Patents

Literature

42results about How to "Improves resistance to sulfate attack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

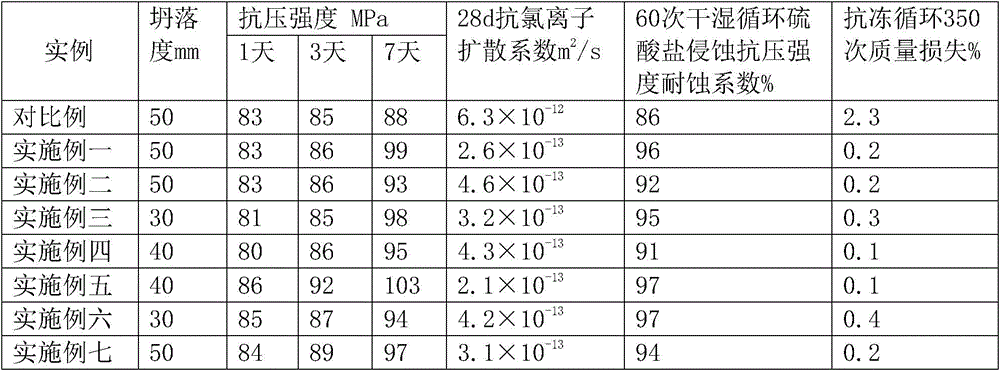

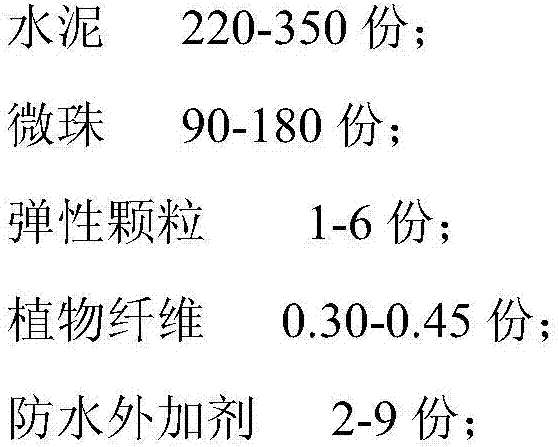

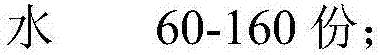

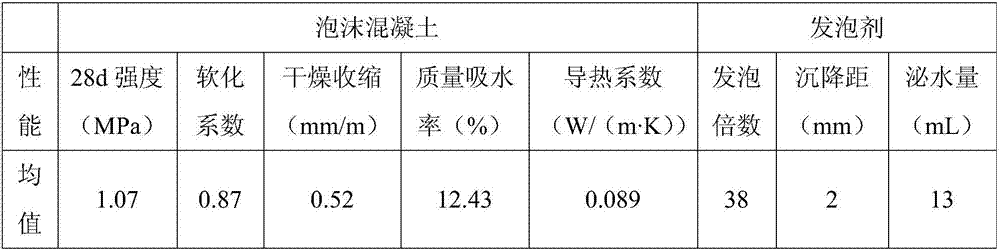

Waterproof crack-resistant foam concrete and manufacture method

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Magnesian sulphoaluminate cement, and method of preparing sheet material with the cement and fiber-reinforced composite material

InactiveCN105130228AReduce alkalinityEfficient use ofSolid waste managementAluminateAluminum sulphate

The invention relates to magnesian sulphoaluminate cement, and a method of preparing a sheet material with the cement and a fiber-reinforced composite material, and belongs to the technical field of magnesian cement formulas and products. The magnesian sulphoaluminate cement mainly includes the following raw materials: light-burned magnesium oxide, magnesium sulfate, aluminum sulfate, calcined bauxite and water. The invention, compared with the prior art, has following beneficial effects: 1) the cement is high in strength; 2) the cement is low in alkali degree; 3) low-grade bauxite can be utilized so that a novel approach is developed for effective utilization and reasonable allocation of resources; 4) the cement is long in service life; and 5) the magnesian sulphoaluminate cement can be composited with plant fiber directly.

Owner:谌萌 +1

Seepage-scouring-resistant concrete and preparation method thereof

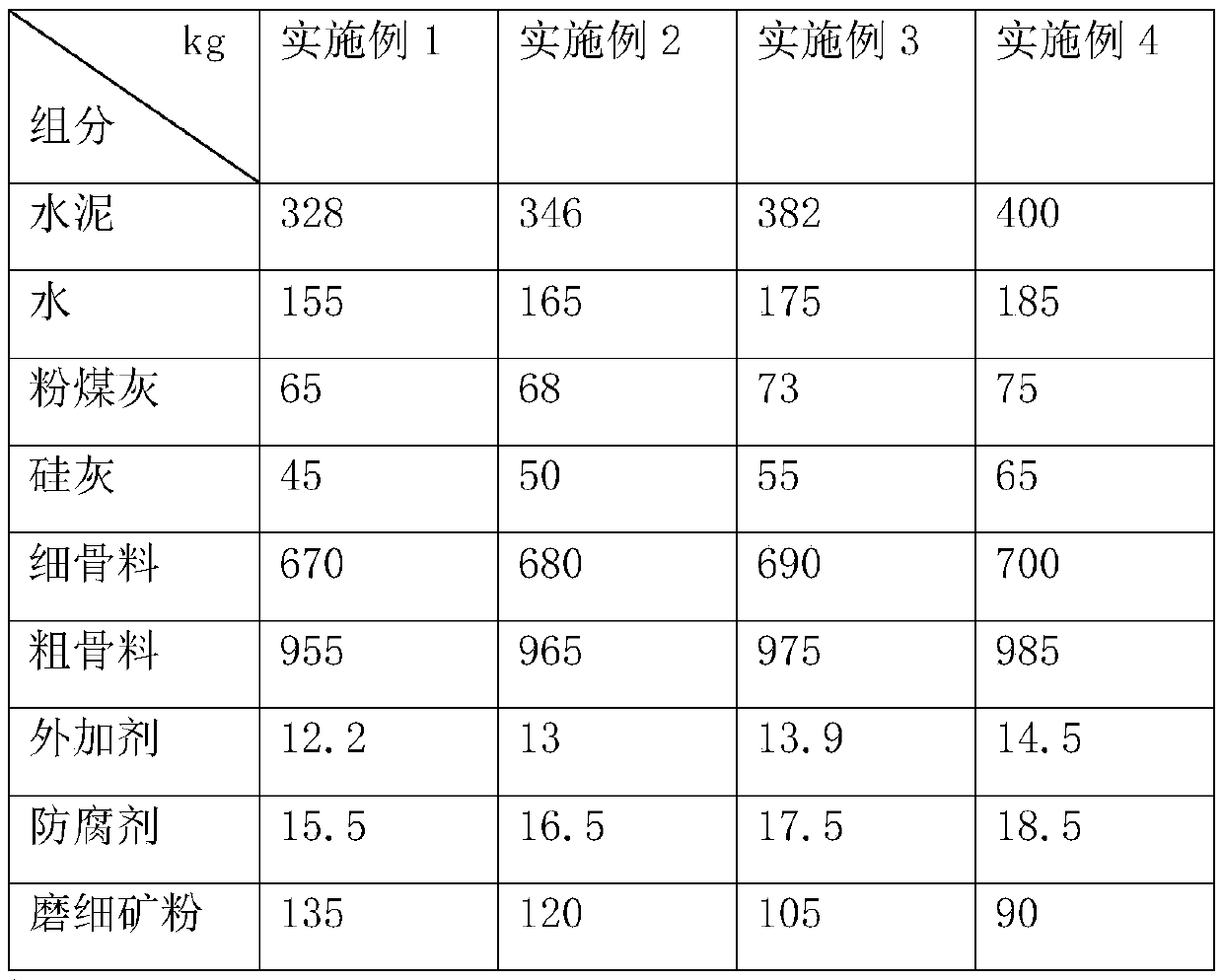

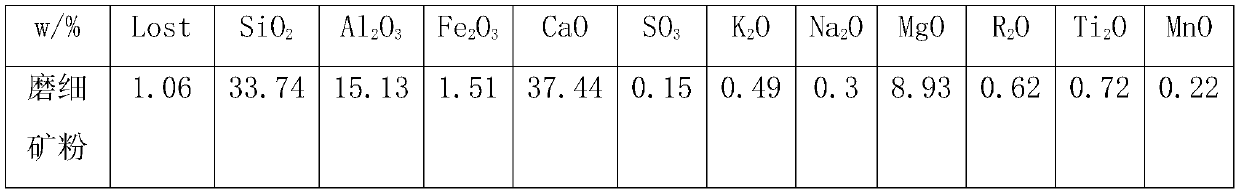

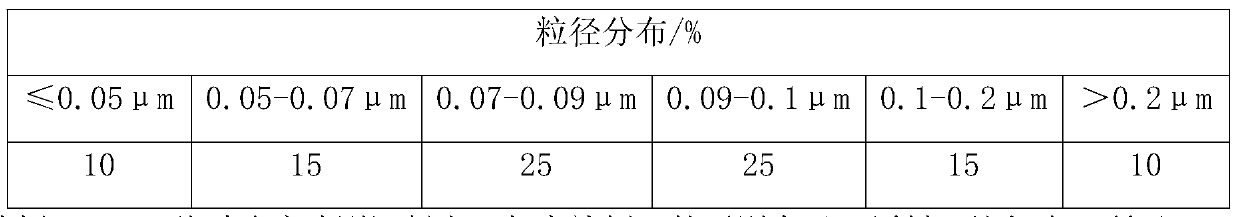

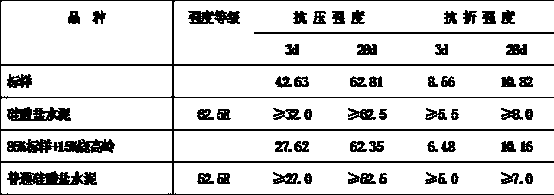

The invention discloses seepage-scouring-resistant concrete and a preparation method thereof. The seepage-scouring-resistant concrete comprises the following components: cement, water, fly ash, silicafume, a fine aggregate, a coarse aggregate, an additive, a preservative and ground mineral powder; wherein the coarse aggregate comprises granite and basalt at a mass ratio of 1: (1.5-1.8); the additive comprises an expanded fiber anti-cracking waterproof agent, an air entraining agent and a water reducing agent at a mass ratio of 1: (0.3-0.5): (0.5-0.7); the preservative is prepared from the following raw materials in parts by weight: 2 to 5 parts of isobutyltriethoxysilane, 1.2 to 1.6 parts of eleostearic acid, 0.8 to 1.6 parts of barium nitrate, 0.5 to 1 part of 2BaO*SiO2 and 3 to 7 partsof polyurethane resin. The seepage-scouring-resistant concrete has the advantages of seawater seepage erosion resistance, strong corrosion resistance and good durability.

Owner:山东中建西部建设有限公司

Preparation method of superfine calcined kaolin powder

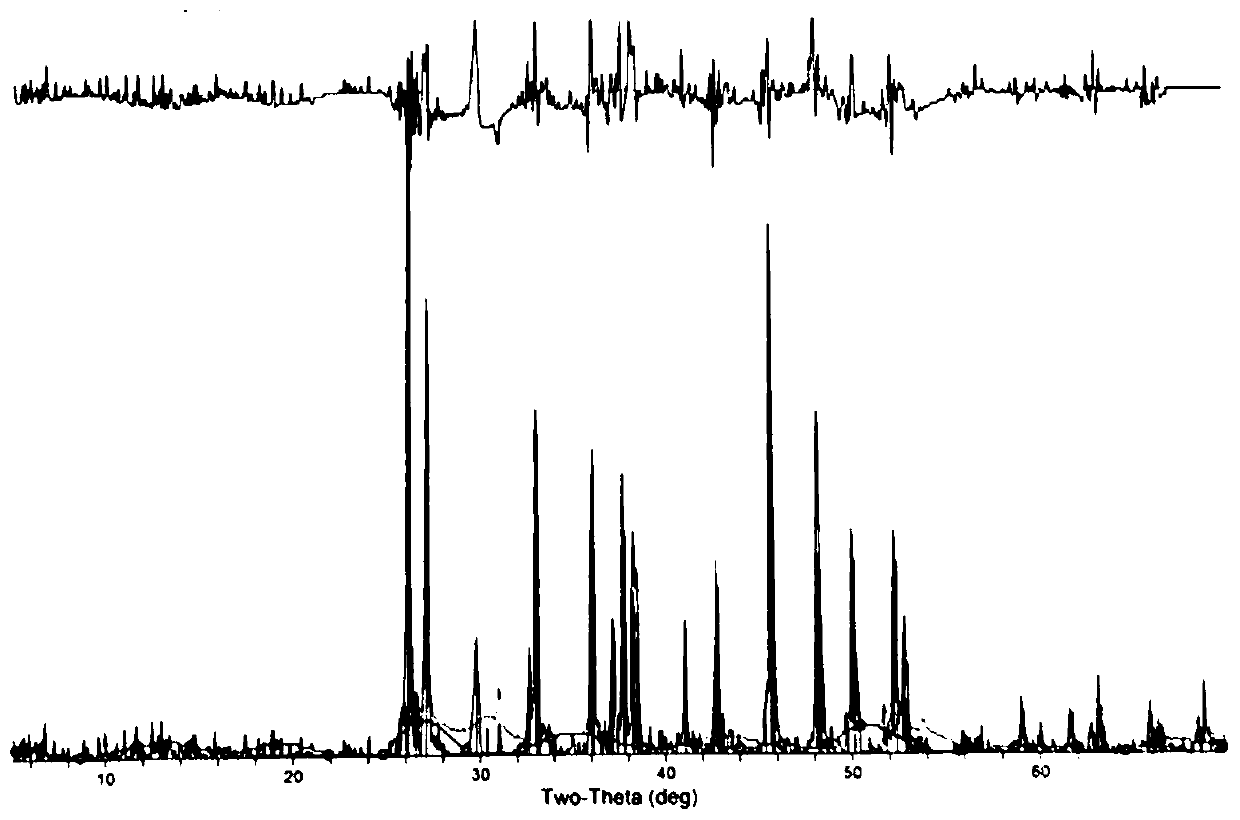

InactiveCN108046750AImproves resistance to sulfate attackLow leaching rateClaywaresThree stageKaolin clay

