Patents

Literature

36results about How to "Avoid brushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

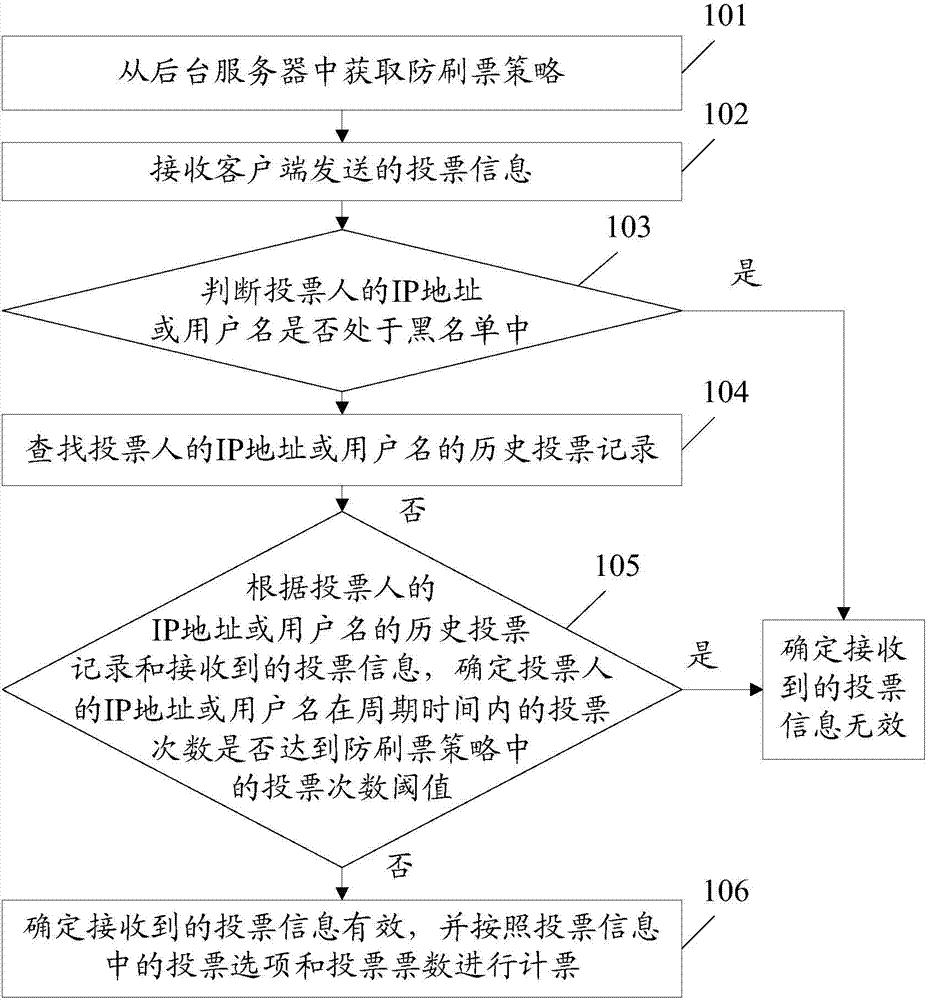

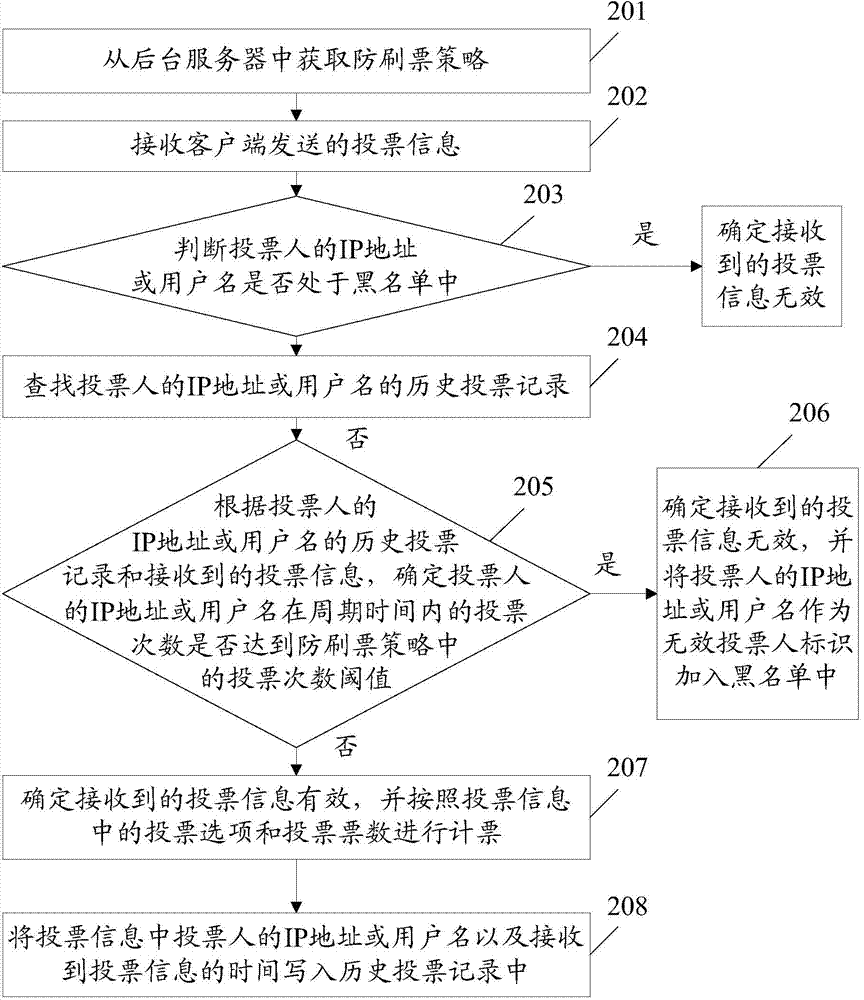

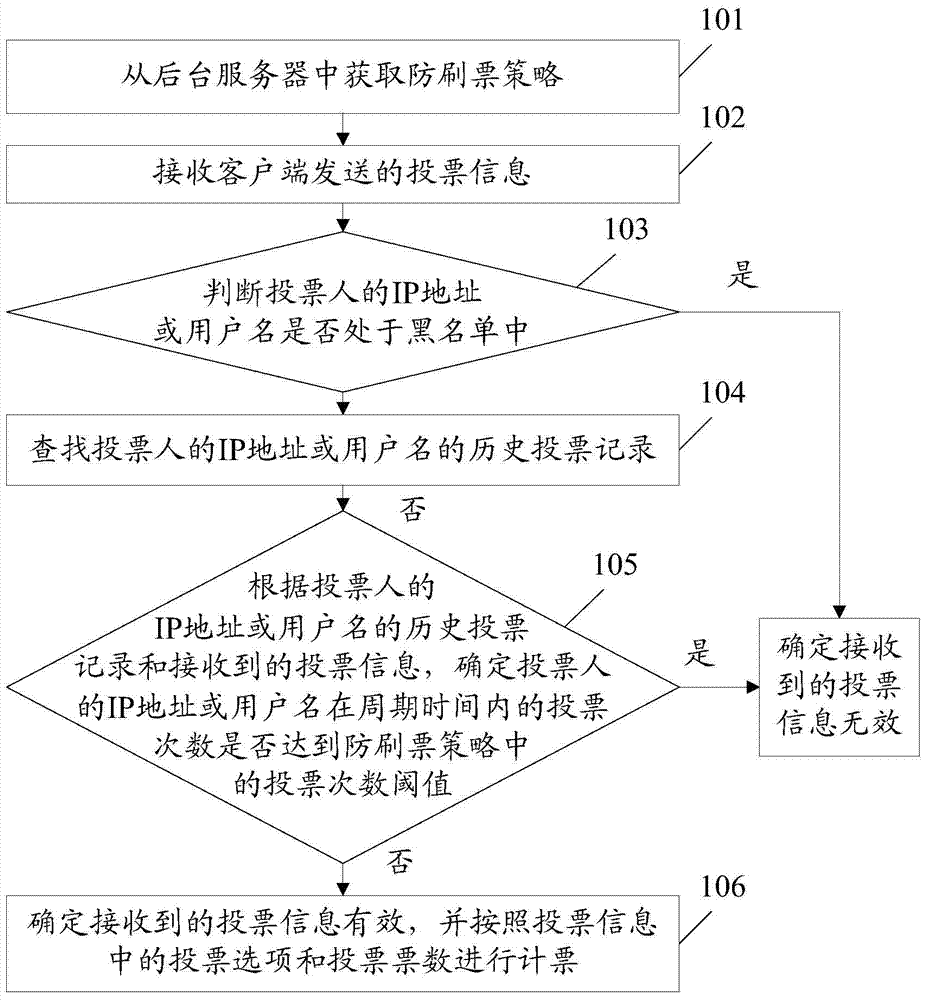

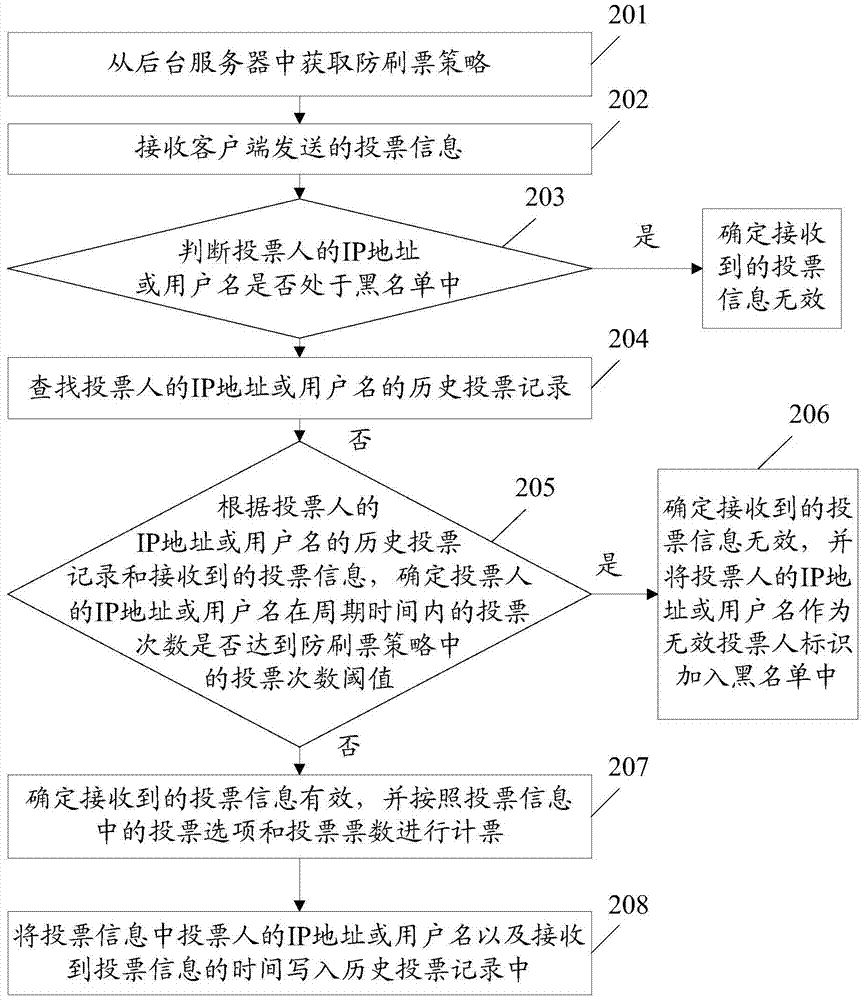

Network voting method and device

The invention discloses a network voting method and device and belongs to the network application technical field. The network voting method comprises obtaining a ticket-checking prevention strategy from a backend server; receiving the voting information sent from a client, wherein the voting information comprises the voting identification, IP (Internet Protocol) addresses or user names of voters, voting options and votes; judging whether the IP addresses or the user names of the voters are located in a blacklist or not; searching historical voting records of the IP addresses or the user names of the voters if not; determining the votes of the IP addresses or the user names of the voters within the periodic time according to the historical voting records of the IP addresses or the user names of the voters and the received voting information; determining that the received voting information is valid if the votes of the IP addresses or the user names of the voters within the periodic time do not reach a vote threshold value in the ticket-checking prevention strategy and performing counting according to the voting options and the votes in the voting information.

Owner:广州方硅信息技术有限公司

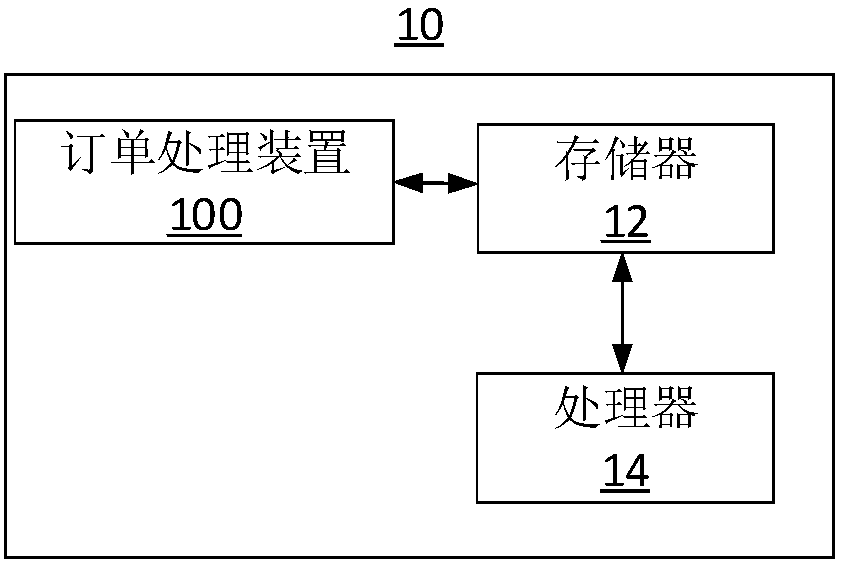

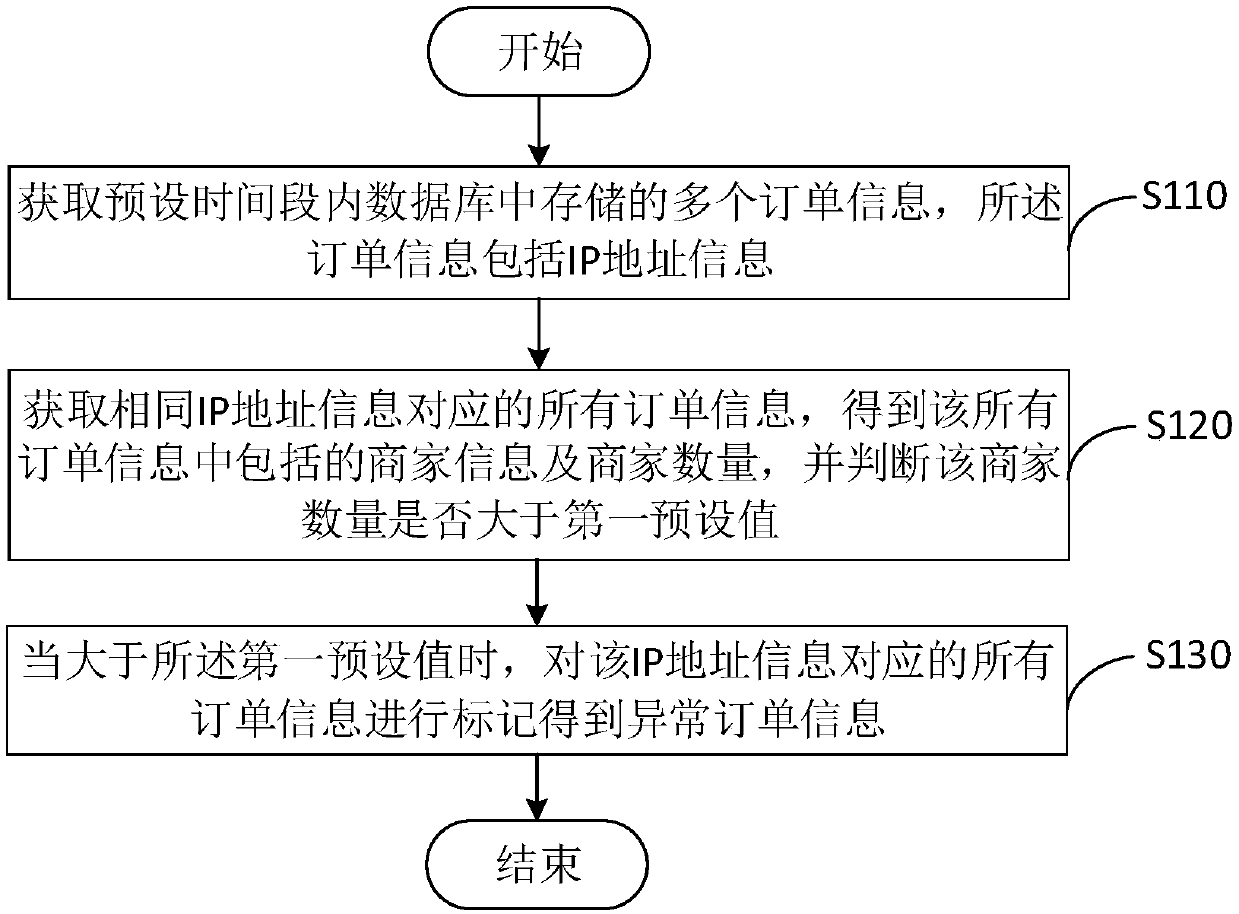

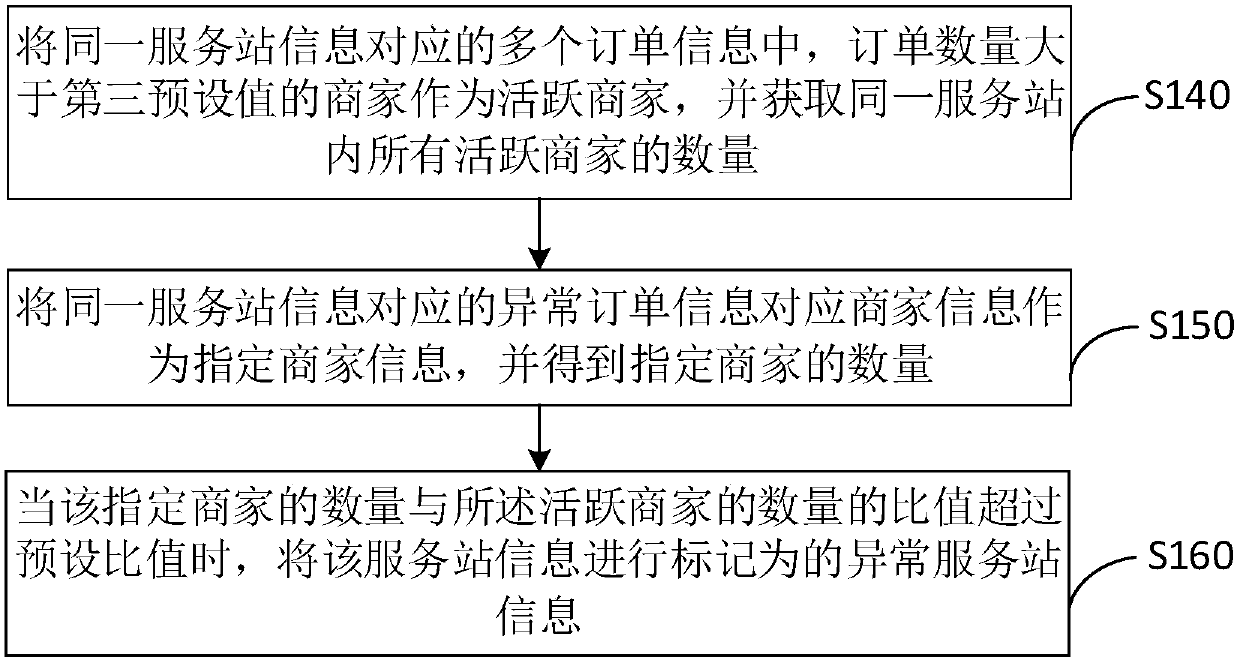

Order processing method and device

InactiveCN107609950ALong-term effective and reliable monitoringAvoid brushingBuying/selling/leasing transactionsIp addressThe Internet

The invention relates to the technical field of the Internet, and specifically relates to an order processing method and device. The method comprises the steps: obtaining a plurality of pieces of order information stored in a database in a preset time period, wherein the order information comprises IP address information; obtaining the order information corresponding to the same IP address information and the number of orders, and judging whether the number of orders is greater than a first preset value or not: carrying out the marking of the order information corresponding to the IP address information when the number of orders is greater than the first preset value, and obtaining abnormal order information. Through the above setting, the method achieves the long-term effective and reliable monitoring of the order information, so as to effectively avoid order scalping.

