Patents

Literature

44 results about "Natural-gas condensate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural-gas condensate, also called natural gas liquids, is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields. Some gas species within the raw natural gas will condense to a liquid state if the temperature is reduced to below the hydrocarbon dew point temperature at a set pressure.

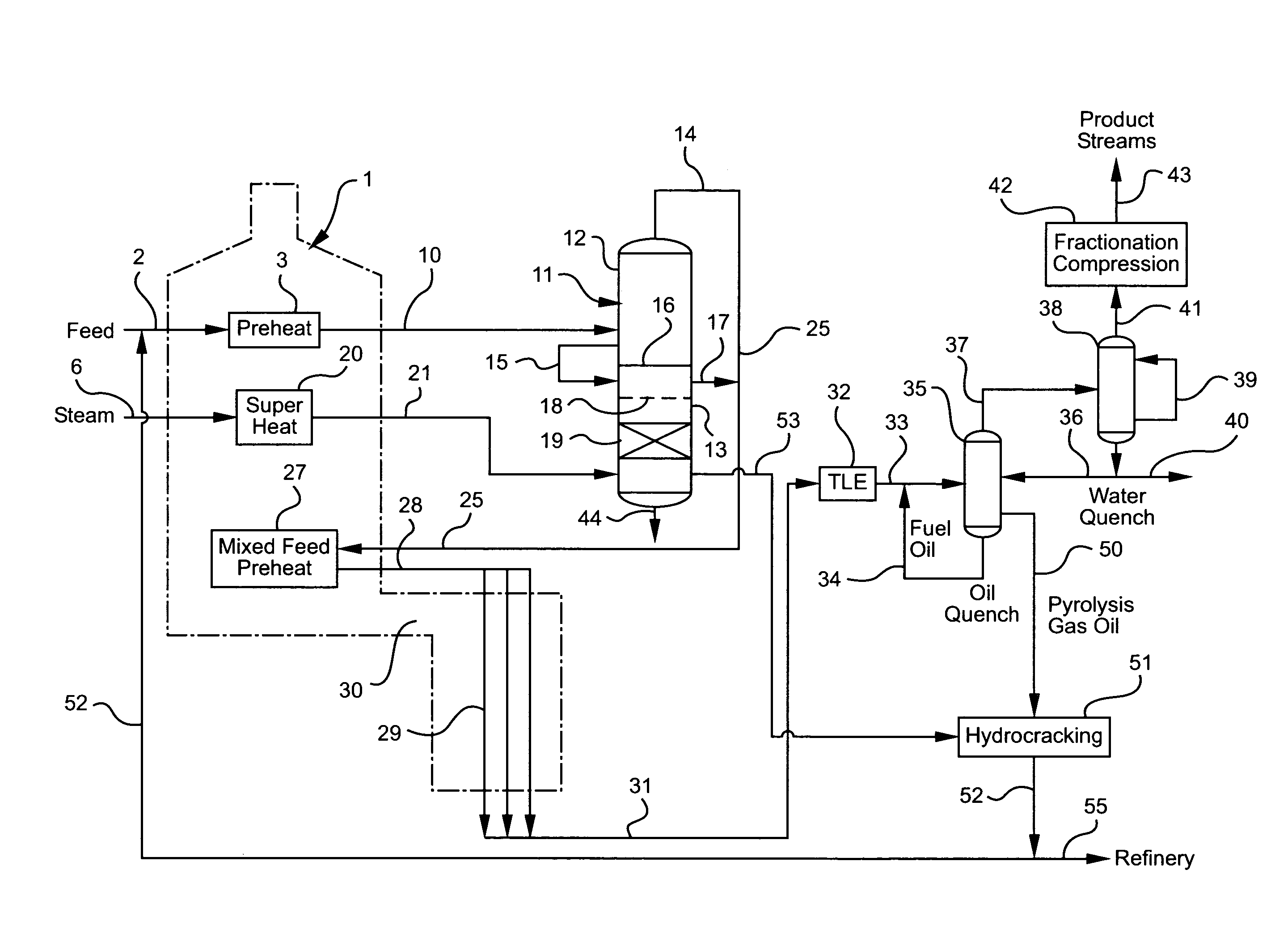

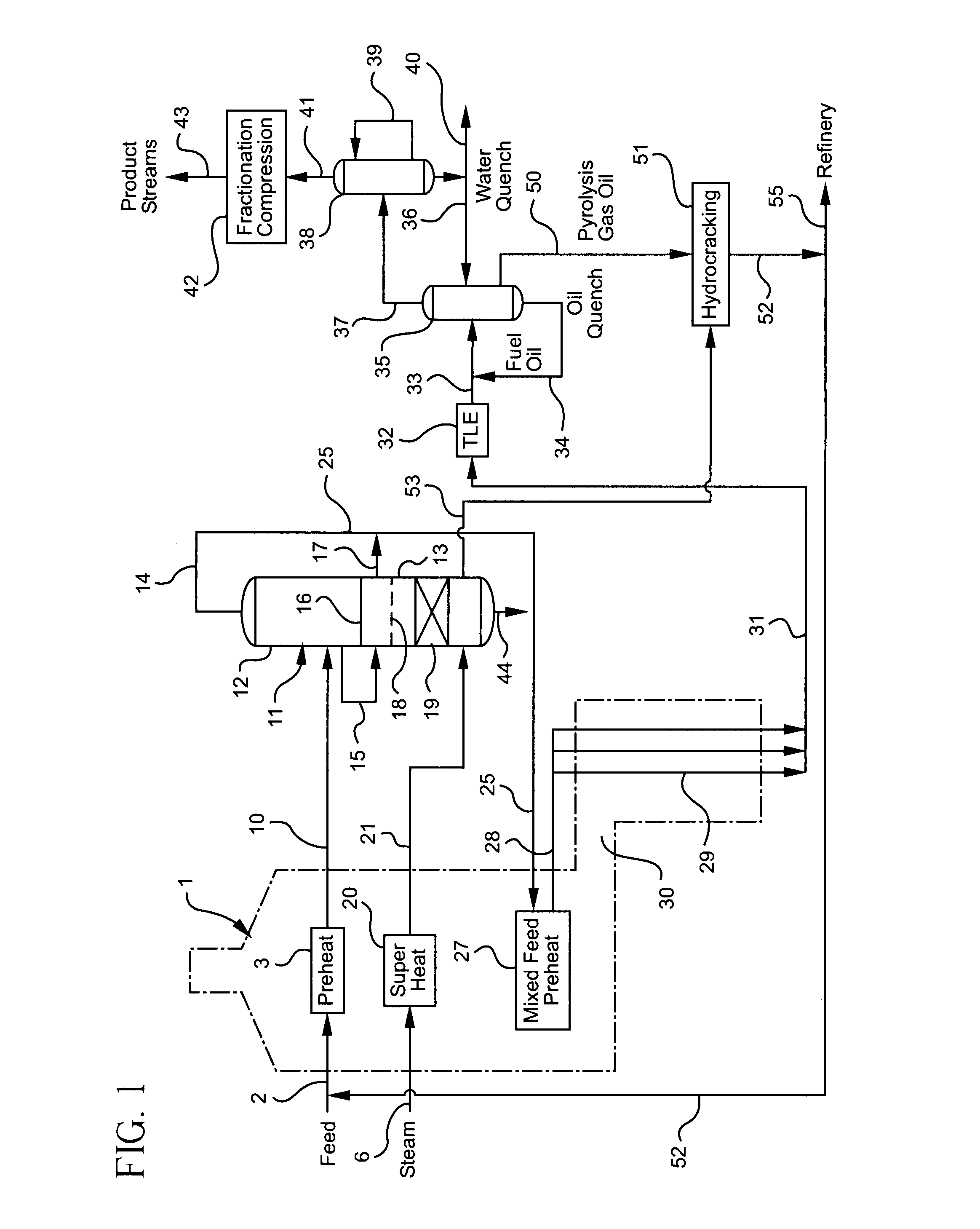

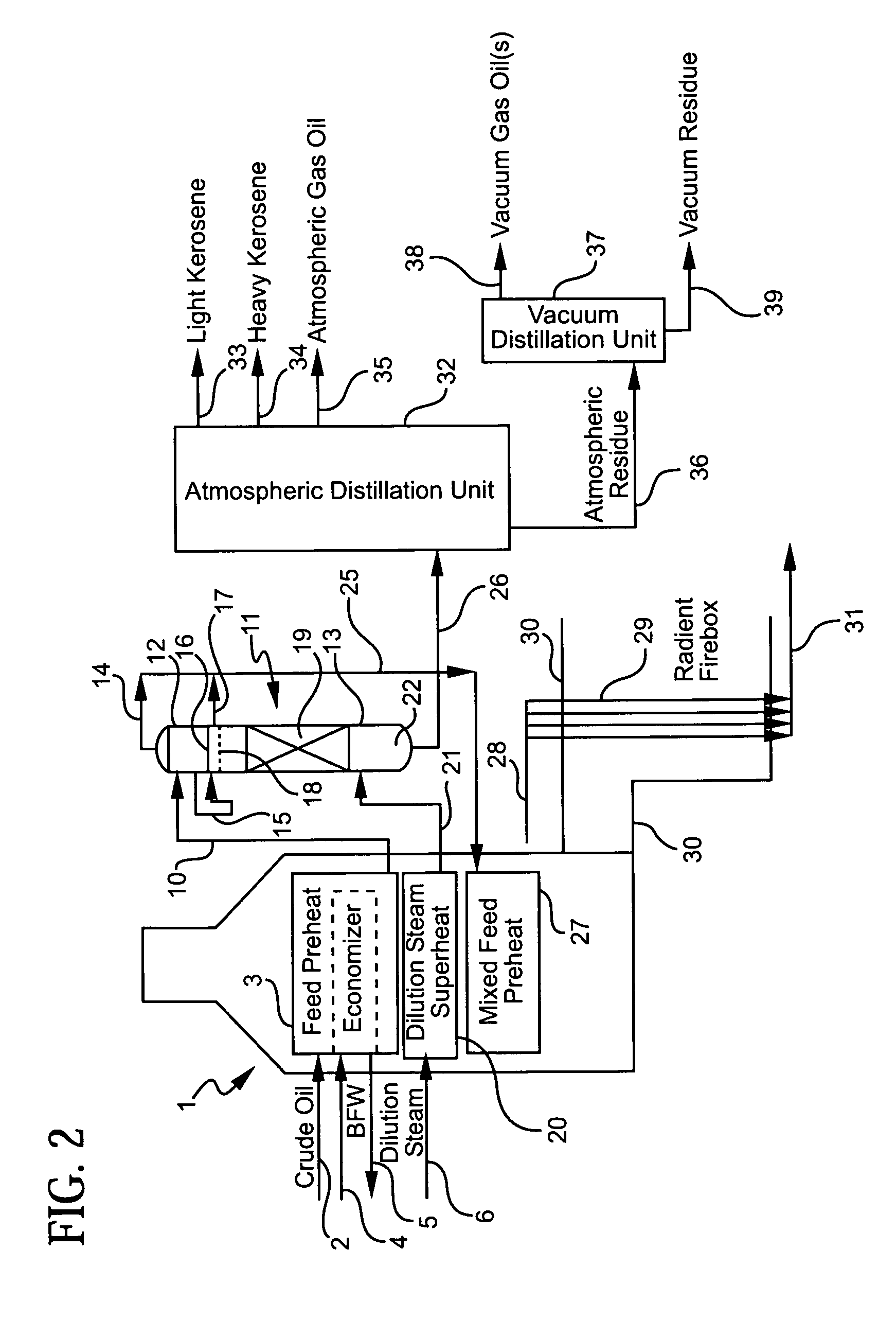

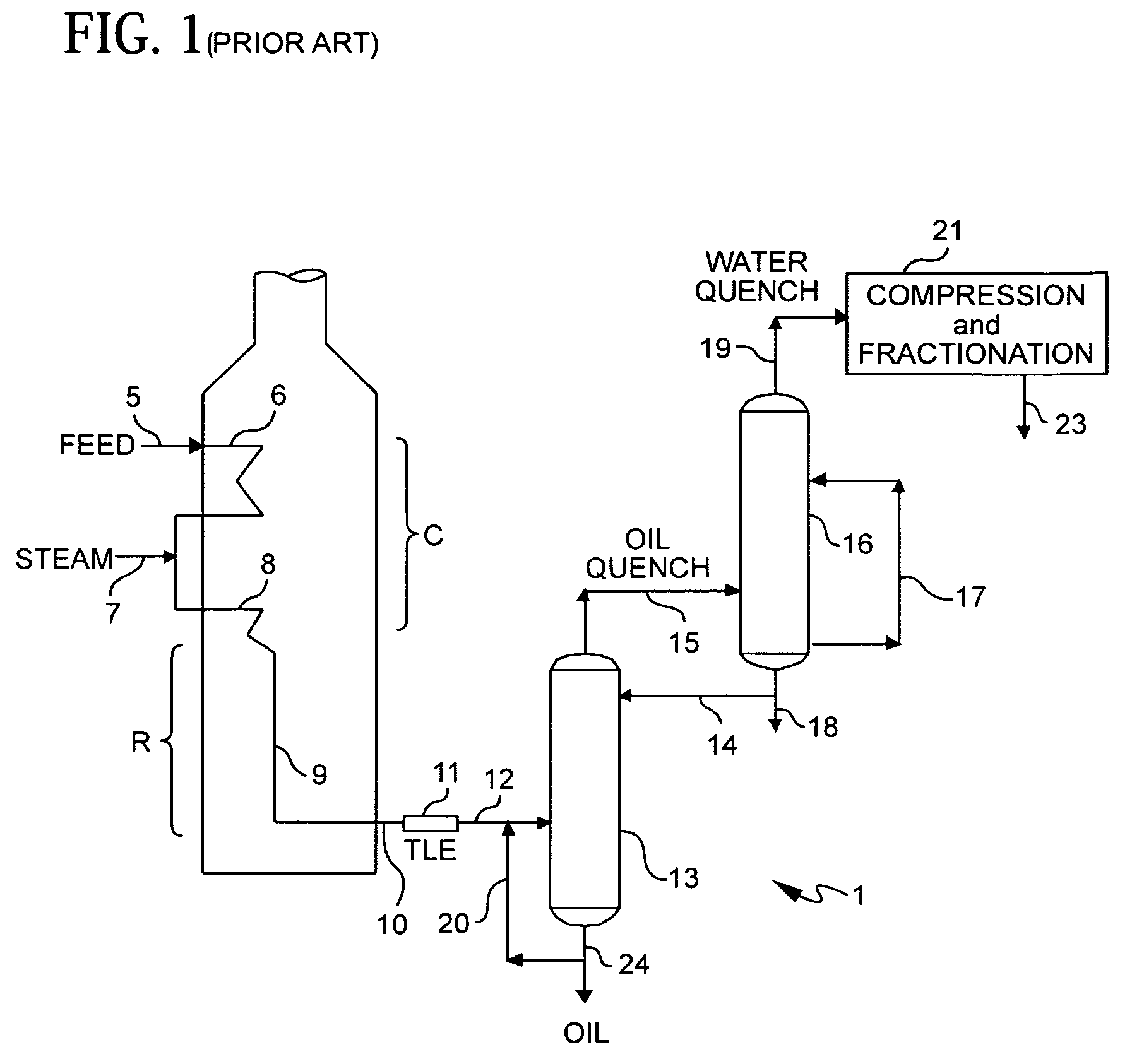

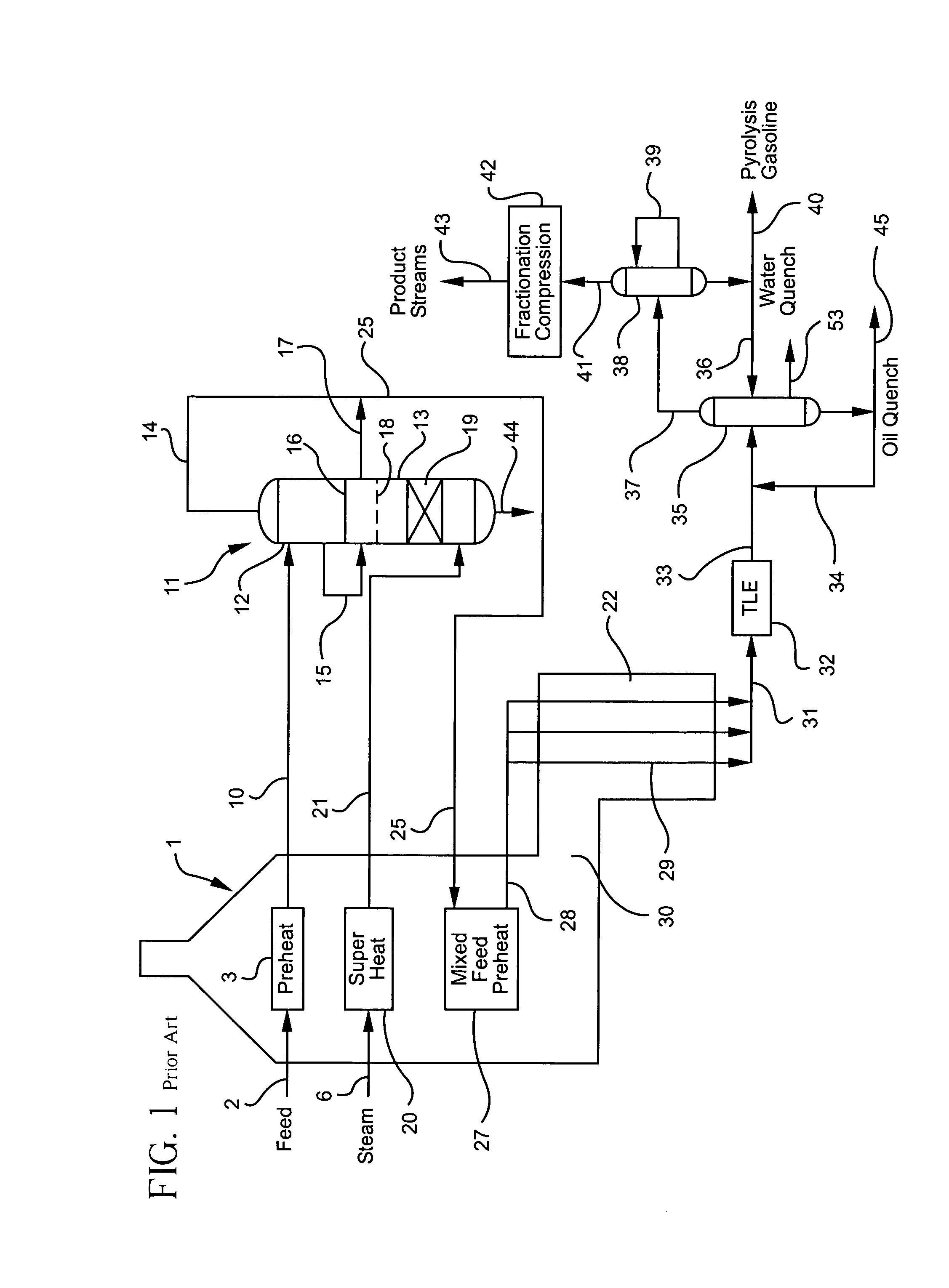

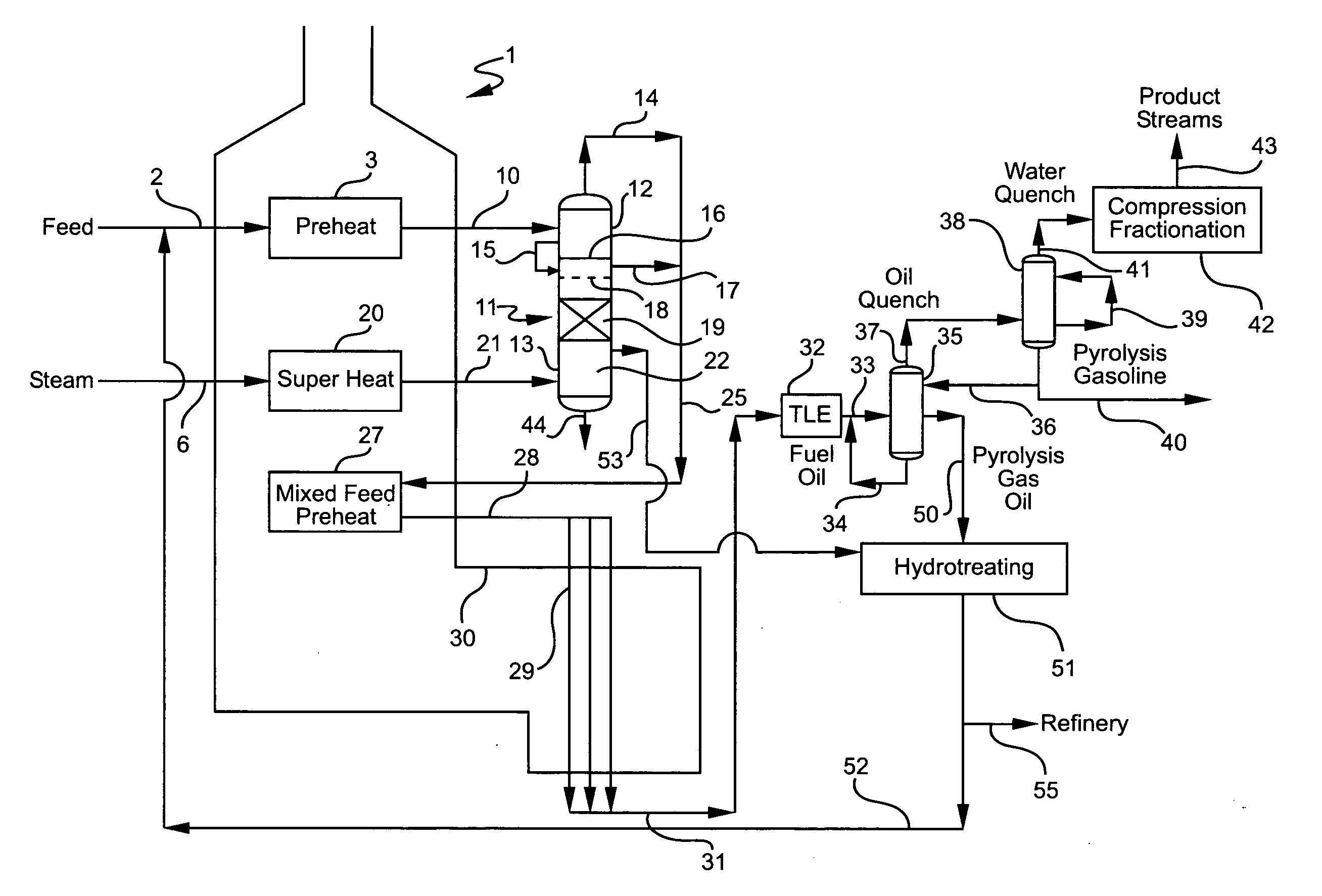

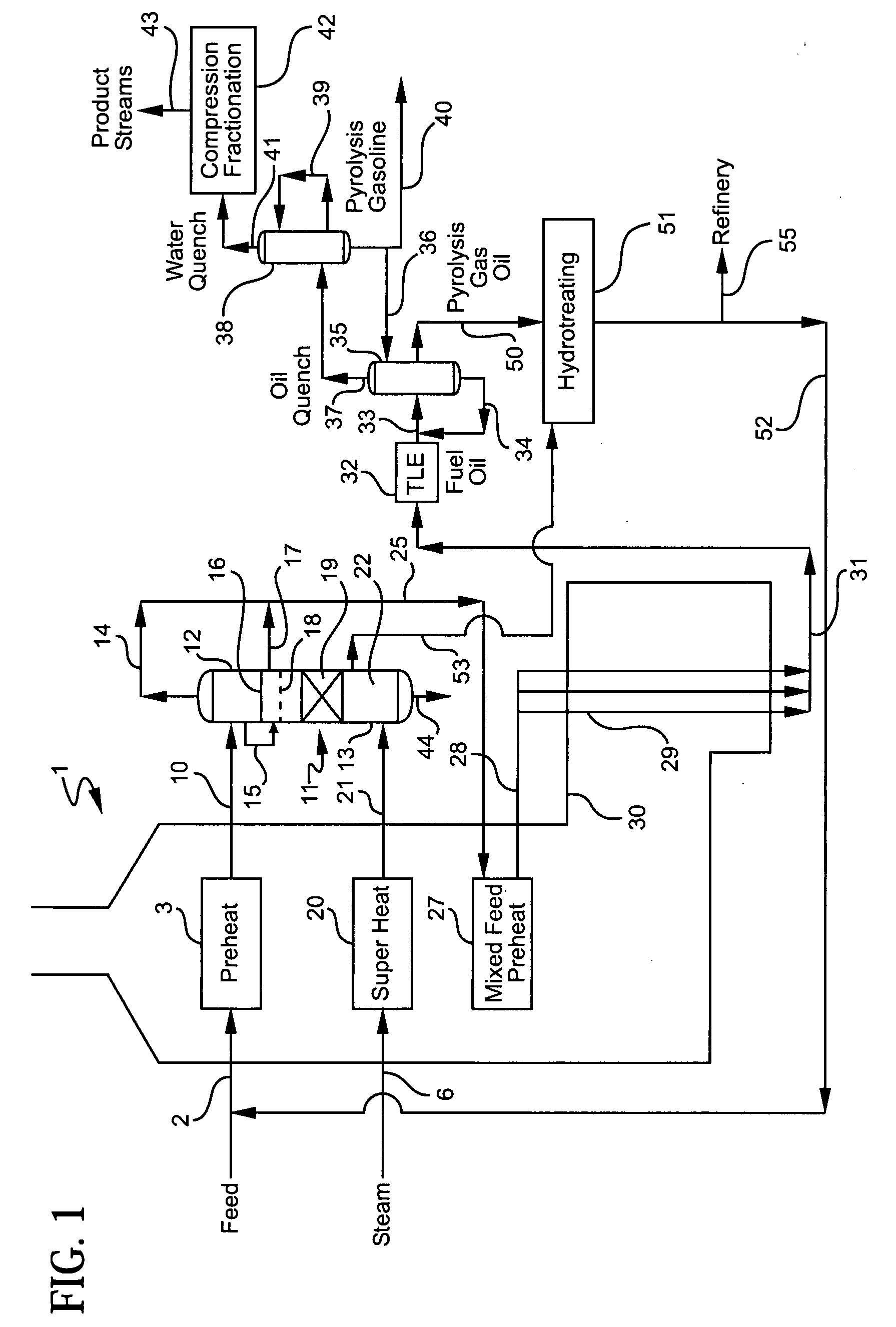

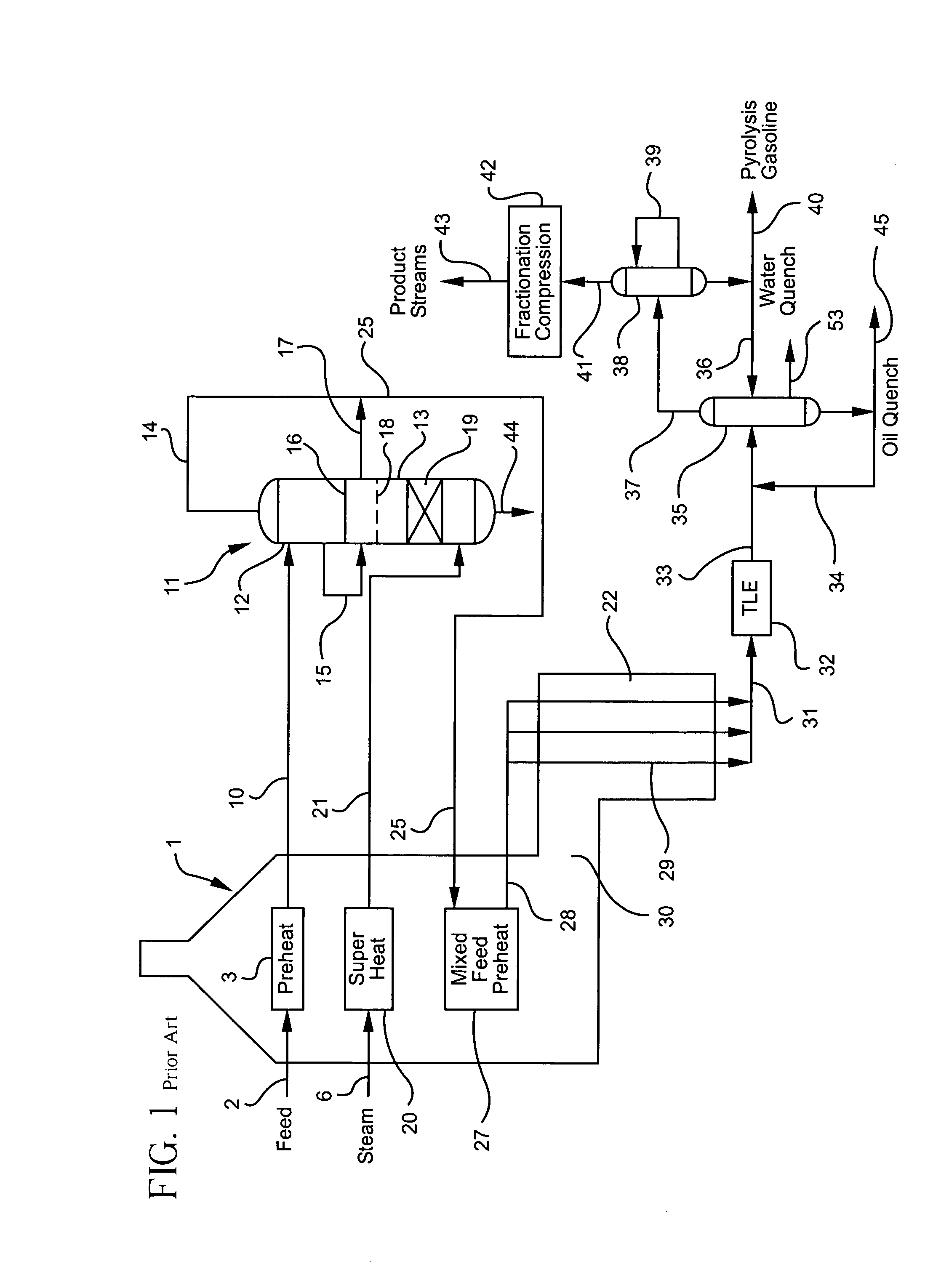

Olefin production utilizing whole crude oil/condensate feedstock and selective hydrocracking

