Patents

Literature

425results about How to "No creases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

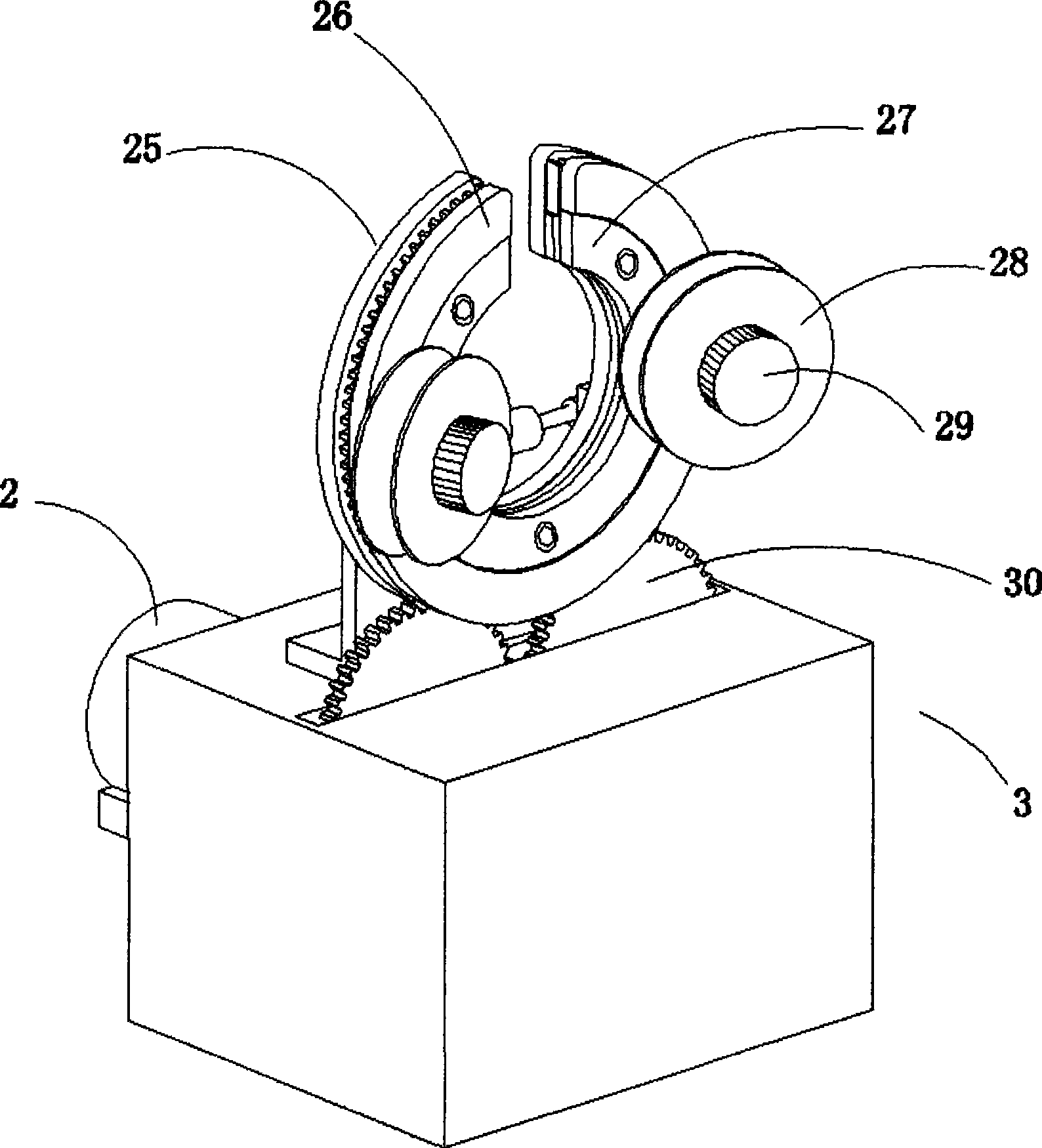

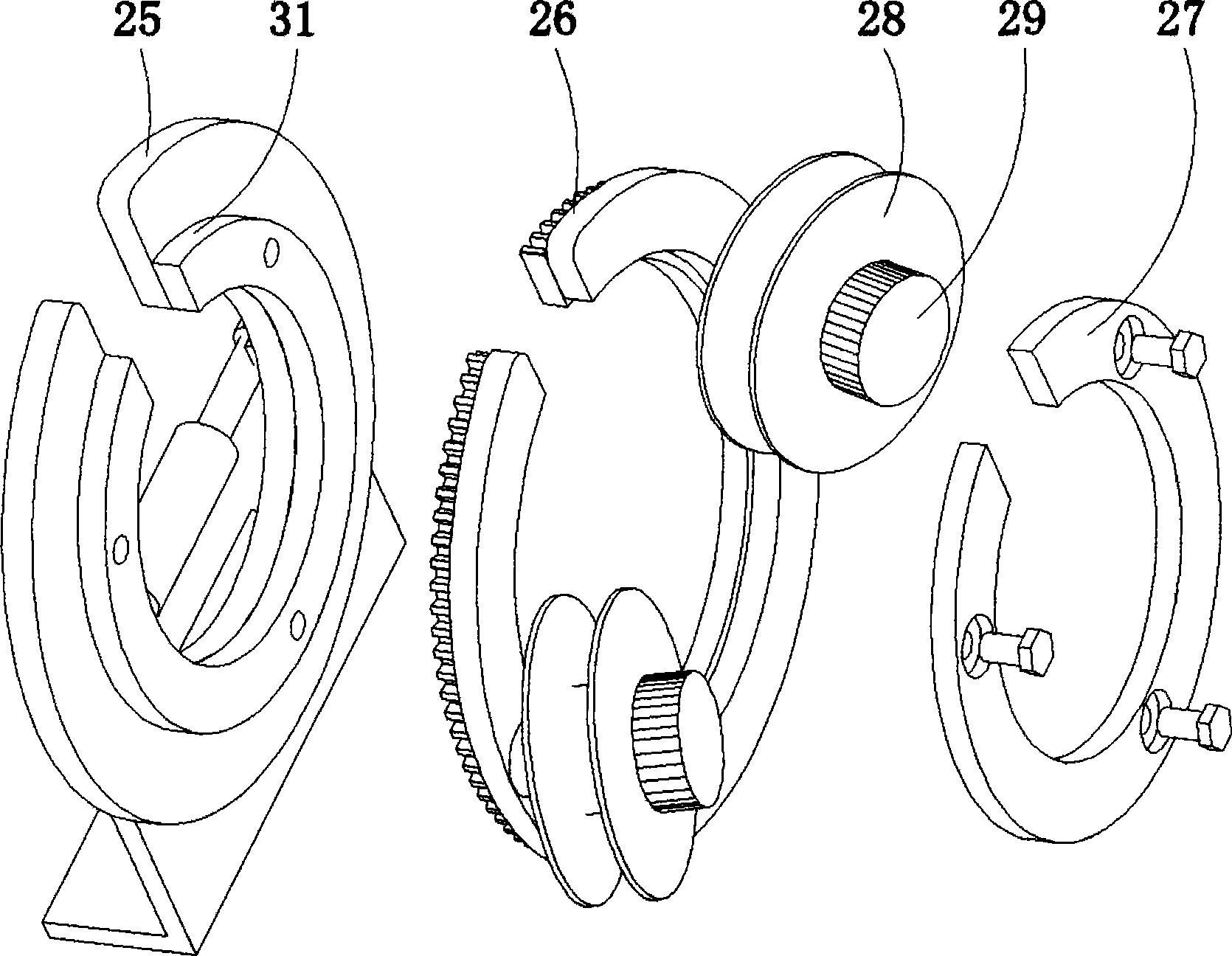

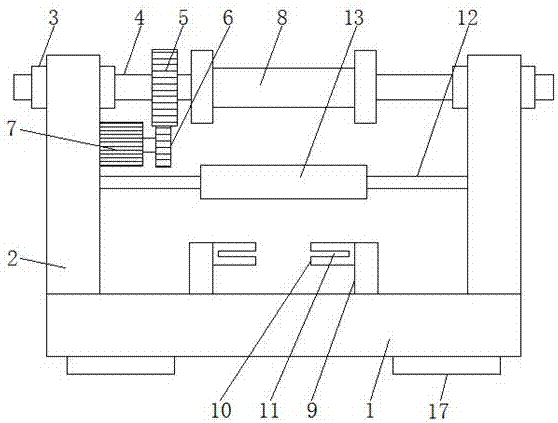

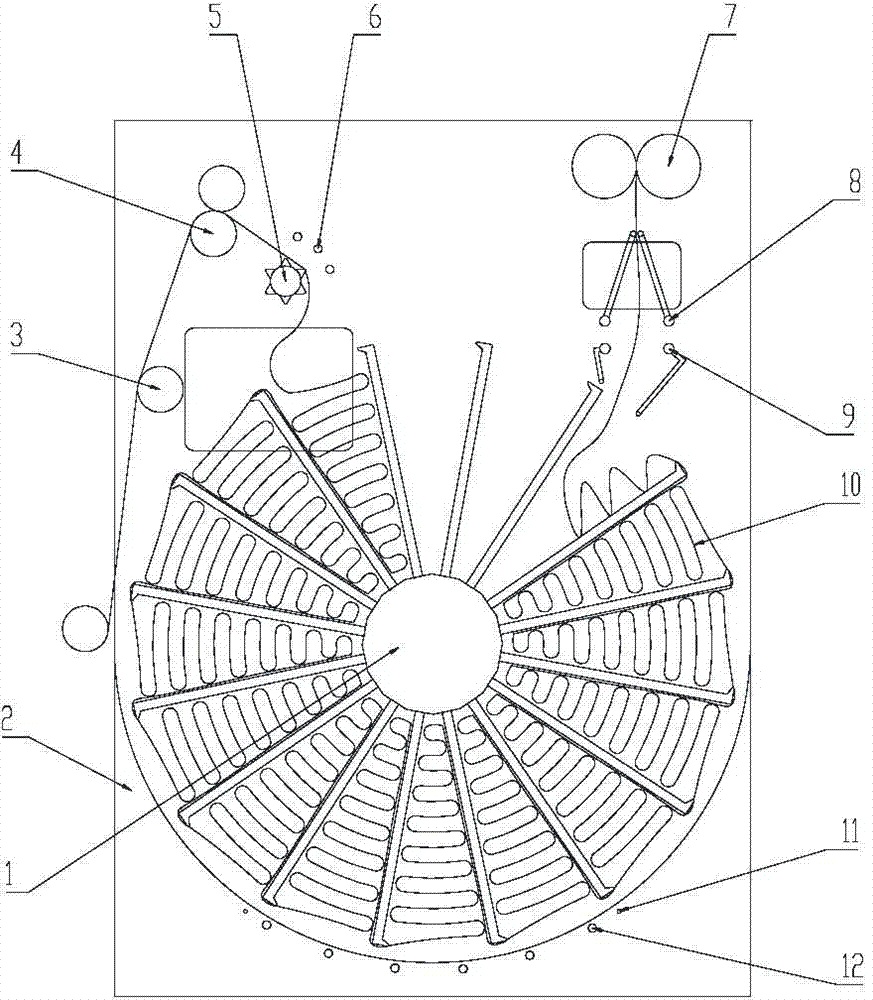

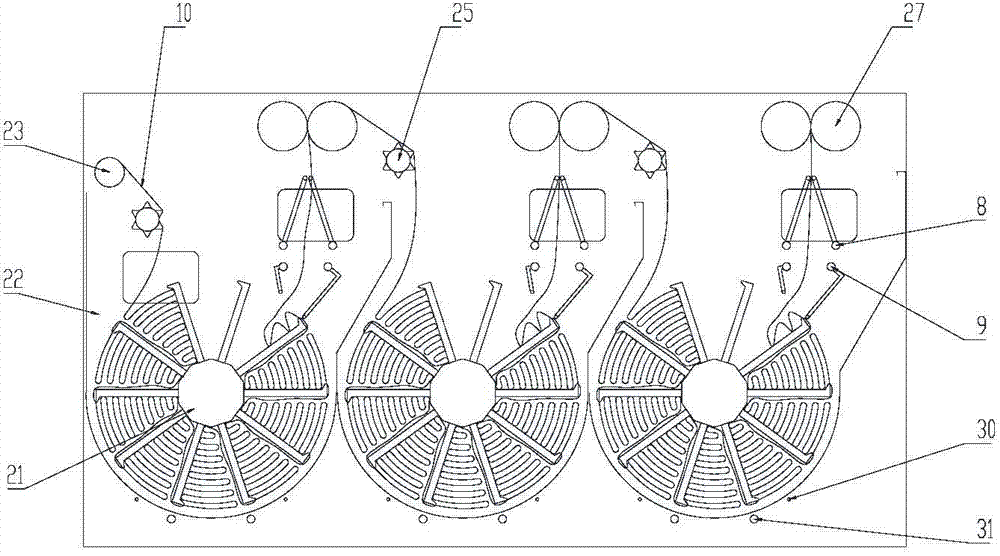

Coil-tapping machine

InactiveCN101453152AEasy to operateGood strap qualityApplying solid insulationMotor driveEngineering

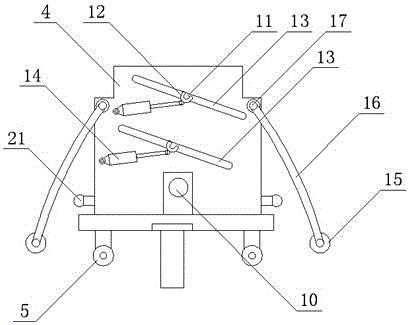

The invention discloses a coil wrapping machine. The wrapping machine comprises a pedestal, a coil fixing device, a rotary working platform and a machine head; the rotary working platform can be driven to move by a transverse servo motor and a vertical servo motor; the machine head is arranged on the rotary working platform; in the machine head, a machine head servo motor drives two synchronizing gears through a reduction gear; two synchronizing gears are engaged with gap gear rings; a gap gear ring sleeves on a small circular protrusion of in a gap circular seat and is limited by a gap circular retaining plate; and the outer side of the gap gear ring is provided with two adhesive tape clamping discs. The machine can realize the control of wrapping operation by a program through a computer and has the advantages of simple structure, high automation degree, convenient operation, good wrapping and binding quality and the like.

