Patents

Literature

541results about "Refining by filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

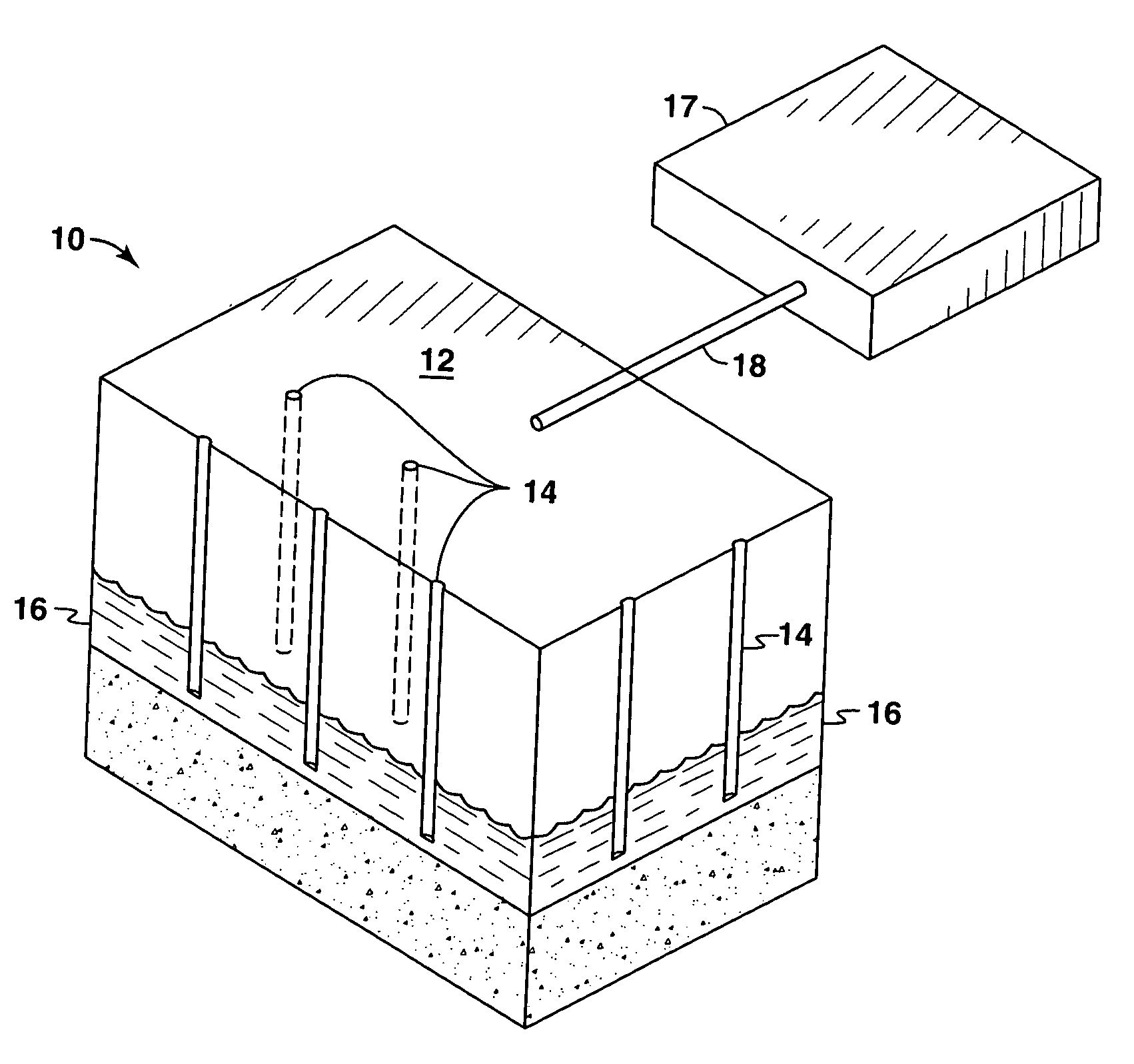

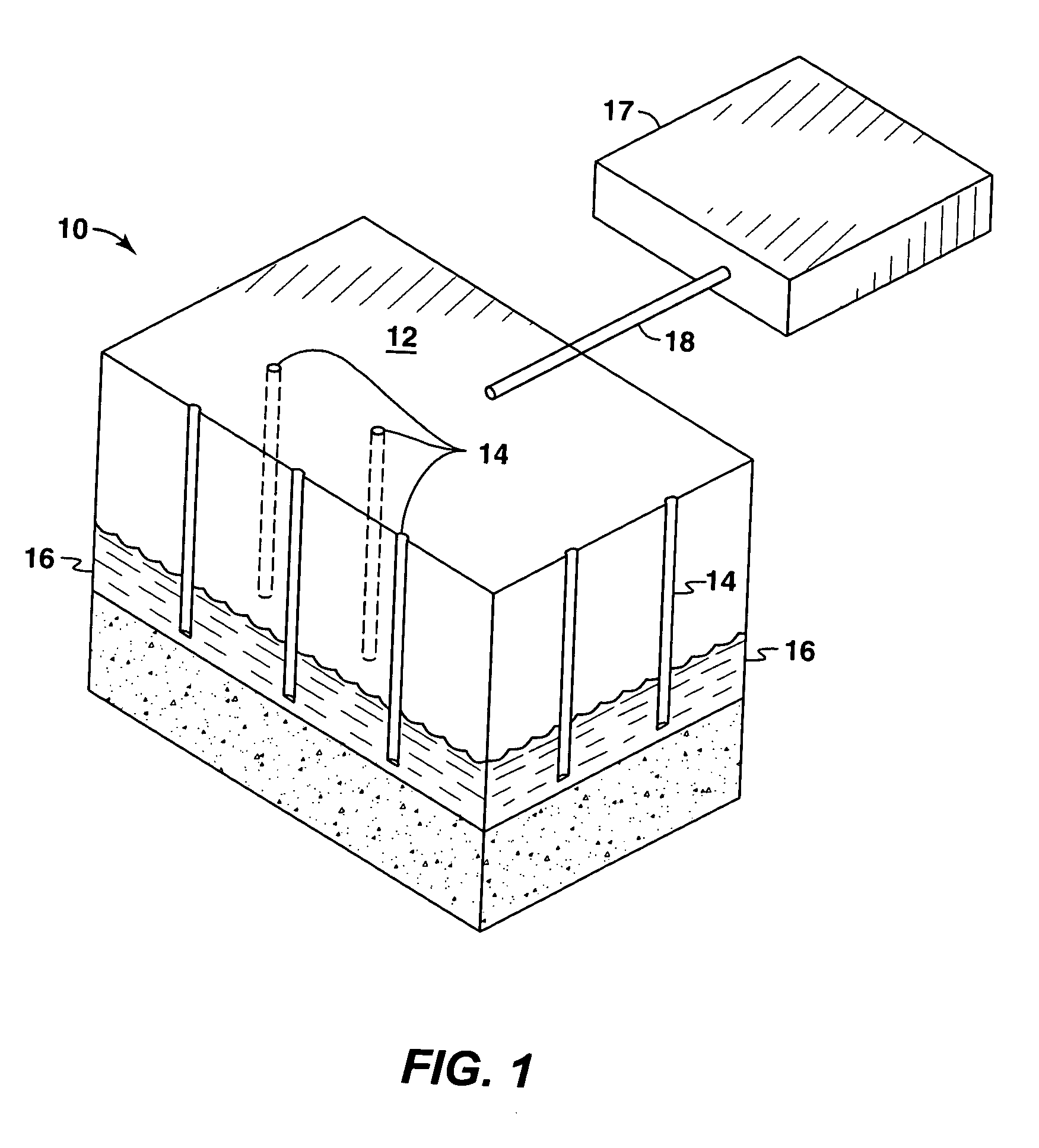

Process for producing Hydrocarbon fluids combining in situ heating, a power plant and a gas plant

An in situ method of producing hydrocarbon fluids from an organic-rich rock formation is provided. The method may include heating an organic-rich rock formation, for example an oil shale formation, in situ to pyrolyze formation hydrocarbons, for example kerogen, to form a production fluid containing hydrocarbon fluids. The method may include separating the production fluid into at least a gas stream and a liquid stream, where the gas stream is a low BTU gas stream. The low BTU gas stream is then fed to a gas turbine where it is combusted and is used to generate electricity.

Owner:KAMINSKY ROBERT D +4

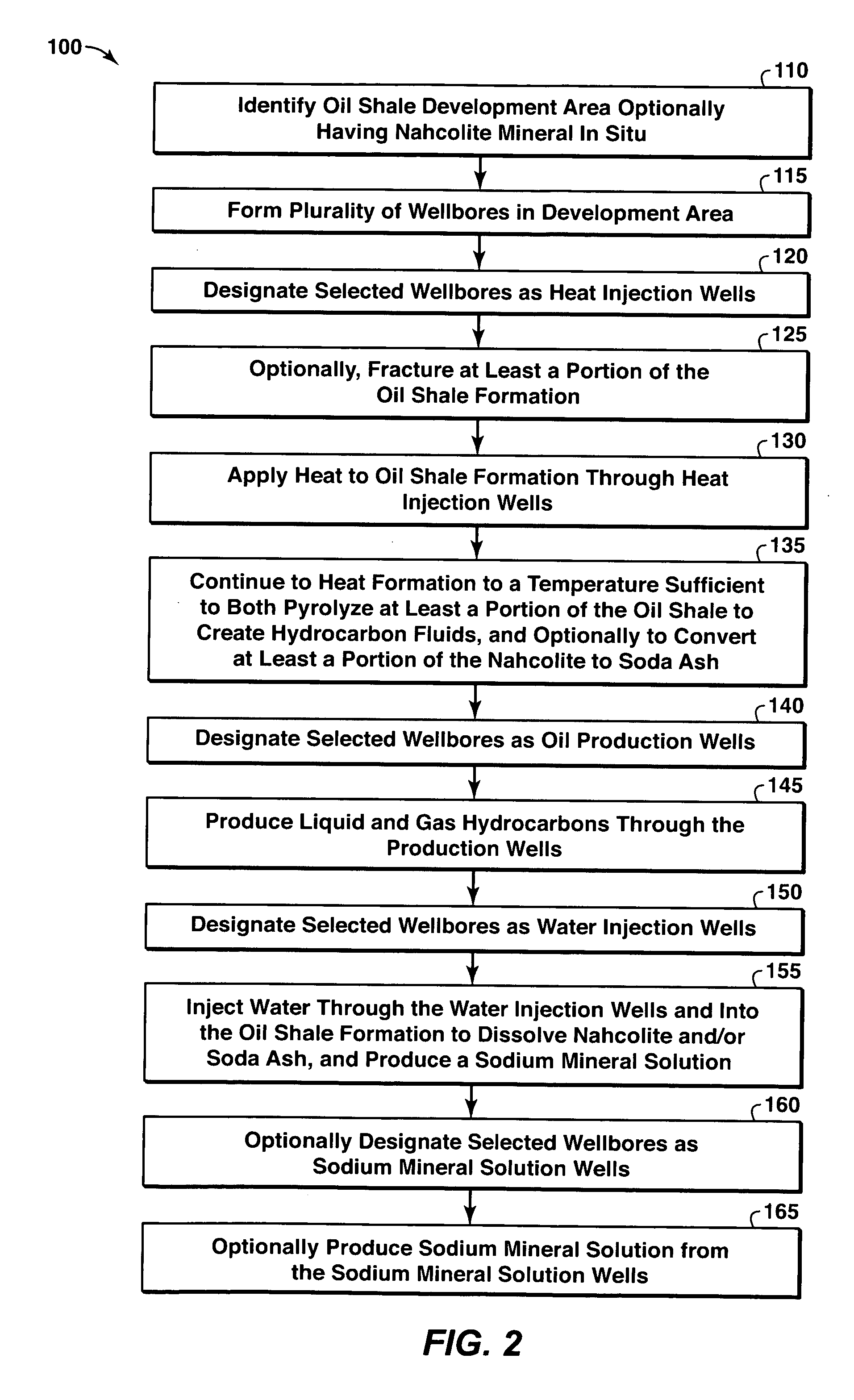

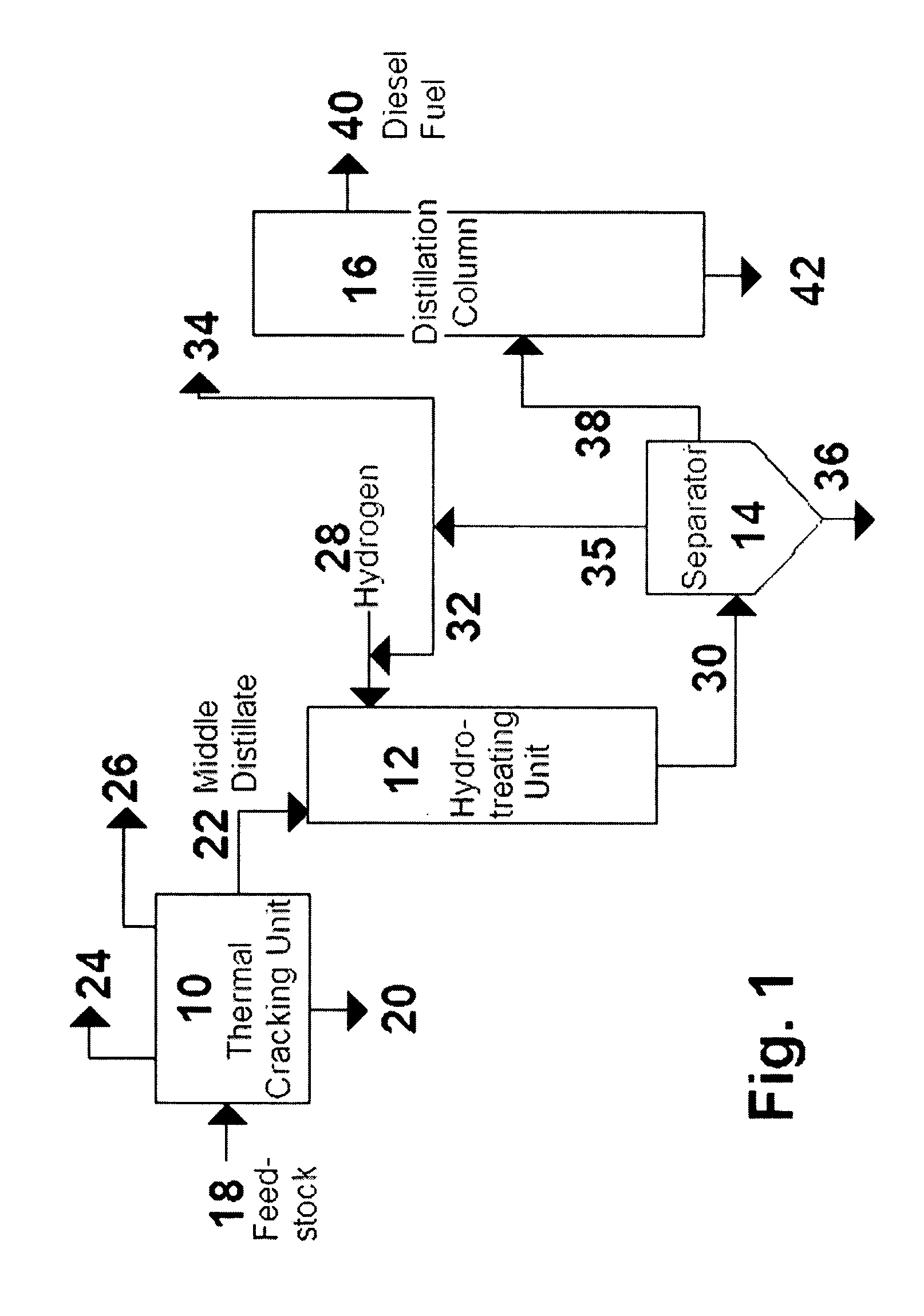

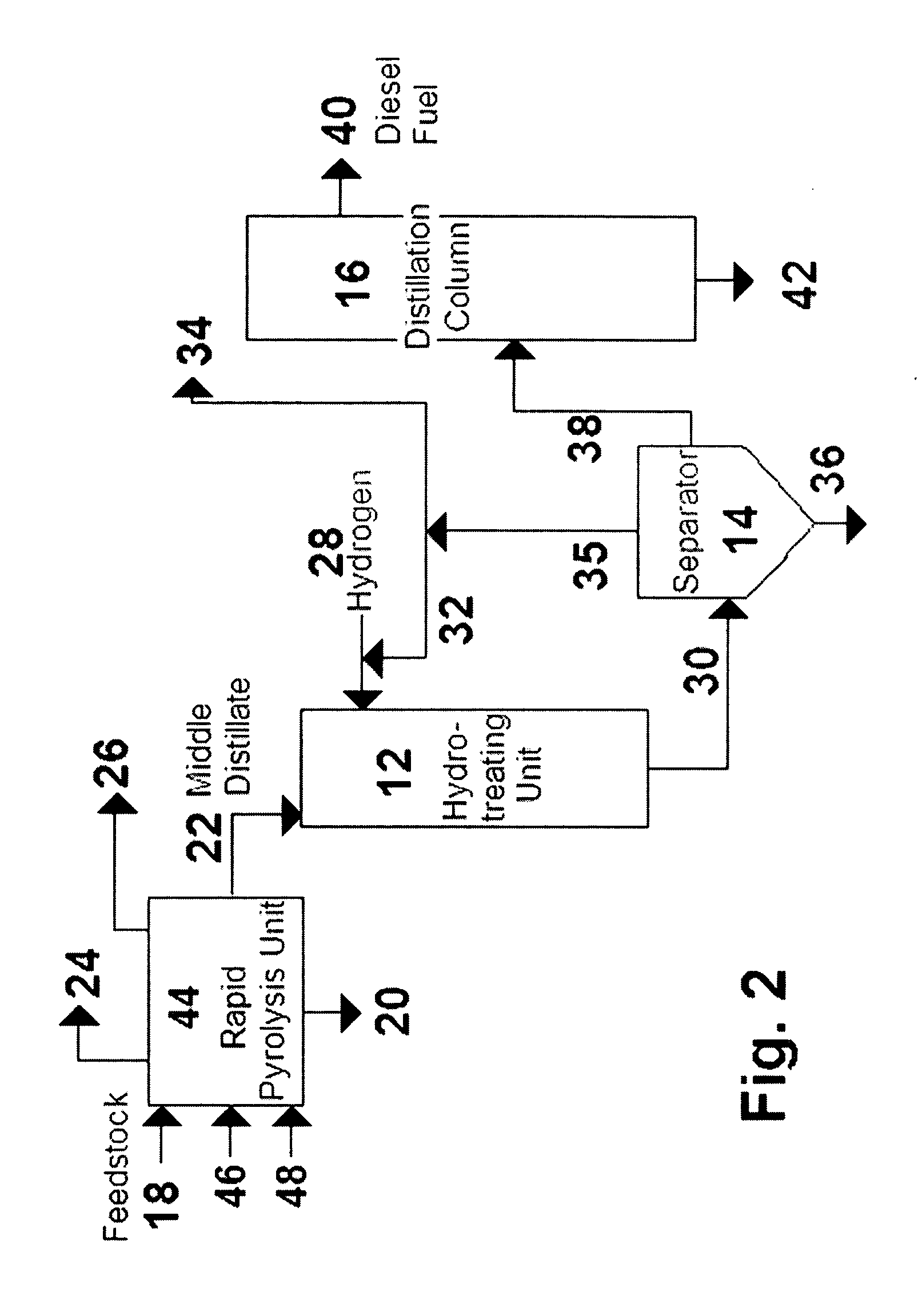

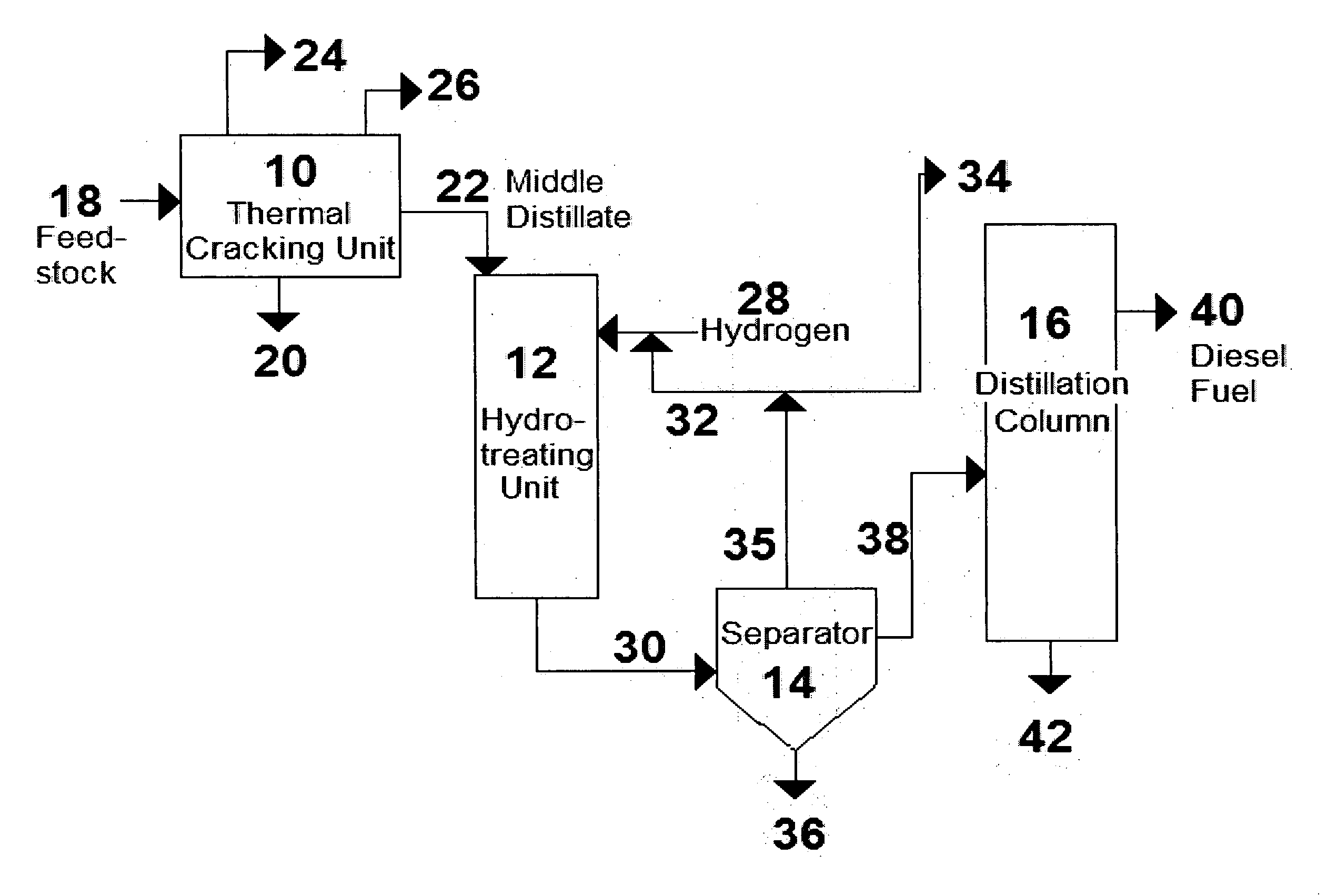

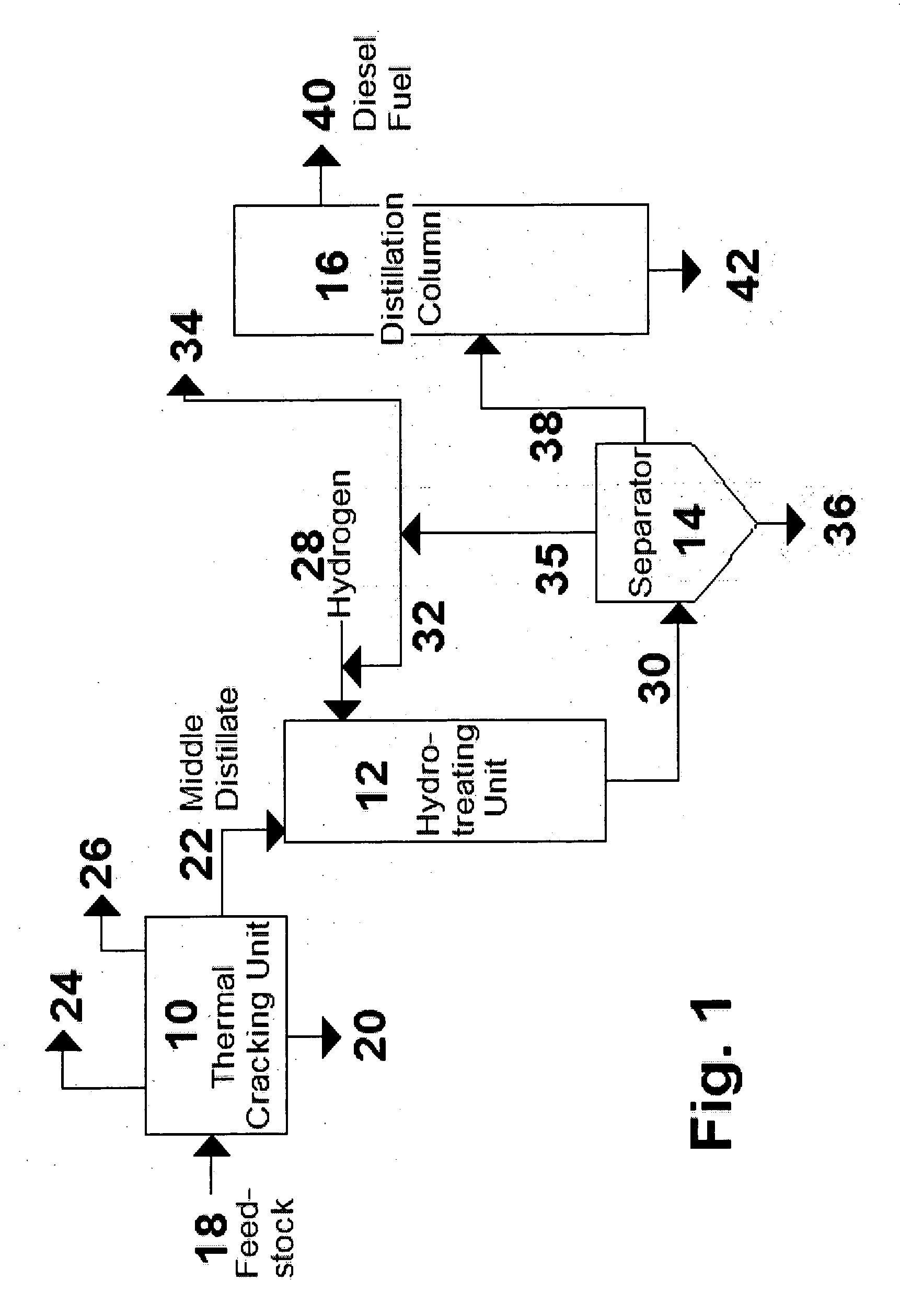

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

ActiveUS20070068848A1Increase cetane numberBiofuelsLiquid hydrocarbon mixture productionTG - TriglyceridePre treatment

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

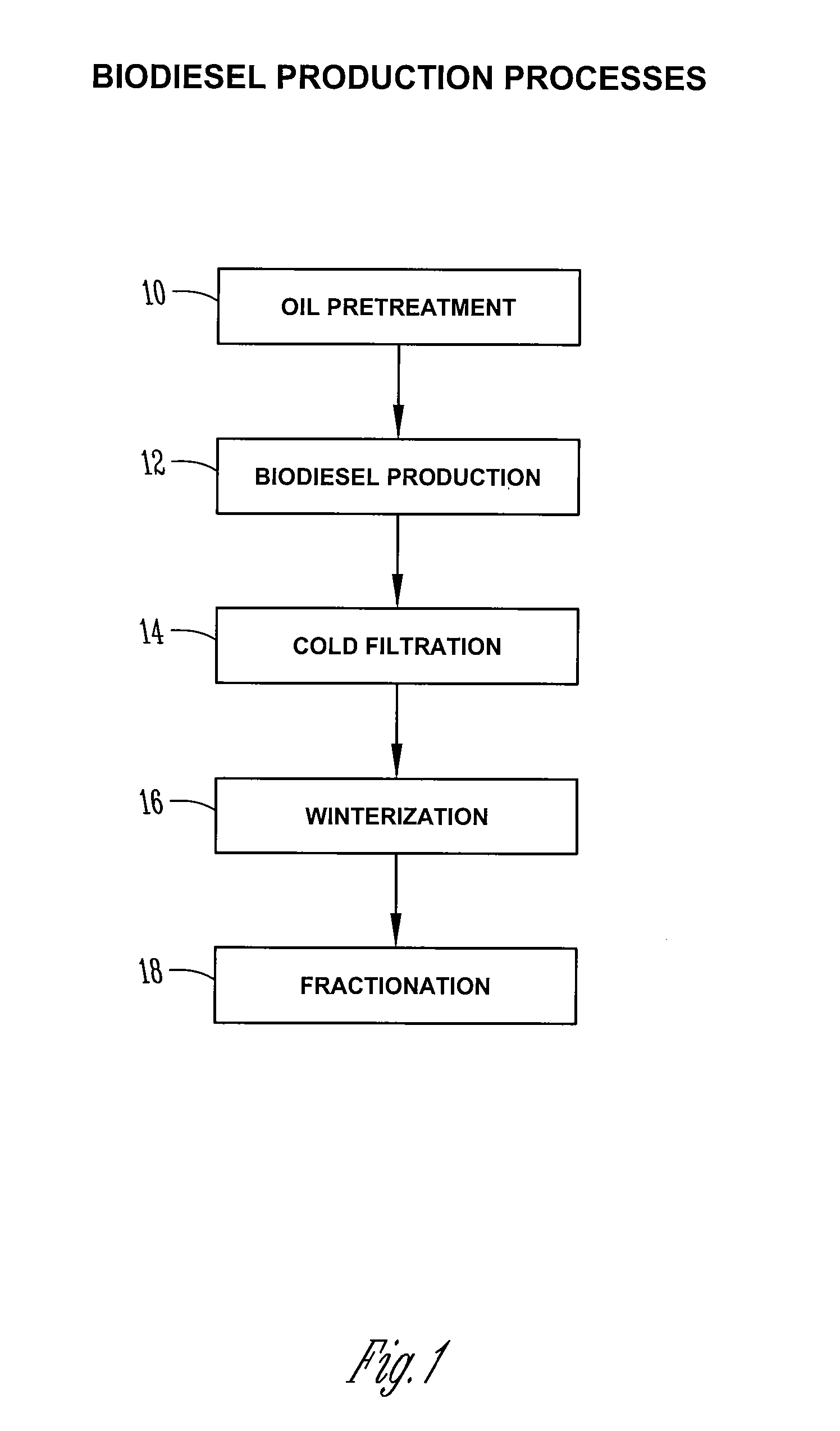

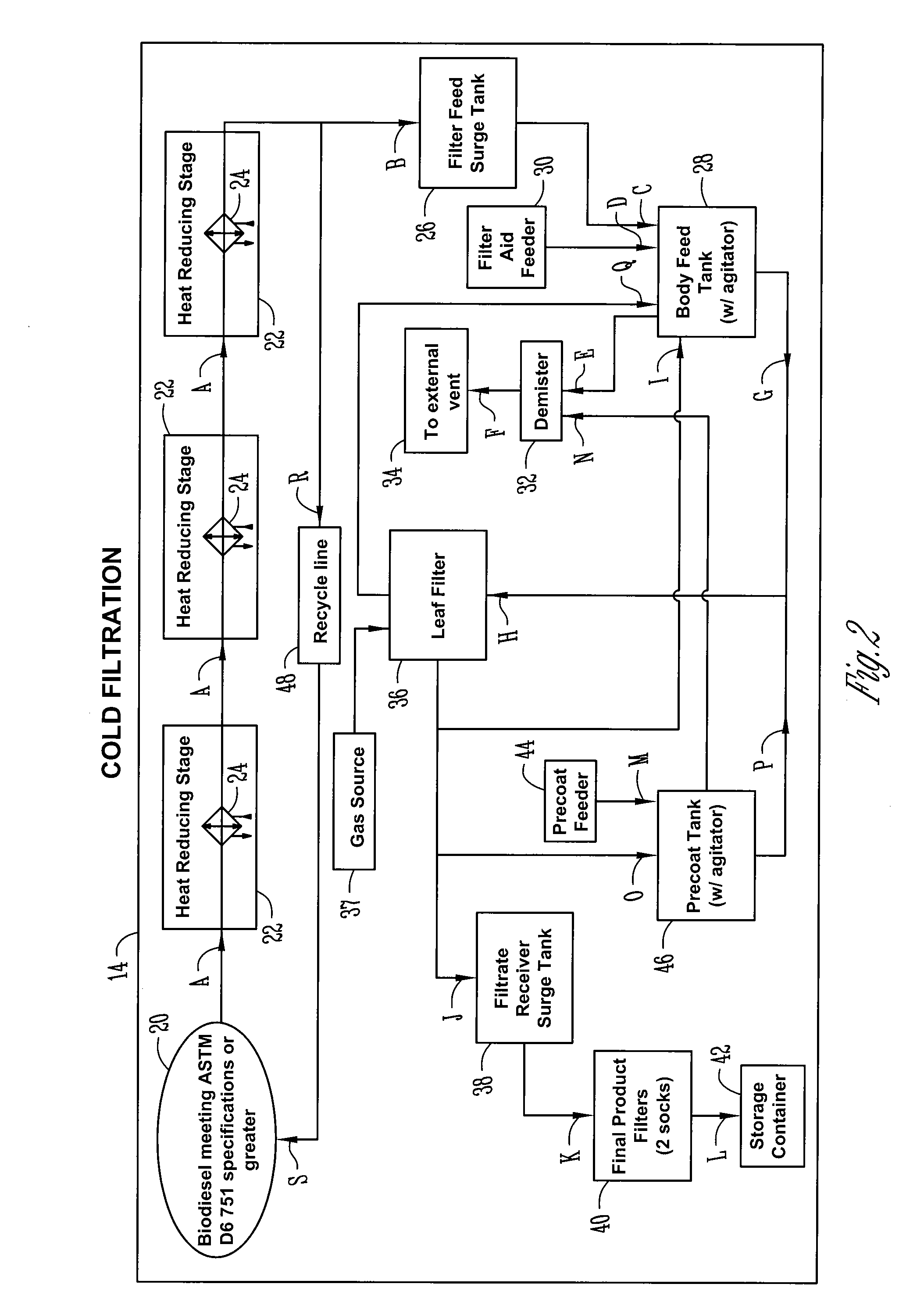

Biodiesel cold filtration process

An improved biodiesel production process includes the steps of processing a feedstock to produce biodiesel, cooling the biodiesel so as to form sediment, and filtering the biodiesel to remove the sediment. The resulting biodiesel from the cold filtration process avoids problems of sediment formation during storage and transportation.

Owner:REG BIOFUELS

System for improving crude oil

InactiveUS20060231462A1Increase heightEnhancing crude oilThermal non-catalytic crackingSemi-permeable membranesAPI gravityFiltration

Crude oil can be refined through a filtration media. Cavitation bubbles having localized areas of very high temperatures and pressures may be created thereby causing several physical and chemical phenomena, including thermal cracking of carbon-carbon bonds as the crude moves through the flux cartridge membrane. Heavy hydrocarbons are residues are thereby cracked into smaller lowering boiling molecules having a higher API gravity. Once the relatively smaller hydrocarbons pass through the flux cartridge membrane into the flux cartridge, the effluent can be routed to a second separator annulus. It should also be pointed out that lighter hydrocarbons formed can volatilize and special provisions may be needed to efficiently capture these gases.