The invention relates to a preparation method of active kaolin powder. The method comprises the following steps: grinding and homogenizing kaolin raw materials in a vertical drying mill, feeding powder into a three-stage preheating cylinder, feeding the powder into a calcining furnace to complete flash calcination, separating the high-temperature powder from hot air flow by a separating cylinder,feeding micro-powder into a cylinder cooler through a pipeline, cooling high-temperature material blocks by primary air in the cylinder cooler, and collecting the material blocks at the kiln tail, finely grinding the collected material into fine powder being smaller than or equal to 0.044 mm or micro-powder being smaller than or equal to 0.010 mm. The calcined product has advantages of high activity, low production cost and the like and is used for replacing or partially replacing silica fume and alumina micro-powder for fire-resistant concrete, or admixtures of building concrete and cement, and accordingly, the purposes of fully using resources, reducing emissions, increasing income and saving expenses are achieved; the calcined product can also be used as raw materials or filler in industries including ceramic, paper making, rubber, coating, plastic, paint, cable, petrochemistry, medicine and the like.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

High-performance nanofiber modified polymer cement-based repairing mortar and preparation method thereof

The invention relates to a high-performance nanofiber modified polymer cement-based repairing mortar. The repairing mortar comprises, by mass, 25.0-29.5% of cement, 52.2-52.7% of quartz sands, 1.4-2.0% of dispersible latex powder, 0.4-1.0% of nano-SiO2, 3.5-5.2% of fly ash, 1.8-3.5% of metakaolin, 0.07-0.14% of fibers, 0.18-0.24% of a water reducer, 0.03-0.04% of a silicone antifoaming agent, 0.01-0.02% of cellulose ether, and the balance of water. The invention discloses a preparation method of the repairing mortar. The method of the invention is simple and is easy to implement, and the obtained repairing mortar has excellent performances, and is suitable for repairing the reinforced concrete structure.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

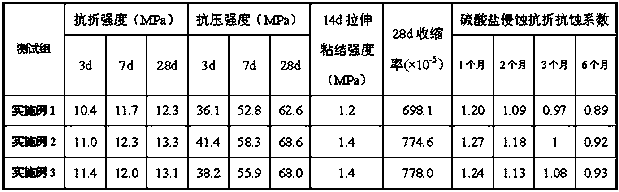

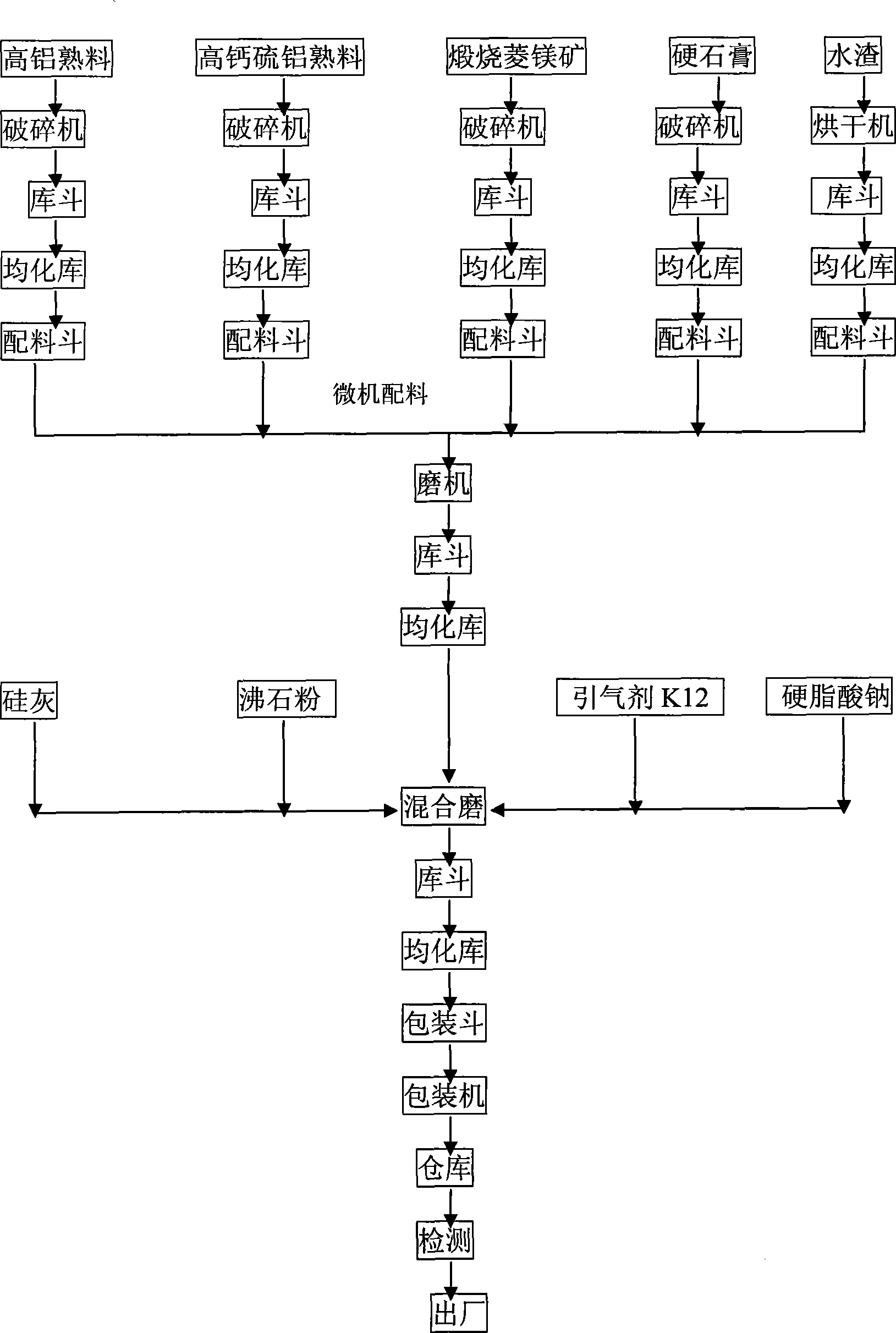

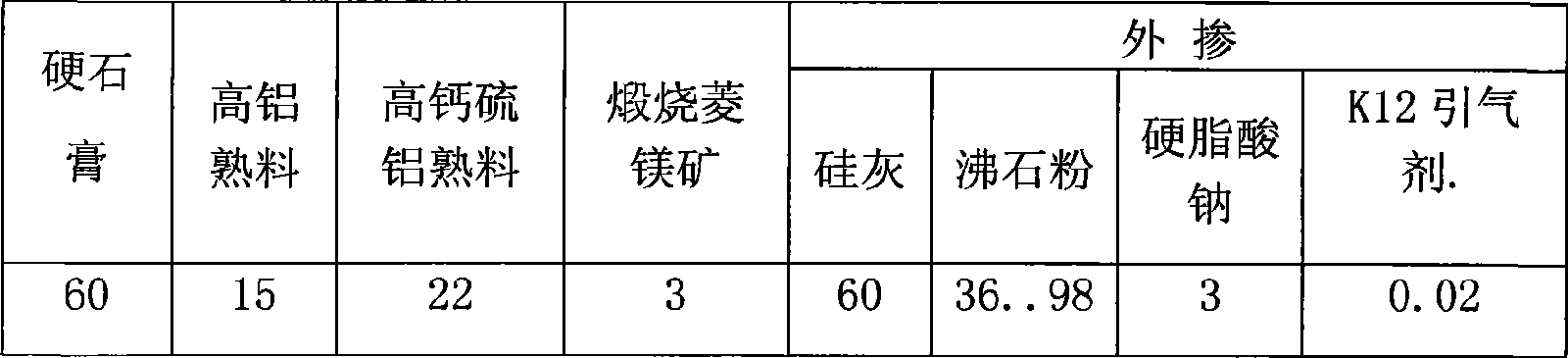

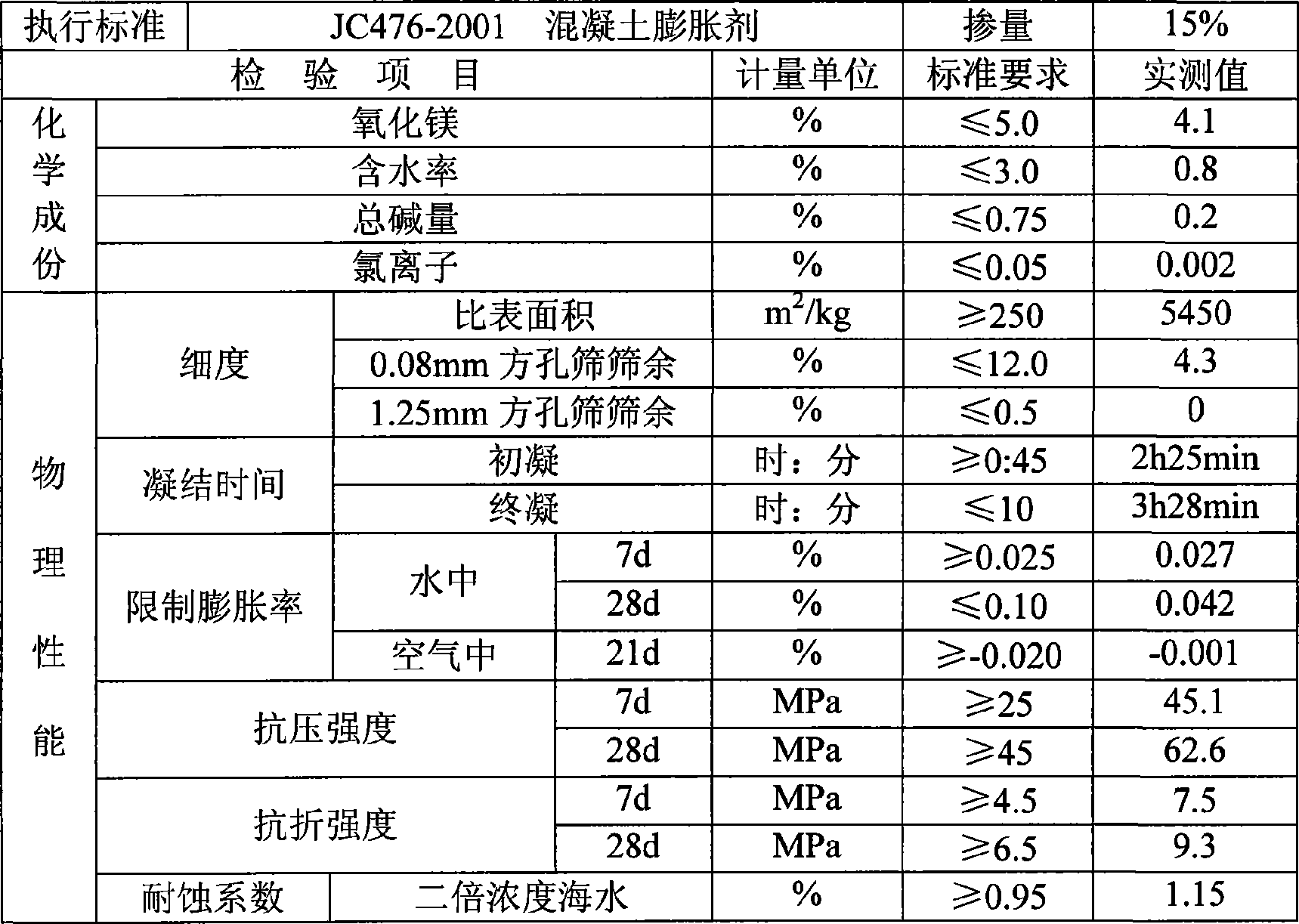

Durable type three-expansion source cement expansive material

InactiveCN101456694AImprove resistance to chloride ion penetrationImprove permeabilitySolid waste managementSodium stearateCrack resistance

The invention discloses durable three expansion source concrete expanding agent, which is characterized by comprising anhydrite, high-aluminum clinker, high calcium-sulfur-aluminum clinker, calcined magnesite and the like as the preparation raw materials according to a weight proportion, in addition, the raw materials are added with air entraining agent K12, siliceous dust, zeolite powder and water repellent sodium stearate. A preparation method comprises steps of crushing, common blending, blended powder grinding and external finished product blending. The expanding agent has low alkali content, has certain expansibility, and improves cracking resistance and impermeability of concrete. The expanding agent after being added into the concrete can remarkably improve compactness, impermeability, anti-scouring property and abrasion-resisting property of the concrete, reduces permeability and water absorption greatly so that the concrete has higher self-defending capability and environmental medium erosion resistance, improves sulphate erosion resistance and carbonizing resistance of the concrete greatly, is favorable for improving safety and durability of the reinforced concrete, and is suitable for various concretes.

