Patents

Literature

43results about How to "Little change in mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

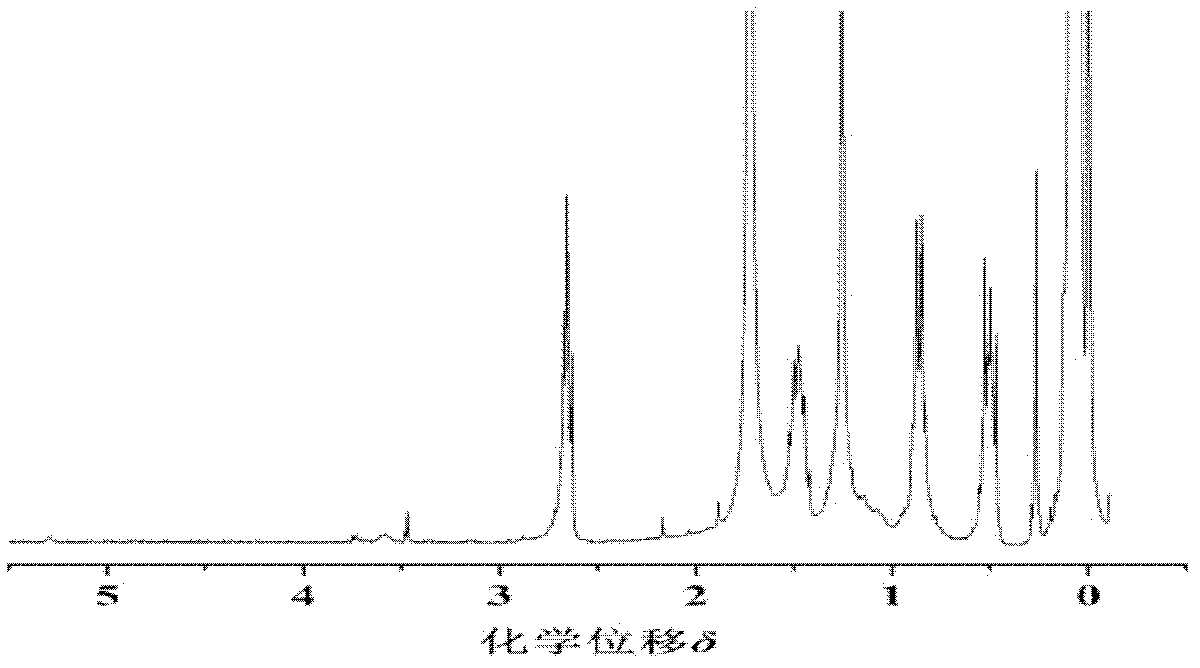

Organic silicon modified thermoplastic polyurethane elastomer (TPU) and preparation method thereof

ActiveCN105399917AImprove hydrophobicityImprove thermal stabilityChemical structureStructural regularity

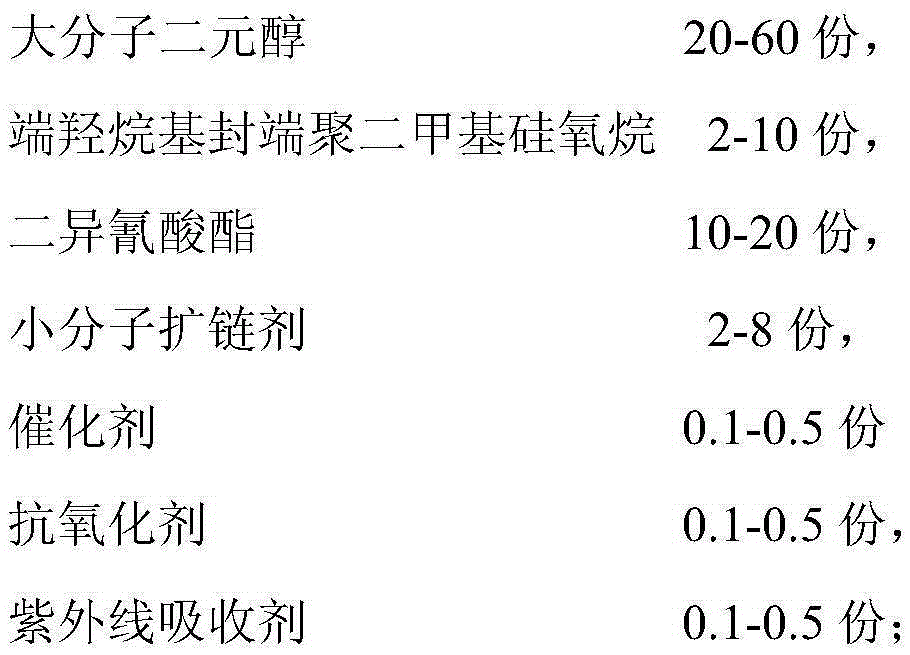

The invention belongs to the field of high polymer material research, and provides an organic silicon modified thermoplastic polyurethane elastomer (TPU) in order to overcome the defects of poor temperature resistance and hydrophobic property of the existing TPU. The elastomer consists of the following components in parts by weight: 20-60 parts of macromolecular dihydric alcohol, 2-10 parts of terminal hydroxyalkyl end-blocked polydimethylsiloxane, 10-20 parts of diisocyanate, 2-8 parts of a micromolecular chain extender, 0.1-0.5 part of a catalyst, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of an ultraviolet light absorber. Due to the unique chemical structure and composition, organic silicon has a series of excellent properties, such as high temperature and low temperature resistance and hydrophobic property, which just can make up the defects of the TPU. The invention also provides a preparation method of the elastomer, the preparation method adopts a prepolymer two-step process and is less in side reaction, and the prepared TPU is good in structural regularity.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Environmental-friendly polyvinyl chloride (PVC) extraction-resistant anti-seepage film and preparation method thereof

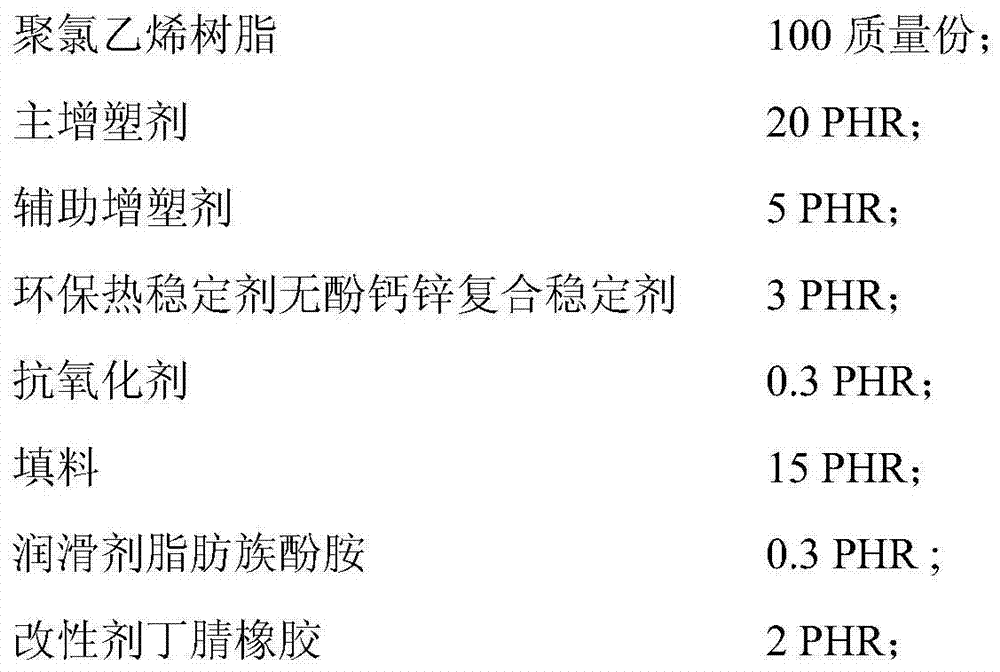

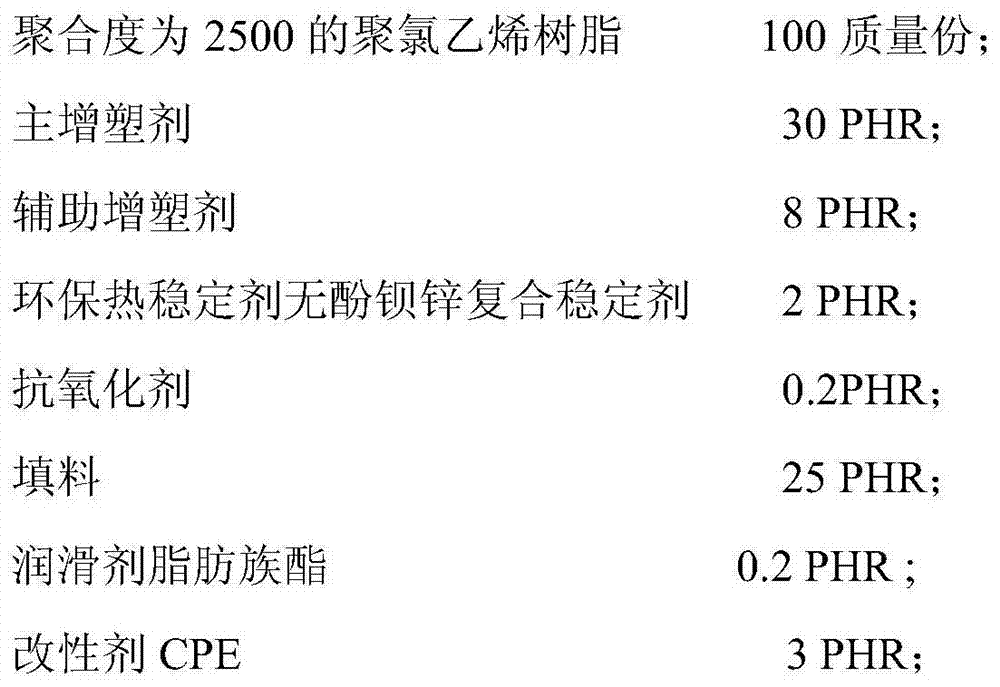

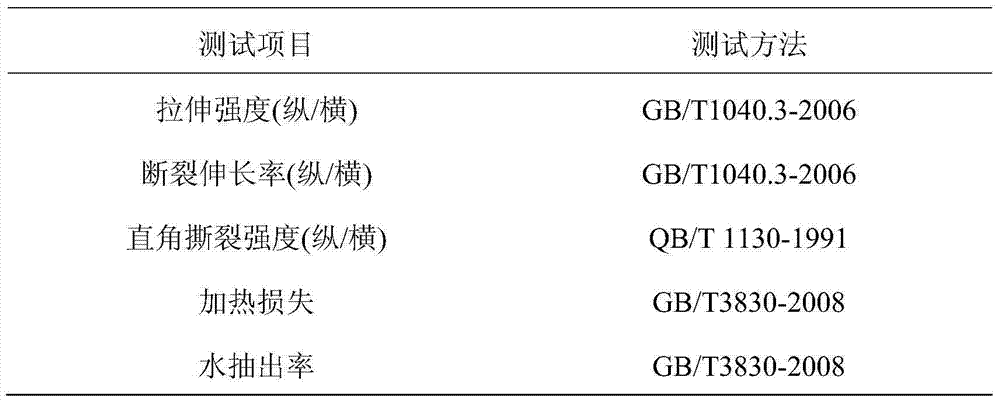

The invention relates to an environmental-friendly polyvinyl chloride (PVC) extraction-resistant anti-seepage film and a preparation method thereof, belonging to the technical field of salt film preparation. The environmental-friendly PVC extraction-resistant anti-seepage film contains the following ingredients in proportioning ratio: 100 parts by mass of PVC resin, 10-50PHR of primary plasticizer, 2-10PHR of secondary plasticizer, 2-5PHR of environmental-friendly heat stabilizer, 0.1-0.5PHR of antioxidant, 6-30PHR of filler and 0.1-0.3PHR of lubricant. The preparation method of the environmental-friendly PVC extraction-resistant anti-seepage film comprises the steps of (1) preparing a kneaded material: metering all the ingredients, mixing and cooling; (2) plasticizing: plasticizing by using a planetary extruder; (3) calendering: filtering the material in a filter, and feeding the material to a calender; (4) spreading: after the material passes through the calender, spreading to widen, and then, cooling for forming, thereby preparing the environmental-friendly PVC extraction-resistant anti-seepage film. According to the environmental-friendly PVC extraction-resistant anti-seepage film and the preparation method thereof, the preparation process is simple, and the controllability is good; the product has the advantages of good water and brine extraction resisting performance, high mechanical properties, little loss, high retention rate, and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

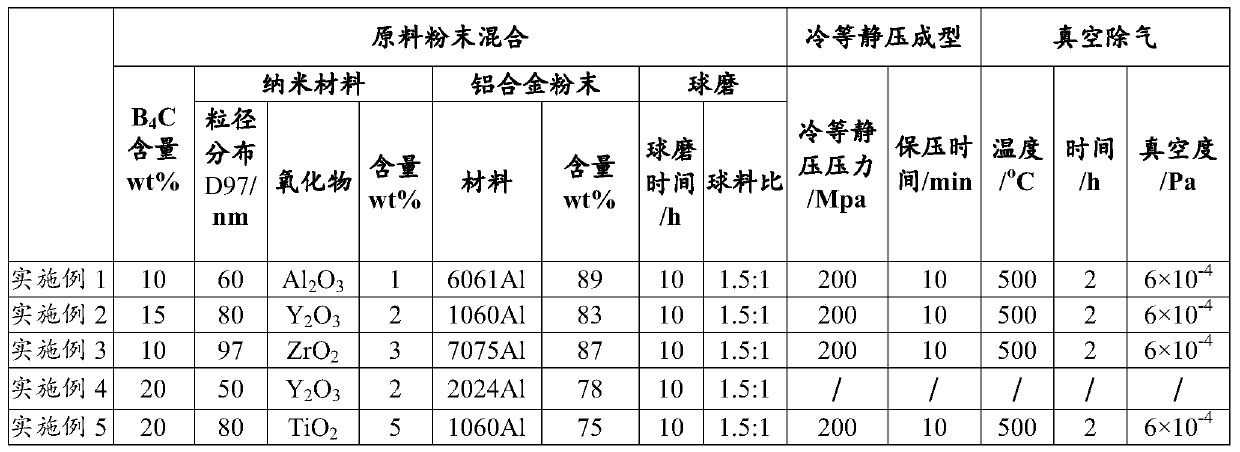

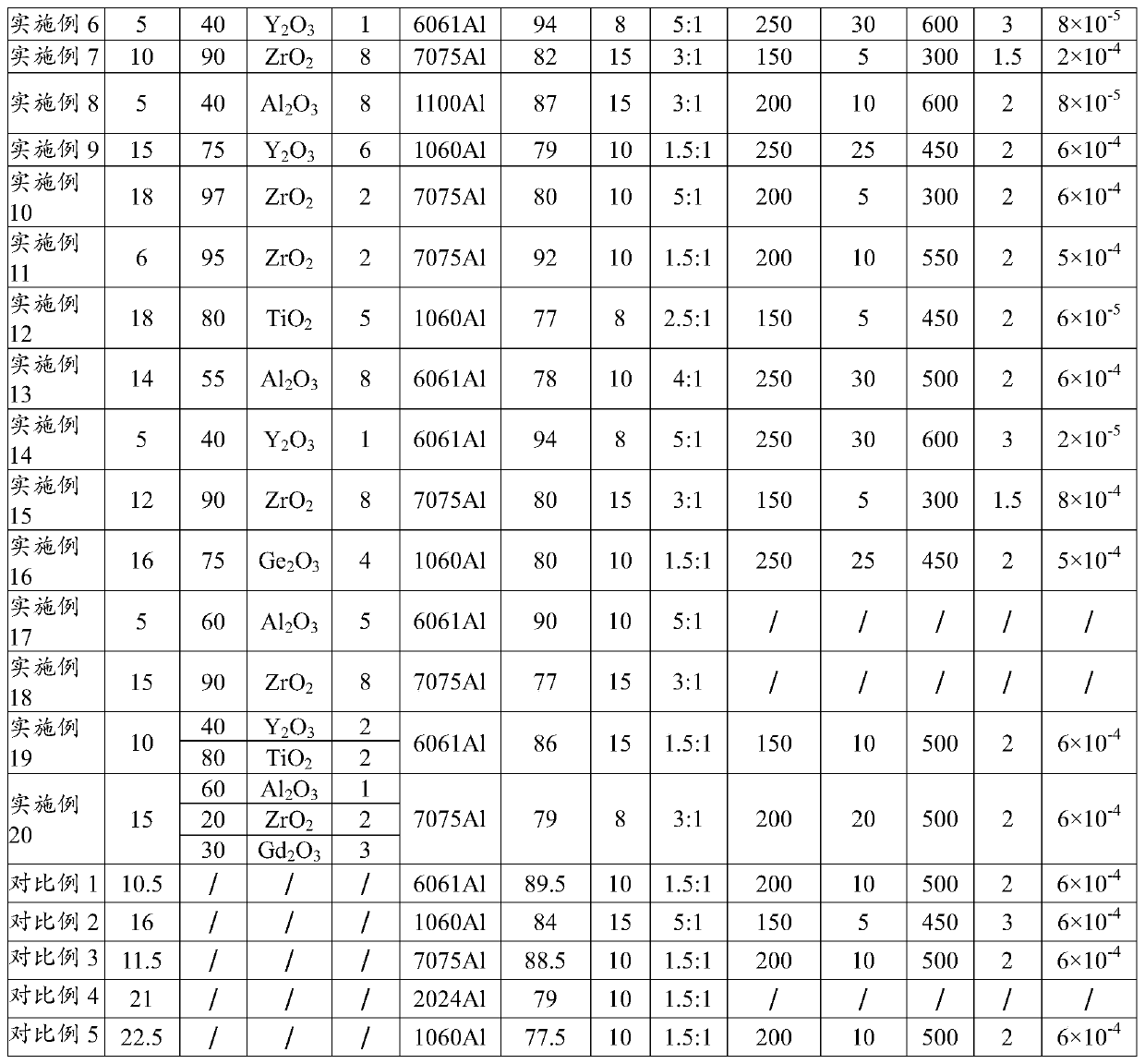

Preparation method of high-temperature structure-function combining B4C/Al neutron absorbing material

