Method of removing soap and dissociative glycerin in biological diesel oil

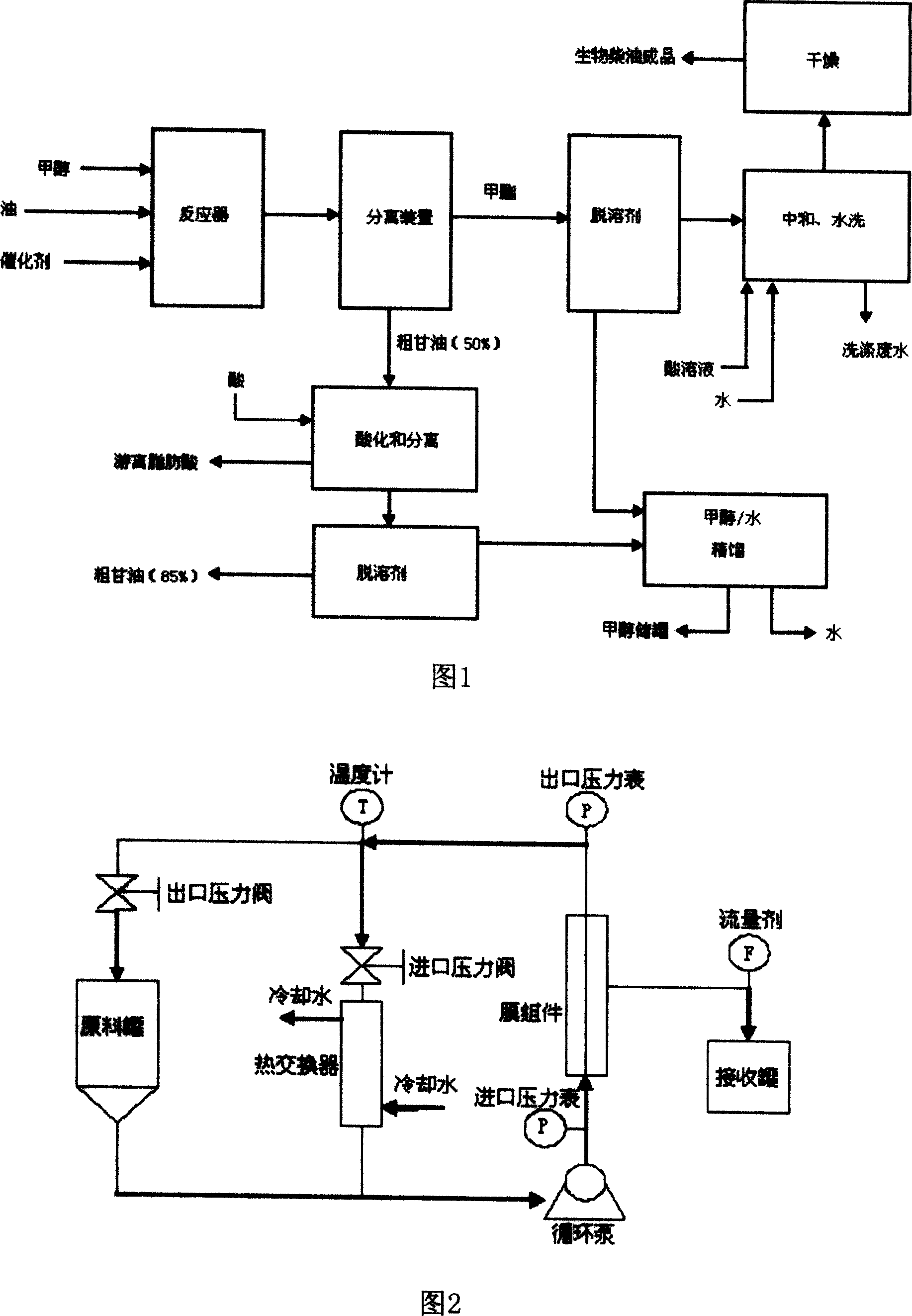

A biodiesel and glycerin technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems of limiting soap content, excessive engine emissions, affecting the performance of diesel engines, etc., and achieves the goal of reducing equipment investment and simplifying processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