Owner:LJC TECH

Catalytic filtering of a Fischer-Tropsch derived hydrocarbon stream

InactiveUS7150823B2Avoid cloggingRefining with metalsPhysical/chemical process catalystsParticulatesUltra fine

Novel methods of treating a Fischer-Tropsch derived hydrocarbon stream with an active filtering catalyst are disclosed. Such methods are capable of removing soluble (and ultra-fine particulate) contamination, fouling agents, and / or plugging precursors from the Fischer-Tropsch derived hydrocarbon stream such that plugging of the catalyst beds of a subsequent hydroprocessing process is substantially avoided.

Owner:CHEVROU USA INC

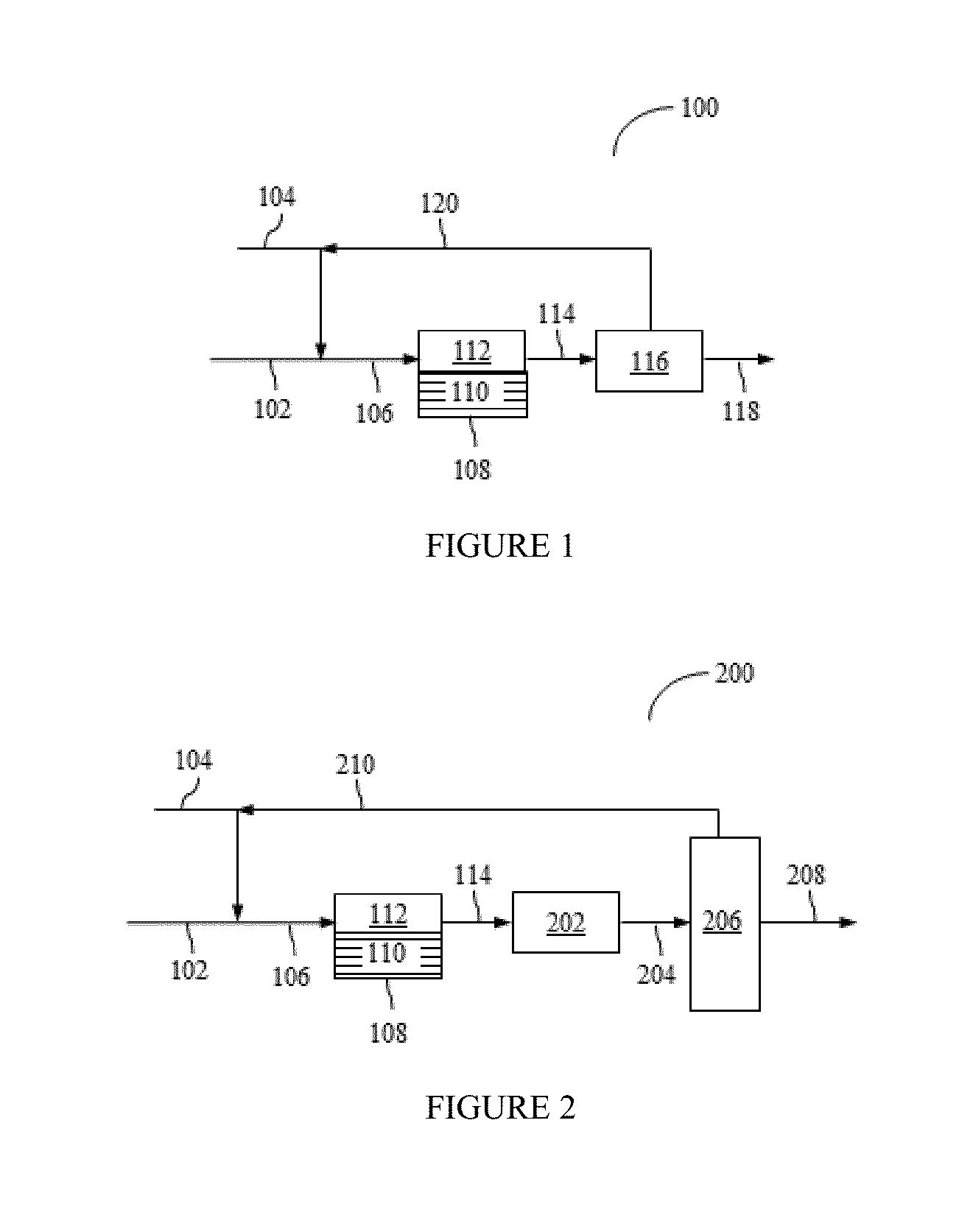

Methods and apparatuses for forming low-metal biomass-derived pyrolysis oil

Embodiments of methods and apparatuses for forming a low-metal biomass-derived pyrolysis oil are provided. The method comprises the steps of filtering a biomass-derived pyrolysis oil with a high flux rate filter arrangement having a flux rate of about 10 L / m2 / hr or greater to form a low-solids biomass-derived pyrolysis oil. The low-solids biomass-derived pyrolysis oil is filtered with a fine filter arrangement having a pore diameter of about 50 μm or less to form an ultralow-solids biomass-derived pyrolysis oil. The ultralow-solids biomass-derived pyrolysis oil is contacted with an ion-exchange resin to remove metal ions and form the low-metal biomass-derived pyrolysis oil.

Owner:UOP LLC

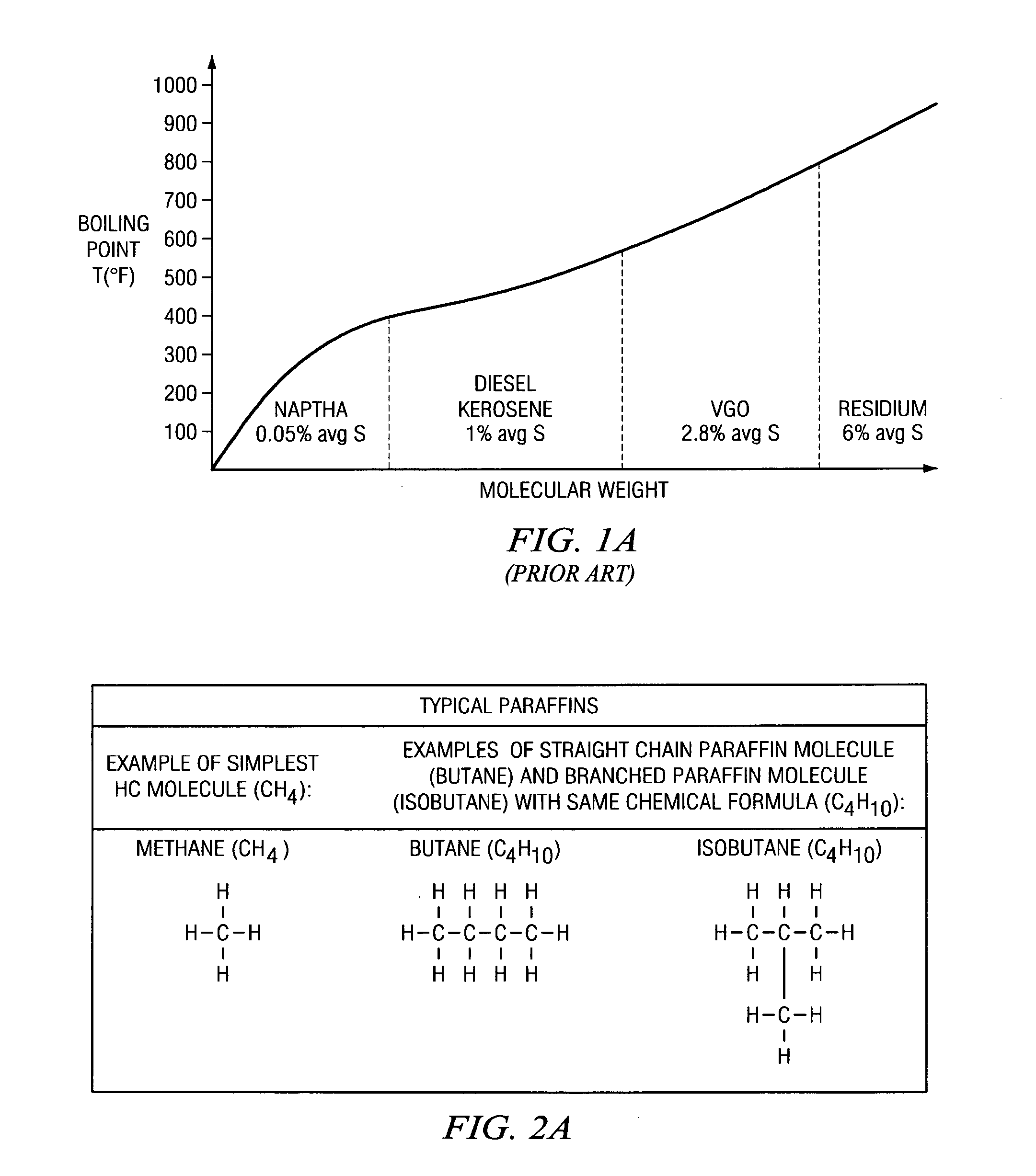

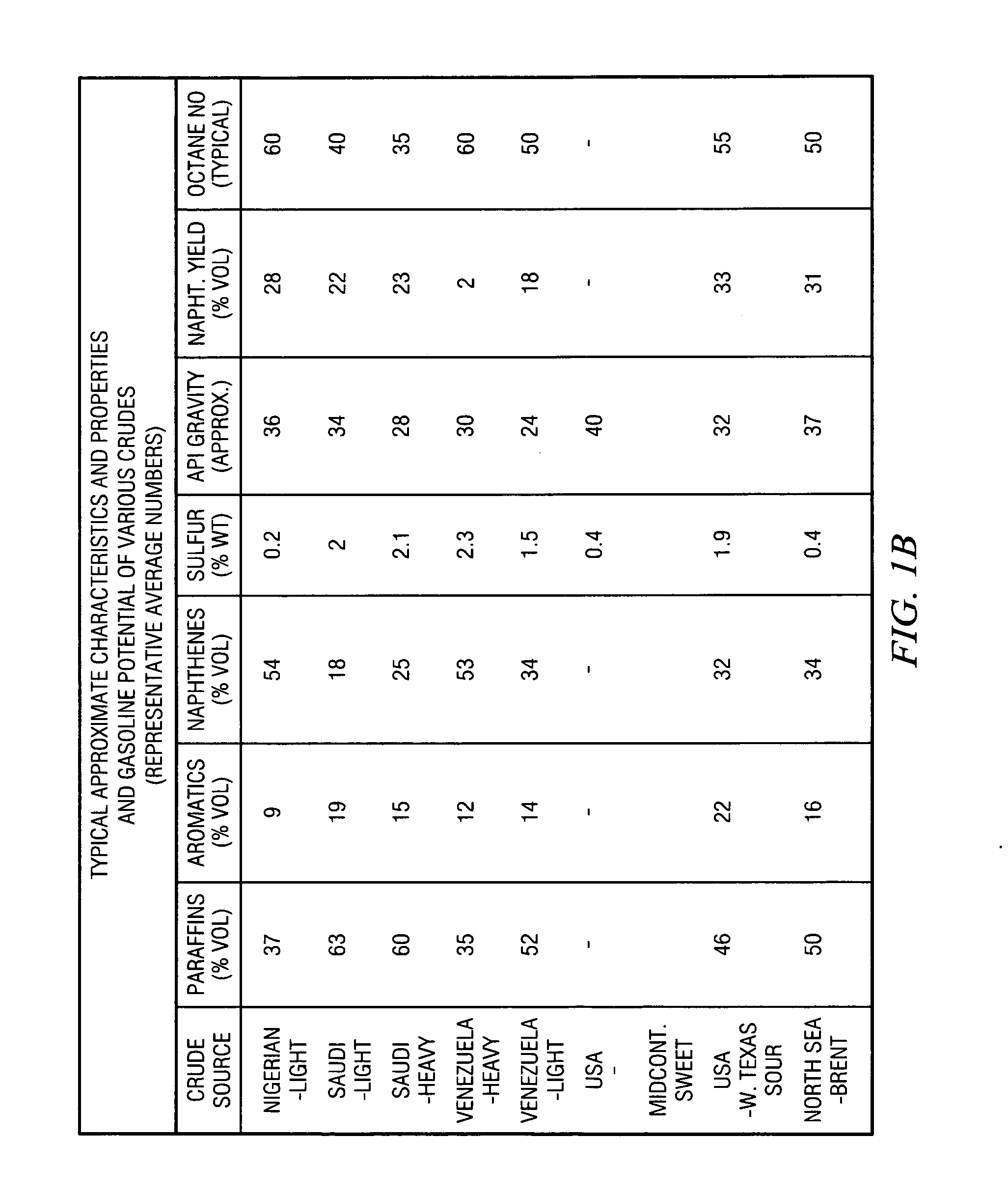

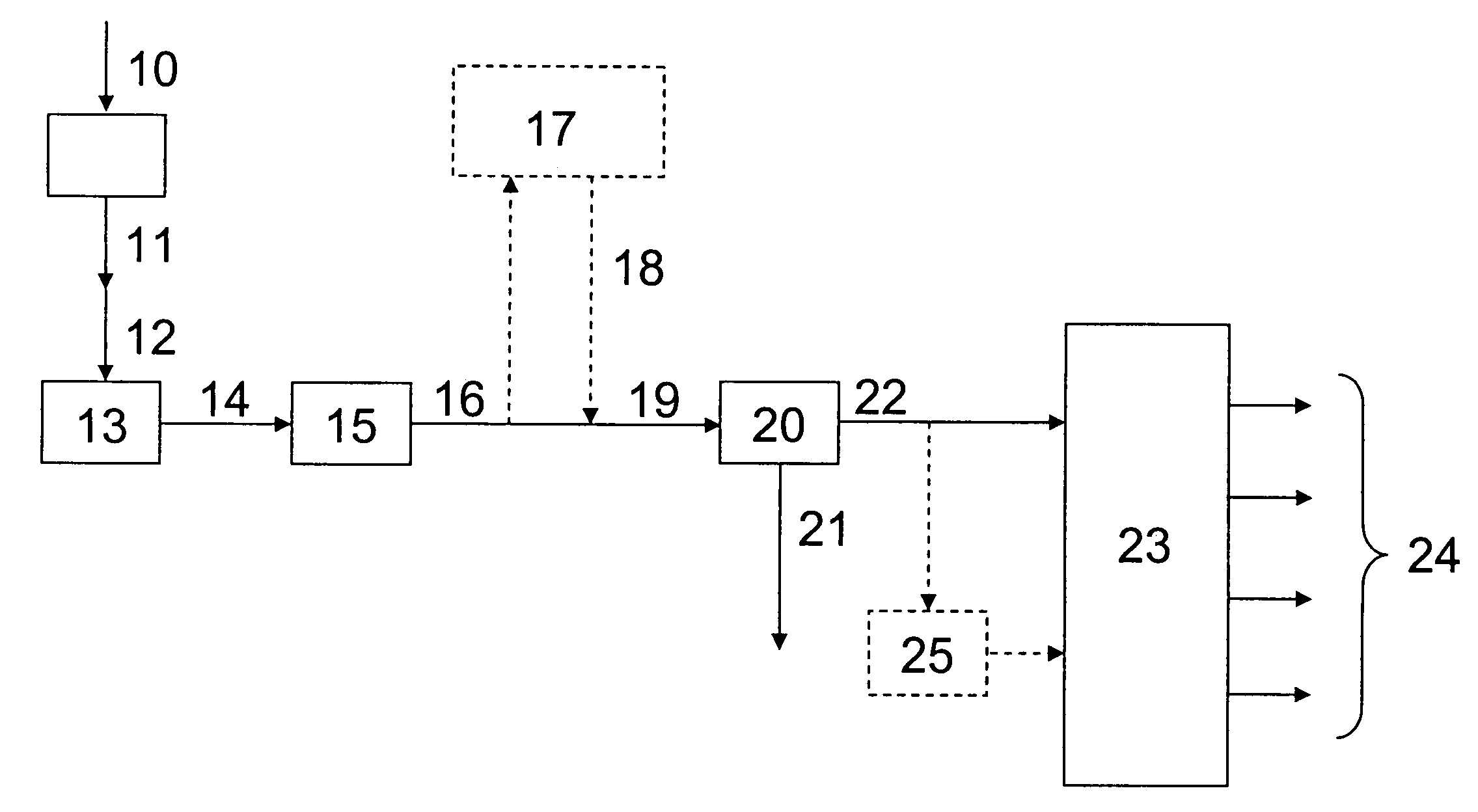

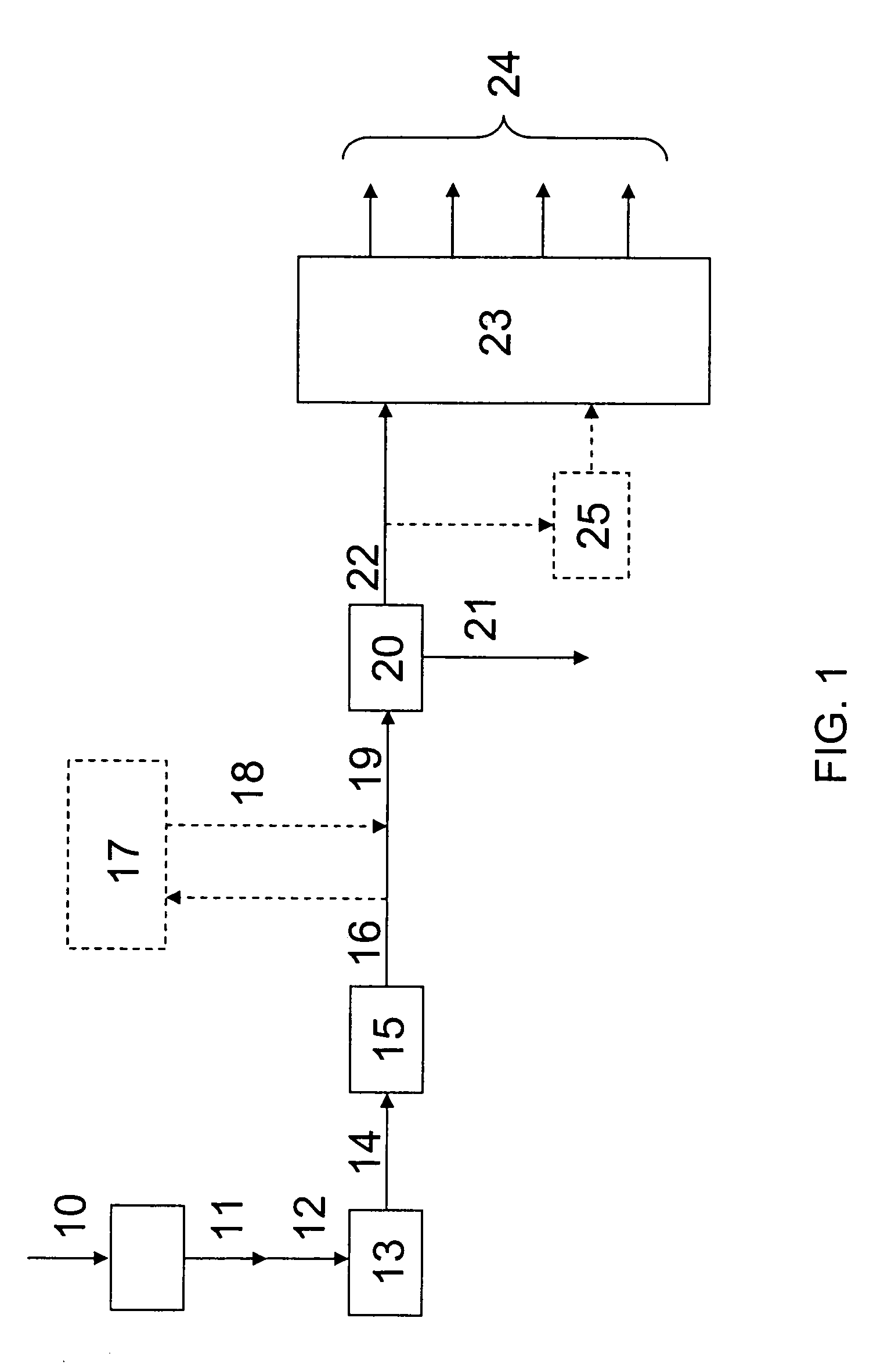

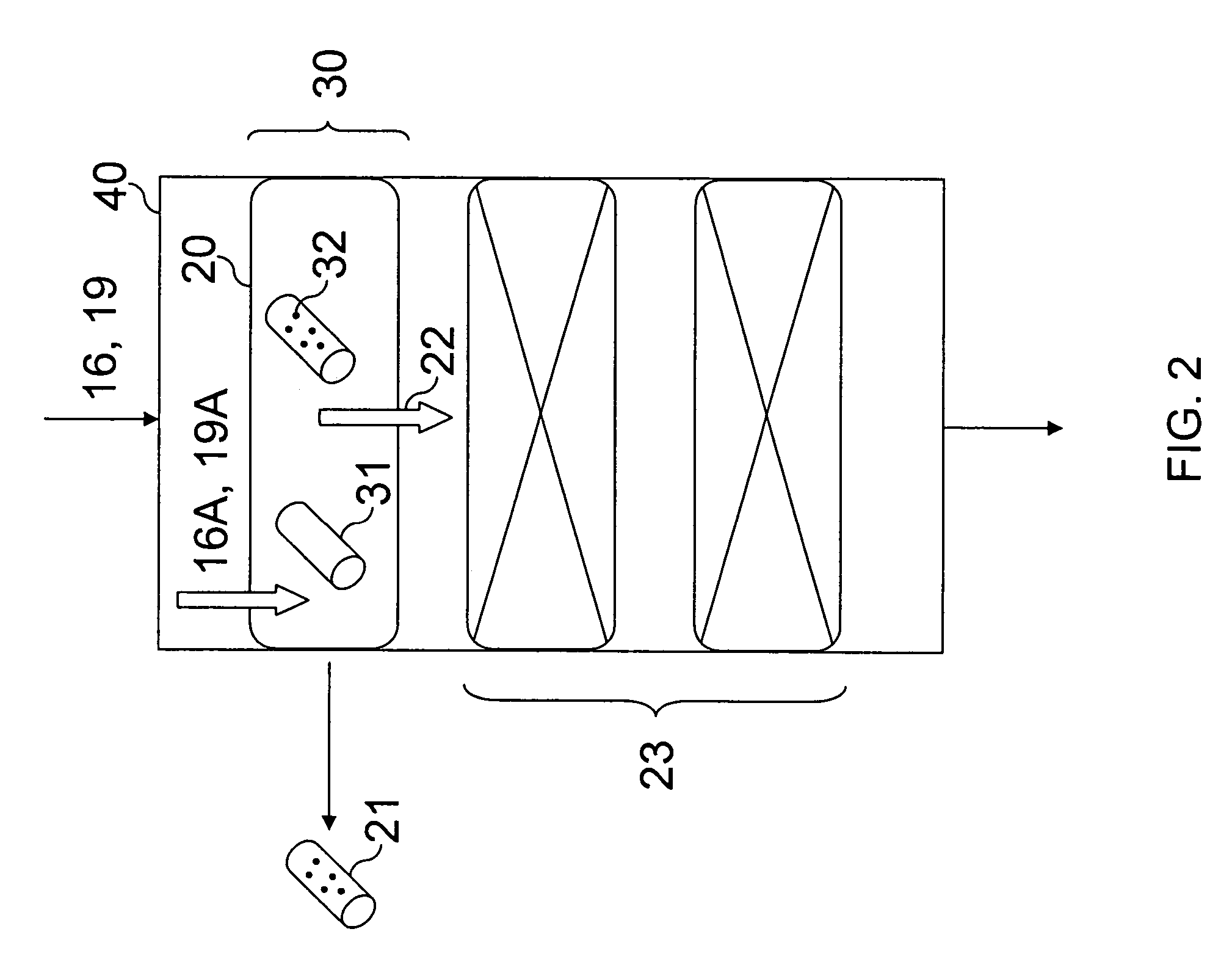

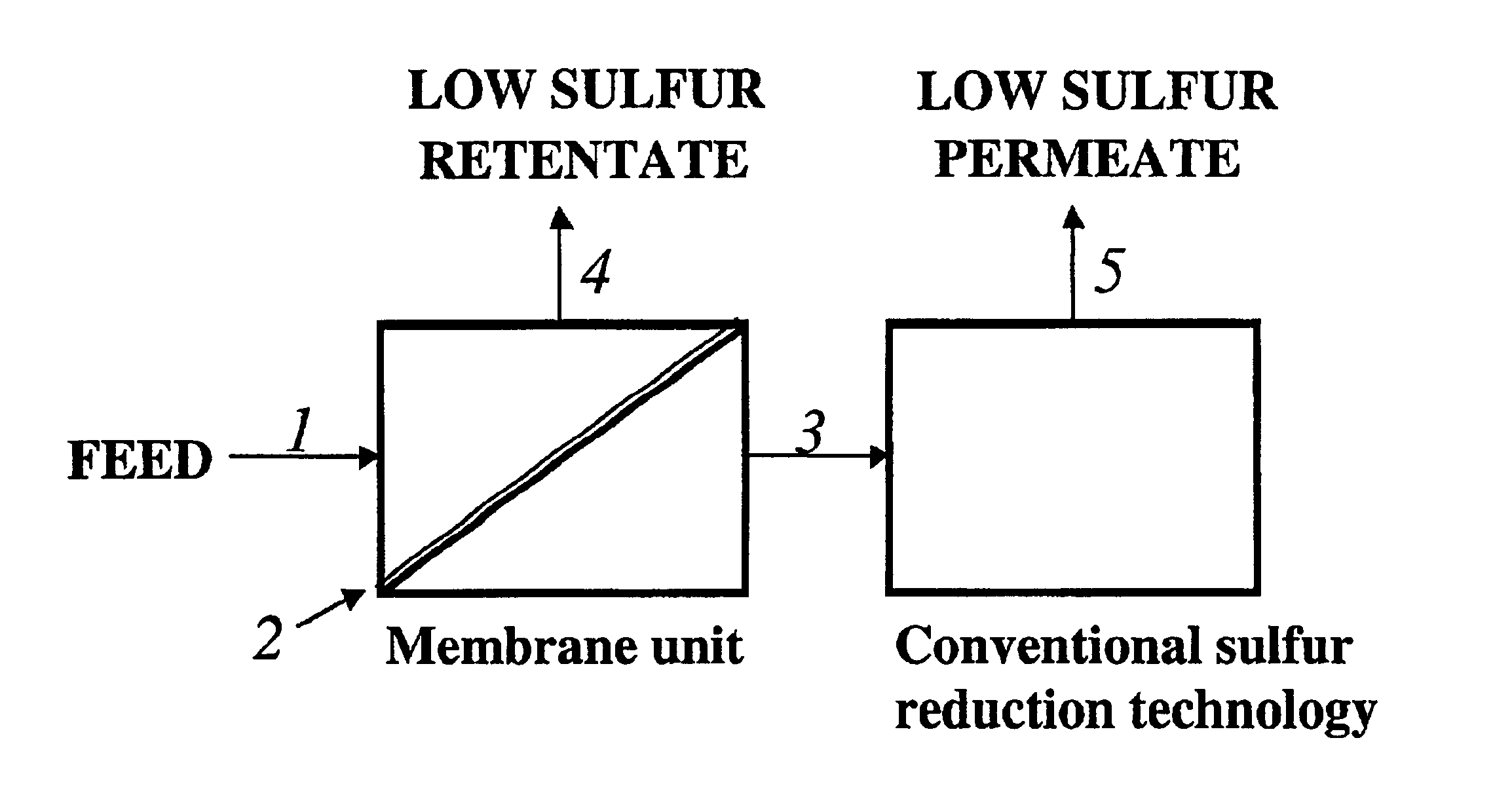

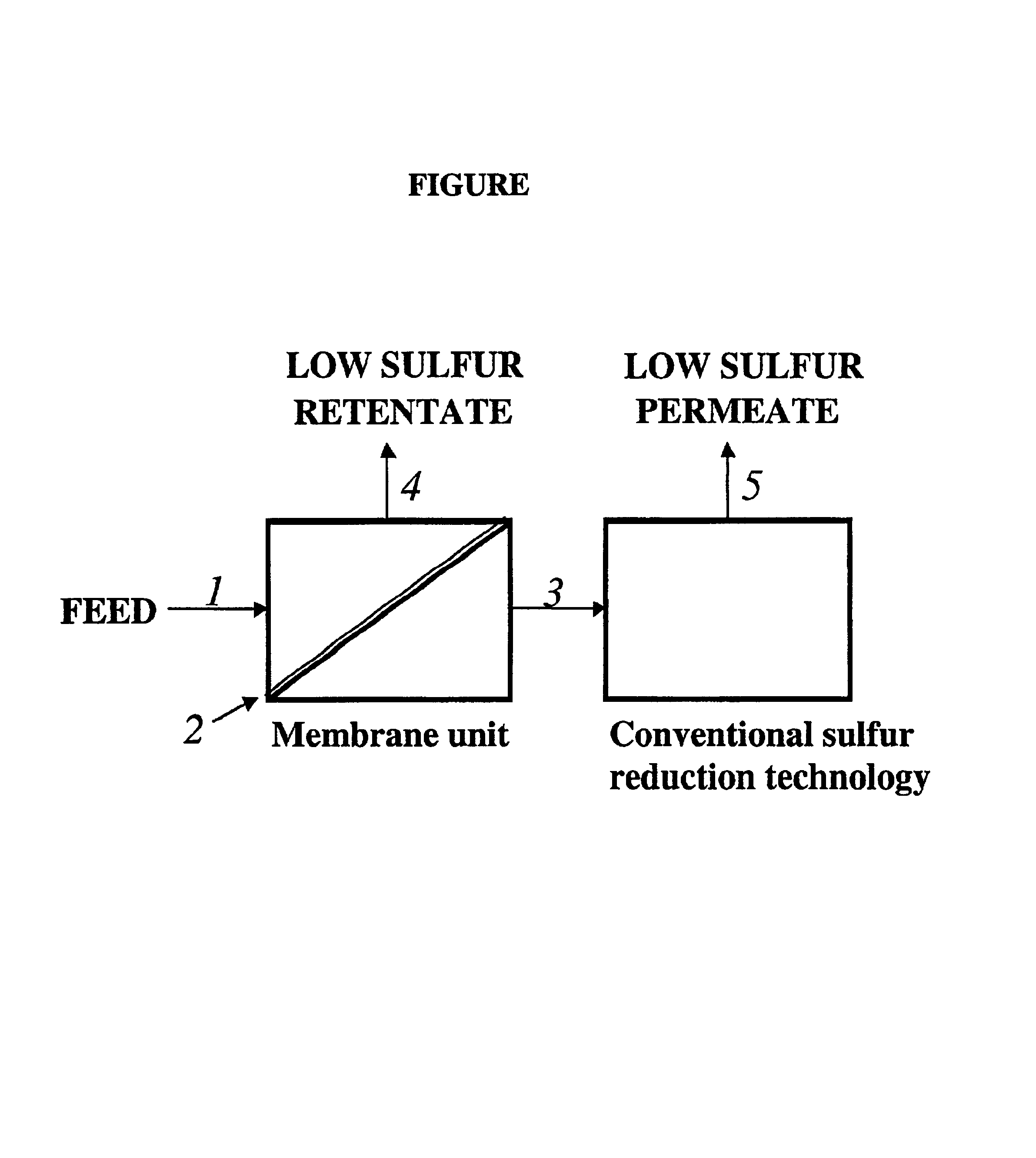

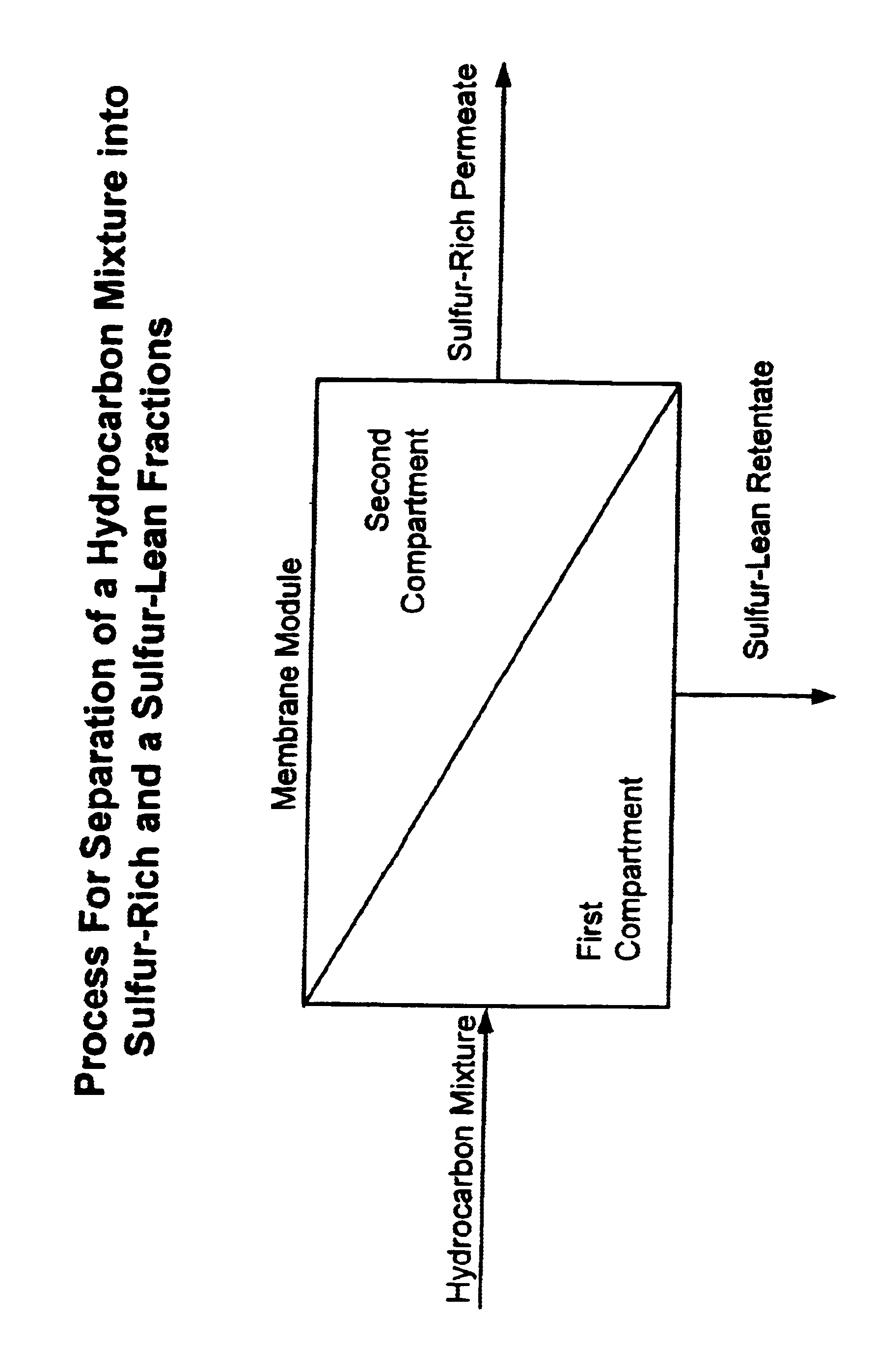

Membrane separation for sulfur reduction

InactiveUS6896796B2Improve economyMinimized volumeDialysisTreatment with plural serial refining stagesNaphthaGasoline

A membrane process for the removal of sulfur species from a naphtha feed, in particular, a FCC light cat naphtha, without a substantial loss of olefin yield is disclosed. The process involves contacting a naphtha feed stream with a membrane having sufficient flux and selectivity to separate a sulfur deficient retentate fraction from a sulfur enriched permeate fraction, preferably, under pervaporation conditions. Sulfur deficient retentate fractions are useful directly into the gasoline pool. Sulfur-enriched permeate fractions are rich in sulfur containing aromatic and nonaromatic hydrocarbons and are further treated with conventional sulfur removal technologies, e.g. hydrotreating, to reduce sulfur content. The process of the invention provides high quality naphtha products having a reduced sulfur content and a high content of olefin compounds.

