Patents

Literature

101results about How to "No air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

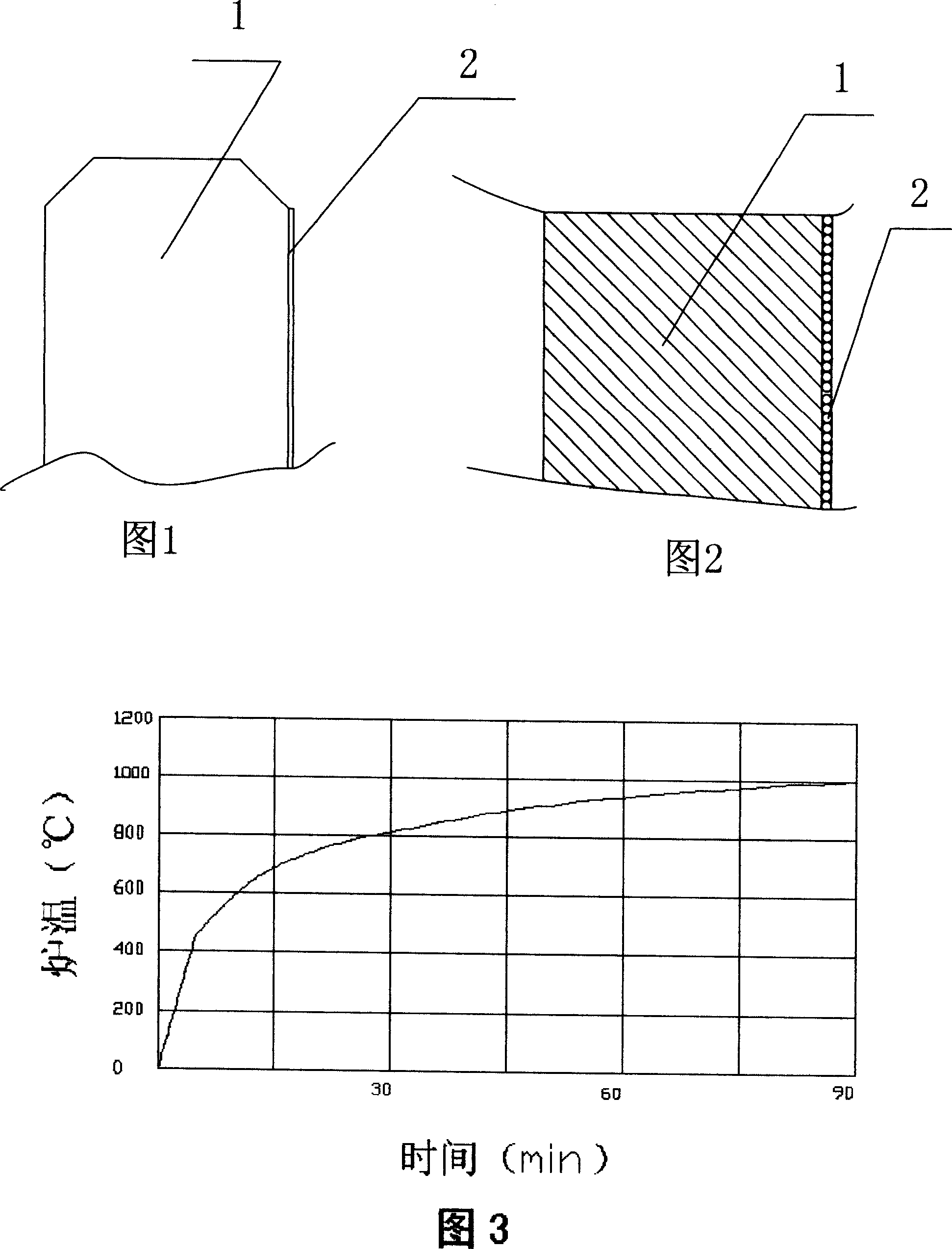

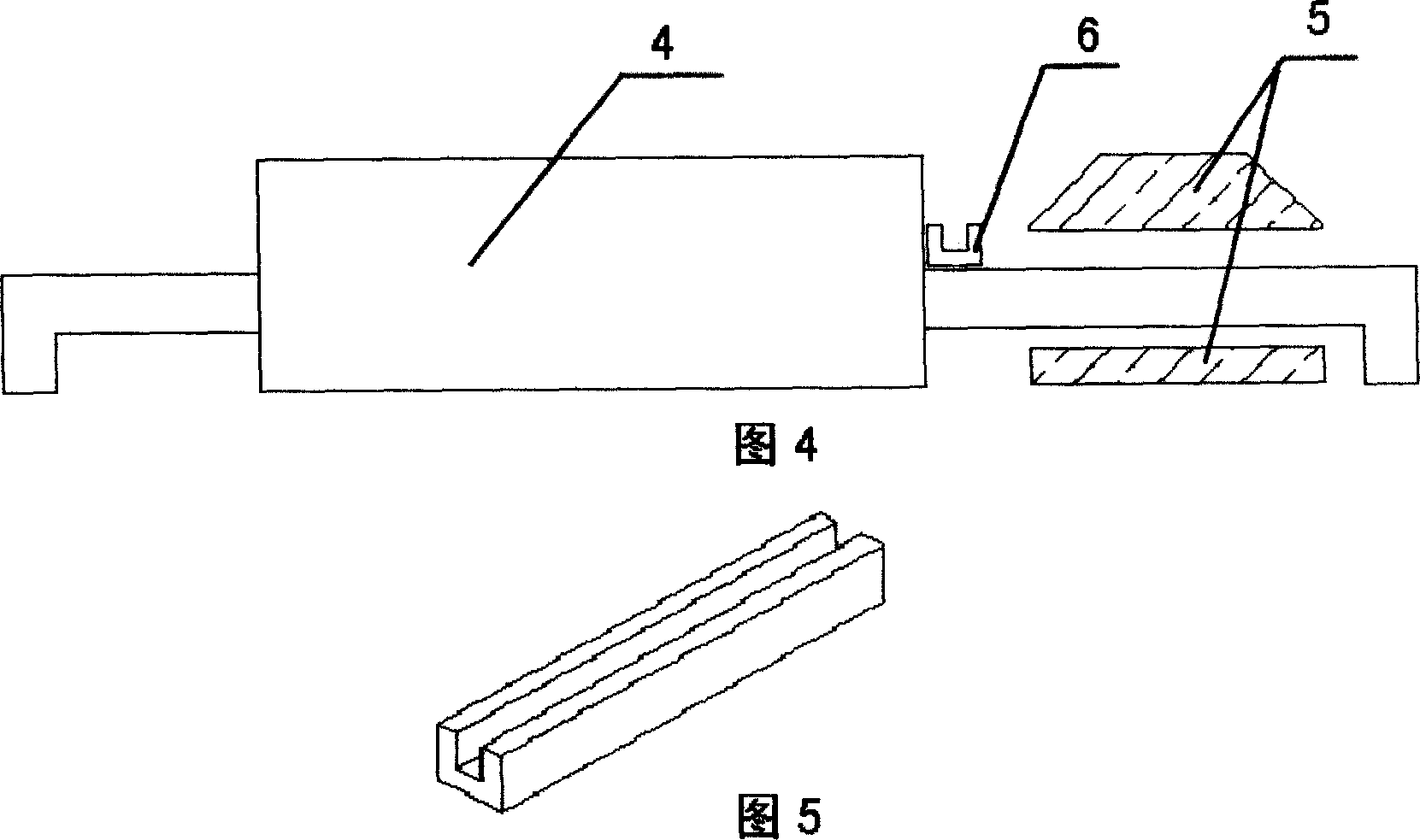

Method for producing fire-resisting glass and dedicated production equipment

ActiveCN101092286AAccelerates the ion exchange reaction processWon't peel off easilyGlass tempering apparatusGratingHeat resistance

This invention discloses method and specific apparatus for producing fireproof glass. The apparatus comprises: an upper stage plate, a furnace, a cooling wind grating and a lower stage plate. A baffle is set between the heating furnace and the cooling wind grating. The method comprises: (1) spray-coating a cesium / potassium salt solution onto glass at normal temperature; (2) naturally wind-drying the spray-coated glass at normal temperature, placing in a 680-725 deg.C tempering furnace, rapidly heating, cooling, circulating the glass between the heating furnace and the cooling wind grating by a roll so that the heating and cooling temperature is uniform, and unloading to obtain fireproof glass. The cesium / potassium salt solution comprises: cesium salt 0.8-1.2%, potassium salt 38-41%, acetone 40-45%, formic acid 8-13%, and Swiss-78 6-8%. The fireproof glass has such advantages as high heat resistance, low specific gravity, high light permeability, no yellowing, and no air bubbles.