Owner:广西云燕特种水泥建材有限公司

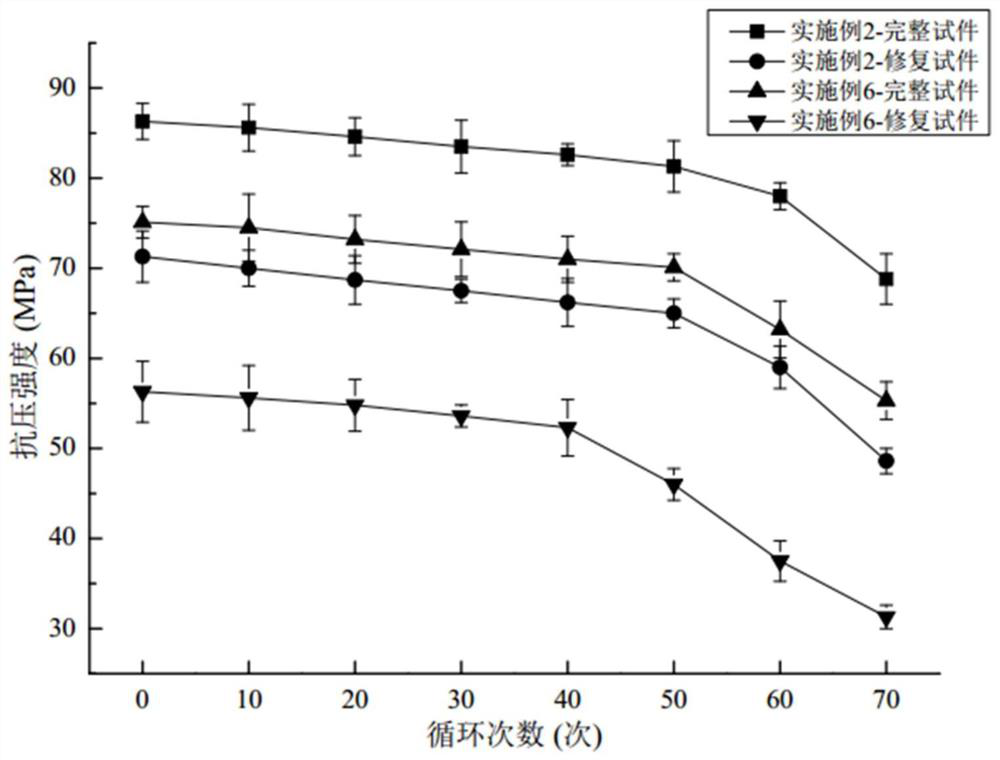

Microbial immobilization method for self-repairing of concrete cracks

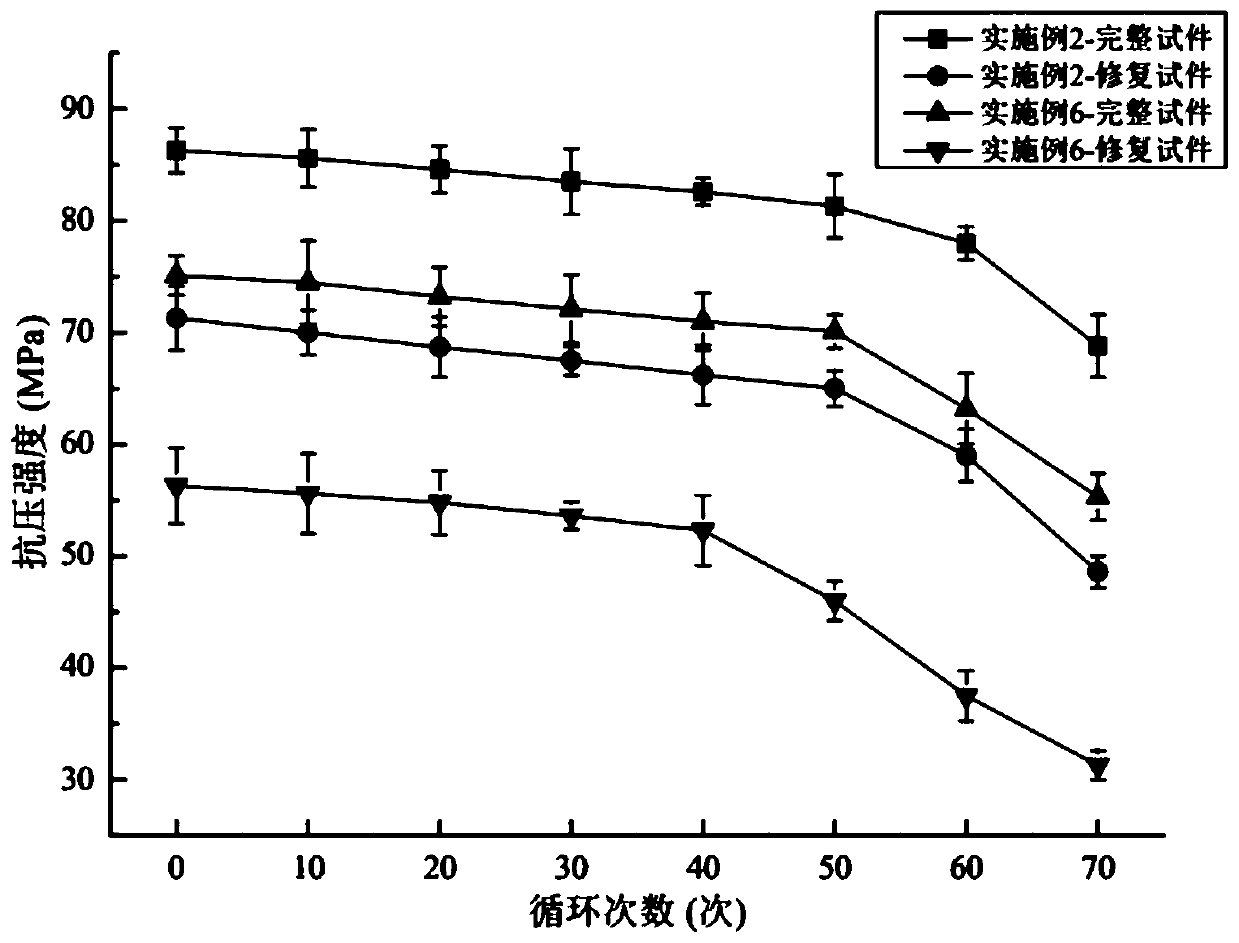

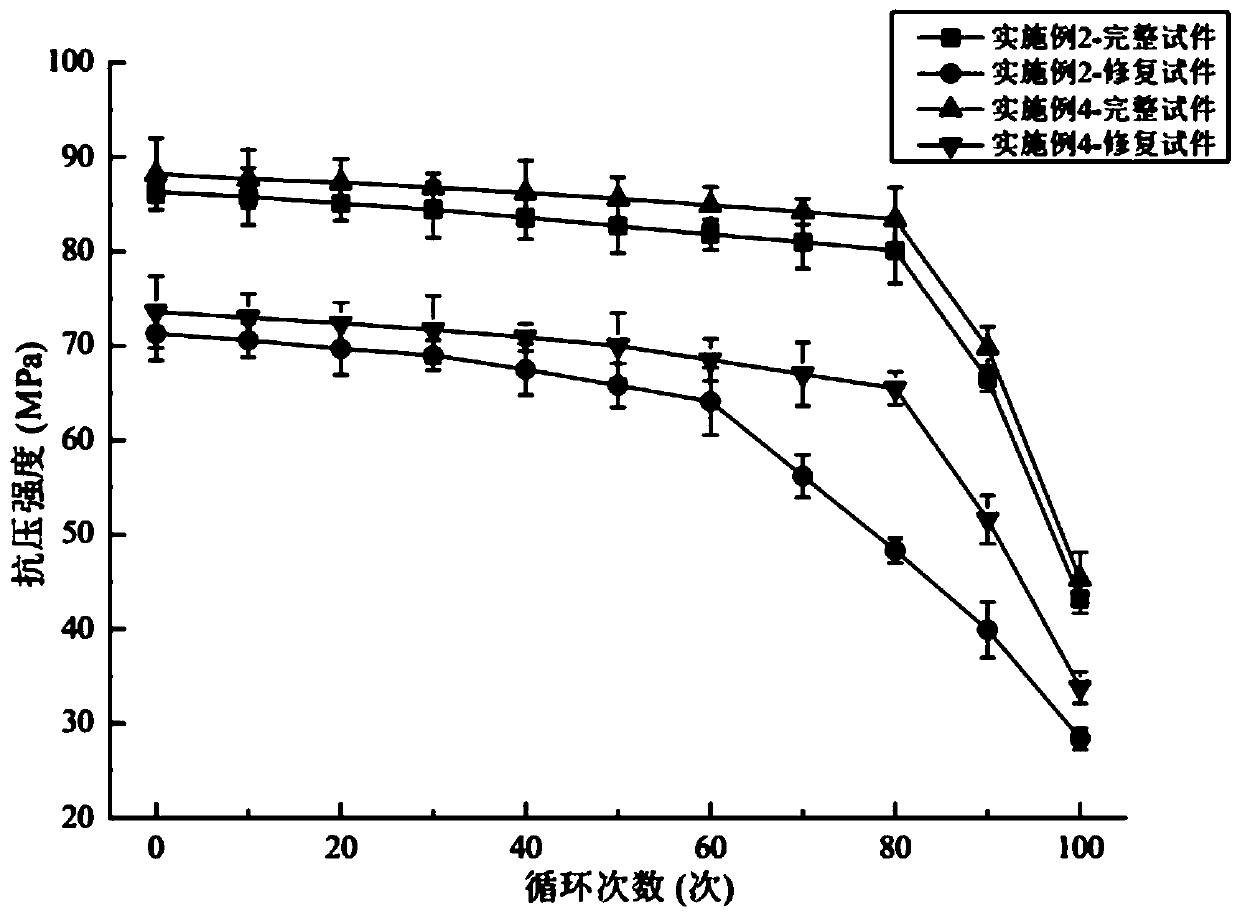

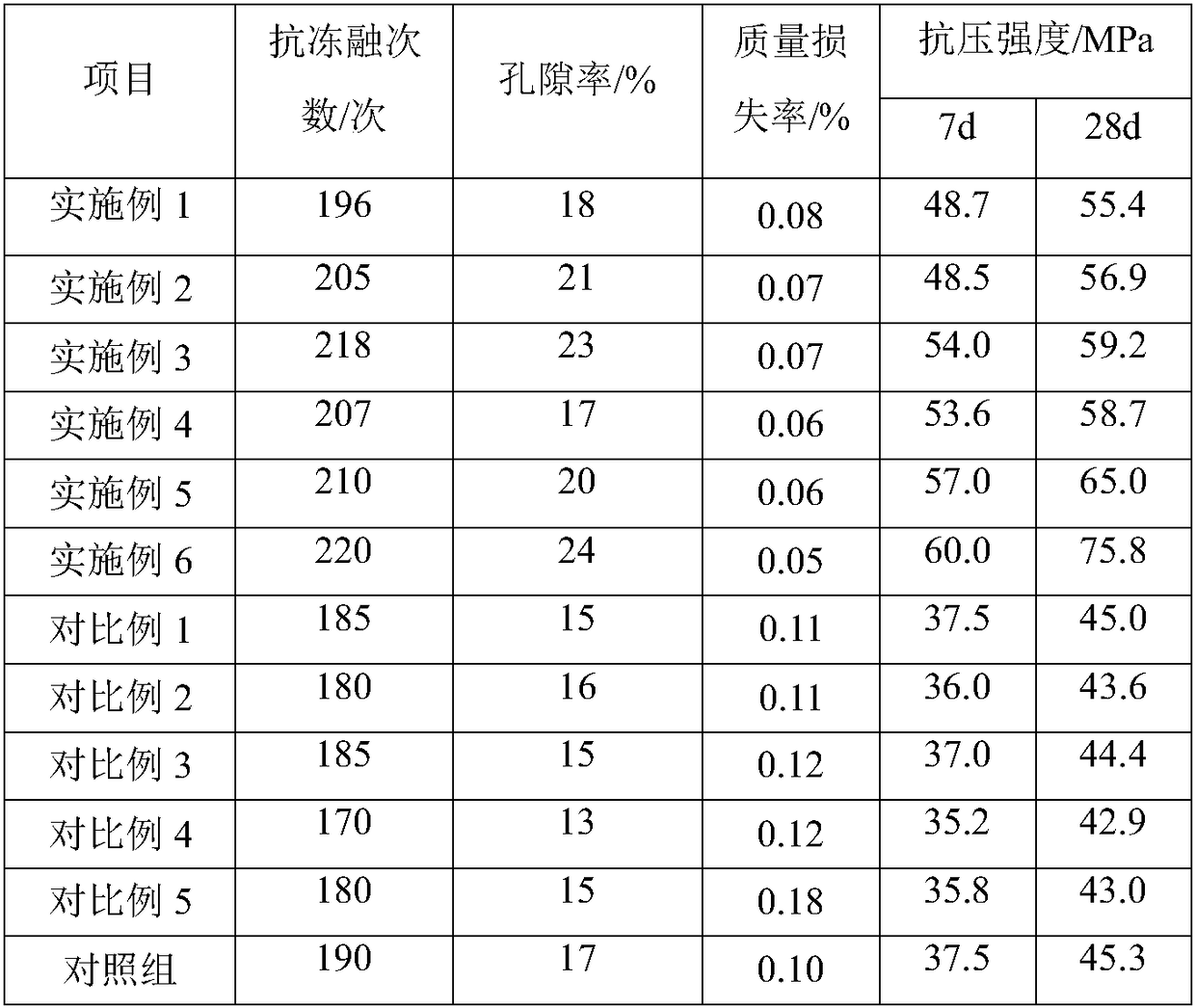

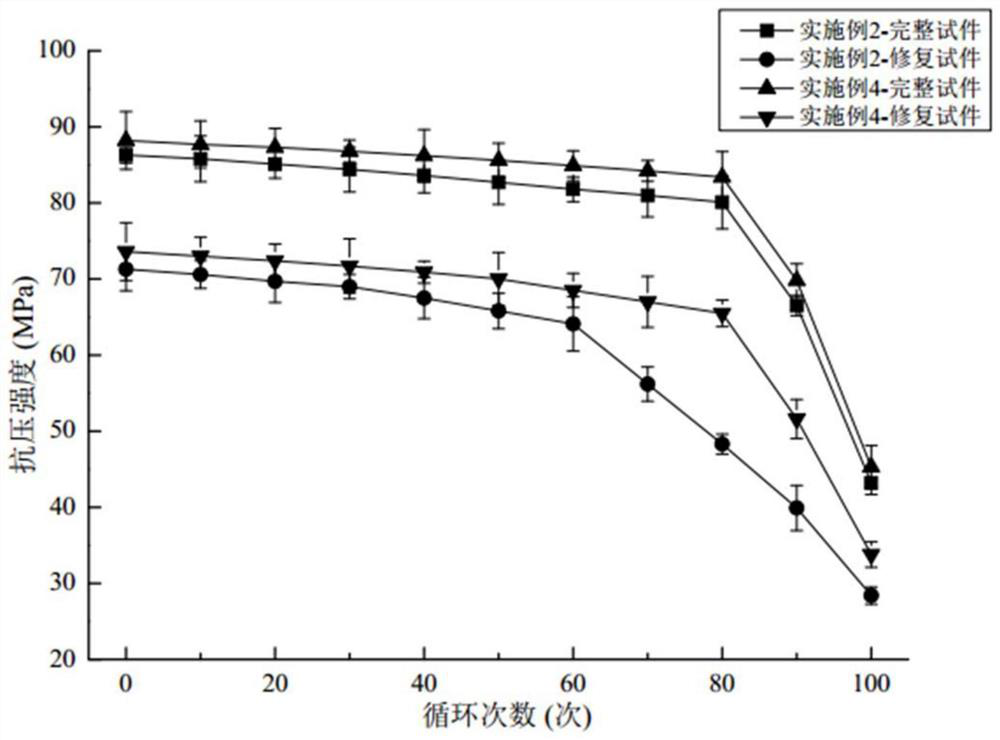

ActiveCN111138107AReduced loss of compressive strengthEnhanced resistance to sulfate attackSodium phosphatesNutrient

The invention provides a microbial immobilization method for self-repairing of concrete cracks and belongs to the field of microbiology and civil engineering material crossing technologies. The methodcomprises the following steps: immobilizing microorganisms or microbial spores in a carrier, and carrying out an immobilization process of wrapping treatment; carrying out a secondary immobilizationprocess of loading nutrient substances in the carrier; and carrying out an embedding process of doping the immobilized carrier obtained by the secondary immobilization process into a concrete raw material, wherein the carrier is coral reef calcareous sand; and the nutrient substances comprise 3, 5-dinitrobenzyl alcohol and sodium trimetaphosphate. According to the method provided by the invention,the survival rate of microorganisms can be increased; the crack repairing width can be increased (the maximum repairing width reaches 1 mm or above, and the average repairing width reaches 0.7-0.9 mm), and the concrete compressive strength is recovered by 80% or above; the compressive strength loss of the repaired concrete under sulfate erosion can be effectively reduced, the sulfate erosion resistance of the repaired concrete is improved, and the durability of the concrete is improved.