Owner:掌合天下(北京)信息技术有限公司

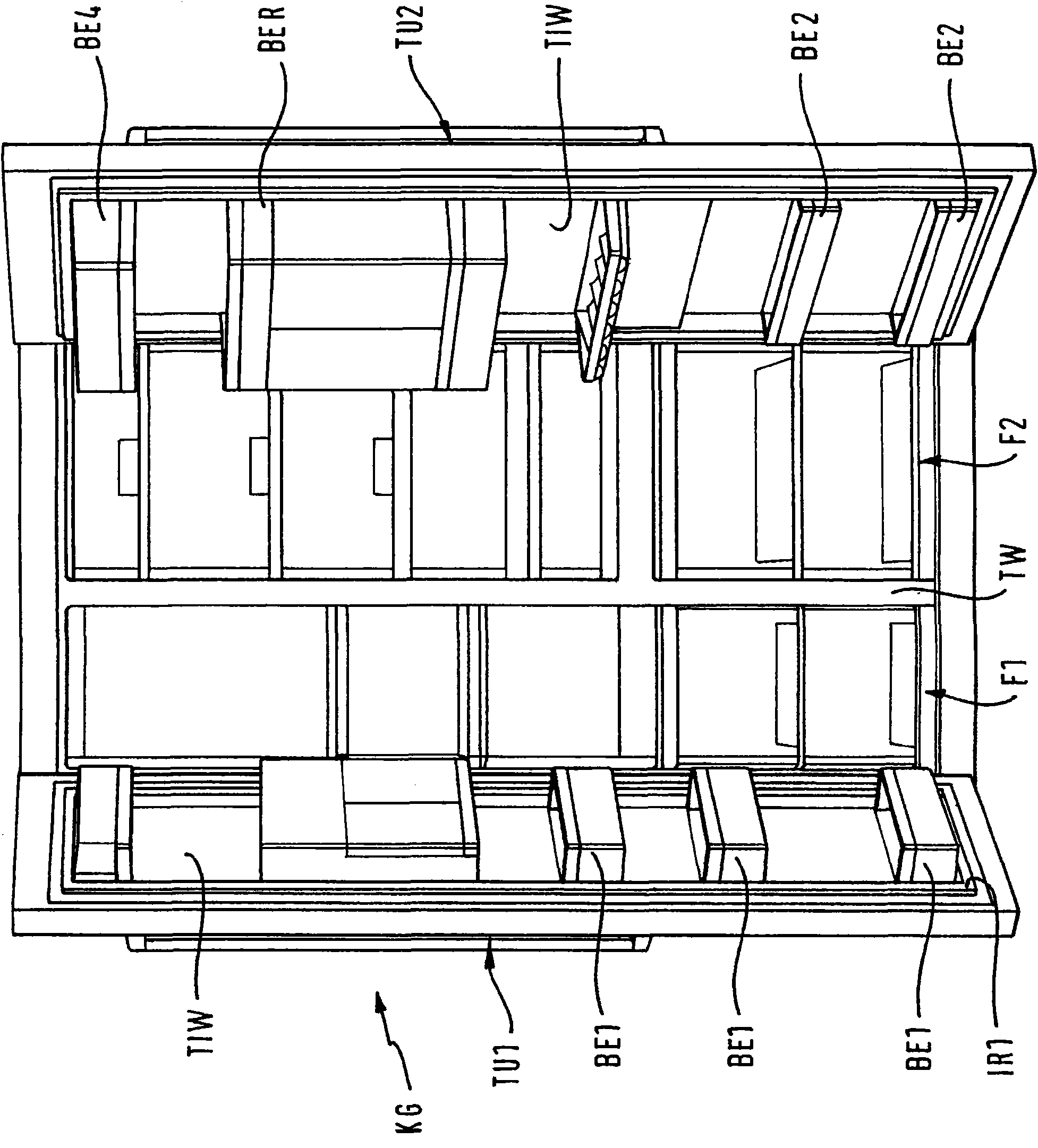

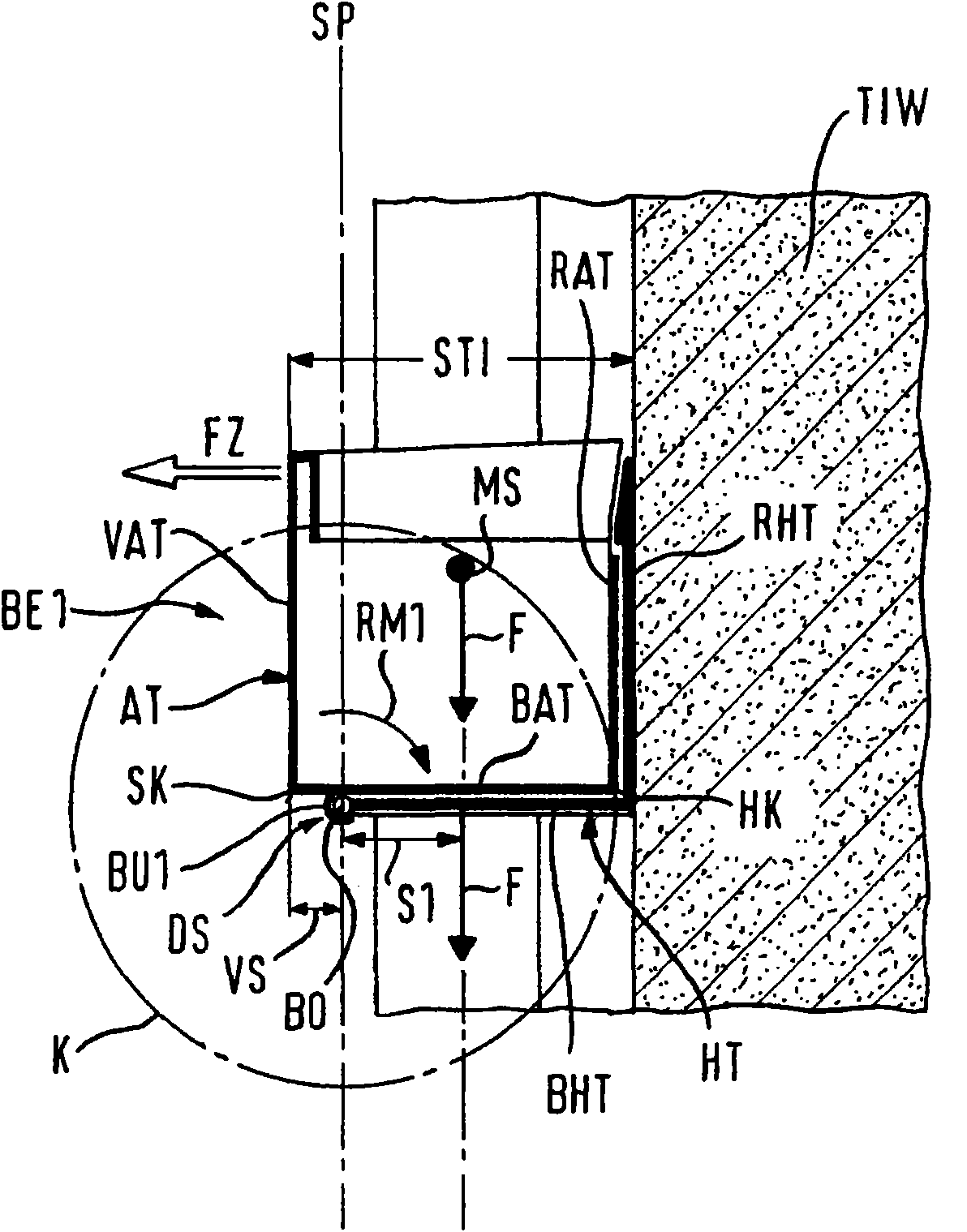

Refrigerator and associated storage container

ActiveCN101960243AImprove convenienceAvoid brushingLighting and heating apparatusSupportEngineeringFront edge

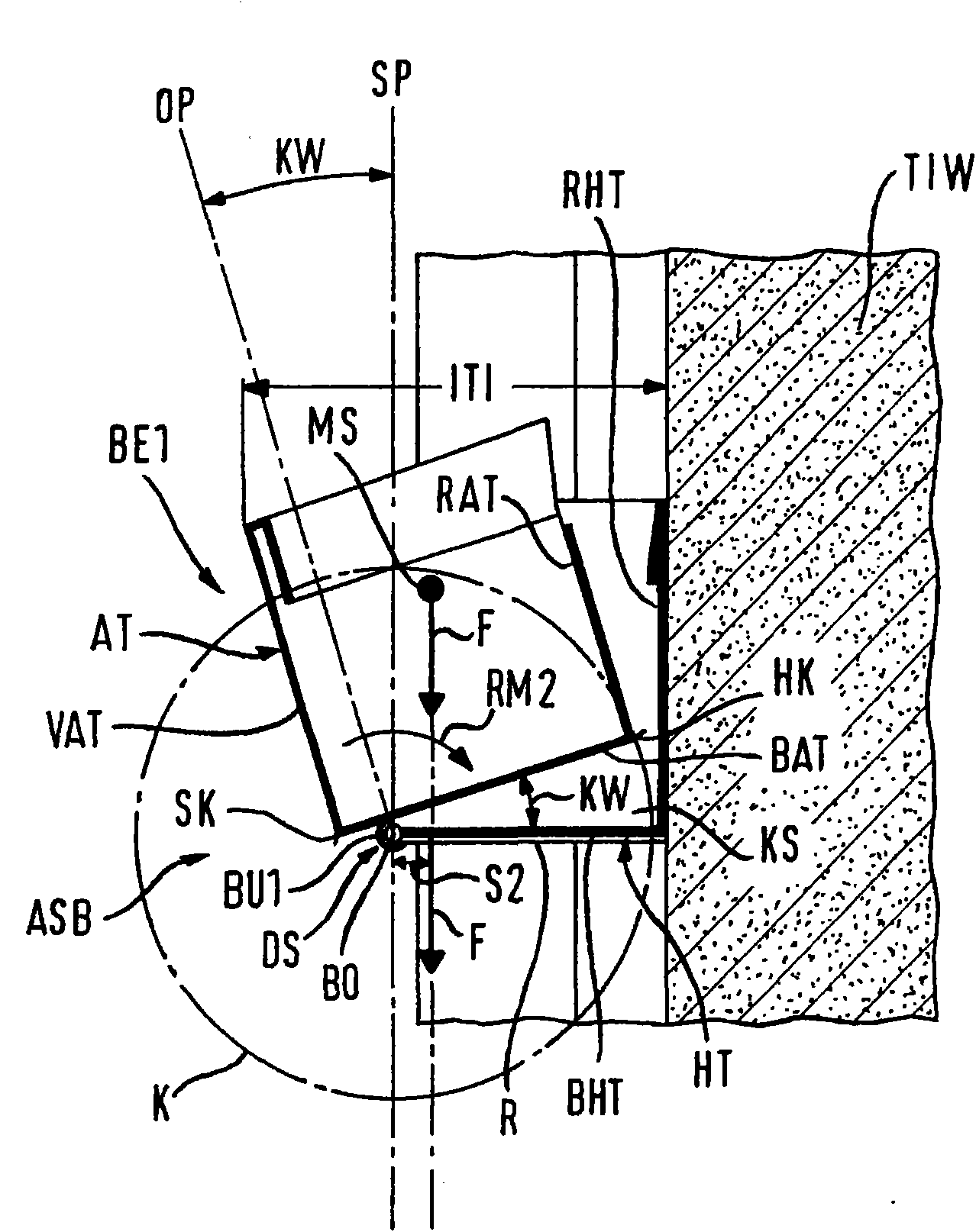

At least one storage container (BE1) for a refrigerator (KG) comprises a stationary holder part (HT) and a receiving part (AT) which is movably mounted thereon and is used for storing products that are to be cooled. The receiving part (AT) is rotatably mounted on the holder part (HT) by means of at least one rotary joint (DS) in the region of the lower front edge (SK) of the receiving part (AT) in such a way that a net restoring torque (RM2) is applied to the receiving part (AT) in the respective opening position between the final closed position (SP) and the final open position (OP) of the receiving part (AT), said restoring torque (RM2) causing the receiving part (AT) to be automatically tilted back into the final closed position (SP).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Device for oral care of senile patients

PendingCN110368122AImprove cleanlinessAvoid brushingAntifouling/underwater paintsBristleMouth careBristle

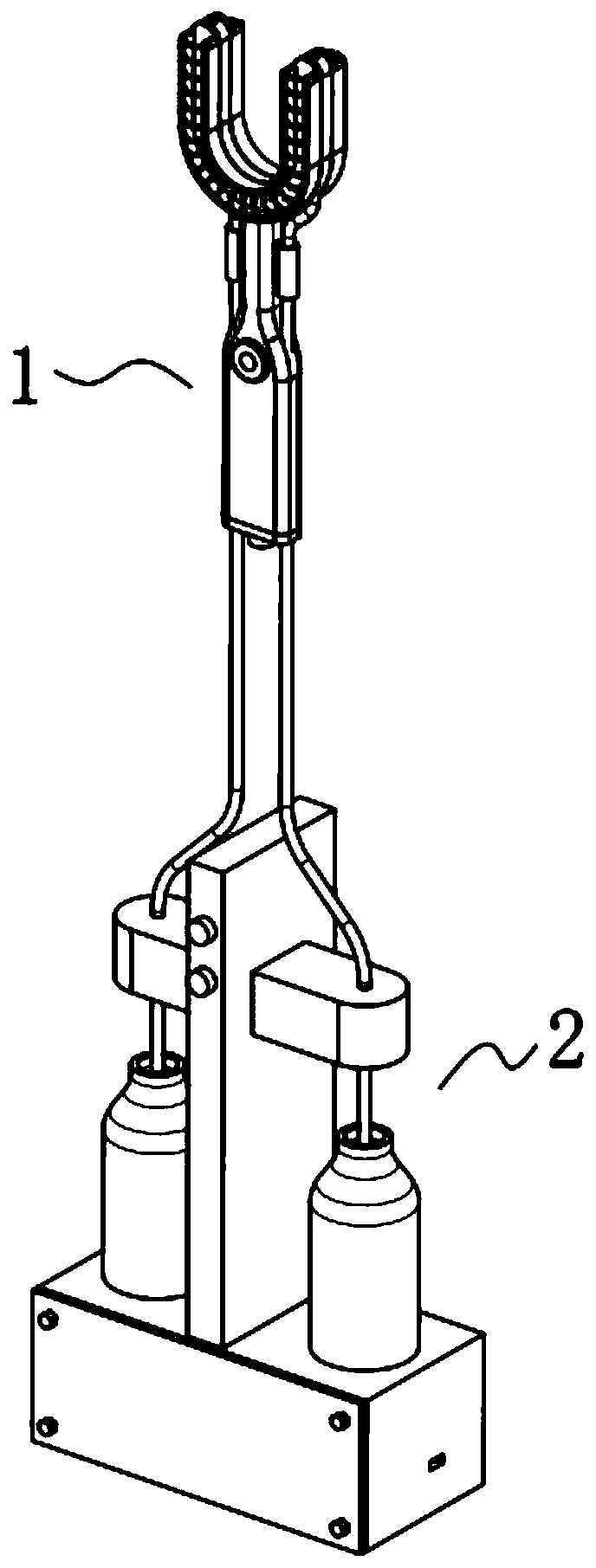

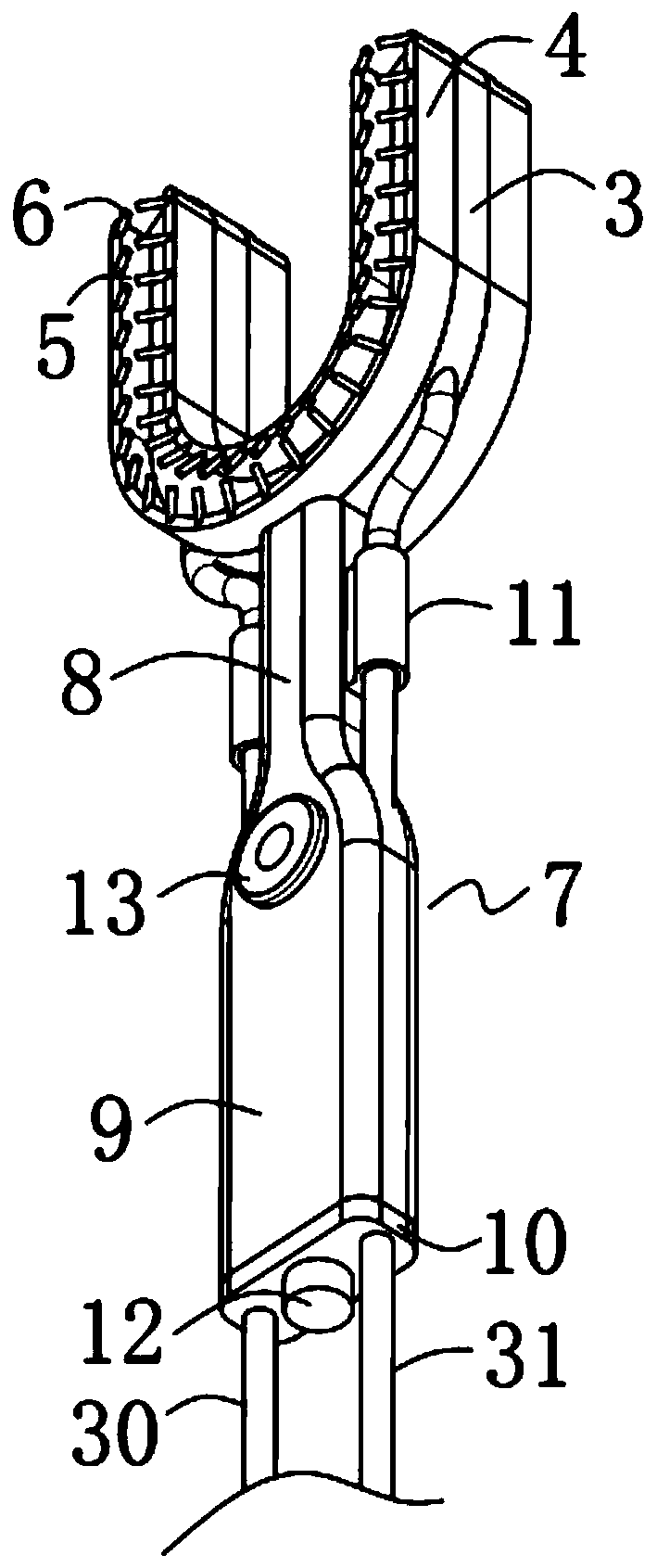

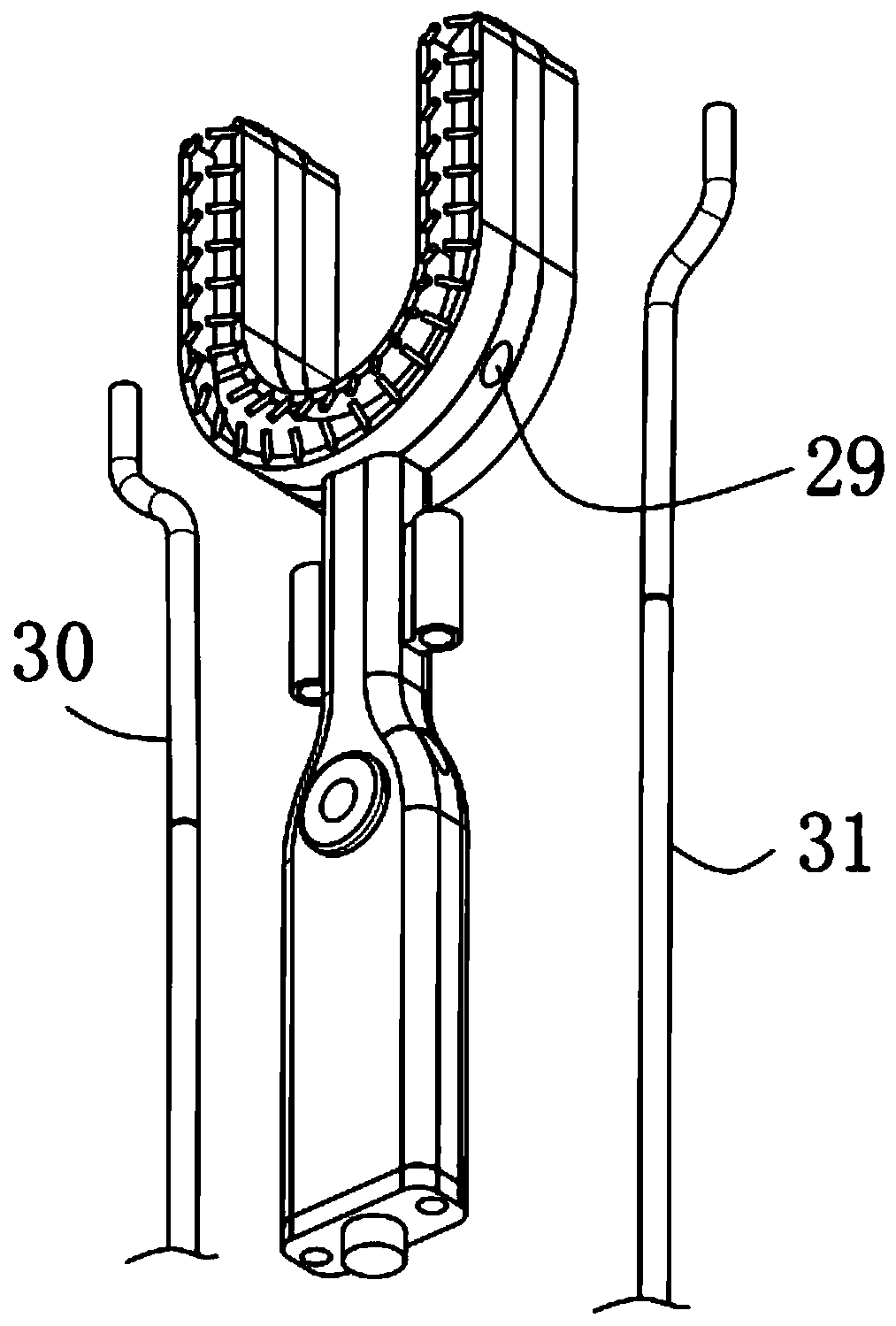

The invention discloses a device for oral care of senile patients. The device comprises a tooth brushing unit which comprises a U-shaped base, two U-shaped brush heads and a handle, the U-shaped brushheads are fixedly mounted at the bottom and on the upper portion of the U-shaped base respectively and arranged symmetrically, a groove is formed in the side face, back to the U-shaped base, of eachU-shaped brush head, and a plurality of bristles are integrally formed at the upper edge of the groove wall on each of two sides of each groove. The device is designed for oral care of the senile patients suffering from paralysis or dementia, thereby being good and thorough in oral care cleaning effect, comparatively convenient for oral care of the senile patients suffering from paralysis or dementia, comparatively convenient for mouth rinsing and capable of avoiding the senile patients drinking mouth wash and can conveniently complete oral care of unconscious patients; the surface of a handlehas good antiskid effect and antibacterial performance, thereby being less prone to bacteria breeding, clean and sanitary.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

