Patents

Literature

56results about How to "Deceleration achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

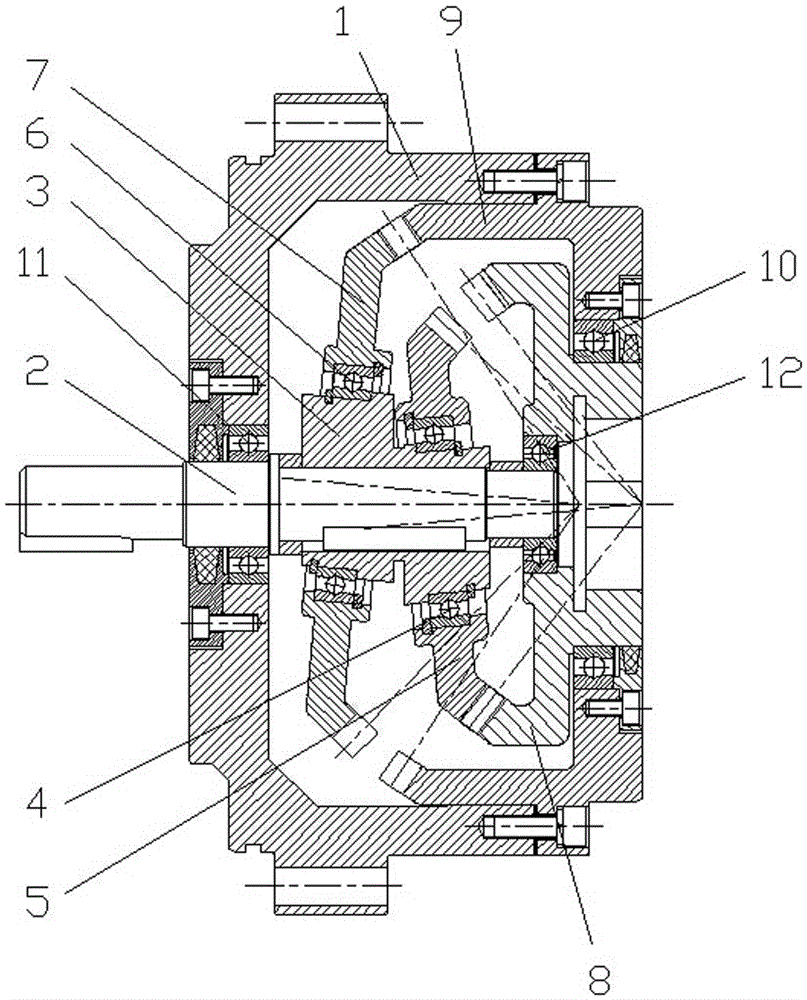

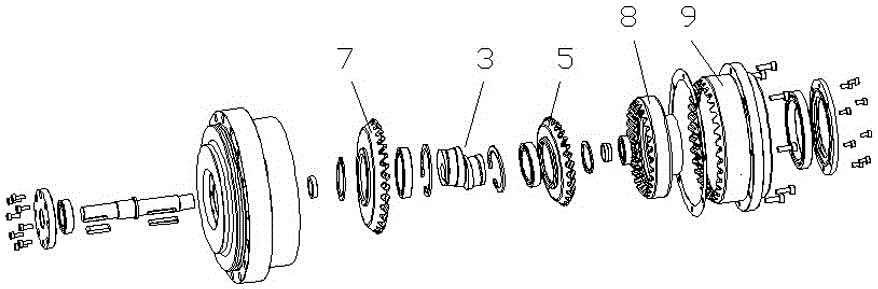

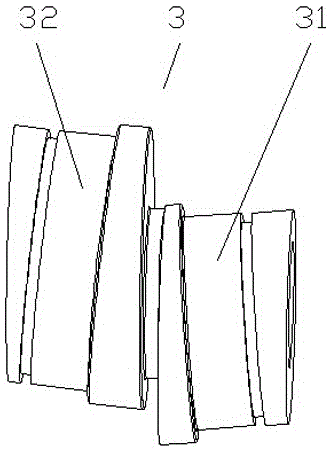

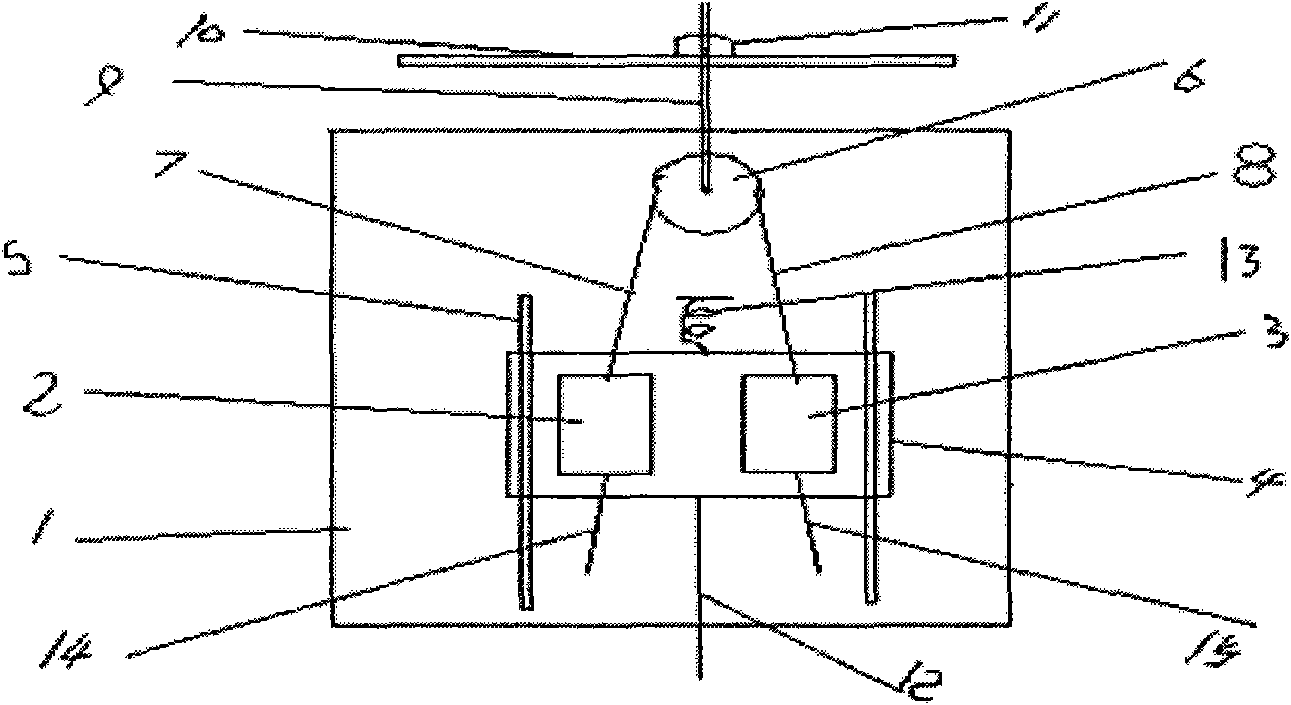

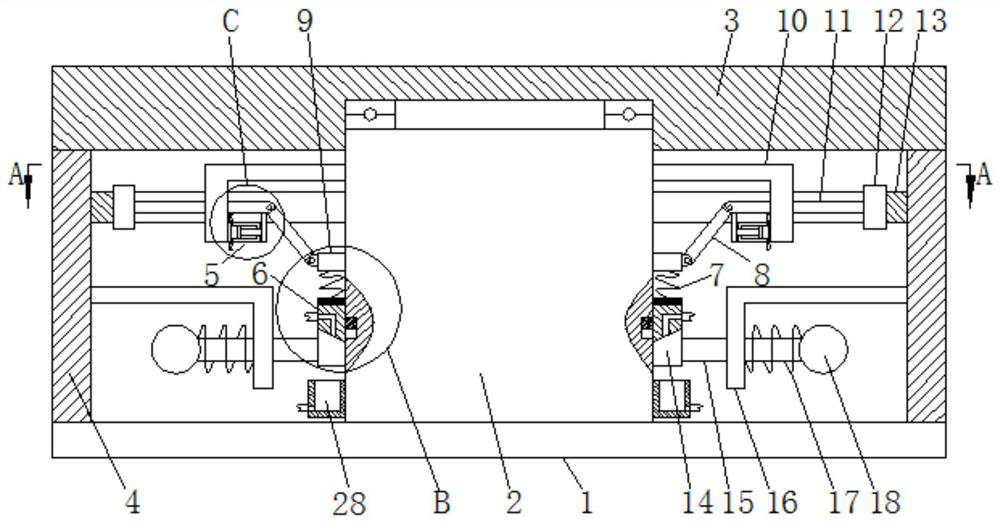

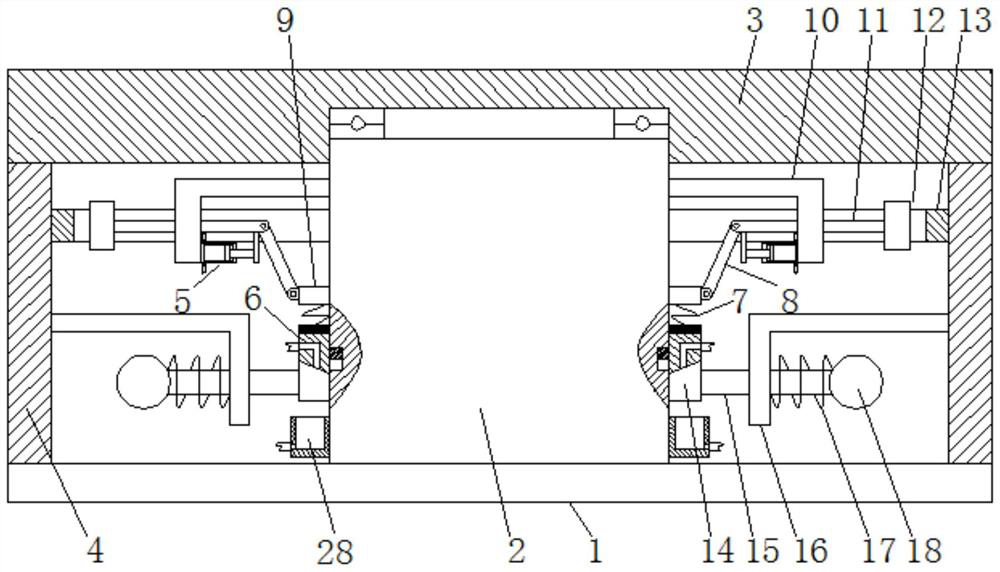

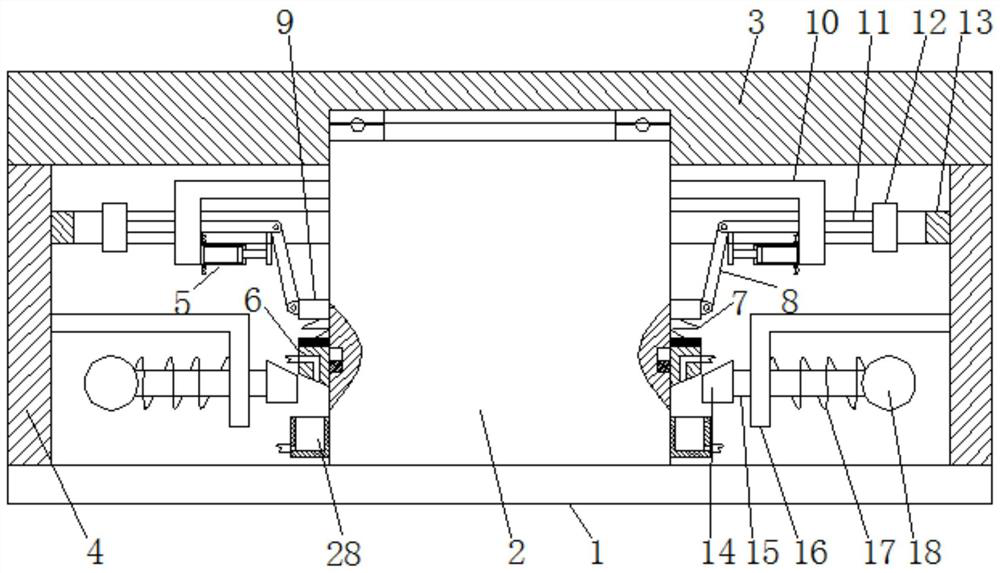

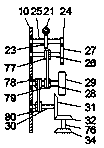

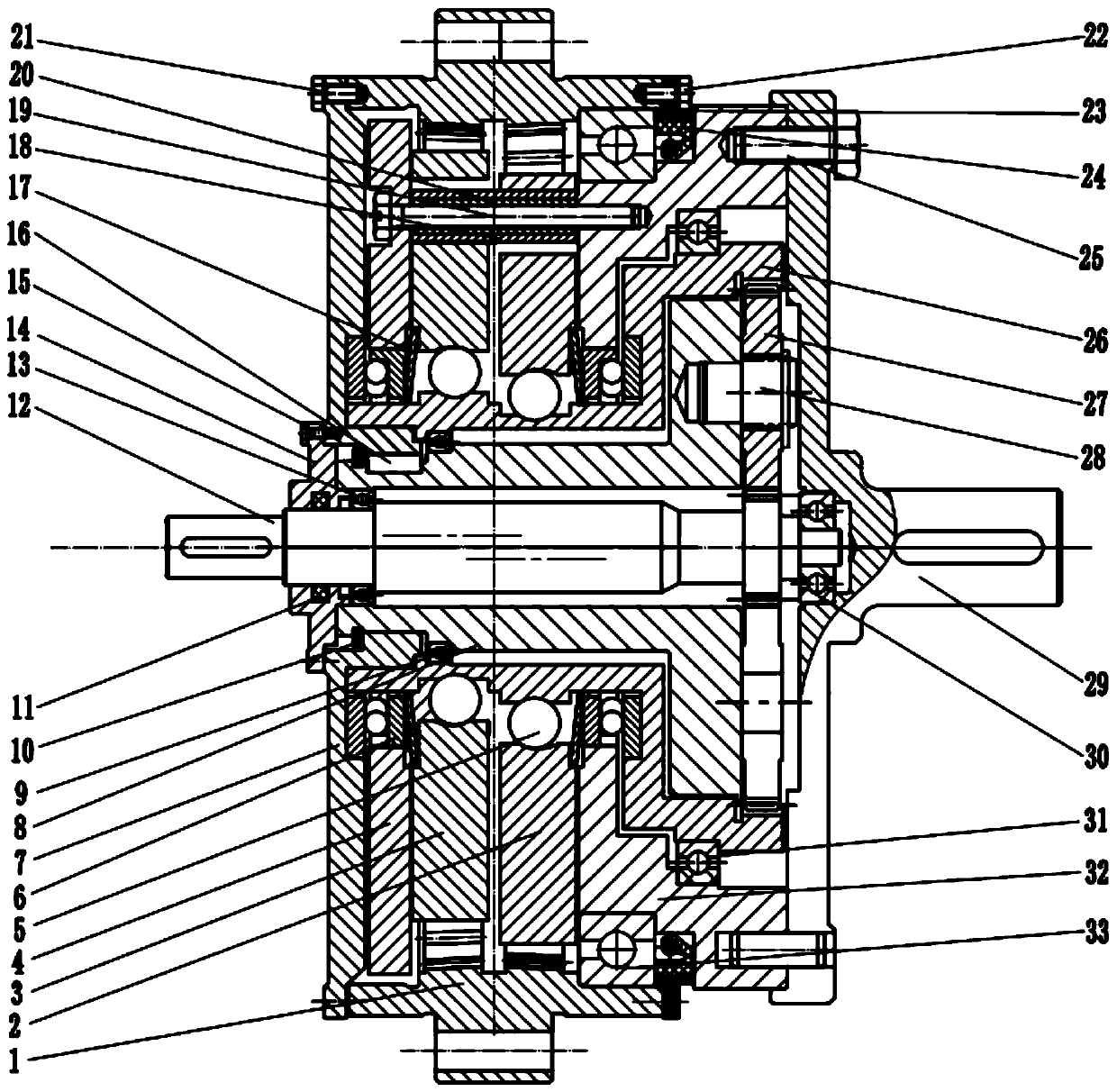

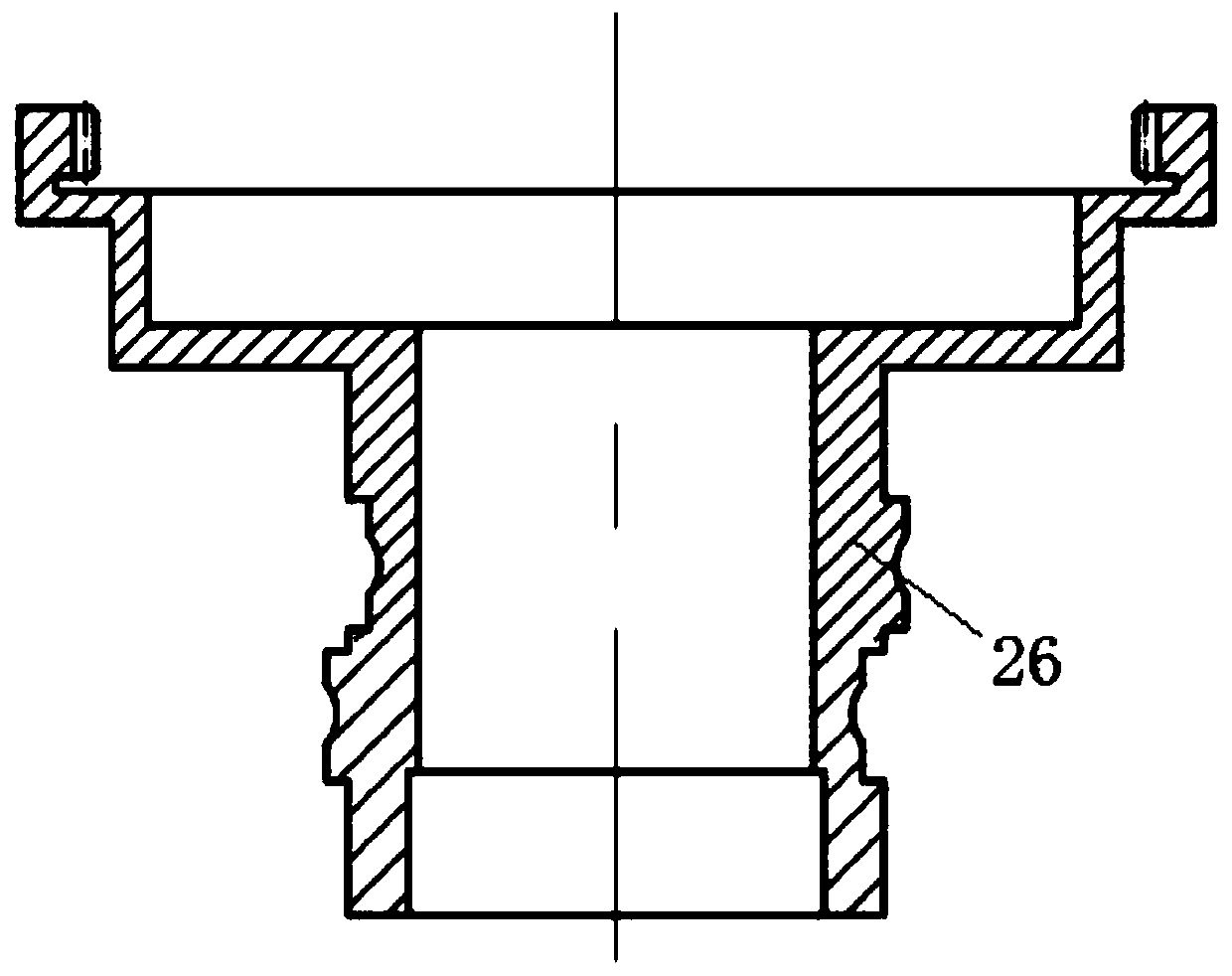

Bilateral two-stage internal engagement biarc bevel gear nutation speed reducer and working method

ActiveCN106246812AReasonable structural designLarge speed ratioToothed gearingsGearing detailsNutationBevel gear

The invention relates to a bilateral two-stage internal engagement biarc bevel gear nutation speed reducer which comprises a box. An input shaft is arranged at one end of the box in a penetrating manner. The shaft section, located in the box, of the input shaft is provided with a nutation sleeve. A variable-speed biarc bevel gear is connected to the nutation sleeve through a first bearing. A balance biarc bevel gear is further connected to the nutation sleeve through a second bearing. An output biarc bevel gear and a fixed biarc bevel gear are arranged at the other end of the box in a penetrating manner. The output biarc bevel gear is connected with the fixed biarc bevel gear through a third bearing. The variable-speed biarc bevel gear is in transmission engagement with the output biarc bevel gear, the balance biarc bevel gear is in transmission engagement with the fixed biarc bevel gear, and the two engagement points appear at the same time and are located on the two sides of the input shaft. The invention further relates to a working method of the bilateral two-stage internal engagement biarc bevel gear nutation speed reducer. The bilateral two-stage internal engagement biarc bevel gear nutation speed reducer is reasonable in structural design, efficient and convenient and fast to operate.

Owner:FUZHOU UNIVERSITY

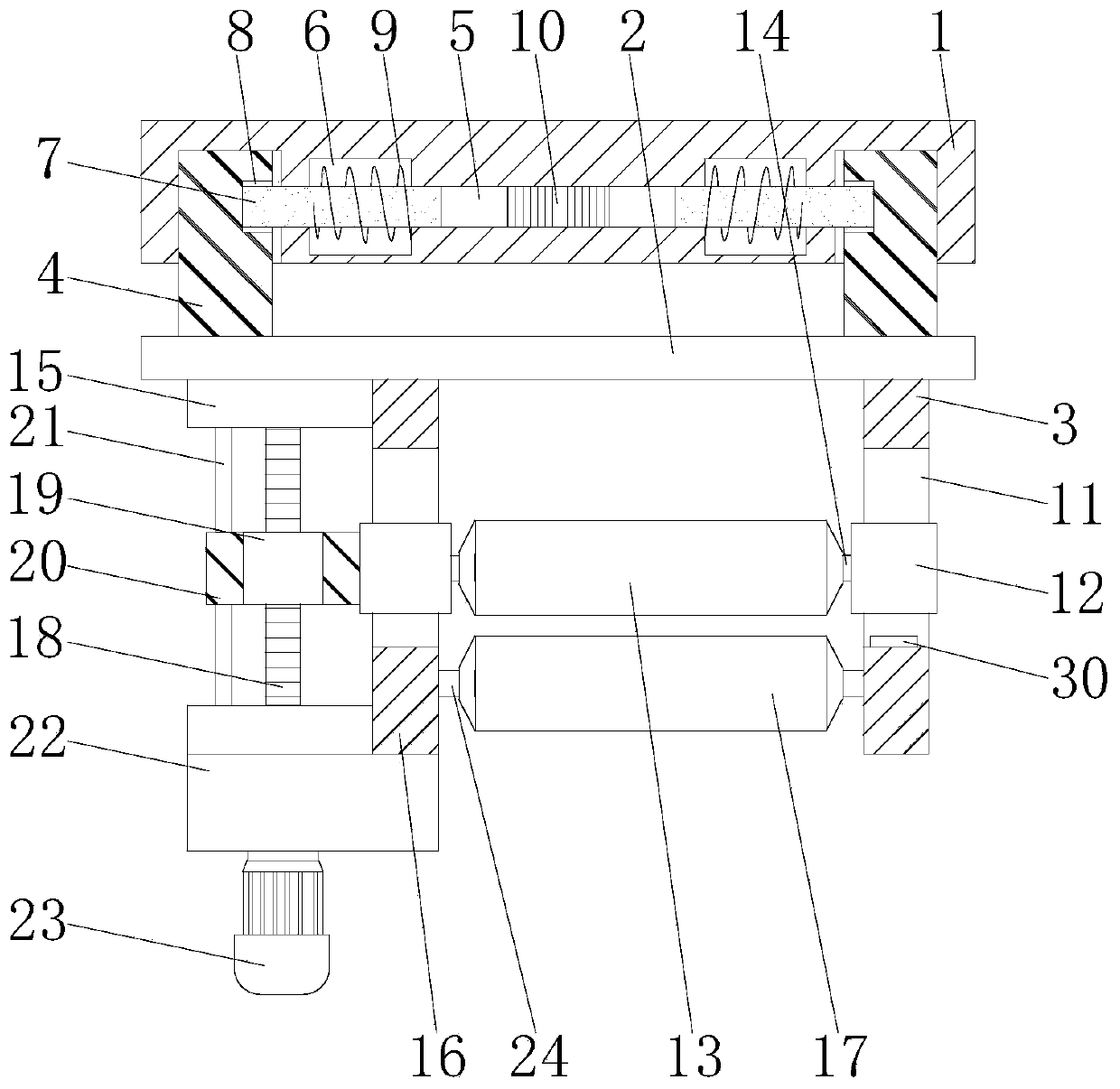

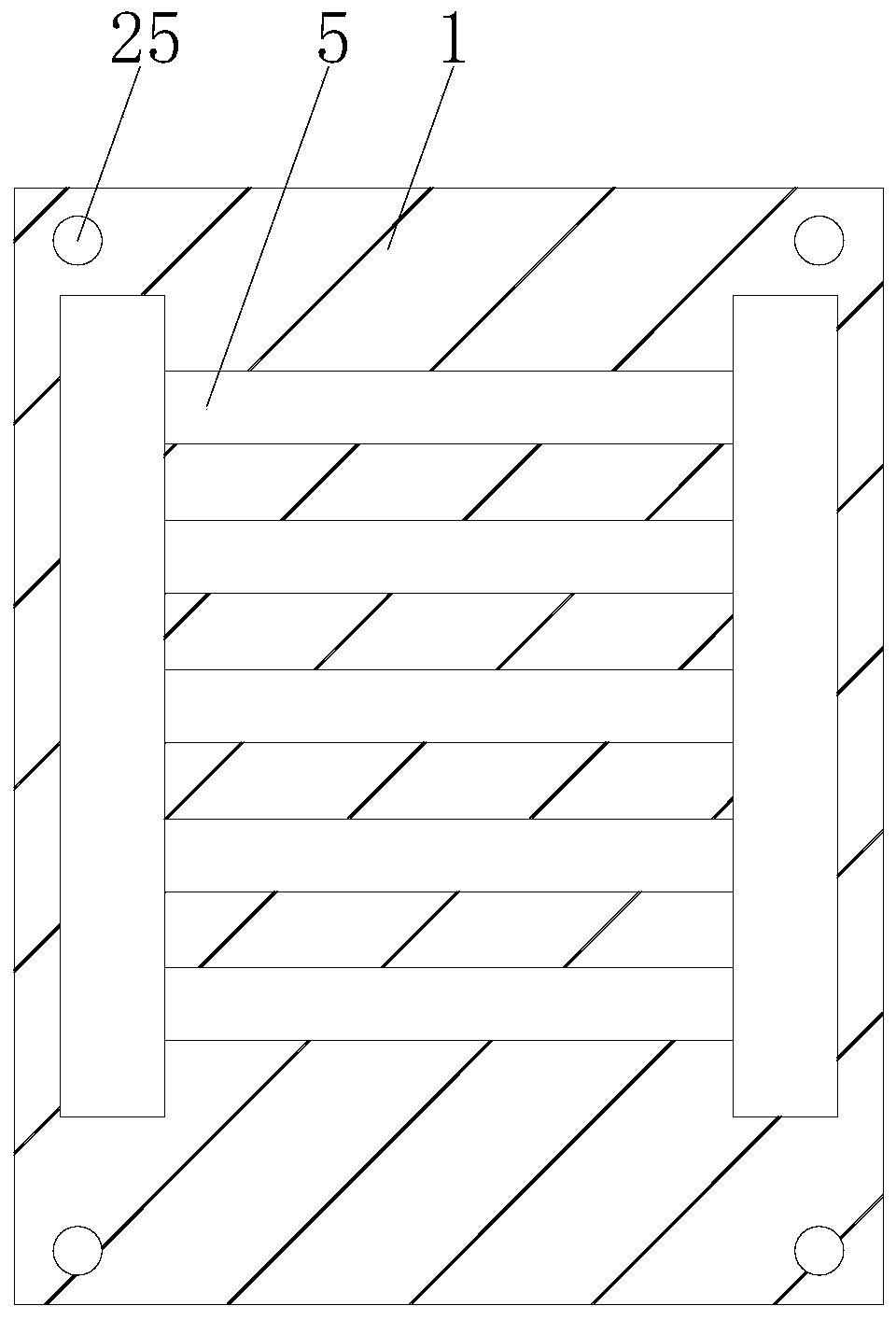

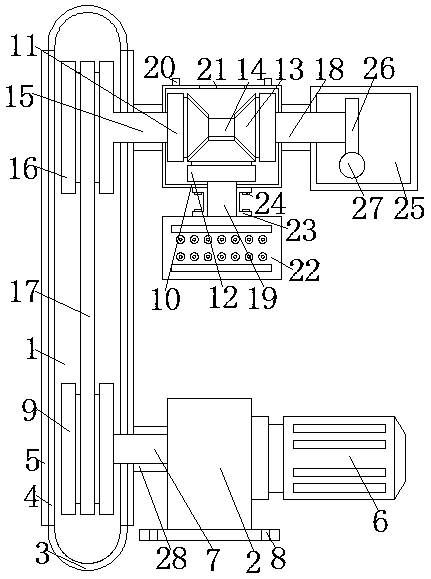

Pole piece cold-pressing device for lithium battery production

InactiveCN109786671AEffective liftingDeceleration is effectiveElectrode manufacturing processesImpellerMicrocomputer

