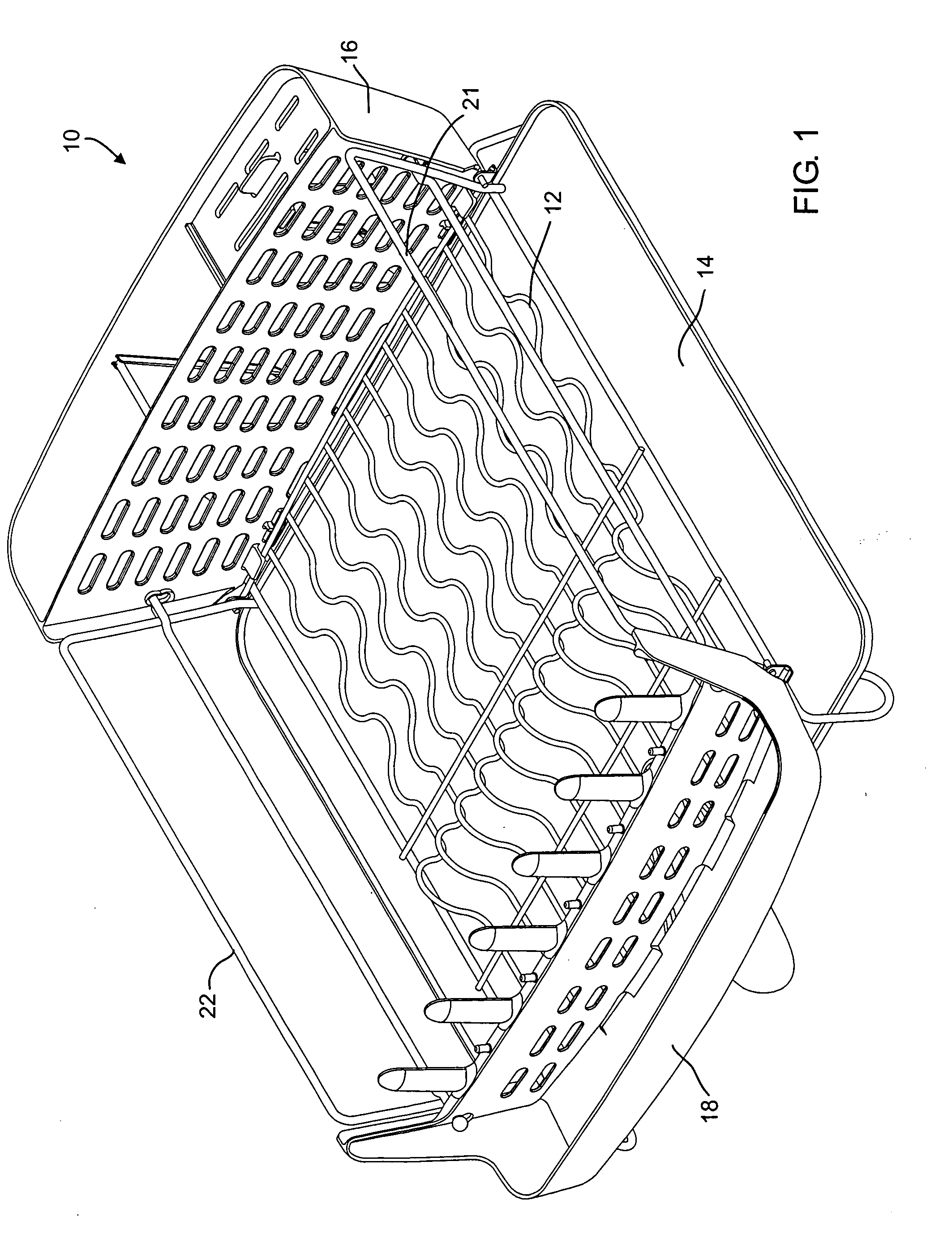

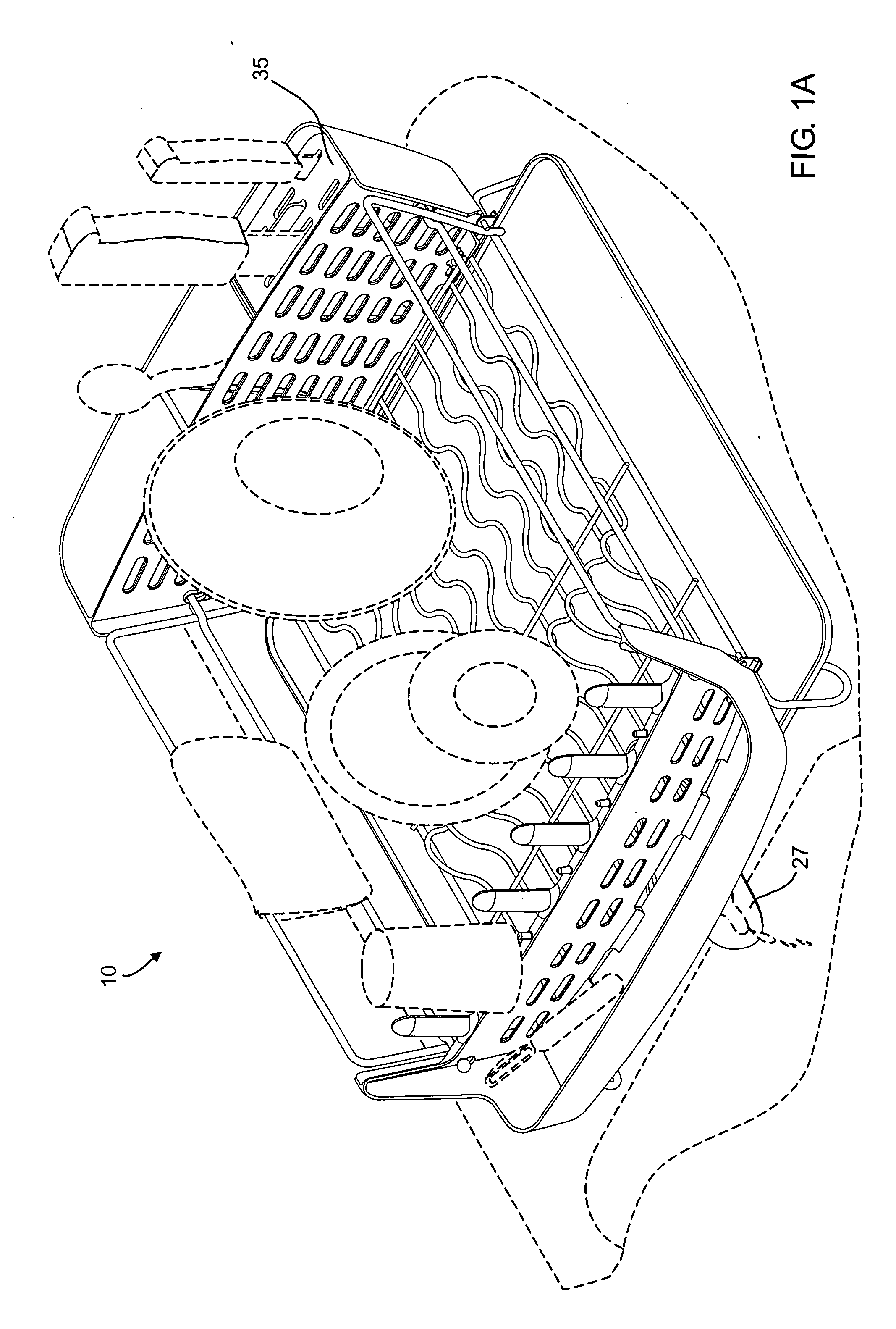

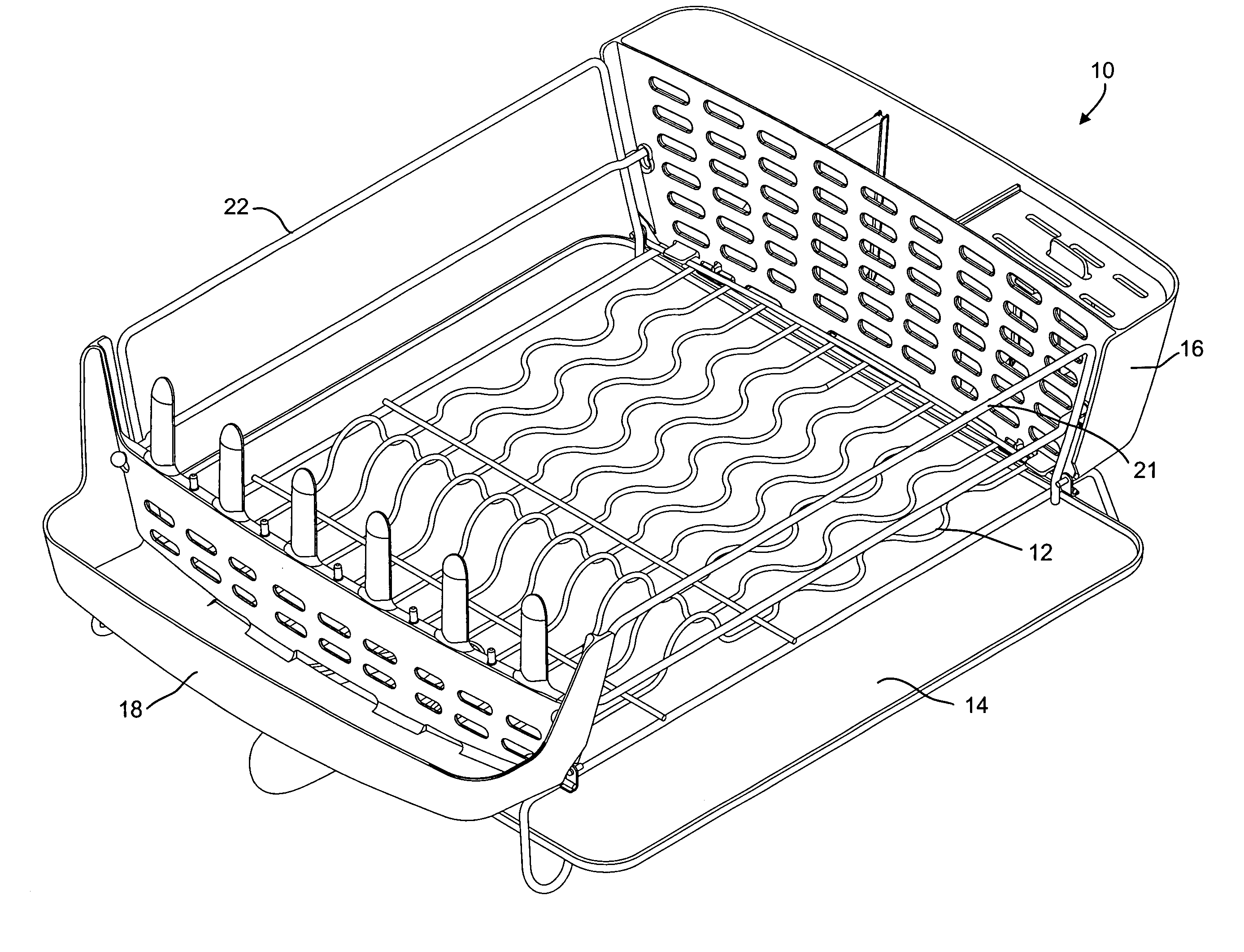

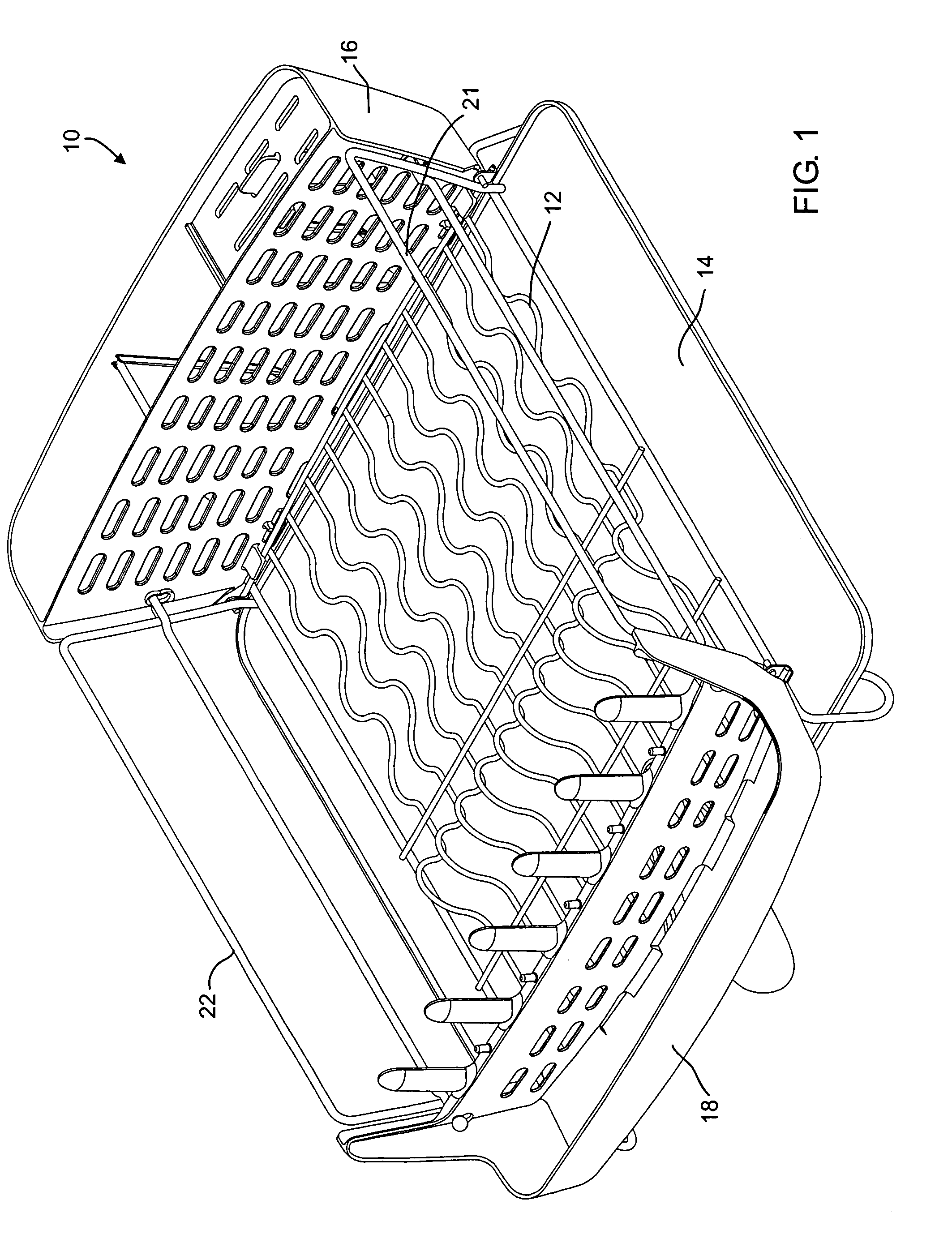

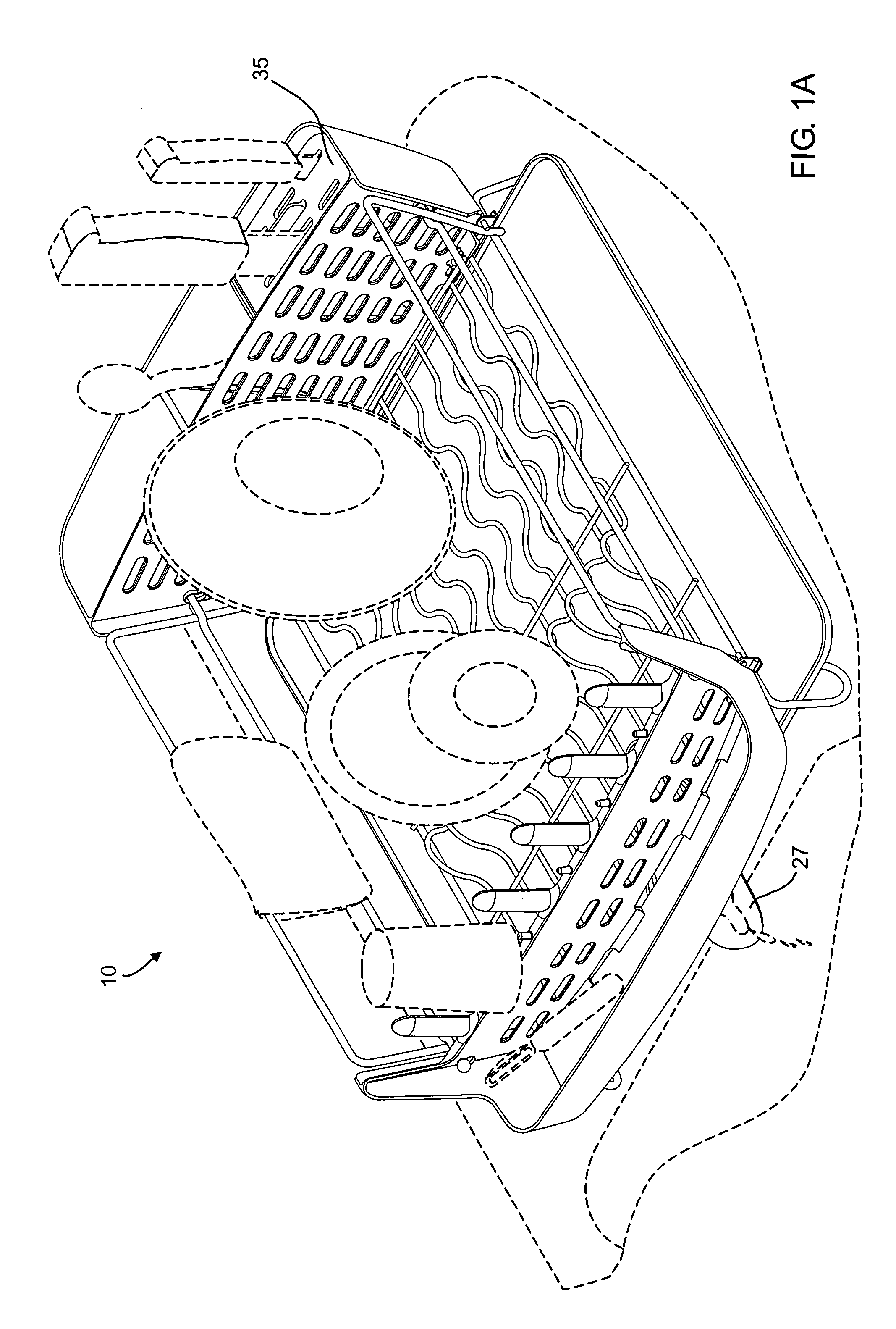

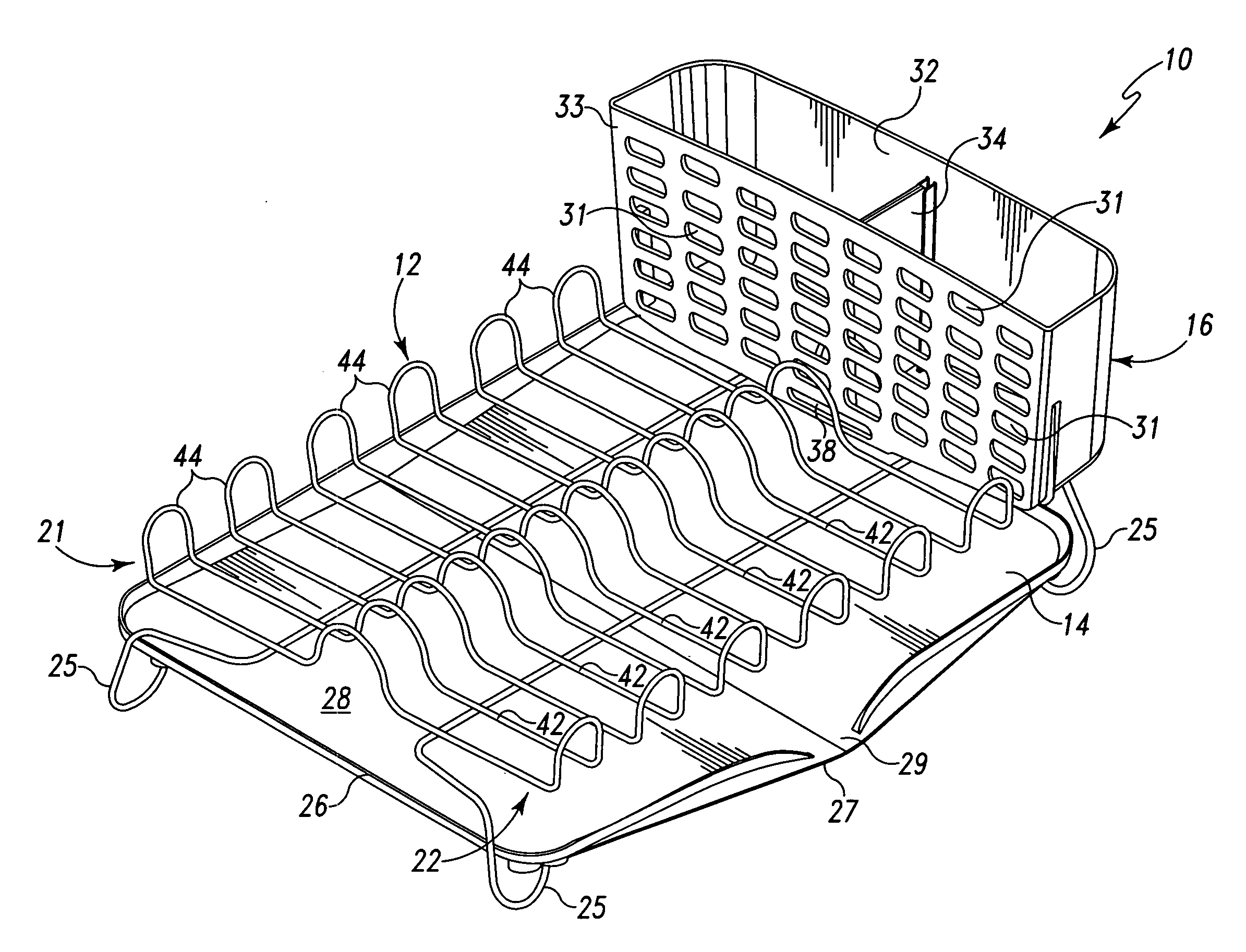

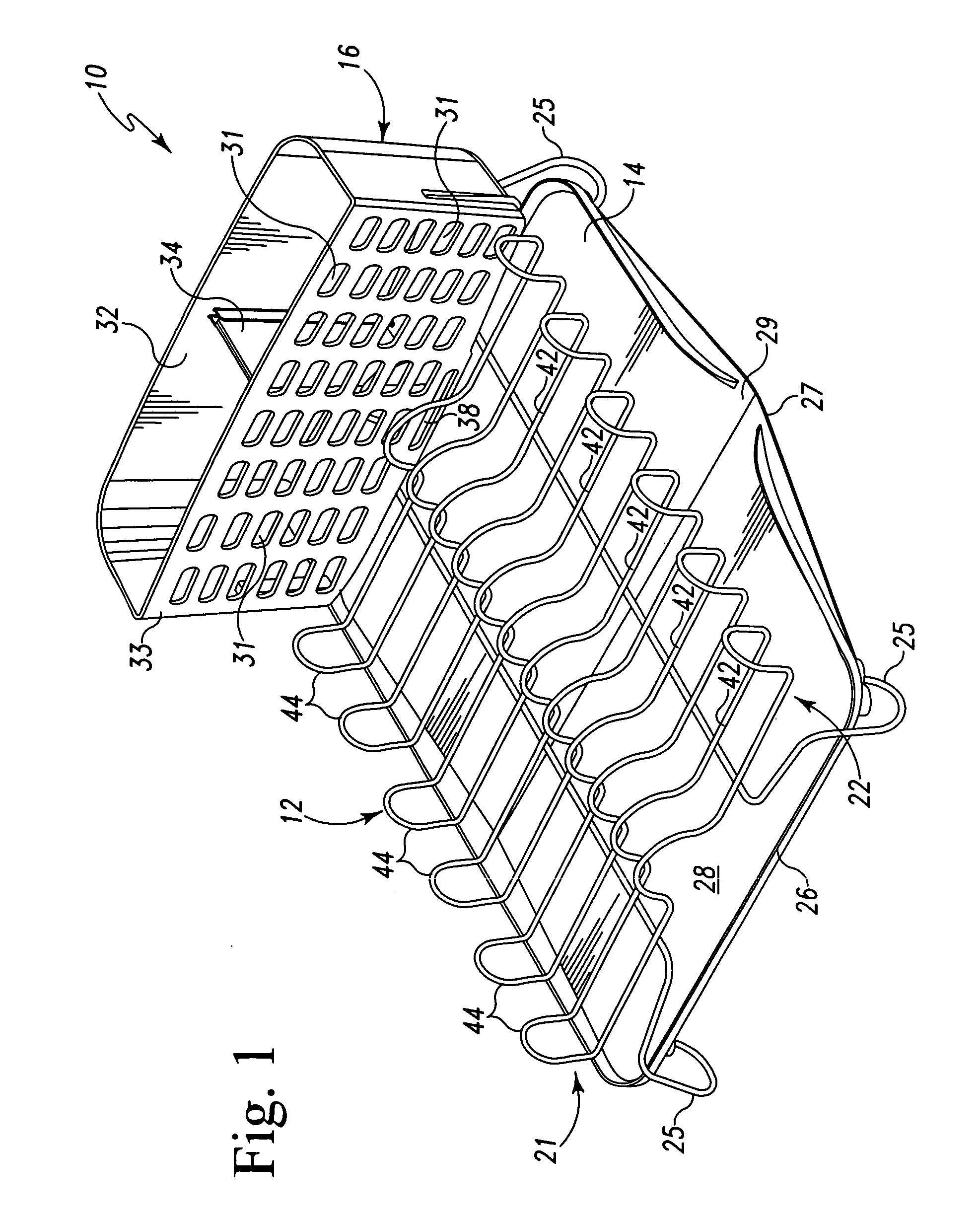

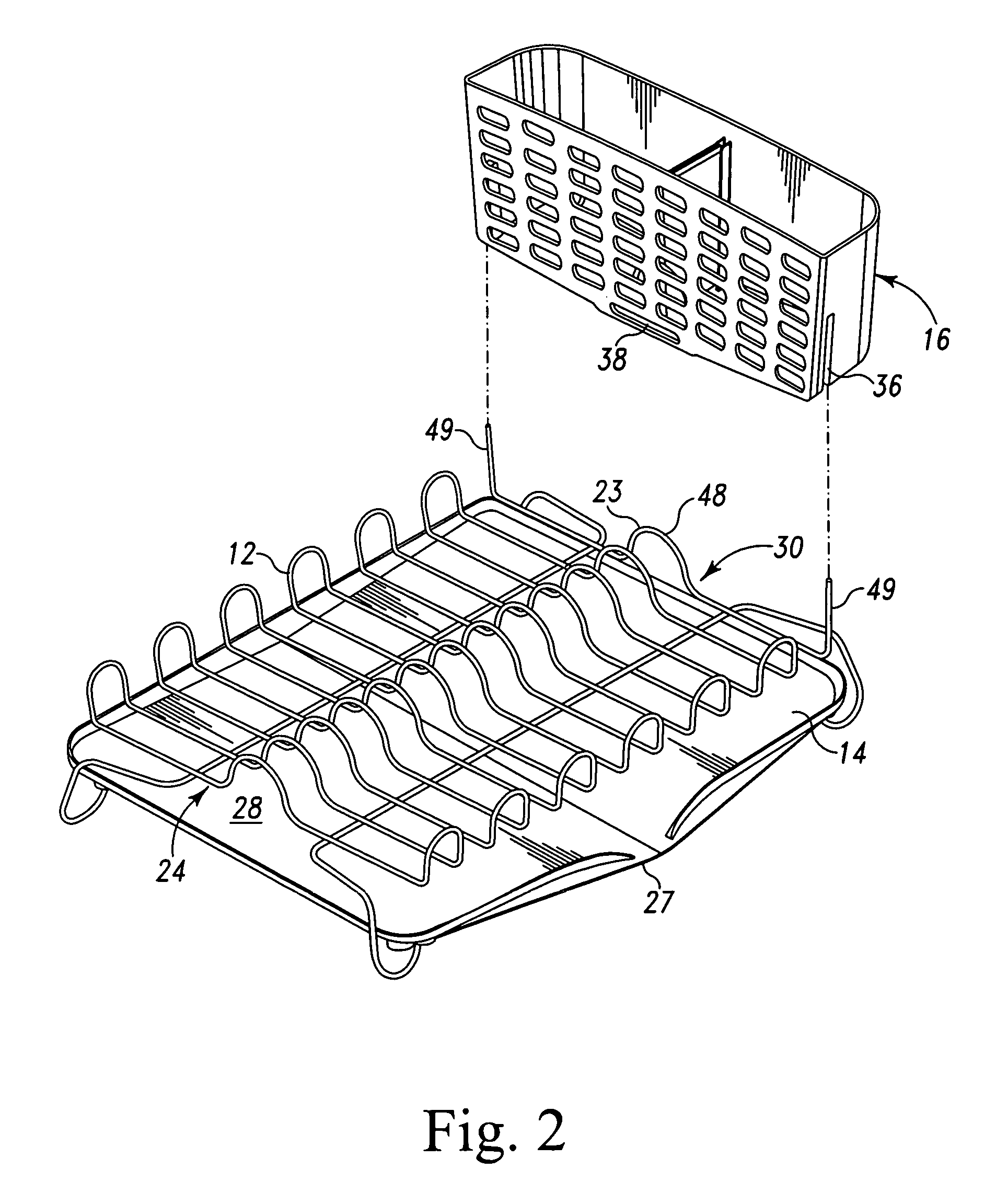

Drying storage rack

ActiveUS20070131629A1Simple structureAdditional operating advantageKitchenware cleanersPlatesEngineeringMechanical engineering

A storage rack for retaining items to be dried, which can be used in conjunction with a drain basin, such as a sink, or as a stand alone system is disclosed. The rack includes a support body having a bottom surface, a plurality of side surfaces, and a plurality of foot members extending from the body in a direction opposite the side surfaces. The rack also includes three detachable basins: two side basins and a lower drain basin. The lower basin includes a flexible spout extending beyond an edge, the spout being capable of movement between a downward position extending below the surface of the basin and an upward position extending the spout above the surface of the basin.

Owner:HELEN OF TROY LIMITED

Drying storage rack

ActiveUS7407059B2Enhanced advantageAvoid disadvantagesKitchenware cleanersPlatesMechanical engineeringDry storage