Owner:新福兴玻璃工业集团有限公司

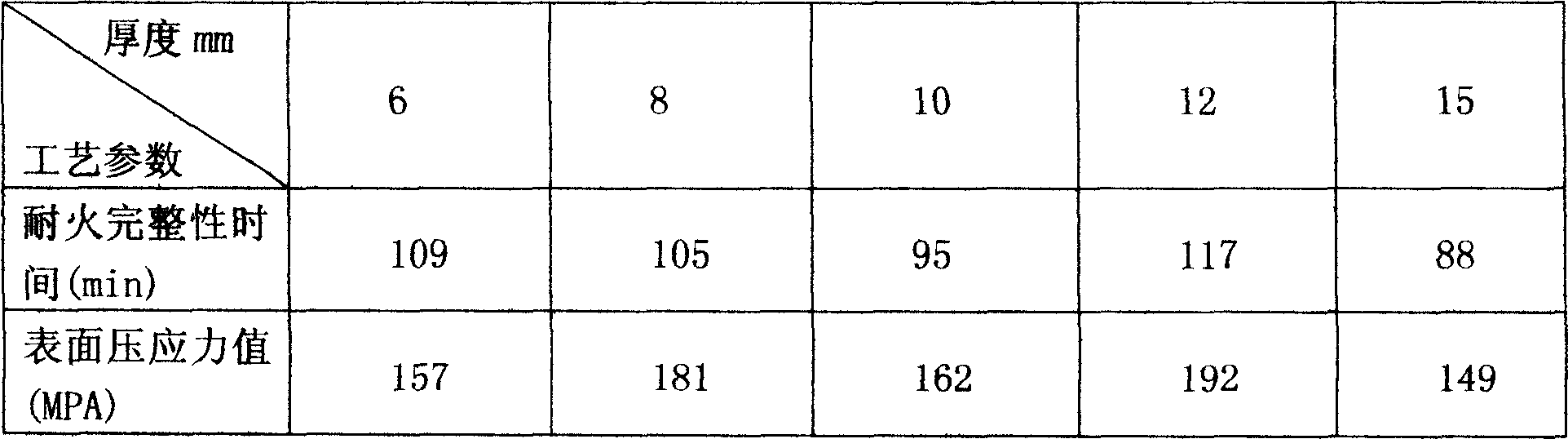

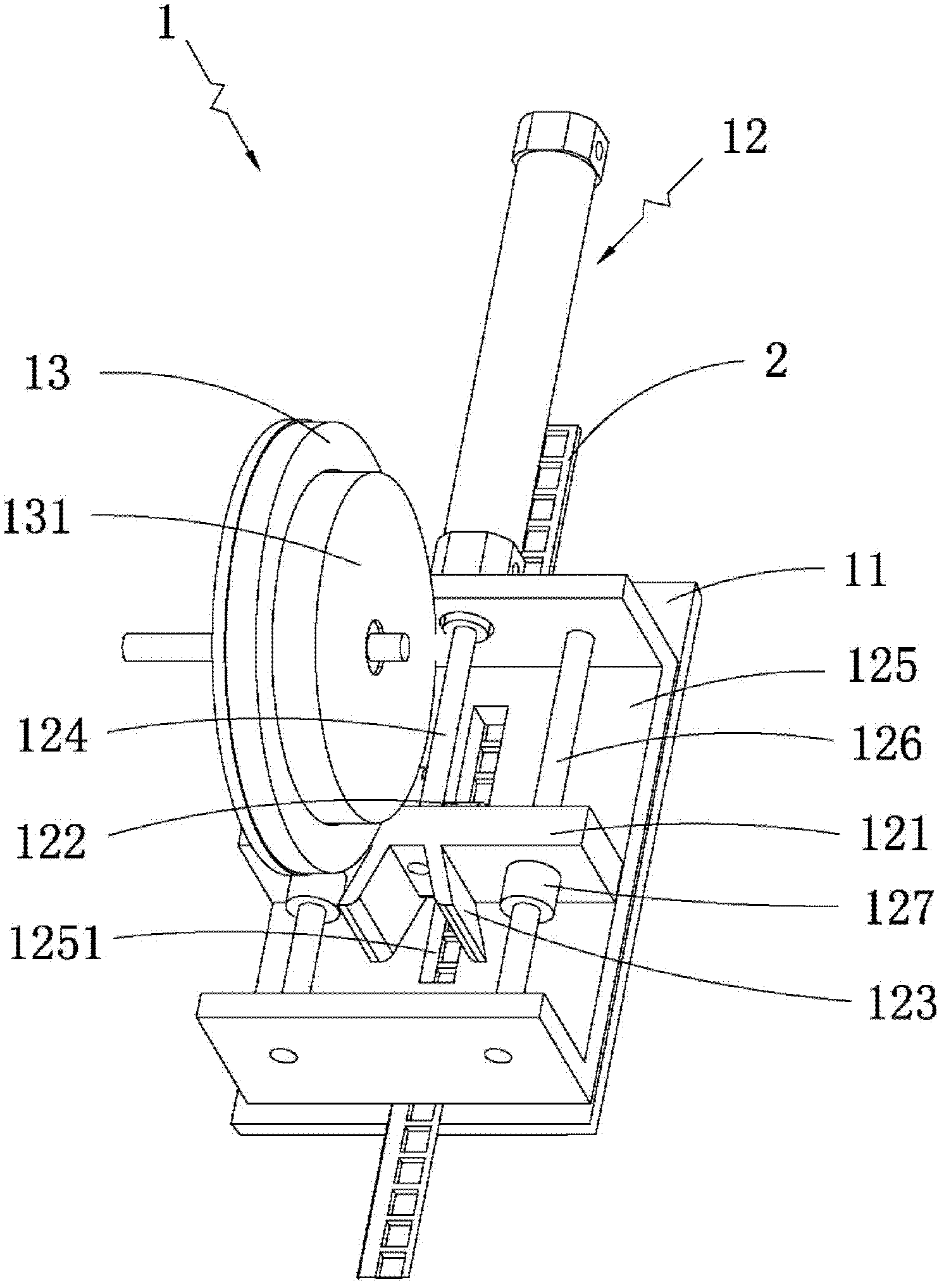

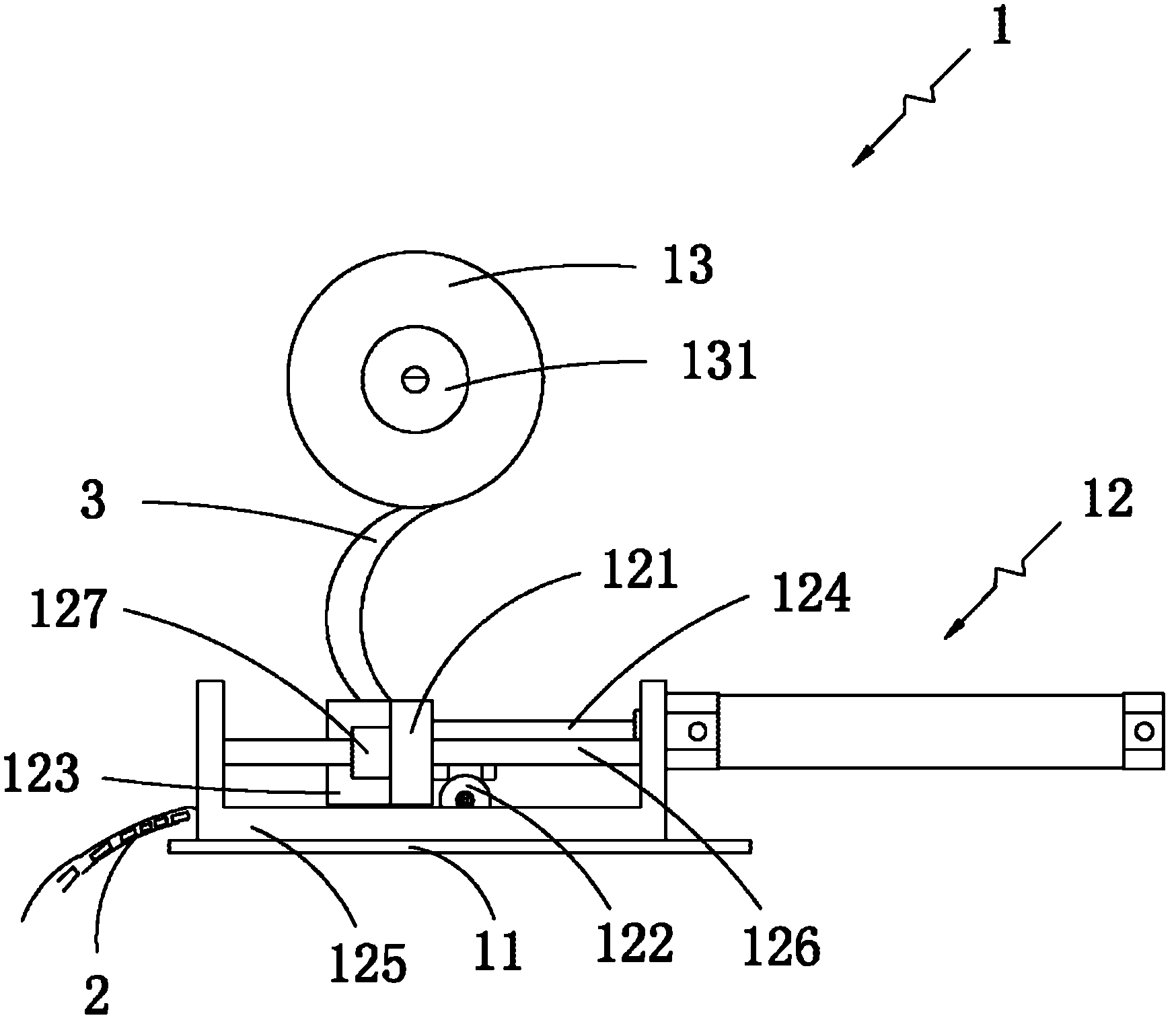

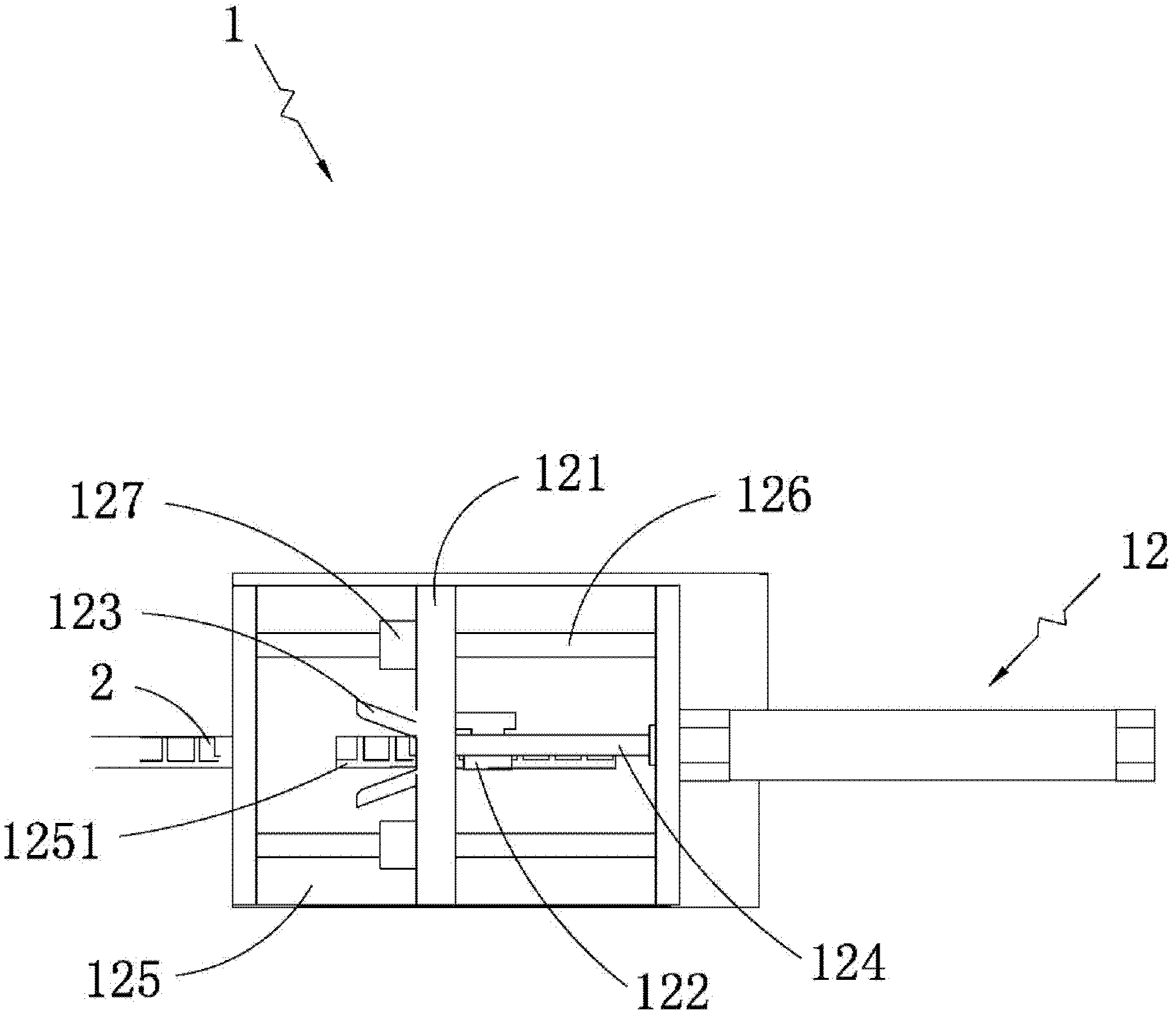

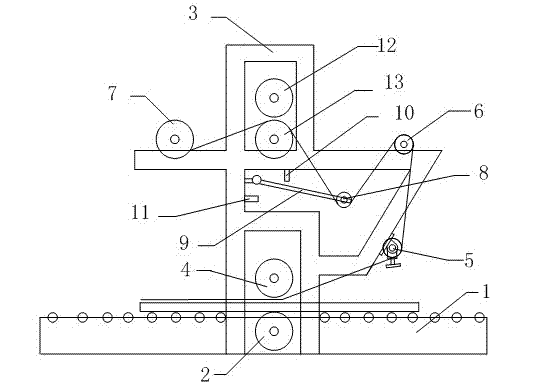

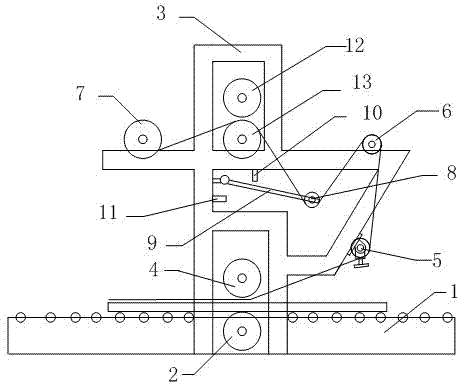

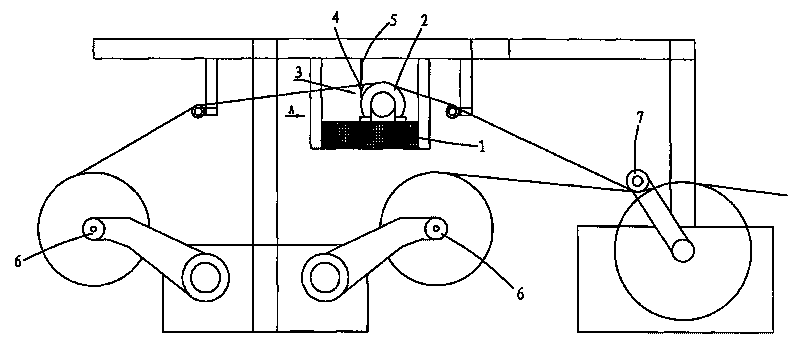

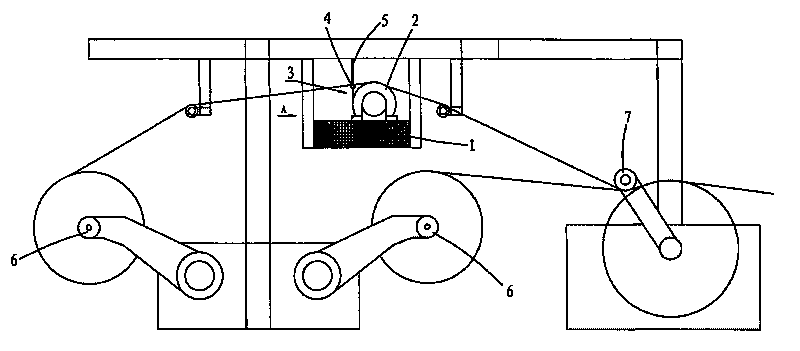

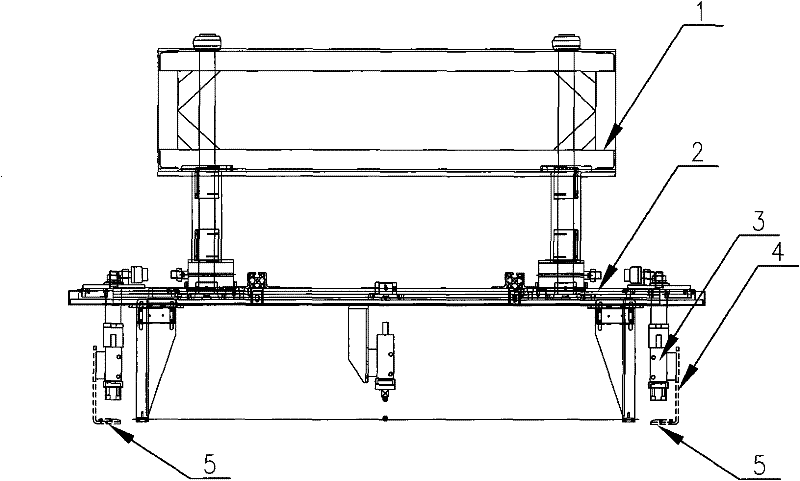

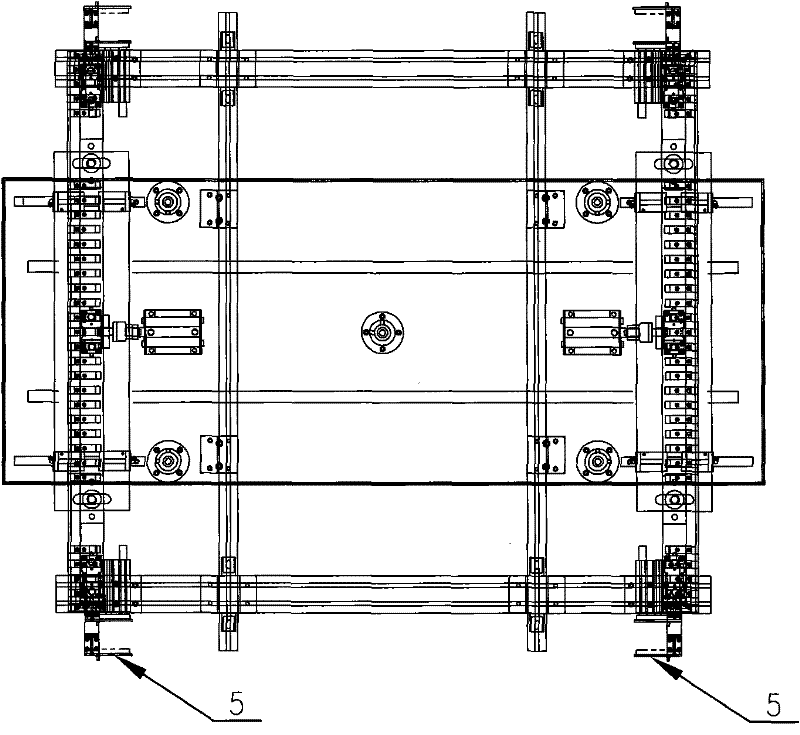

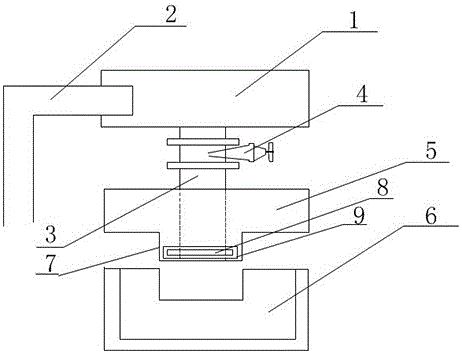

Automatic adhering device of transparent adhesive tape

ActiveCN102305228ASmooth transmissionAutomatic paste evenlyFastening meansMechanical engineeringAir bubble

The invention provides an automatic adhering device of a transparent adhesive tape. The automatic adhering device adheres to an object to be adhered by utilizing the transparent adhesive tape and comprises a driving mechanism. The driving mechanism is arranged on a base plate, the base plate is provided with a guiding slot through which the object to be adhered passes, the driving mechanism drives a sliding block to carry out sliding displacement on the base plate, a rolling wheel is arranged on one side of the sliding block and can roll on the object to be adhered, and a locating structure is arranged on the other side of the sliding block and is used for locating the transparent adhesive tape. The transparent adhesive tape is suspended above the rolling wheel, the head of the transparent adhesive tape is firstly adhered on the object to be adhered, and the driving mechanism drives the rolling wheel to roll and drives the transparent adhesive tape to roll and automatically press the object to be adhered, thus the adhesion is ensured to be more uniform, firmer and better quality, and no bubbles or adhesion misalignment generates in the adhering process; the transparent adhesive tape is located by utilizing the locating structure so as to ensure that the transparent adhesive tape can stably convey without interruption; in addition, the automatic adhering device further has the advantages of simple structure and low cost, and the labor and the time are saved due to manual adhesion replaced by the automatic adhesion.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