Owner:上海闵行机械工程技术研究所有限公司

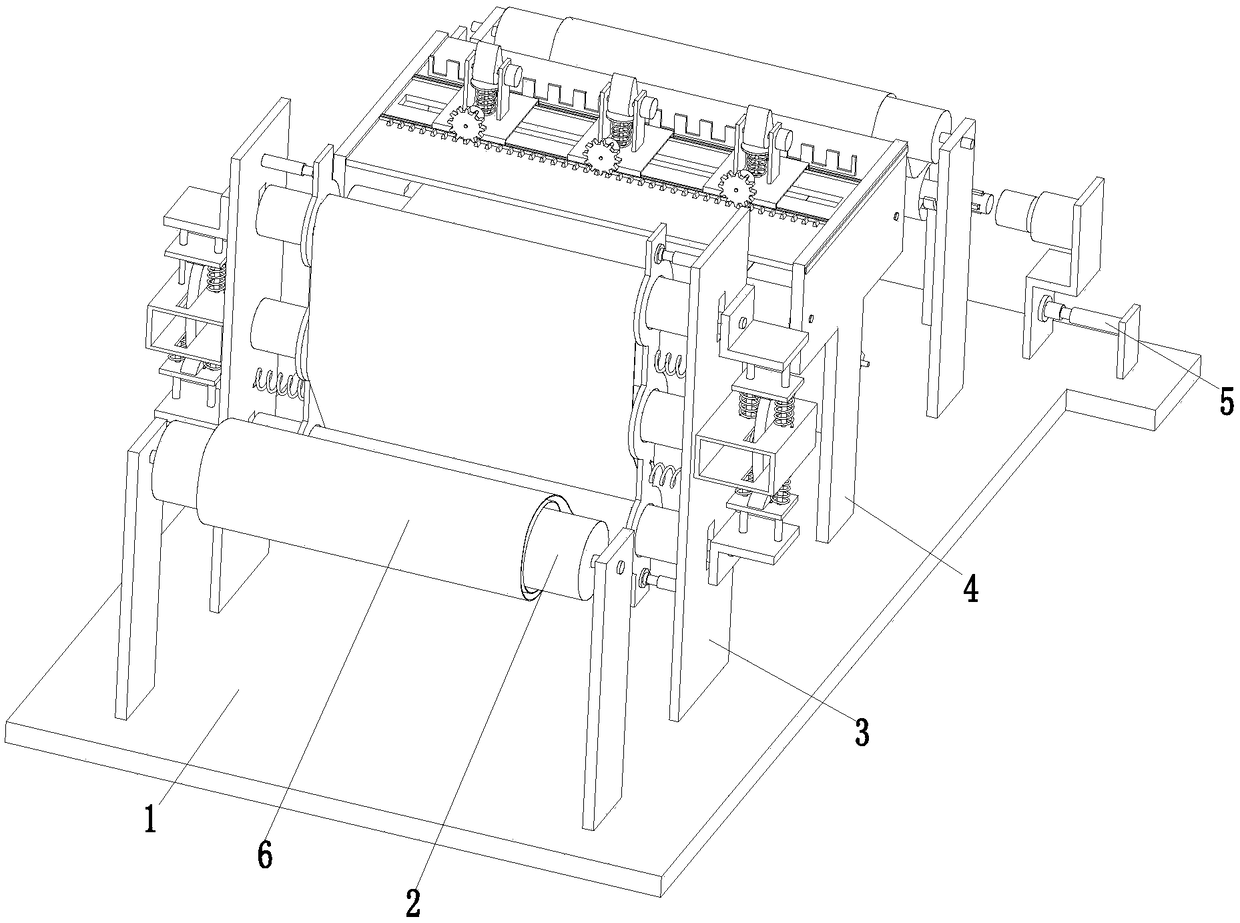

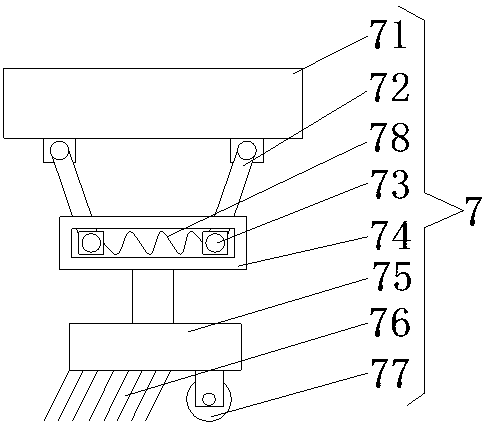

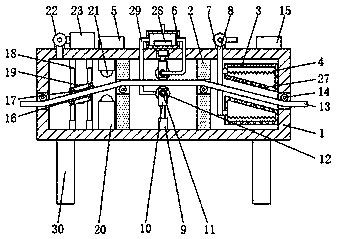

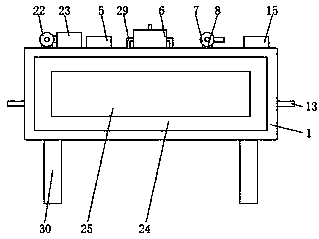

Medical gauze production instrument

ActiveCN108792728APlay a buffer roleNo tiltSevering textilesArticle deliveryMechanical engineeringEngineering

The invention relates to a medical gauze production instrument. The medical gauze production instrument comprises a bottom plate. The bottom plate is sequentially provided with a winding roller, a tensioning device, a cutting device and a winding device from front to back. A gauze body is wound around the winding roller. The tensioning device comprises tensioning fixing frames symmetrically arranged on the bottom plate, and a tensioning auxiliary roller is arranged between the inner walls of the tensioning fixing frames through bearings. The medical gauze production instrument can solve the problems that in the existing medical gauze producing and processing process, a machine needs to be manually controlled to cut gauze, existing equipment needs to be utilized for winding the cut gauze, the cutting precision is hard to guarantee since the machine is manually controlled to cut the gauze, the gauze cannot be accurately cut according to the rule, resource waste is likely to be caused, the gauze is likely to incline in the moving process, the cutting accuracy is influenced, the wound gauze is prone to wrinkling due to inclination, and after the gauze is wound, existing equipment needsto be manually utilized for detaching an instrument around which the gauze is wound.