InactiveUS20090050523A1Improve productivityReduce sulfur contentThermal non-catalytic crackingHydrocarbon oil crackingAlkaneNatural-gas condensate

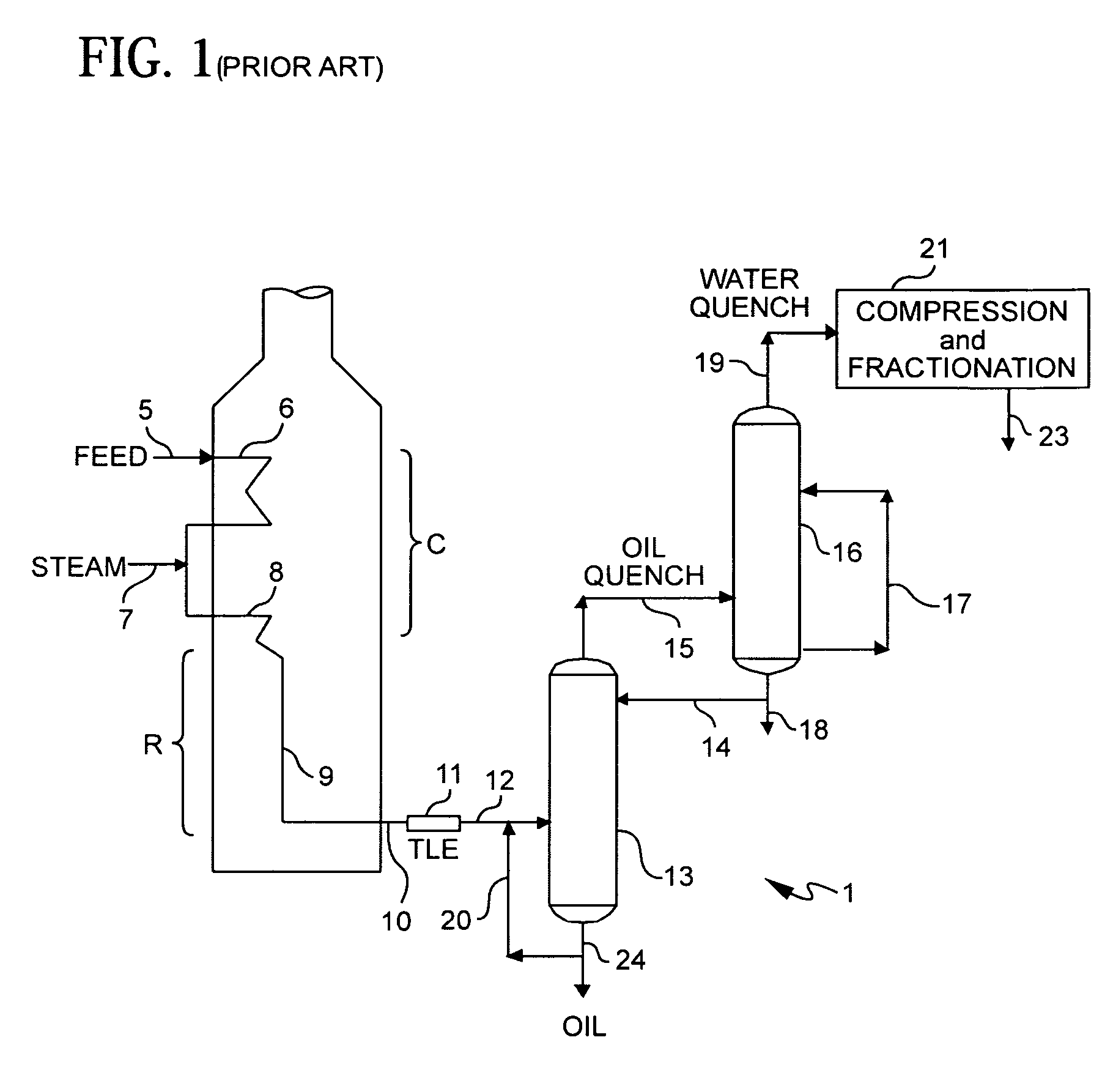

A method for thermally cracking a feed composed of whole crude oil and / or natural gas condensate using a vaporizer to vaporize the feed before cracking same, recovering pyrolysis gas oil from the cracked feed, subjecting the recovered pyrolysis gas oil to hydrocracking to form a paraffinic hydrocracked product, and passing at least part of the hydrocracked product to the vaporizer as additional thermal cracking feed.

Owner:EQUSR CHEM LP

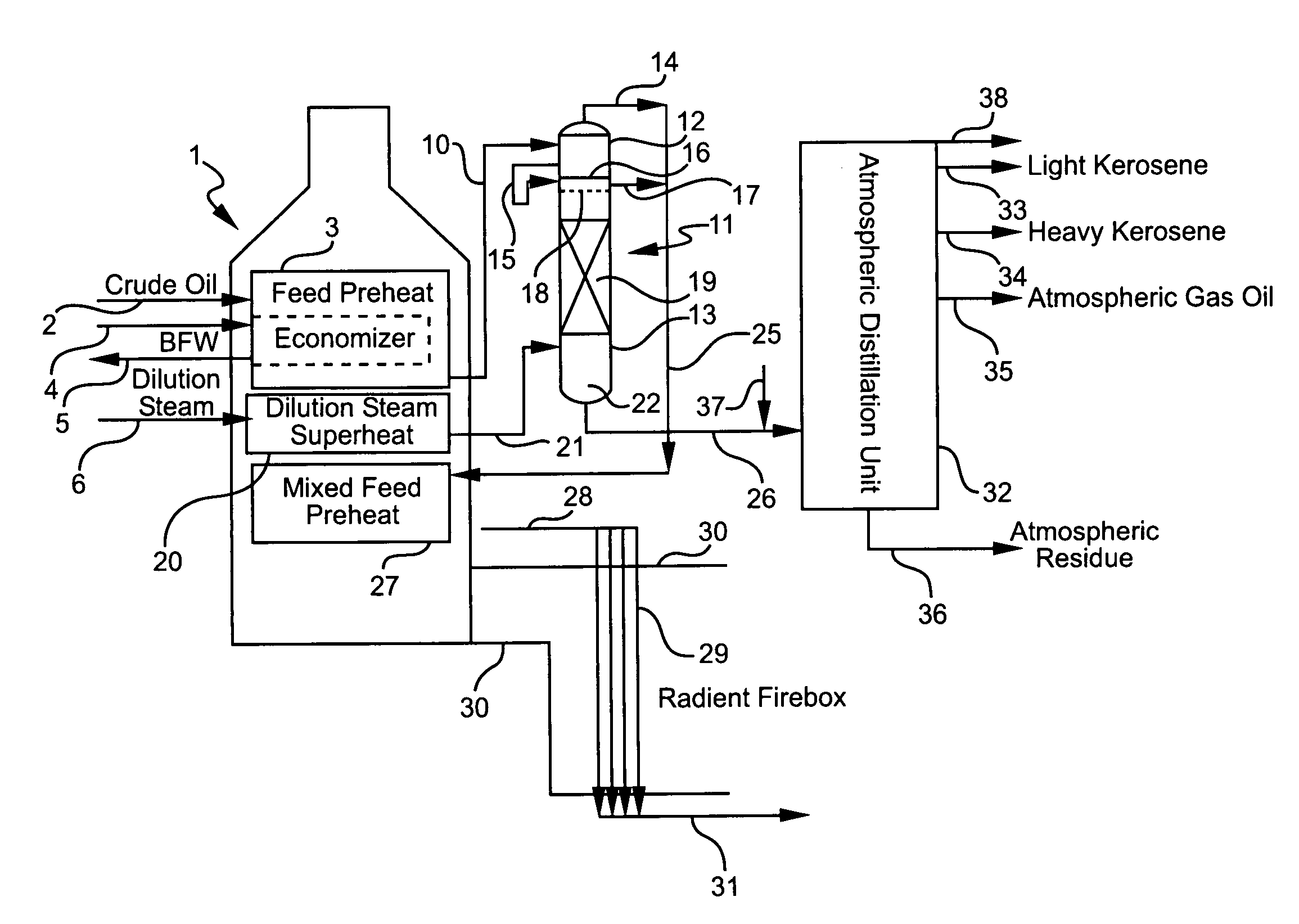

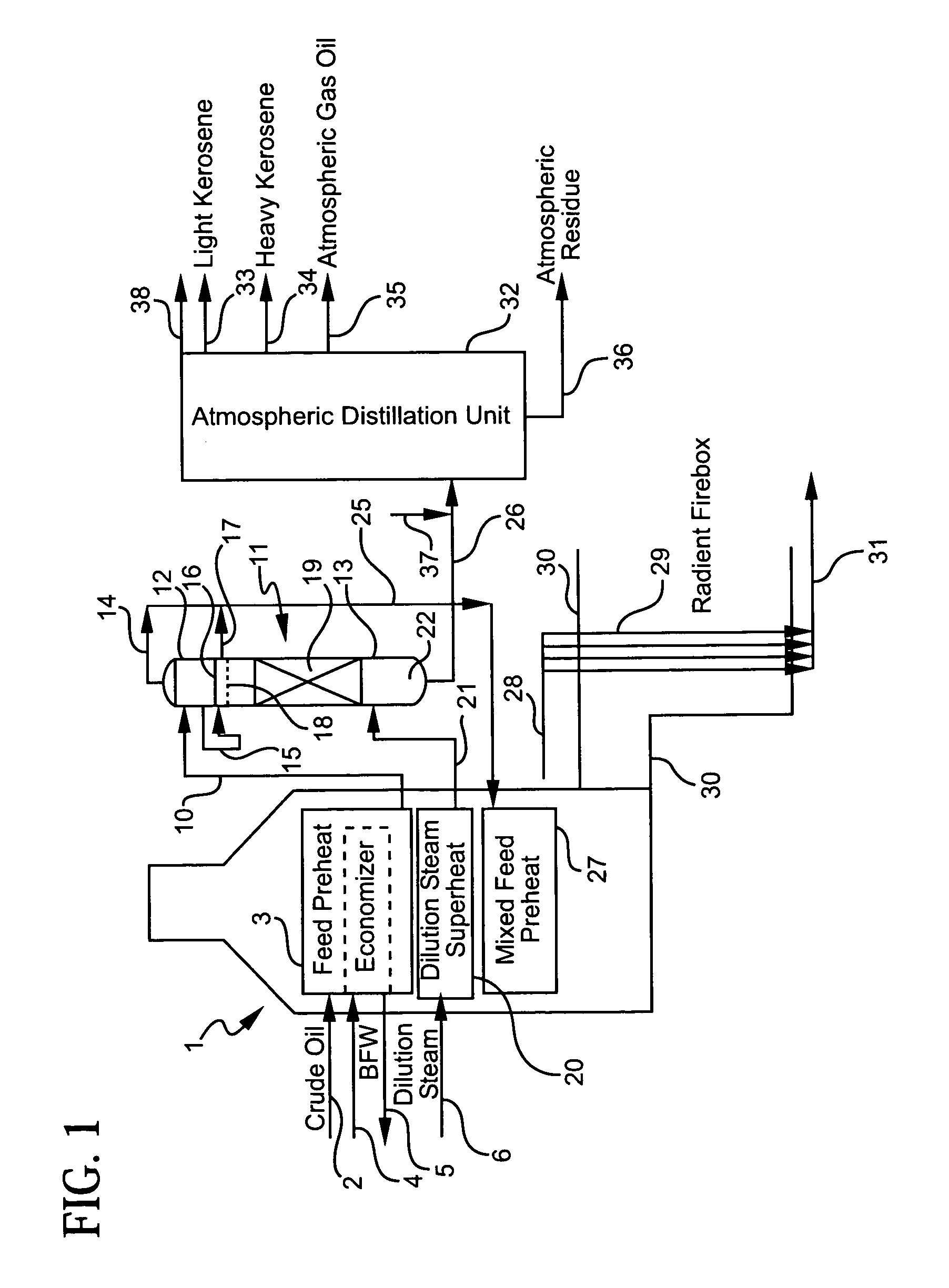

Olefin production utilizing whole crude oil/condensate feedstock with enhanced distillate production

InactiveUS7550642B2Maximize recoveryThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productNatural-gas condensate

A method processing a liquid crude and / or natural gas condensate feed comprising subjecting the feed to a vaporization step to form a vaporous product and a liquid product, subjecting the vaporous product to severe thermal cracking, and subjecting the liquid product to crude oil refinery processing.

Owner:EQUSR CHEM LP

Process for removing mercury from liquid hydrocarbons

InactiveUS6537443B1Reduce concentrationEasy maintenanceRefining with non-metalsRefining with metal saltsParticulatesNatural-gas condensate

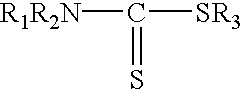

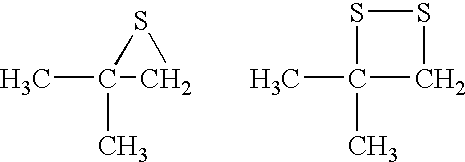

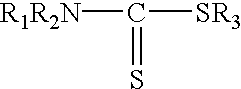

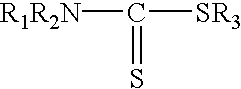

Mercury is removed from crude oils, natural gas condensates and other liquid hydrocarbons by first removing colloidal mercury and solids that contain adsorbed mercury and then treating the hydrocarbons with an organic or inorganic compound containing at least one sulfur atom reactive with mercury. The sulfur compound reacts with dissolved mercury that contaminates the hydrocarbons to form mercury-containing particulates that are then removed from the hydrocarbons to produce a purified product having a reduced mercury content. Preferably, the treating agent is an organic sulfur-containing compound such as a dithiocarbamate or sulfurized isobutylene.

Owner:UNION OIL OF CALIFORNIA

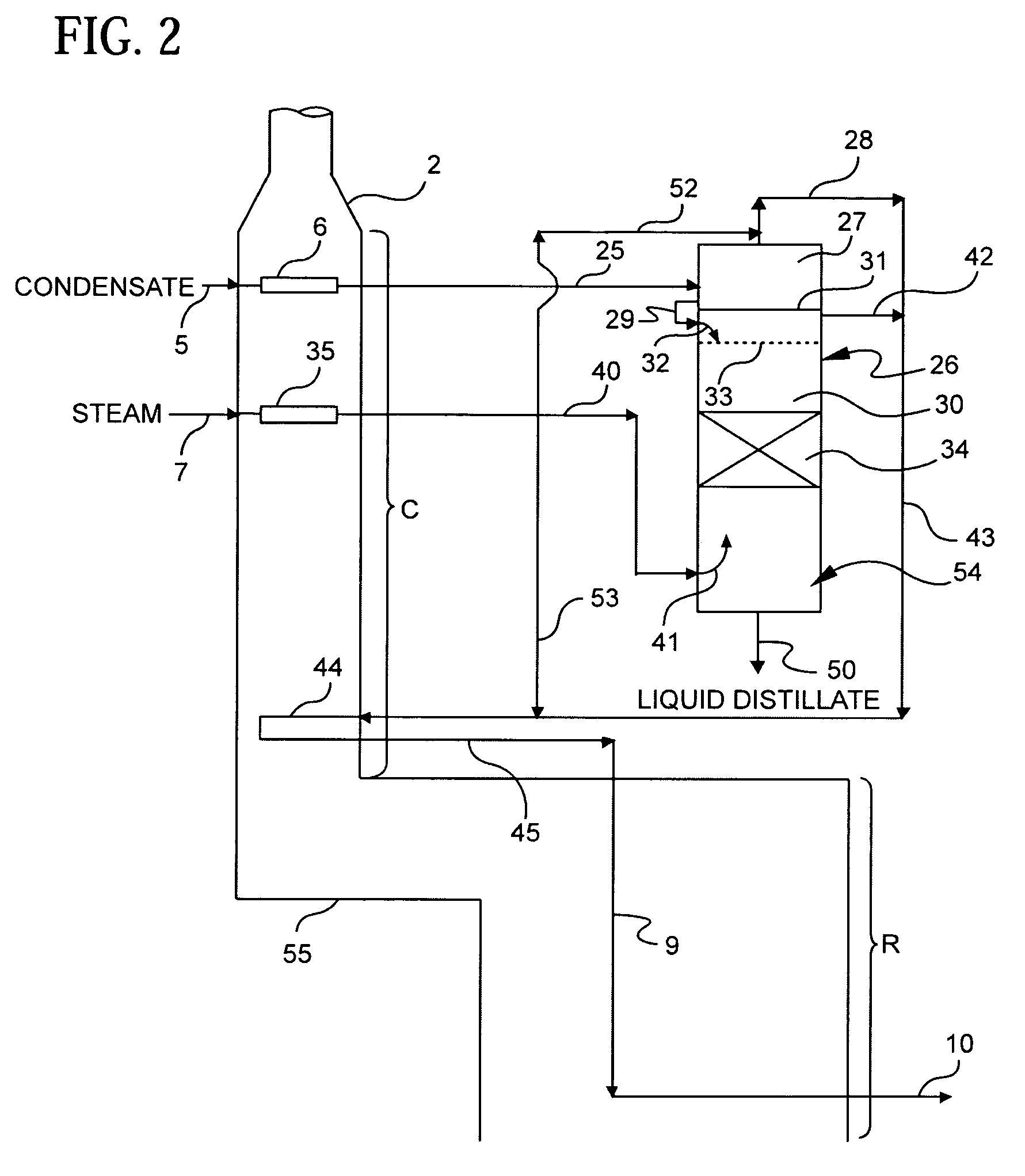

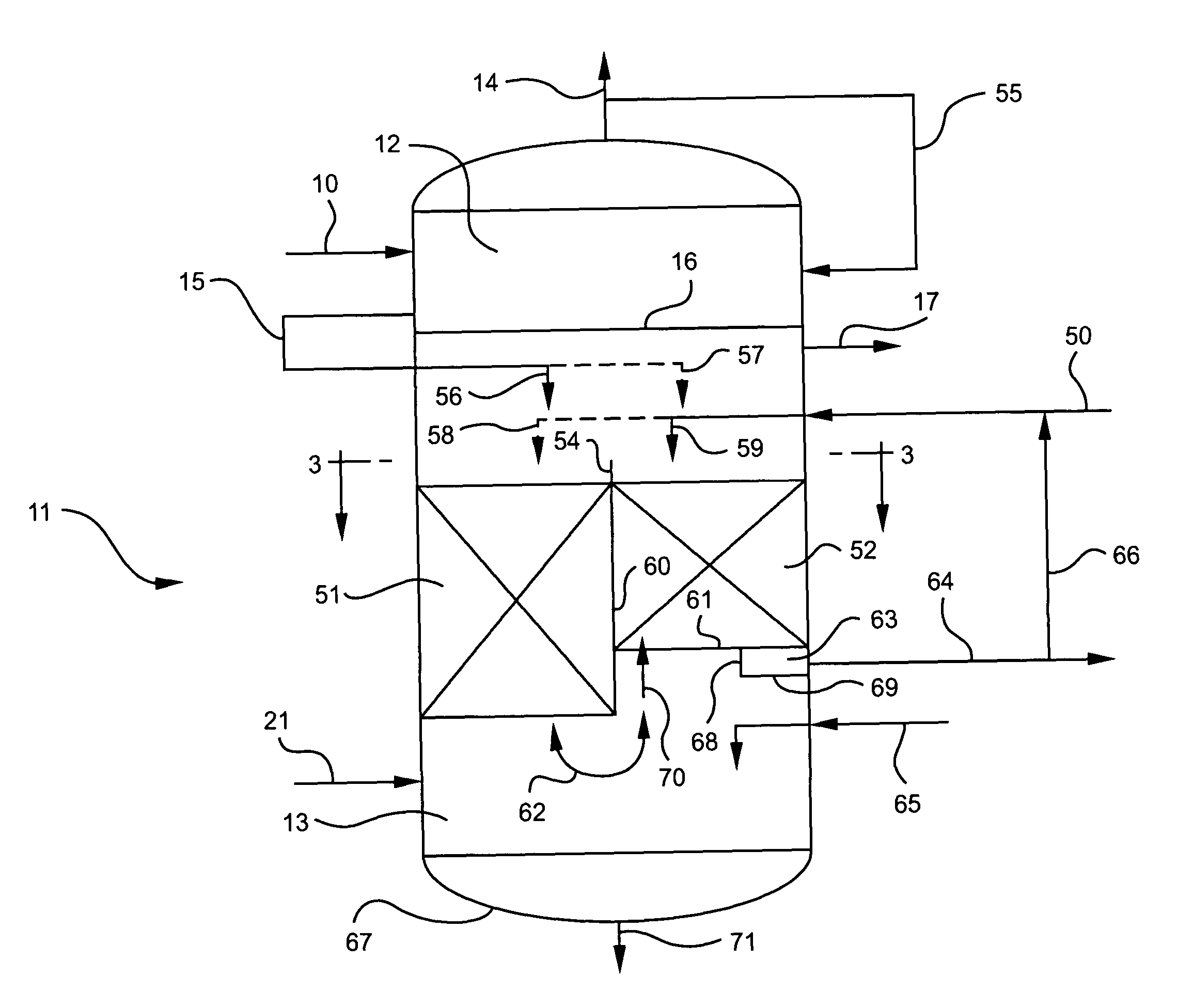

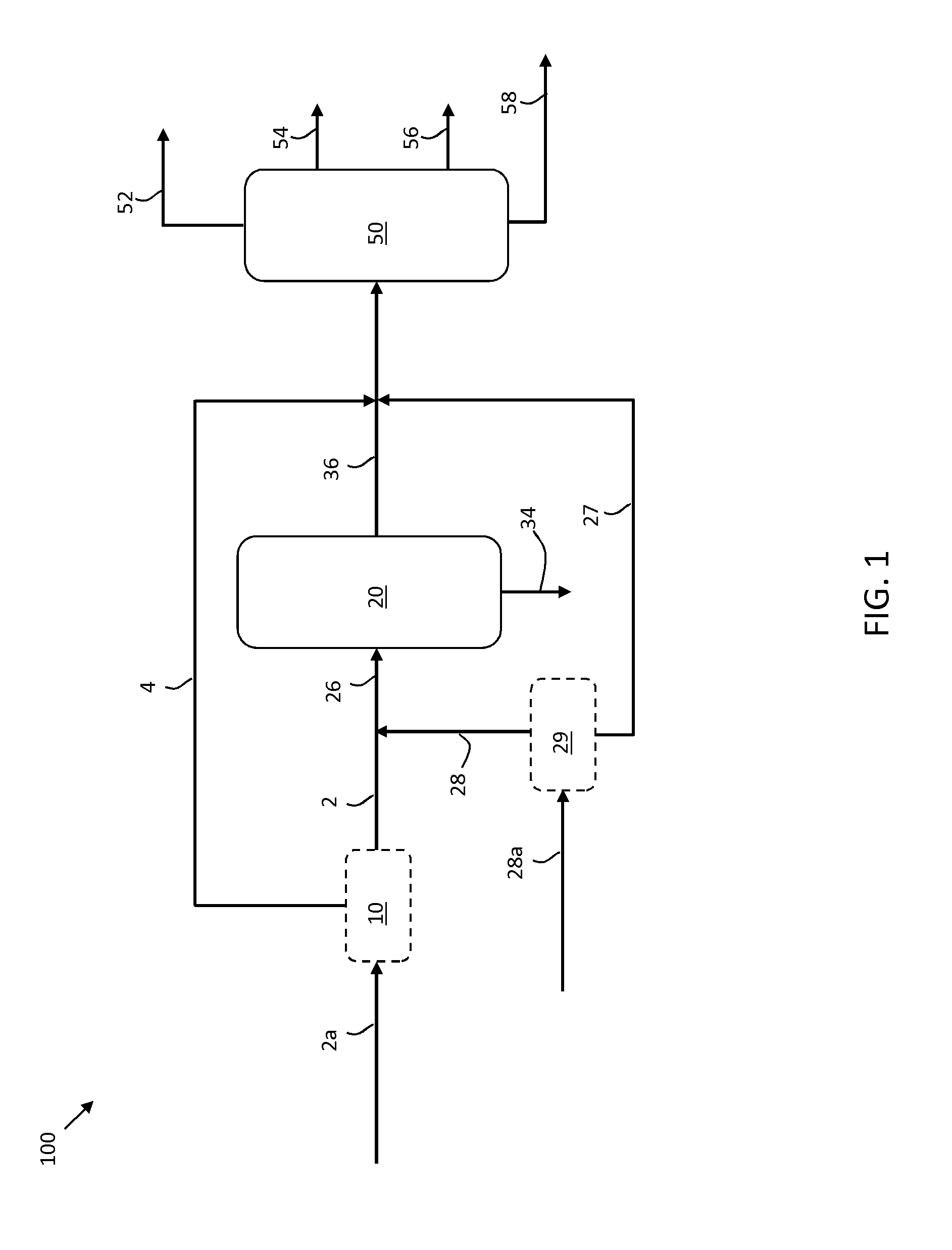

Olefin production utilizing condensate feedstock

InactiveUS7396449B2Maximize recoveryThermal non-catalytic crackingCatalytic crackingNatural-gas condensateThermodynamics