InactiveCN106756164AGood mechanical propertiesLittle change in mechanical propertiesHigh energyStructure function

The invention relates to a preparation method of a high-temperature structure-function combining B4C / Al neutron absorbing material. The preparation method comprises the concrete steps of (1) adopting a high energy ball milling method for ball-milling aluminum powder into flake aluminum powder; (2) placing the flake aluminum powder into an air furnace for pre-oxidizing, and forming a layer of nanometer aluminum oxide film on the surface of the aluminum powder; (3) uniformly mixing the pre-oxidized flake aluminum powder and micron-sized B4C particles; (4) pressing molding the uniformly mixed powder; (5) conducting pressureless sintering or hot pressed sintering on a pressing-molded pressing blank; and (6) forging, extruding or rolling a sintered billet so as to obtain the high-temperature structure-function combining B4C / Al neutron absorbing sectional material or sheet material. By adopting the method, a certain amount of nanometer aluminum oxide can be introduced into a pure aluminum matrix, and the micron-sized B4C particles are added, so that the aluminum-based neutron absorbing material with two-phase reinforcement of micron B4C and nano Al2O3 can be prepared, has both a neutron absorbing performance and an excellent high-temperature mechanical property, and can be applied in the fields of spent fuel dry storage, transportation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

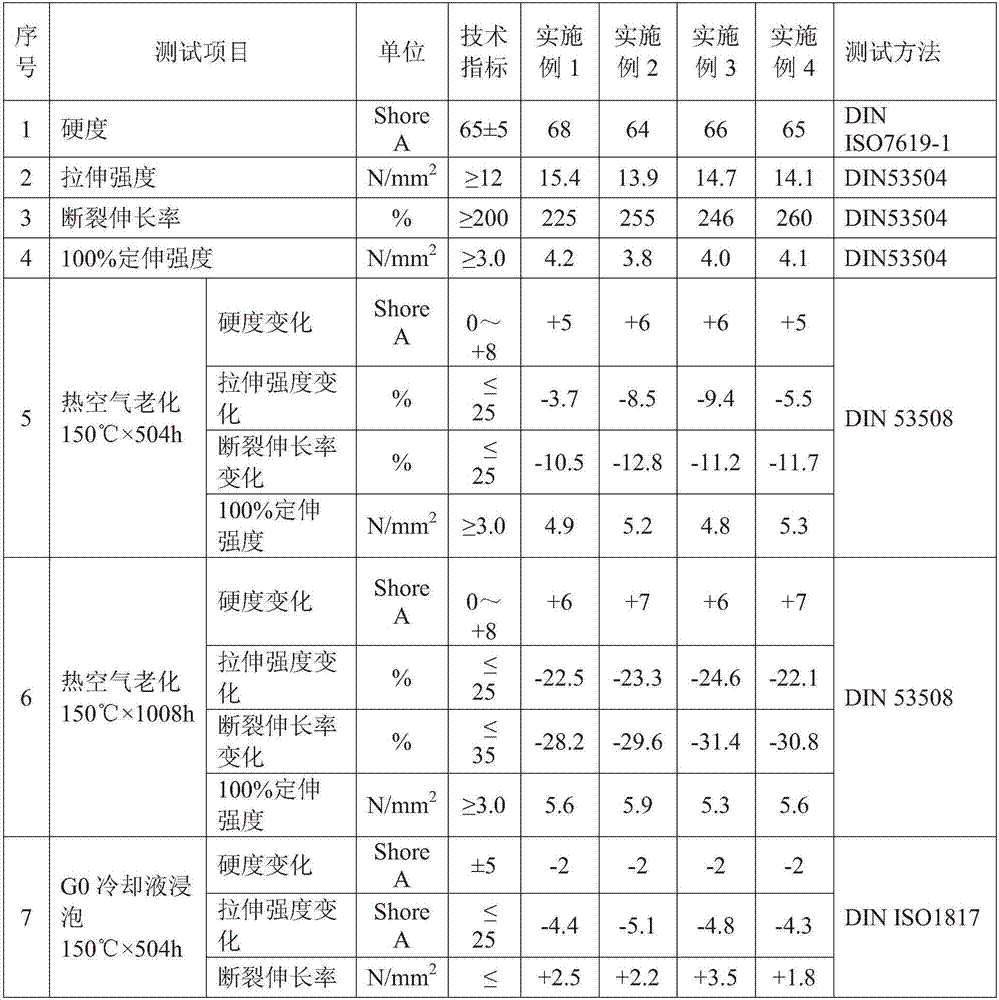

Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

InactiveCN107090133AImprove high temperature resistanceLow temperature resistanceCross-linkRubber material

The invention discloses an ethylene propylene rubber material for a sealing part of an automobile heat dissipation system and a production method of the ethylene propylene rubber material and belongs to the technical field of rubber. The rubber material is prepared from the following components in parts by weight: 100 parts of raw ethylene propylene rubber, 5 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 3 to 6 parts of an anti-ageing agent, 20 to 30 parts of fast extruding carbon black N550, 10 to 20 parts of semi-reinforced carbon black N774, 3.5 to 7 parts of a cross-linking auxiliary agent Ricon 153D and 5 to 8.5 parts of a vulcanizing agent Perkadox 14-40B-GR. The rubber material disclosed by the invention has excellent high-temperature-resisting performance and can be used for a long time under the condition that the temperature is -50 DEG C to 150 DEG C; meanwhile, the rubber material has remarkable advantages of low temperature resistance and low-compression permanent deformation.

Owner:南京金三力高分子科技有限公司

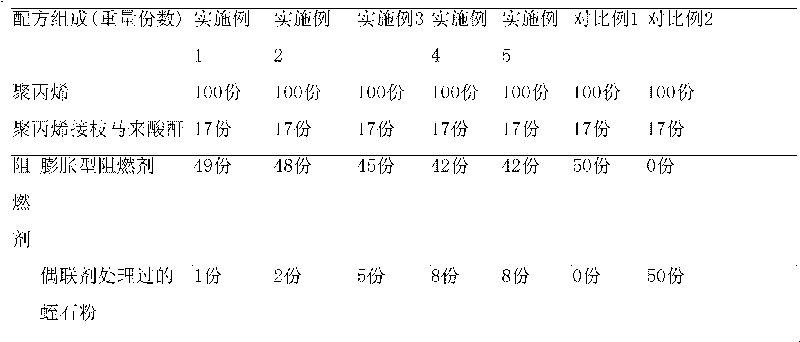

Preparation method of flame retardant polypropylene material

InactiveCN101701096AQuality improvementHigh strengthPigment treatment with non-polymer organic compoundsPolymer scienceOxygen

The invention discloses a preparation method of flame retardant polypropylene material. The flame retardant polypropylene material is characterized in that non-expanded vermiculite powder is subject to surface treatment by titanate coupling agent and is fused and mixed with expanded flame retardant, polypropylene and olypropylene grafted by maleic anhydride to obtain the flame retardant polypropylene material. The novel flame retardant polypropylene material has higher flame retardant performance than singled-used commensurate expanded flame retardant, oxygen index can reach 37% (v%), mechanical property has small variation, and cost is lower. Compared with PP substrate material, the tensile strength retention rate of the flame retardant material is more than 75%, impact strength is more than 67%, so that the flame retardant polypropylene material is suitable for means of transport, building materials and the like having flame retardant requirements.

Owner:SHANGHAI JIAO TONG UNIV

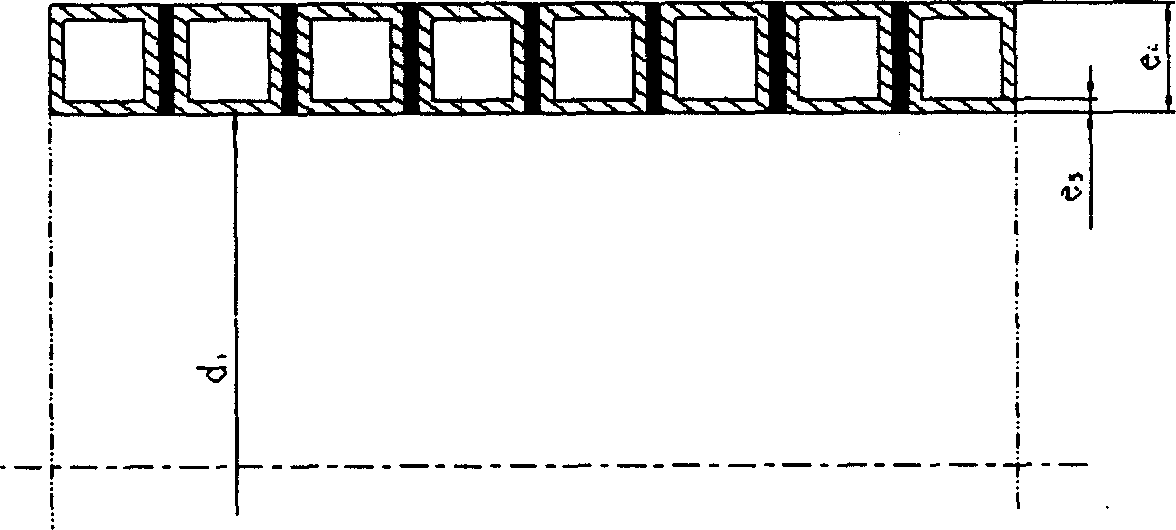

Structure wall pipe for coal mine

InactiveCN1884889ALight in massEasy to installRigid pipesTubular articlesHigh densityAntistatic agent

The invention relates to a mine structural tube material, which is characterized in that: said tube is formed by high-density polythene added with anti-static agent and flameproof agent, while the mass percentages comprise: high-density polythene at 80-87%; the flameproof agent at 8-10%, wherein the flameproof agent is micro capsule red phosphorus; the anti-static agent is conductive carbon black. The invention can be used to supply water, discharge water, compress wind, plate pulp, and exhaust gas. The invention has the advantages that: the tube is added with flameproof agent to obtain high flameproof property; the tube is added with anti-static agent to reduce the surface resistance. The invention has light weight and anti-pressure property.

Owner:金德管业集团有限公司

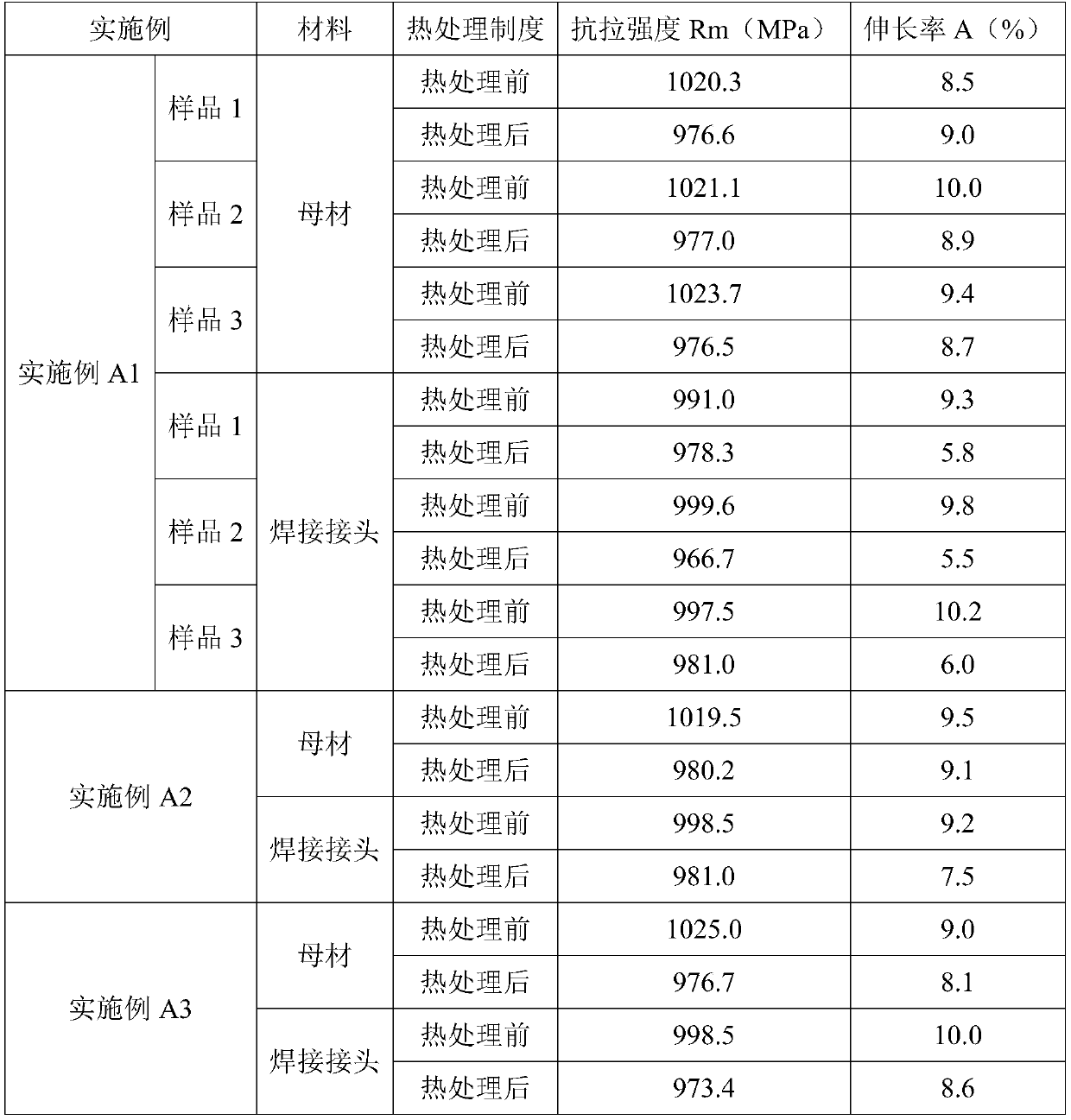

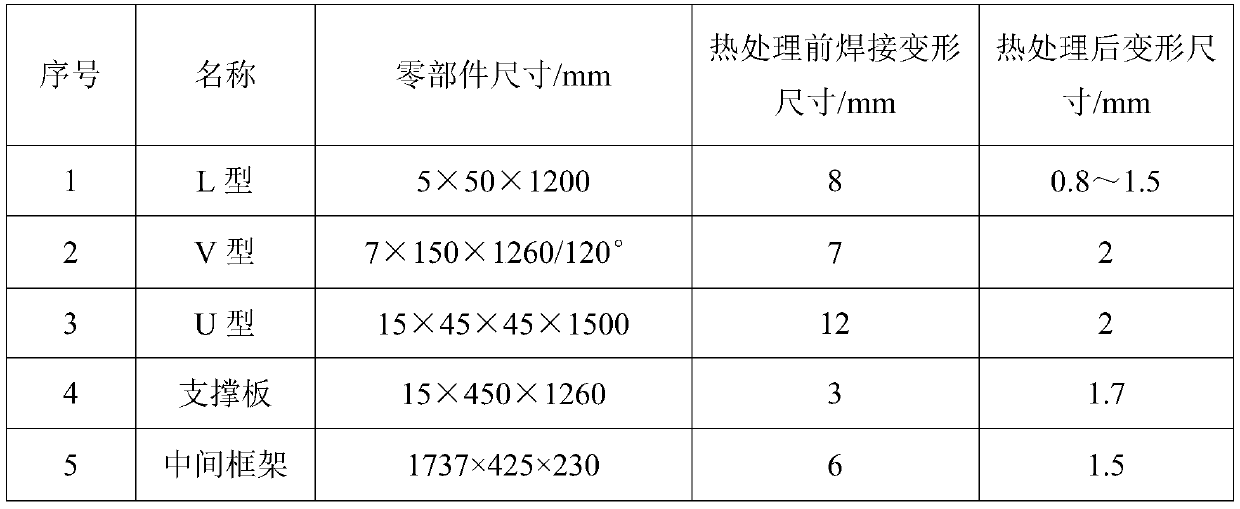

Technological method for heat treatment to titanium alloy welded component

The invention relates to a technological method for heat treatment to a titanium alloy welded component. The technological method comprises the following step (1) of removing oil stain from the surface of the titanium alloy welded component to be treated; the step (2) of adding a little water to high temperature anti-oxidation coatings for dilution, and mixing the water and the coatings uniformlyto obtain high temperature anti-oxidation coating aqueous solutions, and coating the aqueous solutions on the surface of the titanium alloy welded component to be treated; the step (3) of clamping andfixing the titanium alloy welded component to be treated with a tool after drying the high temperature anti-oxidation coating aqueous solutions; the step (4) placing the titanium alloy welded component clamped and fixed with the tool properly into a resistance furnace, and setting heat treatment process parameters, wherein the annealing temperature Tm is 500-600 DEG C, the temperature rise time tis 1.5-2.0 h, and the holding time tm is 2.0-2.5 h; cooling the titanium alloy welded component in the furnace to 200 DEG C and below, taking out the titanium alloy welded component from the furnace,and air-cooling the titanium alloy welded component to room temperature; and the step (5) of cleaning the coatings on the surface of the titanium alloy welded component. Compared with the prior art,the technological method has the advantages of convenient operation, and high economy and adaptability.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

