Manufacture method of color filter

A technology of color filter and manufacturing method, which is applied in the direction of optical filter, optics, optical components, etc., can solve the problems of not having high temperature resistance, bubble bonding, and poor quality, and achieve the effect of improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

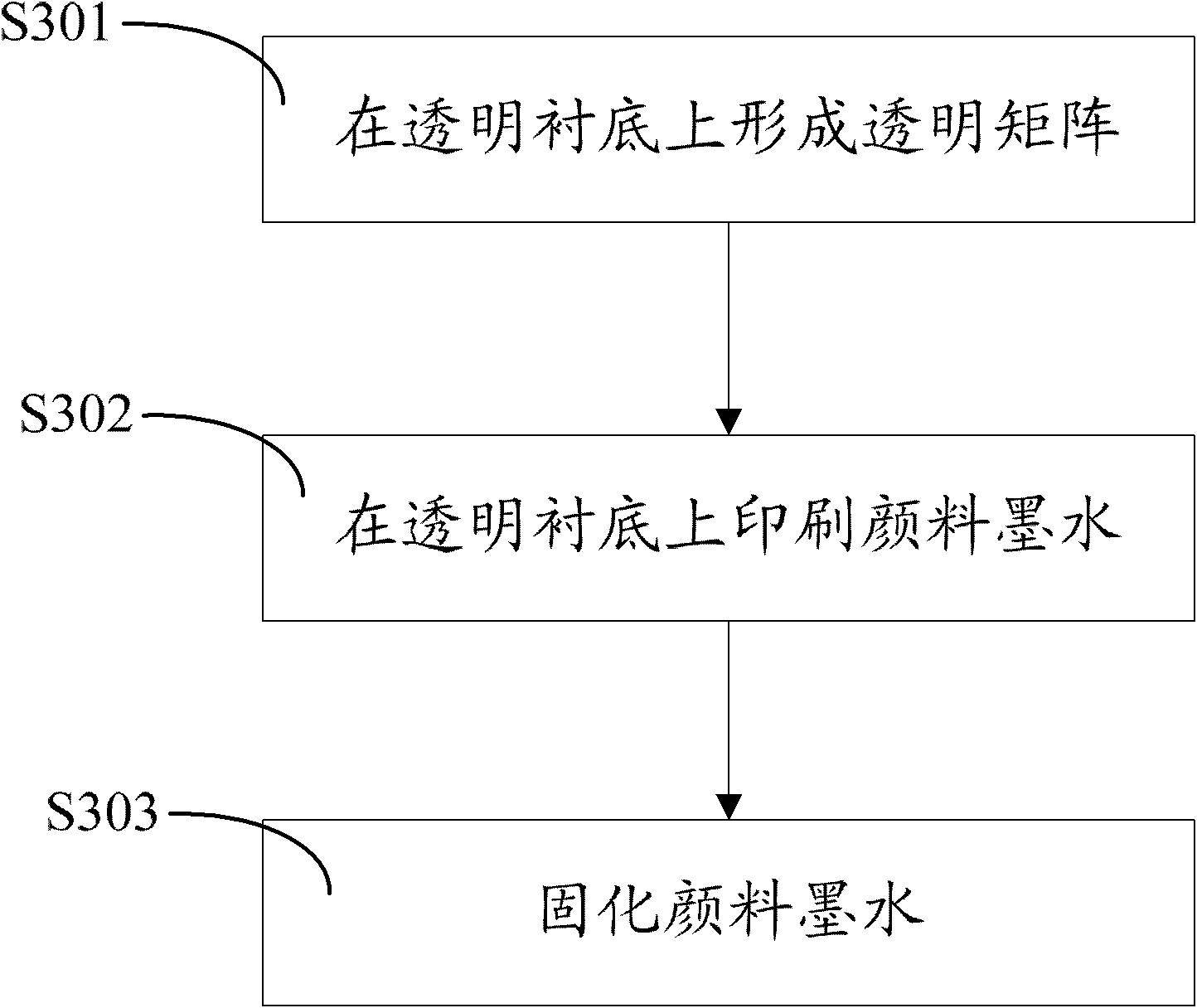

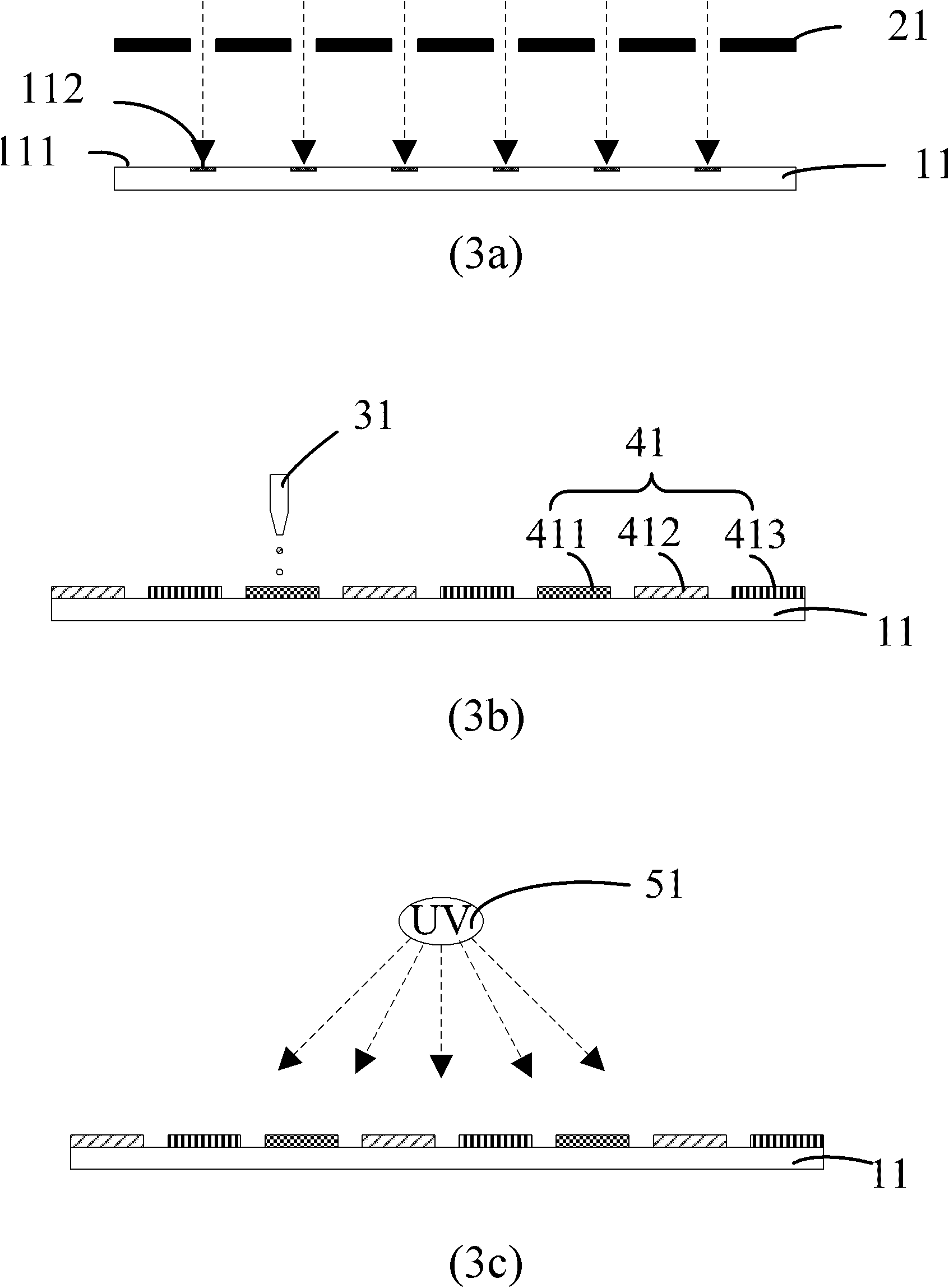

[0018] see figure 1 , is a flow chart of the method for manufacturing the color filter with a flexible substrate in a preferred embodiment of the present invention. The method includes steps: Step S301, forming a transparent matrix on a transparent substrate, the transparent matrix divides a plurality of pixel regions on the transparent substrate, and the transparent matrix and the pixel regions have different surface wettability; Step S302, Use the inkjet printing method to apply pigment ink in multiple pixel areas, specifically, inkjet printing is used to position the pigment ink (red pigment ink, green pigment ink, blue pigment ink) on the pixel by using nozzles In the area; step S303, curing the pigment ink to form a plurality of color filter films, wherein specifically exposing the transparent substrate coated with the pigment ink to an ultraviolet light source.

