Surface treatment method for hard alloy circular saw blade

A surface treatment and hard alloy technology, which is applied to the device and coating of the surface coating liquid, can solve the problems affecting the working performance of the sawtooth part, uneven paint coating thickness, paint accumulation, etc., to achieve accurate The effect of controlling paint coating range, improving flatness and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

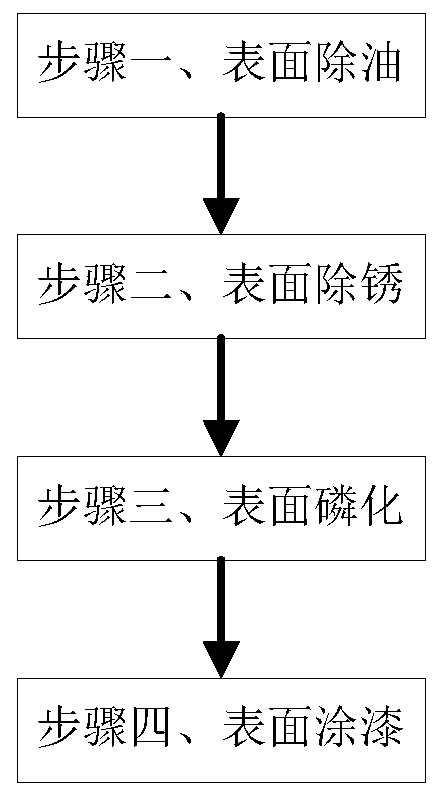

[0039] Such as figure 1 As shown, the present embodiment provides a method for surface treatment of a cemented carbide circular saw blade, comprising the following steps:

[0040] Step 1. Degreasing the surface: Soak the alloy circular saw blade in degreasing agent, then turn it into clean water for cleaning;

[0041] Step 2. Surface derusting: Soak the alloy circular saw blade in the derusting solution, and then turn it into neutralizer and clean water for cleaning;

[0042] Step 3, surface phosphating: soak the alloy circular saw blade in phosphating solution, then transfer it to clean water for cleaning, and finally dry it;