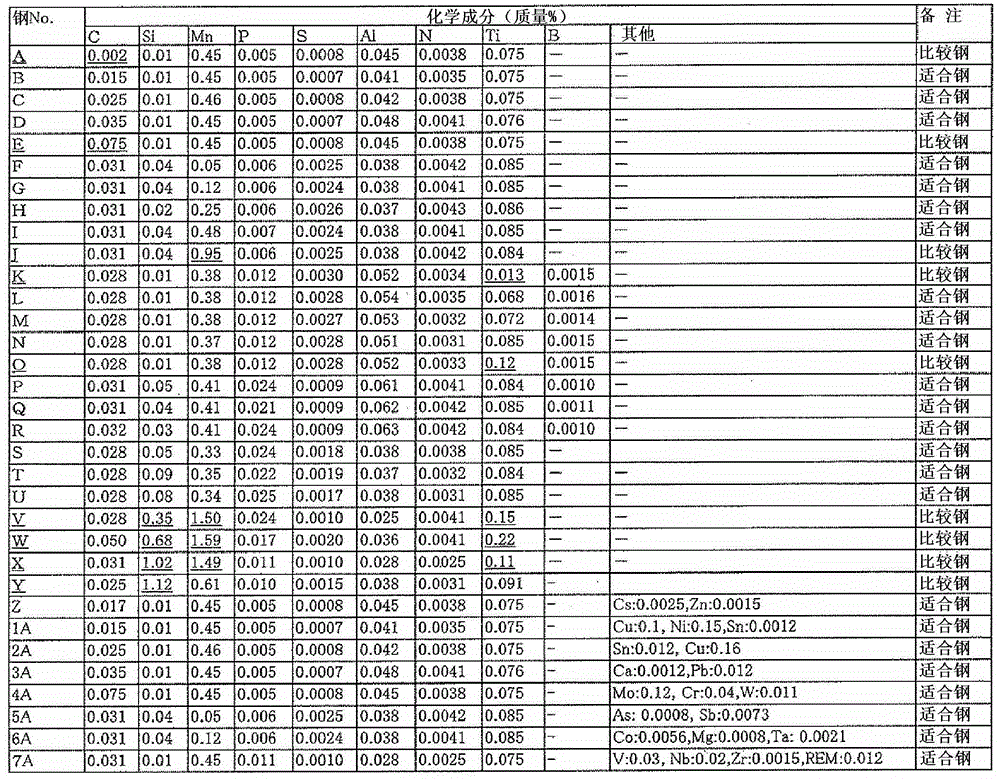

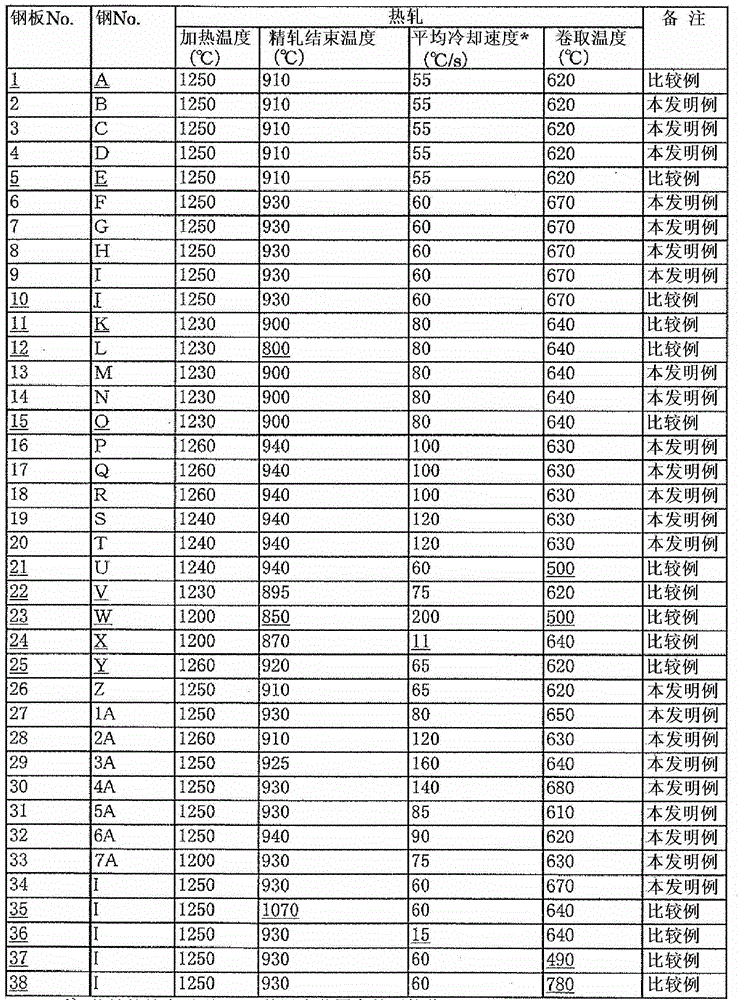

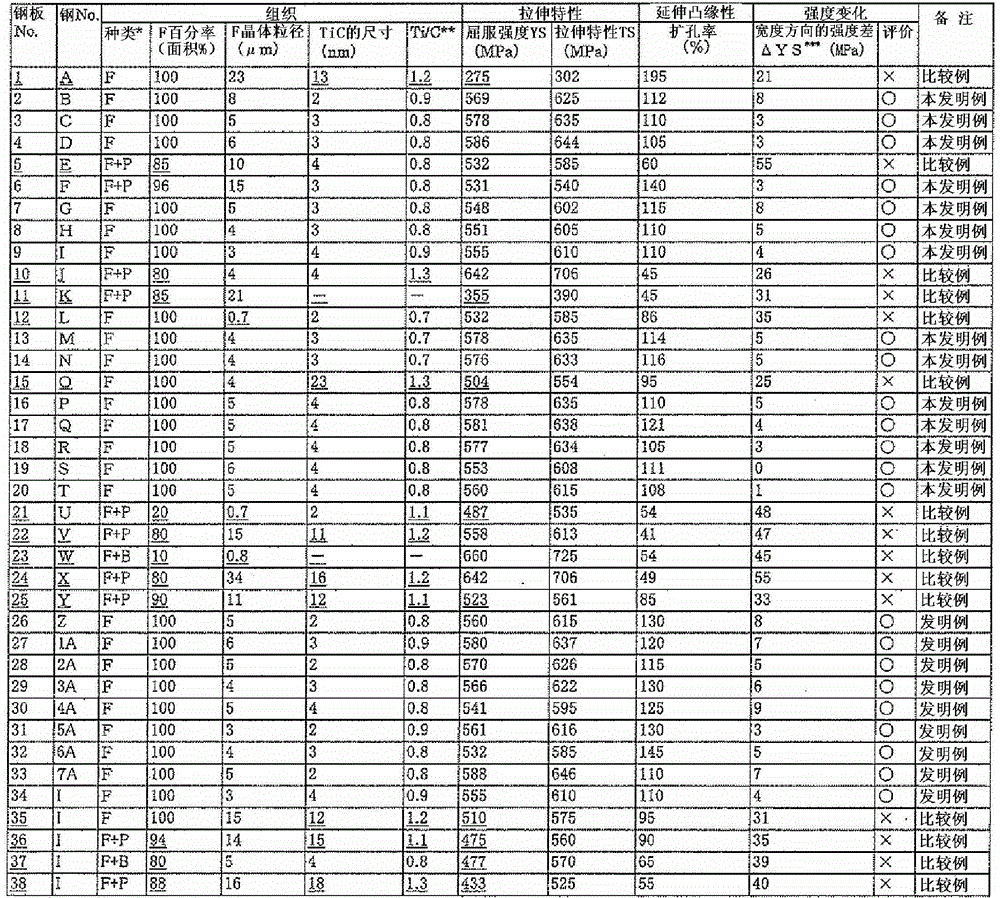

High-strength hot-rolled steel sheet and manufacturing method therefor

ActiveCN104024460ALittle change in mechanical propertiesExcellent stretch flangeabilityFurnace typesThin material handlingMean diameterManganese

Provided is a high-strength hot-rolled steel sheet that exhibits little inter-coil variability in mechanical properties and excellent stretch flangeability. By mass, said steel sheet contains more than 0.010% and no more than 0.06% carbon, up to 0.3% silicon, up to 0.8% manganese, up to 0.03% phosphorus, up to 0.02% sulfur, up to 0.1% aluminum, up to 0.01% nitrogen, and 0.05-0.10% titanium, with the remainder comprising iron and unavoidable impurities. The amounts of silicon and manganese are minimized, the amount of segregation and the like is reduced, and strength variation due to inter-coil position differences is decreased. The structure of the steel sheet is such that the area fraction of a ferrite phase is at least 95%, the mean diameter of ferrite crystal grains is at least 1 [mu]m, and TiC with a mean grain diameter of at most 7 nm is dispersed inside the ferrite crystal grains. This results in a high-strength hot-rolled steel sheet that maintains a yield strength of at least 530 MPa.

Owner:JFE STEEL CORP

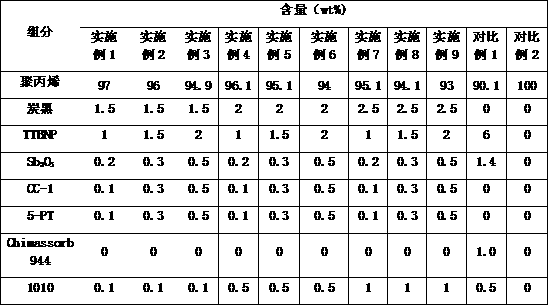

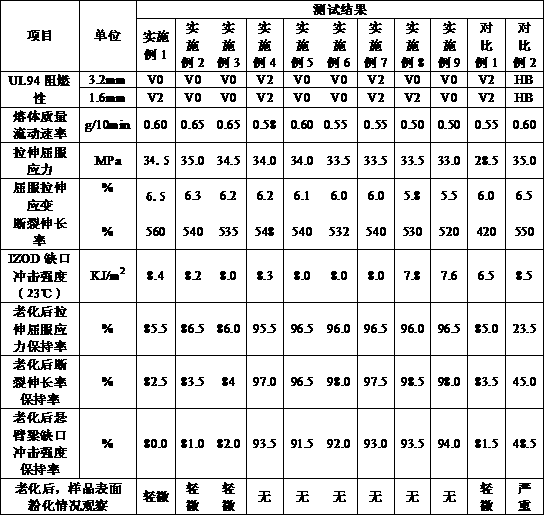

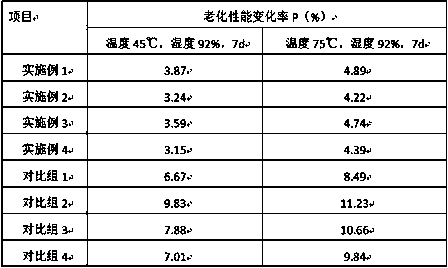

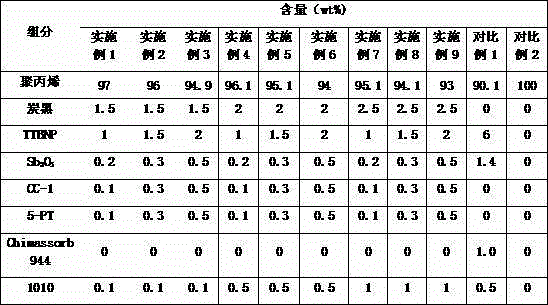

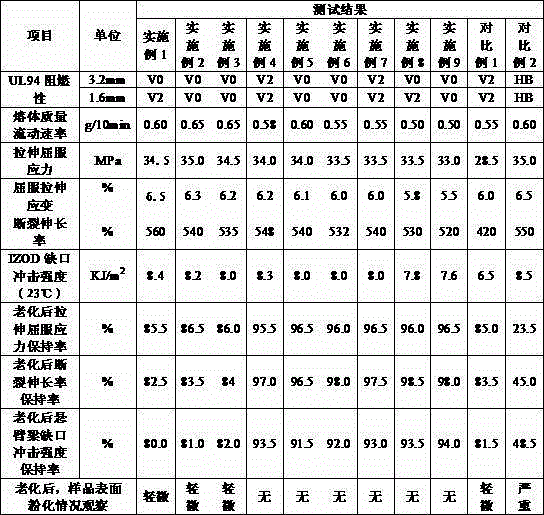

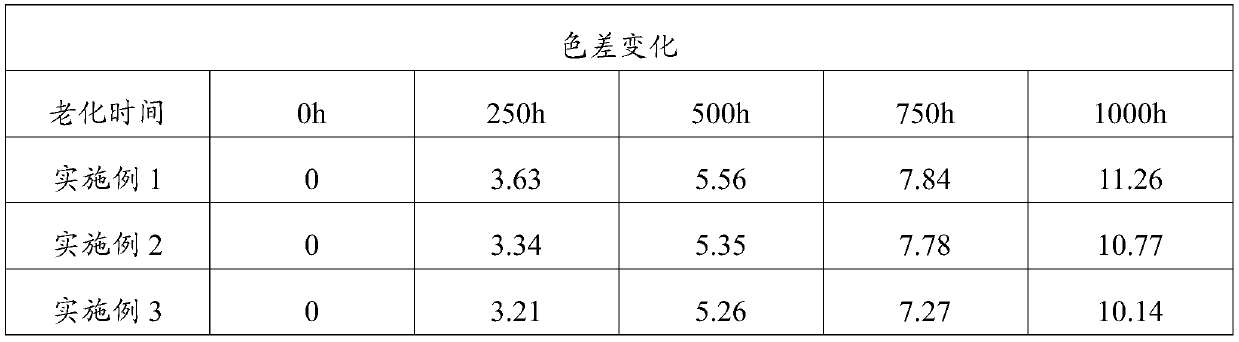

Weather-resistant flame-retardant polypropylene composite material and preparation method thereof

