High-durability concrete

A concrete and durable technology, applied in the field of high-durability concrete, can solve the problems of water content decline, poor regularity of groundwater enrichment in aquifers, and development depth limited by groundwater dynamic conditions, so as to enhance its own durability and improve sulfate resistance. The effect of erosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

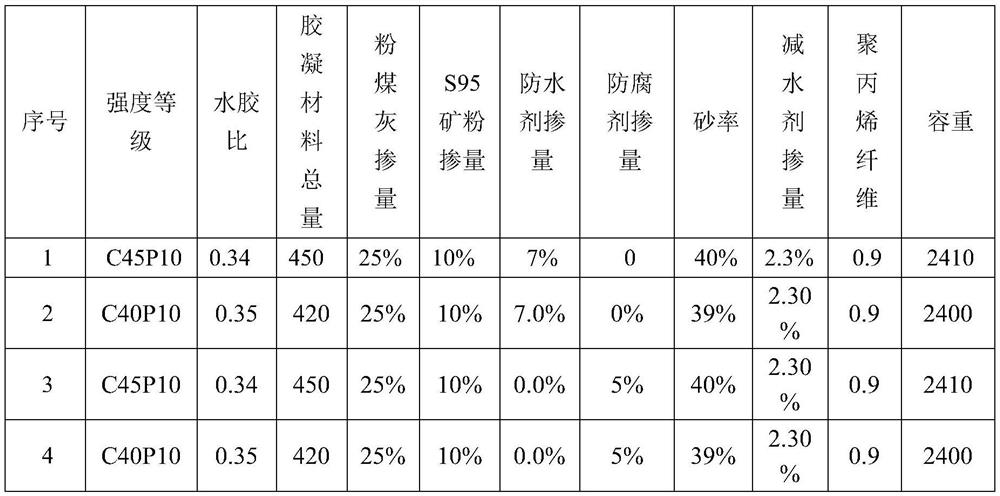

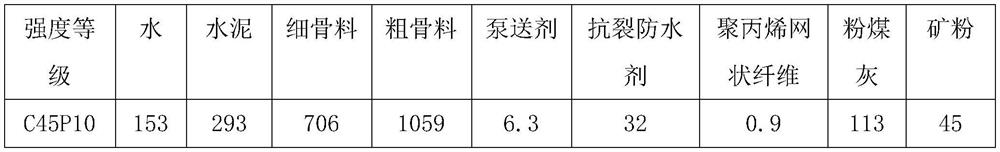

[0021] The present embodiment 1 provides a kind of high durability concrete, and the raw material proportion of concrete described in every cubic meter comprises: cement 273~293kg / m 3 , The total amount of gelling material is 340~450kg / m 3 , Sand 703~710kg / m 3 , Stone 1064~1099kg / m 3 , Admixture 9.66~10.35kg / m 3 , Polypropylene fiber 0.9~1.2kg / m 3 and the remaining amount of water; the cementitious material includes fly ash 105~113kg / m 3 , S95 mineral powder 42~45kg / m 3 And waterproofing agent 29~32kg / m 3 .

[0022] Compared with the existing technology, due to the presence of sulfate in groundwater and the irregularity of its flow direction, for large-volume concrete, the sulfate in groundwater has a strong erosive force on concrete. This solution provides a High-durability concrete, adopting this scheme, improves the sulfate erosion resistance, crack resistance and chloride ion penetration resistance of concrete through the preparation of the combination ratio of conc...

Embodiment 2

[0034] Embodiment 2 is further optimized on the basis of Embodiment 1, and a specific implementation manner is provided.

[0035] 1. Mass concrete design

[0036] The thickness of the floor is 1.8m, the thickness of the shear wall is 1m, 2m, 3m, the thickness of the roof is 2.5m, 2.8m, 3.0m, the concrete is grade C45P10, and the construction technology of pumping concrete is adopted. The mass concrete of this project uses the 60-day post-strength of concrete as the basis for concrete design, strength evaluation and acceptance.

[0037] 1.1. Durability design

[0038] 1) The maximum water-binder ratio of concrete is 0.40, and the minimum amount of cementitious material is 340kg / m3 / . Ⅲ; Anti-carbonization performance level T-Ⅳ;

[0039] 2) Portland cement and ordinary Portland cement should be used for concrete, and its strength grade should not be lower than No. 42.5; when other types of cement are used, it should be determined through experiments, and high-hydration concret...

Embodiment 3

[0069] Embodiment 3 is further optimized on the basis of Embodiment 2.

[0070] Regarding the curing of concrete, the curing of concrete is one of the key steps in concrete construction. For high-performance concrete, due to the small water-binder ratio, the amount of bleeding after pouring is very small. When the moisture lost by evaporation on the concrete surface is not fully replenished, the plastic shrinkage of the concrete is intensified. At this time, the concrete does not yet have the strength required to resist deformation, which easily leads to the generation of plastic shrinkage cracks, affecting durability and strength. In addition, the amount of high-performance concrete cementitious material is large, and the hydration temperature rises, which leads to increased self-shrinkage and temperature stress. For high-performance concrete with high fluidity, due to the large amount of cementitious material, large When molding to the component, it will cause a large propo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com