Ventilation device for laneway grubbing with roadheader

A technology for roadheaders and equipment, applied in the field of ventilation equipment, can solve the problems of inability to reliably eliminate dust explosions, difficulty, and dust-laden airflow that cannot sufficiently pass through the return air duct to remove dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

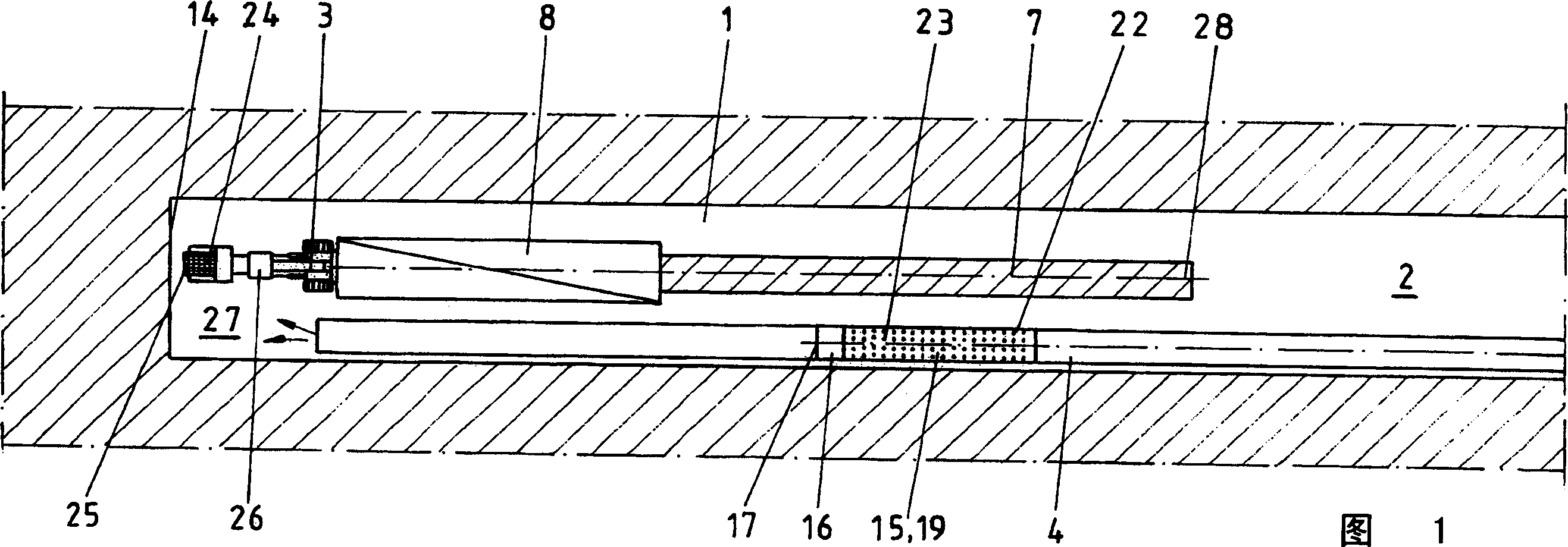

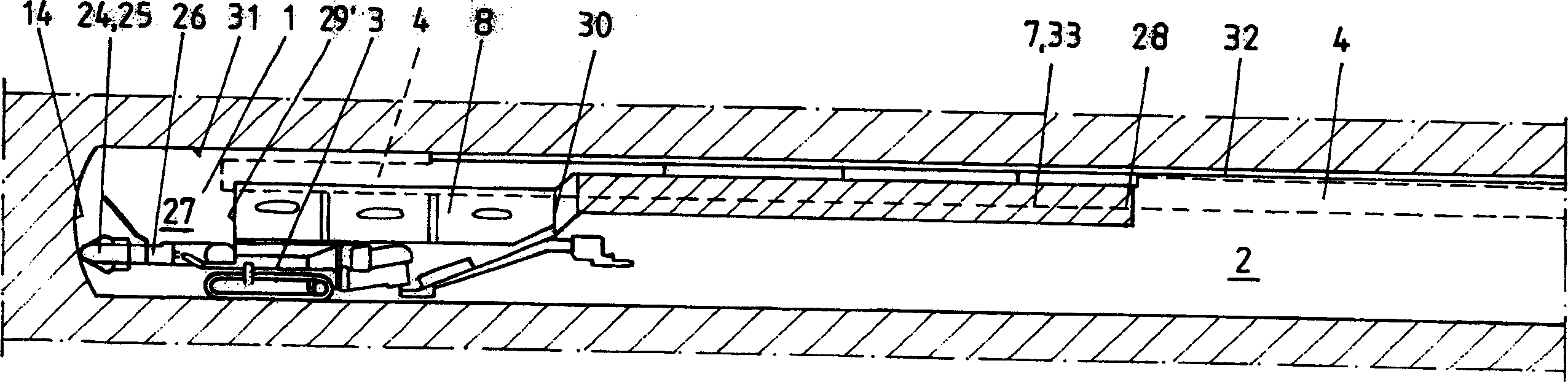

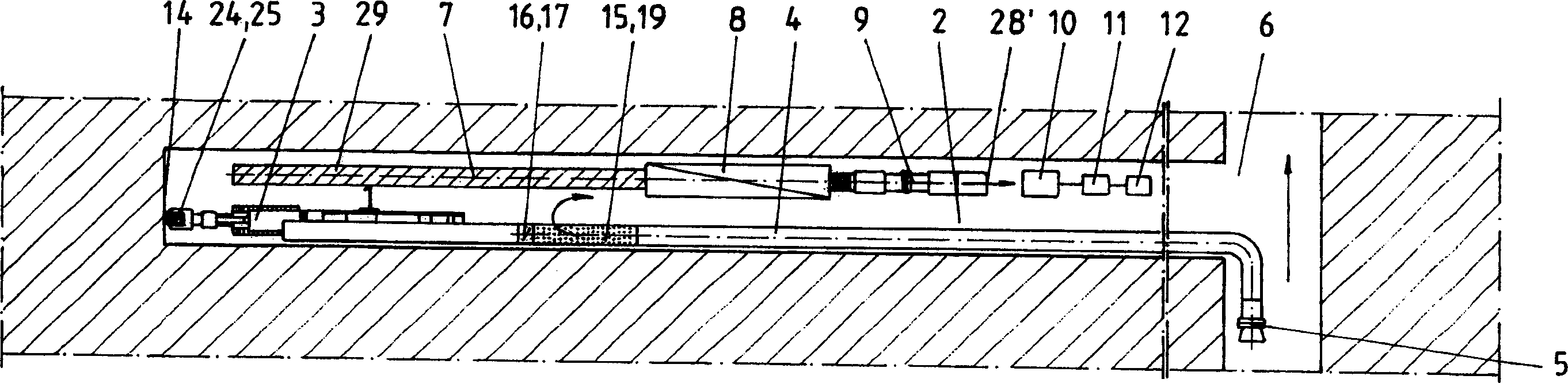

[0022]Fig. 1 shows a top view of a roadway excavation 1 in which, for example, the roadway is dug in the rock. The rock is cut by a roadheader 3, in which a fresh air inlet pipe 4 with a ventilator 5 and a return air pipe 7 with a dust removal device 8 are used for ventilation. The fresh air is sucked from the fresh air lane 6, such as image 3 Shown. For this reason, the ventilator 5 is arranged in the fresh air tunnel 6 and is used to always send a corresponding amount of fresh air through the fresh air inlet pipe 4 to the position of the front wall 14 of the work.

[0023] press image 3 It is shown that only the suction pipe 29 of the suction joint or the dust removal device 8 is provided in the part of the roadheader 3, and the dust removal device 8 itself is arranged far back in the tunnel 2. After the dust removal device 8 is provided a fan station 9, an end 28 of the return air pipe 7, a compressor 10, a compressed air container 11 and a general distribution box 12.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com