A storage rack for retaining items to be dried, which can be used in conjunction with a drain basin, such as a sink, or as a stand alone system is disclosed. The rack includes a support body having a bottom surface, a plurality of side surfaces, and a plurality of foot members extending from the body in a direction opposite the side surfaces. The rack also includes three detachable basins: two side basins and a lower drain basin. The lower basin includes a flexible spout extending beyond an edge, the spout being capable of movement between a downward position extending below the surface of the basin and an upward position extending the spout above the surface of the basin.

Owner:HELEN OF TROY LTD

Compositions and methods for biological sample storage

InactiveUS20140065627A1Prevent degradationMicrobiological testing/measurementDead animal preservationDry storageZwitterion

Compositions and methods are disclosed for substantially dry storage at ambient or elevated temperatures of biological samples such as nucleic acids, proteins and cells in a form from which the samples can be substantially recovered, using a dissolvable or dissociable dry storage matrix comprising a borate composition and a stabilizer as disclosed, such as any of a number of zwitterionic stabilizers.

Owner:BIOMATRICA INC

Split-range drying method for paddy

InactiveCN101878813AIncrease productionFast precipitationSeed preservation by dryingSocial benefitsEconomic benefits

The invention discloses a split-range drying method for paddy. The method has the technical points: performing preliminary cleaning and hot air drying on harvested high-moisture paddy, tempering, redrying and retempering the paddy, and keeping the ratio of the drying time to the tampering time within the range from 1 to 6 until the moisture content is reduced to 18.5 to 18 percent; conveying the paddy into a paddy temporary storage warehouse for slow cooling, ventilation and temporary storage; performing the hot air drying on the paddy of the temporary storage warehouse with a dryer after the paddy harvest season, retempering, drying and retempering the paddy, keeping the ratio of the drying time to the tampering time within the range from 1 to 8 until the moisture of the paddy is reduced to be below 14.5 percent; and conveying the paddy to a warehouse for storage. The method has the advantages of improving the moisture reducing rate and the utilization efficiency of the paddy dryer, reducing the loss after the paddy production caused by high moisture during the concentrated paddy harvest season, ensuring the safety for dry storage of the foodstuffs and having obvious economic benefit and social benefit on the premise of ensuring the drying quality of the paddy.

