Flexible composite lining pipe material

A lined pipe, flexible technology, applied in the field of industrial application of polymer materials, can solve the problems of not being able to cross the elbow, the influence of mechanical properties, and the small repair distance at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

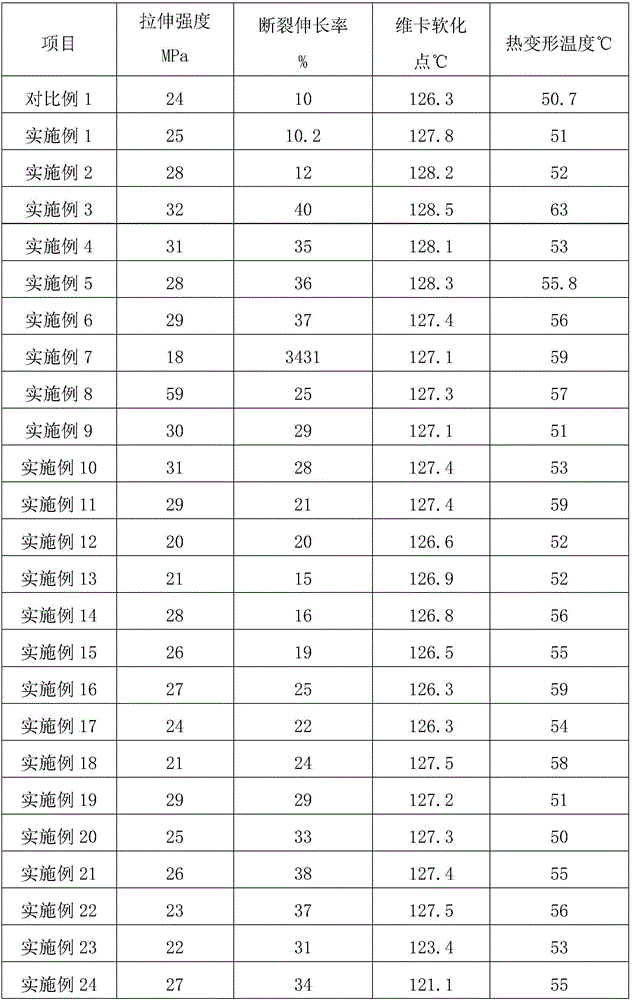

[0071] 100 parts by weight of high-density polyethylene and 5 parts by weight of nano-zinc oxide, 3 parts by weight of talcum powder, 15 parts by weight of nylon 6, and 5 parts by weight of high-density polyethylene grafted with maleic anhydride are blended, and melt extruded through an extruder The injection molding machine was injected into samples, and the performance test of the samples was carried out. The experimental test results are shown in Table 1.

Embodiment 2

[0073] 100 parts by weight of high-density polyethylene and 5 parts by weight of nano-zinc oxide, 4 parts by weight of montmorillonite, 10 parts by weight of nylon 6, and 8 parts by weight of high-density polyethylene grafted with maleic anhydride are blended, and melted through an extruder Extrusion, injection molding machine for injection molding into samples, performance test of the samples, the experimental test results are shown in Table 1.

Embodiment 3

[0075] 100 parts by weight of high-density polyethylene and 5 parts by weight of nano-zinc oxide, 5 parts by weight of sepiolite, 5 parts by weight of nylon 6, and 10 parts by weight of high-density polyethylene grafted with maleic anhydride are blended and melted through an extruder Extrusion, injection molding machine for injection molding into samples, performance test of the samples, the experimental test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com