Owner:常州阿尔丰机械有限公司

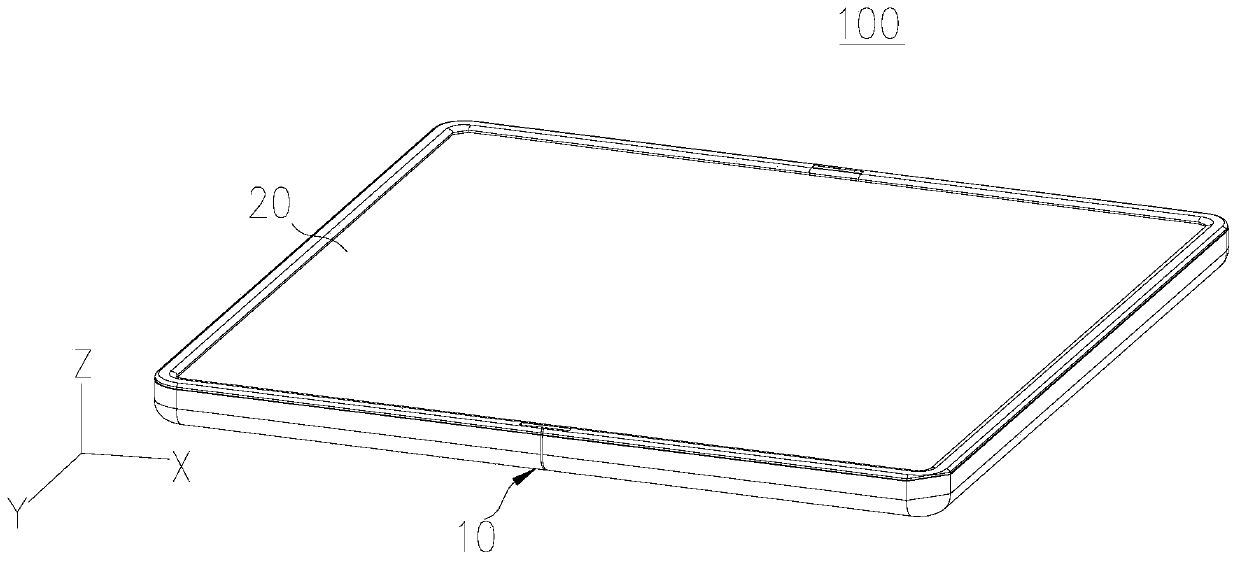

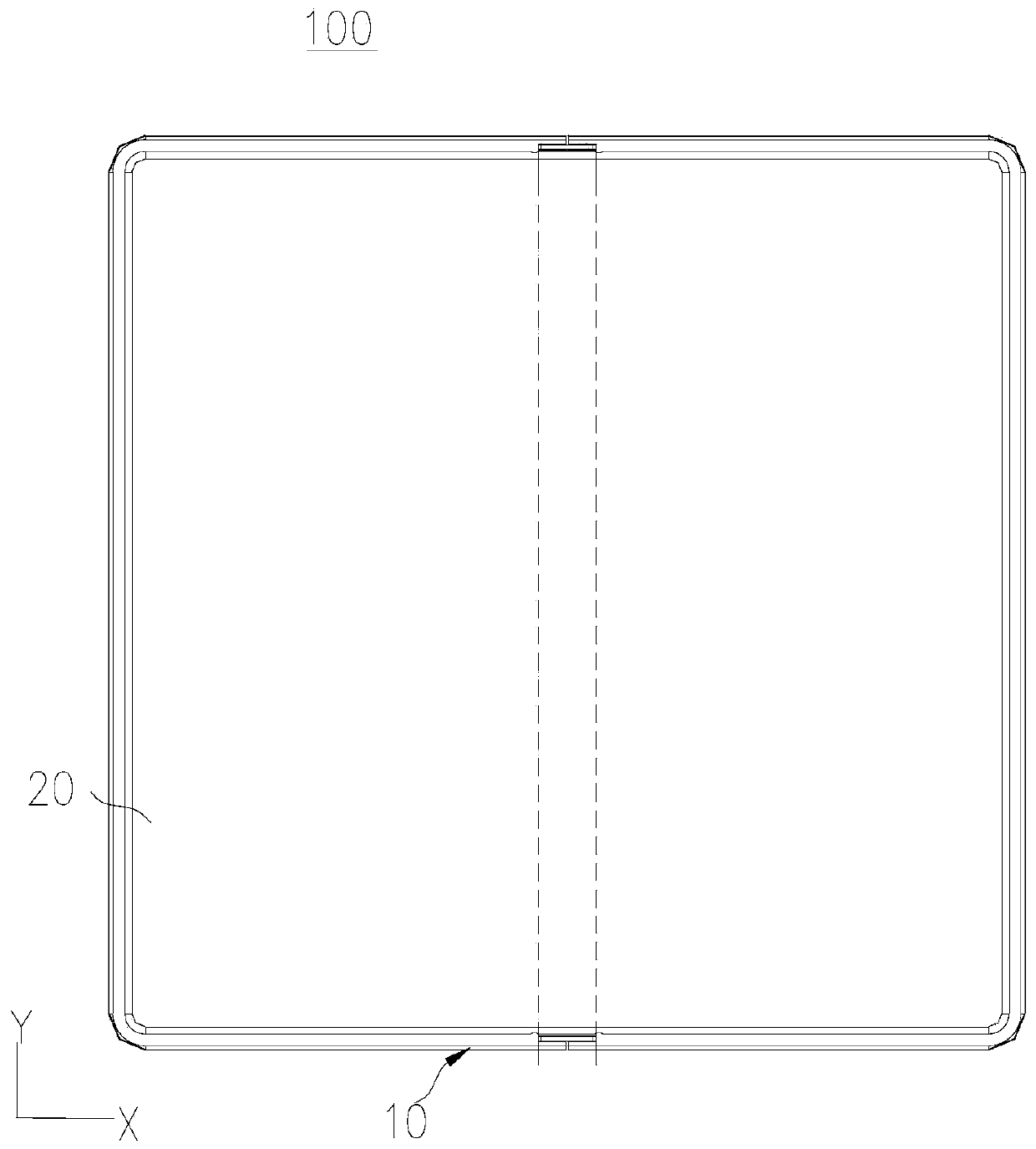

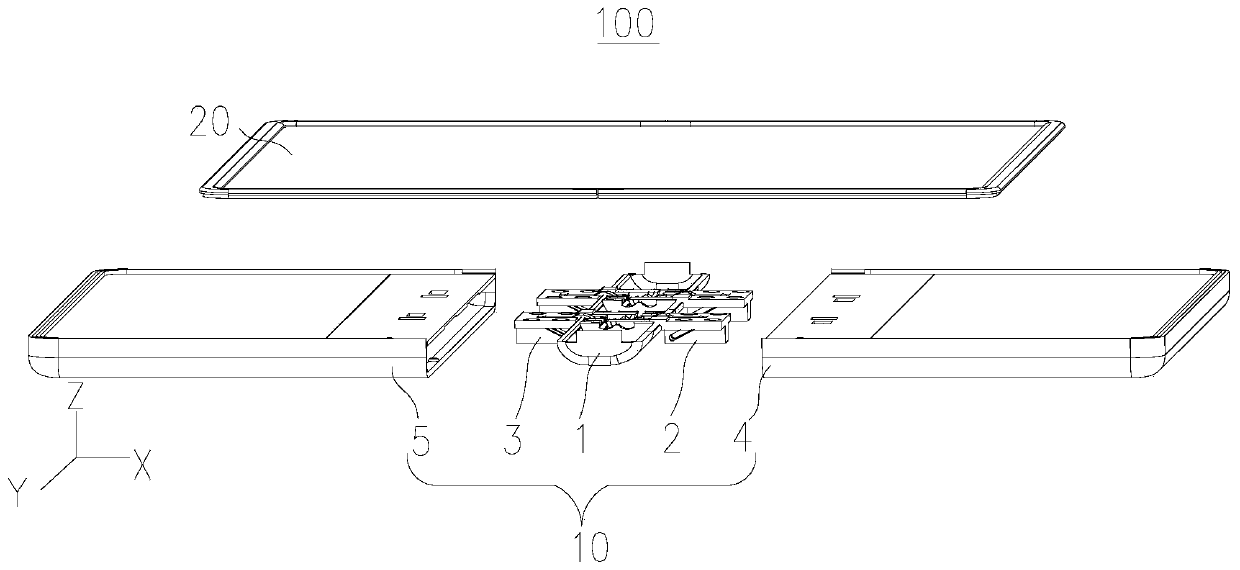

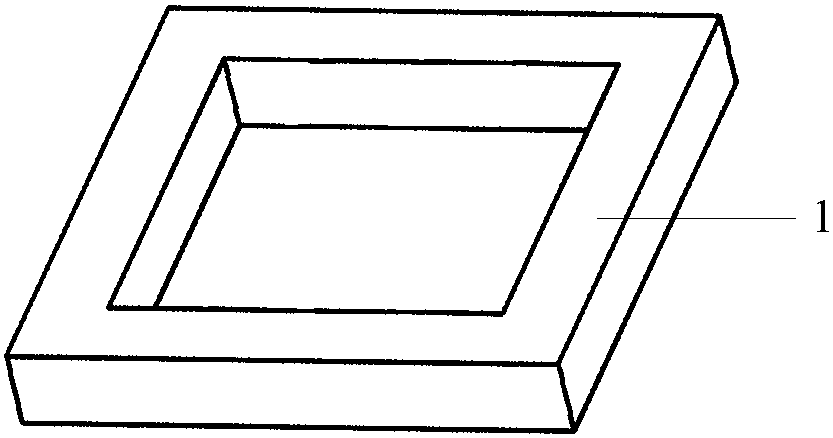

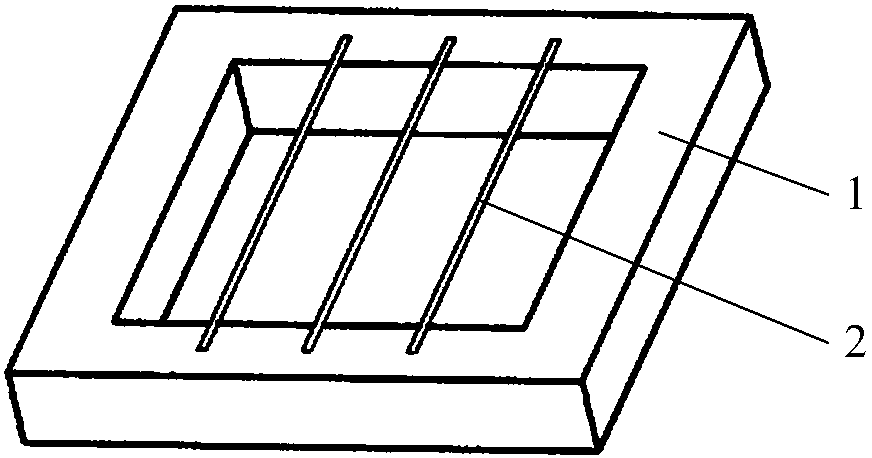

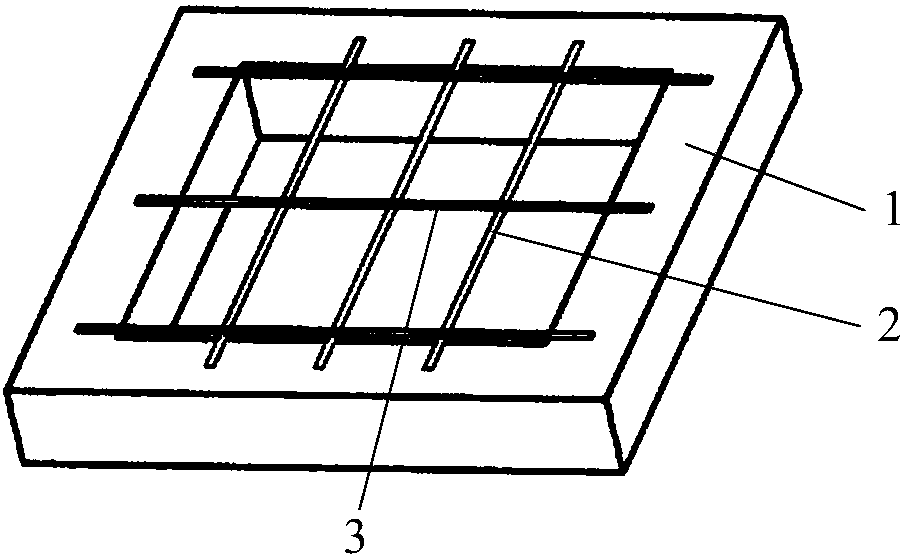

Rotating assembly and electronic equipment

The embodiment of the invention provides a rotating assembly and electronic equipment, and the rotating assembly comprises a rotating shaft assembly which is provided with a first limiting part and asecond limiting part; a first rotating arm and a second rotating arm, wherein the first rotating arm and the second rotating arm are rotationally connected with the rotating shaft assembly from the two sides of the rotating shaft assembly correspondingly. The first rotating arm comprises a first positioning piece, the second rotating arm comprises a second positioning piece, when the first rotating arm and the second rotating arm are in a flattened state, the first positioning piece is clamped with the first limiting part, and the second positioning piece is clamped with the second limiting part. According to the rotating assembly and the electronic equipment provided by the invention, the shells on the two sides of the electronic equipment can be kept in a form when being completely unfolded.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

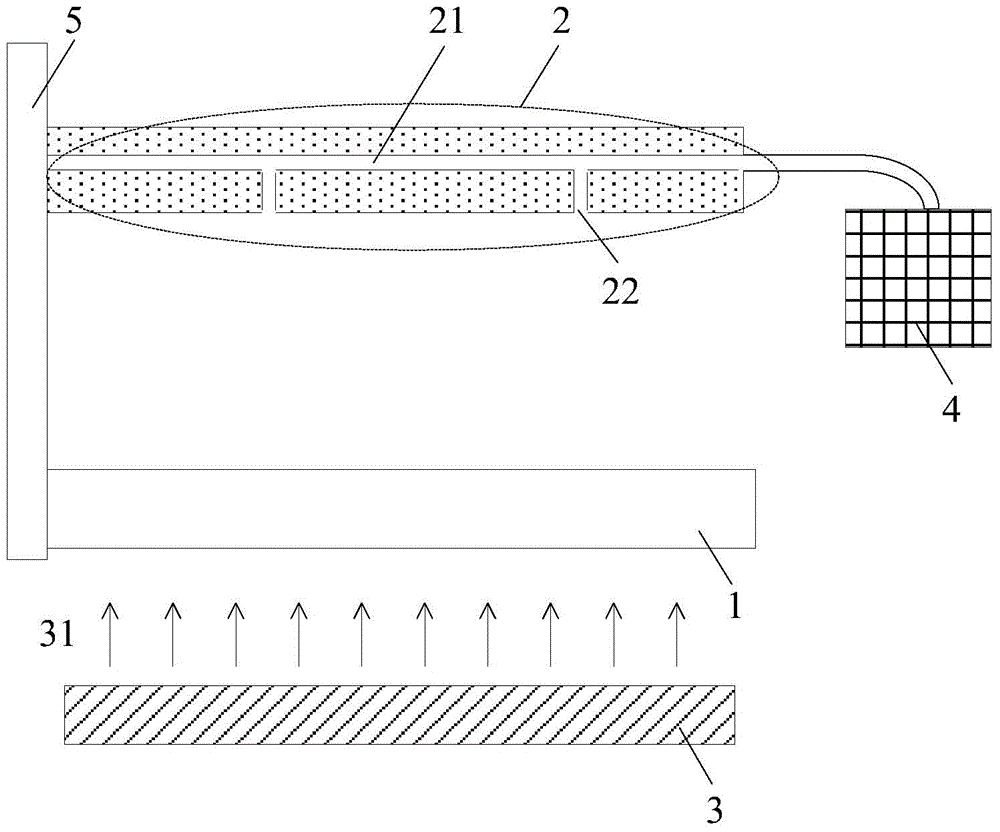

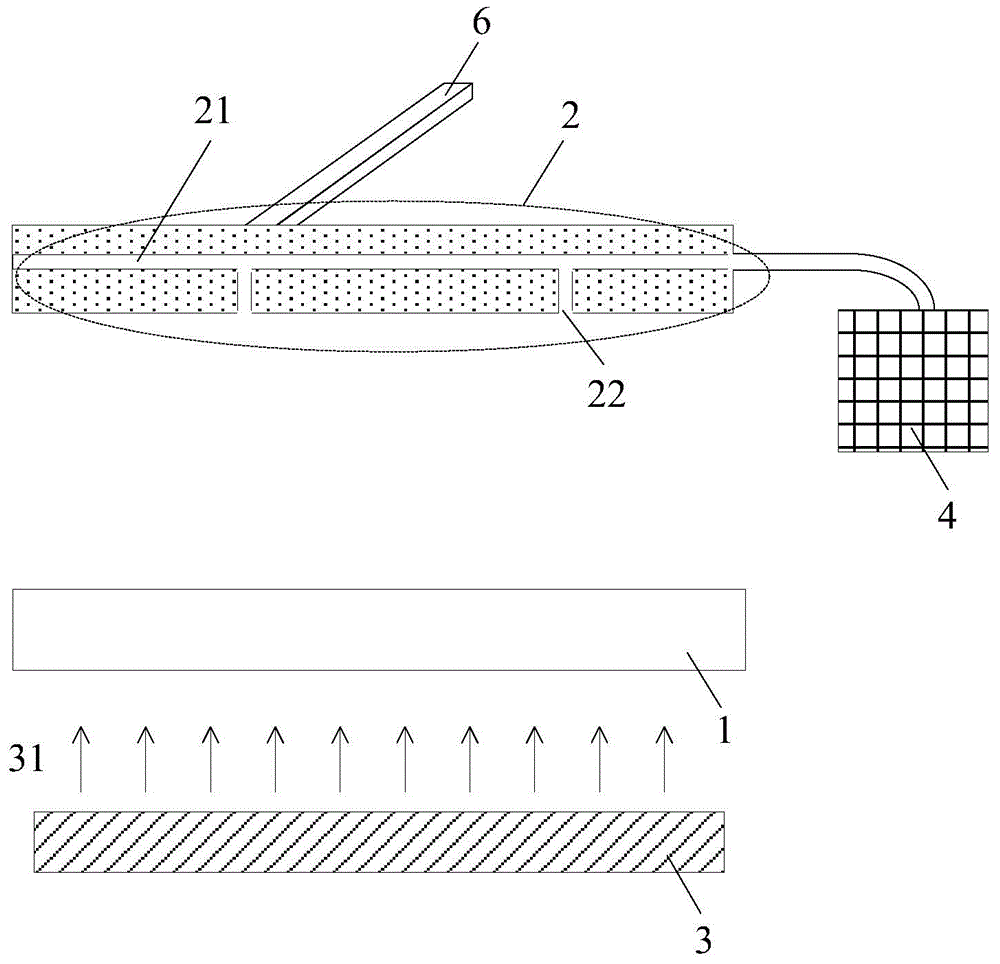

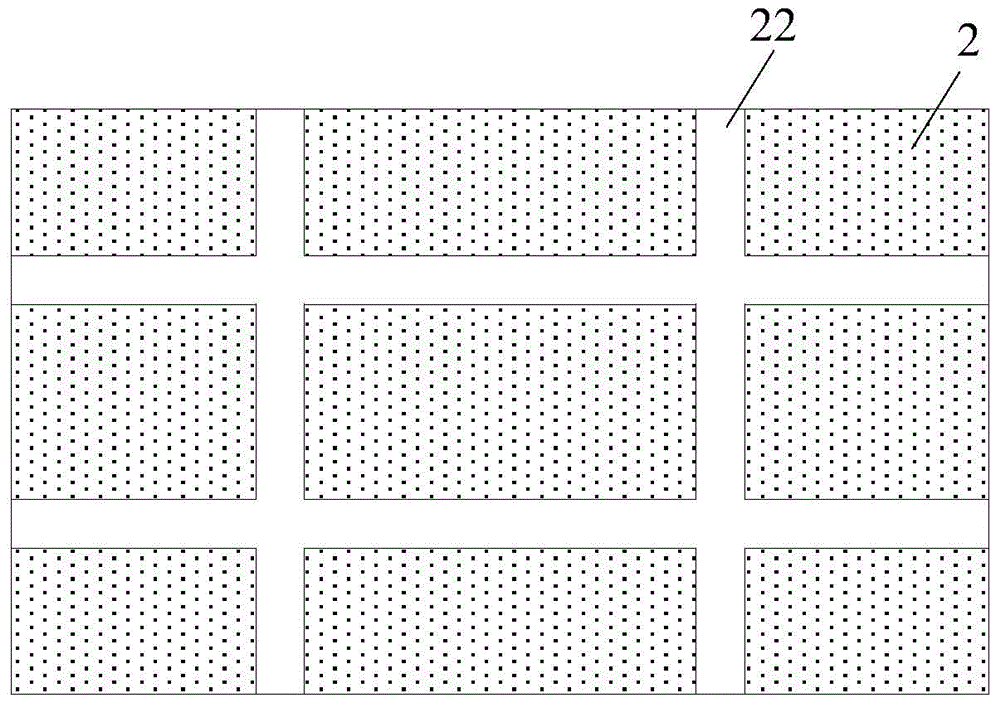

Adsorption device and method of metal pattern plates, evaporation equipment and evaporation method