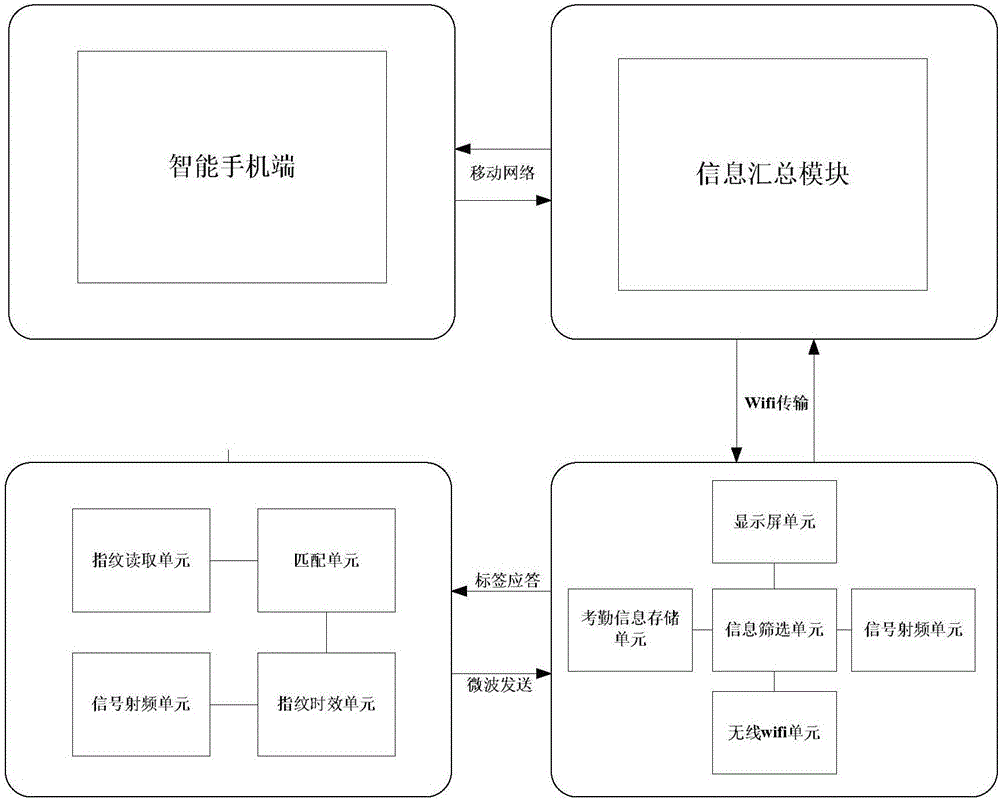

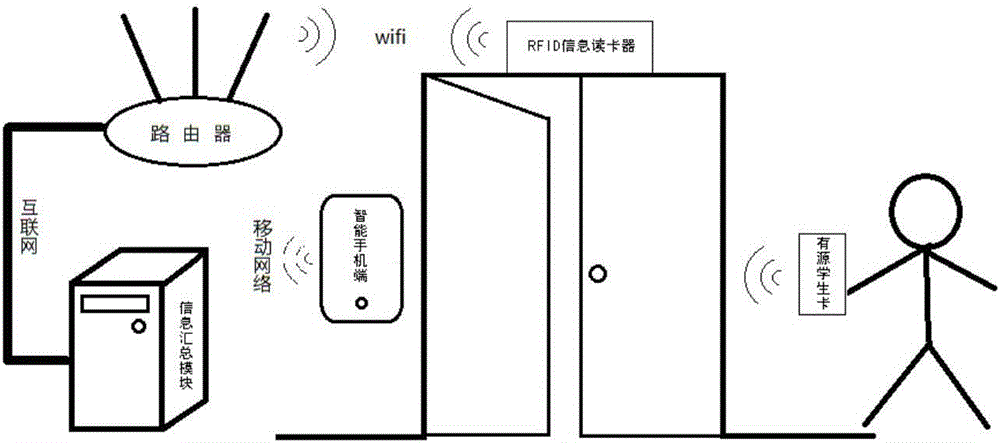

RFID-based moveable classroom attendance system

InactiveCN106780818ASupervise on timeSupervise classRegistering/indicating time of eventsCo-operative working arrangementsElectronic taggingMobile end

The invention discloses an RFID-based moveable classroom attendance system. The system comprises an active student card with an electronic label, an RFID information reader, an intelligent mobile terminal and an information collecting module, wherein a fingerprint reading unit, a matching unit, a fingerprint aging unit and a signal radio frequency unit are arranged in the active student card with the electronic label; the active student card is carried by a student; the student can activate the signal radio frequency unit in the card through the fingerprint; the RFID information reader is used for sending an attendance ID, receiving a signal fed back by the signal radio frequency unit in the active student card with the electronic label and recording the attendance information in the whole T time period; the information collecting module is used for collecting the attendance information and sending the attendance information to an intelligent mobile terminal held by each attendance person according to the attendance ID. The RFID-based moveable classroom attendance system has a simple structure; the classroom time is saved; the students can be supervised and urged to actively attend class on time; and the card-wiping replacement problem can be solved.

Owner:HANGZHOU NORMAL UNIVERSITY

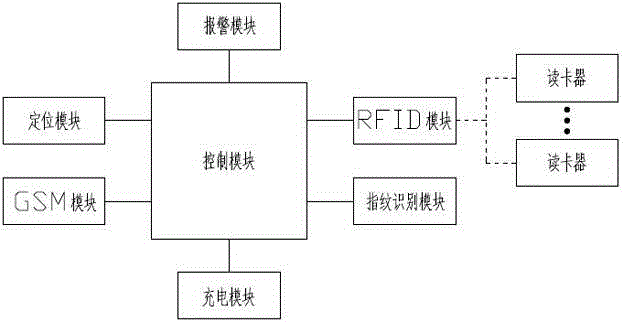

Intelligent electronic student ID card

InactiveCN106557801APrecise positioningStatistics for classesSensing record carriersRecord carriers used with machinesComputer hardwareEmbedded system

Owner:HUBEI GENSTON INFORMATION TECH CO LTD

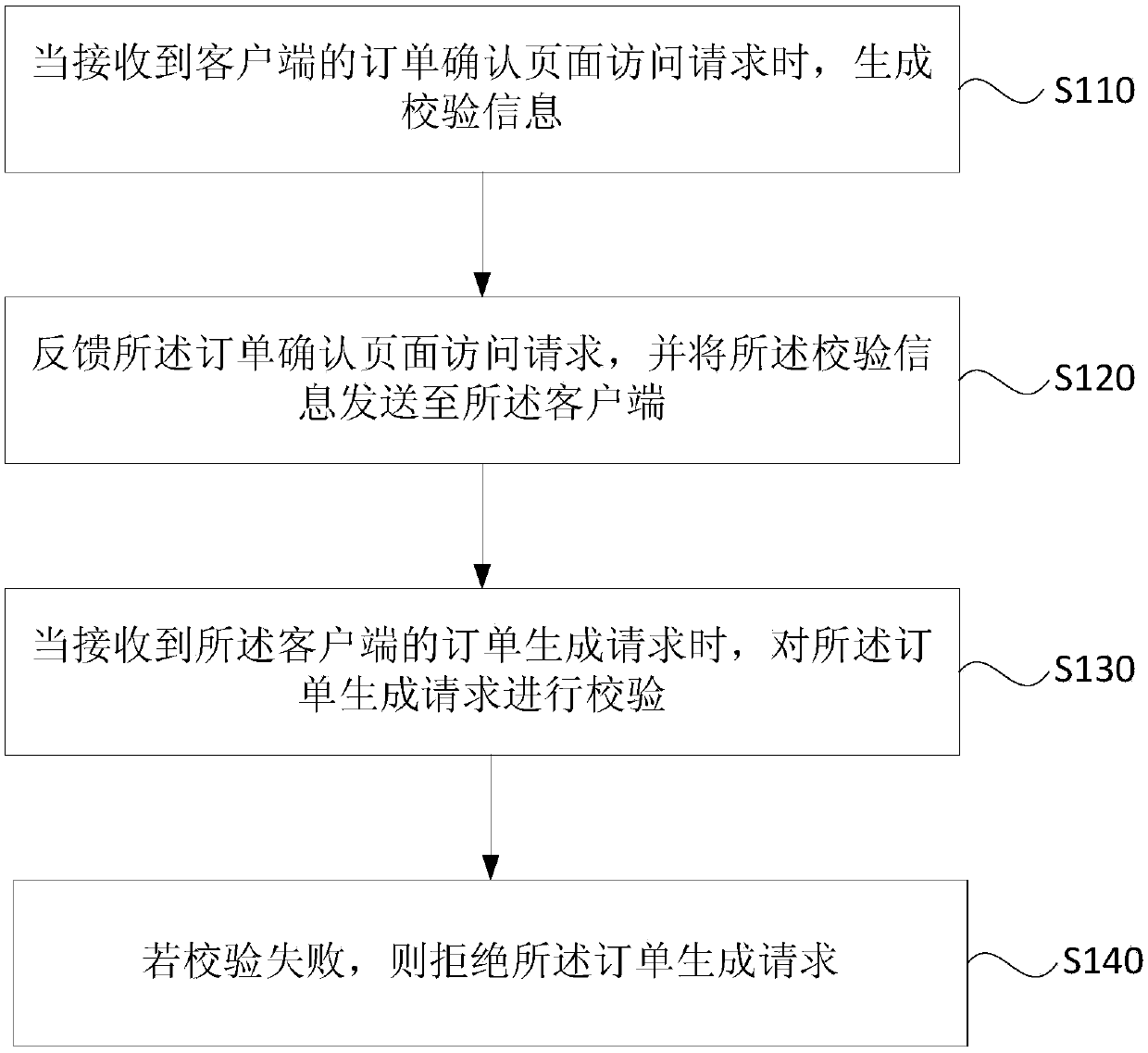

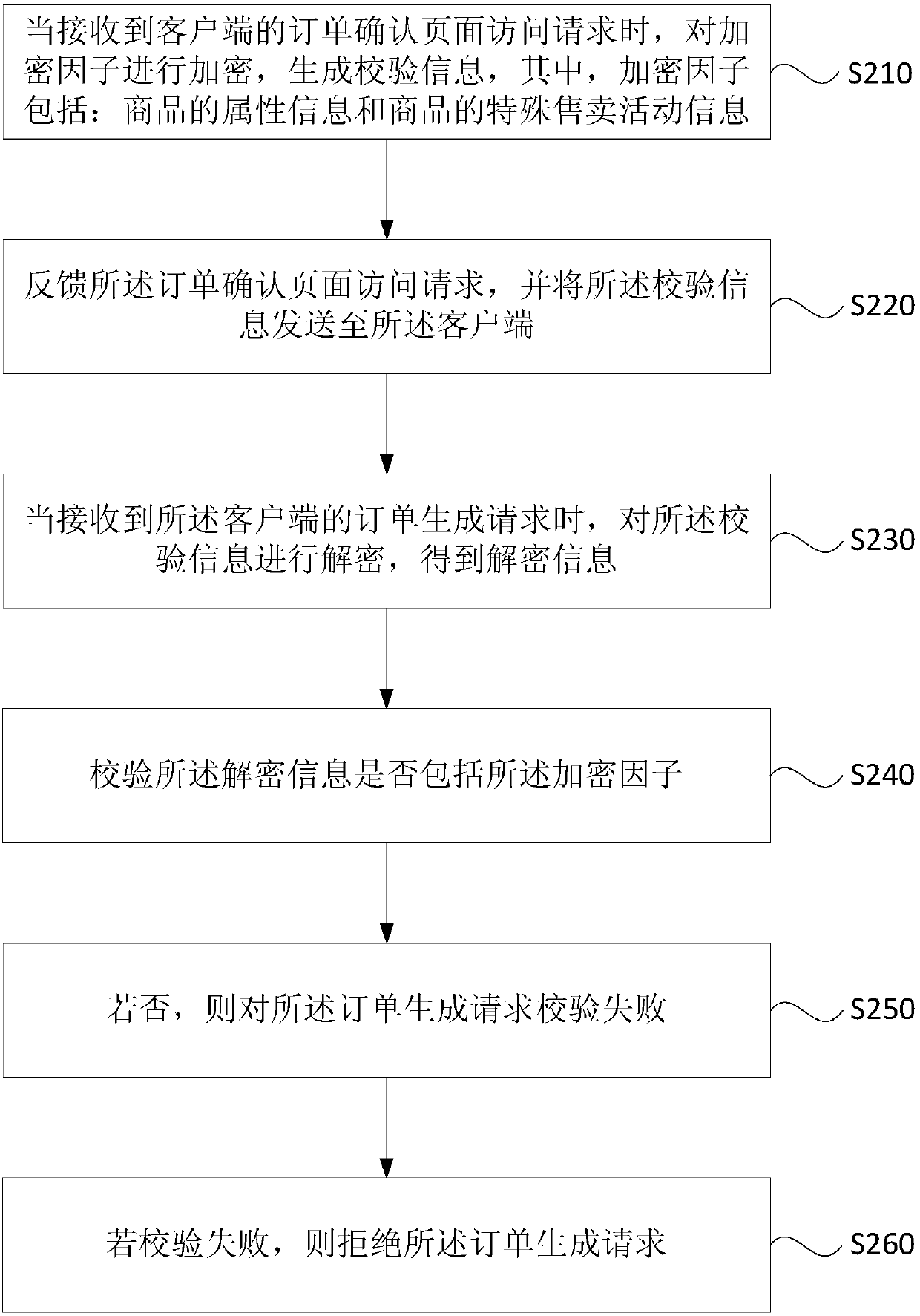

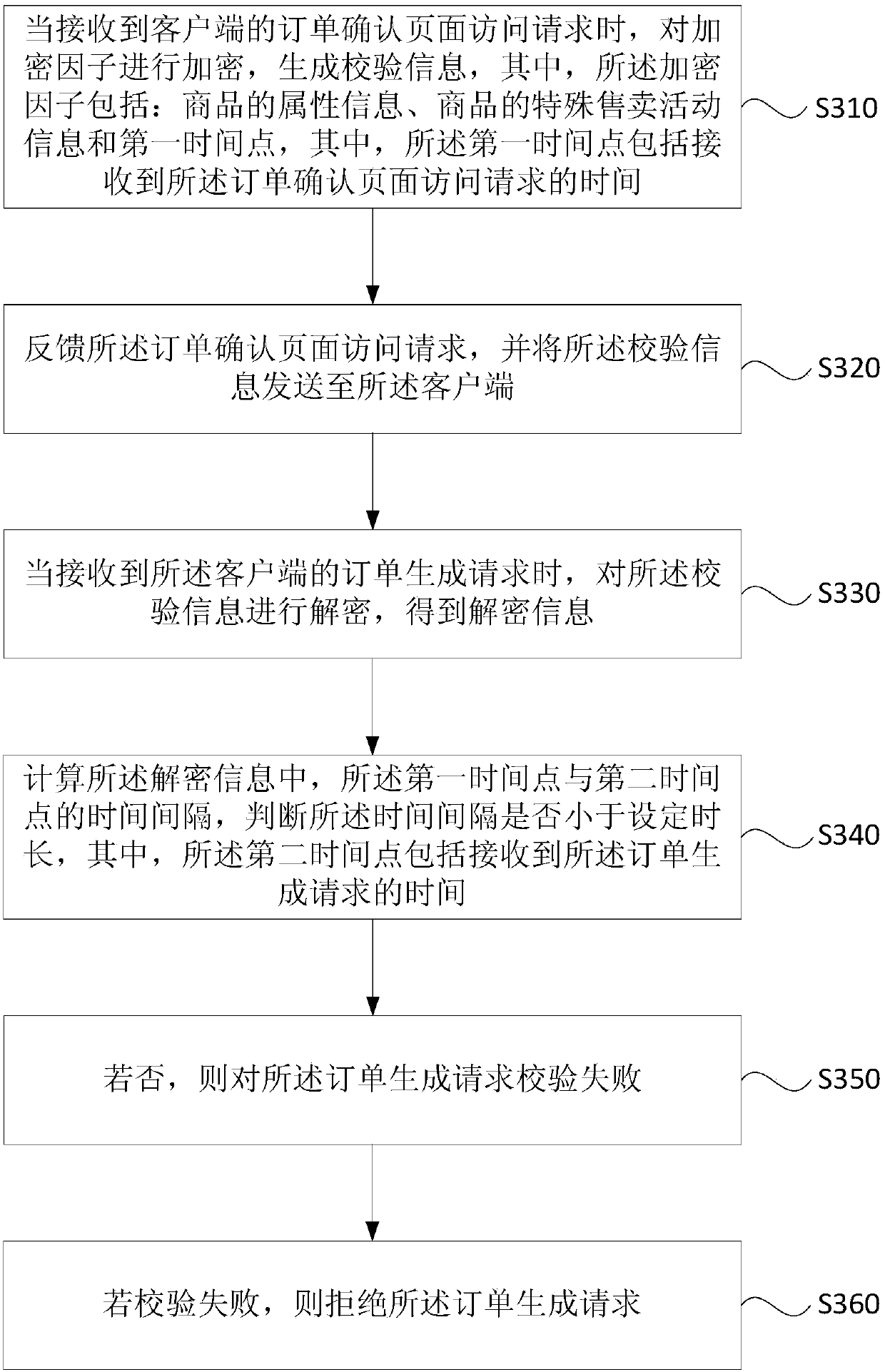

Order processing method, device, storage medium, server and terminal equipment

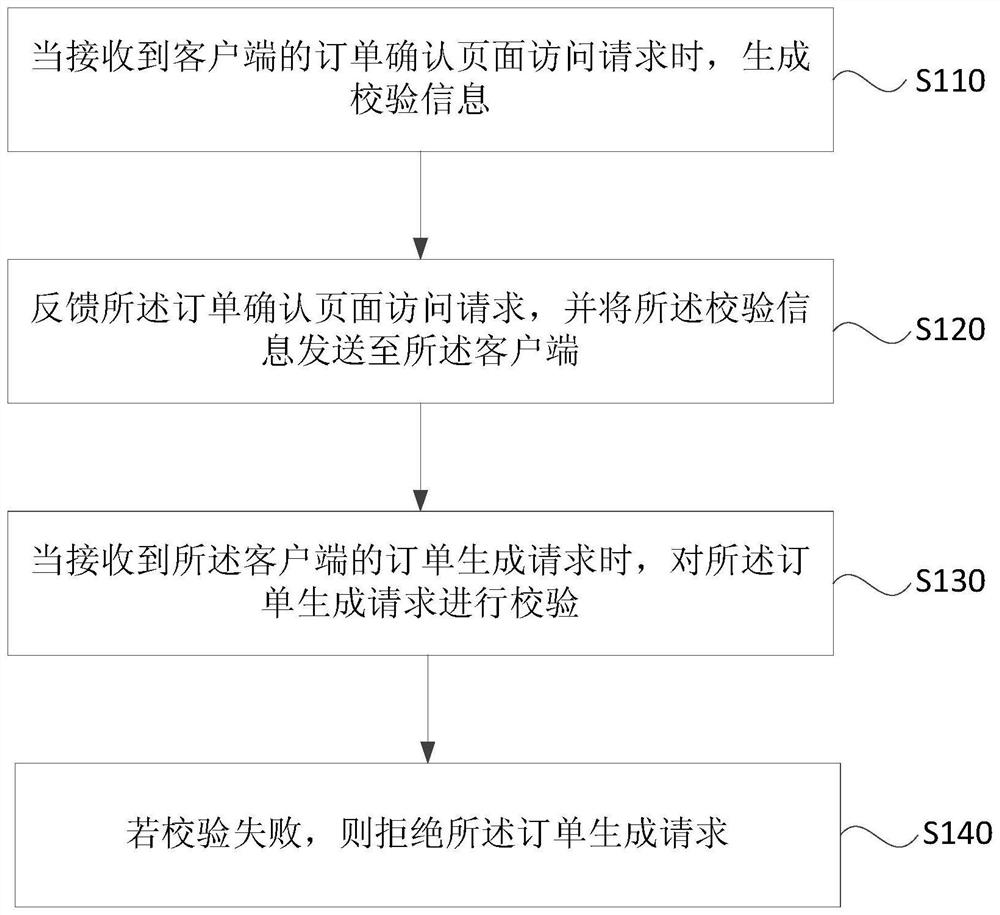

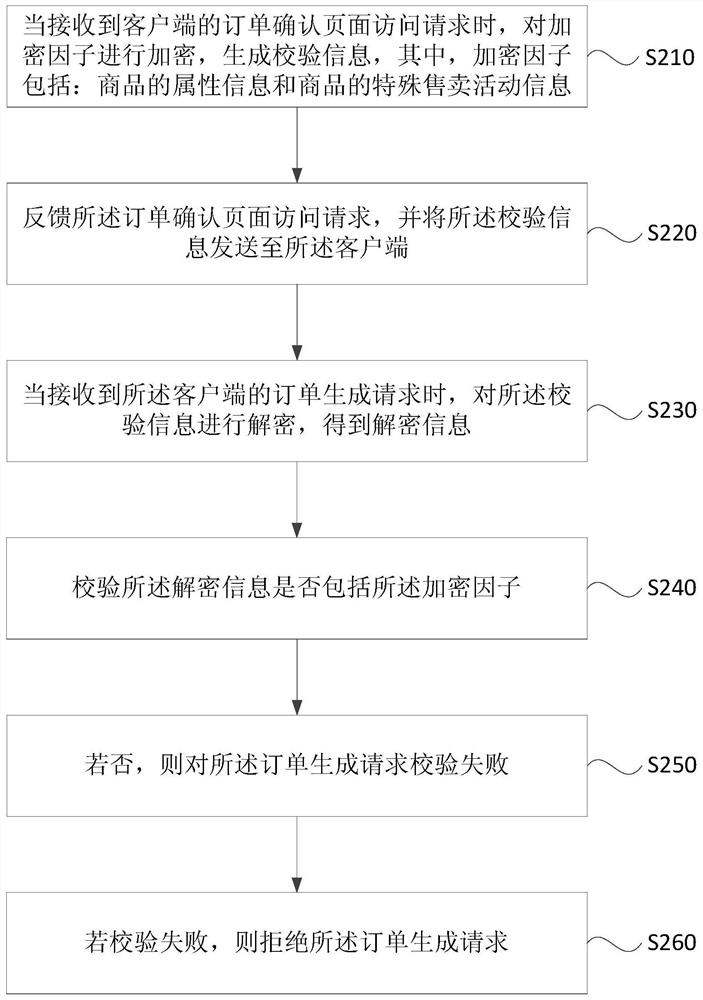

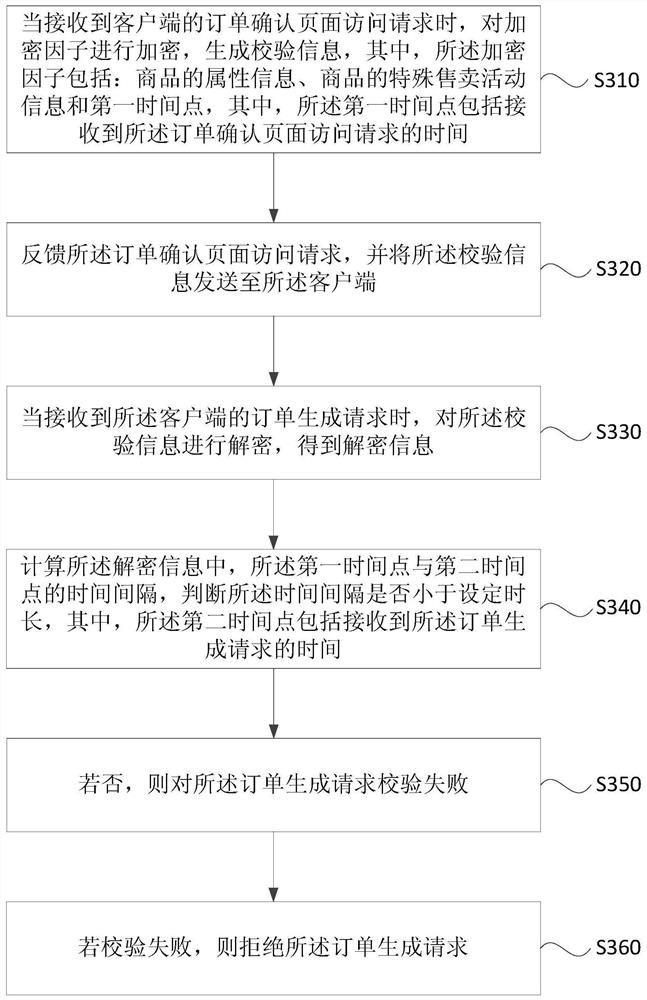

ActiveCN107784554APrevent fraudulent billing by abnormal meansSolve the problem of brushing orders by abnormal meansBuying/selling/leasing transactionsOrder processingOrder form

The embodiment of the invention discloses an order processing method, a device, a storage medium, a server and terminal equipment; the method comprises the following steps: receiving an order confirmpage access request of a client end, and forming verification information; feedbacking the order confirm page access request, and sending the verification information to the client end; receiving a client end order forming request, and verifying the order forming request; if fails, rejecting the order forming request. By using the method, the fake ordering effect caused by abnormal means can be prevented.