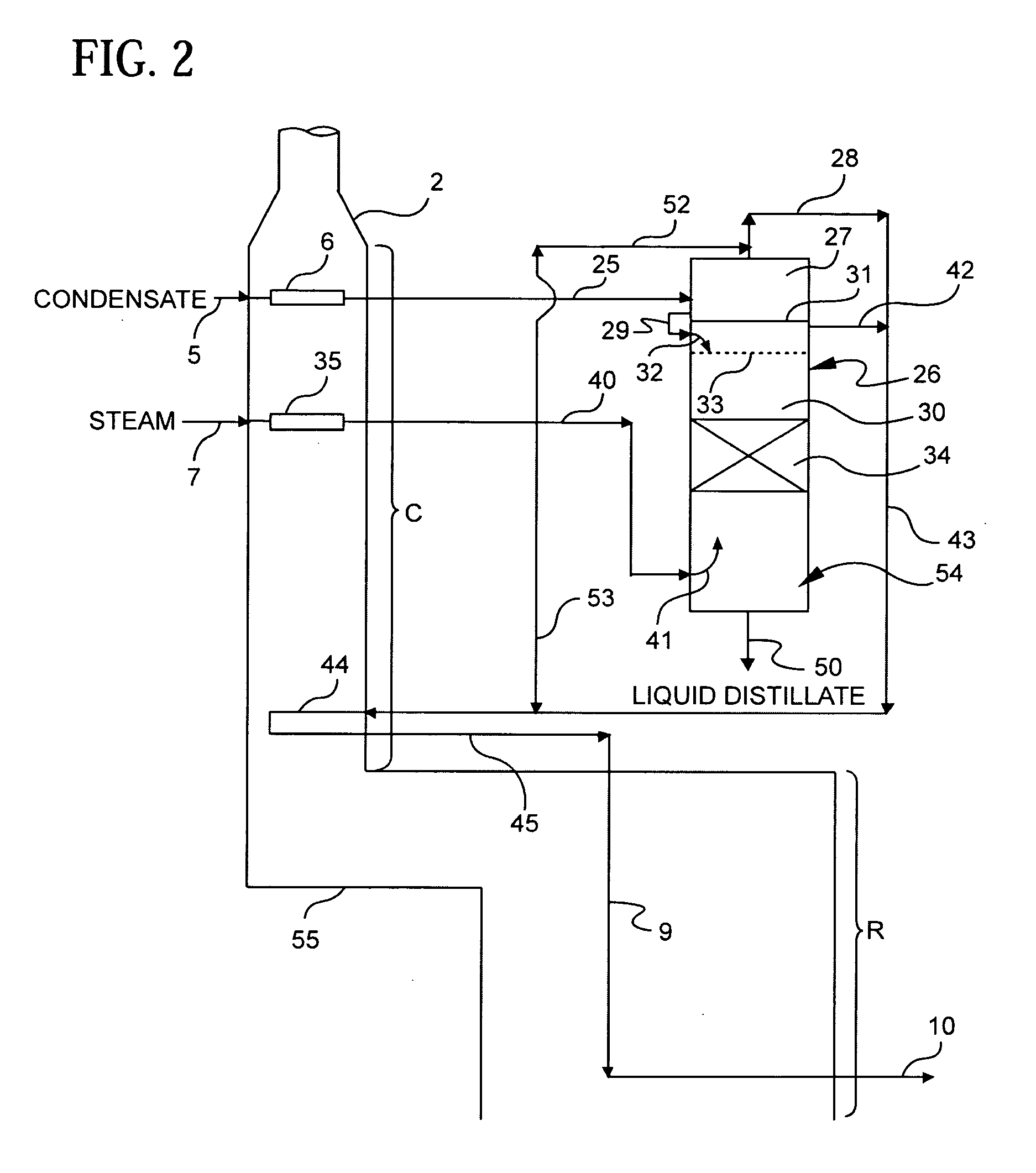

A method for utilizing natural gas condensate as a feedstock for an olefin production plant wherein the feedstock is subjected to vaporization and separation conditions that remove light hydrocarbons from the condensate for thermal cracking in the plant, and leave liquid distillate for separate recovery.

Owner:EQUSR CHEM LP

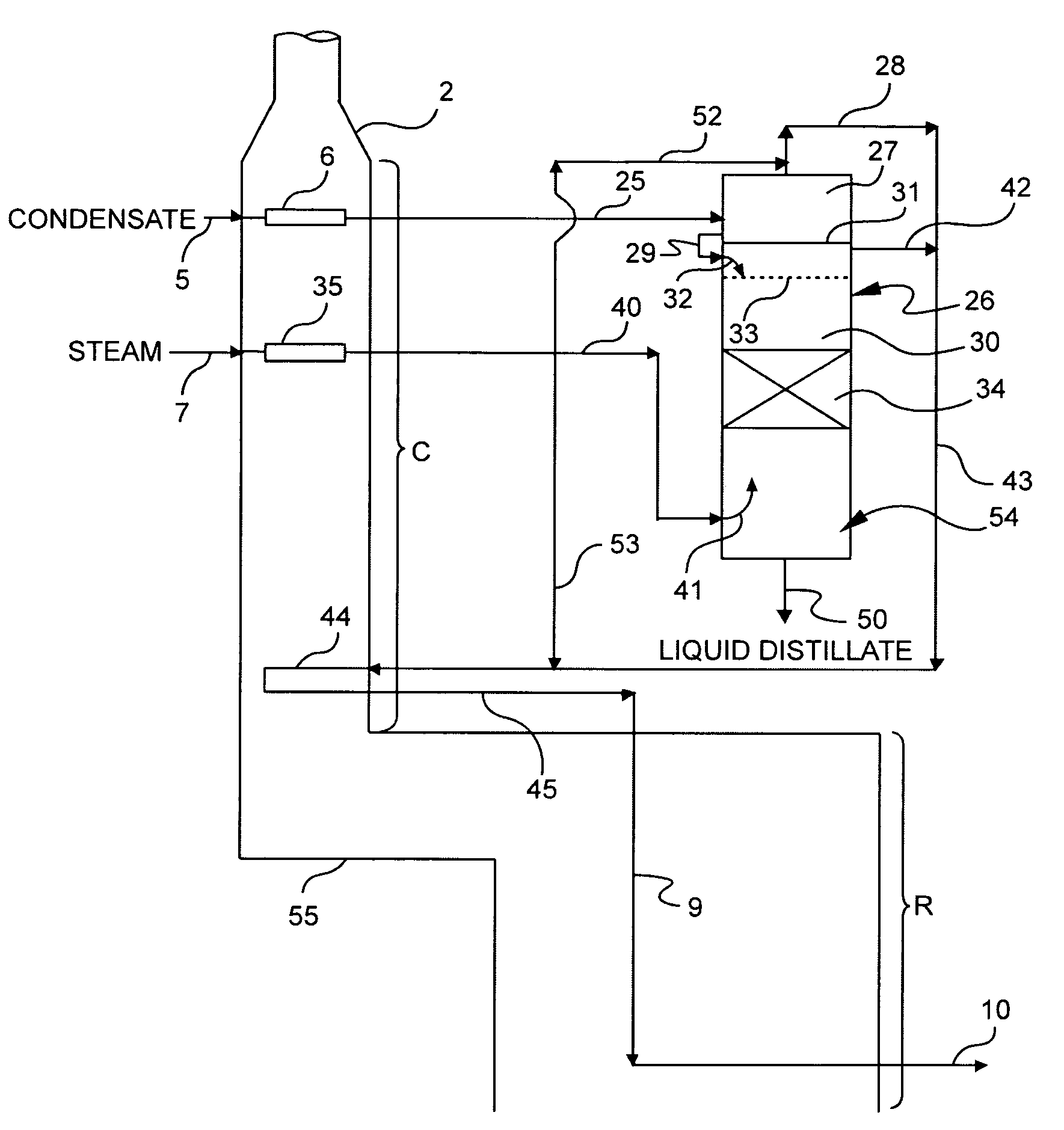

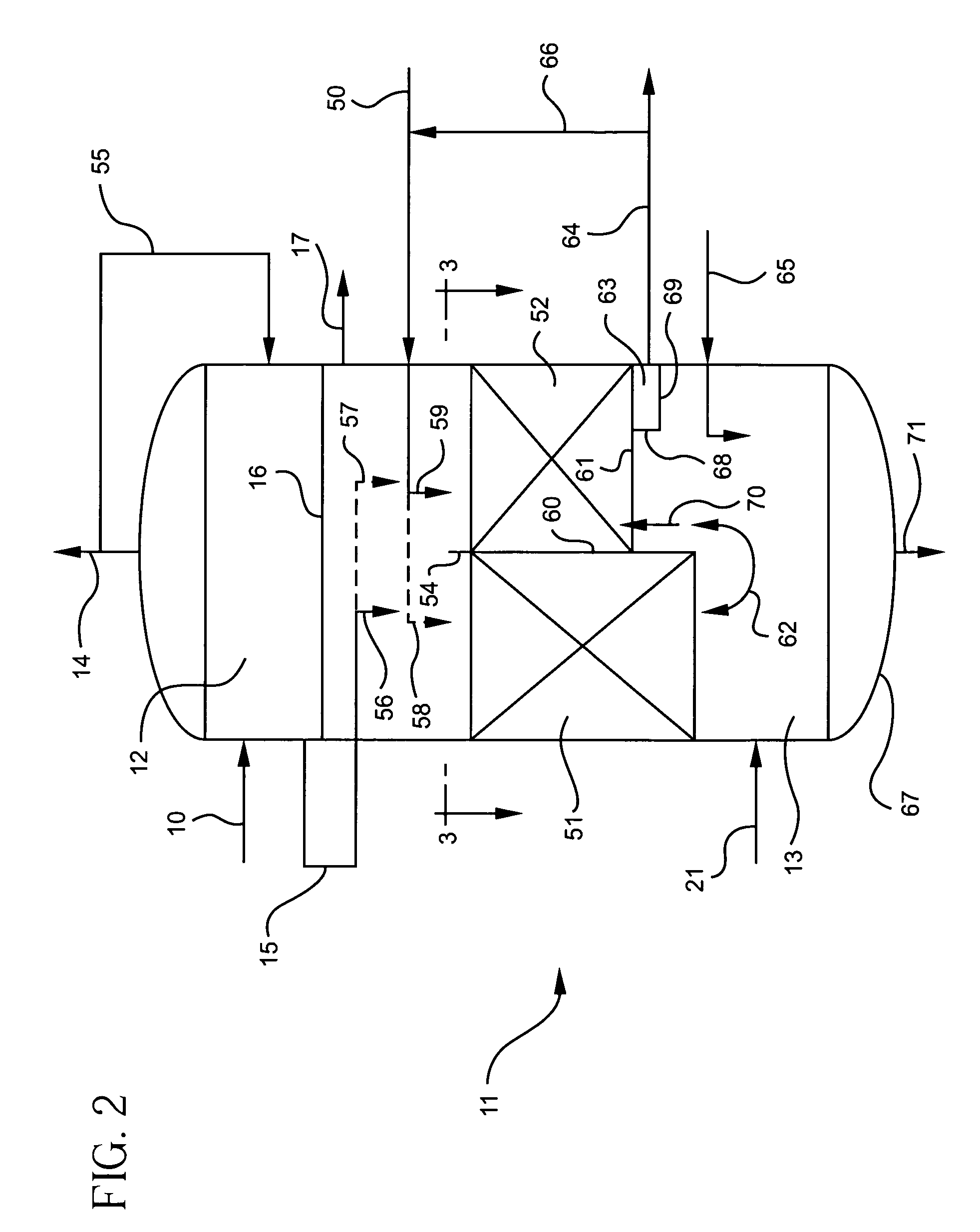

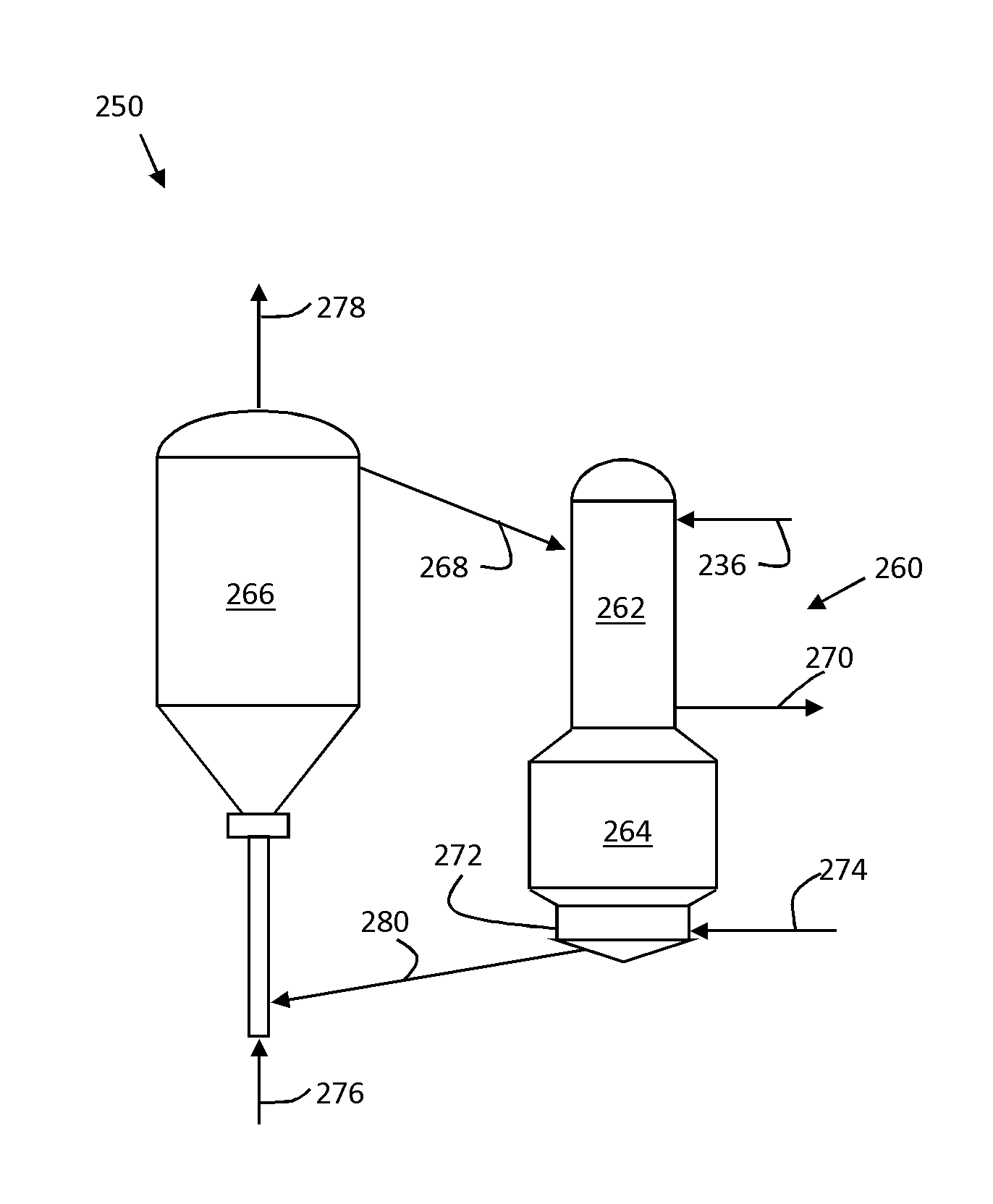

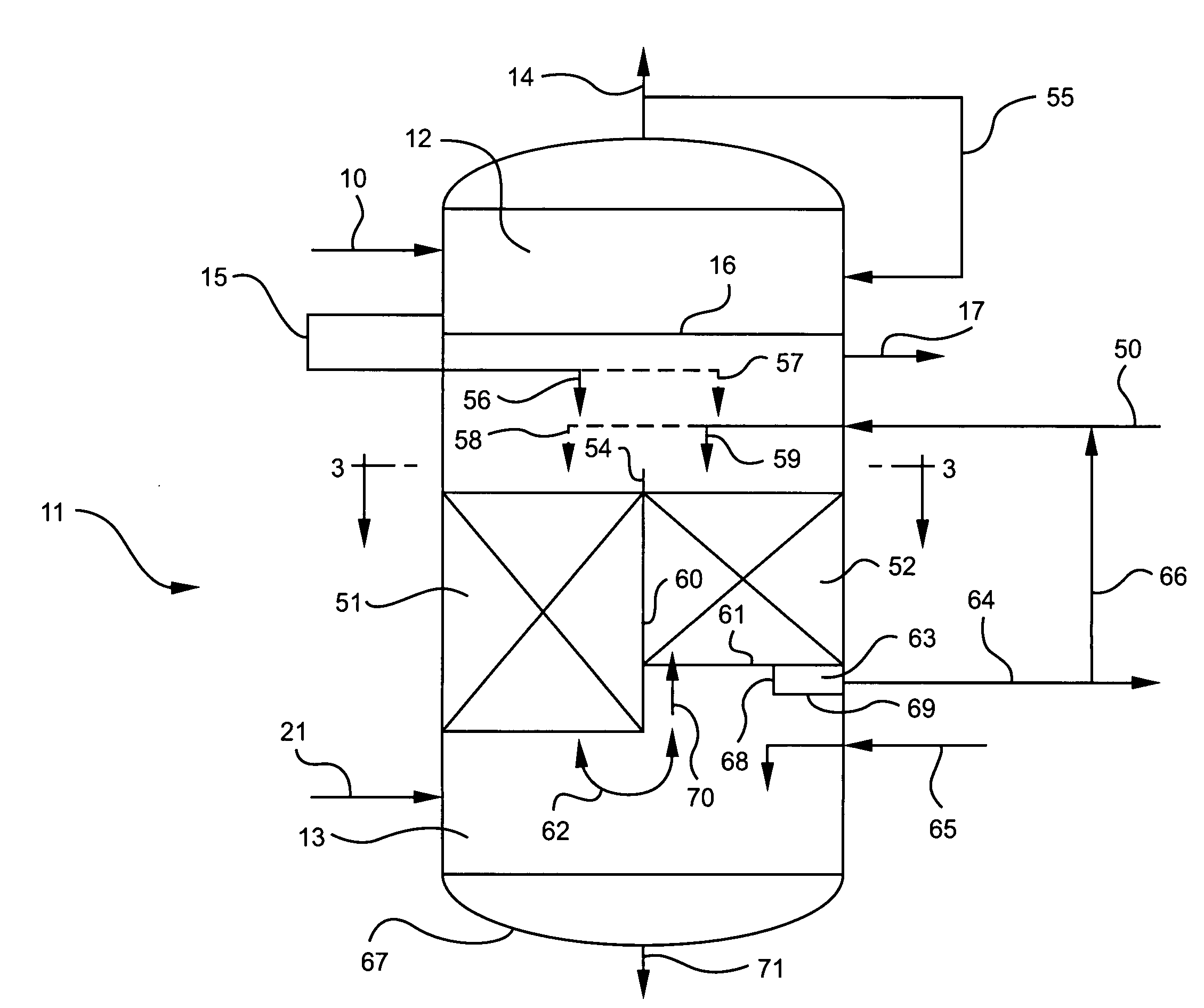

Olefin production utilizing whole crude oil/condensate feedstock with a partitioned vaporization unit

InactiveUS7744747B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyNatural-gas condensateVaporization

A method for thermally cracking a feed composed of whole crude oil and / or natural gas condensate using a partitioned vaporizer to gasify the feed before cracking same.

Owner:EQUSR CHEM LP

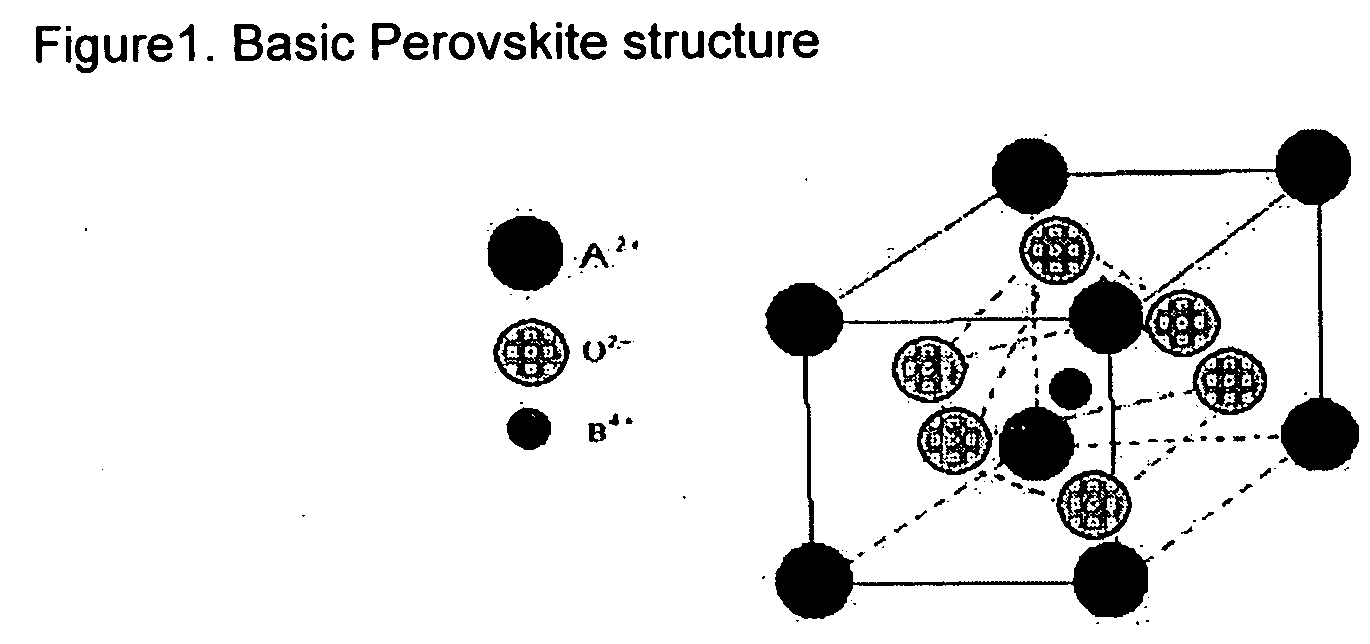

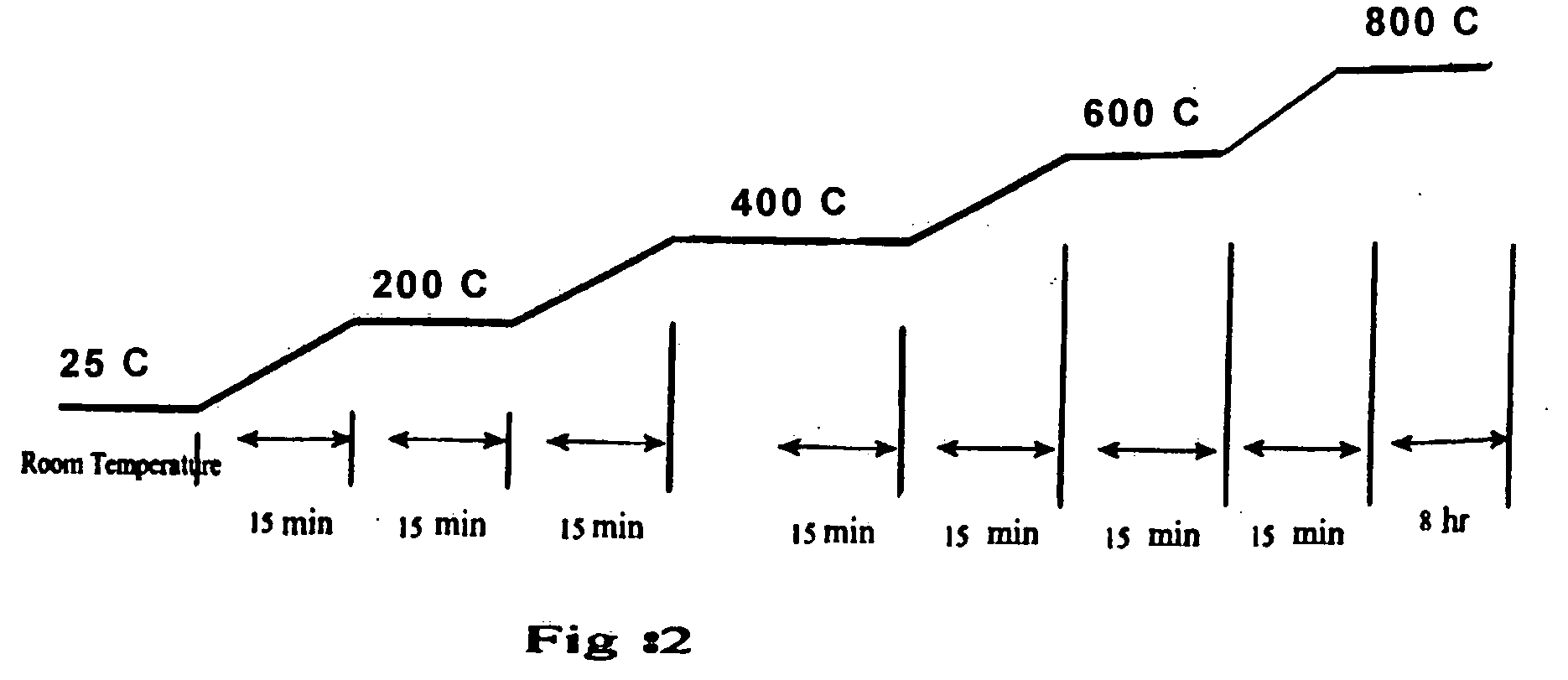

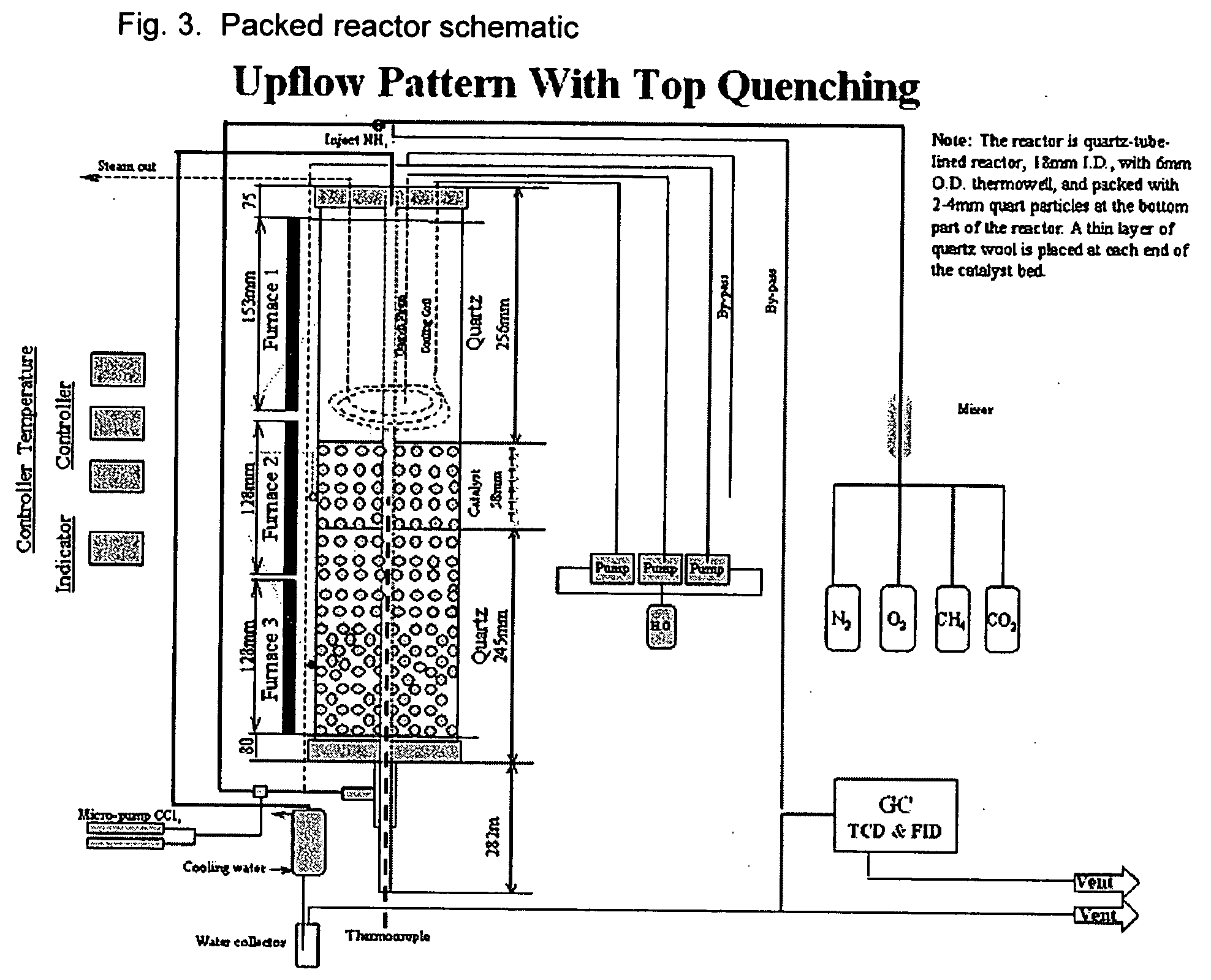

Catalyst and method for converting low molecular weight paraffinic hydrocarbons into alkenes