The invention discloses a pole piece cold-pressing device for lithium battery production. The device comprises an installing plate, a flat plate, a first vertical plate, fixed strips, round holes, concave holes, iron rods, mating holes, springs, an electromagnet, sliding slots, sliding blocks, a first roller, a first connecting shaft, fixed plates, a second vertical plate, a second roller, a screw, a ball nut, a lantern ring, a guide rod, a reduction box, a first rotary shaft, a first gear, a second rotary shaft, a second gear, a third gear, a fourth gear, a servo motor, a second connecting shaft, installing holes, straight pipes, suction nozzles, connecting rods, fixed covers, distance sensors, connecting pipes, T-pipes, suction motors, a display screen, a single-chip microcomputer and centrifugal impellers. According to the device, through a lifting structure and the internal structure of the reduction box, ascending and descending of the first roller in the vertical direction can beeffectively realized, therefore, the distance between the first roller and the second roller can be adjusted, a pole piece can be pressed into a required thickness, and meanwhile the adjusted numbercan be displayed on the display screen in real time.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

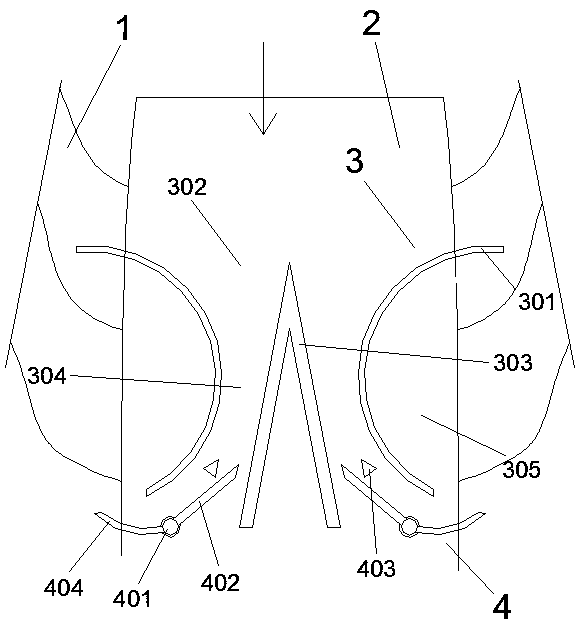

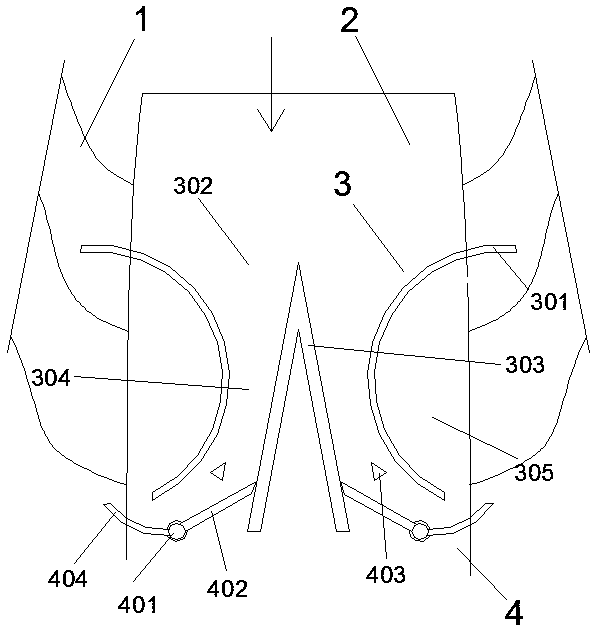

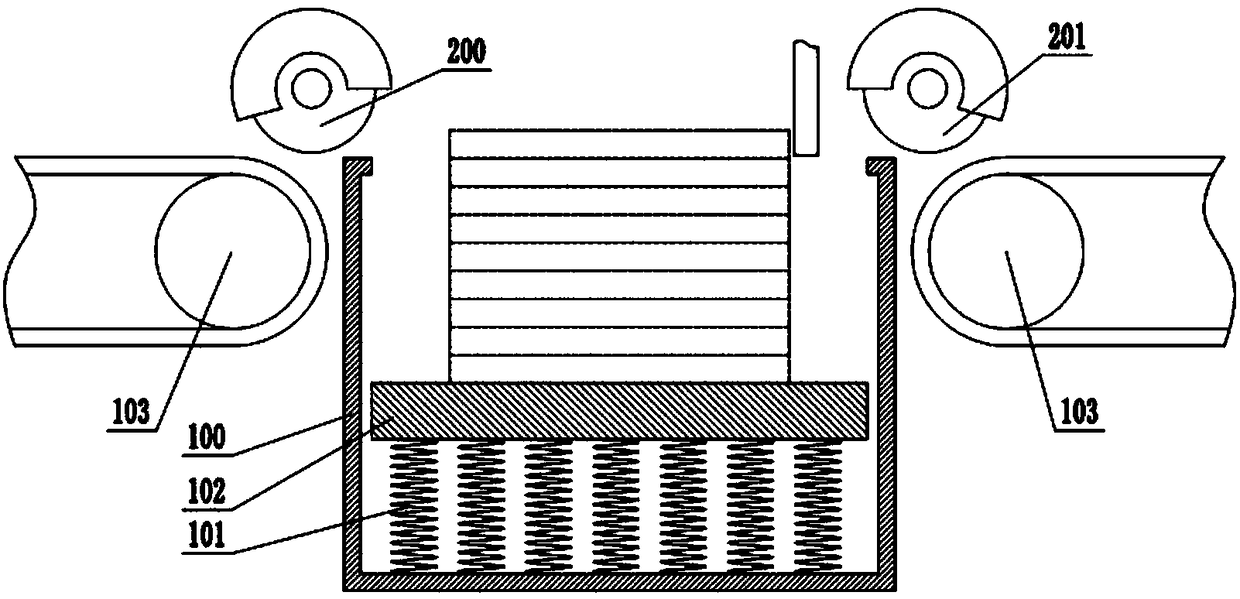

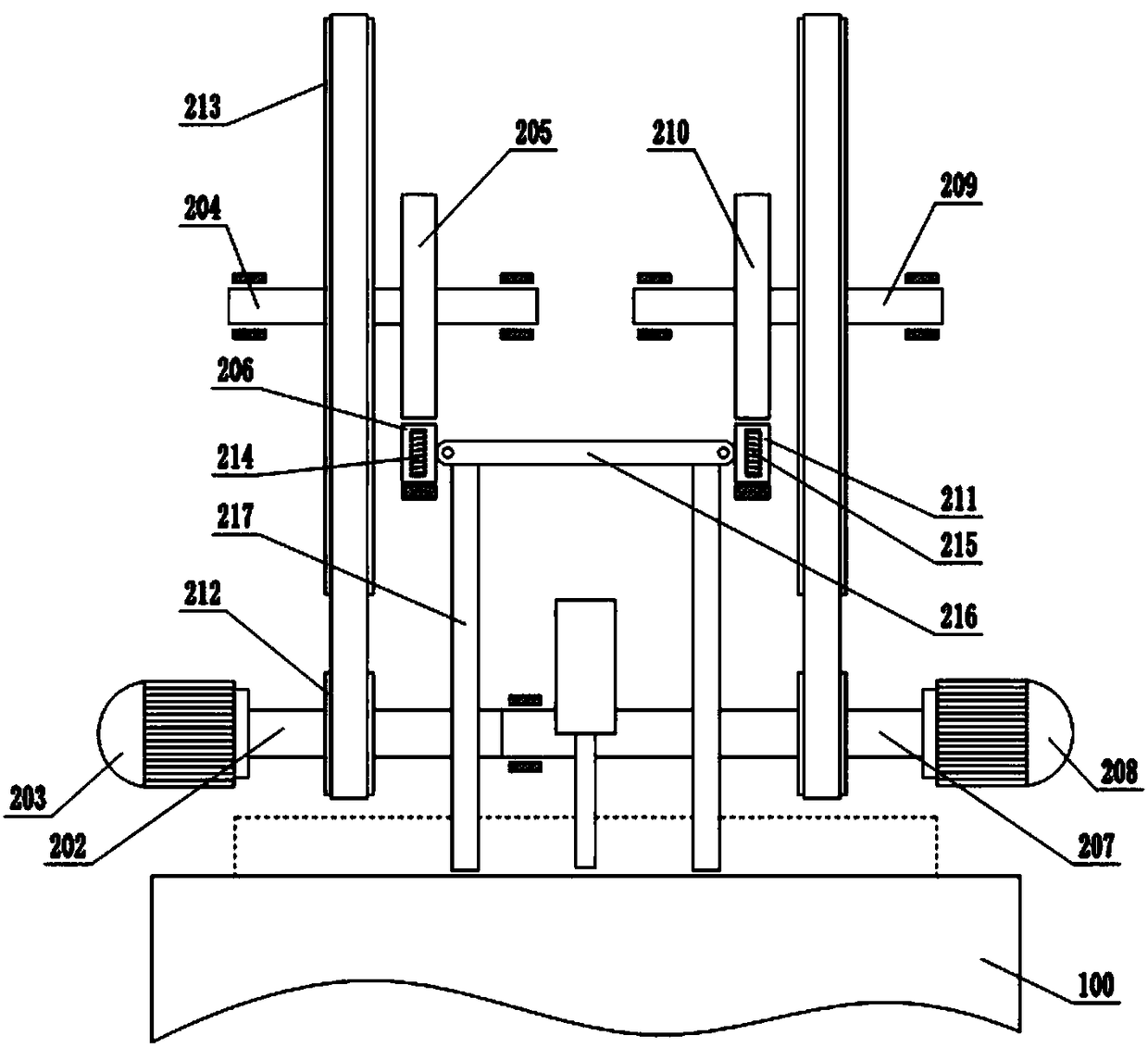

Movable diversion device for debris flow interception

The invention relates to a movable diversion device for debris flow interception. The movable diversion device is arranged in a debris flow passage formed between highlands on two sides and comprisesa stopping and silting diversion dam and two movable flow guidance mechanisms. The stopping and silting diversion dam divides the debris flow into two streams and constructs multiple new stopping andsilting areas, so that the debris flow can slow down, settle down and partially stop. The movable flow guidance mechanisms can automatically judge whether partial interception is required according tothe flow size of the debris flow. When the flow of the debris flow is large, the movable flow guidance mechanisms are pushed to deflect to filter and divert the debris flow, and guide part of the filtered debris flow into the stopping and silting areas for storage. Therefore, the flow of the debris flow is reduced, and the impact and destructiveness of the debris flow are greatly reduced. Moreover, an interception system has strong resistance to geological hazards. Even if partial damage occurs, the prevention and control effect cannot be greatly affected.

Owner:段刚强

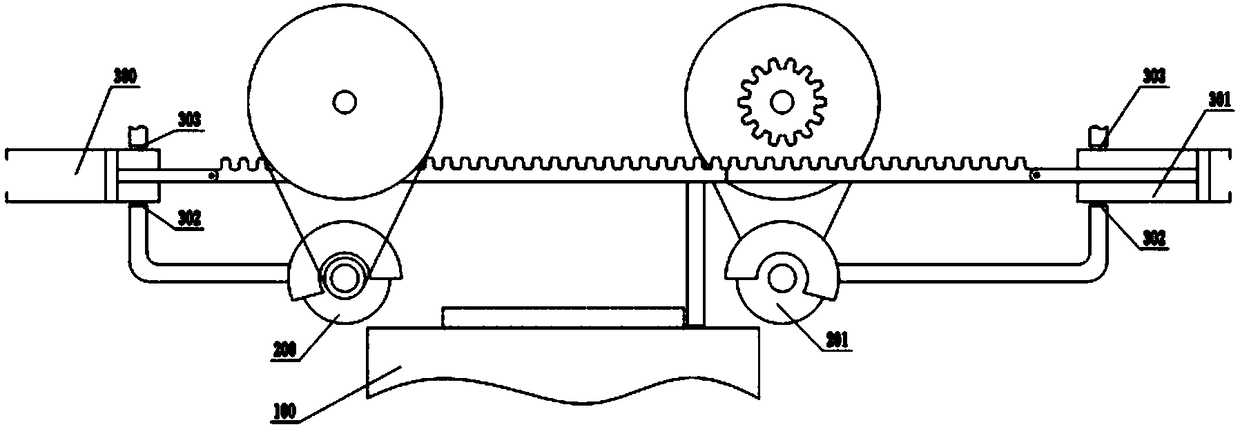

Batch ceramic tile cutting device

InactiveCN108327099AShorten the timeImprove cutting efficiencyWorking accessoriesStone-like material working toolsMechanical engineeringElectromagnet

The invention belongs to the technical field of cutting equipment and particularly discloses a batch ceramic tile cutting device. The device comprises a working box and a cutting mechanism, wherein anelastic part is arranged at the bottom of the working box, a support plate is connected with the upper end of the elastic part, and a transfer device is also arranged; the cutting mechanism comprisesa first cutting wheel and a second cutting wheel, the first cutting wheel is fixed on a first rotating shaft driven by a forward rotation motor, a first support shaft is arranged above the first rotating shaft, a first gear is fixed on the first support shaft, and a first rack is arranged below the first gear; the second cutting wheel is fixed on a second rotating shaft driven by a reverse rotation motor, a second support shaft is arranged above the second rotating shaft, a second gear is fixed on the second support shaft, and a second rack is arranged below the second gear; a first electromagnet is arranged in the first rack, a second electromagnet is arranged in the second rack, a support rod is hinged between the first rack and the second rack, and a push rod is connected to the support rod. The device requires no manual taking and placement in the ceramic tile cutting process and has high working efficiency.

Owner:重庆谦谦装饰工程有限公司

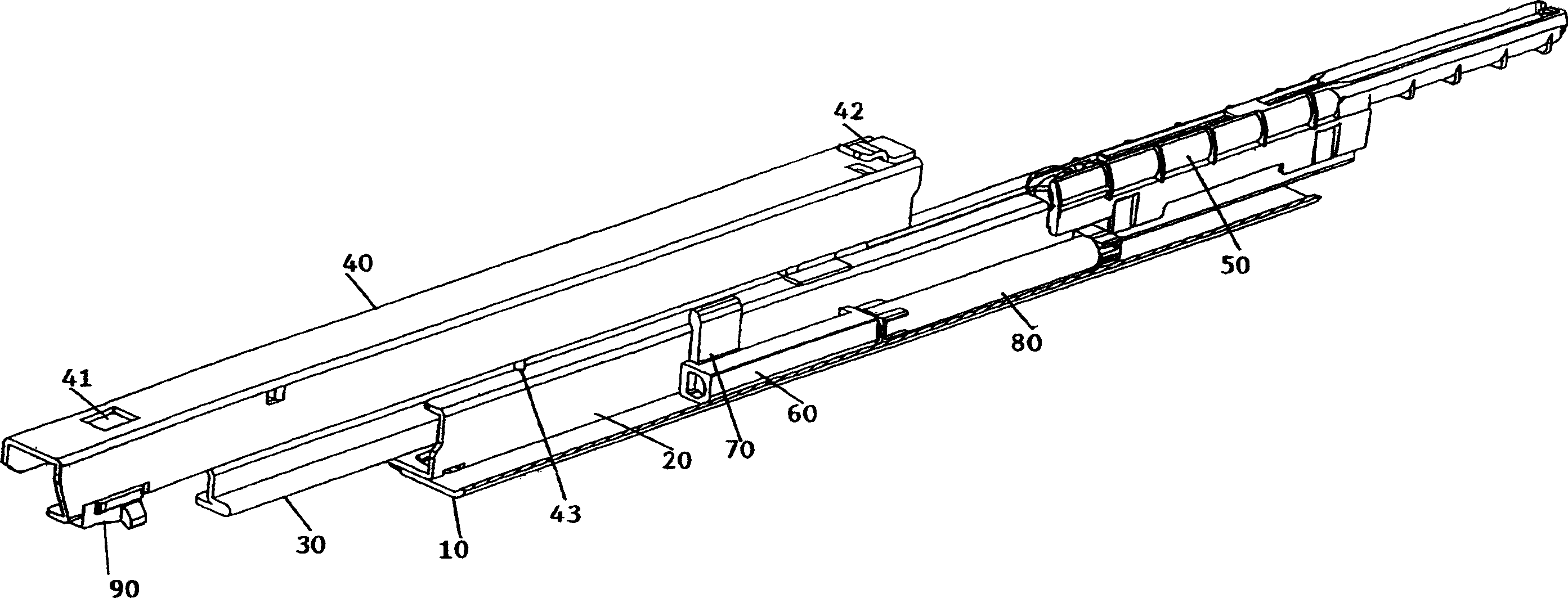

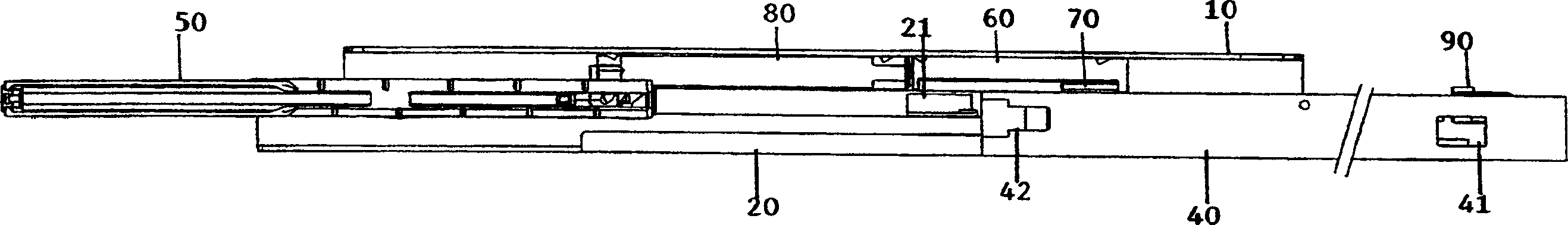

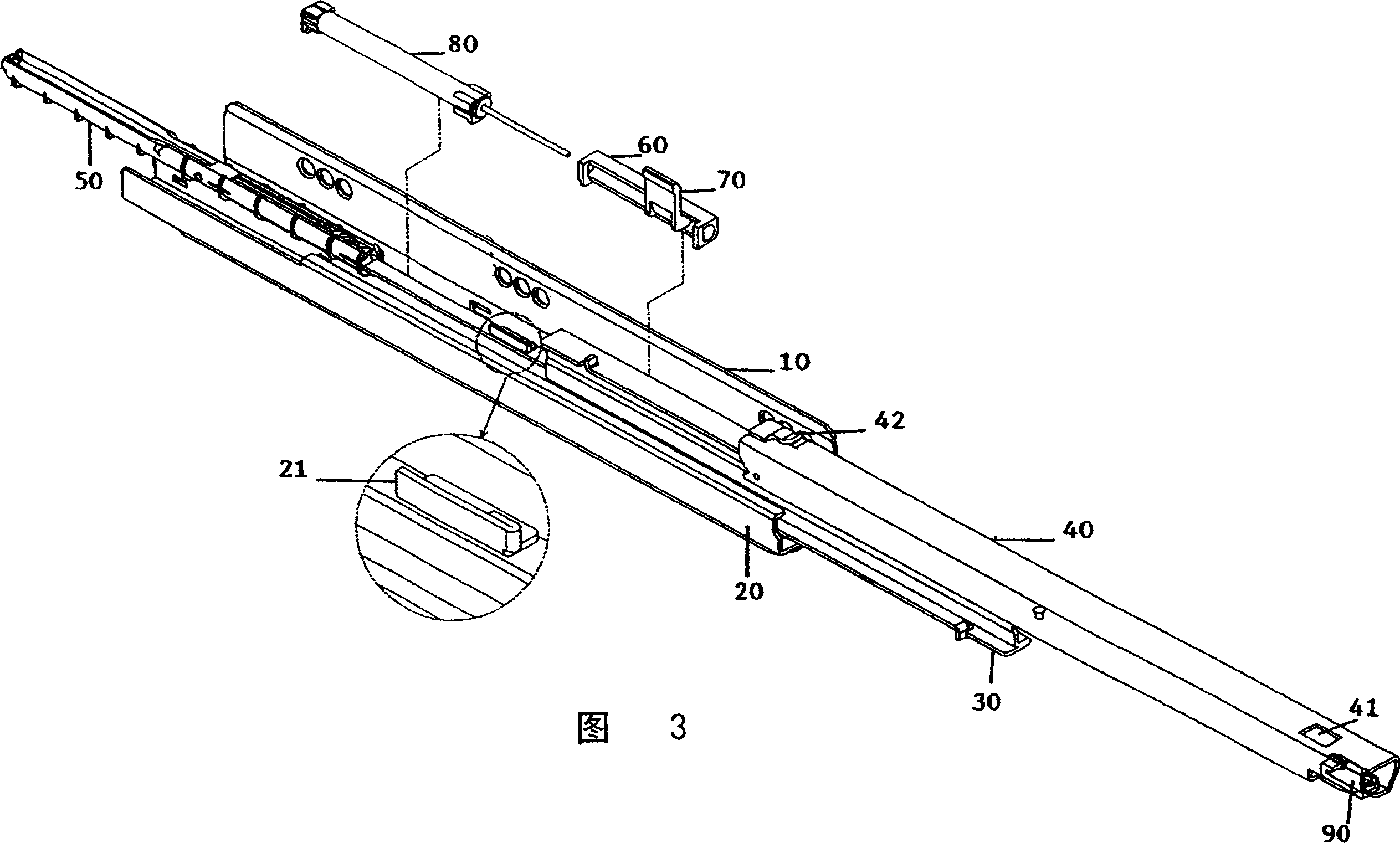

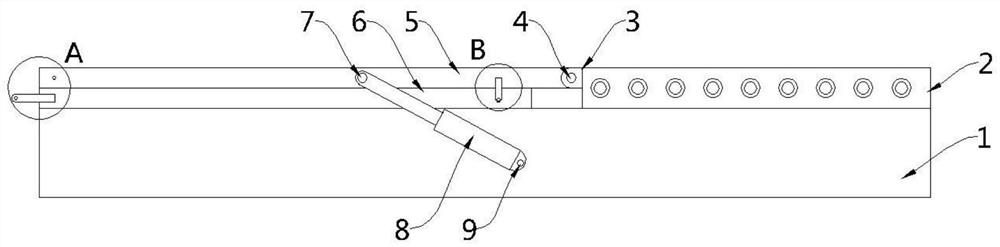

Drawer guide rail assembly

A guide rail assembly comprises a mounting bracket having a fixed rail on the mounting bracket for receiving an intermediate rail capable of sliding back and forth relative to the fixed rail, an outer pull out guide for attachment to the drawer and being capable of sliding back and forth on the intermediate rail relative to the intermediate rail and the fixed rail, a protrusion on the bottom surface of the outer pull out guide, a damping device and a channel guide disposed along the mounting bracket adjacent the fixed rail. The damping device is resiliently compressible in a lengthwise direction and the channel guide is provided with a sliding member. The sliding member includes an inner portion that travels within the guide and an outer portion that extends outwardly from the guide so as to be contactable by the pull out guide protrusion. The inner portion of the sliding member locates an end of the damping device that can be pushed inwardly to provide damping. During a closing action of the assembly, the outer pull out guide is caused to slide in a drawer-closing direction and when the protrusion reaches and contacts the sliding member outer portion, the sliding member travels within the channel guide against the resilience of the damping device and causes deceleration of the drawer-closing motion.

Owner:HARN MARKETING

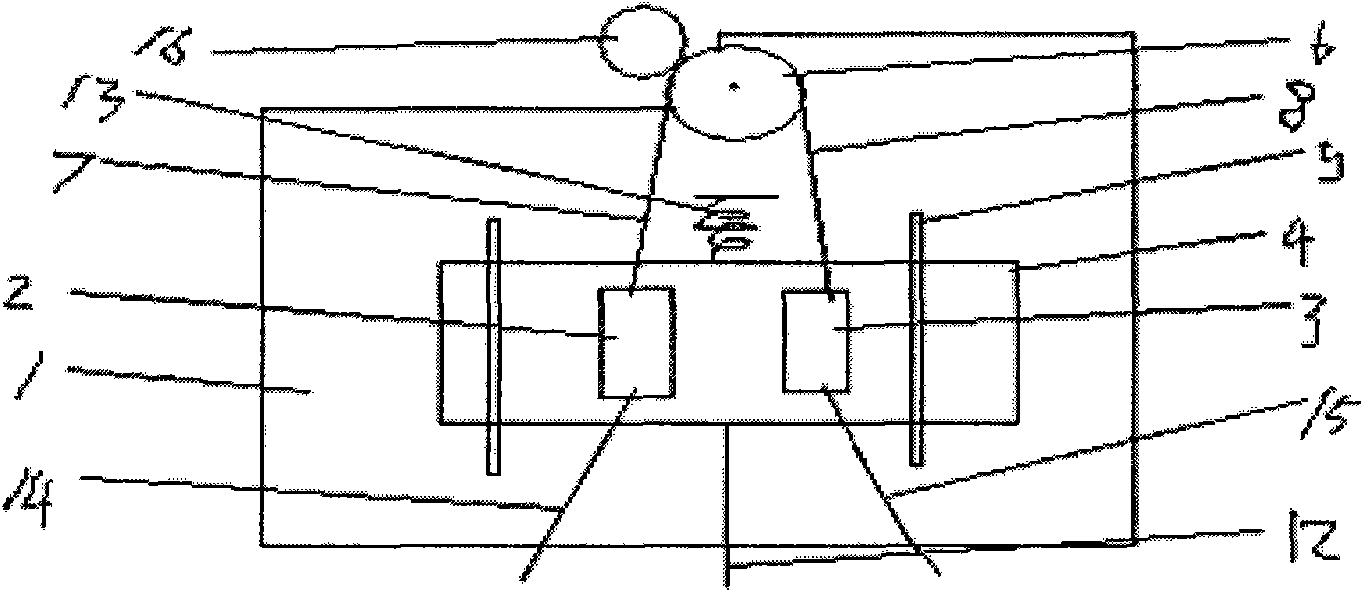

Multi-motor drive control system of electric vehicle and working method thereof

InactiveCN101934742AAcceleration and deceleration to achieveDeceleration achievedSpeed controllerElectric machinesMotor driveElectric machine