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

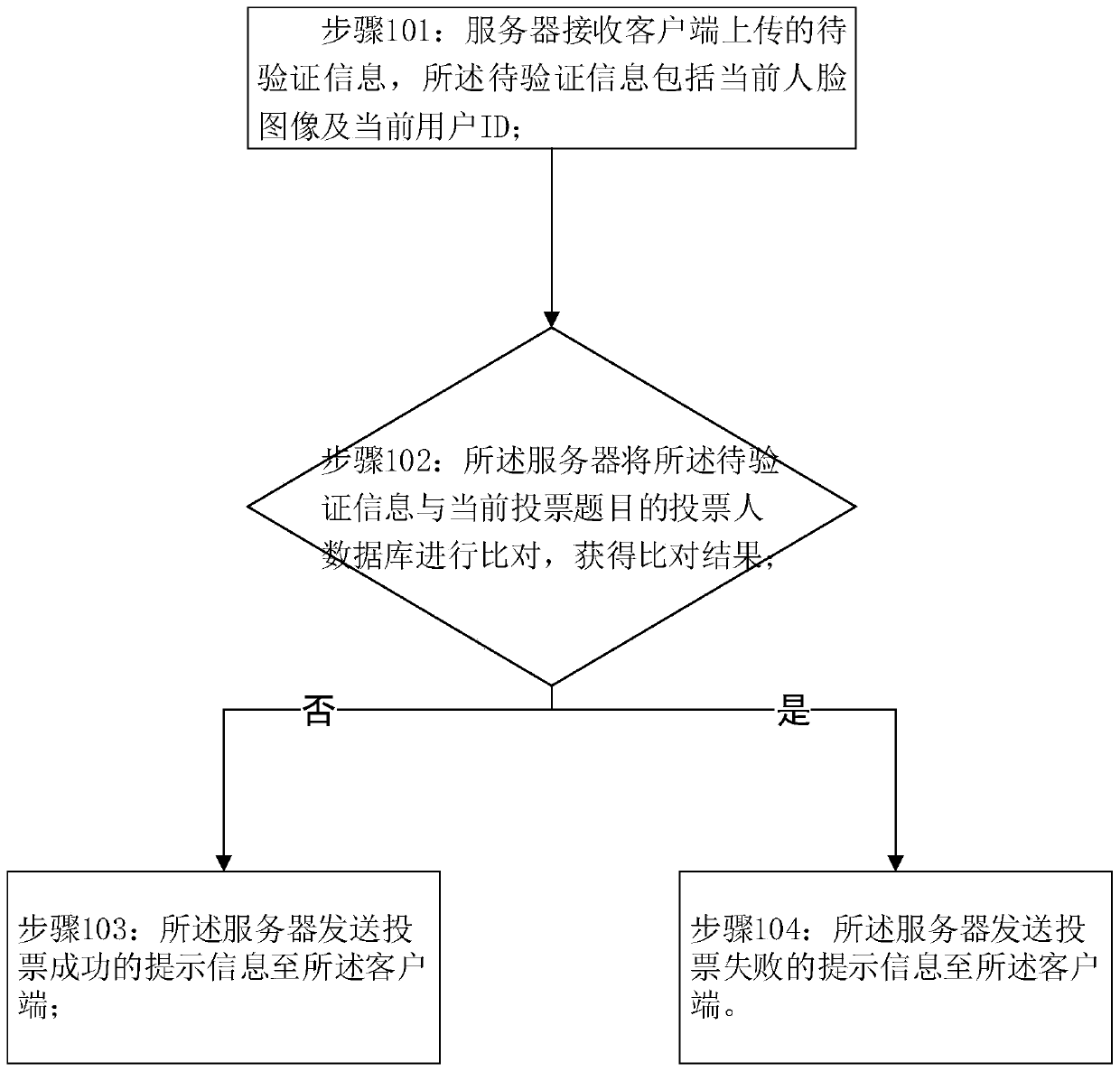

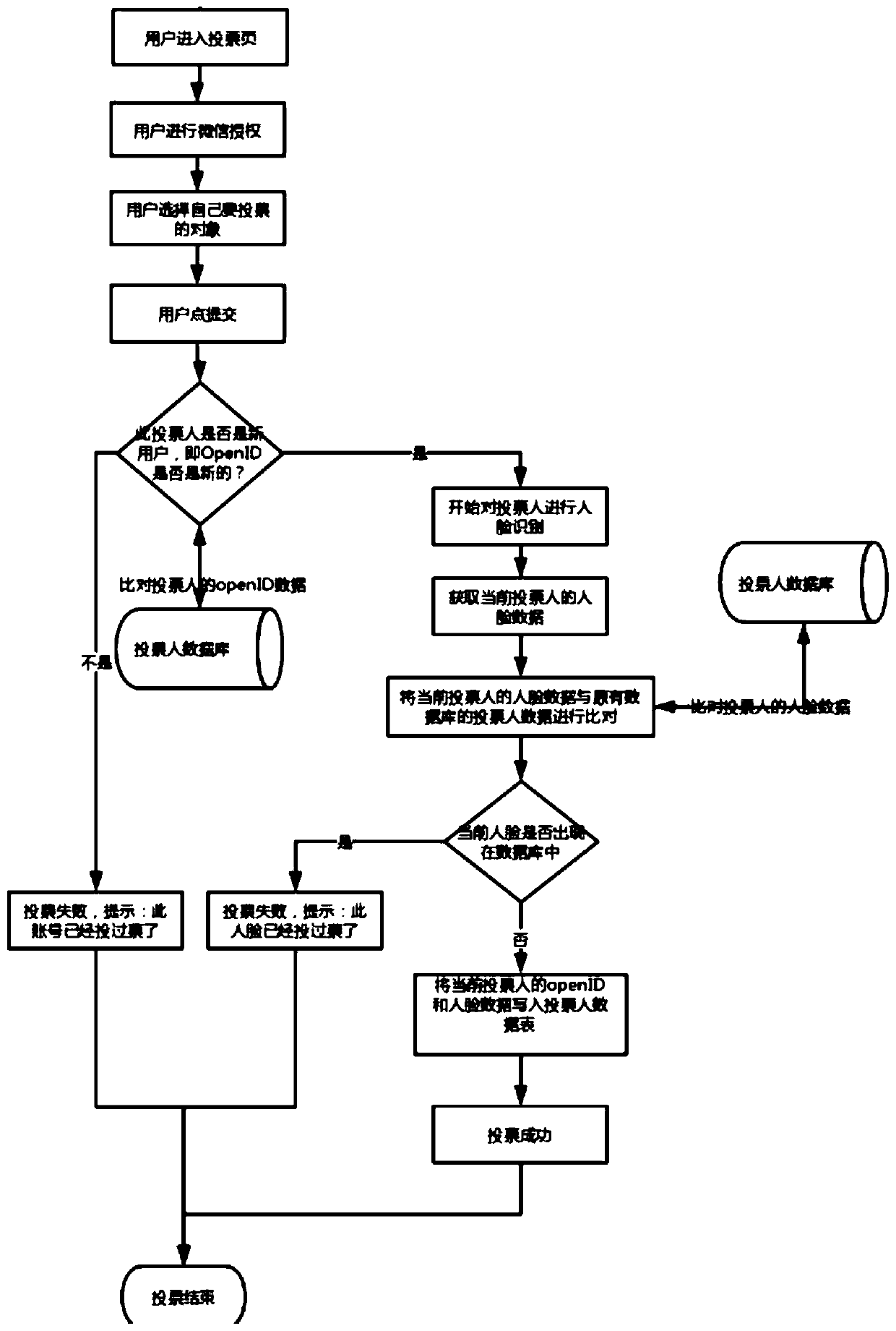

Ticket swiping prevention method and system based on face recognition

The embodiment of the invention discloses a ticket swiping prevention method and system based on face recognition, and the method comprises the steps that a server receives to-be-verified informationuploaded by a client, and the to-be-verified information comprises a current face image and a current user ID; the server compares the to-be-verified information with a voter database of a current voting topic to obtain a comparison result; and if the comparison result comprises that the current face image and the current user ID do not appear in a voter database of the current voting topic, the server sends voting success prompt information to the client. According to the embodiment of the invention, real-name authentication is carried out through face recognition, whether different voting programs are used or different accounts of the same voting program are used for voting, only one user needs to vote once, and the ticket swiping behavior is effectively prevented.

Owner:厦门小狮科技有限公司

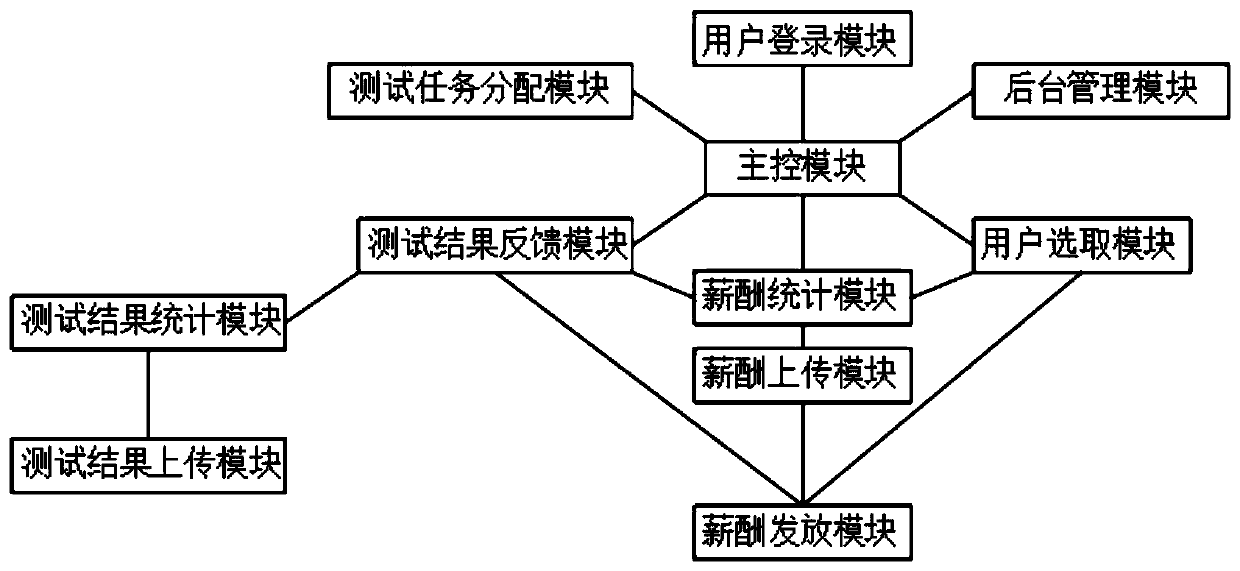

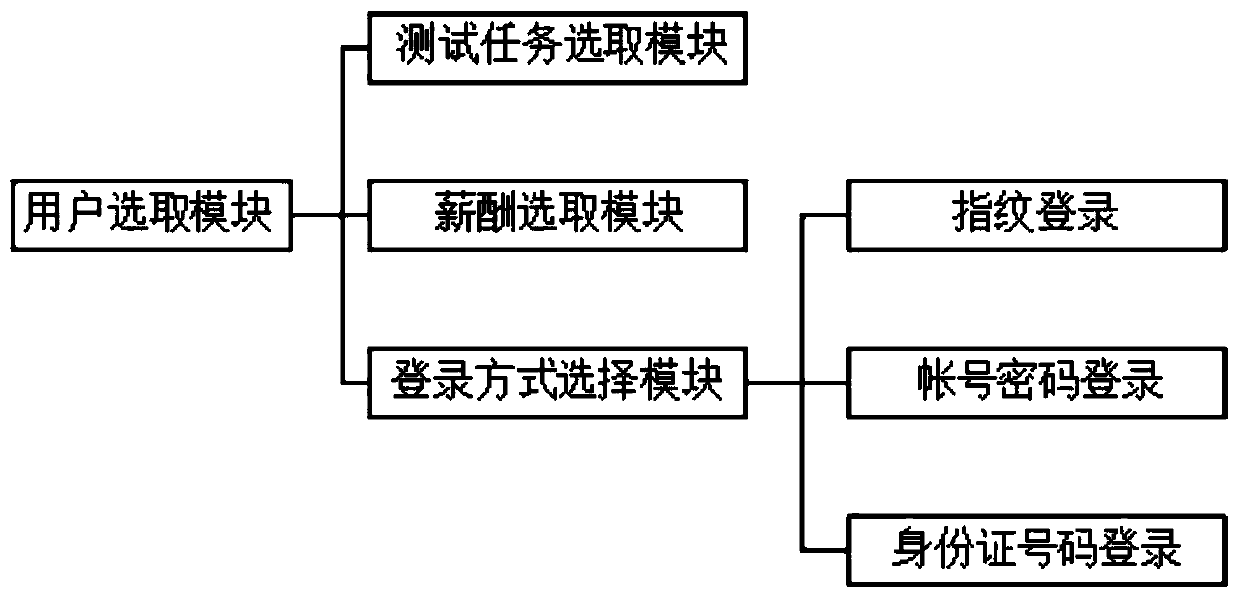

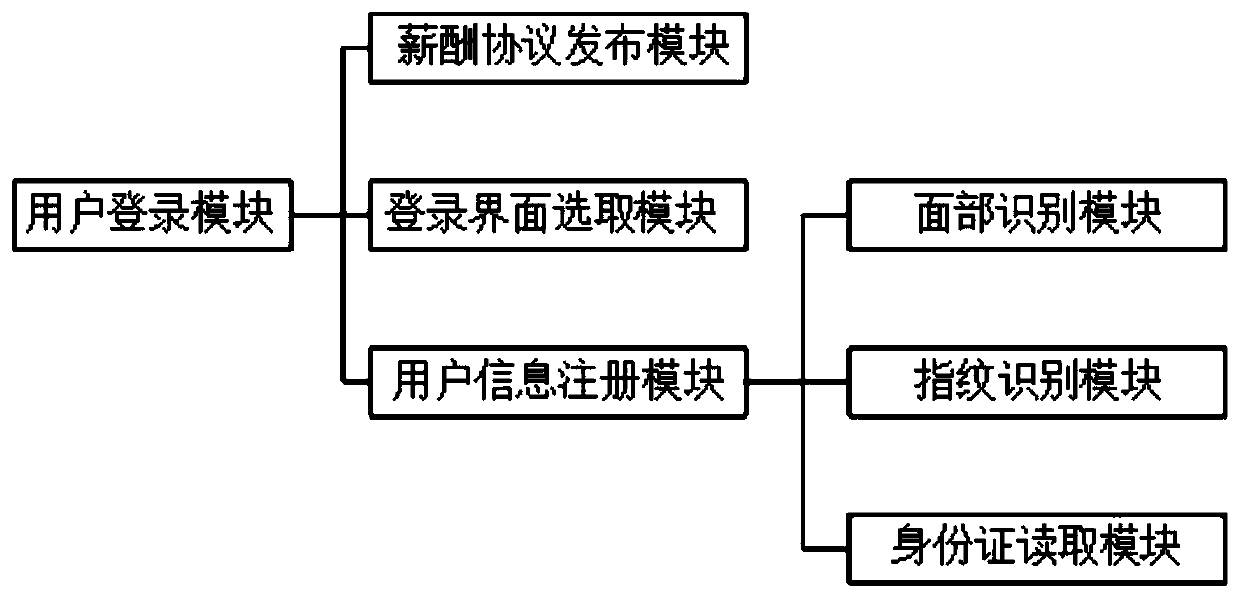

Information processing module of public test system

PendingCN111340392AAvoid brushingImprove test efficiencyDigital data authenticationOffice automationInformation processingTest efficiency

The invention discloses an information processing module of a public test system. The system comprises a main control module arranged in an information processing module, the main control module is electrically connected with a user login module, a test task distribution module, a background management module, a user selection module, a salary statistics module, a test result statistics module anda test task distribution module. Wherein tThe user login module is used for a user to log in the public test system and perform related operations, and the test task allocation module is used for allocating test tasks to the user logging in the public test system. According to the invention, face recognition and fingerprint recognition are combined to recognize the identity of the user, and the user information is called from the database, so that the situation of scalping is effectively prevented; statistical feedback is performed on a user test result, the test feedback is analyzed firstly,the test feedback is determined to be effective feedback and then adopted, the test feedback does not need to be collected completely and then screened manually, and therefore the test efficiency isimproved.