Owner:WUHAN POLYTECHNIC UNIVERSITY

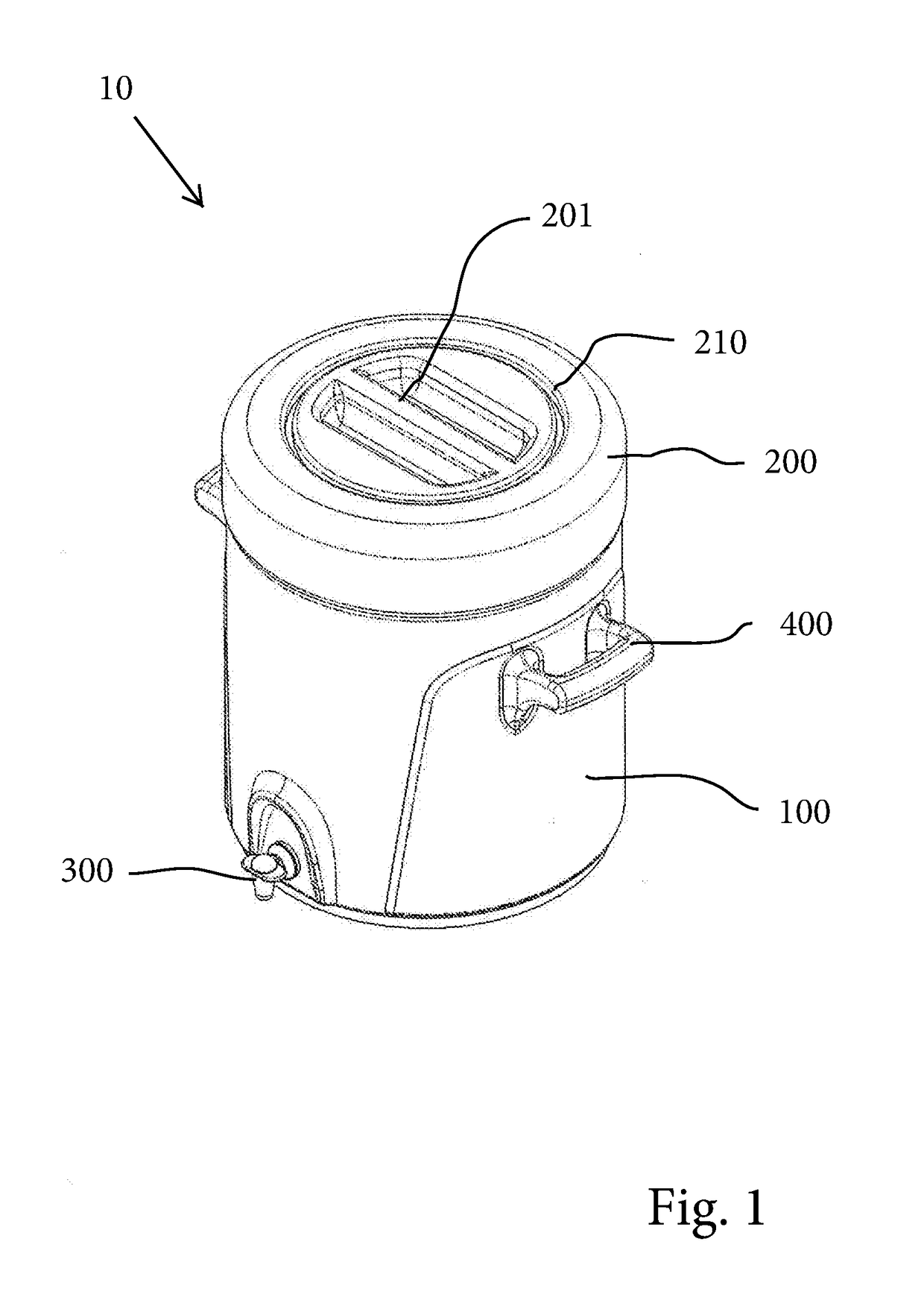

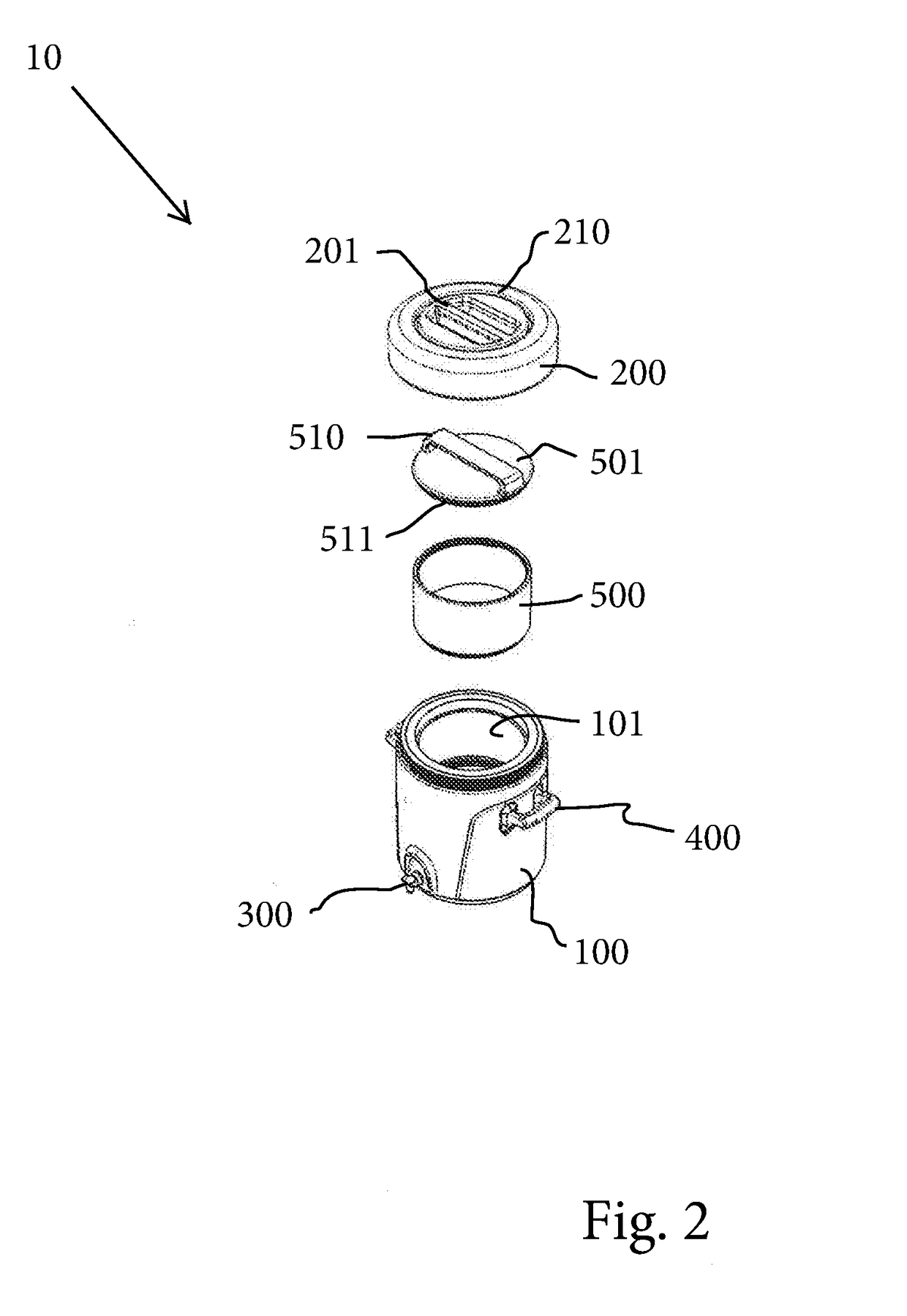

Combination liquid and dry cooler assembly

ActiveUS20180003425A1Easy to transportEasy to useTravelling sacksLighting and heating apparatusEngineeringMechanical engineering

A liquid cooler device. The liquid cooler device having an interior cavity with a ledge, the ledge segregating the interior cavity into a lower portion for the placement of liquid and an upper portion for the receipt of an upper tray portion. The upper tray portion including a gasket for engagement with the ledge and designed for the dry storage of bulk items within the interior cavity. In use, the device acts as a combination cooler for both liquids and dry items.

Owner:GOODLOE DAVID R

Thermoplastic polyurethane hollow fiber membrane and preparation method thereof

InactiveCN102000515AHigh strengthImprove throughputSemi-permeable membranesHollow filament manufactureFiltrationMelt extrusion

The invention discloses a thermoplastic polyurethane hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is made of polyurethane and prepared by adopting a thermally induced phase separation process. The preparation method comprises the following steps of: mixing thermoplastic polyurethane, thinner, inorganic pore-forming agent and antioxidant uniformly by using a high-speed stirrer, melting and extruding the mixture into granules by using a double-screw extruder, then melting and extruding the granules into hollow fibers by using a single-screw extruder, performing cooling molding, and finally extracting the thinner and the inorganic pore-forming agent in the hollow fibers. The prepared thermoplastic polyurethane hollow fiber membrane has the advantages of high flux, tensile strength and compressive strength, good flexibility of membrane silks, high elongation of the membrane silks at break, good chemical tolerance, permanent hydrophilic property, dry storage and the like. The fiber membrane can be applied to filtration of household and commercial drinking water, filtration and purification of brewed wine, food and medicaments, municipal tap water and sewage treatment, industrial sewage treatment, sea water desalinization pretreatment and the like.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

Drying storage rack

InactiveUS20070144984A1Simple structureAdditional operating advantageKitchenware cleanersPlatesEngineeringMechanical engineering

A storage rack for retaining items to be dried, which can be used in conjunction with a drain basin, such as a sink, or as a stand alone system is disclosed. The rack includes a rack component having a first and second ends, first and second sides, and a plurality of foot members, a drain mat supported by the foot members, and a detachable basin attached to a side or end of the rack component. The drain mat includes two sets of positioning members of two distinct lengths on a lower surface. By engaging longer positioning members on one side of the mat and shorter positioning members on the opposite side of the mat, the mat is held in a sloped configuration. The slope may be either toward the integral spout, thereby draining water from the mat, or opposite the integral spout, thereby retaining a substantial amount of water on the mat. The latter configuration permitting the storage rack to be used as a stand alone system.