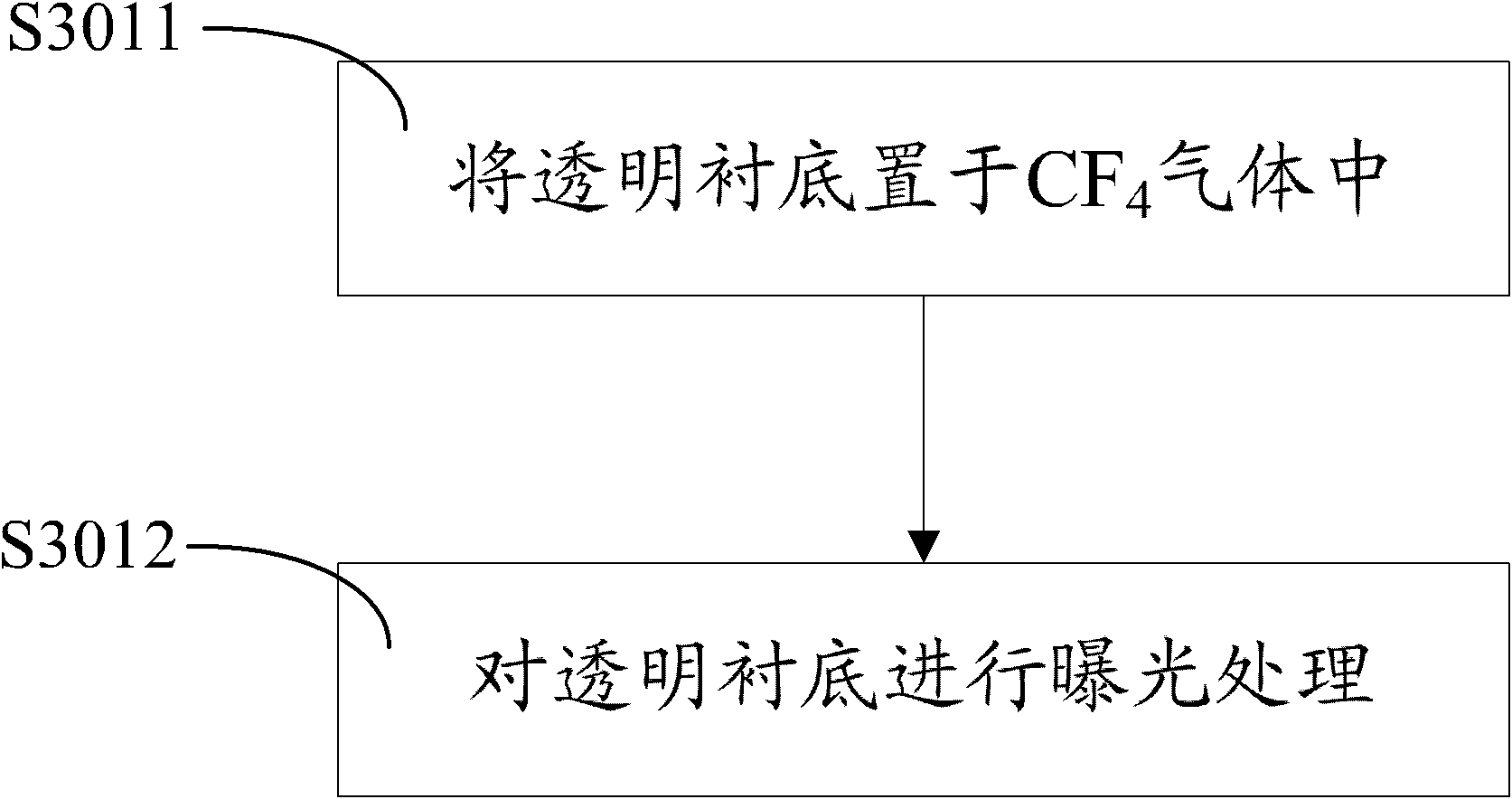

[0019] Please also refer to figure 2 and image 3 , figure 2 It is a subflow chart of step S301 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com