Owner:ZHEJIANG OCEAN UNIV +2

Water permeable concrete

ActiveCN109400078AIncrease slumpImprove liquiditySolid waste managementCeramicwareCompressive strengthUltimate tensile strength

The invention relates to the technical field of the concrete processing and in particular to water permeable concrete. The water permeable concrete comprises the following raw material components in parts by weight: 300-380 parts of a binding material, 1000-1250 parts of coarse aggregate, 10-30 parts of coal ash floating beads, 1-5 parts of an air entraining agent, 5-12 parts of an additive, 3-5 parts of steel fibers, 100-135 parts of water and 10-30 parts of organic fibers, wherein the organic fibers comprise polyacrylonitrile fibers and Dura fibers of which a weight matching ratio is 1:(0.5-1). The concrete has better water permeability performance, and has higher compressive strength and freezing and thawing resistance.

Owner:辛集市建和预拌混凝土有限公司

Slag-limestone powder supplementary cementious material-based concrete

The invention discloses slag-limestone powder supplementary cementious material-based concrete and belongs to concrete. The water-binder ratio of the concrete is between 0.37-0.51, the concrete is prepared from the following components by weight percent: 14-20% of cementing materials, 27-33% of sand, 44-46% of pebbles, 7.1-7.4% of water and an additive accounting for 1.5% of cementious material; the cementing material is prepared by mixing the components by weight percent: 50% of ordinary portland cement, 30% of slag and 20% of limestone powder; and the specific surface area of the limestone powder is 350m<2> / kg, 450m<2> / kg or 650m<2> / kg. The slag-limestone powder supplementary cementious material-based concrete has the advantages that the concrete is prepared from slag-limestone powder as the supplementary cementious material of the portland cement, so that the mechanical property and the working performance of the concrete are improved, the endurance characteristics such as the freezing resistance, the anti-permeability and the sulfate corrosion resistance of the concrete are improved, the cement content is reduced, the hydration heat of the cement is further reduced, the concrete temperature rise is reduced, the material source is abundant, and the preparation cost of the composite cement and the concrete can be greatly reduced by adopting industrial wastes such as tailings and coal gangue and the raw materials such as abandoned stones and stone chips as raw materials.

Owner:CHINA UNIV OF MINING & TECH

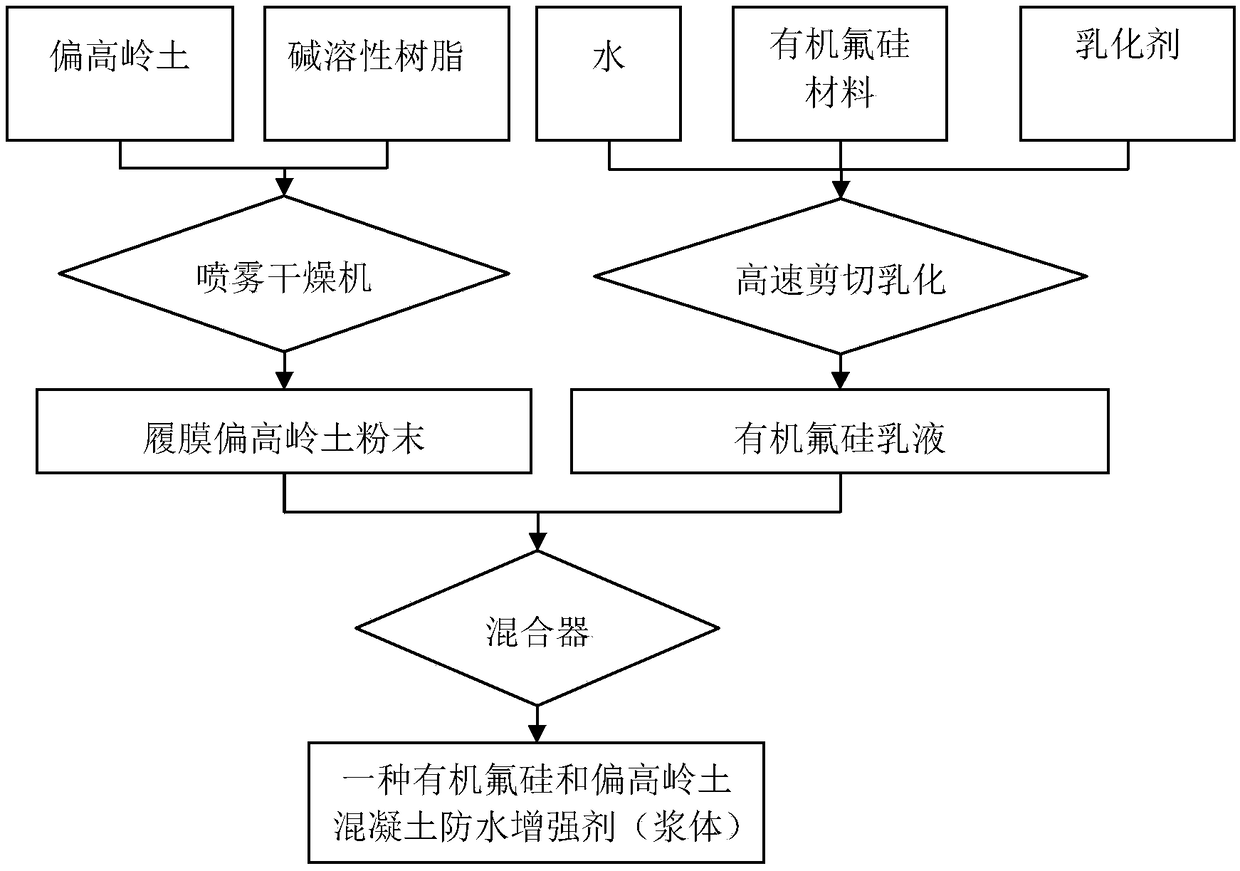

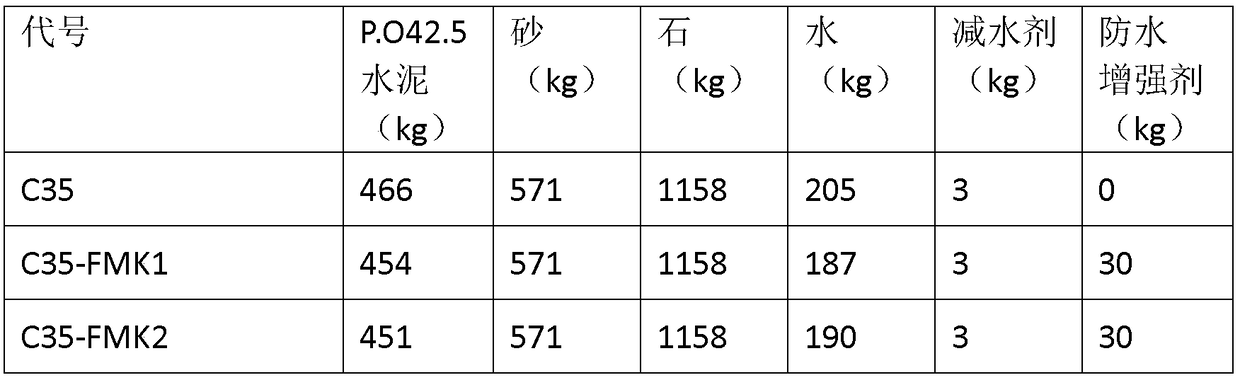

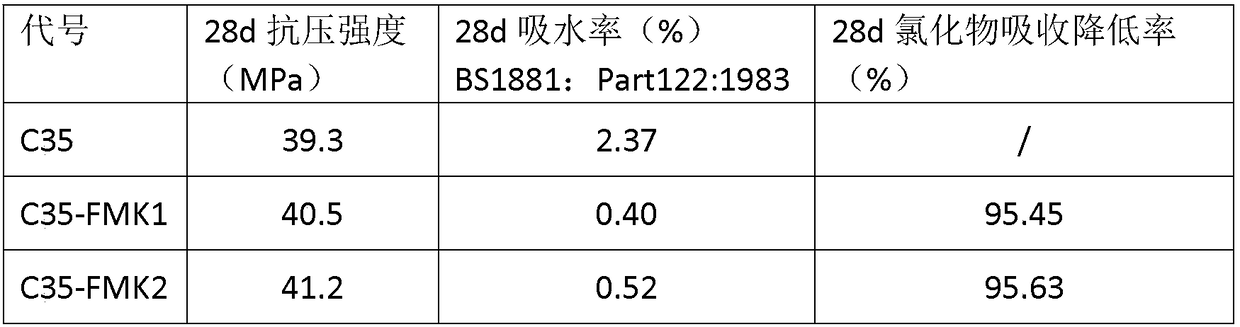

Organic fluorosilicone and metakaolin concrete waterproofing fortifier and preparation method and application thereof

The invention discloses an organic fluorosilicone and metakaolin concrete waterproofing fortifier and a preparation method and application thereof. The organic fluorosilicone and metakaolin concrete waterproofing fortifier contains the following ingredients (by weight): 30-50% of metakaolin, 3-5% of alkali-soluble resin, 5-15% of an organic fluorosilicone hydrophobic component, 0.1-1.0% of an emulsifier, 0.5-1.0% of a pH regulator and 30-50% of water, wherein the metakaolin is made into metakaolin powder with an alkali-soluble protective adhesive film. By mixing the metakaolin powder with thealkali-soluble protective adhesive film into an organic fluorosilicone oil-in-water emulsion with pH value being neutral, the organic fluorosilicone and metakaolin concrete waterproofing fortifier isprepared. Concrete with the application of the organic fluorosilicone and metakaolin concrete waterproofing fortifier as an additive has the following advantages: water absorption is obviously reduced; chloride absorption reduction rate, sulfate corrosion resistance and freezing and thawing cycle resistance of the concrete are remarkably raised; and durability of the concrete is obviously enhanced.

Owner:CCCC FOURTH HARBOR ENG INST +2

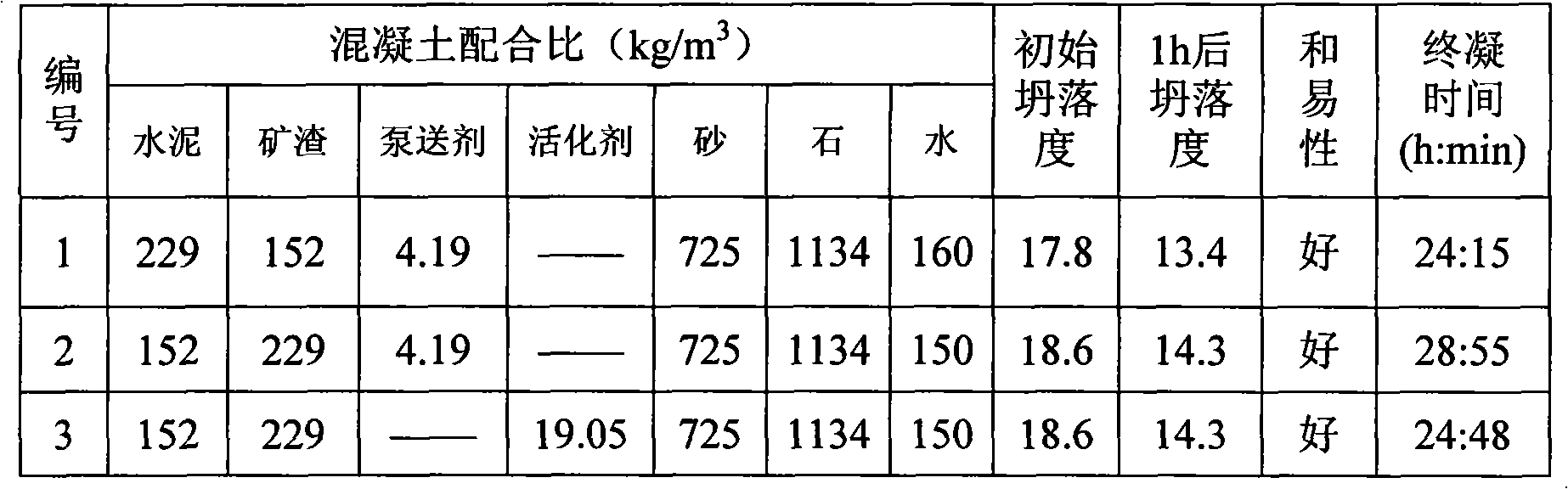

Liquid concrete activating agent

InactiveCN101265049AIncrease dosageShorten the setting timeSolid waste managementSlagSuperplasticizer

The invention discloses a liquid concrete activator which is made from the following raw materials according to mass percentage: superplasticizer 10-60%, aluminum sulfate 5-20%, triethanolamine 0.05-0.2%, slump-retaining agent 0-6%, gas content regulator 0-0.4%, hydroxyl compounds 0-0.02%, and water 30-77%. With the use of the inventive liquid concrete activator, the addition amount of ground slag in concrete is increased from 20-40% to 50-70% and the solidification and curing of concrete with a large amount of ground slag are accelerated, so that the concrete is similar in curing time and early strength to the common concrete, thereby facilitating the construction application. The invention can reduce the requirement for cement in concrete material, and also greatly improve the durability of concrete (e.g. resistance to sulphate corrosion and chloride ion corrosion) since the additional amount of ground slag in the concrete system is increased.

