Multi-layer flexible circuit board and its producing method

A flexible circuit board and outer layer technology, which is applied in the direction of multilayer circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of affecting the product yield rate, circuit etching circuit break, and dry film pressing, so as to improve reliability , Simple operation, good reinforcement effect

Active Publication Date: 2007-10-31

NAIR ENERGY EQUIP

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The gold finger area of the multi-layer flexible circuit board is a dynamic area. Generally, during the design and manufacturing process, the inner layer corresponding to the gold finger area is washed away to avoid it, so as to meet the thickness requirements and bending performance requirements of the gold finger are

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

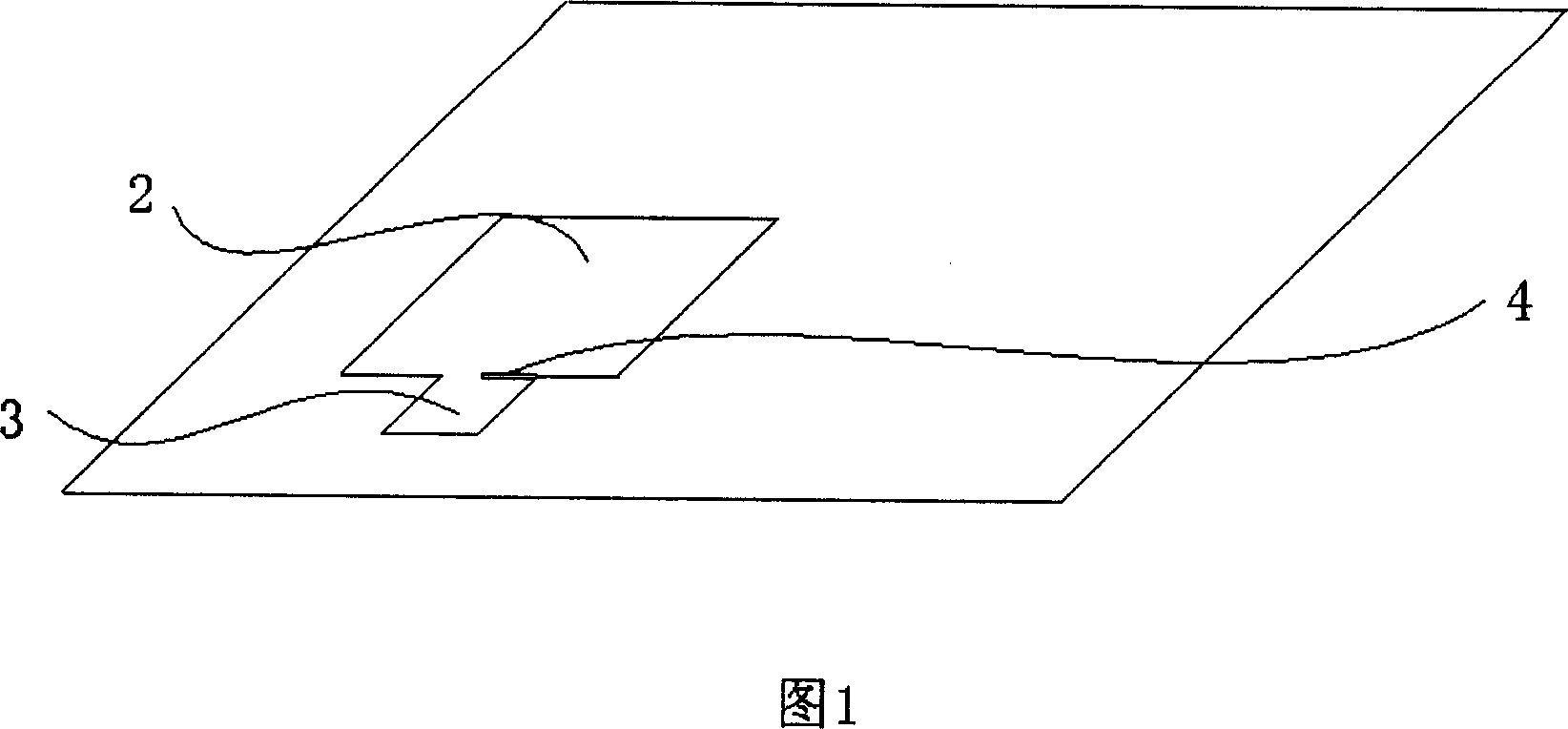

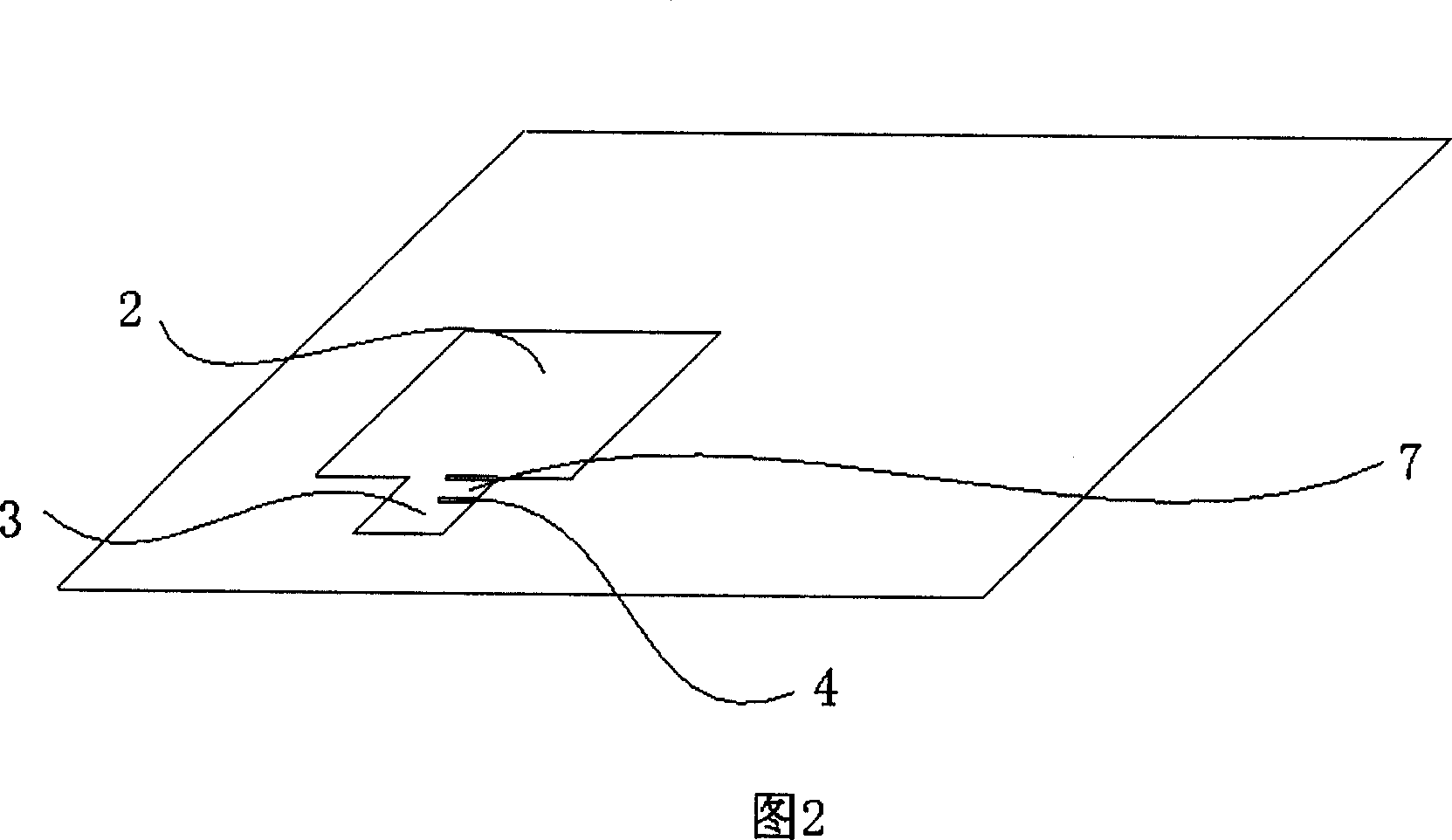

Abstract

The invention discloses a multiple layer flexible circuitry board and preparing method, it includes three layers or more than three layers of single flexible circuitry board, and each of which is adhibited with half solid piece, the first outer layer possesses golden finger area for setting golden finger, the inner layer separately includes entity and die-cutting piece which can be tore with each other; the second layer includes entity and die-cutting piece which can be tore with each other, the die-cutting piece of inner layer and the second layer aligns at the golden finger area of the first outer layer. During the pressure of the multiple layer flexible circuitry board, the inner layer and the second layer which aligns at the golden finger area of the first outer layer are always kept, that is the die-cutting piece, so the altitude difference between the golden finger area and other area can be decreased, so dry film is pressed on outer layer, the perfect fill will be realized, and without air bubble, later perfect line etching is guaranteed, the problem of ill plough of line can be avoided.