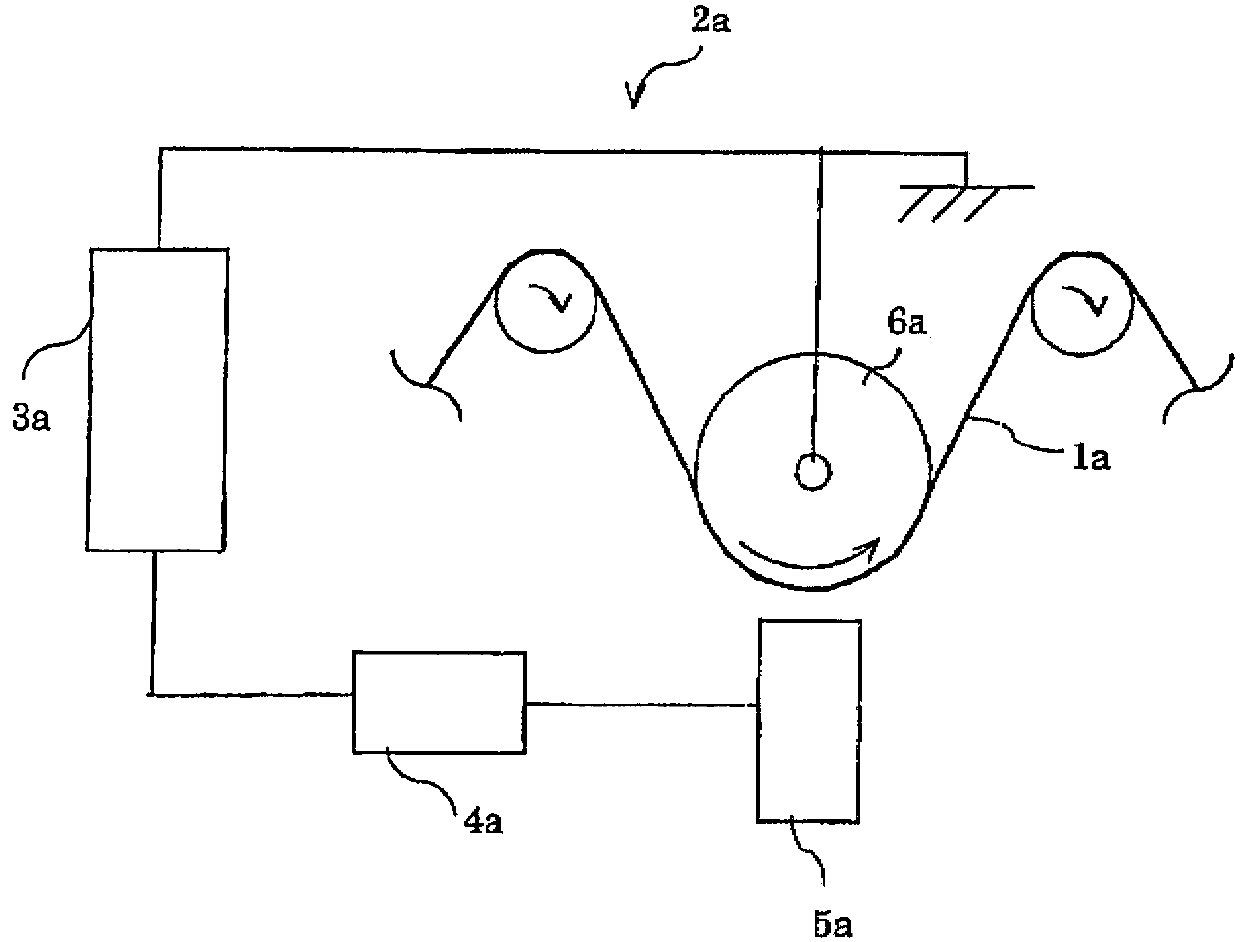

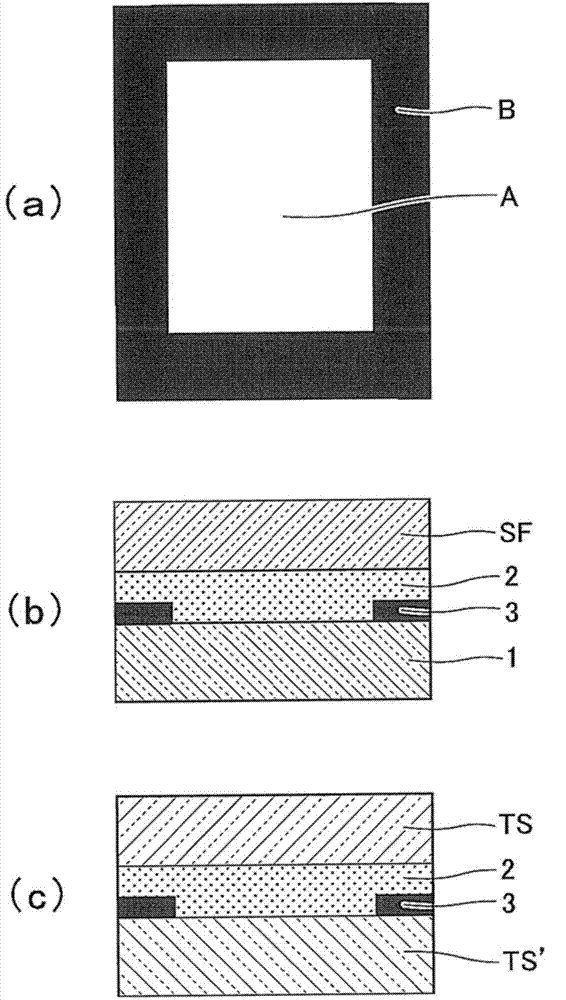

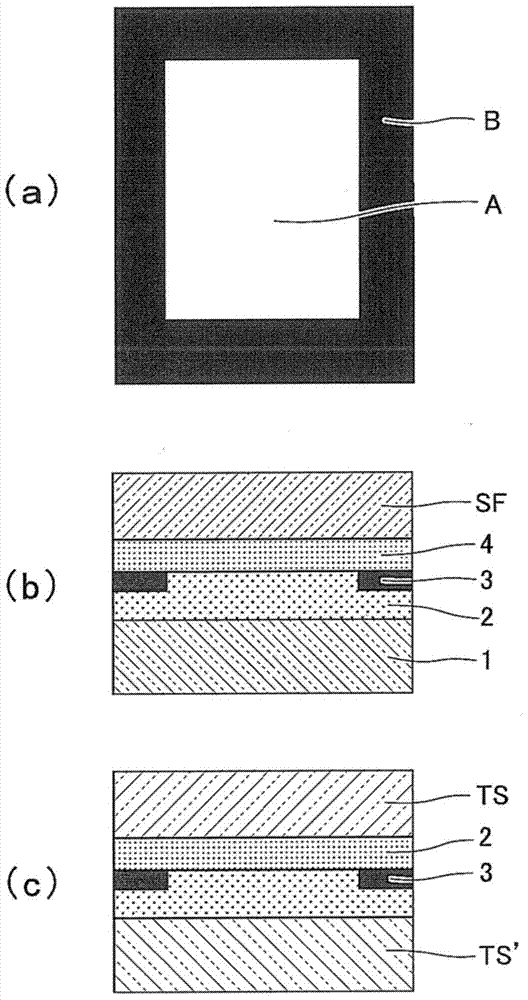

ActiveCN108165927AReduce wrinklesAvoid wrinklesVacuum evaporation coatingSputtering coatingWrinkle skinEvaporation

The invention provides an adsorption device and method of metal pattern plates, evaporation equipment and an evaporation method so as to solve the problem that in evaporation, the metal pattern platesare adsorbed, and then an FMM wrinkles. The adsorption method comprises the steps that adsorption begins from a certain area or certain areas of each metal pattern plate, and then the adsorption range is gradually enlarged from the initial adsorption area till the whole metal pattern plates are attached to substrate base plates. The adsorption method is applied to the evaporation process of manufacturing of OLED display panels so as to improved the evaporation quality.

Owner:BOE TECH GRP CO LTD +1

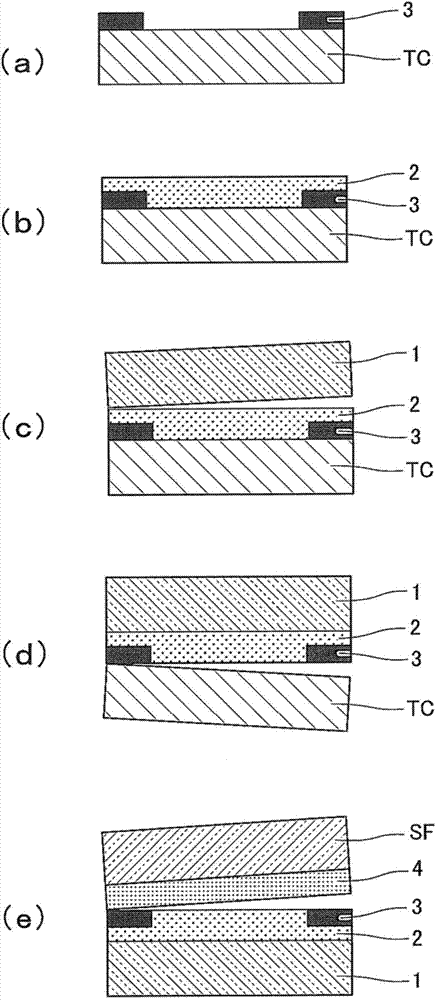

Peeling device of flexible substrate and peeling method of flexible substrate

ActiveCN104898313ANo creasesInhibit swellingLamination ancillary operationsLayered product treatmentLaser cuttingMechanical engineering

The invention discloses a peeling device of a flexible substrate and a peeling method of the flexible substrate. The peeling device and the peeling method are used for solving the problems of wrapped local part of the flexible substrate and bad product quality when the flexible substrate is peeled off by a laser peeling technology. The peeling device includes a base platform, a pressing plate arranged at the upper part of the base platform and a laser generator arranged at the lower part of the base platform; the pressing plate is provided with a negative pressure channel, one face towards the base platform is provided with a suction covering opening connected with the negative pressure channel; the base table is used for bearing a lining base plate formed with a flexible substrate to be peeled; the flexible substrate to be peeled is provided with an exhaust passage formed by laser cutting; a laser generator is used for emitting laser and heating the flexible substrate to be peeled, so that one contact face between the flexible substrate to be peeled and the lining substrate is decomposed and then peeled; the pressing covering plate is used for pressing and covering the flexible substrate to be peeled and absorbing gas by the negative pressure channel through the suction covering opening when the flexible substrate to be peeled is decomposed.

Owner:BOE TECH GRP CO LTD

Cloth winding device having dust removal function and used for textiles

ActiveCN106915644AWith dust removal functionEasy to remove dustCleaning using toolsCleaning using gasesBristleEngineering

The invention relates to the technical field of textiles, and discloses a cloth winding device having a dust removal function and used for textiles. The cloth winding device comprises a supporting base. The top of the supporting base is fixedly connected with a supporting frame. Bearings are connected to the supporting frame in a clamping manner. A rotating shaft is connected in the bearings in a sleeving manner. The surface of the rotating shaft is fixedly connected with a first gear. The first gear is engaged with a second gear. The second gear is fixedly connected to an output shaft of a motor. The motor is fixedly connected to one side of the supporting frame. According to the cloth winding device having the dust removal function and used for the textiles, by arranging a supporting rod, a brush plate, an empty groove, air blowers and bristles, dust removal can be better conducted when cloth is wound, the problem that an existing cloth winding device does not have the dust removal function when the cloth is wound is solved, and therefore the situation that dust is attached to the back face of the cloth after the cloth is wound is avoided, and appearance of the cloth can be better when the cloth is sold in the later period.

