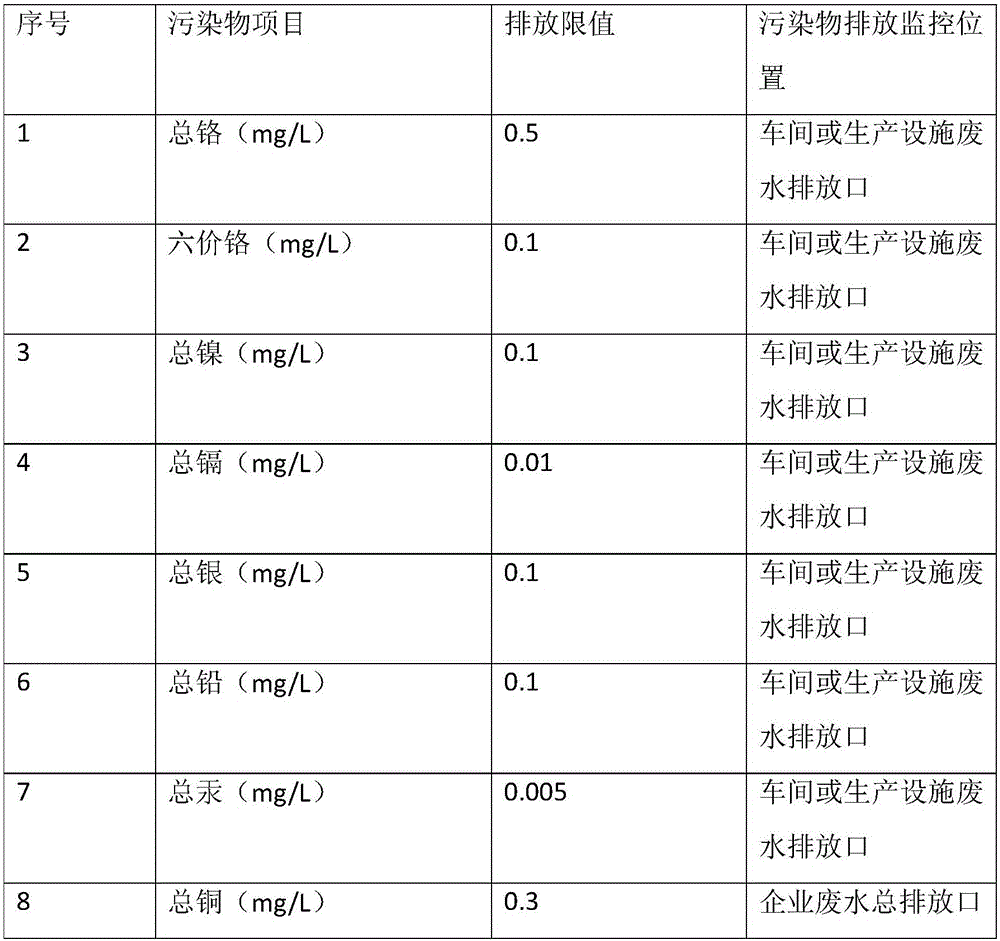

Patents

Literature

108results about How to "Achieve settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

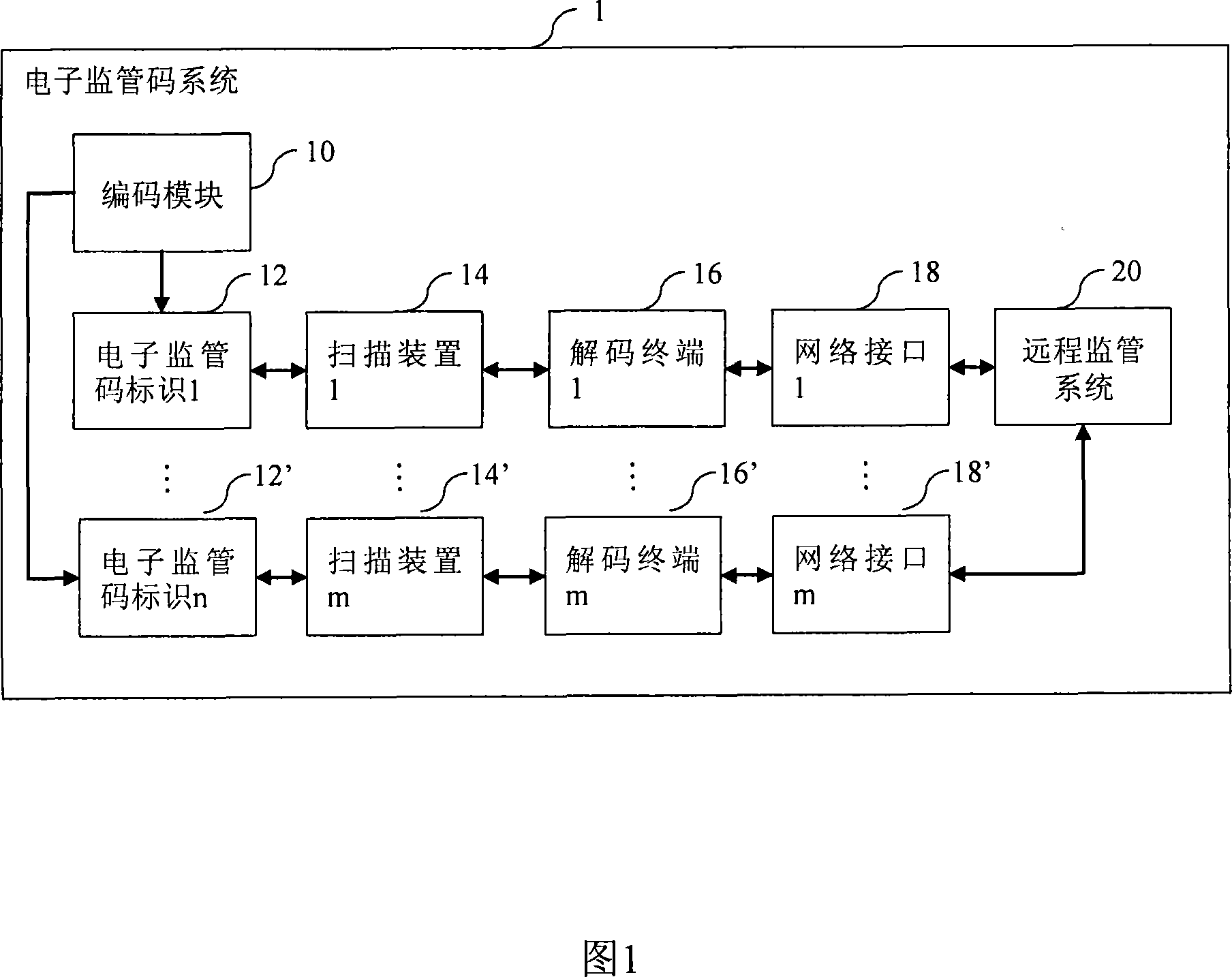

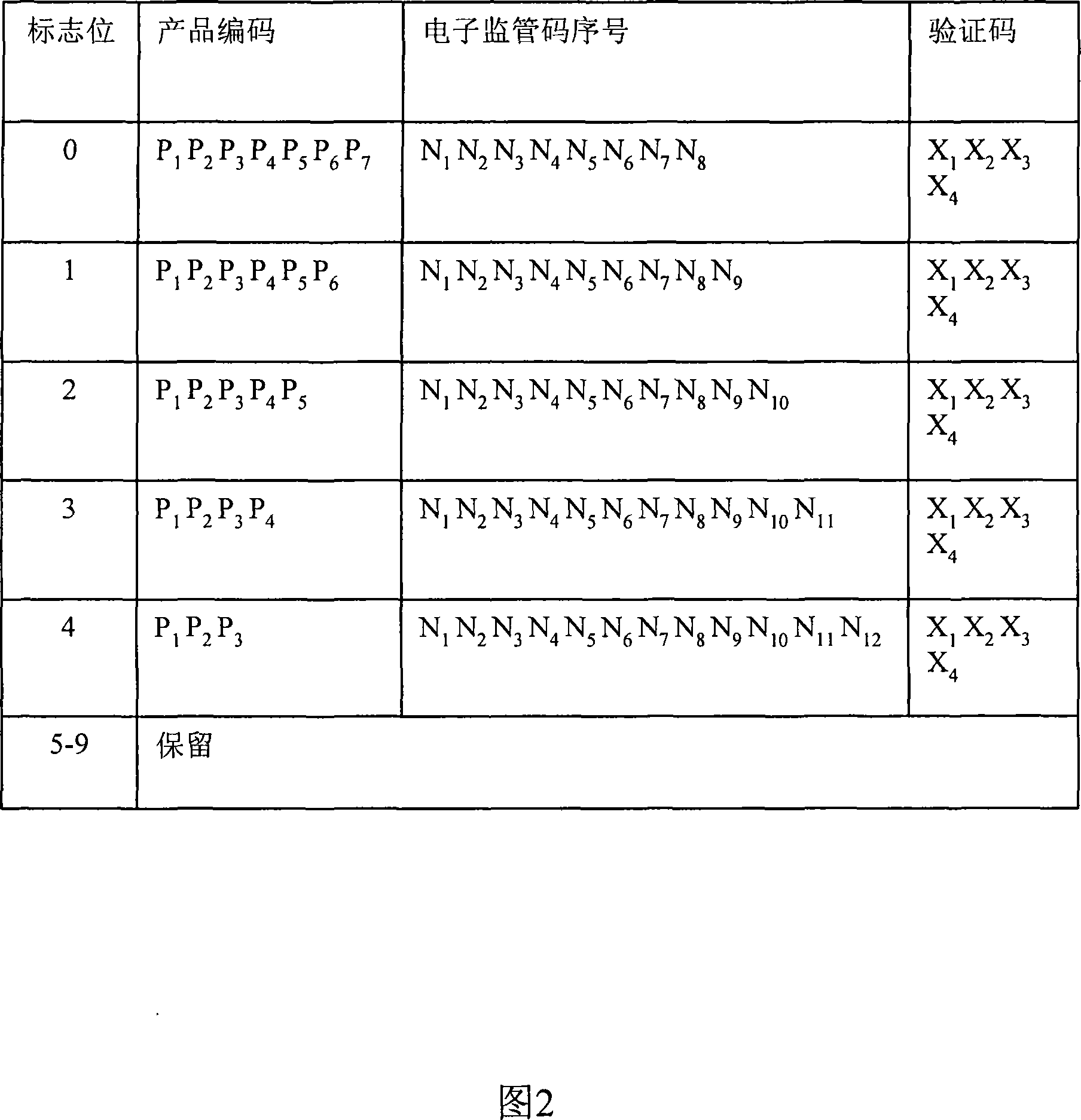

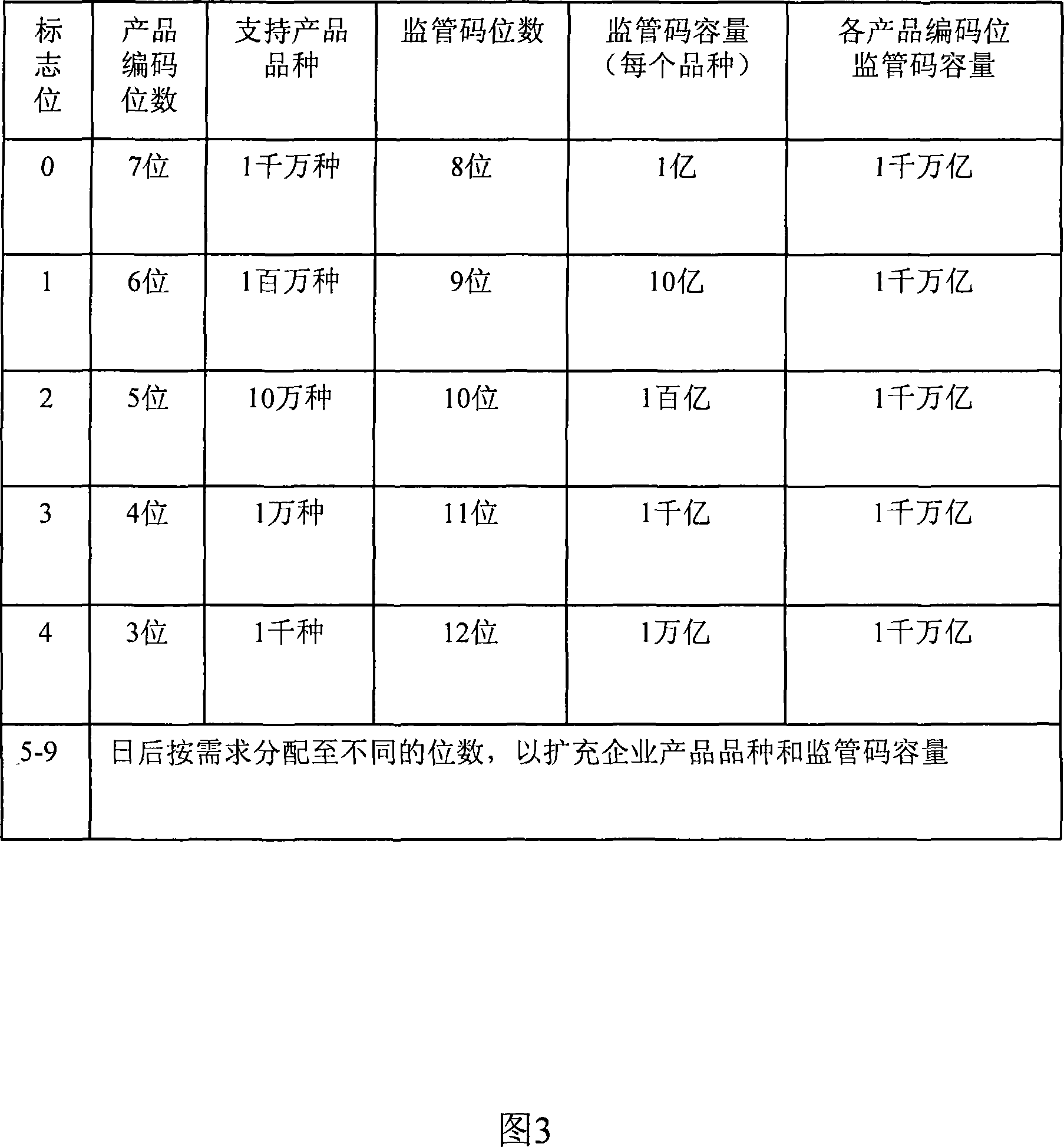

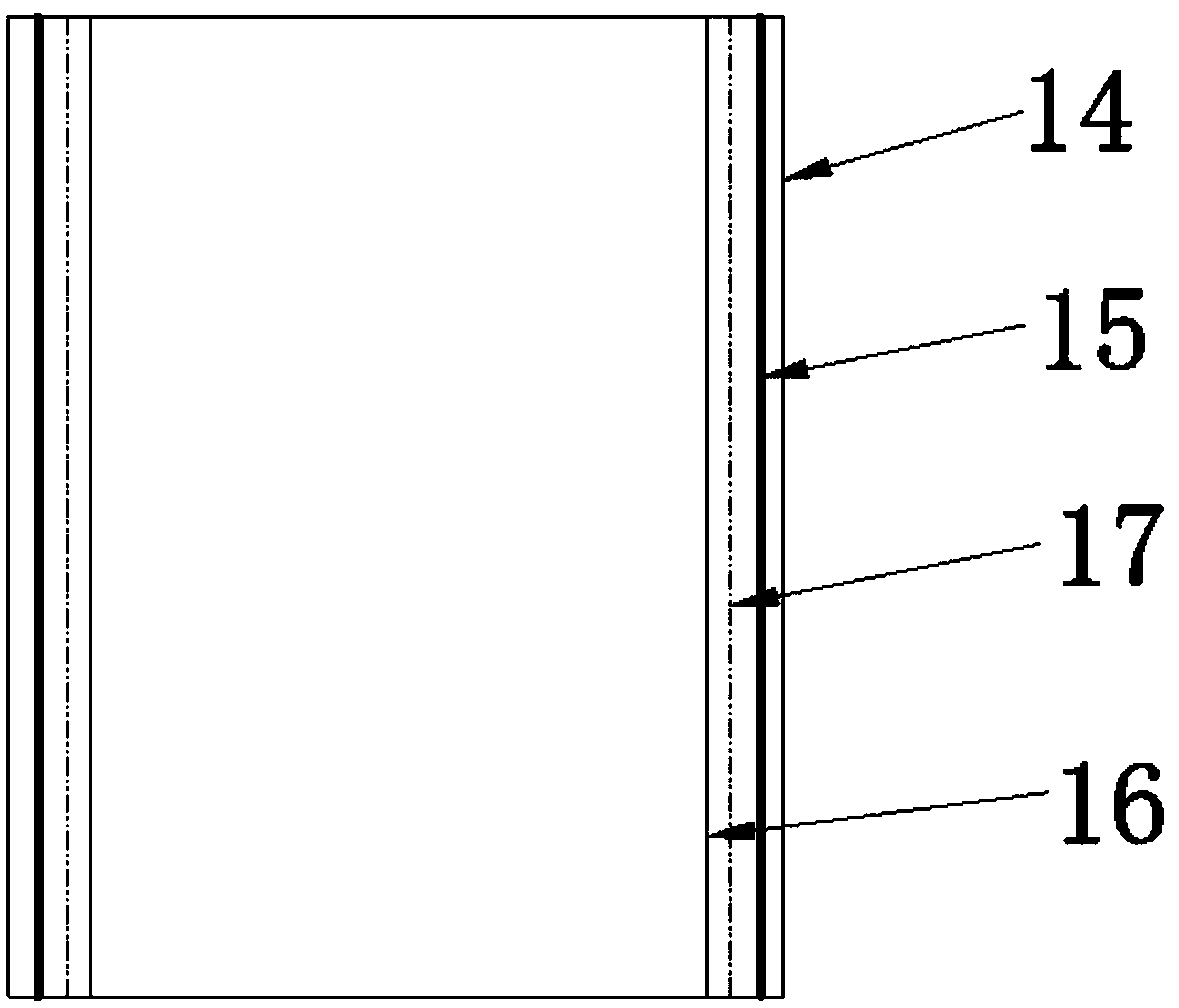

Electronic monitoring code system

InactiveCN101236623AAchieve settlementRealize electronic information supervisionCo-operative working arrangementsRemote monitoring and controlQuality monitoring

The present invention discloses an electronic supervisory code system comprising a coding module of the electronic supervisory code which is uniquely corresponding to the obtained information on a code-attached product according to a certain coding rule, a scan device which scans and identifies the electronic supervisory code markers attached on products, a plurality of decoding terminals arranged in each stage in the circulation of the code-attached products, and a remote supervisory system. The decoding device decodes the identifying information of the scan device to obtain the electronic supervisory code of the code-attached products and the product information of the code-attached product in the corresponding stage of production or circulation, and uploads the product information to the remote supervisory system. The remote supervisory system receives the data information uploaded from each decoding terminal in real-time, and carries out remote monitoring and control on the corresponded decoding terminal via comparison and query. The electronic supervisory code system uses the electronic supervisory code and is combined with a network system to realize information electronic supervision for the code-attached products so as to timely and effectively obtain the data information, such as flow tracking, quality monitoring and information feedback, of the code-attached products.