InactiveUS20060135838A1Hydrocarbon by hydrocarbon condensationChemical recyclingPartial oxidationChemistry

A process and catalyst for the partial oxidation of low molecular weight paraffinic hydrocarbons, such as methane, ethane, propane, naphtha, and natural gas condensates to form alkenes, such as ethylene, propylene and other valuable by-products. The process involves contacting the low molecular weight paraffinic hydrocarbon with the catalyst in the presence of oxygen or air and optionally steam. The catalyst has a perovskite-type crystalline structure, and lends itself to fixed and fluidized bed reactor configurations. The conversion process is less costly than conventional processes due to low pressure operation, the use of air and steam as a source of oxygen, and lower operating temperatures resulting in less coking, downtime, and reduced cost for materials of construction. Catalyst activity is extended and reactor downtime for catalyst regeneration is minimized by addition of chlorides and / or amines.

Owner:HRD CORP

Olefin production utilizing whole crude oil/condensate feedstock and hydrotreating

InactiveUS20080277314A1Improve productivityReduce sulfur contentThermal non-catalytic crackingHydrocarbon oil crackingNatural-gas condensateAlkene

A method for thermally cracking a feed composed of whole crude oil and / or natural gas condensate using a vaporizer to vaporize the feed before cracking same, recovering pyrolysis gas oil from the cracked feed, subjecting the recovered pyrolysis gas oil to hydrotreating to form a hydrotreated product, and passing the hydrotreated product to the vaporizer as additional thermal cracking feed.

Owner:EQUSR CHEM LP

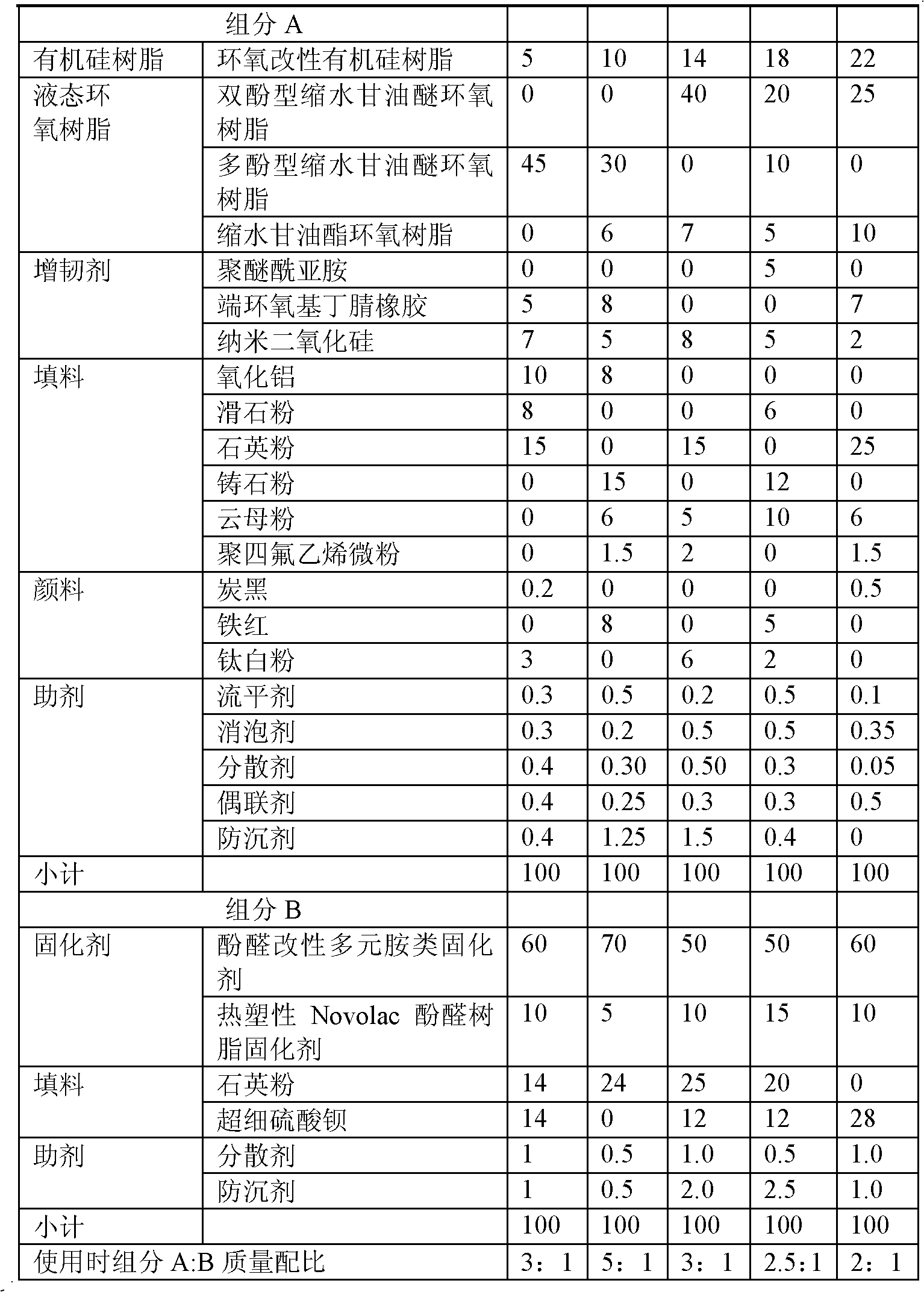

Anti-drag and anticorrosion coating for inner wall of natural gas/condensed liquid pipeline and preparation method thereof

InactiveCN102146251ANo air bubblesQuick releaseAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses an anti-drag and anticorrosion coating for an inner wall of a natural gas / condensed liquid pipeline and a preparation method thereof. The coating comprises an ingredient A and an ingredient B according to a mass ratio of (2-4):1, wherein the ingredient A comprises the following ingredients in parts by mass: 5-30 parts of liquid organic silicon resin, 30-55 parts of liquid epoxy resin, 1-15 parts of flexibilizer, 0.1-2 parts of leveling agent, 0.1-1.5 parts of defoaming agent, 0.05-1.5 parts of dispersing agent, 0.1-2 parts of coupling agent, 0.0-2 parts of anti-settling agent, 0-15 parts of pigment and 10-60 parts of filler; the ingredient B comprises the following ingredients in parts by mass: 40-70 parts of modified polyamine curing agent, 5-35 parts of phenolic resin curing agent, 0.5-2.5 parts of dispersant, 0.5-2.5 parts of anti-settling agent and 15-50 parts of filler; and the ingredient A and the ingredient B in the coating are packaged in a binary manner. The coating has the advantages of good resistance to high pressure natural gas or gas-liquid decompression and bubbling, shear resistance, high bonding strength, good wear resistance, resistance to corrosion of natural gas condensed liquid, smoothness and compactness of the coating, no solvent, quick drying and the like below 50 DEG C, and is suitable for mining requirements under anti-drag, anticorrosion and wear-resistant environments.

Owner:CHINA NAT OFFSHORE OIL CORP +2

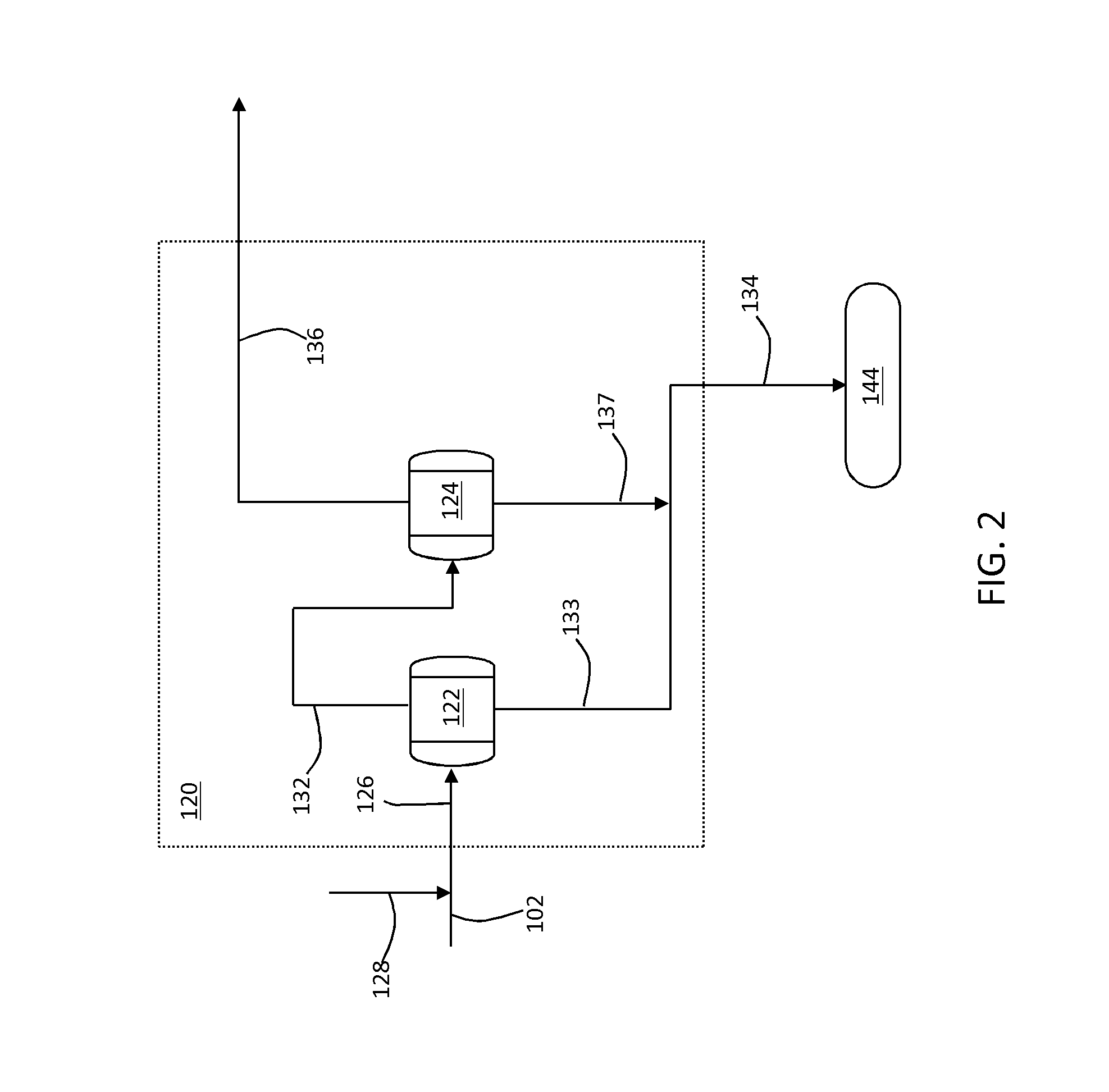

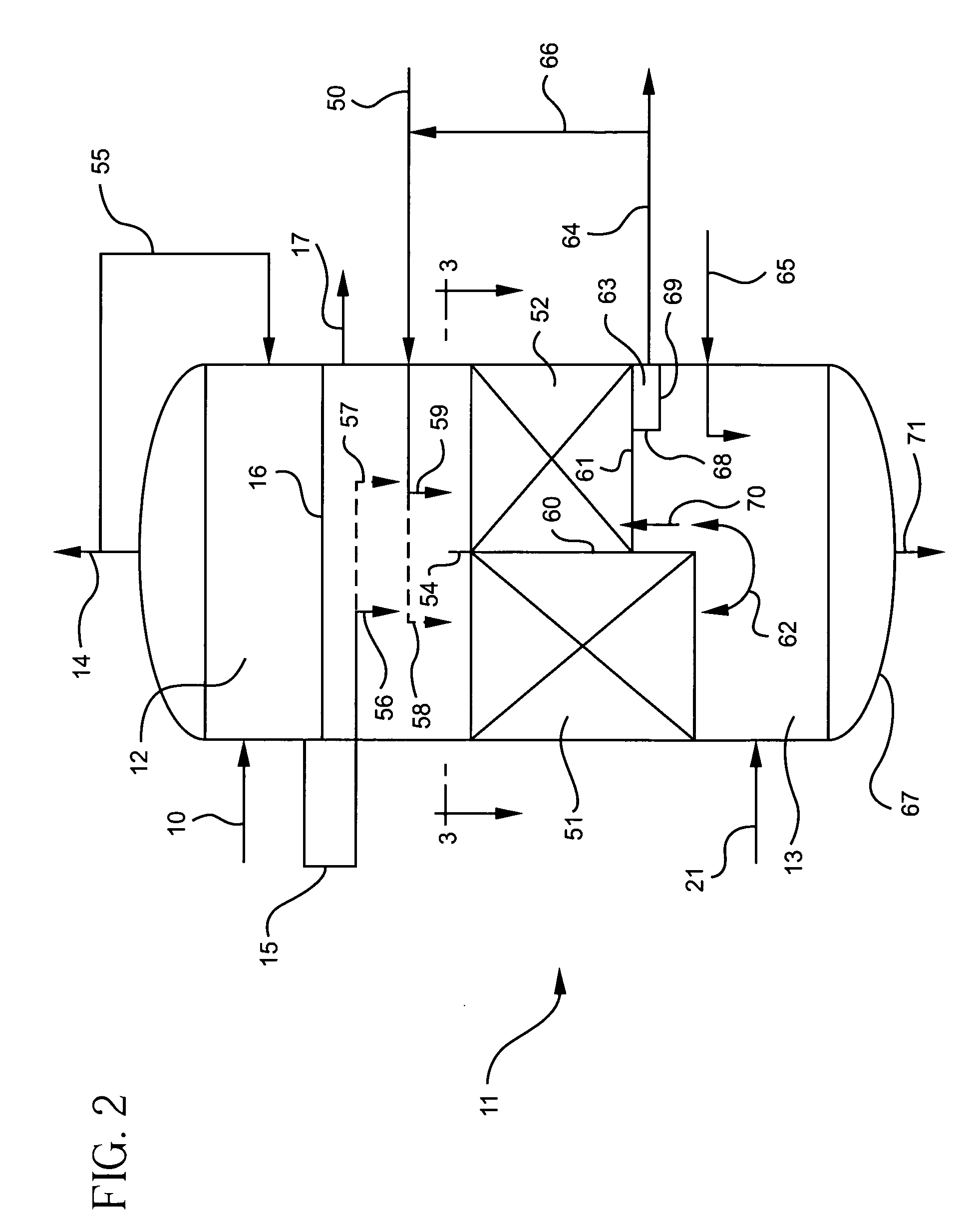

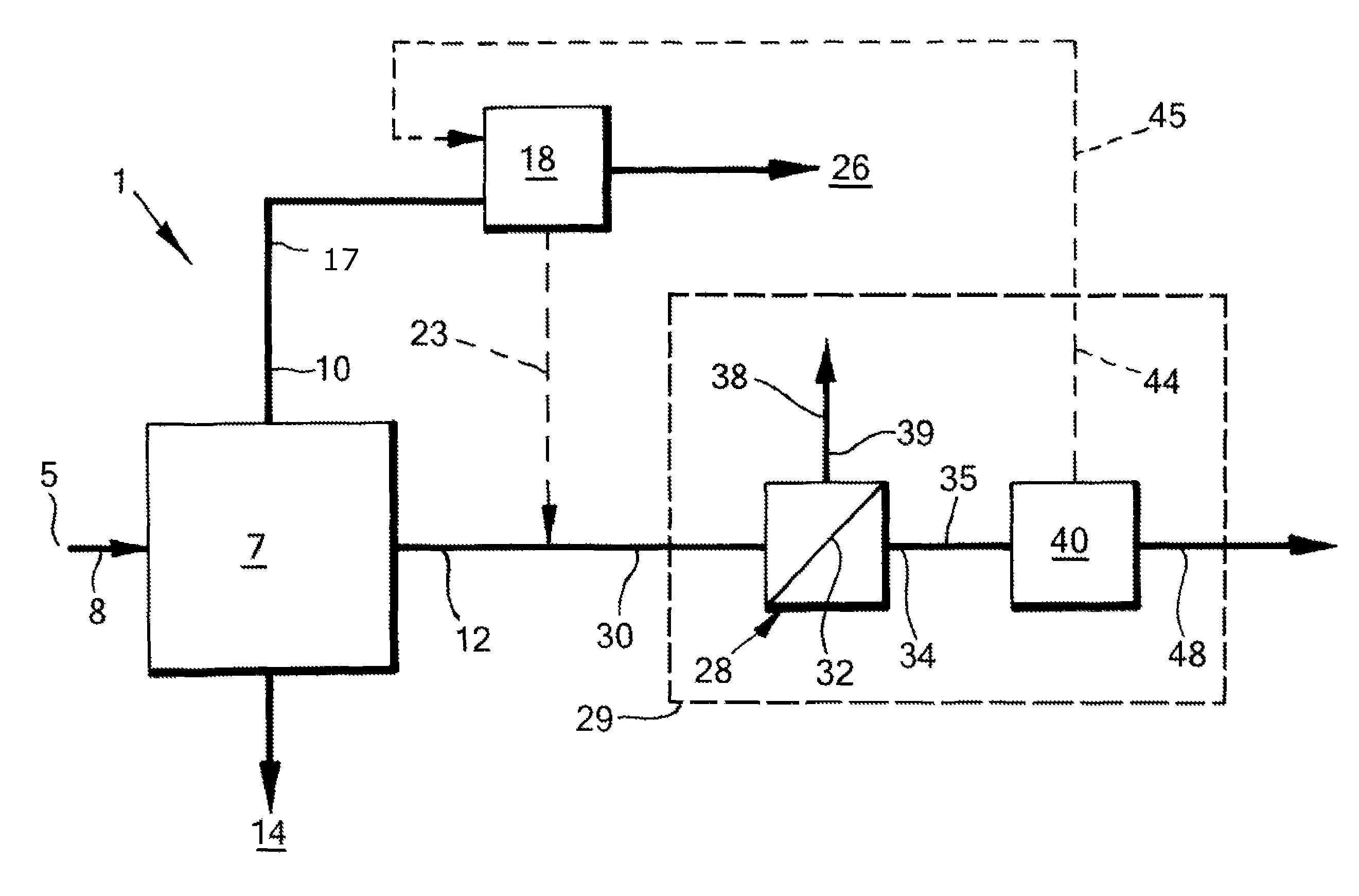

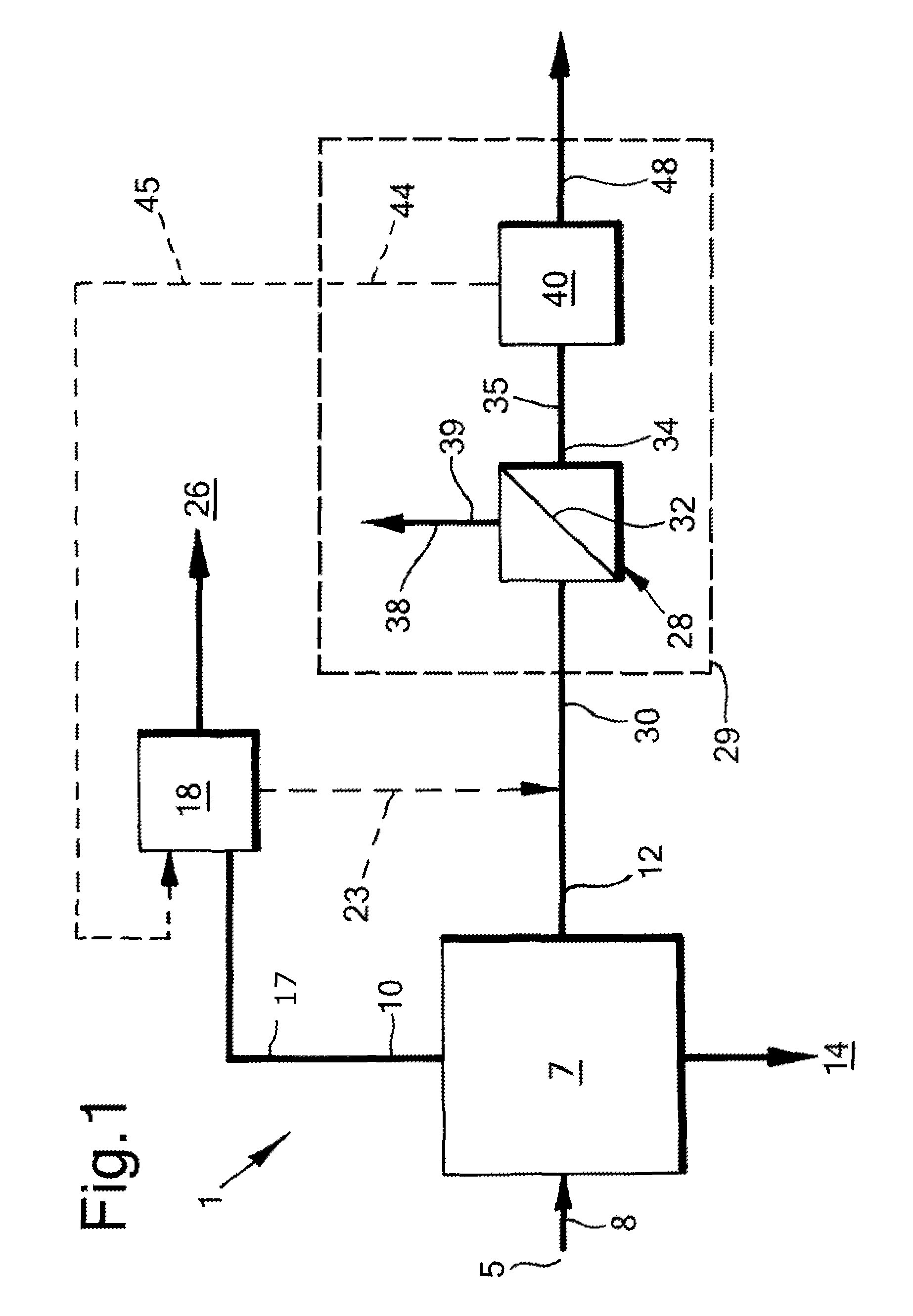

Method for reducing the mercury content of natural gas condensate and natural gas processing plant

InactiveUS20100147745A1Avoid typingMembranesGas treatmentNatural-gas condensateNatural-gas processing

A method for reducing the mercury content of natural gas condensate, comprising the steps of providing a nanofiltration membrane having a feed side and a permeate side; contacting the natural gas condensate with the feed side of the membrane; and obtaining a mercury-depleted natural gas condensate at the permeate side of the membrane; and a natural gas processing plant comprising a condensate workup section including a nanofiltration membrane separation unit for reducing the mercury content of natural gas condensate.

Owner:SHELL OIL CO

Synergistic surfactant compositions for unloading fluids from oil and gas wells

InactiveUS20070181307A1Easy to useEasy to uninstallCleaning apparatusFluid removalNatural-gas condensateProduction rate

A method for unloading fluids from an oil and gas well, pipeline or flowline includes using a synergistic combination of an alkyl glucoside and an amphoteric surfactant as a foaming composition. Use of the combination foaming composition improves unloading of formation fluids, particularly production fluids having natural gas condensate and water and therefore increases the rate of production from the oil and gas well.