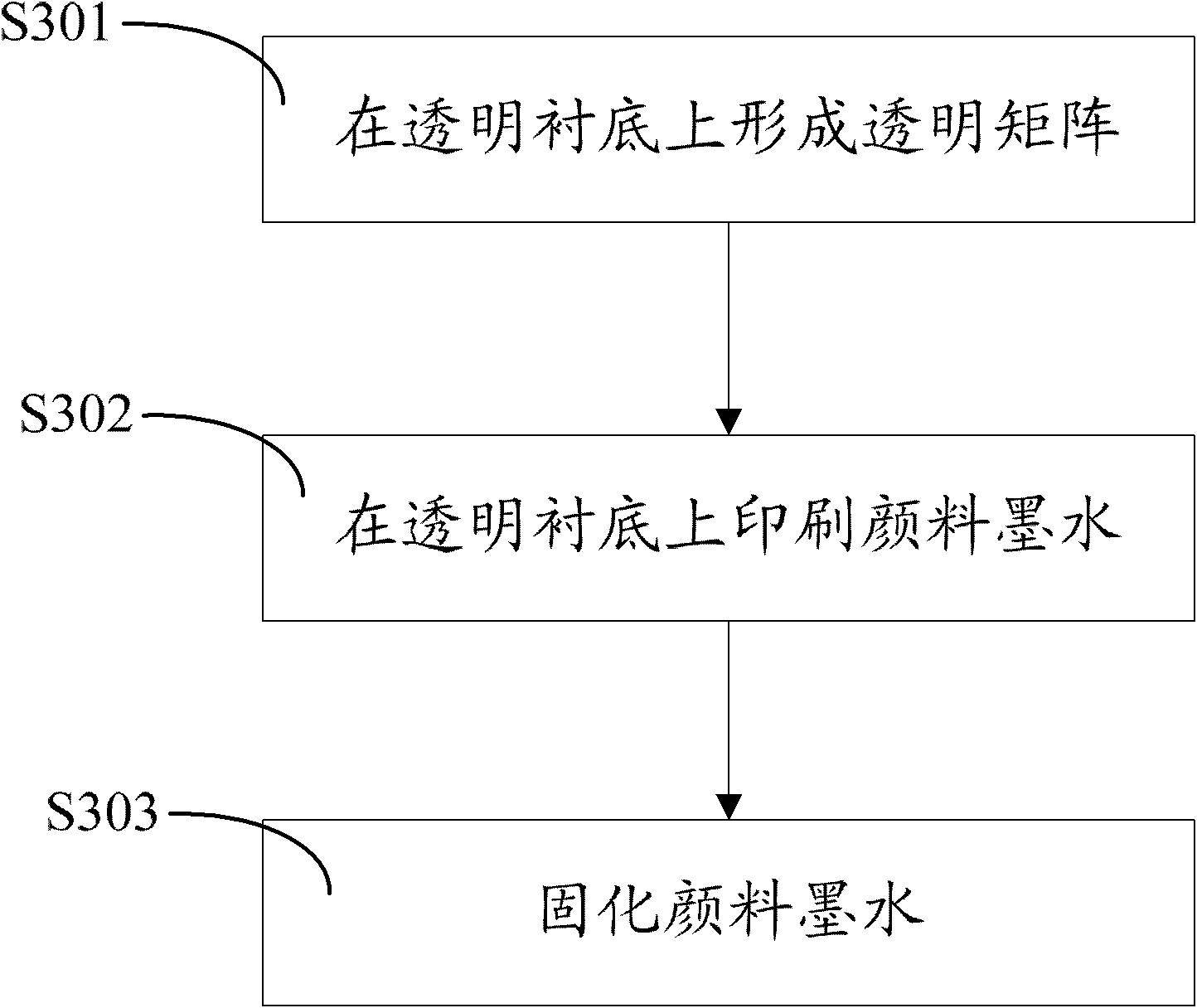

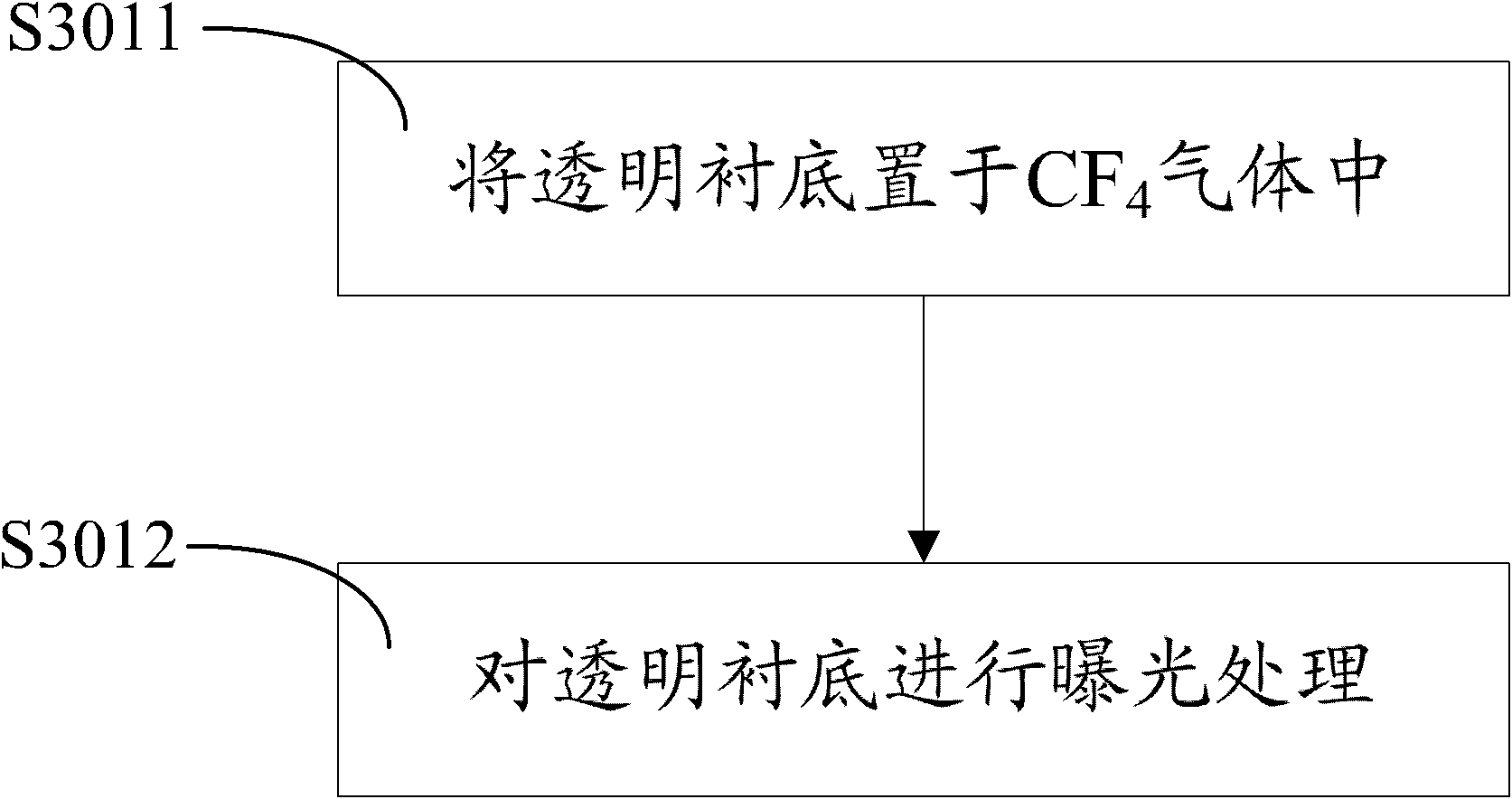

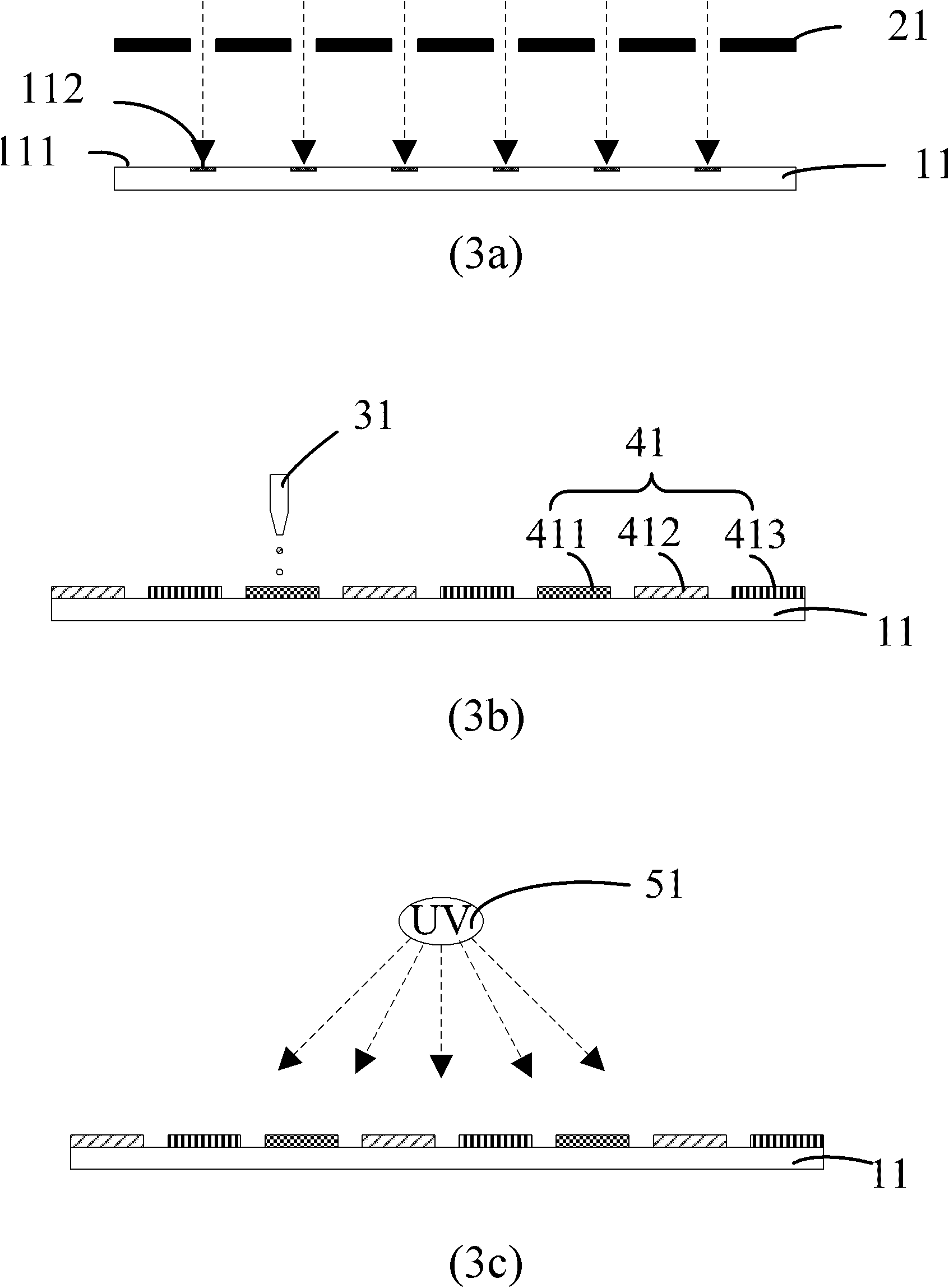

Manufacture method of color filter

ActiveCN101840013AHigh light transmittanceNo air bubblesOptical filtersNon-linear opticsHeat resistanceLight filter

The invention relates to a manufacture method of a color filter, in particular to a flexible transparent substrate. The manufacture method of the color filter comprises the following steps of: forming a transparent matrix on the transparent substrate to divide the transparent substrate into a plurality of pixel regions, wherein the transparent matrix and the pixel regions have different surface wettabilities, the transparent matrix presents hydrophobicity, and the pixel regions present hydrophilicity; and coating pigment ink in a plurality of pixel regions by utilizing an inkjet printing method and solidifying the pigment ink to form a plurality of color filter films. In the invention, no black matrix needs forming on the substrate, the transparent matrix is directly formed on the transparent substrate to improve the luminousness of the filter, the pigment ink is solidified without a heat roasting program but in a low-temperature thermal solidifying mode or an UV (UltraViolet) solidifying mode to avoid generating adverse influence on a flexible substrate without heat resistance.

Owner:美尚精密制造(南通)有限公司

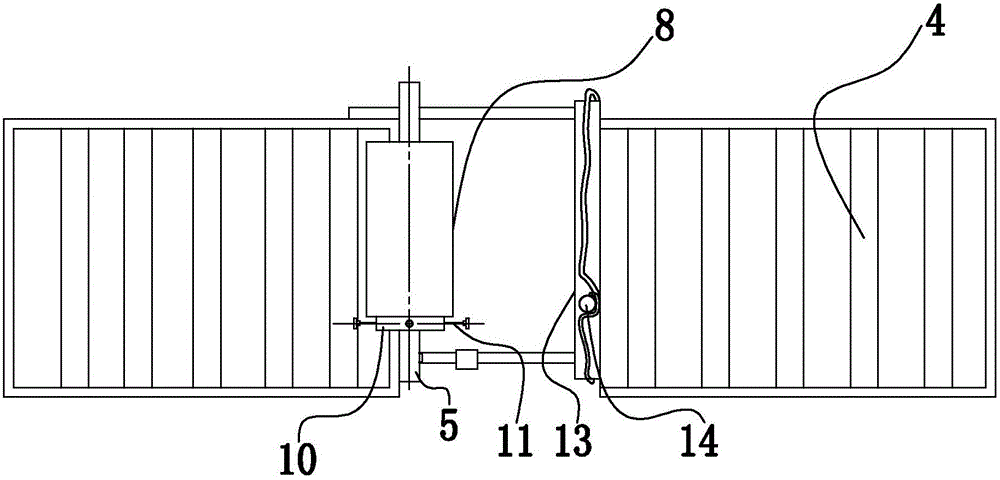

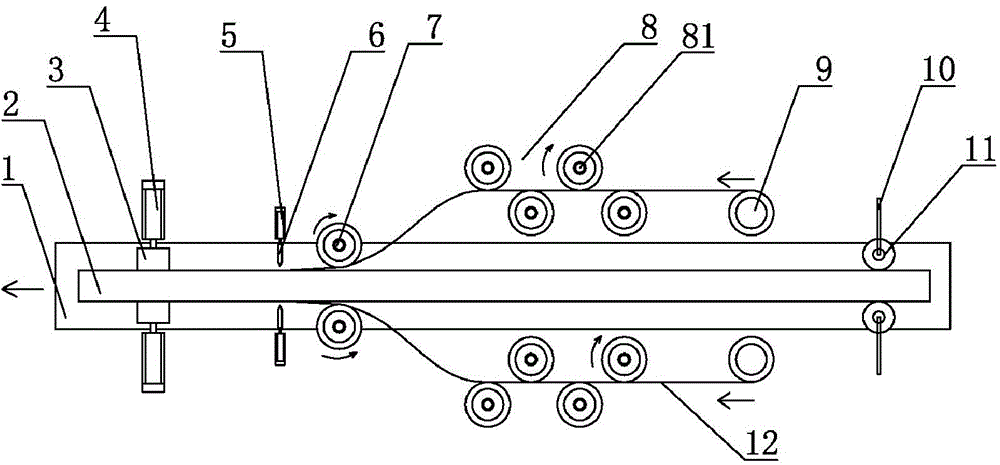

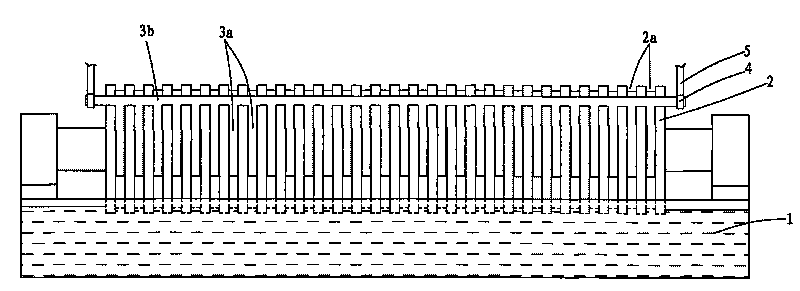

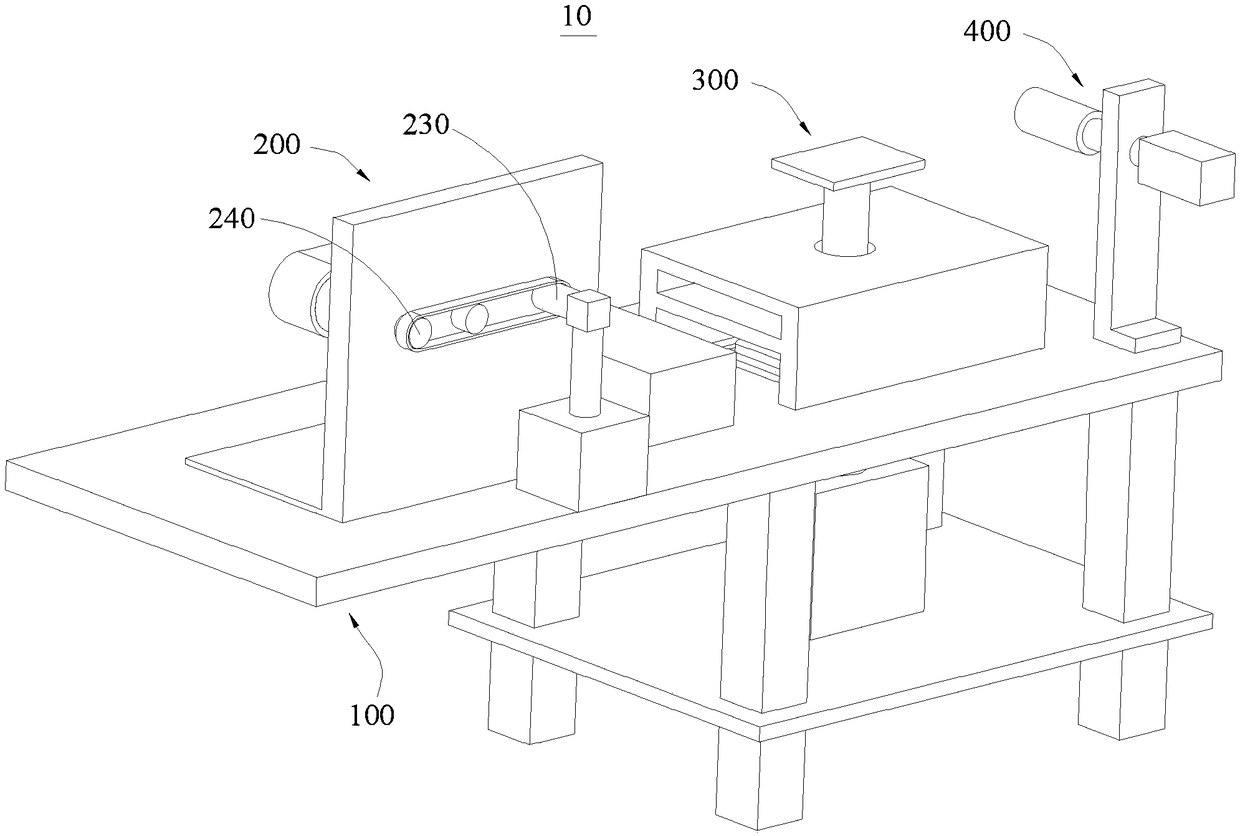

Film pasting device for tempered glass

InactiveCN106005546AGuaranteed uptimeFilm evenlyWrapping material feeding apparatusFree rotationEngineering

The invention relates to a film pasting device for tempered glass. The film pasting device comprises a support, a conveying mechanism, a film pasting mechanism and a cutting mechanism. The conveying mechanism comprises a feeding channel, a discharging channel and a conveying roller set. The feeding channel and the discharging channel are both provided with the conveying roller set. The conveying roller set comprises multiple roller shafts. The roller shafts are distributed on the two sides of a support at equal intervals and rotate freely. The film pasting mechanism comprises a winding drum roller, an adjusting roller and a pressing roller which are sequentially distributed on a rack from top to bottom. The roller shafts are distributed on the two sides of the support at equal intervals to drive the glass to slide and advance. By the adoption of the structure, in the glass conveying process, stable glass conveying is guaranteed, so that film pasting is uniform, and no bubble is generated; and meanwhile, the film pasting tension is adjusted through the winding drum roller, the adjusting roller and the pressing roller, a film is straightened and conveyed to the surface of the glass to be preliminarily attached to the surface of the glass in a fit manner, a glass plate is conveyed through the roller shafts at the bottom and pressed through the pressing roller above the roller shafts in a press-fit manner, and the film pasting process is more efficient.

Owner:浙江飞越汉禾坊新材料有限公司

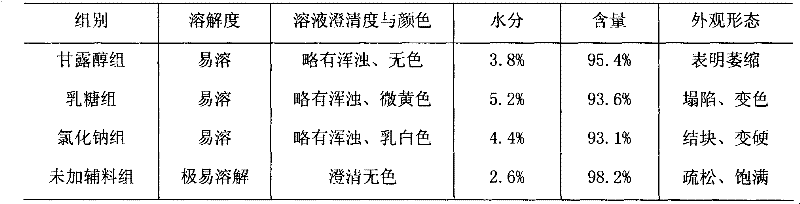

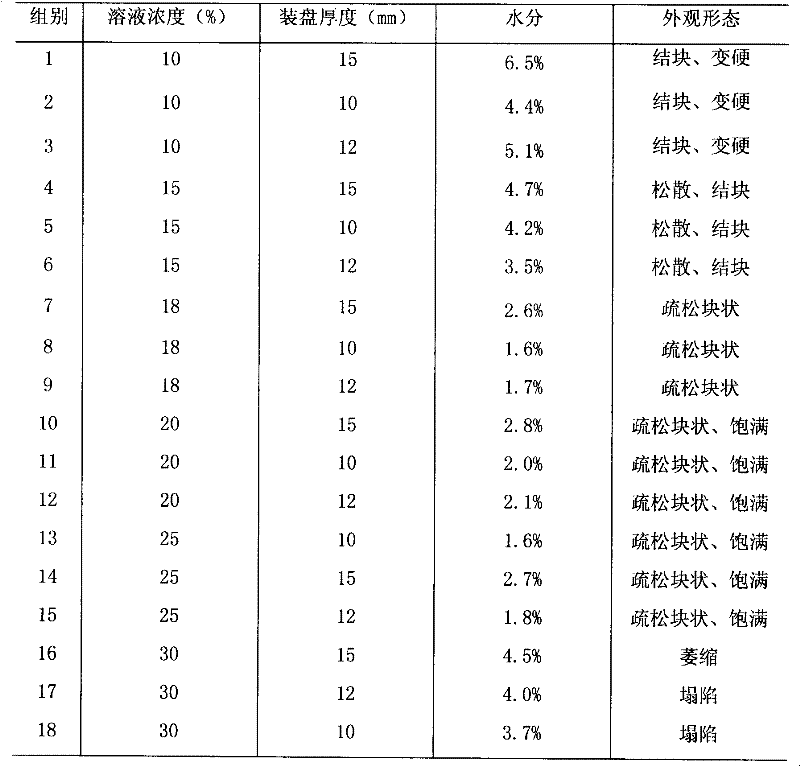

N(2)-L-alanyl-L-glutamine preparation for injection and preparation method thereof

ActiveCN102228444AAvoid stabilityAvoid water solubility effectsPowder deliveryDipeptide ingredientsL-alanyl-l-glutamineFreeze-drying

The invention discloses an N(2)-L-alanyl-L-glutamine preparation for injection and a preparation method thereof. The preparation is prepared through directly preparing a liquid with a raw material N(2)-L-alanyl-L-glutamine, freeze-drying, and carrying out separate packing. The method comprises the following steps: (1) taking the raw material N(2)-L-alanyl-L-glutamine, adding water for injection, and fully stirring to completely dissolve N(2)-L-alanyl-L-glutamine; (2) adding needle active carbon to a solution obtained in step (1), fully stirring, filtering to decarburize, and carrying out germ filtering through passing through a filter with a diameter of 0.2 [mu]m; (3) putting a filtrate obtained in step 2 into a sterilized freeze-dried disc, loading the disc into a cooling chamber of a freeze dryer, and carrying out pre-freezing, vacuumizing, heating, sublimation drying, desorption drying, and vacuum break to end freeze-drying; and (4) accessing high purity nitrogen for drying and degerming, taking out of the chamber, carrying out asepsis packing, tamponading, and capping. So N(2)-L-alanyl-L-glutamine for injection is obtained.