Owner:HELEN OF TROY LIMITED

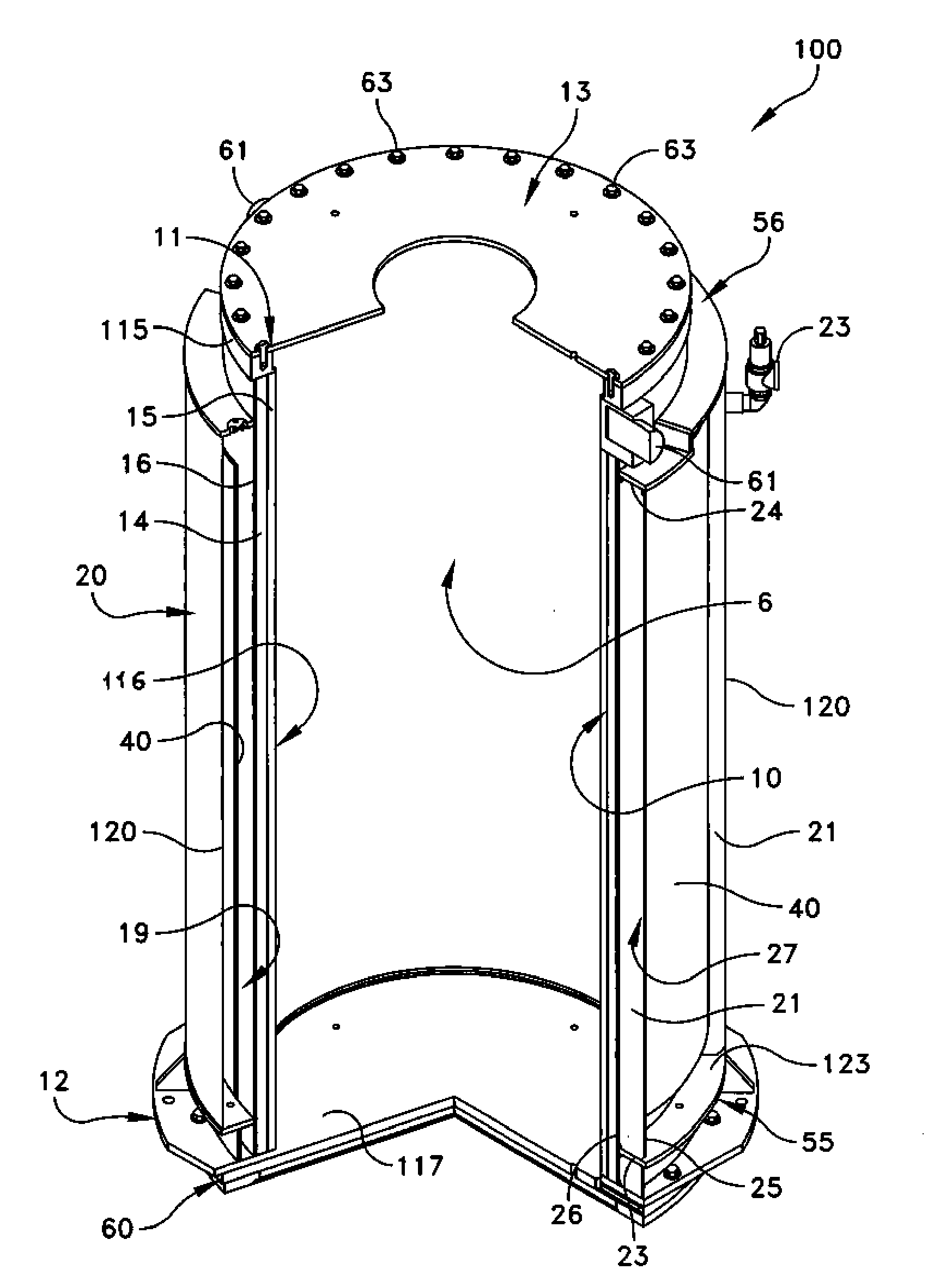

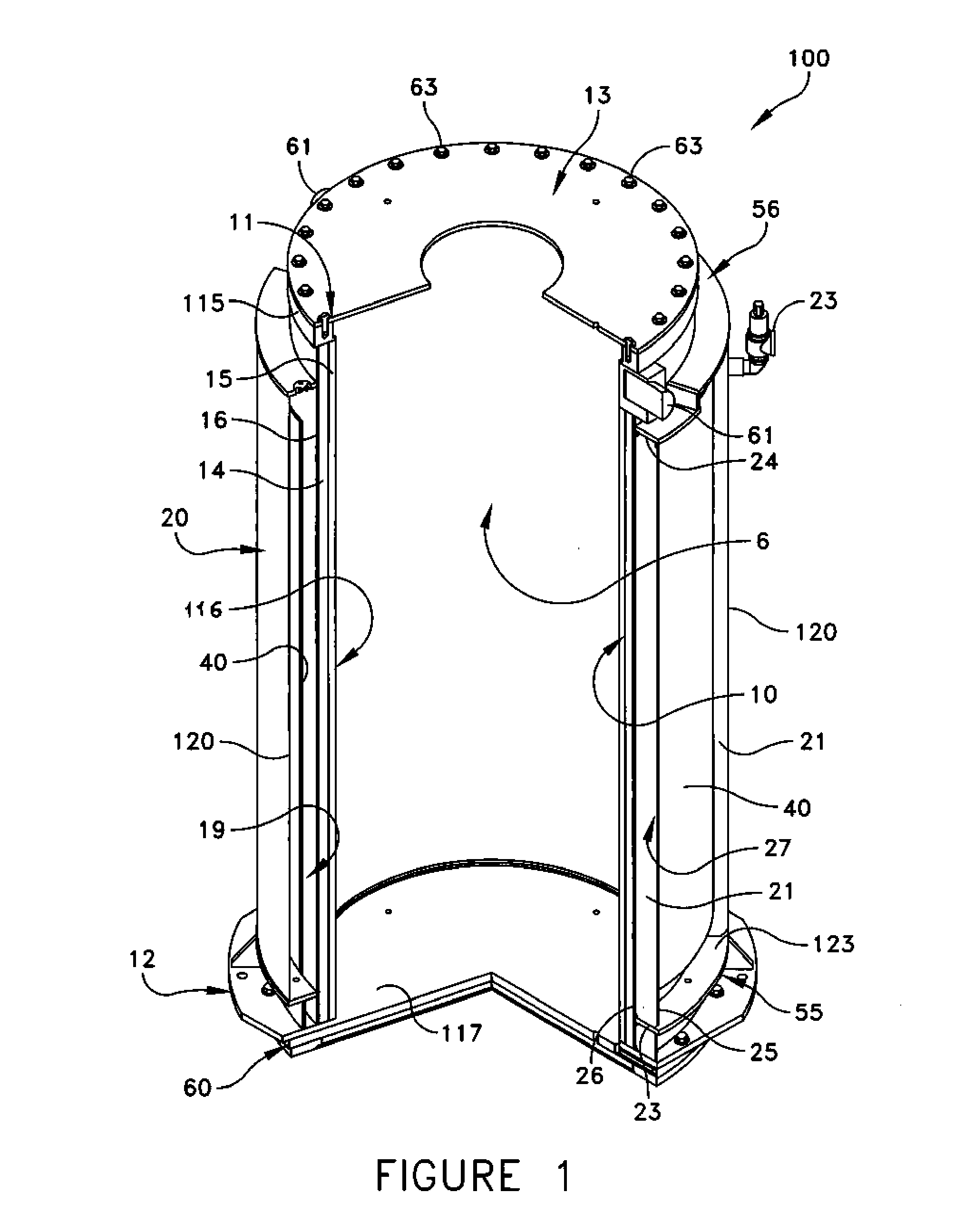

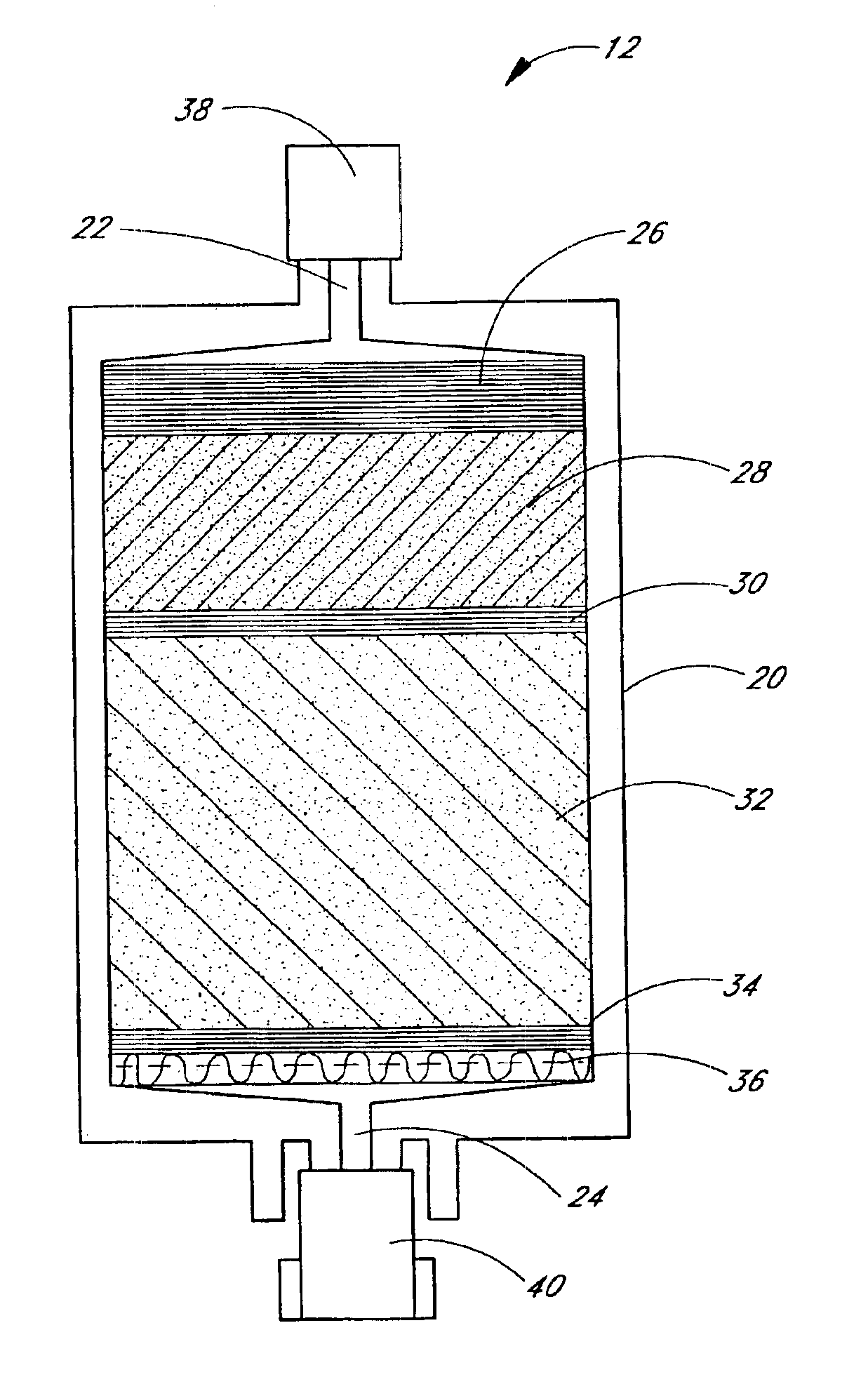

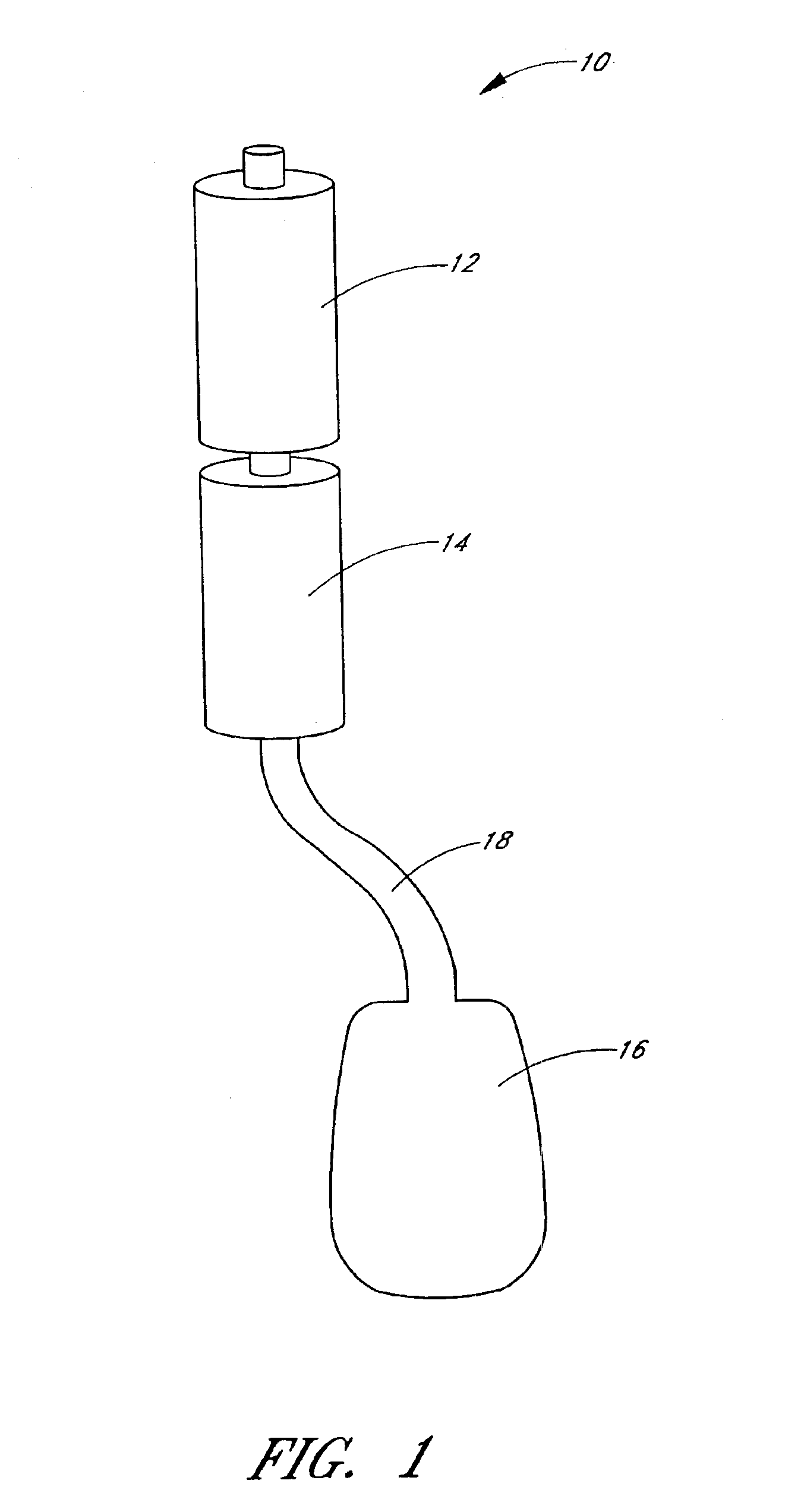

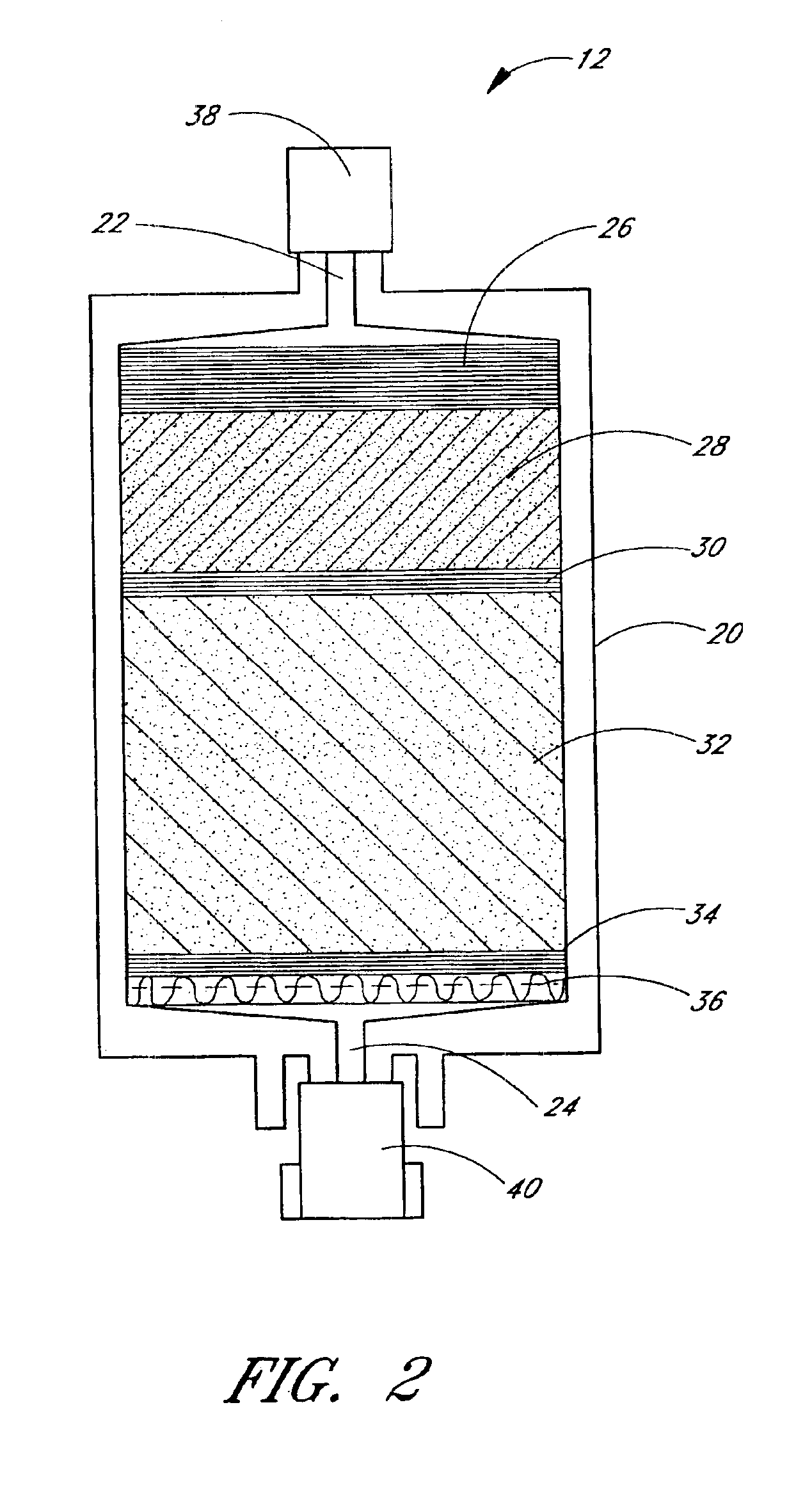

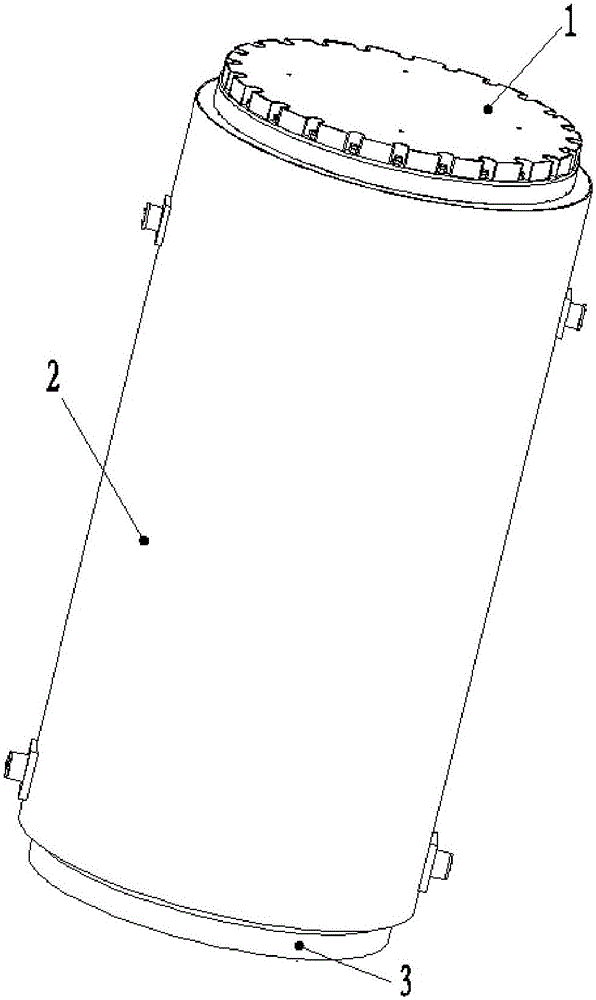

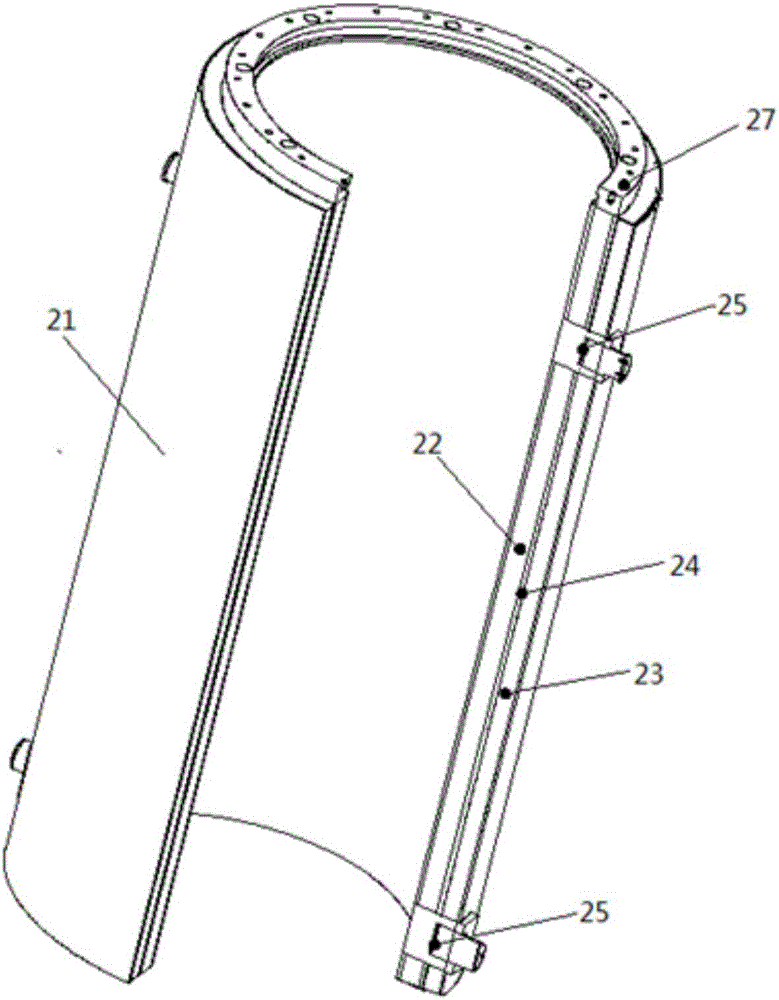

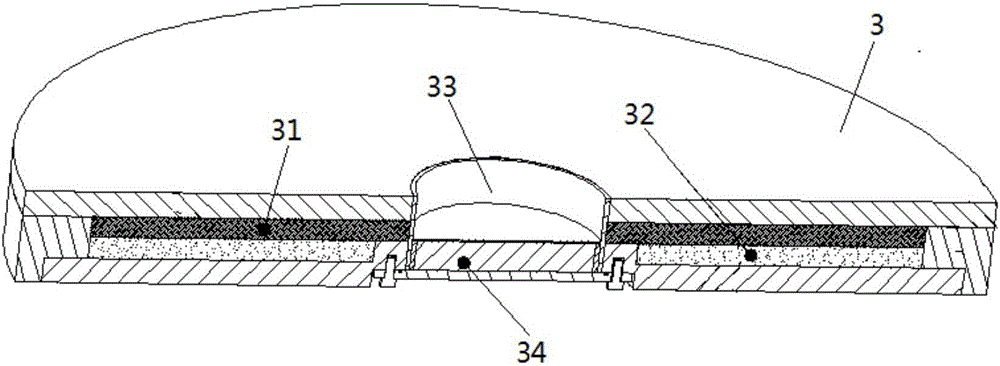

Transfer container for dry storage of nuclear power plant spent fuel

InactiveCN106024085AReliable neutron shielding functionImprove thermal conductivityShieldingPortable shielded containersHeat conductingNuclear power

The invention discloses a transfer container for dry storage of nuclear powder plant spent fuel. The transfer container comprises a barrel body, a top cover arranged on the upper end face of the barrel body and a bottom cover arranged on the lower end face of the barrel body. The top cover and the barrel body are detachably and fixedly connected. The wall of the barrel body is of a hollow interlayer structure and comprises an inner barrel wall, an outer barrel wall and an inner cavity defined by the inner barrel wall and the outer barrel wall. The inner cavity is filled with a lead layer and a boron-containing resin plate layer. A middle shell wall is arranged between the lead layer and the boron-containing resin plate layer for partition. A waveform heat transfer plate is arranged in the boron-containing resin plate layer and makes face contact with the outer barrel wall and the middle shell wall. Compared with the prior art, the transfer container for dry storage of nuclear powder plant spent fuel has a reliable neutron shield function and excellent heat conducting property, can provide structural protection and radiation shield for a fuel storage pot when fuel is loaded in the fuel storage pot and can achieve the transfer function from the fuel storage pot to a concrete storage container.

Owner:中广核工程有限公司 +1

Preparation method of high-temperature structure-function combining B4C/Al neutron absorbing material

InactiveCN106756164AGood mechanical propertiesLittle change in mechanical propertiesHigh energyStructure function

