Impact-erosion resistant marine concrete dual-ash gelling powder and preparation method and device thereof

A marine concrete and anti-abrasion technology, applied in the field of cementitious materials, can solve the problems of poor anti-abrasion ability, achieve good anti-cracking and anti-abrasion ability, improve cold and heat resistance and corrosion resistance, and resist seawater penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

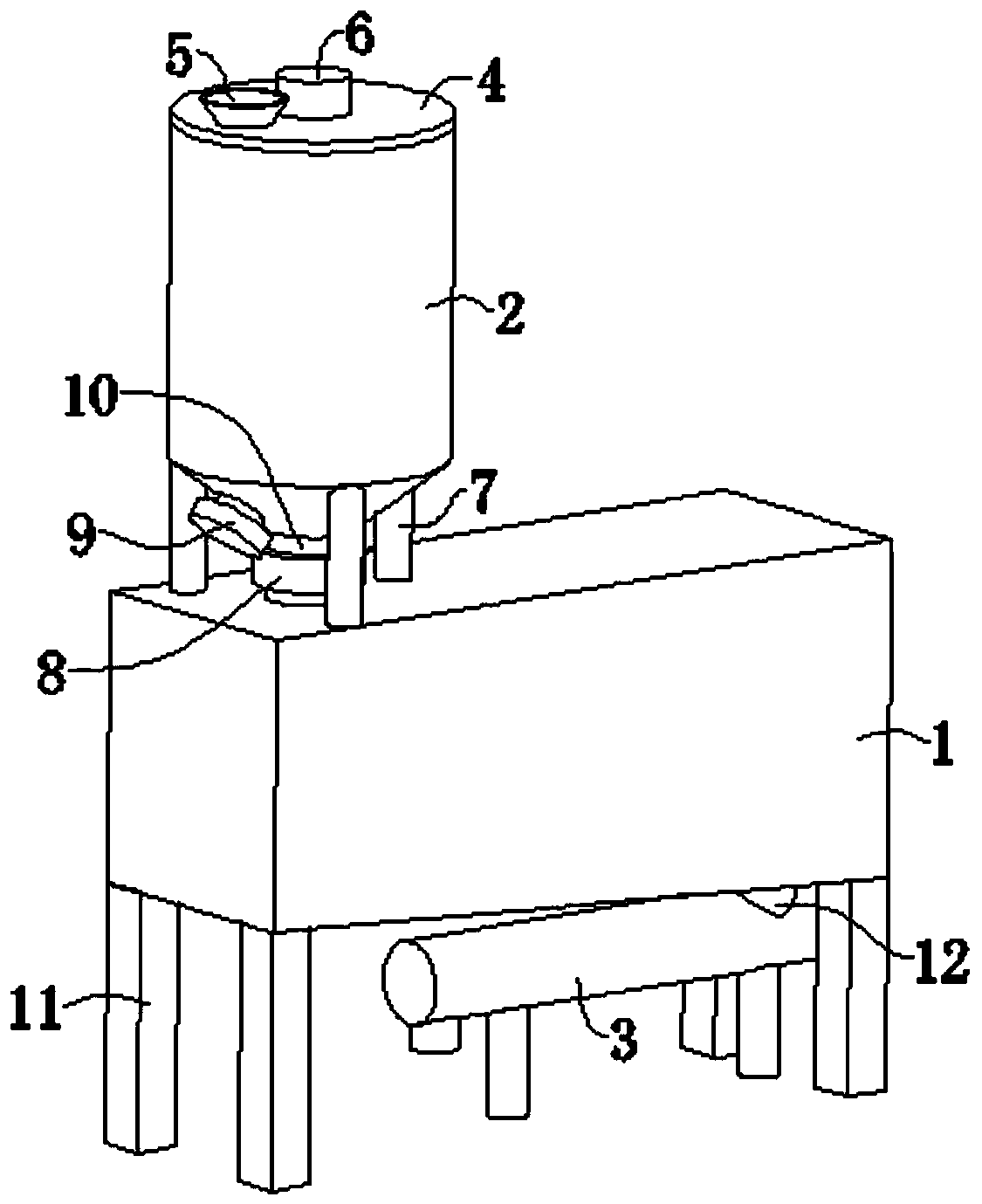

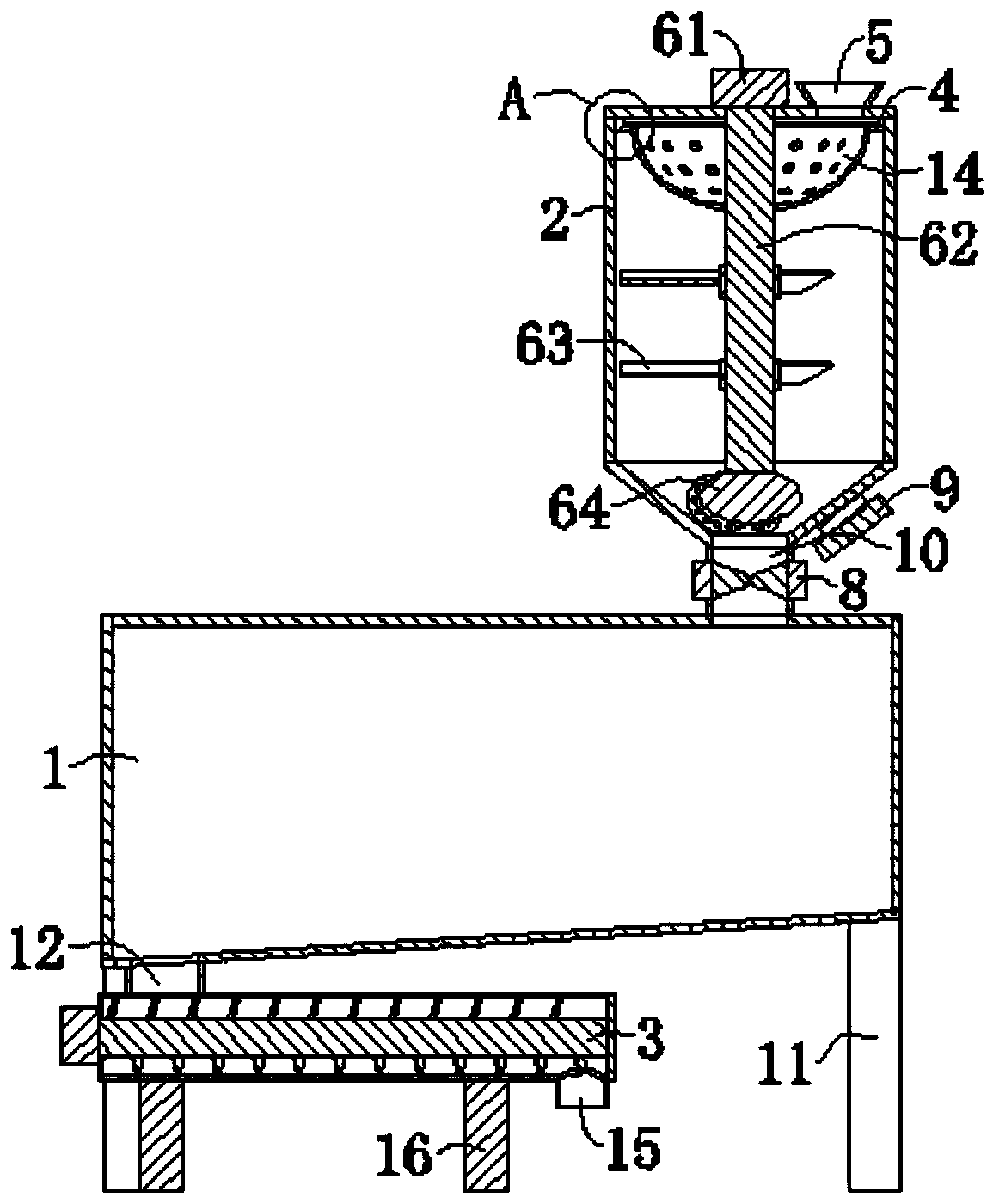

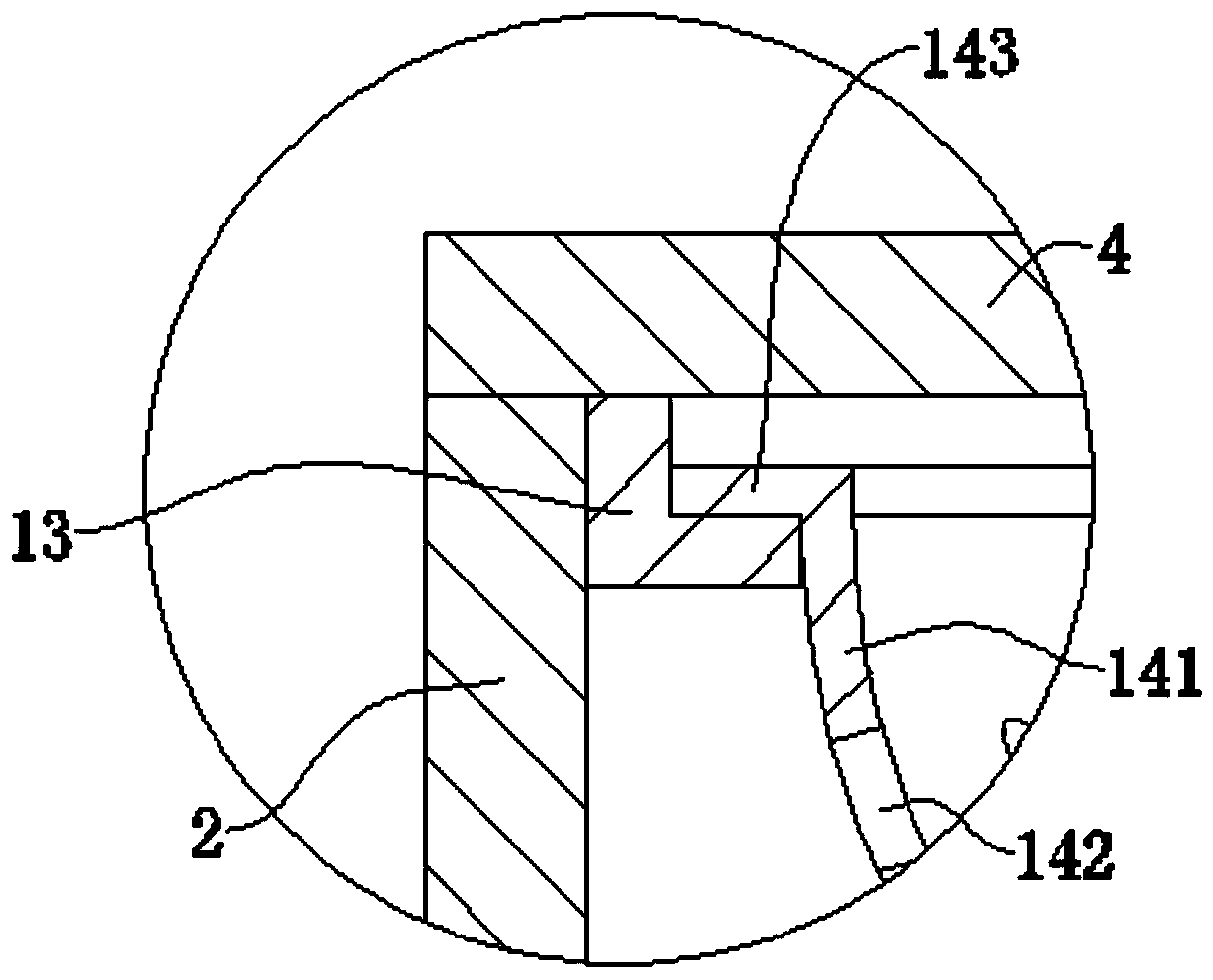

Method used

Image

Examples

Embodiment 1

[0051] Example 1: A scour-resistant marine concrete double-ash cementitious powder and its preparation method and device. The double-ash cementitious powder includes the following raw material components and parts by weight:

[0052] Cement 35kg;