Owner:GUIZHOU YIBAI PHARMA CO LTD

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof

ActiveCN107338020ALow shrinkageReduce pollutionNon-macromolecular adhesive additivesFilm/foil adhesivesHydrogenSilicone oil

An addition type silicone pressure-sensitive adhesive used for medicines and a preparing method thereof are disclosed. Raw materials of the addition type silicone pressure-sensitive adhesive include, by weight, 100 parts of vinyl silicone oil, 5-10 parts of hydrogen-containing silicone oil, 3-5 parts of a filler, 0.03-0.3 part of an inhibitor and 0.03-0.3 part of a catalyst. The pressure-sensitive adhesive is nontoxic, nonirritant, waterproof and breathable, has good initial adhesive force, holding power and peel strength, can be uncovered and adhered repeatedly, and is a pressure-sensitive adhesive material having ideal properties for medicines.

Owner:南宁市六分仪生物科技有限责任公司

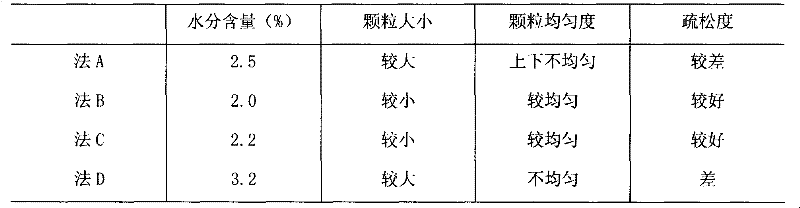

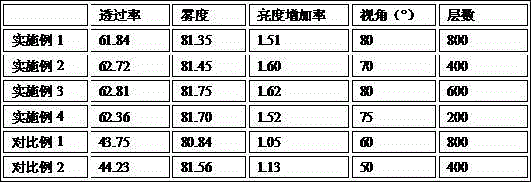

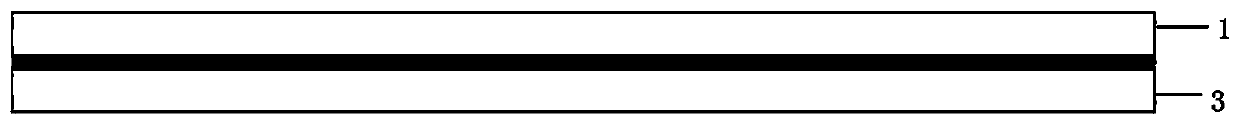

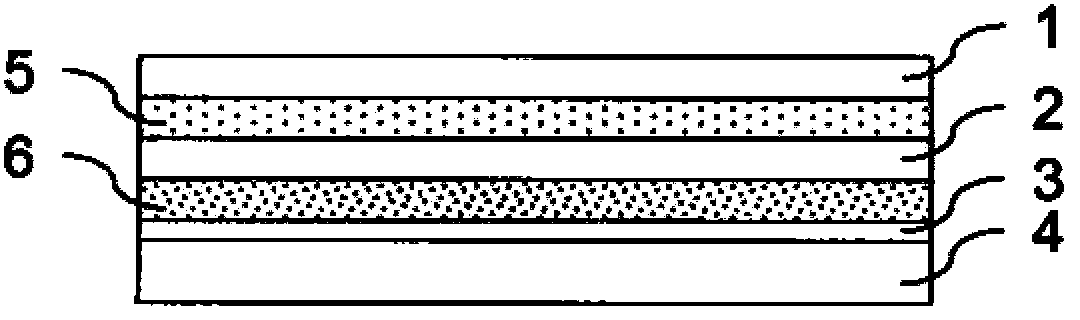

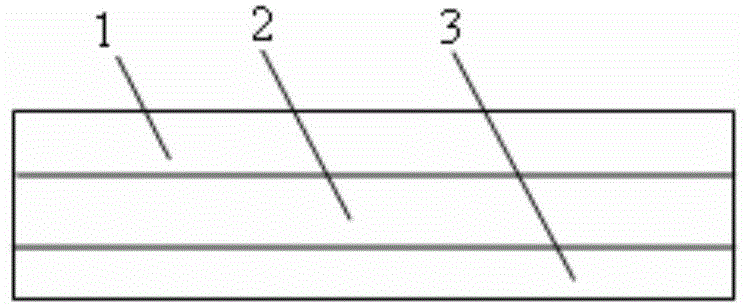

Reflection polarization brightening diffusion composite film

ActiveCN104316986ANo polarizing effectReduce processDiffusing elementsSynthetic resin layered productsDiffusionComposite film

The invention discloses a reflection polarization brightening diffusion composite film which comprises a base film, a first adhesive layer formed on the surface of the base film and a second adhesive layer on the other surface of the base film. A first mist layer is arranged on the first adhesive layer, a second mist layer is arranged on the second adhesive layer, the first mist layer and the second mist layer has uneven surfaces, the first mist layer is provided with a fine mist face with the roughness as 13-17mum and a coarse mist face with the roughness as 25-30 mum, and the fine mist face of the first mist layer is connected with the first adhesive layer. The second mist layer is provided with a fine mist face with the roughness as 13-17mum and a coarse mist face with the roughness as 25-30 mum, the fine mist face of the second mist layer is connected with the second adhesive layer, and the first mist layer and the second mist layer are non-stretching isotropic films. The brightness of the film is improved by over 50% compared with a common prism film, the view angle is increased, and the flow of the base film can be shielded, and the requirement of a backlight module is met.

Owner:昆山乐凯锦富光电科技有限公司

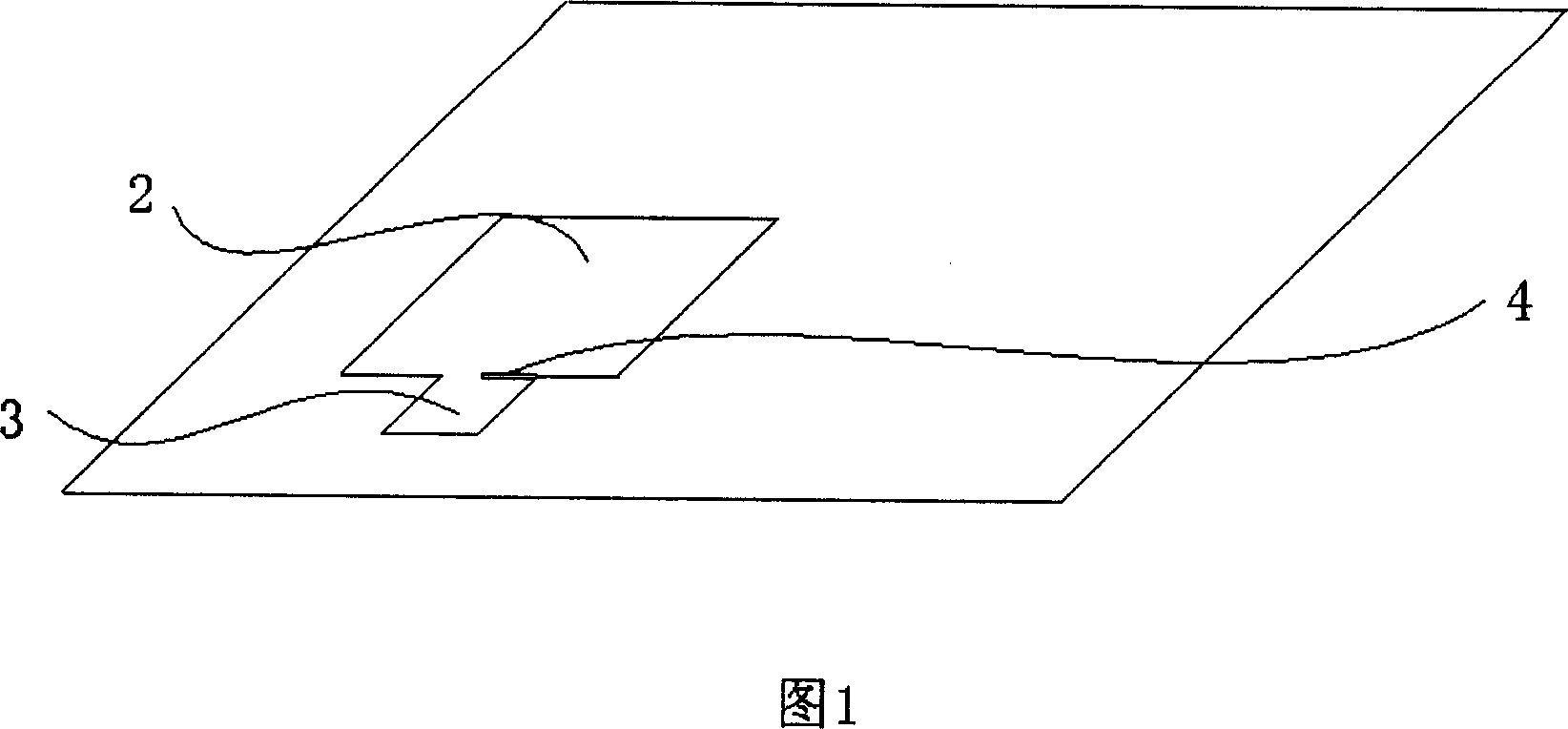

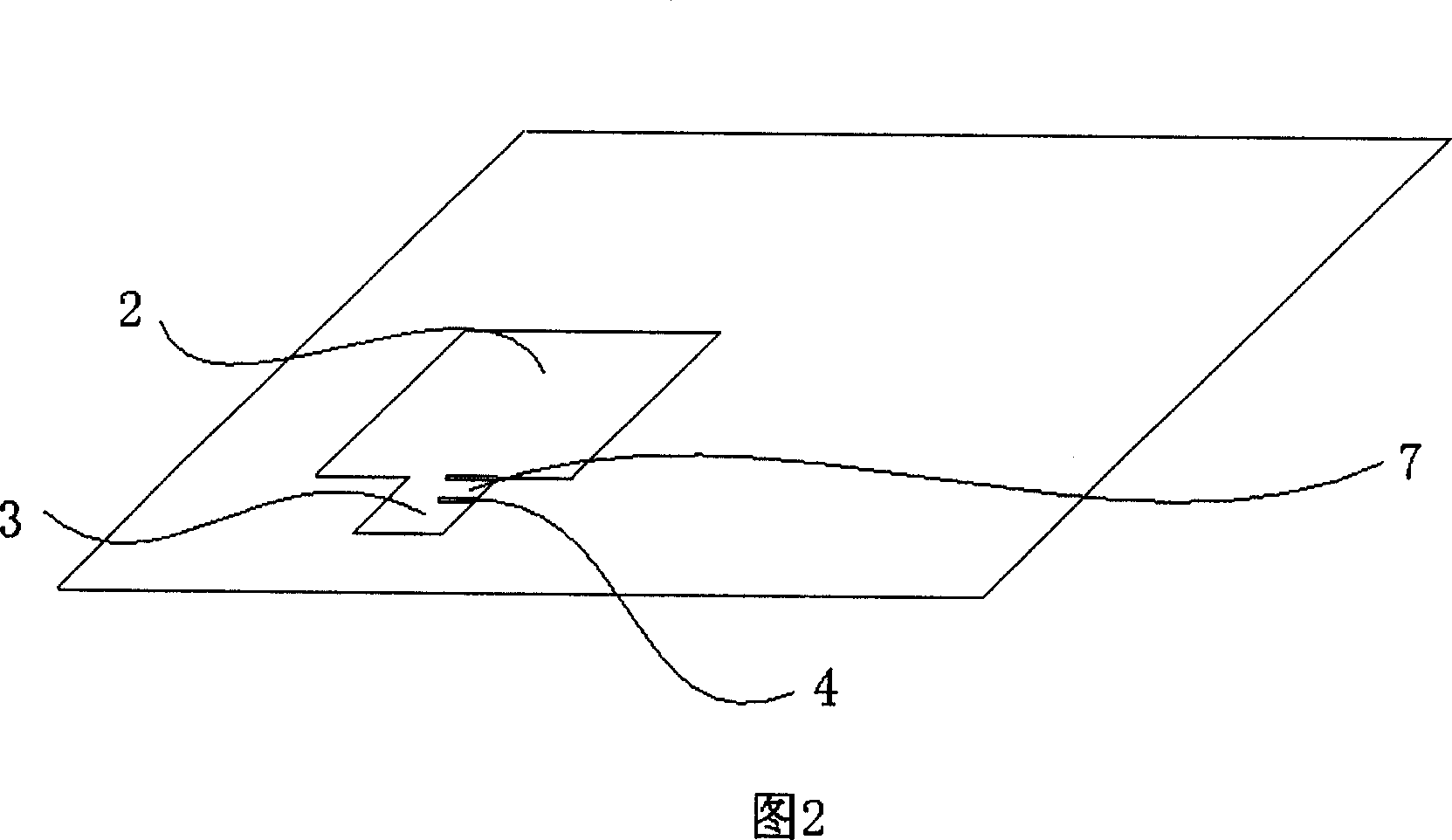

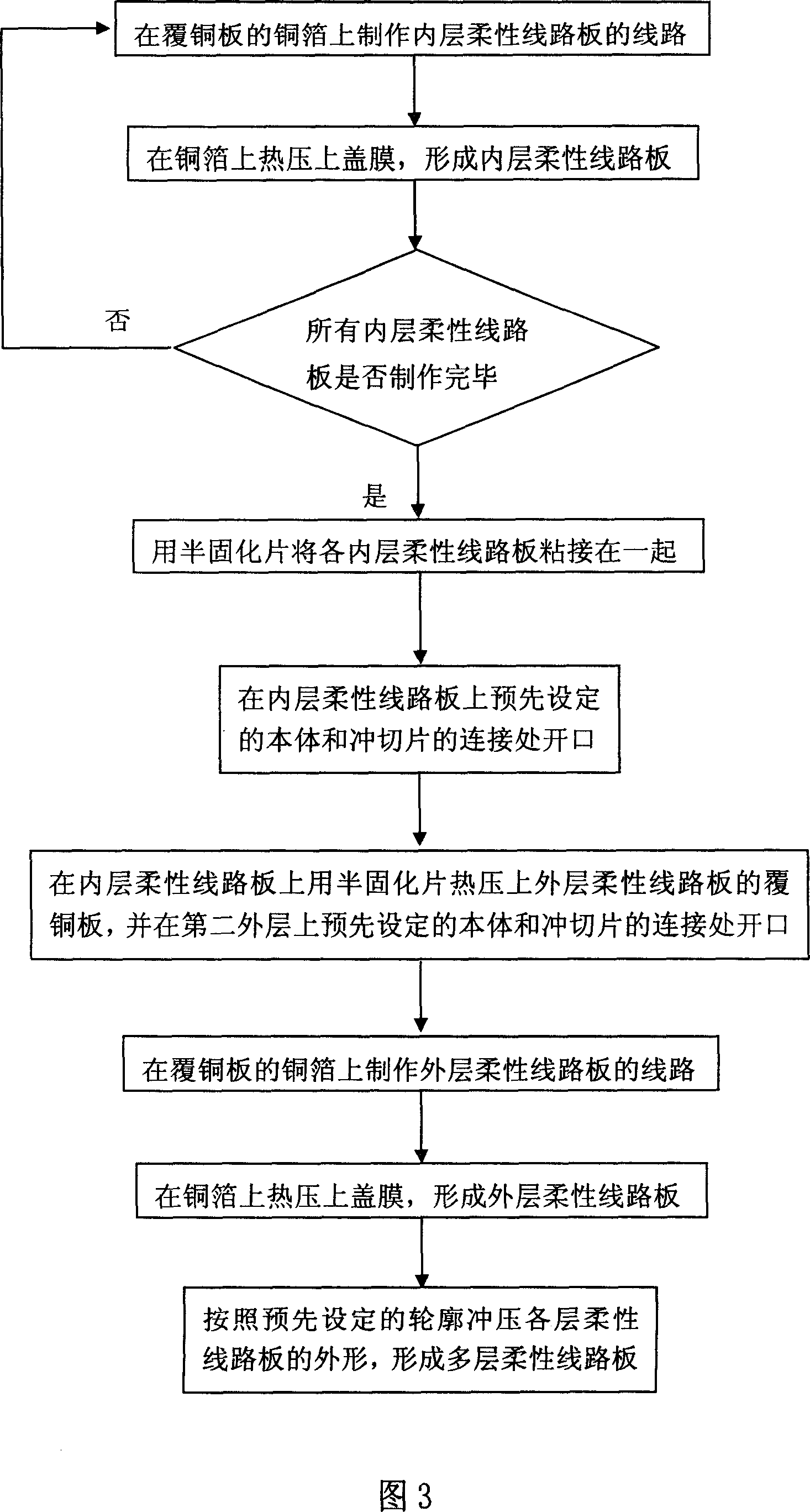

Multi-layer flexible circuit board and its producing method

ActiveCN101064989AAvoid hard-to-locate problemsImprove reliabilityMultilayer circuit manufactureEtchingFlexible circuits

Owner:NAIR ENERGY EQUIP

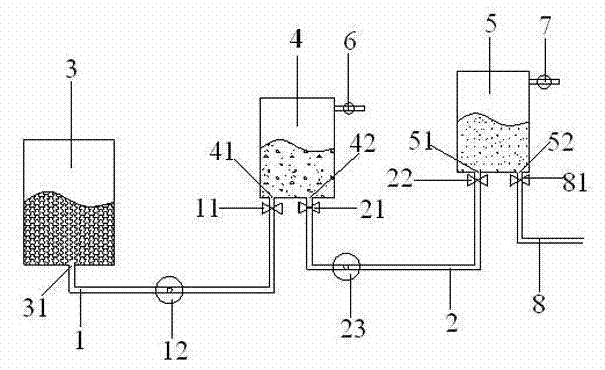

Preparation apparatus and method for lithium ion battery slurry

ActiveCN102824872AWell mixedReduce generationCell electrodesMixing methodsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

Emulsified lipstick and preparation method thereof

ActiveCN109674687AIncrease moisture contentGood moisturizing effectCosmetic preparationsMake-upDimethyl siloxanePolydimethylsiloxane