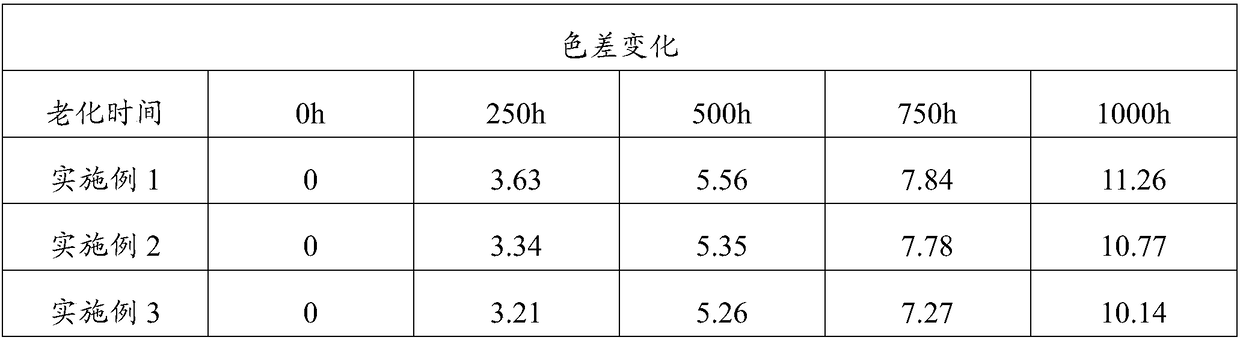

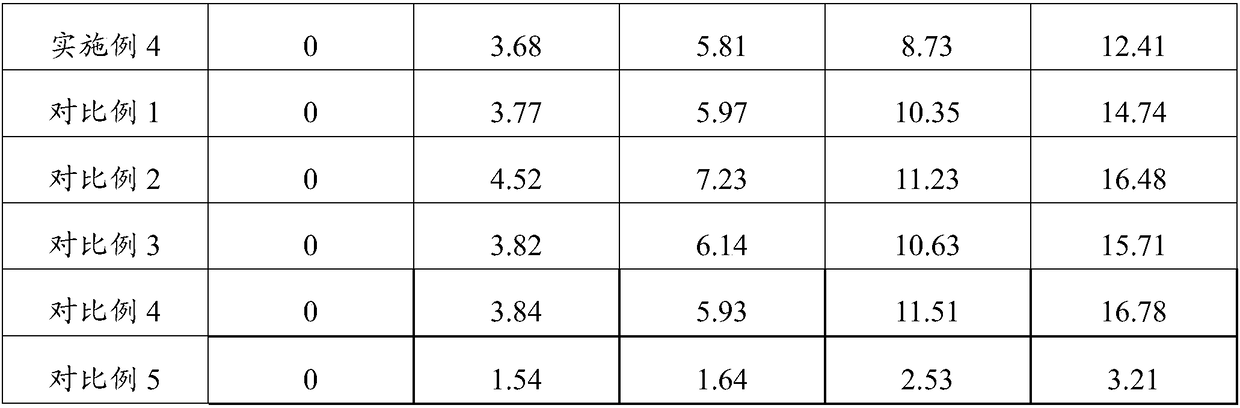

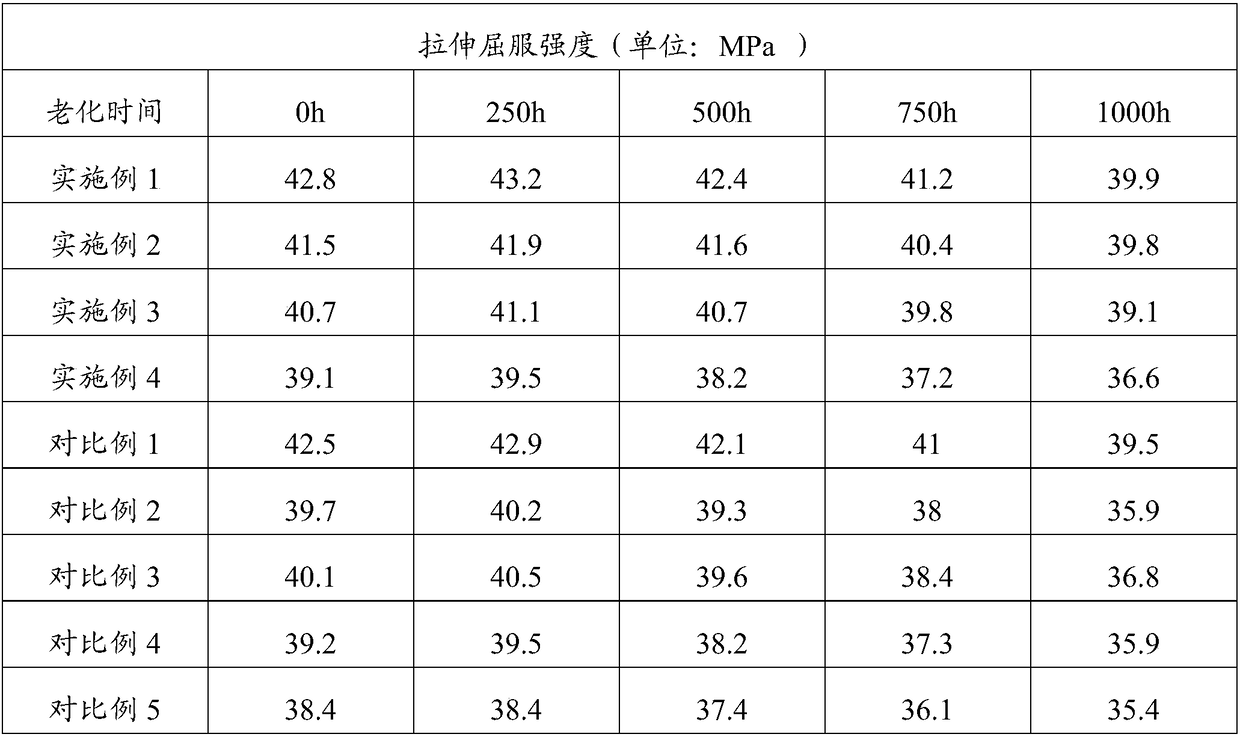

ActiveCN103275394AGood weather resistanceLittle change in mechanical propertiesBromineWeather resistance

The invention discloses a weather-resistant flame-retardant polypropylene composite material which is characterized by comprising 93-97wt% of polypropylene, 1-2wt% of main flame retardant, 0.2-0.5wt% of synergistic flame retardant, 0.1-0.5wt% of chain-cutting agent, 0.1-0.5wt% of foaming agent and 1.5-2wt% of carbon black, and further comprising 0.1-1wt% of other assistants, wherein the other assistants include one or more of antioxidant, dispersant and lubricant; and the carbon black is channel carbon black, and the particle size is 15-25nm. The invention also discloses a preparation method of the weather-resistant flame-retardant polypropylene composite material. According to the invention, the carbon black is selected as weather resistance modifier; the bromine-containing flame retardant, the synergistic flame retardant, the high-temperature chain-cutting agent and the high-temperature foaming agent are combined; the weather-resistant flame-retardant polypropylene composite material is prepared through melt blending; the weather resistance is excellent; the flame retardance is up to UL94V-0 level; the mechanical performance of the material changes little before and after modification; and the weather-resistant flame-retardant polypropylene composite material is low in raw materials and simple and easy to process.

Owner:青岛海科模内装饰有限公司

High-temperature strengthening method for structural-functional integrated neutron absorbing material

InactiveCN109797309AImprove mechanical propertiesGuaranteed mechanical propertiesShieldingHigh energyNeutron

The invention discloses a high-temperature strengthening method for a structural-functional integrated neutron absorbing material. According to the high-temperature strengthening method, powder metallurgy and pressure forming are adopted, and the high-temperature strengthening method comprises the following steps that (1), 5 to 20wt.% of B4C, 1 to 8wt.% of a nanometer oxide material, and aluminumalloy powder are uniformly mixed by high-energy ball milling; (2), uniformly mixed powder is subjected to isostatic cold pressing and then compression-molded into a billet, the compression-molded billet is placed in an aluminum wrapping sleeve to be subjected to high-temperature vacuum degassing treatment, the billet is sealed and welded in the aluminum wrapping sleeve after a required vacuum degree is reached, and then the billet andaluminum wrapping sleeve subjected to high-temperature vacuum degassing treatment are subjected to hot-pressing molding, hot forging molding, hot extrusion molding, or hot rolling molding; or the uniformly mixed powder in the step (1) is directly subjected to hot extrusion molding; (3), the material molded in the step (2) is compression-molded through isostatic cold pressing; and (4), the compression-molded material in the step (3) is rolled at a certain temperature to obtain a desired neutron absorbing material.

Owner:中广核工程有限公司 +2

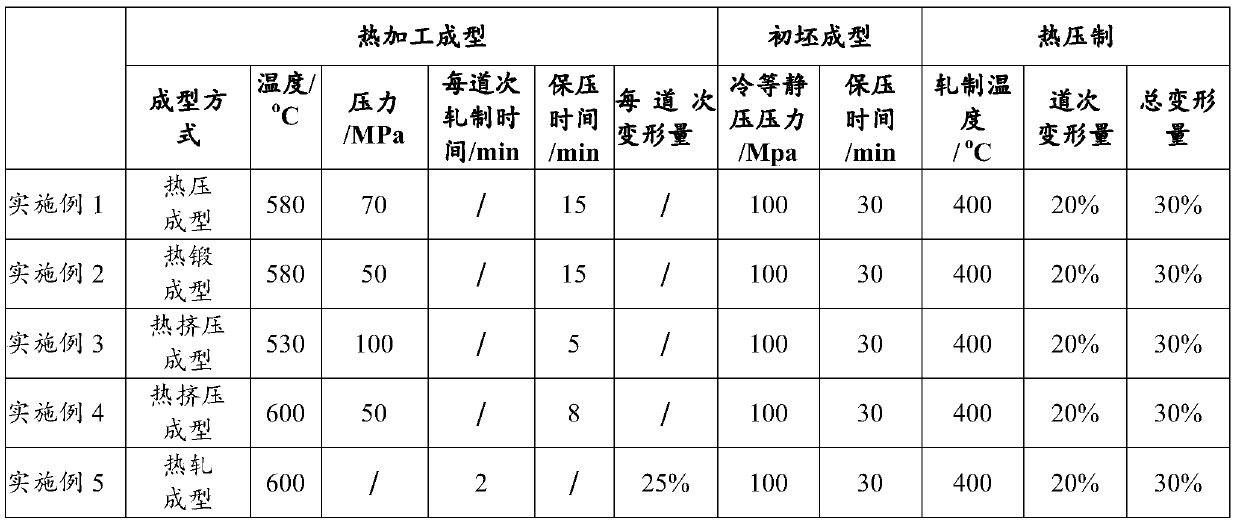

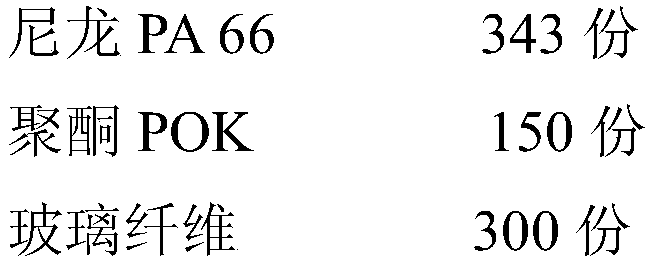

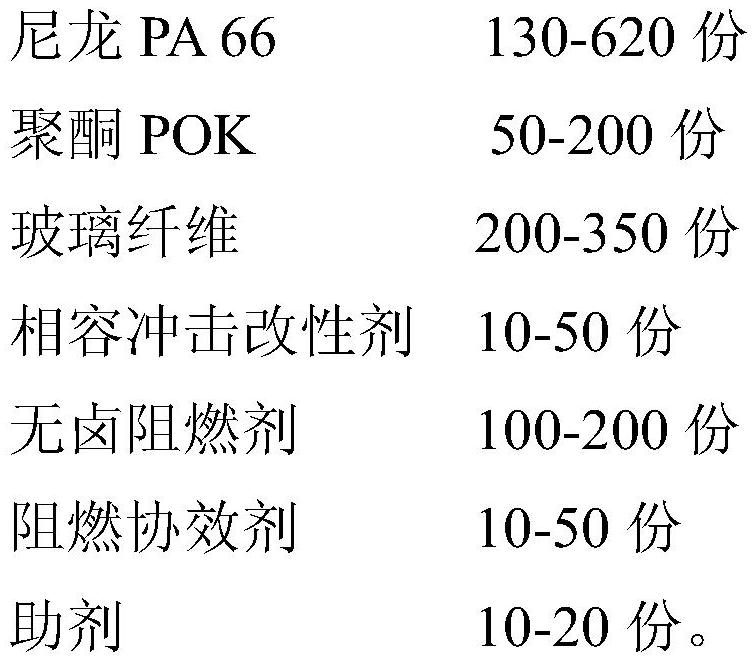

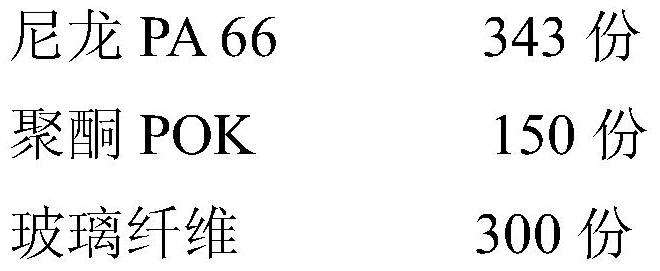

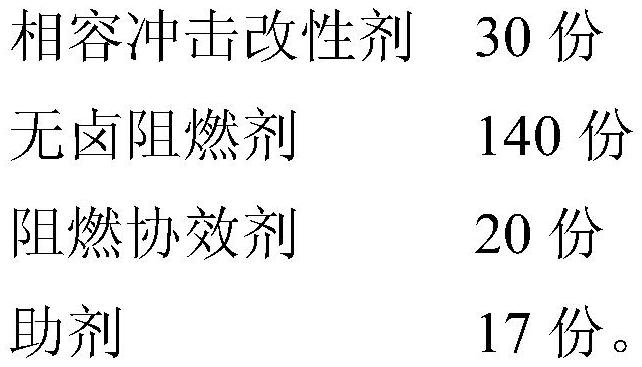

Halogen-free flame-retardant reinforced PA/POK alloy material with hygrothermal aging resistance

ActiveCN109608878AGood mechanical propertiesLittle change in mechanical propertiesPhosphoric acidHalogen

The invention relates to the field of polymer composite materials, specifically to a halogen-free flame-retardant reinforced PA / POK alloy material with hygrothermal aging resistance. The halogen-freeflame-retardant reinforced PA / POK alloy material is composed of the following components by weight: 130 to 620 parts of PA66, 50 to 200 parts of POK, 200 to 350 parts of glass fiber, 10 to 50 parts ofa compatible impact modifier, 100 to 200 parts of a halogen-free flame retardant, 10 to 50 parts of a flame-retardant synergist and 10 to 20 parts of an auxiliary agent. The alloy material provided by the invention adopts aluminum diethyl hypophosphite and polysiloxane to compound for retarding flame, can reach the flame retardancy of V-0, and has good mechanical properties; the alloy material provided by the invention can still reach the flame retardancy of V-0 after hygrothermal aging, and has small change in mechanical properties; and the alloy material provided by the invention has abrasion coefficient superior to the abrasion coefficient of pure flame-retardant PA66 + GF.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

