Movable diversion device for debris flow interception

A diversion device and mud-rock flow technology, applied in water conservancy projects, dikes, sea area engineering, etc., can solve problems such as unsatisfactory mud-rock flow effects, achieve strong geological disaster resistance, reduce impact and destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

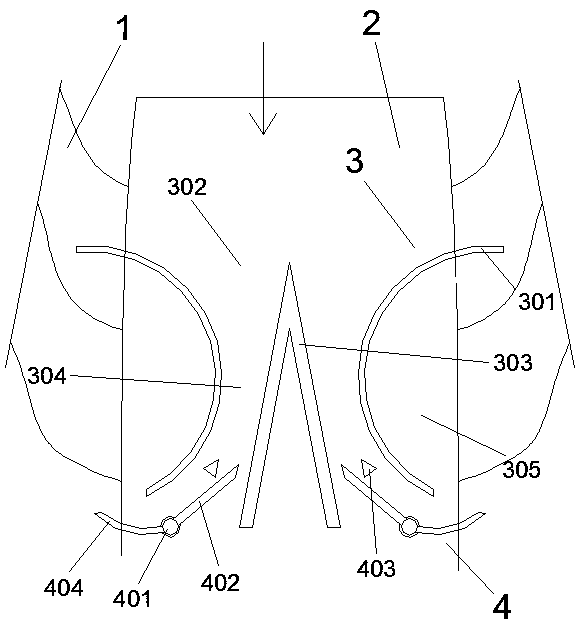

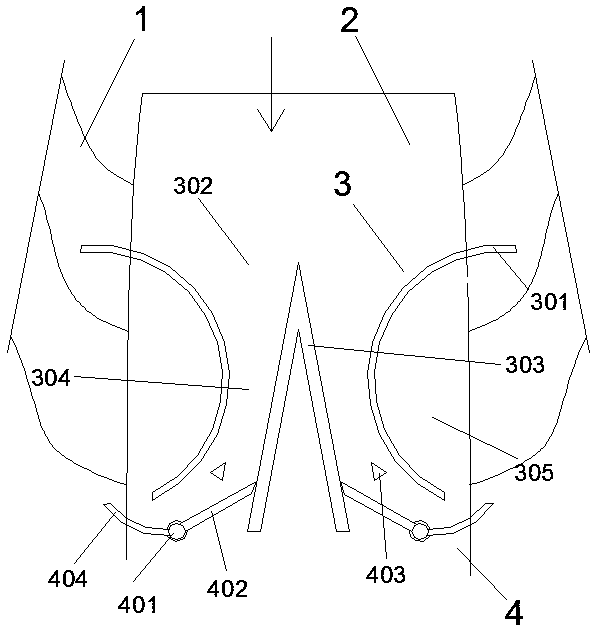

[0038] Such as figure 1 and 2 As shown, a movable diversion device for intercepting debris flow is arranged in the debris flow channel 2 formed between the highlands 1 on both sides. The movable diverter device includes a silting diversion dam 3 and two movable Type diversion mechanism 4, wherein, the silting and diversion dam 3 includes the first arc-shaped dam body 301 symmetrically arranged on both sides of the debris flow channel 2, and the upstream ends of the two first arc-shaped dam bodies 301 respectively cross the debris flow channel The two sides of 2 are connected to the high grounds 1 on both sides, and there is a gap between the downstream end and the two sides of the debris flow channel 2, so that the backwater surface of the two first arc-shaped dam bodies 301 cooperates with the high grounds 1 on both sides to form a The silting zone 305 that opens toward the downstream direction; a hyperbolic drainage channel 302 is formed between the two first arc-shaped dam...

Embodiment 2

[0045] This embodiment is an improvement made on the basis of Embodiment 1, its basic structure is the same as that of Embodiment 1, and the improvements are as follows: figure 1 and 2 As shown, the first diversion plate 402 is provided with a limit pile 403 to limit its deflection to the side of the diversion dam 303 toward the side of the first arc-shaped dam body 301 on this side, and the limit pile 403 is a triangular cement pile. And one of the sharp corners of its triangle faces the direction of the debris flow. The bottom of the first diversion plate 402 and the second diversion plate 404 are provided with several support columns along their length direction, the bottom end of each support column has a spherical support 405 supported on the ground, the spherical support 405 is actually The upper part is a sphere supported by cement concrete, so that the contact area with the ground is small, and it can be rotated conveniently when being impacted by debris flow; a diver...

Embodiment 3

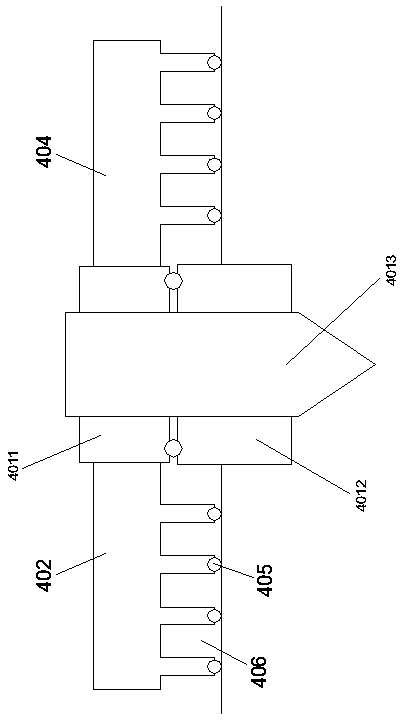

[0047] This embodiment is another improvement made on the basis of embodiment 1, its basic structure is the same as that of embodiment 1, and the improvements are as follows: image 3 As shown, the rotator 401 includes a rotating base 4011 connecting the first flow guide plate 402 and the second flow guide plate 404. The rotation base 4011 is a disc, and the disc is rotated by a number of second balls provided on its bottom surface. On the fixed base 4012, the lower part of the fixed base 4012 is buried in the ground, and a corresponding through hole is provided at the center of the rotating base 4011 and the fixed base 4012, and a rotating shaft 4013 is provided in the through hole, the rotation The shaft 4013 is wedged into the ground through the tip of its bottom end, so that the rotating base 4011 forms a rotating part that can rotate around the rotating shaft 4013 .

[0048] In fact, the rotator 401 is a structure similar to a stone mill. Two stone mills can rotate relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com