Owner:CITIC 21CN CHINA TECH

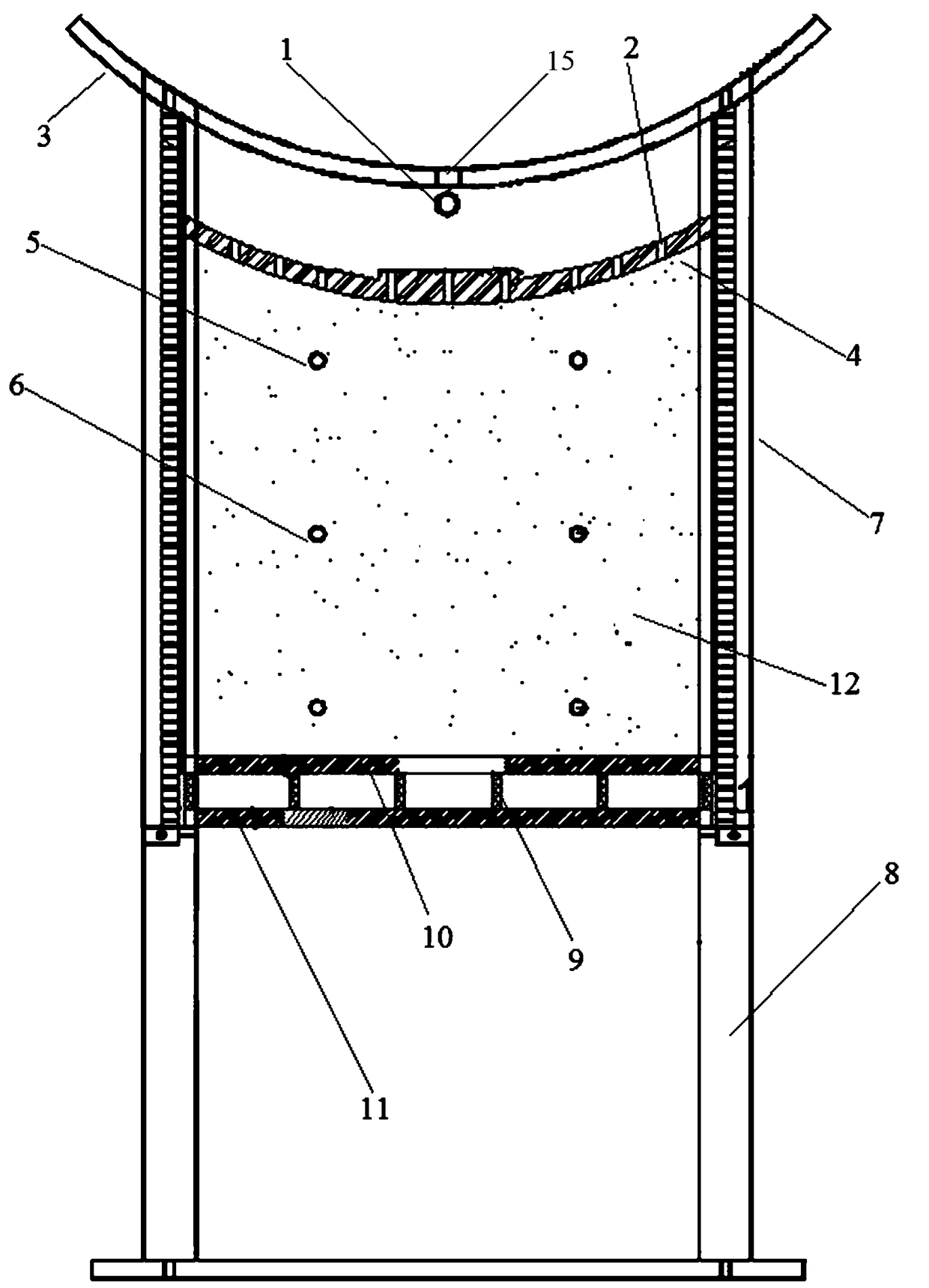

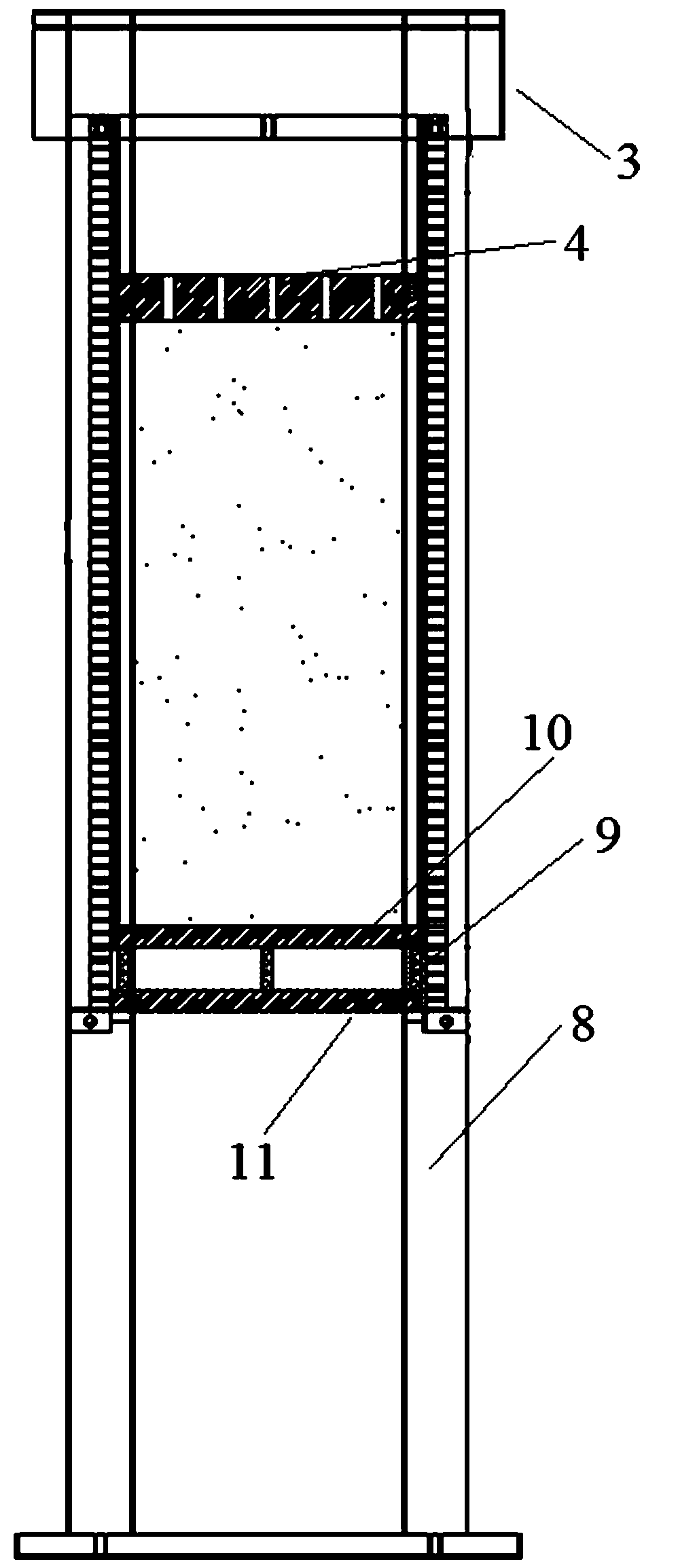

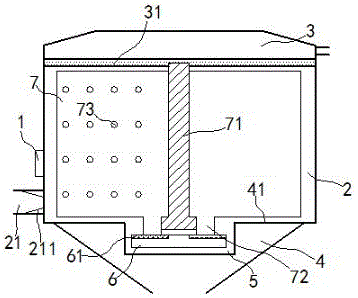

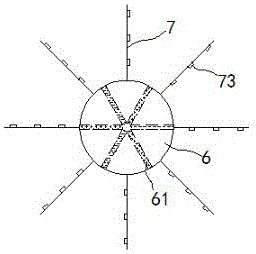

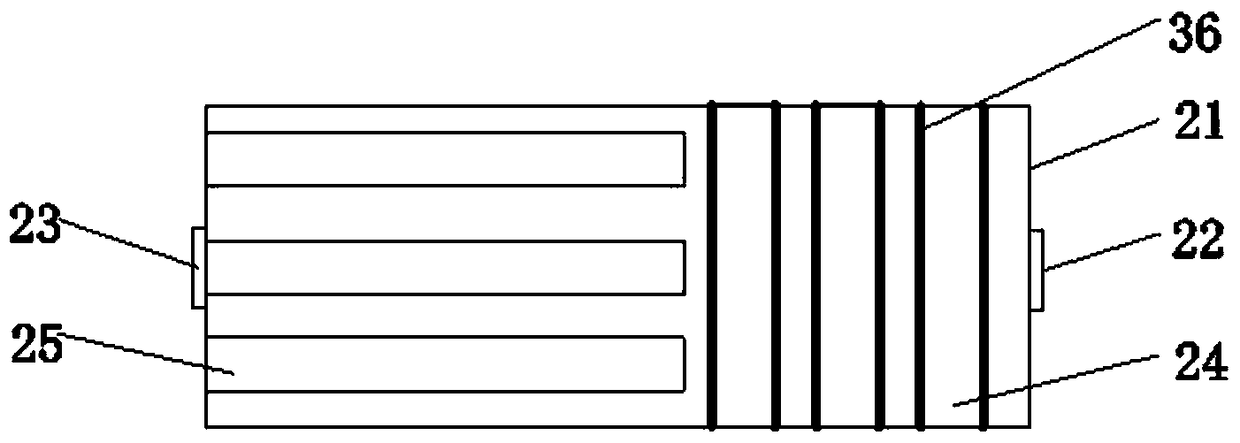

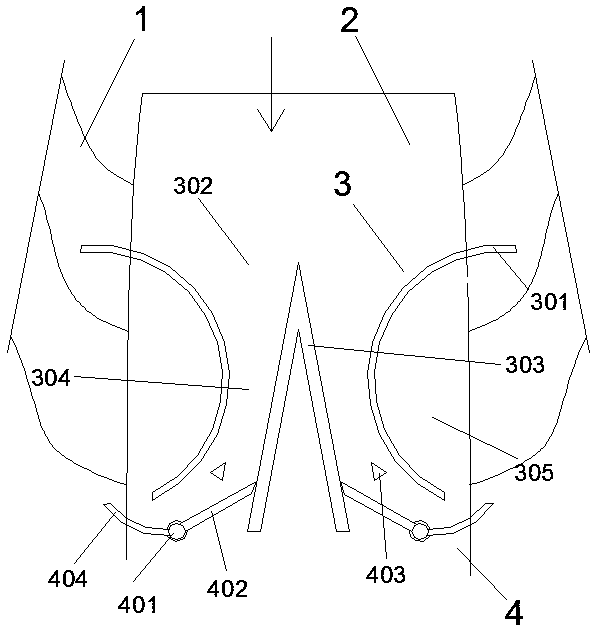

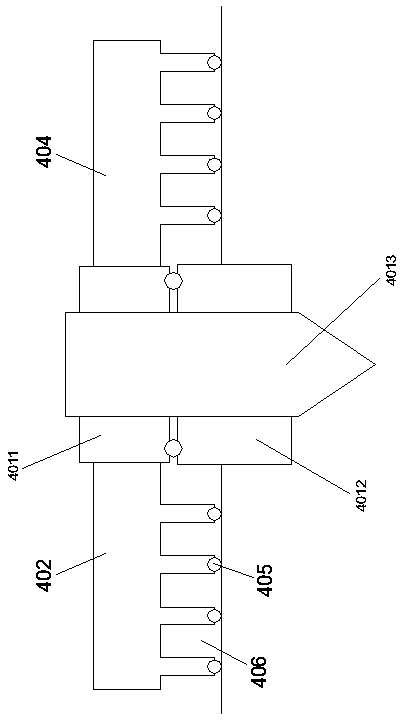

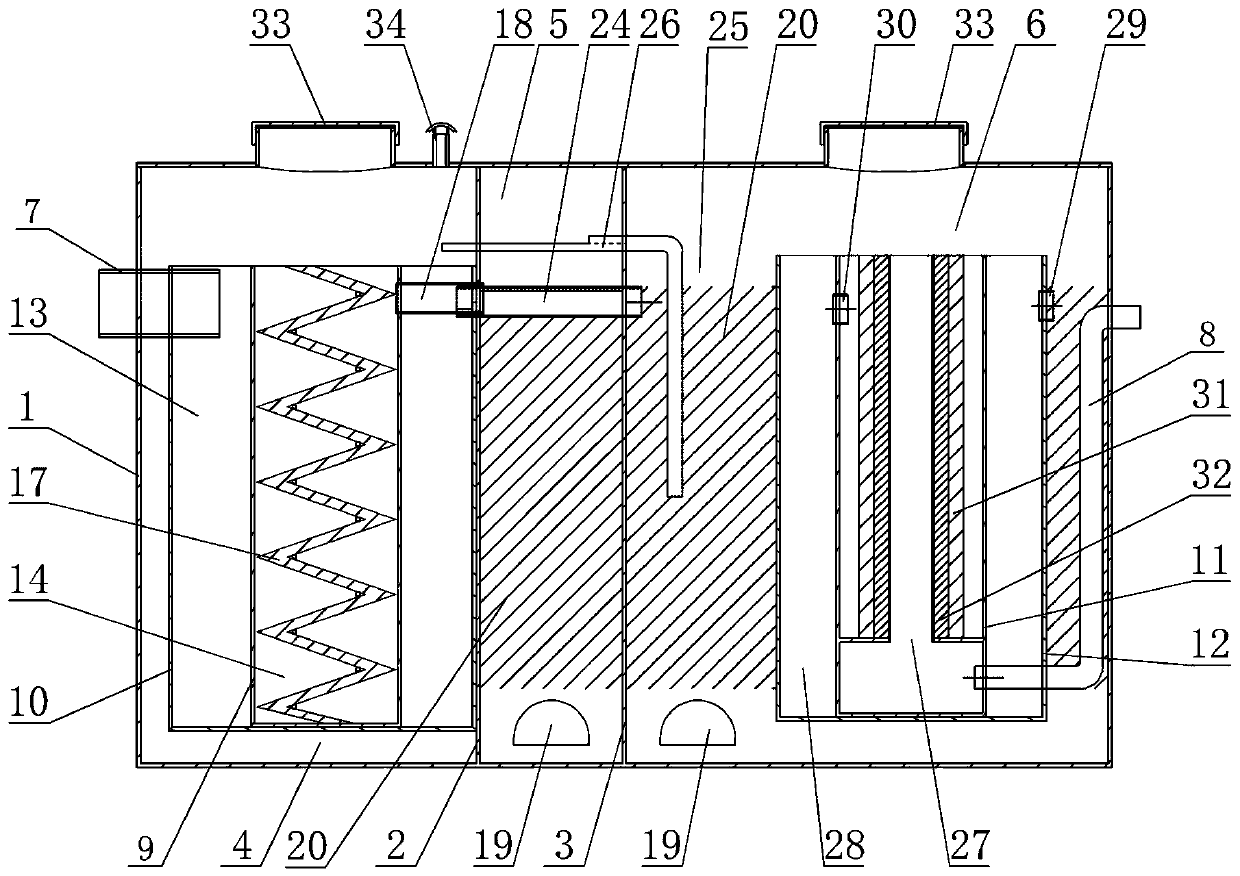

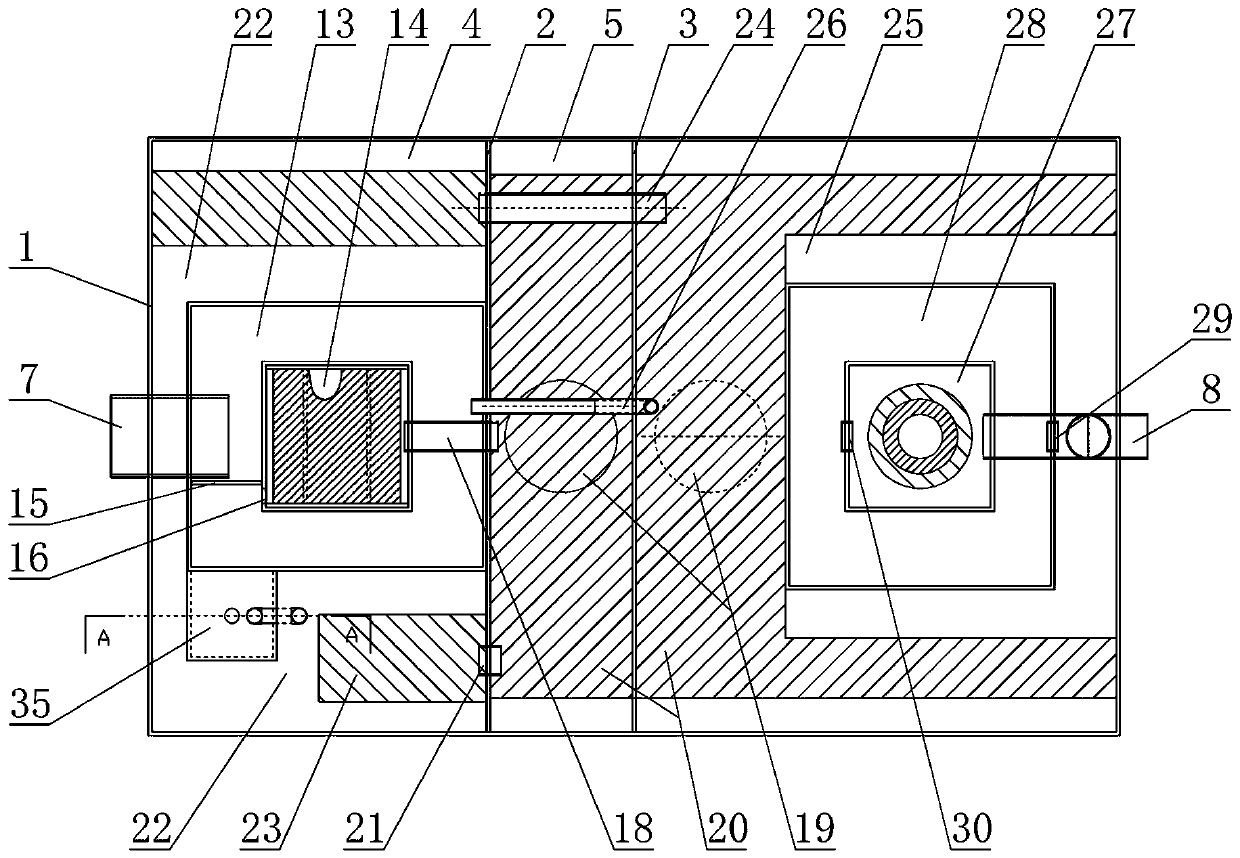

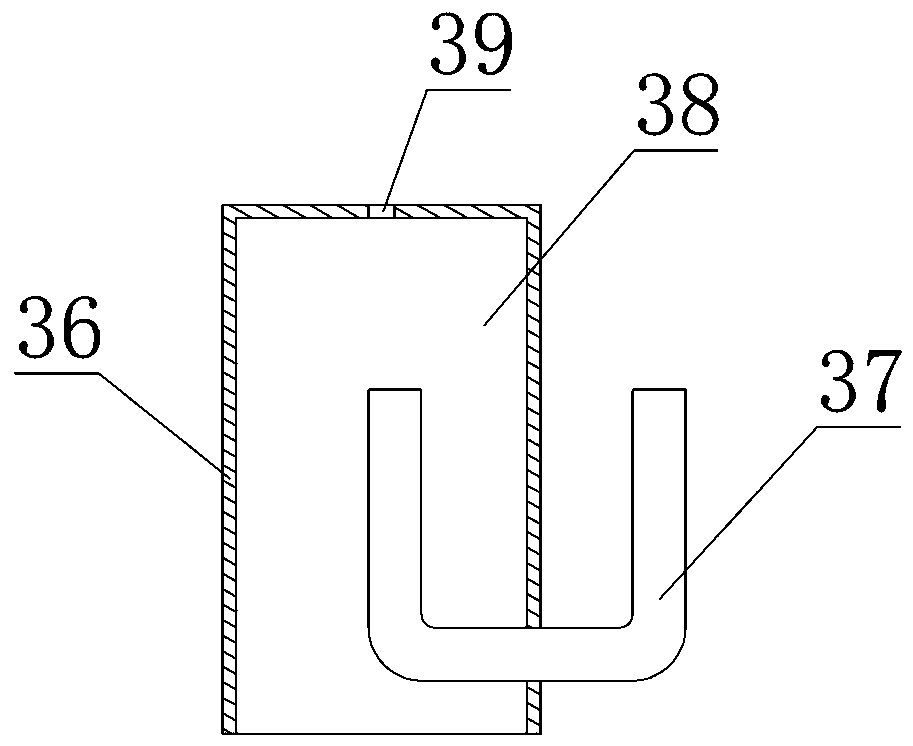

Model test device for shield-tail grouting slurry condensing and duct piece floating processes

PendingCN108872297AFloating to achieveAchieve settlementInvestigating phase/state changeShield machineEngineering

The invention relates to a model test device for shield-tail grouting slurry condensing and duct piece floating processes, and the model test device comprises a model box for bearing and filling modelsoil. The model test device is characterized in that the top end of the model box is detachably connected with a steel duct piece model; the bottom end of the model box is provided with a loading plate assembly; the loading plate assembly comprises a loading plate, a spring connected with the loading plate and a counter-force beam fixedly connected with the spring; the loading plate, the spring and the counter-force beam are sequentially arranged from top to bottom; the upper side plate surface of the loading plate is in contact with the model soil; and the model test device further comprisesa pressure applying mechanism for applying pressure to the counter-force beam. The model test device solves the problem that the dust piece floats as the dust piece is separated from the shield tailand then is syncrhously grouted in a process of stimulating a shield tunneling machine tunneling process in the prior art.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP +2

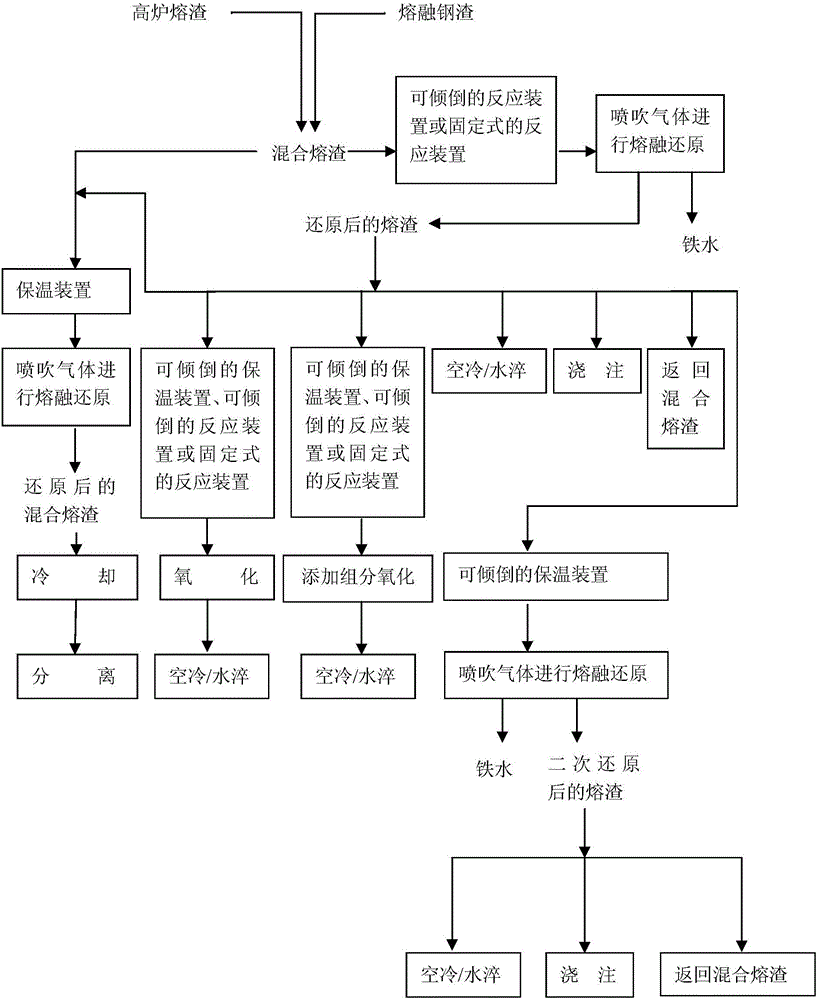

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

Method for smelting reduction production of zinc smelting slag

InactiveCN107699699ASolve the accumulationTake advantage ofProcess efficiency improvementIndiumBismuth

The invention discloses a method for smelting reduction production of zinc smelting slag. The method for smelting reduction production of the zinc smelting slag comprises the following steps that S1,the zinc smelting slag is added into an insulation device or a smelting reaction device allowing slag to flow out, calcium minerals and additives are added, all the components are heated to be in