Owner:BAKER HUGHES INC

Olefin production utilizing condensate feedstock

InactiveUS20070208207A1Maximizes recovery of distillateMaximize recoveryThermal non-catalytic crackingCatalytic crackingNatural-gas condensateVaporization

A method for utilizing natural gas condensate as a feedstock for an olefin production plant wherein the feedstock is subjected to vaporization and separation conditions that remove light hydrocarbons from the condensate for thermal cracking in the plant, and leave liquid distillate for separate recovery.

Owner:EQUSR CHEM LP

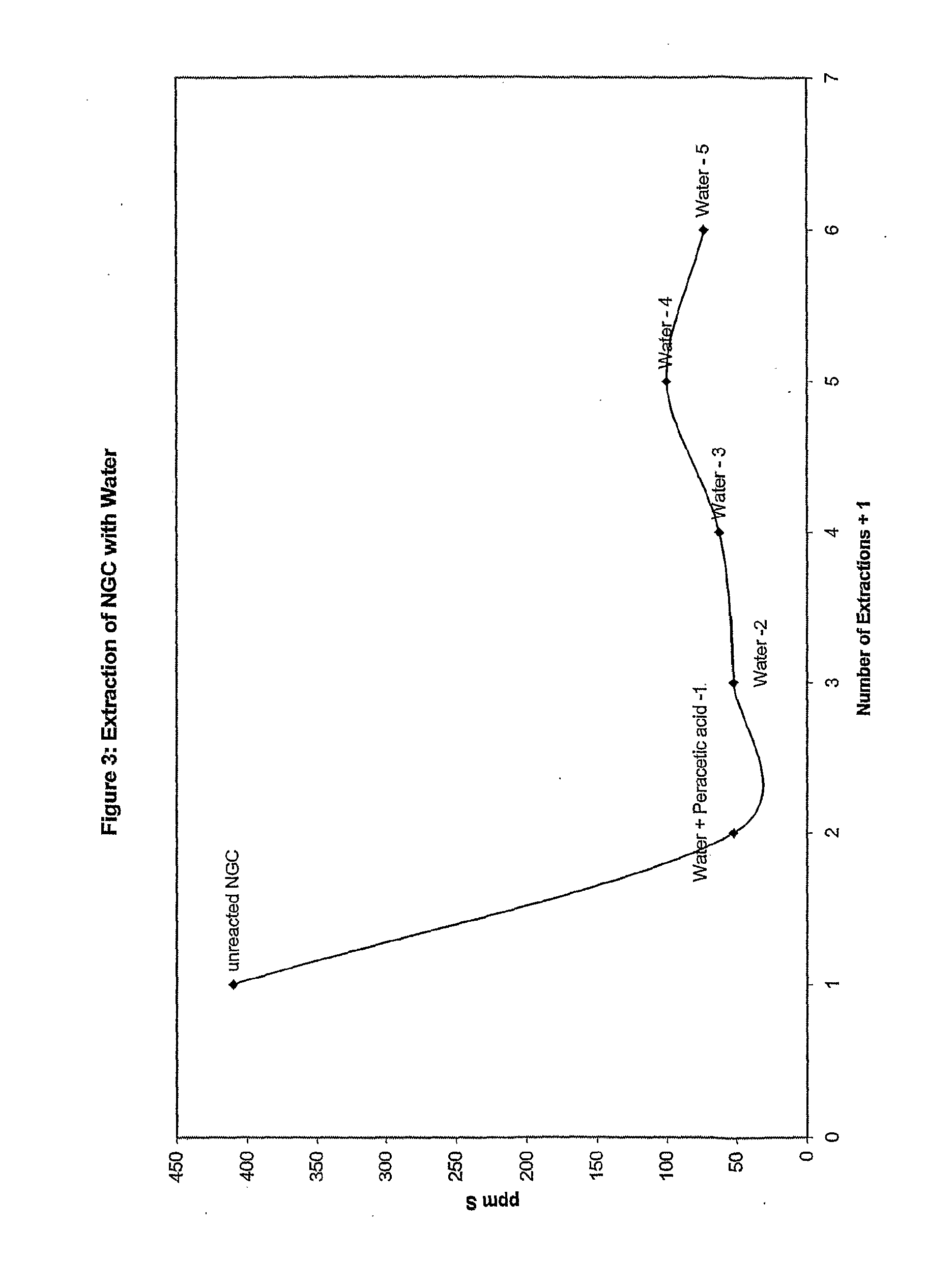

Process for Removing Sulphur From Liquid Hydrocarbons

ActiveUS20110203972A1Low and easy to handle waste streamSimple and economically viableRefining with oxygen compoundsTreatment with plural serial refining stagesPartial oxidationDistillation

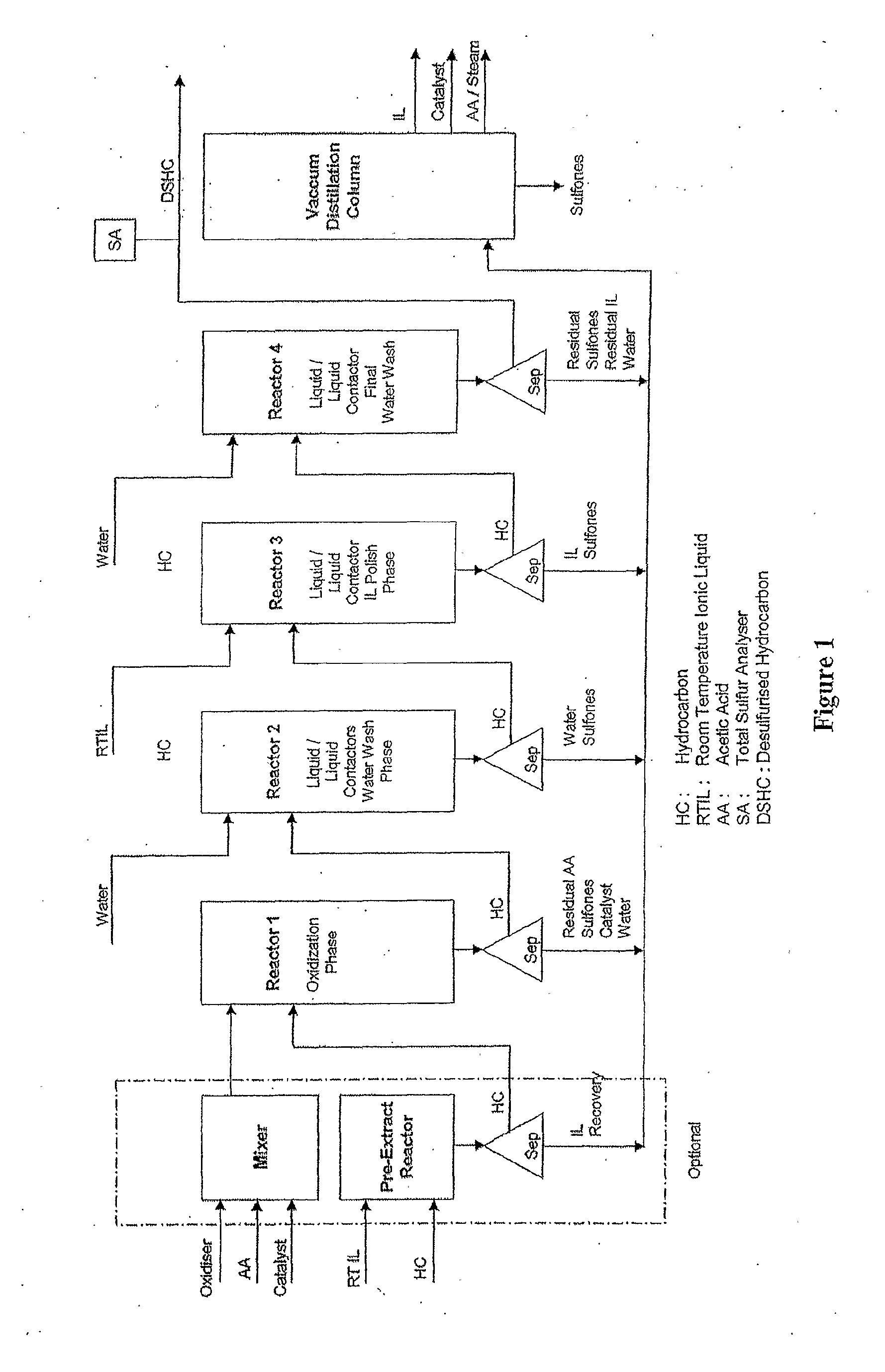

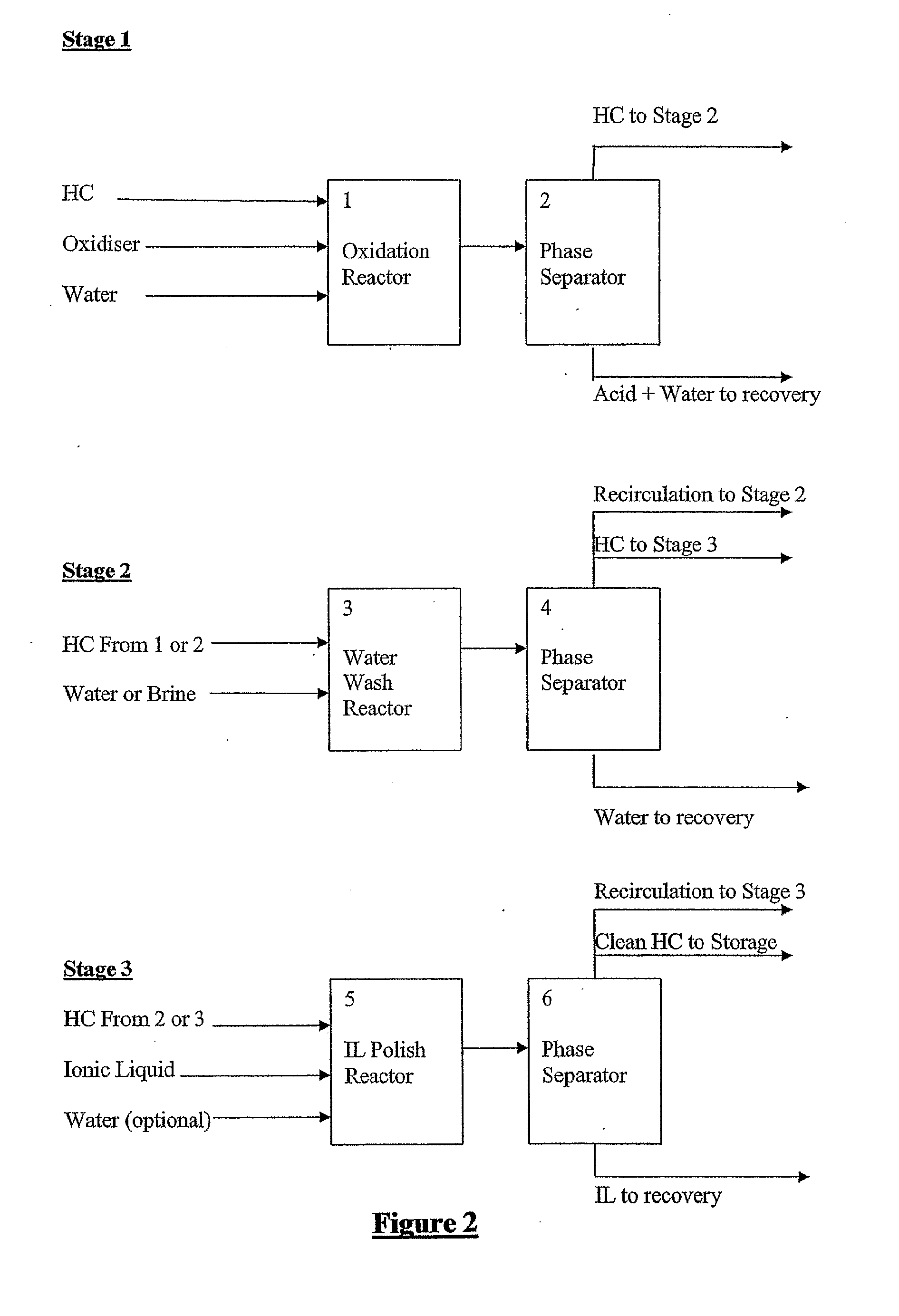

A process for the deep desulfurisation of hydrocarbons (HC), in particular Natural Gas Condensate (NGC), and HC comprising diesel, pre-extracted diesel and naphtha, is described which is capable of reducing the sulfur content of these HC from 500 to 30 ppm. The process comprises contacting the hydrocarbon material with an oxidant selected from organic peroxy acids, organic peroxides, inorganic peroxides and mixtures thereof, in at least a stochiometric amount sufficient to oxidise a sulfur compound to a sulfone compound; contacting the hydrocarbon material with an aqueous extractant to allow at least a portion of the oxidised sulfur compounds to be extracted into the aqueous extractant, and separating the hydrocarbon material from the aqueous extractant to give a hydrocarbon material of reduced sulfur content. Optionally, the process may include a second and subsequent extractions with the aqueous extractant to further reduce sulfur content. A final extraction with an IL may be conducted. The invention also provides for substitution of the aqueous extractant with an IL in one or more of the other extraction steps. The extractants and by products generated during f01 oxidation can be recovered by simple distillation techniques.

Owner:ULTRACLEAN FUEL LTD

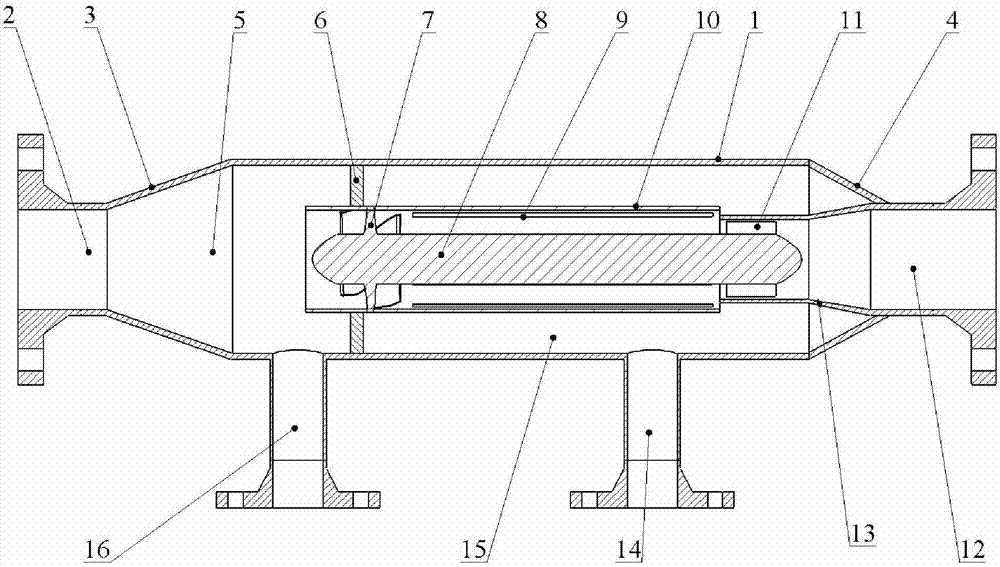

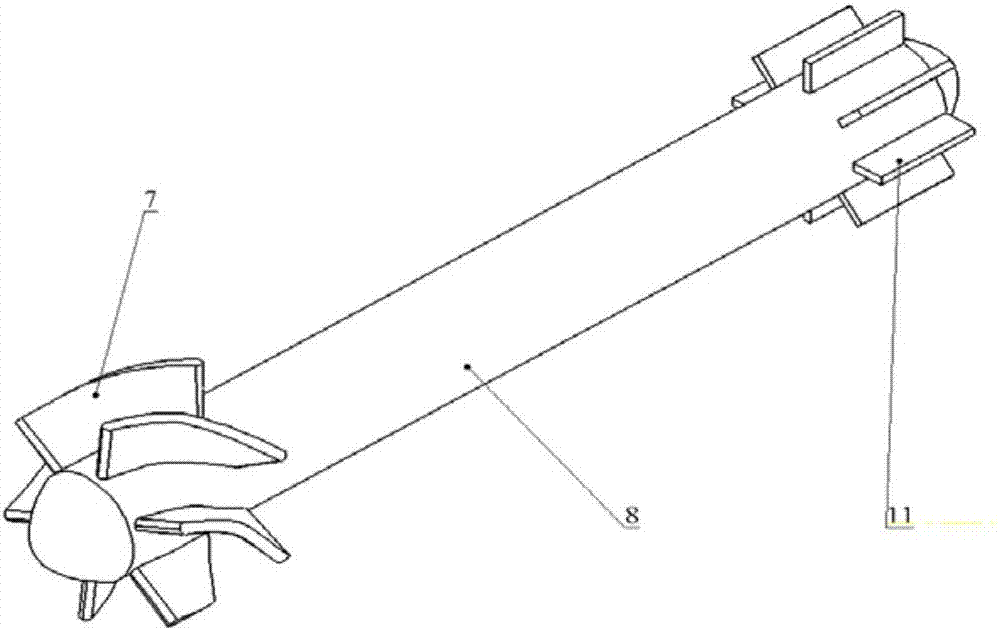

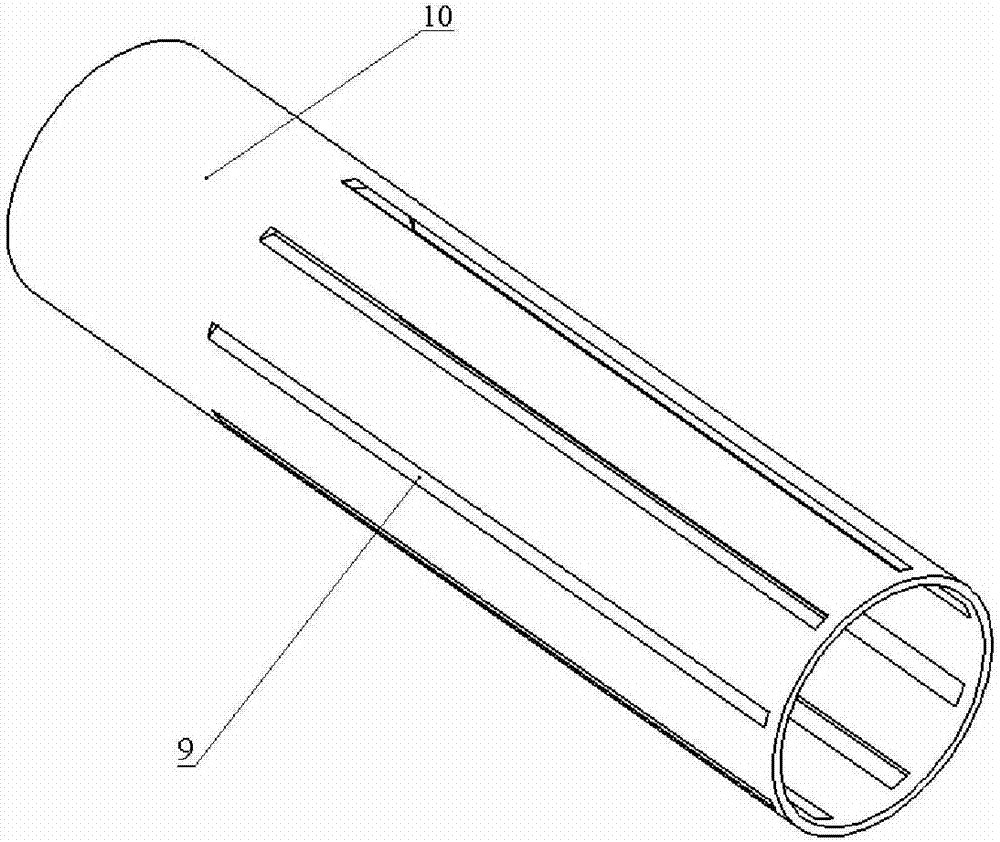

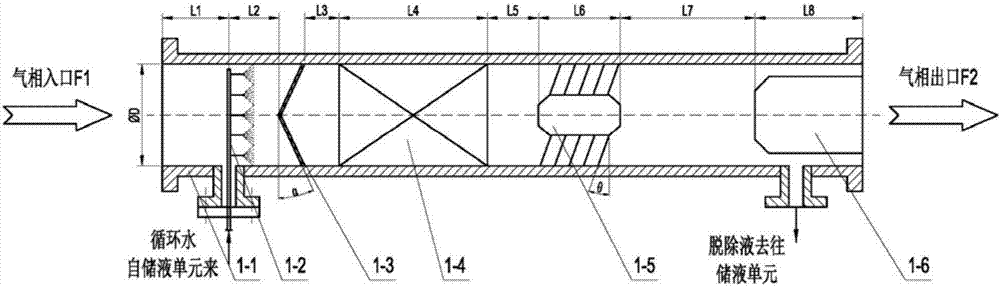

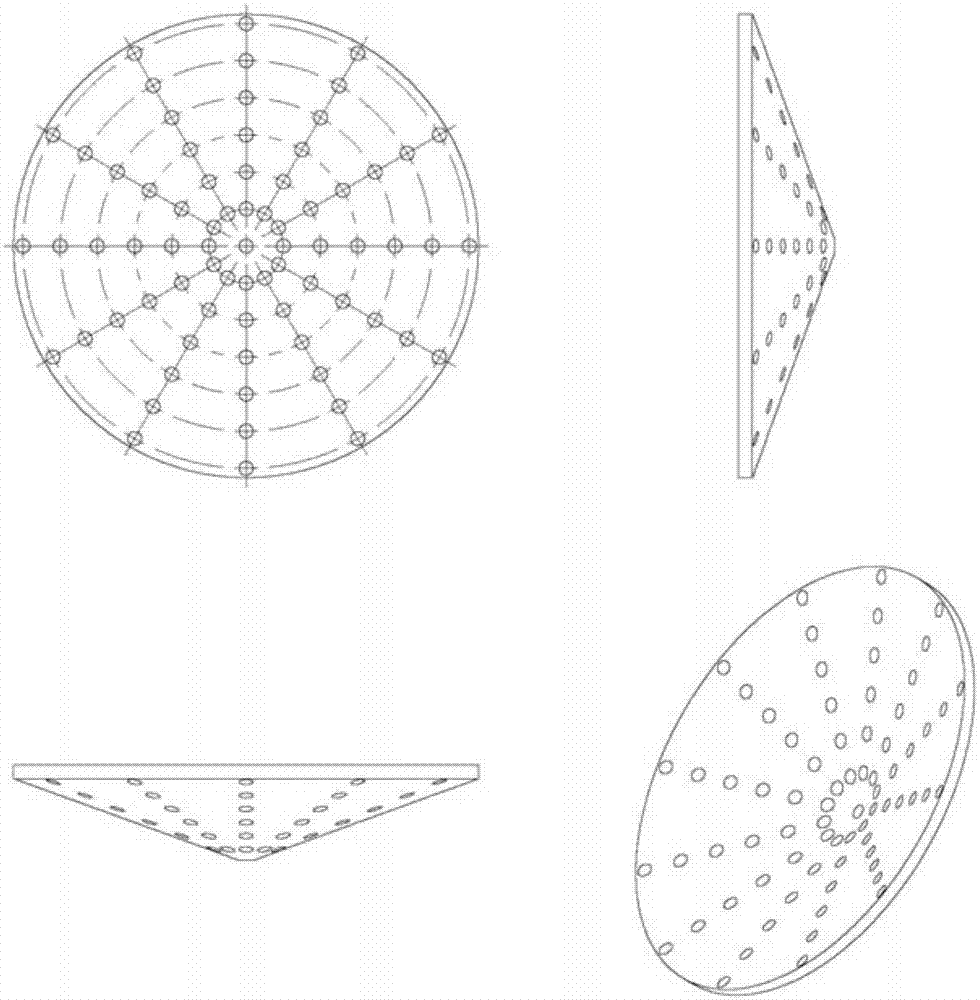

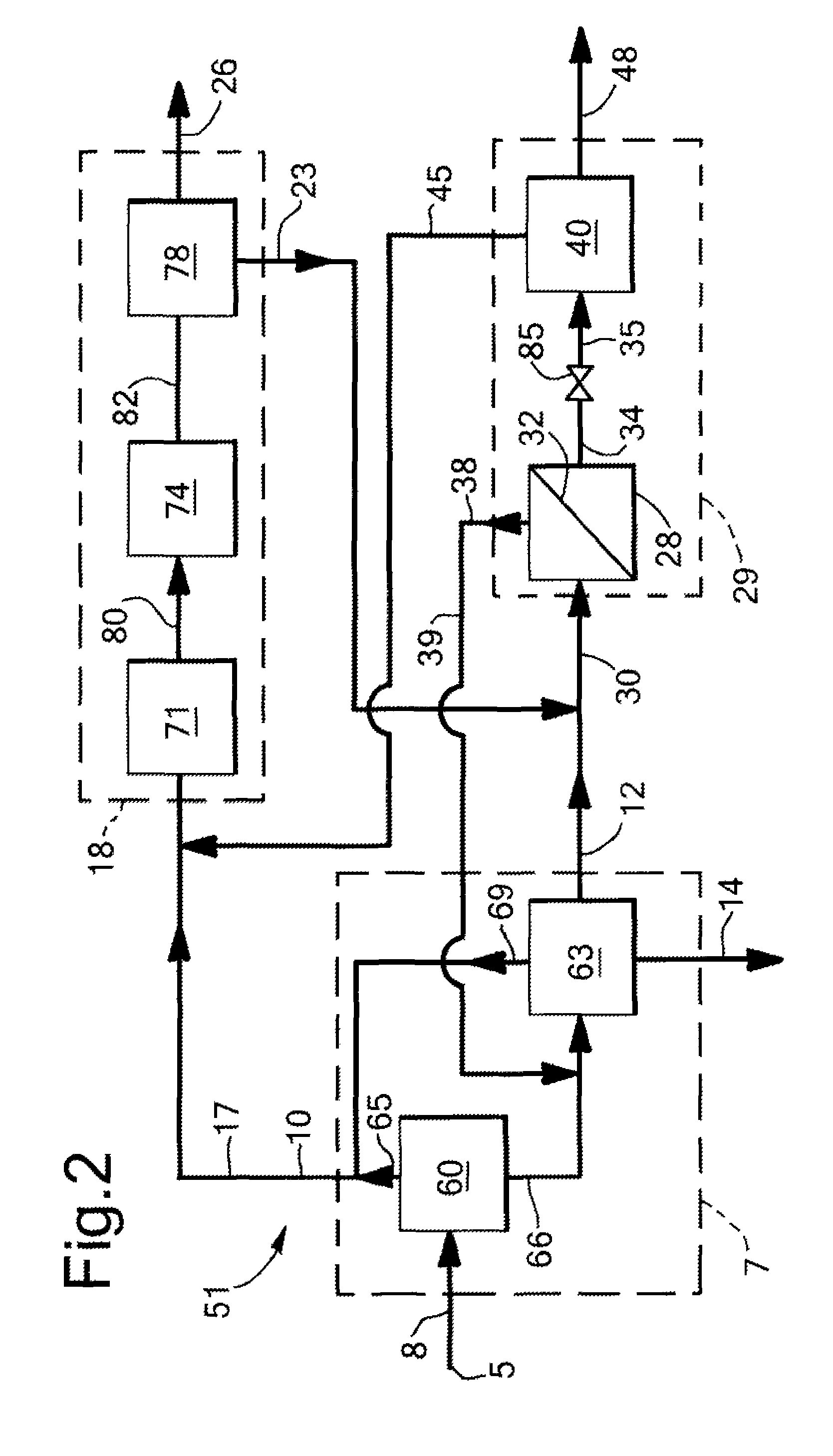

Pipeline type natural gas condensed liquid rotating flow separator

ActiveCN106861296AReduce the strength of the rotationReduce breakageGaseous fuelsDispersed particle separationNatural-gas condensateEngineering

The invention relates to a pipeline type natural gas condensed liquid rotating flow separator, which comprises a cylinder tube body, an axial inlet, an inlet cone section, an outlet cone section, an axial outlet, a front liquid discharging pipe, a back liquid discharging pipe, an annular plate, an inner tube, a flow guide body, an inlet guide blade and a support blade, wherein the inside of the separator is divided into a pre-separation region and a main separation region by the annular plate; the inner tube passes through the annular plate to extend in the separator and forms an annular cavity with the flow guide body; the inlet guide blade is formed by combining a smoothly transiting circular arc-shaped and linear blades; the outer edge and the inner edge of the inlet guide blade are respectively and fixedly connected with the inner tube and the flow guide body; a longitudinal seam is formed in the wall surface of the inner tube; the tail part and the outlet gradual expansion section form an annular opening; the inner edge of the support blade is connected with the tail end of the flow guide body; the outer edge of the support blade is connected with the linear pipe section of the outlet gradual expansion section. The pipeline type natural gas condensed liquid rotating flow separator has the advantages that the integral structure is compact; the two ends are provided with standard flanges; the pipeline connection with the pipeline and the dismounting from the pipeline are convenient; the separation efficiency is high; the pressure drop loss is small; a pre-separation region is installed; a good separation effect is achieved on the high-liquid-contact gas liquid incoming flow.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Integrated solvent-deasphalting and fluid catalytic cracking process for light olefin production

InactiveUS20150152027A1Raise the ratioEfficient crackingCatalytic crackingMolecular sieve catalystNatural-gas condensateNaphtha

The process described herein broadly comprehends an integrated process that permits the use of straight run residual fractions as a feedstock to produce lighter olefins including propylene. A blend of natural gas condensate and / or naphtha, and heavy oil residue(s), is catalytically cracked to produce a light olefin-rich product stream. In particular, the light natural gas condensate and / or naphtha stream is used as both solvent in a solvent-deasphalting unit and a portion for the feedstock to a fluidized catalytic cracking process. In addition, blending a heavy boiling hydrocarbon stream with a light natural gas condensate or naphtha stream enables efficient cracking in fluidized catalytic cracking process processes while sustaining the heat balance within the cracking unit.