Owner:WR GRACE & CO CONN

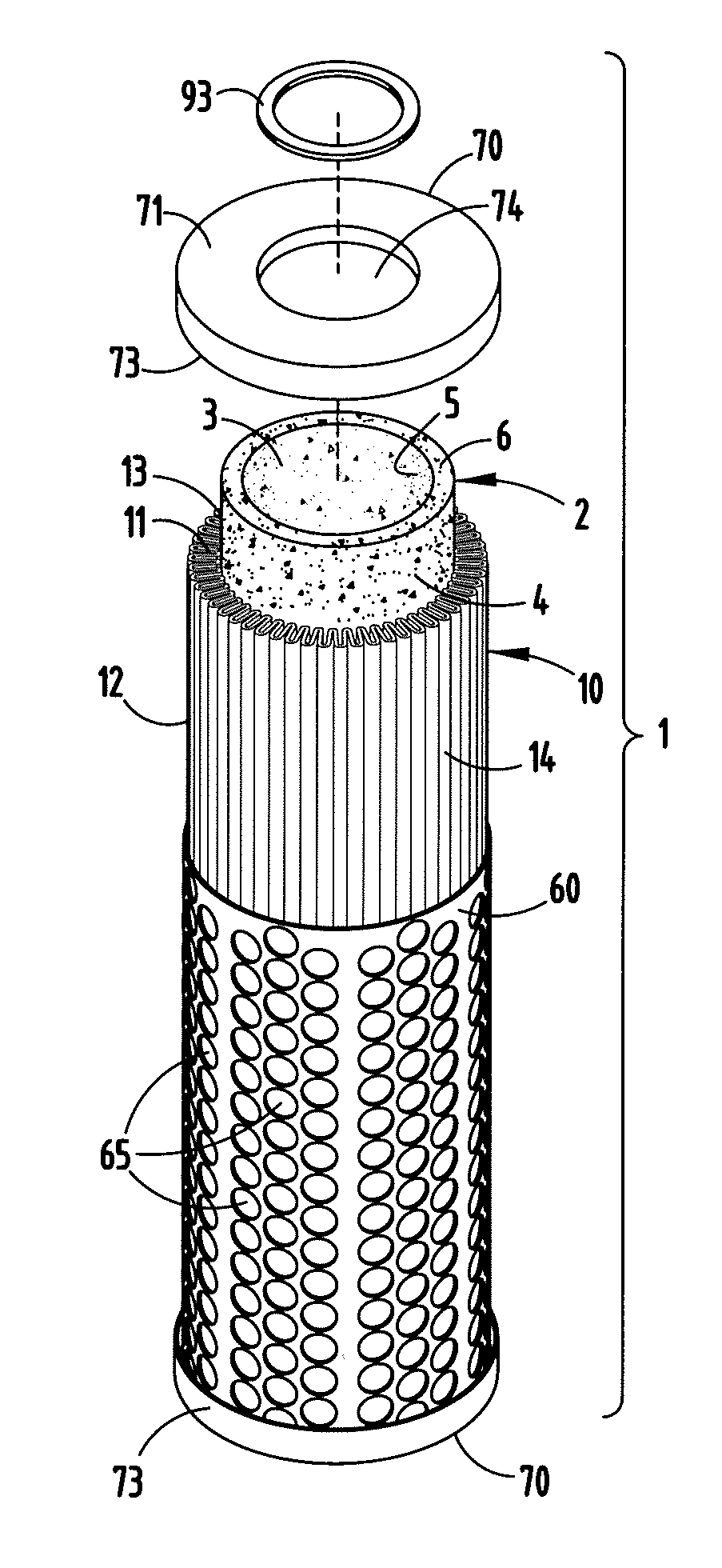

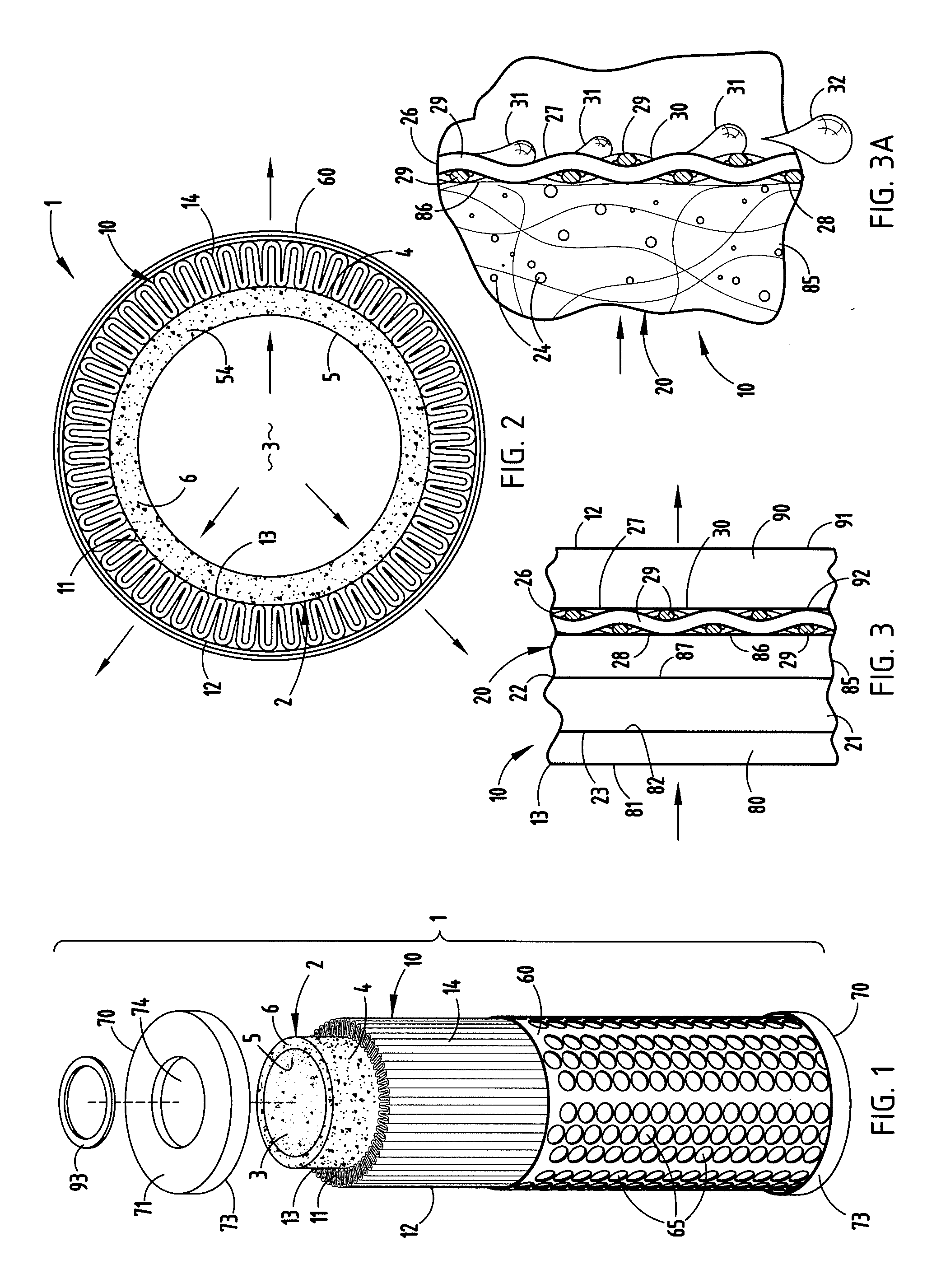

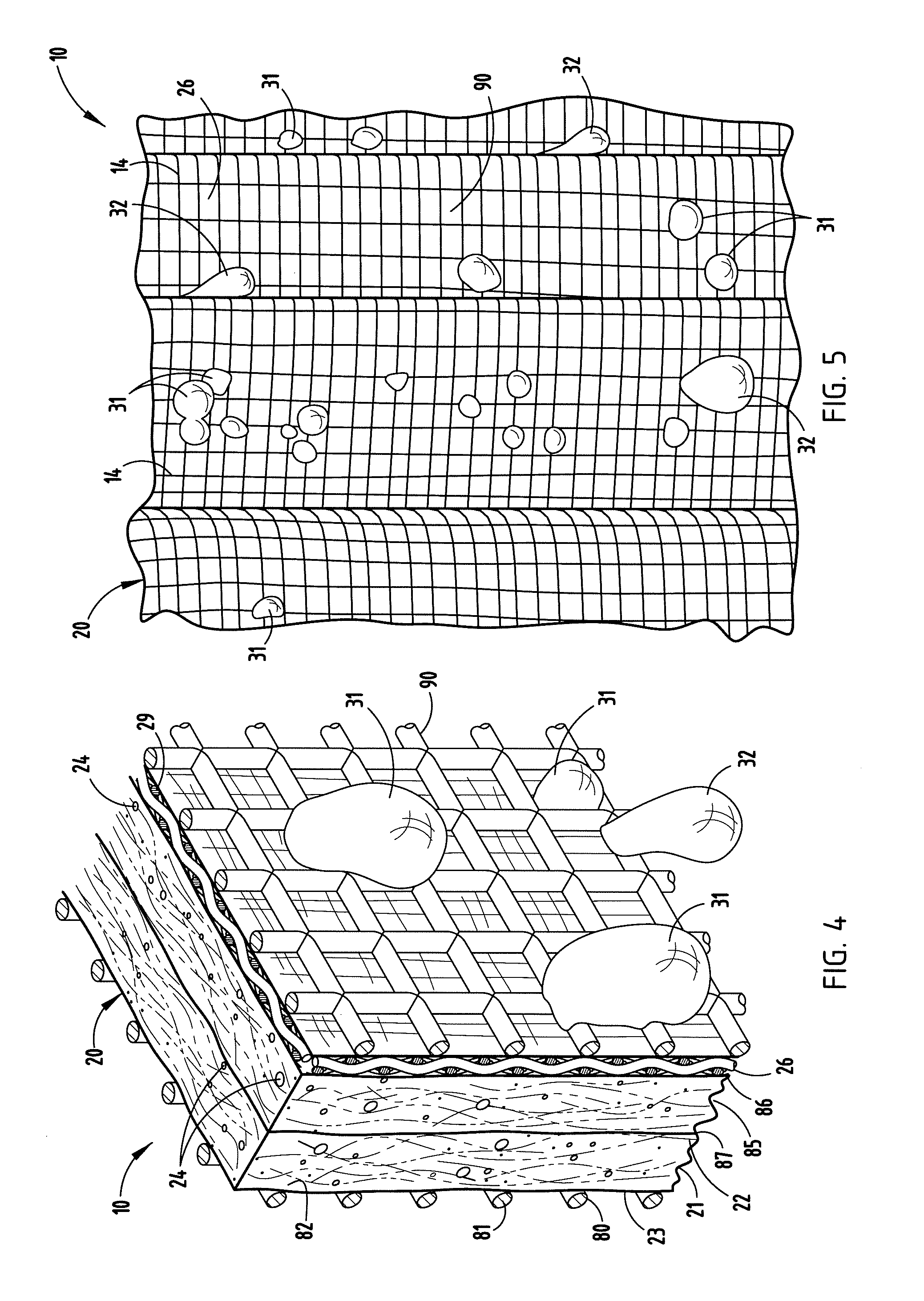

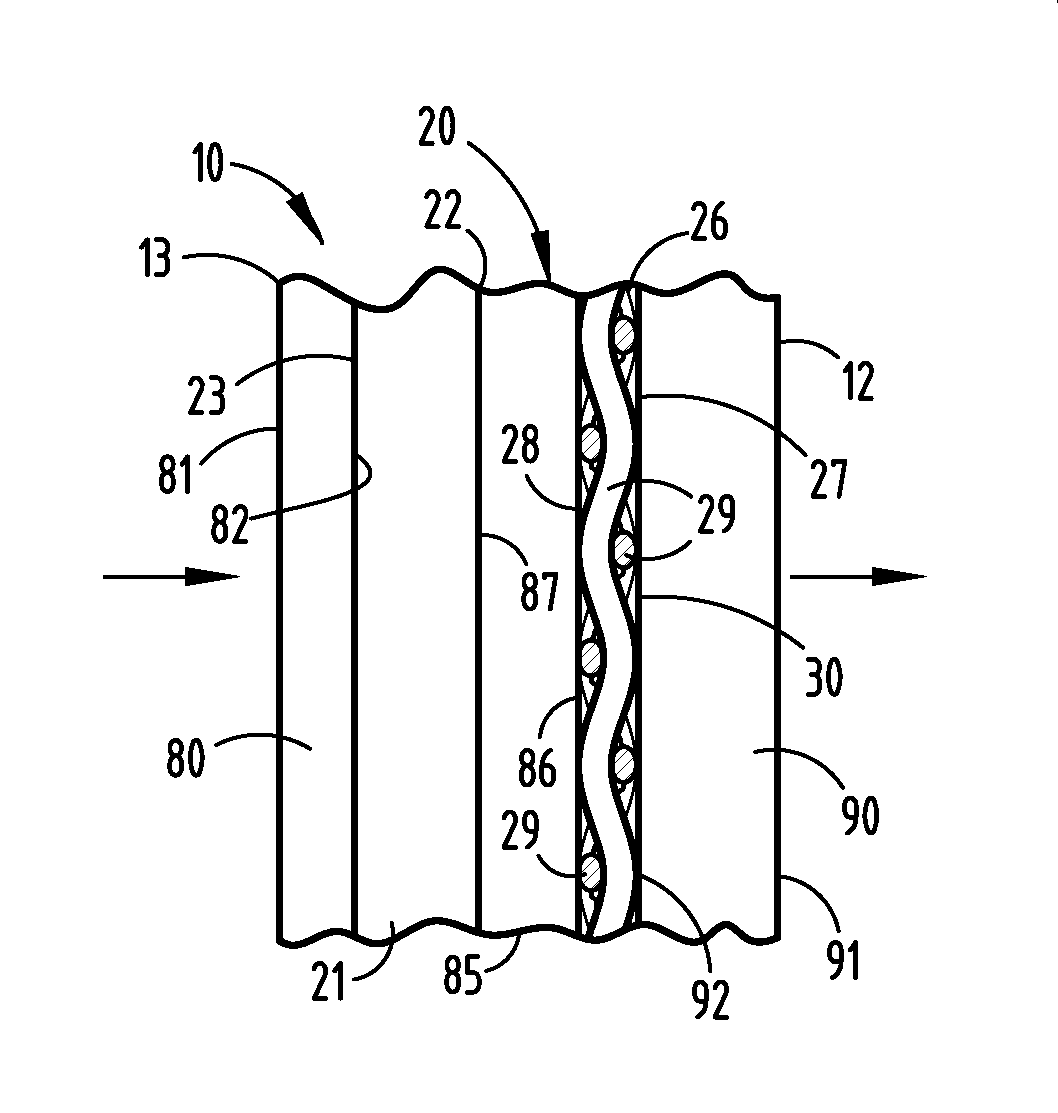

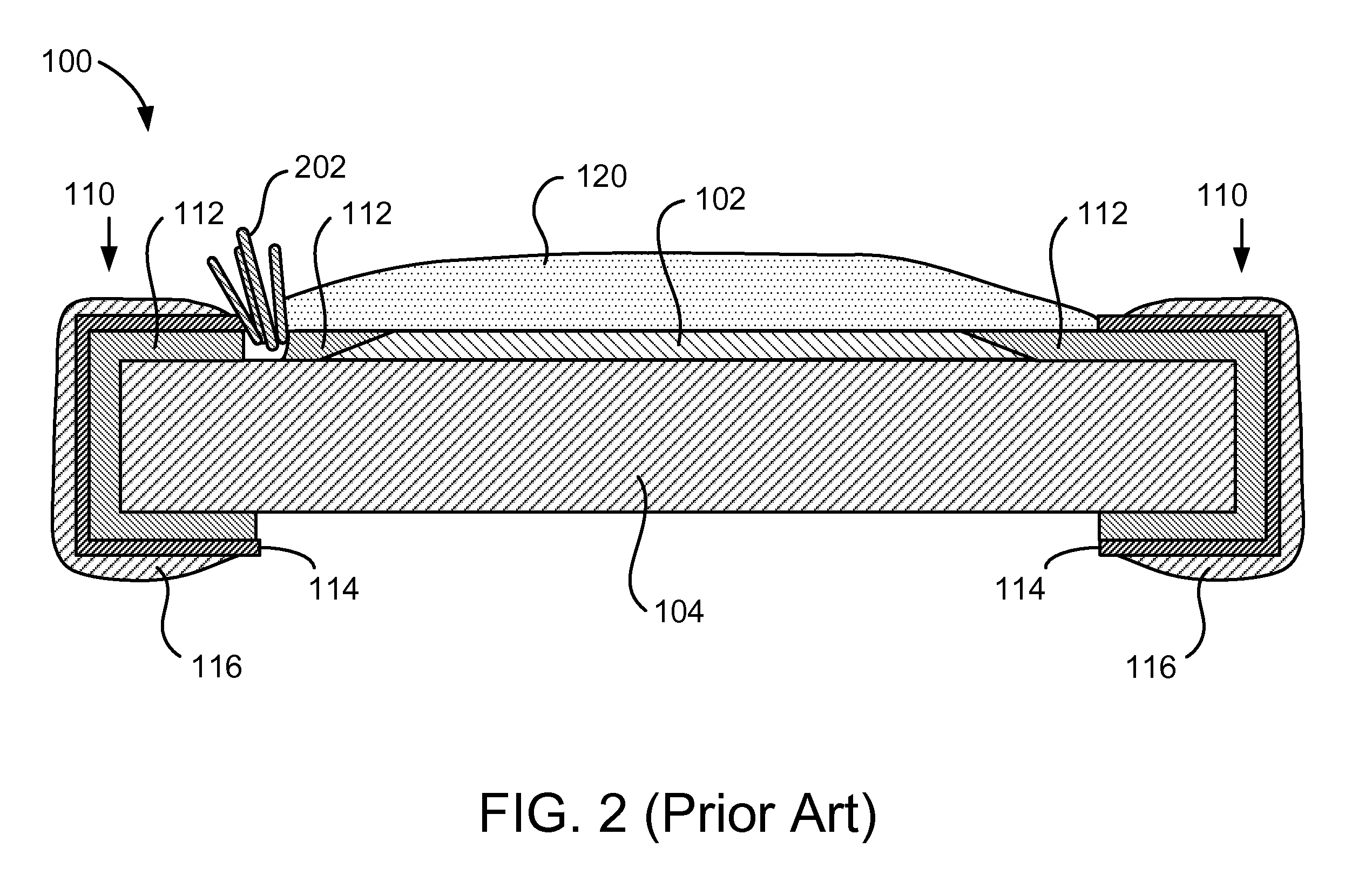

Apparatus and method for removing contaminants from industrial fluids

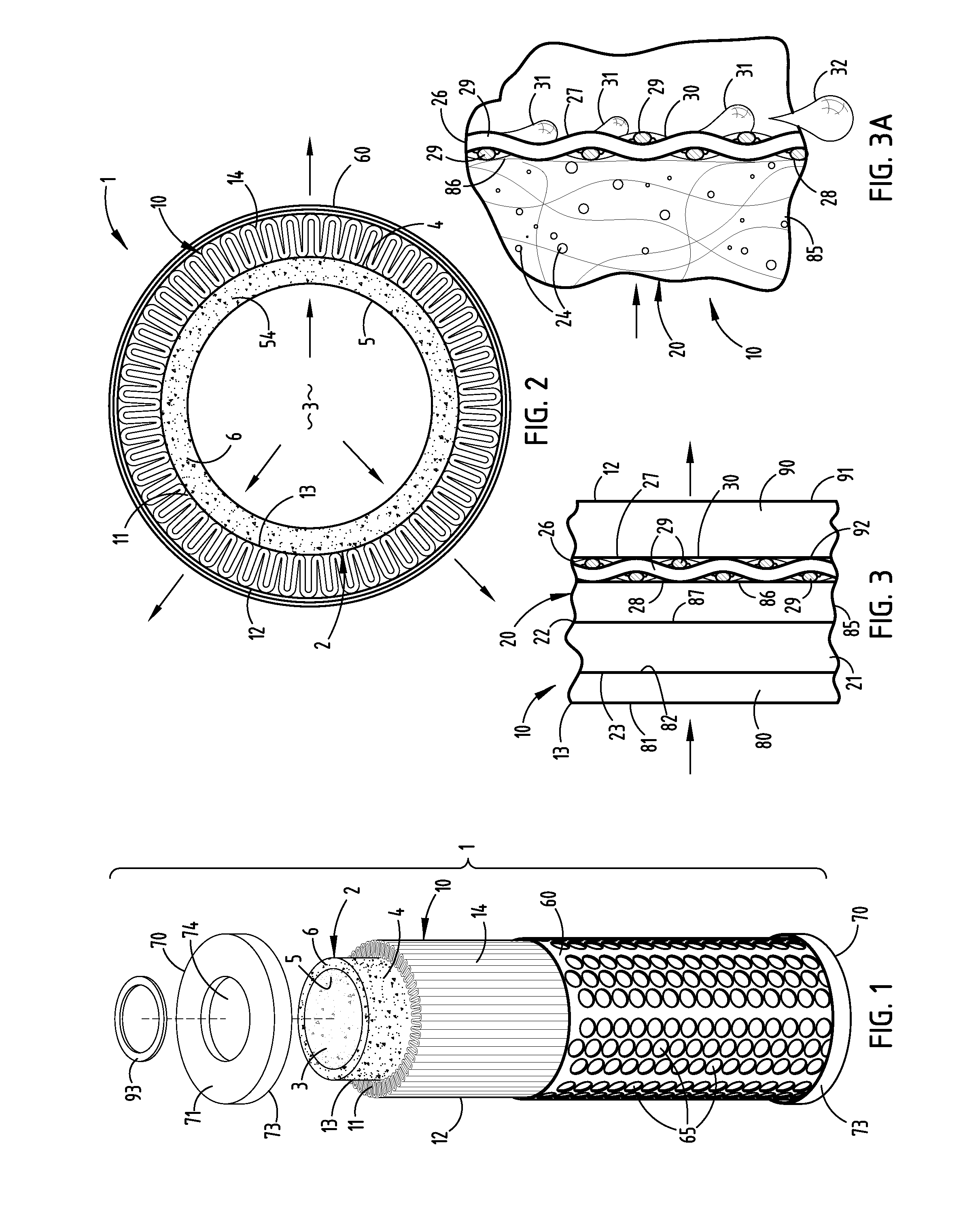

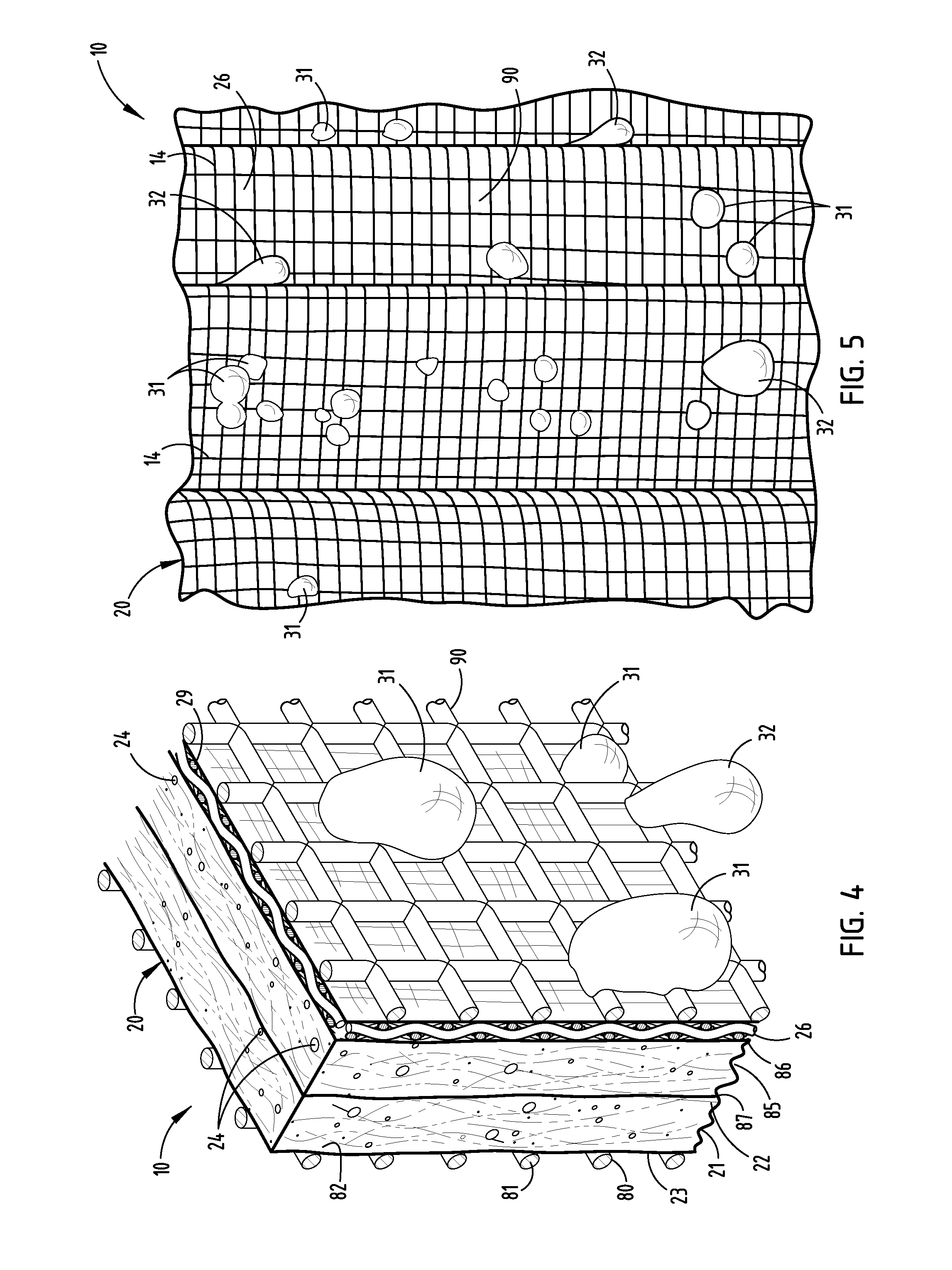

InactiveUS20110259796A1Efficiently and effectively removedReduce manufacturing costSemi-permeable membranesDewatering/demulsification with mechanical meansFilter systemEngineering

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

Apparatus and method for removing contaminants from industrial fluid

InactiveUS20140034580A1Efficiently and effectively removedReduce manufacturing costDewatering/demulsification with mechanical meansWater/sewage treatmentFilter systemEnvironmental engineering

A filter system for removing contaminants from oil based industrial liquids and the like includes a support tube with a permeable sidewall through which the industrial liquid flows in an inside out direction. A multilayer coalescence media surrounds the support tube, and includes at least one layer of a non-woven fibrous material that is partially wettable by the dispersed water in the industrial liquid, and commences coalescence of the same to form small primary water droplets, and at least one sheet of a precisely woven monofilament fabric stacked on the downstream side of the non-woven material. The woven fabric is substantially wettable by the dispersed water, and has a fixed open mesh with uniformly sized and spaced apart pore openings which continue to coalesce the primary water droplets into large water drops which fall from the filter for collection along the bottom of the apparatus.

Owner:KAYDON CUSTOM FILTRATION CORP

Silicone-based chemical filter and silicone-based chemical bath for removing sulfur contaminants

ActiveUS20120187046A1Waste water treatment from quariesUsing liquid separation agentCross-linkData center

Sulfur contaminants, such as elemental sulfur (S8), hydrogen sulfide and other sulfur components in fluids (e.g., air, natural gas, and other gases, as well as water and other liquids) are removed using a silicone-based chemical filter / bath. In one embodiment, a silicone-based chemical filter includes a membrane having a cross-linked silicone that is a reaction product of an olefin and a polyhydrosiloxane. For example, sulfur contaminants in air may be removed by passing the air through the membrane before the air enters a data center or other facility housing computer systems. In another embodiment, a silicone-based chemical bath includes a housing having an inlet port, an outlet port, and a chamber containing a silicone oil. For example, sulfur contaminants in air may be removed by passing the air through the silicone oil in the chamber before the air enters a data center or other facility housing computer systems.

Owner:IBM CORP

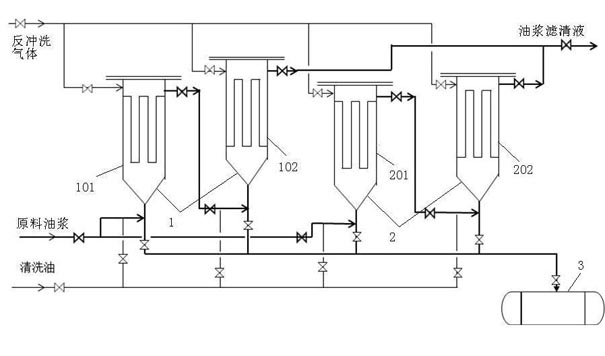

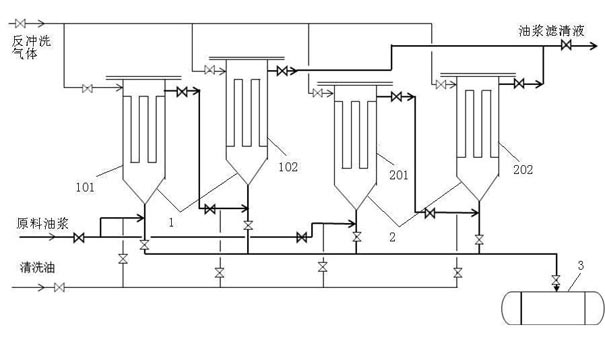

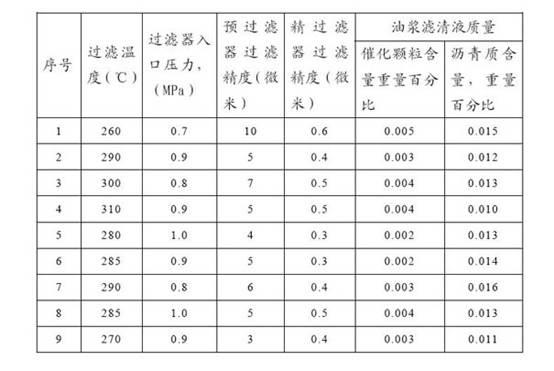

Device and method for separating residue from catalytic cracking oil slurry

The patent discloses a device for separating residue from catalytic cracking oil slurry, which comprises at least two filter sets and a filter cake tank, wherein the at least two filter sets are formed by connecting pre-filters and fine filters; the filter cake tank is arranged between the bottoms of the pre-filters and the fine filters for accommodating a peeled filter cake and washed washing oil; the bottom of each pre-filter is connected with a raw material oil slurry inlet and a washing oil inlet, and the bottom of each fine filter is connected and provided with a washing oil inlet for washing the filter core of the filter; an oil slurry filtrate outlet is formed on the top of each fine filter; and backwash air inlets are formed on the tops of both the pre-filters and the fine filters. Meanwhile, the patent also discloses a method using the device. The residual catalyst content of the oil slurry filtrate processed by the device in the patent is less than 0.01 percent, and filtrate content is less than 0.02 percent.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