themolten state, one or more of copper oxide minerals, copper sulfide minerals and copper-containing materials are added into the insulation device or the smelting reaction device at the moment, reactionslag is monitored in real time, and molten slag is obtained by regulating and controlling the temperature and the CaO / SiO2 basicity ratio of the reaction slag; and S2, the molten slag is obtained, aferrum-containing silicate mineral phase, a copper-rich phase, a ferrum-rich phase and dust containing zinc, lead, bismuth and smoke are obtained through settlement separation, gold and silver are migrated and enriched to enter the copper-rich phase, and all the phases are separated. According to the method for smelting reduction production of the zinc smelting slag, the slag copper content (lowerthan 0.1 wt%) can be decreased, efficient recovery of components such as copper, ferrum, gold, silver, lead, zinc, indium, bismuth, sodium and potassium can be achieved, and low-copper ferrum-containing materials are obtained; and the metal recovery rate is high, the production cost is low, environmental friendliness is achieved, and economic benefits are high.

Owner:NORTHEASTERN UNIV

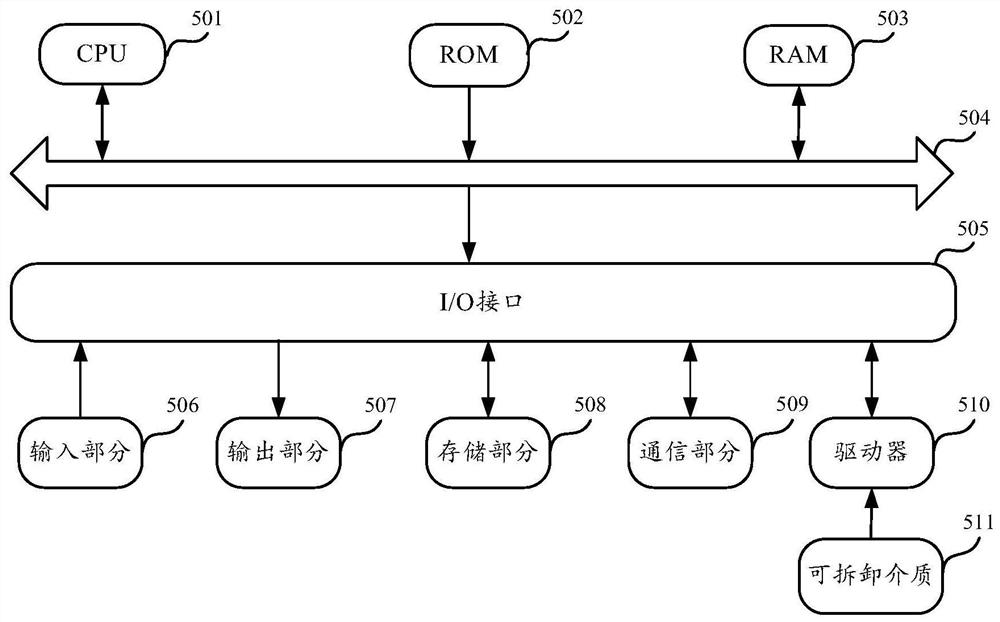

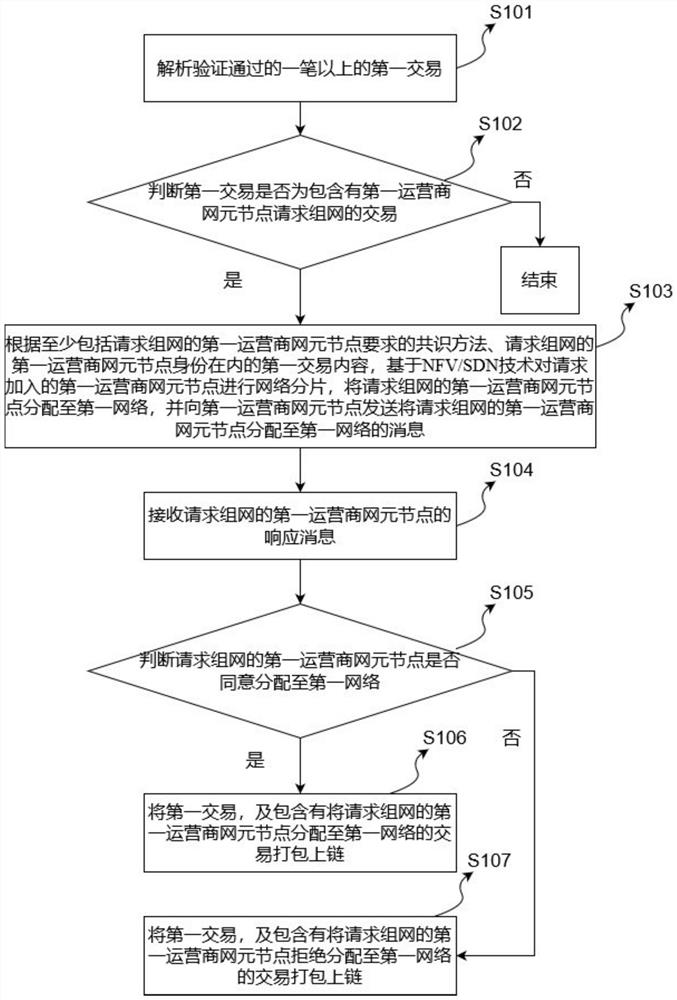

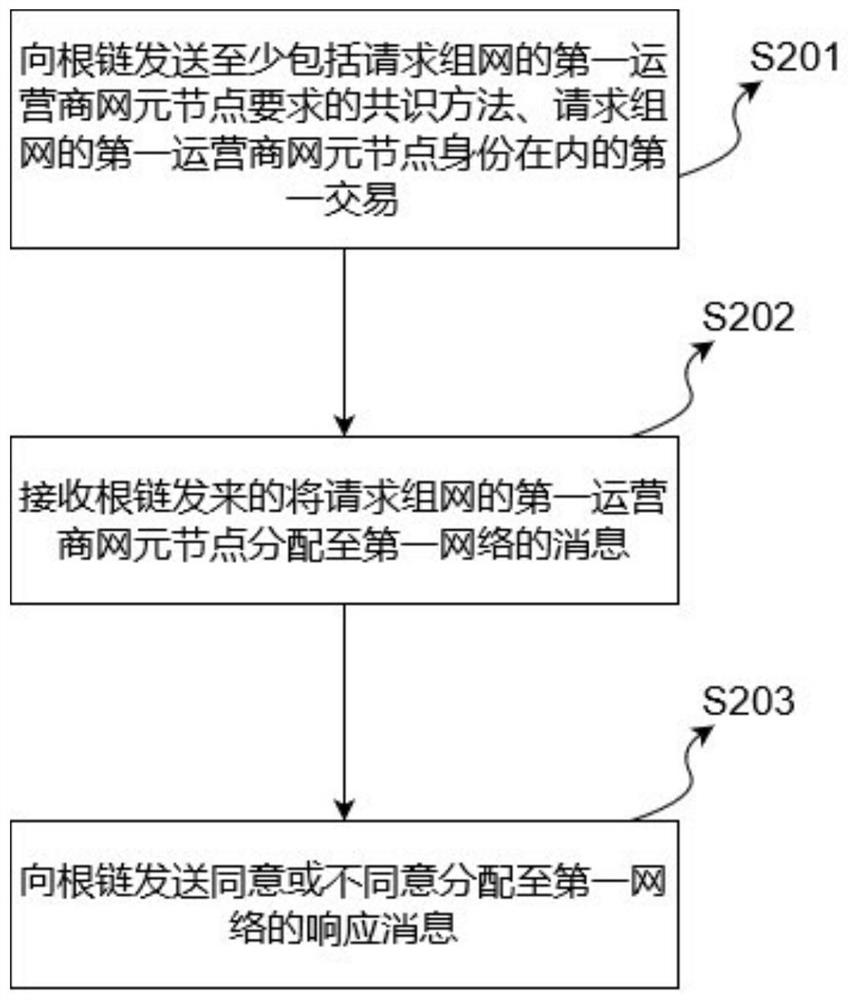

Network convergence, networking method and device thereof, and storage medium

ActiveCN111934919AFix security issuesSolve the problem of difficult deploymentData switching networksNetwork ConvergenceEngineering

The invention discloses a network convergence, a networking method and device thereof, and a storage medium, and belongs to the technical field of block chains. The method comprises the following steps: analyzing more than one first transaction passing verification; judging whether the first transaction contains a transaction requested to be networked by a first operator network element node or not; if yes, requesting first transaction content including the identity of the first operator network element node requesting networking according to a consensus method at least including the requirement of the first operator network element node requesting networking, wherein network fragmentation is carried out on the first operator network element node requested to be added based on the NFV / SDNtechnology, and rapid networking can be realized; security isolation, network convergence and resource sharing are realized; the access speed and experience are improved.