Owner:SAUDI ARABIAN OIL CO

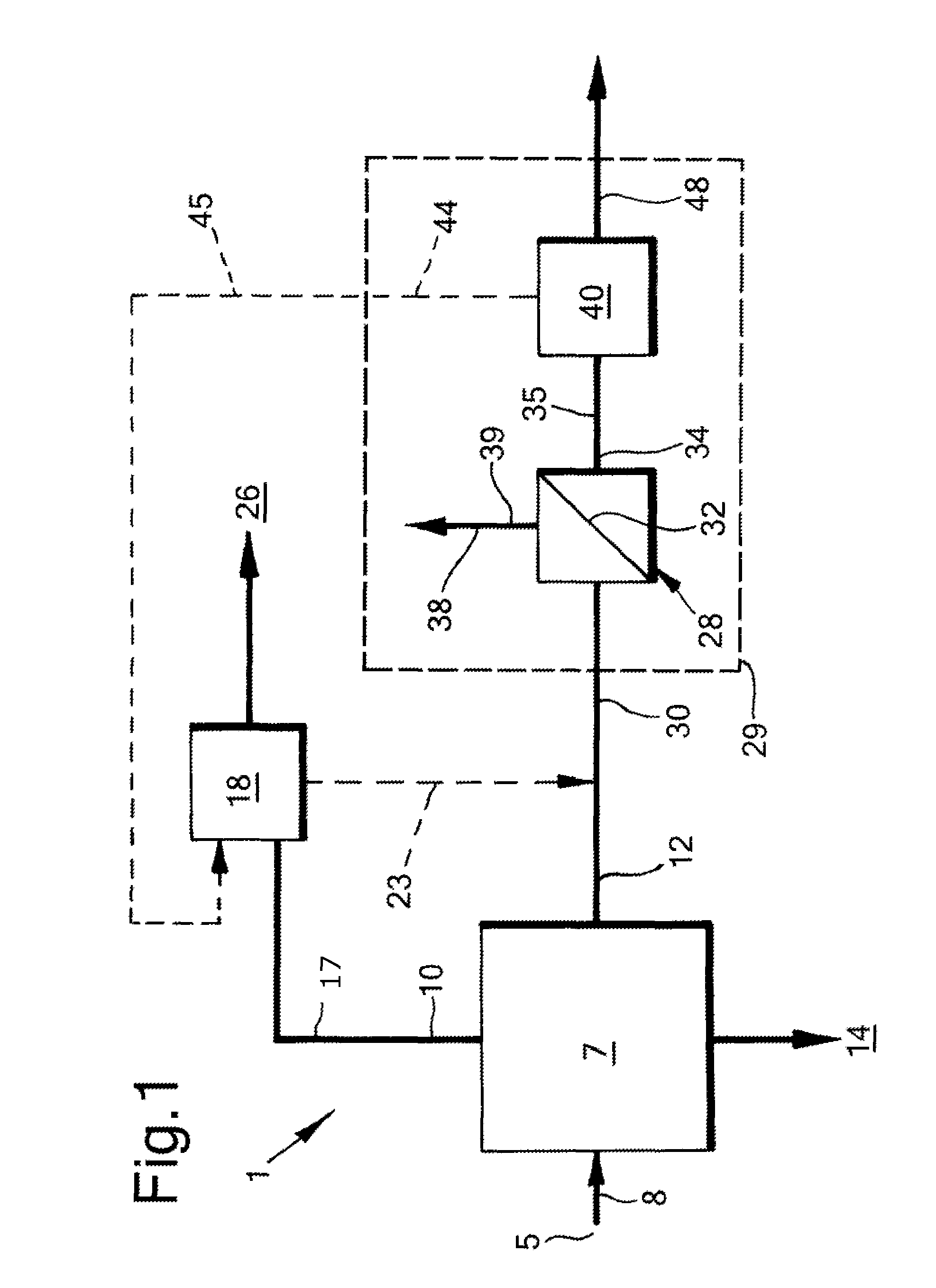

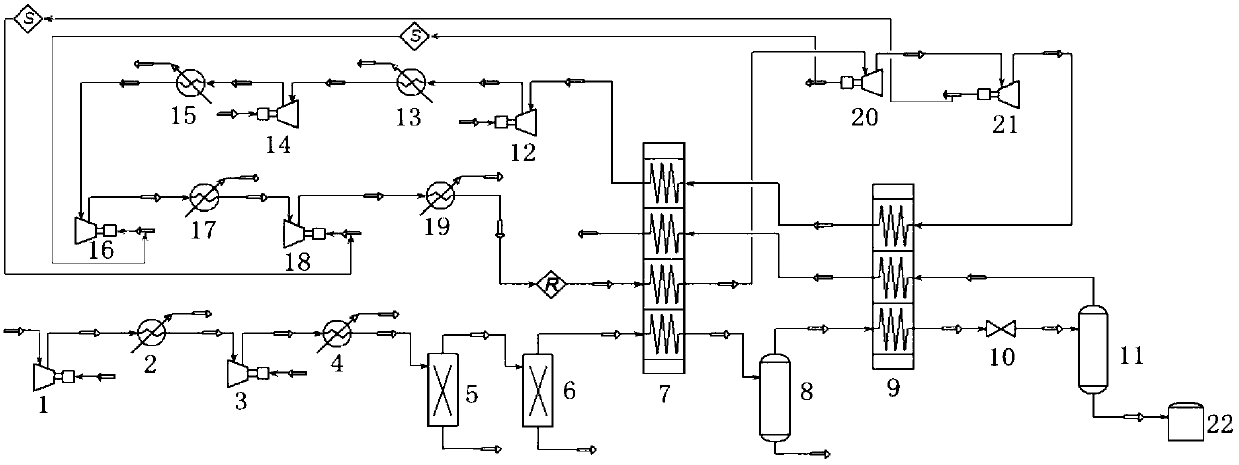

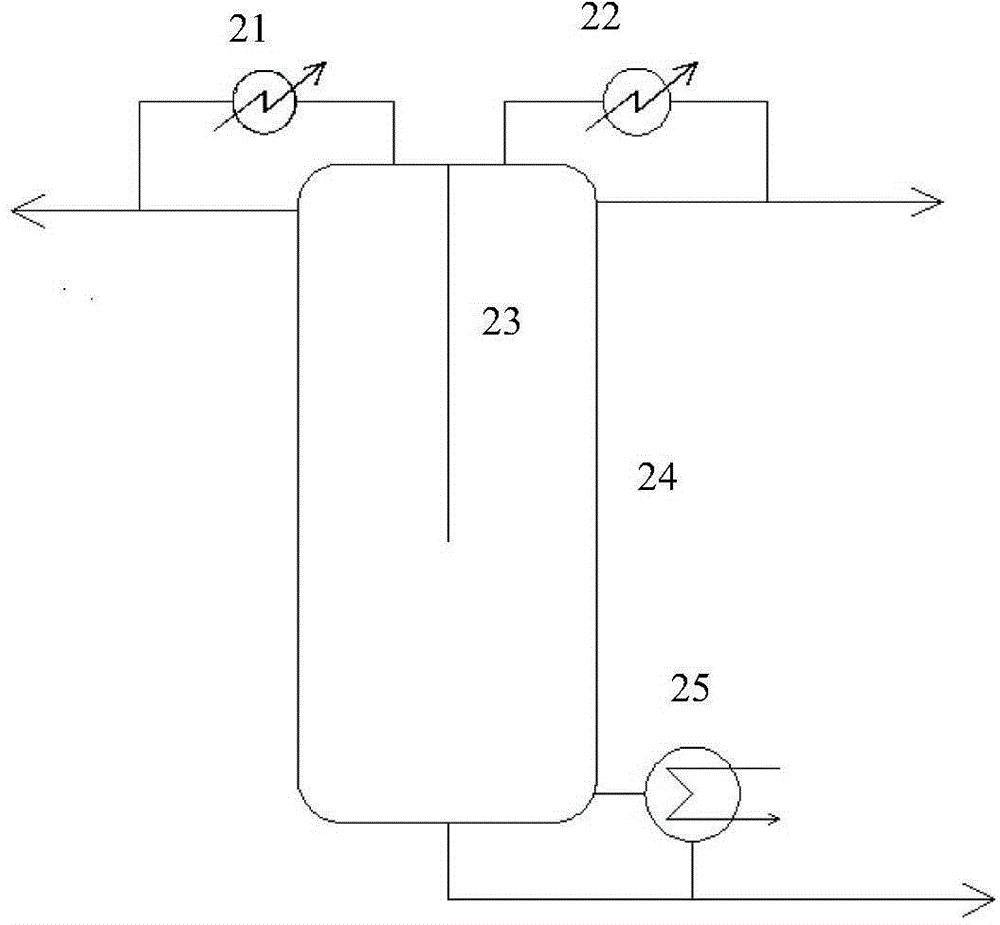

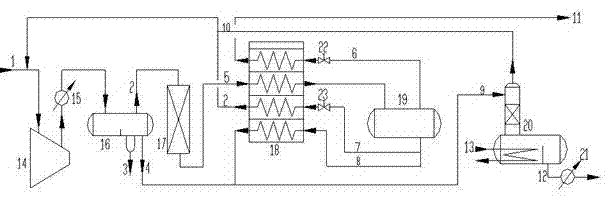

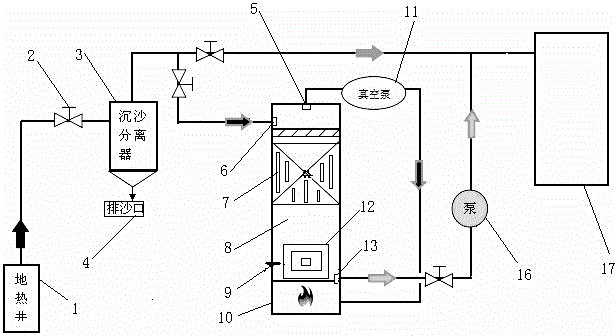

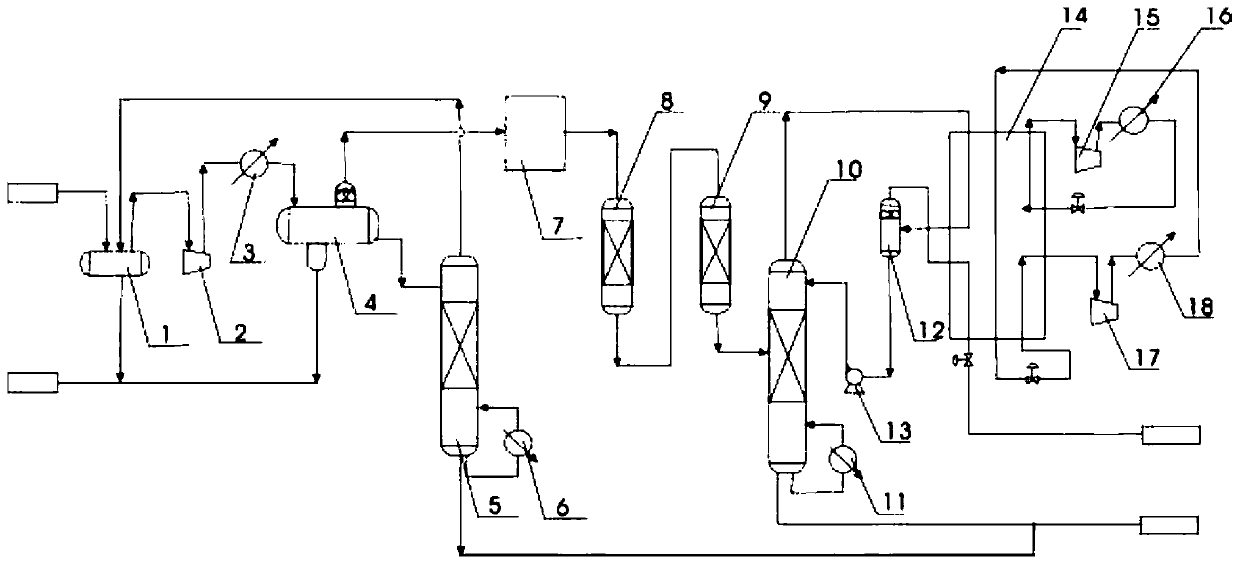

Miniature skid type nitrogen expansion natural gas liquefaction system and method thereof

ActiveCN103215093AReduce liquefaction energy consumptionSimple processSolidificationLiquefactionNatural-gas condensateNitrogen

The invention discloses a miniature skid type nitrogen expansion natural gas liquefaction system and method thereof. Natural gas is supercharged by a natural gas supercharging prying block and cooled, and enters into a natural gas depickling and dehydrating prying block for removing impurity, and is cooled by a first stage heat exchanger and then enters into a heavy hydrocarbon separator, thereby obtaining a heavy hydrocarbon from the bottom; after the heavy hydrocarbon is removed, the natural gas is cooled by a second stage heat exchanger for liquefaction; after pressure of a throttle valve is reduced to the storage pressure of the liquefied natural gas, the natural gas enters into a natural gas liquefaction separator for obtaining a liquefied natural gas, and a flash evaporation gas returns to the heat exchanger for providing cooling capacity. A nitrogen is supercharged and cooled by a nitrogen compression prying block, and is supercharged and cooled by a two-stage supercharger, and then enters into the first stage heat exchanger for precooling; after precooling, the nitrogen is expanded and refrigerated by the two-grade expander and providing a cooling capacity for liquefaction of natural gas. The miniature skid-mounted type nitrogen expansion natural gas liquefaction has the advantages of simple flow, fast starting and convenient maintenance, and is convenient for prying equipment with low energy consumption, and simultaneously has better adaptability for different gas sources.

Owner:合肥万豪能源设备有限责任公司

Process for removing mercury from liquid hydrocarbons using a sulfur-containing organic compound

InactiveUS20030116475A1Reduce concentrationEasy maintenanceRefining with metalsRefining with metal saltsParticulatesNatural-gas condensate

Mercury is removed from crude oils, natural gas condensates and other liquid hydrocarbons by first removing colloidal mercury and solids that contain adsorbed mercury and then treating the hydrocarbons with an organic or inorganic compound containing at least one sulfur atom reactive with mercury. The sulfur compound reacts with dissolved mercury that contaminates the hydrocarbons to form mercury-containing particulates that are then removed from the hydrocarbons to produce a purified product having a reduced mercury content. Preferably, the treating agent is an organic sulfur-containing compound such as a dithiocarbamate or sulfurized isobutylene.

Owner:UNION OIL OF CALIFORNIA

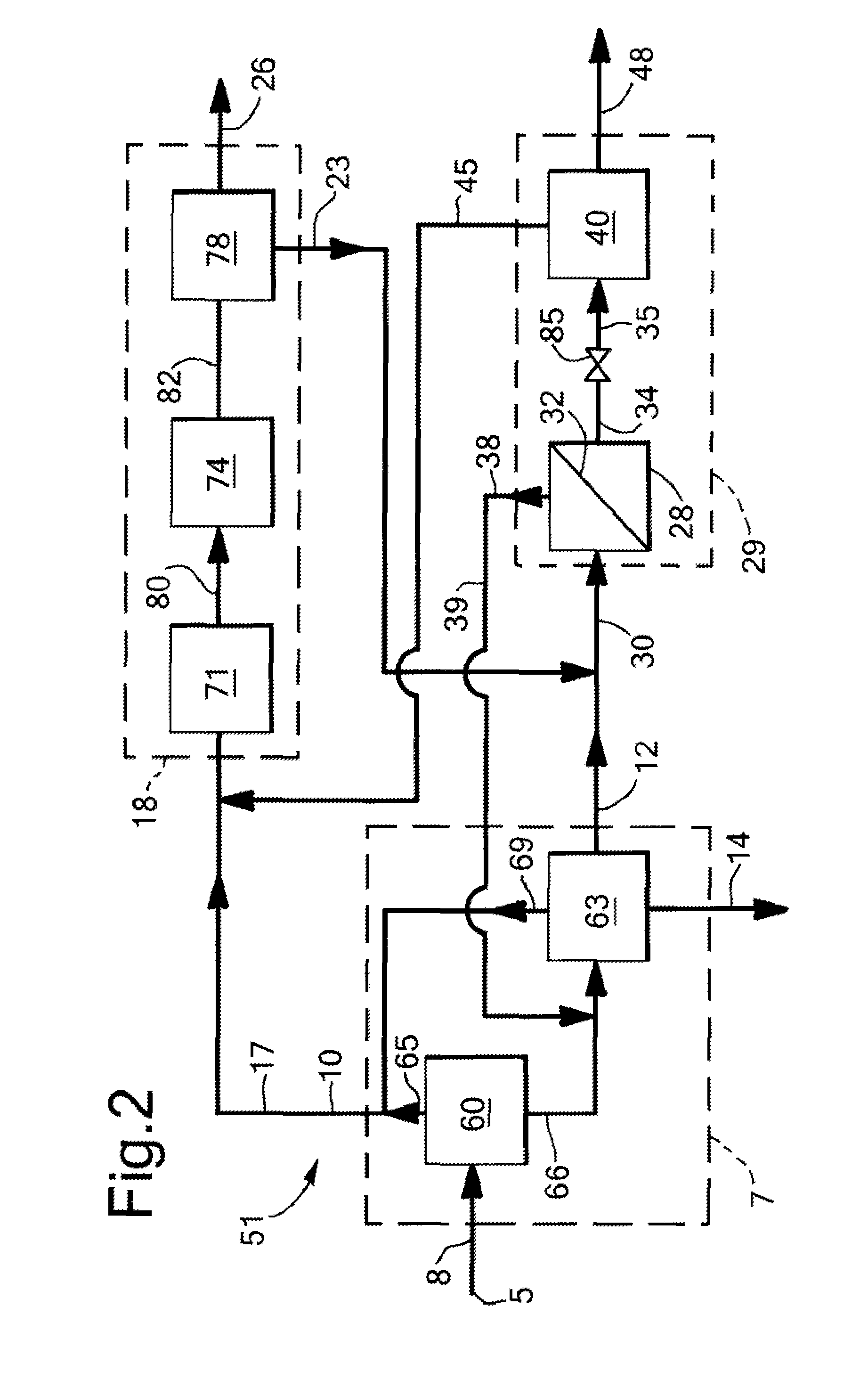

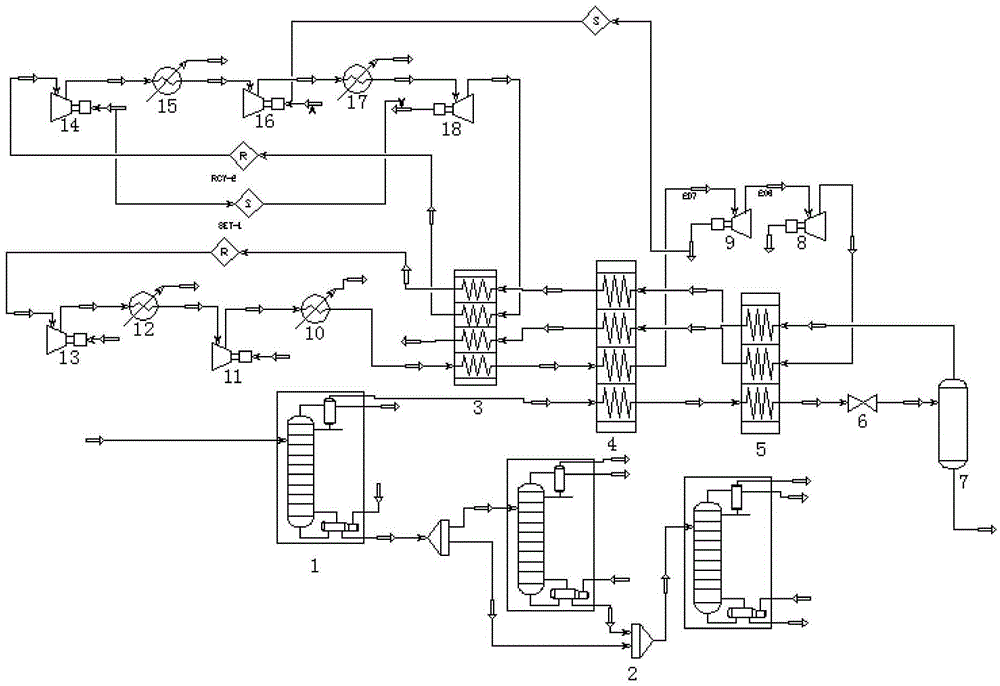

Marine natural gas liquefaction and NGL recycling system and application

InactiveCN104930815AReduce liquefaction energy consumptionSimple processSolidificationLiquefactionNatural-gas condensateNitrogen

The invention provides a marine LNGFPSO natural gas liquefaction and NGL recycling system. The system comprises an NGL fractionation module used for recycling natural gas condensate, a natural gas liquefaction module used for liquefying and supercooling natural gas, a CO2 transcritical circular precooling module and a nitrogen expansion refrigerating circulation module used for providing the cooling capacity for liquefying and supercooling natural gas. Compared with the prior art, the marine LNGFPSO natural gas liquefaction and NGL recycling system has the advantages that according to a marine LNG-FPSO prizing type nitrogen expansion natural gas liquefaction and NGL recycling technology, the process is simplified under the premise that the unit liquefaction energy consumption is low, and the process has the advantages that starting is fast, starting, shutting down and maintaining are convenient, equipment arrangement is compact, and prizing is convenient.