Owner:王建排

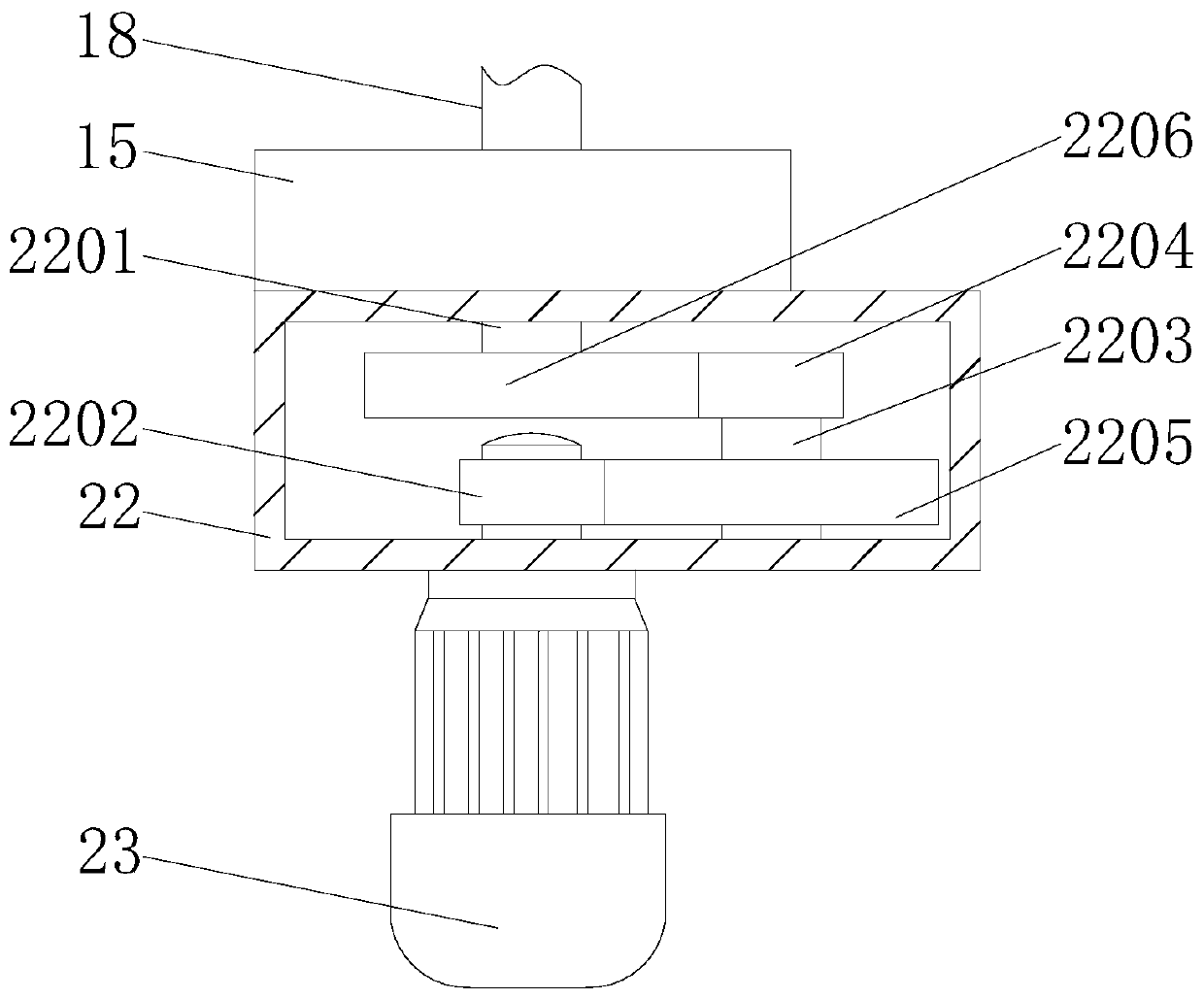

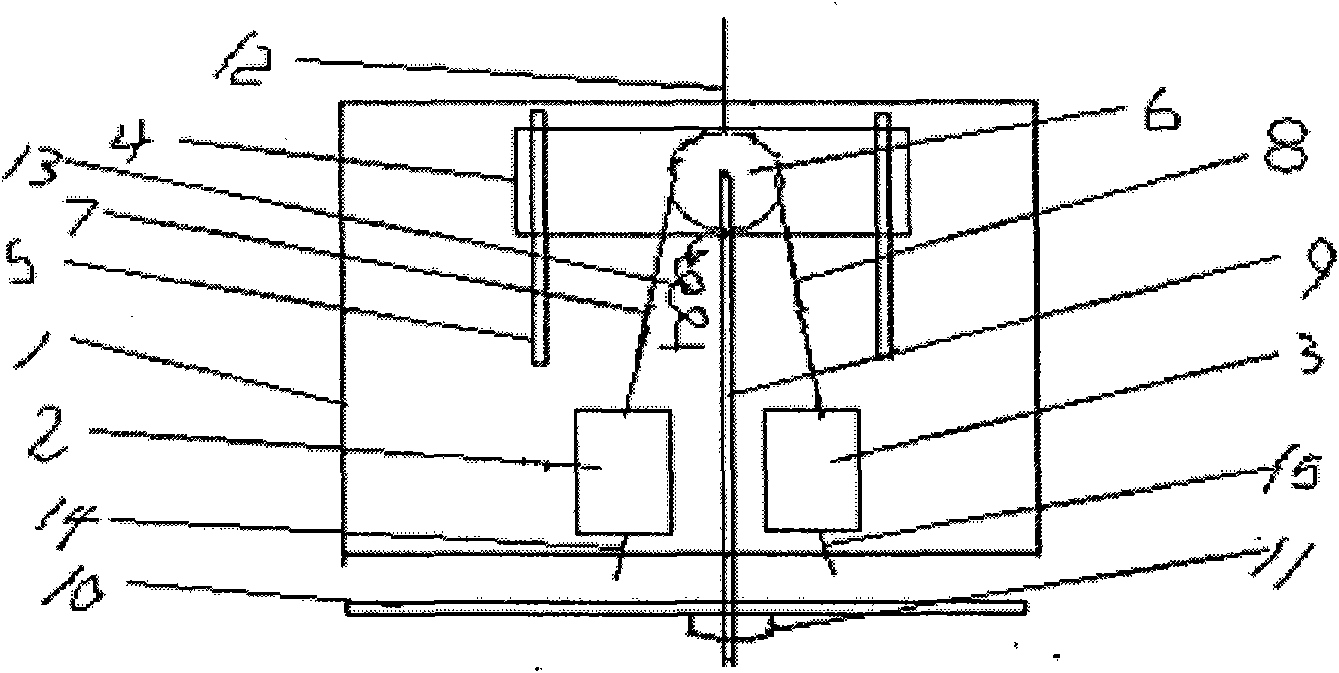

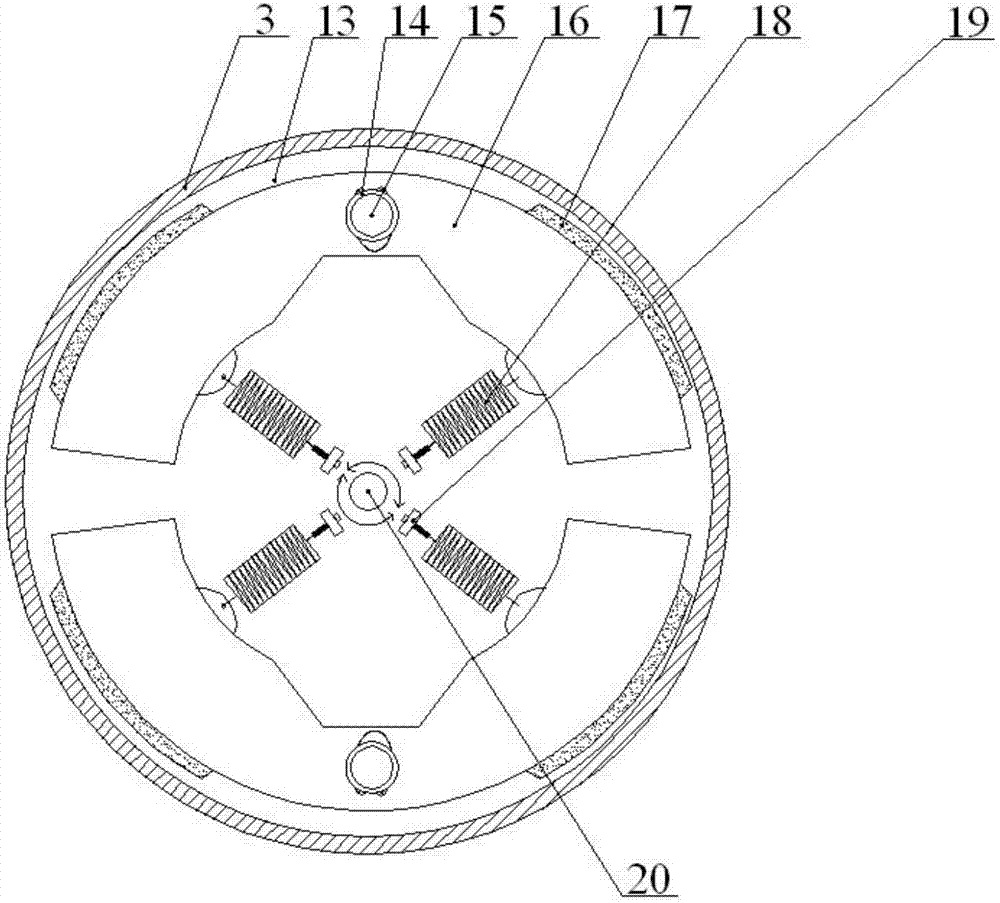

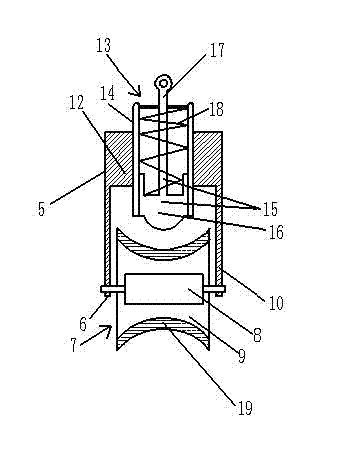

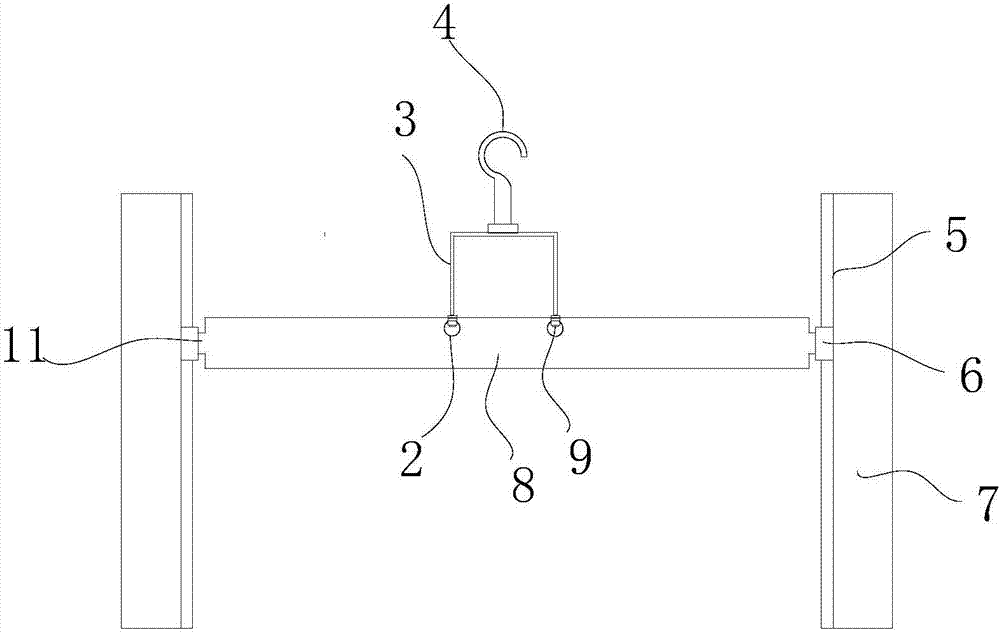

Bidirectional landing speed-reduction device

PendingCN107174760AReduce centrifugal forceDeceleration achievedBuilding rescueDrive shaftReduction drive

The invention relates to a bidirectional landing speed-reduction device. The bidirectional landing speed-reduction device comprises a shell, a drive shaft and ropes. The drive shaft comprises a driving shaft and a driven shaft. A driving gear is coaxially mounted on the driving shaft. The driven shaft is coaxially sleeved with a driven gear. The driven gear and the driving gear are assembled in an engaged mode. A centrifugal speed reducer which is coaxial with the driven shaft is mounted on the outer side of the upper top surface of the shell. The bidirectional landing speed-reduction device is scientific and reasonable in design and simple in structure; the bidirectional landing speed-reduction device is different from a unidirectional landing speed-reduction device in that the two ropes are wound on the drive shaft in a bidirectional mode so that both unidirectional landing and bidirectional landing can be achieved, using cost is reduced, and using efficiency is improved; and the bidirectional landing speed-reduction device is suitable for emergent forced landing of airplanes or emergent escape under high-altitude building fires and dangerous conditions and can also be popularized to other application fields.

Owner:刘睿达

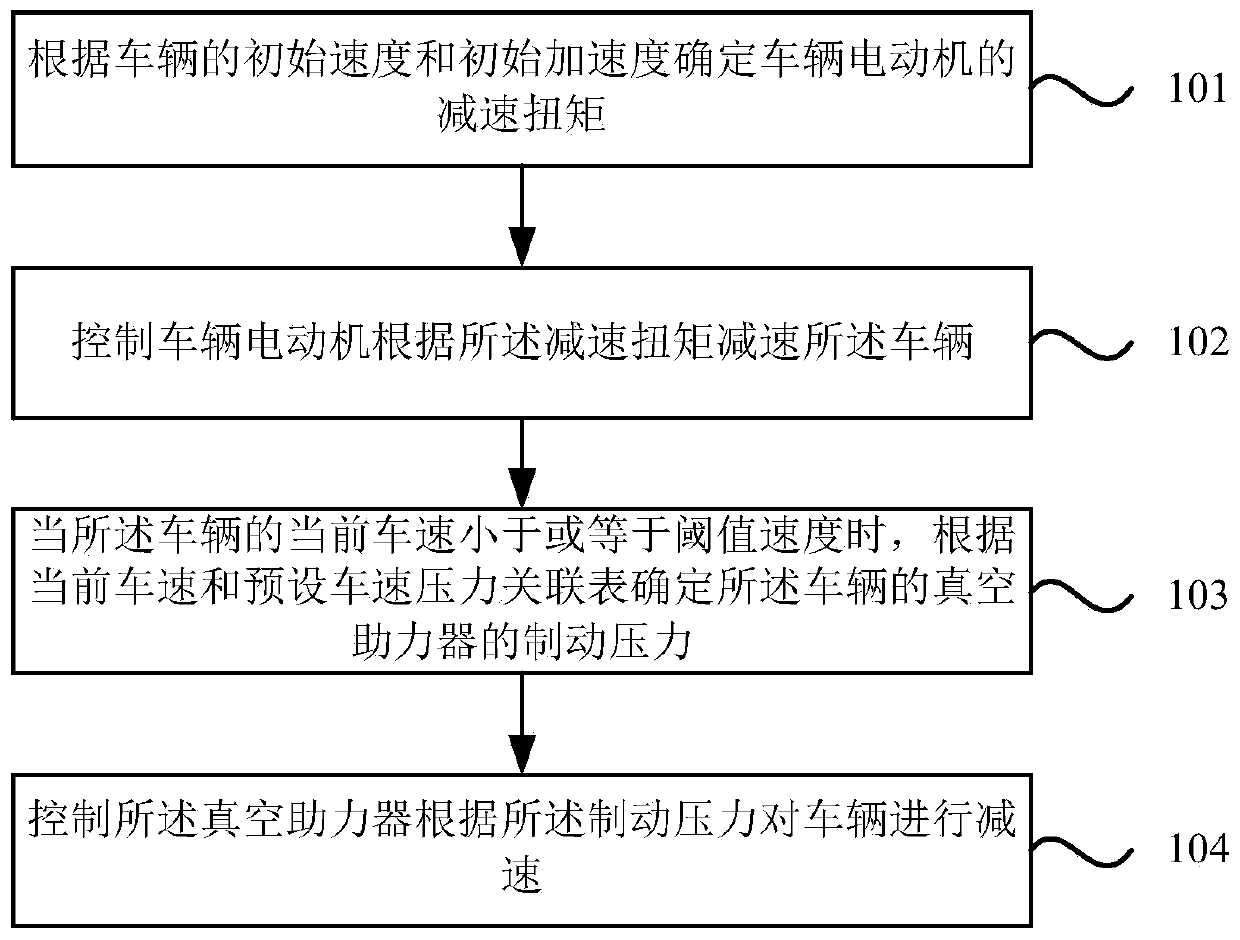

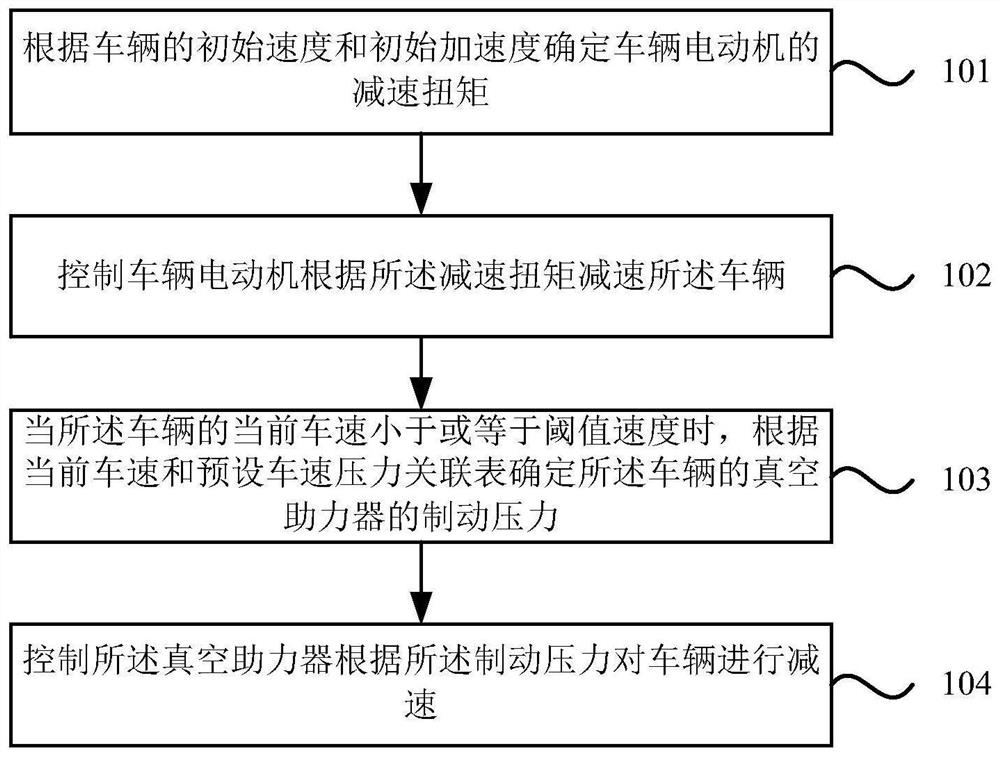

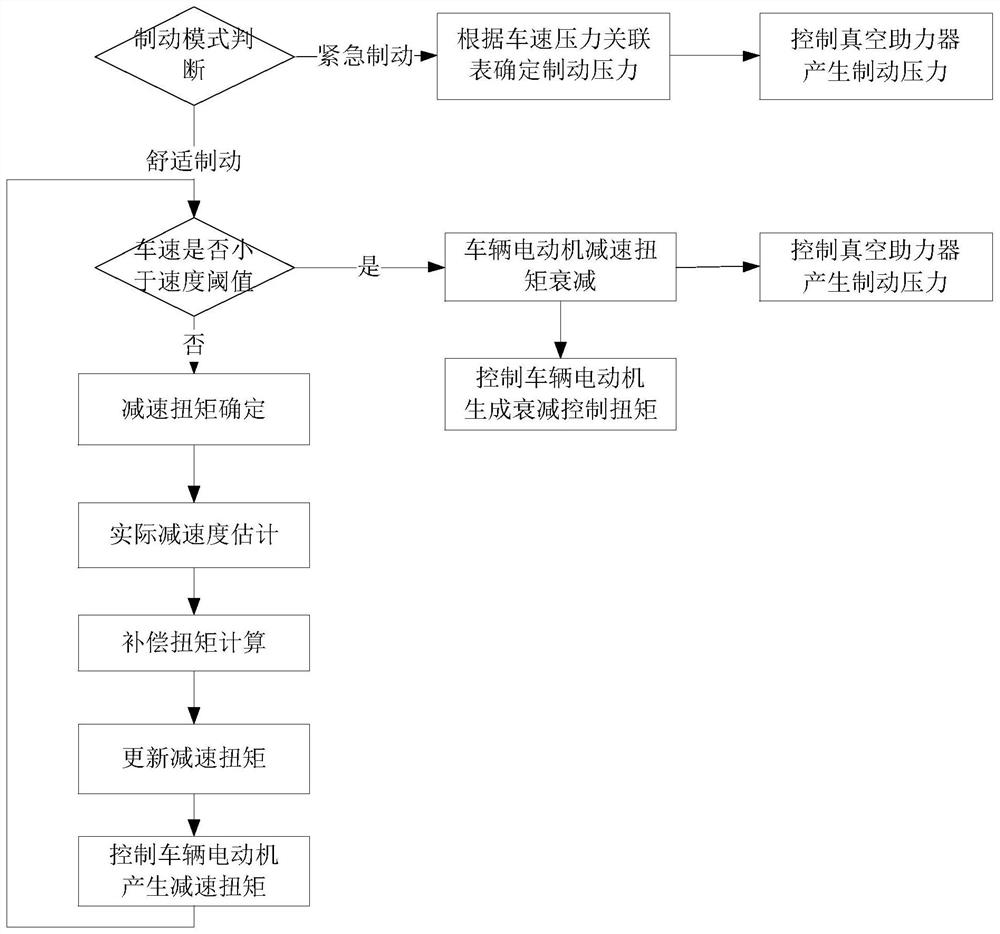

Redundant braking control method, device and system, vehicle and storage medium

ActiveCN110834612AAvoid vehicle instabilityImprove stability and securitySpeed controllerBraking action transmissionBrake pressureBrake control

The invention discloses a redundant braking control method, device and system, a vehicle and a storage medium. The method comprises the following steps that the deceleration torque of a vehicle motoris determined according to the initial speed and the initial acceleration of the vehicle; the vehicle motor is controlled to enable the vehicle to decelerate according to the deceleration torque; whenthe current vehicle speed of the vehicle is less than or equal to the threshold speed, the braking pressure of a vacuum booster of the vehicle is determined according to the current vehicle speed anda preset vehicle speed pressure association table; and the vacuum booster is controlled to enable the vehicle to decelerate according to the braking pressure. According to the method provided by theembodiment, the braking control under redundant braking of the vehicle is realized, the stability of the vehicle can be improved, the instability of the vehicle is prevented, and the comfort of vehicle driving is improved.

Owner:CHINA FIRST AUTOMOBILE

Reverse-gear synchronizer assembly

InactiveCN105736597AAchieve decelerationGood for putting into reverse gearMechanical actuated clutchesGearing controlEngineeringGear tooth

The invention discloses a reverse-gear synchronizer assembly used in a manual transmission. The reverse-gear synchronizer assembly comprises an input shaft, hubs, gear sleeves and reverse-gear gear sets. Each gear sleeve is located between a corresponding bearing and the corresponding reverse-gear gear set, a fixing taper ring is further arranged between each bearing and the corresponding gear sleeve, and each gear sleeve is further provided with a first synchronous ring. Each reverse-gear gear set is further provided with a synchronous gear ring, wherein one end of the synchronous gear ring is connected with the reverse-gear gear set in an engaged manner, and the other end of the synchronous gear ring extends towards the corresponding gear sleeve side. Each gear sleeve is further provided with a second synchronous ring used for being matched with the corresponding synchronous gear ring, the second inner ring face of each second synchronous ring is in a conical shape, and each second inner ring face can be kept to be tightly matched with the outer ring face of the corresponding gear ring. The reverse-gear synchronizer assembly is simple in structure and convenient to install, the input shaft can be effectively decelerated so as to achieve synchronous input shaft deceleration, a reverse gear can be better engaged, and reverse-gear tooth collisions are avoided.

Owner:SAIC GENERAL MOTORS +1

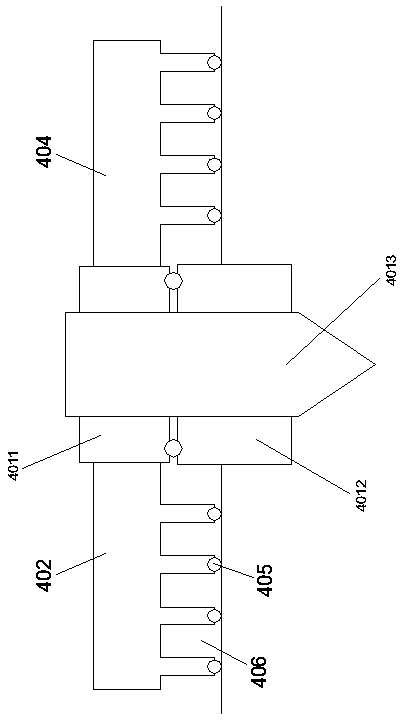

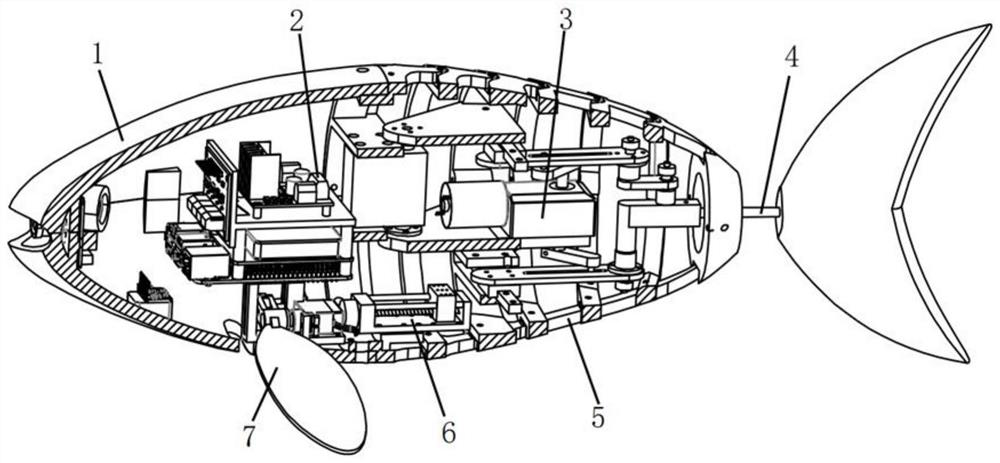

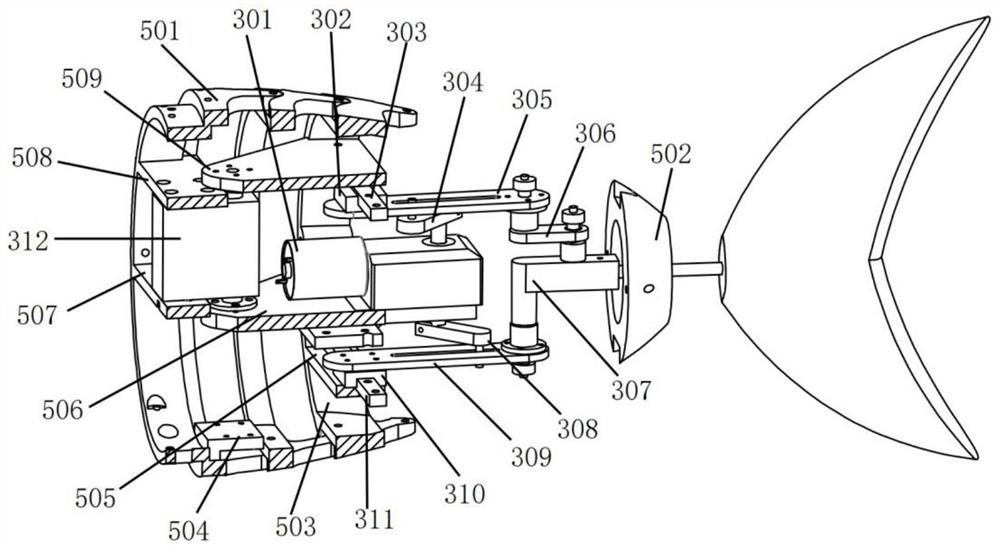

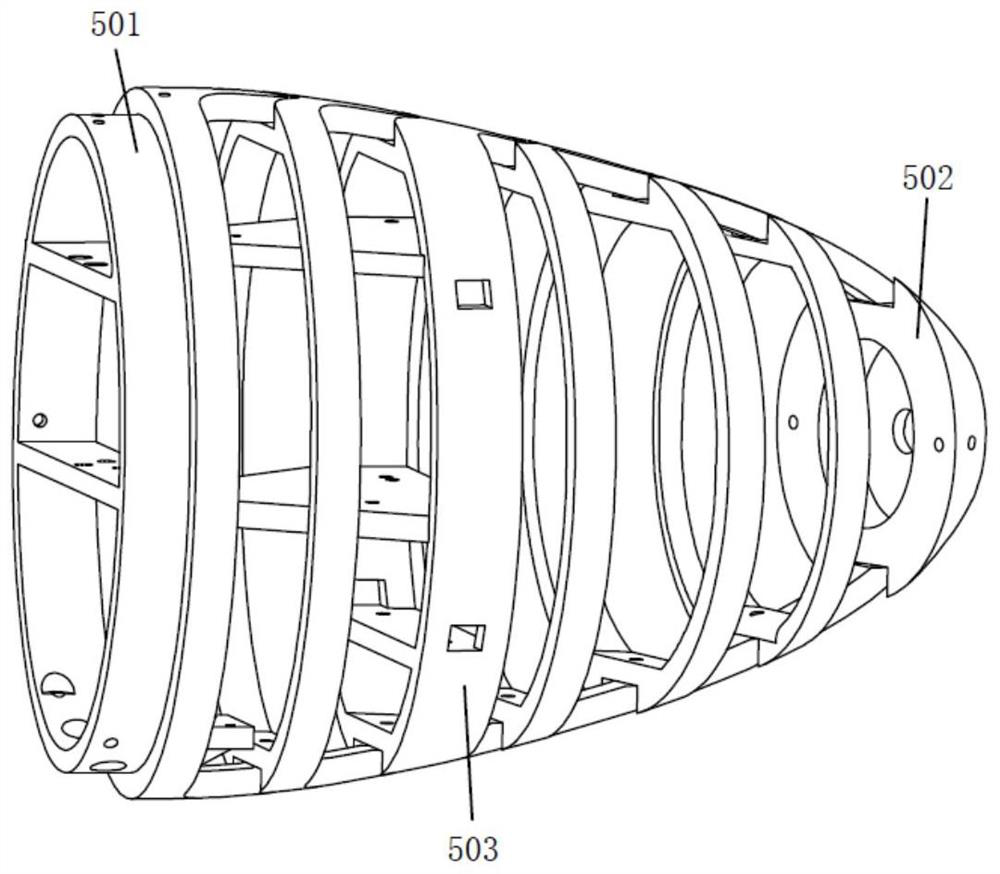

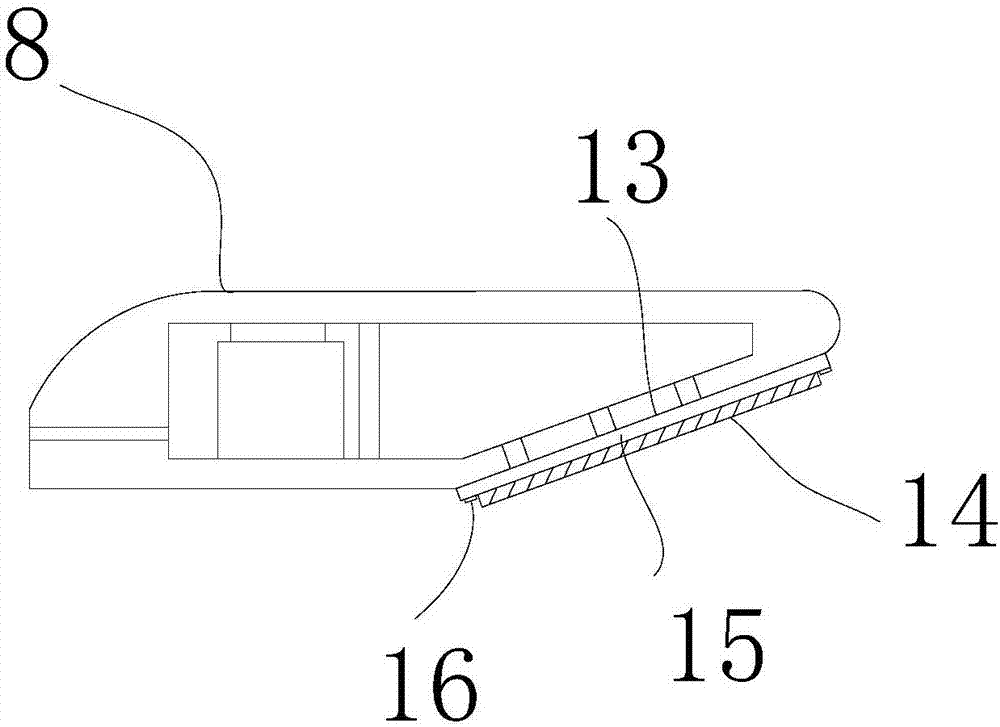

Tail fin propelled autonomous swimming bionic robotic fish based on composite connecting rod mechanism