Owner:XIAMEN TANHONG INFORMATION TECH CO LTD

Method for recycling valuable components from copper-containing slag

InactiveCN107699702ARealize comprehensive utilizationTake advantage ofProcess efficiency improvementHeavy metalsCalcium

The invention relates to a method for recycling valuable components from copper-containing slag. The method includes the steps that S1, clinker is mixed, wherein copper slag is added in a smelting reaction device, calcium-series mineral and an additive are added, mixed slag is formed, the mixed slag is heated to the molten state to be used as reaction slag and is evenly mixed, the reaction slag ismonitored in real time, the mixed reaction slag is made to meet the condition a and the condition b at the same time through regulation and control, and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, hot-state slag can be processed, molten copper slag physical heat resources and hot-state metallurgy flux are sufficiently utilized, cold-state clinker can also be processed; by adjusting the physicochemical property of the slag and using the mature physicochemical property of the copper-containing slag, the copper-containing slag metallurgy process is achieved, and the problem that because a large amount of clinker is stacked at present, environment pollution is caused and the problem of heavy metal element pollution are solved.

Owner:NORTHEASTERN UNIV

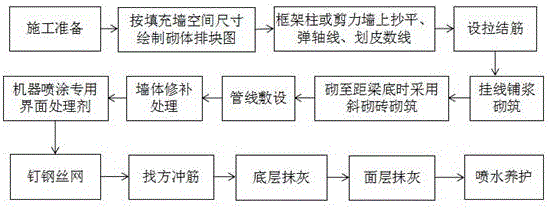

Improved anti-crack construction technique for aerated concrete block wall

The invention discloses an improved anti-crack construction technique for an aerated concrete block wall. The technological process of the improved anti-crack construction method comprises the steps of construction preparation; drawing of a masonry block arrangement map according to the spatial size of a filler wall; leveling of frame columns or a shear wall, snapping of axes, and scribing and brick layer lines; arrangement of tie bars; line hanging, mortar laying and construction; construction of skew bricks when construction is conducted to the position 130 mm away from the beam bottom; pipeline laying; repairing treatment of the wall; spraying of a special interface treating agent through a machine; nailing of a steel wire gauze; alignment and bar embedding; plastering of the bottom layer; plastering of the surface layer; and water spraying for curing. The improved anti-crack construction technique for the aerated concrete block wall has the characteristics that construction operation is easy and convenient, comprehensive cost is reduced, the construction period is shortened, the anti-crack requirement of the wall is met, and accordingly the quality of the wall is improved; and the improved anti-crack construction technique for the aerated concrete block wall has extremely good application prospects.

Owner:轩重建筑节能科技(上海)有限公司

Method for recycling valuable components from mixed slag containing nickel and iron

InactiveCN107663589ASolve pollutionAchieve recyclingProcess efficiency improvementLead smeltingIron alloys

The invention relates to a method for recycling valuable components from mixed slag containing nickel and iron. The method comprises the following steps: S1, mixing slag, namely adding nickel smeltingslag into a smelting reaction device, and adding one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag, thus forming mixed slag; heating the mixed slag to be in a smelting state to be taken as reaction slag, mixing uniformly, monitoring the reaction slag in real time, and meanwhile, regulating to enable the mixed slag containing nickel and iron to meet conditions aand b simultaneously, thus obtaining the reacted slag; and S2, separating for recycling. According to the method, the mixed slag containing nickel and iron can be treated efficiently, so that the problems that a great amount of slag is accumulated to result in environment pollution and heavy metal pollution are solved, and the heavy metal components can be recycled.

Owner:NORTHEASTERN UNIV

Method for recovering valuable components from zinc smelting slag

InactiveCN107674985ASolve pollutionRealize comprehensive utilizationProcess efficiency improvementMolten stateIndium

The invention discloses a method for recovering valuable components from zinc smelting slag. The method comprises the following steps that S1, the zinc smelting slag is added to a heat insulating device or a smelting reaction device in which slag can flow out, calcium-based minerals and additives are added, and mixed slag is formed; the mixed slag is heated to a molten state, reaction slag is formed, the reaction slag is monitored in real time, and by regulating and controlling the temperature of the reaction slag and the specific value of alkalinity CaO / SiO2, the slag obtained after a reaction is completed is obtained; and S2, the obtained slag is subjected to sedimentation separation, smoke dust containing a ferrous silicate mineral phase, a copper-rich phase and an iron-rich phase and smoke dust containing zinc, lead, bismuth and indium are obtained, and gold and silver components are migrated and enriched and enter the copper-rich phase; and all the phases are recovered. By the adoption of the method, the copper-containing slag (copper-containing slag smaller than 0.1wt%) can be lowered, besides efficient recovery of the components of copper, iron, gold, silver, lead, zinc, indium, bismuth, sodium, potassium and the like can be achieved, low-copper materials containing iron are obtained, the metal recovery rate is high, the production cost is low, environmental friendlinessis achieved, and the economic returns are high.

Owner:NORTHEASTERN UNIV

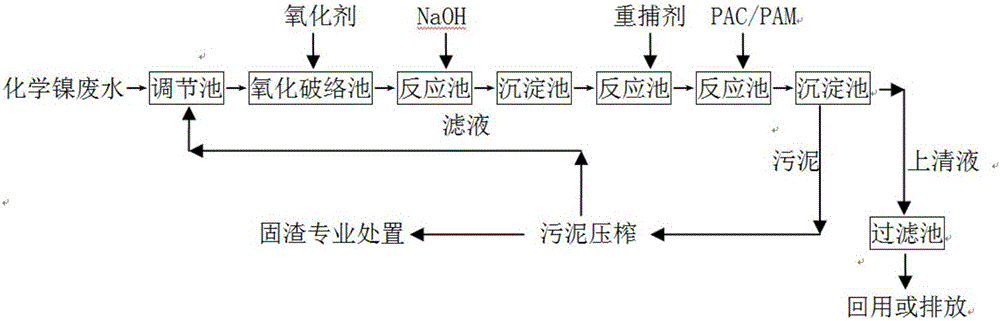

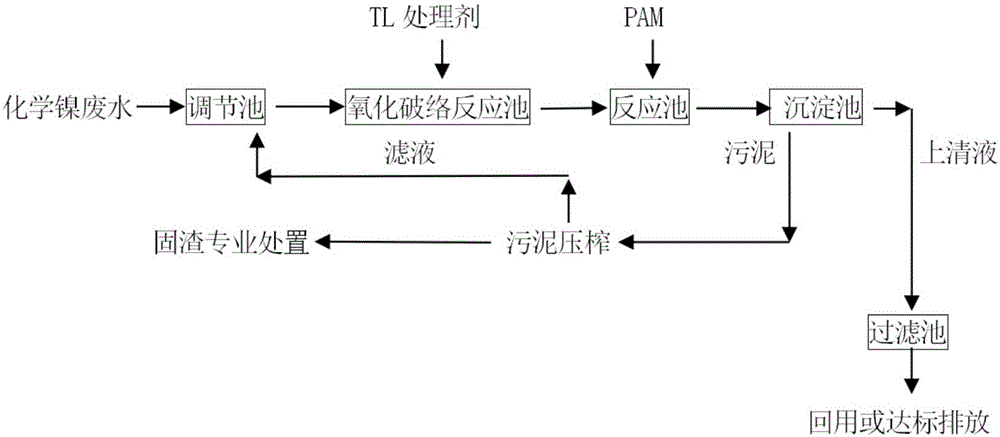

Chemical nickel waste water treating method

InactiveCN105884078AAchieve complete subsidenceAchieve settlementSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeWastewater

The invention provides a chemical nickel waste water treating method. The chemical nickel waste water treating method comprises the following steps: oxidizing a treating agent in a breaking reaction pond; aerating and stirring for reacting for 15-40 minutes; controlling the PH value to be 10-12; entering the reaction pond; adding a coagulant aid; precipitating in a settling pond; collecting supernatant; squeezing sludge in the settling pond; introducing squeezed filtrate into an adjusting pond; performing residue fixing treatment on the squeezed sludge, wherein the treating agent contains 70-90 percent by weight of alkaline matter and 10-30 percent by weight of oxidizing agent; the alkali substrate is one or more of NaOH, Na2CO3 and CaO; the oxidizing agent is H2O2 or / and Na2S2. By adopting the chemical nickel waste water treating method, complete precipitation of nickel ion and phosphorus is realized, the water quantity can reach the discharge standard in table 3 of GB21900_2008 Galvanized Pollutant Discharge Standard, and can stably reach the standard for a long time; the rate of reaching the standard is 99.9 percent or above.