Owner:NANJING RUIDI HIGH TECH

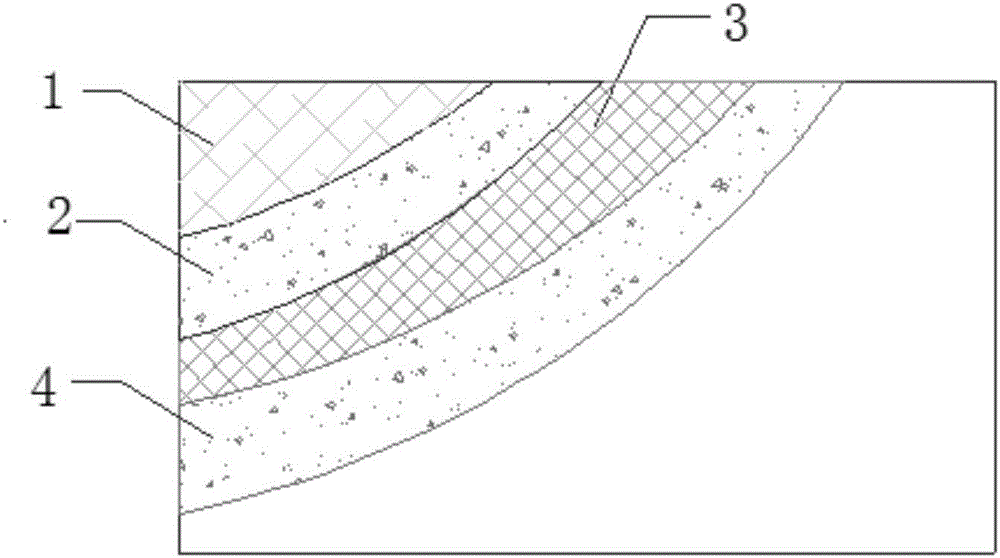

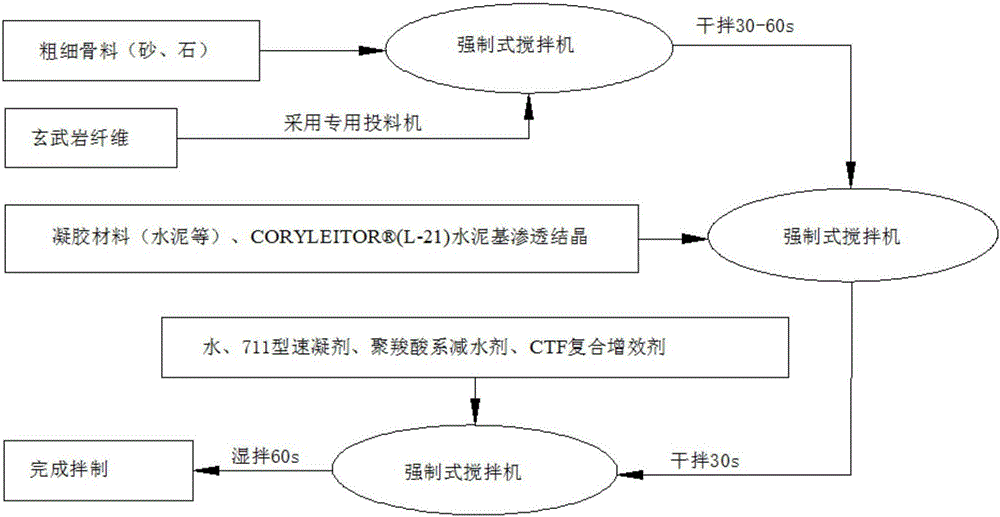

Sprayed basalt fiber concrete and side slope supporting surface layer construction method

The invention discloses sprayed basalt fiber concrete and a side slope supporting surface layer construction method. The sprayed basalt fiber concrete per cubic meter comprises, by weight, 2-4 parts of basalt fibers, 365-410 parts of cement, 73-82 parts of superfine active mineral admixtures, 3-5 parts of cement based permeable crystal, 4-5 parts of concrete compound synergist, 13-19 parts of accelerating agents, 4-5 parts of water reducing agents, 900-925 parts of river sand, 785-815 parts of broken stones and 170-185 parts of water. Compared with the prior art, the sprayed concrete prepared by mixing the basalt fibers is good in consistency and workability, stable in volume and low in spraying rebound loss, tensile strength, crack resistance and frost resistance are remarkably improved, service life is prolonged, and service environments are improved.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

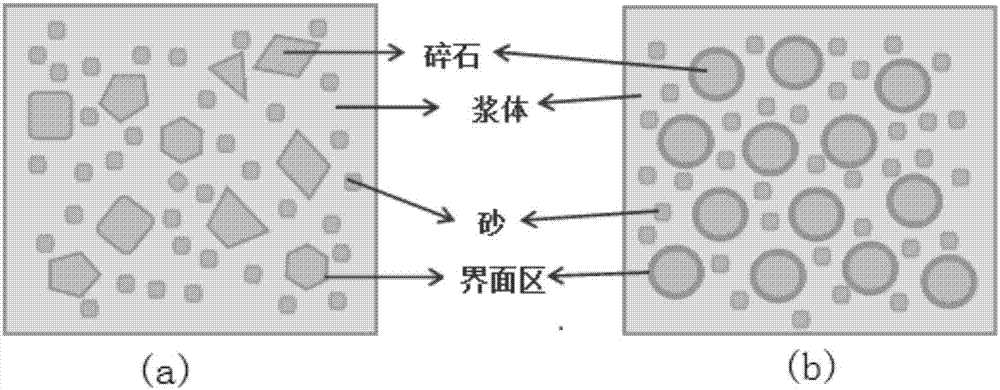

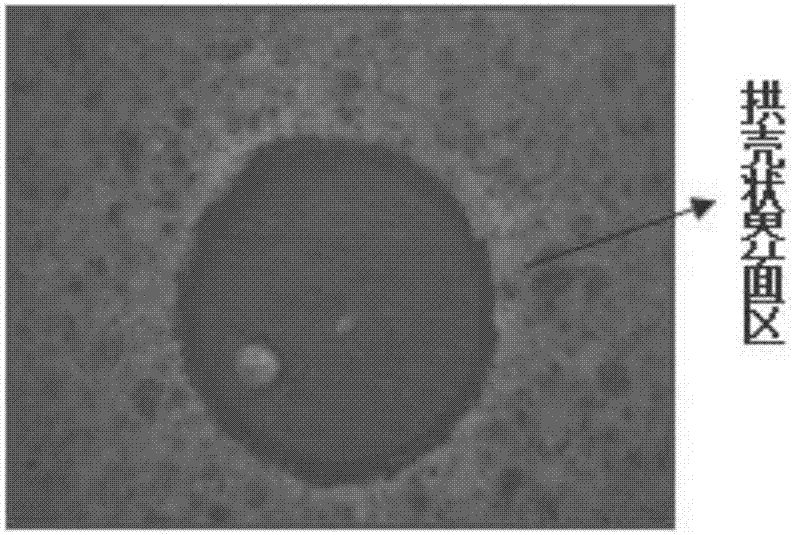

High-strength lightweight aggregate concrete based on arch shell-shaped interface region and preparation method thereof

The invention belongs to the field of building materials, and concretely relates to a high-strength lightweight aggregate concrete based on an arch shell-shaped interface region and a preparation method thereof. The high-strength lightweight aggregate concrete is prepared from the components: 400 to 500 kg / m<3> of cement, 40 to 80 kg / m<3> of pulverized fuel ash, 10 to 60 kg / m<3> of silica fume, 520 to 640 kg / m<3> of lightweight aggregate, 600 to 800 kg / m<3> of river sand, 6 to 8 kg / m<3> of high-efficient water reducer, 0.2 to 0.3 kg / m<3> of tackifier, 18 to 24 g / m<3> of air entraining agent, and 140 to 170 kg / m<3> of water. The high-strength lightweight aggregate concrete provided by the invention mainly adopts a spheroidal lightweight aggregate as an aggregate, and an internal curing effect and an arch shell interface effect of a prewet spheroidal lightweight aggregate are utilized, so that the lightweight aggregate concrete has performances of light weight, high strength, impermeability and corrosion resistance, the workability of the high-strength lightweight aggregate concrete is better, the lightweight aggregate is not easy to float upwards, and the concrete is high in strength, good in endurance quality and not easy to crack.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Patching material for preventing and treating corrosion and disease of tunnel lining concrete salt

InactiveCN102167555ASmall capillary adsorptionLow penetrationSolid waste managementFiberPortland cement

The invention discloses a patching material for preventing and treating the corrosion and the disease of a tunnel lining concrete salt. The patching material consists of ordinary portland cement, a silica alumina mineral component, an expansion component, a rubber mass polymer component, polyacrylonitrile fiber and a condensation adjusting component, wherein the mass ratio of the components is 60:30:8:2-3:0.3:2-4. The patching material can be used for effectively patching, preventing and treating the corrosion and the disease of the tunnel lining structural salt, obviously improving the endurance quality of the existing disease tunnel structure, and prolonging the service life of the tunnel structure, and has the characteristics of being high in cost performance, simple to operate and good in adaptability.

Owner:CENT SOUTH UNIV

High performance concrete prepared from waste slag powder and preparation method thereof

The invention provides high performance concrete prepared from waste slag powder, and relates to the technical field of concrete pipes. The high performance concrete prepared from the waste slag powder is prepared from the following raw materials: waste slag powder, modified hydrotalcite, modified polypropylene, polycarbonate, glass fibers, an anti-stress cracking agent, and water. With the addition of all raw materials of the high-performance concrete, the mechanical and working performance of the concrete is improved, the frost resistance, impermeability, sulfate corrosion resistance and other durability properties of the concrete are increased, the waste slag powder material has abundant sources, and can take tailings, coal gangue and other industrial waste slag and waste rock materialsand stone chips produced in the production process of machine-made sand as raw material; the production cost of the concrete is greatly reduced, a large amount of industrial waste slag can be used, the environment is improved, the pollution is reduced, the energy is saved, and good social and economic benefits are generated.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

Liquid concrete activating agent

InactiveCN101265049BIncrease dosageShorten the setting timeSolid waste managementSlagSuperplasticizer

The invention discloses a liquid concrete activator which is made from the following raw materials according to mass percentage: superplasticizer 10-60%, aluminum sulfate 5-20%, triethanolamine 0.05-0.2%, slump-retaining agent 0-6%, gas content regulator 0-0.4%, hydroxyl compounds 0-0.02%, and water 30-77%. With the use of the inventive liquid concrete activator, the addition amount of ground slag in concrete is increased from 20-40% to 50-70% and the solidification and curing of concrete with a large amount of ground slag are accelerated, so that the concrete is similar in curing time and early strength to the common concrete, thereby facilitating the construction application. The invention can reduce the requirement for cement in concrete material, and also greatly improve the durability of concrete (e.g. resistance to sulphate corrosion and chloride ion corrosion) since the additional amount of ground slag in the concrete system is increased.

Owner:NANJING RUIDI HIGH TECH

High-efficiency sulfate-resistant concrete additive and preparation method thereof

The invention discloses a high efficiency sulfate attack resistant concrete additive and a preparation method thereof. The technical scheme of the concrete additive comprises the following raw materials in parts by weight: 15-25 parts of barium salt, 5-10 parts of sorbitol, 15-30 parts of calcined diatomaceous earth, 0.5-1.0 part of a grinding aid, 30-50 parts of silica fume, 10-20 parts of ultrafine fly ash and 1.0-2.0 parts of a water reducer. The high efficiency sulfate attack resistant concrete additive can reduce the proper shrinkage cracks of concrete, improve the compactness, and greatly improve the multi-type attack resistant properties of the concrete effectively for a long time.

Owner:HUBEI UNIV OF TECH

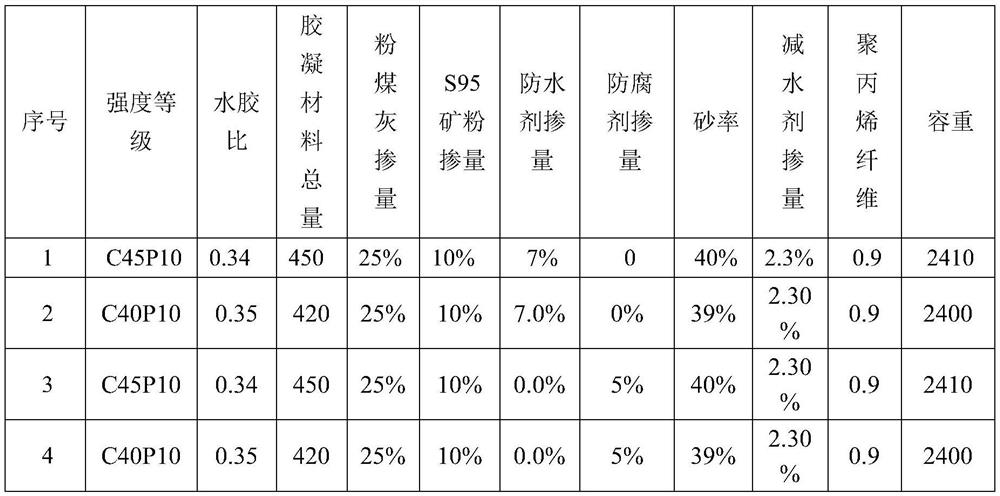

High-durability concrete

The invention discloses high-durability concrete, and relates to the technical field of building engineering construction, and each cubic meter of the concrete comprises the following raw materials: 273-293 kg / m < 3 > of cement, 340-450 kg / m < 3 > of a cementing material, 703-710 kg / m < 3 > of sand, 1064-1099 kg / m < 3 > of stone, 9.66-10.35 kg / m < 3 > of an additive, 0.9-1.2 kg / m < 3 > of polypropylene fiber and the balance of water. The cementing material comprises 105-113kg / m < 3 > of fly ash, 42-45kg / m < 3 > of S95 mineral powder and 29-32kg / m < 3 > of a waterproof agent; according to the scheme, the sulfate corrosion resistance, the early-stage crack resistance and the chloride ion penetration resistance of the concrete are improved by preparing the concrete combination proportion, and the durability of the concrete is enhanced.

