Organic fluorosilicone and metakaolin concrete waterproofing fortifier and preparation method and application thereof

A technology of metakaolin and metakaolin powder, which is applied in the field of organofluorosilicon and metakaolin concrete waterproof enhancer and its preparation, and can solve the problems affecting the shelf life of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Metakaolin 40%; Alkali-soluble resin 4%; Organic fluorosilicone resin 5%; Organic fluorosiloxane 3%; Organic fluorosilane 2%; Emulsifier 0.4%; The alkali-soluble resin is alkali-soluble acrylic resin, the emulsifier is fluorinated polyethylene glycol, and the pH regulator is mixed phosphate with pH=6.86.

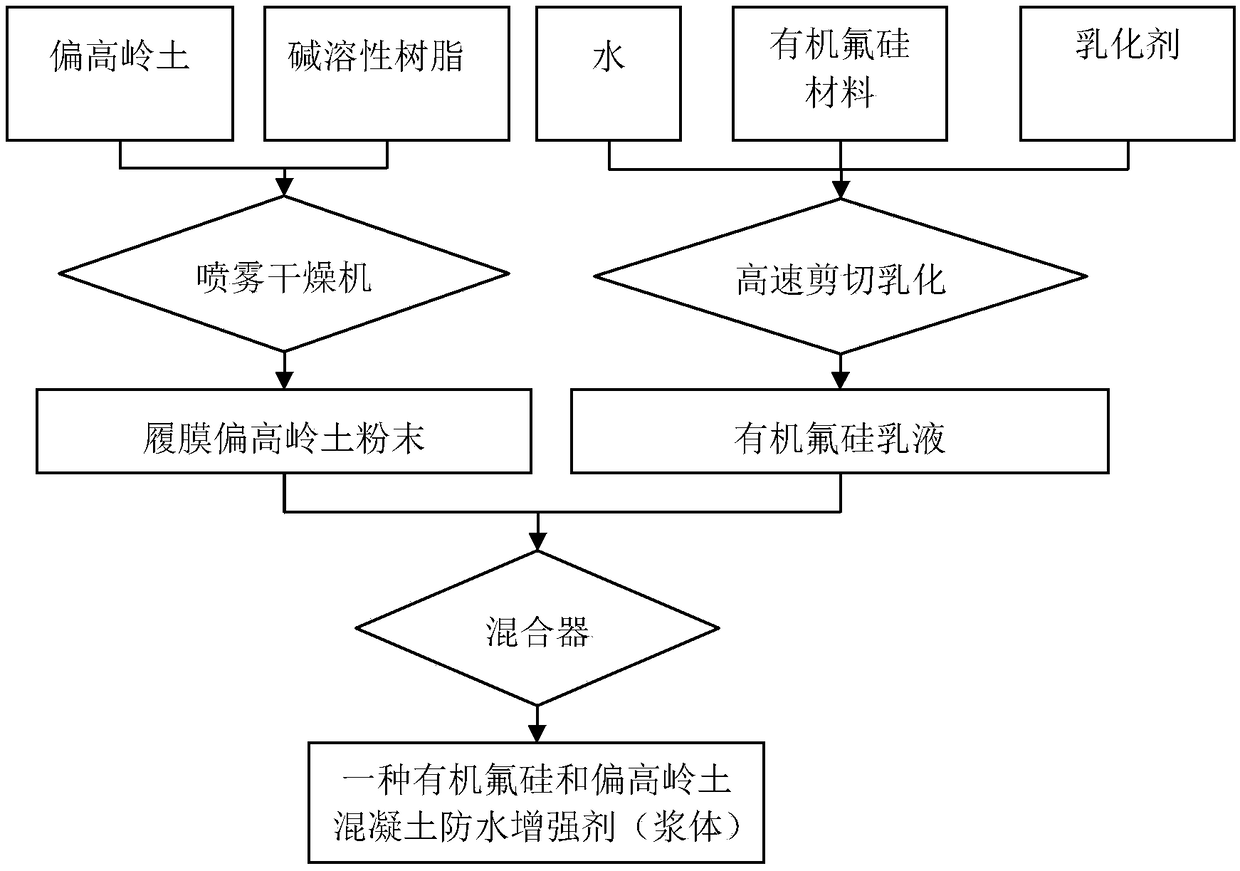

[0030] Prepare concrete waterproof reinforcing agent according to the following steps:

[0031] (1) Ingredients;

[0032] (2) Metakaolin is soaked with an alkali-soluble resin, so that the surface of the metakaolin particles is coated with a layer of alkali-soluble resin film, and then the metakaolin powder with an alkali-soluble protective film is prepared by a spray drying process;

[0033] (3) The organofluorosilicon hydrophobic component is dispersed into the aqueous solution of the emulsifier through a high-speed shear emulsification process to prepare a stable organofluorosilicon oil-in-water emulsion; the pH value is adjusted to neutral;

[0034] (4) Mix met...