Owner:SHANGHAI JIAO TONG UNIV

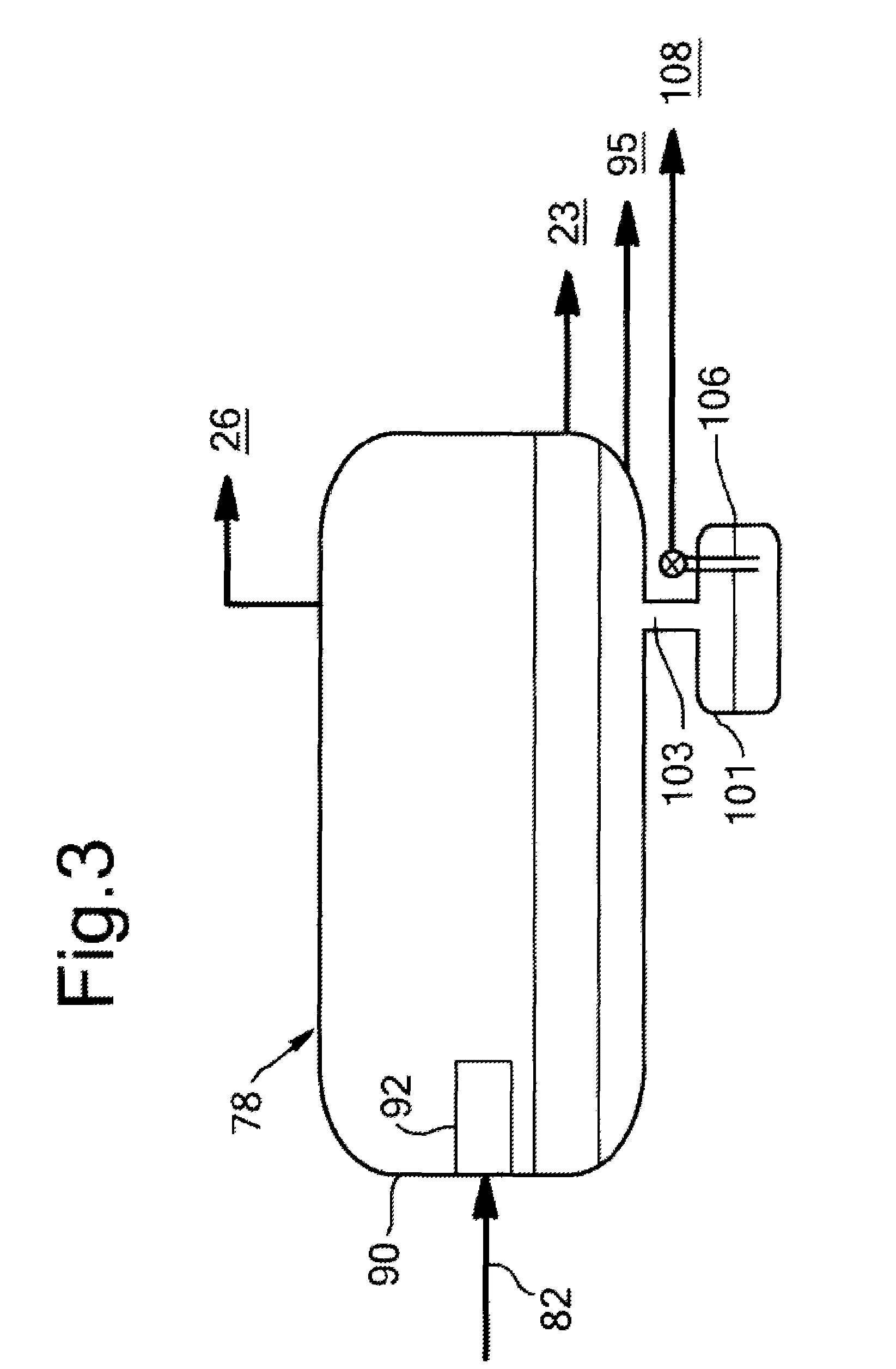

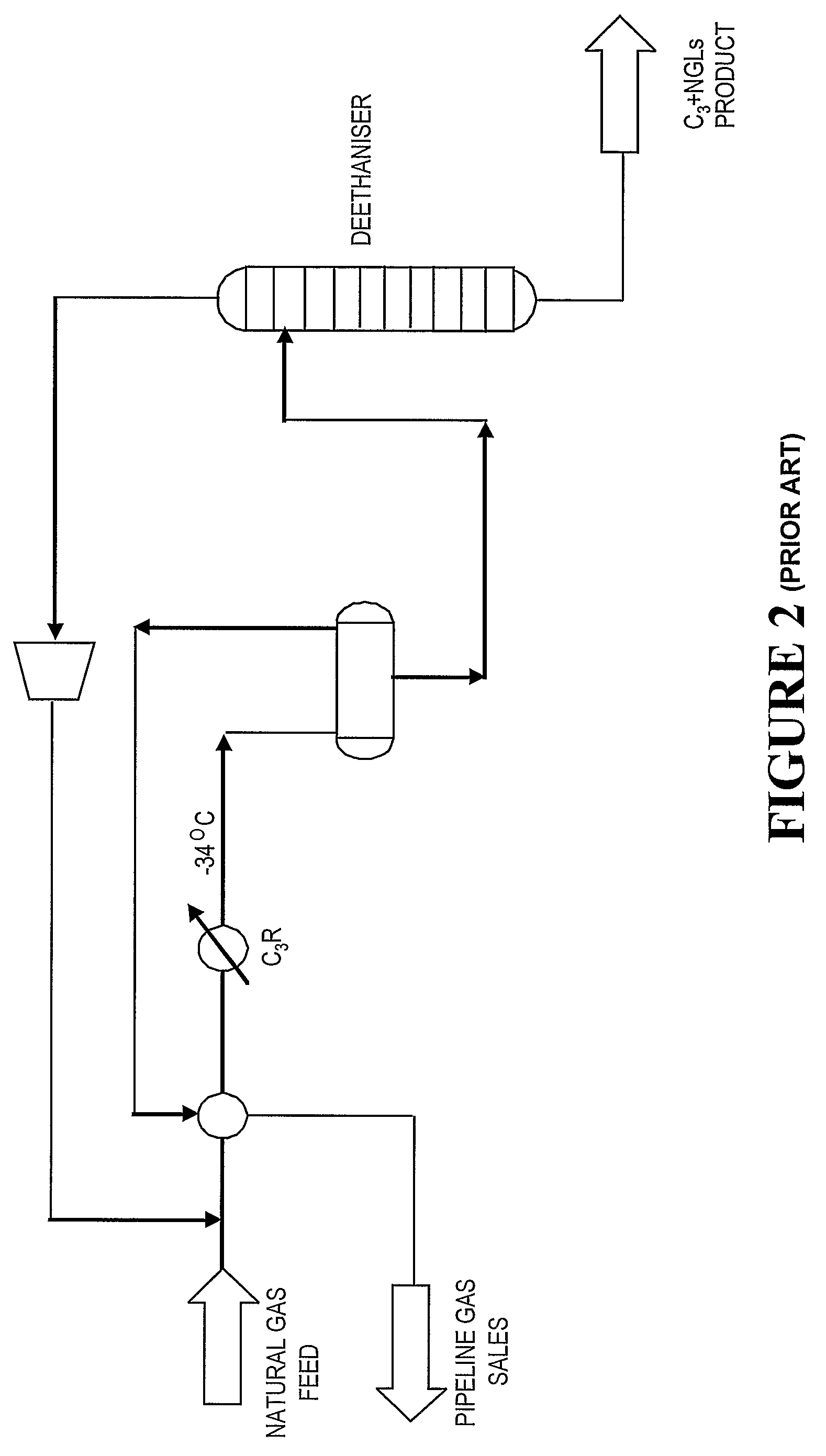

A natural gas condensate recovery device and method using mixed light hydrocarbon as refrigerant

ActiveCN102288007ASimple processSimplify equipmentSolidificationLiquefactionRecovery methodNatural-gas condensate

The invention relates to a natural-gas condensed-liquid recovery method using mixed light hydrocarbon as a refrigerant, which comprises the following steps of: 1) separating low-temperature mixed light hydrocarbon from raw-material gas which is rich in liquefied-gas components; and 2) using one part of the separated low-temperature mixed light hydrocarbon as the refrigerant to enter a system for circulation, enabling the other part of the separated low-temperature mixed light hydrocarbon to enter a condensed-liquid stabilizing tower for stabilization, and using condensed liquid at the tower bottom of the condensed-liquid stabilizing tower as a product to exit from a device for recovery after being stabilized. Because the mixed light hydrocarbon which is condensed in the natural-gas condensed-liquid recovery process is adopted as the refrigerant to cool natural gas and recover the condensed liquid in the natural gas, a refrigerating set does not need to be independently configured, thereby the process flow and equipment are greatly simplified, and the cost is lowered; and the method is particularly applicable to small skid-mounted type natural-gas condensed-liquid recovery devices.

Owner:XIAN CHANGQING TECH ENG

Olefin production utilizing whole crude oil/condensate feedstock with a partitioned vaporization unit

InactiveUS20090166255A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyNatural-gas condensateThermodynamics

A method for thermally cracking a feed composed of whole crude oil and / or natural gas condensate using a partitioned vaporizer to gasify the feed before cracking same.

Owner:EQUSR CHEM LP

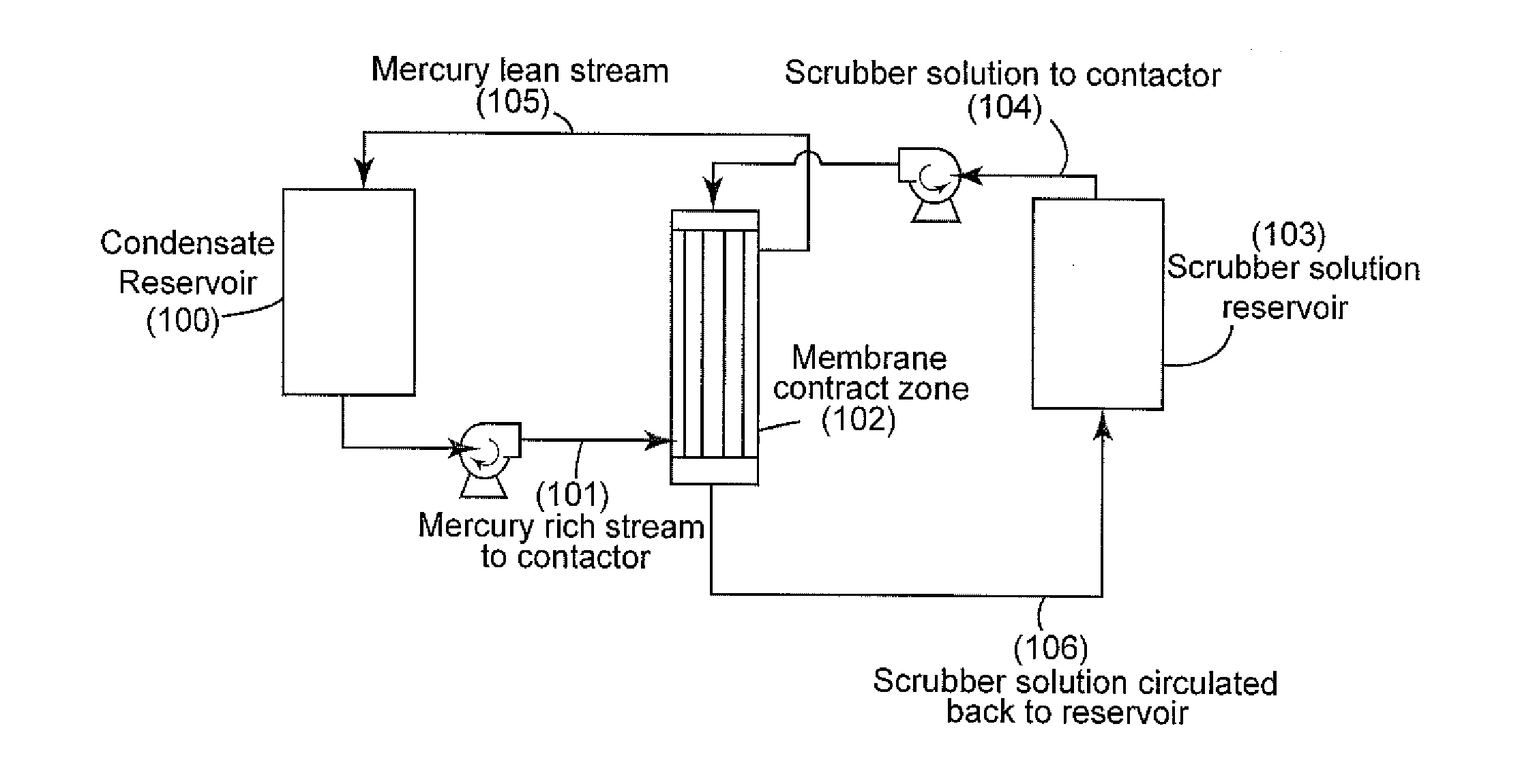

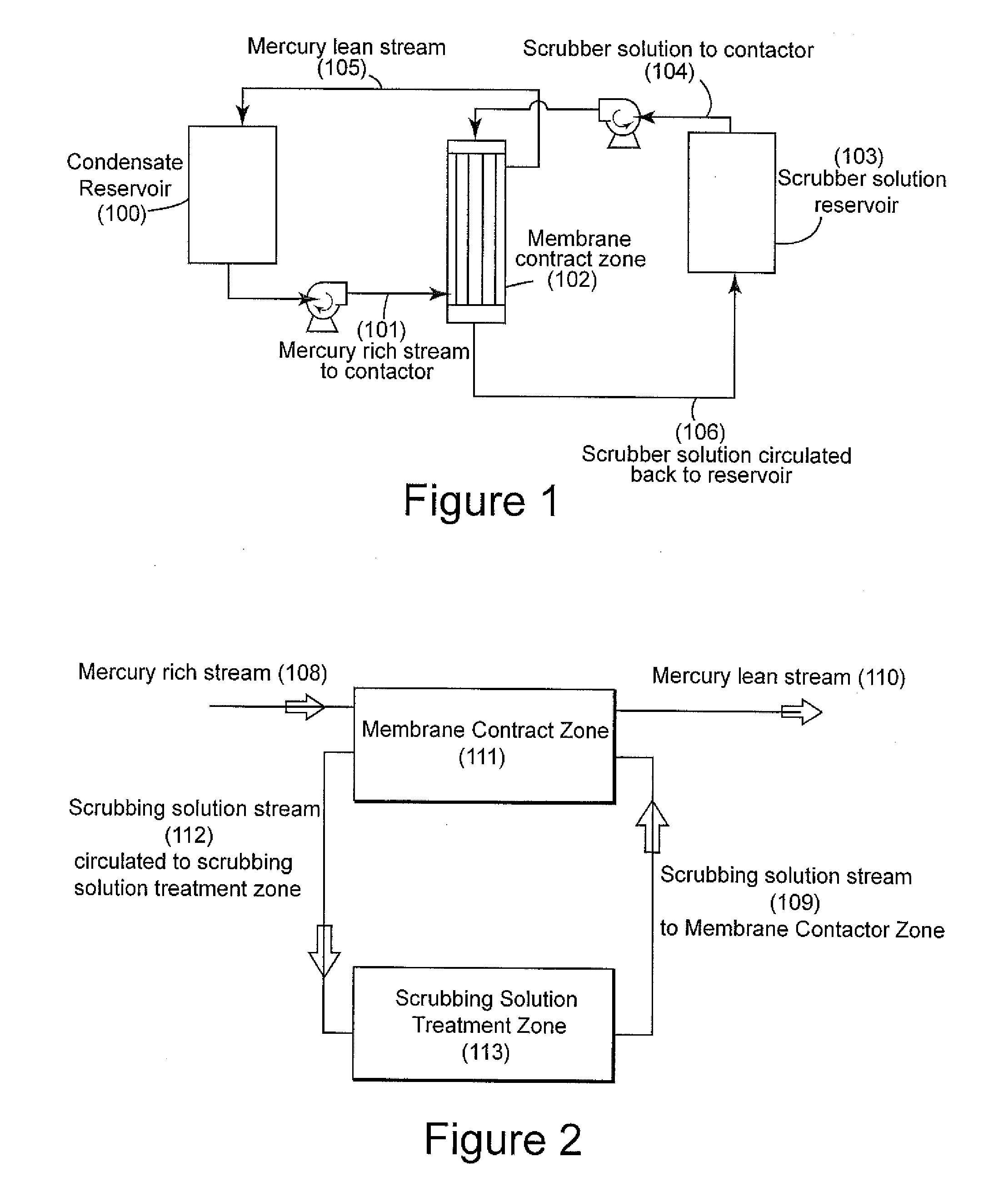

Method for removing mercury from a gaseous or liquid stream

ActiveUS20130287655A1Avoid problemsHigh bulk densitySemi-permeable membranesGas treatmentNatural-gas condensateReactive components

The invention relates to a method for removing mercury from mercury containing materials, such as feedstreams, natural gas streams, natural gas condensates, and so forth. The method involves passing a fluid (e.g., gas or liquid) stream containing mercury along a polymeric membrane contact module, while a cleaning or scrubbing solution passes along the other side of the membrane. The scrubbing solution facilitates removal of mercury from the first solution via, e.g., mercury reactive components contained in it.

Owner:SAUDI ARABIAN OIL CO

Gas soluble water separation technology device

InactiveCN104990293AIncrease temperatureRealize comprehensive utilizationOther heat production devicesGeothermal energy generationNatural-gas condensateCombustor

The invention provides a gas soluble water separation technology device which comprises an integrated separation tank, a natural gas burner, a heat exchange component, a water level gauge or a thermometer and multiple valves. The integrated separation tank is provided with a gas soluble water inlet, a water outlet and a natural gas outlet. The heat exchange component is further arranged in the separation tank. Natural gas enters the natural gas burner to be burned, generated heat is used for heating the heat exchange component so as to heat water in the separation tank, and finally hot water flows out of the water outlet, so that separation and full utilization of the natural gas are achieved. According to the gas soluble water separation technology device, separated gas does not need to be stored or transported, safety is improved, and investment is reduced. The temperature of geothermal water is increased through burned natural gas, and the geothermic heat value is increased.

Owner:SHANGHAI YIJING ENERGY TECH

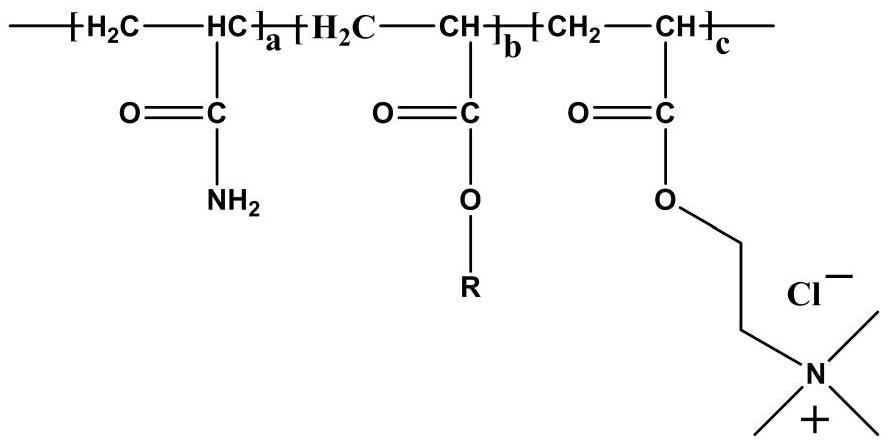

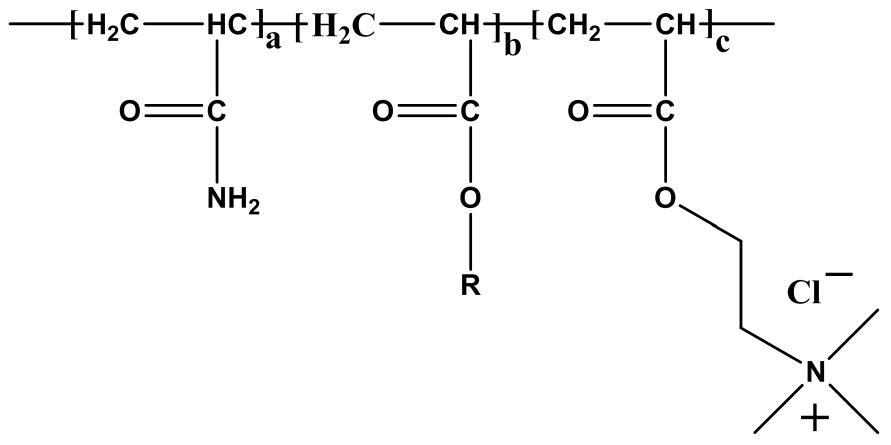

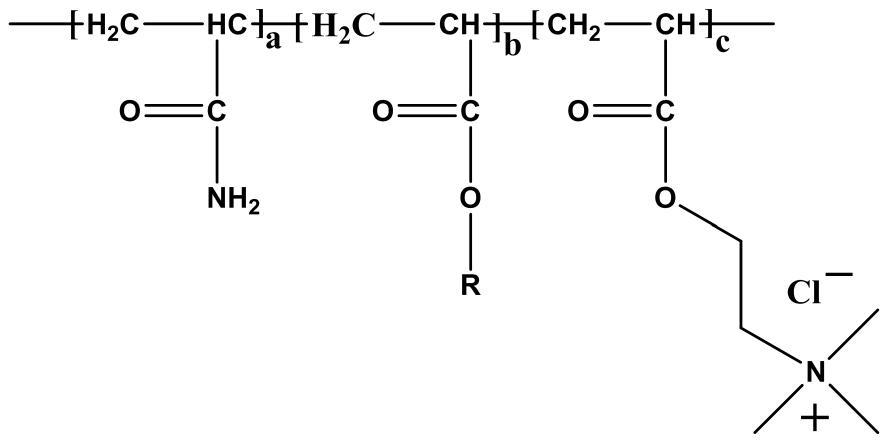

Demulsifying agent for treating natural gas condensate oil produced liquid as well as preparation method and application thereof

InactiveCN111995709AWill not corrodeNo irritating smellDewatering/demulsification with chemical meansNatural-gas condensateFlocculation

The invention provides a demulsifying agent for treating natural gas condensate oil produced liquid as well as a preparation method and application thereof. The demulsifying agent comprises the following components in percentage by mass: 15-30% of alcohol, 50-75% of a monomer, 0.5-6% of an initiator and the balance of water, wherein the monomer is formed by mixing cationic acryloyloxyethyl fatty ammonium salt, acrylate and acrylamide according to the molar ratio of (1-5): (1-5): 1. The demulsifying agent has good demulsification and flocculation effects, and is especially suitable for treatment of natural gas condensate oil produced liquid with clay suspended solids. According to the demulsifying agent, condensate oil and water can be effectively separated at room temperature, meanwhile, suspended solids in the condensate oil can be effectively flocculated, recycling of the condensate oil is achieved, the demulsifying agent has the advantages of high demulsification speed and clear demulsified oil water, the problem of separation, recycling and reusing of the condensate oil is solved, and the demulsifying agent can be widely applied to after-treatment of condensate oil produced liquid.

Owner:PETROCHINA CO LTD

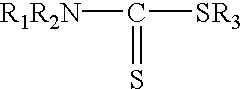

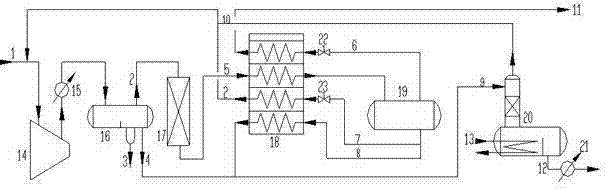

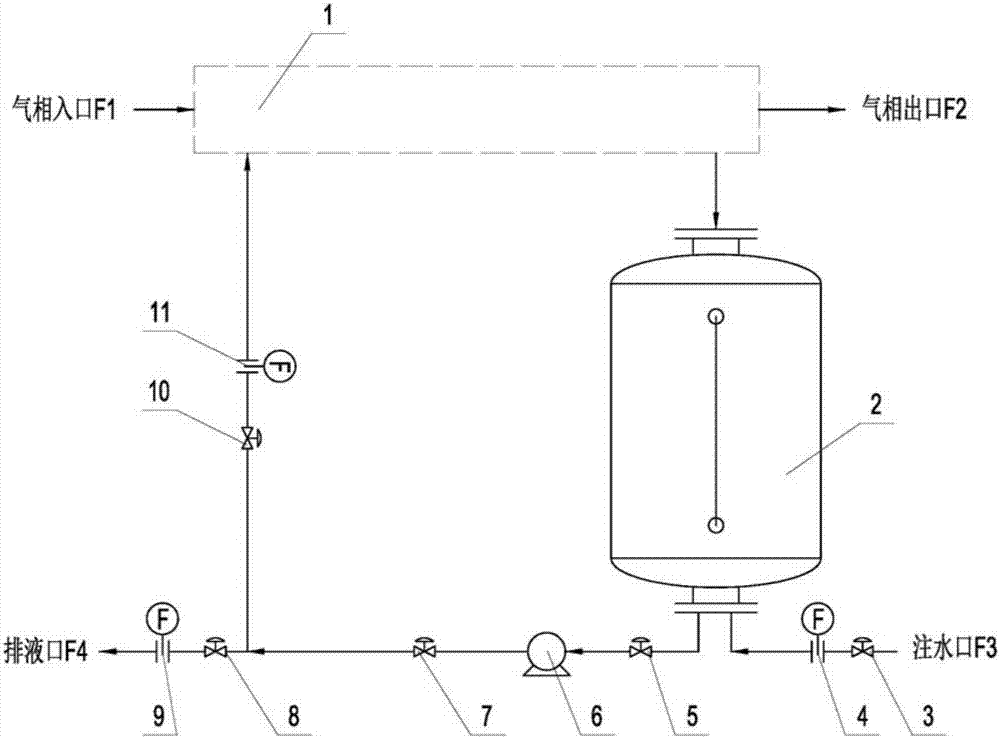

Compact type natural gas pretreatment and purification method and device suitable for offshore platform

ActiveCN107353956ASolve the small spaceSmall footprintGaseous fuelsNatural-gas condensatePretreatment method

The invention relates to a compact type natural gas pretreatment and purification method and device suitable for an offshore platform. The compact type natural gas pretreatment and purification method and device are suitable for pretreatment and purification of natural gas exploited from the offshore platform as well as removal of heavy hydrocarbon, soluble salt ions and most moisture from the natural gas. The exploited natural gas enters the device from a gas phase inlet, sequentially passes through a spray washing unit, a uniform gas and liquid distributing unit, a natural gas and washing water mixing and mass transferring unit, a spiral forming unit and a natural gas and washing water separation unit and flows out from a gas phase outlet. A removed liquid enters a liquid storage unit. Fresh water is injected to the spray washing unit from the liquid storage unit through a pipeline circulating pump and sprayed out. Natural gas treated with the method does not contain soluble salt ions and most moisture in original wet natural gas. The compact type pretreatment method performs online treatment on natural gas on the offshore platform with a narrow space and can quickly remove impurities and liquids.

Owner:EAST CHINA UNIV OF SCI & TECH

Synergistic surfactant compositions for unloading fluids from oil and gas wells

InactiveUS20130252856A1Easy to useEasy to uninstallDistillation purification/separationFluid removalProduction rateNatural-gas condensate

A method for unloading fluids from an oil and gas well, pipeline or flowline includes using a synergistic combination of an alkyl glucoside and an amphoteric surfactant as a foaming composition. Use of the combination foaming composition improves unloading of formation fluids, particularly production fluids having natural gas condensate and water and therefore increases the rate of production from the oil and gas well.

Owner:BAKER HUGHES INC

Thermal cracking vaporization unit construction

InactiveUS20080078696A1Thermal non-catalytic crackingCatalytic crackingNatural-gas condensateVaporization

In the process of employing a liquid whole crude oil and / or natural gas condensate in a thermal cracking process that uses a vaporization / mild cracking unit upstream of a thermal cracking furnace, a martensitic steel is employed in the construction of the unit and the unit is subjected to a de-hydrogenation treatment.