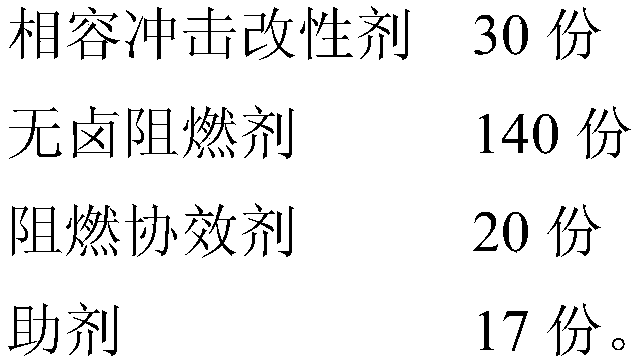

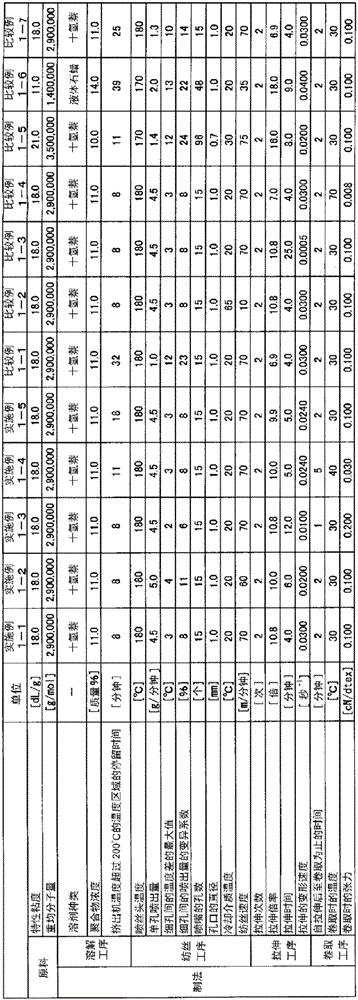

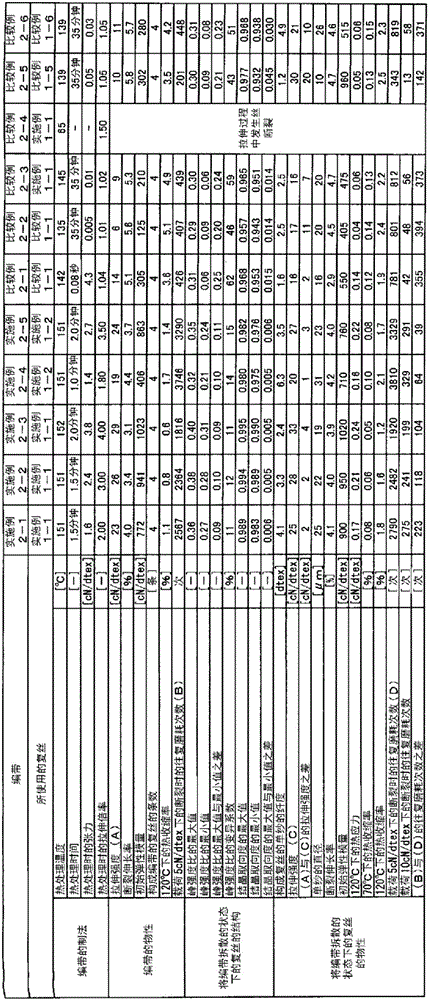

Multifilament and braid

ActiveCN106133215ALittle change in mechanical propertiesGood dimensional stabilityDomestic articlesDry spinning methodsUltimate tensile strengthWear resistance

Provided are a multifilament and braid capable of being processed into a product over a wide temperature range, and having excellent dimensional stability and wear resistance. A multifilament comprising five or more monofilaments, wherein the multifilament is characterized in including a polyethylene having a limiting viscosity ([eta)) of 5.0-40.0 dL / g, the repeating units thereof being substantially ethylene, and the ratio of diffraction peak intensity of an orthorhombic crystal (200) surface in relation to the diffraction peak intensity of a orthorhombic crystal (110) surface in a cross-section of the monofilaments having a difference of 0.22 or less between the maximum and minimum value.

Owner:TOYOBO MC CORP

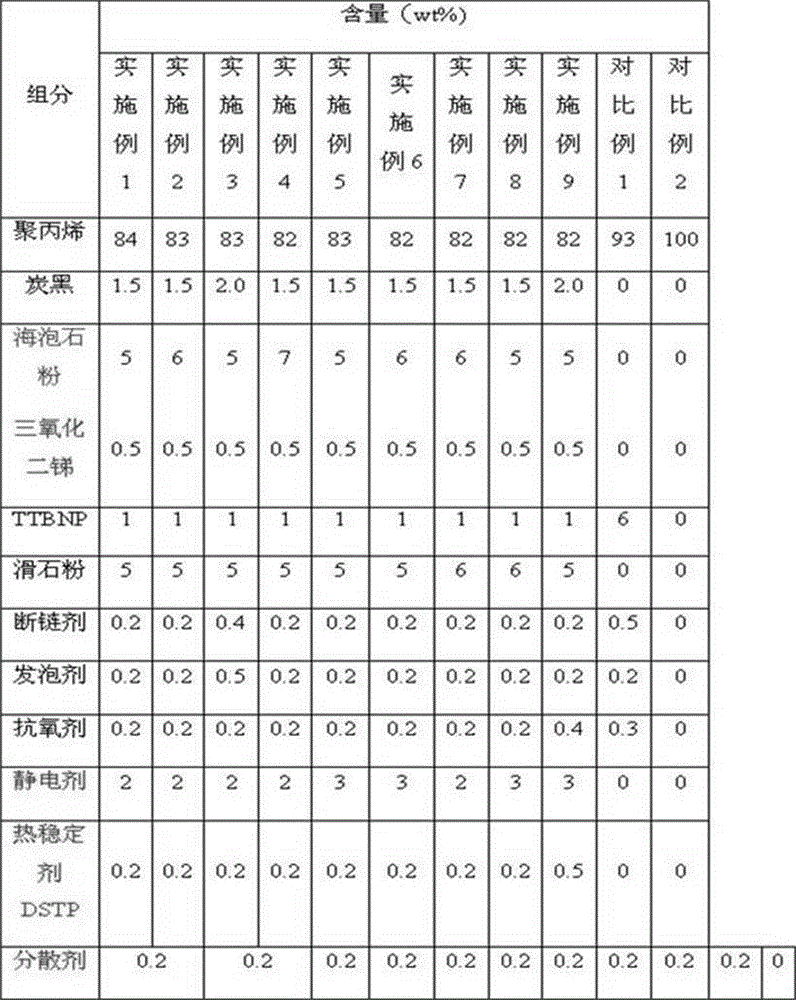

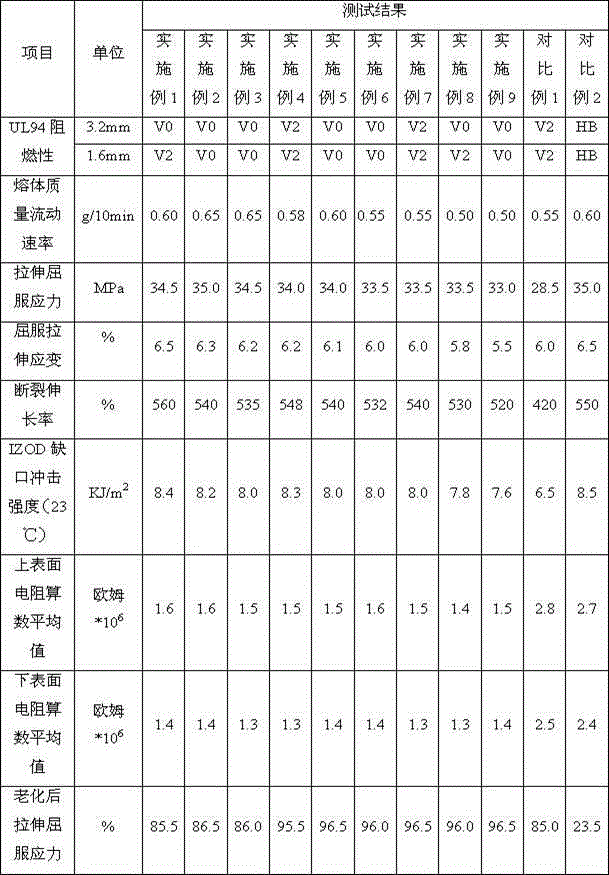

Multifunctional polypropylene material

InactiveCN104448540AGood weather resistanceImprove temperature resistancePolymer scienceAntimony trioxide

The invention discloses a multifunctional polypropylene material which is characterized by comprising the following raw materials in percentage by weight: 75-90% of polypropylene, 5-10% of hormites clay meerschaum powder, 1-2% of main flame retardant TTBNP, 0.2-0.5% of synergistic flame retardant antimony trioxide, 1.5-2.5% of carbon black, 5-6% of talcum powder, 0.2-0.5% of chain-cutting agent 3,4-dimethyl-3,4-diphenylhexane, 0.2-0.5% of foaming agent 5-phenyltetrazole, 2-3% of electrostatic agent epoxyethane, 0.2-0.3% of antioxidant sodium phosphite, 0.2-0.3% of heat stabilizer DSTP, 0.2-0.3% of penetrant sodium alpha-alkenyl sulfonate and 0.2-0.3% of dispersing agent sodium lignosulfonate. The polypropylene material produced by the invention has excellent weather resistance, flame retardancy, electrical resistance, temperature impact resistance and mechanical property, and is cheap in the materials, simple and easy to process and suitable for industrial production.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

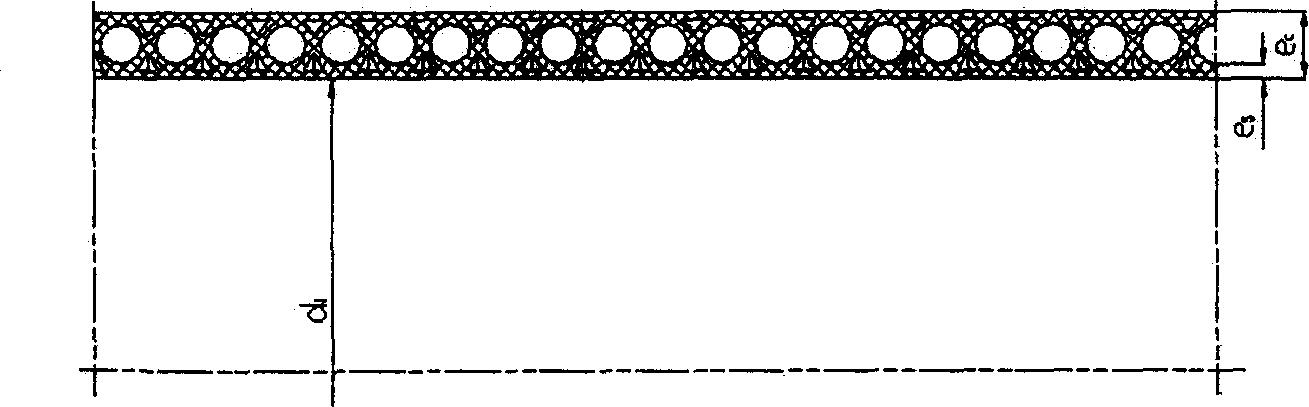

Flexible composite lining pipe material

The present invention relates to a flexible composite lining pipe material, which comprises a pipe material inner layer, wherein the material of the pipe material inner layer is a high density polyethylene material, and the high density polyethylene material comprises, by weight, 100 parts of a high density polyethylene resin, 1-10 parts of inorganic nanoparticles, one or a plurality of materials selected from 2-10 parts of talc powder, 1-9 parts of montmorillonite and 1-10 parts of sepiolite, one or a plurality of materials selected from 1-20 parts of nylon 6, 1-20 parts of nylon 66, 1-20 parts of polyethylene glycol terephthalate and 1-20 parts of glass fiber, and 1-20 parts of high density polyethylene grafted maleic anhydride adopted as a compatibilizer, and / or 1-20 parts of ethylene-octene copolymer grafted maleic anhydride as a compatibilizer. According to the present invention, the flexible composite lining pipe material is provided, which can be used as the water delivery material and the oil delivery material in industrial applications, and can ensure the no change of the material, the increased temperature resistance, the little mechanical property change and the increased thermal performance increasing under the conditions of high temperature and high pressure.

Owner:SHANDONG KELINRUIER PIPELINE ENG

Method for synthesizing water-expandable body material

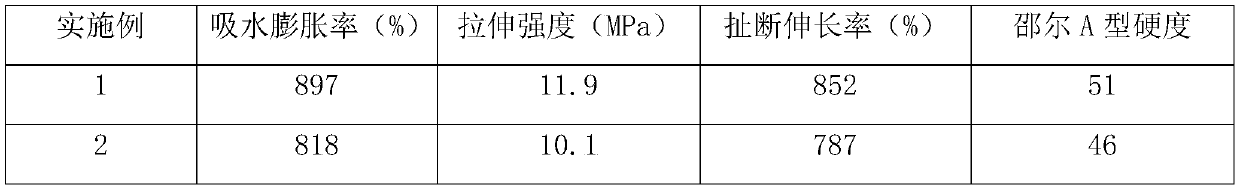

ActiveCN110527058AHigh water expansion rateTo achieve the effect of water expansionToluene diisocyanateWear resistant

The invention discloses a method for synthesizing a water-expandable body material. The method comprises the following steps: 1. adding ethylene oxide, propylene oxide, pentaerythritol and potassium hydroxide into a vacuum pump, and carrying out a reaction, so as to obtain a macromolecular polyether; 2. subjecting the macromolecular polyether to a reaction with toluene diisocyanate, so as to obtain a special prepolymer; and 3. stirring the special prepolymer with liquid rubber, bentonite, an anti-aging agent, white carbon black, a chain extender and a hydrophilic chain extender, injecting themixture into a casting machine, and carrying out demolding, thereby obtaining the water-expandable body material. According to the water-expandable body material, the water absorbency of the water-expandable body material is improved, and the water-expandable body material has the advantages of high water absorption rate and high water absorption expansion rate. The water absorbency of the water-expandable body material is improved, and meanwhile, the water-expandable body material has the characteristics that the mechanical properties are good, the change of the mechanical properties is smallbefore and after water absorption, and the stability is high; and the water-expandable body material is oil-resistant, wear-resistant and aging-resistant and is an ideal material applied to the fields of waterproofing and anti-seepage.

Owner:ZHEJIANG SHENZHOU TECH CHEM IND

Modified polyvinyl chloride material and preparation method thereof

The invention relates to a preparation method for a modified polyvinyl chloride material. The preparation method comprises the following steps: mixing titanium dioxide with carbon black; raising temperature to 60-80 DEG C; then, adding titanate coupling reagent, stirring for 10-20min, and drying and grinding to obtain weather-proof accessory ingredient of which the particle size is 100nm or below,wherein the mass ratio of titanium dioxide, carbon black to the titanate coupling reagent is (4-7): (2-5):1; after polyvinyl chloride, auxiliary materials and the weather-proof accessory ingredient are evenly mixed, carrying out extrusion molding to obtain the modified polyvinyl chloride material. According to the preparation method, through preprocessing, titanium dioxide, carbon black and the titanate coupling reagent are more favorably dispersed and combined with polyvinyl chloride, in addition, the synergetic anti-ultraviolet function of titanium dioxide and carbon black can be improved,meanwhile, the titanate coupling reagent is more favorable for combining titanium dioxide, carbon black and polyvinyl chloride than other coupling reagents, so that the resistance ability of the polyvinyl chloride material for ultraviolet can be improved, the polyvinyl chloride material is unlikely to be decomposed, aged and discolored, mechanical performance change is small, excellent weather fastness is obtained, and the preparation method is especially suitable for preparing various classes of PVC (polyvinyl chloride) pipe materials.

Owner:日丰企业(天津)有限公司

Alimentary canal stent and manufacture process thereof

ActiveCN109172069ASmooth structureLittle change in mechanical propertiesStentsAdditive manufacturing apparatusState of artInsertion stent

The invention relates to the technical field of medical devices, in particular to an alimentary canal stent and a manufacturing process thereof. The alimentary canal comprises a main body, a first support portion and a second support portion; The main body, the first support portion and the second support portion are formed of degradable polymer material by 3D printing, the first support portion and the second support portion are provided at both ends of the main body, and the first support portion and the second support portion are used for matching and abutting with the digestive tract portto support the digestive tract. So as to alleviate the technical problem that the stent needs to be removed by a second operation after being used, thereby increasing the burden of the patient in theprior art.