Owner:中国华西企业股份有限公司

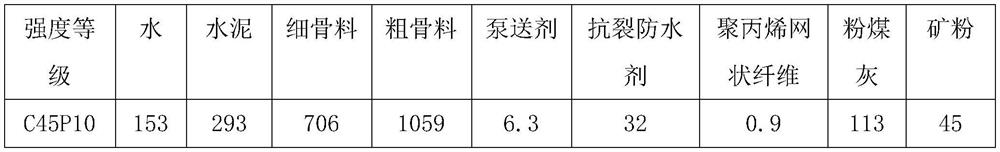

Magnesia sulfoaluminate cement composition as well as product and manufacturing method thereof

The invention relates to a magnesia sulfoaluminate cement composition as well as a product and a manufacturing method thereof. The composition comprises light calcined magnesia, magnesium sulfate heptahydrate, calcined bauxite, phosphoric acid or phosphate and water. The composition and the cement product thereof have the advantages that (1) the cement is high in strength; (2) the alkalinity of the cement is low; (3) the cement can utilize low-grade bauxite, so that effective utilization and reasonable allocation of resources can be realized; (4) the service lifetime of the cement product is long; and (5) the cement can be directly compounded with a fiber material to prepare fiber reinforced magnesia cement products meeting various requirements.

Owner:北京水木华宸科技发展有限公司 +1

Sulfur-fixing ash dry-mixed mortar and preparation method thereof

The invention belongs to the technical field of dry-mixed mortar, and particularly relates to sulfur-fixing ash dry-mixed mortar and a preparation method thereof. The preparation method comprises thefollowing steps: taking sulfur-fixing ash, desulfurized gypsum, Portland cement clinker, river sand and a polycarboxylate superplasticizer as raw materials; and putting the treated sulfur-fixing ash,desulfurized gypsum, Portland cement clinker, river sand and polycarboxylate superplasticizer into a mixer for stirring to obtain the sulfur-fixing ash dry-mixed mortar. According to the preparation method disclosed by the invention, the cement is replaced with the sulfur-fixing ash, the desulfurized gypsum and the Portland cement clinker; the Portland cement clinker and the desulfurized gypsum which are subjected to grinding treatment have suitable fineness, so that heterogeneous nucleation in the hydration process is enhanced and further the early strength of the mortar is promoted; and meanwhile, after the sulfur-fixing ash is doped and then is subjected to ultrafine grinding, the grain composition of the raw materials can be effectively improved and is enabled to be closer to an optimal particle packing state, the void content of a mortar system is reduced, and eventually sulfate corrosion resistance and frost resistance of the sulfur-fixing ash dry-mixed mortar can be improved.

Owner:山西平朔煤矸石发电有限责任公司

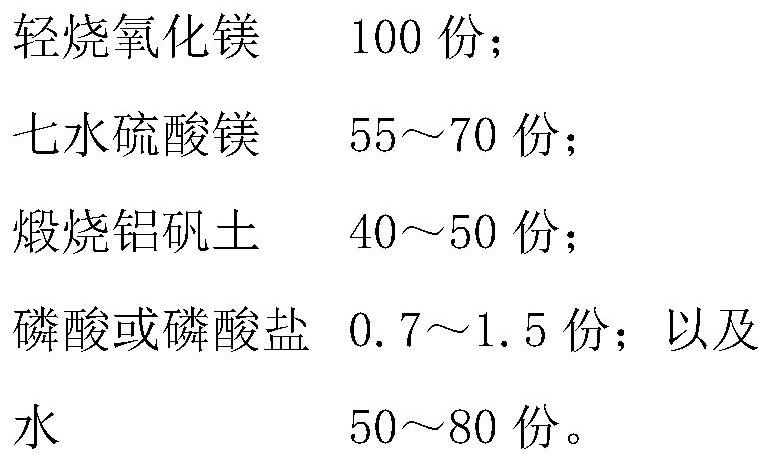

Double-component water-based ceramic tile back adhesive and preparation method thereof

The invention belongs to the technical field of ceramic tile processing, and particularly relates to a double-component water-based ceramic tile back adhesive and a preparation method thereof. The water-based ceramic tile back adhesive is prepared from the following raw materials in parts by weight: 50-200 parts of cement and 10-40 parts of styrene-acrylic emulsion. According to the invention, theepoxy modified styrene-acrylic emulsion has the advantages of high strength, corrosion resistance and strong adhesion of epoxy resin and the characteristics of weather resistance, good gloss and thelike of the styrene-acrylic emulsion, so that the hardness, the pollution resistance and the water resistance of a coating film are excellent; quartz sand has the effects of high temperature resistance, small thermal expansion coefficient, high insulation and corrosion resistance, so that the use stability in a high-temperature environment is guaranteed; and zeolite powder plays a role in improving the workability of a concrete mixture and the strength of concrete, excessive or harmful bubbles in the concrete are inhibited or eliminated by doping a defoaming agent into the concrete, the compactness of the concrete can be improved, and the strength of the ceramic tile back adhesive is guaranteed.

Owner:清远市厦鼎新材料科技有限公司

A kind of pressure-free steaming prestressed high-strength pipe pile concrete and pipe pile preparation method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

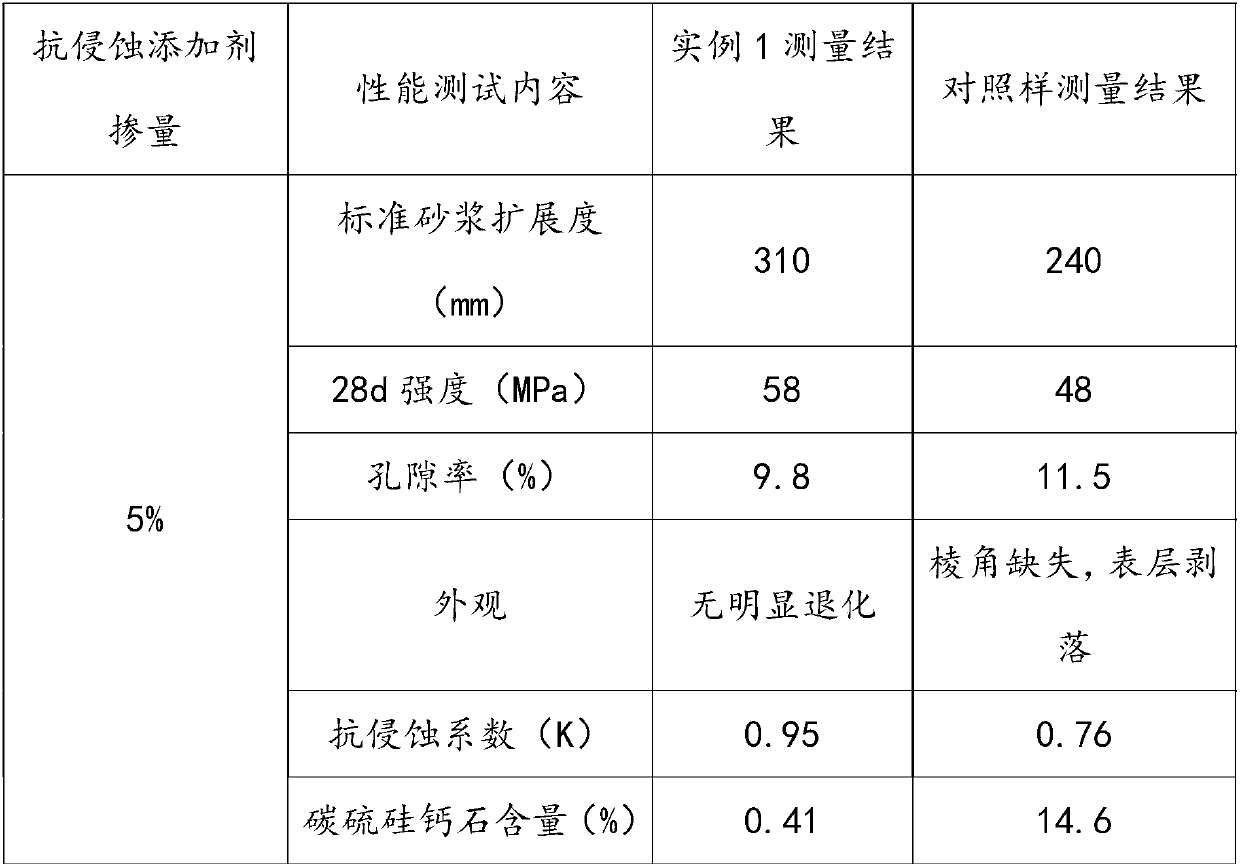

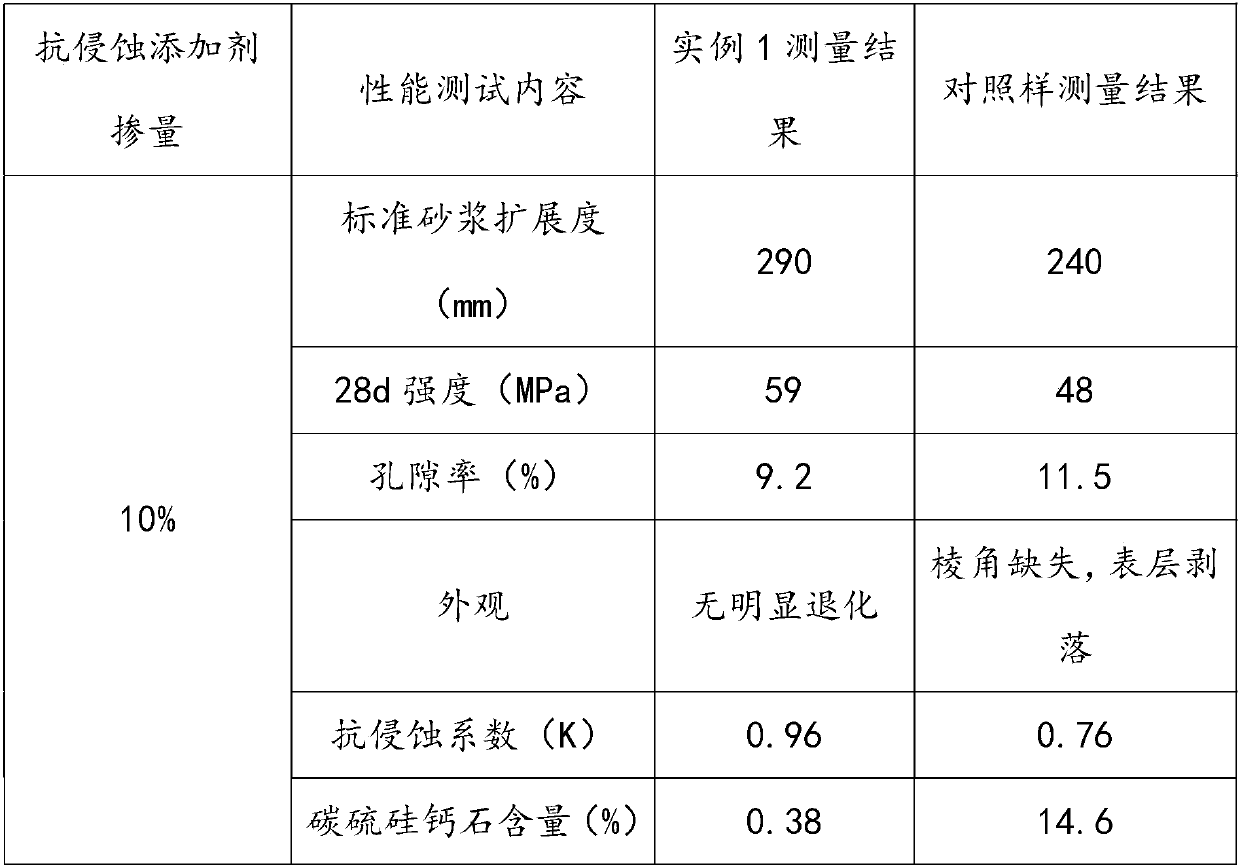

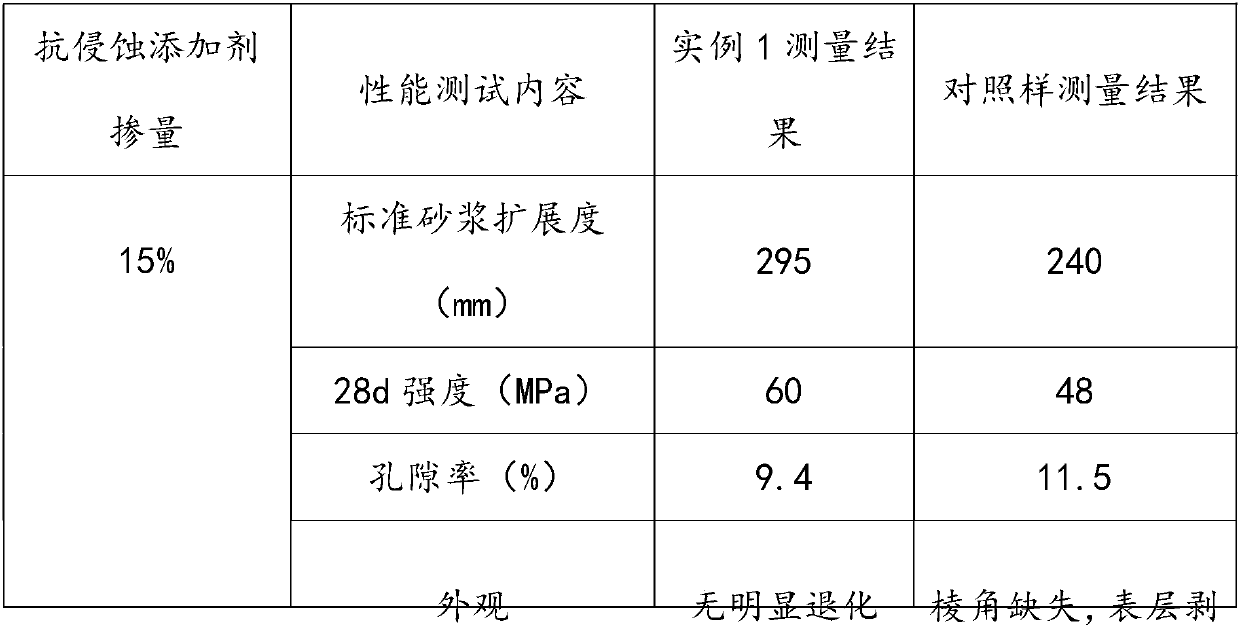

Anti-erosion concrete admixture and preparation method thereof

The invention discloses an anti-erosion concrete admixture and a preparation method thereof, belonging to the technical field of building materials. The concrete admixture is prepared from 30-50 parts of fly ash, 10-20 parts of superfine slag powder, 5-10 parts of a modified expanding agent, 5-10 parts of a water reducing agent and 3-8 parts of a grinding aid component. According to the invention, erosion resistance is realized through two dimensions; firstly, the fly ash and the superfine slag powder are added, so formation of sulfate erosion products is effectively prevented from a chemical level; secondly, fine gaps of a cement material are fully filled with the expanding agent and other components, so the compactness of the material is increased, and the overall strength of the material is improved; and the superfine slag powder and the modified expanding agent cooperate with each other, so the sulfate attack resistance of the material is jointly improved. The additive is low in addition amount; the preparation method is simple; a test piece still meets use requirement after being eroded by high-concentration sulfate for 120 days; and thus, the additive has wide market prospects.