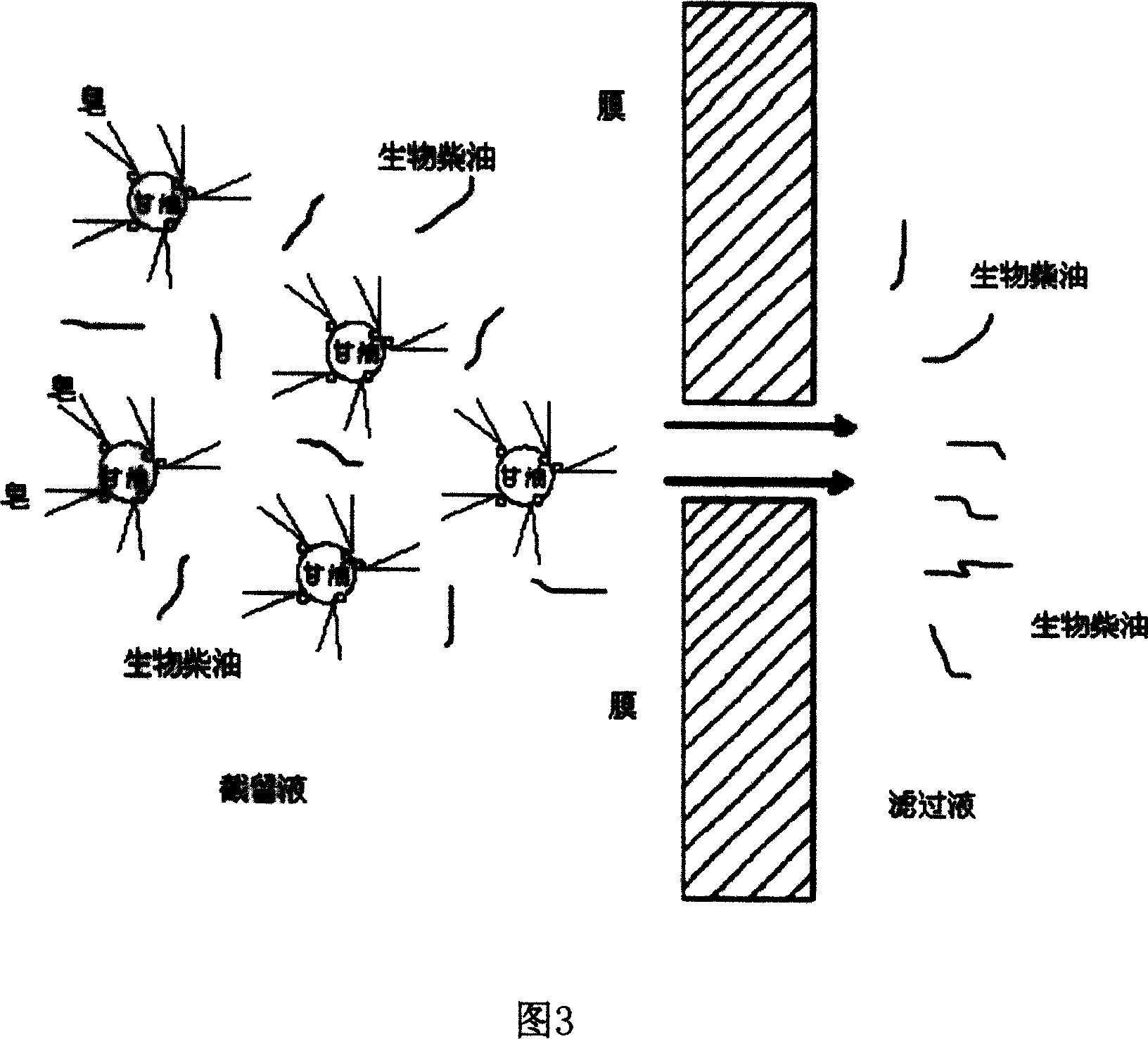

[0023] Add 10Kg of crude biodiesel (free glycerin content 0.05%, K element content 25.2mg / kg, Na element content 217.6mg / kg) into the raw material tank, open the circulation pump, adjust the inlet and outlet valves, so that the ultrafiltration inlet pressure is 0.20MPa , The outlet pressure is 0.05MPa. A ceramic membrane with a pore size of 0.6 μm (the material of the membrane layer is alumina and the material of the support layer is ceramic) is used to cross-flow filter crude biodiesel at 40°C, the filtrate is collected, and the flux of the membrane is automatically recorded every 3 minutes. When the concentration ratio is 4:1, stop the pump. Determination of total filtrate K, Na element content is 1.4 and 3.25mg / kg, free glycerin content is 0.006%.

Embodiment 2

[0025] Add 10Kg of crude biodiesel (free glycerol content 0.261%, K element content 159.72mg / kg, Na element content 8.98mg / kg) into the raw material tank, open the circulation pump, adjust the inlet and outlet valves, so that the ultrafiltration inlet pressure is 0.26MPa , The outlet pressure is 0.06MPa. A ceramic membrane with a pore size of 0.2 μm (the material of the membrane layer is alumina and the material of the support layer is ceramic) is cross-flow filtered at 50°C for crude biodiesel, the filtrate is collected, and the flux of the membrane is automatically recorded every 3 minutes. When the concentration ratio is 6:1, stop the pump. Determination of total filtrate K, Na element content is 2.20 and 0.88mg / kg, free glycerin content is 0.0257%.

Embodiment 3

[0027] Add 10Kg of crude biodiesel (free glycerol content 0.364%, K element content 206.5mg / kg, Na element content 20.8mg / kg) into the raw material tank, open the circulation pump, adjust the inlet and outlet valves, so that the ultrafiltration inlet pressure is 0.30MPa , The outlet pressure is 0.08MPa. A ceramic membrane with a pore size of 0.1 μm (the material of the membrane layer is alumina and the material of the support layer is ceramic) is cross-flow filtered at 60°C for crude biodiesel, the filtrate is collected, and the flux of the membrane is automatically recorded every 3 minutes. When the concentration ratio is 8:1, stop the pump. Determination of total filtrate K, Na element content is 1.70 and 1.36mg / kg, free glycerin content is 0.0152%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com