Owner:漆雅丽 +1

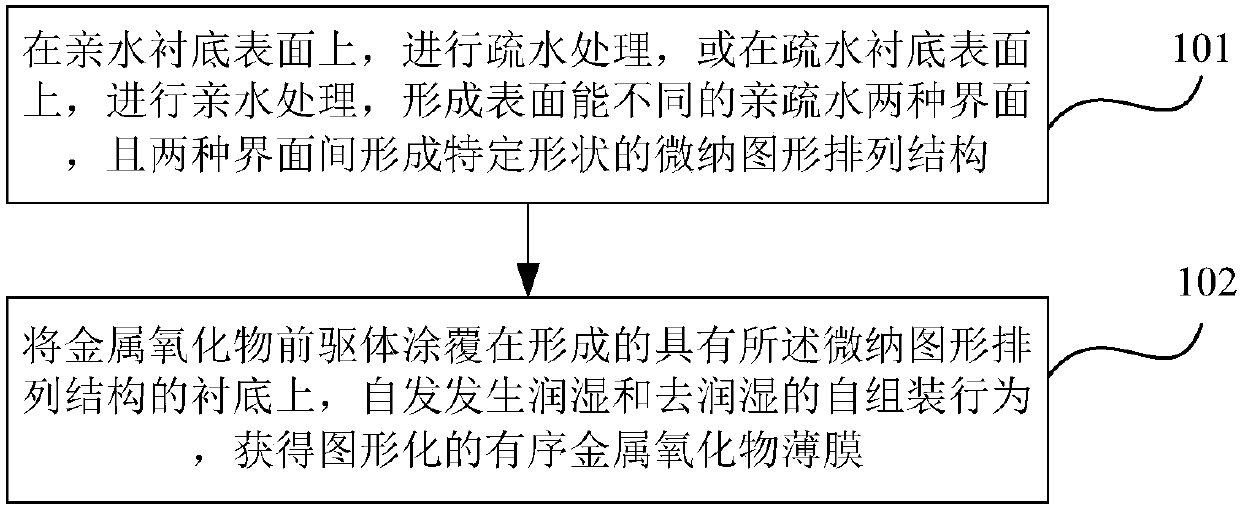

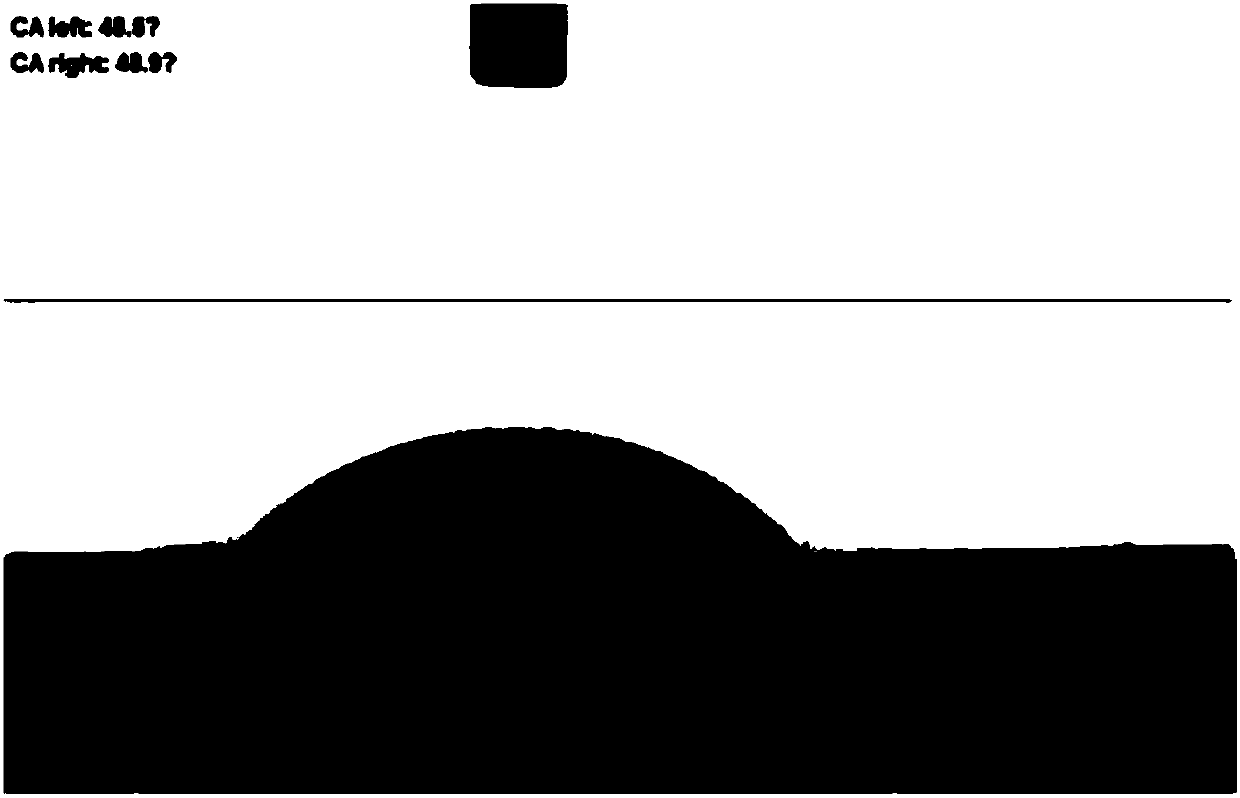

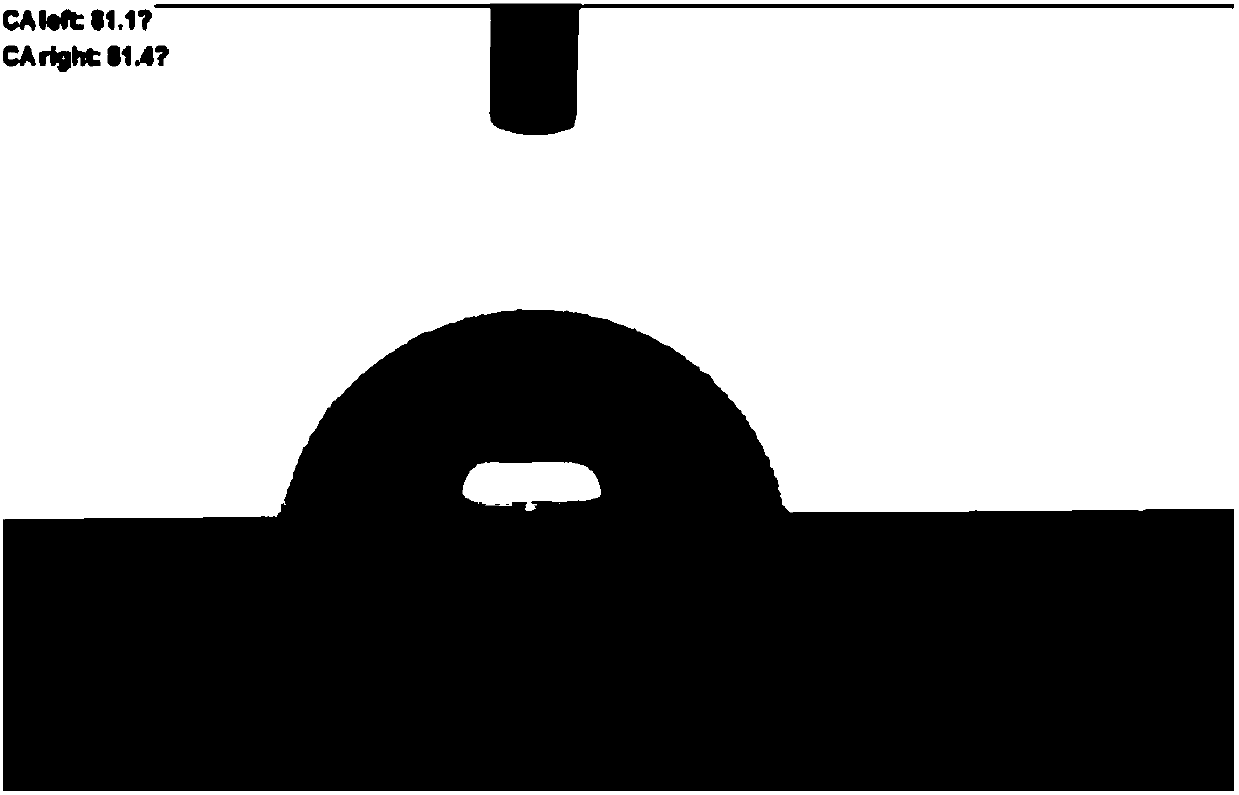

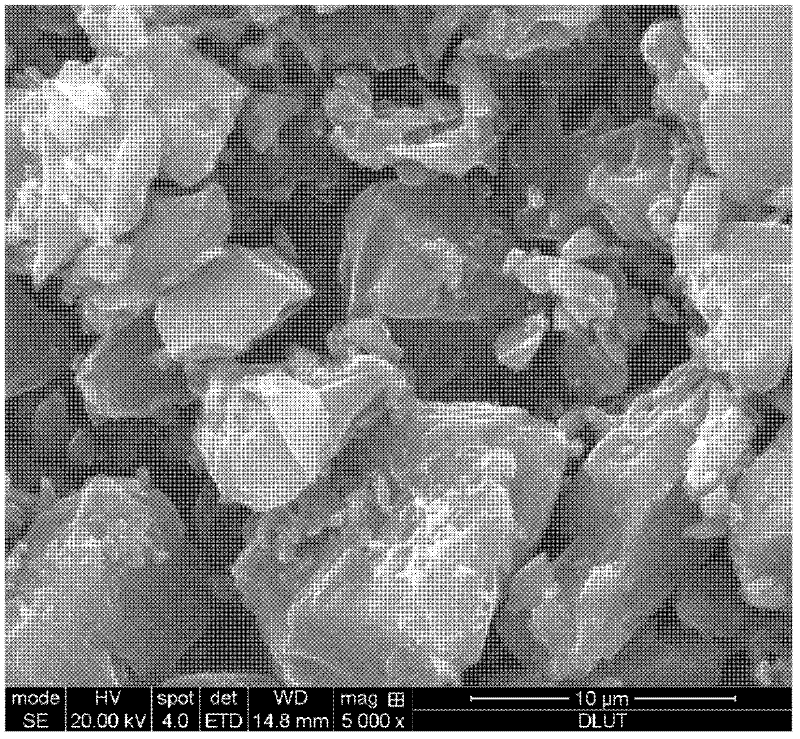

Metal oxide ordered self-assembly patterned preparation method and metal oxide film

InactiveCN107644806AAchieve settlementNo damageSemiconductor/solid-state device manufacturingSilicon dioxideCompanion animal

The embodiment of the invention provides a metal oxide ordered self-assembly patterned preparation method and a metal oxide film. The method includes: performing a hydrophobic treatment on the surfaceof a hydrophilic substrate, or performing a hydrophilic treatment on the surface of a hydrophobic substrate to form a hydrophilic interface and a hydrophobic interface that have different surface energy, and forming a micro-nano pattern arrangement structure in a specific shape between the two kinds of interfaces; coating the formed substrate having the micro-nano patterned arrangement structurewith a metal oxide precursor in order to spontaneously generate wetting and de-wetting self-assembly behaviors and to obtain a patterned ordered metal oxide film. In another aspect, the embodiment ofthe present invention provides a metal oxide film prepared by the metal oxide ordered self-assembly patterned preparation method. The method has no damage and low consumption, achieves one-time patterning, and is also applicable to hard substrates (glass, silicon dioxide, silicon and the like) and flexible substrates (PET, PDMS, PI and the like).

Owner:SUN YAT SEN UNIV

Method for producing copper-containing slag

InactiveCN107641717ARealize comprehensive utilizationSolve the accumulationProcess efficiency improvementThermal stateCopper oxide

The invention relates to a method for producing copper-containing slag. The method comprises the following steps: S1, furnace slag mixing: adding copper slag into a reaction device, and adding a calcium-system mineral and an additive; heating the slag into a molten state, and adding one or more of a copper oxide mineral, a copper sulphide mineral and a copper-containing material; uniformly mixingthe materials to obtain reaction slag, monitoring the reaction slag in real time, and treating the mixed reaction slag through regulation and control to enable the mixed reaction slag to simulatenously meet conditions a and b, thus obtaining reacted slag; S2, separation and recycling. According to the method, both thermal-state slag and cold-state furnace slag can be treated; by full use of moltencopper slag physical thermal resources and a thermal-state metallurgical flux, treatment of copper-containing furnace slag and treatment of the copper oxide mineral are realized; the problem of bulkdeposition of furnace slag at present is solved; simultaneous production of copper and iron is realized; two world problems that the copper oxide mineral is difficult to treat and an iron component isdifficult to recycle are solved; meanwhile, the problems of environmental pollution and heavy metal pollution are solved.

Owner:NORTHEASTERN UNIV

Method for conducting production through nickel smelting slag

InactiveCN107699703ASolve the accumulationSolve the two major worldwide problems that are not easy to recycleProcess efficiency improvementSmelting processCopper sulfide

The invention relates to a method for conducting production through nickel smelting slag. The method includes the following steps that S1, clinker is mixed, wherein the nickel smelting slag is added in a smelting reaction device, calcium-series mineral and an additive are added; stirring is conducted, the slag is heated to the molten state, and one or more of copper oxide ore mineral, nickel oxidemineral, copper sulfide mineral, nickel sulfide mineral and a copper-containing material are added; the mixture is evenly mixed to be used as reaction slag, monitoring is conducted in real time, andmeanwhile the mixed copper-containing slag can meet the condition a and the condition b at the same time through regulation and control and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, the hot-state slag can be processed, and the cold-state clinker can also be processed; molten nickel smelting slag physical thermal resources and hot-state metallurgy flux are sufficiently utilized, copper-containing clinker can be processed, the copper oxide mineral and / or the nickel sulfide mineral can also be processed, the method is a new copper smelting process, and simultaneous production of copper and iron is achieved.

Owner:NORTHEASTERN UNIV

Method for recovering valuable components in mixed slag containing copper and iron

InactiveCN107699704AAchieve recyclingSolve pollutionRecycling and recovery technologiesProcess efficiency improvementLead smeltingZinc

The invention relates to a method for recovering valuable components in mixed slag containing copper and iron. The method for recovering the valuable components in the mixed slag containing copper andiron comprises the steps of S1, slag mixing, specifically, copper slag is added into a smelting reaction device, and one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag are added at the same time so as to form mixed slag, the slag is heated to be in a molten state to form reaction slag, the reaction slag is evenly mixed and monitored in real time, the mixed reaction slag is regulated and controlled to meet a condition a and a condition b, and thus reacted slag is obtained; and S2, separation and recovery. By adoption of the method for recovering the valuablecomponents in the mixed slag containing copper and iron, copper, iron, zinc, lead, gold, silver, phosphorus, calcium and silicon in non-ferrous metallurgical slag and ferrous metallurgical slag are comprehensively utilized, and the problems of accumulation of a large quantity of slag and environmental pollution in the prior art are solved.

Owner:NORTHEASTERN UNIV

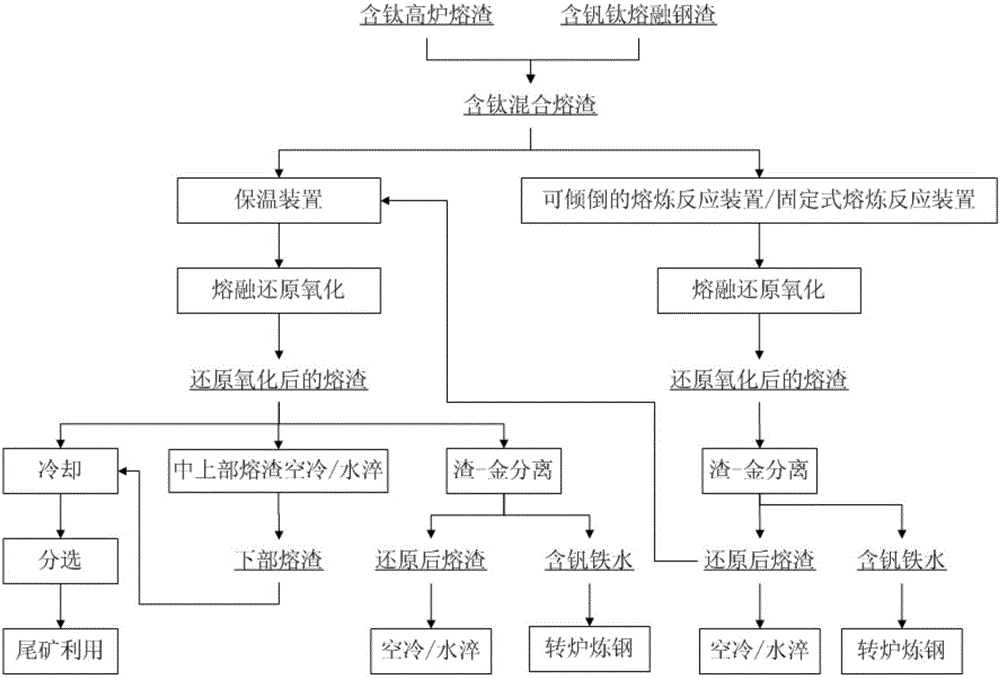

Method for smelting reduction, recycling and thermal refining of titaniferous mixed slag

ActiveCN106048108AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementThermal energySlag

The invention discloses a method for smelting reduction, recycling and thermal refining of titaniferous mixed slag. The method comprises the following steps: (1) mixing titaniferous blast furnace slag with vanadium-titanium-containing molten steel slag to form titaniferous mixed slag, and controlling the temperature of the titaniferous mixed slag within a set temperature range; (2) jetting oxidizing gas for smelting reduction and oxidization; during the process, the temperature of the titaniferous mixed slag is ensured to be within the set temperature range, and in the titaniferous mixed slag, low-valence titanium is oxidized into high-valence titanium, and iron oxide is reduced into metallic iron; and (3) carrying out separation and recycle according to different reaction devices. According to the invention, efficient recycle of the titanium component, iron component, vanadium component, phosphorus component and free calcium oxide component in the mixed slag is realized, and cold-state vanadium-titanium-iron-containing material can be treated to realize efficient comprehensive utilization of a resource; the reaction time is short, the metal recovery rate is high, the production cost is low, the raw material adaptability is high, the handing capacity is high, environment-friendliness is realized, the economic benefit is high, and the problem about efficient recycle of the metallurgy resource and thermal energy can be effectively solved.

Owner:NORTHEASTERN UNIV

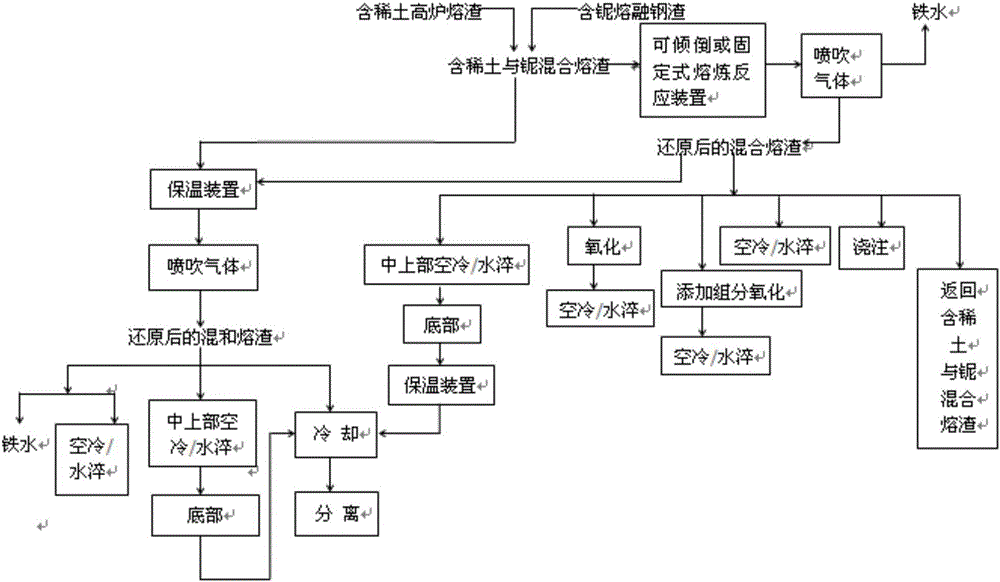

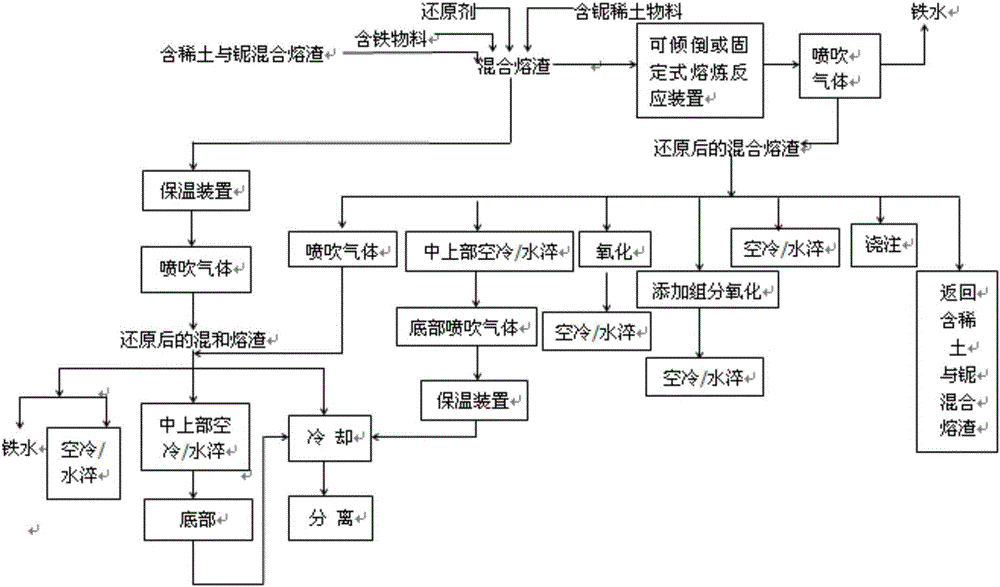

Smelting reduction recovery and thermal refining method for rare-earth-niobium-containing slag mixture

ActiveCN106048106AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementNiobiumSlag

The invention relates to a smelting reduction recovery and thermal refining method for a rare-earth-niobium-containing slag mixture and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The smelting reduction recovery and thermal refining method for the rare-earth-niobium-containing slag mixture comprises the following steps of (1) mixing rare-earth-containing blast furnace slag and niobium-containing molten steel slag to form the rare-earth-niobium-containing slag mixture and controlling the temperature of the rare-earth-niobium-containing slag mixture within a set temperature range; (2) injecting oxidative gas and conducting smelting reduction to reduce iron oxide into metallic iron fully; and (3) conducting separation and recovery according to different reaction devices. According to the method, the rare earth, the calcium component, the niobium component and the phosphorus component in the slag mixture can be efficiently recycled; cold-state niobium-rare-earth-iron-containing materials can be processed and at the same time thermal refining of the slag can be realized, so that the efficient resource comprehensive utilization can be achieved. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity, friendly with environment, high in economic income and capable of solving the problems of efficient recovery and utilization of metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

Fan type electrostatic dust remover

InactiveCN105665138ARealize periodic adsorptionAchieve settlementExternal electric electrostatic seperatorElectrostatic separation detailsEngineeringElectrostatic generator

The invention relates to a fan type electrostatic dust remover. The fan type electrostatic dust remover comprises an electrostatic generator, a dust removal cavity, a purification cavity and a dust hopper. A discharging piece is electrically connected to an air inlet. The discharging piece is electrically connected with the negative electrode of the electrostatic generator. The dust removal cavity is spaced from the dust hopper through a dust collection screen plate. A driving box is fixedly installed in the center of the dust collection screen plate. A power disc is installed in the driving box. Conducting strips are embedded in the disc surface of the power disc in the circumferential direction. All the conducting strips are insulated from one another and electrically connected with a ground wire or a positive electrode wire of the electrostatic generator. A dust removal fan is installed above the power disc and can rotate freely around a fixing rotary shaft. Conducting brushes extend out downwards from all fan surfaces of the dust removal fan. All the conducting brushes are closely attached to the disc surface of the power disc. The fan type electrostatic dust remover is novel in structure, dust accumulation and dust residues can be effectively prevented while efficient dust removal is conducted, and the dust removal continuity is effectively improved.