The invention relates to a preparation method of a high-temperature structure-function combining B4C / Al neutron absorbing material. The preparation method comprises the concrete steps of (1) adopting a high energy ball milling method for ball-milling aluminum powder into flake aluminum powder; (2) placing the flake aluminum powder into an air furnace for pre-oxidizing, and forming a layer of nanometer aluminum oxide film on the surface of the aluminum powder; (3) uniformly mixing the pre-oxidized flake aluminum powder and micron-sized B4C particles; (4) pressing molding the uniformly mixed powder; (5) conducting pressureless sintering or hot pressed sintering on a pressing-molded pressing blank; and (6) forging, extruding or rolling a sintered billet so as to obtain the high-temperature structure-function combining B4C / Al neutron absorbing sectional material or sheet material. By adopting the method, a certain amount of nanometer aluminum oxide can be introduced into a pure aluminum matrix, and the micron-sized B4C particles are added, so that the aluminum-based neutron absorbing material with two-phase reinforcement of micron B4C and nano Al2O3 can be prepared, has both a neutron absorbing performance and an excellent high-temperature mechanical property, and can be applied in the fields of spent fuel dry storage, transportation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nuclear fuel assembly end cap arrangement

InactiveUS20060018422A1Restrict movementLoose materialNuclear energy generationFuel element assembliesDry storageNuclear fuel

A method and arrangement to control fuel material debris originating from a fuel assembly for a dry storage system wherein the method includes providing a damaged boiling water reactor nuclear fuel assembly, providing a bottom end cap configured to fit on a bottom of a boiling water reactor nuclear fuel assembly, inserting the bottom end cap into the damaged boiling water reactor nuclear fuel assembly such that the bottom end cap prevents debris from inside the damaged nuclear fuel assembly from leaving the bottom of the fuel assembly, providing a top end cap configured to fit on a top of the boiling water reactor nuclear fuel assembly, and inserting the top end cap into the top of the damaged boiling water reactor nuclear fuel assembly such that the top end cap prevents debris from inside the damaged nuclear fuel assembly from leaving the top of the fuel assembly.

