Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

A prestressing and concrete technology, applied in the field of concrete pipe piles, can solve the problems of lithium slag occupying land, polluting the environment, and high energy consumption, and achieve the effects of saving cement consumption, reducing energy consumption, and good grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

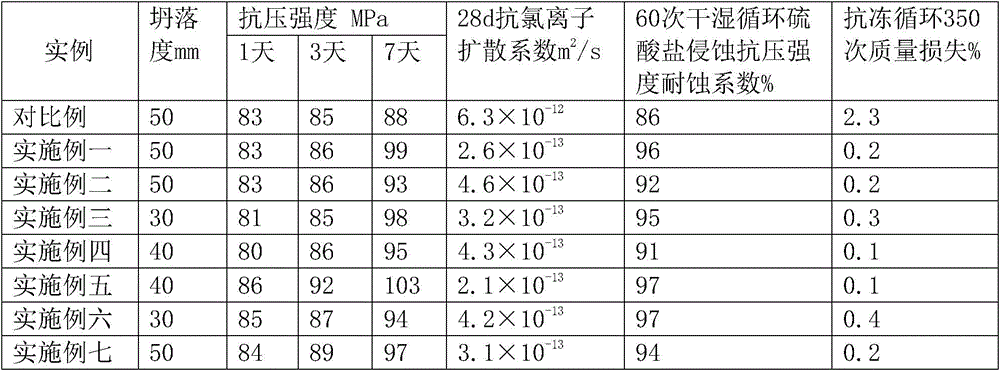

Examples

Embodiment 1

[0053] The steam-free prestressed high-strength pipe pile concrete is composed of the following components by mass: 340 parts of PII52.5 cement, 50 parts of mineral powder, 100 parts of lithium slag powder, 25 parts of glass microbead powder, 680 parts of sand, and 1160 parts of crushed stone , 135 parts of water, 5 parts of polycarboxylate superplasticizer, Al 2 (SO 4 ) 3 18H 2 O2 copies.

[0054] The preparation of pressure-free prestressed high-strength pipe piles includes the following steps:

[0055] 1) Al 2 (SO 4 ) 3 18H 2 O mixed in cement, mineral powder, lithium slag powder, glass microbead powder and stirred evenly;

[0056] 2) Then the remaining materials: sand, gravel, water, polycarboxylate superplasticizer are stirred into uniform concrete;

[0057] 3) Concrete is poured into the pipe pile mold equipped with a steel cage, the fabric is stretched, prestressed, and centrifugally formed;

[0058] 4) Stand still for 2 hours, steam curing at 80°C for 6 hours...

Embodiment 2

[0061] The steam-free prestressed high-strength pipe pile concrete is composed of the following components by mass: 370 parts of PII52.5 cement, 80 parts of mineral powder, 25 parts of lithium slag powder, 40 parts of glass microbead powder, 720 parts of sand, and 1125 parts of crushed stone , 130 parts of water, 4 parts of polycarboxylate superplasticizer, 3 parts of Yuanming powder.

[0062] The preparation of pressure-free prestressed high-strength pipe piles includes the following steps:

[0063] 1) Mix the sodium sulfate into cement, mineral powder, lithium slag powder, and glass microbead powder and stir evenly;

[0064] 2) Then the remaining materials: sand, gravel, water, polycarboxylate superplasticizer are stirred into uniform concrete;

[0065] 3) Concrete is poured into the pipe pile mold equipped with a steel cage, the fabric is stretched, prestressed, and centrifugally formed;

[0066] 4) Stand still for 1 hour, then steam curing at 60°C for 8 hours;

[0067] ...

Embodiment 3

[0069] The steam-free prestressed high-strength pipe pile concrete is composed of the following components by mass: 300 parts of PI52.5 cement, 80 parts of mineral powder, 80 parts of lithium slag powder, 32 parts of glass microbead powder, 700 parts of sand, and 1170 parts of crushed stone , 125 parts of water, 5 parts of polycarboxylate superplasticizer, and 5 parts of gypsum.

[0070] The preparation of pressure-free prestressed high-strength pipe piles includes the following steps:

[0071] 1) Mix gypsum into cement, mineral powder, lithium slag powder, glass microbead powder and stir evenly;

[0072] 2) Then the remaining materials: sand, gravel, water, polycarboxylate superplasticizer are stirred into uniform concrete;

[0073] 3) Concrete is poured into the pipe pile mold equipped with a steel cage, the fabric is stretched, prestressed, and centrifugally formed;

[0074] 4) Stand still for 1 hour, then steam curing at 80°C for 8 hours;

[0075] 5) Demoulding, then na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com