Owner:宣城市锦绣超细重质碳酸钙厂(普通合伙)

Operation expense calculation and payment device, system and method

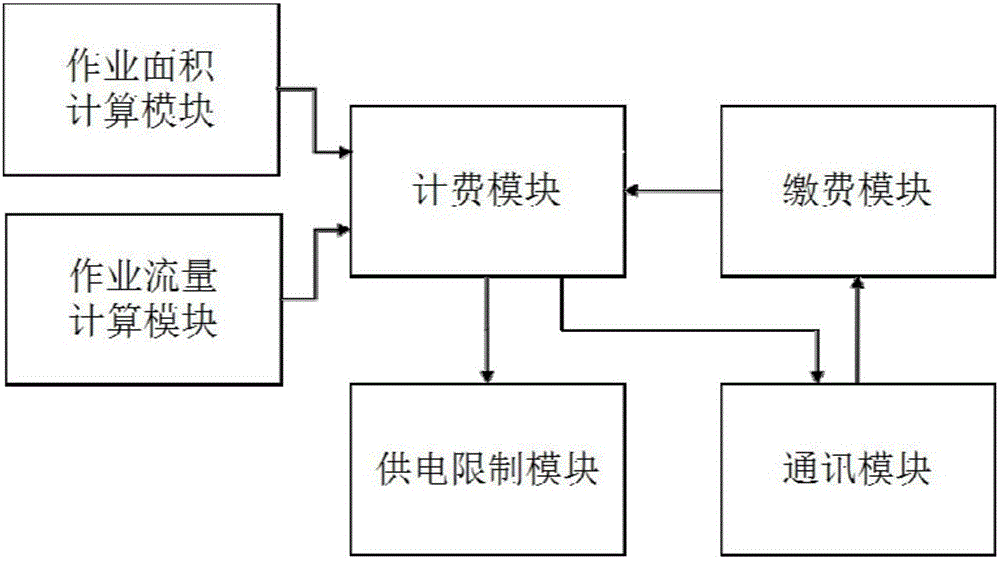

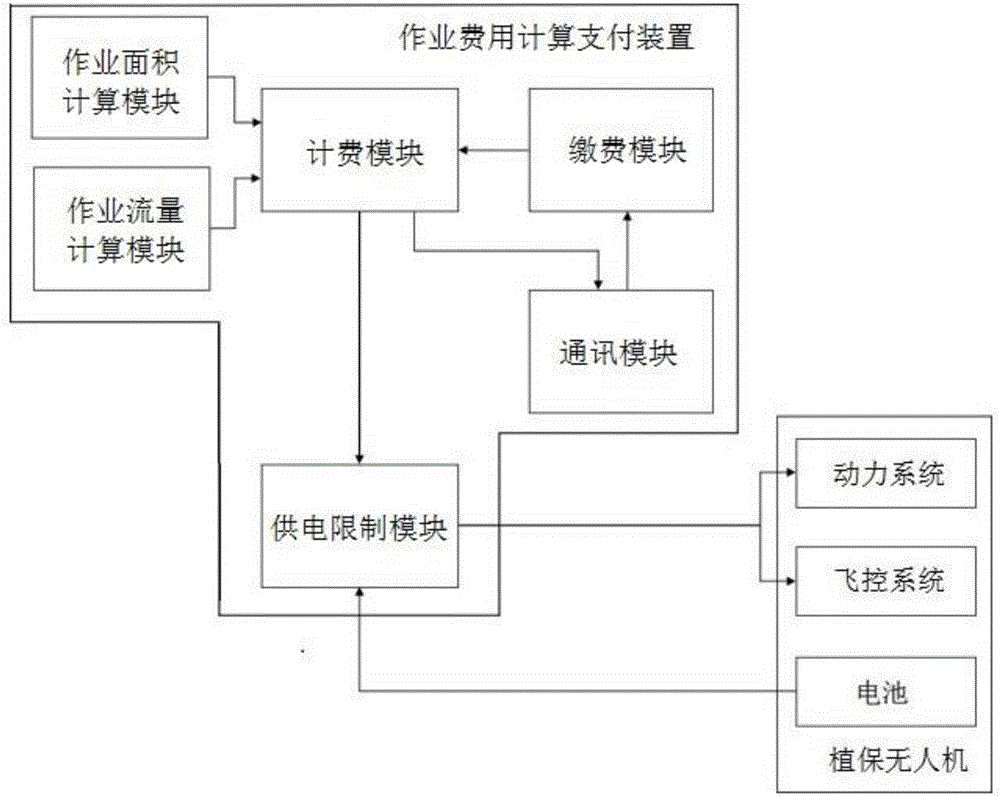

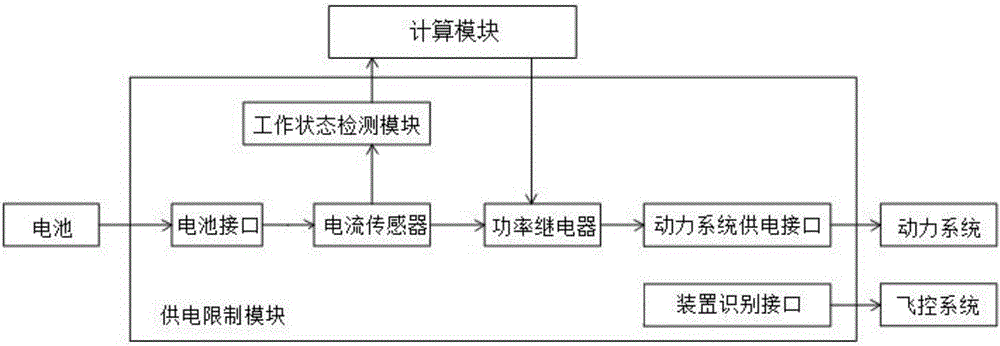

ActiveCN106251129ARealize automatic calculationRealize paymentPayment architectureApparatus for meter-controlled dispensingPaymentComputer science

The invention discloses an operation expense calculation and payment device, system and method. The operation expense calculation and payment device comprises a payment module, a calculation module, a charge module, a communication module, and a power supply restriction module, wherein the charge module is in communication connection with the payment module and the calculation module, the communication module is in communication connection with the charge module and the payment module, and the power supply restriction module is in communication connection with the charge module. The operation expense calculation and payment device, system and method provided by the invention has the advantages of higher accuracy and high automation level, and achieves monitoring and settlement in different places; and after equipped with the operation expense calculation and payment device, a plant protection unmanned aerial vehicle can achieve automatic calculation and payment for operation areas and spraying amounts, as well as collection of operation information, so that agricultural operation big data can be achieved for convenient searching and viewing.

Owner:广西圣尧智能科技有限公司

Method for recycling valuable components from nickel-containing smelting slag

InactiveCN107699700ASolve pollutionRealize comprehensive utilizationProcess efficiency improvementSlagNickel

The invention relates to a method for recycling valuable components from nickel-containing smelting slag. The method includes the steps that nickel smelting slag is added in a reaction device, calcium-series mineral and an additive are added, mixed slag is formed, the mixed slag is heated to be in the molten state to be used as reaction slag and is evenly mixed, the reaction slag is monitored in real time, the mixed reaction slag is made to meet the condition a and the condition b at the same time through regulation and control, and slag subjected to reaction is obtained; and S2, separation and recycling are conducted. By means of the method, molten nickel slag physical heat resources and hot-state metallurgy flux can be sufficiently utilized, and cold-state clinker can also be processed;by adding the additive, conducting even mixing and controlling the slag oxygen position, slag metallurgy is achieved, and the synchronous separation technology for copper and iron in the nickel smelting slag is achieved; and the problem that because a large amount of clinker is stacked at present, environment pollution is caused, and heavy metal element pollution is caused are solved.

Owner:NORTHEASTERN UNIV

Method for smelting reduction production and quenching and tempering treatment of rare earth and niobium containing mixed slag

ActiveCN106119447ARealize efficient and comprehensive utilization of resourcesEasy to removeRecycling and recovery technologiesProcess efficiency improvementOxideNiobium

The invention discloses a method for smelting reduction production and quenching and tempering treatment of rare earth and niobium containing mixed slag. The method comprises the steps that (1) a reducing agent, a niobium and rare earth containing material and / or an iron containing material are added into the rare earth and niobium containing mixed slag to form mixed slag, the mixed slag is heated to be in a smelted state, smelting reduction is carried out, oxidizing gas is blown, and the temperature range of the mixed slag and the specific value and temperature of alkaline CaO / SiO2 are controlled in the process; and (2) separating and recycling are carried out according to different reaction devices, components of rare earth, iron, niobium and phosphorus in the mixed slag, free calcium oxide and the like are efficiently recycled, solid rare earth, niobium and iron materials are treated in a large scale through the smelting reduction process, meanwhile, quenching and tempering of the slag are achieved, resources are efficiently and comprehensively utilized, and the method is a new smelting reduction ironmaking process. The method is short in reaction time, high in metal recycling rate, low in production cost, high in raw material adaptability, environment-friendly and high in economic benefit, and the aim of efficient recycling of multi-metal grandidierite metallurgy resources and heat energy can be effectively achieved.

Owner:NORTHEASTERN UNIV

Parabolic grading concentration tank

ActiveCN106976944ATo achieve the graded effectRealize quantitative dosingWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationLiquid mediumProcess engineering

The invention belongs to the technical field of slime water treatment and specifically relates to a parabolic grading concentration tank. The invention designs the grading principle according to the difference of parabolic tracks of coal slime particles in different shape, weight and size in a liquid medium. The parabolic grading concentration tank at least comprises a drug adding system, a feeding system, a concentration tank body, a first draining mud-lagging plate unit, a second draining mud-lagging plate unit, a first adjustable vibrating plate device and a second adjustable vibrating plate device; the quantitative addition of the drug can be realized in a manner of mixing the drug with the ore pulp once while passing by an annular drug disperser; the ore pulp after being mixed once can be added again according to the practical requirement by a secondary dosing pipe in the feeding system; a big horn-shaped drug dispersing port and a surrounding zigzag structure thereof can violently disperse the ore pulp flowing out of a small horn-shaped dispersing port; the slime water is deeply cleared by a free settling area formed by encircling of an annular separating plate in the concentration tank body. The parabolic grading concentration tank has the advantages of simple structure, low construction cost, low maintenance load, obvious effect, and the like.

Owner:ANHUI UNIV OF SCI & TECH

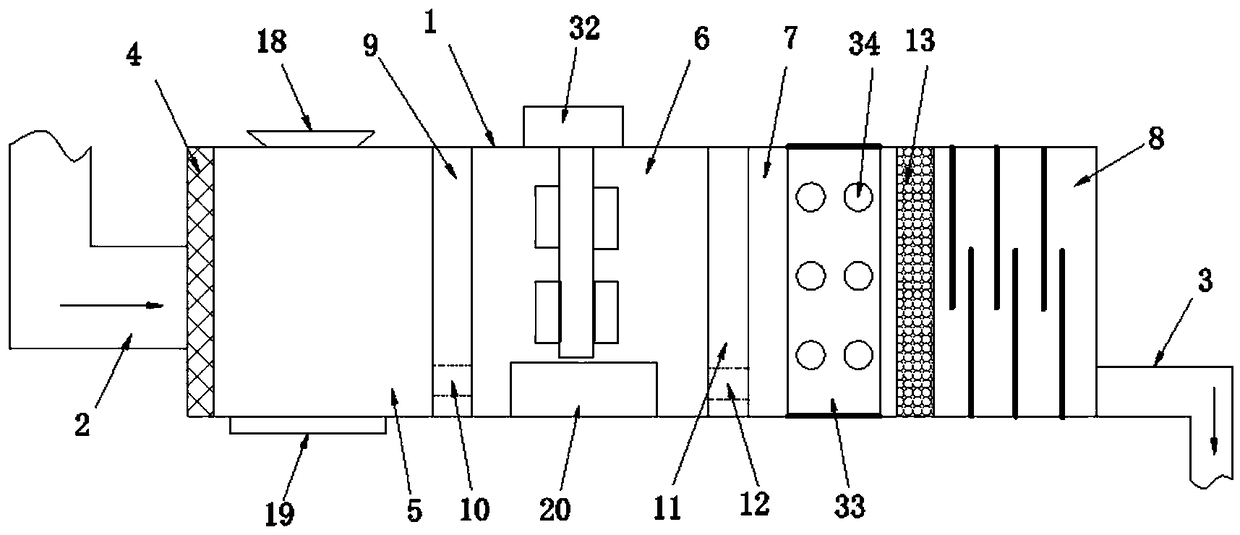

Microbial sewage treatment device and using method thereof

InactiveCN108658396AImplement filteringAchieve settlementTreatment using aerobic processesWater contaminantsFiltrationSewage

The invention discloses a microbial sewage treatment device and a using method thereof. The microbial sewage treatment device comprises a treating pond body; a sewage inlet pipe is arranged at one side of the treating pond body, and a drain pipe is arranged at the other side of the treating pond body; a filter screen assembly is arranged at the inner side of the sewage inlet pipe; a flocculating tank, an aeration tank, a filtering tank and a deodorization tank are arranged in the inner cavity of the treating pond body; the flocculating tank and the aeration tank are separated from each other by means of a first spacer plate, and a first drain outlet is formed under the first spacer plate; the aeration tank and the filtering tank are separated from each other by means of a second spacer plate, and a second drain outlet is formed under the second spacer plate; a porous ceramic filter plate is arranged between the filtering tank and the deodorization tank. The microbial sewage treatment device is simple in structural principle, and can realize the filtration, sedimentation, aeration treatment and deodorization of microbial sewage, thus increasing the sewage purification efficiency andachieving the aims of energy conservation and emission reduction.