Owner:广东云印科技有限公司

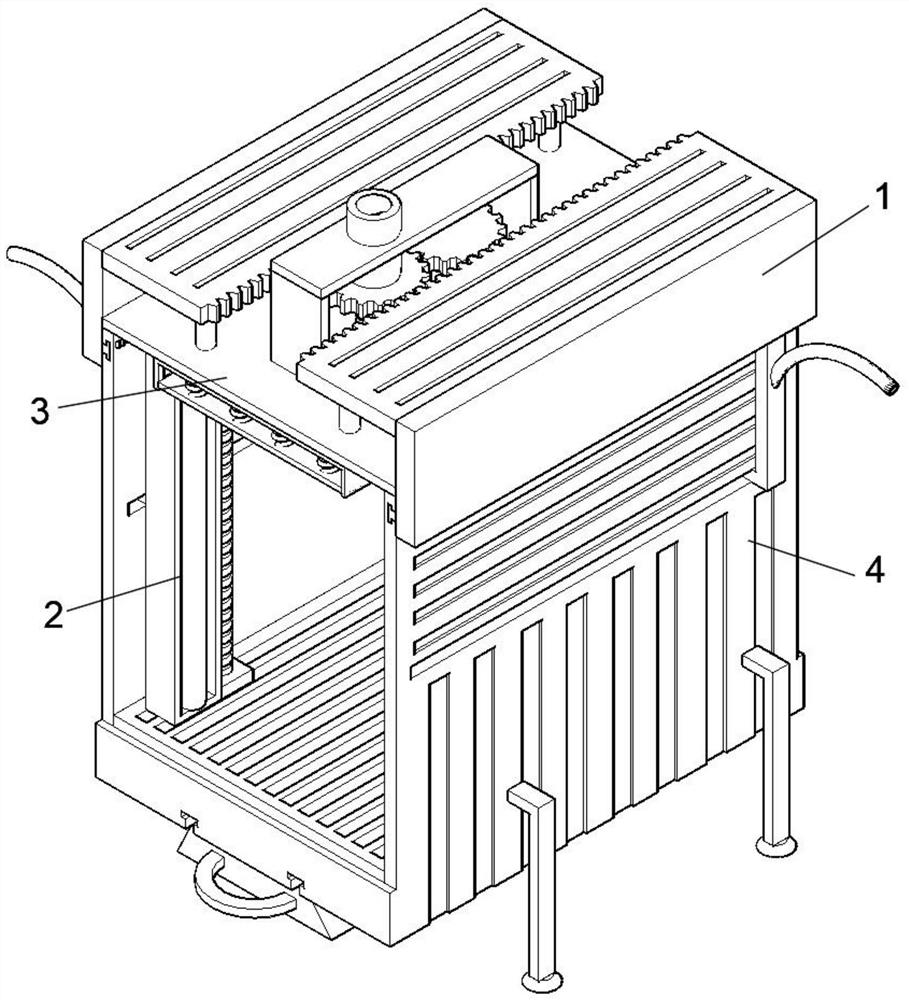

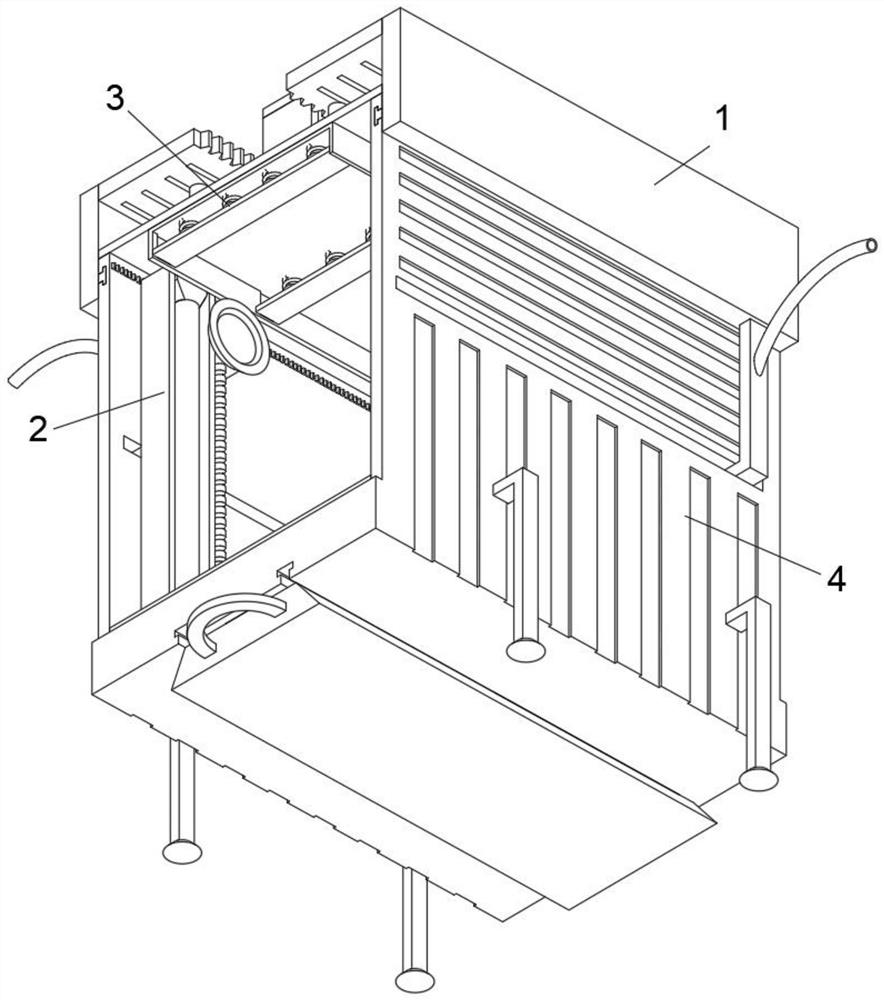

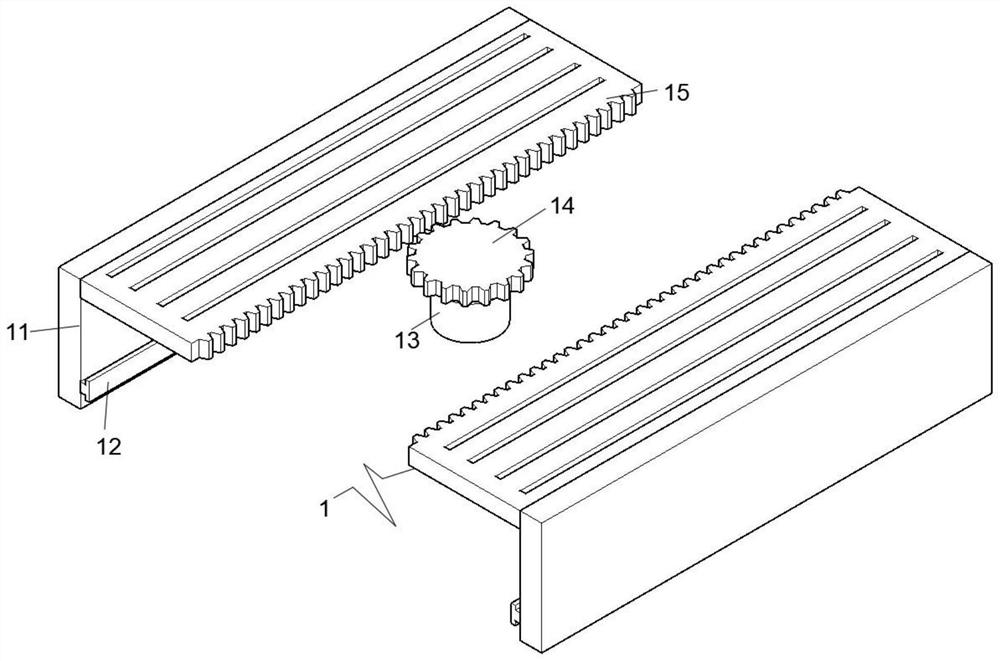

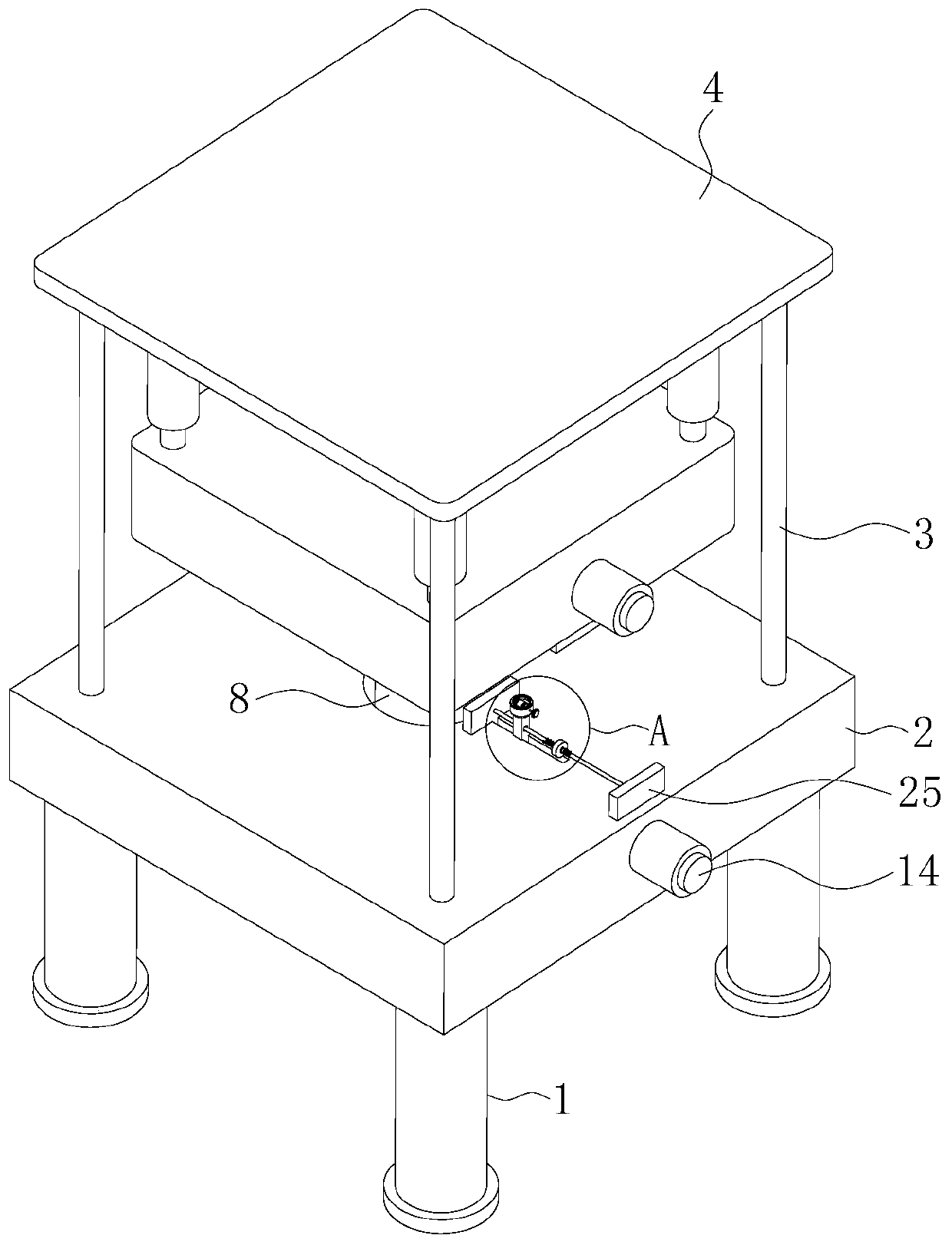

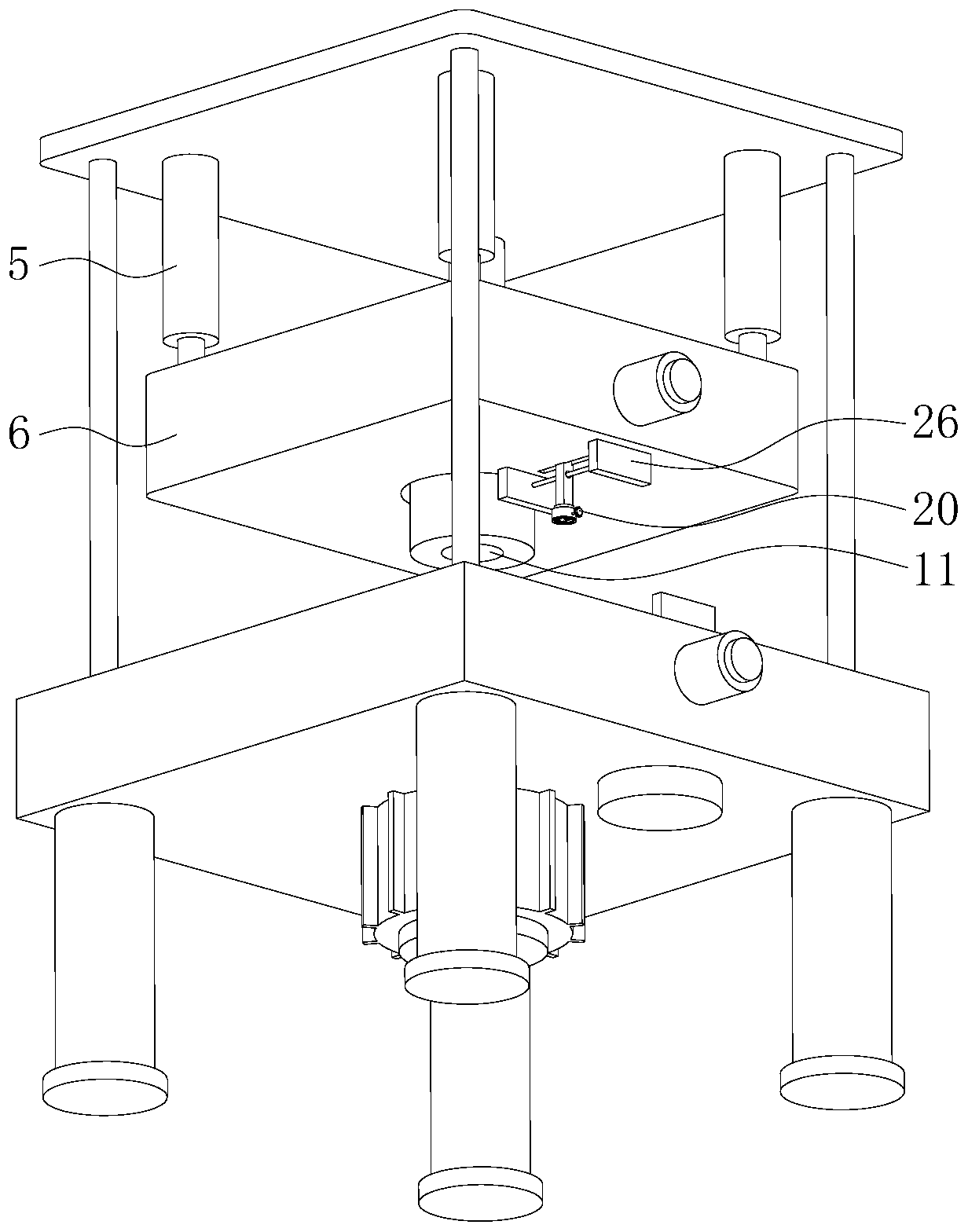

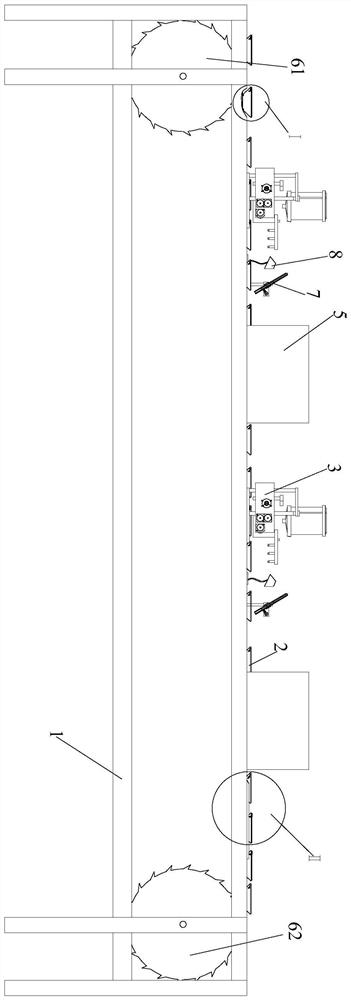

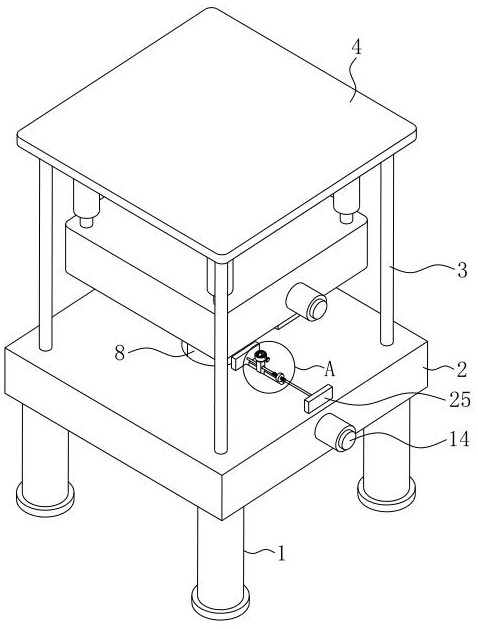

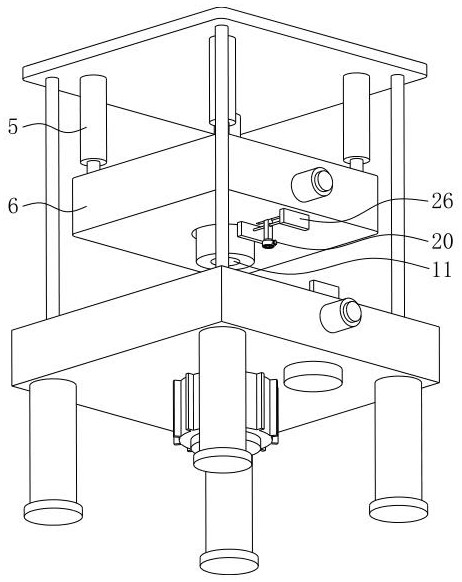

Multi-layer coating brushing device for environment-friendly corrosion-resistant paper-plastic production line

ActiveCN113117953AEasy to paintAvoid brushingLiquid surface applicatorsCoatingsElectric machineGear wheel

The invention relates to the field of brushing devices, in particular to a multi-layer coating brushing device for an environment-friendly corrosion-resistant paper-plastic production line. The multi-layer coating brushing device comprises a supporting device, a moving device is fixedly connected to the top end of the supporting device, an auxiliary fixing device is meshed with a gear at the side end of the moving device, brushing and drying devices are symmetrically and fixedly connected to the bottom end of the moving device, the moving device comprises moving side plates, fixed sliding keys, a motor, a rotating gear and rack transverse plates, the rotating gear is fixedly connected to the top end of the motor, the rack transverse plates are symmetrically engaged to the two sides of the rotating gear through gears, the moving side plates are symmetrically and fixedly connected to the bottoms of the ends, away from the motor, of the rack transverse plates, and the fixed sliding keys are symmetrically and fixedly connected to the bottom ends of the inner sides of the moving side plates. Through the arrangement of the moving device, the brushing and drying devices and the auxiliary fixing device, the uniform brushing and drying work of a paper-plastic box can be stably completed.

Owner:苏州市恒顺纸塑有限公司

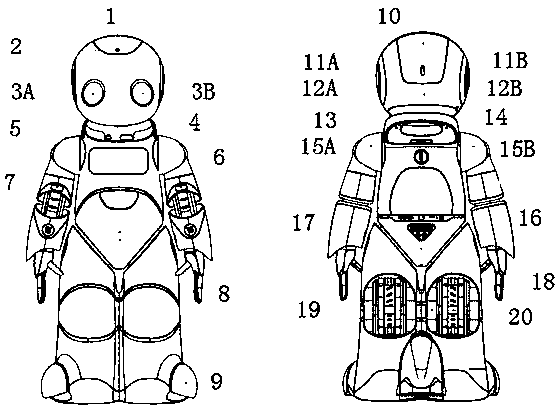

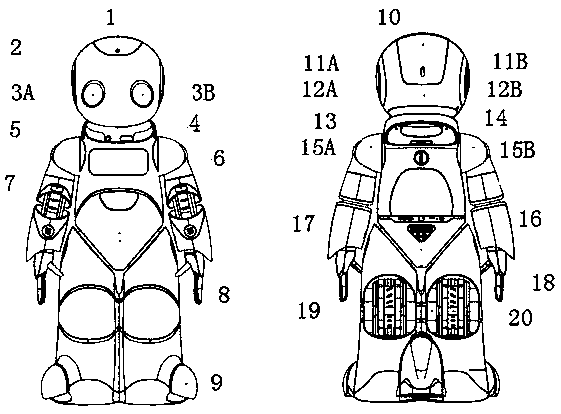

An access control system, an access control robot and an operating method of the system

ActiveCN108038949APrevent fraudulent brushing or proxy brushingImprove securityIndividual entry/exit registersRobotic systemsFingerprint

An operating method of an access control robot system is disclosed. The method includes detecting a fact that fingers of a user are pressed one or more press button zones on an input panel; measuringand recording the area pressed by the fingers of the user in each press button zone; measuring and recording partial fingerprints of user's fingers in each press button zone; for each press button zone, forming a fingerprint code of each press button zone by combining the measured partial fingerprint and the area pressed by the corresponding user's finger; connecting the fingerprint codes in the press button zones in series to form a total fingerprint code for one time of pressing; and connecting the total fingerprint code in each time of pressing to form a password of the access control system. According to the access control robot and the operating method thereof, the compound password is obtained by combining fingerprints in different button zones on the input panel according to areas and input sequences by utilizing an input habit of the user, and unauthorized or acting access card brushing can be efficiently prevented, thus improving safety.

Owner:BEIJING UNISROBO TECH CO LTD

Method for increasing size of kiwi fruit

The invention discloses a method for increasing the size of a kiwi fruit. The method comprises the steps of performing ringing on a fruit tree, binding up by a film, thinning, bagging, and strengthening fertilization. The method for increasing the size of the kiwi fruit disclosed by the invention is ensured in various steps by corresponding measures; the size of the kiwi fruit can be effectively increased; the kiwi fruit does not contain artificially applied hormone substances harmful to human bodies.

Owner:安徽奥林园艺有限责任公司

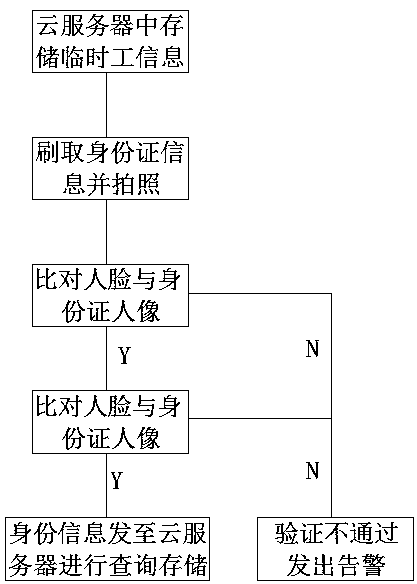

Temporary worker management method for a hotel

InactiveCN109191070AEffective statistical working hoursAvoid brushingRegistering/indicating time of eventsCharacter and pattern recognitionDependabilityOperating system

The invention relates to a temporary worker management method for a hotel, which comprises the following working steps: identifying: scanning and identifying the identity card of the temporary workerentering the hotel, and taking a head picture for the temporary worker at the same time; face recognition: comparing the photographed head picture with the portrait on the ID card, displaying the comparison result, and packaging the comparison result to the corresponding ID card information and sending it to the cloud server. The cloud server receives and stores the entry information of the corresponding temporary workers. The invention can manage and control the temporary workers entering and leaving the hotel, can accurately record the attendance time and automatically check and verify the identity information of the temporary workers, has high working reliability, and simultaneously effectively improves the safety of the hotel management.

Owner:常州零零壹网络科技有限公司

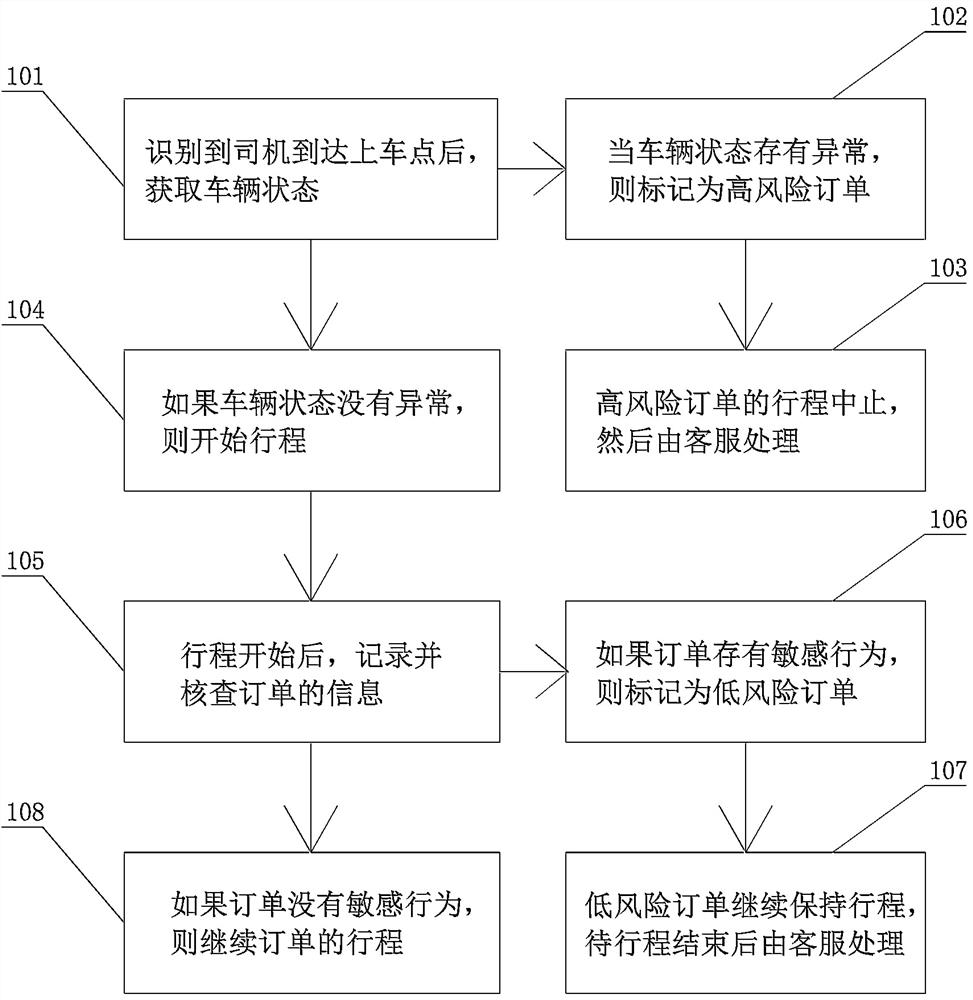

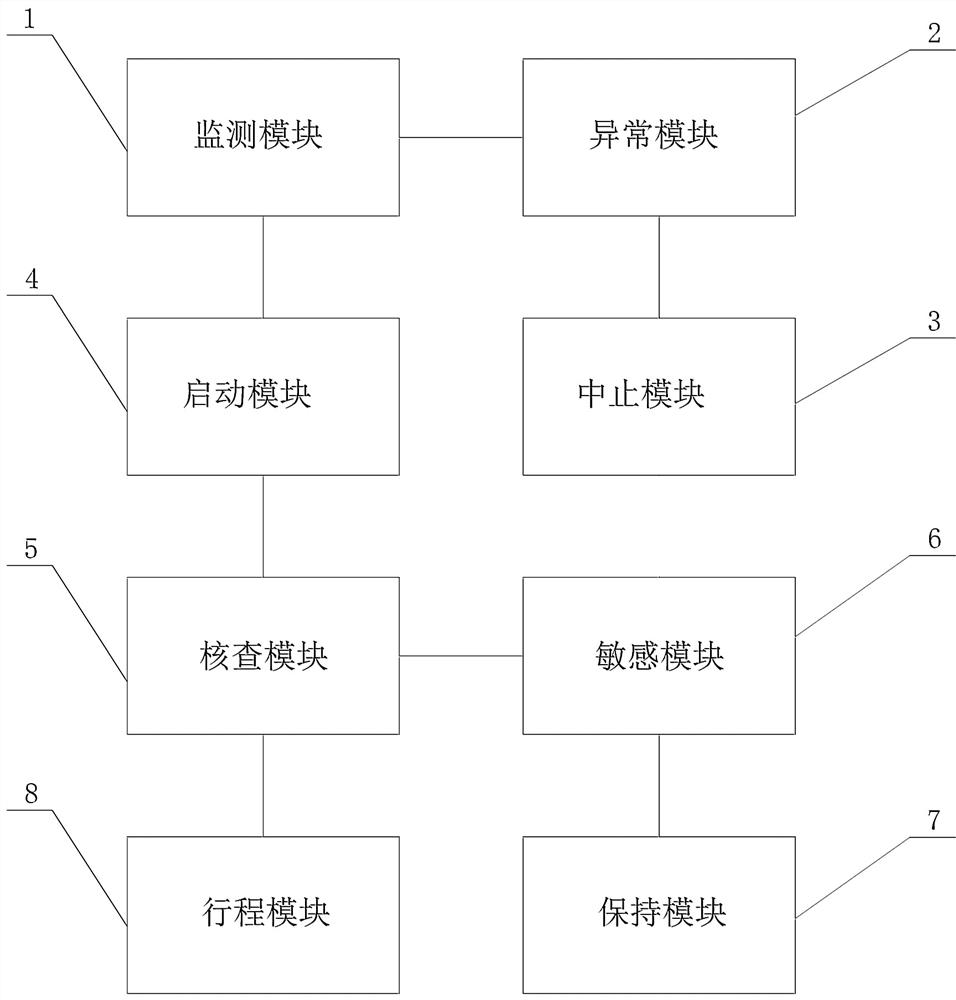

Detection method and system for preventing driver from scalping based on vehicle-mounted system