ActiveCN114537629ASimple controlStrong mobilityPropulsion power plantsPropulsive elements of non-rotary typePhysicsElectric machinery

The invention relates to a tail fin propelled autonomous swimming bionic robotic fish based on a composite connecting rod mechanism. The bionic robotic fish comprises a fish head assembly, a fish tail skeleton, a tail fin, a tail swinging mechanism, a pectoral fin mechanism, a sinking and floating mechanism and a control module. The pectoral fin mechanism and the control module are arranged in the fish head assembly, the fish tail framework is fixedly connected with the fish head assembly, the tail swinging mechanism and the sinking and floating mechanism are arranged in the fish tail framework, and the tail fin is connected with the fish tail framework and the tail swinging mechanism; the control module controls movement of the tail swinging mechanism, the pectoral fin mechanism and the sinking and floating mechanism through closed-circuit feedback, drives the tail fin and the fishtail framework to complete swinging action, drives the pectoral fin to complete flapping action, and meanwhile adjusts the pitching angle of the fish body to achieve floating and diving. According to the bionic robotic fish, the compound motion of transverse movement of the tail handle and swinging of the tail fin is achieved through the single motor, the swinging track of the fish tail is highly fitted, autonomous swimming is achieved in combination with the control module, and the flexibility and simulation degree of the bionic robotic fish are greatly improved; the propelling efficiency is high, the maneuverability is high, the structure is novel, and the innovativeness is high.