Owner:HEFEI CAREER TECHNICAL COLLEGE

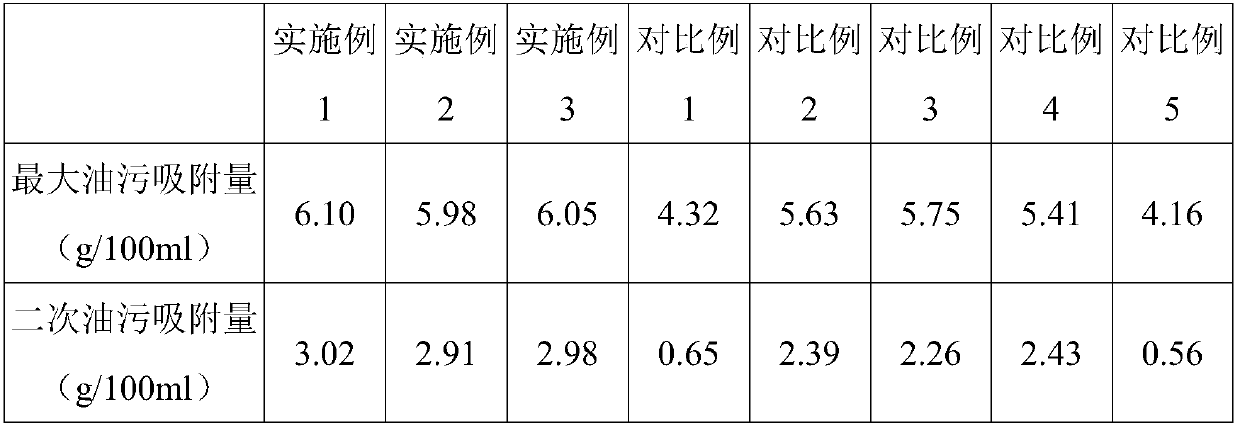

Kitchen fume purifying aqueous solvent and preparation method thereof

ActiveCN108031212AImprove stabilityAvoid aggregation and sedimentationGas treatmentUsing liquid separation agentSolventPolypropylene

The invention discloses a kitchen fume purifying aqueous solvent and a preparation method thereof. The kitchen fume purifying aqueous solvent comprises the following raw materials: sodium dodecyl benzene sulfonate, fatty alcohol polyoxyethylene ether sulfate, nonylphenol polyoxyethylene ether-10, isopropanol, triethanolamine, sodium silicate, sodium citrate, polypropylene dialkyl ammonium chloride, carboxymethyl cellulose fiber, fumed silica and water, wherein the mass ratio of the polypropylene dialkyl ammonium chloride to the carboxymethyl cellulose fiber to the fumed silica is (6-10):(2-4):(0.6-1); and the kitchen fume purifying aqueous solvent is prepared by grading and mixing the raw materials. Compared with the prior art, the product has the advantages that the maximal oil dirt adsorption quantity and the secondary oil dirt adsorption quantity are further increased.

Owner:广州珺凯清洁剂有限公司

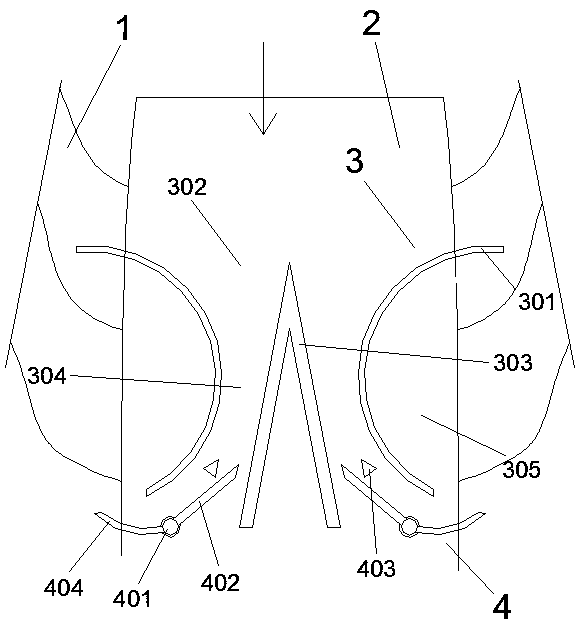

Movable diversion device for debris flow interception

The invention relates to a movable diversion device for debris flow interception. The movable diversion device is arranged in a debris flow passage formed between highlands on two sides and comprisesa stopping and silting diversion dam and two movable flow guidance mechanisms. The stopping and silting diversion dam divides the debris flow into two streams and constructs multiple new stopping andsilting areas, so that the debris flow can slow down, settle down and partially stop. The movable flow guidance mechanisms can automatically judge whether partial interception is required according tothe flow size of the debris flow. When the flow of the debris flow is large, the movable flow guidance mechanisms are pushed to deflect to filter and divert the debris flow, and guide part of the filtered debris flow into the stopping and silting areas for storage. Therefore, the flow of the debris flow is reduced, and the impact and destructiveness of the debris flow are greatly reduced. Moreover, an interception system has strong resistance to geological hazards. Even if partial damage occurs, the prevention and control effect cannot be greatly affected.

Owner:段刚强

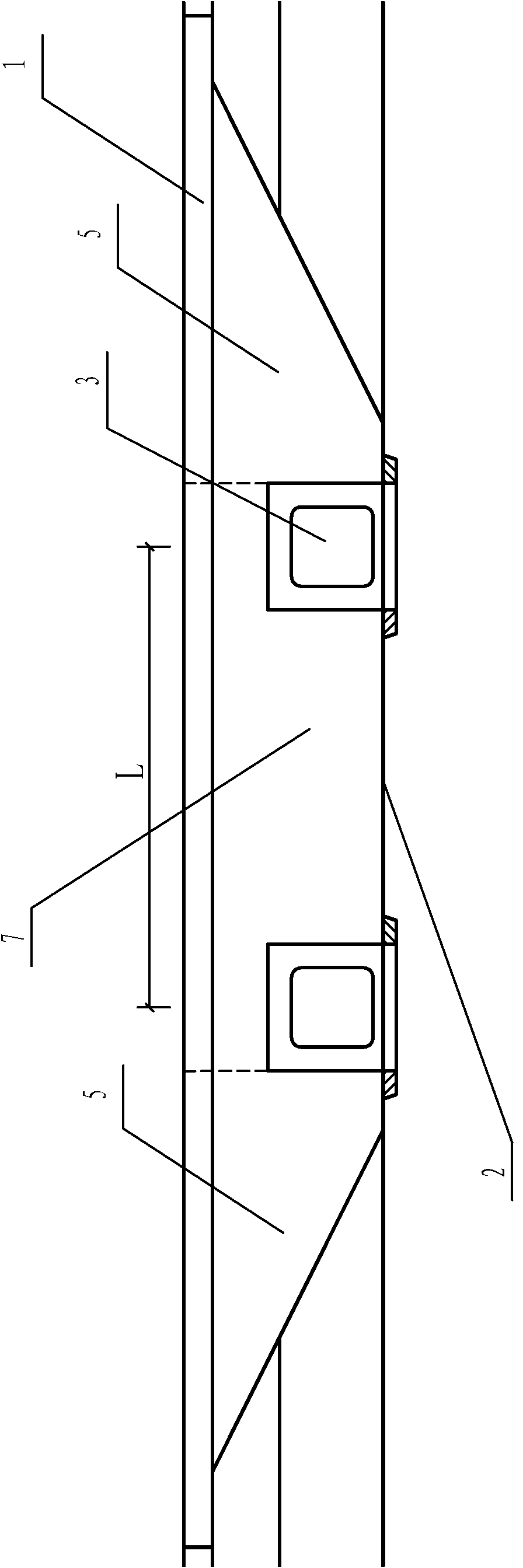

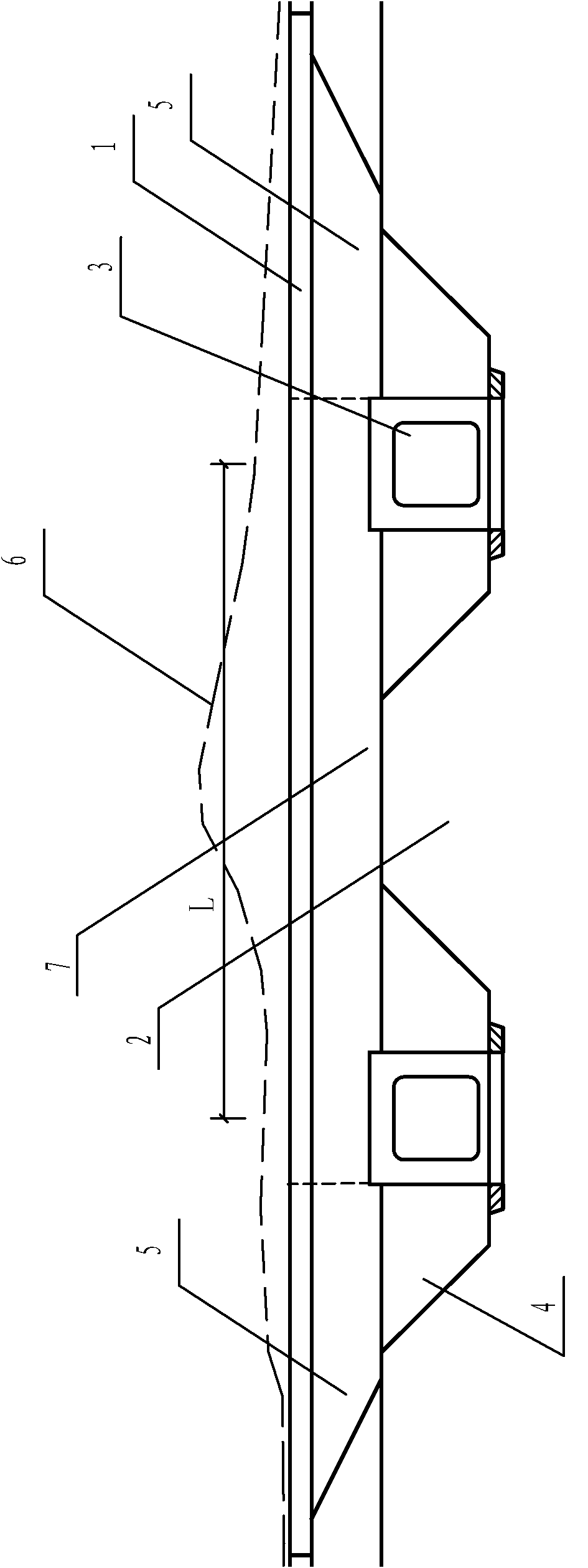

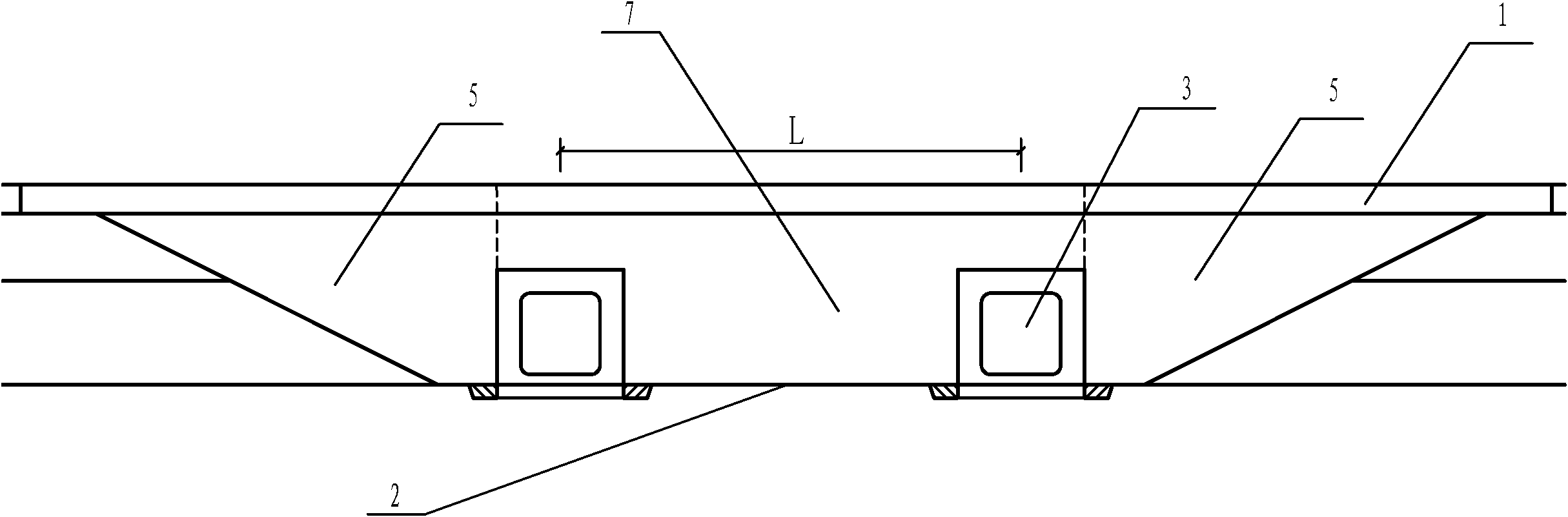

Short roadbed transition section structure between culverts of high speed railway

The invention discloses a short roadbed transition section structure between culverts of a high speed railway. The structure comprises an inverted trapezoidal transition section and an intra-culvert transition section roadbed, wherein the inverted trapezoidal transition section roadbed is laid between a culvert and a roadbed; the intra-culvert transition section roadbed is laid between two adjacent culverts; both the inverted trapezoidal transition section and the intra-culvert transition section roadbed comprise surface layers of sub-grade beds; the intra-culvert transition section roadbed and the inverted trapezoidal transition section below the surface layers of the sub-grade beds are filled with the same material; the material is graded gravels doped with cement which accounts for 3 to 5 weight percent of graded gravels; and the space between the central lines of the two adjacent culverts is less than or equal to 45m. When the space between the central lines of the two adjacent culverts of the high speed railway is less than or equal to 45m, the graded gravels doped with cement which is 3 to 5 weight percent of graded gravels are filled in the intra-culvert transition section roadbed and the inverted trapezoidal transition section below the surface layers of the sub-grade beds; and thus the dynamic response superposition brought by the over-short distance between the two adjacent culverts can be resisted, and the rigidity between buildings and stable transition of the sedimentation can be realized.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Method for metallurgic smelting reduction recovery of titanium-contained mixed slag

InactiveCN106755657AIncrease the speed of the reduction reactionAchieve settlementRecycling and recovery technologiesProcess efficiency improvementMolten stateSlag

The invention discloses a method for metallurgic smelting reduction recovery of titanium-contained mixed slag, and belongs to the field of non-blast furnace iron refining and resource comprehensive utilization. The method comprises the following steps: 1) molten-state vanadium-contained slag and molten-state steel slag are added in an insulation device or a smelting reaction device capable of flowing out slag liquid, and are mixed to form reaction mixed slag; the reaction mixed slag is monitored in real time; the following conditions are synchronously guaranteed through control: (a) the temperature of the reaction mixed slag is in a set range; (b) the reaction mixed slag realizes full stirring; and (c) in the reaction mixed slag, the mass concentration of FeO is not more than 1.0%; in the reaction mixed slag, when the mass concentration of FeO is not more than 1.0%, the operation in the step 1 is stopped, and the slag after reduction oxidation is obtained; and 2) the separation and the recovery are performed. The recovery rate of metal ion in the method is 92-96%; the whole process needs no or low heat compensation; the operability is high; the production cost is low; no solid waste is generated in the whole process; the reaction conditions are mild; the energy conservation and the emission reduction are realized; and the method is a green metallurgy process.