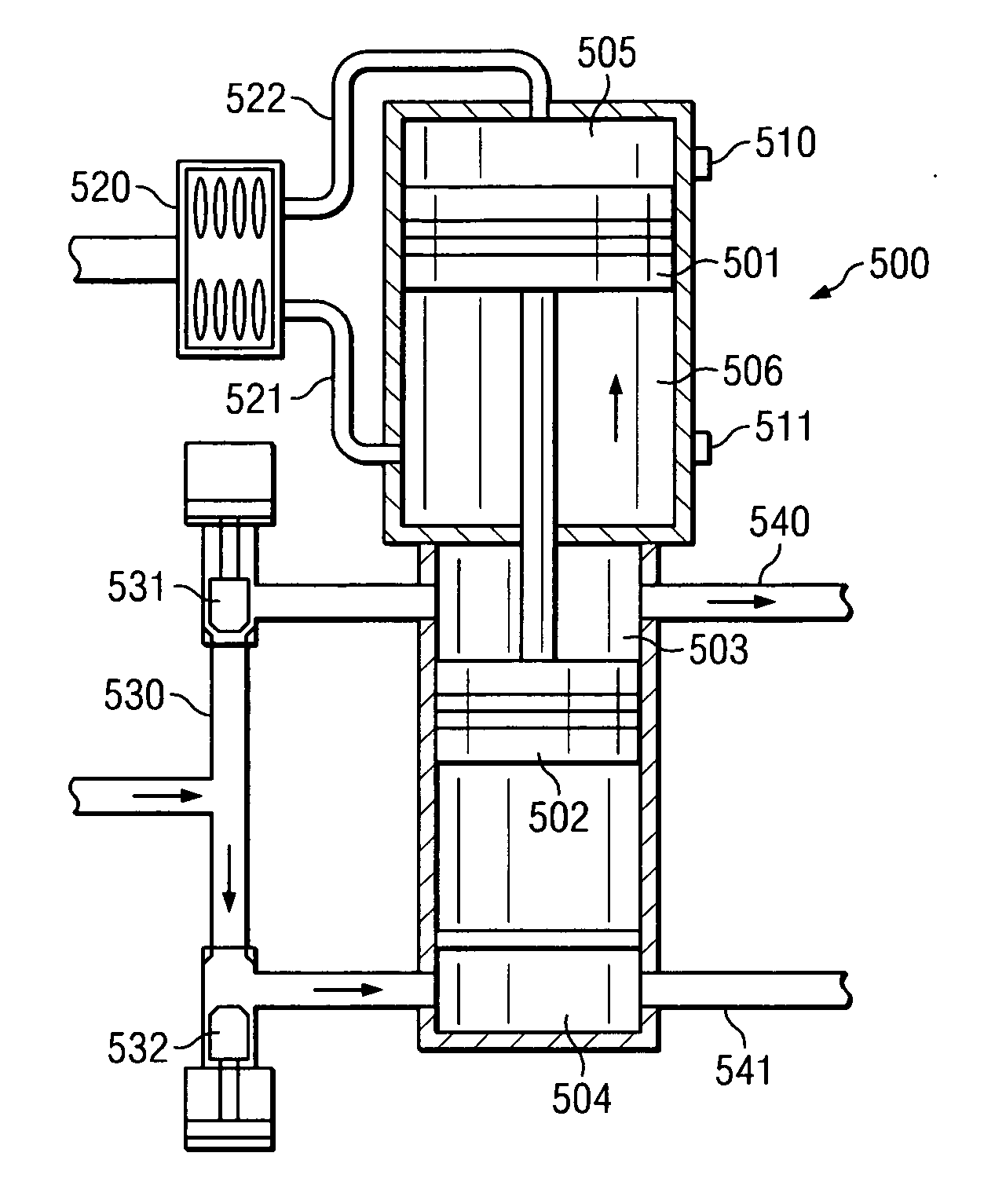

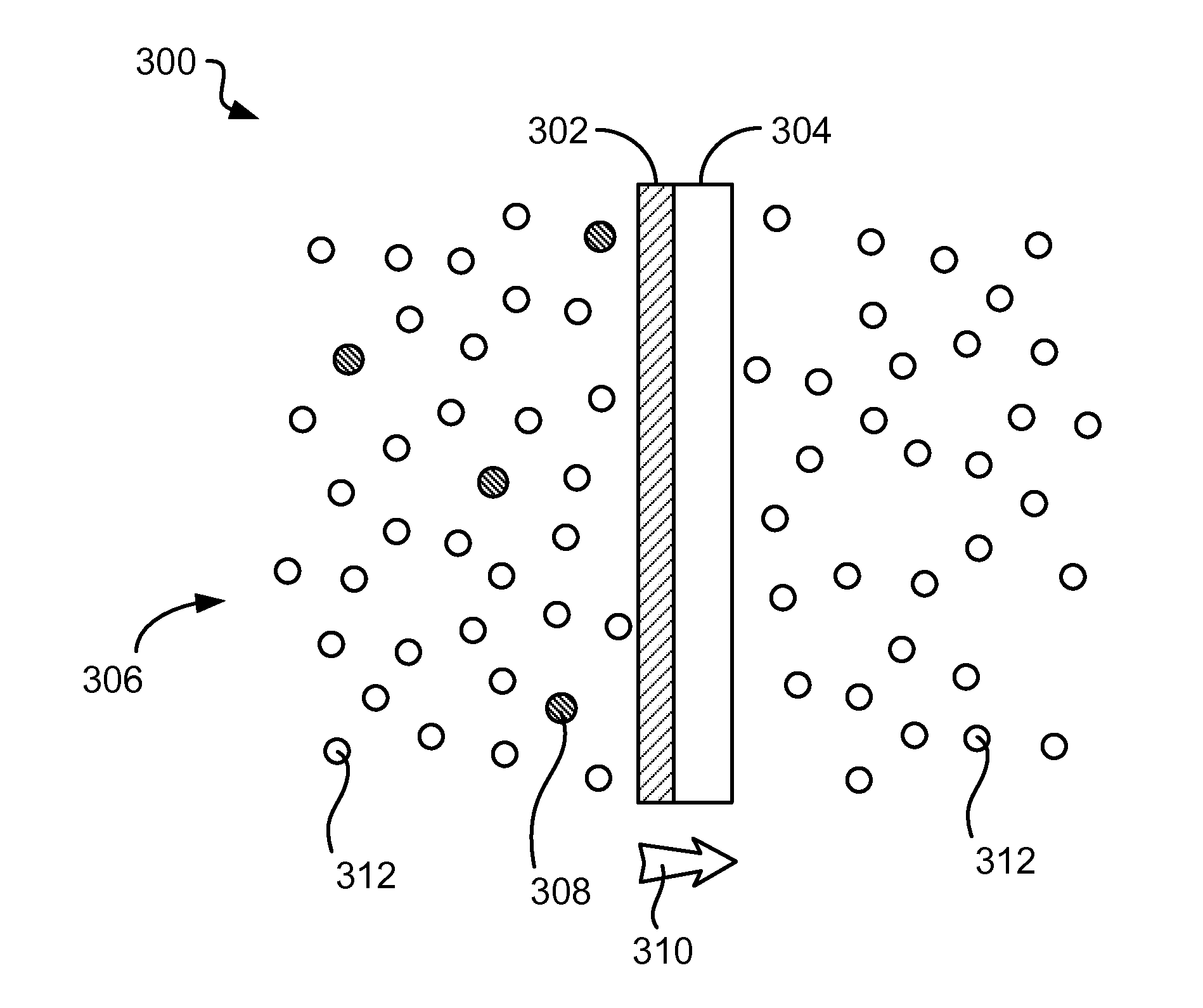

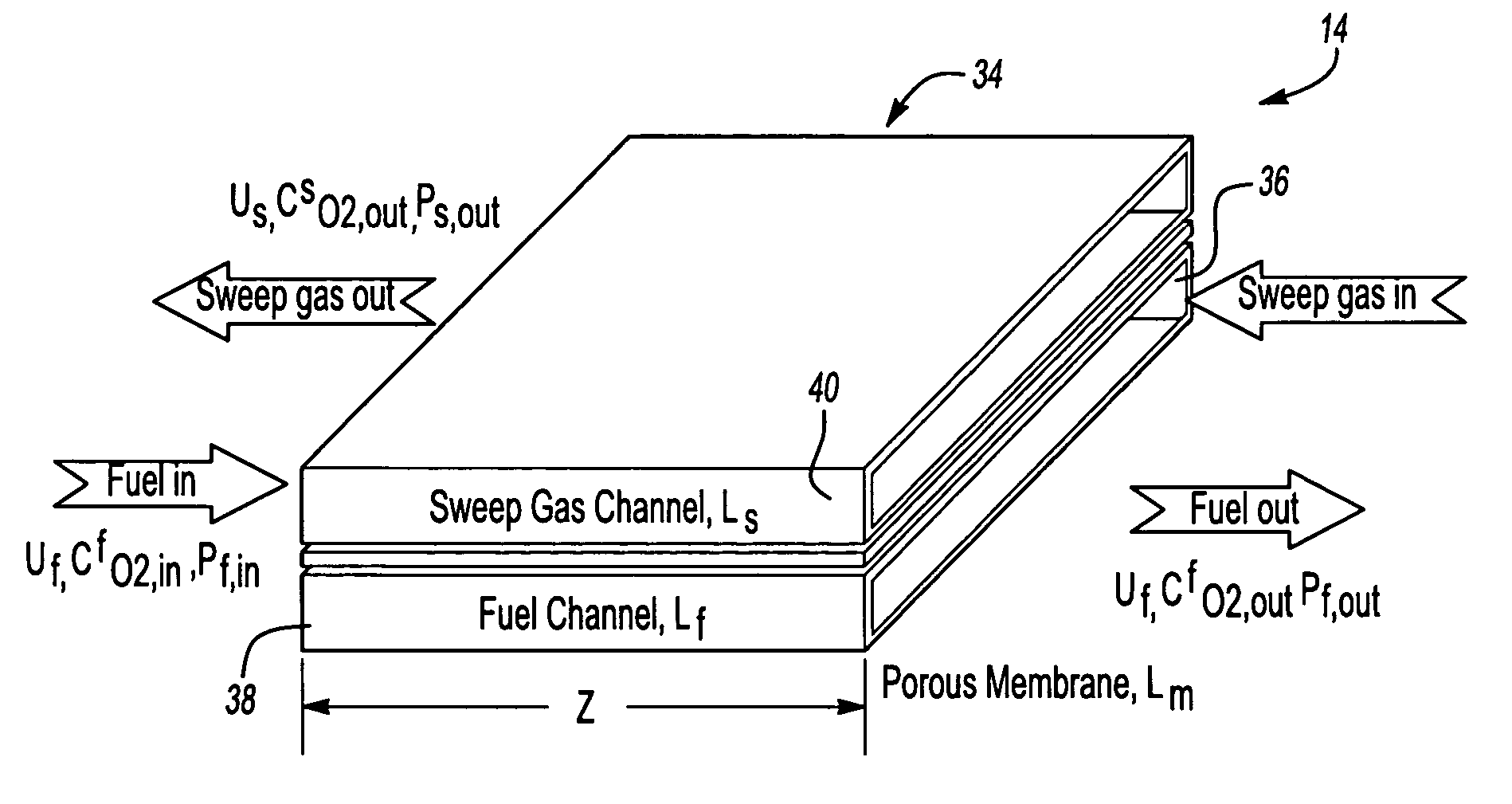

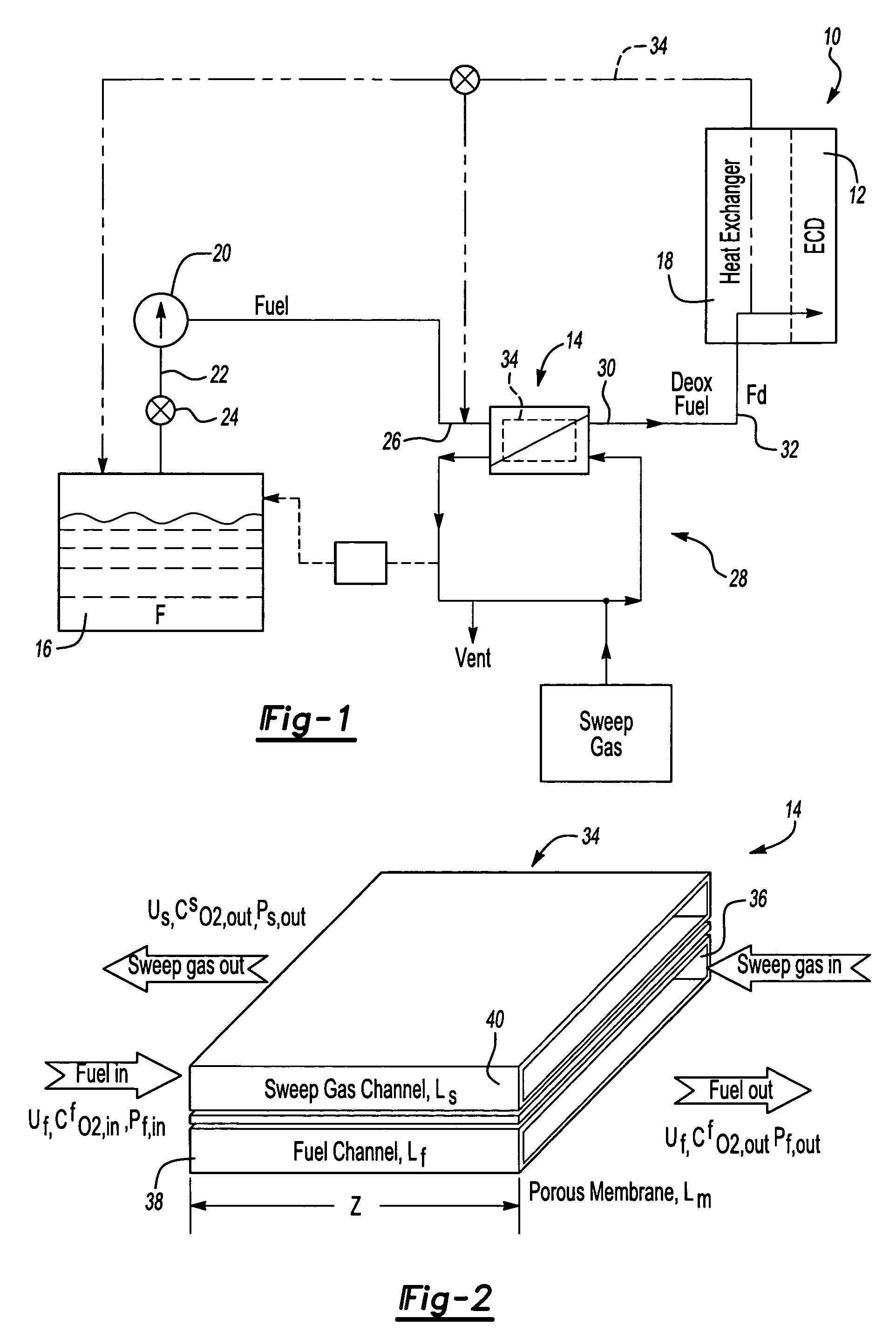

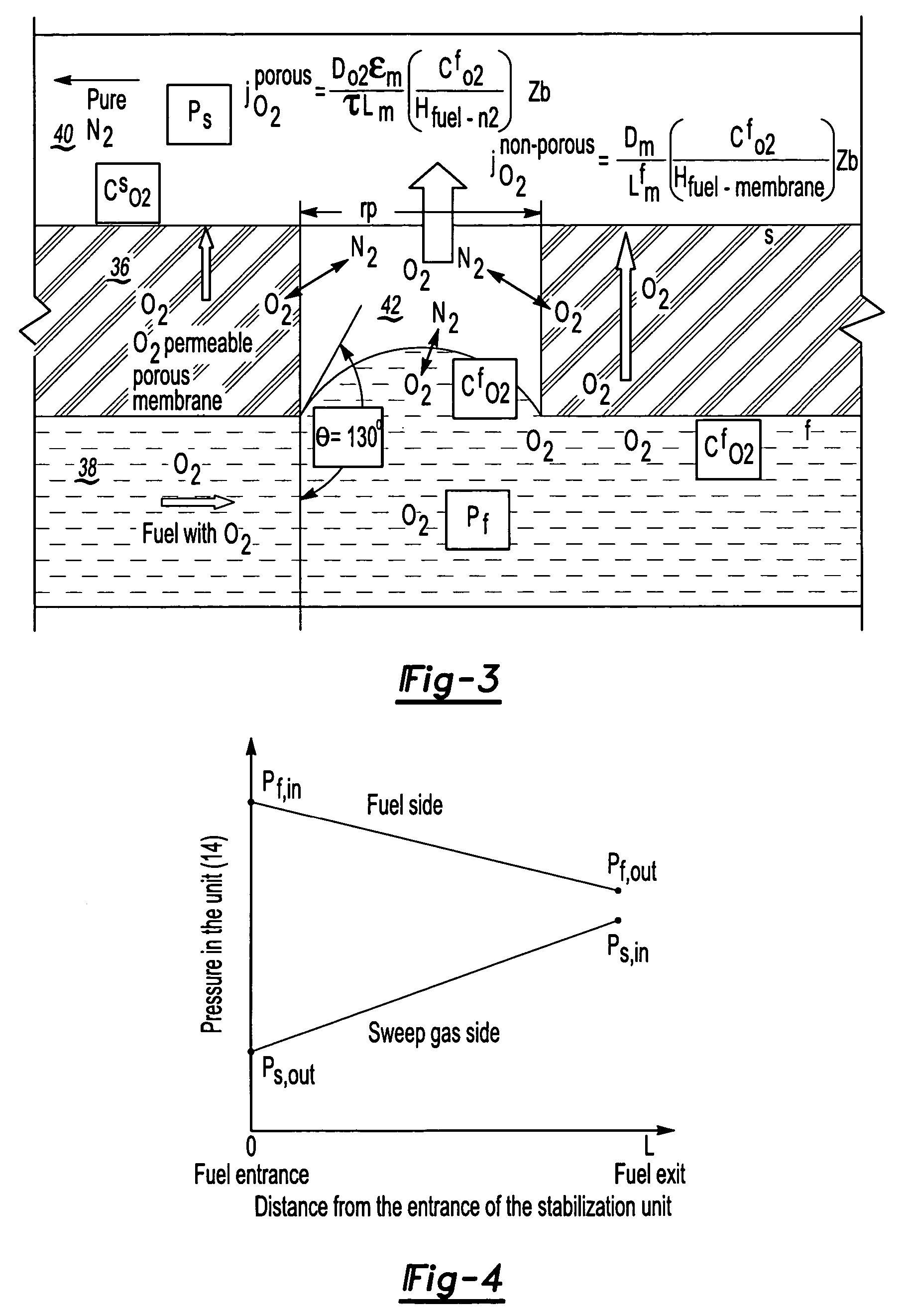

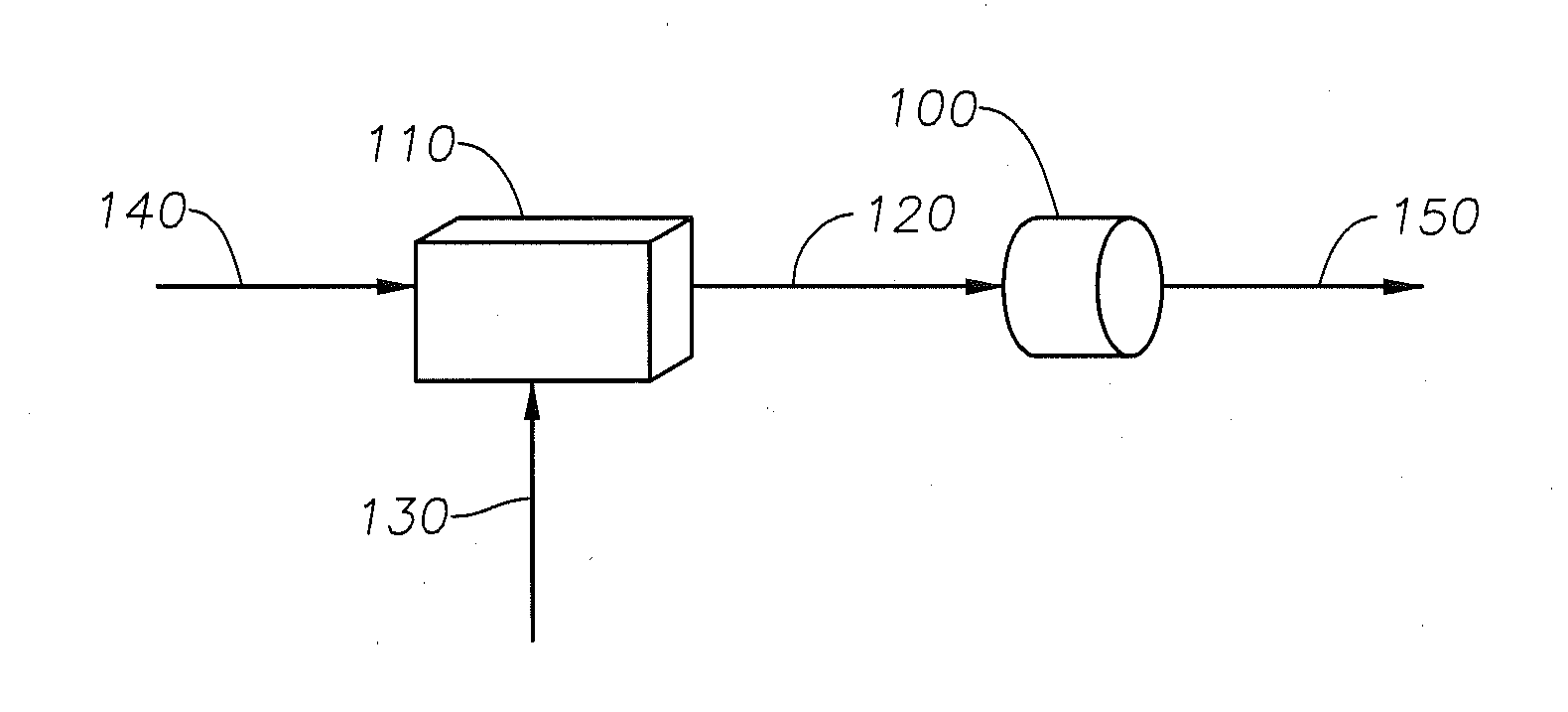

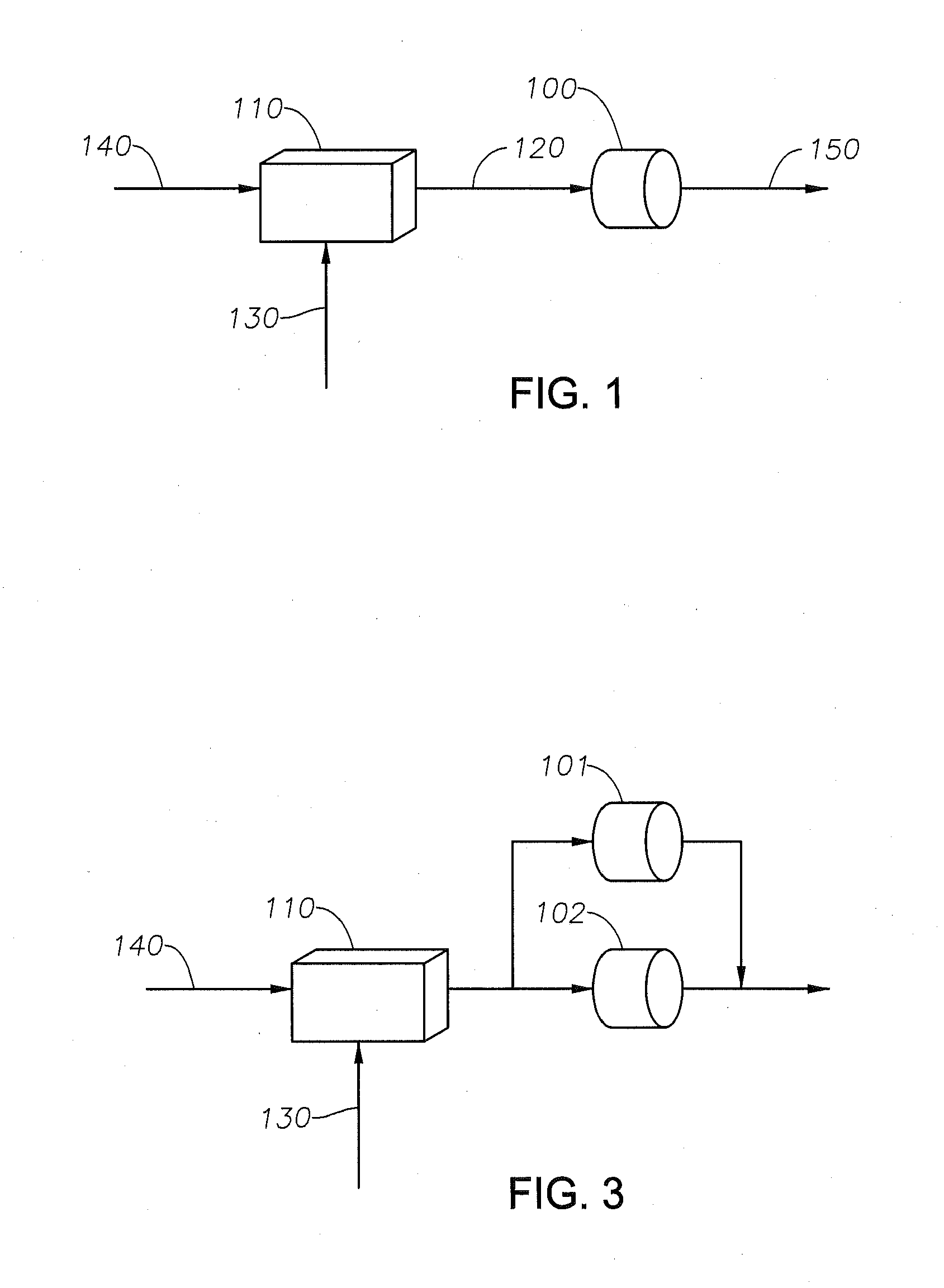

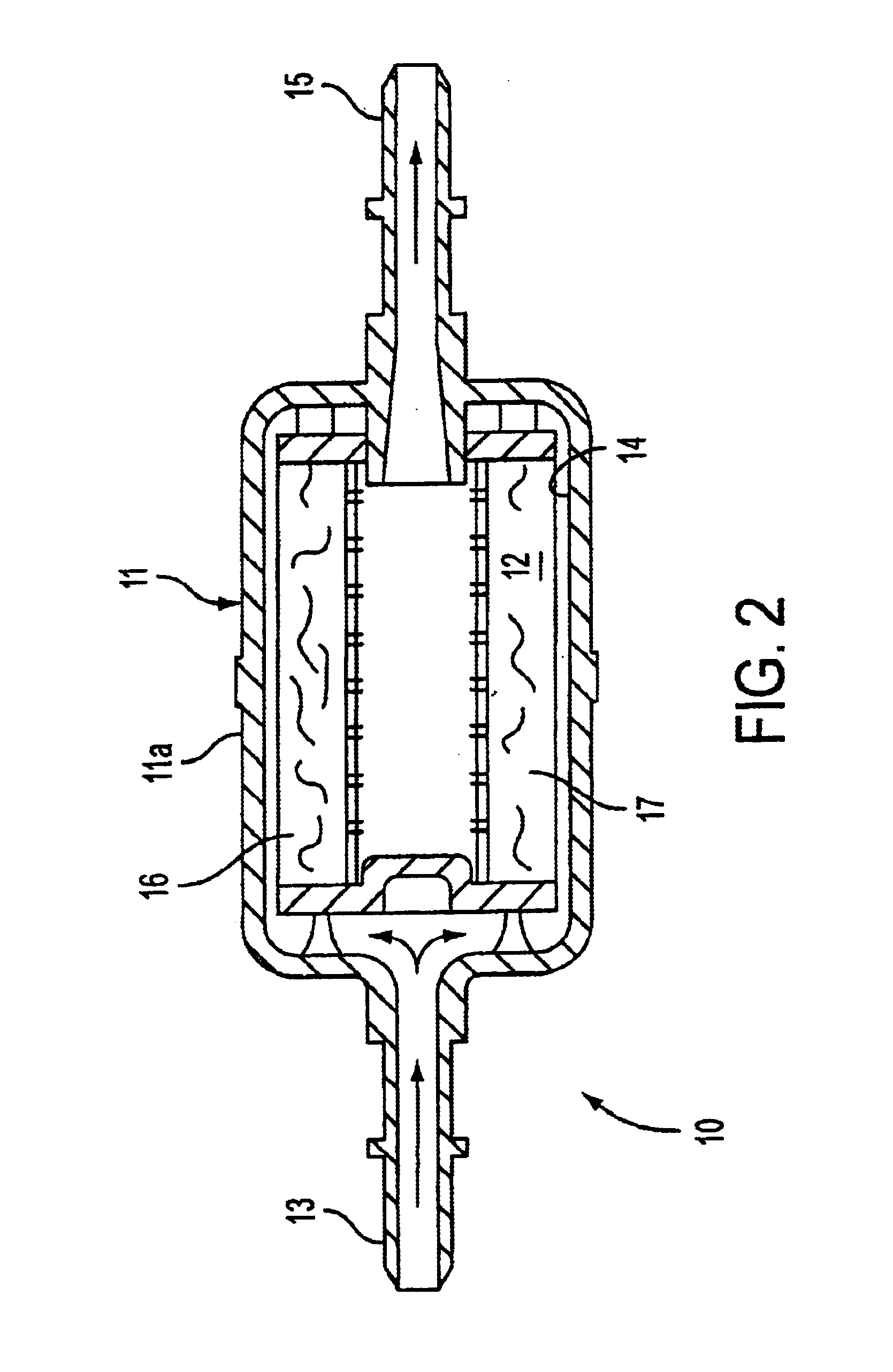

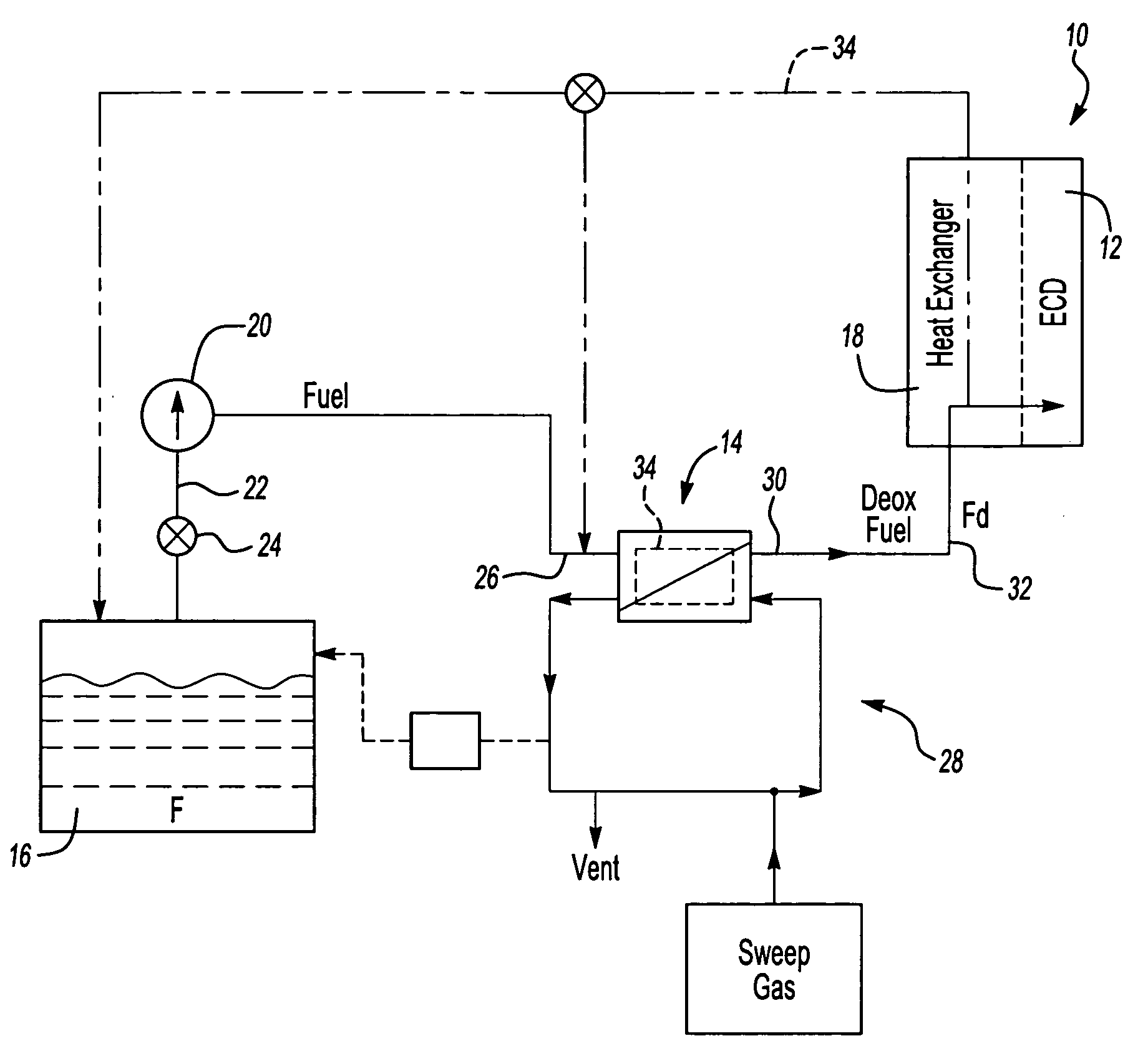

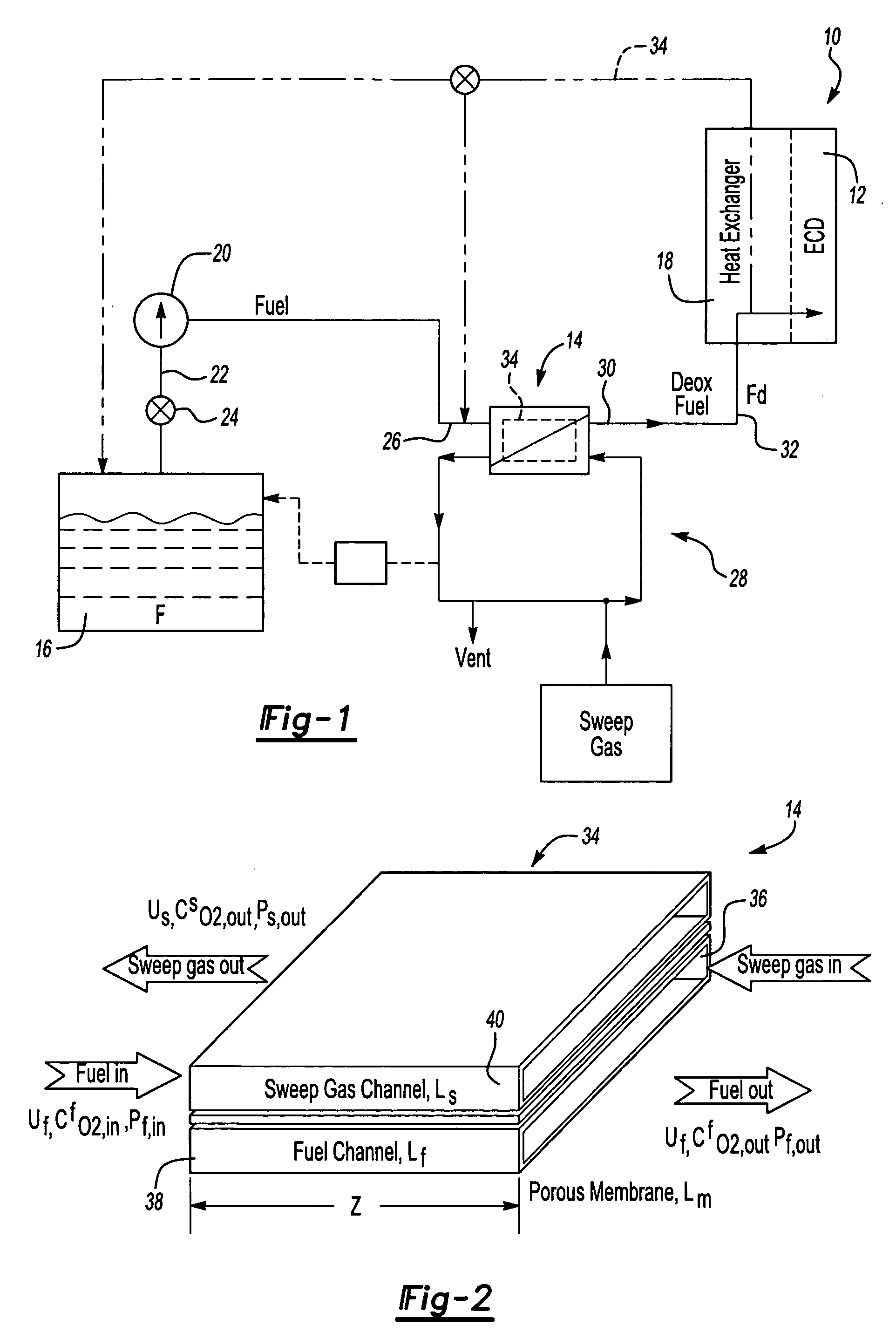

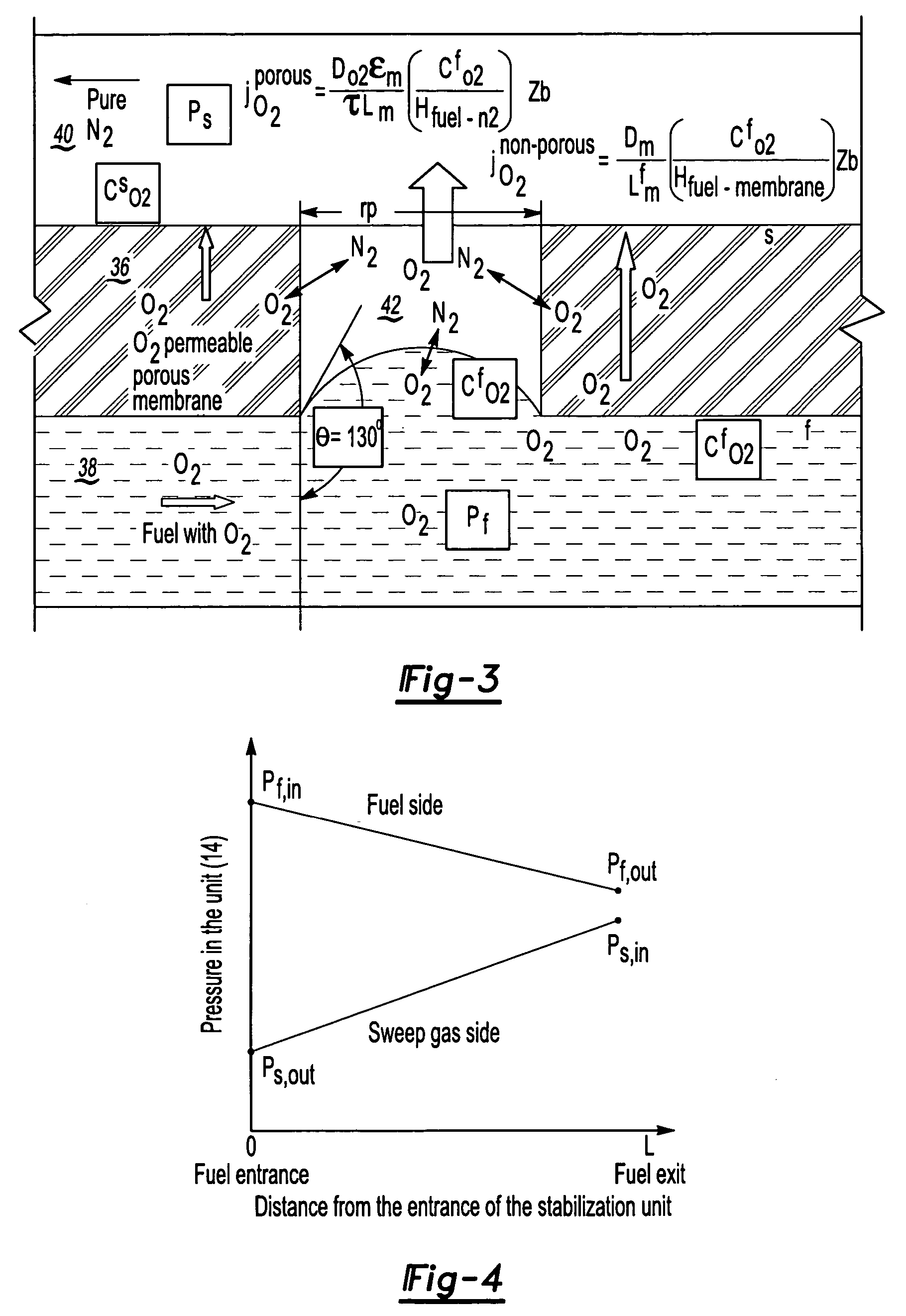

Fuel deoxygenation system

ActiveUS7153343B2Inexpensive sizeInexpensive weightLiquid fuel feeder/distributionSemi-permeable membranesPorous membraneEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a porous membrane. The deoxygenator includes an oxygen receiving channel separated from the fuel channel by the porous membrane. The capillary forces counteract the pressure differential across the membrane, preventing any leakage of the fuel, while the oxygen concentration differential across the membrane allows for deoxygenation of the fuel through the porous membrane.