[0053] Furnace steel ash 18kg;

[0054] Slag 15kg;

[0055] Silica fume 16kg;

[0056] Expanded graphite 3kg;

[0057] Ceramic powder 3kg;

[0058] Rubber powder 8kg;

[0059] Anti-rust powder 1kg.

[0060] The fineness of expanded graphite is 600-900 mesh. The specific surface area of slag is 488m 2 / kg, the density is 2.86g / cm 3 .

[0061] The preparation method of double gray gelled powder, comprises the following steps:

[0062] S1, material preparation: according to the parts by weight of the above-mentioned double ash gelatinized powder raw material components, weigh each raw material component;

[0063] S2: Preparation of base material: Place cement, furnace steel ash, slag and silica fume in a mixing and stirrin...

Embodiment 2

[0078] Embodiment 2: A kind of scour-resistant marine concrete double-ash cementitious powder and its preparation method and device. The difference from Example 1 is that the double-ash cementitious powder includes the following raw material components and parts by weight:

[0079] Cement 30kg;

[0080] Furnace steel ash 15kg;

[0081] Slag 12kg;

[0082] Silica fume 15kg;

[0083] Expanded graphite 2kg;

[0084] Ceramic powder 2kg;

[0085] Rubber powder 5kg;

[0086] Anti-rust powder 0.5kg.

Embodiment 3

[0087] Example 3: A scour-resistant marine concrete double-ash cementitious powder and its preparation method and device. The difference from Example 1 is that the double-ash cementitious powder includes the following raw material components and parts by weight:

[0088] Cement 40kg;

[0089] Furnace steel ash 25kg;

[0090] Slag 20kg;

[0091] Silica fume 18kg;

[0092] Expanded graphite 5kg;

[0093] Ceramic powder 5kg;

[0094] Rubber powder 12kg;

[0095] Anti-rust powder 1.8kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com