The invention discloses an emulsified lipstick. The emulsified lipstick is prepared from an emulgator, a humectant, an emollientand a colorant; the emulgator is prepared from the following componentsin parts by weight: 1-8 parts of cetyl PEG / PPG-10 / 1 polydimethylsiloxane, and 1-10 parts of polyglycerol-2 triisostearate. The emulsified lipstick adopts an optimized formula, by applying the cetyl PEG / PPG-10 / 1-polydimethylsiloxane and the polyglycerol-2-triisostearate to the lipstick formula in a certain matching ratio, the lipstick is higher in water content, good in moistening property, and notgreasy. The lipstick of the formula has long-acting moisturizing and moistening effects to lips, and is strong in coloring capacity, lasting in makeup, not easy to fade, less in usage amount of pigment, low in heavy metal content, higher in safety, good in touch and ductility, and not easy to break. Water in the lipstick is adequately dispersed, locked and not easy to volatilize, and a water dropcannot be generated on the surface of the lipstick.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

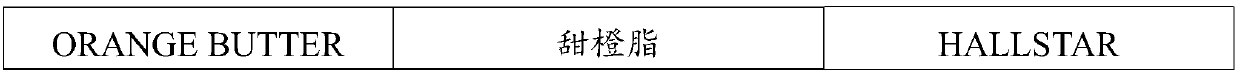

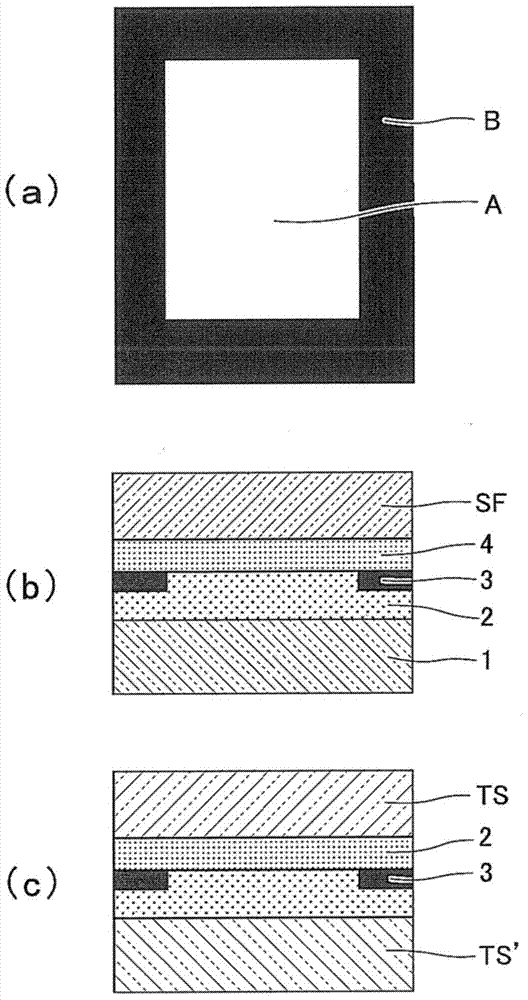

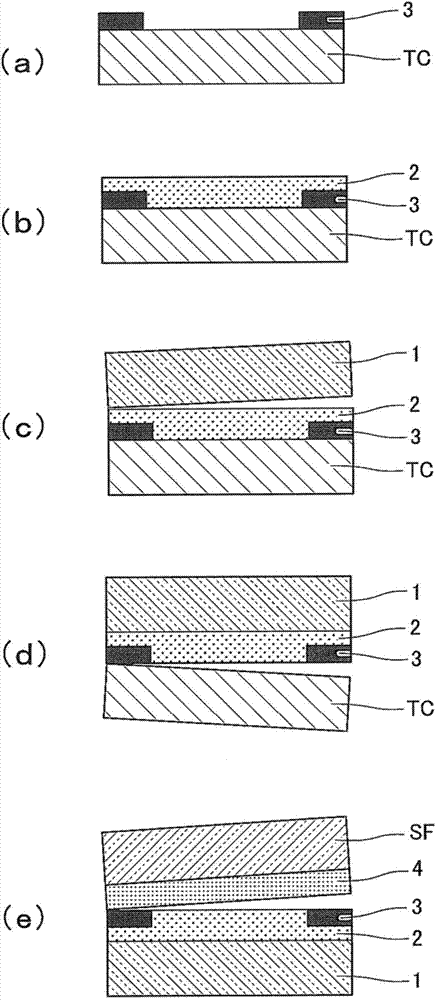

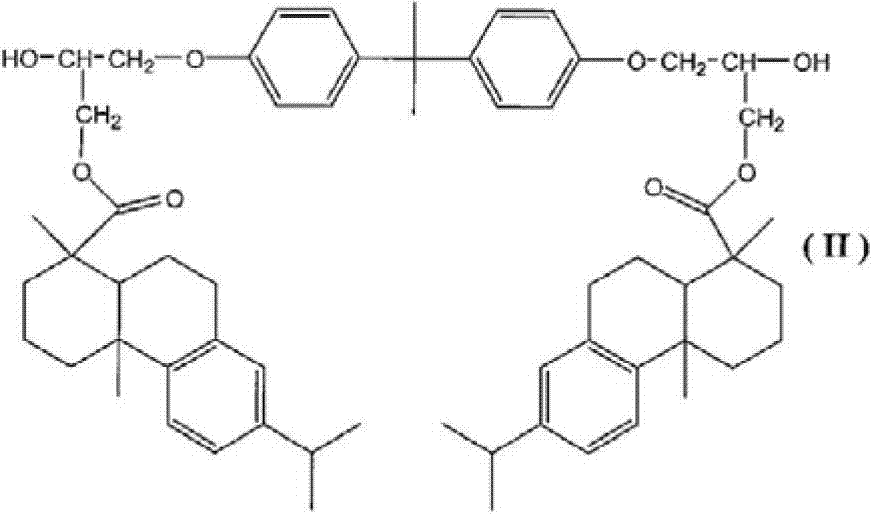

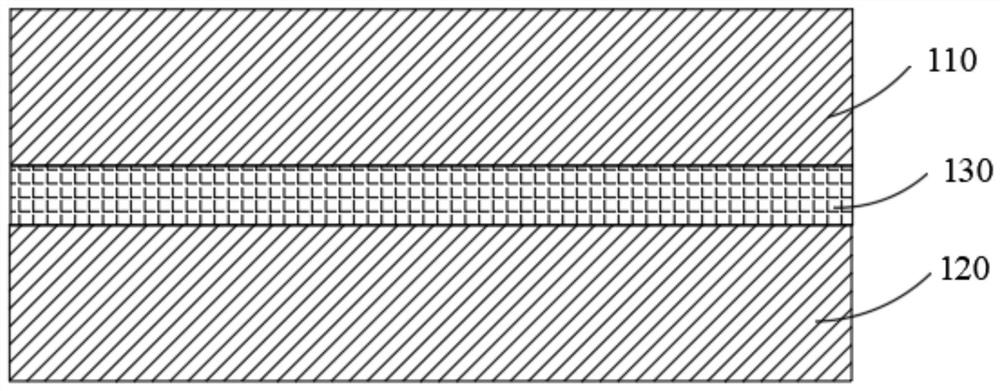

Double-sided adhesive film and manufacturing method thereof

The invention provides a double-sided adhesive film and a manufacturing method thereof, wherein a transparent substrate can be attached to easily form a display panel. Meanwhile, the generation of bubbles, wrinkles and the like is less likely to occur. The double-sided adhesive film is used for the adhesion of a plurality of transparent substrates to form a display panel. The double-sided adhesive film is characterized by comprising a releasable film, and a laminated body formed on the releasable film and provided with a first adhesive layer and a decorative layer. When the transparent substrates are attached together by means of the double-sided adhesive film to form the display panel, the decorative layer is arranged on the laminated body in such a manner that the other part of the display panel, except a display part, is covered by the decorative layer.

Owner:TOPPAN TDK LABEL CO LTD

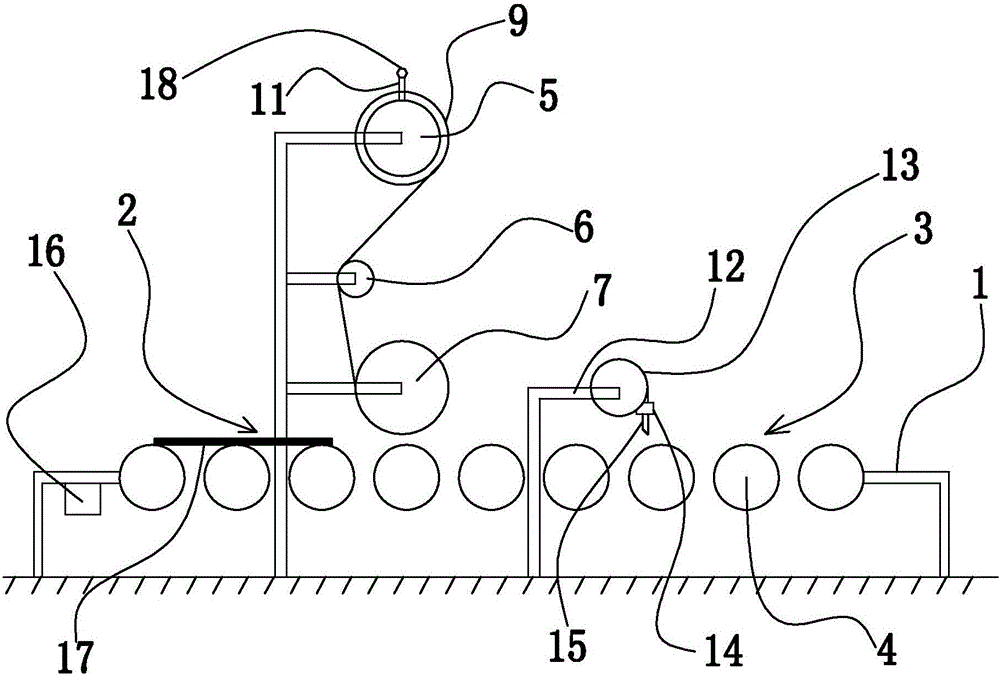

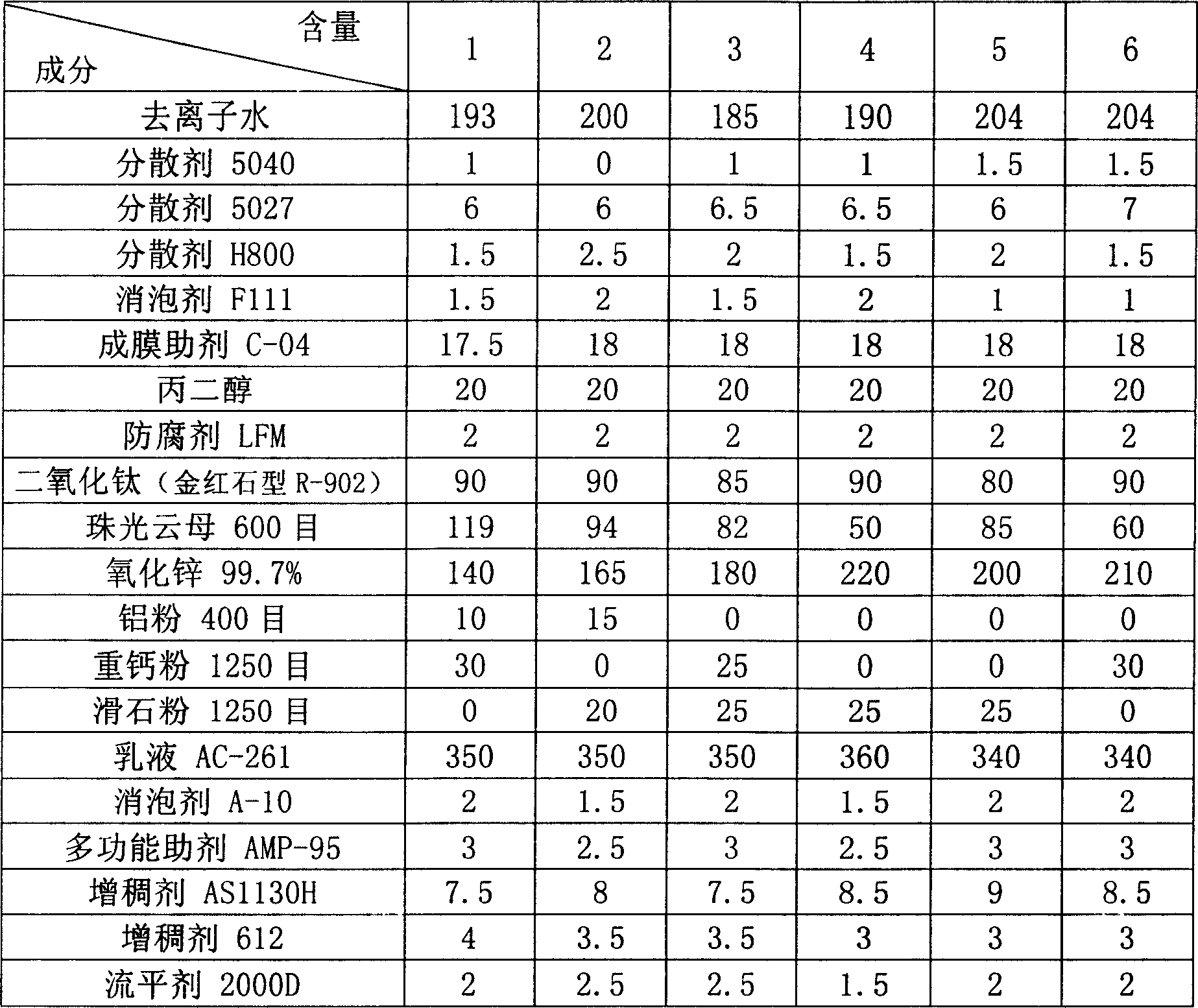

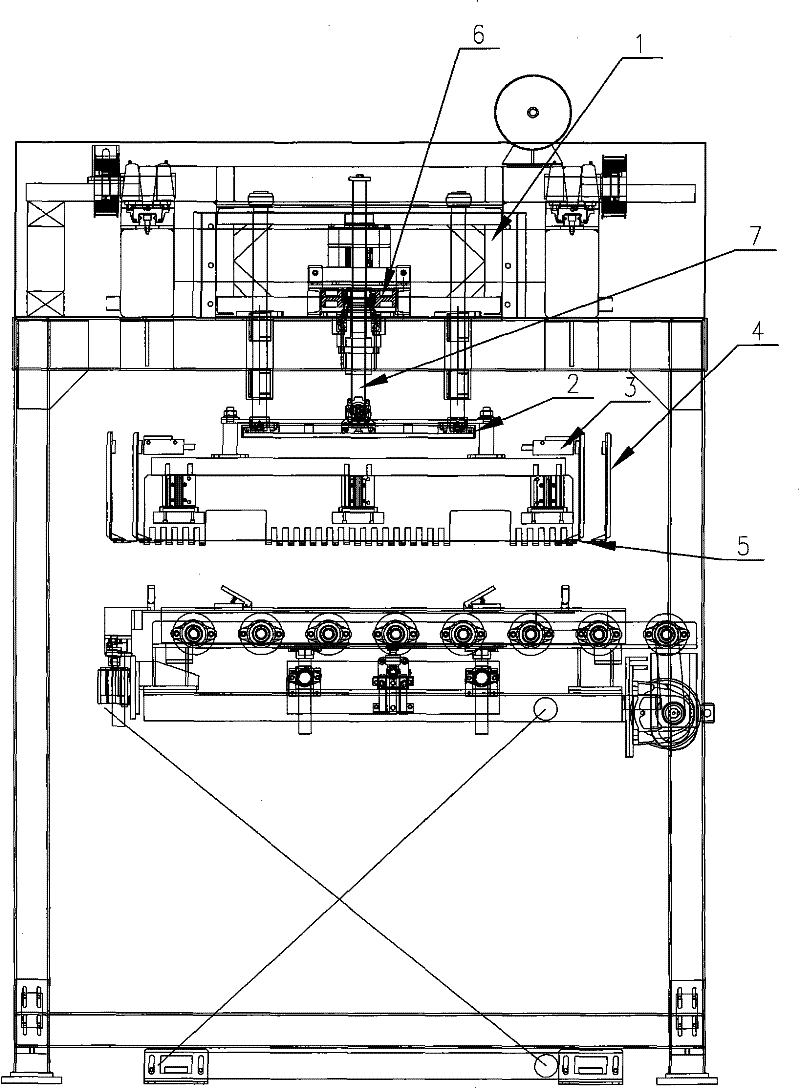

Automatic film pasting equipment

Owner:TIANJIN KUNHAO PLASTIC PROD

Method for manufacturing resin plug hole in PCB

InactiveCN110446350ANo air bubblesReduce plug hole underfillPrinted circuit aspectsPrinted element electric connection formationCopper platingEngineering

The invention relates to the technical field of circuit board production and manufacturing, in particular to a method for manufacturing a resin plug hole in a PCB. According to the invention, silk screen printing of resin ink is performed on the bottom surface and the front side of a production board twice; the resin ink with viscosity of 450-640 dpa.s is screen-printed at a speed of 15-20 mm / s and 30-35 mm / s under a vacuum degree of 40-80 Pa; the fullness of the resin ink in the front hole at the time of the silk screen printing of the first time is controlled of be 60%-70%; and three-stage plate baking treatment is carried out according to the temperature and the time, so that the problem of occurring of bubbles in the resin plug hole can be avoided, and the problem that the plug hole isnot full can be effectively reduced, thereby solving the problems that the resin plug holes of the existing resin plug hole plate are uneven in copper plating or cannot be plated with copper, and plate explosion occurs when a production plate passes through a tin furnace. The silk-screen effect can be further guaranteed by simultaneously controlling the parameters such as the scraper thickness, the scraper angle and the scraper speed, the fullness of the resin ink in the front hole is better controlled, and tiny bubbles contained in the resin ink in the front hole are reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Adhesive agent composition

ActiveCN103025837AIncreased durabilityExcellent whitening suppression abilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHigh humidityCopolymer

To provide an adhesive agent composition that is used in the adhesion of an optical film, exhibits superior durability even in high-temperature high-humidity environments, and has an excellent ability to suppress white spots from arising. [Solution] The adhesive agent composition contains: a (meth)acrylic copolymer (A) containing a carboxyl group; a (meth)acrylic copolymer (B) containing a carboxyl group and a hydroxyl group; 5-20 parts by weight of a tolylene diisocyanate compound (C) for every total of 100 parts by weight of the (meth)acrylic copolymers (A and B); and an epoxy-group-containing silane coupling agent (D).