Owner:REGENOVO BIOTECH

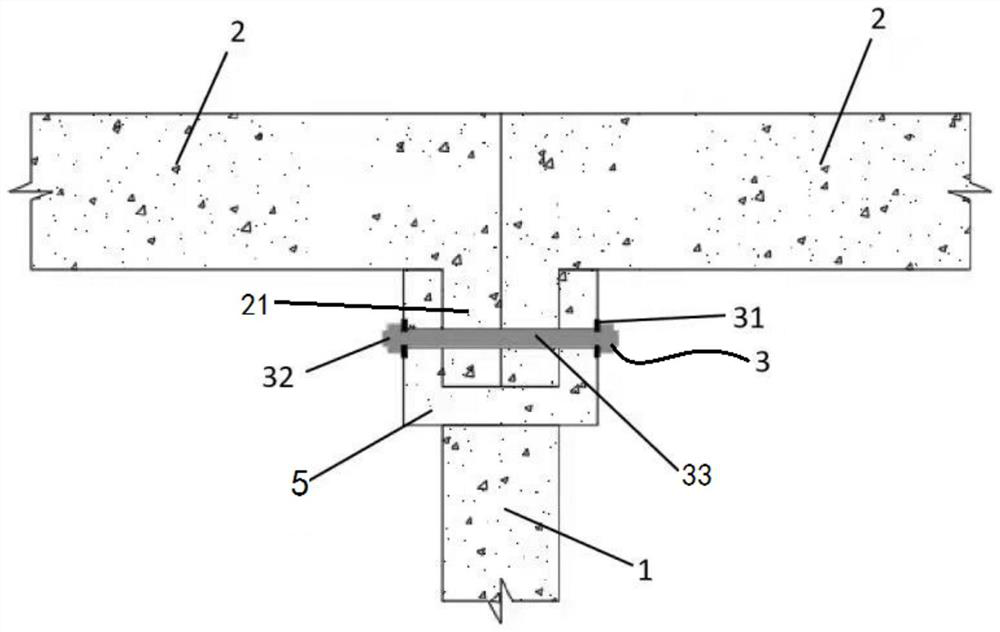

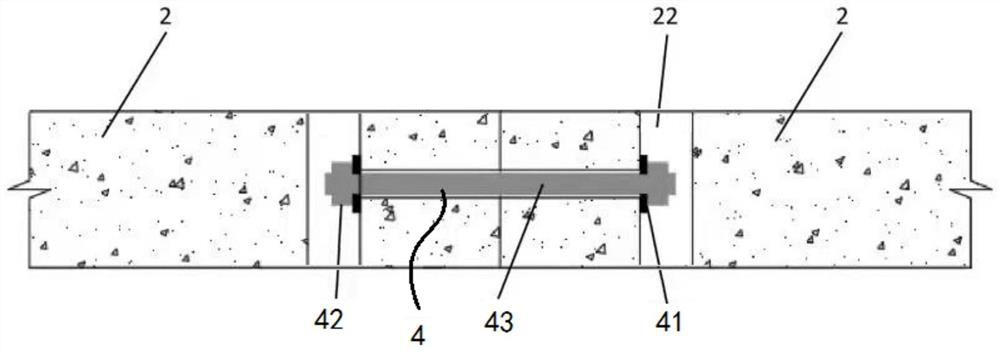

Assembly type roadbed pile plate connecting structure

ActiveCN113818288ALittle change in mechanical propertiesFast constructionRailway tracksBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to an assembly type roadbed pile plate connecting structure. The structure comprises a plurality of prefabricated bearing plates which are sequentially spliced end to end, wherein every two adjacent prefabricated bearing plates are spliced through a connecting assembly, inserting blocks are symmetrically arranged at the two ends, in the splicing direction, of the prefabricated bearing plate, the inserting blocks are located on the lower surface of the prefabricated bearing plate, the connecting assembly comprises a prefabricated pipe pile and a first connecting assembly, and the first connecting assembly comprises a first connecting bolt and a first nut; the prefabricated pipe pile comprises a pile body and a concave bearing platform fixed to an end of the pile body, the inserting blocks located on the two adjacent prefabricated bearing plates are jointly inserted into the concave bearing platform, and the first connecting bolts penetrate through the concave bearing platform and the inserting blocks in the concave bearing platform and are fixed through first nuts. Compared with the prior art, the structure has advantages of high efficiency, small environmental pollution, strong reusability, convenience in maintenance and replacement, low cost and the like.

Owner:TONGJI UNIV

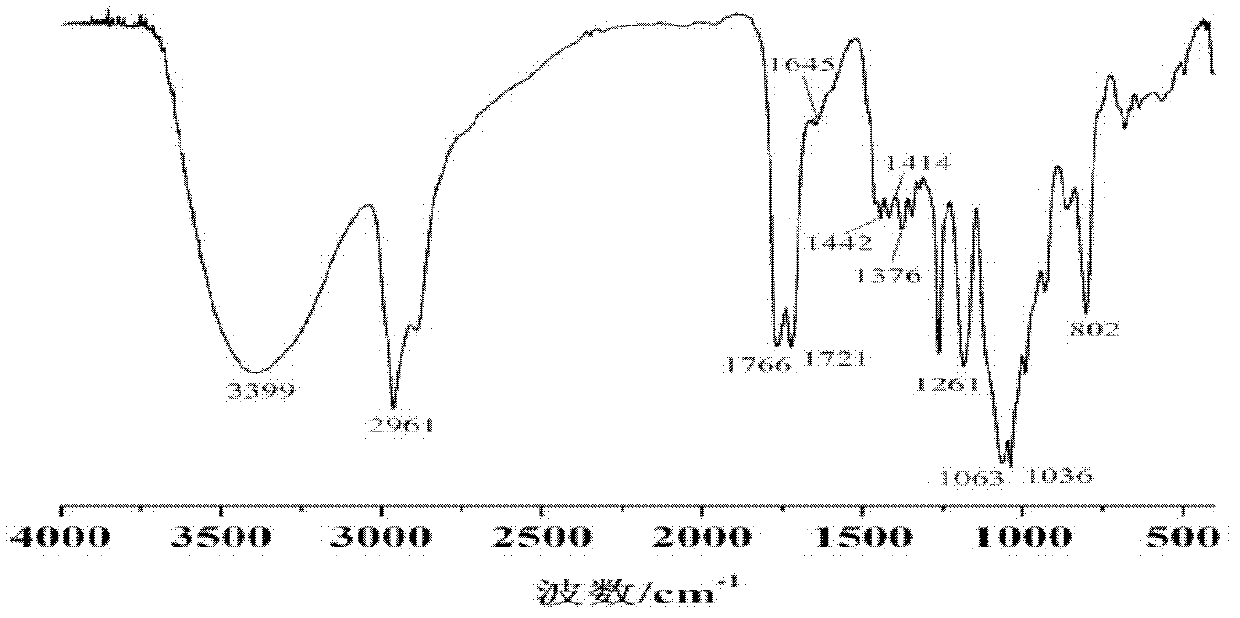

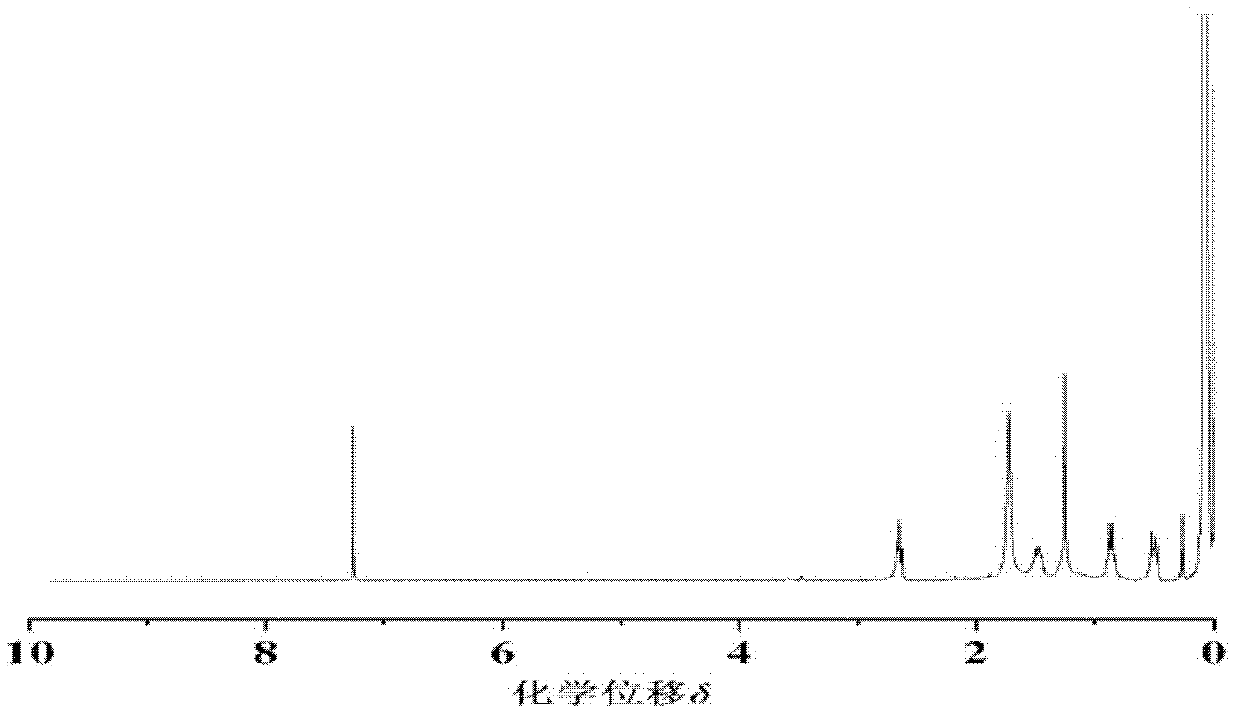

Organosilicon fire retardant for ABS and preparation method thereof

The invention relates to an organosilicon fire retardant for ABS and a preparation method thereof. The invention provides an organosilicon fire retardant for ABS with good consistency with ABS, small mechanical properties influence on ABS, less addition, excellent flame retardation performance and other characteristics and provides a preparation method of the organosilicon fire retardant for ABS.The organosilicon fire retardant of ABS is a polymer. Under a condition of nitrogen protection, dimethyl siloxane cycle, aminosilane, trialkoxy silane and catalyst undergo a reaction with hexamethyldisiloxane as an end-capping reagent at a temperature of 80 to 140 DEG C. After the reaction, a low-boiling-point substance is extracted by pressure reduction and the organosilicon fire retardant product for ABS can be obtained.

Owner:XIAMEN UNIV

Substrate for preparing polyurethane screen with high temperature resistance and moisture and heat resistance

The invention relates to the technical field of polyurethane screens and in particular relates to a substrate for preparing a polyurethane screen with high temperature resistance and moisture and heatresistance. The substrate comprises four main preparation steps of preparation of a dispersion liquid, preparation of a latex mixed liquid, preparation of a composite filler and preparation of a polyurethane substrate. According to the substrate, the composite filler is prepared by using a latex coprecipitation method, moisture in the polyurethane substrate can be effectively absorbed through thehydrophilcity of latex in the filler and is prevented from diffusion, and meanwhile, through the reinforcing function of black carbon white and glass beads, the black carbon white and the glass beadsare modified and mixed with the latex to form the composite filler which is dispersed into polyurethane, so that large internal heat generated inside the polyurethane under a dynamic condition can beeffectively reduced, and properties of high temperature resistance and moisture and heat resistance of the polyurethane can be improved.

Owner:太和县绿源滤材有限公司

Method for preparing polyester fiber reinforced epoxy composite material based on ultraviolet radiation modification

InactiveCN106317786ALittle change in mechanical propertiesRealize the coupling reactionFibre treatmentPolyesterResin matrix

The invention provides a method for preparing a polyester fiber reinforced epoxy composite material based on ultraviolet radiation modification and relates to a resin-matrix composite material. The method comprises the following steps of: grafting active groups including acylamino and carboxyl to the surface of the polyester fiber by virtue of ultraviolet radiation modification; compositing epoxy resin with a polyester fiber fabric by virtue of a vacuum flow guide technique; and curing the resin, thereby obtaining the polyester fiber reinforced epoxy composite material. The method provided by the invention is simple, convenient, free from pollution and practicable.

Owner:TIANJIN POLYTECHNIC UNIV

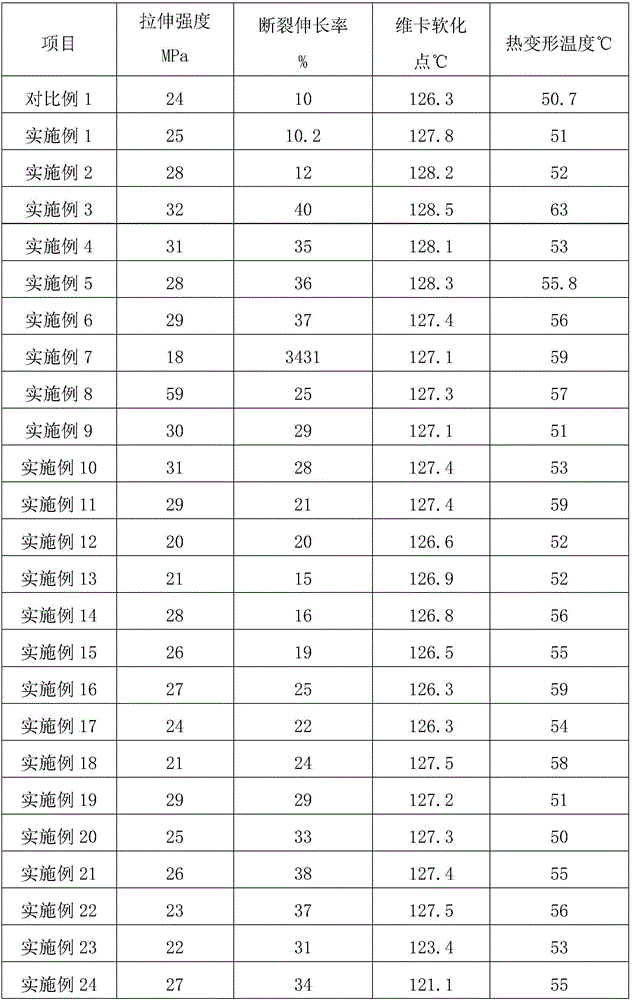

Weather-resistant and flame-retardant polypropylene composite material and preparation method thereof

ActiveCN103275394BGood weather resistanceLittle change in mechanical propertiesPolypropylene compositesPolymer science

The invention discloses a weather-resistant flame-retardant polypropylene composite material which is characterized by comprising 93-97wt% of polypropylene, 1-2wt% of main flame retardant, 0.2-0.5wt% of synergistic flame retardant, 0.1-0.5wt% of chain-cutting agent, 0.1-0.5wt% of foaming agent and 1.5-2wt% of carbon black, and further comprising 0.1-1wt% of other assistants, wherein the other assistants include one or more of antioxidant, dispersant and lubricant; and the carbon black is channel carbon black, and the particle size is 15-25nm. The invention also discloses a preparation method of the weather-resistant flame-retardant polypropylene composite material. According to the invention, the carbon black is selected as weather resistance modifier; the bromine-containing flame retardant, the synergistic flame retardant, the high-temperature chain-cutting agent and the high-temperature foaming agent are combined; the weather-resistant flame-retardant polypropylene composite material is prepared through melt blending; the weather resistance is excellent; the flame retardance is up to UL94V-0 level; the mechanical performance of the material changes little before and after modification; and the weather-resistant flame-retardant polypropylene composite material is low in raw materials and simple and easy to process.