Owner:RTX CORP

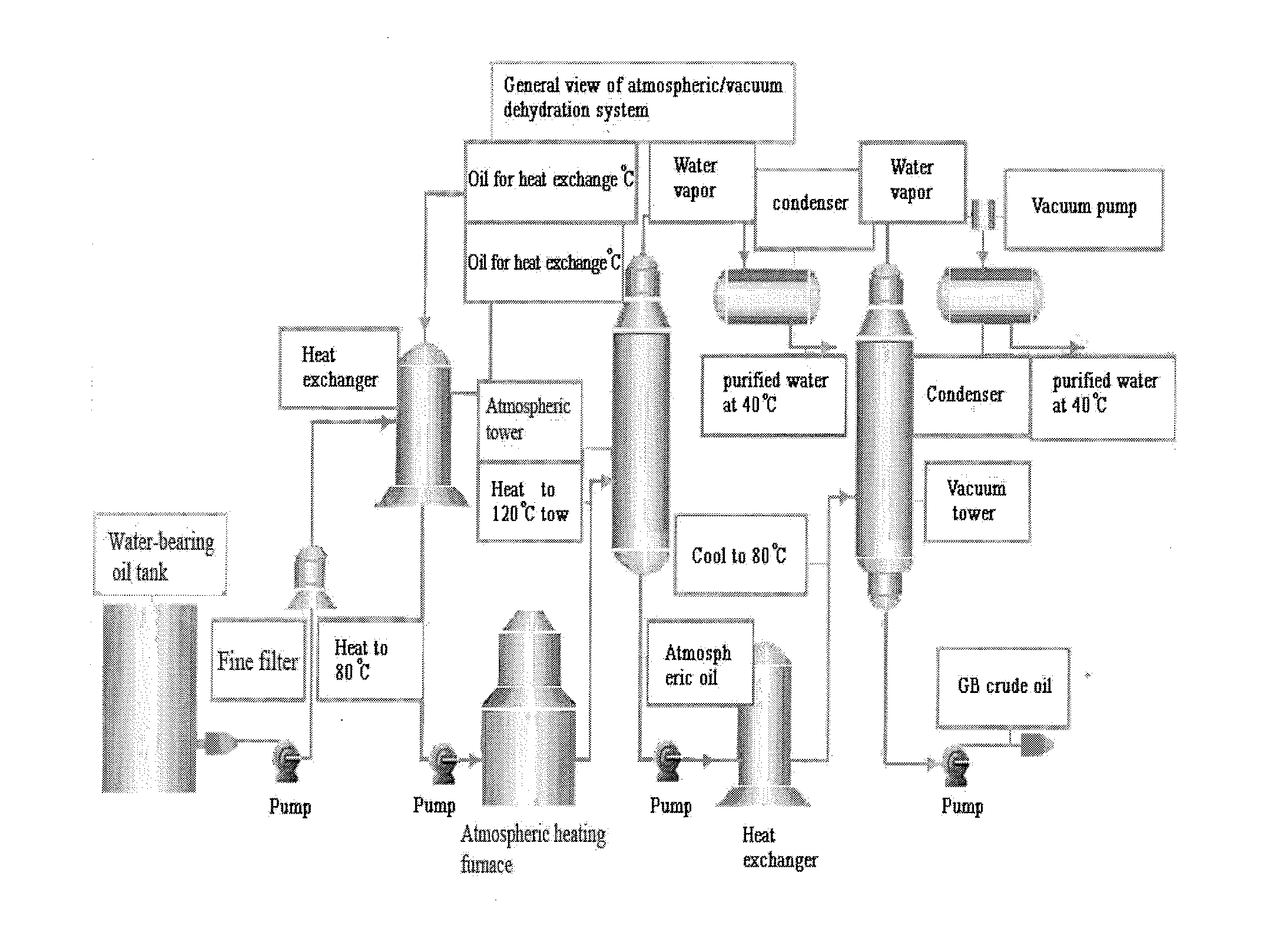

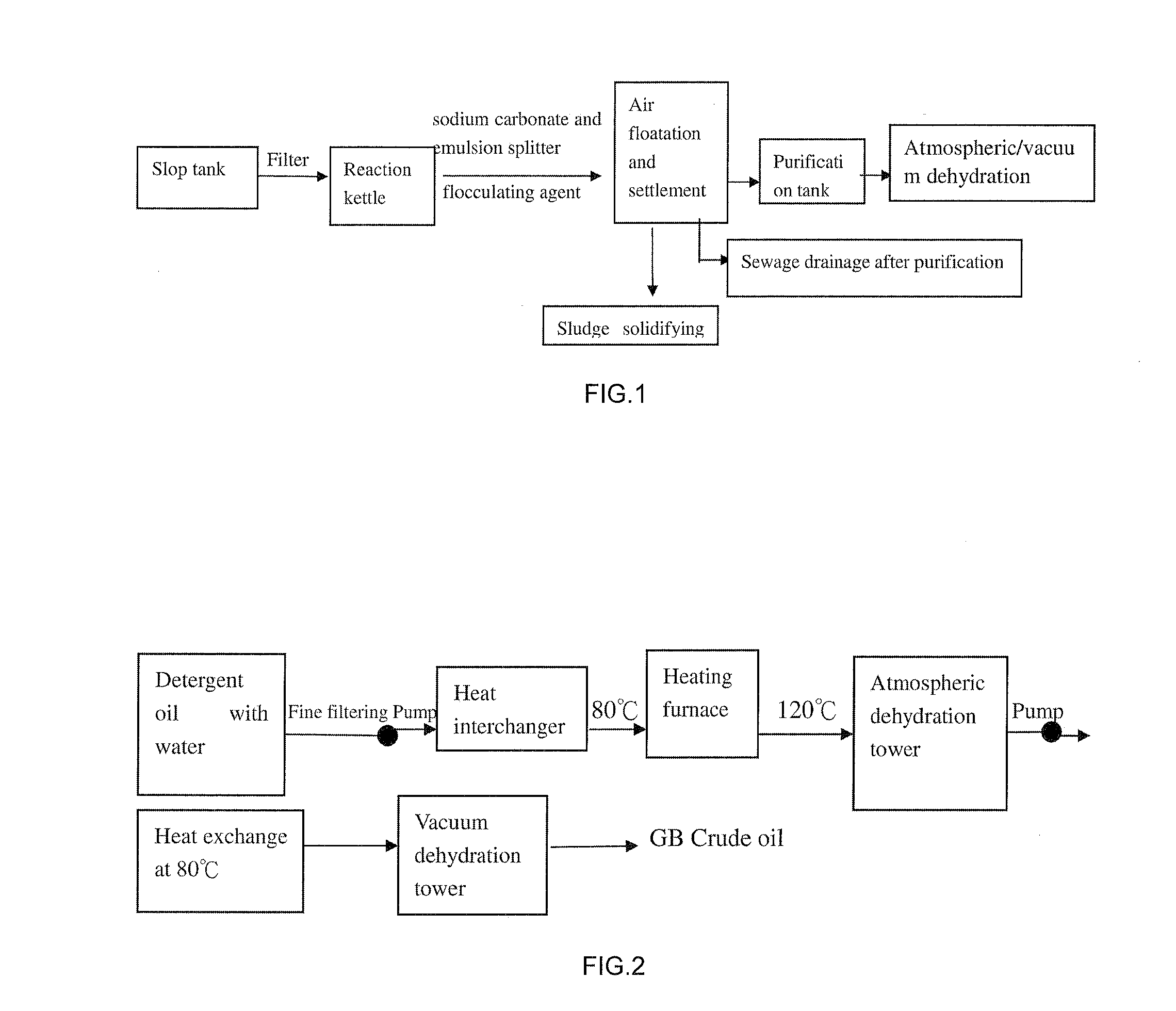

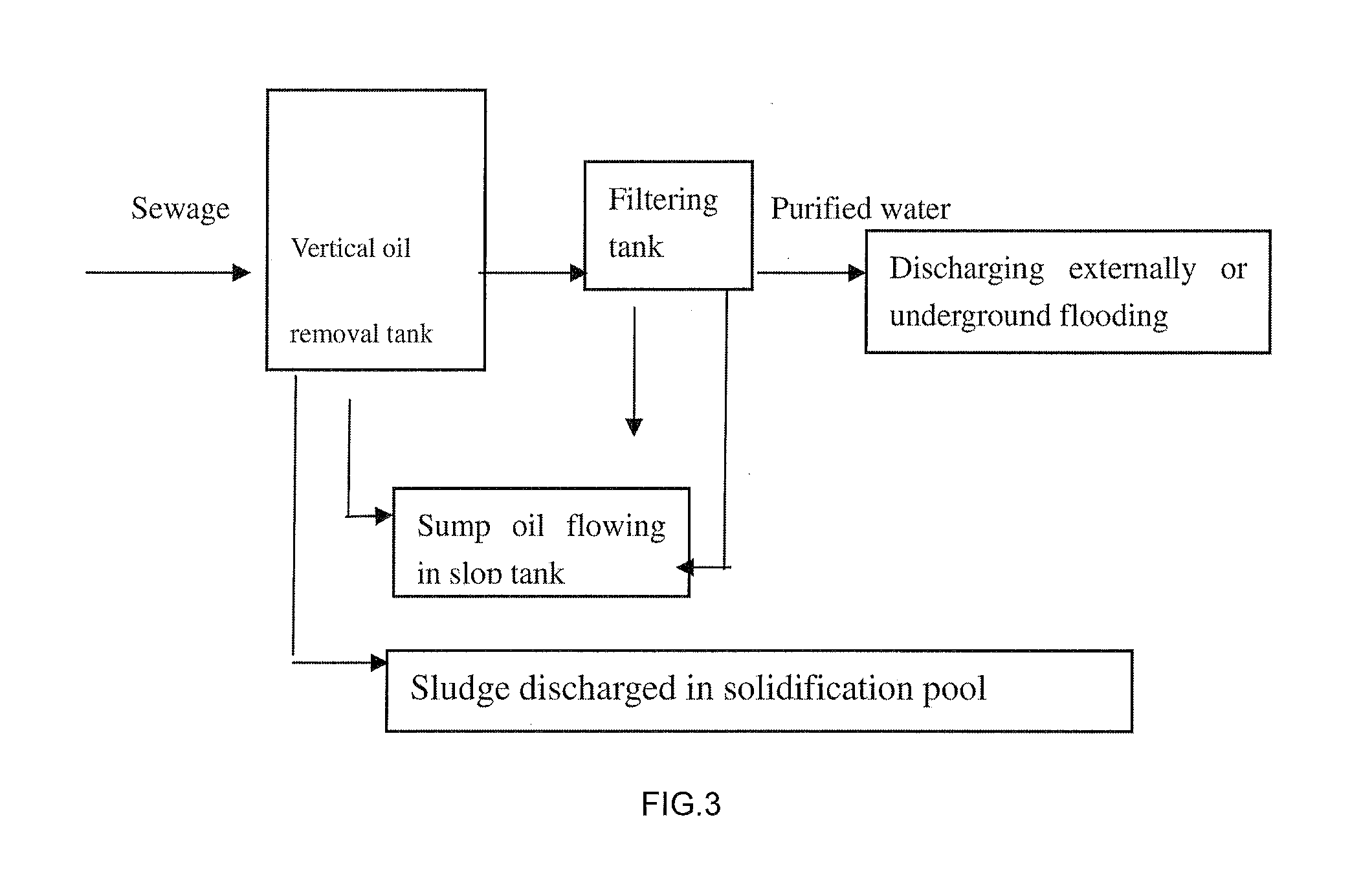

Centralized Sump Oil and Acid Oil treatment process and System

InactiveUS20120103914A1Easy to separateLow cost of treatmentSludge treatmentVacuum distillation separationSludgePollution

This invention reveals to the public the centralized sump oil and acid oil treatment process and system. The process consist of (1) the filter; (2) entry to reaction kettle, the sodium carbonate solution added at the time of air floatation till PH value keeps about 6.0-8.0; and emulsion splitter and flocculating agent added for further reaction; (3) suspension of air floatation and static settlement; (4) the international crude oil is collected after the detergent oil at the upper level of the reaction kettle is dehydrated under normal and reduced pressure; the wastewater is drained after filtering by the natural oil removal tank and the oil-water filter; the sludge is solidified by the cement and the quick lime and aluminium oxide are used as the coagulant aid for solidifying the sludge. The centralized treatment process of sump oil and acid oil not only greatly lowers the pollution of surroundings of the oilfield and corrosion of equipment, but also changes waste into valuable, reuses a great amount of crude oil and improves the economic benefits of the oilfield. The sludge solidified can be directly used for buildings.

Owner:YUAN GANG

Process to upgrade and desulfurize crude oil by supercritical water

ActiveUS20140251871A1Enhance overall process operation stabilityEasy to operateSolvent extractionRefining by water treatmentChemistryPollutant

This present invention generally relates to a process for upgrading and desulfurizing crude oil using supercritical water. In general, the invention provides a process for removal of contaminants from a crude oil stream by mixing the crude oil stream with supercritical water and then filtering out the precipitated solid compounds that result from mixing the crude oil stream with supercritical water.

Owner:SAUDI ARABIAN OIL CO

Apparatus and process for the separation of liquids and solids

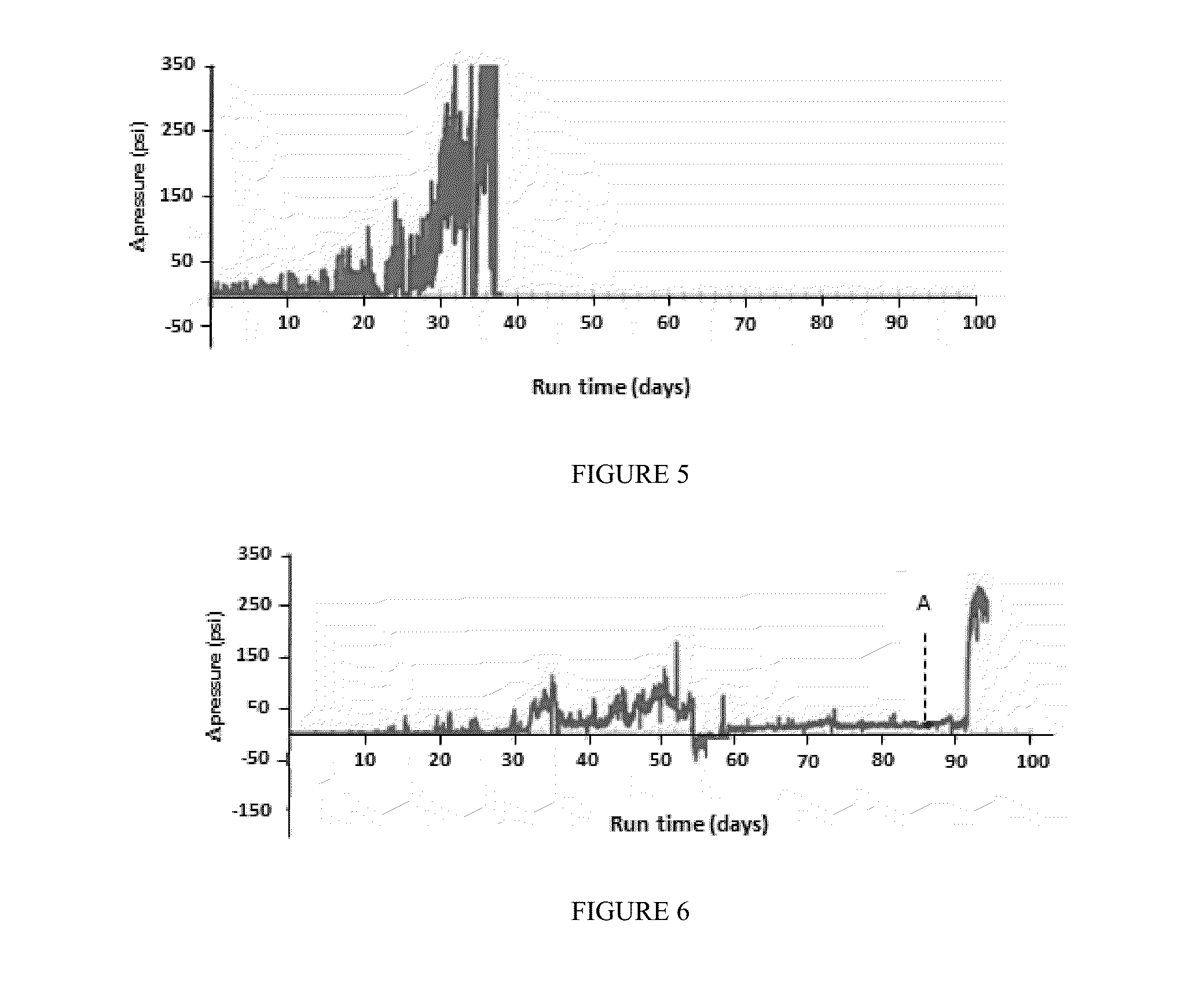

InactiveUS6110390AReduce liquid contentPrevent buildupLiquid separation auxillary apparatusUltrafiltrationFiltrationSystem pressure

A liquid solid separation apparatus having a porous metal pipe sealed inside a non-porous metal pipe which allows a portion of the liquids, e.g., hydrocarbons and water to pass through the first pipe into the non porous pipe from which they are removed while solids are retained within the porous pipe. In the process there is a system pressure which aids in the filtration and a circulating velocity which removes the detained solids. Preferably a portion of these solids with reduced liquid content are recycled back to the system, mixed with fresh feed. By recycling a porion of the recovered solid concentrate the velocity of the flow in the system kept constant and the system itself is stabilized.

Owner:ENVIRONMENTAL SAFEGUARDS

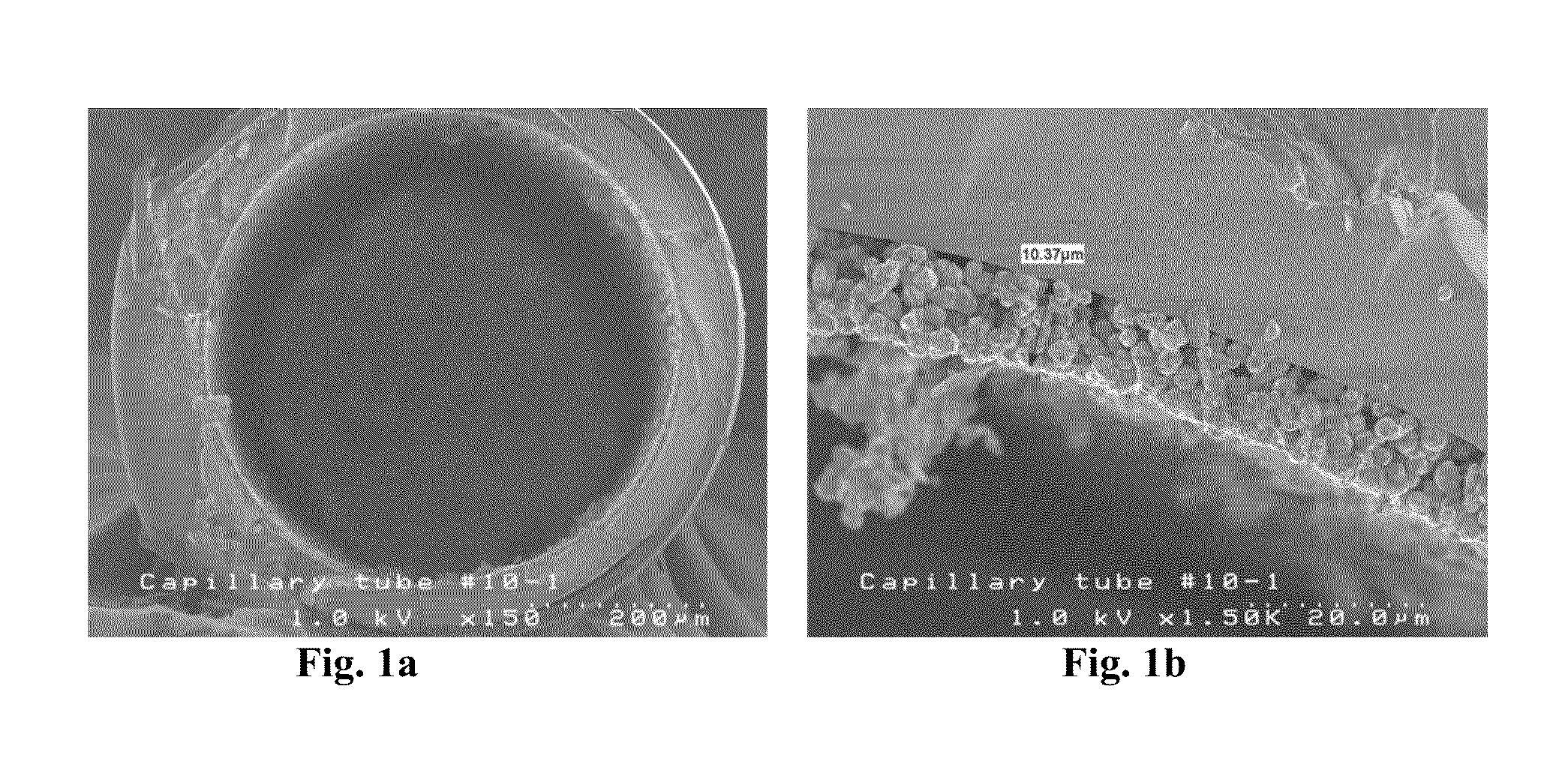

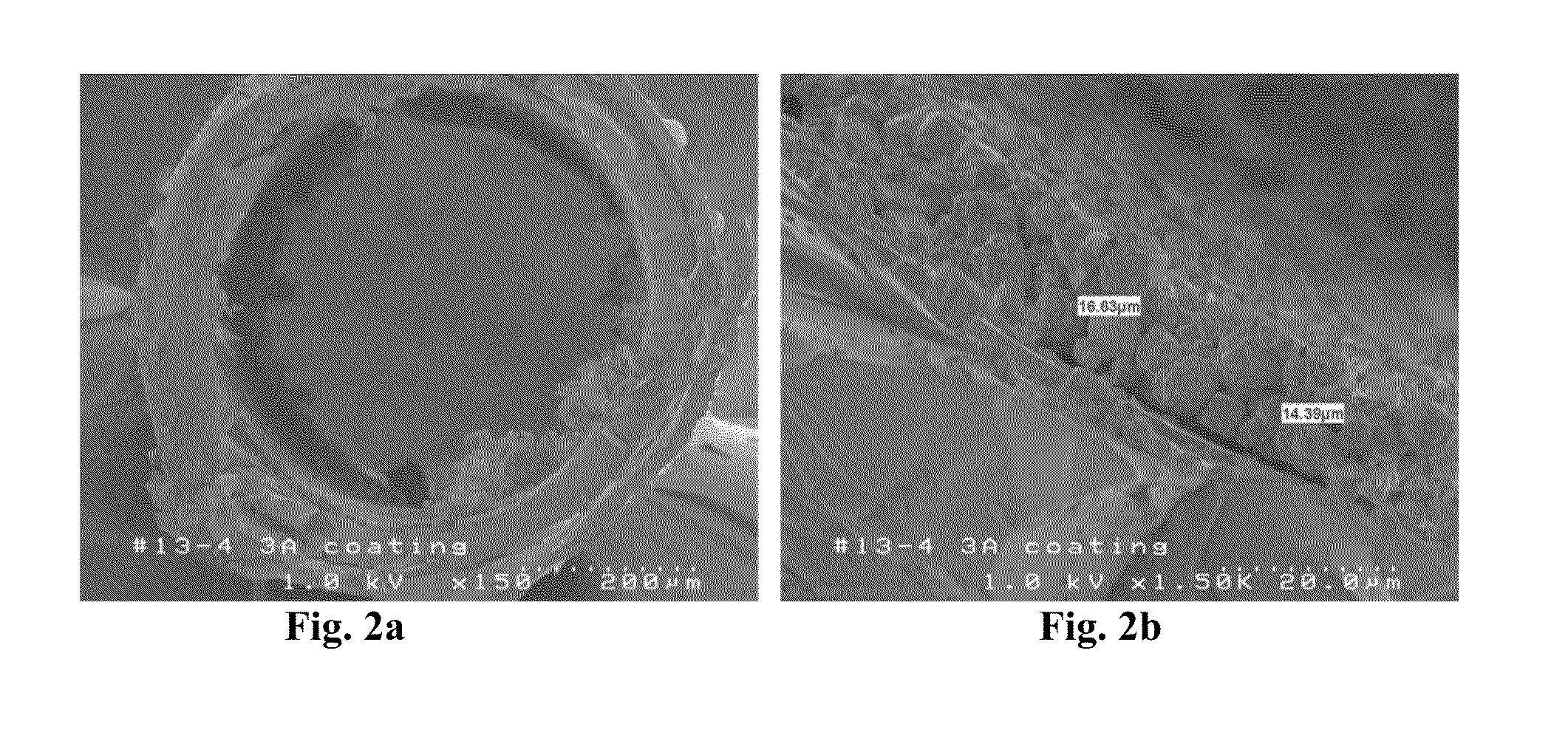

Coating methods using organosilica materials and uses thereof

InactiveUS20160167016A1Isotope separationGas purification with selectively adsorptive solidsAlkoxy groupActive site

Methods for coating a substrate with a coating including an adsorbent material and a binder comprising an organosilica material which is a polymer comprising independent units of Formula [Z3Z4SiCH2]3 (I), wherein each Z3 represents a hydroxyl group, a C1-C4 alkoxy group or an oxygen atom bonded to a silicon atom of another unit or an active site on the substrate and each Z4 represents a hydroxyl group, a C1-C4 alkoxy group, a C1-C4 alkyl group, an oxygen atom bonded to a silicon atom of another unit or an active site on the substrate are provided. Methods of gas separation are also provided.

Owner:EXXON RES & ENG CO

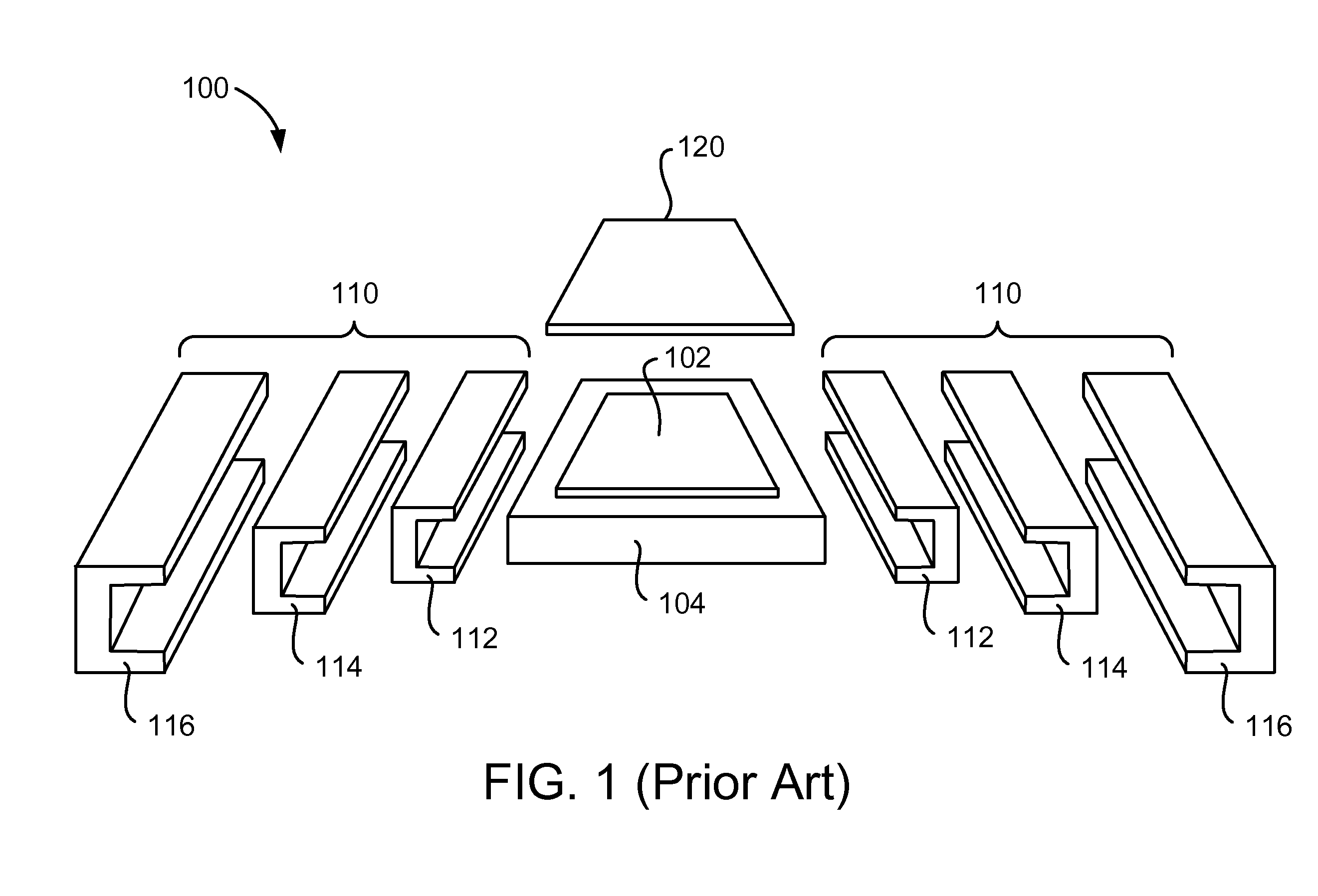

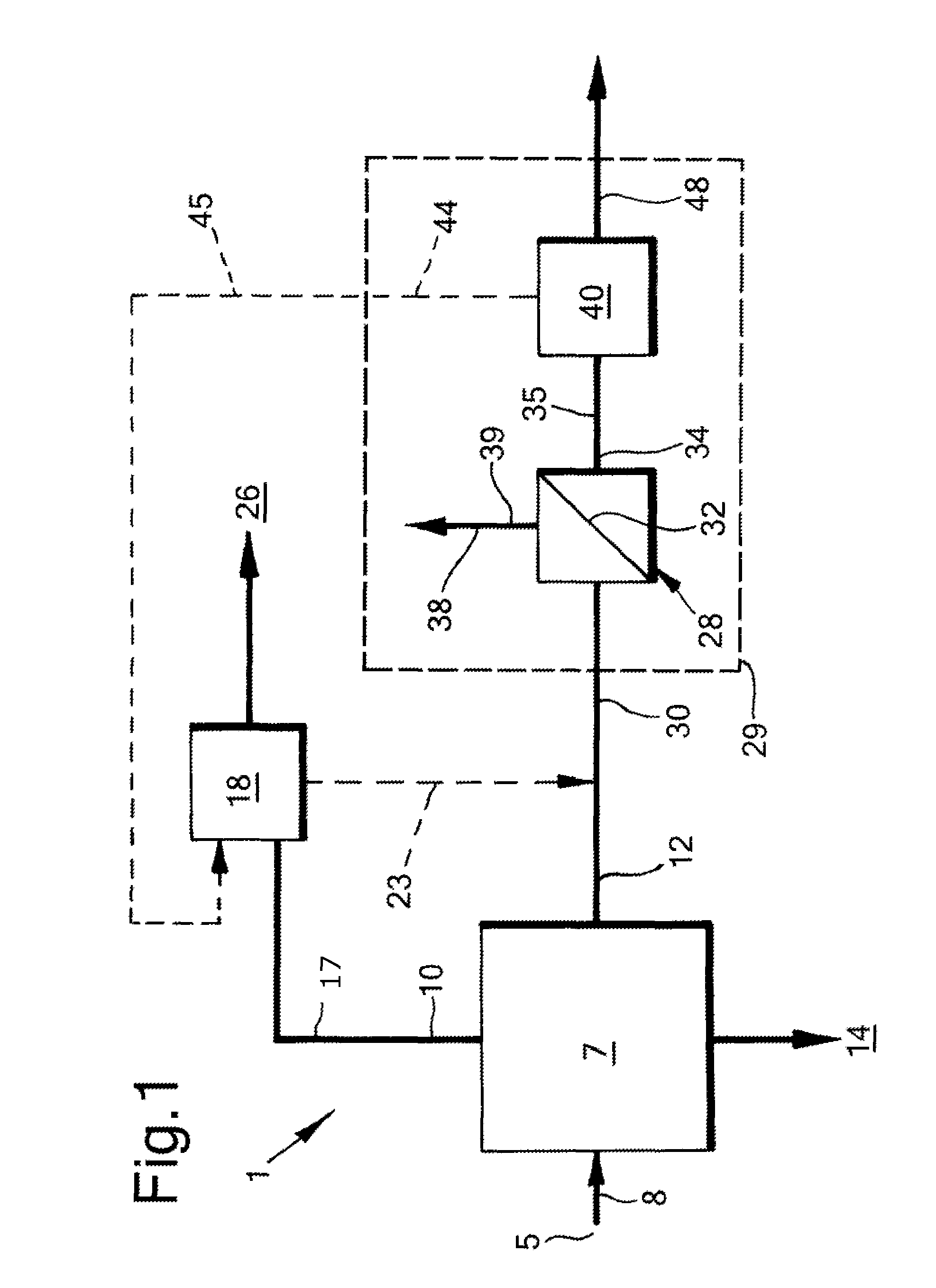

Device for separating fuel components

InactiveUS20120132576A1Digital data processing detailsGaseous engine fuelsNuclear engineeringLiquid phase

A device for separating fuel components comprising a separating membrane for separating high-octane fuel components from un-separated fuel and a heat exchanger between first liquid passing through the heat exchanger and second liquid passing through the heat exchanger, is provided. The first liquid is un-separated fuel passing through the heat exchanger before being supplied to the separating membrane. The second liquid is low-octane fuel remaining when the high-octane fuel components are separated from the un-separated fuel, passing through the heat exchanger after changing to an almost liquid phase.