Owner:SANYANG TEXTILE

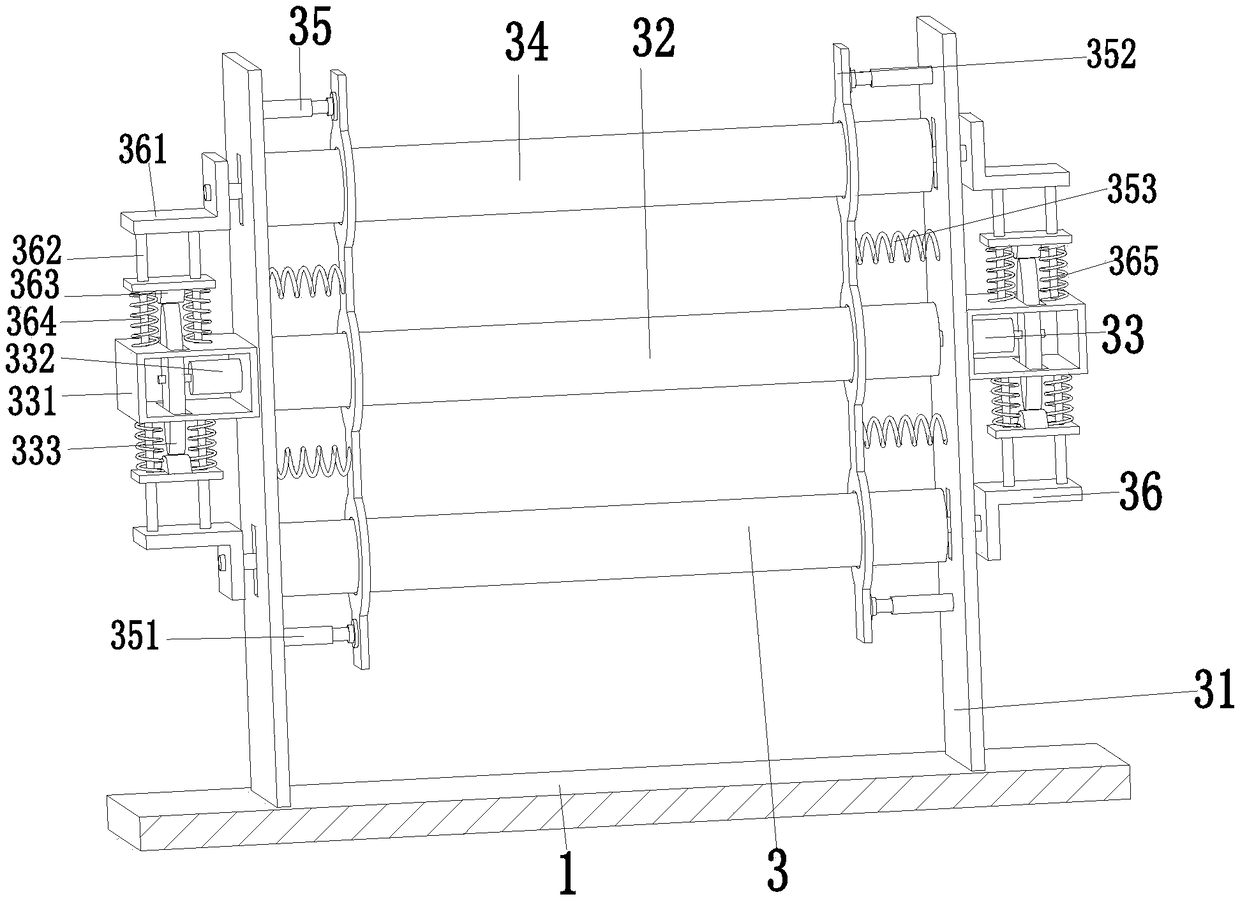

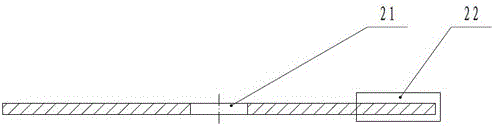

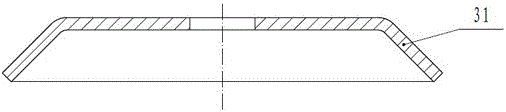

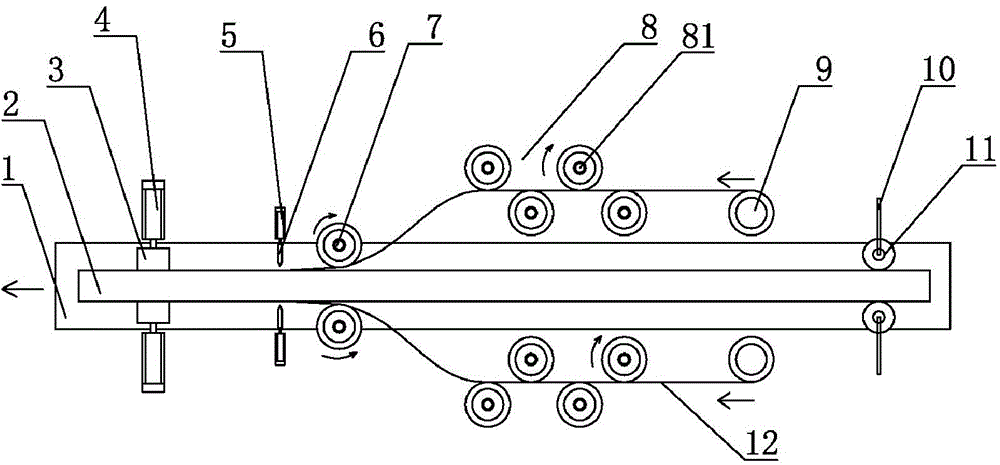

Tightening winding mechanism for fabrics

InactiveCN105905651ANo creasesImprove output qualitySevering textilesWebs handlingEngineeringConductor Coil

The invention discloses a tightening winding mechanism for fabrics. A cropping component and a rolling component are respectively arranged on a frame; the cropping component is used for cropping processed fabrics; the rolling component is used for reeling the fabrics; a slide rail is arranged on a bracket of the rolling component provided by the invention; after a roll of fabric is completely reeled, a winding roll can be conveniently taken out, another winding roll to be used for reeling a fabric is placed again conveniently, and the winding process of the fabrics of various lengths and widths is facilitated; a counter arranged between the cropping component and the rolling component is used for calculating the walking length of the fabrics, so that each roll of fabric is kept in certain quantity and the batched accurate reeling can be conveniently performed; a tightening component is arranged between the cropping component and the counter and is used for tightening the fabrics in the fabric transmission and reeling processes, so that the fabrics are kept under a tightening state all the time and thus are free of folds and are kept flat when reeled, and the output and quality of the fabrics are increased. The tightening winding mechanism for weaving has the advantages of high reeling efficiency, convenience in use and suitability for batched reeling.

Owner:WUJIANG HUAYUN TEXTILE

TPE-base composite film material and preparation method thereof

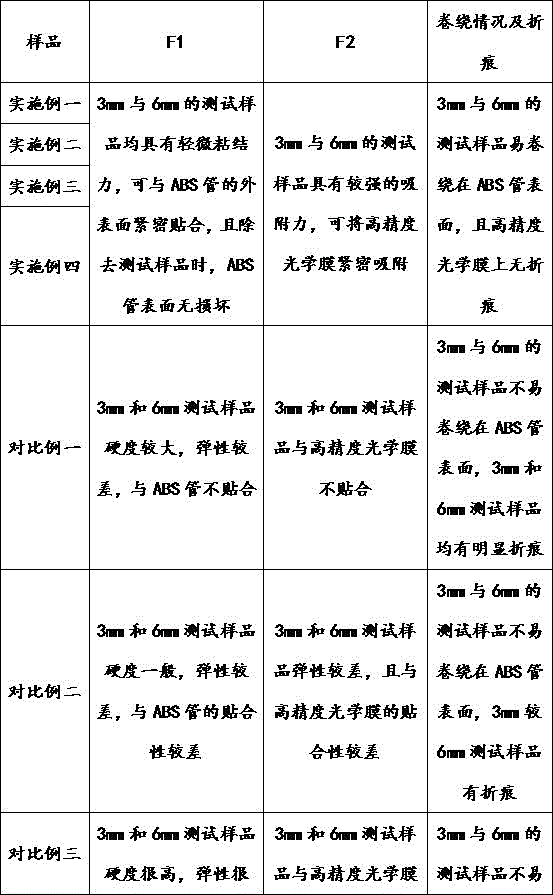

The invention discloses a TPE-base composite film material. The TPE-base composite film material comprises, by weight, 100-120 parts of SEBS, 40-80 parts of PP, 10-30 parts of toughening material, 10-20 parts of cellulose-type adhesive, 3-10 parts of compound stabilizer, 10-30 parts of extending oil, 5-10 parts of paraffin lubricant and 1-2 parts of antioxidant. A TPE-base composite film prepared according to the formula is excellent in elastomeric performance, good in adsorption capacity for rolling core pipes and high in fit performance and can be used for being attached to buffer layers of some high-precision optical films to guarantee that the high-precision optical films are free of creases when wound on the TPE-base composite film.

Owner:SUZHOU TIANYU PLASTIC

Electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment

ActiveCN106087028AGood electrical contactImprove plating uniformityCellsContacting devicesElectricityStructural reliability

The invention discloses electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment. The electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment is composed of an unreeling machine, a front treatment section, an electroplating section, a rear treatment section and a reeling machine, wherein the electroplating section is provided with an electroplating cylinder, a plurality of cathode clamps, a clamp drive control device, a positive plate and a power source system; the clamp drive control device can drive the cathode clamps to be opened before entering the incoming end position, closed when moving from the incoming end position to the outgoing end position, and opened after leaving from the outgoing end position; the power source system is provided with a direct current power source, a cathode conductive mechanism and a positive wire; and the cathode clamps are electrically connected with the cathode of the direct current power source through the cathode conductive mechanism when moving from the incoming end position to the outgoing end position. The electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment has the advantages of being high in electroplating uniformity, wide in application range of electroplated flexible circuit boards, small in occupied space, capable of electroplating the electroplated flexible circuit boards smaller in thickness, high in working safety and high in structural reliability, and the electroplated boards are not likely to have an electroplating layering phenomenon.

Owner:GREAT CHIEFTAIN ELECTRONICS MACHINERY

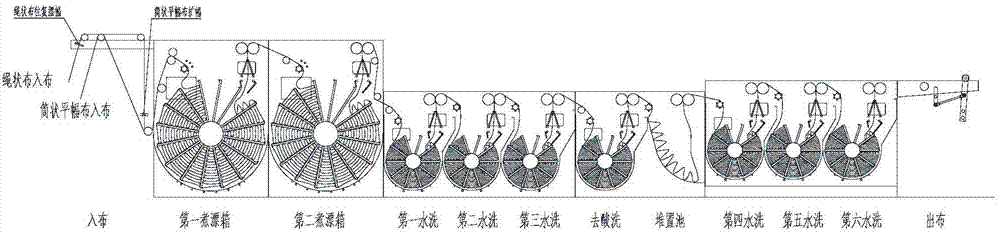

Heat preservation technology for continuous dip bleaching stage of one bath one step method for cotton fabric and cotton blended fabric

ActiveCN104846576AVersatilitySuitable for flexible productionTextile treatment containersSucessive textile treatmentsElectricityFiber

The invention discloses a heat preservation technology for a continuous dip bleaching stage of a one bath one step method for cotton fabric and cotton blended fabric. According to the heat preservation technology, based on the prior art, a structure comprising a boiling box and a washing machine is improved to a sealed drum structure with an impeller so that the fabric can be fully spread and will not cluster or gather or form a pile in the processing process, and the boiling off effect and the blenching effect are good; the fabric is boiled and blenched at a low temperature firstly and then boiled and blenched at a high temperature, so that the decomposition rate and the decomposition products of hydrogen peroxide are effectively controlled, various kinds of processing liquid flow in the direction opposite to the movement direction of the fabric in a drum, and therefore the processing effect is further improved; through the continuous production mode, the good boiling-off effect and the good blenching effect are achieved, the degree of oxidative damage to fibers is reduced to the greatest extent, the production efficiency is high, the consumption of water, electricity and steam is low, technical control is simple, adjustment is convenient, and flexible production can be achieved.