PendingCN112926881AAvoid brushingPrevent cheatingBuying/selling/leasing transactionsResourcesIn vehicleCar door

The invention relates to the technical field of taxi-taking travel, in particular to a detection method and system for preventing a driver from scalping based on a vehicle-mounted system. The method comprises the following steps: acquiring a vehicle state after identifying that a driver arrives at a boarding point; when the vehicle state is abnormal, marking the order as a high-risk order; stopping the travel of the high-risk order, and then delivering to the customer service; if the vehicle state is not abnormal, starting the travel; after the travel is started, recording and checking information of the order; if the order has sensitive behaviors, marking the order as a low-risk order; enabling the low-risk order to continue to travel and processing by the customer service after the travel is finished; and if the order does not have the sensitive behavior, continuing the travel of the order. The detection method and system have the advantages of being good in recognition effect and avoiding cheating behaviors, the vehicle door state, the riding state and the chat state are detected through physical means, the problems that an existing click farming prevention technology is poor in recognition effect and difficult to prevent cheating are solved, and the click farming prevention requirement in the travel field is met.

Owner:广州宸祺出行科技有限公司

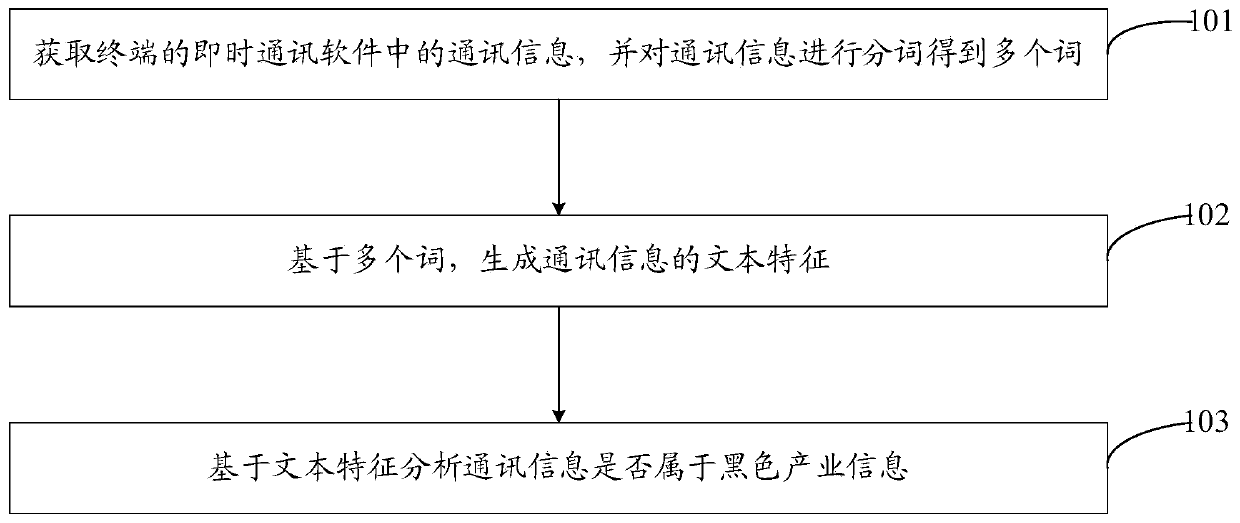

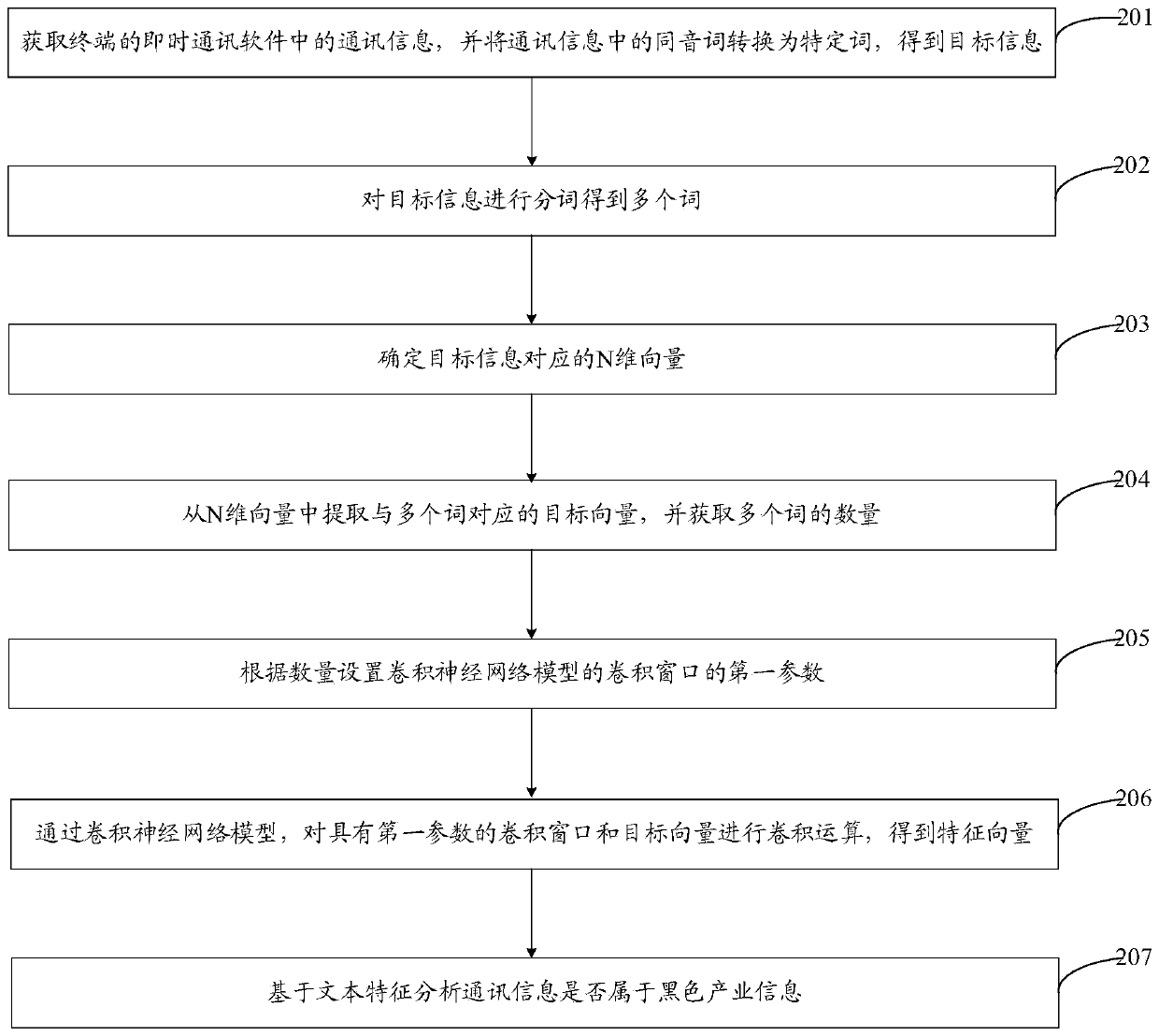

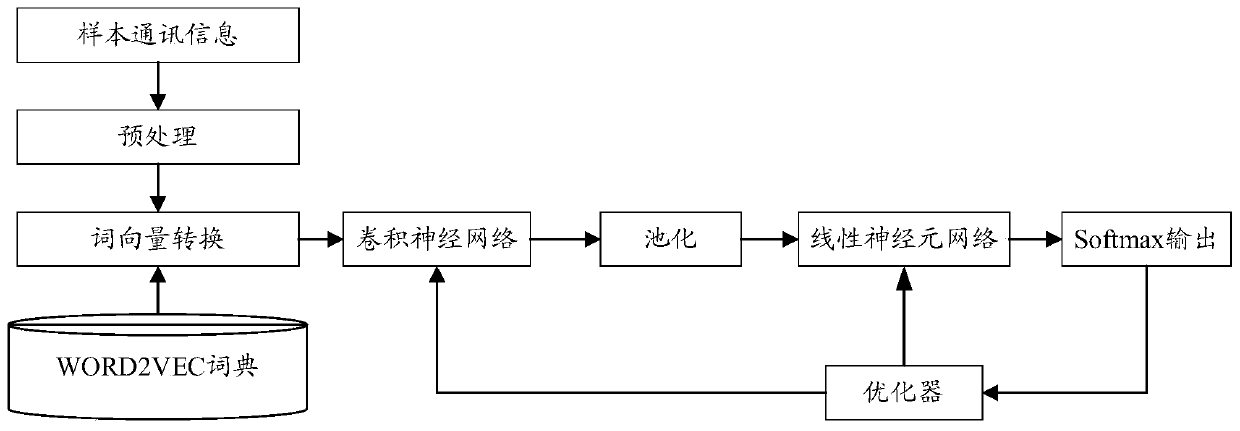

Information analysis method, terminal and storage medium

PendingCN111581959AReduce manslaughterAvoid brushingNatural language data processingNeural architecturesInformation analysisEngineering

The embodiment of the invention provides an information analysis method, a terminal and a storage medium, and the information analysis method comprises the steps: obtaining communication information in instant messaging software of the terminal, and carrying out the word segmentation of the communication information to obtain a plurality of words; generating text features of the communication information based on the plurality of words; and analyzing whether the communication information belongs to black industry information based on the text features.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

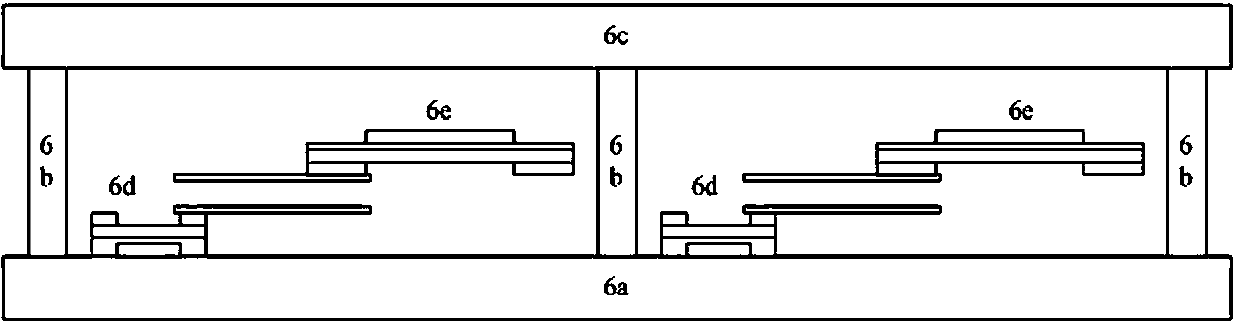

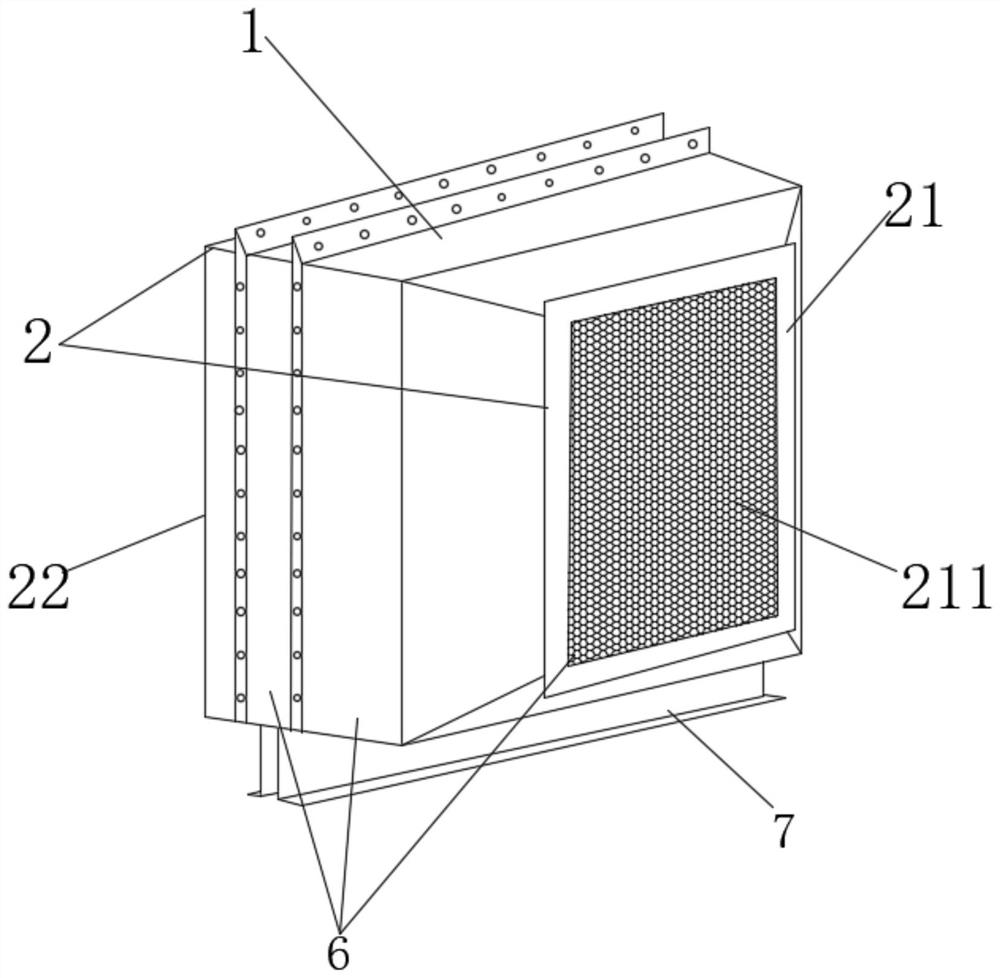

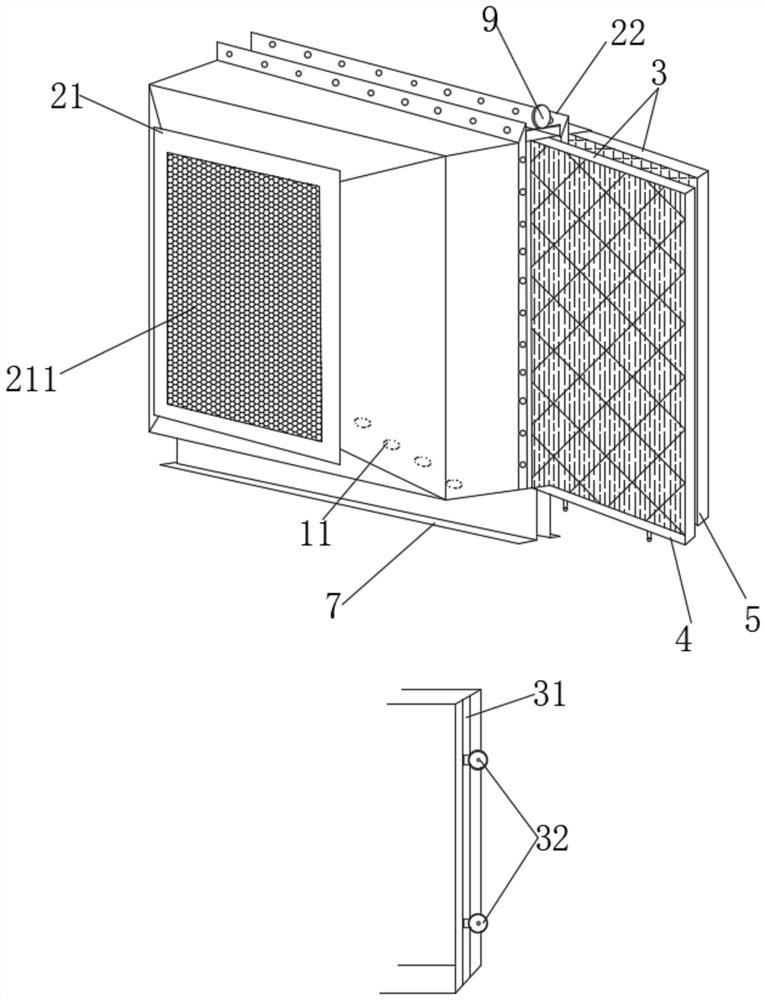

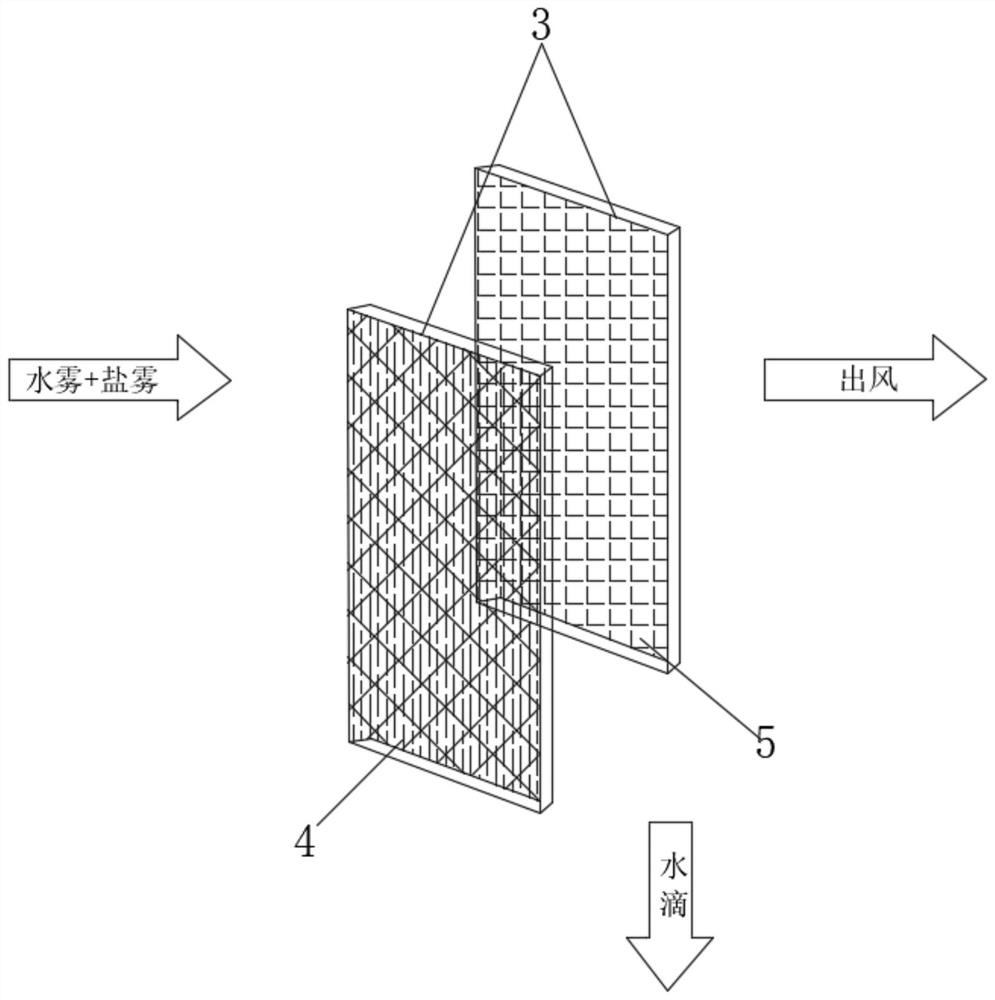

Salt mist removal filtering system

ActiveCN111939676AHigh tensile strengthReduce the chance of being corrodedDispersed particle filtrationTransportation and packagingGlass fiberElectric machinery

A salt mist removal filtering system is characterized in that a system body box comprises an outer frame and filters, the outer frame comprises a top outer frame and a bottom outer frame, the filterscomprise a first filter and a second filter, a first filtering layer and a second filtering layer are arranged in the first filter, and the first filtering layer is located above the second filteringlayer in the vertical direction; a chemical fiber layer and a glass fiber layer are arranged in the second filter; the bottom outer frame is connected with a rain cover through bolts, and the rain cover is fixedly connected to the outer side of the bottom outer frame; and a stainless steel net with compact holes is mounted at the top end of the top outer frame. The salt mist filtering device is installed in a high-humidity and high-salt environment, salt mist can be filtered, the probability that a motor and the like are corroded is reduced, and the service life is prolonged; by observing thecondition of a differential pressure gauge, the filters can be sequentially moved out of the system body box in the direction of a sliding rail to be replaced in time; and the replaced filter can be washed by clear water or other water washing modes to be reused.