Owner:NIPPON CARBIDE KOGYO KK

Laminating machine

The invention relates to a laminating machine, which comprises a conveying roller table, wherein the conveying roller table is provided with a lower driving wheel. The laminating machine is characterized in that: a bracket is arranged above the conveying roller table; the bracket is provided with a lower driving wheel corresponding to the upper side of the driving wheel; the outer side of the bracket is provided with a flattening adjustor; the input end of the flattening adjustor is provided with a driven transmission wheel; the input end of the driven transmission wheel is provided with a conveying control assembly; the input end of the conveying control assembly is provided with a film separating assembly; and the input end of the film separating assembly is provided with a viscose glue plastic film input wheel. By adopting the laminating machine, the requirements of thin materials to be processed can be met to the maximum extent, and a plate surface is smooth after laminating. More importantly, air bubbles and crumples are prevented in the processing process. Meanwhile, the defect of film residue or tension fracture of a viscose film occurring during separation can be avoided.

Owner:江苏博腾新材料股份有限公司

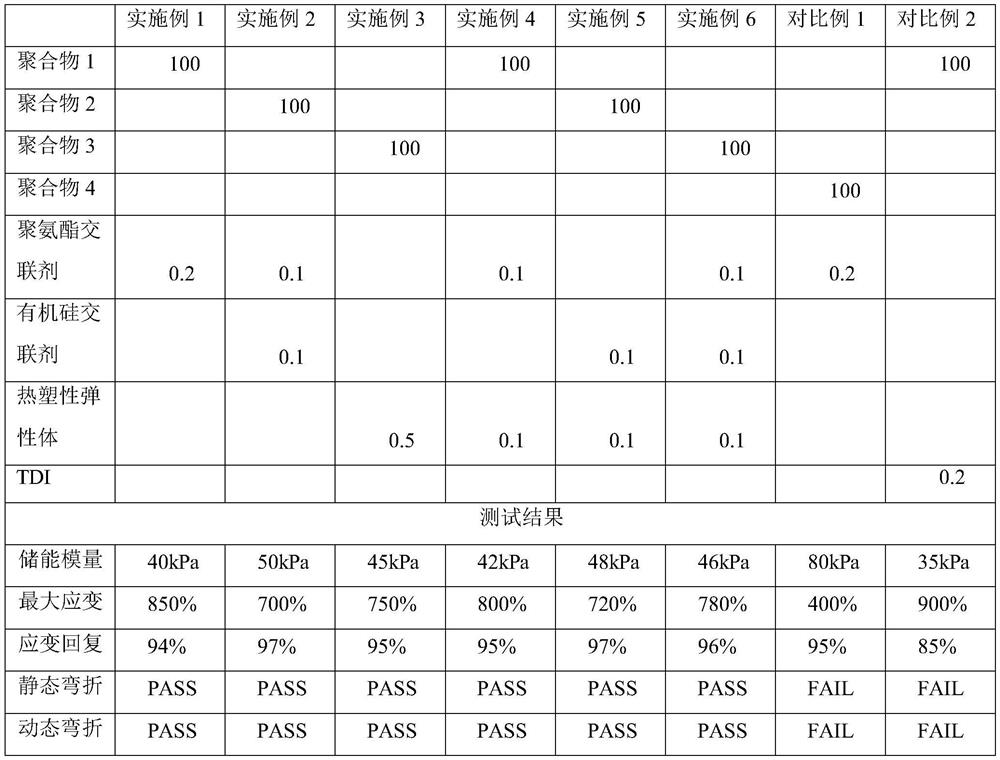

Adhesive for flexible display and flexible display assembly layer

ActiveCN112625623AImprove adhesionMeet the performance requirements of long-term dynamic bendingMacromolecular adhesive additivesEster polymer adhesivesPolymer scienceOligomer

The invention provides an adhesive for flexible display and a flexible display assembly layer. The adhesive for flexible display includes: an acrylate polymer, which has a reactive group in a side chain of the polymer molecular chain; a flexible cross-linking agent, which is an oligomer of which the weight-average molecular weight is greater than or equal to 1kDa; wherein the polymer and the flexible cross-linking agent are cured to form a cross-linked network structure. The adhesive provided by the invention has excellent high and low temperature modulus stability, rapid creep recovery and stress relaxation performance, and greatly prolongs the bending life of the flexible display device on the premise of realizing effective adhesion.

Owner:新纶电子材料(常州)有限公司

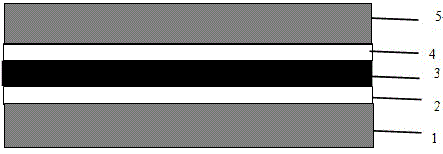

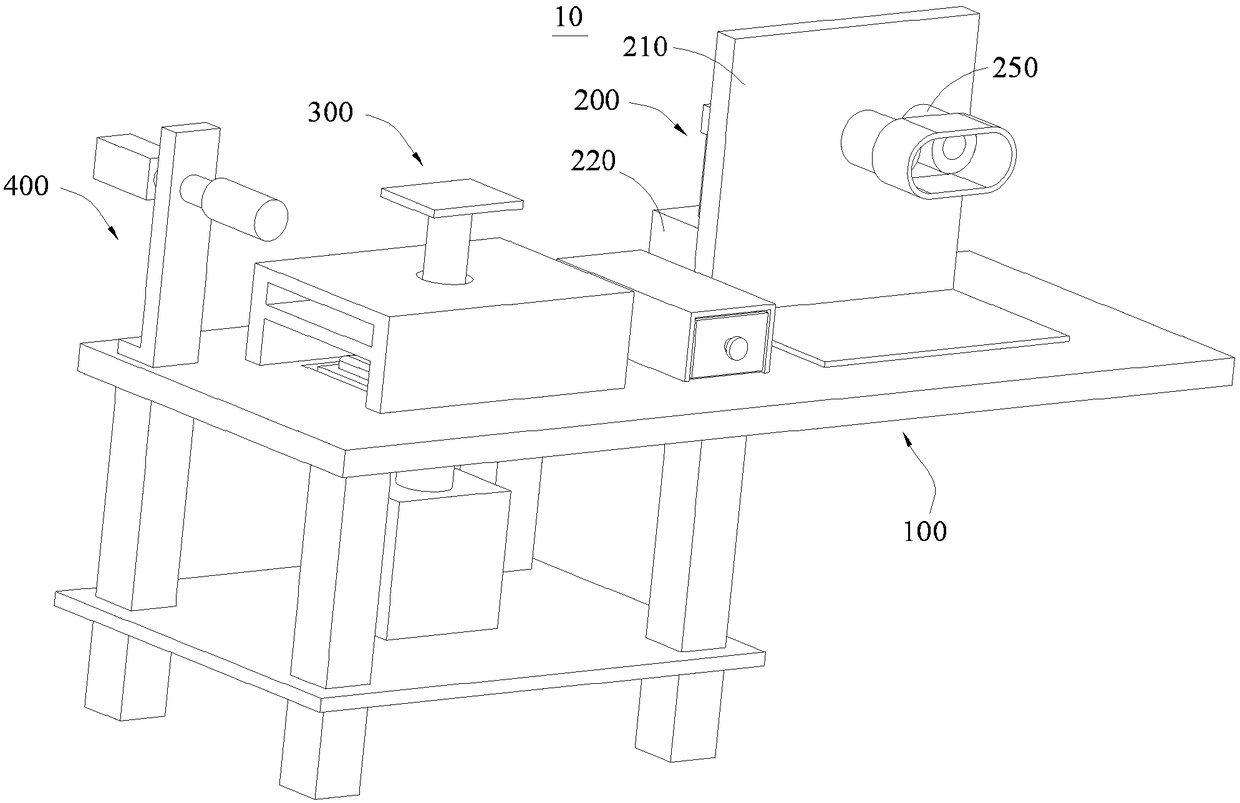

Production process of composite cardboard

The invention discloses a production process of a composite cardboard. The production process comprises the following steps: pulling out the paper head of a cardboard paper scroll; coating glue on a gumming roller (2) of a glue-coating device so that glue is coated by gumming roller (2) on the cardboard paper in rows; passing the coated cardboard paper above scrolled bobbin paper; overlapping the cardboard paper and the bobbin paper to pass the same paper-guiding roller; gluing the lower surface of the cardboard paper and the upper surface of the bobbin paper; pasting the cardboard paper and the bobbin paper together; preheating and conveying the cardboard paper and the bobbin paper which are pasted together into a single-side corrugating machine; pasting at both sides of corrugated paper in the single-side corrugating machine; and thermal pressing and molding into a composite cardboard. The invention firstly gums and pastes the cardboard paper and the bobbin paper, thermally presses and molds with the corrugated paper without leaving bubbles or corrugation between the cardboard paper and the bobbin paper, has low defective rate of the finally molded the cardboard, improves the efficiency, can recycle glue scraped by a scraping gear and save the raw materials and the cost.

Owner:重庆市金山鑫泰包装(集团)有限公司

Rack plating method of trivalent color zinc

The invention relates to the field of electroplating, in particular to a rack plating method of trivalent color zinc. The rack plating method comprises the steps of step I, carrying out thermal degreasing; step II, carrying out primary electrolytic degreasing; step III, carrying out ultrasonic degreasing; step IV, carrying out pickling; step V, carrying out last-stage electrolysis; step VI, carrying out electroplating; step VII, carrying out bright dipping; step VIII, carrying out trivalent color zinc plating; step IX, cleaning with hot water; and step X, placing a treated product in a tray. According to the rack plating method, surface treatment is carried out on a product which has thick grease and is high in rusting degree through combination of thermal degreasing, primary electrolytic degreasing, ultrasonic degreasing and final last-stage electrolysis, the effect is good, and after the product is electroplated, bubbles are avoided.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

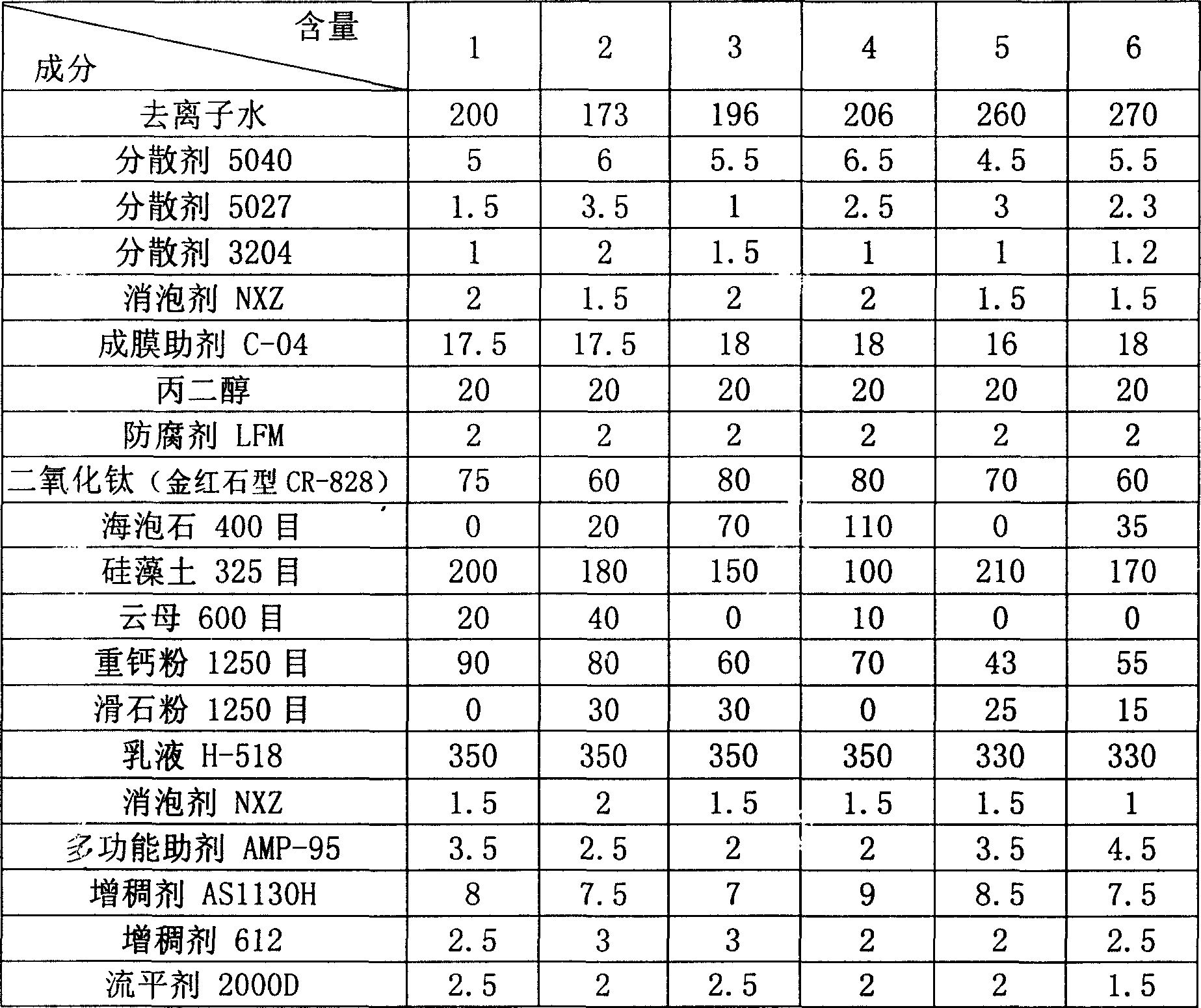

Water thermal insulative reflecting paint

InactiveCN1302078CEasy constructionNo air bubblesPolyurea/polyurethane coatingsEpoxy resin coatingsResource savingPolymer emulsion

Water thermal insulating reflection coating consists of base coat and face coat. The components comprises polymer emulsion, deionized water, thermal insulating material(or reflector material), coating filler and assistants. Its reflectivity can reach 83.5-92.5% and its thermal-radiant ratio can reach 91%. It achieves good radiation, resource saving and better thermal insulating reflection effect.

Owner:四川谷黄金集团有限公司

Film pasting device for screen of touch screen mobile phone

The invention discloses a film pasting device for a screen of a touch screen mobile phone. The film pasting device comprises a mounting table, a film placing assembly and a film pasting assembly; andthe film placing assembly and the film pasting assembly are arranged on the mounting table correspondingly. According to the film pasting device for the screen of the touch screen mobile phone, the mounting table, the film placing assembly and the film pasting assembly are arranged so that the film pasting operation of the mobile phone can be automatically carried out; and compared with an existing film pasting mode, the device is characterized in that the working efficiency is improved, the labor cost is reduced, moreover, the situation that bubbles or the dust do not exist at the pasted mobile phone film is also guaranteed, the flatness of the mobile phone subjected to film pasting is guaranteed to be high, and the experience degree of a user is improved.