Owner:QINGDAO UNIV

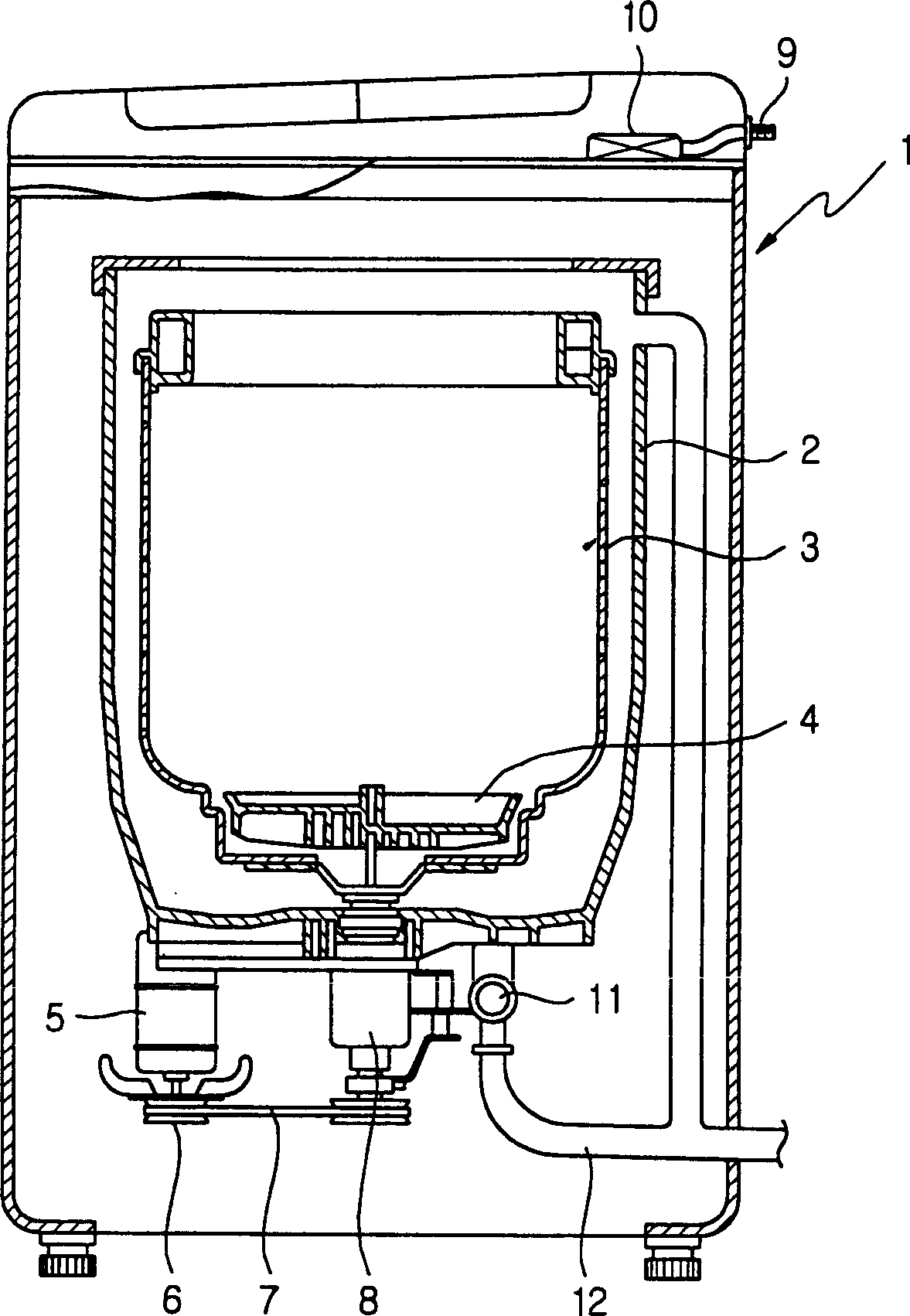

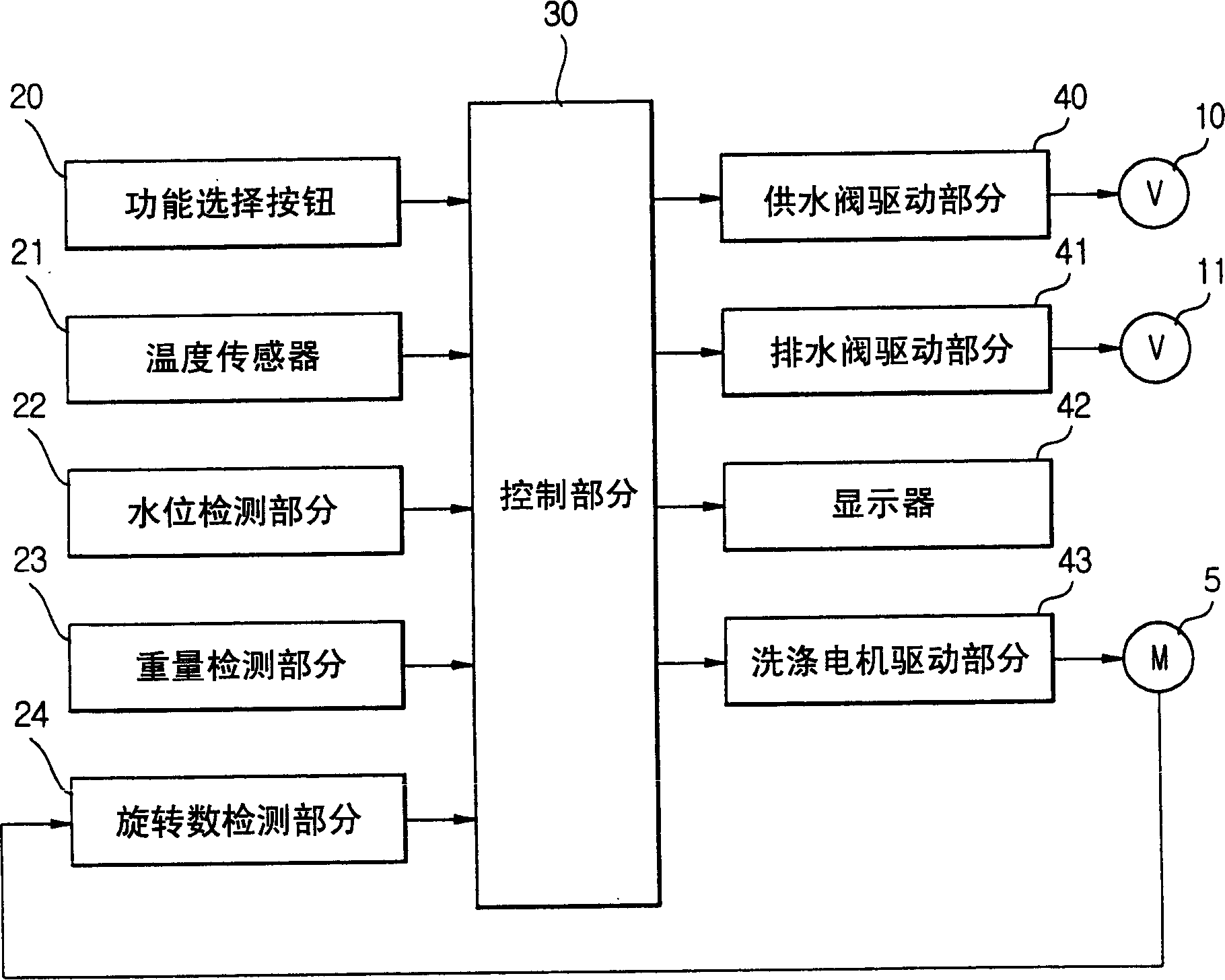

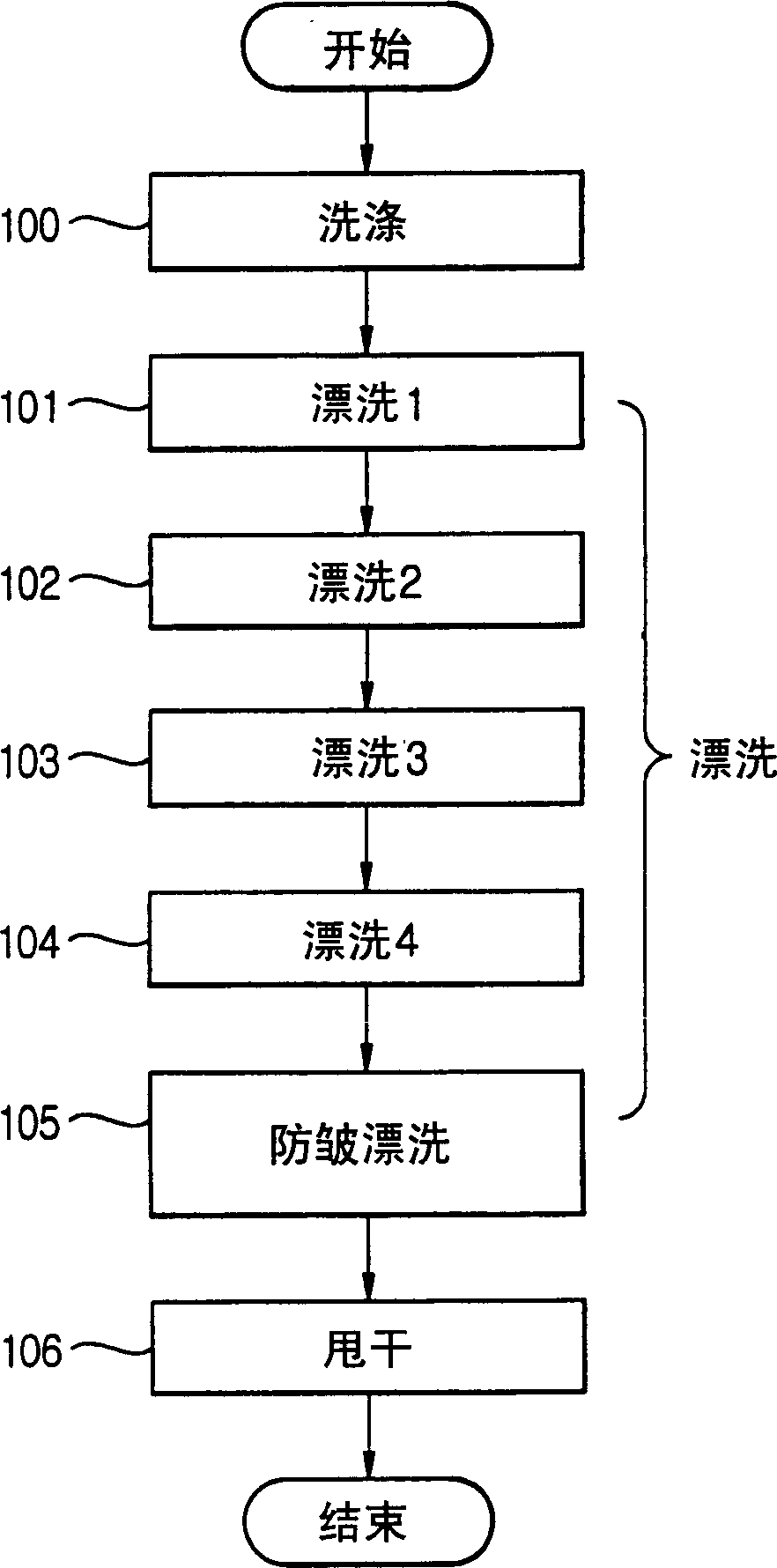

Controlling method for washing procedure of washer

InactiveCN1459528AAvoid entanglementNo creasesOther washing machinesControl devices for washing apparatusStop timeWater flow

A method of controlling a rinsing operation of a washing machine having a pulsator to wash laundry, the method includes a wrinkle prevention rinsing process. During the wrinkle prevention rinsing process, the pulsator is stopped for a pulsator stopping time which is set to be longer than a pulsator driving time, thereby forming wrinkle preventing water flows to minimize wrinkles in the laundry. The wrinkle preventing rinsing process may be performed before a final spin-drying operation is performed. The wrinkle preventing rinsing process may be performed after a general rinsing process, which is performed at least once. The wrinkle preventing rinsing process may be performed for a wrinkle preventing rinsing time that is set to be longer than a general rising time for the general rinsing process.

Owner:SAMSUNG ELECTRONICS CO LTD

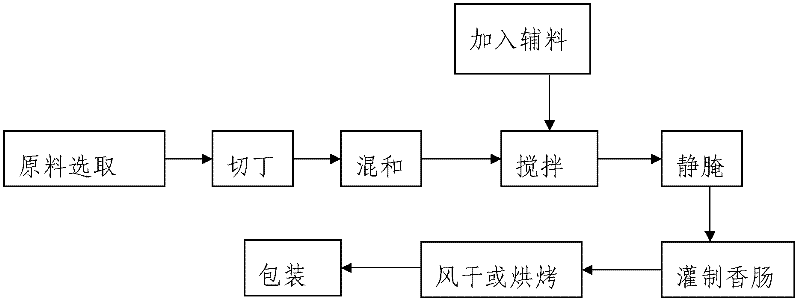

Rabbit meat sausage and preparation method thereof

The invention provides a rabbit meat sausage and a preparation method thereof. The rabbit meat sausage comprises the following raw materials in parts by weight: 70-90 parts of rabbit meat and 10-30 parts of back pork fat; and auxiliary materials of the rabbit meat sausage comprise the following materials in parts by weight: 2-3 parts of salt, 1-6 parts of granulated sugar, 0.15-0.3 parts of monosodium glutamate, 0.005-0.01 parts of sodium nitrite and 2-3 parts of soy sauce. By using rabbit meat with a health care effect, the rabbit meat sausage provided by the invention has the advantages of strong grain feeling, elastic meat texture, outstanding meat perfume, special flavor, good palatability, rich nutrition of the final product as well as ruddy appearance and color; and the types of the traditional featured rabbit meat product are enriched and the rabbit meat industry development is promoted.

Owner:CHINA MEAT RES CENT

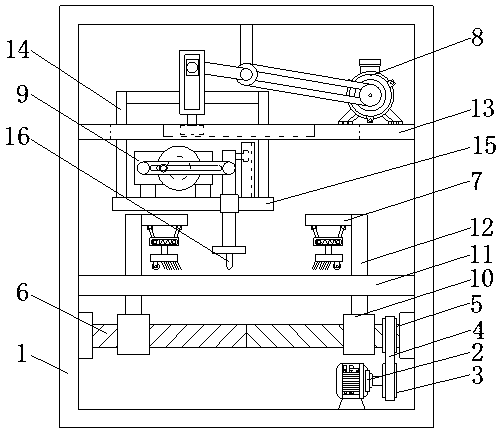

Leather punching equipment for luggage manufacturing

InactiveCN107745417ANo creasesQuality assuranceMetal working apparatusManufacturing technologyPunching

The invention discloses a leather punching device for making bags, which comprises a casing, a workbench is fixedly connected between the two sides of the inner wall of the casing, a motor is fixedly connected to the bottom of the inner wall of the casing, and a motor is fixedly connected to the bottom of the inner wall of the casing. The output shaft is fixedly connected with a first pulley, the surface of the first pulley is connected with a second pulley through the first belt transmission, the shaft center of the second pulley is fixedly connected with a screw rod, and the two surfaces of the screw rod Rotating blocks are provided on both sides, and the invention relates to the technical field of bag manufacturing. The leather punching equipment for luggage manufacturing ensures that the leather will not wrinkle when punching holes, ensures the quality of leather punching, facilitates subsequent processing, and facilitates adjusting the position of the punching device. It can punch holes in different positions of the leather. The use effect is good, the punching head is prevented from scratching the leather during the movement, the position of the punching head is conveniently adjusted, the punching quality is improved, and the manual labor is reduced.