Owner:WUHAN UNIV

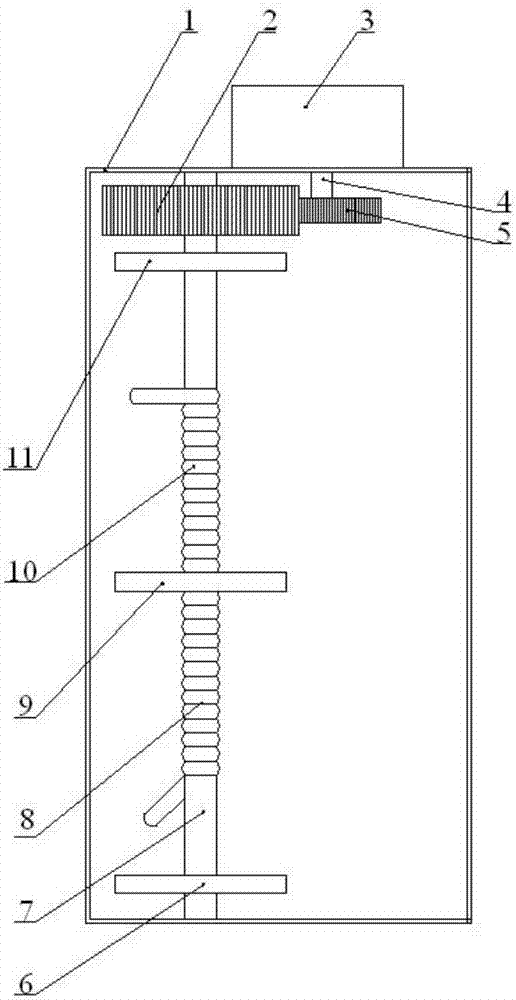

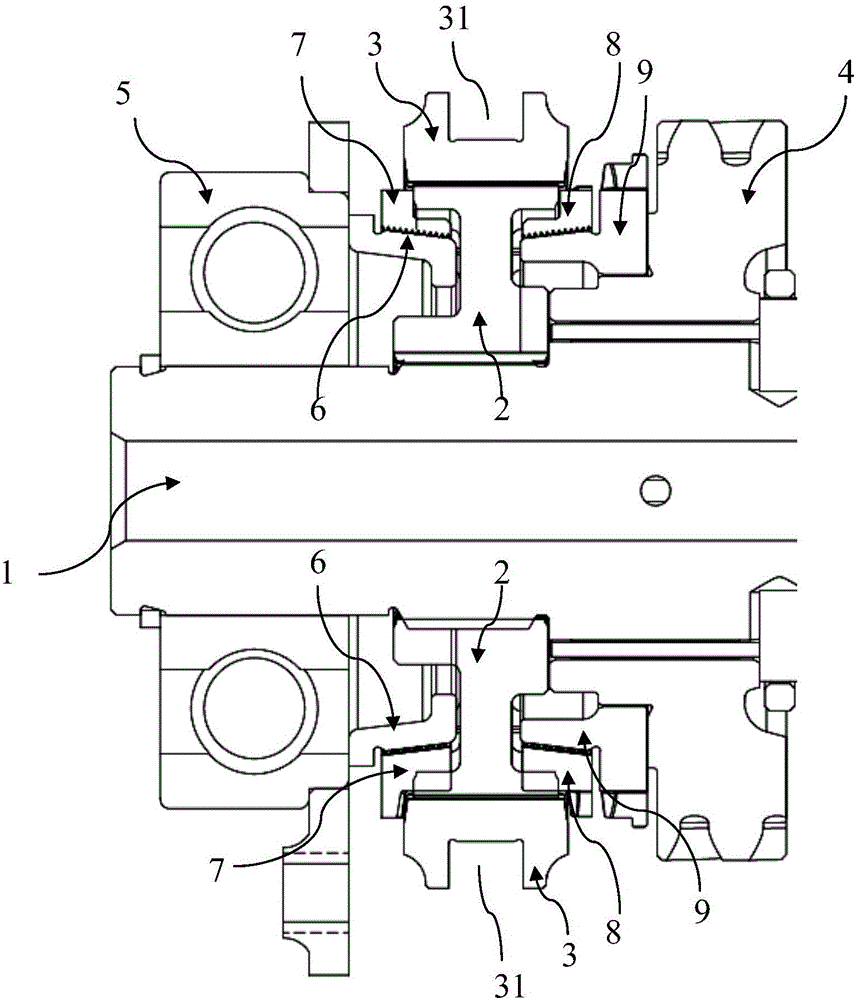

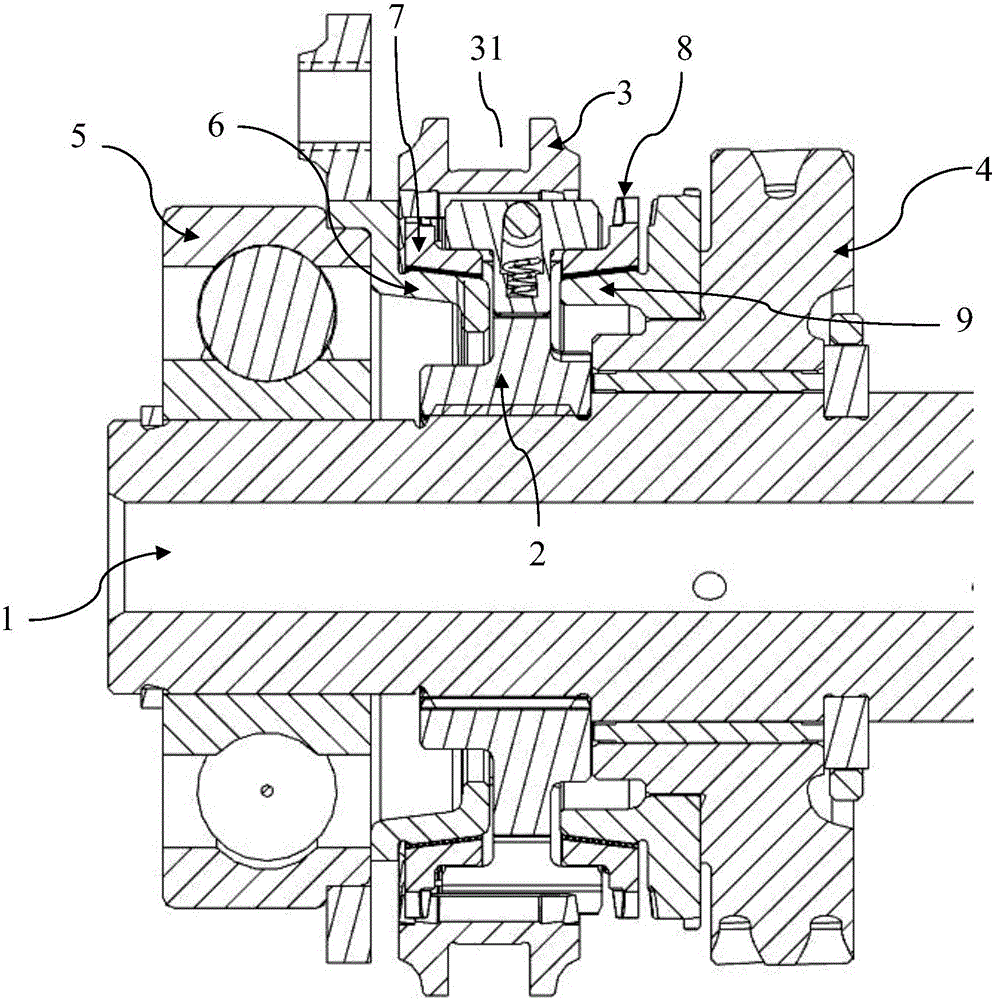

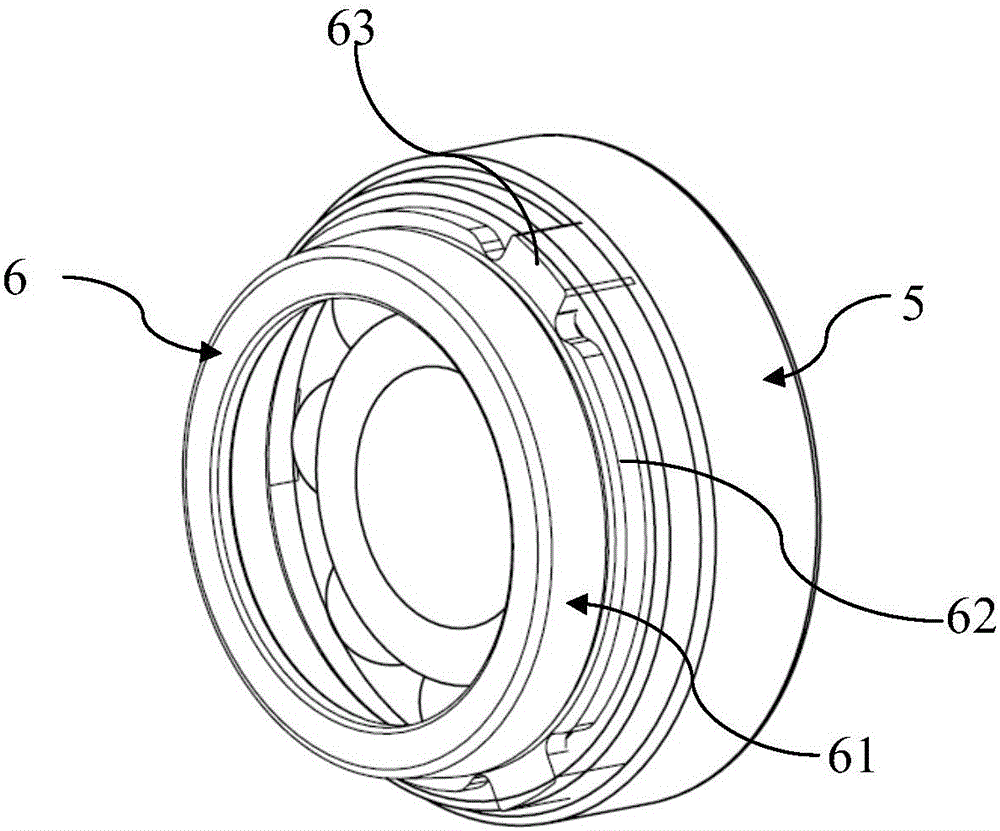

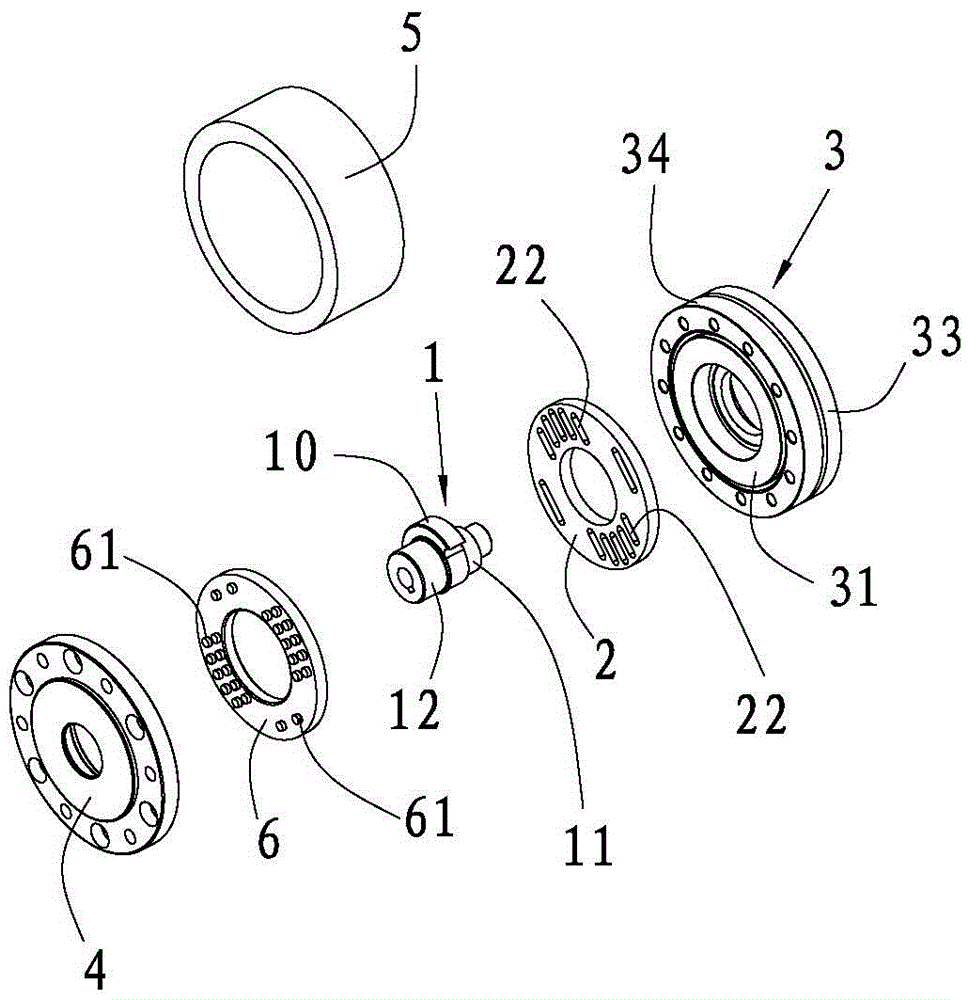

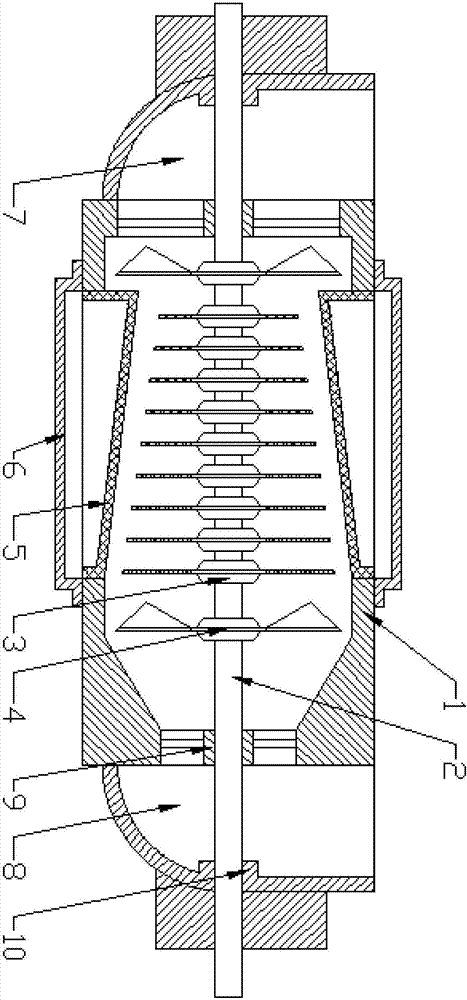

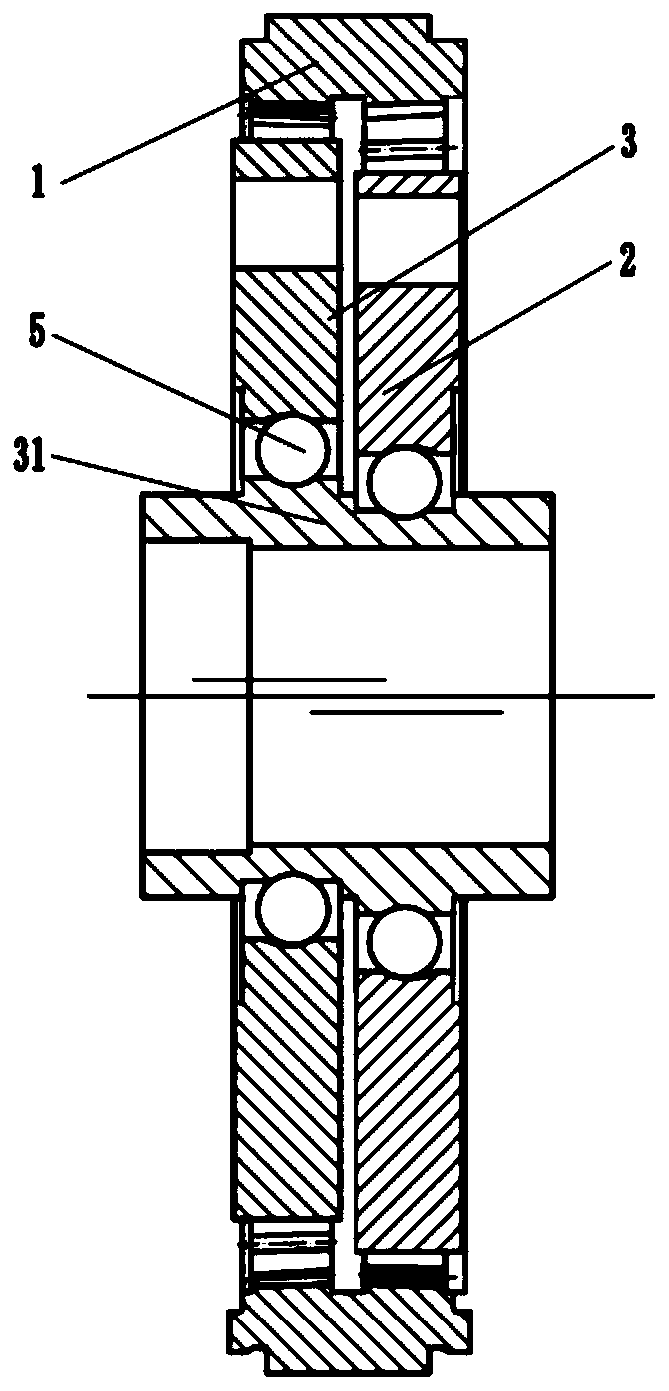

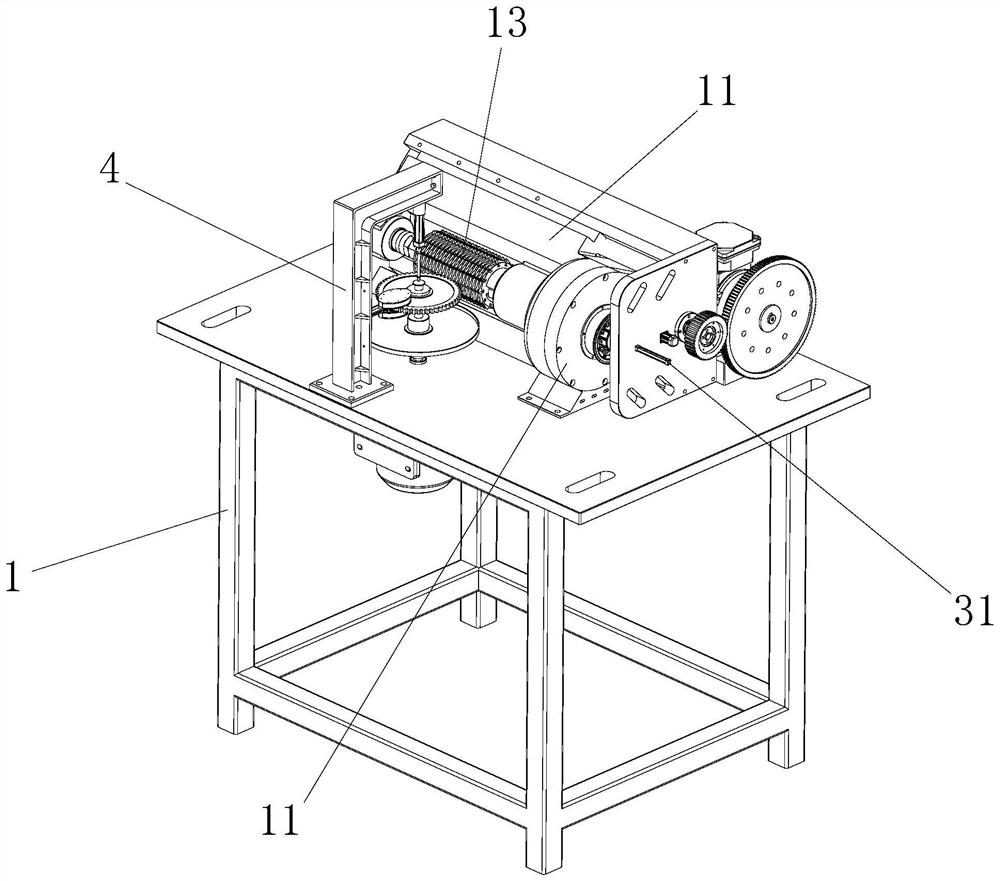

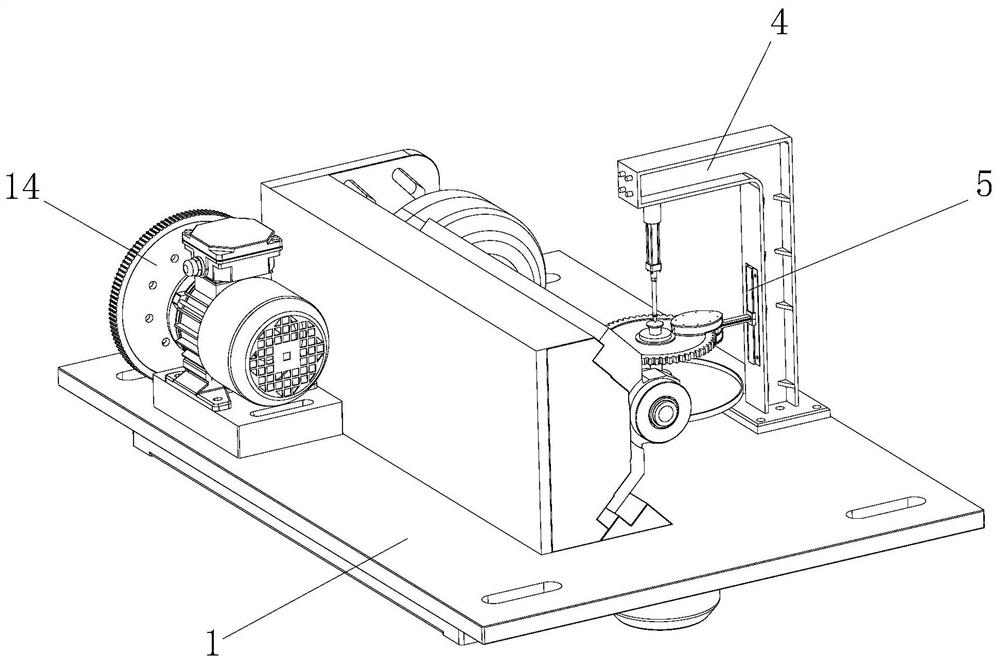

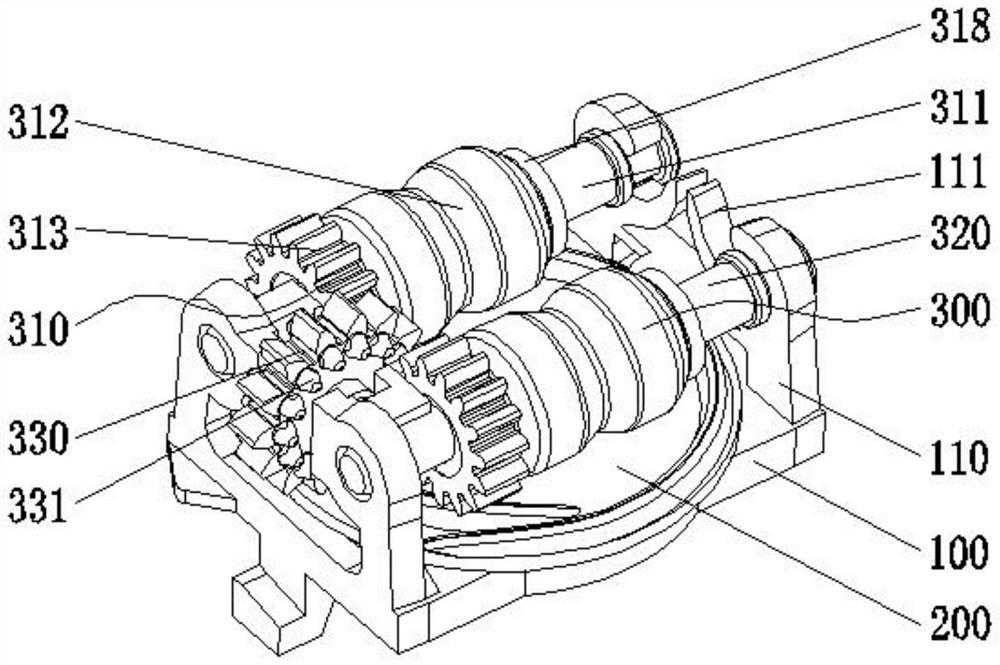

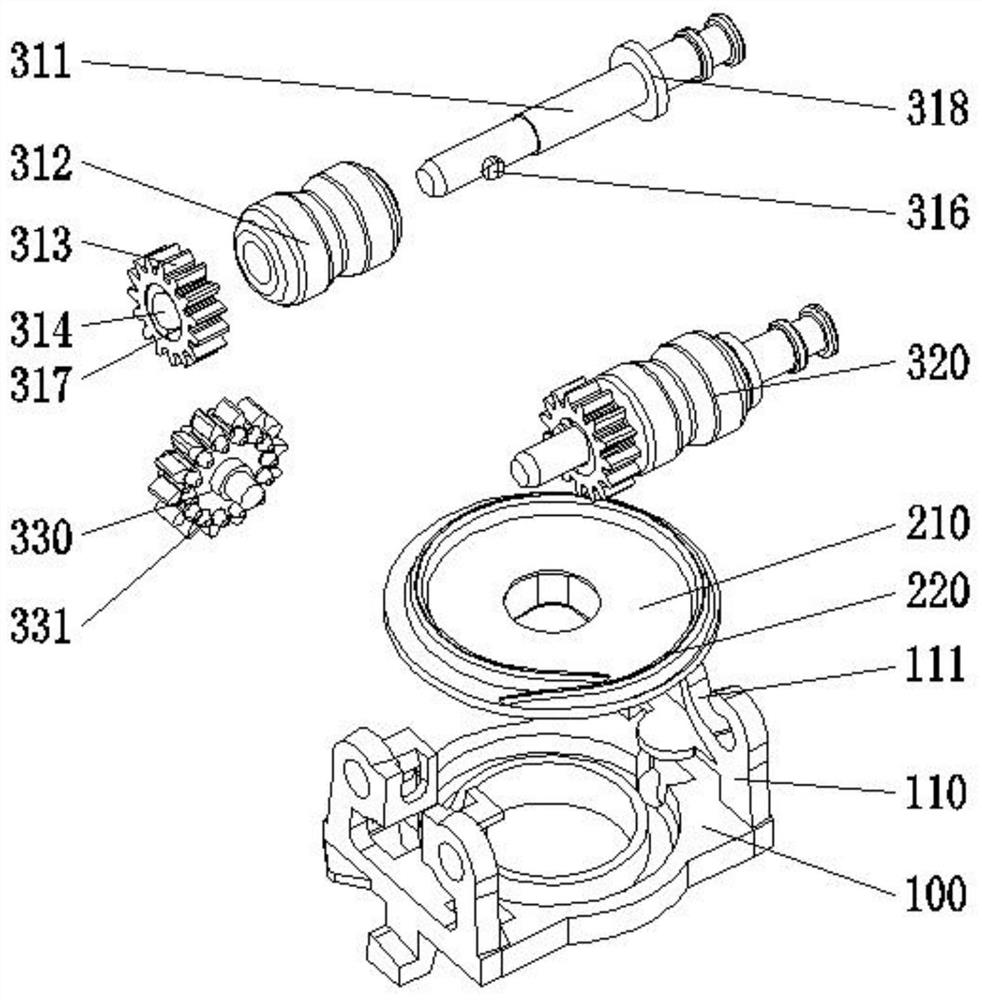

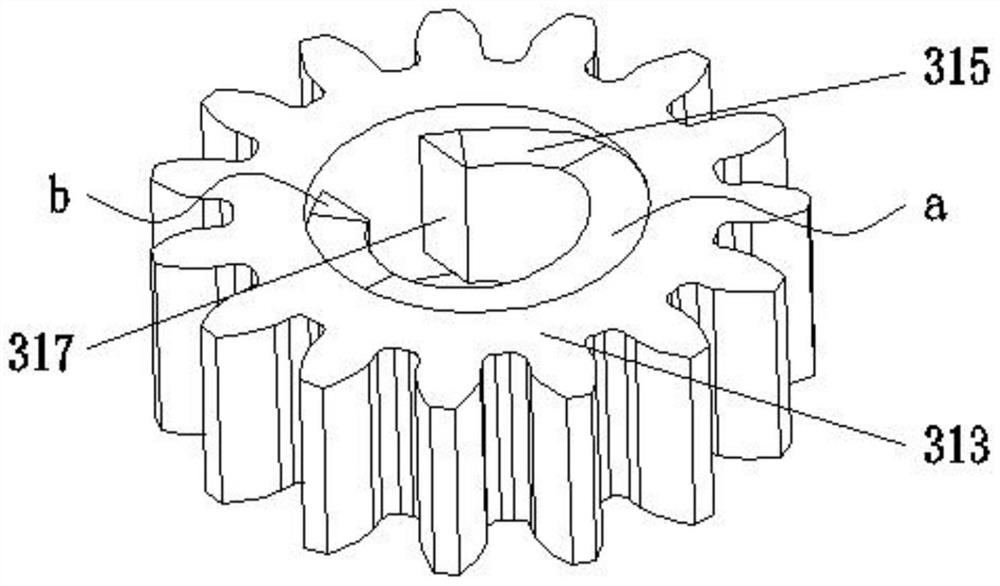

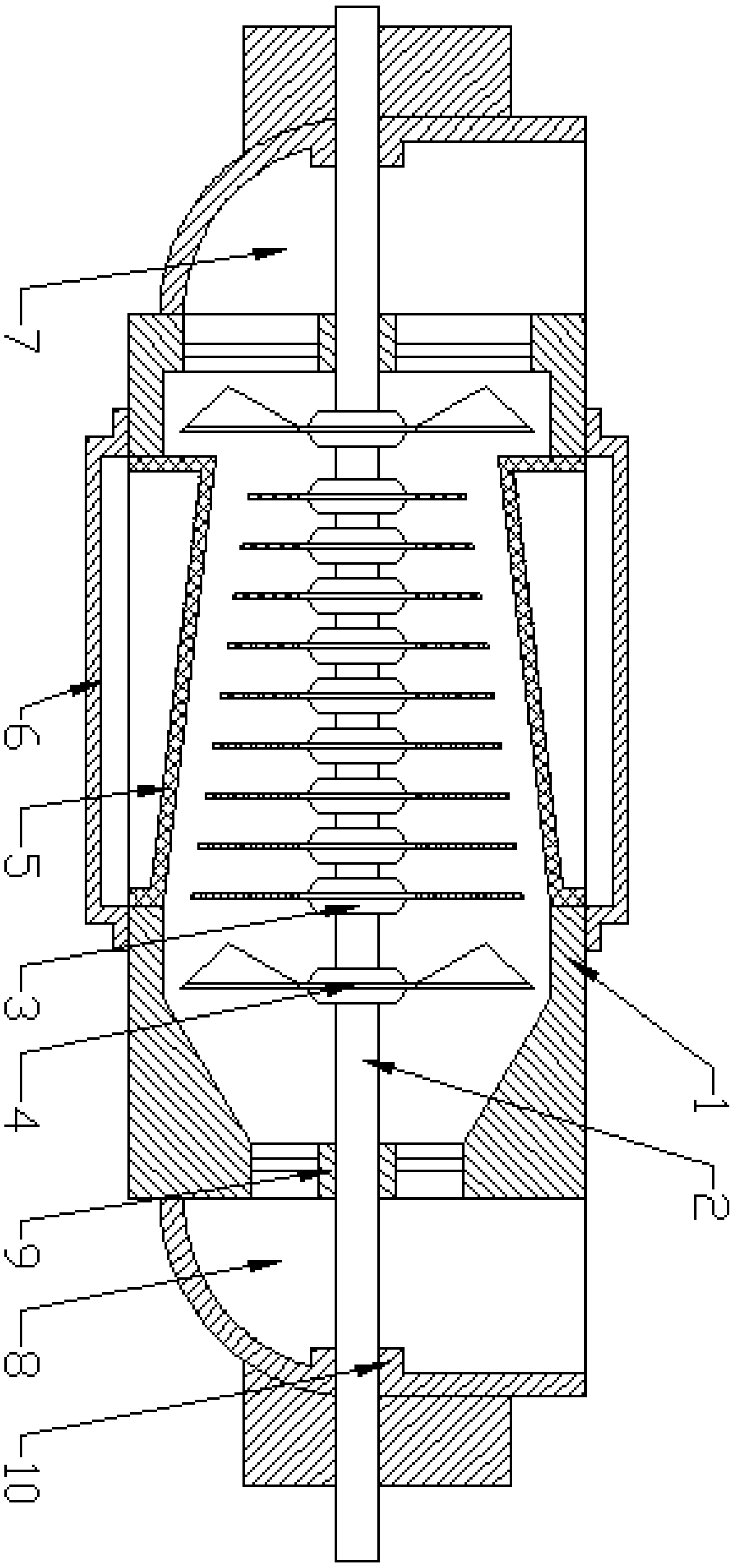

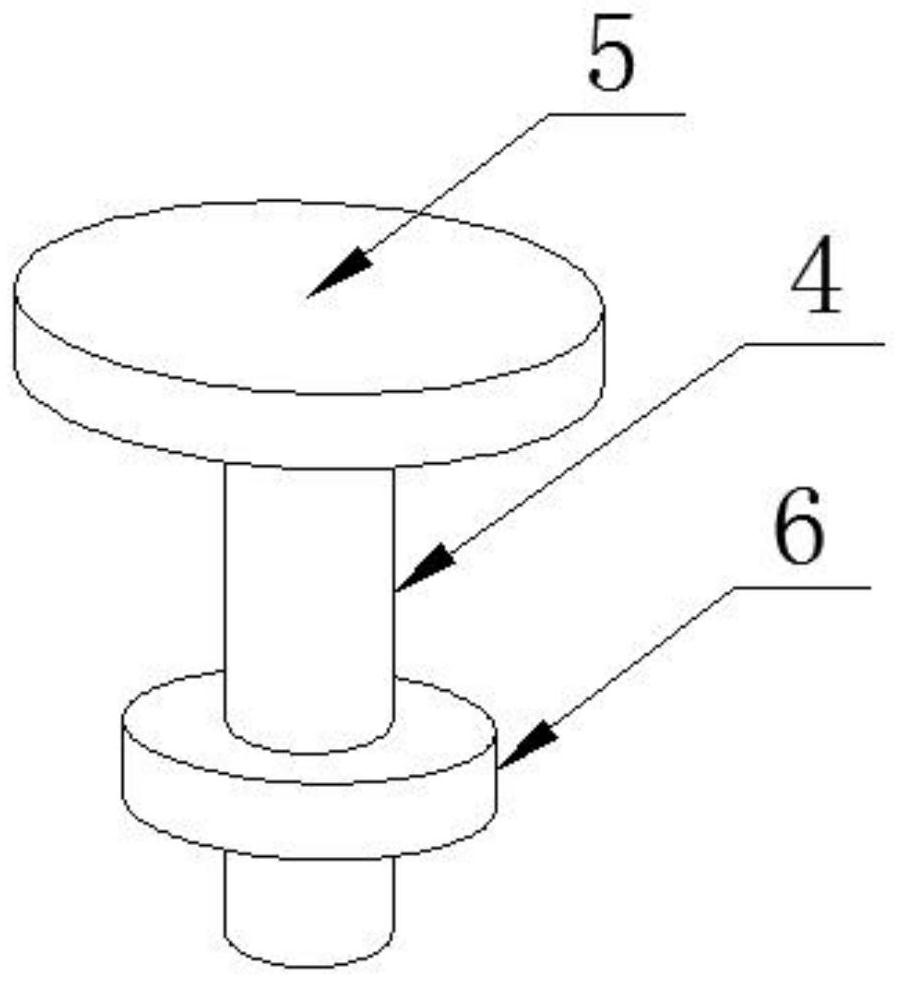

Ball reducer

ActiveCN105626800ADeceleration achievedReduce frictionFriction gearingsRolling resistanceReduction drive

The invention relates to the technical field of reducers, and particularly discloses a ball reducer. The ball reducer comprises a shaft body. The shaft body comprises a mounting part and an eccentric part connected with the mounting part. The eccentric part is provided with a drive disc. The mounting part is provided with an output disc. The output disc comprises an inner ring, an outer ring and a plurality of balls. The mounting part is sleeved with the inner ring. The inner ring is sleeved with the outer ring. The multiple balls are arranged between the inner ring and the outer ring. A hypocycloid ring groove is formed in the side, close to the inner ring, of the drive disc. An epicycloid ring groove is formed in the side, close to the drive disc, of the inner ring. A plurality of roll balls are arranged between the hypocycloid ring groove and the epicycloid ring groove. During actual application, the shaft body of the ball reducer is connected with a motor, the inner ring serves as an output shaft, movement is transferred through rolling of the roll balls, and speed reduction on the motor is achieved; and rolling friction during rolling of the roll balls is smaller than friction during engagement of gears in a traditional gear reducer, the loss is small, and the transmission efficiency is greatly improved.

Owner:佛山市力普鑫精密技术有限公司

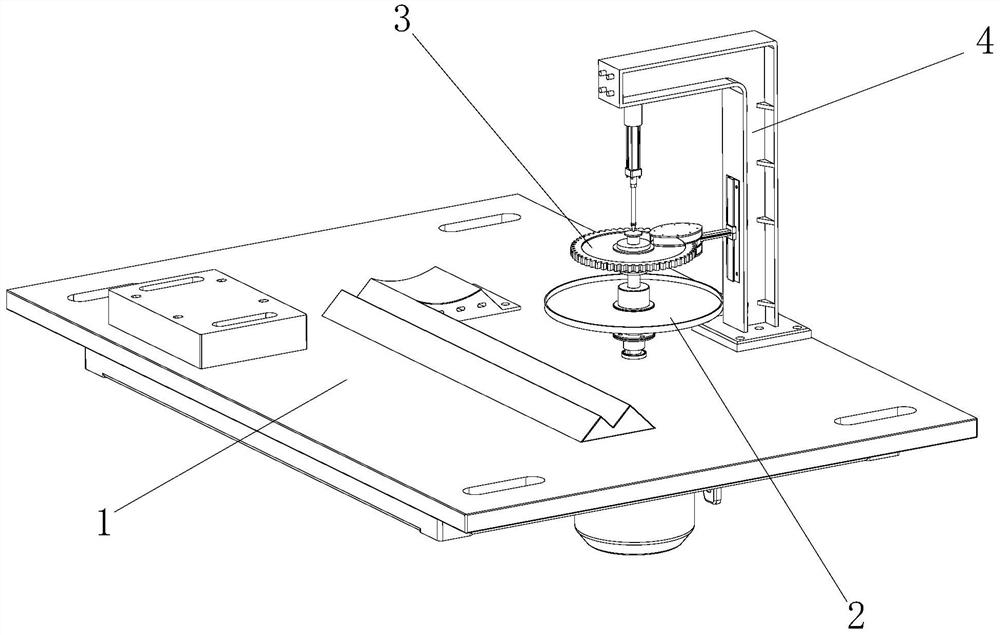

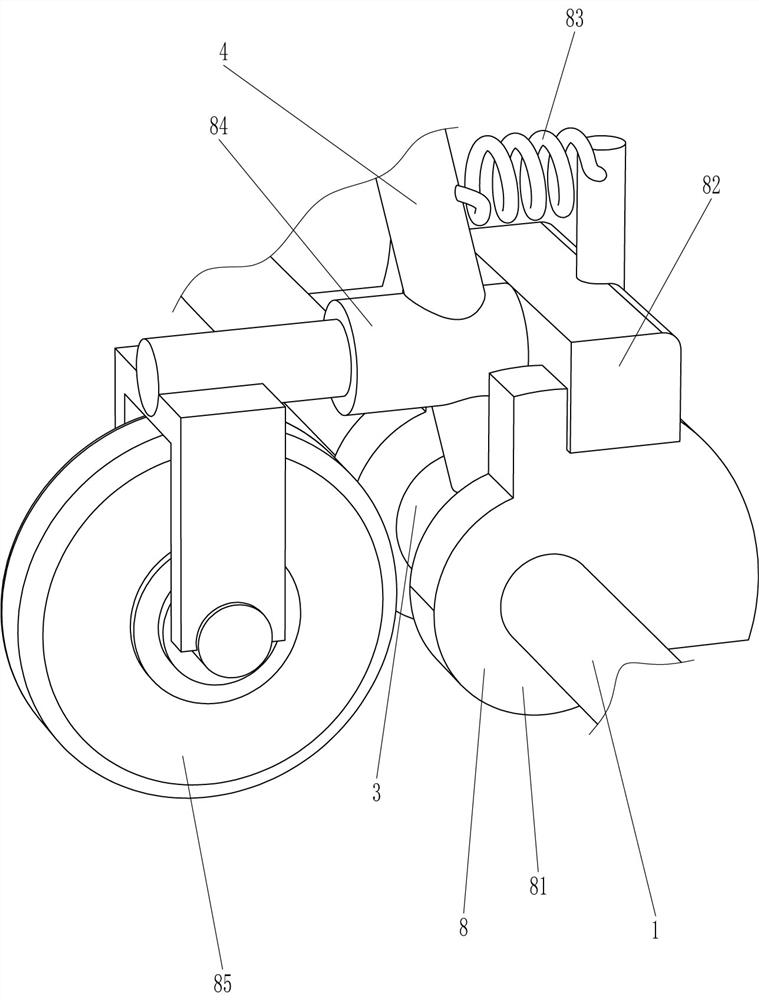

Locking mechanism for rotating of pneumatic index plate and using method of locking mechanism

ActiveCN112676917ASmall moment of inertiaAct as a cooling effectPrecision positioning equipmentGrinding work supportsInertia forceEngineering

The invention relates to the field of pneumatic index plates, in particular to a locking mechanism for rotating of a pneumatic index plate and a using method of the locking mechanism. The locking mechanism comprises a base, a supporting column is fixed to the base, the supporting column is arranged in the vertical direction, the index plate is arranged at the upper end of the supporting column, the center of the bottom face of the index plate is rotationally connected to the supporting column through a rotary disc bearing fixed shaft, a decelerating mechanism is arranged on the bottom face of the index plate, a locking mechanism body is arranged on the supporting column, the decelerating mechanism can be in transmission connection with the locking mechanism body, a cooling mechanism is arranged on the locking mechanism body, and the locking mechanism body is in transmission connection with the cooling mechanism. According to the locking mechanism for rotating of the pneumatic index plate and the using method of the locking mechanism, the index plate is decelerated through the decelerating mechanism in the stopping process of the index plate, deceleration of the index plate is achieved, impact of inertia force on a toothed plate when the index plate is stopped is reduced, the service life is prolonged, the locking mechanism body is driven by the decelerating mechanism to lock the index plate when the index plate is kept static, and the index plate is ensured to be locked and not to rotate when being stopped.

Owner:吴天乐

Integrated device for friction power generation and braking of bicycle

InactiveCN102774467ADeceleration achievedOptical signalMechanical energy handlingVehicle frameFriction force

The invention discloses an integrated device for friction power generation and braking of a bicycle, belongs to a brake technology of bicycles and particularly belongs to a technology of bicycle brake and power generation using brake friction forces. According to the device, an external rotating type generator is arranged at a hollow position at an opening end of a concave fixing frame, an internal stator of the external rotating type generator is fixedly connected with the opening end of the concave fixing frame, an external rotor of the external rotating type generator is located at a position close to a bicycle tyre, the side wall of the concave fixing frame is slidingly connected with a frame of the bicycle, and an elastic braking device is fixed at a bottom edge of the concave fixingframe. The device has the advantages that one set of devices are used for achieving speed reduction, braking and power generation, and energy which is used for achieving speed reduction and braking of the bicycle is converted into electric energy for recycling.

Owner:黄甜雪

Petroleum screening device

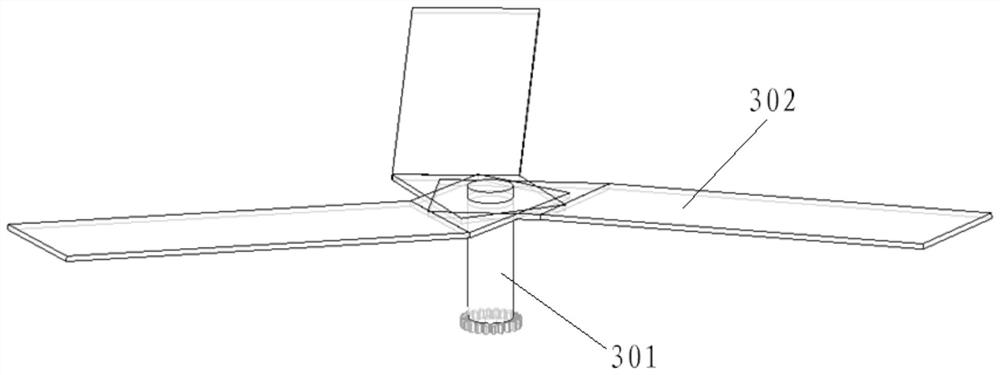

ActiveCN107090304AAchieve captureEasy to driveRefining by filtrationMoving filtering element filtersImpellerPetroleum

The invention relates to a petroleum screening device. The petroleum screening device comprises a circular-tube-shaped screening device body, wherein a screening hole channel is formed in the screening device body; a feeding pipe and a discharging pipe, which are communicated with the screening hole channel, are arranged at two transverse ends of the screening device body; the middle part of the screening device body is rotatably connected with a rotary shaft; a plurality of filtering impellers are arranged through the rotary shaft in an annular array; in a filtering impeller array, the diameter of the filtering impeller close to one side of the feeding pipe is relatively small and the diameter of the filtering impeller close to one side of the discharging pipe is relatively great; each filtering impeller comprises a rotary table which is fixedly connected with the rotary shaft; filtering blades are arranged on the rotary tables in the annular array; each filtering blade comprises a sector-shaped outer frame and each outer frame is internally provided with a capturing net; a certain included angle is formed between the plane on which each outer frame is located and the plane on which the corresponding rotary table is located.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

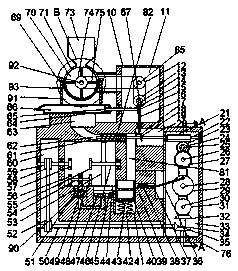

Tobacco filler processing equipment and operating method thereof

InactiveCN108685153AIncrease profitSimple structureTobacco preparationTobacco treatmentEmbedded system

The invention discloses tobacco filler processing equipment comprising a main transmission case and a separation box arranged on the main transmission case; the main transmission case is provided witha first transmission cavity with an opening to the left; a second transmission cavity on a lower side of the first transmission cavity is disposed in the main transmission case; a third transmissioncavity located on the right side of the second transmission cavity is disposed in the main transmission case; a fourth transmission cavity located on the left side of the third transmission cavity isdisposed in the main transmission case; a fifth transmission cavity located on the right side of the fourth transmission cavity is disposed in the main transmission case; a front wall of the fifth transmission cavity is provided with a material tank outlet, and the main transmission case is provided with a material tank chamber located on the left side of the fifth transmission cavity and with anopening to the front; the material tank chamber is connected with the fifth transmission cavity, and the main transmission case is provided with a material passing cavity on the upper side of the fifth transmission cavity.

Owner:项侠风

Transmission device for ditching machine

InactiveCN111102341AEnsure safetyGuaranteed stabilityPlantingFurrow making/coveringStructural engineeringServomotor

The invention discloses a transmission device for a ditching machine, and relates to the technical field of transmission devices for ditching machines. The transmission device comprises a protective cover, a bearing seat and a gearbox, wherein the two ends of the bottom of the bearing seat are each provided with a penetrating hole, a servo motor is fixedly installed on the side of the bearing seat, an input shaft is movably mounted on the other side of the bearing seat, and one end of the input shaft is sleeved with an input belt wheel; and a linkage bevel gear, a variable speed bevel gear anda driven bevel gear are sequentially arranged inside the gearbox from left to right. According to the transmission device for the ditching machine, the collision of an external object to the belt wheel is prevented, the protection of the integrity of the belt wheel is facilitated, and the damage to workers or accidents in the device operation process are avoided; the improvement of the strength and the toughness of the protective cover can be facilitated, the safety and the stability of the transmission device can be ensured, and heat dissipation can be increased; and in addition, a certain dust-proof effect is achieved, and the realization of the speed reduction performance of the transmission device can be facilitated.

Owner:丰县鑫耀机械制造有限公司

Single-crank composite small-tooth-difference speed reducer

InactiveCN110307295ADeceleration achievedRealize the second gear shiftJointsToothed gearingsReduction driveReducer

The invention belongs to the technical field of speed reducers and relates to a single-crank composite small-tooth-difference speed reducer. A first-stage fixed-shaft gear comprises an input gear shaft, an intermediate gear arranged outside the input gear shaft, an intermediate gear fixing sleeve fixed on a left large end cover through a key and a retainer ring and an inner gear sleeve sleeved outside the intermediate gear fixing sleeve. A second-stage small-tooth-difference involute variable-tooth-thickness gear comprises two involute variable-tooth-thickness outer gears and a rigid disc, wherein the two involute variable-tooth-thickness outer gears are sleeved outside an inner gear sleeve in a parallel rotating mode, the involute variable-tooth-thickness outer gears are sleeved with involute variable-tooth-thickness inner gears, and clearance adjusting devices are arranged between the involute variable-tooth-thickness outer gears and the inner gear sleeve. Single-crank integrated bearing design and involute variable-tooth-thickness gear transmission are adopted in gear transmission, the number of transmission components is reduced, the tooth side clearance of a gear pair in the meshing process is reduced through the clearance adjusting device, and the precision, the bearing capacity and the service life of the speed reducer are improved.