Owner:黄慧婵

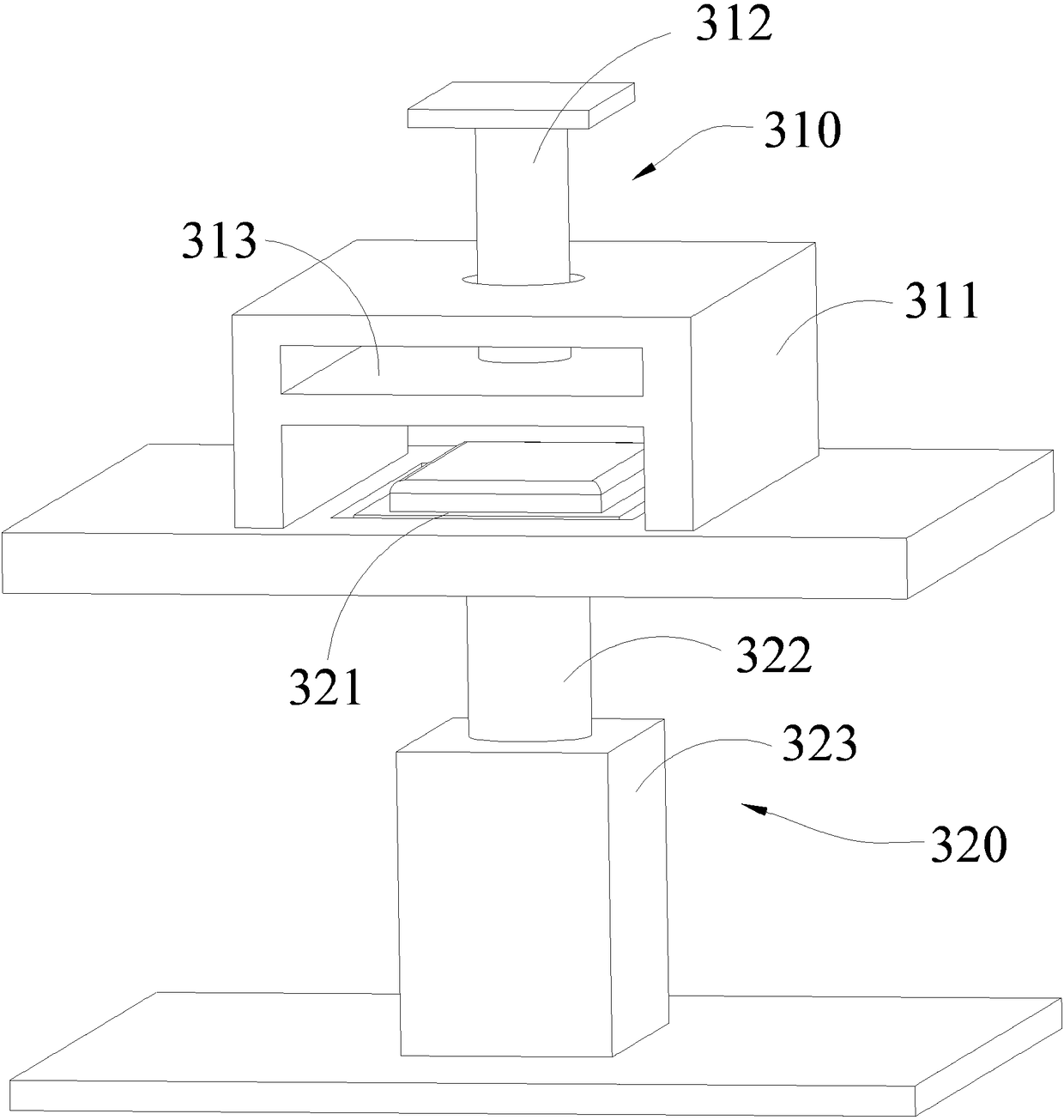

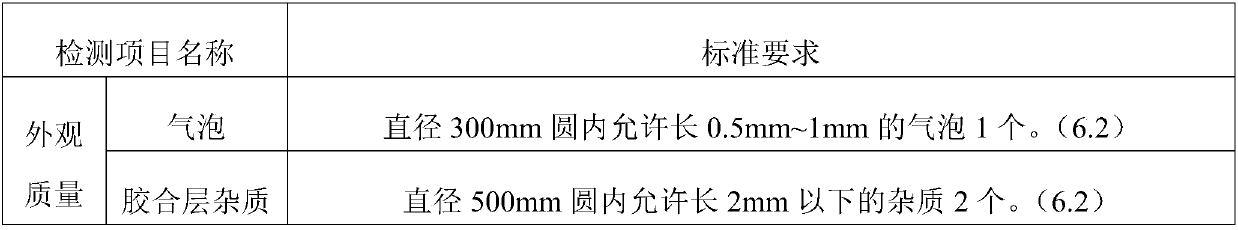

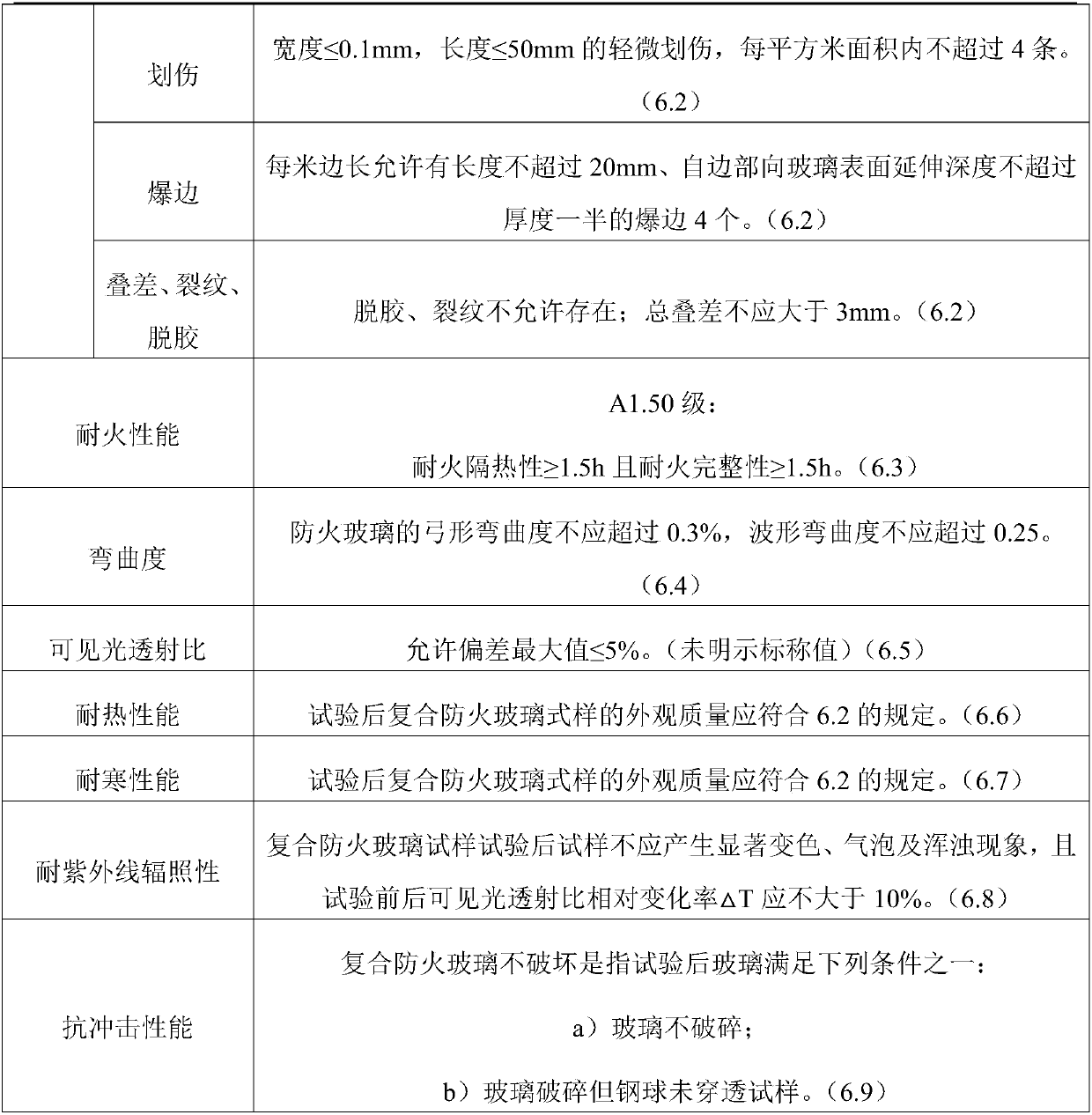

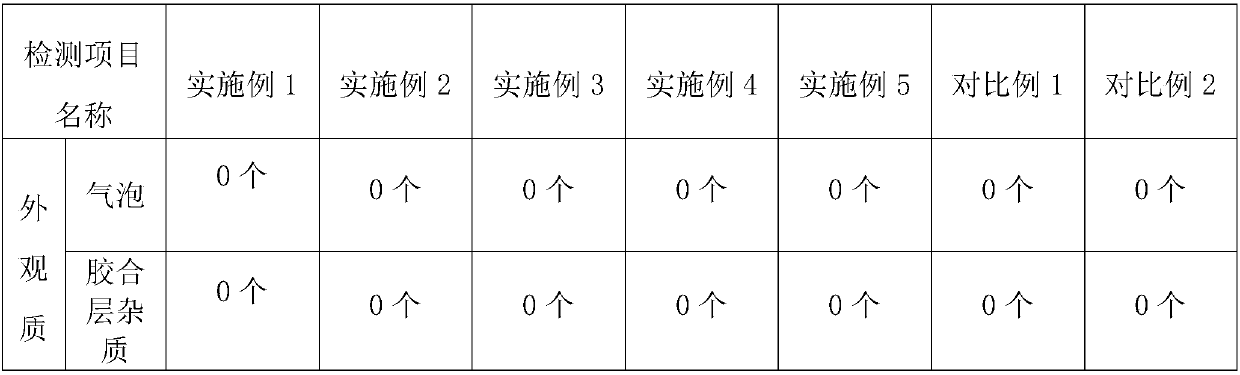

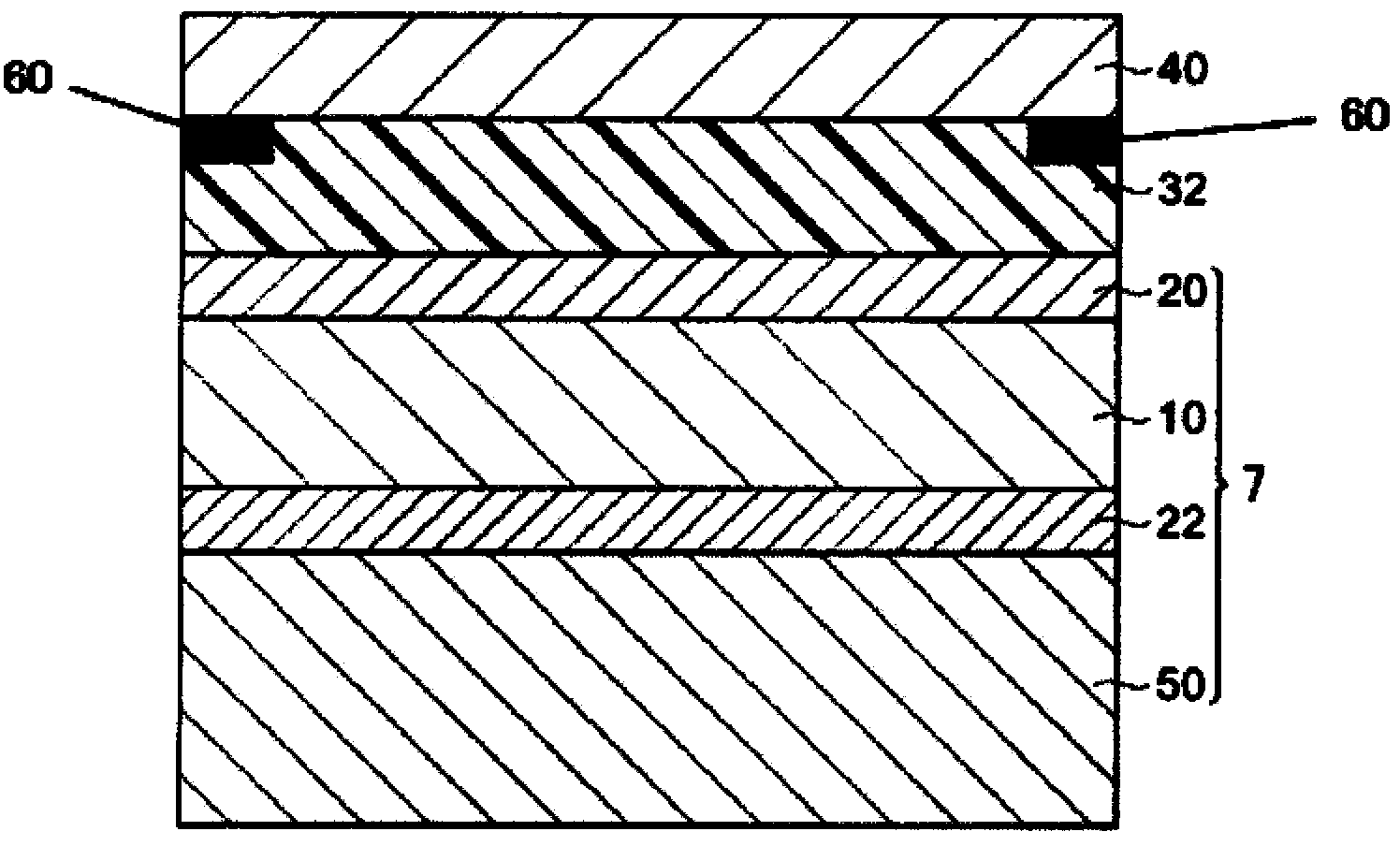

Composite fireproof glass and preparation method thereof

InactiveCN109605866AGood fire resistanceGood impact resistanceNon-macromolecular adhesive additivesSynthetic resin layered productsAmmonium sulfatePhosphoric acid

The invention belongs to the technical field of building material glass and provides composite fireproof glass and a preparation method thereof. The composite fireproof glass comprises two flat glasspieces and fireproof glue. The fireproof glue is arranged in a cavity formed by the two flat glass pieces and characterized by being prepared from, by weight, 125-134 parts of acrylamide,1,800-1,994 parts of water, 420-447 parts of sodium chloride, 1-2 parts of phosphoric acid, 5-10 parts of ammonium persulfate, 5-10 parts of sodium metabisulfite and 0.168-0.192 part of methylene bisacrylamide. The fireproof glass solves the problems that after being irradiated by ultraviolet rays outdoors, traditional fireproof glass can generate bubbles and is lower in light transmittance and the service performance of the traditional fireproof glass is thus seriously influenced.

Owner:河间市晶正玻璃有限公司

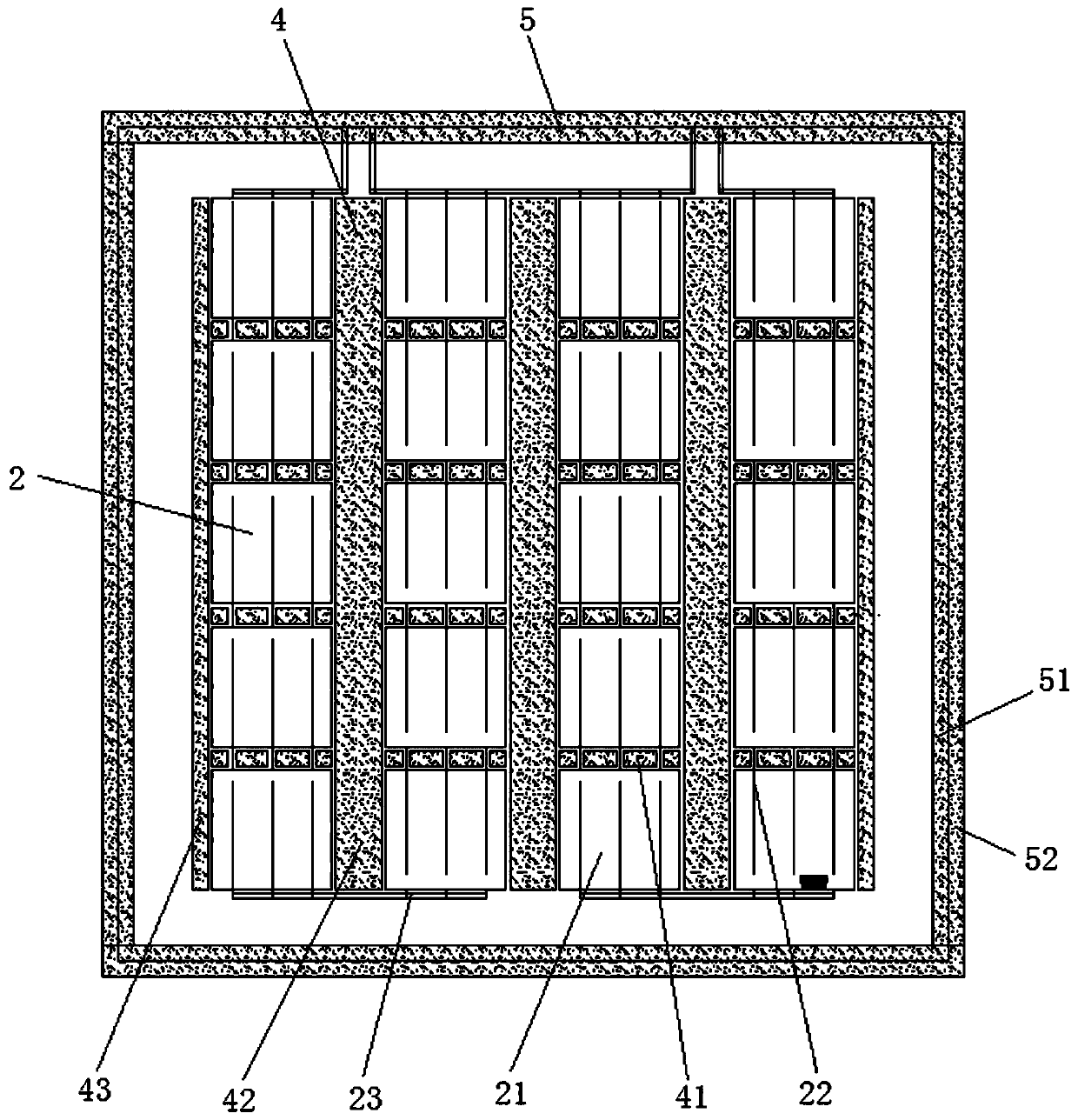

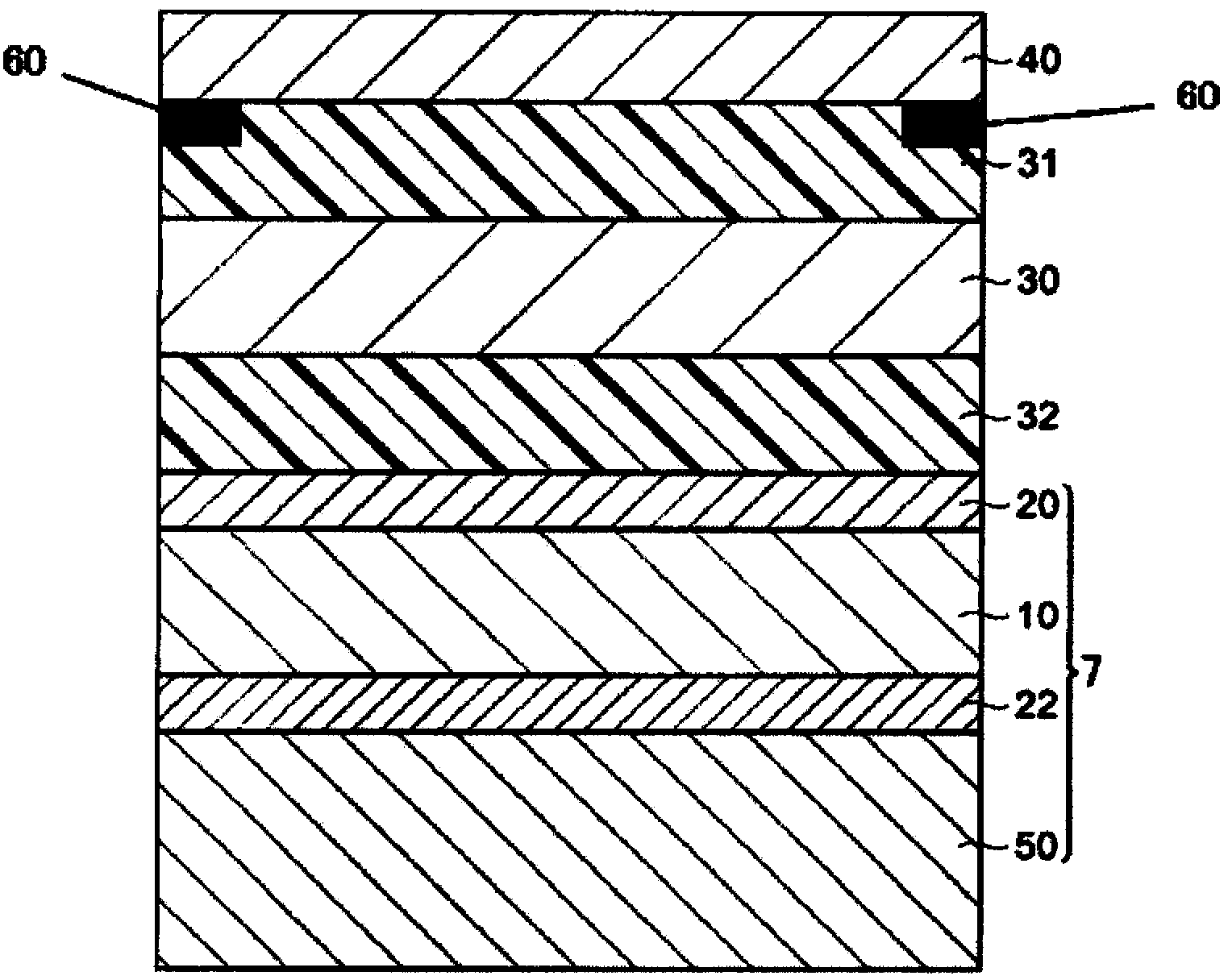

Method for packaging and producing BIPV assembly by using PVB

ActiveCN110212047AIncrease productivityImprove product qualification rateClimate change adaptationPhotovoltaic energy generationEngineeringHigh pressure

The invention discloses a method for packaging and producing a BIPV assembly by using PVB. The BIPV assembly packaging method comprises the specific steps of laying a lower-layer hot-melt adhesive film on clean lower-layer toughened glass; welding battery pieces: welding the battery pieces into battery strings by adopting welding strips; laying the battery strings on the lower-layer hot-melt adhesive film, and welding the battery strings by adopting bus bars; using a small PVB block, a first PVB bonding strip and a second PVB bonding strip to form a middle anti-bubble bonding structure; layingan upper-layer hot-melt adhesive film, and laying upper-layer toughened glass on the upper-layer hot-melt adhesive film; sleeving a first PVB bonding frame body outside the edge of the laid assembly;putting the laid assembly into a laminating machine; putting the laminated assembly into a heating packaging device for curing packaging; and independently putting the packaged BIPV assembly into a dehumidifying room. According to the method, the high-pressure kettle process is omitted, and the secondary air pressure operation is not needed, so that the production time is greatly shortened and the cost is greatly reduced.