Owner:陈华

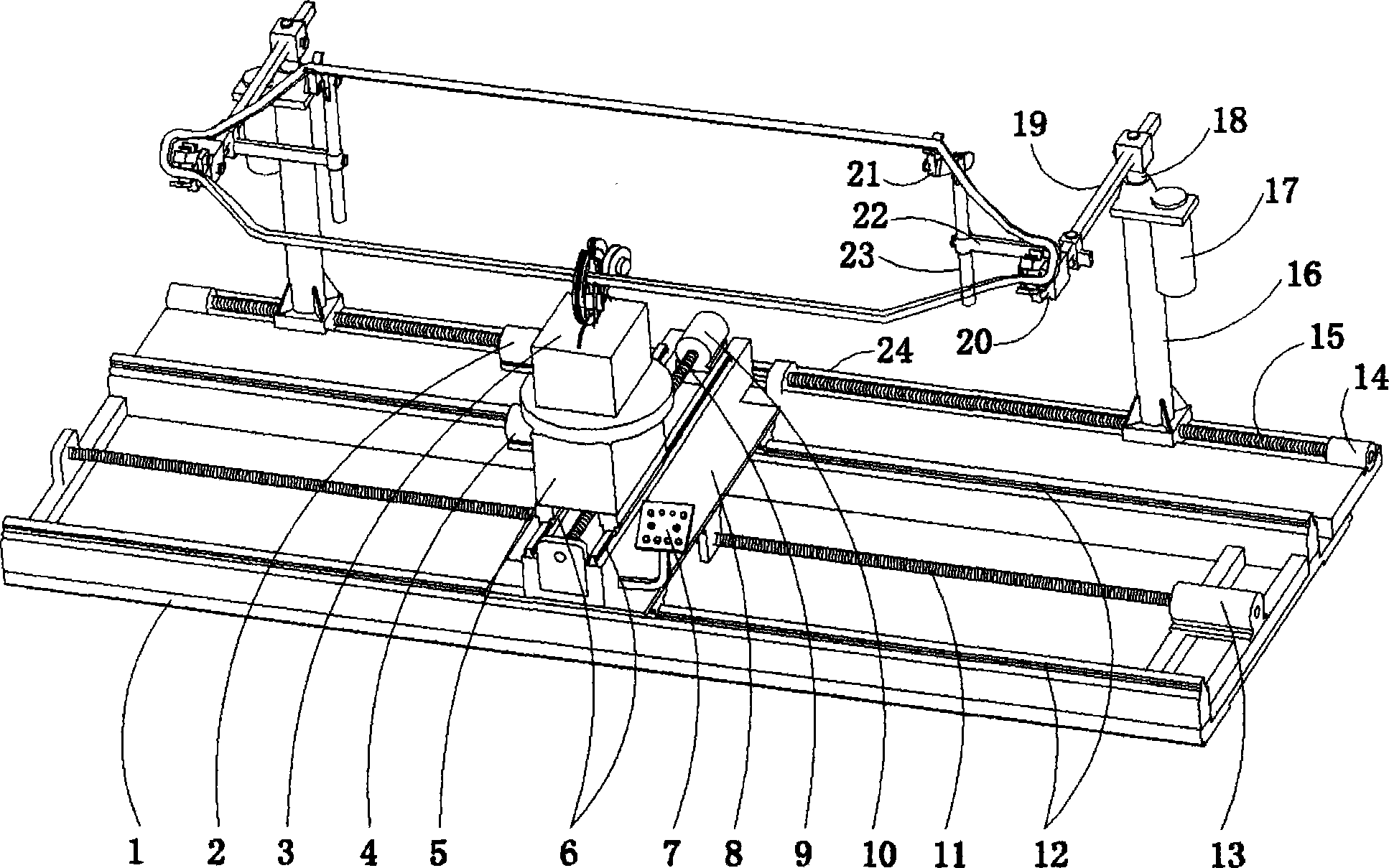

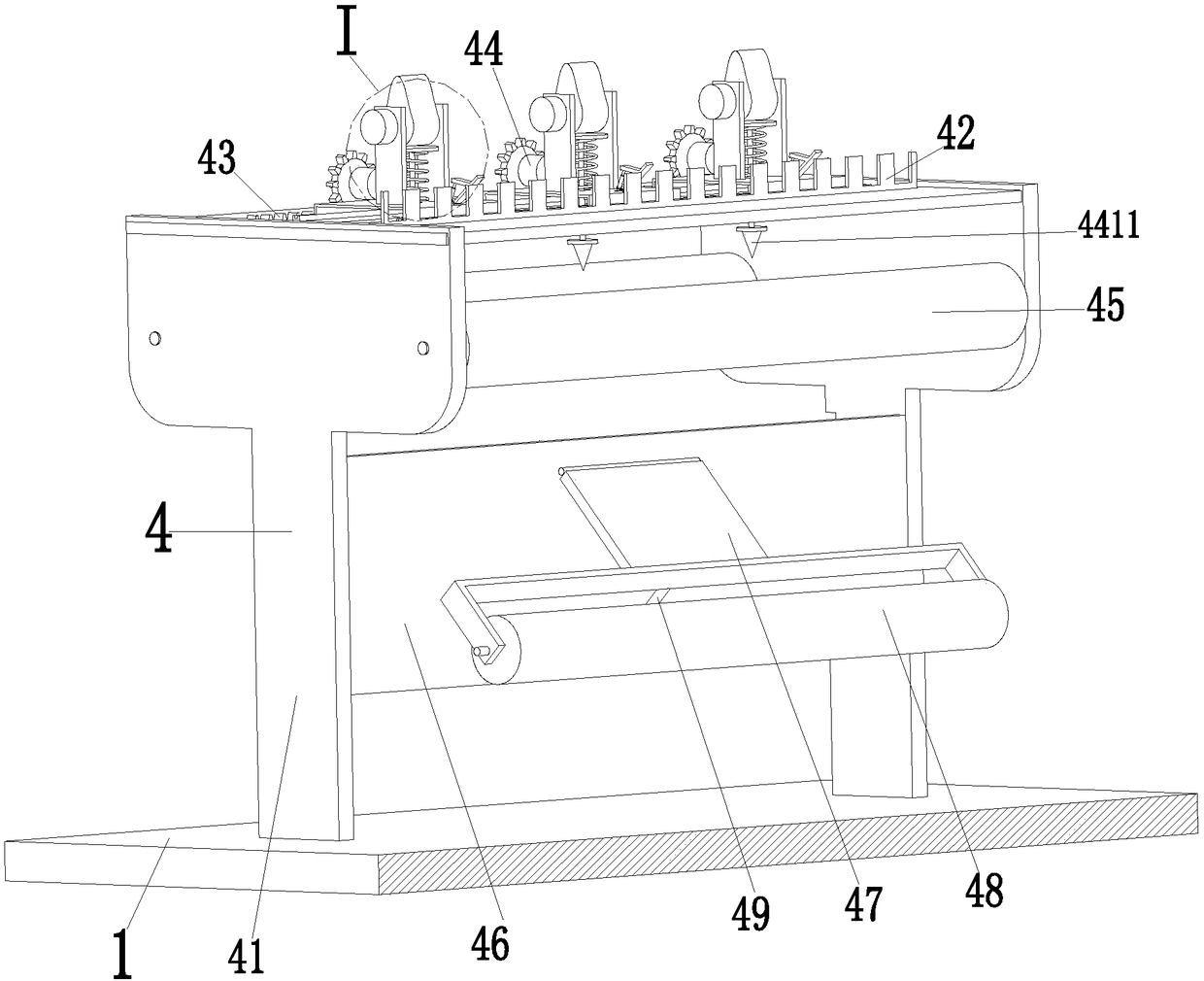

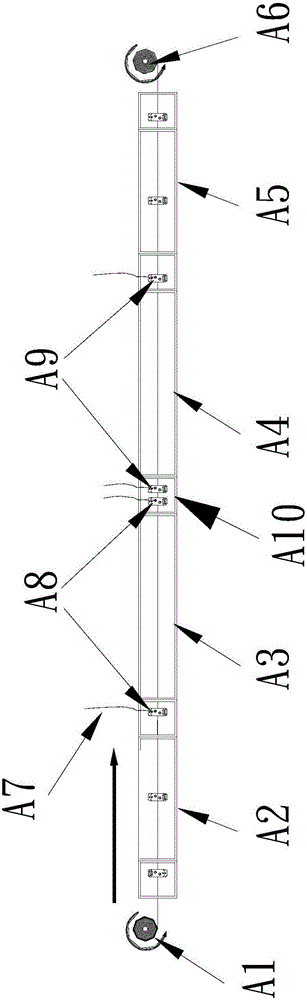

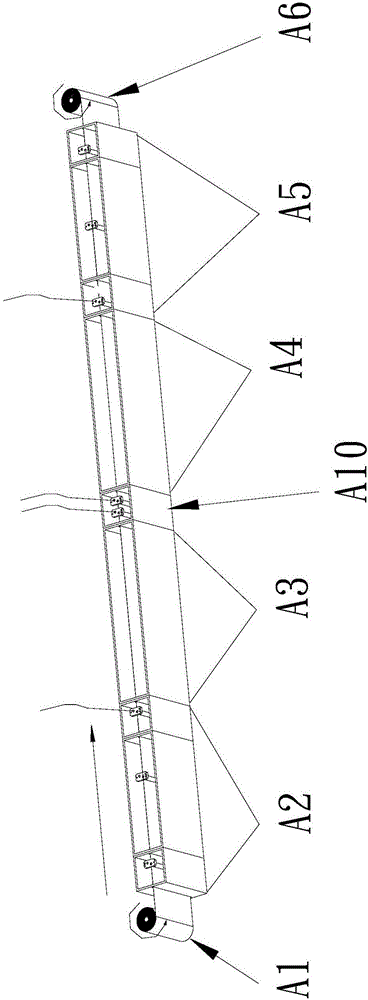

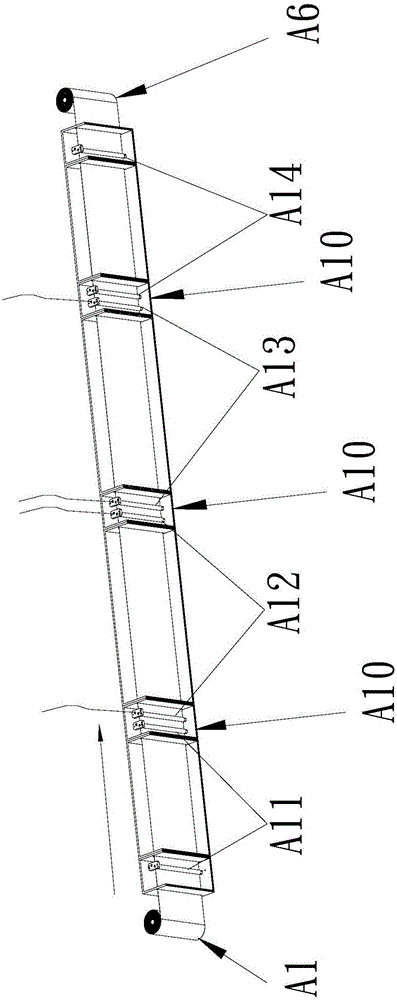

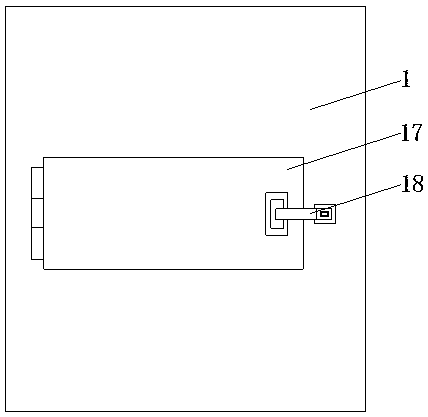