Owner:青岛海科模内装饰有限公司

Modified polyvinyl chloride material and its preparation method

Owner:日丰企业(天津)有限公司

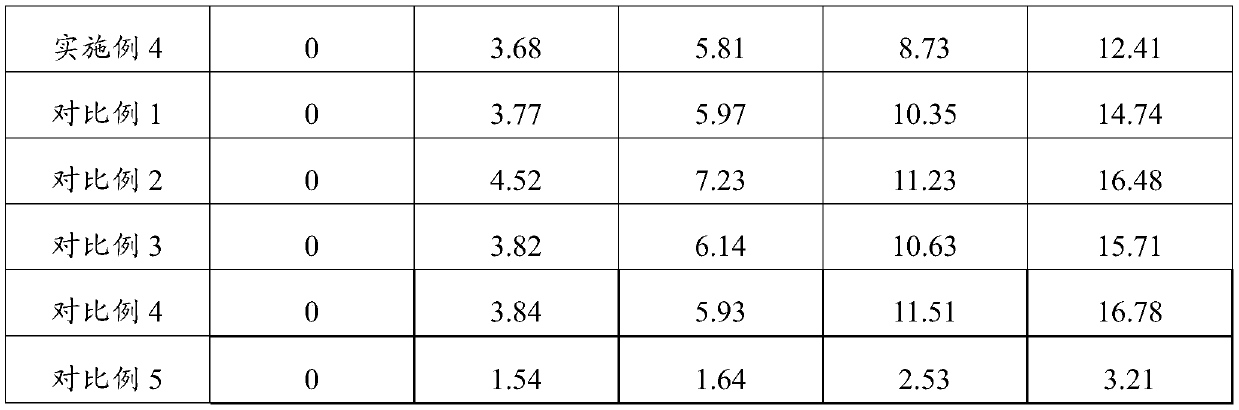

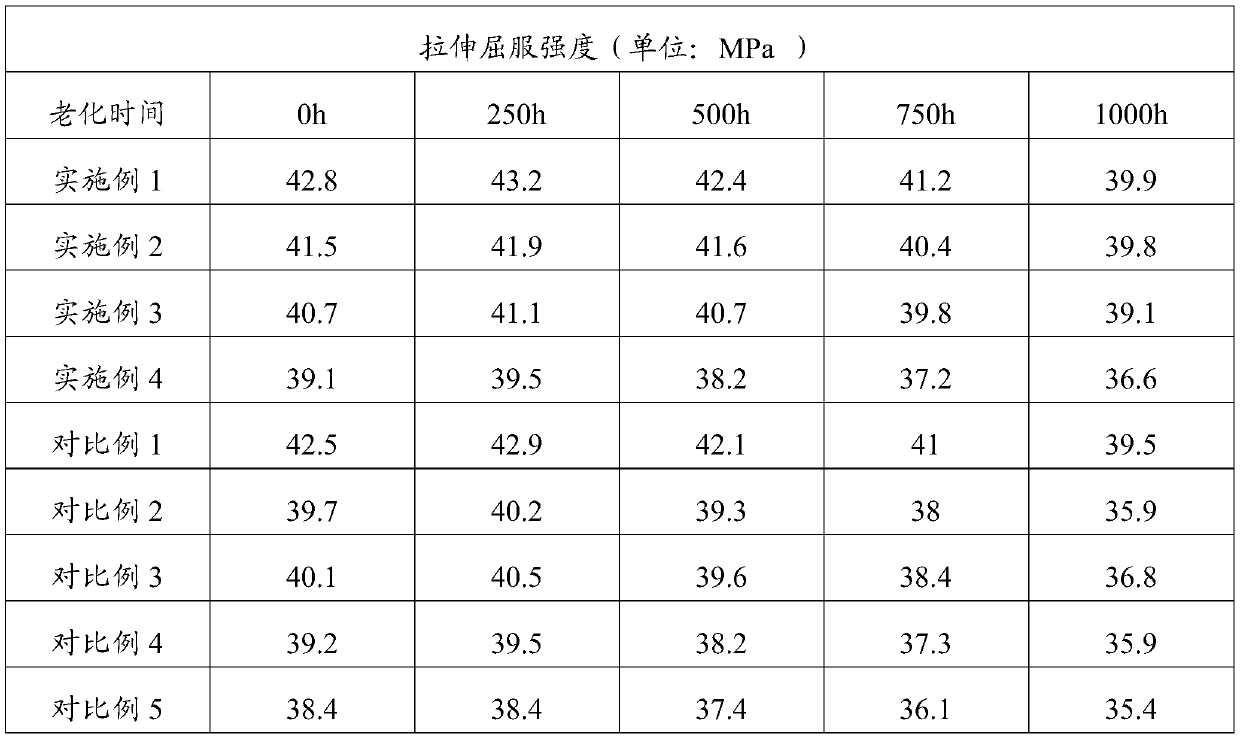

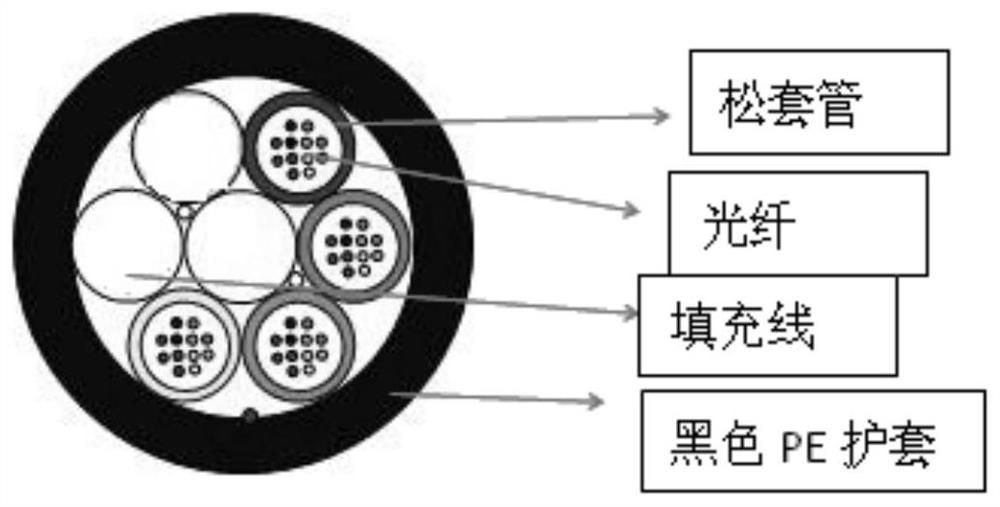

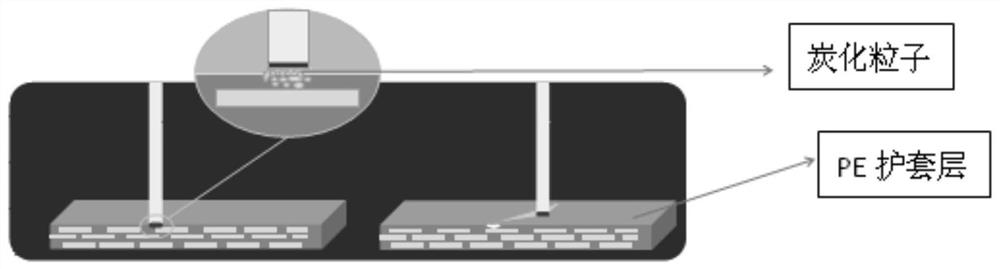

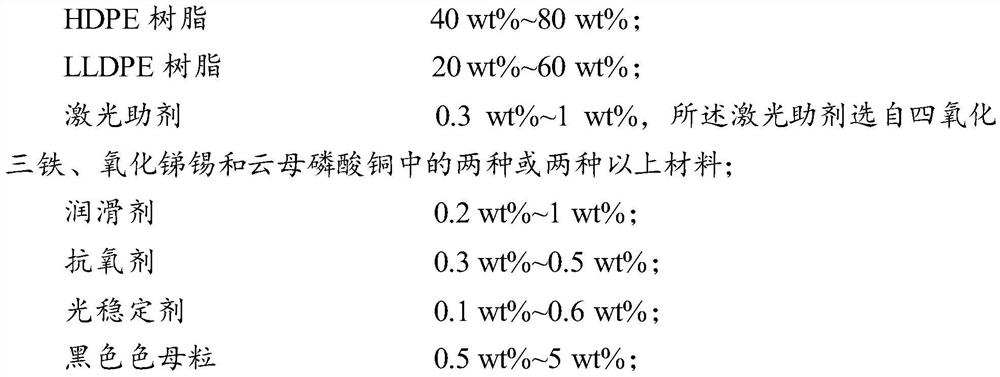

A kind of high-efficiency laser marking material and preparation method thereof

ActiveCN110294883BLittle change in mechanical propertiesReduce carbon black contentDuplicating/marking methodsMasterbatchColored white

The invention provides a high-efficiency laser marking material. In the formula system of the high-efficiency laser marking material provided by the invention, the addition amount of laser auxiliary agent and black color masterbatch plays a leading role in the printing effect. With the increase of additive content and the decrease of carbon black content, the mechanical properties of the material will not change much, but the printing effect will be significantly improved. In addition, the laser additive can help improve the black PE material to absorb the special wavelength emitted by the laser, so that the surface layer of the polymer is carbonized, and through foaming, it appears white, which is in sharp contrast with the black PE sheath.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

A halogen-free flame retardant reinforced pa/pok alloy material resistant to humidity and heat aging

ActiveCN109608878BImprove mechanical propertiesLittle change in mechanical propertiesFiberALUMINUM PHOSPHATE

The invention relates to the field of polymer composite materials, in particular to a halogen-free flame-retardant reinforced PA / POK alloy material resistant to damp heat aging, which consists of the following components in parts by weight: 130-620 parts of PA66, 50-200 parts of POK, glass Fiber 200-350 parts, compatible impact modifier 10-50 parts, halogen-free flame retardant 100-200 parts, flame retardant synergist 10-50 parts, additives 10-20 parts. The alloy material of the present invention adopts aluminum diethyl hypophosphite and polysiloxane compound flame retardancy, the flame retardancy can reach V-0, and has good mechanical properties; the alloy material of the present invention is flame retardant after damp heat aging The resistance can still reach V-0, and the change of mechanical properties is small; the wear coefficient of the alloy material of the present invention is better than that of pure flame-retardant PA66+GF.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

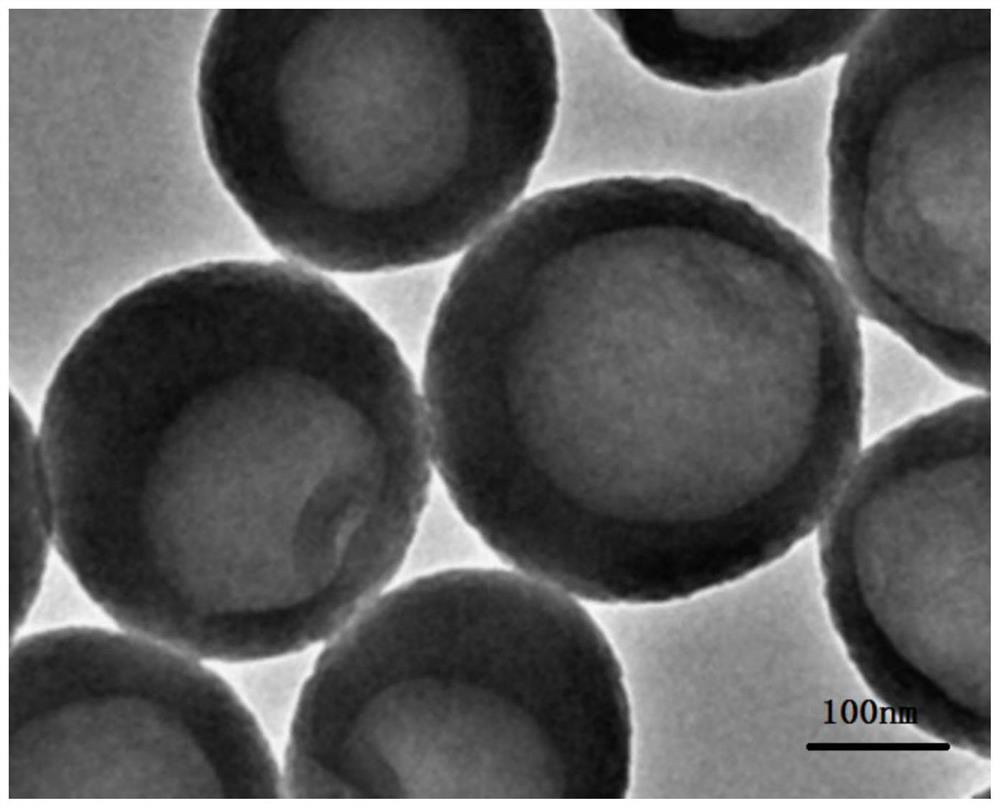

Graphene composite PVC material and preparation method thereof

The invention provides a graphene composite PVC material and a preparation method thereof, and belongs to the technical field of PVC materials. Comprising the following raw materials in parts by weight: 7-12 parts of porous graphene hollow microspheres, 70-100 parts of PVC resin, 1-2 parts of a compatilizer, 0.5-1 part of an antioxidant, 0.2-0.5 part of monoglyceride, 5-10 parts of a plasticizer and 1-3 parts of a heat stabilizer. According to the invention, the compatibility of the inorganic porous graphene hollow microspheres in PVC resin is improved, so that the mechanical properties of the PVC plastic are not greatly changed, the antistatic property of the PVC plastic is greatly improved due to good conductivity of graphene, and the preparation method is simple, wide in raw material source and wide in application prospect.

Owner:杭州耕鑫生物科技有限公司

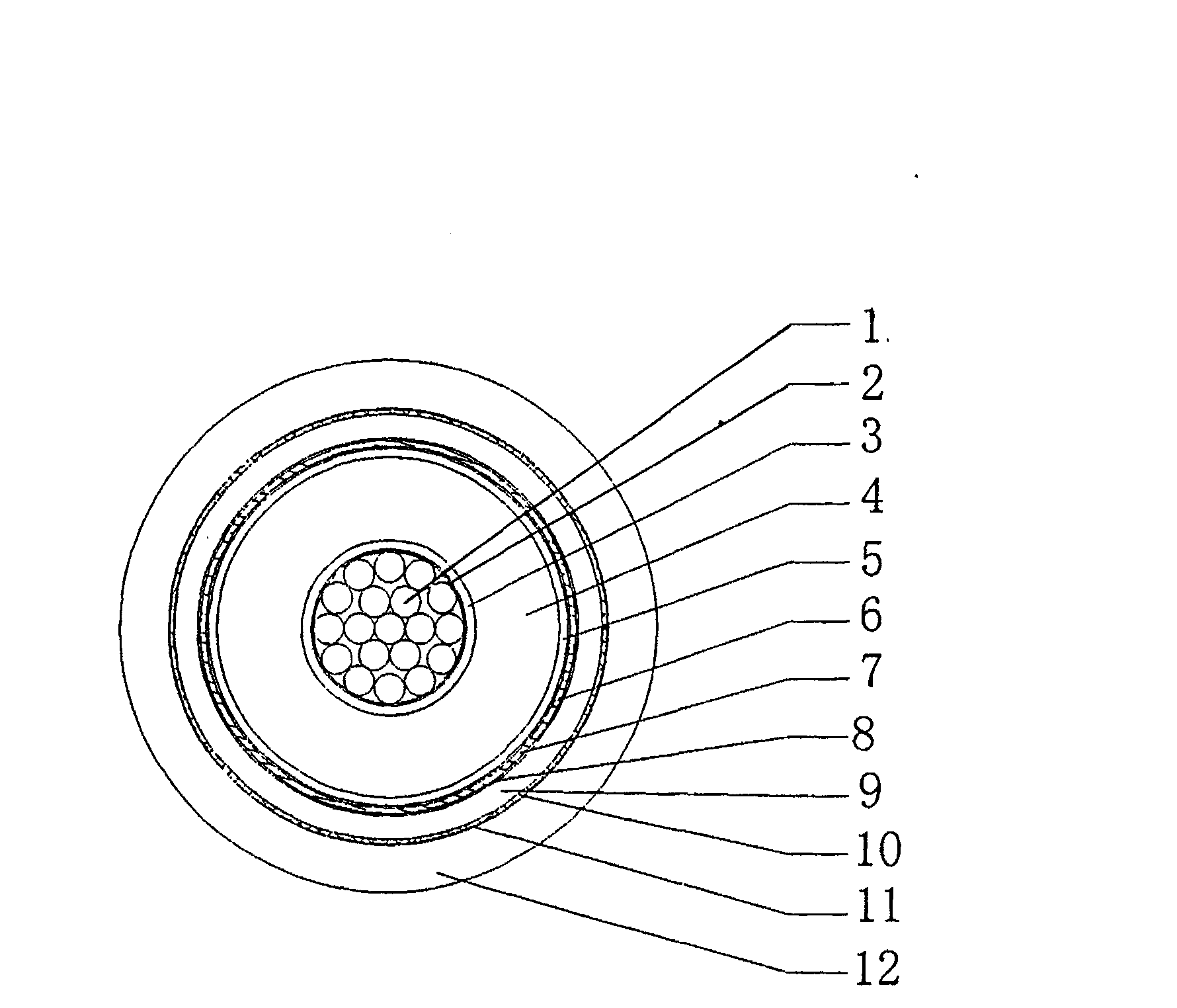

Ethylene propylene rubber insulated non-stick sheath electrical hand cable with 10kV rated voltage

ActiveCN100530446CImprove waterproof performanceMake up for the shortcomings of relatively poor mechanical strengthRubber insulatorsPlastic/resin/waxes insulatorsElectrical conductorPower cable

The present invention relates to a rated voltage 10kV ethylene-propylene rubber insulated and non-sticky sheathed power flexible cable, which includes a conductor, a semi-conductive nylon tape A is arranged outside the conductor, and a conductor shielding layer is provided between the semi-conductive nylon tape A and the rubber insulating layer , an insulating shielding layer is provided between the rubber insulating layer and B semiconducting nylon tape, an inner sheath is provided outside the insulating shielding layer through B semiconducting nylon tape and C semiconducting nylon tape, and a water blocking tape is provided outside the inner sheath There is an outer sheath, which is characterized in that there is a tinned annealed copper wire braided shielding layer between the B semi-conductive nylon tape and the C semi-conductive nylon tape, and a nylon wire braided shield is provided between the inner sheath and the water-blocking tape layer, and the outer sheath is a chlorosulfonated polyethylene rubber outer sheath mixed with melted polytetrafluoroethylene. The invention has the advantages of good flexibility and excellent waterproof and surface salt preventing properties of the sheath.