Owner:BAODING JIASHENG PHOTOVOLTAIC TECH

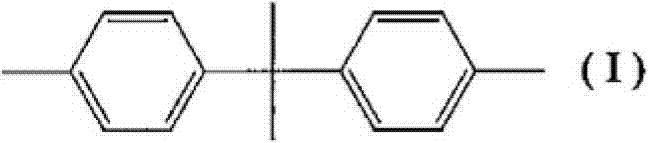

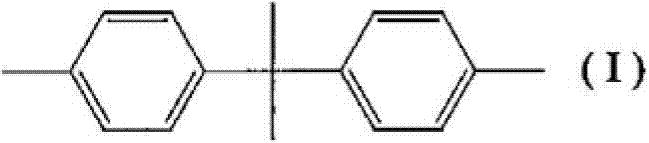

Adhesive sheet for image display device, image display device, and adhesive resin composition

ActiveCN103403119AImprove visibilityImprove impact resistancePolyureas/polyurethane adhesivesEster polymer adhesivesHydrogen atomHigh humidity

Provided is an adhesive sheet for an image display device, the adhesive sheet containing a structural unit that is derived from general formula (a), and having a glass transition temperature of 10-50 DEG C and a tand of 0.5-1.1 at 40-80 DEG C. The present invention can provide the adhesive sheet for an image display device, the adhesive sheet being useful in preventing cracks and mitigating stress and shocks, having excellent transparency, having improvement with respect to cloudiness of a displayed image, flickering, and the like, and in particular, having suppressed occurrence of air bubbles, lifting, peeling, and the like under high temperature conditions (for example, at least 80 DEG C) and high humidity conditions (for example, 85 DEG C / 85% RH or greater). The present invention can further provide an image display device and an adhesive resin composition for an image display device. (In the formula, X is a hydrogen atom or a methyl group.)

Owner:SUZHOU FINESET MATERIAL TECH CO LTD

Copper crinkle removing mechanism

The invention discloses a copper crinkle removing mechanism which comprises a sandwich clamp crane, a support frame, cylinders, mirror surface bending plates and perching knives, wherein in the term of a using direction, the sandwich clamp crane can drive the support frame to move longitudinally, at least two cylinders are symmetrically and fixedly arranged at two sides of the lower end of the support frame, piston rods of the symmetrical cylinders are mutually separated, piston rods of the cylinders at two sides are respectively fixedly connected with the mirror surface bending plates, and mutually close side walls of lower ends of the two mirror surface bending plates are respectively fixedly provided with the symmetrically distributed perching knives. A steel plate of a sandwich plate is rapidly separated and overlapped with a lower copper foil through mutual matching of modes that a sandwich clamp crane drives the support frame to lift and the cylinders drive the perching knives to flex, thus depth of parallelism, planeness and perpendicularity of the steel plate and the lower copper foil are ensured. The copper crinkle removing mechanism is convenient to use, can ensure no existence of bubbles, scratch and damage when a combined copper foil and an eccentric film are spread, and has high production yield.

Owner:KUNSHAN JUHONG MACHINERY TECH

Battery casing and manufacturing process for the battery

InactiveCN101459228AIncrease productivityLarge capacityCell component detailsPunchingMetallic materials

The invention discloses a manufacturing method for battery cases and batteries, which comprises steps as following: utilizing the CA thermal compound process to respectively compound segments of metal materials easy to be welded to an aluminum alloy plate or a pure aluminum plate according to the dimension requirements of a case required to be manufactured, thereby forming a uniform unit between each segment of metal materials easy to be welded and the aluminum alloy plate or the pure aluminum plate, and then cutting and punching the aluminum alloy plate or the pure aluminum plate compounded with the easy-welded metal materials to the case according to the dimension requirements of the case to be manufactured, wherein the punching relates to punching the metal materials easy to be welded to the outside of the case. By utilizing the technical scheme, metal materials easy to be welded can be processed on the battery casing firmer.

Owner:SHENZHEN BAK BATTERY CO LTD

Molding equipment for functional chemical fiber cotton processing

The invention discloses a molding equipment for functional chemical fiber cotton processing, which includes a mold base, the mold base is provided with a mold cavity, and a feeding device for feeding the mold base; the feeding device includes a hot-melt cavity, The feed pipe and the discharge pipe connected to the hot melt cavity, the discharge port of the discharge pipe is located above the mold cavity, and the first control valve is installed on the discharge pipe; the mold base includes an upper mold base, a lower The mold base, the upper mold base is located above the lower mold base, the mold cavity is located on the upper surface of the lower mold base, the upper mold base is provided with a pressing device that matches the shape of the mold cavity, and the discharge pipe passes through the upper mold base and the mold base. A pressing device, one side of the pressing device is provided with an opening for inserting a baffle plate, the opening passes through the discharge pipe, and the opening is located at the bottom of the pressing device. The structural design is simple, which reduces the installation cost; the working principle is simple, and the operation is simple and easy to understand.

Owner:成都开悦家居用品有限公司

Peripheral sealing process of foamed instrument panel

The invention discloses a peripheral sealing process of a foamed instrument panel and a processing technology of automotive interior parts, mainly solving the problems of leakage and lack of materials, and the like of an existing peripheral sealing process of the foamed instrument panel. The peripheral sealing process comprises the following steps: sealing the front edge of the instrument panel bya soft seal, and placing an inflatable sealing strip in a U-shaped groove of a foaming mold; inserting both ends of the inflatable sealing strip into an inflatable core port; heating the foaming mold, paving the surface in a fixing mold to enable the surface to be adsorbed on the fixing mold, placing an instrument panel skeleton on the surface, closing a moving mold and the fixing mold, pressingcopper blocks on the left and right sides of the instrument panel against the surface by a cylinder, and pushing the inner side against the instrument panel skeleton by the moving mold to achieve thesealing effect. The main and co-driver positions are pressed against a sealing rib by the interaction of the moving mold and the fixing mold of the foaming mold to achieve the sealing effect. The sealing strip can be pressed against the front end of the instrument panel after being fully filled to achieve the sealing effect. The peripheral sealing process has the advantage of avoiding the problemof leakage and lack of materials of the foamed product.

Owner:JINXING AUTOMOTIVE INTERIOR DECORATION

Removable vehicle paster and preparation method and application thereof

InactiveCN107603508AEasy to removeEasy to integrateNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedBenzoyl peroxide

The invention belongs to the technical field of materials and especially relates to a removable vehicle paster and a preparation method and application thereof. The vehicle paster successively contains a water-based ink-jet ink-drawing layer, a primer layer, a PVC layer, a removable pressure sensitive adhesive layer and release paper. The water-based ink-jet ink-drawing layer is obtained by mixingand stirring 17-20% of water-based ink-drawing resin, 0.5-1% of a wetting agent and 79-82.5% of water. The primer layer is obtained by mixing and stirring 10-20% of water-based resin, 0.5-1% of a wetting agent and 89.5-79% of water. The removable pressure sensitive adhesive layer is composed of 20-30% of butyl acrylate, 1.5-3% of acrylic acid, 15-23% of methyl methacrylate, 0.5-2% of benzoyl peroxide, 18-30% of toluene, 27-40% of ethyl acetate, 1-5% of a curing agent, 1-5% of latex powder and 2-6% of nano-attapulgite. The vehicle paster can 100% remove residual gum, has good curved surface adhesion, and has no bubble, crease or edge warping phenomena.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

Super-sticky precoating and preparation method and application thereof

ActiveCN104927695AImprove adhesionNo air bubblesFilm/foil adhesivesSynthetic resin layered productsHot meltDigital printing

The invention provides a super-sticky precoating and a preparation method and application thereof. The super-sticky precoating comprises a base material layer, a holt-melting glue layer and a polyethyleneimine layer which are in contact in sequence. Compared with the prior art, the super-sticky precoating comprises the polyethyleneimine layer, so that the super-sticky precoating has strong bonding force, and the phenomena of bubbles, coating disengagement and infirm bonding can be avoided in the coating process; the super-sticky precoating can penetrate through silicon oil, ink and other substances, the effect of perfect bonding with a printed material can be achieved, and the service life of the printed material is prolonged. It is shown through test results that after a digital printing paper sheet is covered by the super-sticky precoating, the phenomenon of bubbling and disengaging can be avoided in the folding process, and the bonding intensity of the super-sticky precoating is larger than or equal to 3.0 N / m.

Owner:NEW ERA IND

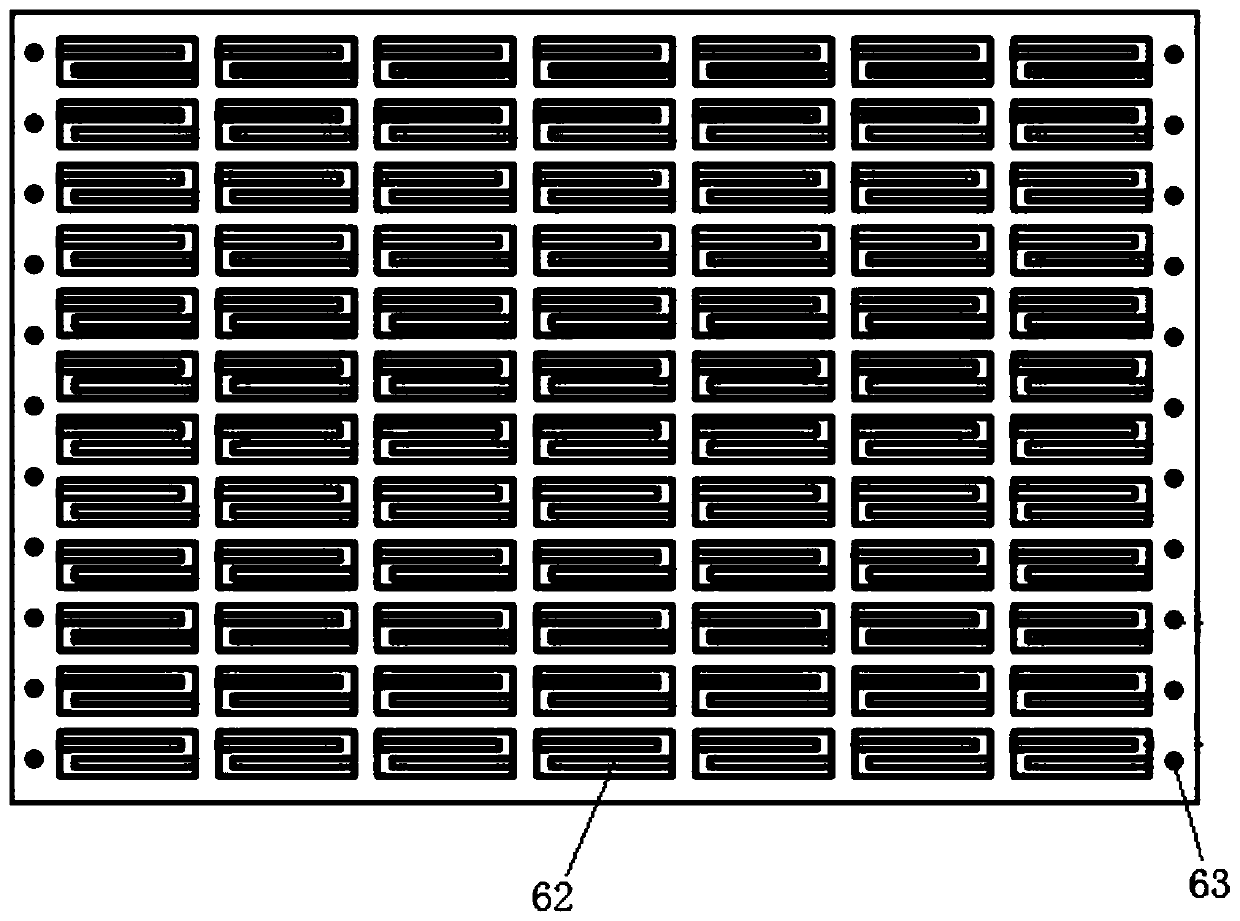

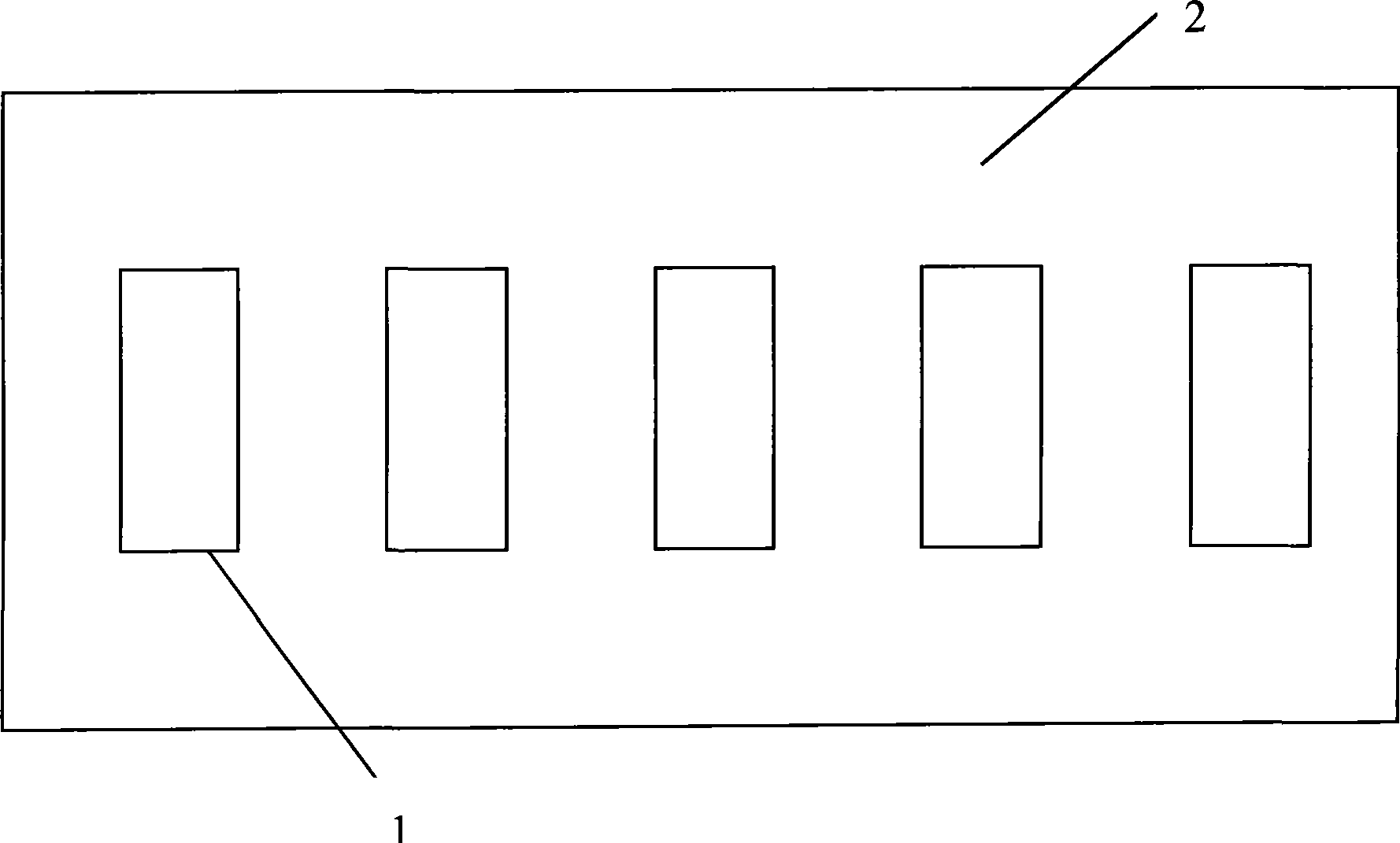

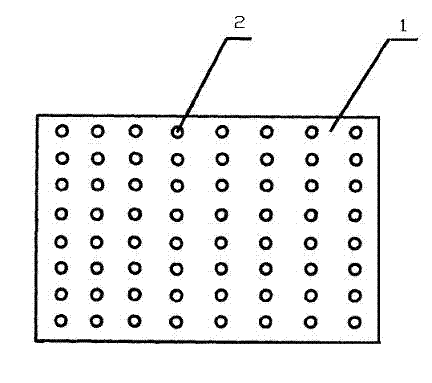

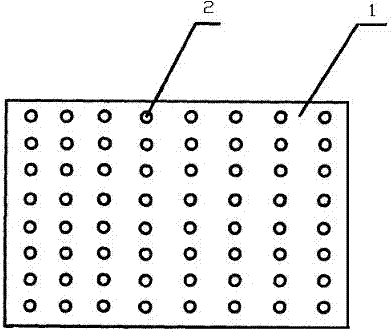

perforated plastic film

The invention discloses a plastic film with holes, which comprises a film base (1) and holes (2), the holes (2) are evenly distributed on the film base (1), and the holes (2) are adjacent to each other in the horizontal and vertical directions. ) between 5-10mm. The hole (2) is a round hole or a square hole. The beneficial effects of the invention are: the perforated plastic film involved in the invention has a simple structure, relatively low cost and is practical. Compared with plastic film without holes, it saves raw materials, and no air bubbles appear during use.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com