Owner:FRAMATOME ANP RICHLAND

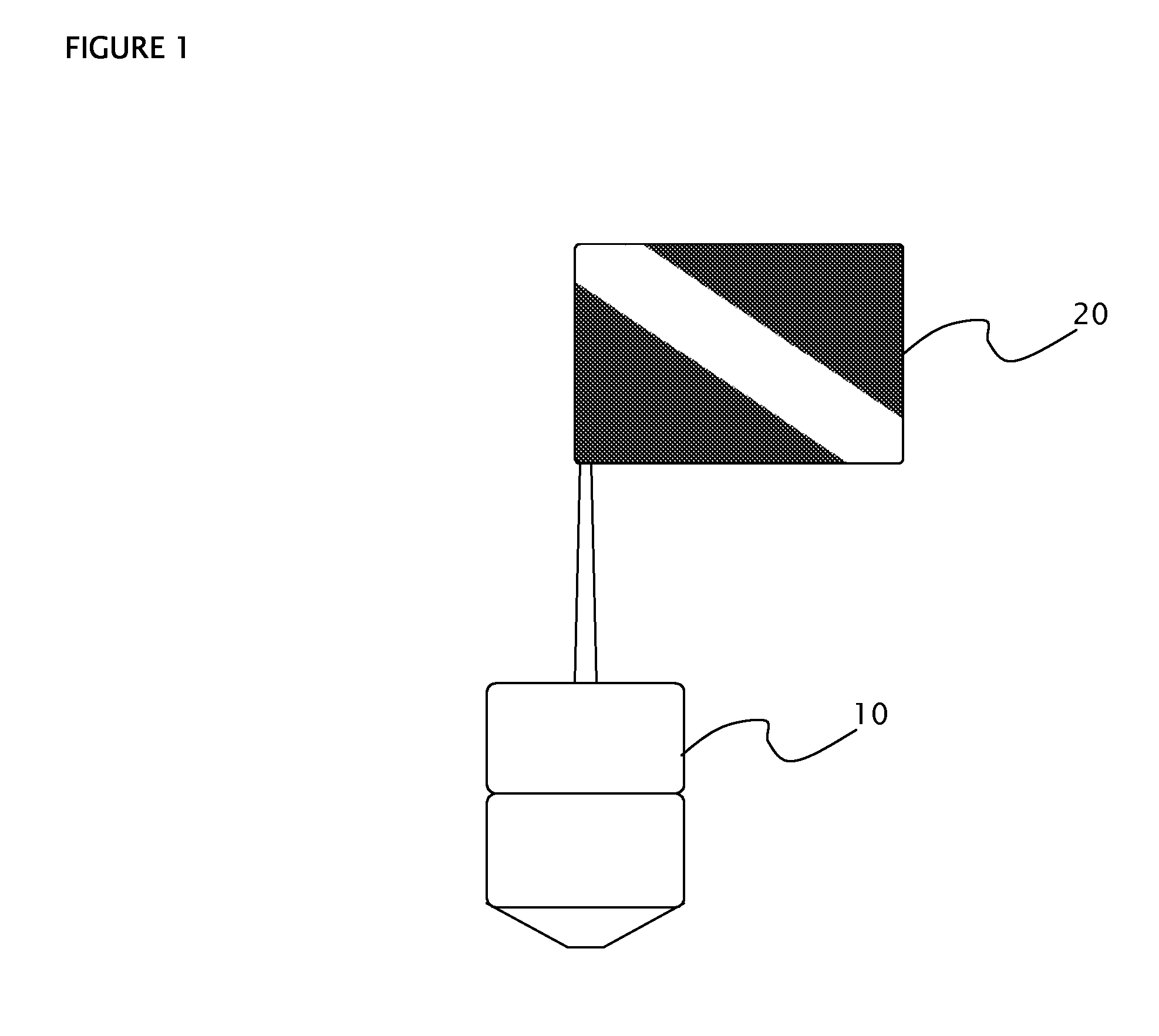

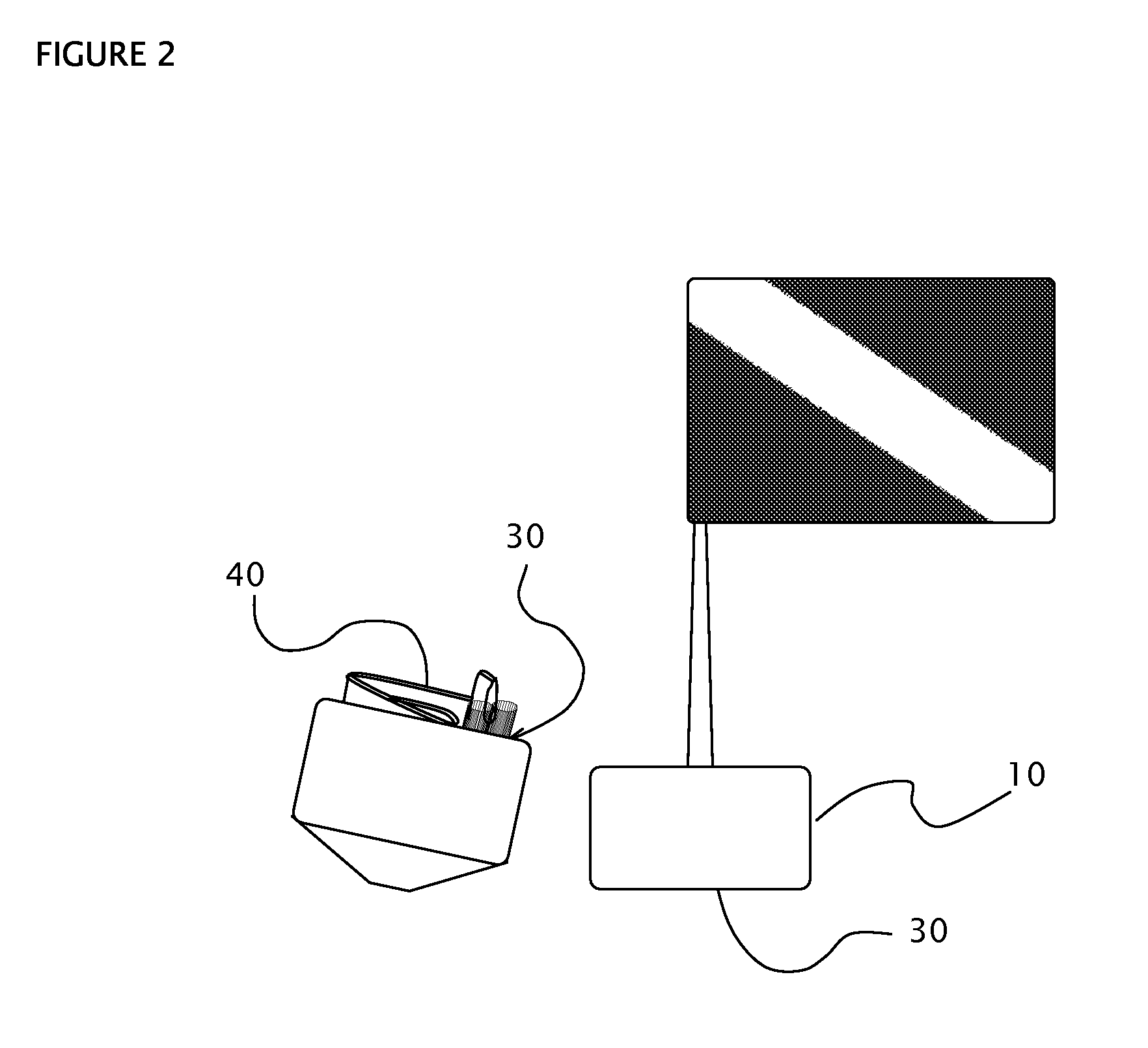

Life-saving diving buoy

InactiveUS20090093176A1Eliminating excess weighEnsure complianceLife-buoysVessel signalling devicesBuoyHuman life

The present invention provides for a novel, but simply structured life-saving diving buoy that protects human lives by indicating presence of divers in a certain area while providing a dry storage compartment to store life-saving equipment useful to mark a submerged scuba diver's location while providing a dry compartment to store emergency and / or lifesaving equipment for when the diver comes to the surface and is far away from his boat.

Owner:ESTRADA LUGO NELSON

Rehydratable matrices for dry storage of TAQ polymerase in a microfluidic device

Formulations for dry storage of PCR reagents are described. These formulations find use in manufacture of self-contained microfluidic card devices for PCR clinical testing in which the reagents are reconstituted at the point of testing. In these cards, TAQ polymerase is stored “on-board” in vitrified dry form without lyophilization or freezing, and is reconstituted by either the sample or a sample eluate during the assay.