Owner:TOYOTA JIDOSHA KK +1

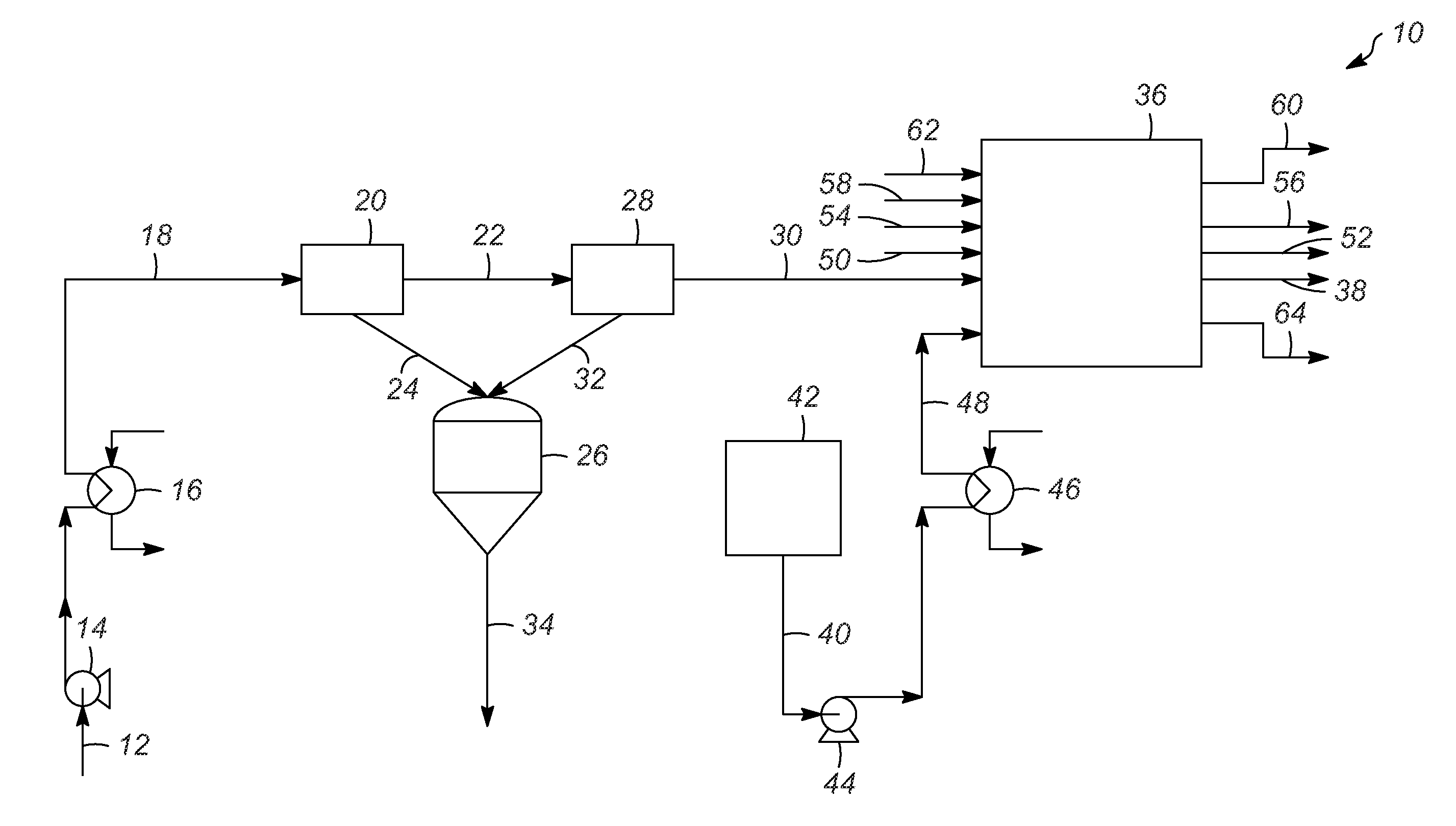

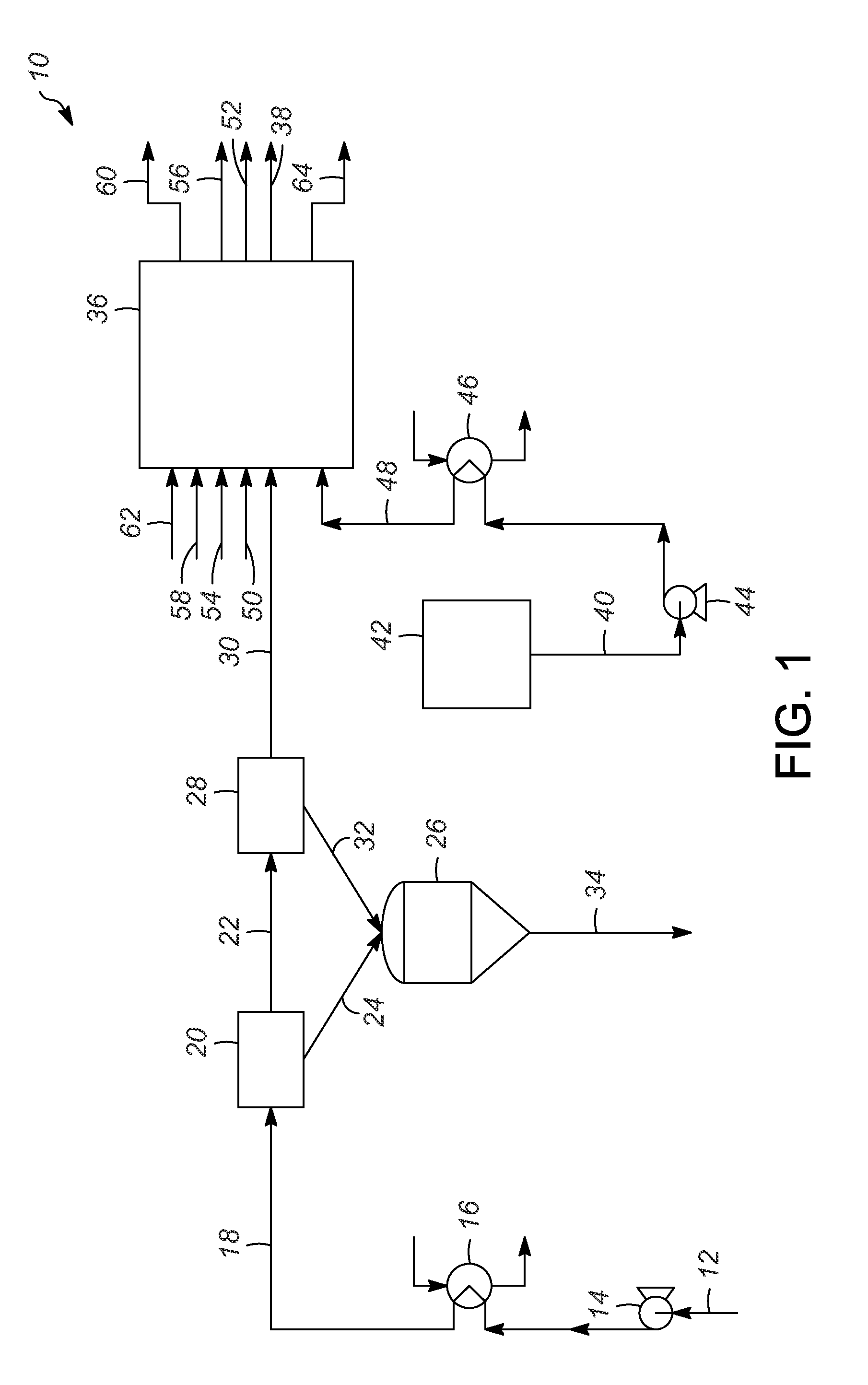

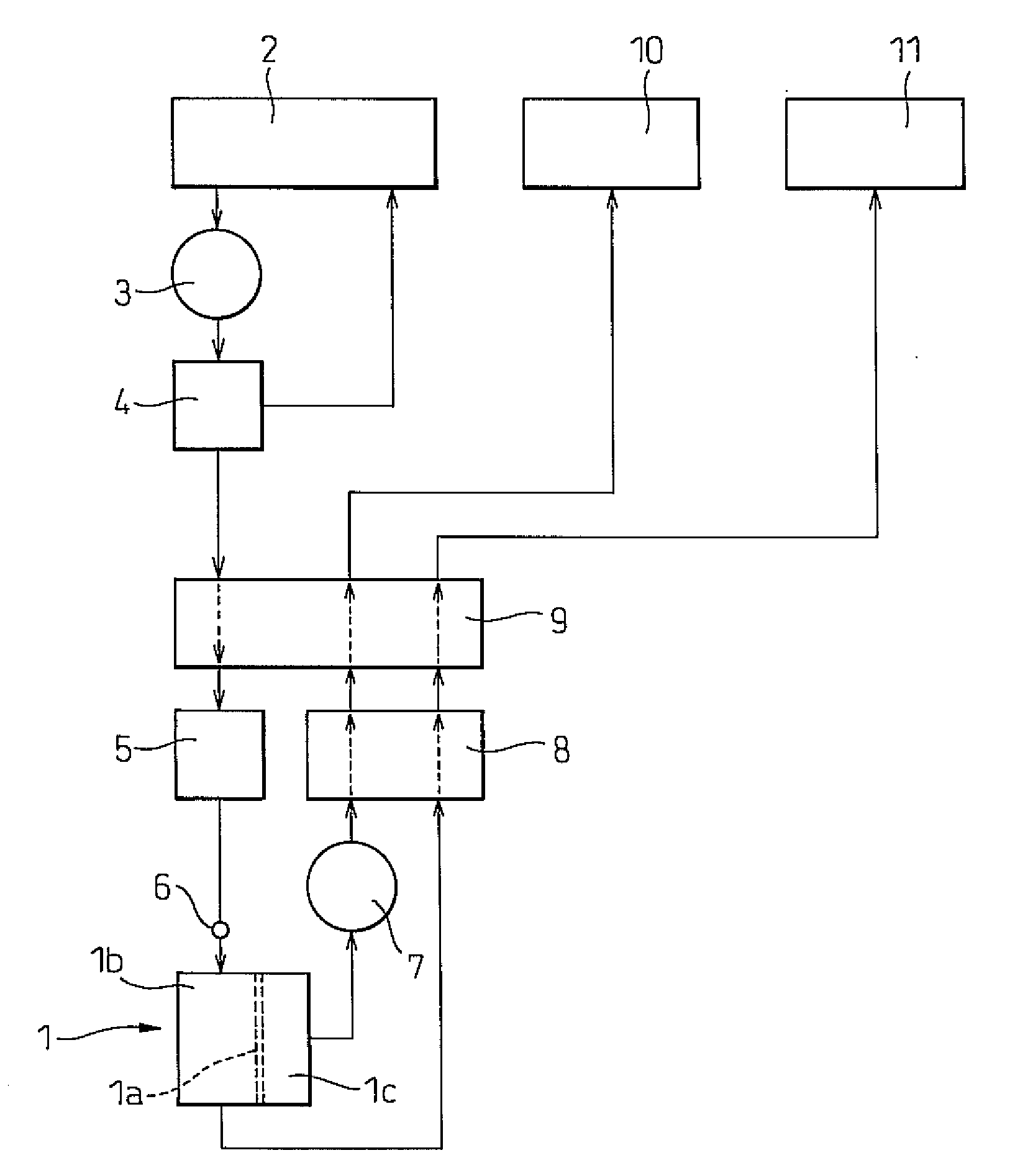

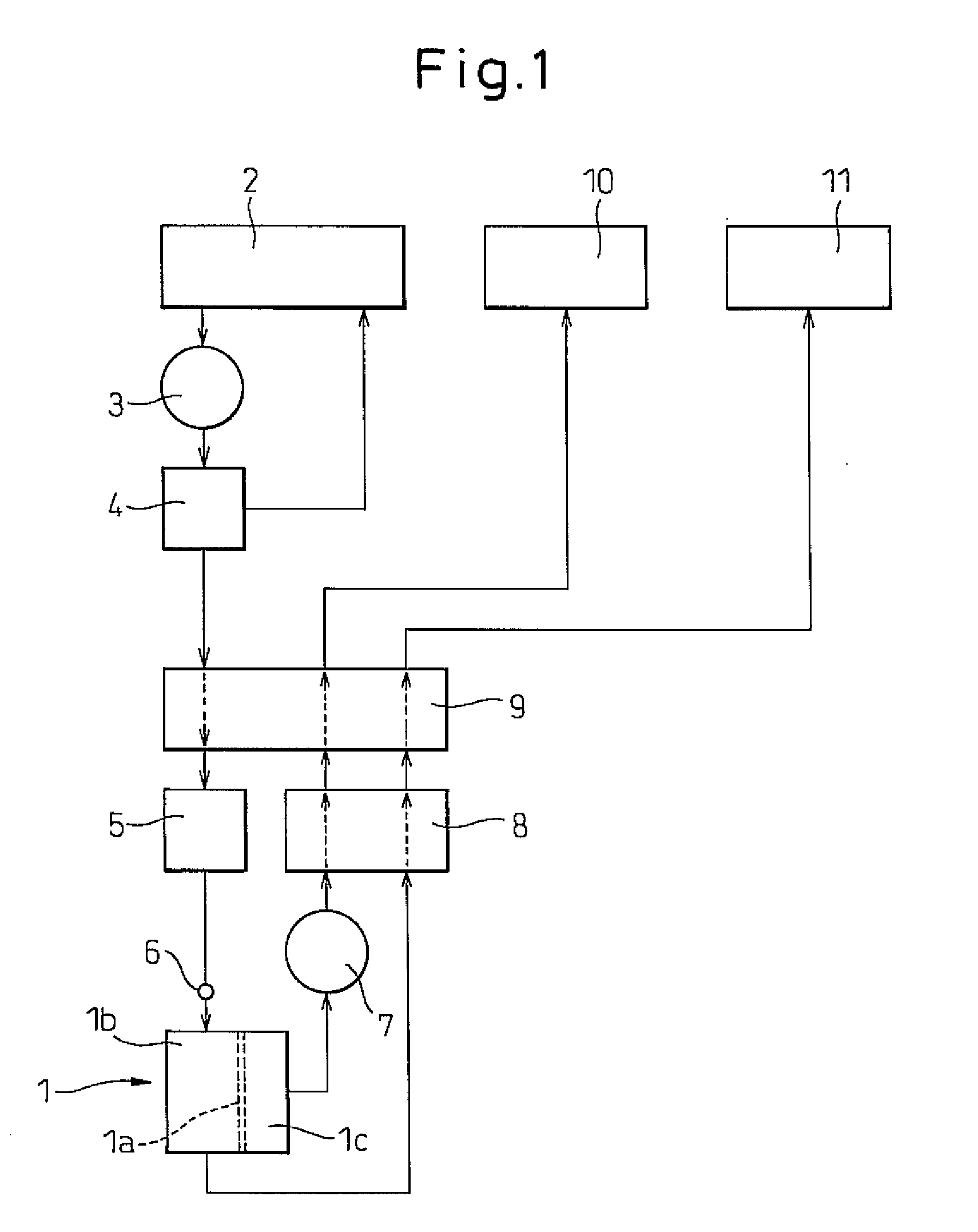

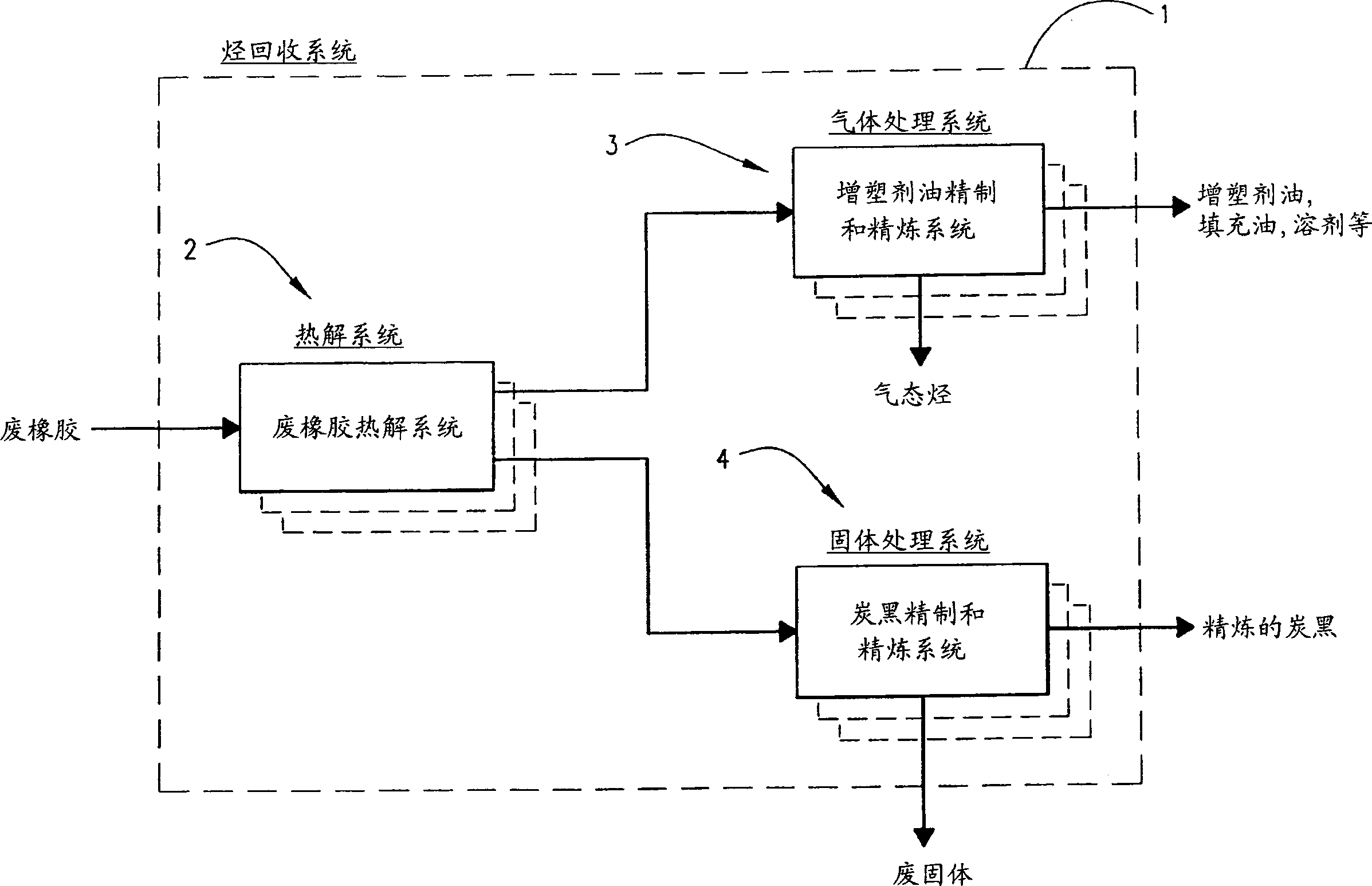

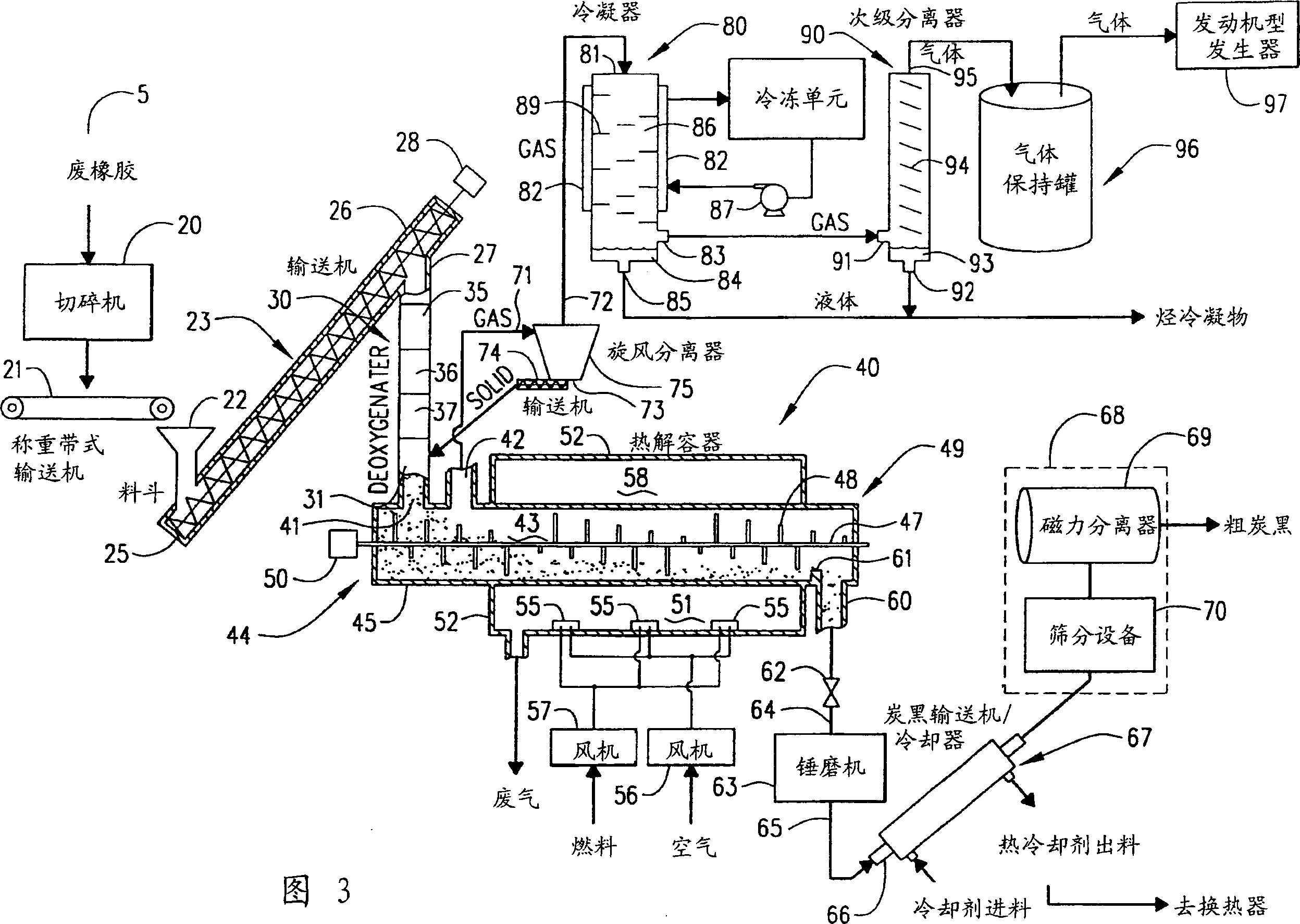

Apparatus and method for recovering marketable products from scrap rubber

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis vessel (40) and pyrolyzing the shreds in a pyrolysis vessel (40) to produce a pyrolysis gas and carbon black mixture. The pyrolysis gas processed by centrifugally separating entrained particles therefrom, separating the pyrolysis gas into a hydrocarbon condensate and a light vapor, removing entrained hydrocarbon condensate from the light vapor, and purifying and refining the hydrocarbon condensate. The carbon black mixture is processed by pulverizing the mixture to break up all strands and clumps of inorganic solids, cooling the carbon black mixture, separating the gross contaminants from the carbon mixture, and purifying and refining the carbon black. The hydrocarbon condensate is purified and refined by removing all remaining contaminants, removing any polycyclic aromatics to produce a clear, colorless plasticizer oil. The carbon black is purified and refined by pulverizing it into a powder, removing all remaining particulate contaminants, optionally pelletizing the carbon black, and bagging or packaging it for shipping.

Owner:FEDERAL RECYCLING TECH +1

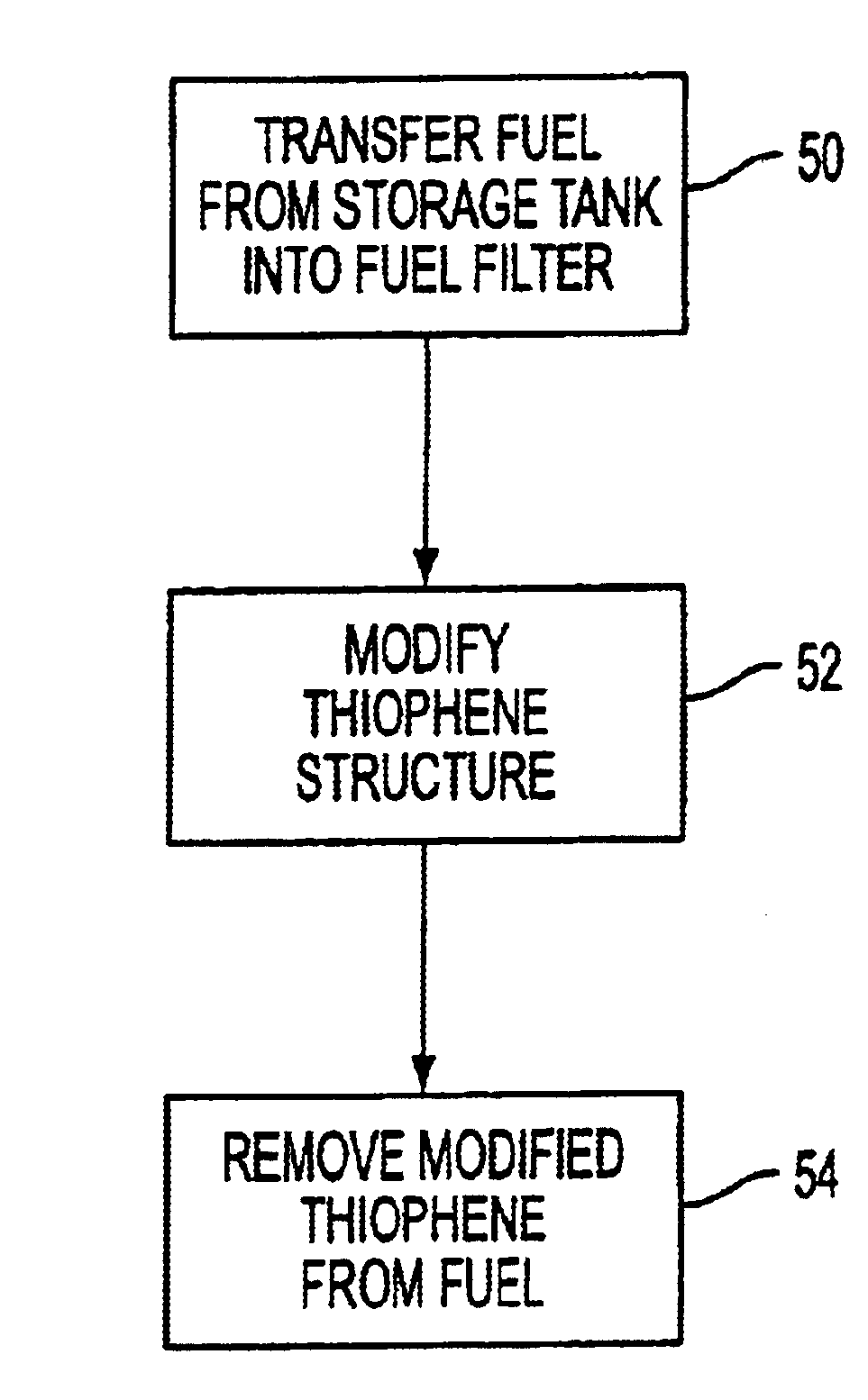

Filter apparatus for removing sulfur-containing compounds from liquid fuels, and methods of using same

InactiveUS6887381B2Reduce concentrationReduce the amount requiredMachines/enginesLoose filtering material filtersFiberSorbent

Owner:FRAM GROUP IP

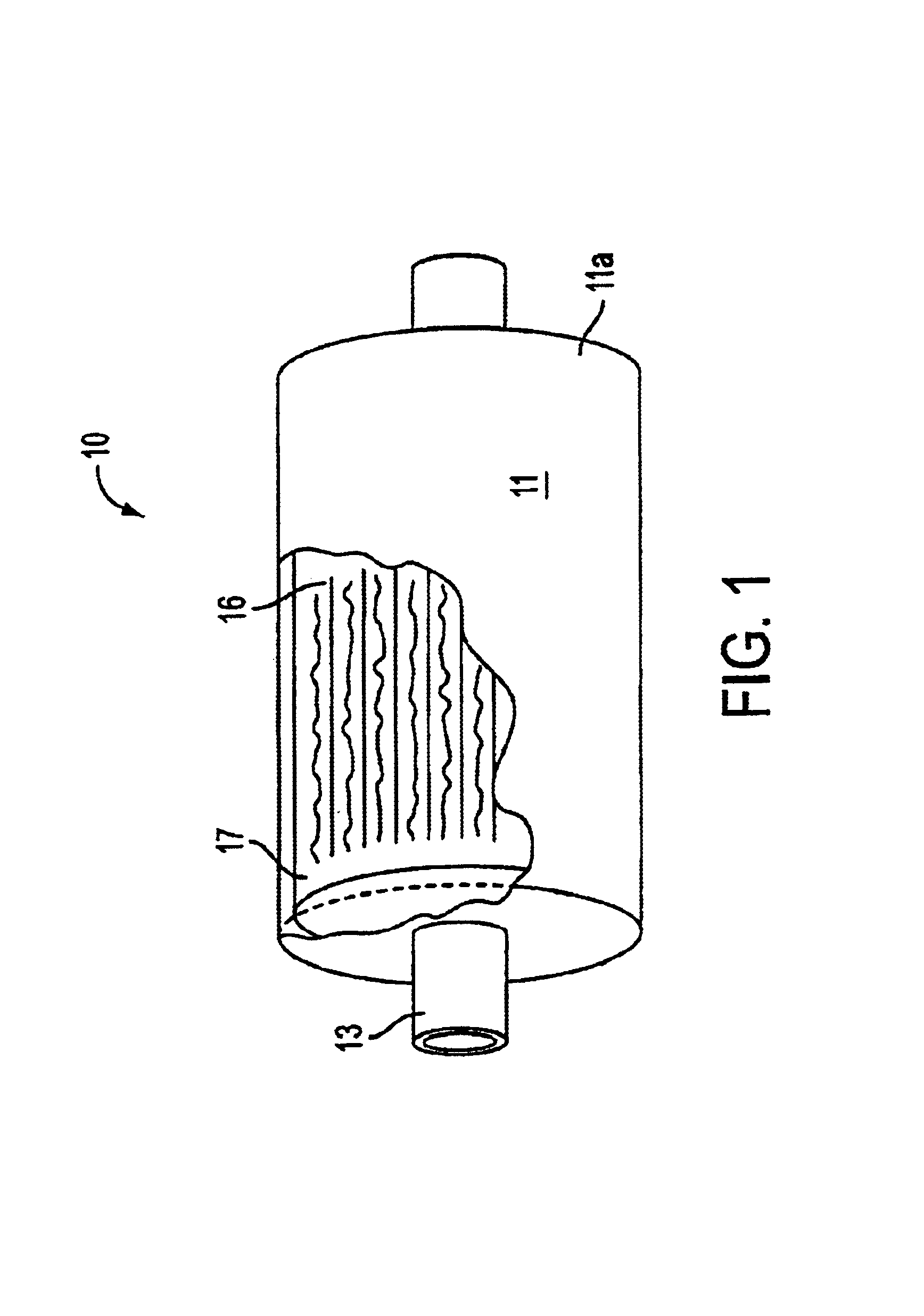

Fuel deoxygenation system

ActiveUS20050211096A1Inexpensive sizeInexpensive weightLiquid fuel feeder/distributionSemi-permeable membranesDifferential pressurePorous membrane

A fuel system for an energy conversion device includes a deoxygenator system with a porous membrane. The deoxygenator includes an oxygen receiving channel separated from the fuel channel by the porous membrane. The capillary forces counteract the pressure differential across the membrane, preventing any leakage of the fuel, while the oxygen concentration differential across the membrane allows for deoxygenation of the fuel through the porous membrane.

Owner:RTX CORP

Method for reducing the mercury content of natural gas condensate and natural gas processing plant

InactiveUS20100147745A1Avoid typingMembranesGas treatmentNatural-gas condensateNatural-gas processing

A method for reducing the mercury content of natural gas condensate, comprising the steps of providing a nanofiltration membrane having a feed side and a permeate side; contacting the natural gas condensate with the feed side of the membrane; and obtaining a mercury-depleted natural gas condensate at the permeate side of the membrane; and a natural gas processing plant comprising a condensate workup section including a nanofiltration membrane separation unit for reducing the mercury content of natural gas condensate.