Owner:EQUSR CHEM LP +1

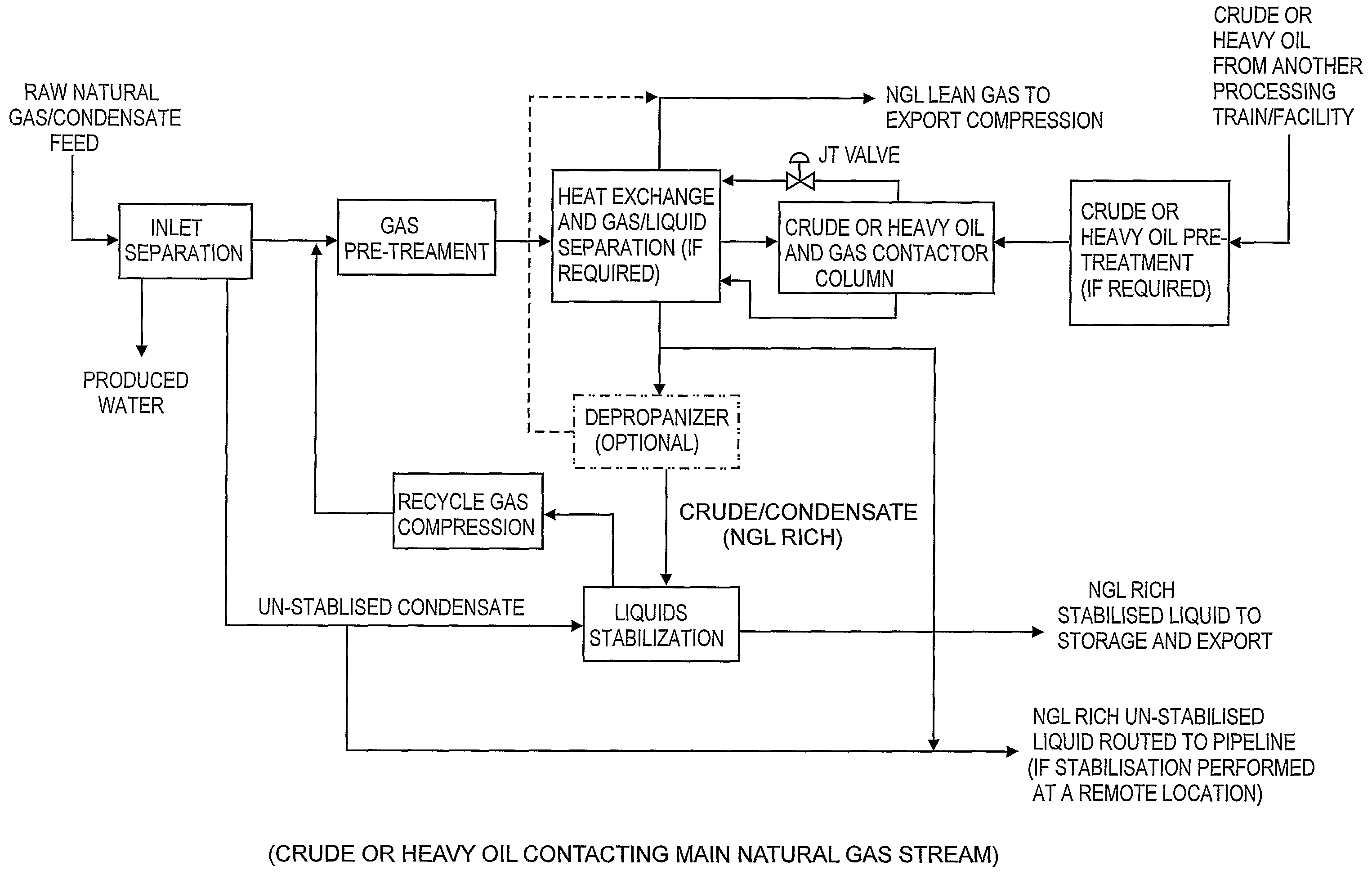

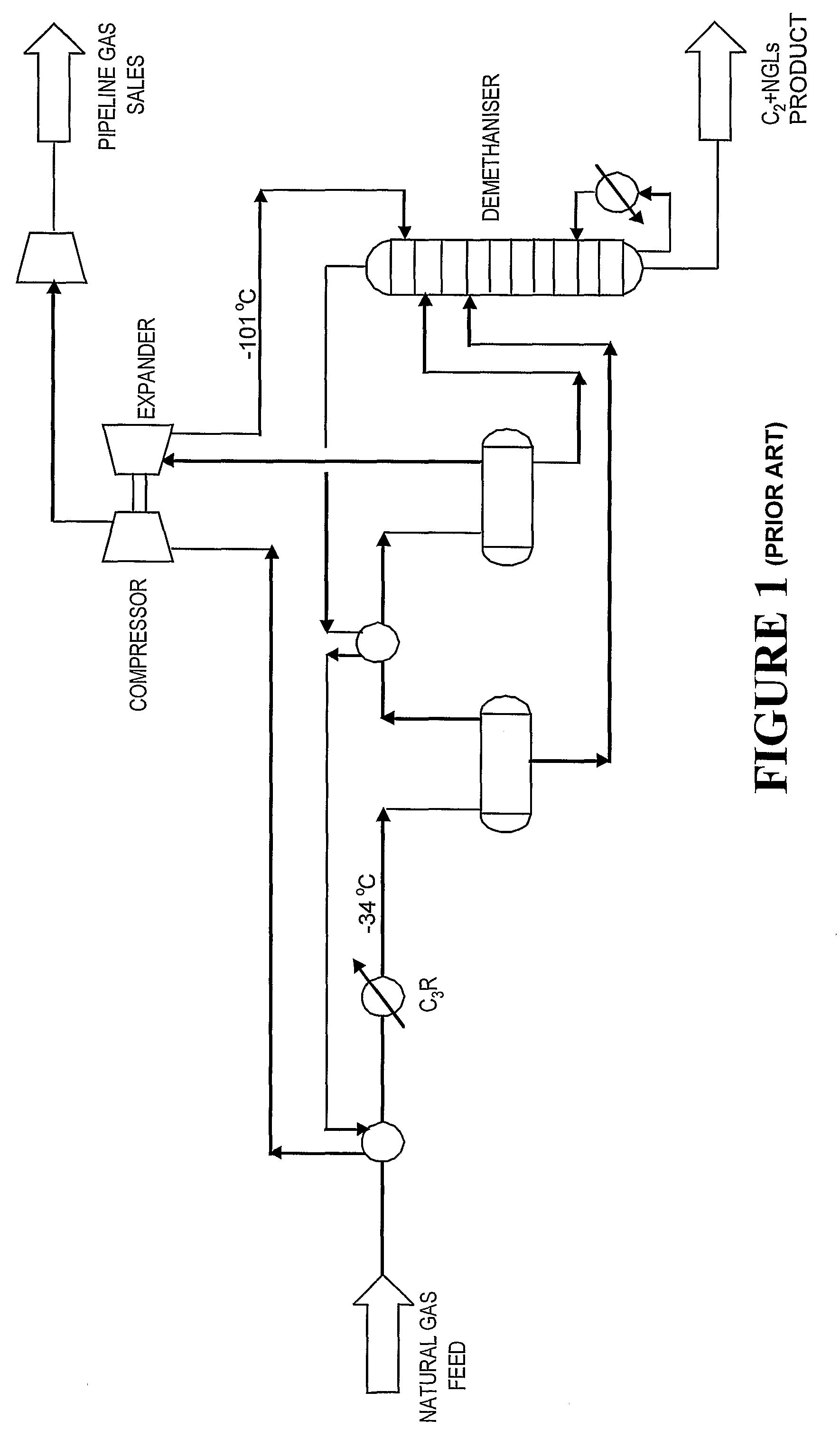

Process for extracting natural gas liquids from natural gas

InactiveUS7875759B2Promote recoveryPrevent regenerationSolidificationLiquefactionNatural-gas condensateFuel oil

A process for extracting natural gas liquids (NGLs) from natural gas that involves contacting natural gas from one source with crude, or heavy, oil from a different source under conditions that promote enrichment of the crude or heavy oil with NGLs from the natural gas. Apart from functioning as an absorbent fluid, the crude or heavy oil also functions as the carrier medium for the absorbed. NGLs. When practicing the process, unlike conventional methods, there is no need to regenerate the absorbent fluid, in this case the crude and heavy oil, for recycling.

Owner:SHAMSUDIN RAFAEL BIN MOHD

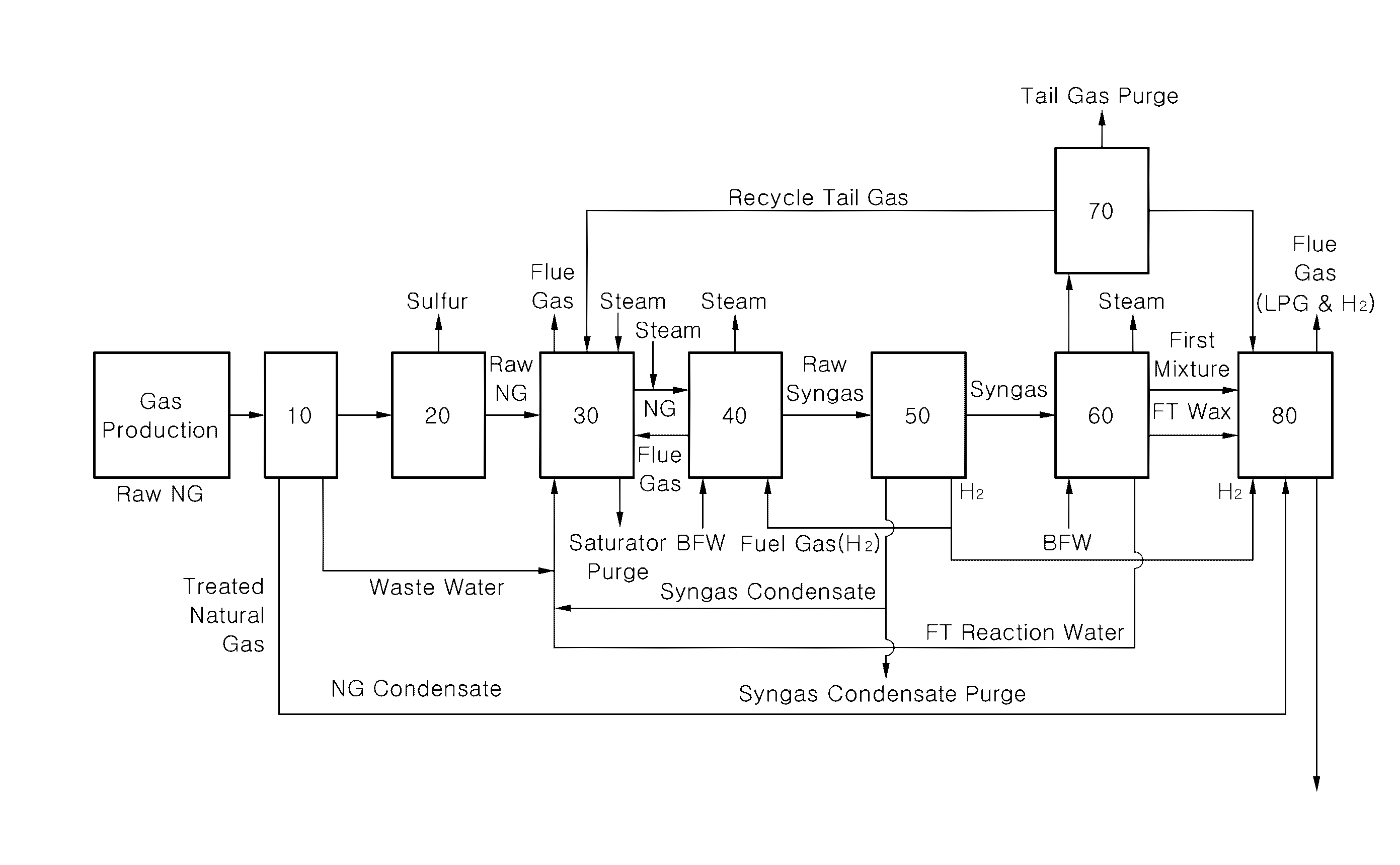

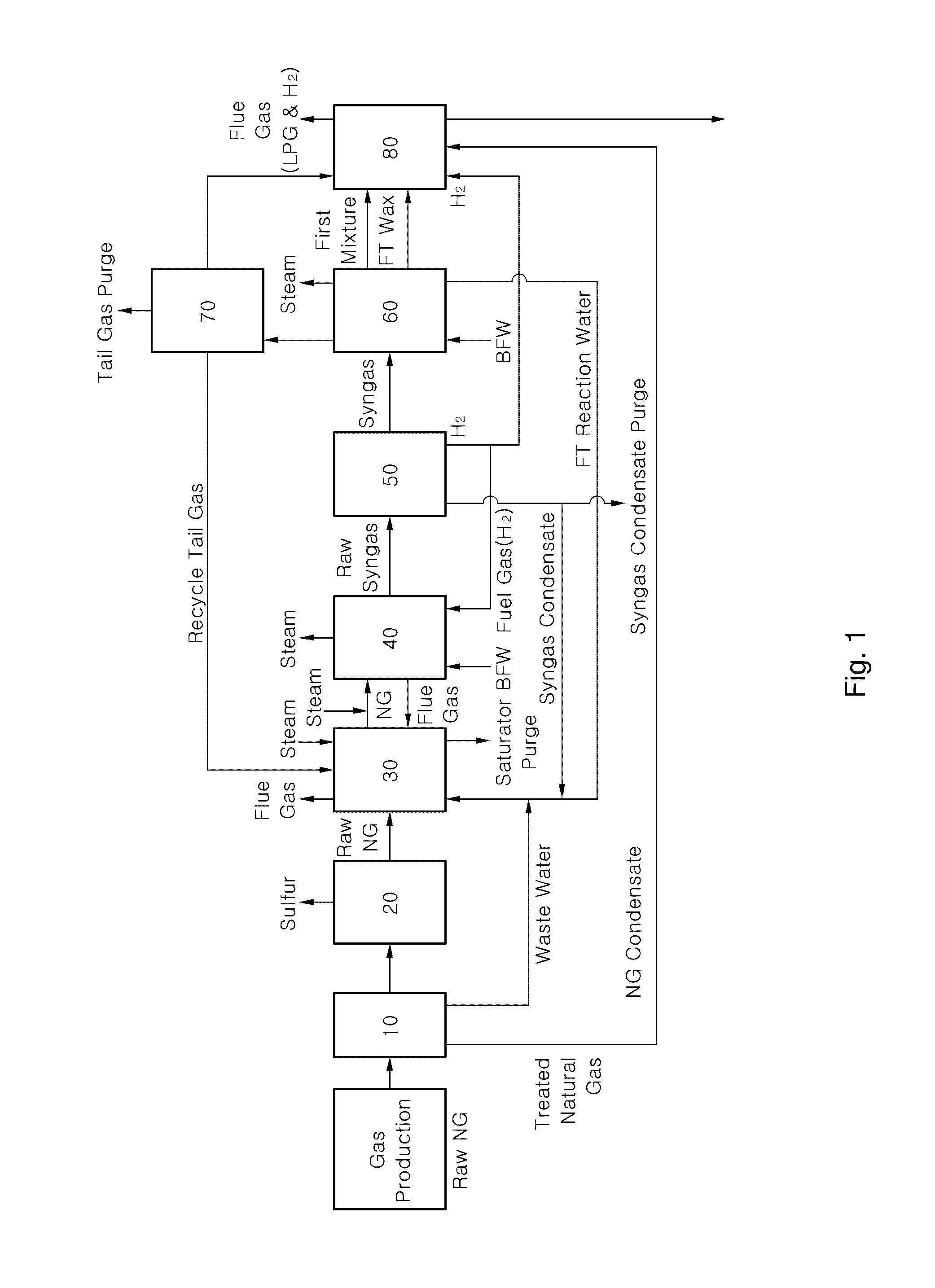

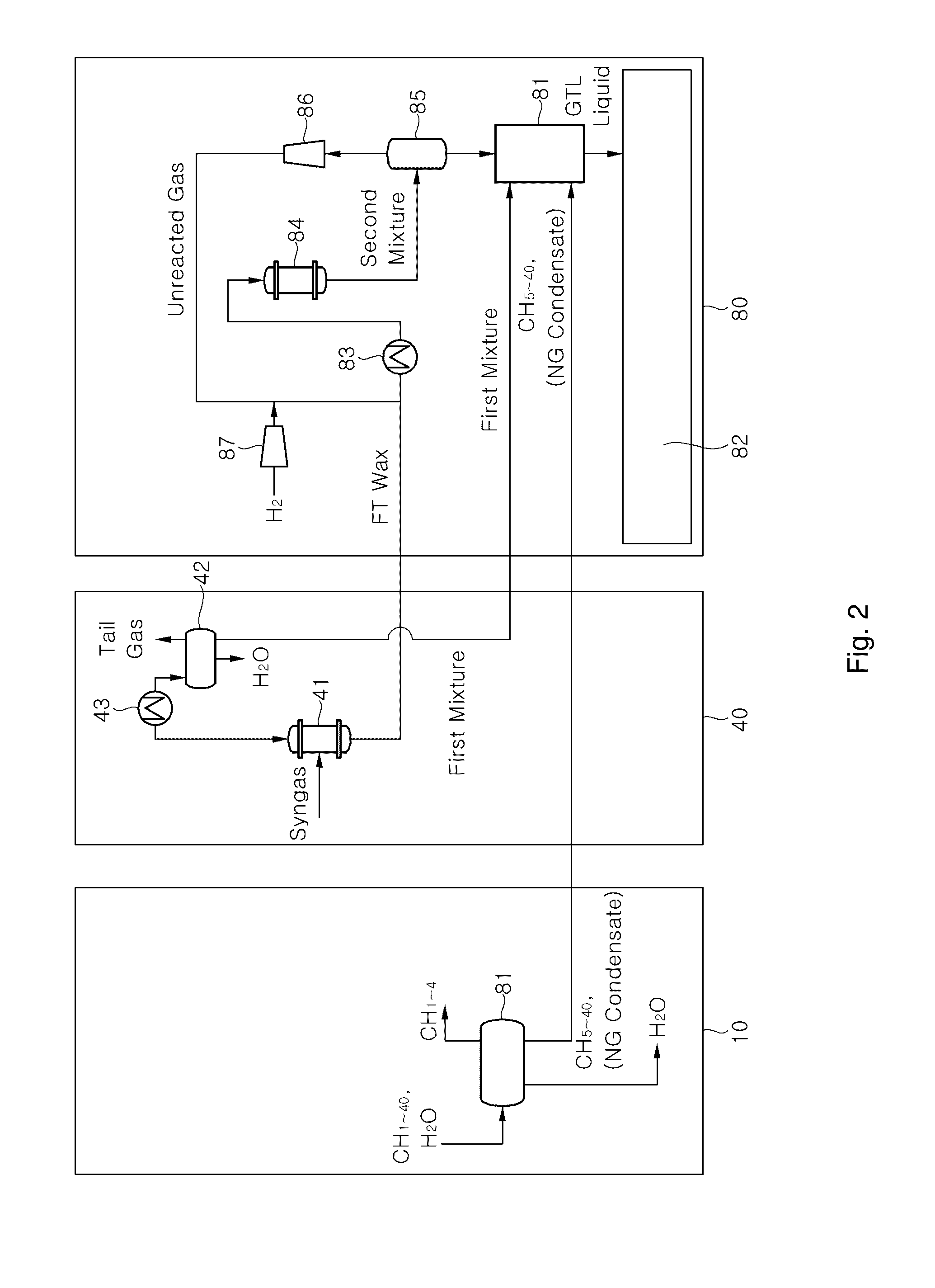

Ft gtl apparatus and method for producing single synthetic crude oil

InactiveUS20160369173A1Save deck spaceLow production costRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture recoveryNatural-gas condensateGas to liquids

Disclosed are a Fischer-Tropsch (FT) gas-to-liquid (GTL) apparatus for producing unitary synthetic crude oil and an FT GTL method for producing unitary synthetic crude oil. The FT GTL apparatus for producing unitary synthetic crude oil of the present invention is an FT GTL apparatus for producing unitary synthetic crude oil from floating production, storage, and off-loading (FPSO), and characterized by comprising: a gas injection stabilization unit for performing stabilization on the produced natural gas to generate a natural gas condensate; and a modification unit for modifying the natural gas, which has been treated in the gas injection stabilization unit, to produce a synthetic crude oil product.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Process method for producing LNG from oilfield associated gas

PendingCN111394145ASolve the poisoning failure problemReduce loadGaseous fuelsFluid removalRefrigeration compressorNatural-gas condensate

The invention provides a process method for producing LNG from oilfield associated gas. The device is characterized by comprising a feed gas buffer tank, a feed gas compressor, a feed gas cooler and the like. External feed gas enters the feed gas buffer tank through a conveying pipeline; the feed gas buffer tank is respectively connected with a wastewater output boundary pipeline, the feed gas compressor and a stable light hydrocarbon tower through conveying pipelines; the feed gas compressor is connected with a three-phase separation tank through the conveying pipeline, and the feed gas cooler is installed on the conveying pipeline. The process method is suitable for oilfield associated gas, natural gas wellhead gas, natural gas condensate gas and crude oil tank area flash steam. The stable light hydrocarbon tower is additionally arranged and used for removing most heavy hydrocarbons, the influence of the heavy hydrocarbons on a subsequent decarburization and desulfurization system and the molecular sieve dryer is reduced, the problems of oil foaming and molecular sieve poisoning failure of the amine liquid absorption tower are solved, and the loads of the cold box and the refrigeration compressor are reduced.

Owner:天津深蓝化工技术有限公司

Method for reducing the mercury content of natural gas condensate and natural gas processing plant

A method for reducing the mercury content of natural gas condensate, comprising the steps of providing a nanofiltration membrane having a feed side and a permeate side; contacting the natural gas condensate with the feed side of the membrane; and obtaining a mercury-depleted natural gas condensate at the permeate side of the membrane; and a natural gas processing plant comprising a condensate workup section including a nanofiltration membrane separation unit for reducing the mercury content of natural gas condensate.

Owner:SHELL OIL CO

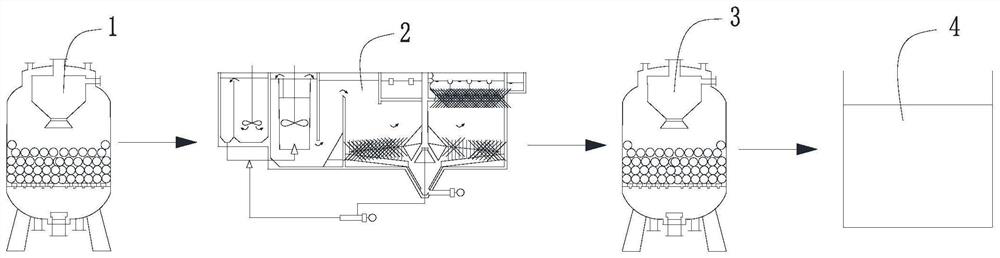

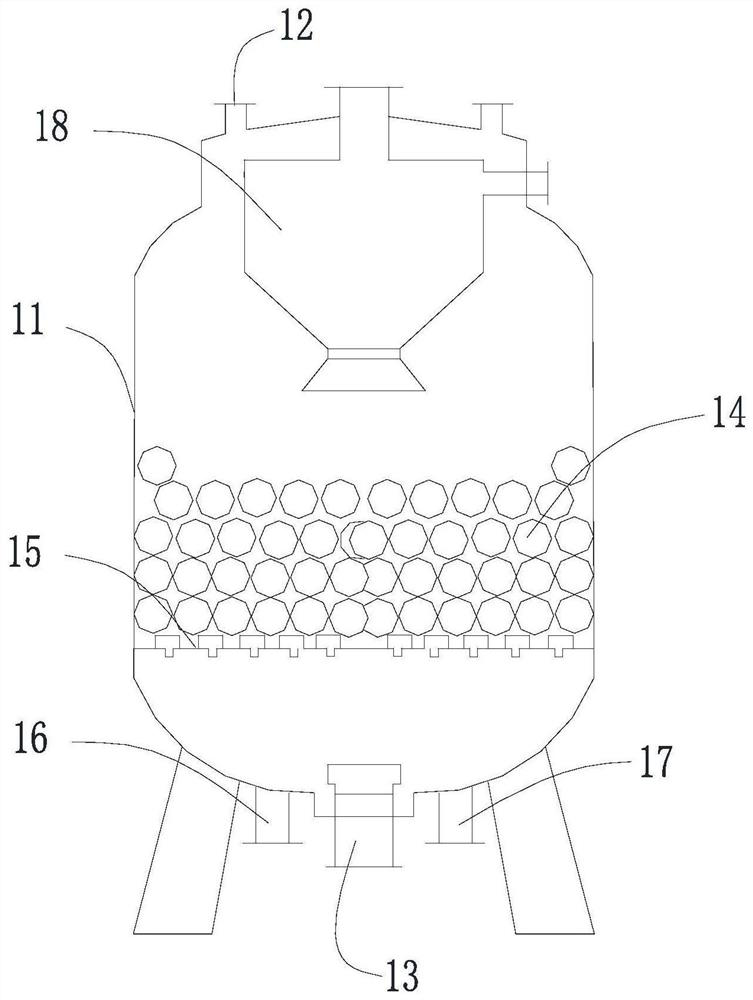

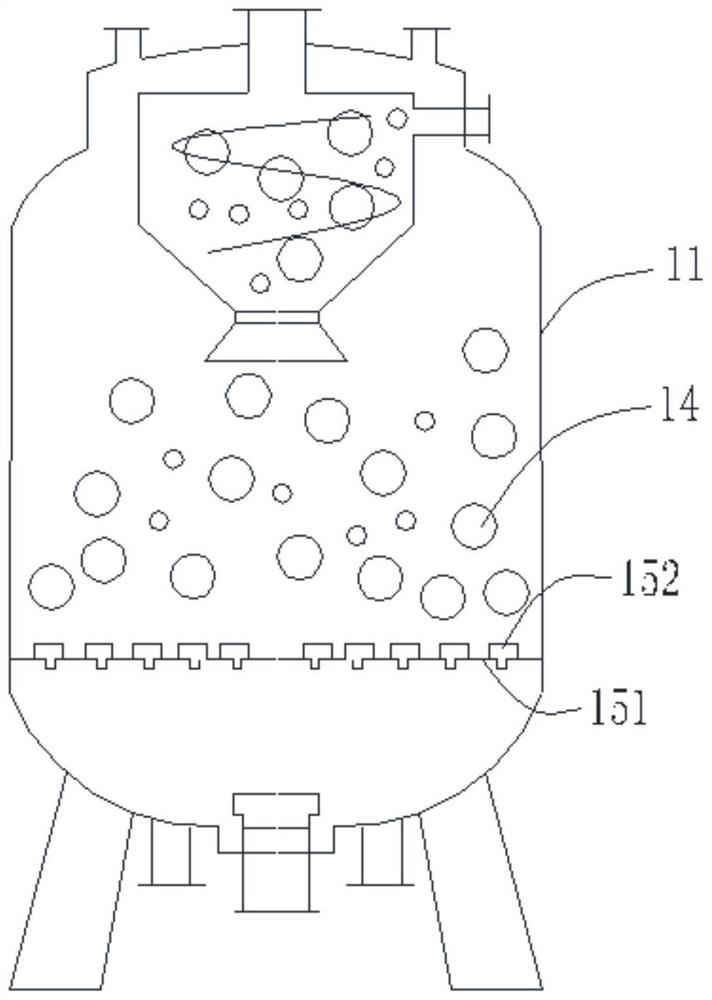

Oil and gas field gas production wastewater treatment system

PendingCN113716753AMeet the requirements of reinjection water qualitySimple structureWaste water treatment from quariesFatty/oily/floating substances removal devicesNatural-gas condensateThermodynamics

The invention relates to the technical field of wastewater treatment, and in particular, relates to an oil and gas field gas production wastewater treatment system which comprises a coagulation softening tank, a first filter separator with a micro-interface oscillation regeneration function and a second filter separator with a micro-interface oscillation regeneration function; and the first filter separator with the micro-interface oscillation regeneration function is connected with a second water inlet of the coagulation softening tank, and the second filter separator with the micro-interface oscillation regeneration function is connected with a second water outlet of the coagulation softening tank. The first filter separator with the micro-interface oscillation regeneration function, the coagulation softening tank and the second filter separator with the micro-interface oscillation regeneration function are used for treating the gas production wastewater of an oil and gas field in sequence, so that the occupied area and the cost of the treatment system are reduced, the volatilization loss of natural gas condensate is reduced, and the concentration of surrounding VOC is reduced. The first filter separator with the micro-interface oscillation regeneration function and the second filter separator with the micro-interface oscillation regeneration function are simple in structure, more convenient to operate and use and better in treatment effect.

Owner:SICHUAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com