Owner:日照联汇建材有限公司

Sulfate-corrosion-resistance concrete additive and preparation method thereof

InactiveCN102173687BImproves resistance to sulfate attackReduce usageSolid waste managementSlagBarium nitrate

Owner:湖南同远新材料科技有限公司

Anti-erosion agent for concrete, preparation method and application thereof

InactiveCN101781100BImproves resistance to sulfate attackExtended service lifeSolid waste managementMicrosphereWater reducer

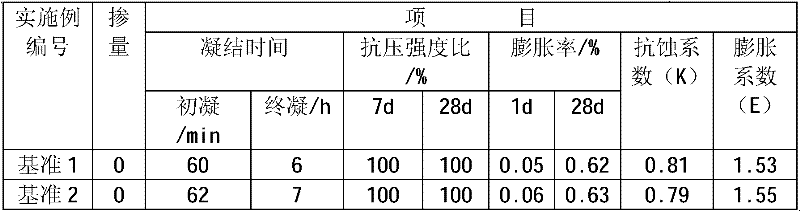

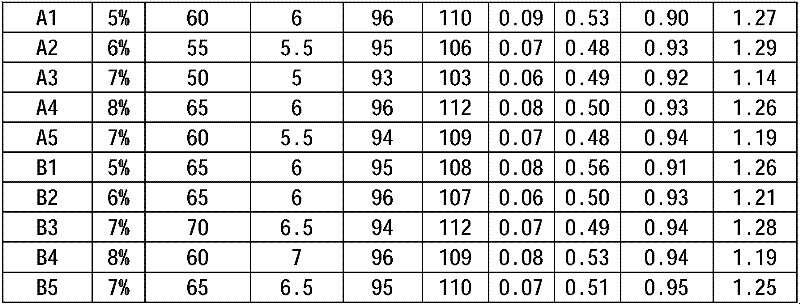

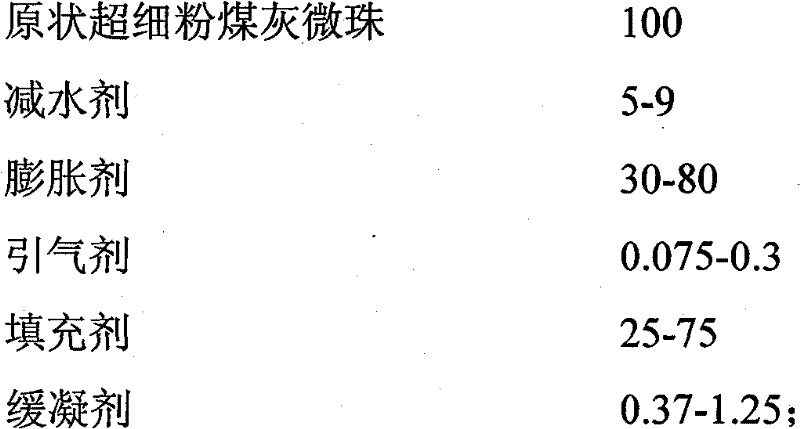

The invention relates to an anti-erosion agent for concrete, a preparation method and an application thereof. The anti-erosion agent comprises the following components in parts by weight: 100 parts of original-state superfine fly ash microsphere, 5-9 parts of water reducer, 30-80 parts of expanding agent, 0.075-0.3 part of air entraining agent, 25-75 parts of bulking agent and 0.37-1.25 parts of retarder. Compared with the prior art, the product of the invention utilizes the original-state superfine fly ash microspheres and has excellent performance, the production process is simple, the application is convenient, the applicability is universal, and the application effect is extremely standout. As for the concrete prepared by adopting the product of the invention, the anti-sulphate-erosion ability thereof can be improved by 5-8 times, the anti-chloridion-penetrating ability can be improved by more than 3 times, and the service life of the concrete structure can be prolonged by 3-4 times under the condition that the service environment of the concrete structure is not changed.

