Ethylene propylene rubber material for sealing part of automobile heat dissipation system and production method of ethylene propylene rubber material

A technology of ethylene-propylene rubber and heat dissipation system, which is applied in the field of rubber, can solve the problems of short aging time of rubber seals, achieve the effects of reducing the consumption of spare parts, excellent high temperature resistance, and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

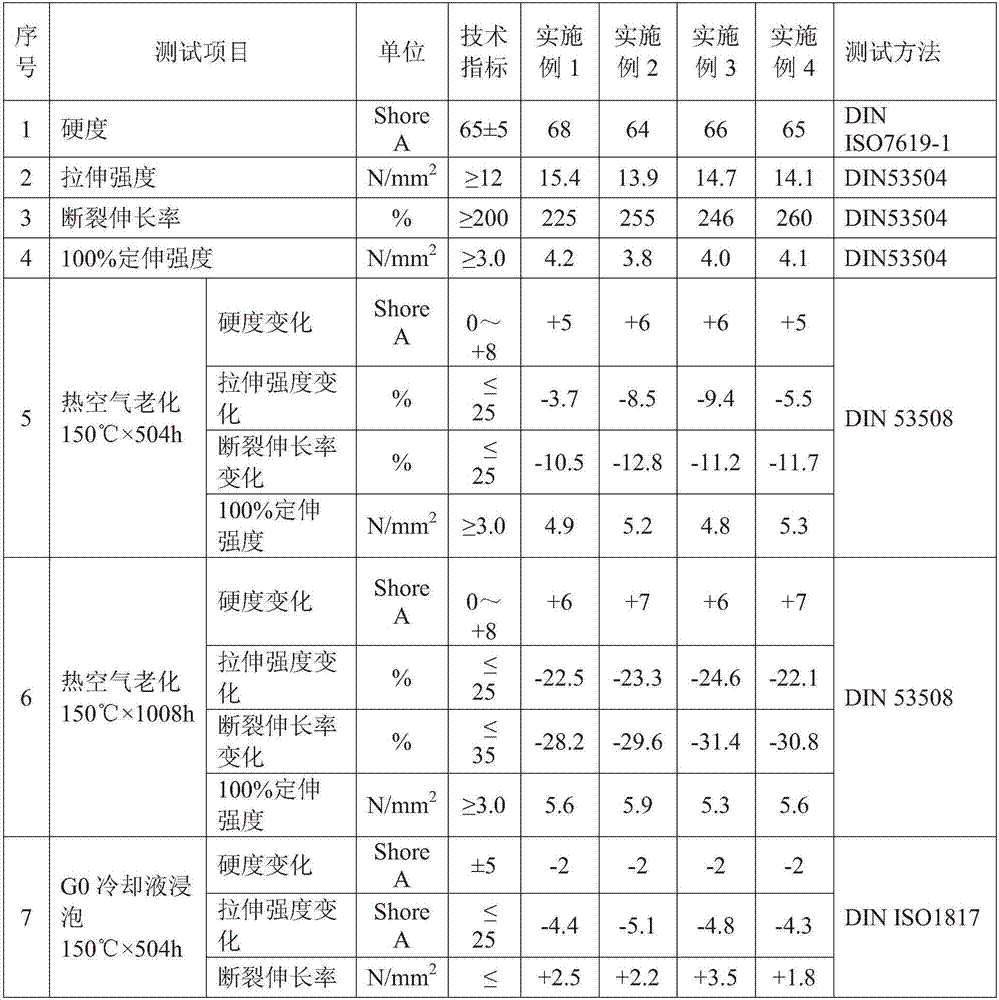

Examples

Embodiment 1

[0040] A kind of ethylene-propylene rubber material for automobile cooling system seals of the present embodiment comprises the following components by weight: ethylene-propylene rubber raw rubber: 100 parts, zinc oxide: 5 parts, stearic acid: 0.5 parts, anti-aging agent RD : 0.5 parts, anti-aging agent 445: 1.5 parts, anti-aging agent ZMTI: 1.0 parts, fast extrusion carbon black N550: 30 parts, semi-reinforcing carbon black N774: 10 parts, cross-linking aid Ricon 153D: 7 parts, vulcanizing agent Perkadox 14-40B-GR: 5 parts.

[0041] A kind of production method step of the ethylene-propylene rubber material of the automobile cooling system seal of the present embodiment is:

[0042] Step S101, masterbatch mixing: prepare materials according to the above formula, send all raw materials except the crosslinking aid Ricon 153D and vulcanizing agent Perkadox 14-40B-GR into the internal mixer for internal mixing to obtain the masterbatch ;

[0043] Step S102, adding vulcanization ...

Embodiment 2

[0046] A kind of ethylene-propylene rubber material for automobile cooling system seals of the present embodiment comprises the following components by weight: 100 parts of ethylene-propylene rubber raw rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 0.67 parts of anti-aging agent RD, 4452 parts of anti-aging agent, 1.33 parts of anti-aging agent ZMTI, 20 parts of fast extrusion carbon black N55020 parts, semi-reinforcing carbon black N77420 parts, 3.5 parts of cross-linking aid Ricon 153D, 8.5 parts of vulcanizing agent Perkadox 14-40B-GR.

[0047] A kind of production method step of the ethylene-propylene rubber material of the automobile cooling system seal of the present embodiment is:

[0048] Step S101, masterbatch mixing: prepare materials according to the formula described in claim 1, and send all raw materials except the crosslinking aid Ricon153D and the vulcanizing agent Perkadox 14-40B-GR into an internal mixer for internal mixing to obtain masterbatch; ...

Embodiment 3

[0052] A kind of ethylene-propylene rubber material for automobile cooling system seals of the present embodiment comprises the following components by weight: 100 parts of ethylene-propylene rubber raw rubber, 5 parts of zinc oxide, 1.0 part of stearic acid, and 1.0 part of antioxidant RD , anti-aging agent 445 3.0 parts, anti-aging agent ZMTI 2.0 parts, fast extrusion carbon black N550 25 parts, semi-reinforcing carbon black N774 15 parts, cross-linking aid Ricon 153D 5 parts, vulcanizing agent Perkadox 14-40B-GR 7 parts.

[0053] A kind of production method step of the ethylene-propylene rubber material of the automobile cooling system seal of the present embodiment is:

[0054] Step S101, masterbatch mixing: prepare materials according to the formula described in claim 1, and send all raw materials except the crosslinking aid Ricon153D and the vulcanizing agent Perkadox 14-40B-GR into an internal mixer for internal mixing to obtain masterbatch;

[0055] Step S102, adding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com