Embodiment 2

[0036] Metakaolin 50%; Alkali-soluble resin 5%; Organic fluorosilicone resin 3%; Organic fluorosiloxane 2%; Organic fluorosilane 5%; Emulsifier 0.3%; The alkali-soluble resin is alkali-soluble acrylic resin, the emulsifier is fluorinated polyethylene glycol, and the pH regulator is mixed phosphate with pH=6.86.

[0037] Prepare concrete waterproof reinforcing agent according to the following steps:

[0038] (1) Ingredients;

[0039] (2) Metakaolin is soaked with an alkali-soluble resin, so that the surface of the metakaolin particles is coated with a layer of alkali-soluble resin film, and then the metakaolin powder with an alkali-soluble protective film is prepared by a spray drying process;

[0040](3) The organofluorosilicon hydrophobic component is dispersed into the aqueous solution of the emulsifier through a high-speed shear emulsification process to prepare a stable organofluorosilicon oil-in-water emulsion; the pH value is adjusted to neutral;

[0041] (4) Mix meta...

Embodiment 3

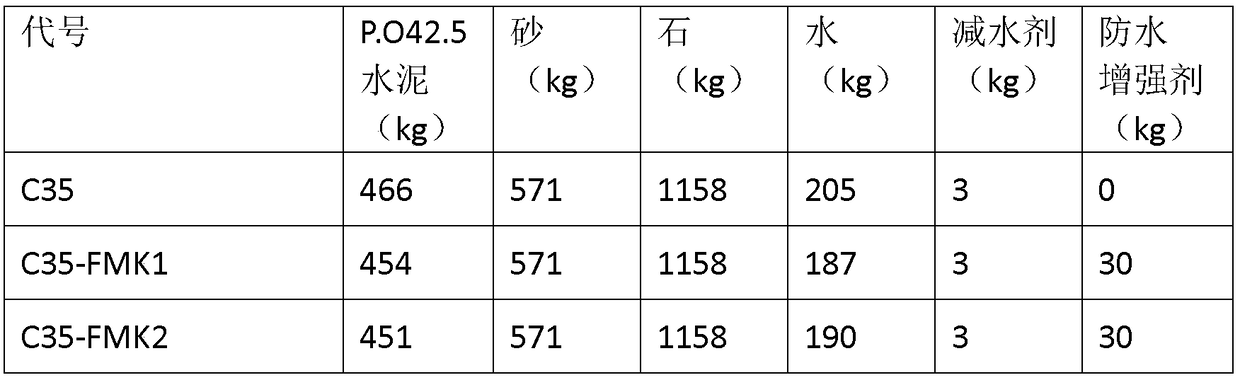

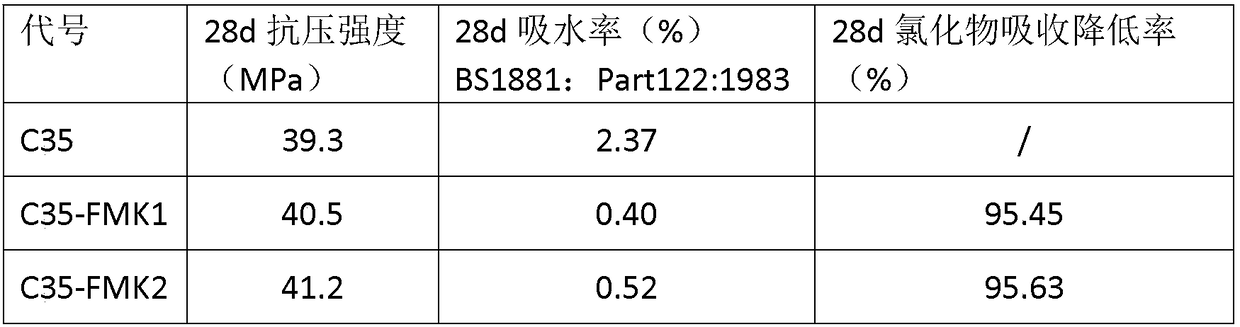

[0043] Sample FMK1, FMK2 gained in embodiment 1, embodiment 2 are mixed in the concrete respectively, carry out waterproof, chloride absorption reduction rate inspection and analysis as follows:

[0044] Table 1 test mix ratio

[0045]

[0046] Among them, C35 is the concrete strength grade, C35 group is the blank control sample, C35-FMK1 group or C35-FMK2 group is the concrete with C35 strength grade mixed with FMK1 or FMK2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com