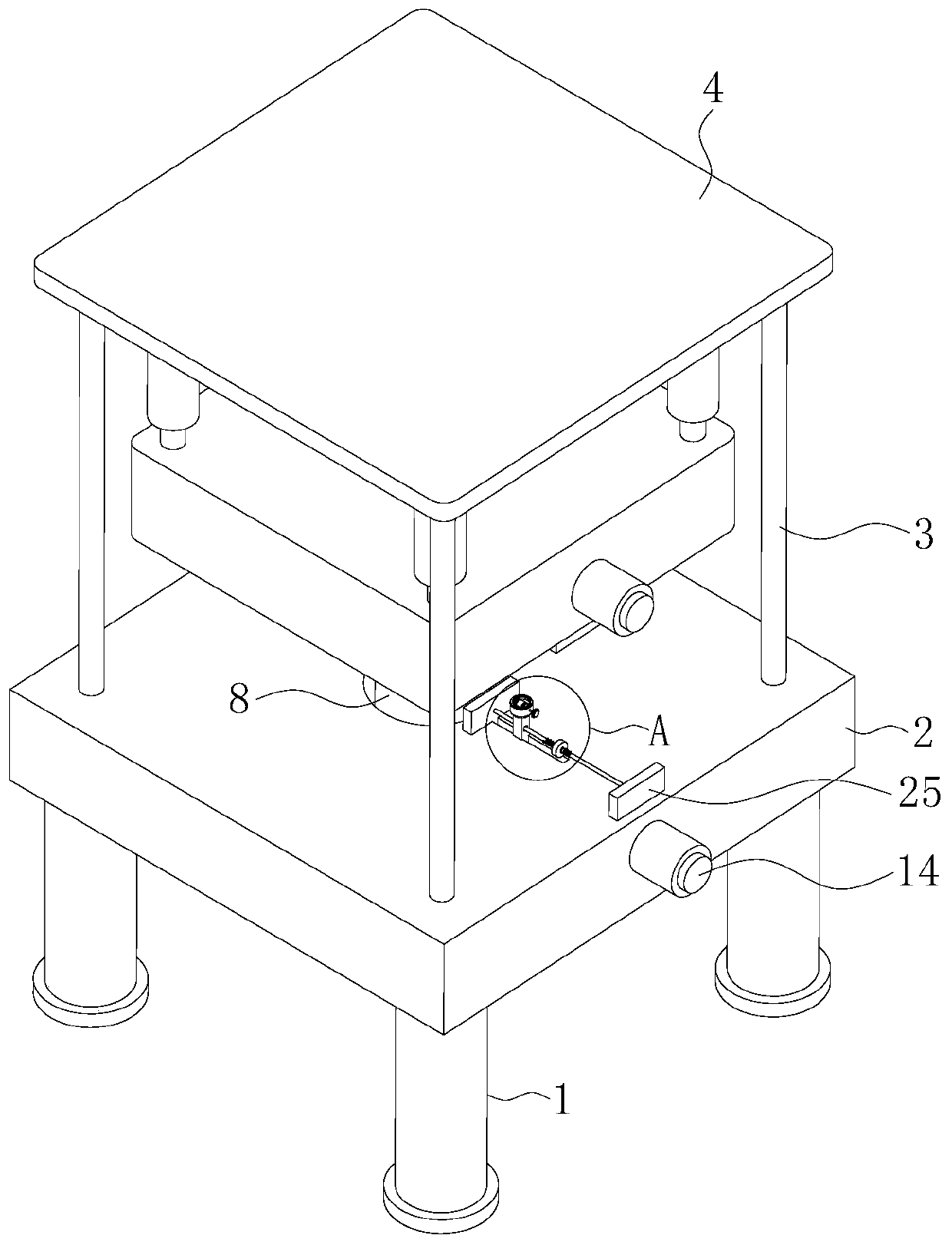

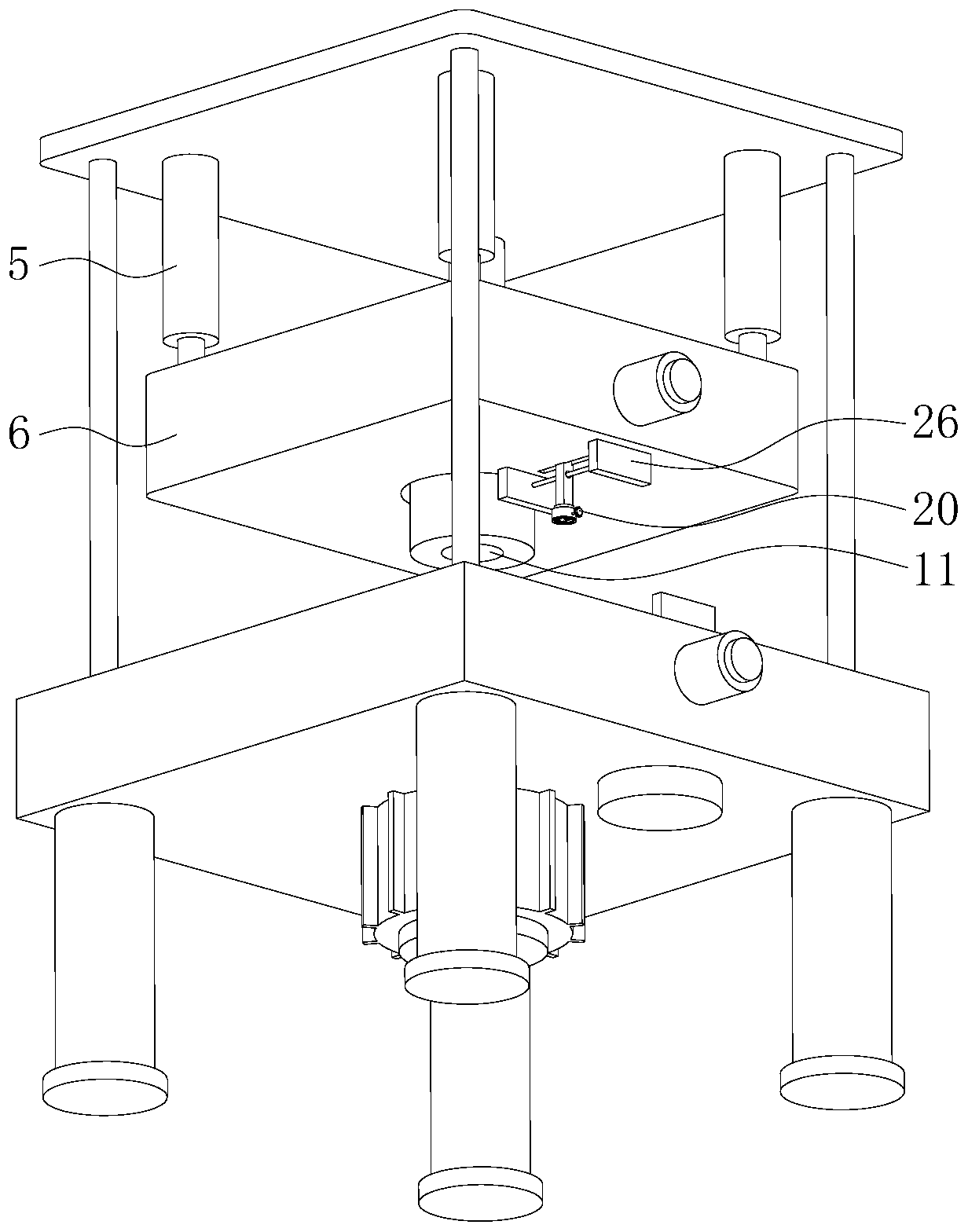

[0043] Step 4, surface painting: fix the alloy circular saw blade on the paint coating device, and coat the surface with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com