Owner:HUNAN CSCEC5B CONCRETE

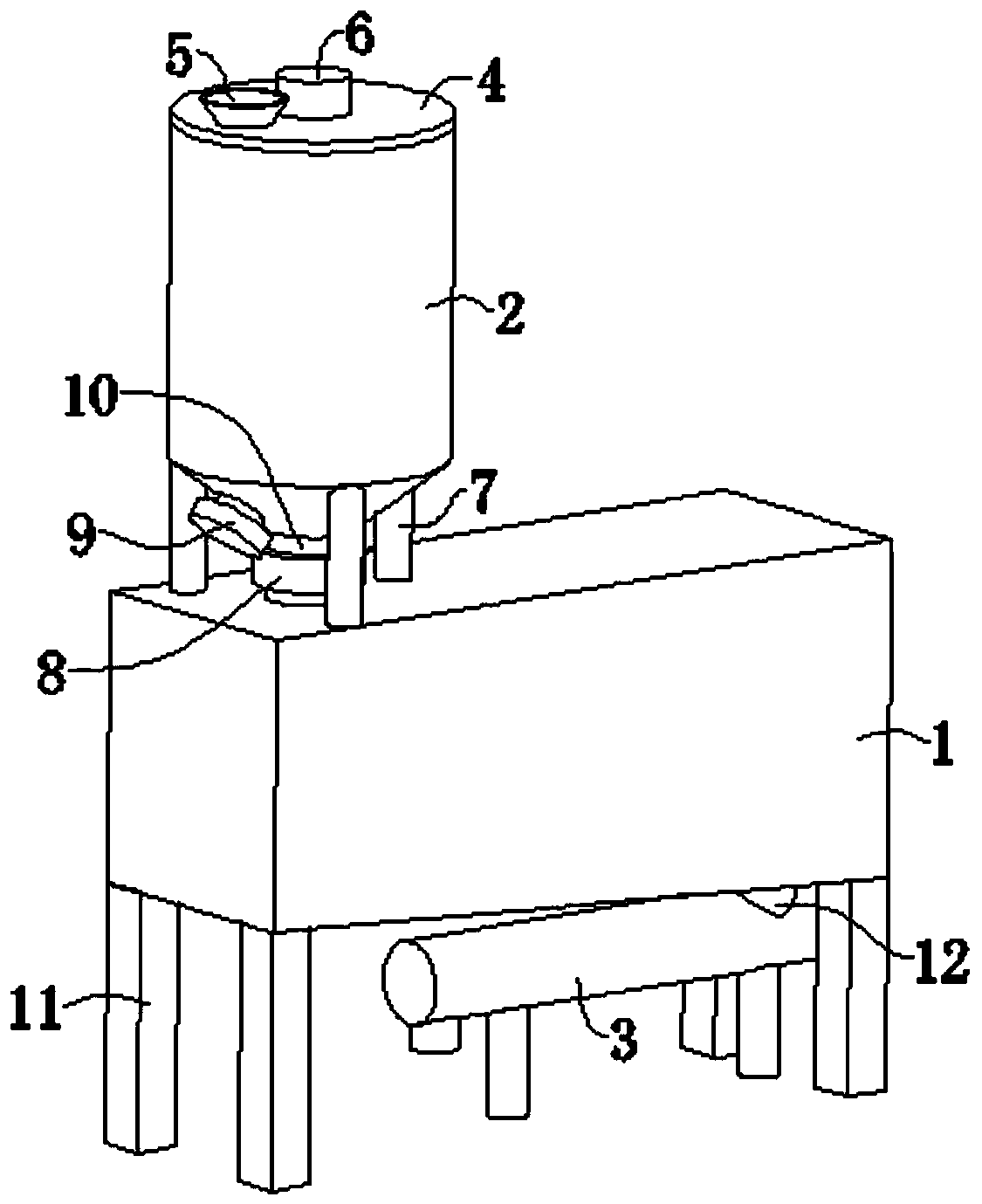

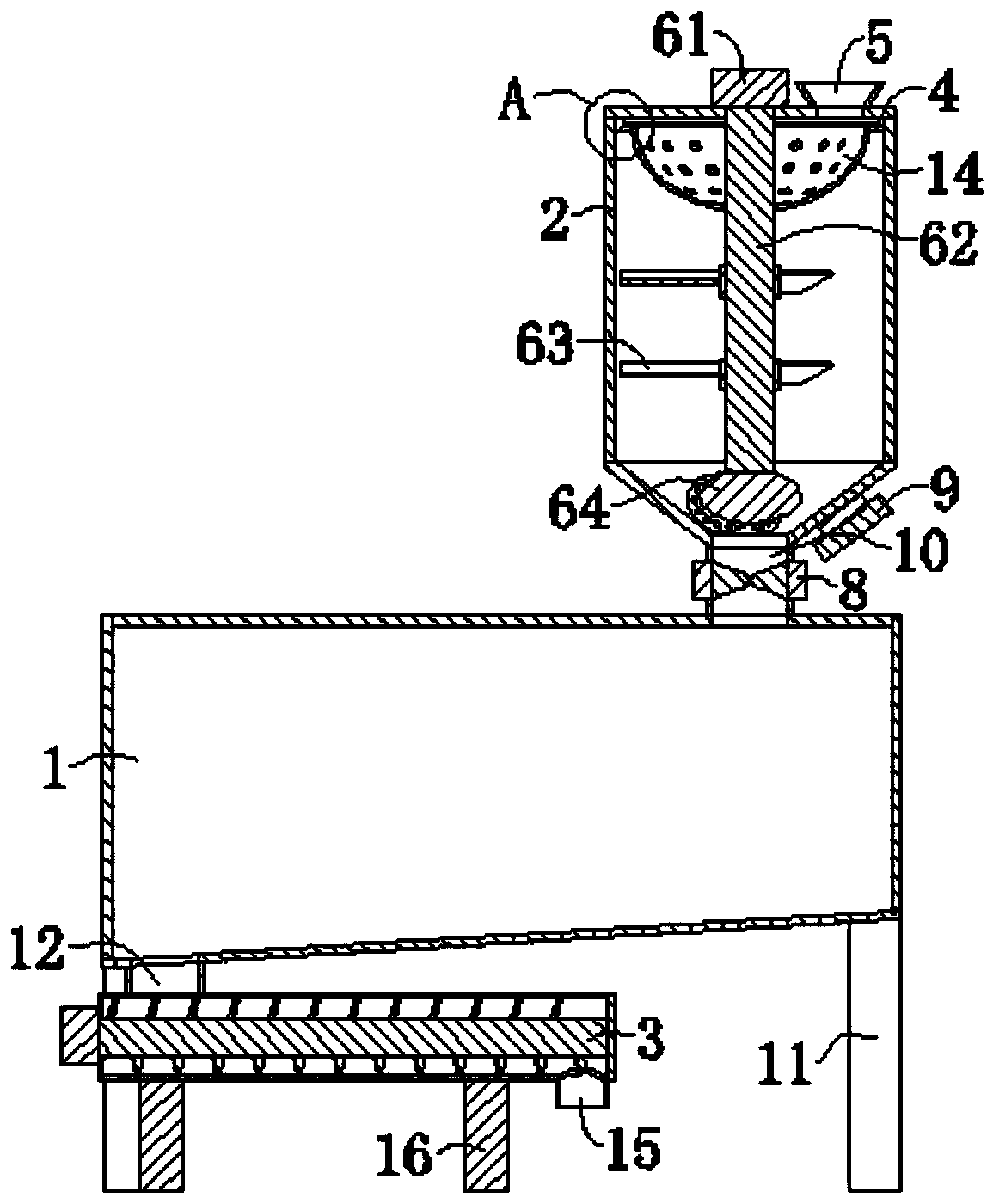

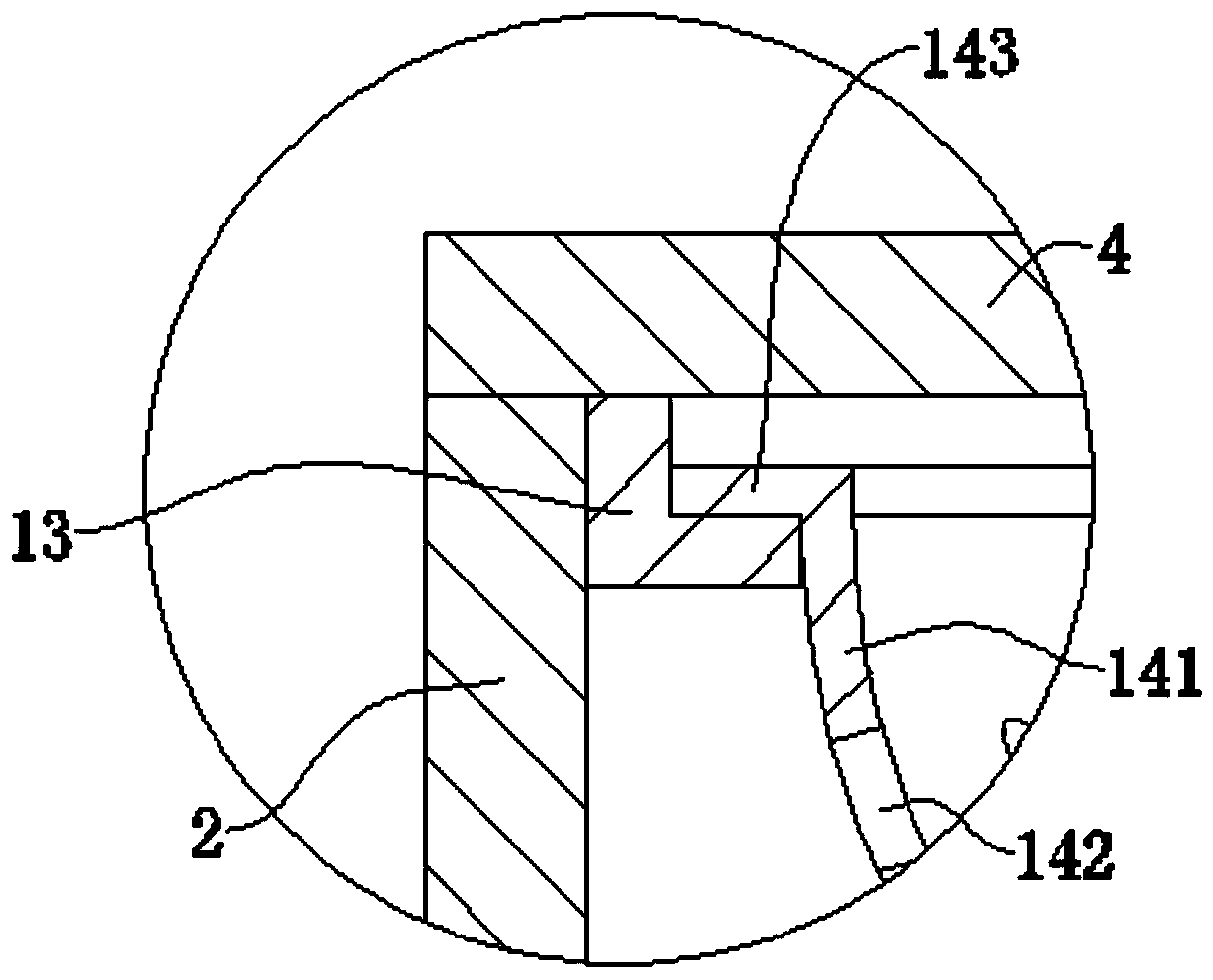

Impact-erosion resistant marine concrete dual-ash gelling powder and preparation method and device thereof

InactiveCN110922117AImproves carbonation resistanceImproves resistance to sulfate attackSlagSilica fume

The invention discloses an impact-erosion resistant marine concrete dual-ash gelling powder and a preparation method and device thereof, and belongs to the field of gelling materials. The dual-ash gelling powder comprises following raw materials in parts by weight: 30 to 40 parts of cement, 15 to 25 parts of furnace steel ash, 12 to 20 parts of slag, 15 to 18 parts of silica fume, 2 to 5 parts ofexpanded graphite, 2 to 5 parts of ceramic micro powder, and 5 to 12 parts of rubber powder. The preparation method comprises following steps: preparing raw materials; preparing a basic material; andpreparing the dual-ash gelling powder. The problem that in the prior art, the impact-erosion resistant performance of conventional marine concrete is bad is solved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

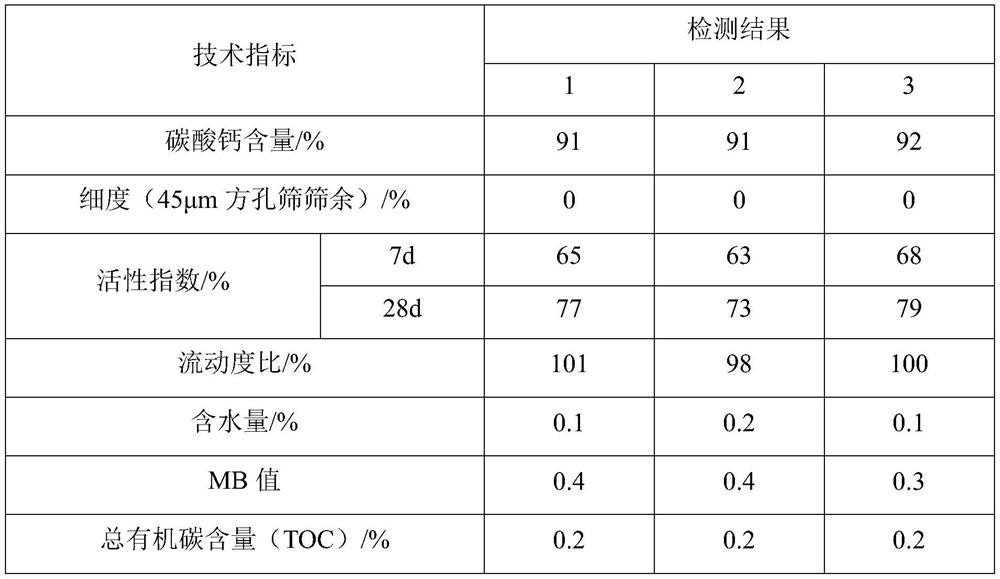

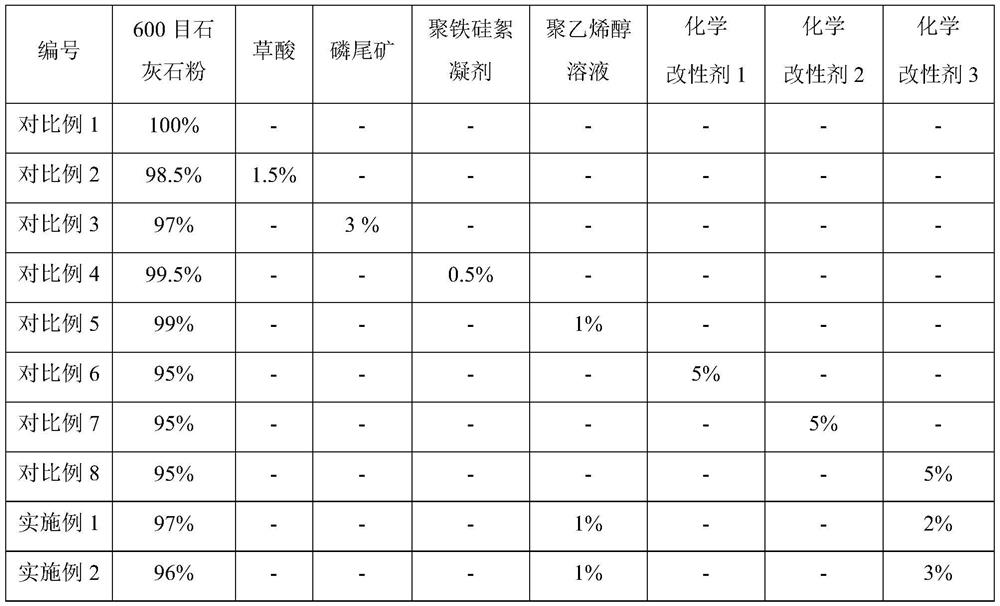

A kind of modified limestone powder and its preparation method and concrete

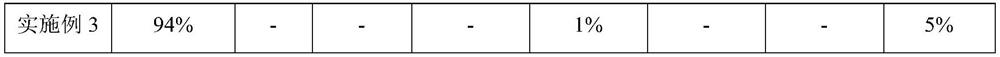

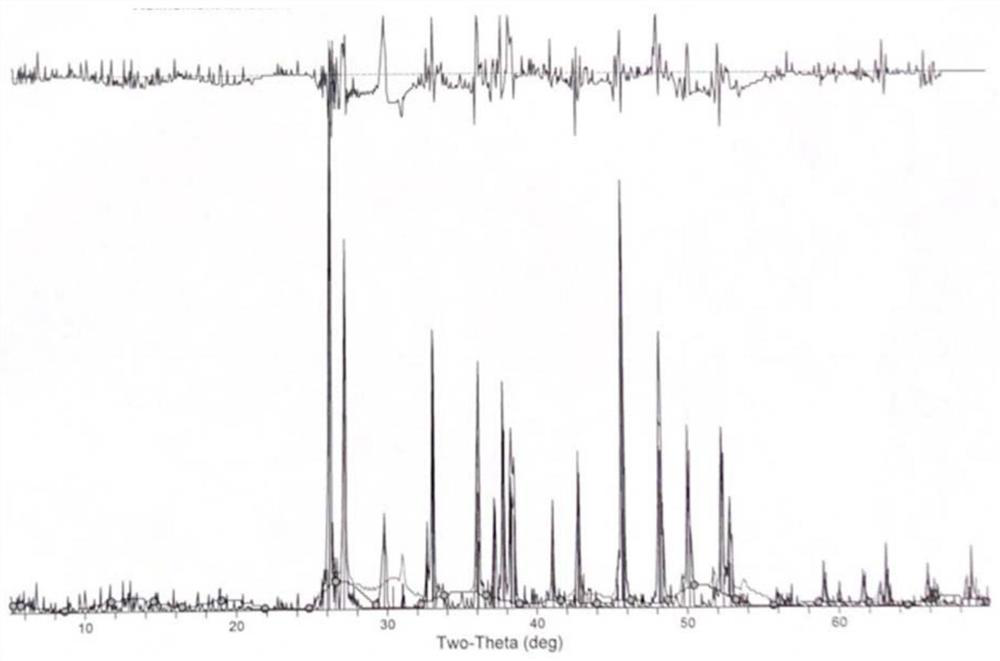

The invention discloses a modified limestone powder, a preparation method thereof and concrete, which is made of 94-97% of limestone powder, 1% of a physical modifier and 2-5% of a chemical modifier according to the mass percentage, wherein the The above-mentioned chemical modifier is a mixture of oxalic acid, phosphorus tailings and polyferrosilicon flocculant. The physical and chemical double modification of the limestone powder solves the problem of sulfate erosion of limestone powder concrete in the prior art, and the obtained modified limestone powder has high density, low porosity, and excellent resistance to sulfate erosion.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

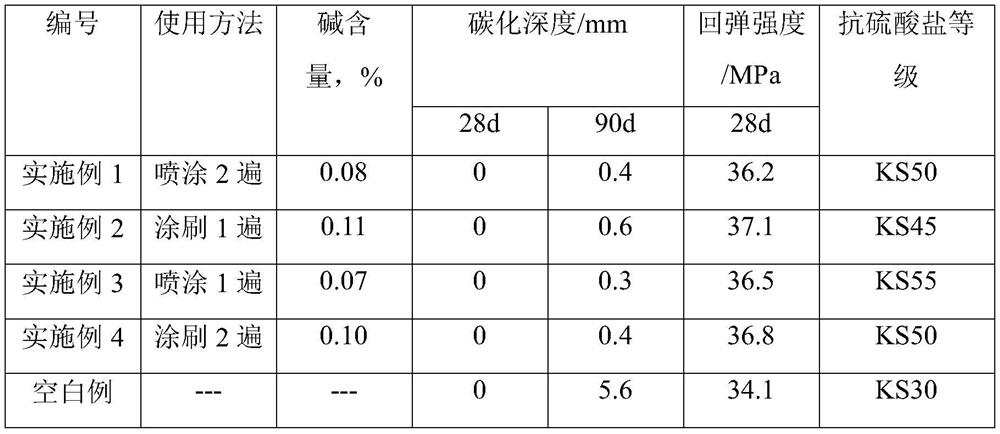

A kind of alkali-free concrete surface protective agent and preparation method thereof

ActiveCN110963821BImproves carbonation resistanceImproves resistance to sulfate attackAlkali freeActive agent

The invention discloses an alkali-free concrete surface protective agent and a preparation method thereof. The raw material composition of the surface protective agent is calculated by mass percentage: 20%-30% of modified fluosilicic acid; 2%-8% of hydrofluoric acid, Chelating agent 2% to 4%, complex surfactant 0.5% to 1.5%, pH regulator 1% to 5%, and the balance is water; first prepare modified fluosilicic acid, add water and stir, then add hydrofluoric acid, Chelating agent, composite surfactant, finally add pH regulator, adjust the pH value to 2-3, the obtained colorless transparent liquid is the concrete surface protective agent; the invention can effectively improve the compactness of the concrete surface, and significantly reduce the concrete surface The depth of carbonation can improve the concrete's ability to resist sulfate attack and rebound strength. The protective agent is convenient to use, has strong operability and is easy to popularize.

Owner:云南凯威特新材料股份有限公司

A microbial immobilization method for concrete crack self-healing

The invention provides a microbial immobilization method for self-repairing concrete cracks, which belongs to the cross-technical field of microbiology and civil engineering materials, including: immobilizing microorganisms or microbial spores in a carrier, and performing an external encapsulation process; The secondary fixation process in which nutrients are loaded in the above-mentioned carrier; and the pre-embedding process in which the fixed carrier obtained from the above-mentioned secondary fixation process is mixed with concrete raw materials; the above-mentioned carrier is coral reef calcareous sand; the above-mentioned nutrients include 3 ,5‑Dinitrobenzyl alcohol and sodium trimetaphosphate. The method provided by the invention can increase the survival rate of microorganisms; it can increase the crack repair width (the maximum repair width reaches more than 1mm, and the average repair width reaches 0.7-0.9mm), and the concrete compressive strength recovers more than 80%; it can effectively reduce sulfate erosion Reduce the loss of concrete compressive strength after repair, improve the sulfate corrosion resistance of repaired concrete, and increase the durability of concrete.

Owner:ZHEJIANG OCEAN UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com