Owner:MAYAIR TECH (CHINA) CO LTD

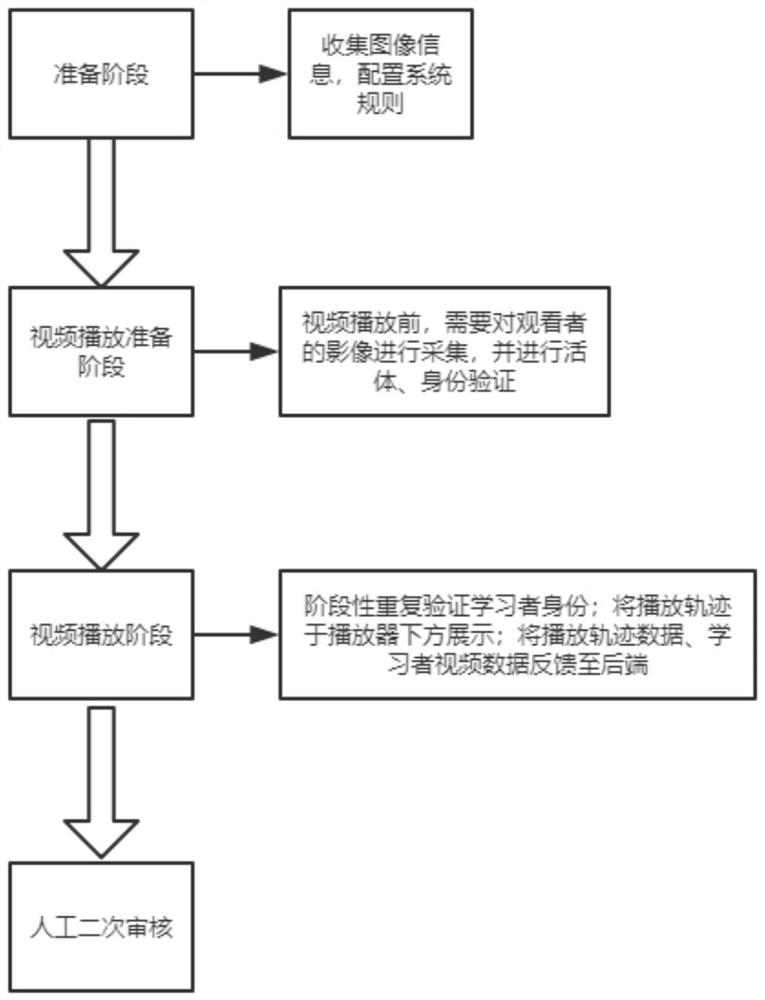

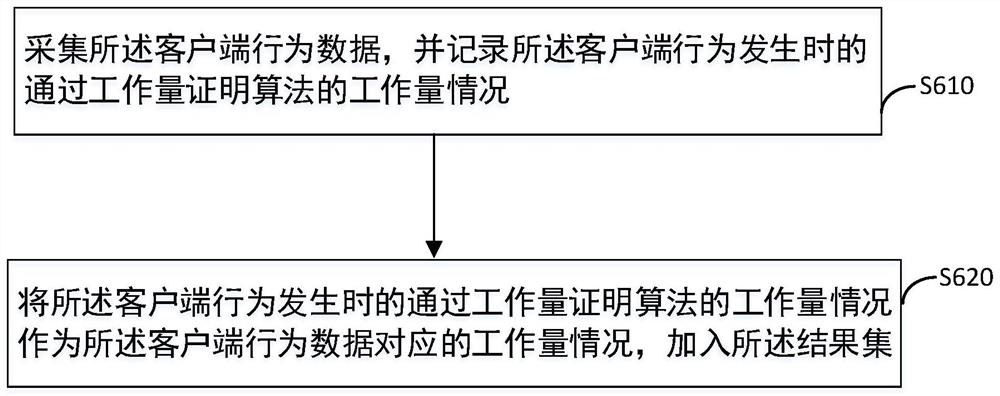

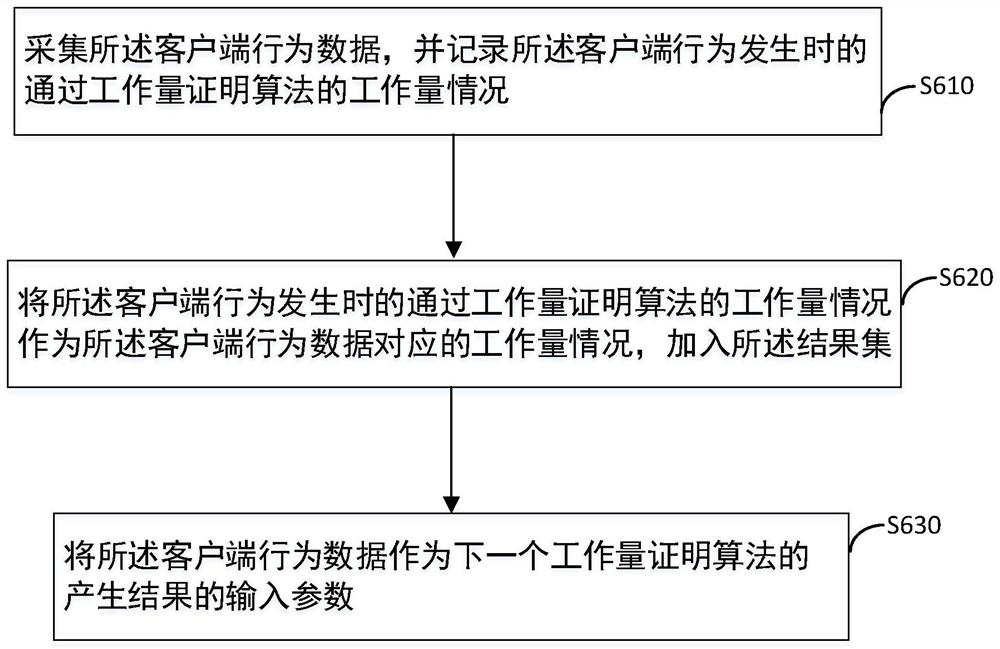

AI assessment method based on learner behaviors

PendingCN113095198APrevent brushingHigh precisionData processing applicationsDigital data authenticationAlgorithmEngineering

The invention discloses an AI assessment method based on learner behaviors, and relates to the technical field of network learning assessment. The method includes the following steps: a preparation stage, a video playing preparation stage, a video playing stage, collection of image information as learner photo information shot by a camera, and configured system rules comprising a video playing snapshot rule and a face recognition rule. The snapshot rule comprises a continuously unidentified tolerance time threshold t1 under the condition that a human face is unidentified, a snapshot frequency n within the tolerance time threshold t1, a repeatedly verified threshold t2 under the condition that verification succeeds and a video is played, and a matching degree threshold t3 of a system comparison image and storage information. According to the method, the situation that online courses are swiped on behalf can be effectively prevented, on the other hand, AI living body recognition is adopted, the recognition accuracy is improved, multiple times of recognition can be continued within a threshold value if recognition fails, and the short interval problem that matching cannot be achieved due to network delay and light rays is solved.

Owner:上海网梯数码科技有限公司

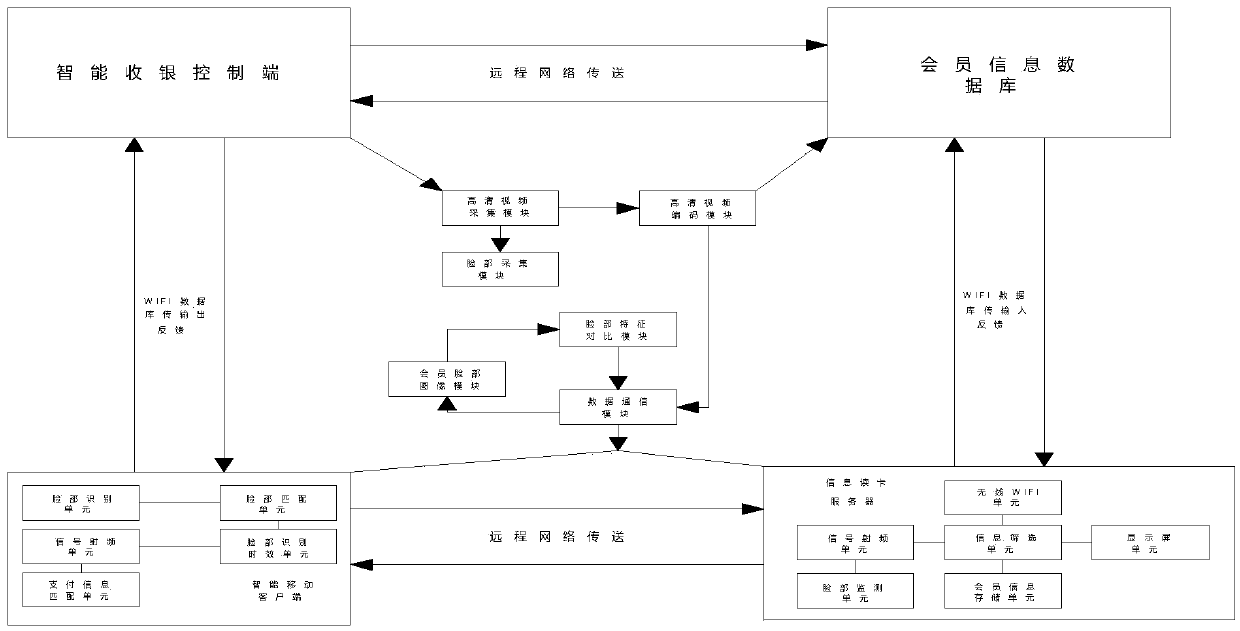

A cashier system capable of recognizing members by swiping faces

PendingCN109658085AShorten the timeSimple structurePoint-of-sale network systemsProtocol authorisationInformation CardMonitoring system

The invention discloses a cashier system capable of recognizing members by swiping faces. The cashier system includes an intelligent cashier control terminal, a member information database, a high-definition monitoring system, an information card reading server, and an intelligent mobile client; the intelligent cashier control end is used for displaying personal data and consumption details of a client and storing the personal data and the consumption details in a member information database; the member information database is provided with a consumption record for storing member information and a T time period; The high-definition monitoring system is provided with a high-definition video acquisition module, a data communication module and the like. the information card reading server isused for receiving and sending client information and signals fed back by the signal radio frequency unit; The intelligent mobile client is provided with a face recognition and face matching unit andthe like, so that the situations of low member recognition efficiency, unauthorized swiping of a virtual card, loss of a card number and the like can be reduced, and accurate and convenient consumption of cashier can be ensured.

Owner:杭州乐优客科技有限公司

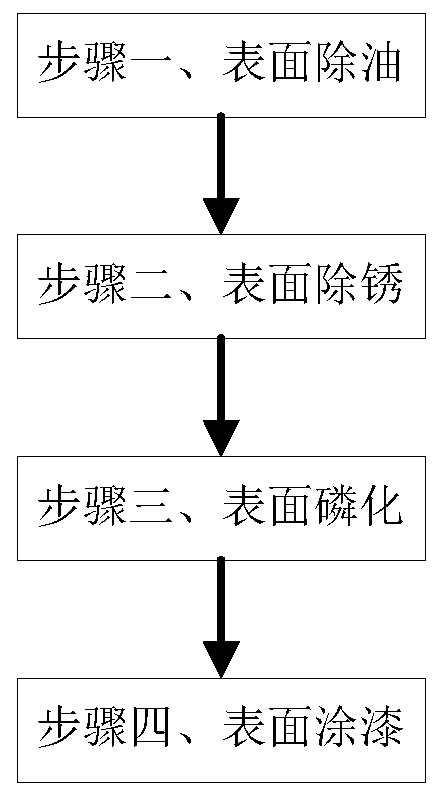

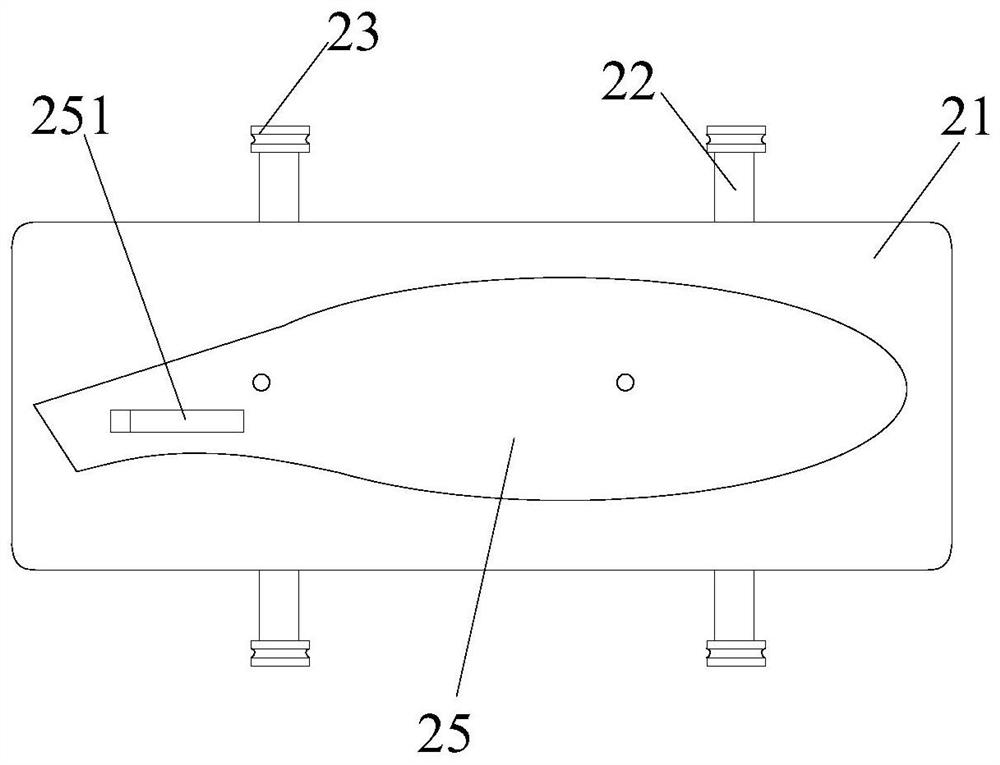

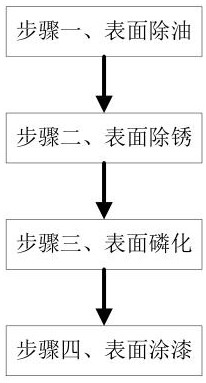

Surface treatment method for hard alloy circular saw blade

ActiveCN110976196APrevent adhesionPrecise position controlLiquid surface applicatorsCoatingsCircular sawAlloy

The invention belongs to the technical field of hardware tools, and particularly relates to a surface treatment method for a hard alloy circular saw blade. The surface treatment method comprises the following steps that 1, surface oil removal is conducted, specifically, the alloy circular saw blade is soaked in a degreasing agent and then transferred into clear water to be cleaned; 2, surface rustremoval is conducted, specifically, the alloy circular saw blade is soaked in a rust removal solution and then sequentially transferred into a neutralizer and clear water to be cleaned; 3, surface phosphating is conducted, specifically, the alloy circular saw blade is soaked in a phosphating solution and then transferred into clear water to be cleaned, and finally drying is conducted; and 4, surface painting is conducted, specifically, the alloy circular saw blade is fixed to a paint coating device, and the surface of the alloy circular saw blade is coated with anti-corrosion paint. When thesurface of the alloy circular saw blade is coated with the paint, the paint coating range can be accurately controlled, paint particles are prevented from being attached to saw tooth parts, the paintcoating the surface of the alloy circular saw blade can be uniformly dispersed, paint accumulation is avoided, and the surface flatness of the alloy circular saw blade is improved.

Owner:江西晖旭实业有限公司

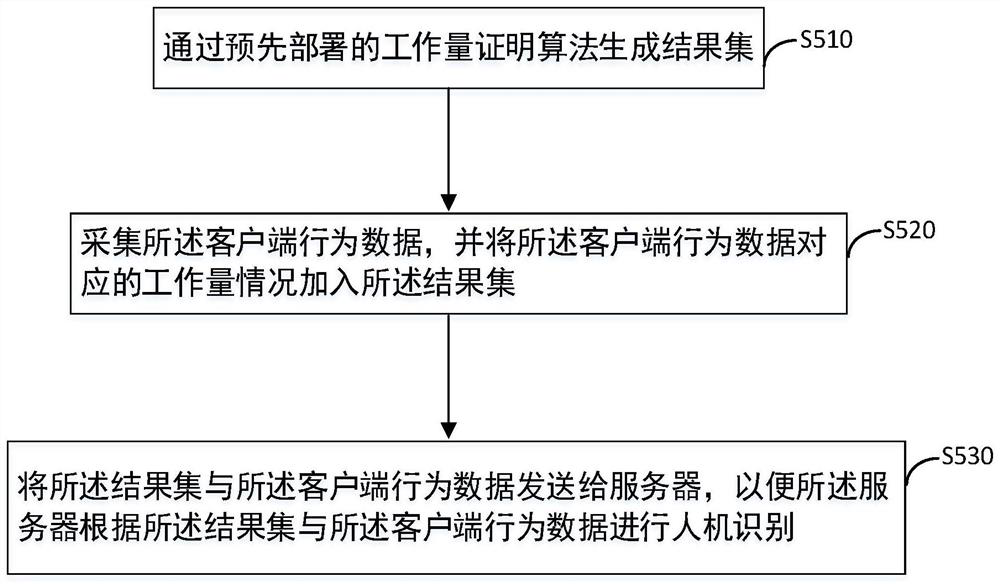

Man-machine identification method, device, server, client and storage medium

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Access control system, access control robot and operating method thereof

ActiveCN108038949BPrevent theftAvoid brushingIndividual entry/exit registersRobotic systemsKey pressing

An operating method of an access control robot system is disclosed. The method includes detecting a fact that fingers of a user are pressed one or more press button zones on an input panel; measuringand recording the area pressed by the fingers of the user in each press button zone; measuring and recording partial fingerprints of user's fingers in each press button zone; for each press button zone, forming a fingerprint code of each press button zone by combining the measured partial fingerprint and the area pressed by the corresponding user's finger; connecting the fingerprint codes in the press button zones in series to form a total fingerprint code for one time of pressing; and connecting the total fingerprint code in each time of pressing to form a password of the access control system. According to the access control robot and the operating method thereof, the compound password is obtained by combining fingerprints in different button zones on the input panel according to areas and input sequences by utilizing an input habit of the user, and unauthorized or acting access card brushing can be efficiently prevented, thus improving safety.

Owner:BEIJING UNISROBO TECH CO LTD

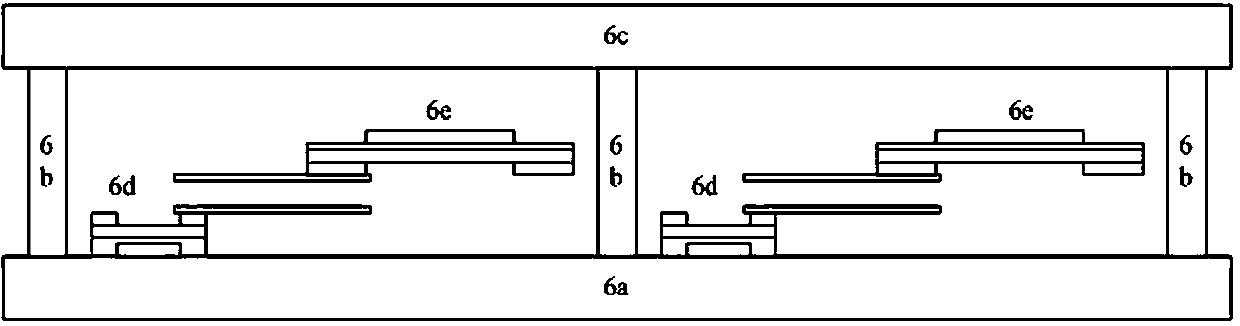

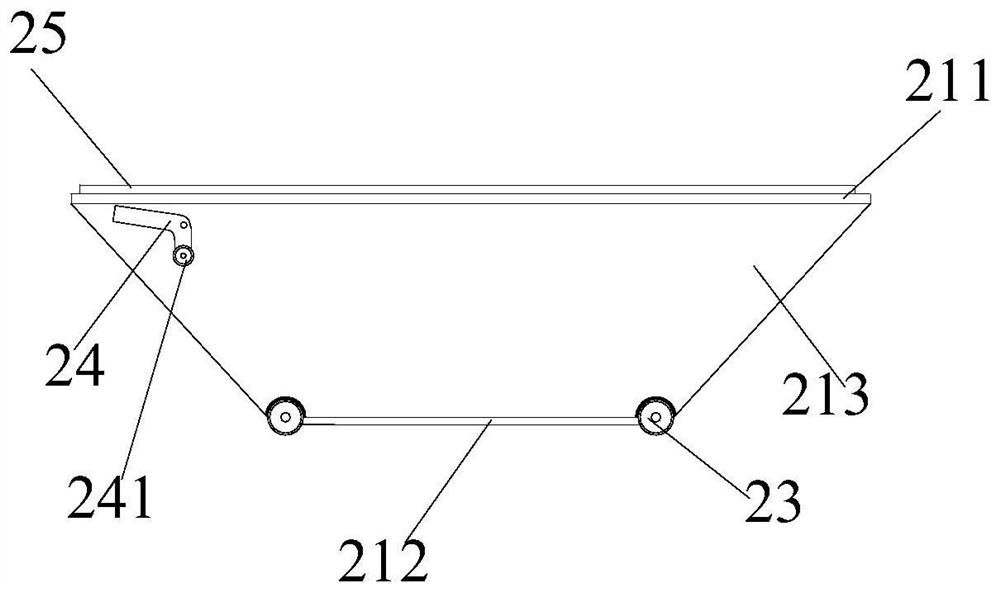

Leather brushing and drying device

ActiveCN106423751BImprove glue brushing efficiencySimple structureLiquid surface applicatorsCoatingsTransfer mechanismIndustrial engineering

The invention relates to a device for brushing and drying leather sheets, which includes a frame, a transmission mechanism arranged on the frame and transported from front to back, and a glue brushing machine and an oven sequentially arranged on the frame along the transmission direction of the transmission mechanism. ; The transmission mechanism includes a number of skin support parts and a driving assembly that is arranged on the frame and drives the movement of the skin support parts; the skin support part includes a skin support seat for carrying the skin and At least 2 support rods are arranged at the bottom of the skin sheet support base at intervals, and the frame is provided with guide rails for supporting the support rods and extending along the conveying direction of the driving components. The present invention has the advantages of simple structure and convenient skin brushing, drying and collection.