Owner:CHONGQING UNIV

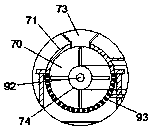

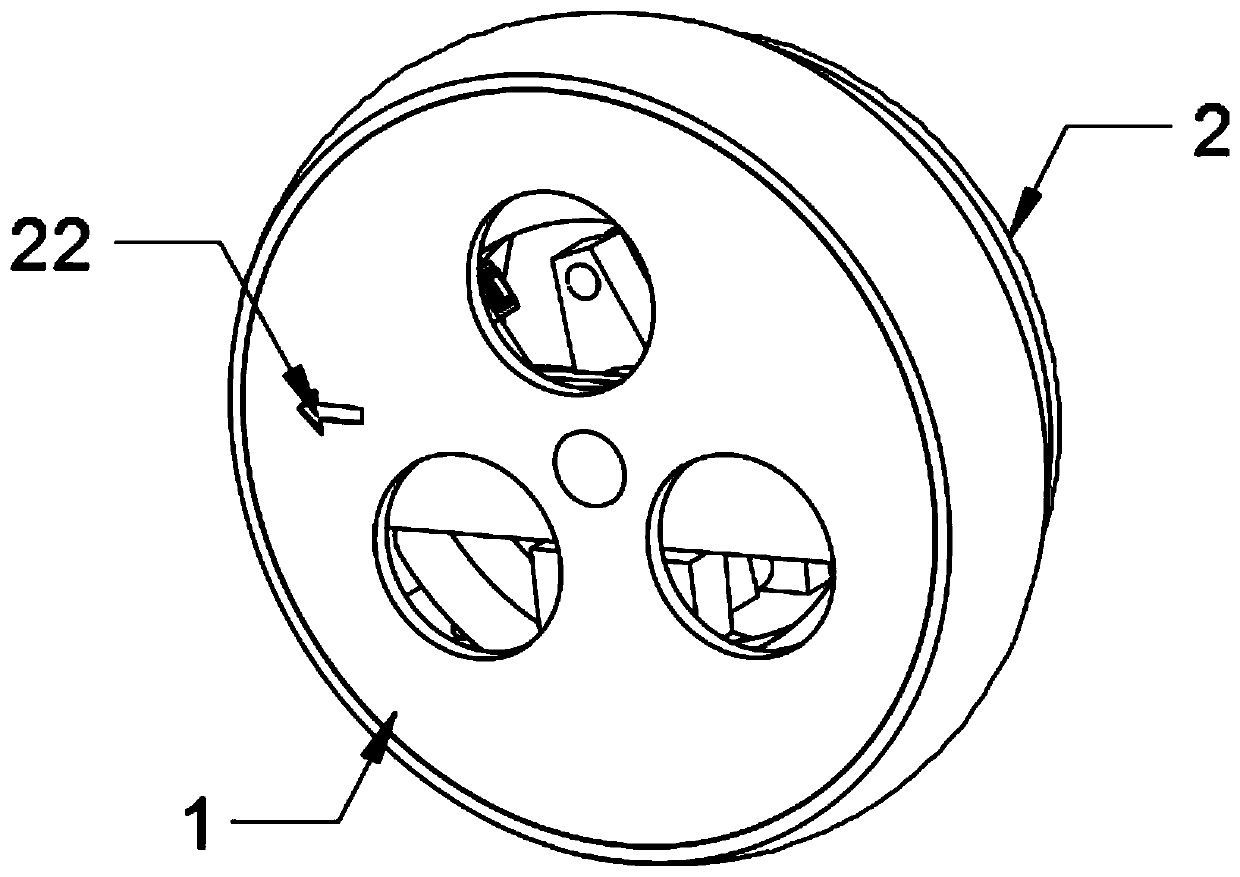

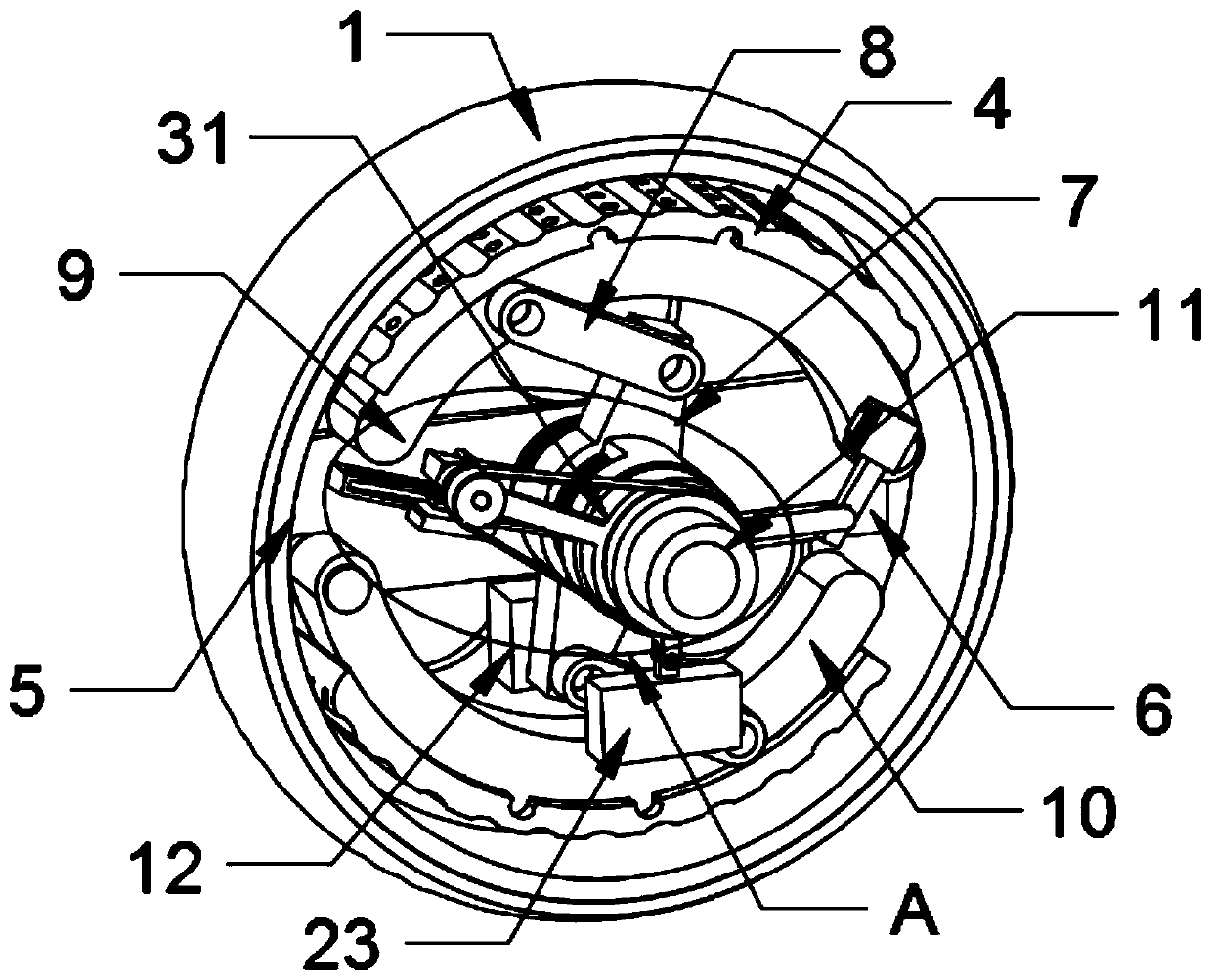

Wheel for automatically controlling speed of hand-pulled forklift

ActiveCN111231572ASimple structureDeceleration achievedBraking element arrangementsSelf acting brakesControl theoryMechanical engineering

The invention discloses a wheel for automatically controlling the speed of a hand-pulled forklift. The wheel comprises a wheel body, a protective cover is mounted on one side of the wheel body; a fixed shaft is integrally connected in the wheel body; the end part of the fixed shaft penetrates through the protective cover; an axis hole is formed in one end, outside the protective cover, of the fixed shaft; a wheel assembly mark is arranged on the other side of the wheel body; a rim is mounted on the inner wall of the wheel body; a positioning frame is mounted on the inner wall of the wheel body; a first friction shoe and a second friction shoe are respectively mounted at two ends of the positioning frame; the first friction shoe and the second friction shoe are symmetrically arranged; friction plates are connected to the outer sides of the first friction shoe and the second friction shoe; the fixing shaft penetrates through the positioning frame, a first balancing weight is installed atthe bottom of the positioning frame, the outer side of the fixing shaft is rotationally connected with a rotating frame through an ejector pin bearing, the outer side of the rotating frame is symmetrically and integrally connected with protruding plates, and the wheel is simple in overall structure and can automatically activate a speed reducer according to the rotating speed of the wheel to achieve the purpose of controlling the vehicle speed.

Owner:浙江新昌博时汽车配件有限公司

Adjustable gear hobbing device for gear machining

ActiveCN114192895AGuaranteed cleanlinessReduce detection errorMeasurement/indication equipmentsDriving apparatusHobbingBrake

The invention relates to the field of gear hobbing machines, and discloses an adjustable gear hobbing device for gear machining, which comprises a mounting table and a to-be-machined gear, and the mounting table is provided with a bearing mechanism capable of driving the to-be-machined gear to rotate and lift and a forming hobbing used for hobbing the to-be-machined gear. The detection assembly can perform flaw detection on the outer wall of the gear to be machined by adopting an ultrasonic flaw detection technology, and can also obtain the gear forming condition in a backlight projection mode to detect the gear hobbing shape of the gear; an arc-shaped sealing gasket attached to the upper side and the lower side of the gear to be machined is arranged on one side of the detection assembly, and a braking assembly and a speed reduction assembly are further arranged on the mounting table. Compared with the prior art, the gear hobbing device has the advantages that gear detection errors during gear hobbing are reduced, industrial hazards caused by the fact that defective gears after gear hobbing are put into use are avoided, the time delay influence caused when defective gears appear can be reduced, abrasion of the brake assembly and the main shaft is relieved, the overall practicability of the device is improved, and the service life of the device is prolonged.

Owner:TAIZHOU LIHUA GEAR MFG

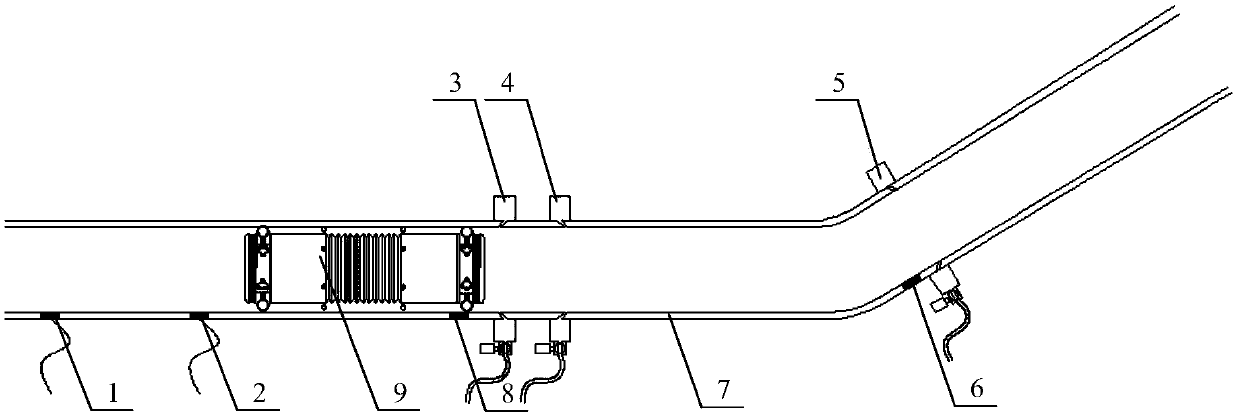

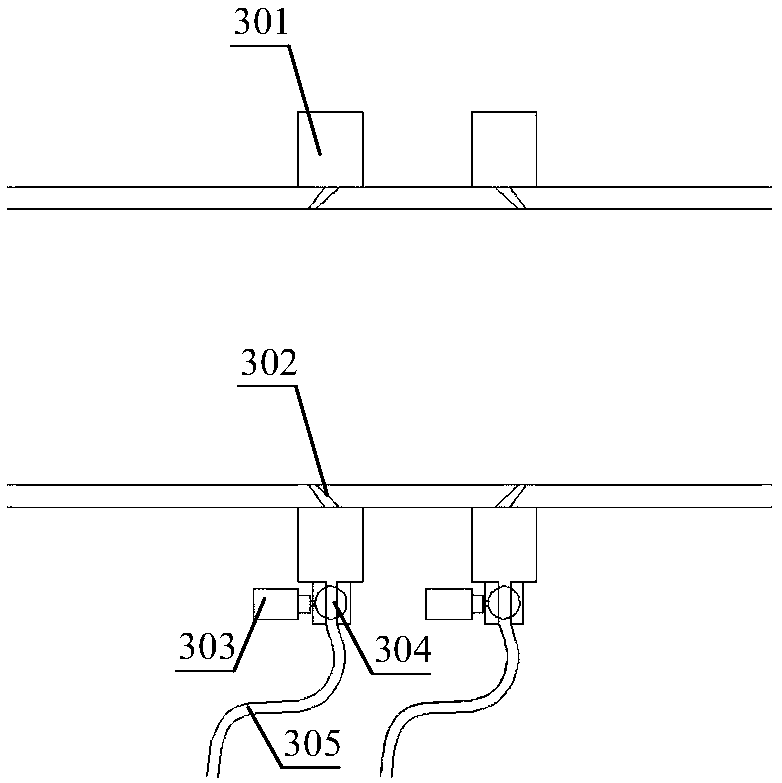

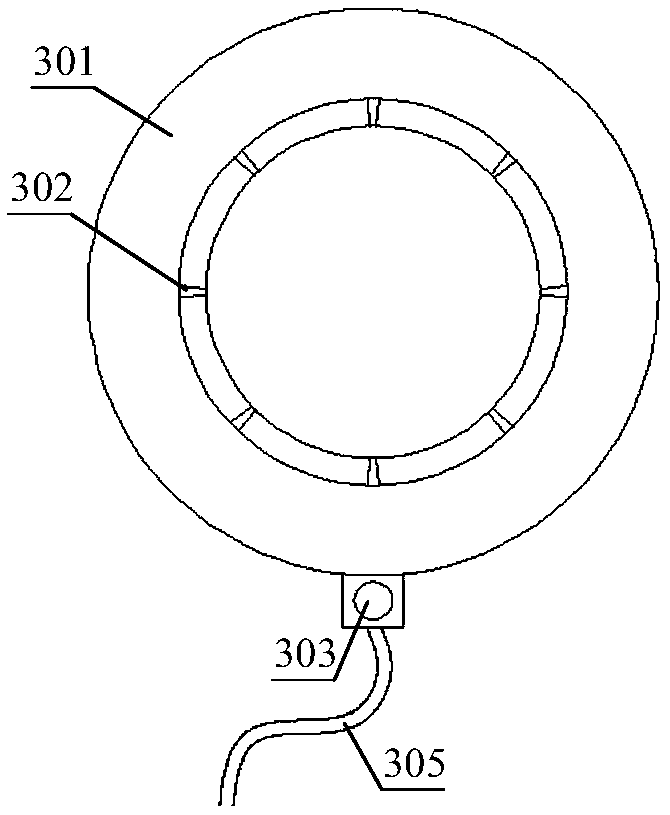

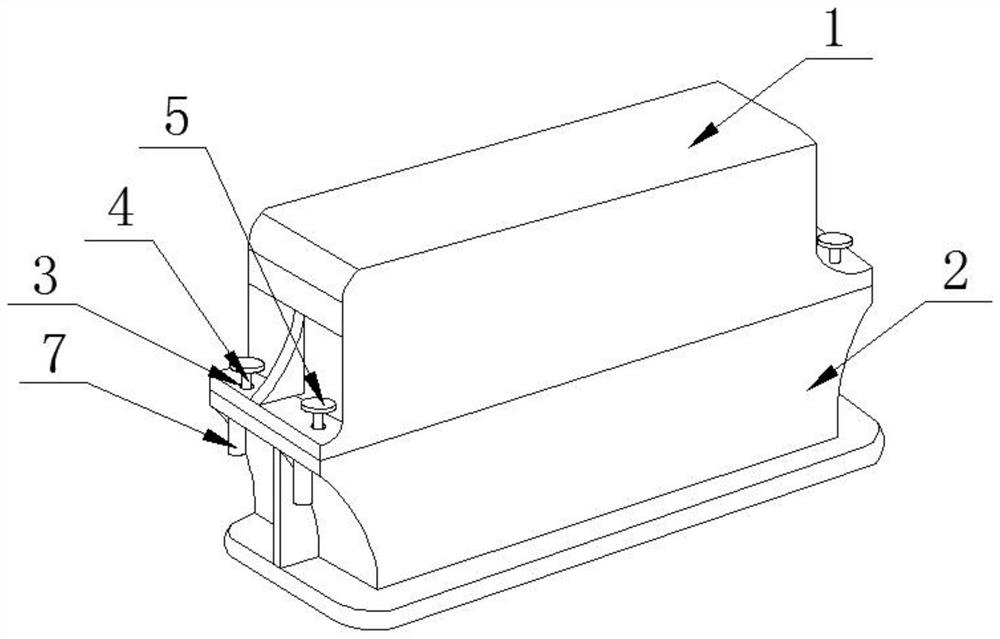

Cold-chain logistics pipeline pneumatic acceleration and deceleration system and method thereof

The invention discloses a cold-chain logistics pipeline pneumatic acceleration and deceleration system. The cold-chain logistics pipeline pneumatic acceleration and deceleration system is characterized in that acceleration and deceleration units are included, the acceleration and deceleration units are arranged in the front parts, on pipeline sections requiring acceleration and deceleration, in the middle of a cold-chain transmission pipeline (7), and that is, facing one sides of running cold chain assemblers (9); the same acceleration and deceleration unit is provided with diagonal air holesfacing opposite directions, and the diagonal air holes are formed in the pipe wall of the cold-chain transmission pipeline (7) correspondingly to conduct intermediate air injection acceleration or deceleration on the corresponding cold-chain assembler (9) passing through the acceleration and deceleration unit. According to the cold-chain logistics pipeline pneumatic acceleration and deceleration system and a method thereof, the cargo transportation process can be smoother, the good quality of cargoes is ensured; and meanwhile, the transmission distance of pipeline transportation is increased,and application and promotion are easier.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Pencil feeding structure of pencil sharpener

The invention provides a pencil feeding structure of a pencil sharpener. A pencil feeding assembly comprises a first rotating shaft assembly and a second rotating shaft assembly, wherein the first rotating shaft assembly and the second rotating shaft assembly match and linked with a driving piece through a synchronous transmission piece, the first rotating shaft assembly comprises a rotating shaft, the pencil feeding assembly further comprises a soft pencil feeding wheel with elastic restoring force, the soft pencil feeding wheel is arranged on the rotating shaft and synchronously moves with the rotating shaft, the pencil feeding assembly further comprises a linkage piece, the linkage piece is provided with a shaft hole for allowing the rotating shaft to penetrate through, the linkage piece is arranged on one side of the rotating shaft in a sleeve mode and can rotate and axially move relative to the rotating shaft, an adjusting slope is arranged on the side wall of the shaft hole of the linkage piece, correspondingly, a radial protrusion is arranged on the side, penetrating through the linkage piece, of the rotating shaft, a gear is controlled to drive the soft pencil feeding wheel to feed a pencil or the gear to idle by changing the frictional resistance between the gear and the soft pencil feeding wheel, and therefore the problem that after a pencil is sharpened, a pencil feeding mechanism still feeds the pencil, and consequently a pencil core is broken is solved.

Owner:温州千里目文具有限公司

City road surface cleaning device

The invention discloses an urban road surface cleaning device. A card slot is provided on the sidewalls on both sides of the road. The card slot is opened straight along the direction of both sides of the road. A guide rail is embedded in the card slot. A movable plate is installed between the guide rails on both sides. At least two hanging holes are provided on one side of the movable plate. A dragging mechanism is hung in the hanging hole, and one end of the dragging mechanism is fixed to the hanging hole. The other end is hung on the vehicle, and the lower end surface of the movable plate is provided with a cleaning surface, which is inclined, and the cleaning surface is arranged on the lower end surface away from the end of the hanging hole. The invention has a simple structure, can quickly clean the road surface, and the movable plate can be used as a mobile speed reduction belt. When the vehicle encounters the moving movable plate, it can realize the deceleration of the vehicle. On the road, it can be used as a speed bump while achieving fast cleaning, killing two birds with one stone.