Owner:SHANGHAI NANDA GROUP

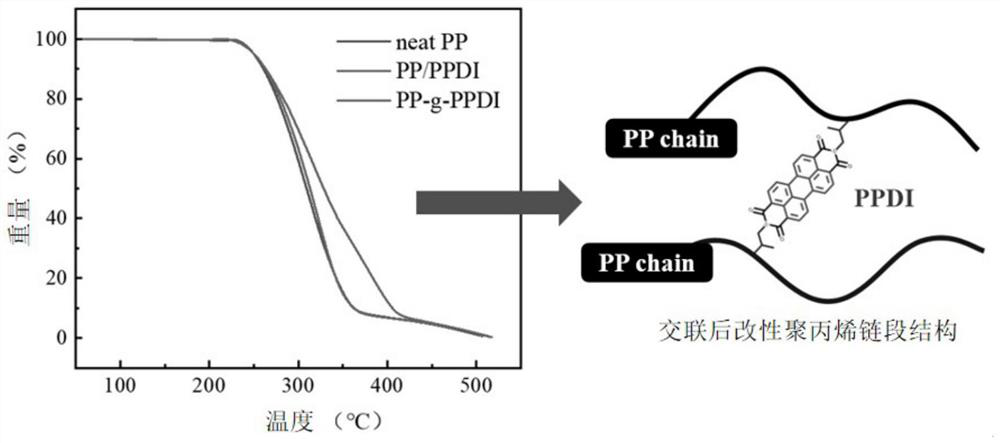

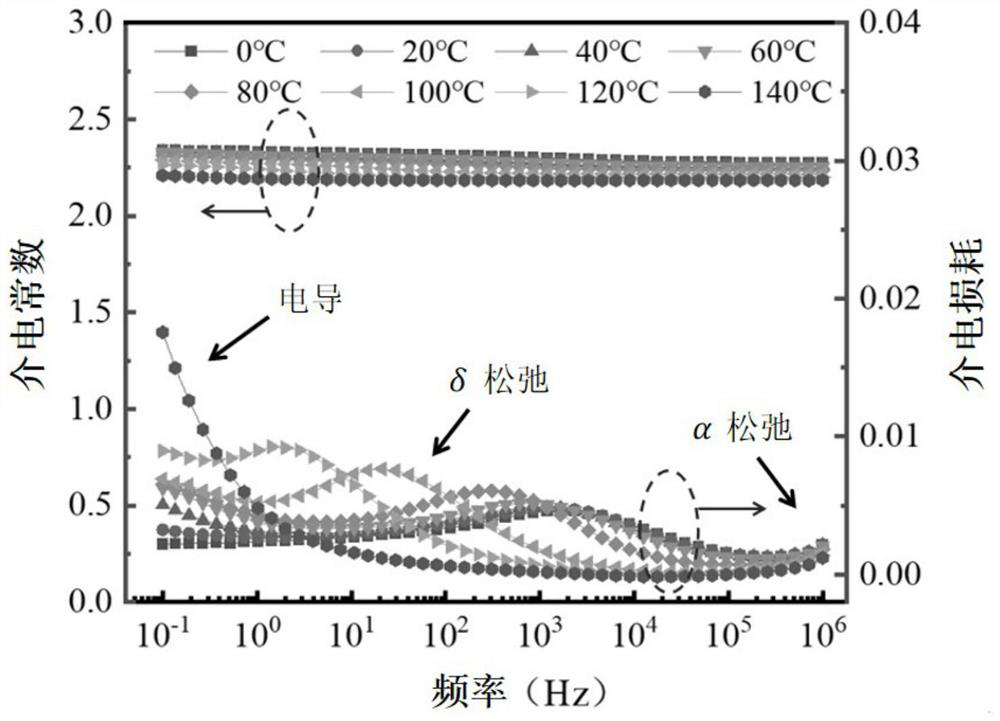

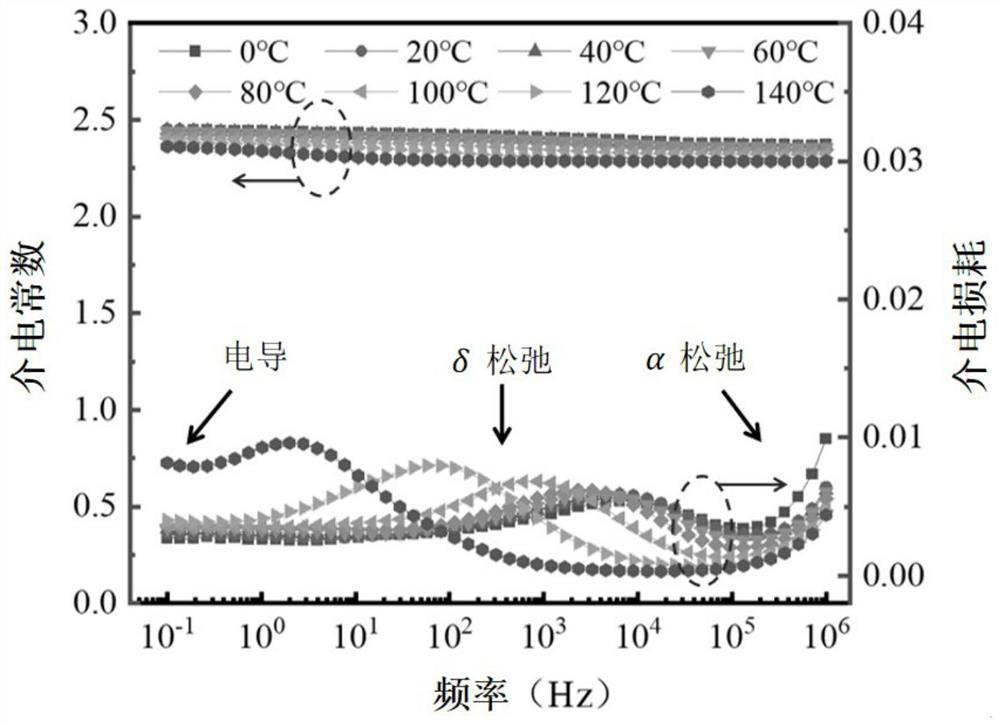

Preparation method of perylene-3, 4, 9, 10-tetracarboxylic dianhydride grafted modified polypropylene film

ActiveCN114395149ALow dielectric constantImprove high temperature resistancePerylenetetracarboxylic dianhydridePolypropylene

The invention discloses a preparation method of a perylene-3, 4, 9, 10-tetracarboxylic dianhydride grafted modified polypropylene film, and the method comprises the following steps: weighing a first predetermined mass fraction of perylene-3, 4, 9, 10-tetracarboxylic dianhydride, and dissolving the perylene-3, 4, 9, 10-tetracarboxylic dianhydride in a non-polar organic solvent under a continuous first stirring condition to obtain a long-term stable PPDI solution at room temperature; weighing a second predetermined mass fraction of 2-methylallylamine, and dissolving the 2-methylallylamine in the PPDI solution under a continuous second stirring condition to react to obtain a PPDI alkenylation solution; weighing the alkenylated PPDI powder, an initiator and polypropylene in a third predetermined mass fraction, and dissolving in a non-polar organic solvent; adding a predetermined amount of acetone solution into the perylene-3, 4, 9, 10-tetracarboxylic dianhydride grafted polypropylene solution under the condition of ice-water bath to separate out solid product crystals; and carrying out hot pressing on the powdery solid PP-g-PPDI to obtain a film-shaped sample so as to obtain the N-type molecular semiconductor grafted modified polypropylene film.

Owner:XI AN JIAOTONG UNIV

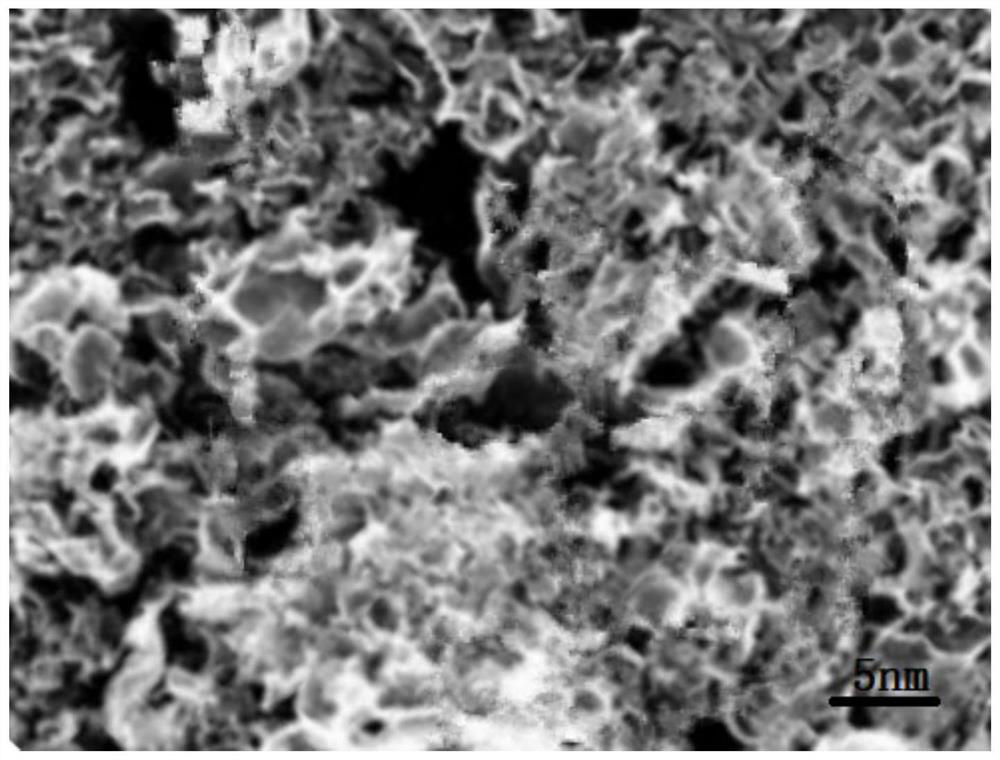

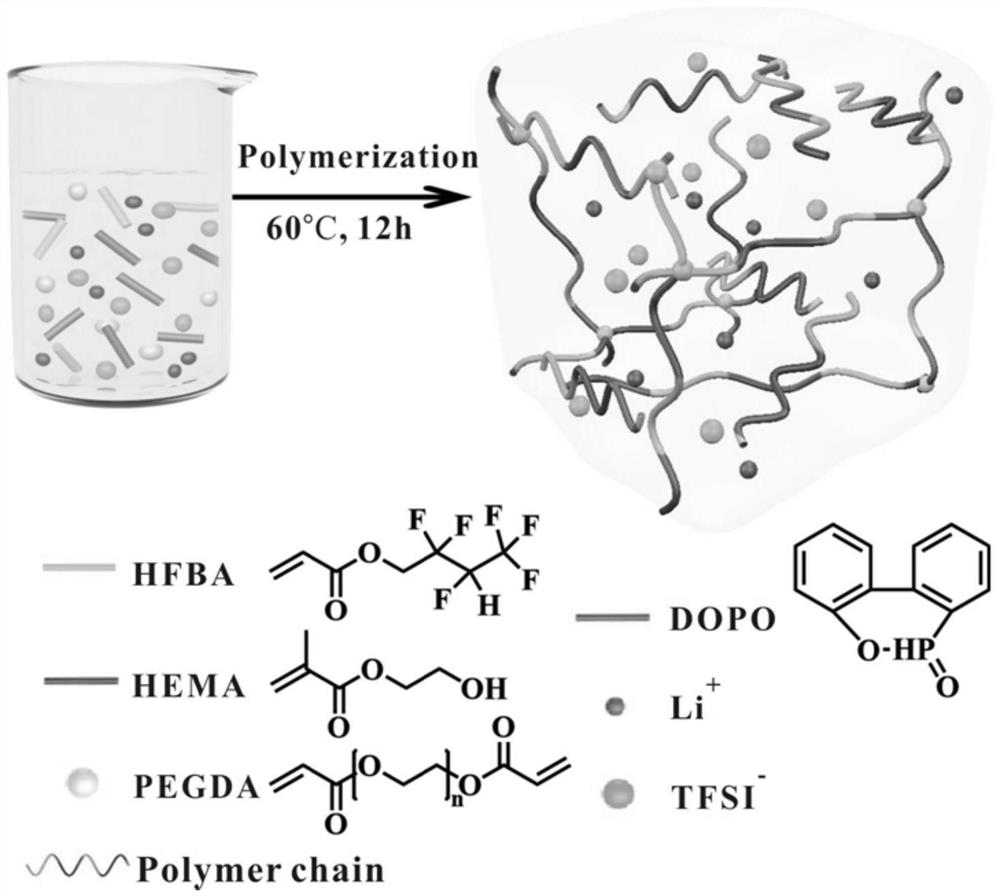

A kind of supercapacitor based on gel polymer electrolyte and preparation method thereof

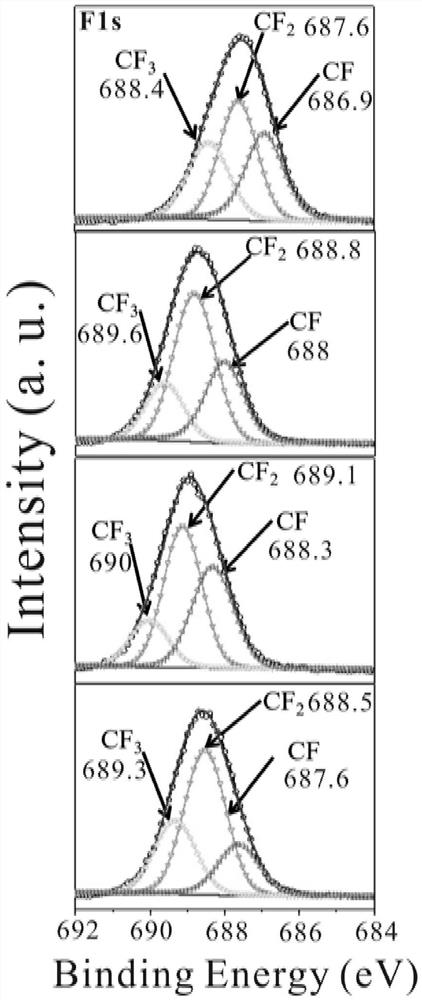

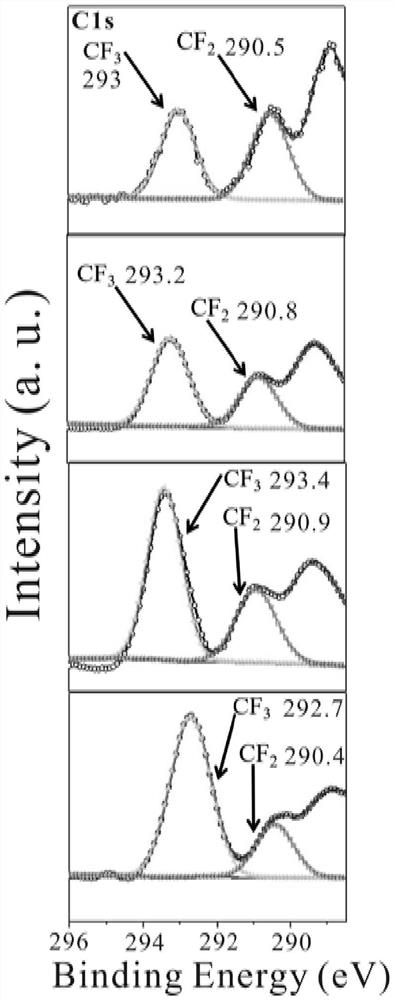

ActiveCN113035583BImprove low temperature toleranceImprove conductivityHybrid capacitor electrolytesHybrid/EDL manufactureCapacitanceElectrical conductor

The invention belongs to the field of energy storage, and relates to a high-performance all-solid-state supercapacitor based on a gel polymer electrolyte and a preparation method thereof. The supercapacitor includes electrodes and a gel polymer electrolyte between the electrodes. The flame retardant gel polymer electrolyte, including gel polymer and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI), lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) in ionic form Exist in gel polymer. Poly(HFBA 8 ‑co‑HEMA 1 ) Electrolyte-based SC electrodes retain 76% of their mass specific capacitance after 8000 cycles; gel-based SCs remain essentially unchanged under multiple bending cycles. Gel-based SCs have good low-temperature tolerance and can function well in the temperature range from ‑20 °C to 60 °C. The multiple advantages of gel electrolytes expand their applications in ion conductors and energy storage devices, and solve the shortcomings of traditional liquid electrolytes due to their volatility, flammability, and easy leakage.

Owner:QILU UNIV OF TECH

A kind of organosilicon modified thermoplastic polyurethane elastomer and preparation method thereof

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com