Owner:漳州华飞体育用品有限公司

A kind of surface treatment method of cemented carbide circular saw blade

ActiveCN110976196BPrevent adhesionPrecise position controlLiquid surface applicatorsCoatingsMetallurgyCircular saw

Owner:江西晖旭实业有限公司

Internet voting method and device

The invention discloses a network voting method and device and belongs to the network application technical field. The network voting method comprises obtaining a ticket-checking prevention strategy from a backend server; receiving the voting information sent from a client, wherein the voting information comprises the voting identification, IP (Internet Protocol) addresses or user names of voters, voting options and votes; judging whether the IP addresses or the user names of the voters are located in a blacklist or not; searching historical voting records of the IP addresses or the user names of the voters if not; determining the votes of the IP addresses or the user names of the voters within the periodic time according to the historical voting records of the IP addresses or the user names of the voters and the received voting information; determining that the received voting information is valid if the votes of the IP addresses or the user names of the voters within the periodic time do not reach a vote threshold value in the ticket-checking prevention strategy and performing counting according to the voting options and the votes in the voting information.

Owner:广州方硅信息技术有限公司

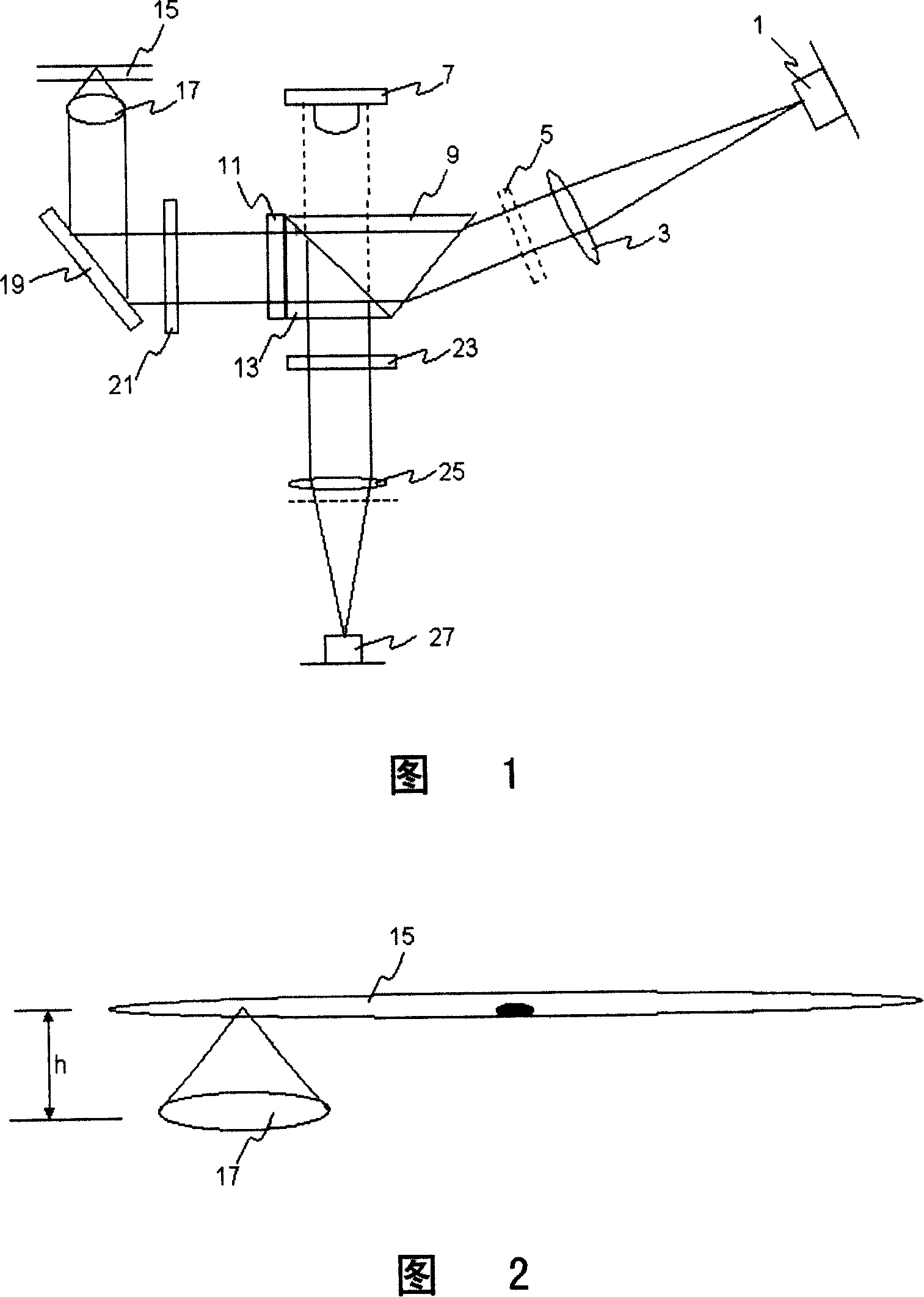

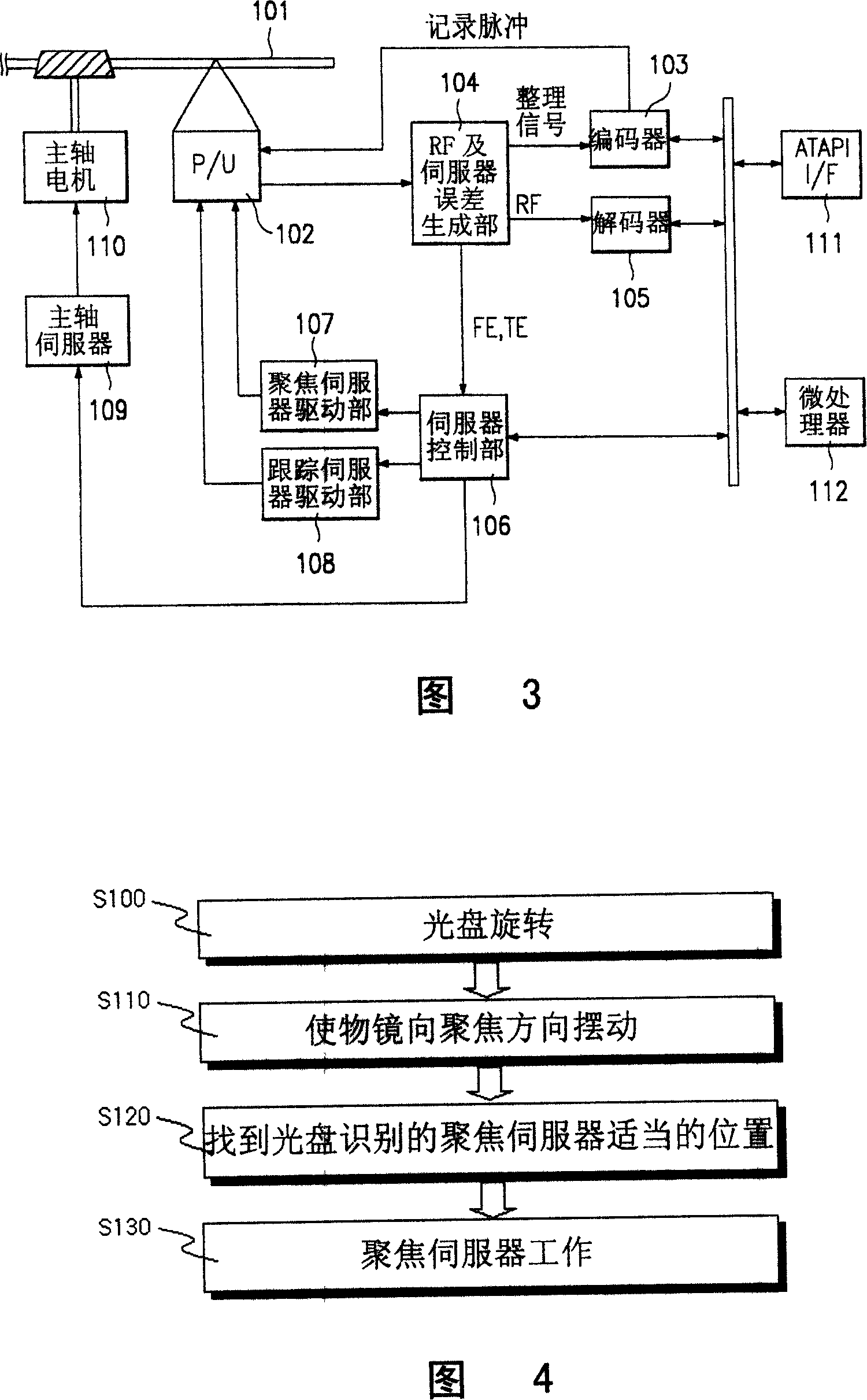

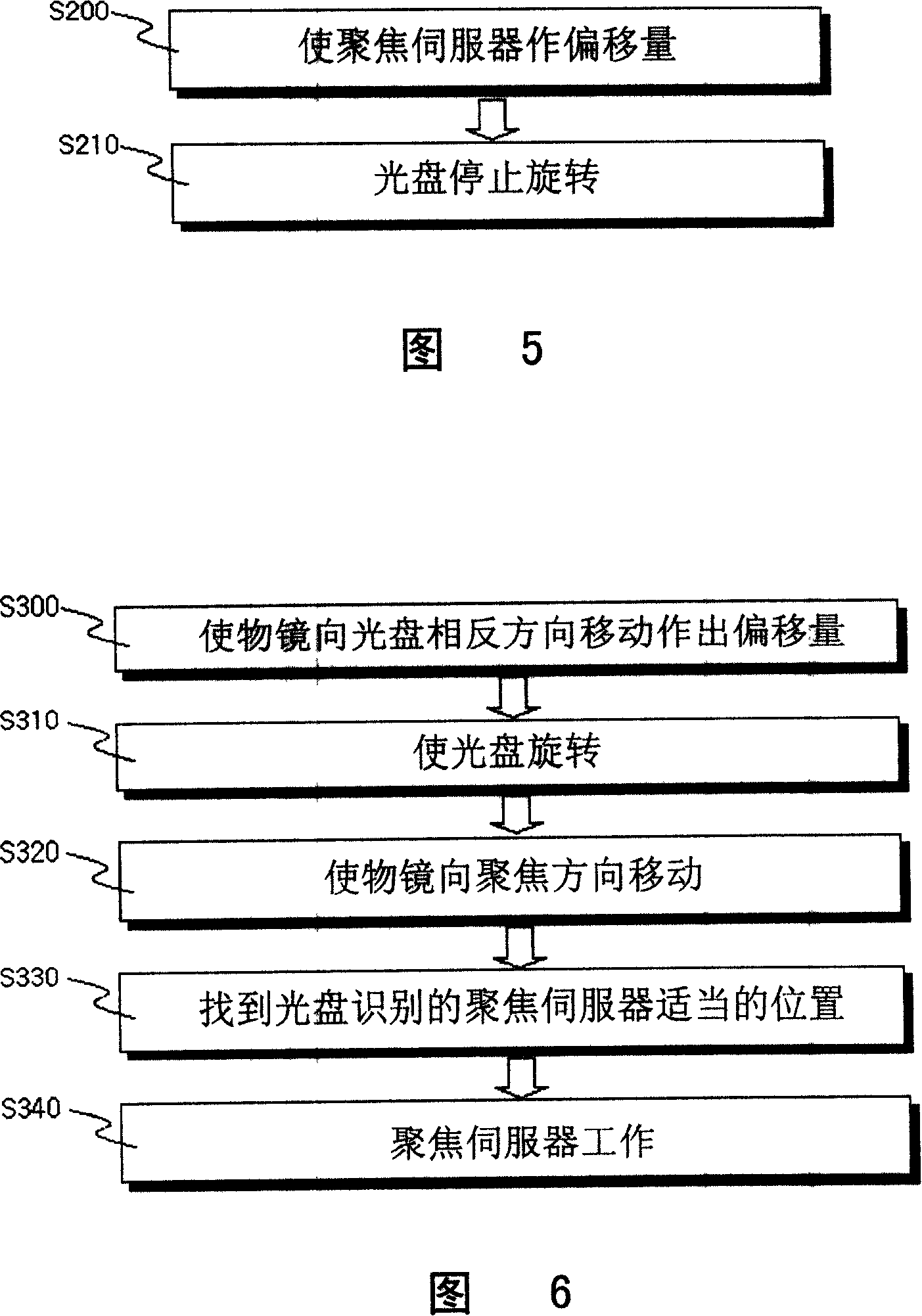

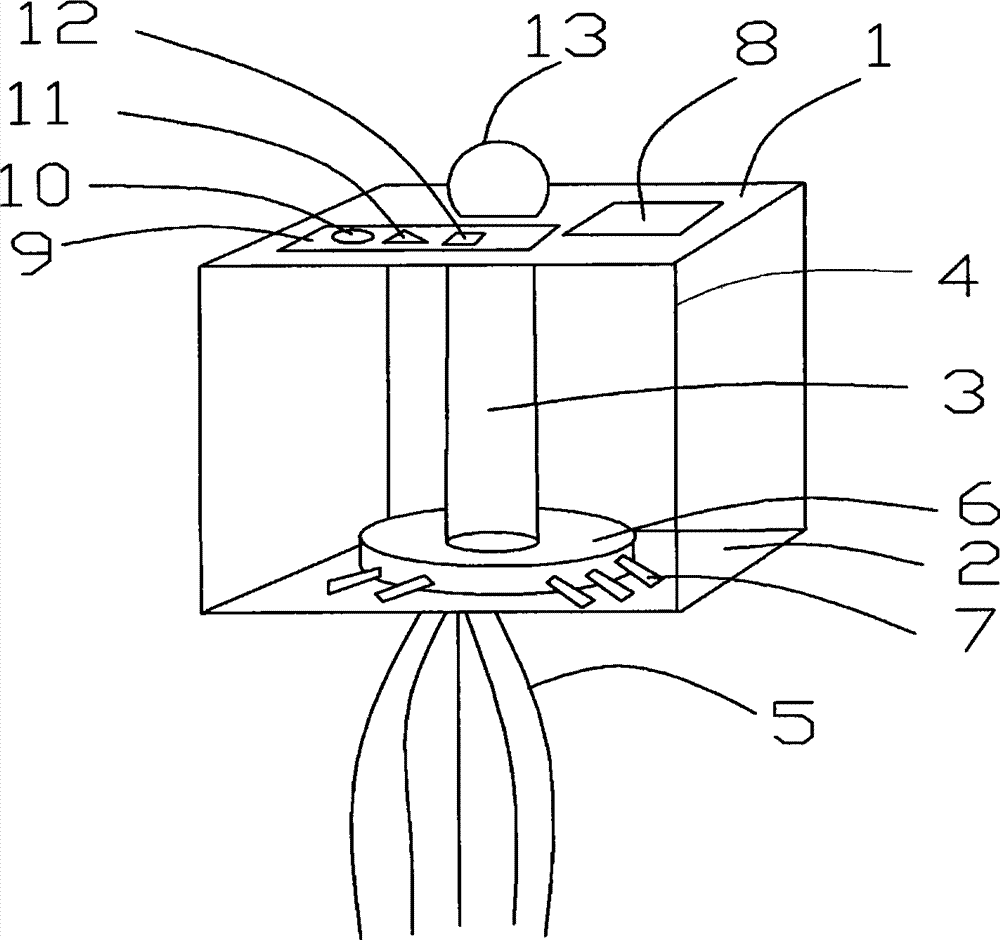

Method for preventing optical pick-up device and CD-disc from destroying

InactiveCN101140766AAvoid brushingRecord information storageDisposition/mounting of headsHigh densityOptic system

The invention relates to a method for avoiding the optical interrogation and CD mis-refreshing., which is to adjust the intervals among the focus servo, optical interrogation lens and CD under the optical system of the optical disc driver, and thus to prevent the mis-refreshing of the optical interrogation CD caused by contact of the lens and CD. The invention is characterized in increasing the distance between lens and CD in opposite directions on the optical interrogation device before the CD's spinning, which is to work out the predetermined distance offset between CD and the lens. The invention has the advantages of preventing the mis-refreshing of the high density CD and protecting the objective and CD in the field of portable storage device.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

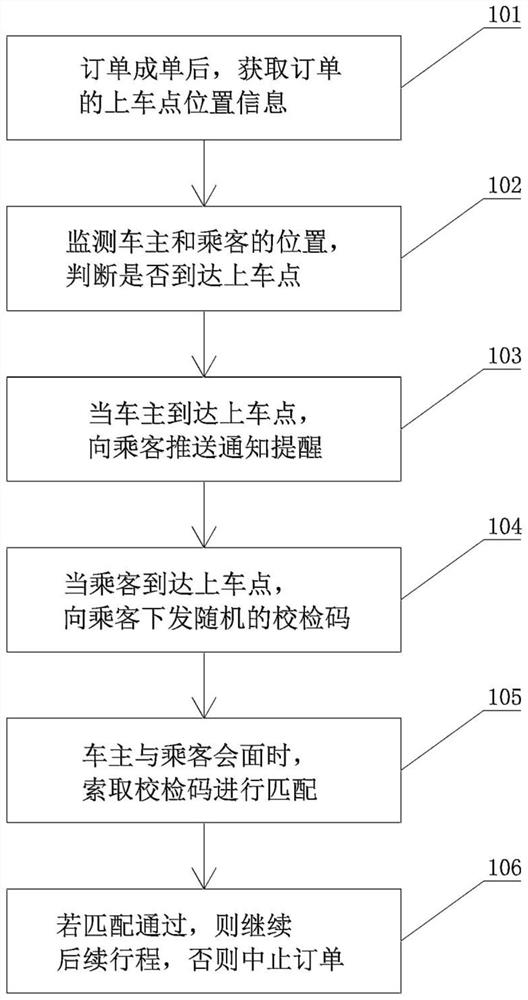

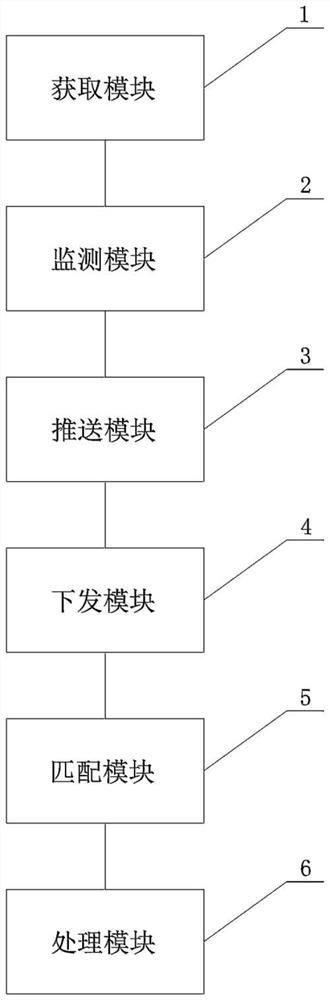

Anti-violation hitchhiking journey verification method and system

PendingCN113327150AMeet verification needsReduce disputesBuying/selling/leasing transactionsReliability engineeringReal-time computing

The invention relates to the technical field of taxi-taking travel, in particular to an anti-violation hitchhiking journey verification method and system. The method comprises the steps that after an order is made, getting-on point position information of the order is acquired; the positions of a vehicle owner and a passenger are monitored, and whether the vehicle arrives at a boarding point is judged; when the vehicle owner arrives at the getting-on point, a notification prompt is pushed to the passenger; when the passenger arrives at the getting-on point, a random verification code is issued to the passenger; when the vehicle owner meets with the passenger, the verification code is asked for matching; and if the matching is passed, continuing the subsequent journey, otherwise, the order is ended. The verification method and system have the advantages of avoiding scalping and enhancing verification, the vehicle owner and the passenger are in butt joint through a verification code, the identity of the passenger can be rapidly and accurately verified, the tedious and low-efficiency inquiry process is reduced, disputes between the vehicle owner and the passenger are reduced, the problems of easy scalping and lack of verification in the existing hitchhiking service are solved, and the verification requirement of hitchhiking travel is met.

Owner:广州宸祺出行科技有限公司

An anti-corrosion and anti-adhesion high-temperature-resistant oil sleeve connector and a preparation method

ActiveCN110284843AHigh activityExtended service lifeDrilling rodsDrilling casingsAlloy coatingUltimate tensile strength

The invention provides an anti-corrosion and anti-adhesion high-temperature-resistant oil sleeve connector, comprising a connector substrate and a tungsten-based amorphous alloy coating, the amorphous alloy coating itself is highly active, and a Ni-P amorphous structural passivation film existing in the coating is uniformly and compactly distributed to be able to prevent further corrosion inside; and in addition, the oil sleeve connector in the application can replace an ordinary oil sleeve connector and a routine work procedure of smearing an anti-sticking agent. Through electroplating the amorphous alloy on the substrate, the steps of brushing a lubricant and an anti-sticking agent are omitted to effectively reduce the labor intensity, improve the efficiency of oil exploitation, avoid the defects of failure of the lubricant and anti-sticking agent under high temperature and prolong the service life of an oil sleeve.

Owner:山西中能企服环保科技有限公司

Anti-corrosion, anti-sticking, high temperature resistant oil casing connector and preparation method thereof

ActiveCN110284843BHigh activityExtended service lifeDrilling rodsDrilling casingsAlloy coatingHigh activity

The invention provides an anti-corrosion, anti-sticking, high-temperature-resistant oil casing connector, which includes a connector base and a tungsten-based amorphous alloy coating, the amorphous alloy coating itself has high activity, and Ni-P amorphous in the coating State structure passivation film, evenly distributed and dense, can prevent further internal corrosion; in addition, the oil casing connector described in this application can replace the ordinary oil casing connector and the conventional process of painting anti-seize agent, etc., through Electroplating amorphous alloy on the substrate saves the steps of brushing lubricants and anti-sticking agents, effectively reduces the labor intensity, improves the efficiency of oil extraction, and avoids lubricants and anti-sticking agents under high temperature. The defect of failure prolongs the service life of the oil casing.

Owner:山西中能企服环保科技有限公司

Mosquito trap device

The invention relates to a mosquito trap device. The mosquito trap device mainly comprises an upper cover, a lower cover, a lamp tube and an electrified net, wherein the lower cover is provided with a rotating brush, the upper cover is provided with a control module, the control module comprises a switch and a power supply, and the switch is connected with the power supply and the rotating brush. The mosquito trap device has the beneficial effect that since the rotating brush is started by controlling the switch, the effect of cleaning the mosquito trap device is achieved.

Owner:张彩萍

Method, device, storage medium, server and terminal equipment for order processing

ActiveCN107784554BSolve the problem of brushing orders by abnormal meansAvoid brushingBuying/selling/leasing transactionsComputer hardwareTerminal equipment

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com