Owner:杨小玲

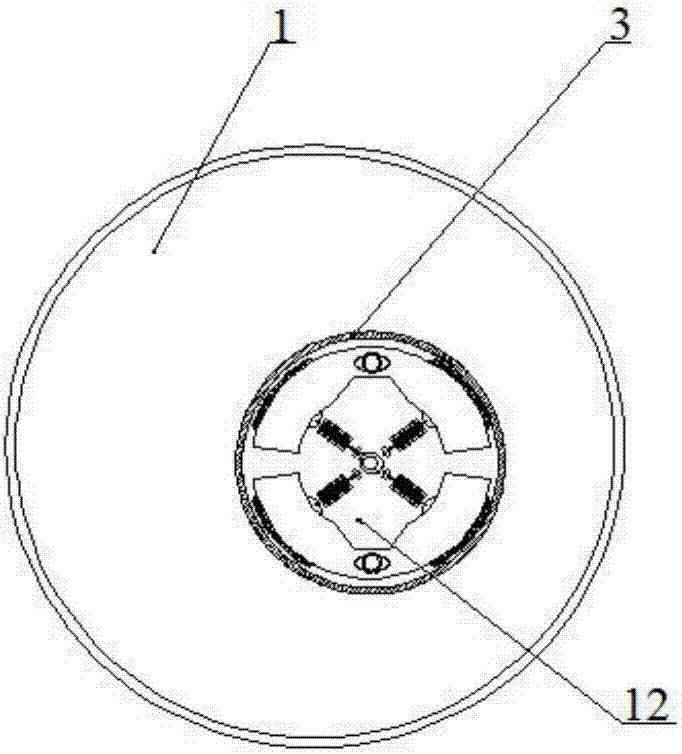

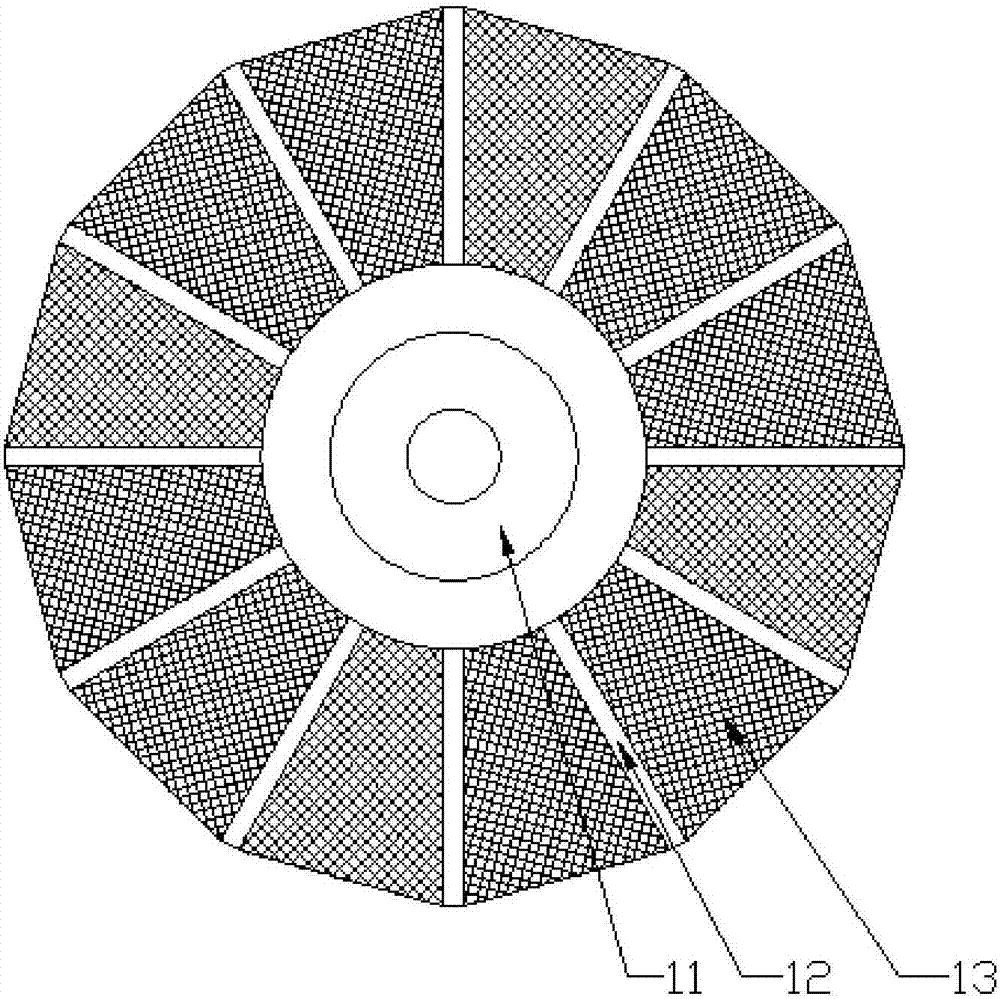

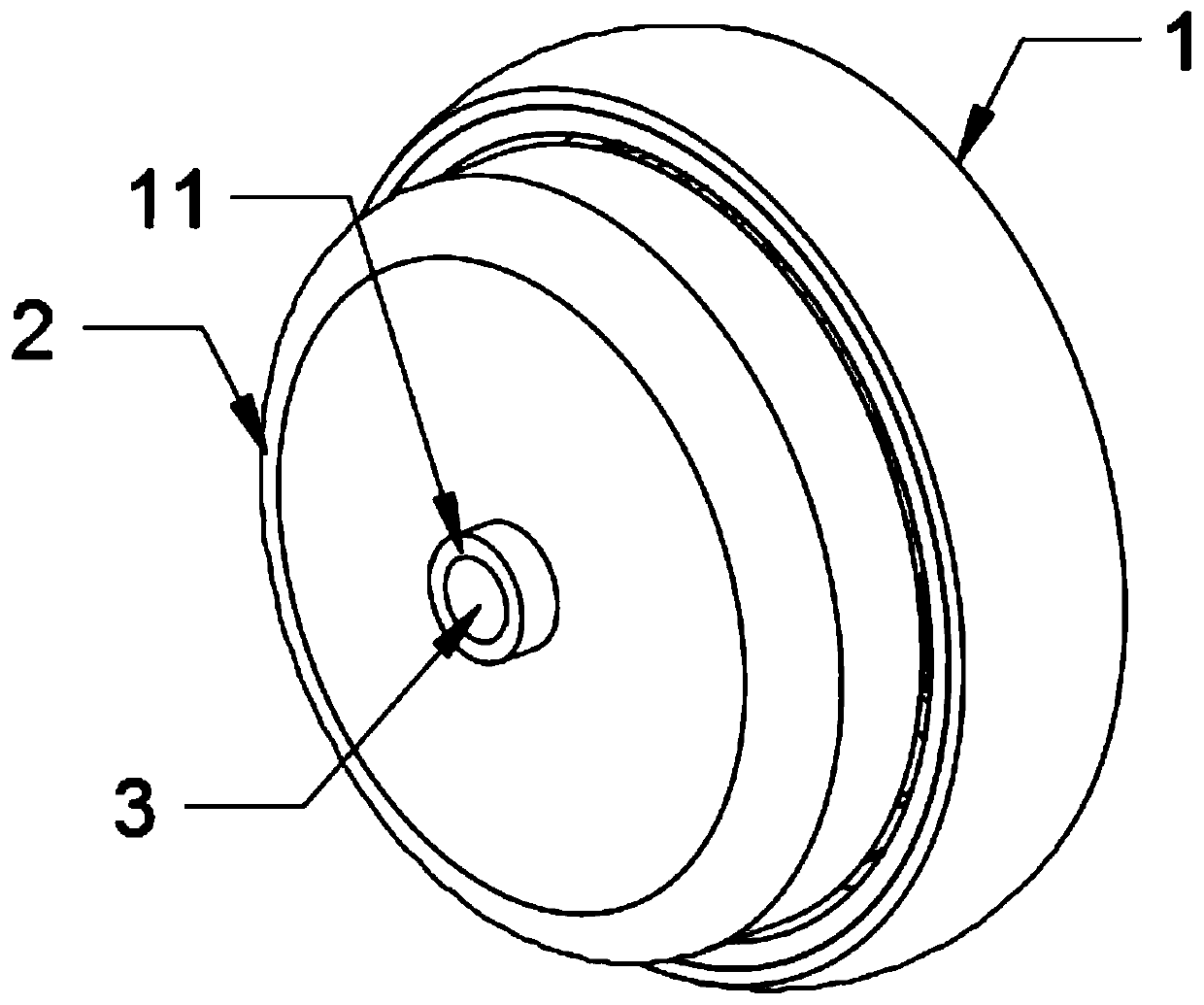

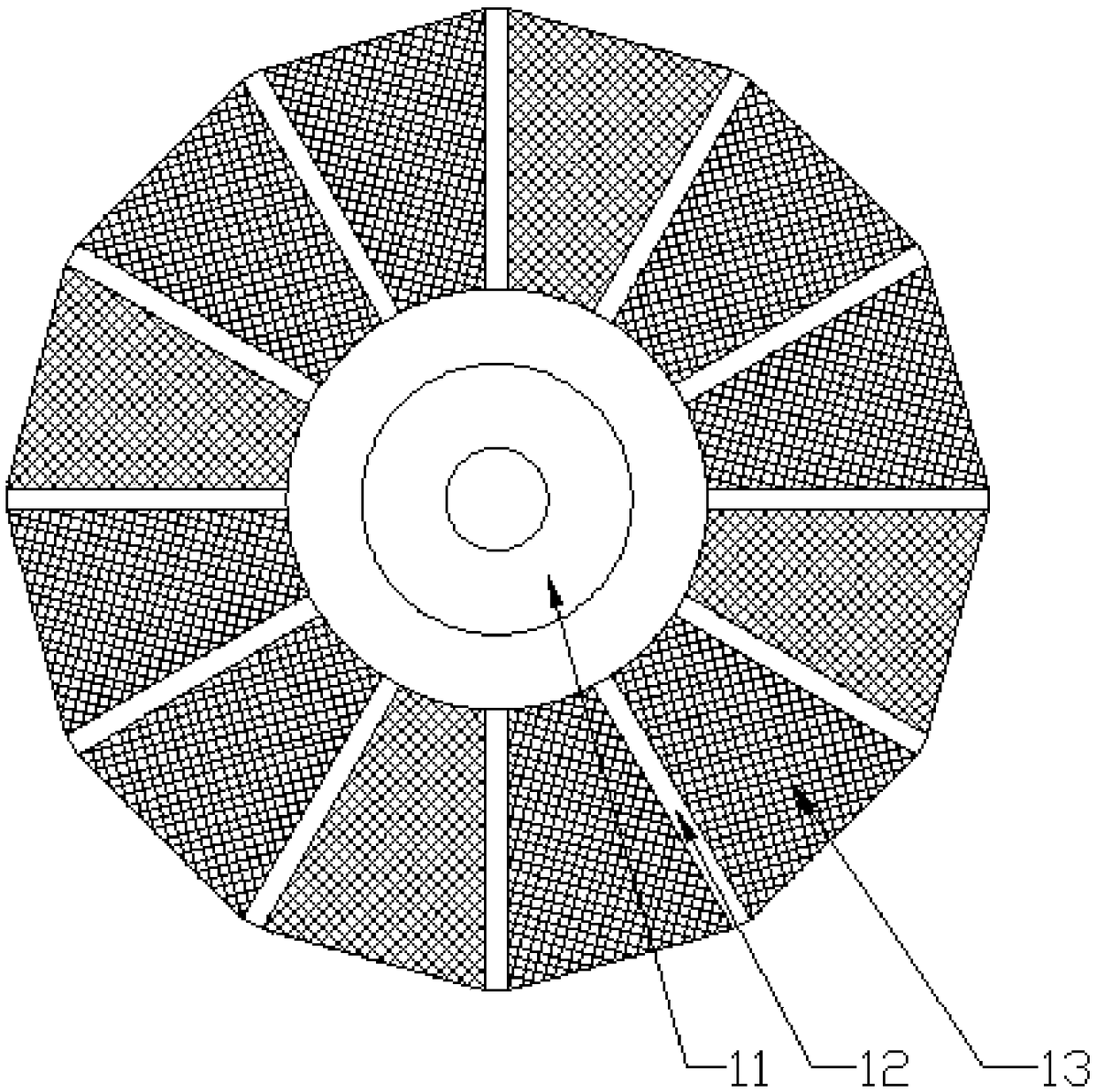

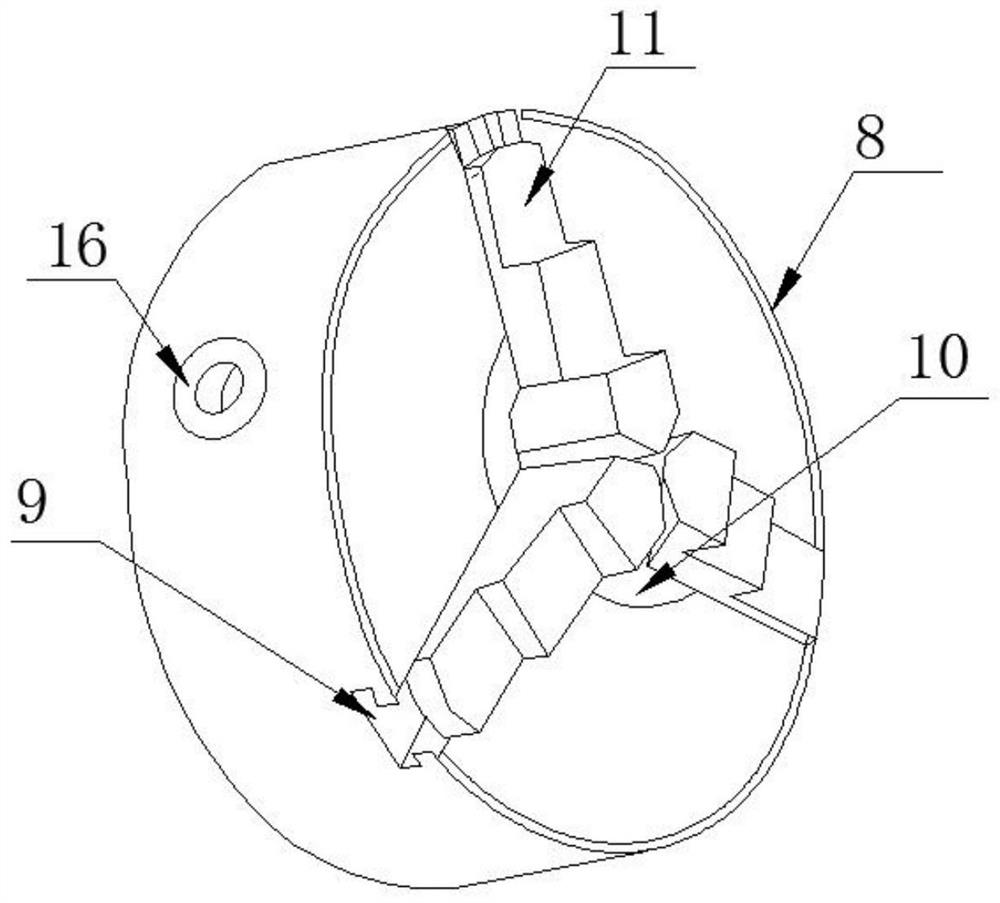

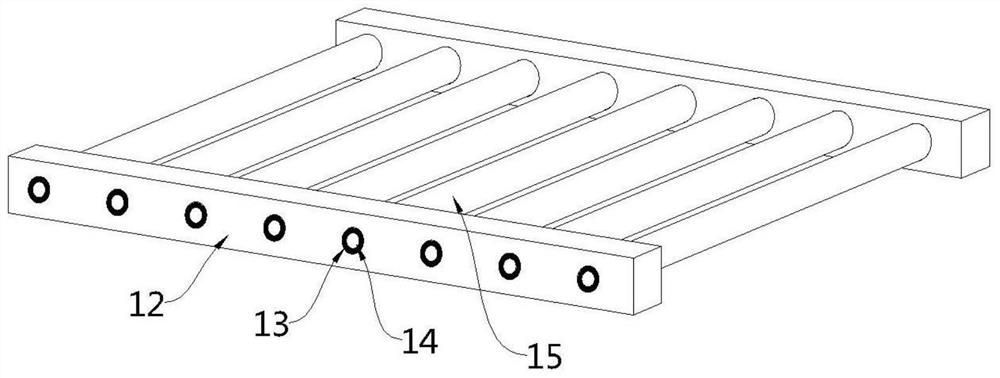

oil sieve

ActiveCN107090304BAchieve captureEasy to driveRefining by filtrationMoving filtering element filtersImpellerEngineering

A petroleum screener, comprising a tubular screener body; a rotating shaft (2) is rotatably connected to the middle portion of the screener body, and several filtering impellers (3) are provided in an annular array by means of the rotating shaft (2); the filtering impellers (3) comprise a rotary table (11) fixedly connected to the rotating shaft (2), the rotary table (11) being provided with filtering blades, each of the filtering blades comprising a fan-shaped outer frame (12) and a capturing net (13), the plane where the outer frame (12) is located forming a certain angle with the plane where the rotary table (11) is located.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

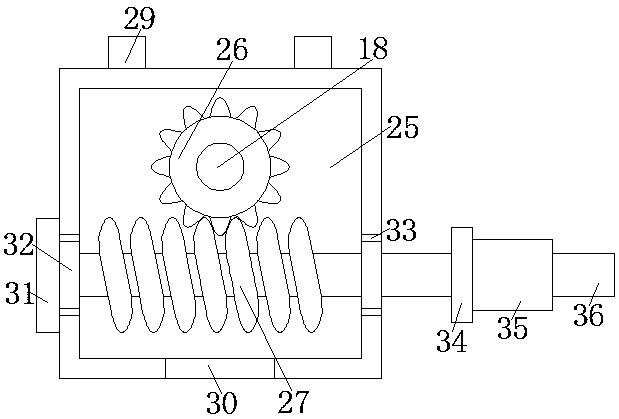

Worm gear reducer convenient to maintain and replace

PendingCN112049918AAchieve fixationEasy to disassemble and fixGearboxesGearing detailsReduction driveEngineering

The invention discloses a worm gear reducer convenient to maintain and replace. The worm gear reducer comprises a box body, the box body is composed of a first shell and a second shell, fixing holes are symmetrically formed in the two ends of the first shell correspondingly, movable rods are arranged in the fixing holes in a penetrating manner, the top ends of the movable rods are connected with pull rings, and the bottoms of the movable rods are sleeved with clamping rings in a clamped manner; fixing assemblies matched with the clamping rings are arranged on the second shell, each fixing assembly comprises a protective cover, the protective covers are connected with the outer wall of the second shell, a plurality of evenly-distributed limiting grooves are formed in each protective cover,and clamping grooves are formed in the ends, close to each other, of the limiting grooves and located in the middles of the protective covers; and clamping jaws matched with the limiting grooves are arranged in the limiting grooves in a sleeved manner correspondingly, and racks are arranged at the bottom ends of the clamping jaws correspondingly. The worm gear reducer has the beneficial effects that the overall design is reasonable, speed reduction of the device can be achieved, and the reducer is convenient to disassemble and maintain.

Owner:许春燕

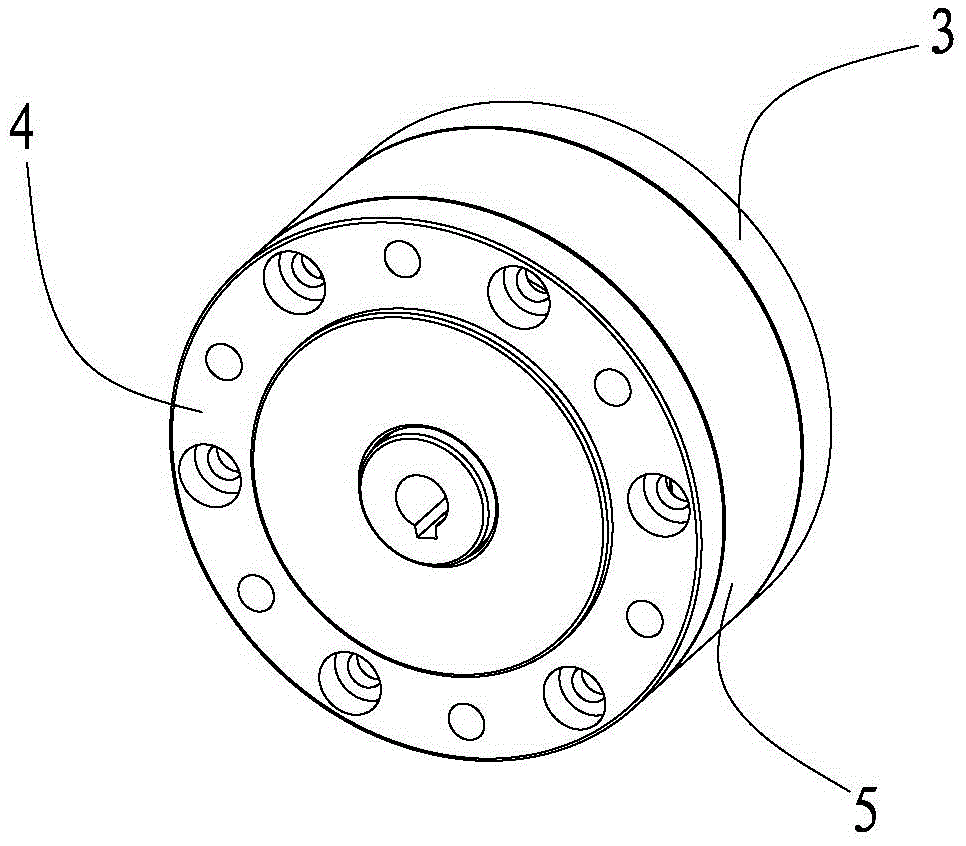

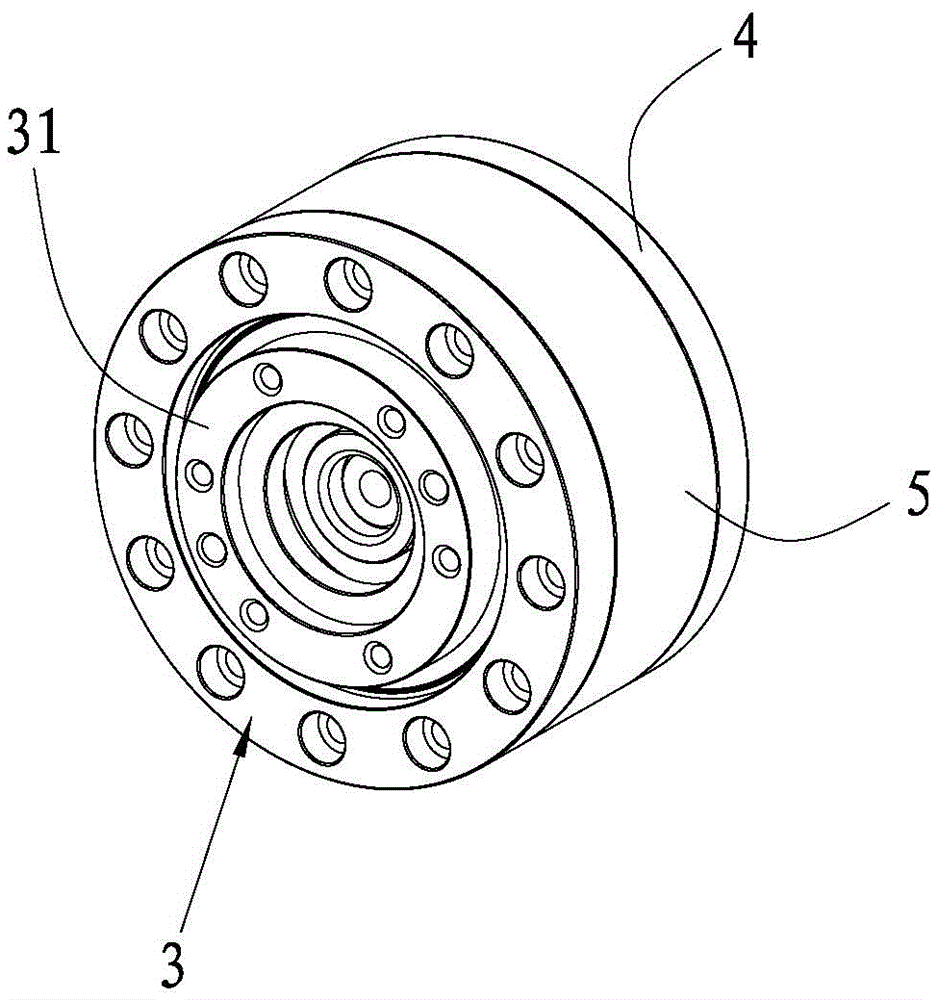

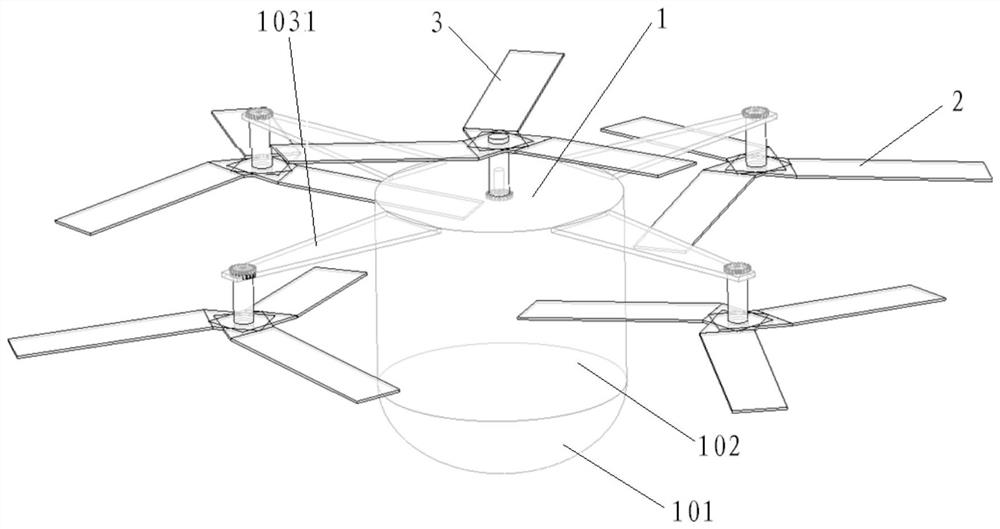

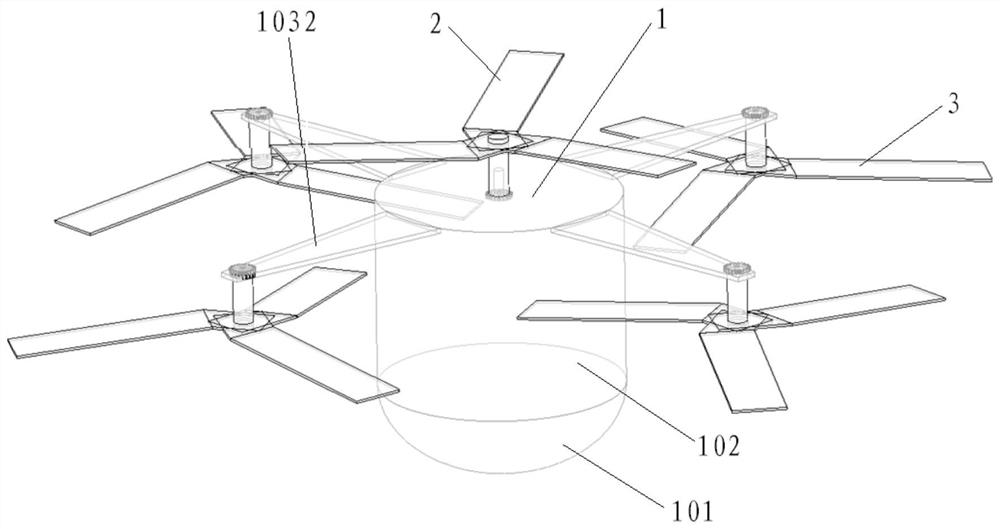

A semi-active rotor type reentry return device

ActiveCN112124637BSlow down reentryDeceleration achievedSystems for re-entry to earthCosmonautic landing devicesFlight vehicleControl theory

Owner:SHANGHAI AEROSPACE SYST ENG INST

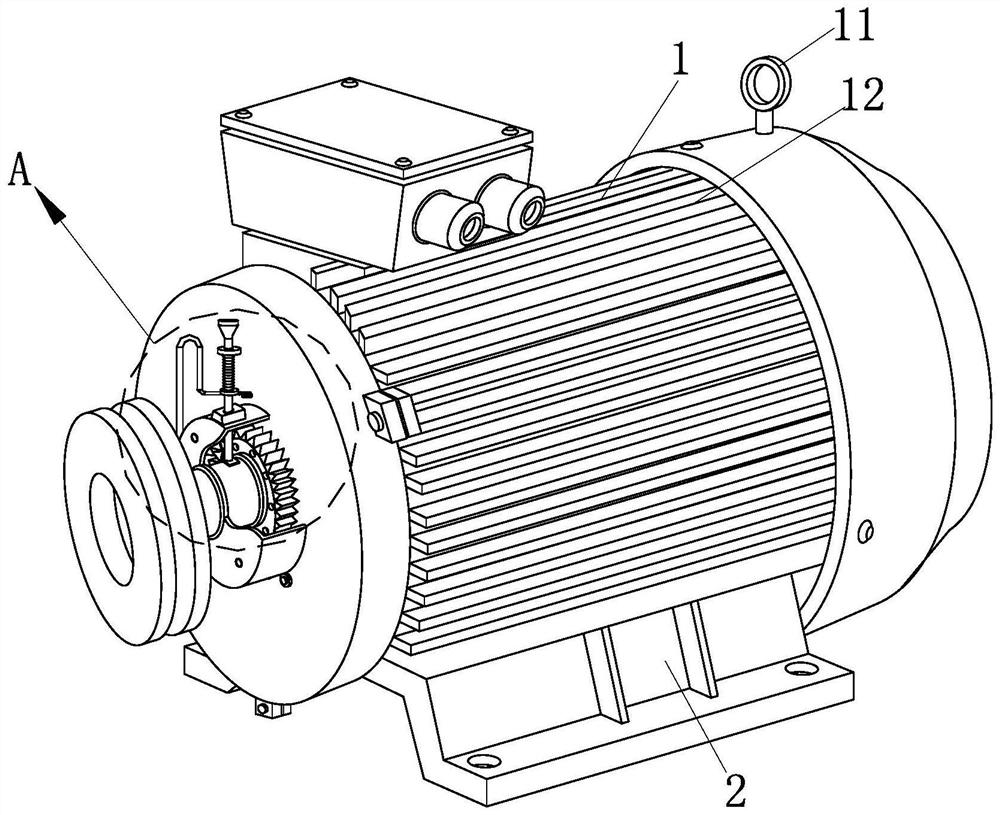

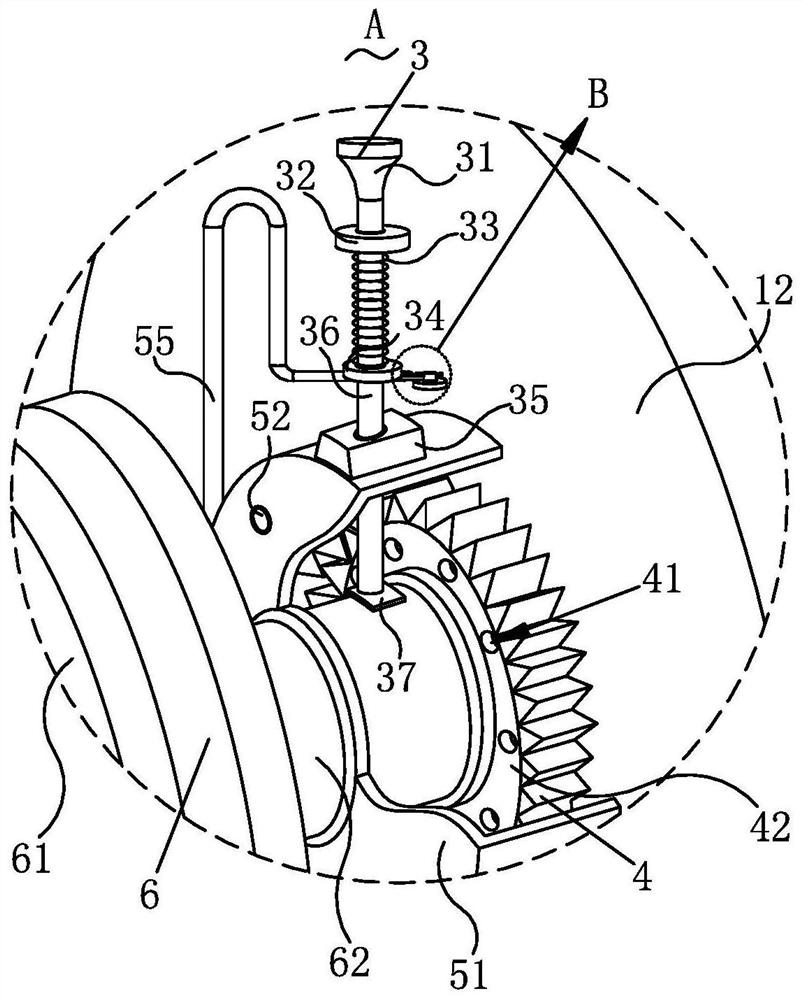

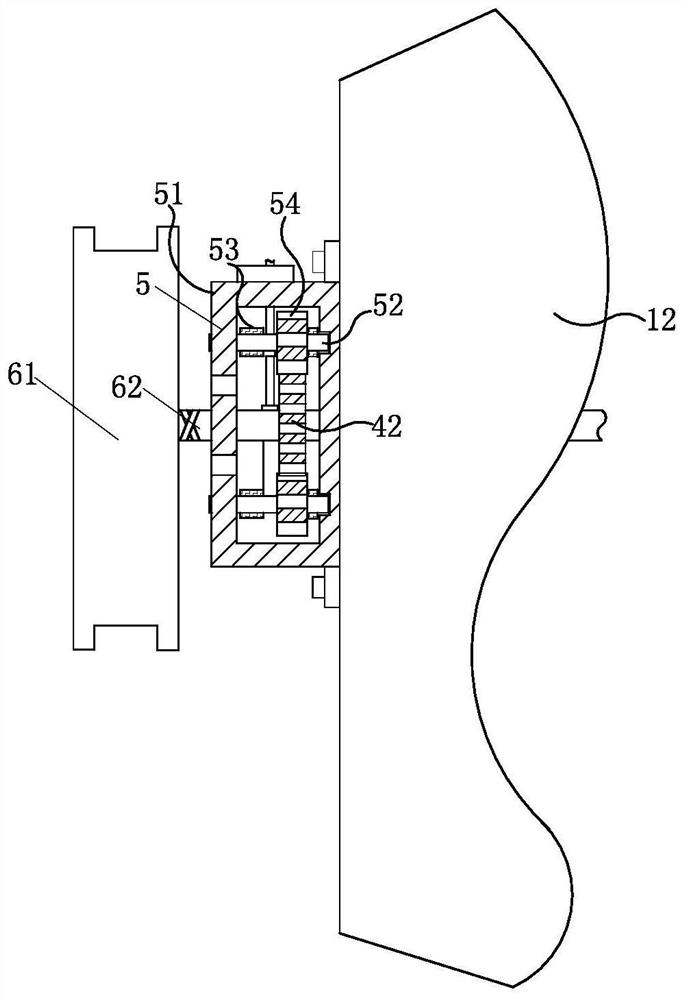

A motor and its motor shaft

ActiveCN110266147BDeceleration achievedEasy to moveMechanical energy handlingCooling/ventillation arrangementCircular discElectric machinery

The invention relates to the field of motors, specifically a motor and its motor shaft, including an engine mechanism, a base, a limit mechanism, a linkage mechanism, a heat dissipation mechanism, a drive mechanism and a push mechanism; One end of the motor body communicates with the air bag on the side wall of the motor body. When the speed of the motor body is too fast and needs to be decelerated, the airflow generated by the fan blade is transported from the air pipe to the inside of the air bag, further realizing The expansion of the airbag pushes the push plate, so that the pulling pin is separated from the disc, and finally the return spring expands the pressing rod to move to the inside of the protective shell, further realizing the The brake pads collide with the motor shaft to brake, decelerate, and protect the motor body. After the motor body drives the motor shaft to rotate, it drives the drive sprocket to rotate. When the pulley drives the equipment that needs to be driven to rotate, the drive sprocket drives The heat dissipation mechanism dissipates heat for the motor shaft.