Owner:SHELL OIL CO

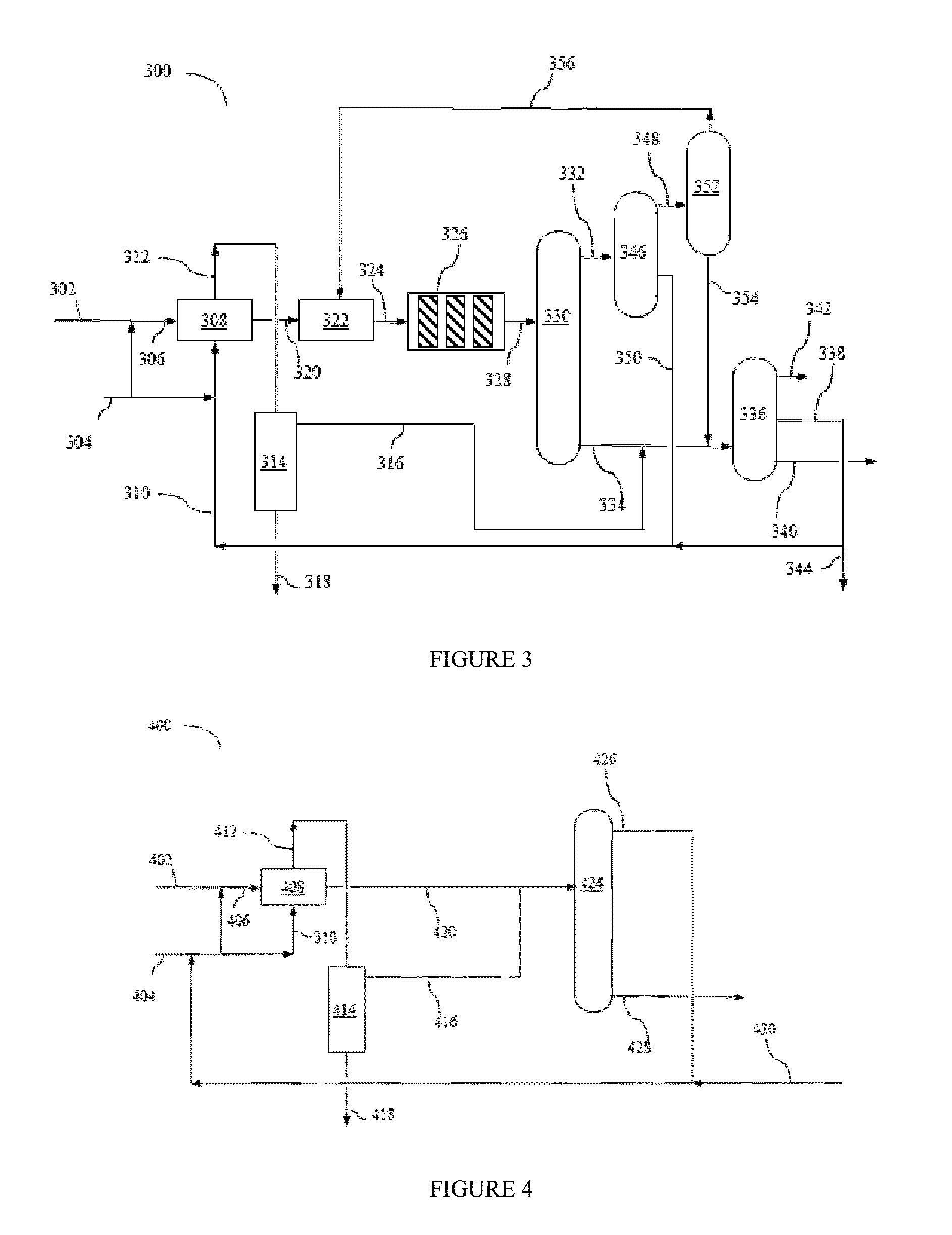

Hydrocarbon Upgrading

ActiveUS20150361359A1Hydrocarbon by isomerisationHydrocarbon purification/separationParticulatesRaffinate

Aspects of the invention provide a process for upgrading a hydrocarbon feed. The process includes providing a hydrocarbon feed and a utility fluid. Then selectively extracting from the feed at least a portion of particulates to produce a raffinate and an extract. Third hydroprocessing at least a portion of the raffinate.

Owner:EXXONMOBIL CHEM PAT INC

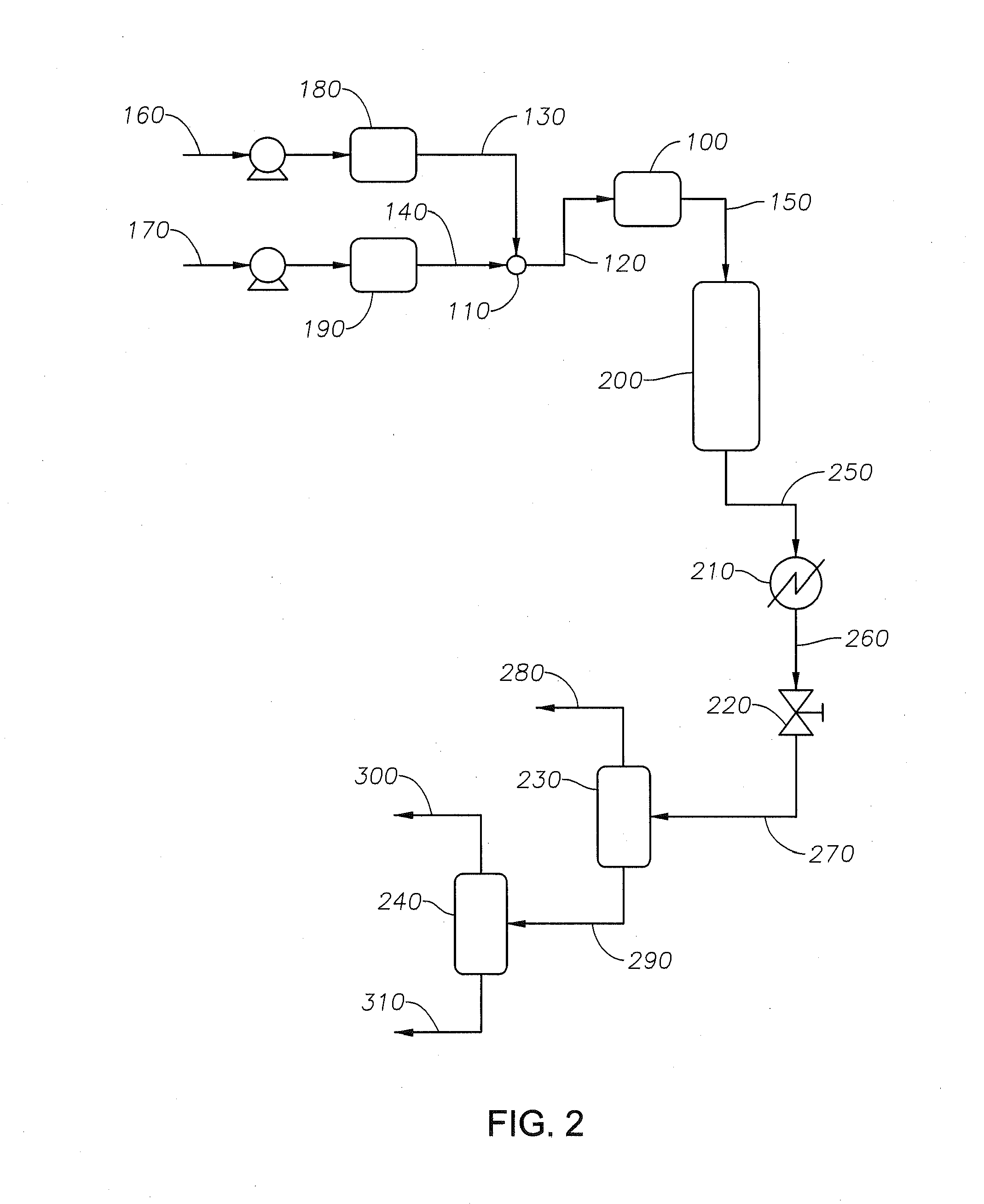

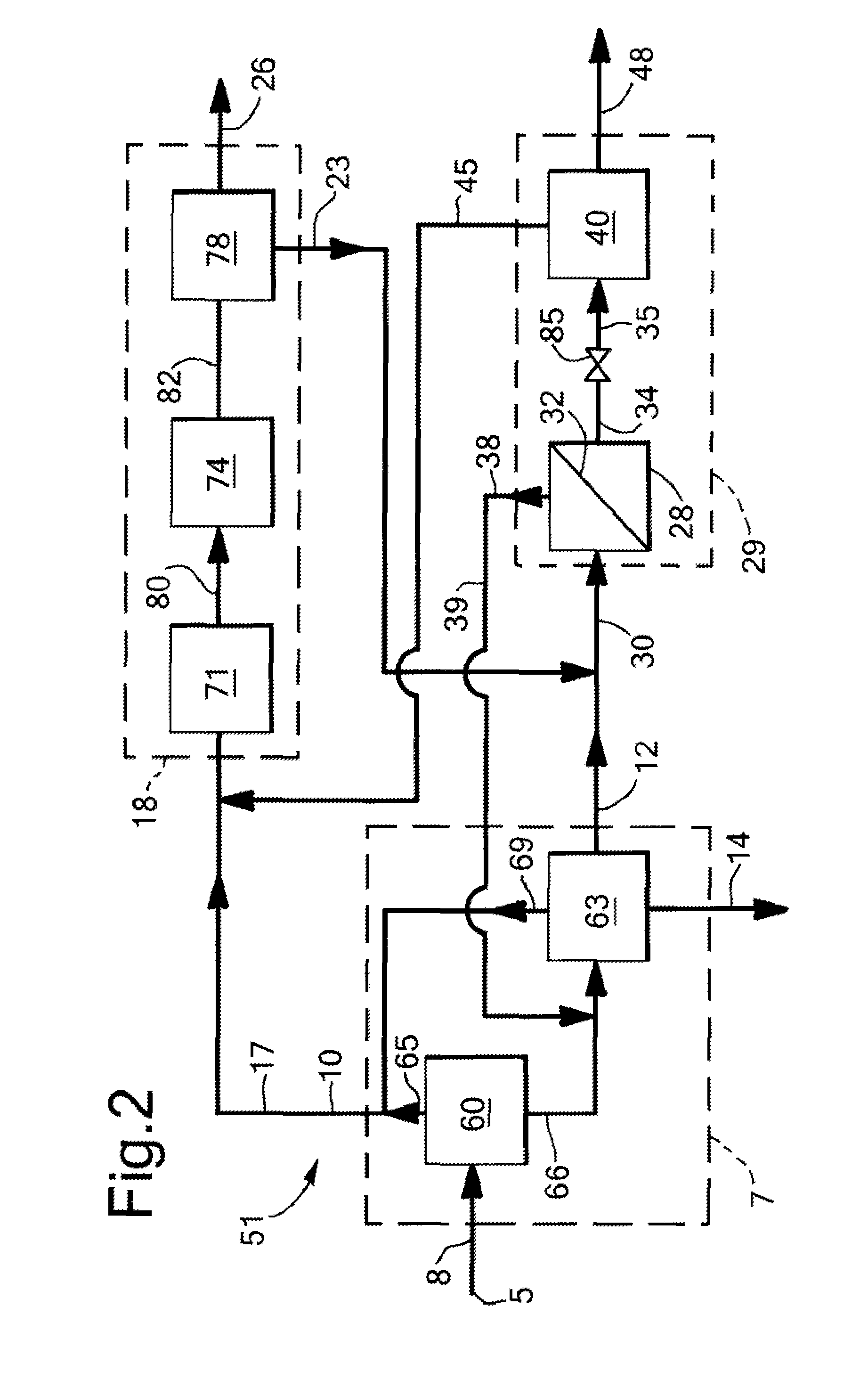

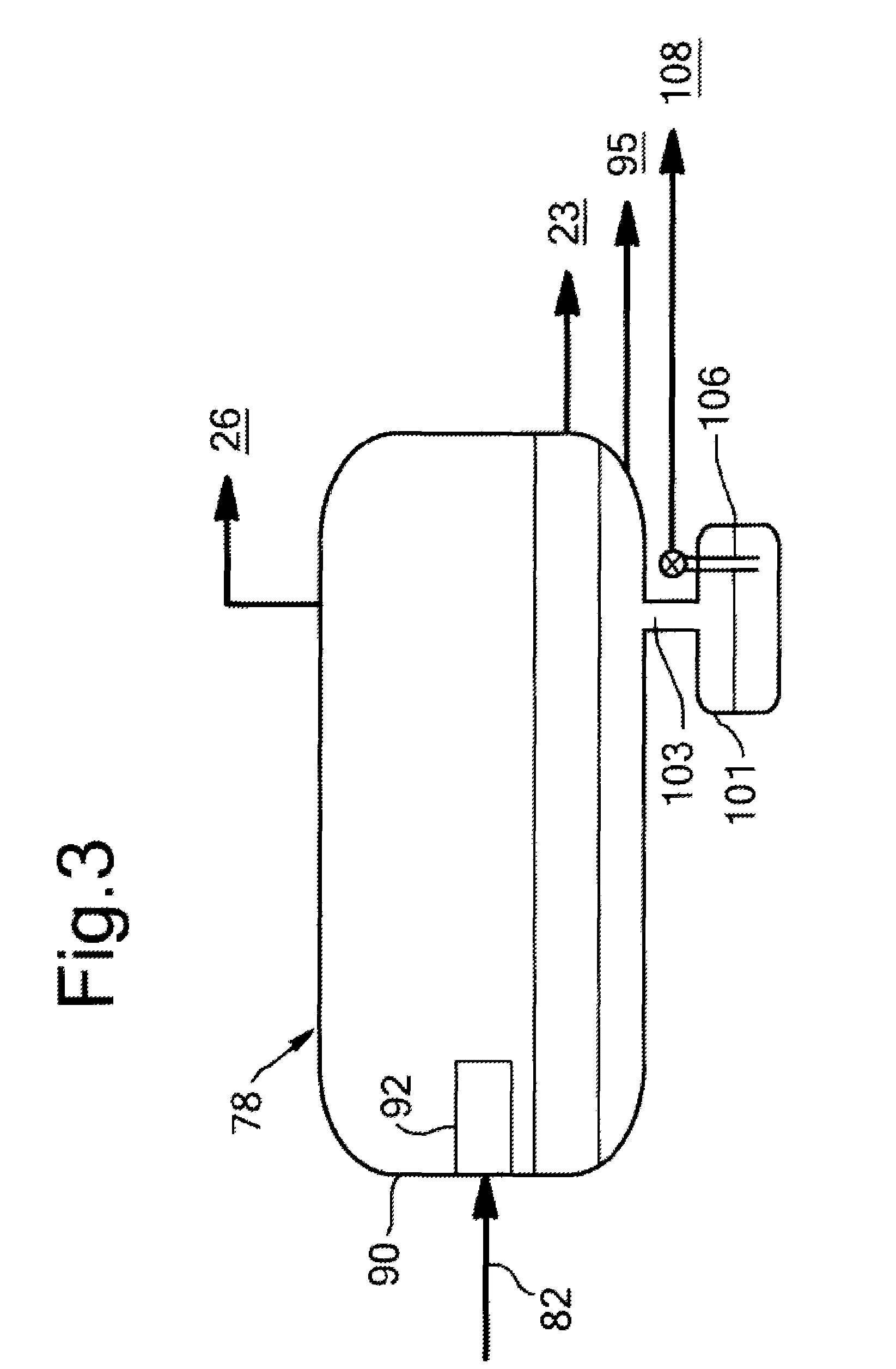

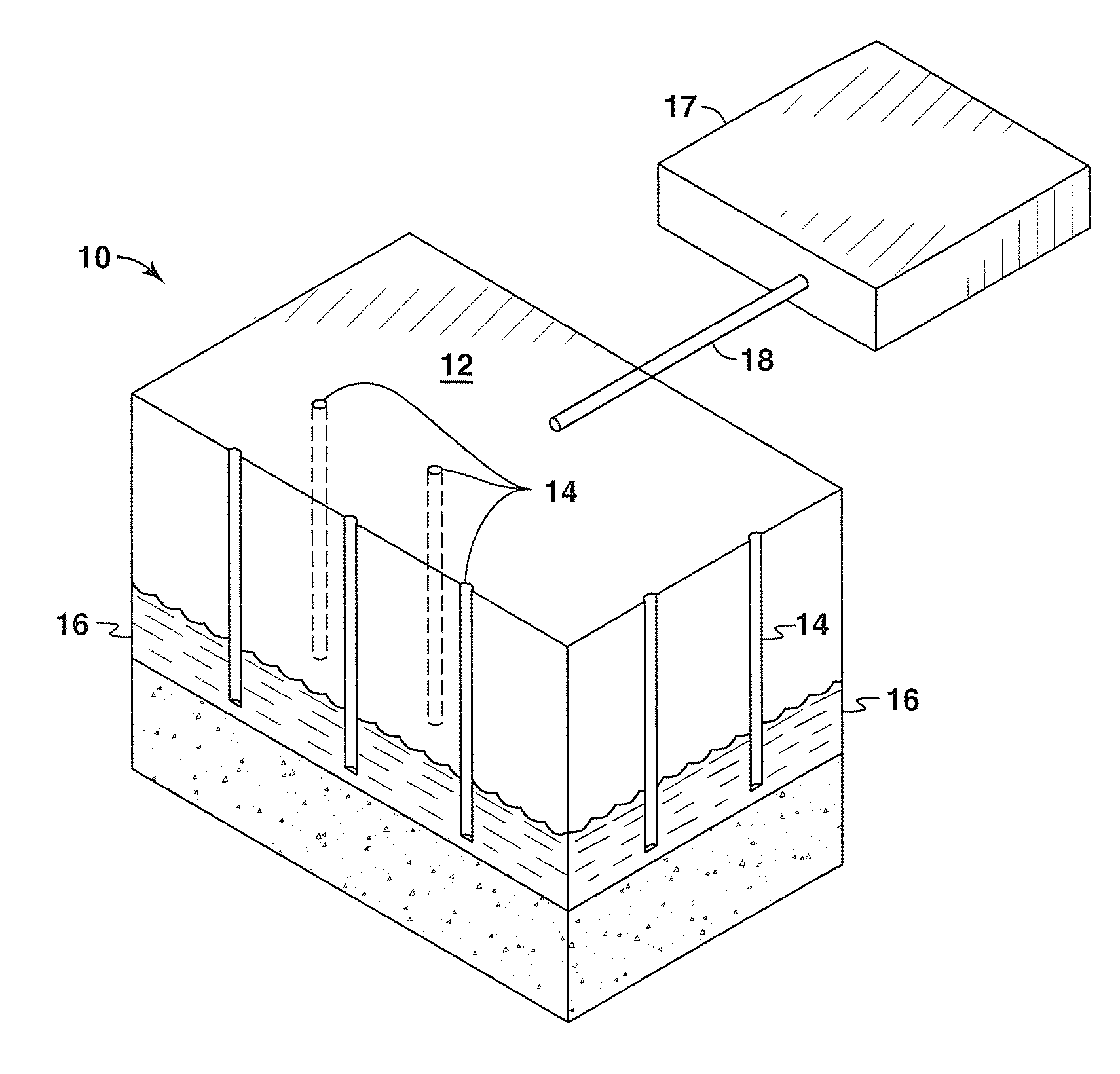

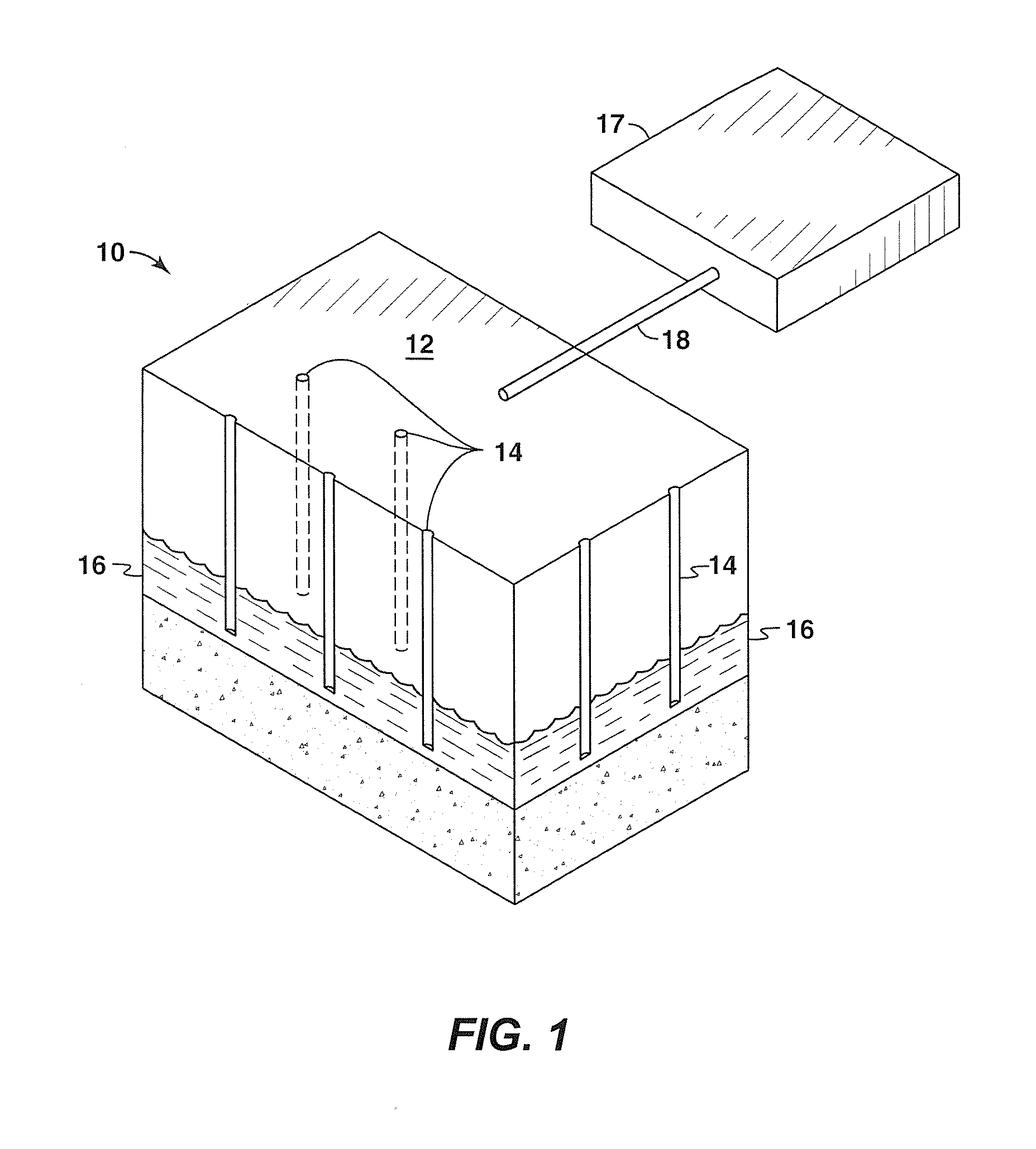

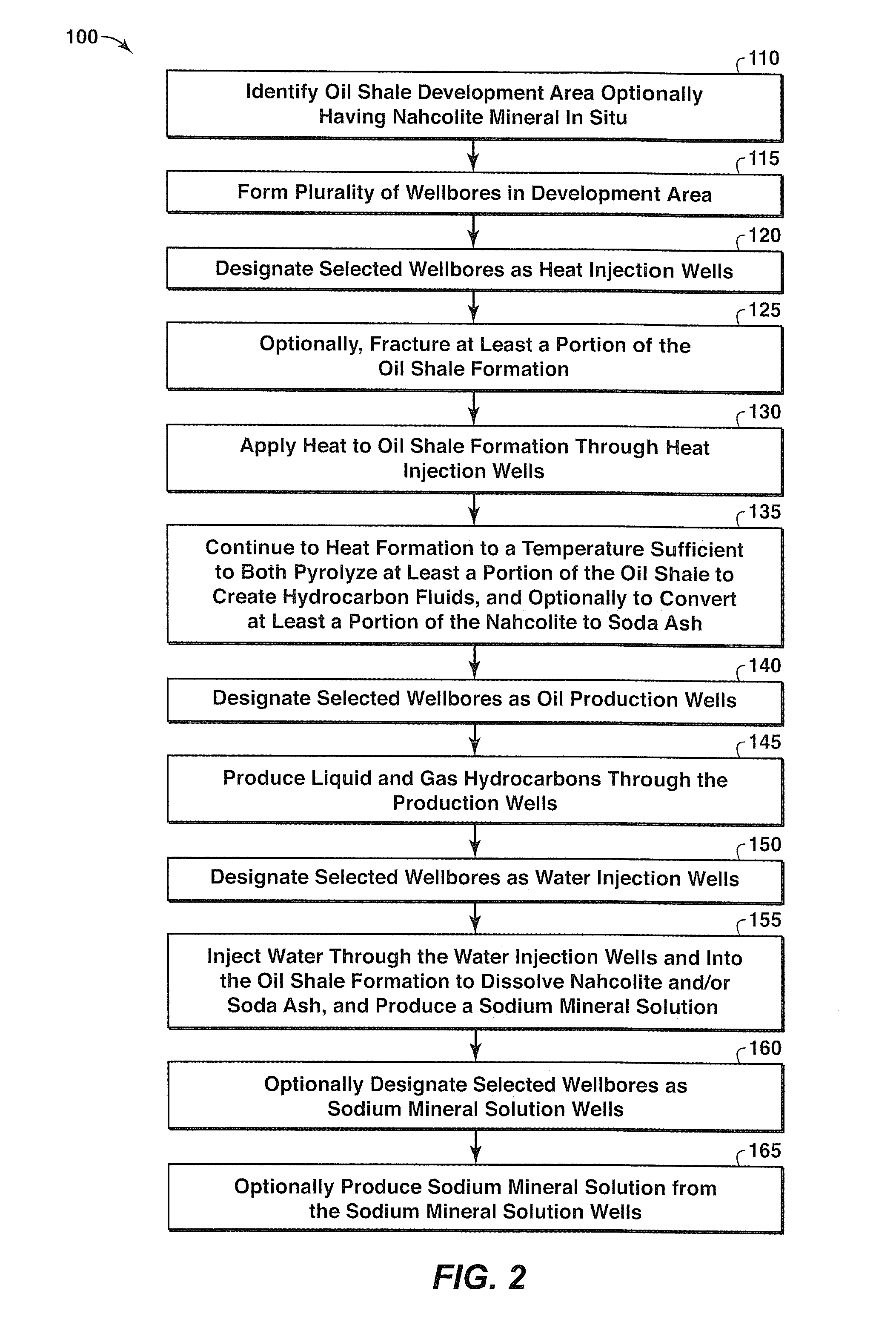

Process For Producing Hydrocarbon Fluids Combining In Situ Heating, A Power Plant And A Gas Plant

An in situ method of producing hydrocarbon fluids from an organic-rich rock formation may include heating an organic-rich rock formation, for example an oil shale formation, in situ to pyrolyze formation hydrocarbons, for example kerogen, to form a production fluid containing hydrocarbon fluids. The method may include separating the production fluid into at least a gas stream and a liquid stream, where the gas stream is a low BTU gas stream. The low BTU gas stream is then fed to a gas turbine where it is combusted and is used to generate electricity.

Owner:EXXONMOBIL UPSTREAM RES CO

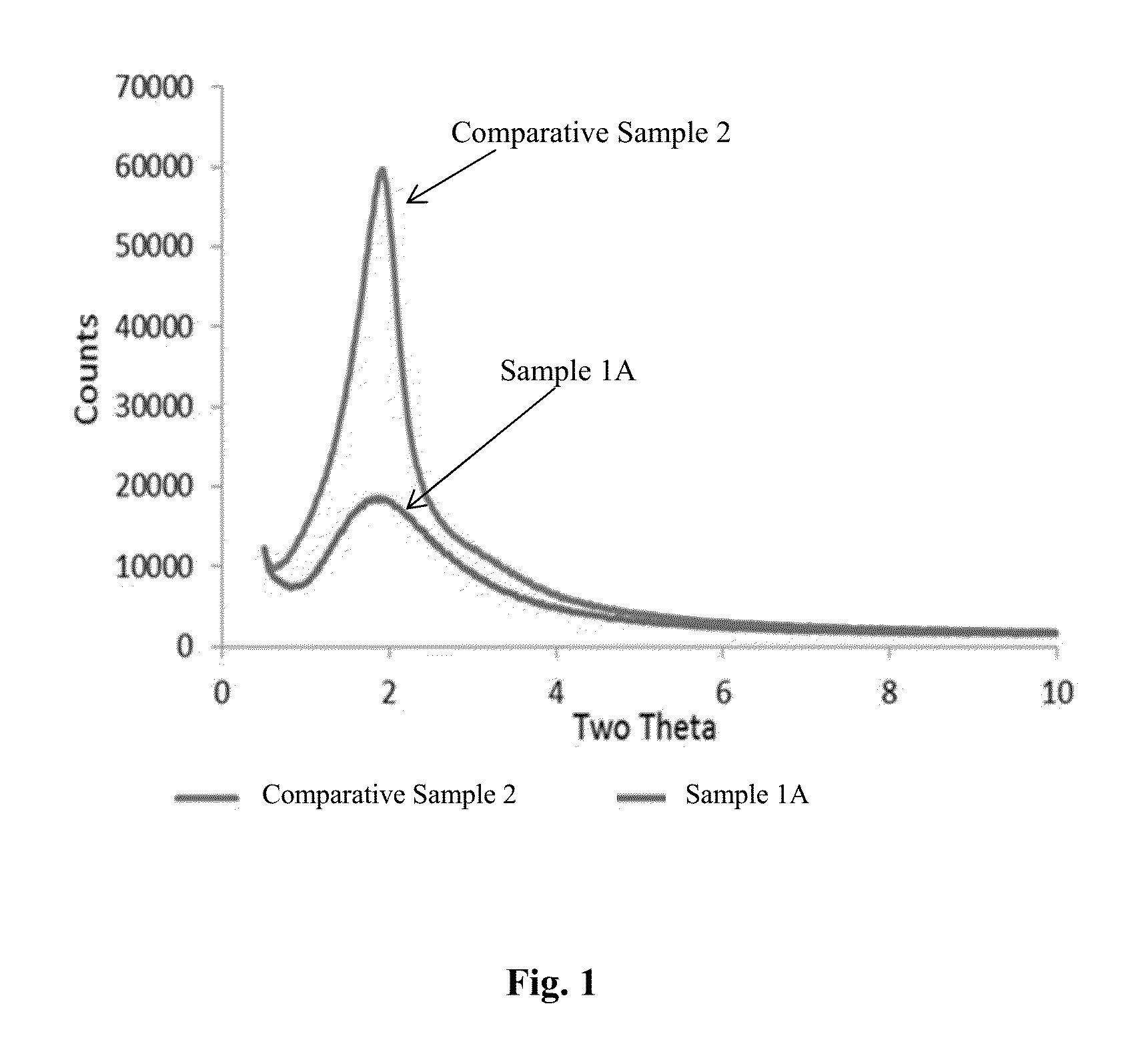

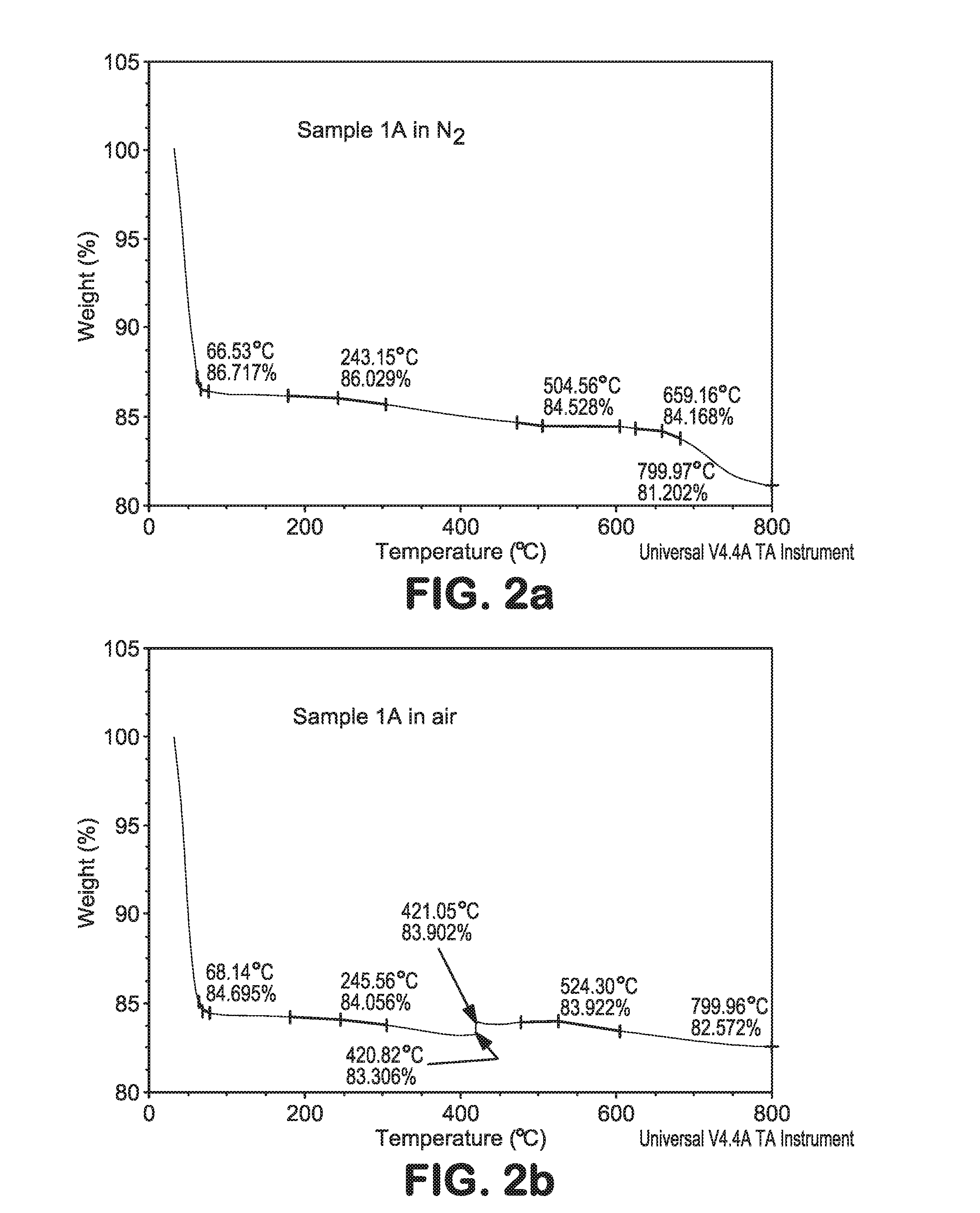

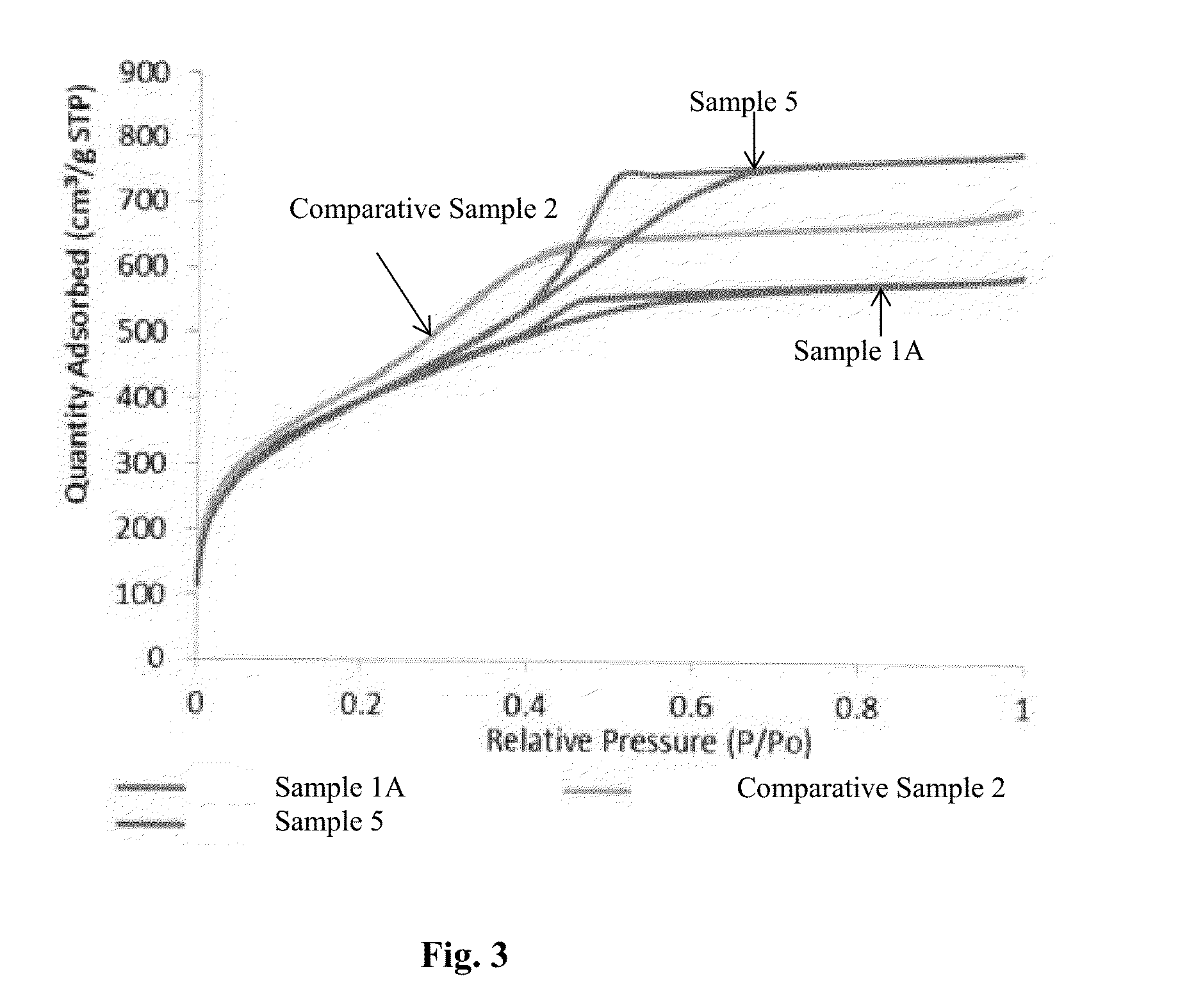

Organosilica materials and uses thereof

InactiveUS20160168172A1Desirable diameter volumeDesirable pore diameter poreCatalytic naphtha reformingSolid sorbent liquid separationHydrogen atomAlkoxy group

Organosilica materials, which are a polymer of at least one independent monomer of Formula [Z1OZ2SiCH2]3 (I), wherein each Z1 represents a hydrogen atom, a C1-C4 alkyl group or a bond to a silicon atom of another monomer and each Z2 represents a hydroxyl group, a C1-C4 alkoxy group, a C1-C6 alkyl group or an oxygen atom bonded to a silicon atom of another monomer and at least one other monomer are provided herein. Processes of using the organosilica materials, e.g., gas separation, etc., are also provided herein.