Description

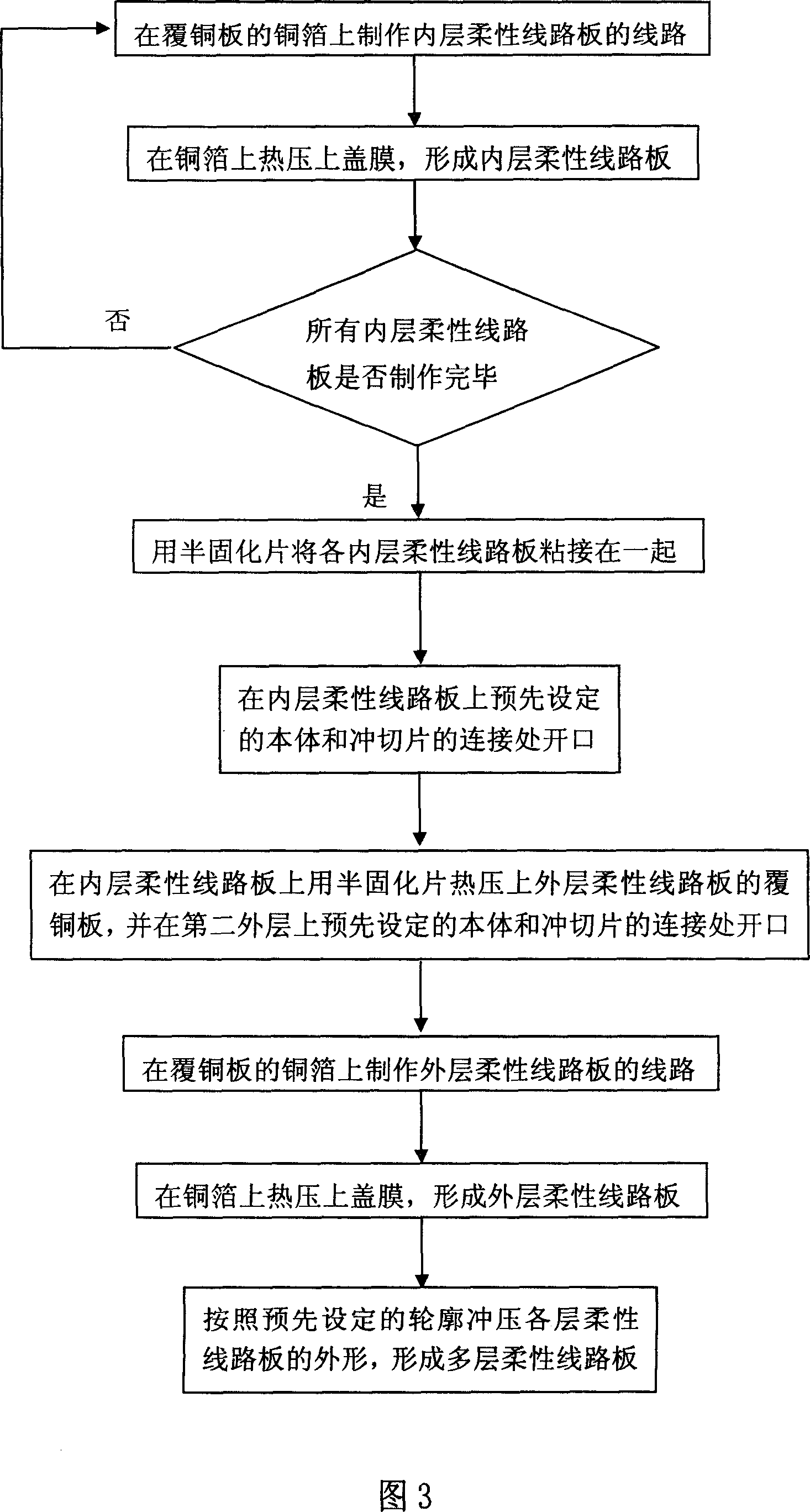

technical field [0001] The invention relates to a multilayer flexible circuit board and a manufacturing method thereof. Background technique [0002] With the miniaturization and lightweight development of various electronic devices, flexible circuit boards with small size, high heat resistance, superior bending performance and multi-functionality are required, and multi-layer flexible circuit boards have emerged as the times require. [0003] Multi-layer flexible circuit board is formed by several single-layer flexible circuit boards, which are formed by adding adhesive between layers and curing the adhesive by hot pressing to achieve firm bonding between layers. The cured adhesive is a prepreg . The multi-layer flexible circuit board also has a dynamic area, that is, an area without adhesive between layers. The dynamic area can be bent and bent, and has excellent bending performance. [0004] The gold finger area of the multi-layer flexible circuit board is a dynamic a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K1/00H05K3/46

Inventor 解耀平

Owner NAIR ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com