Owner:无锡港大电机有限公司

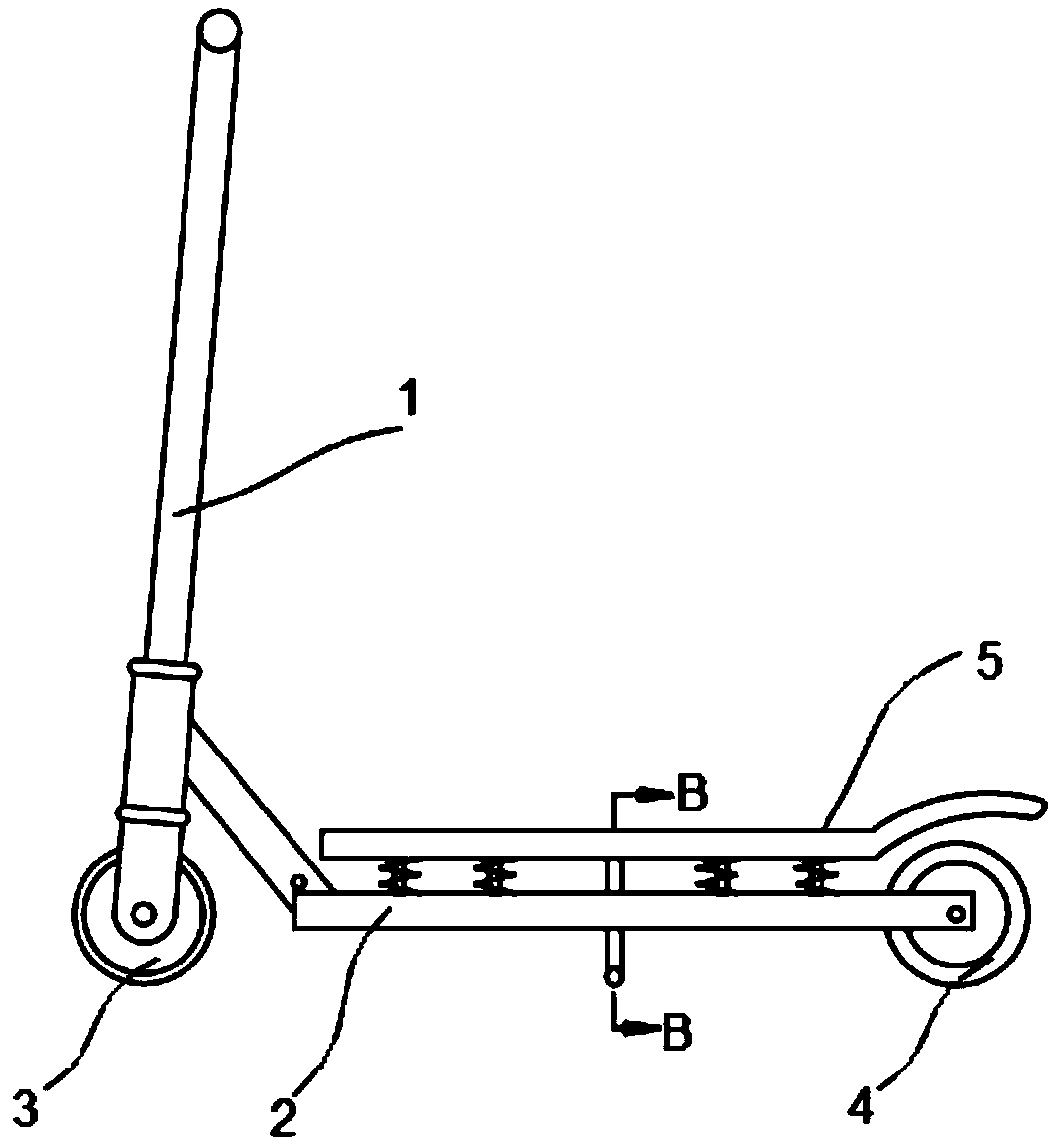

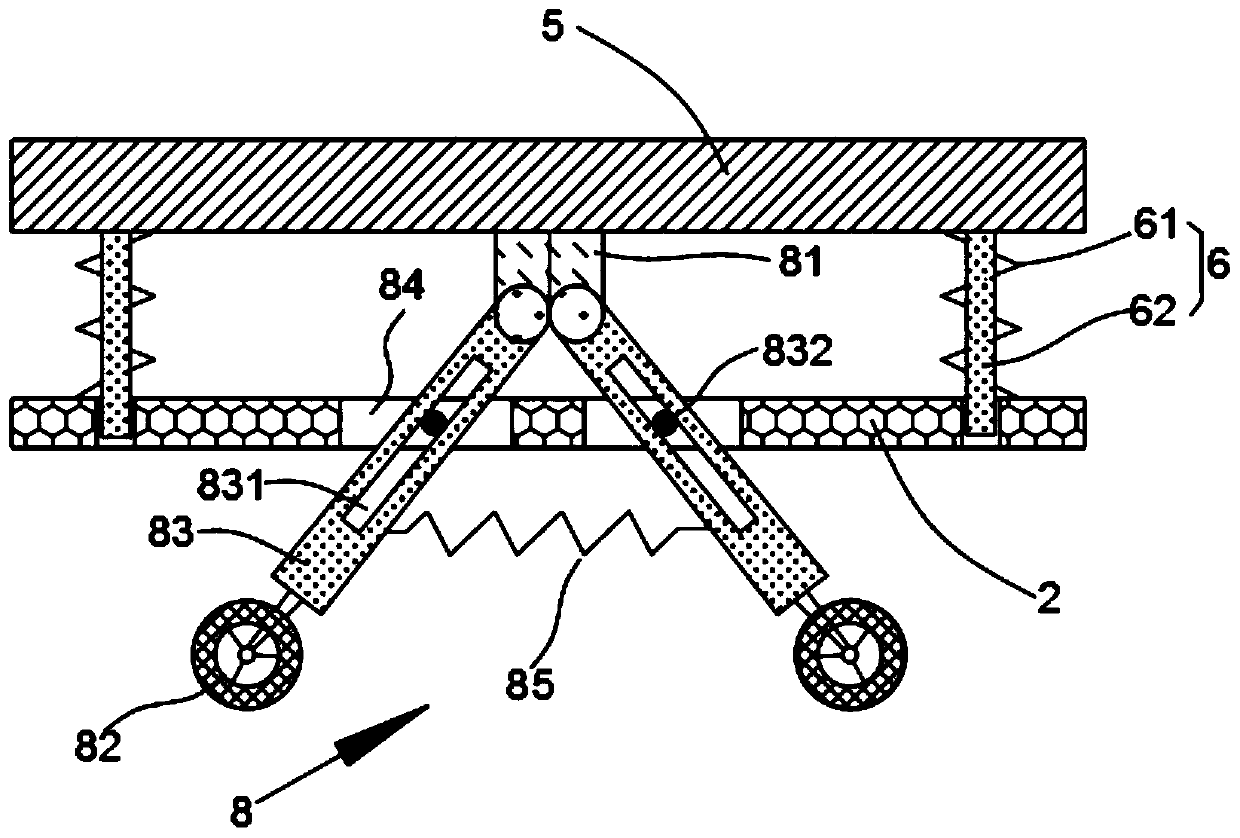

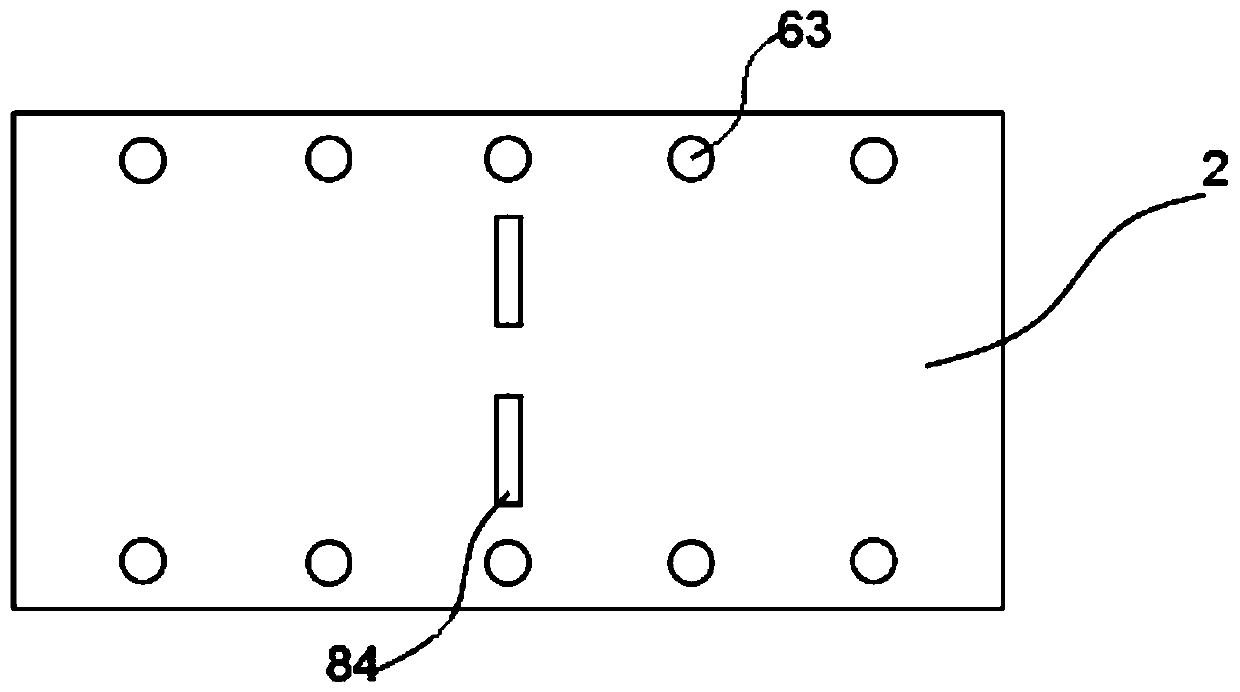

Novel deceleration structure of scooter

InactiveCN110682985ADeceleration achievedImprove securityNon-rotating vibration suppressionCycle brakesControl theoryMechanical engineering

Owner:太仓正实智能科技有限公司

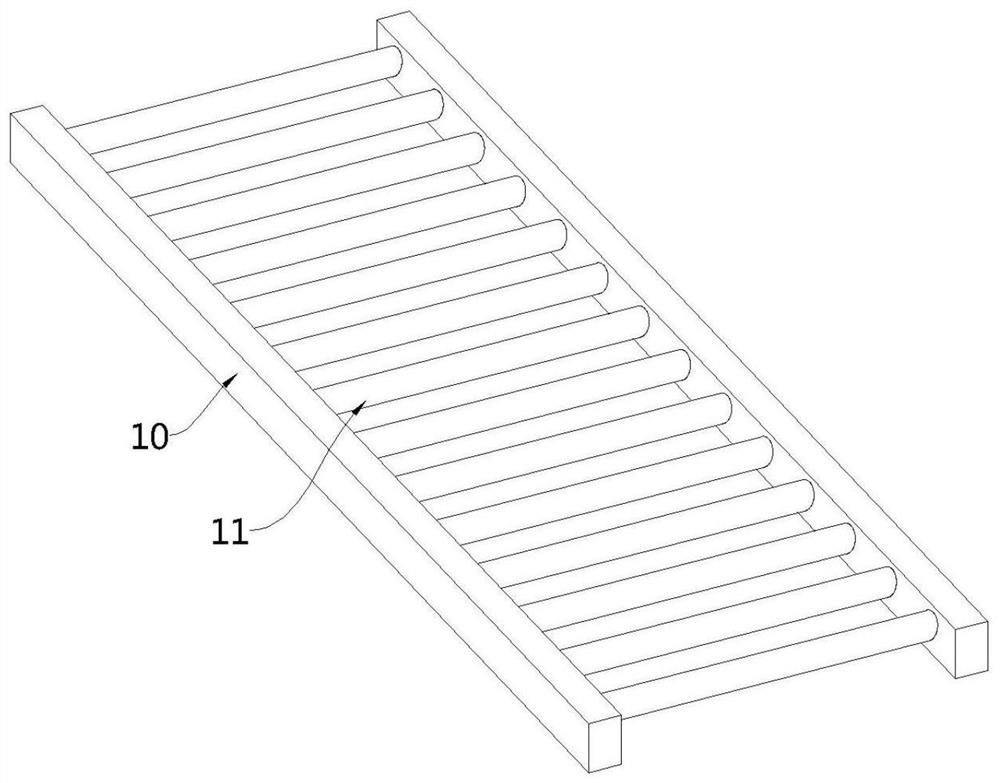

Unloading frame for logistics cargo transport

InactiveCN111674965ADeceleration achievedStop smoothLoading/unloadingRoller-waysLogistics managementStructural engineering

The invention provides an unloading frame for logistics cargo transport, and belongs to the technical field of logistics unloading. The unloading frame comprises a base, a speed reduction assembly isarranged on one side of the upper portion of the base, a first unloading assembly is arranged on the other side, the first unloading assembly is rotatably connected to one side of the speed reductionassembly, power assemblies used for driving the first unloading assembly to rotate upwards are arranged on the front side and the back side of the base symmetrically, the unloading frame has the advantages of being simple in structure, convenient to use and good in unloading effect, cargos are unloaded to second roller shafts corresponding to the speed reduction assembly through the first unloading assembly and can slide along the upper portions of the second roller shafts, when the cargos slide on the upper portions of the second roller shafts, the second roller shafts are driven to rotate, under the effect of a damping ring, rotation of the second roller shafts has certain resistance, speed reduction of the cargos is achieved, and it is ensured that the cargos can be stably stopped on the upper portion of a certain set of second roller shafts.

Owner:岳阳泓发科技服务有限公司

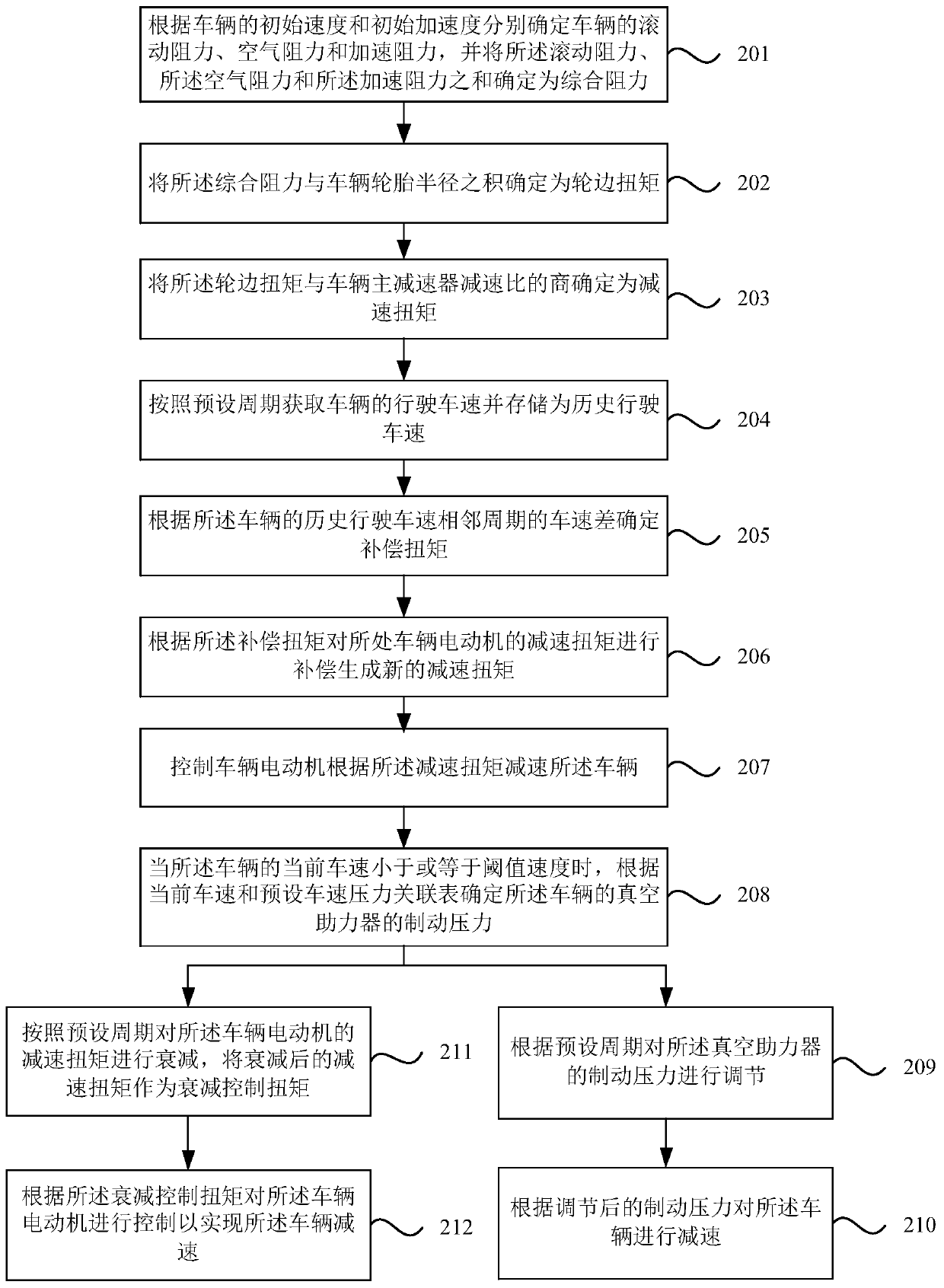

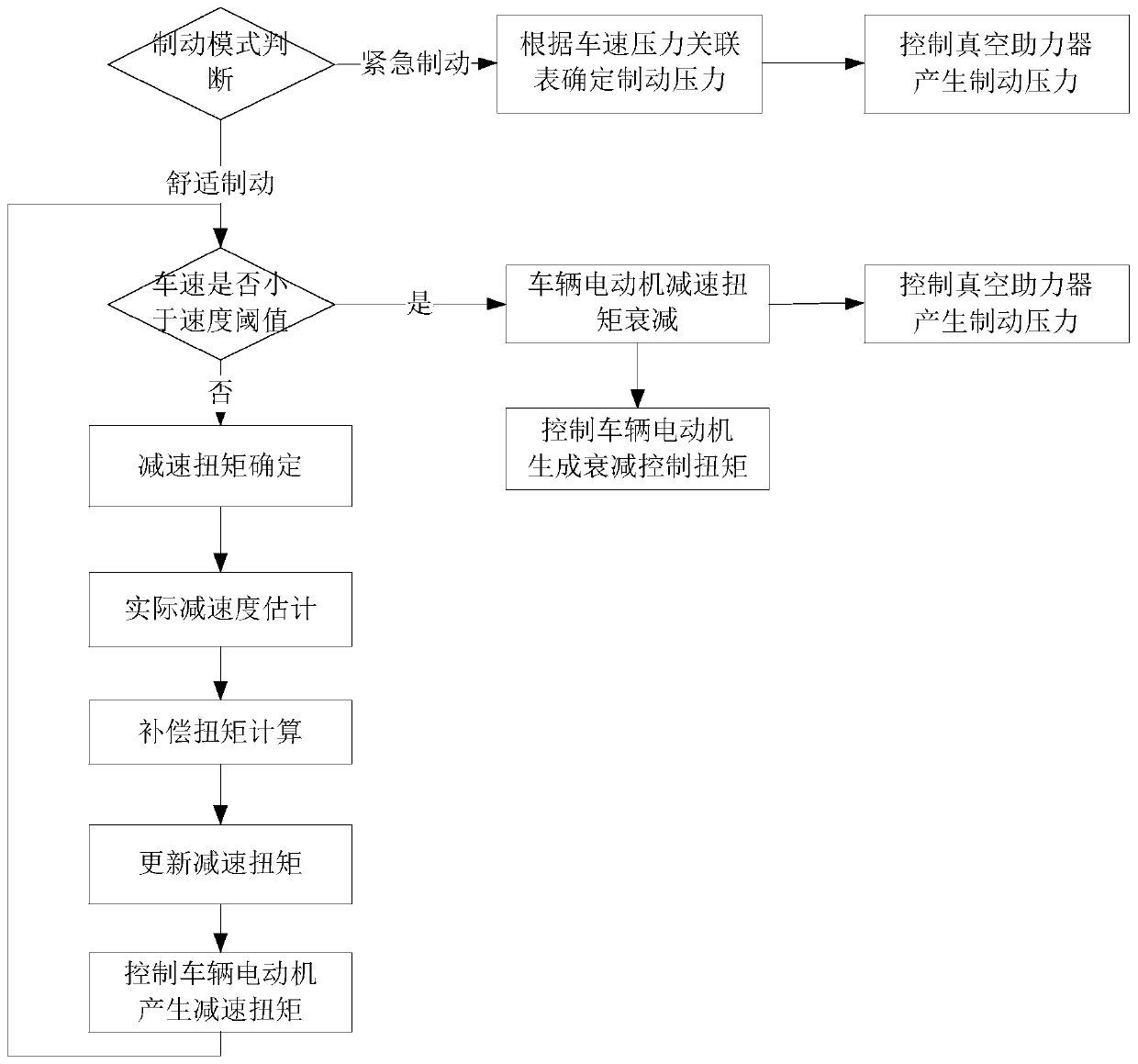

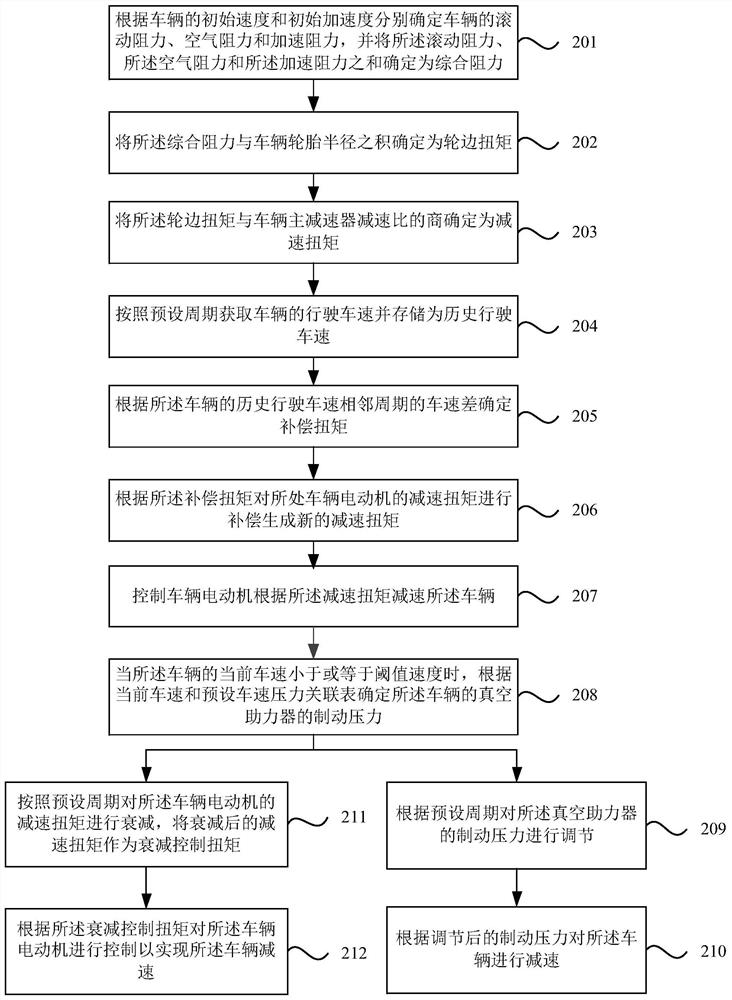

Redundant braking control method, device, system, vehicle and storage medium

ActiveCN110834612BDeceleration achievedAvoid instabilitySpeed controllerBraking action transmissionVehicle drivingControl theory

The invention discloses a redundant braking control method, device, system, vehicle and storage medium. The method includes: determining the deceleration torque of the vehicle motor according to the initial speed and the initial acceleration of the vehicle; controlling the vehicle motor to decelerate the vehicle according to the deceleration torque; when the current vehicle speed of the vehicle is less than or equal to a threshold speed, according to the current vehicle speed and The preset vehicle speed pressure correlation table determines the braking pressure of the vacuum booster of the vehicle; the vacuum booster is controlled to decelerate the vehicle according to the braking pressure. The method provided by the embodiment of the present invention realizes the braking control under the redundant braking of the vehicle, can improve the stability of the vehicle, prevent the instability of the vehicle, and improve the driving comfort of the vehicle.

Owner:CHINA FIRST AUTOMOBILE

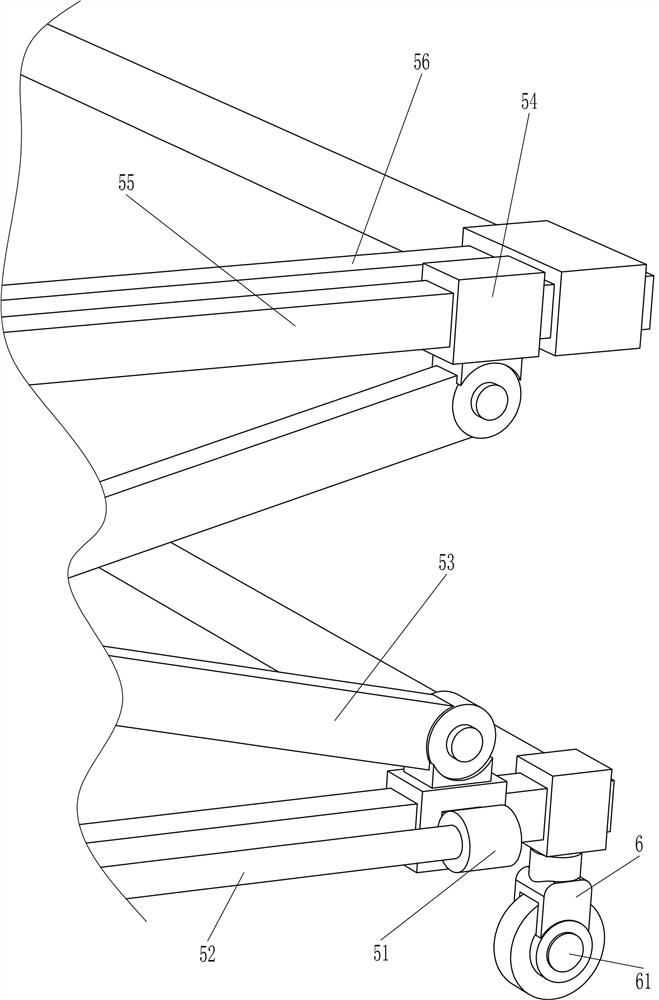

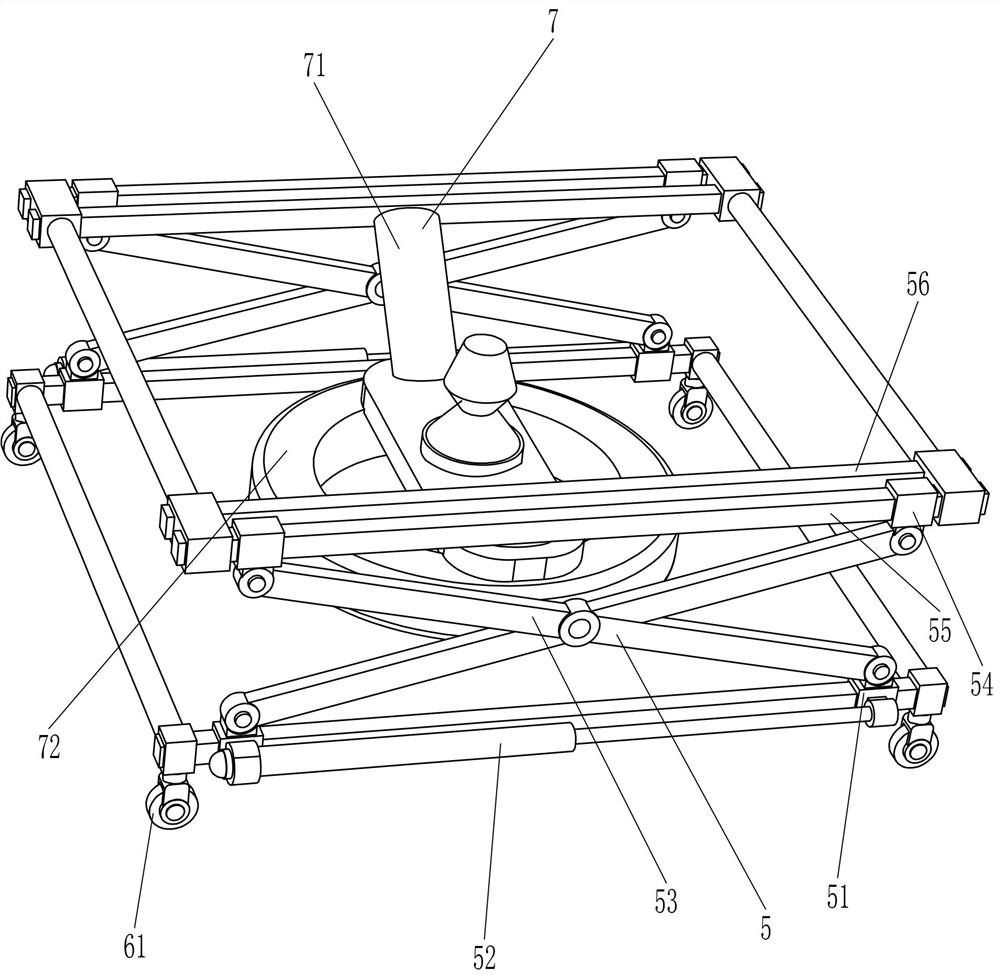

Giant saw disc translation type carrying and stacking equipment

PendingCN112249126AImprove work efficiencyAccurate suctionLifting framesHand carts with multiple axesEngineeringMechanical engineering

The invention relates to stacking equipment, in particular to giant saw disc translation type carrying and stacking equipment. The giant saw disc translation type carrying and stacking equipment can automatically carry giant saw discs and has safety. The giant saw disc translation type carrying and stacking equipment comprises round rods and square rods connected between two sides of the round rods, damping hinge sleeves used for friction fixation and rotatably connected to the two sides of the round rods on one side, a push handle used for a hand pushing device and connected between the topsof the damping hinge sleeves, a lifting mechanism connected between the square rods, and an auxiliary moving mechanism connected with the round rods. Through cooperation of the lifting mechanism, theauxiliary moving mechanism and a magnetic attraction mechanism, it can be achieved that multiple persons do not need to carry the giant saw disc together, the magnetic attraction mechanism can attractthe giant saw disc, carry the giant saw disc to a proper position and put down the giant saw disc, and therefore the working efficiency of people can be improved.

Owner:巨小凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com