Owner:PERKINELMER HEALTH SCIENCES INC

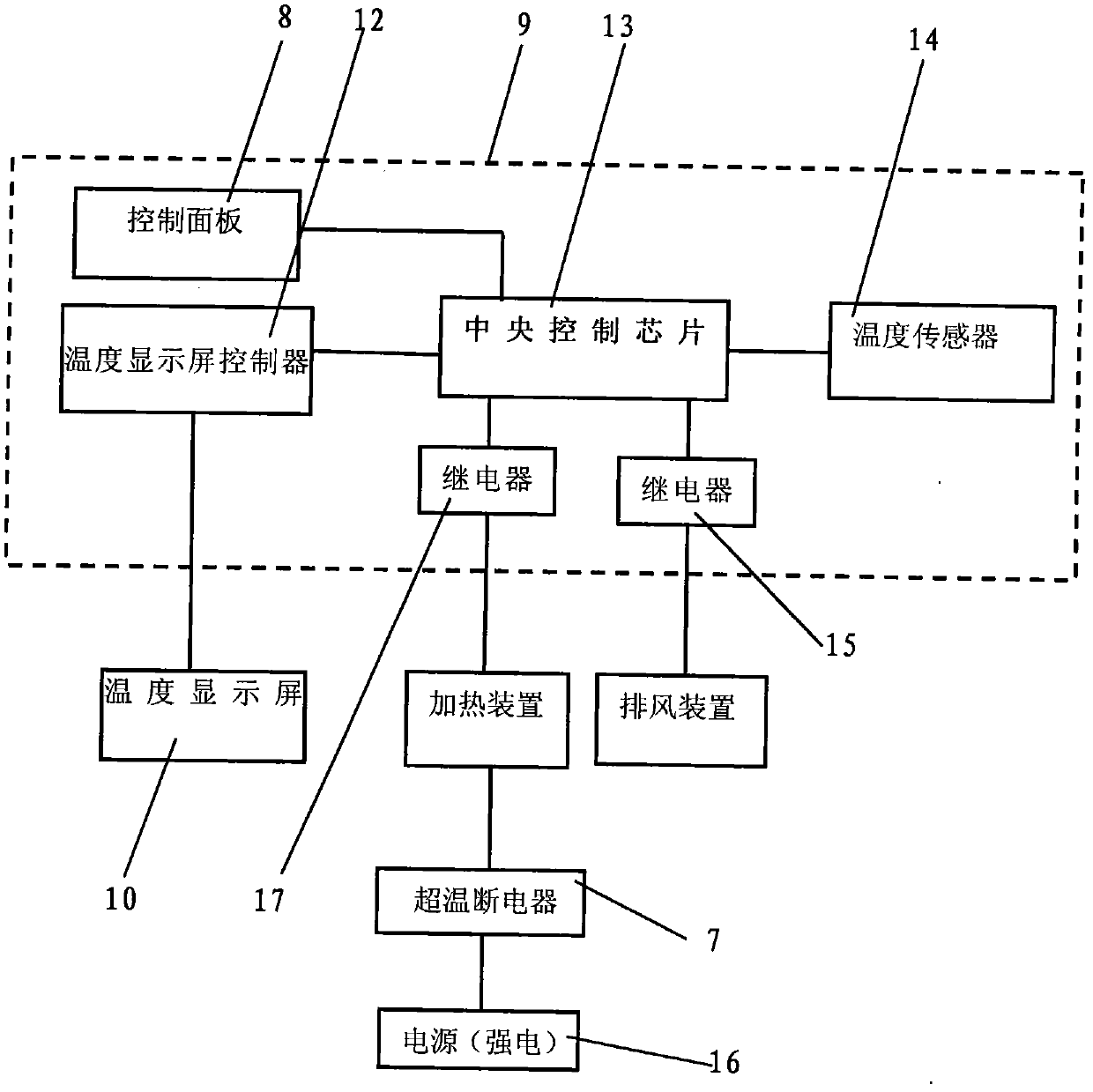

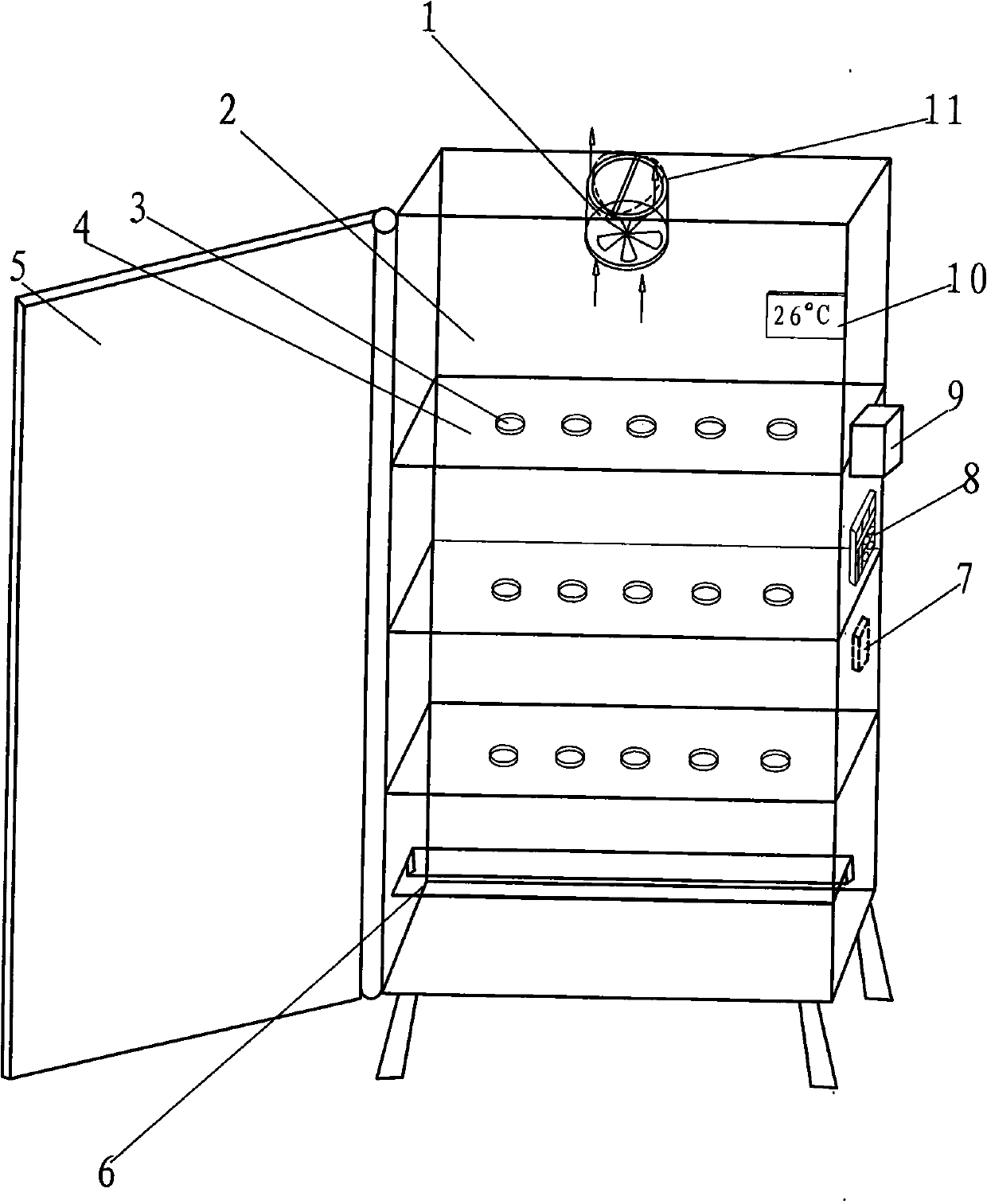

Fully automatic dehumidification safety tool cabinet

InactiveCN102554902AStable temperatureSimple structureWork tools storageAutomatic controlHeating time

The invention relates to a fully automatic dehumidification safety tool cabinet used in the power industry, and aims to solve the problem of providing the safety tool cabinet which has the advantages of small and skilful size, good dehumidification effect, high automation degree and capability of quickly creating a dry storage environment with proper temperature for power tools and instrument. The fully automatic dehumidification safety tool cabinet consists of a cabinet body, a cabinet door, an exhaust device, a heating device, an automatic control system and a temperature display screen, wherein a partition plate is arranged in the cabinet body and is provided with air holes; the top of the cabinet body is provided with an air outlet; the exhaust device which can be used for opening and closing the air outlet is arranged on the air outlet; the heating device is arranged at the bottom in the cabinet body; and the heating device, the exhaust device and the temperature display screen are connected to the automatic control system. The fully automatic dehumidification safety tool cabinet has the positive effects of dust prevention, sanitation, automatic moisture protection and dehumidification, convenience for use, safety and reliability; heating time, exhaust time and the like can be set according to requirements; the dehumidification effect is quick and good; and the fully automatic dehumidification safety tool cabinet is suitable for being promoted and applied in the power industry.

Owner:商丘市天宇电力工程有限公司

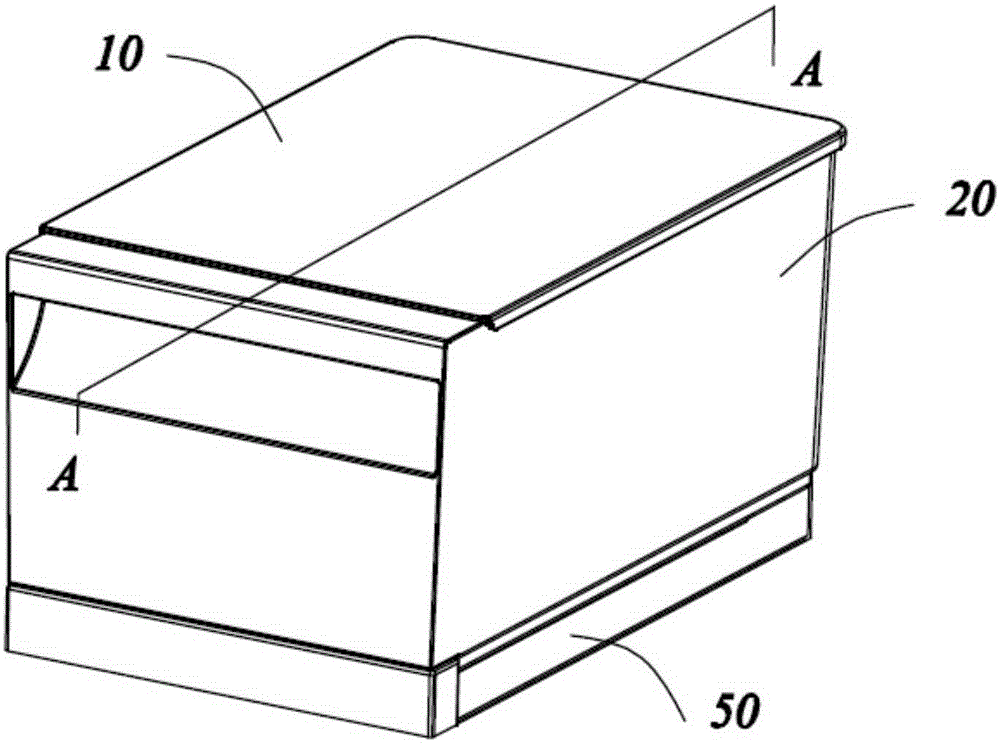

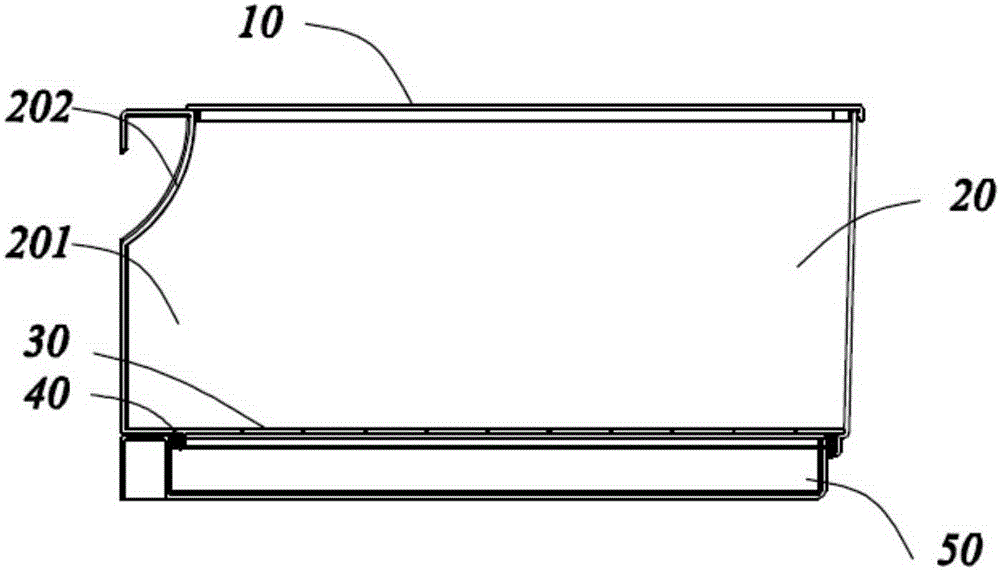

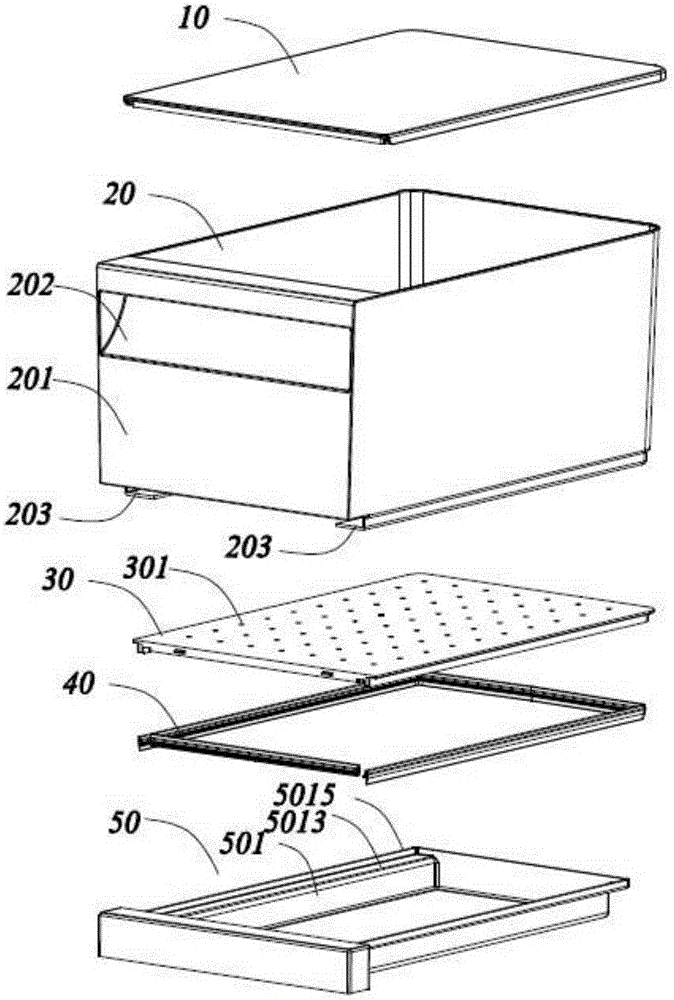

Direct-cooling refrigerator capable of achieving dry storage and moisture storage separately

ActiveCN105180559AEasy to replaceLighting and heating apparatusDomestic refrigeratorsRefrigerator carMoisture storage

The invention discloses a direct-cooling refrigerator capable of achieving drying dry storage and moisture storage separately. The direct-cooling refrigerator comprises a drying box and a moisture preserving box which are located in a compartment of the refrigerator. The drying box is a spliced and sealed box body and is not subjected to air exchange with the compartment of the refrigerator, The drying box comprises a first chamber and a second chamber, wherein the first chamber is in air communication with the second chamber, the first chamber is used for storing articles, and the second chamber is used for containing a drying agent.

Owner:HAIER SMART HOME CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com