Environmental-friendly polyvinyl chloride (PVC) extraction-resistant anti-seepage film and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of environmentally friendly polyvinyl chloride anti-penetration anti-penetration membrane and its preparation, which can solve the problem of anti-penetration membrane resistance to low-temperature cracking, hardening of plasticizer extraction, and changes in mechanical properties and other problems, to achieve the effects of small change in mechanical properties, improved extraction resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

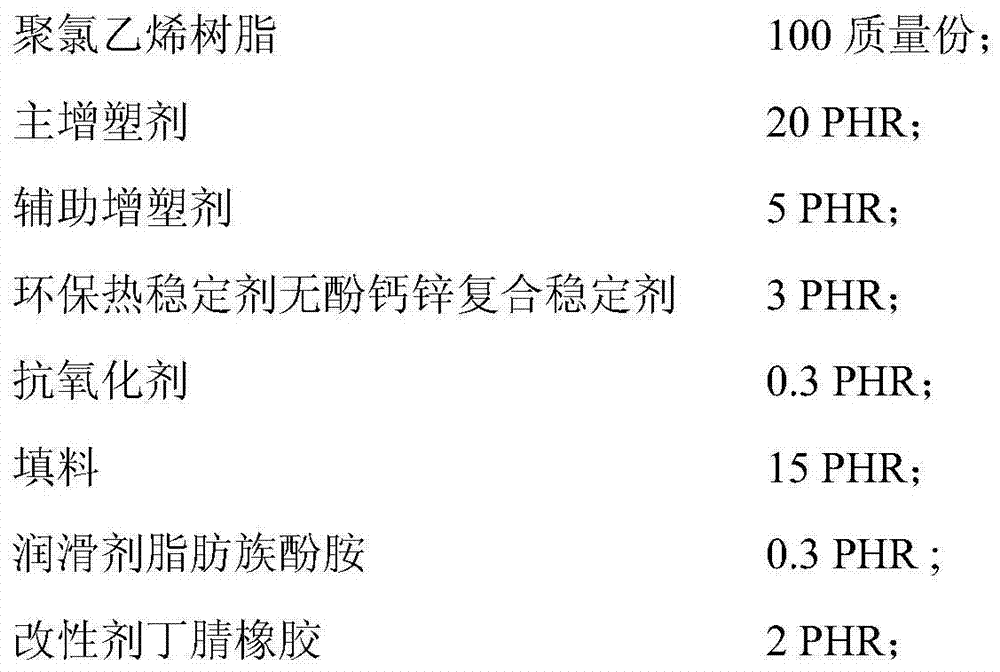

[0048] An environmentally friendly polyvinyl chloride anti-pumping and anti-permeation membrane, comprising the distribution ratio of each component is

[0049]

[0050]Among them, the polyvinyl chloride resin is a mixture of SG-3 polyvinyl chloride with a degree of polymerization of 1300 and a degree of polymerization of 2500 in an equal weight ratio; the main plasticizer is a mixture of phthalic acid and trioctyl trimellitate. More preferably DOP and TOTM are mixed in equal weight ratio; auxiliary plasticizer is fatty acid dibasic acid ester and epoxy plasticizer, more preferably dioctyl adipate or dioctyl sebacate and epoxy soybean oil in equal weight ratio Mixing; the antioxidant is compounded with 2-hydroxy-4-n-octyloxybenzophenone and Doverphos DP-613 in an equal weight ratio; the filler is a mixture of activated calcium carbonate, talcum powder and carbon black, more preferably activated by a coupling agent The activated calcium carbonate is mixed with talcum powder,...

Embodiment 2

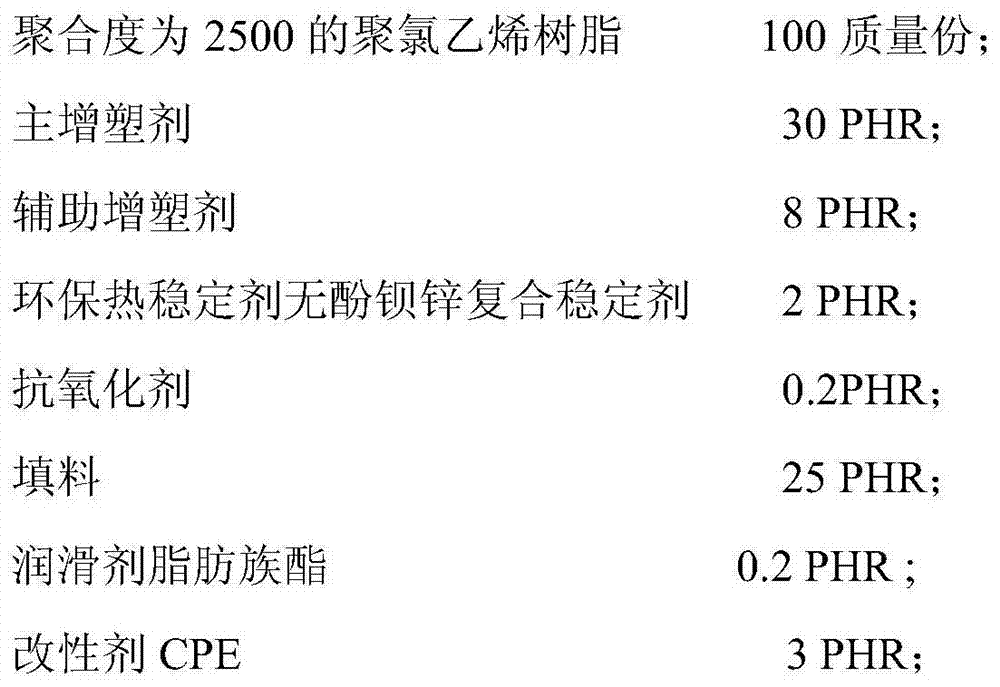

[0052] An environmentally friendly polyvinyl chloride anti-pumping and anti-permeation membrane, comprising the distribution ratio of each component is

[0053]

[0054] The main plasticizer is a mixture of phthalic acid and trioctyl trimellitate, more preferably DOP and TOTM are mixed in equal weight ratios; the auxiliary plasticizer is fatty acid dibasic acid ester and epoxy plasticizer, more preferably Dioctyl adipate or dioctyl sebacate and epoxidized soybean oil are mixed in equal weight ratio; antioxidant is compounded in equal weight ratio of 2-hydroxy-4-n-octyloxybenzophenone and Doverphos DP-613 ; The filler is mixed with active calcium carbonate, talcum powder and carbon black in equal weight ratios.

Embodiment 3

[0056] A method for preparing an environmental-friendly polyvinyl chloride extraction-resistant anti-penetration membrane, comprising the following steps:

[0057] (1) Kneading material preparation: After automatic metering of polyvinyl chloride resin, plasticizer, heat stabilizer, filler, antioxidant, lubricant and modifier, carry out high-speed mixing, and transfer to cold stirring after high-speed mixing to cool; When preparing the kneading material, the high-speed mixing termination temperature is 80-120°C, preferably 90-115°C; the cold stirring termination temperature is 20-60°C, preferably 35-45°C.

[0058] (2) Plasticization: Feed the mixture obtained in step (1) into a planetary extruder for plasticization; during plasticization, the temperature in each zone of the planetary extruder is 140-200°C, preferably 150-180°C, and the extrusion speed It is 20-70 rev / min, preferably 40-60 rev / min;

[0059] (3) Calendering: Put the fully plasticized material obtained in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com