Owner:EXXON RES & ENG CO

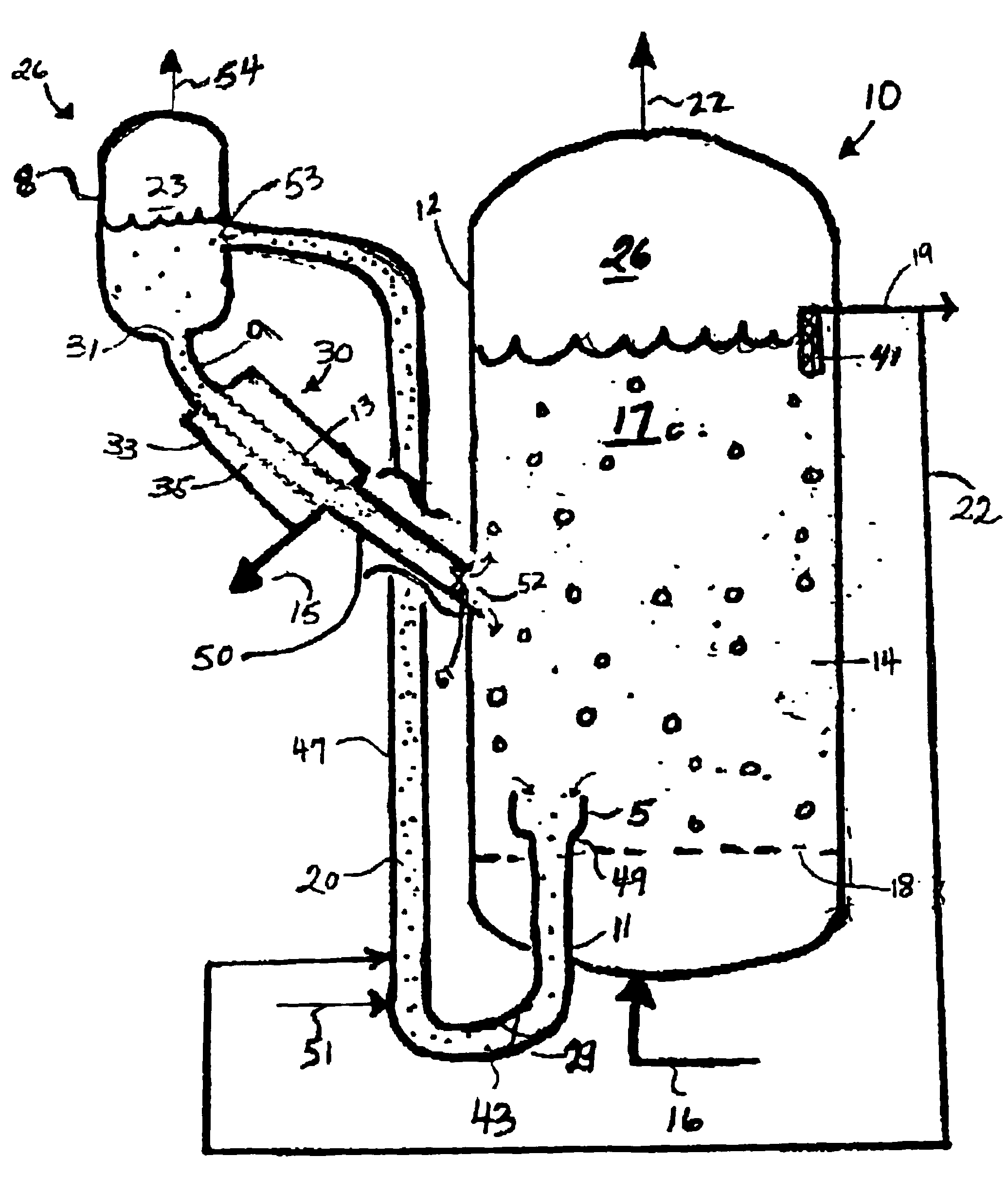

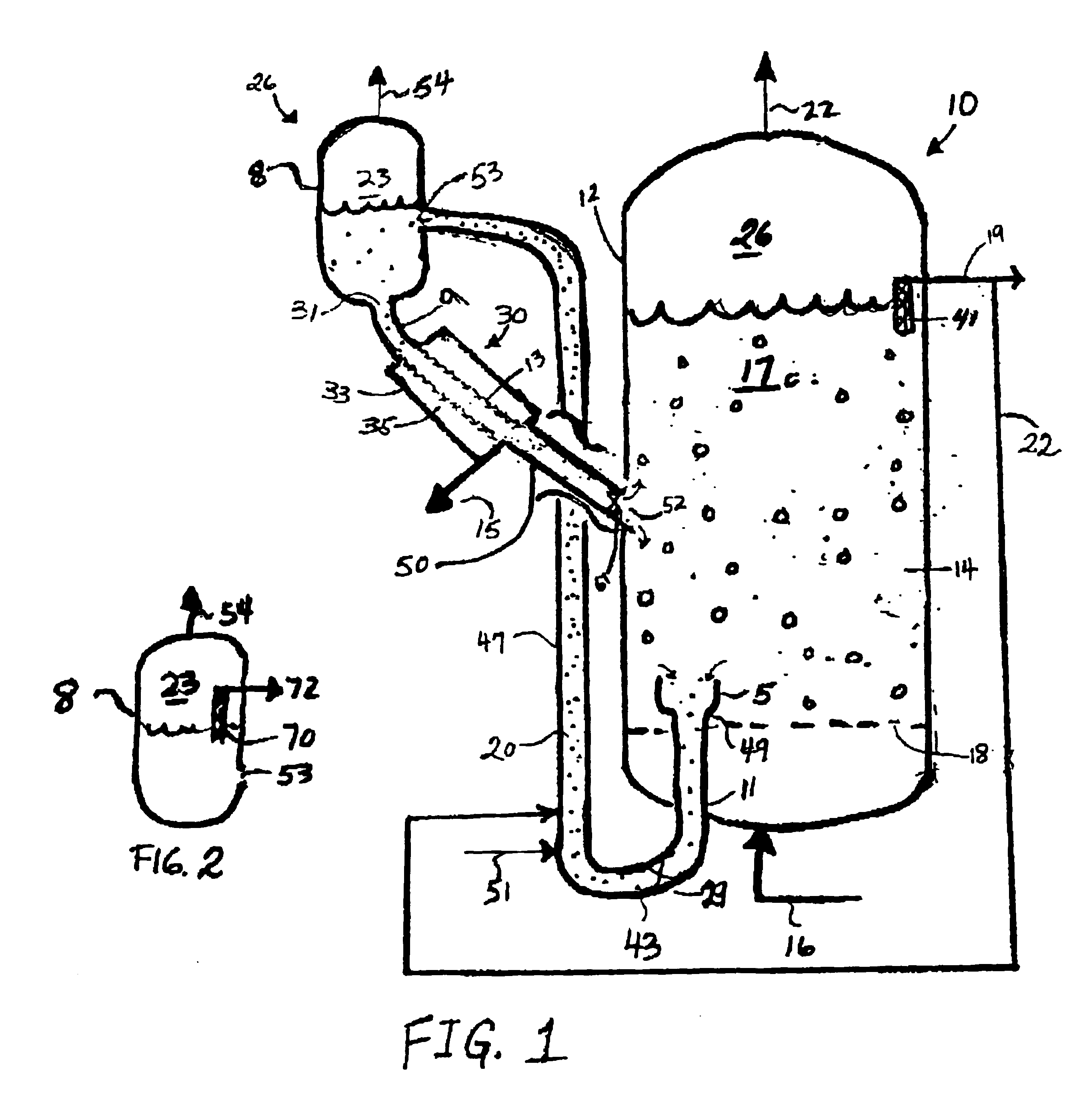

Production of high purity fisher-tropsch wax

InactiveUS6846848B2Great liquid throughputAid removalHydrocarbon from carbon oxidesOrganic compound preparationWaxHydrogen

A hydrocarbon wax product from a hydrocarbon synthesis slurry comprising liquid synthesis product and catalyst particles is purified by introducing a portion of hydrocarbon synthesis slurry from a hydrocarbon synthesis zone to a treatment zone in which a treatment gas contacts the hydrocarbon synthesis slurry. Hydrogen or a hydrogen-containing gas is useful as the treatment gas. The gas treatment removes impurities from the hydrocarbon wax portion of the hydrocarbon synthesis slurry. Purified wax product is separated and removed in situ via wax withdrawal means. This avoids or minimizes the need for further treating the wax product.

Owner:EXXON RES & ENG CO

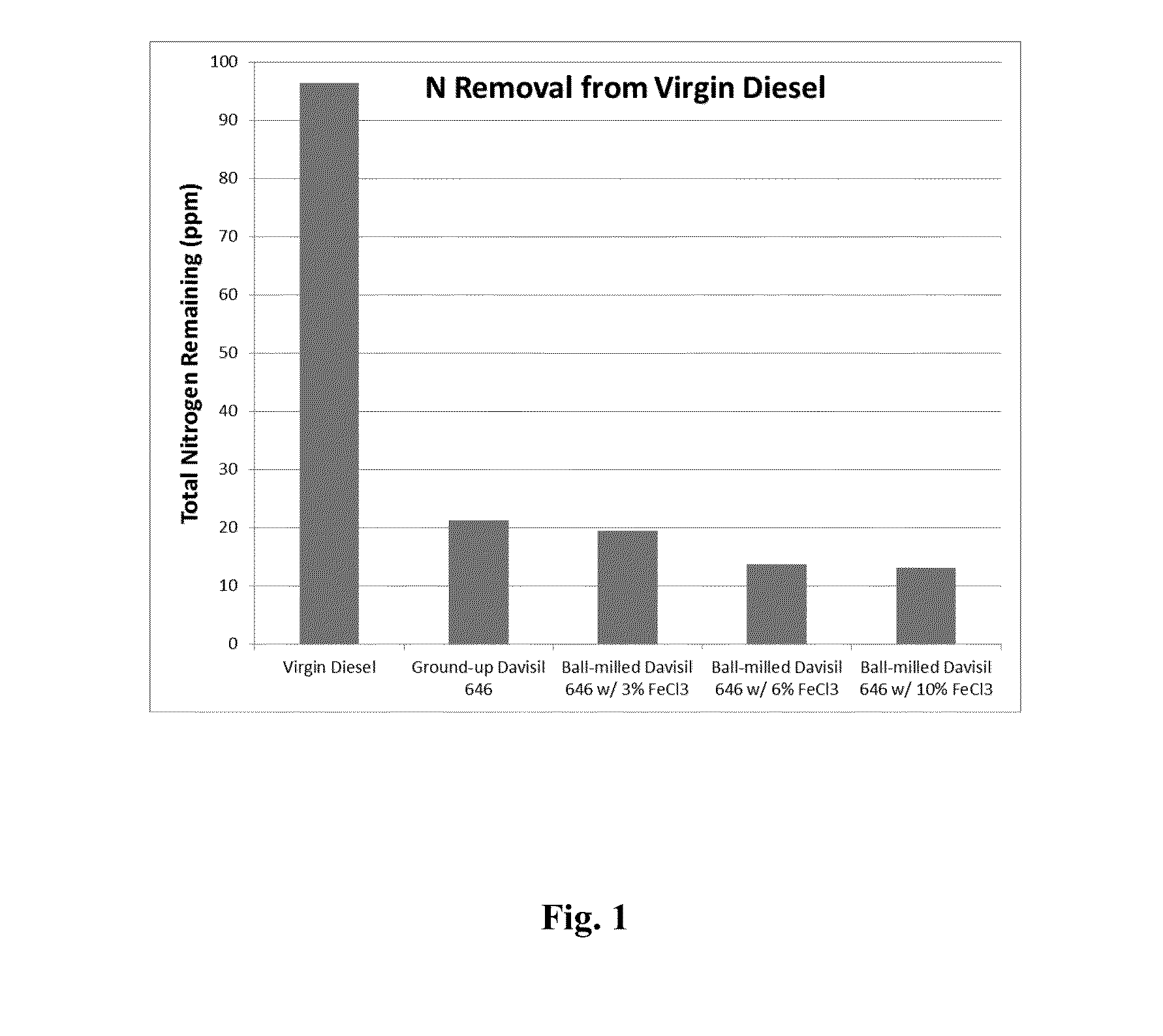

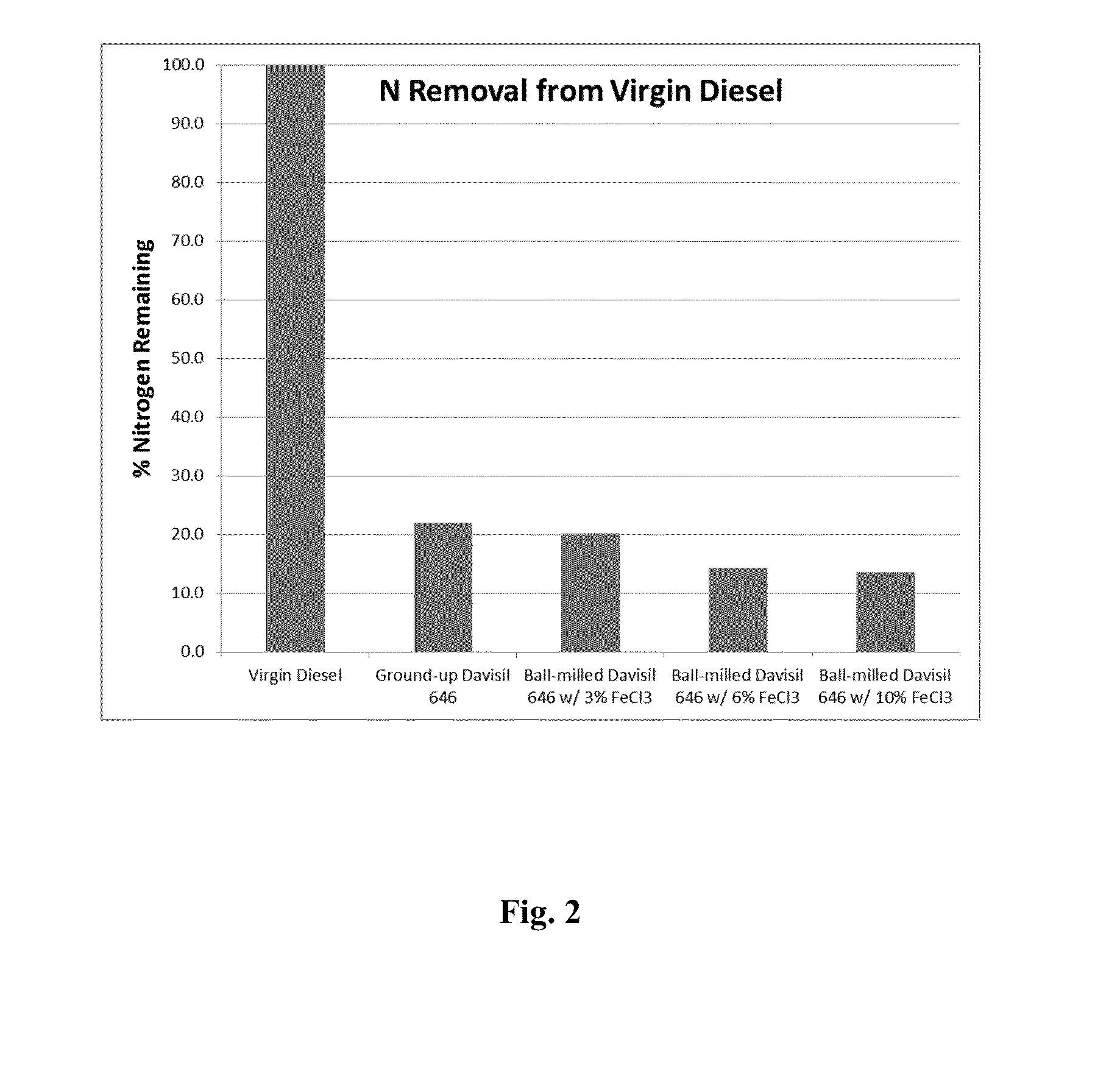

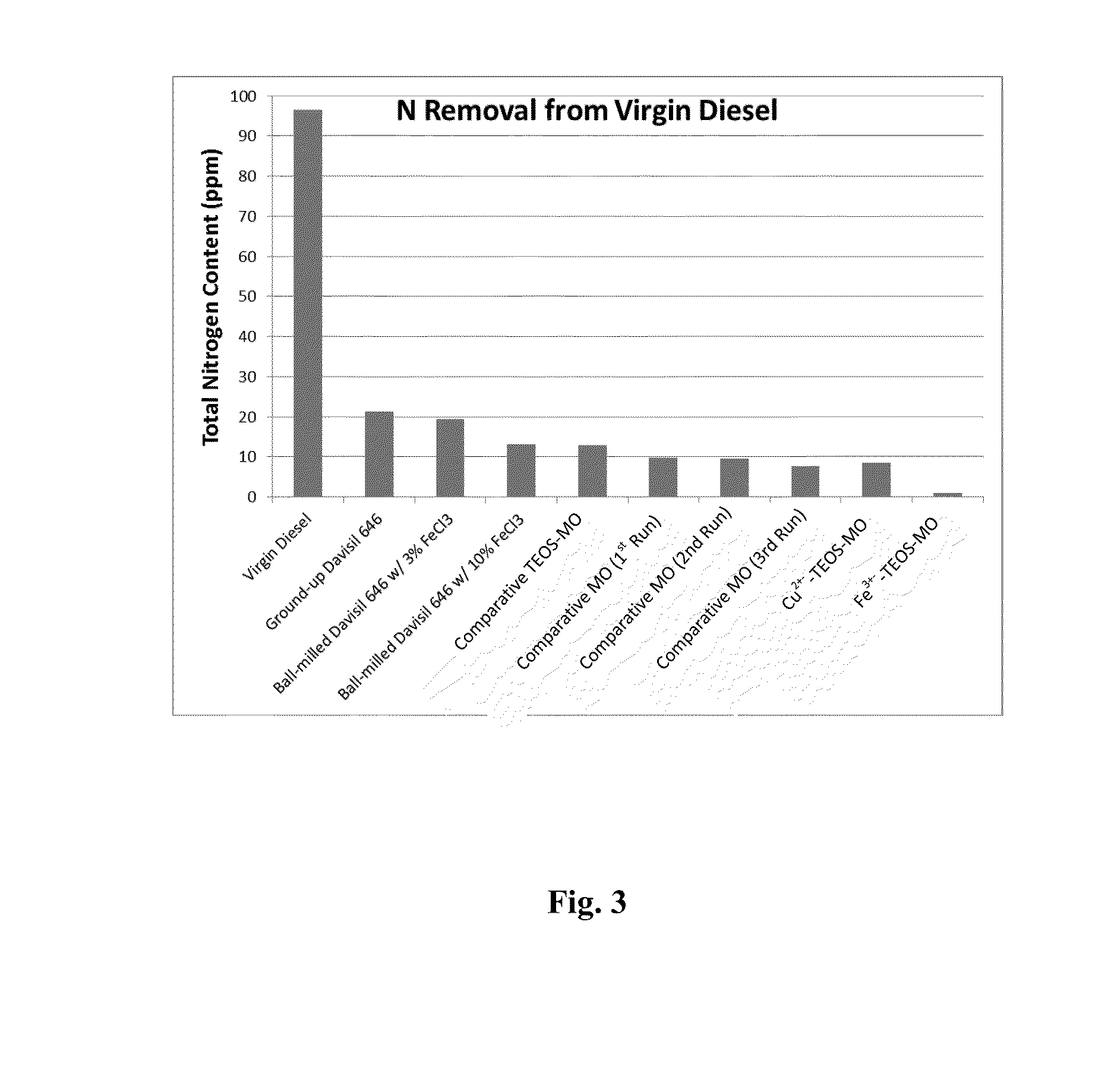

Adsorbent for heteroatom species removal and uses thereof

Adsorbent materials including a porous material support and about 0.5 wt. % to about 30 wt. % of a Group 8 metal ion are provide herein. Methods of making the adsorbent material and processes of using the adsorbent material, e.g., for heteroatom species separation, are also provided herein.

Owner:EXXON RES & ENG CO

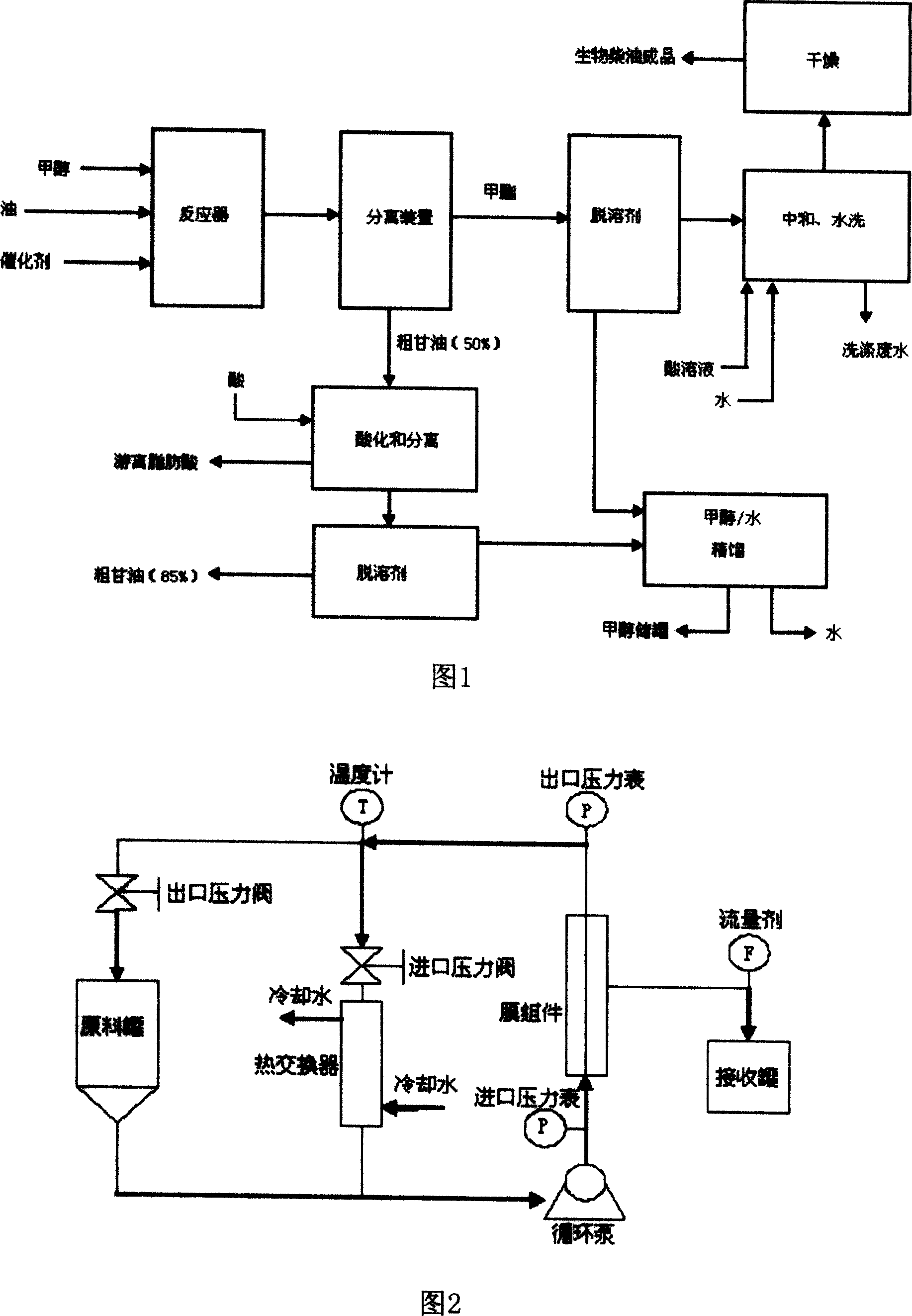

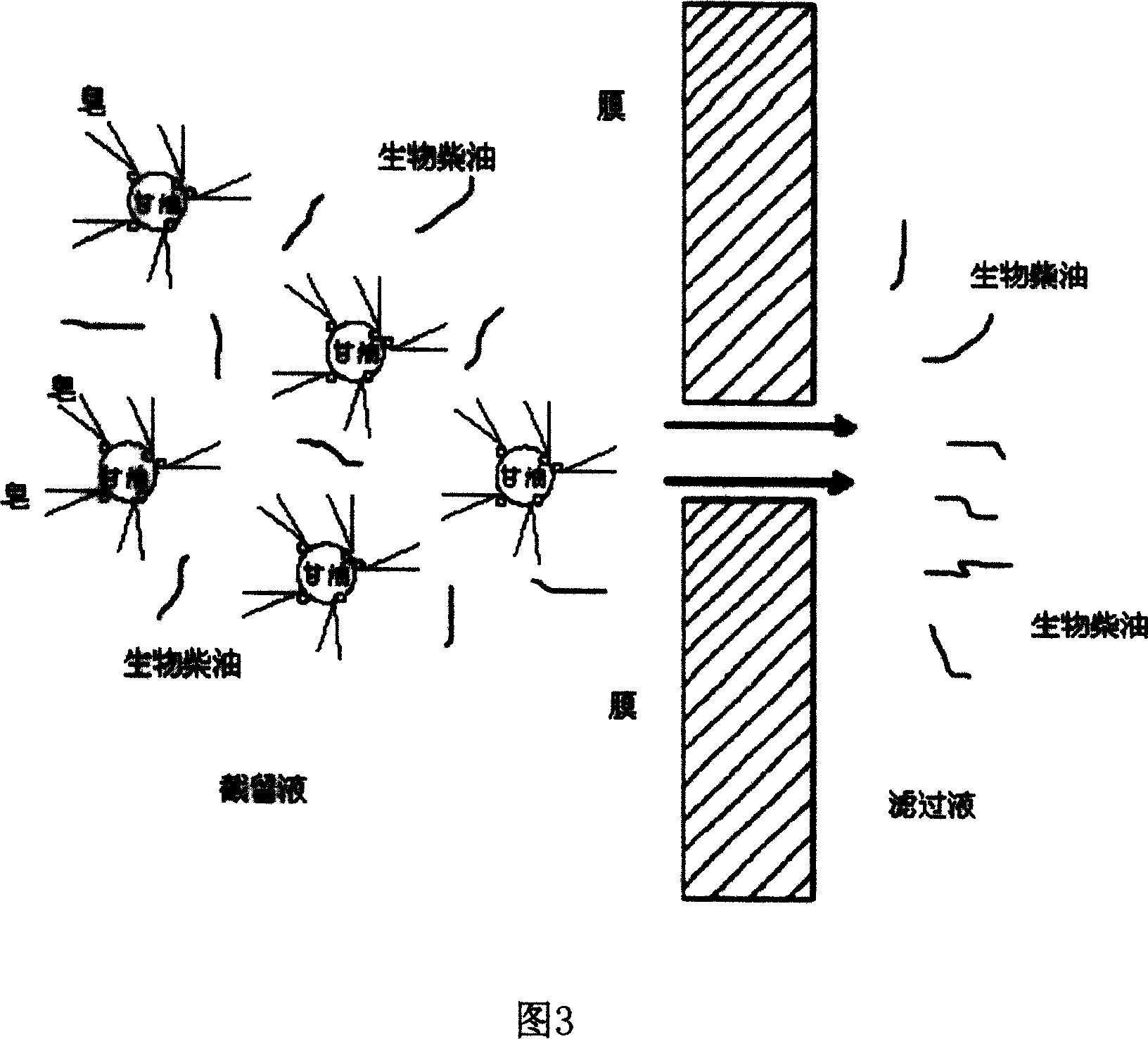

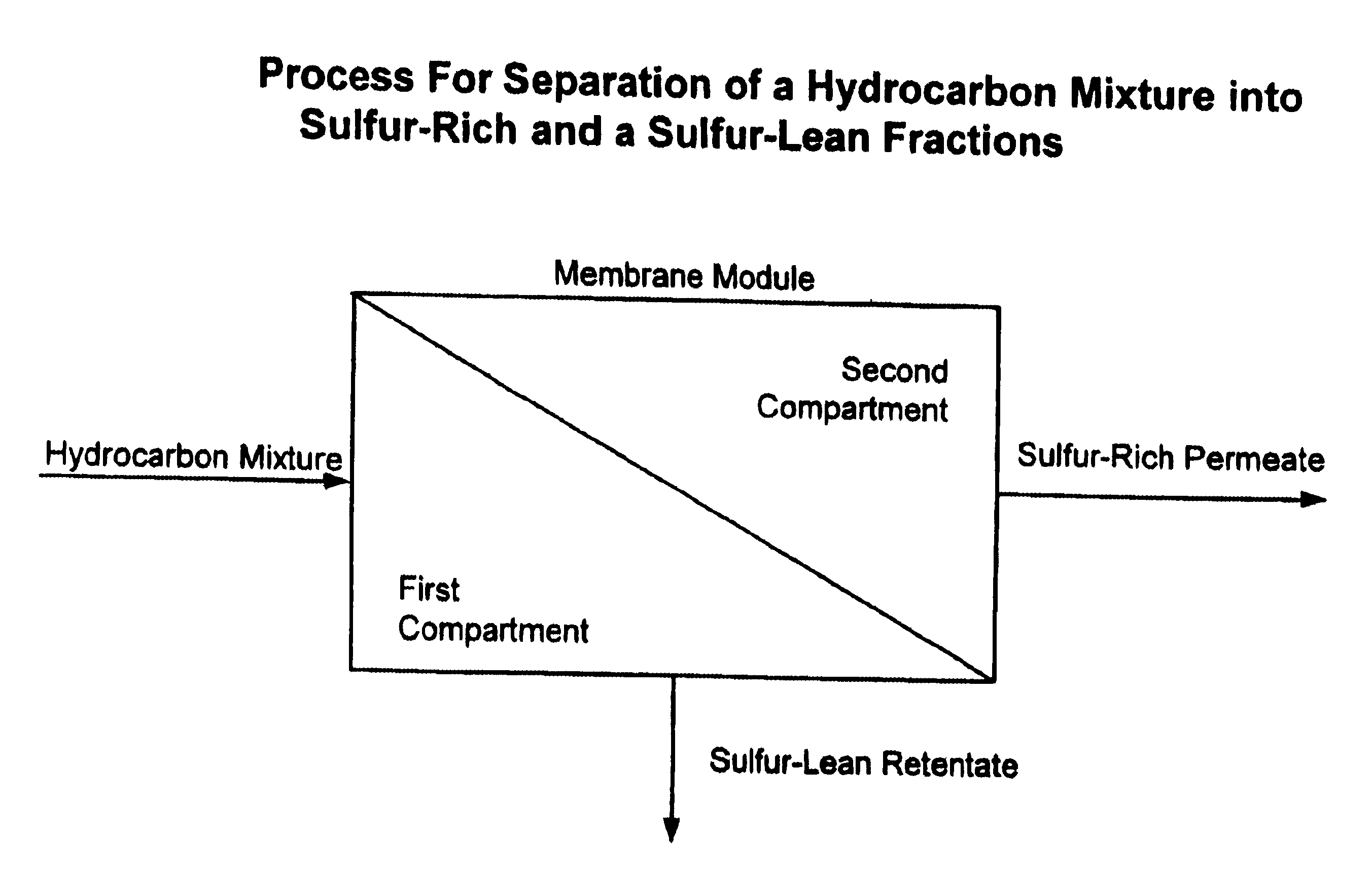

Method of removing soap and dissociative glycerin in biological diesel oil

InactiveCN101012392ASimple processLess investmentBiofuelsLiquid hydrocarbon mixture productionOrganic solventBiodiesel

The invention discloses a making method of rough biological diesel, which is characterized by the following: adopting organic solvent, chemical property stable ceramic film to do micro-filter directly; removing trace soap and free glycerine without washing.

Owner:JINAN UNIVERSITY

Ionic membranes for organic sulfur separation from liquid hydrocarbon solutions

Methods for the separation of sulfur compounds from a hydrocarbon mixture using an ionic membrane are provided. Preferred ionic membranes are Nafion(R)-type (polymers of perfluorosulfonic acid) membranes and derivatives thereof. Preferred applications include the removal of sulfur contaminants from light cracked naphthas.

Owner:EXXON RES & ENG CO

Membrane fabrication methods using organosilica materials and uses thereof

ActiveUS20160168485A1High rejectionTunable surface propertiesCatalytic naphtha reformingSolid sorbent liquid separationAlkoxy groupActive site

Methods for fabricating a membrane with an organosilica material which is a polymer comprising independent units of Formula [Z3Z4SiCH2]3 (I), wherein each Z3 represents a hydroxyl group, a C1-C4 alkoxy group or an oxygen atom bonded to a silicon atom of another unit or an active site on the support and each Z4 represents a hydroxyl group, a C1-C4 alkoxy group, a C1-C4 alkyl group, an oxygen atom bonded to a silicon atom of another unit or an active site on the support are provided. Methods of removing a contaminant from a hydrocarbon stream are also provided.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com