Multi-motor drive control system of electric vehicle and working method thereof

A multi-motor drive and electric vehicle technology, applied in electric vehicles, motors, control drives, etc., can solve the problems of low power efficiency of mechanical differential transmission, difficulty in driving high-power motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

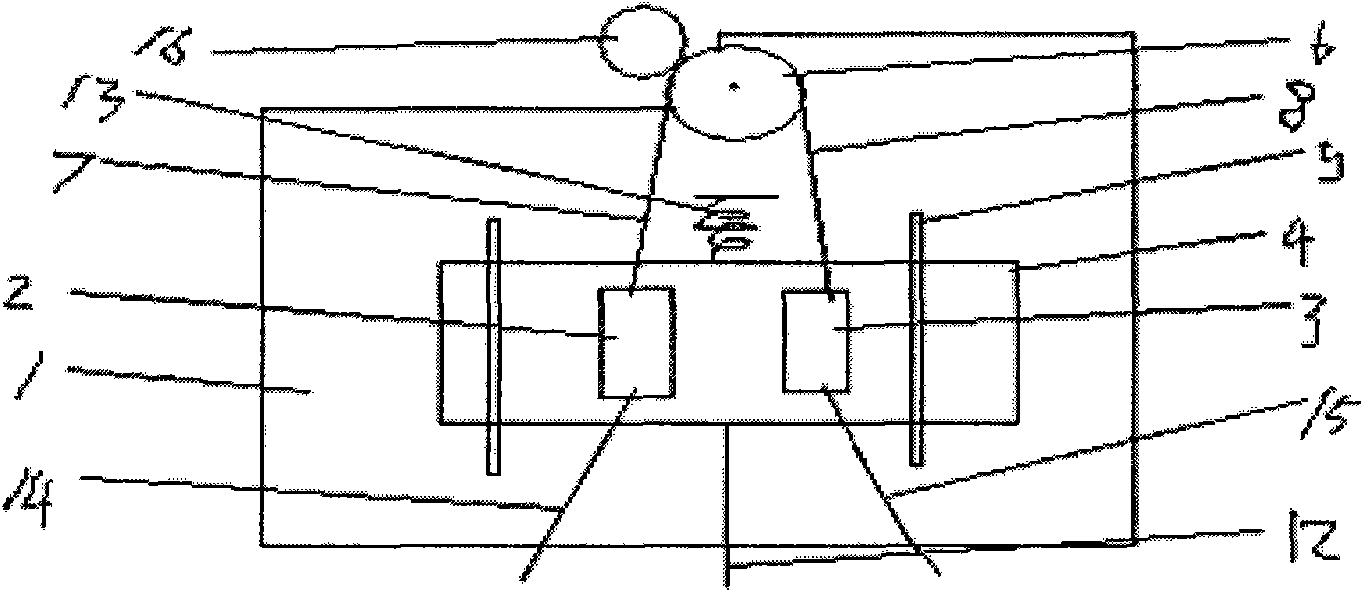

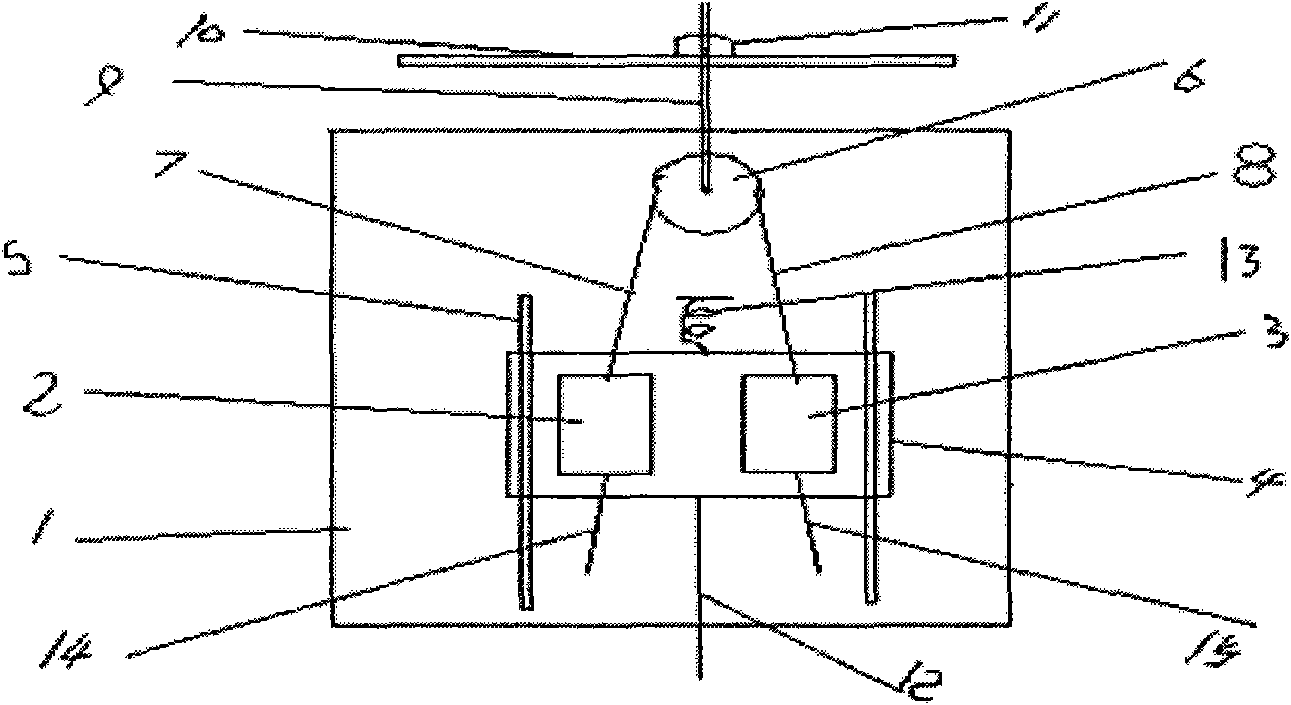

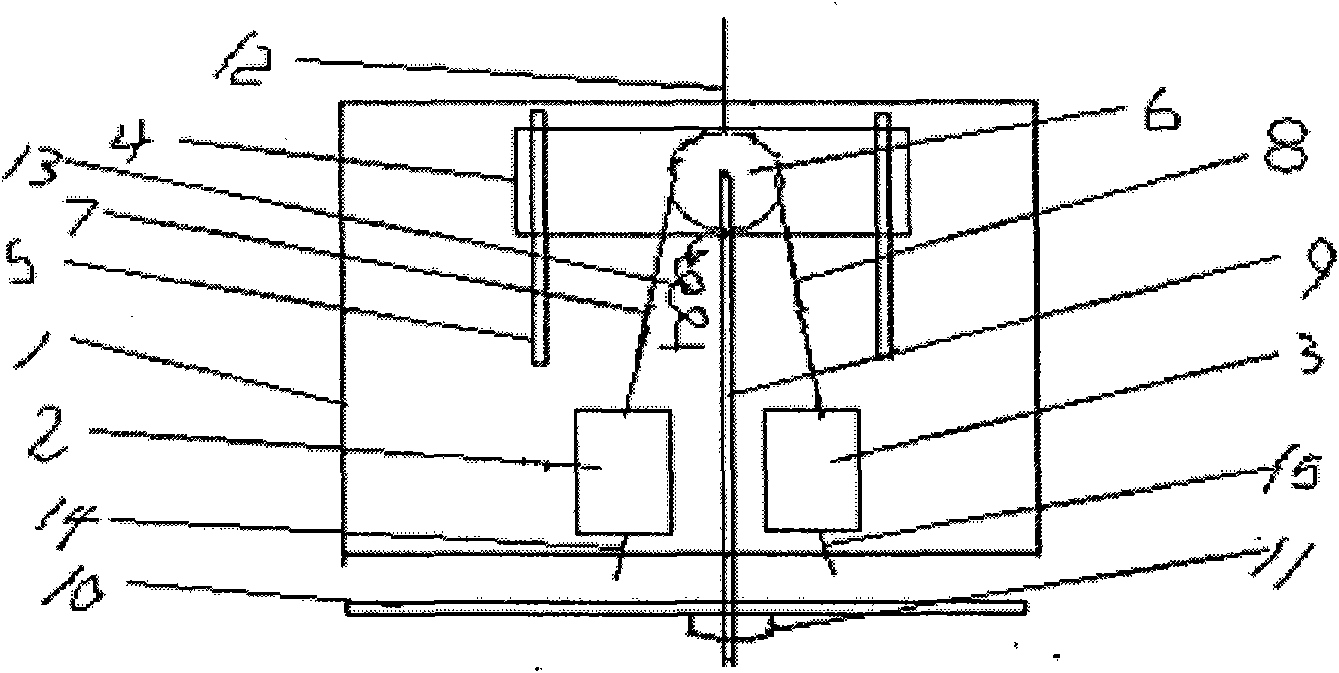

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail;

[0009] Such as figure 1 , figure 2 , as shown, when the driver’s steering wheel turns left, the steering column is connected to the deceleration gear 16 or the bayonet pin 11 on the direction pull rod 10 is connected to the swing rod 9 to drive the adjustment disc 6 to rotate to the left, and the right side acceleration and deceleration signal collector 3 The right acceleration and deceleration backguy 8 is pulled out, and the right signal output line 15 outputs the acceleration signal to the motor controller on the right side, and each motor on the right side increases the rotating speed. And the left acceleration and deceleration backguy 7 retraction of the left acceleration and deceleration signal collector 2, the left signal output line 14 outputs the deceleration signal to the left motor controller, and each motor on the left reduces the rotating speed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com