Owner:NORTHEASTERN UNIV LIAONING

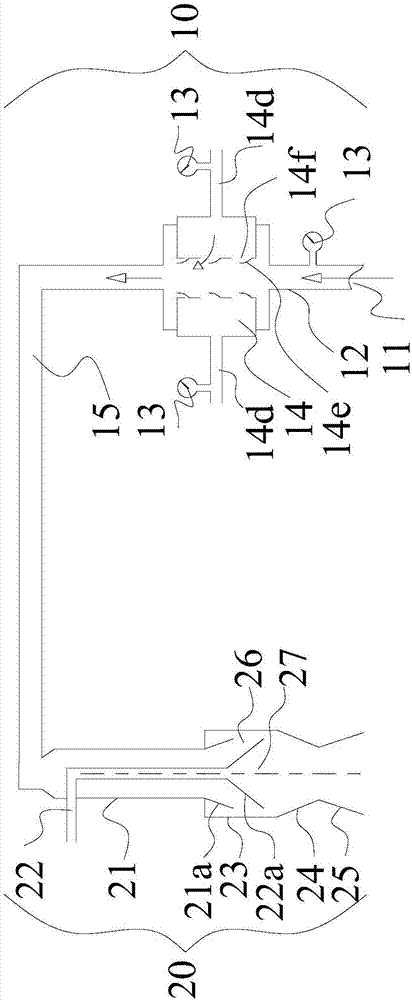

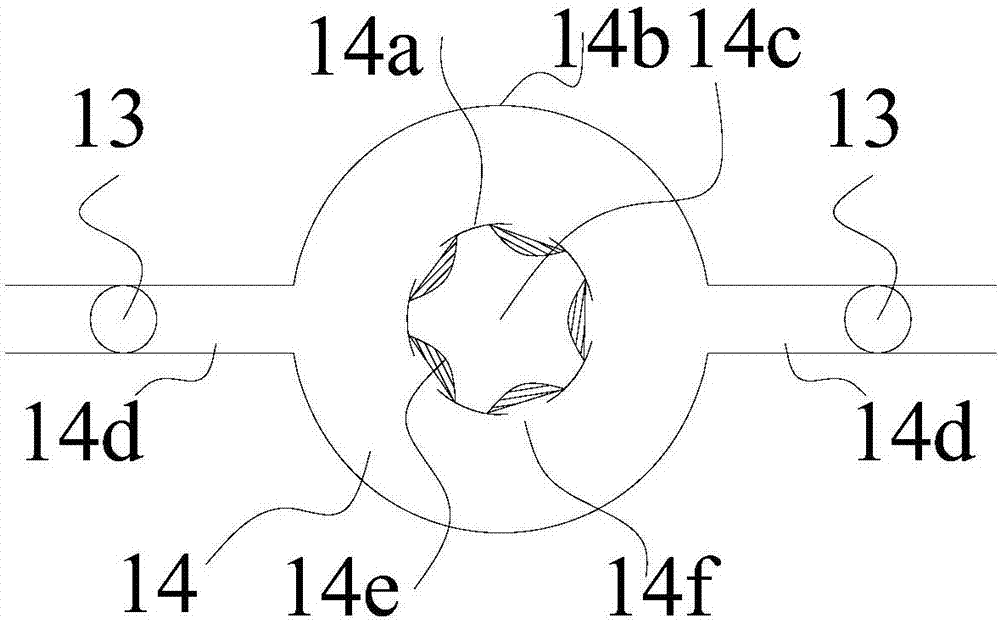

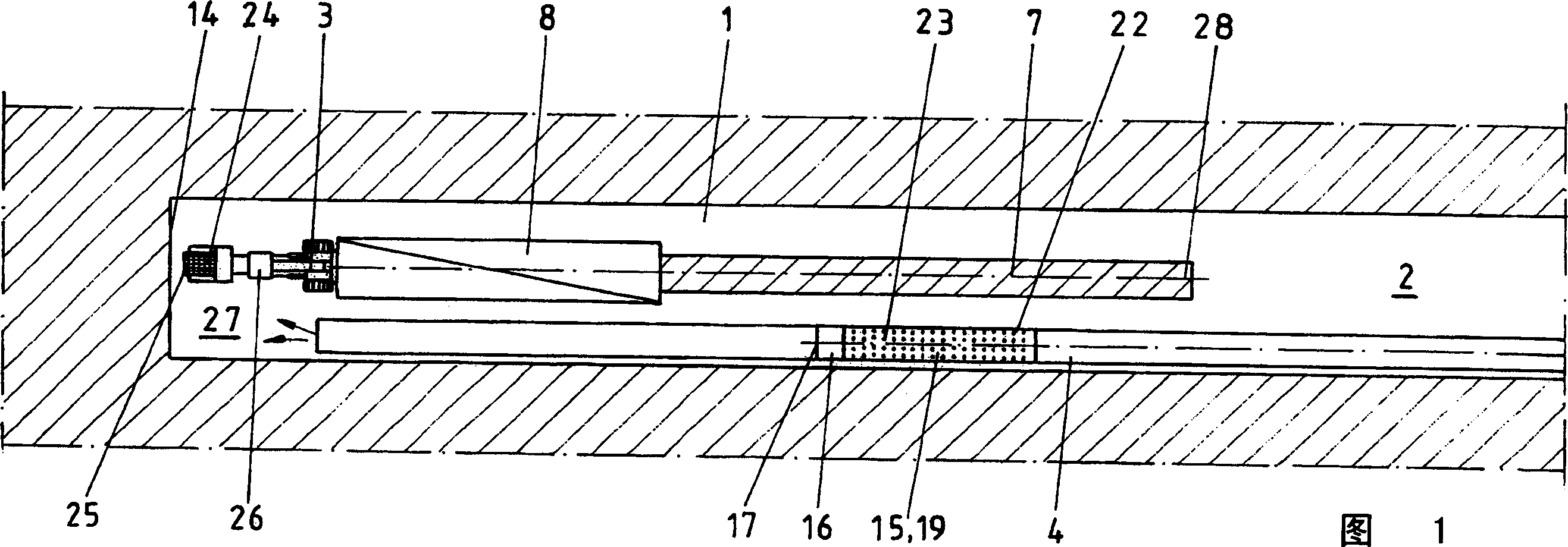

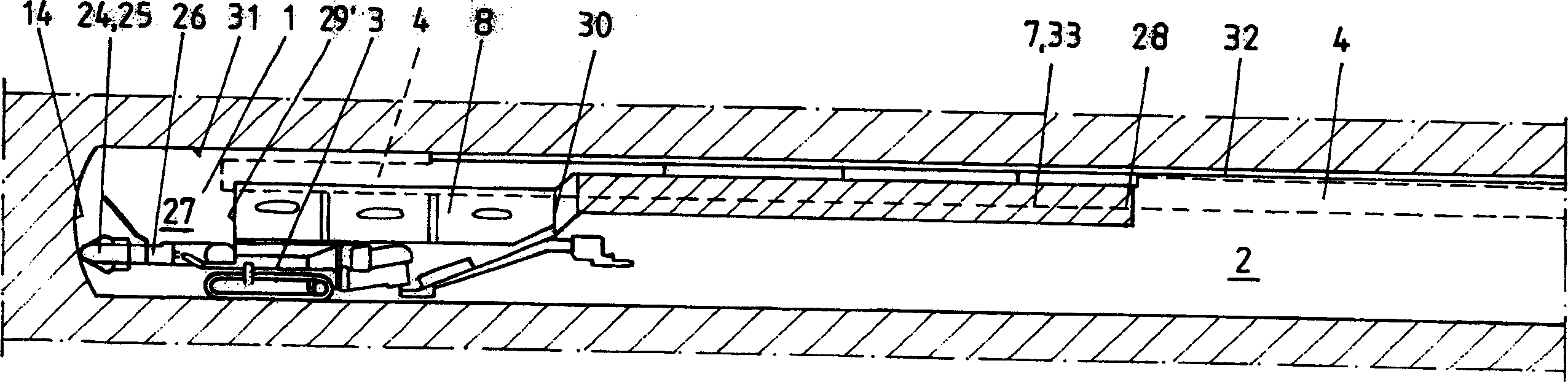

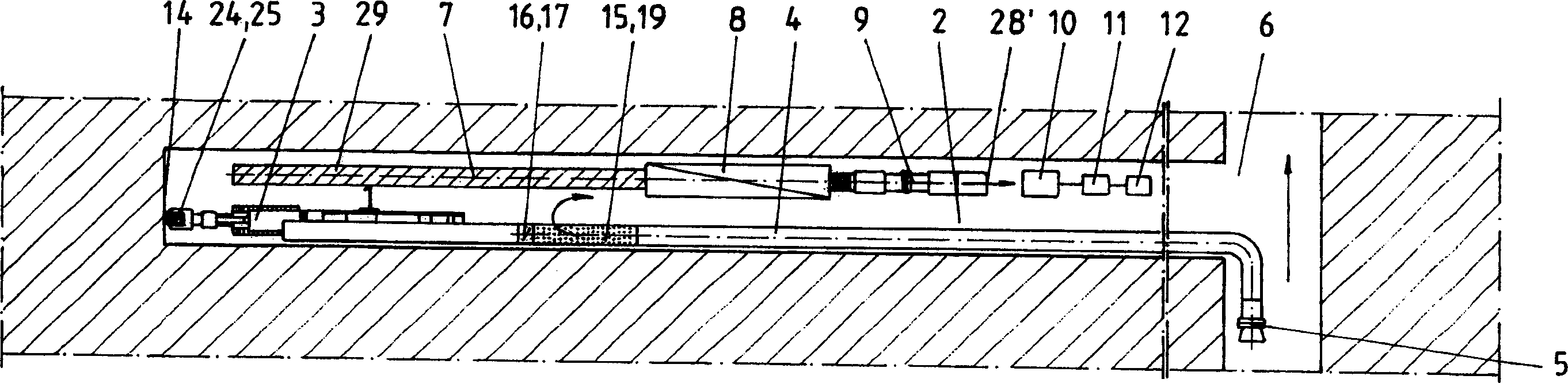

Ventilation device for laneway grubbing with roadheader

A device used for ventilation during roadway excavation (1), wherein the roadheader (3) has a fresh air inlet duct (4) with a secondary discharge device (15) connected in the middle and a dust removal device (8) return air pipe (7). The secondary discharge device (15) is used to form a dust protection wall (20), which is slowly drawn towards the front wall (14) of the working face and is used to divert the dust-laden airflow from the dust area (27) without adverse In the case of turbulence or other influences, it can be reliably introduced into the return air duct (7) or directly into the dust removal device (8) and cleaned there.

Owner:CFT GMBH

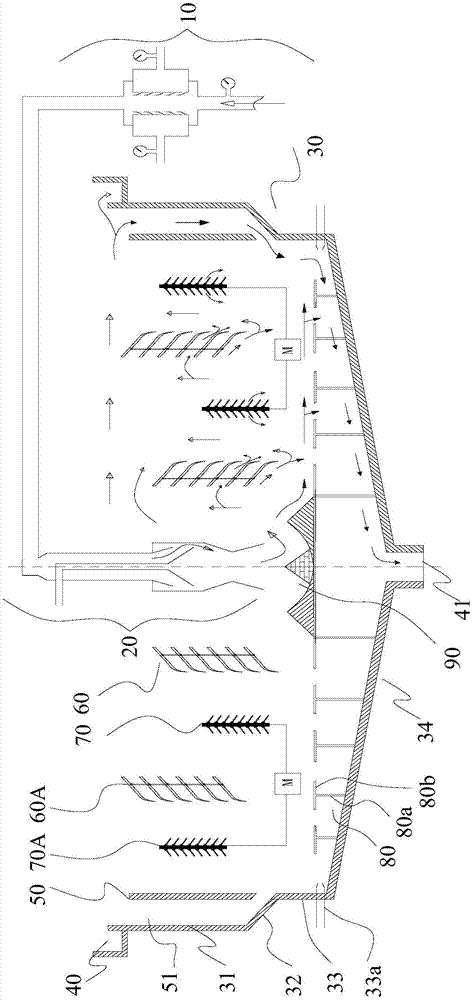

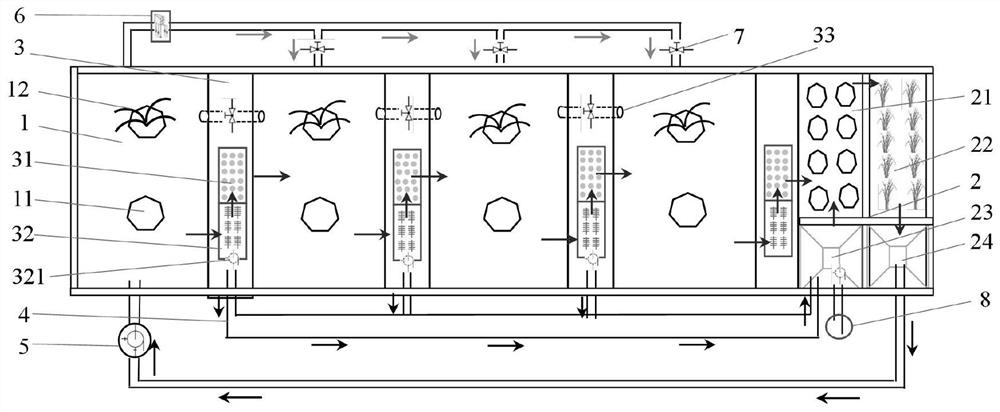

Series multi-step landscape type pond culture integrated system

PendingCN113383742AAvoid lossNo energy consumptionFlowers cultivationTreatment using aerobic processesConstructed wetlandSewage

The invention belongs to the technical field of ecological agriculture, and discloses a series multi-step landscape type pond culture integrated system. The integrated system comprises aquaculture ponds, an ecological ditch and a tail water purification pond, wherein the culture ponds are connected through pipelines; the culture ponds and the tail water purification pond are in gradient distribution; filter dams are arranged between the culture ponds and between the culture ponds and the tail water purification pond; a brush filter tank and a ceramsite nitrification tank are arranged on each filter dam, and the ecological ditch is located on one side of the culture ponds and connected with the brush filter tanks; the tail water purification pond comprises a settling zone, an aeration zone, a constructed wetland restoration zone and a water collecting zone which are connected in sequence; the settling zone is connected with the ecological ditch, and the culture water passing through the filter dams and the settling zone respectively flow into the aeration zone; then the culture water sequentially flows into the constructed wetland restoration zone and the water collecting zone, purified water in the water collecting zone flows back to the culture ponds through a water pump, and water recycling is completed; and the settling zone is connected with a sewage collecting well, so that comprehensive utilization of culture water is realized.

Owner:SOUTH CHINA AGRI UNIV

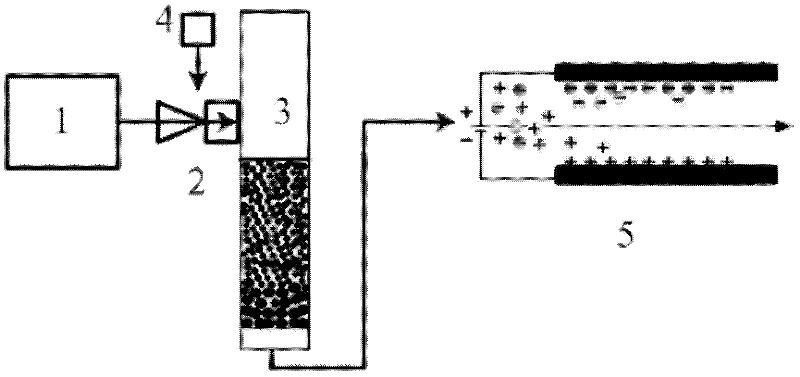

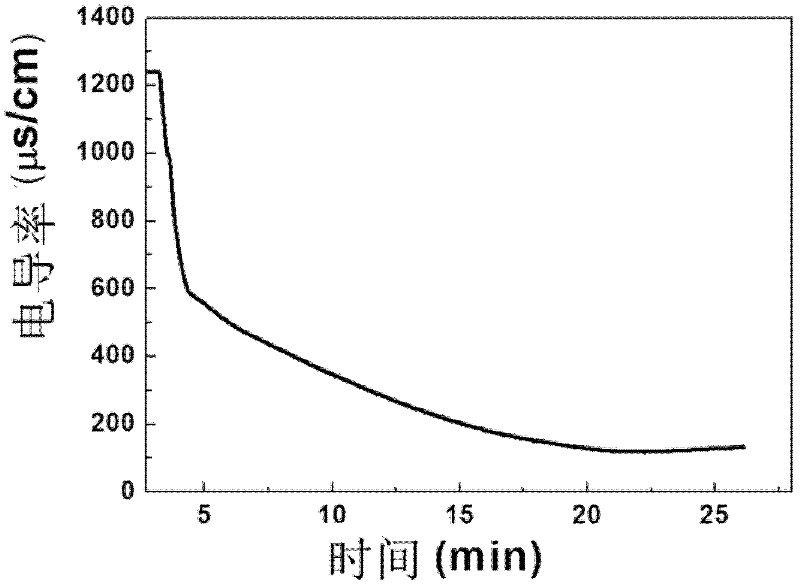

Method for treating coal bed gas produced water by combining pre-oxidation aerated oxidation with capacitive deionization

InactiveCN102417261AAchieve settlementReduce loadMultistage water/sewage treatmentWater/sewage treatment by oxidationCapacitanceHigh concentration

The invention discloses a method for treating coal bed gas produced water by combining pre-oxidation aerated oxidation with capacitive deionization, belonging to the technical field of water treatment. The method comprises the following steps of: oxidizing Fe<2+> and Mn<2+> contained in coal bed gas produced water based on oxygen supply aerated oxidation to form flocculent precipitates of Fe(OH3) and MnO2, and filtering to effectively lower the iron and manganese content of raw water and lower the load for subsequent treatment simultaneously; and treating the pre-oxidized coal bed gas produced water with a capacitive deionization technology to further remove other ions. The technical method can be effectively applied to coal bed gas produced water containing high-concentration iron and manganese ions, and can be applied to the fields of desalination of brackish water and seawater, removal of heavy metal ions and the like simultaneously.

Owner:DALIAN UNIV OF TECH

Rural sewage treatment device and method

PendingCN109761457AReasonable structure layoutImplement filteringWater contaminantsMultistage water/sewage treatmentWater sourceFiltration

The invention relates to a rural sewage treatment device and method. Two partition plates in a tank body divide the tank body into a first grid groove, a second grid groove and a third grid groove, wherein the first grid groove is divided into a sedimentation tank, a first filtration tank and an anaerobic area; the second grid groove is divided into a first aerobic area; the third grid groove is divided into a second aerobic area, a phosphorus-removing tank and a second filtration tank; sewage settles firstly in the sedimentation tank and is filtered in the first filtration tank, and then theremoval of COD, ammonia nitrogen and organic phosphorus in sewage is realized by the first aerobic area; then, the sewage is subjected to deamination treatment in the anaerobic area, afterwards, the COD and a redundant carbon source are removed in the second aerobic area, phosphorus in the sewage is removed by the phosphorus-removing tank, finally, the sewage is filtered by the second filtration tank and then discharged, the successive settling, filtering, aerobic, anaerobic, aerobic, phosphorus-moving and filtering treatments of the sewage are realized, which guarantees that rural domestic sewage is connverted into a qualified water source and discharged, and the pollution and damage to surrounding soil environment and air environment are avoided.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com