Sprayed basalt fiber concrete and side slope supporting surface layer construction method

A technology of basalt fiber and concrete, which is applied in excavation, foundation structure engineering, construction, etc., can solve the problems of poor soil slope deformation adaptability, affecting soil slope stability, poor shotcrete compactness, etc., and achieves improved use environment, improving the ability to resist sulfate erosion, and reducing the loss of jet rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

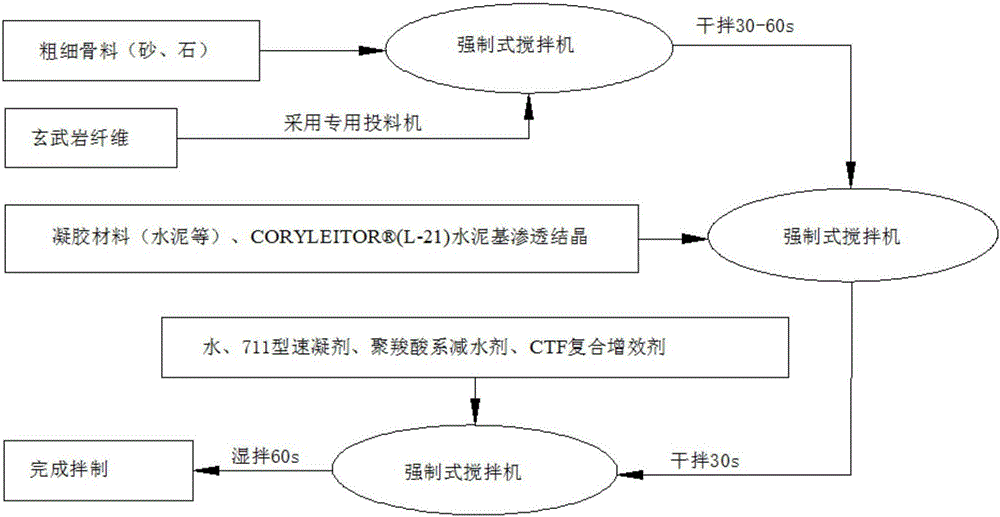

[0052] In this embodiment, according to the design of C20 sprayed basalt fiber concrete, the mass parts of materials used per cubic meter are as follows:

[0053] 3 parts of basalt fiber, 365 parts of P.O42.5 cement, 36 parts of Class II fly ash, 18 parts of S95 granulated blast furnace slag, 19 parts of metakaolin, 3 parts of L-21 cement-based osmotic crystal, 4 parts of CTF composite synergist, 13 parts of 711-type accelerator, 4 parts of polycarboxylate superplasticizer, 925 parts of river sand, 815 parts of gravel, and 172 parts of water;

[0054] Technical indicators: water-binder ratio 0.39, glue-bone ratio 0.25, sand ratio 0.53, bulk density 2377kg / m3.

[0055] Measure the concrete strength of present embodiment as following table:

[0056] age Compressive strength tensile strength 1d 10.6 1.2 7d 28.2 2.2 28d 39.3 2.6

Embodiment 2

[0058] In this embodiment, according to the design of C25 sprayed basalt fiber concrete, the mass parts of materials used per cubic meter are as follows:

[0059] 3 parts of basalt fiber, 385 parts of P.O42.5 cement, 39 parts of Class II fly ash, 19 parts of S95 granulated blast furnace slag, 20 parts of metakaolin, 4 parts of L-21 cement-based osmotic crystal, 4.5 parts of CTF composite synergist, 16 parts of 711-type accelerator, 4.5 parts of polycarboxylate superplasticizer, 915 parts of river sand, 800 parts of gravel, and 176 parts of water;

[0060] Technical indicators: water-binder ratio 0.38, glue-bone ratio 0.27, sand ratio 0.53, bulk density 2386kg / m3.

[0061] Measure the concrete strength of present embodiment as following table:

[0062] age Compressive strength tensile strength 1d 11.2 1.3 7d 30.5 2.3 28d 42.7 2.7

Embodiment 3

[0064] In this embodiment, according to the design of C30 sprayed basalt fiber concrete, the mass parts of materials used per cubic meter are as follows:

[0065] 3 parts of basalt fiber, 410 parts of P.O42.5 cement, 41 parts of Class II fly ash, 20 parts of S95 granulated blast furnace slag powder, 21 parts of metakaolin, 5 parts of L-21 cement-based osmotic crystal, 5 parts of CTF composite synergist, 19 parts of 711-type accelerator, 5 parts of polycarboxylate superplasticizer, 900 parts of river sand, 785 parts of gravel, and 182 parts of water;

[0066] Technical indicators: water-binder ratio 0.37, glue-bone ratio 0.29, sand ratio 0.53, bulk density 2396kg / m3.

[0067] Measure the concrete strength of present embodiment as following table:

[0068] age Compressive strength tensile strength 1d 11.8 1.3 7d 38.5 2.6 28d 51.1 3.0

[0069] The technical solution to further solve the problem that the shotcrete mix ratio meets the design a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com