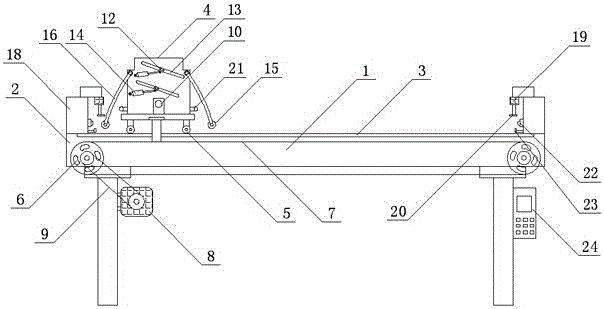

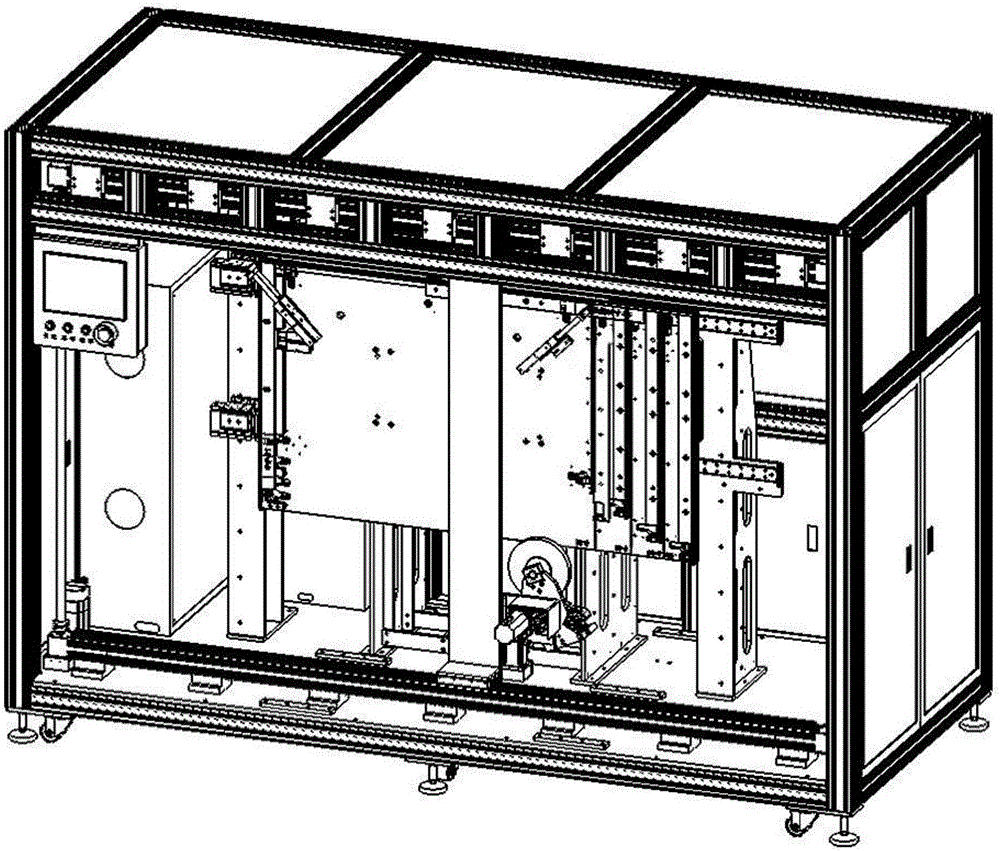

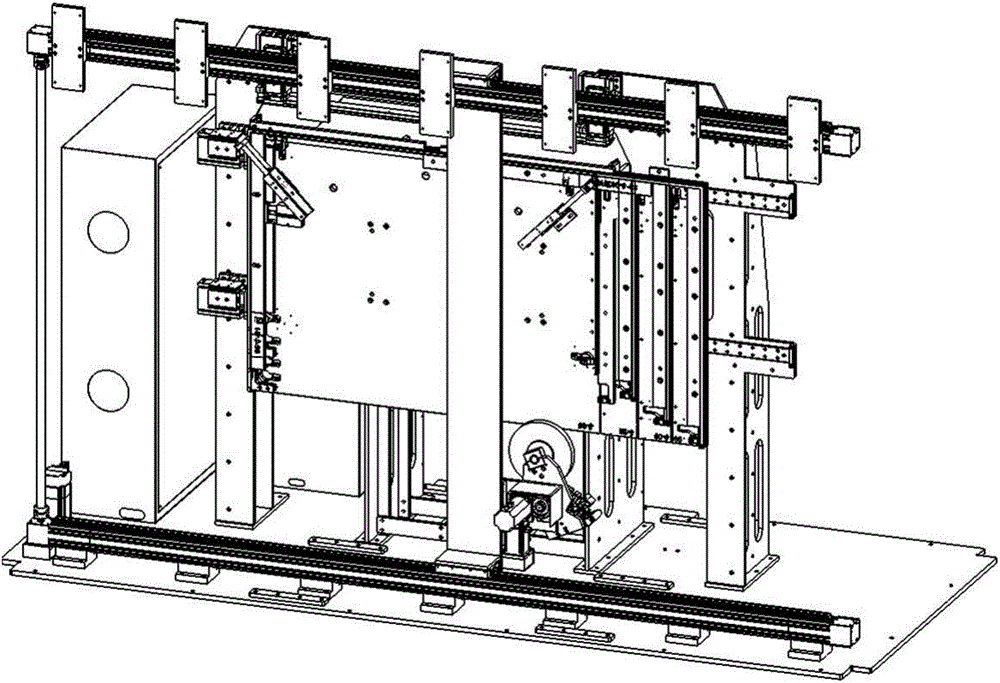

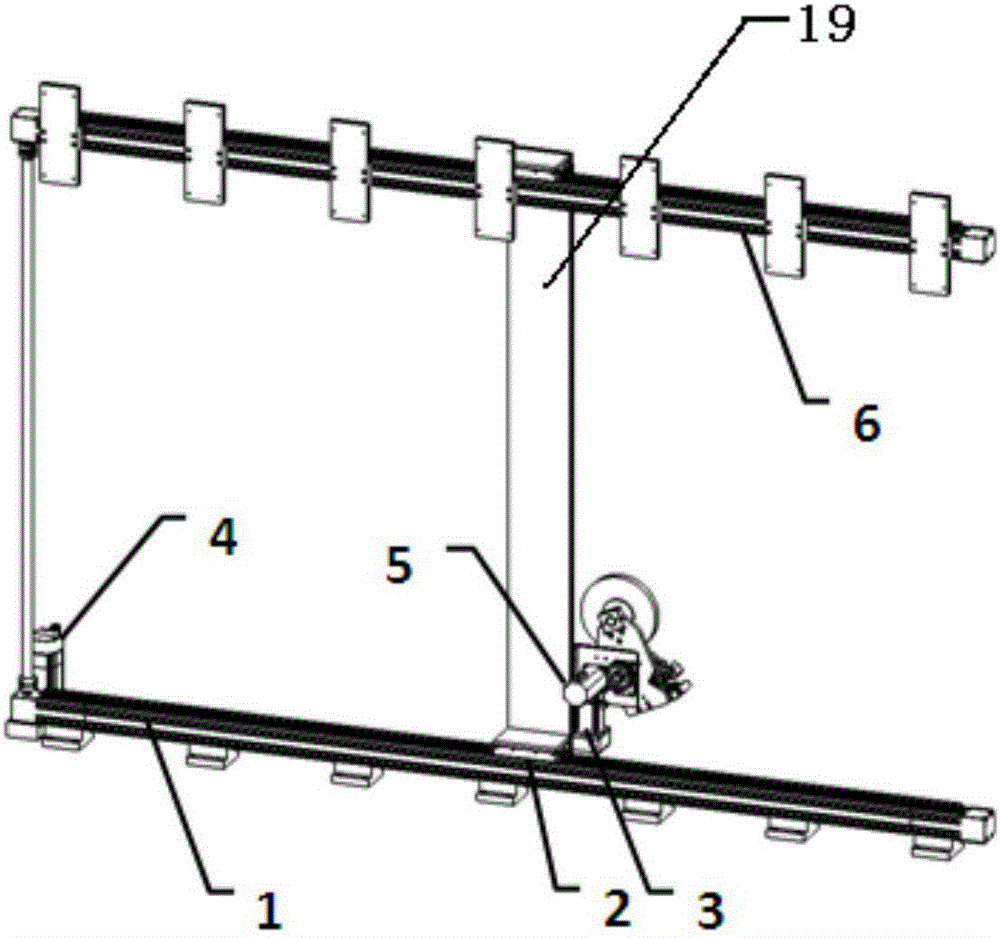

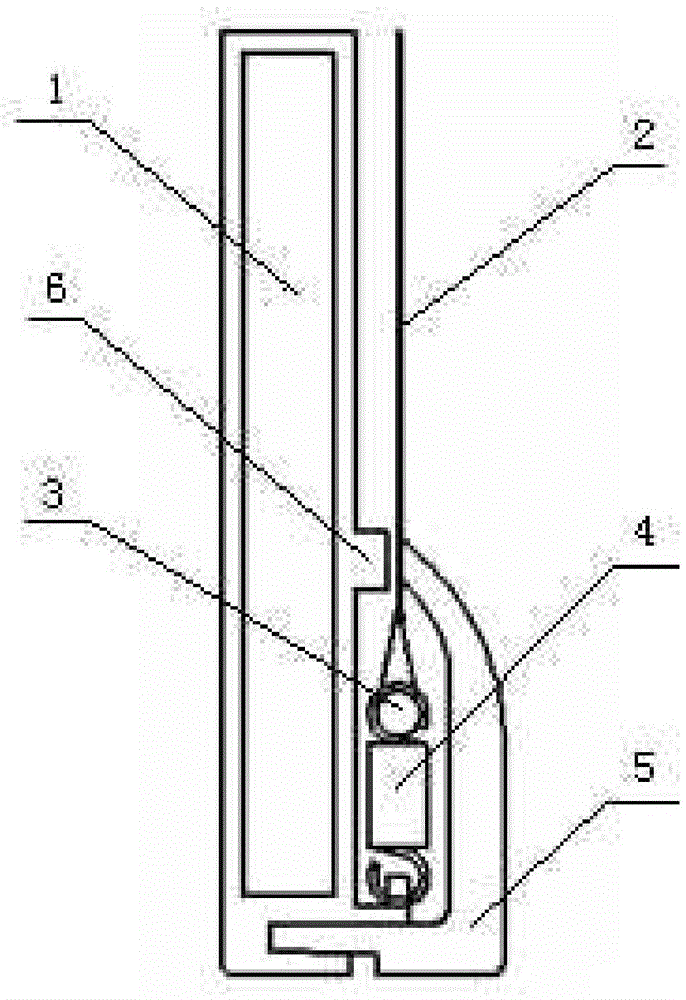

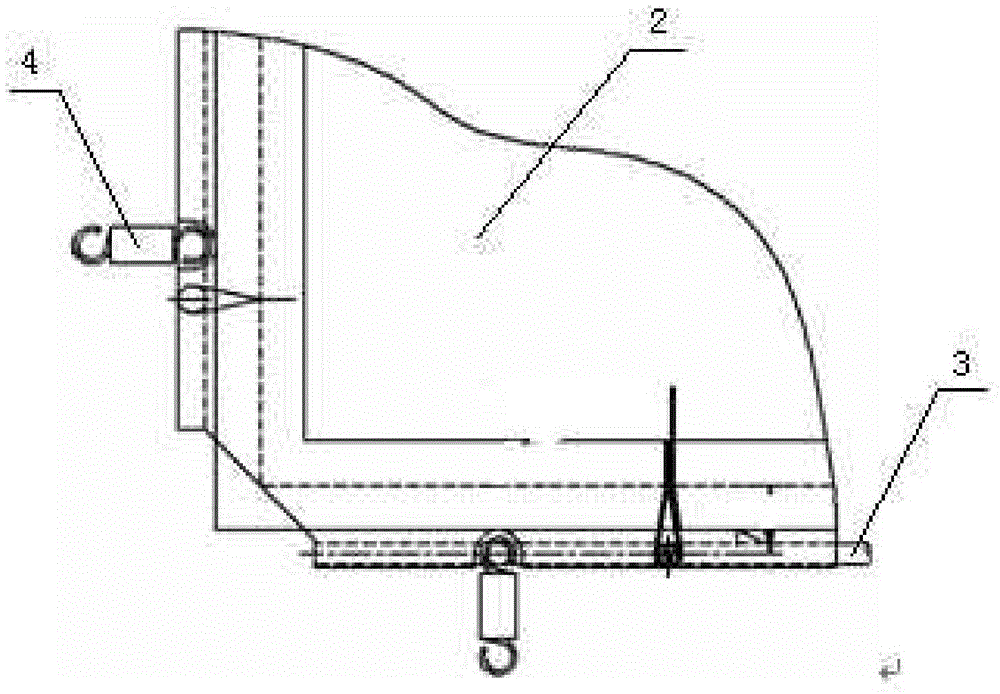

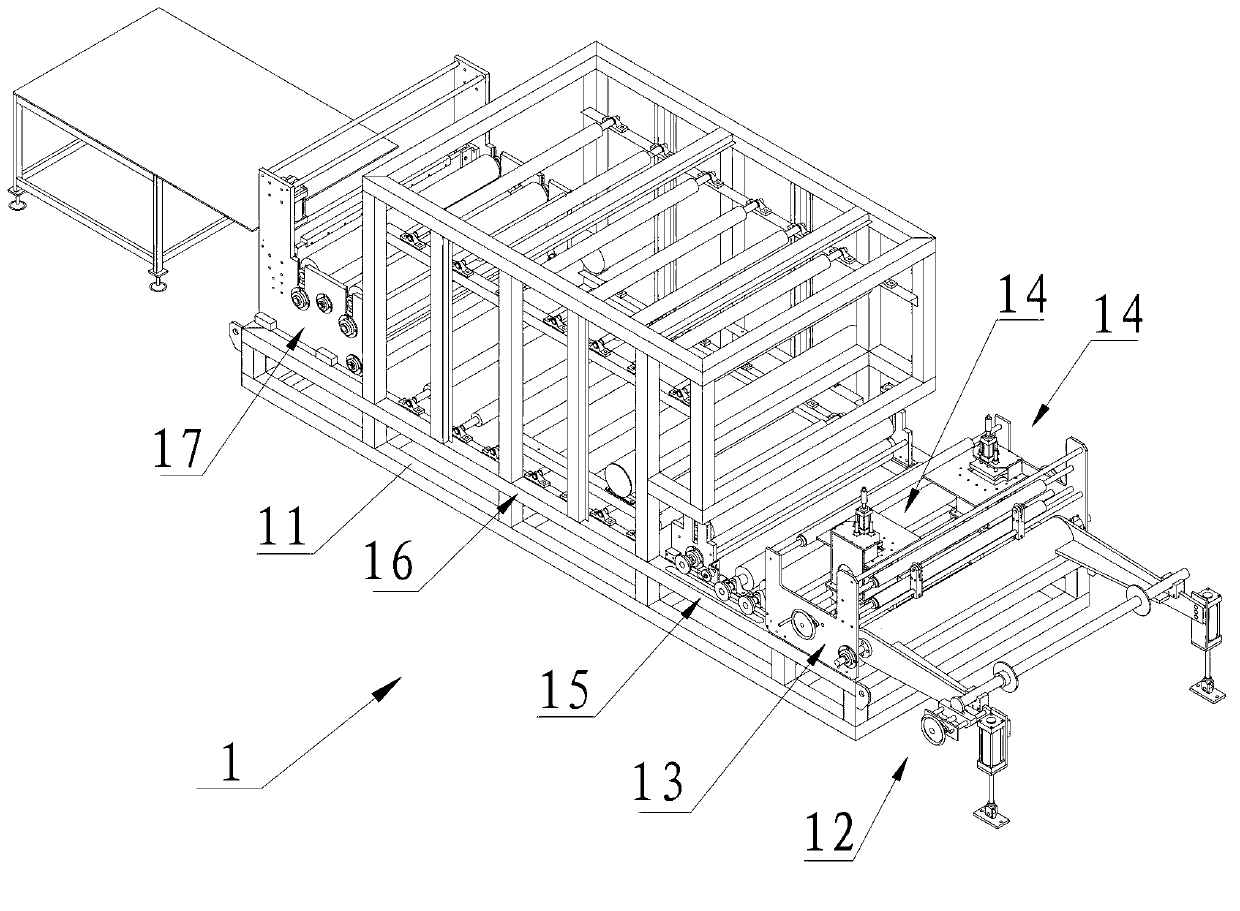

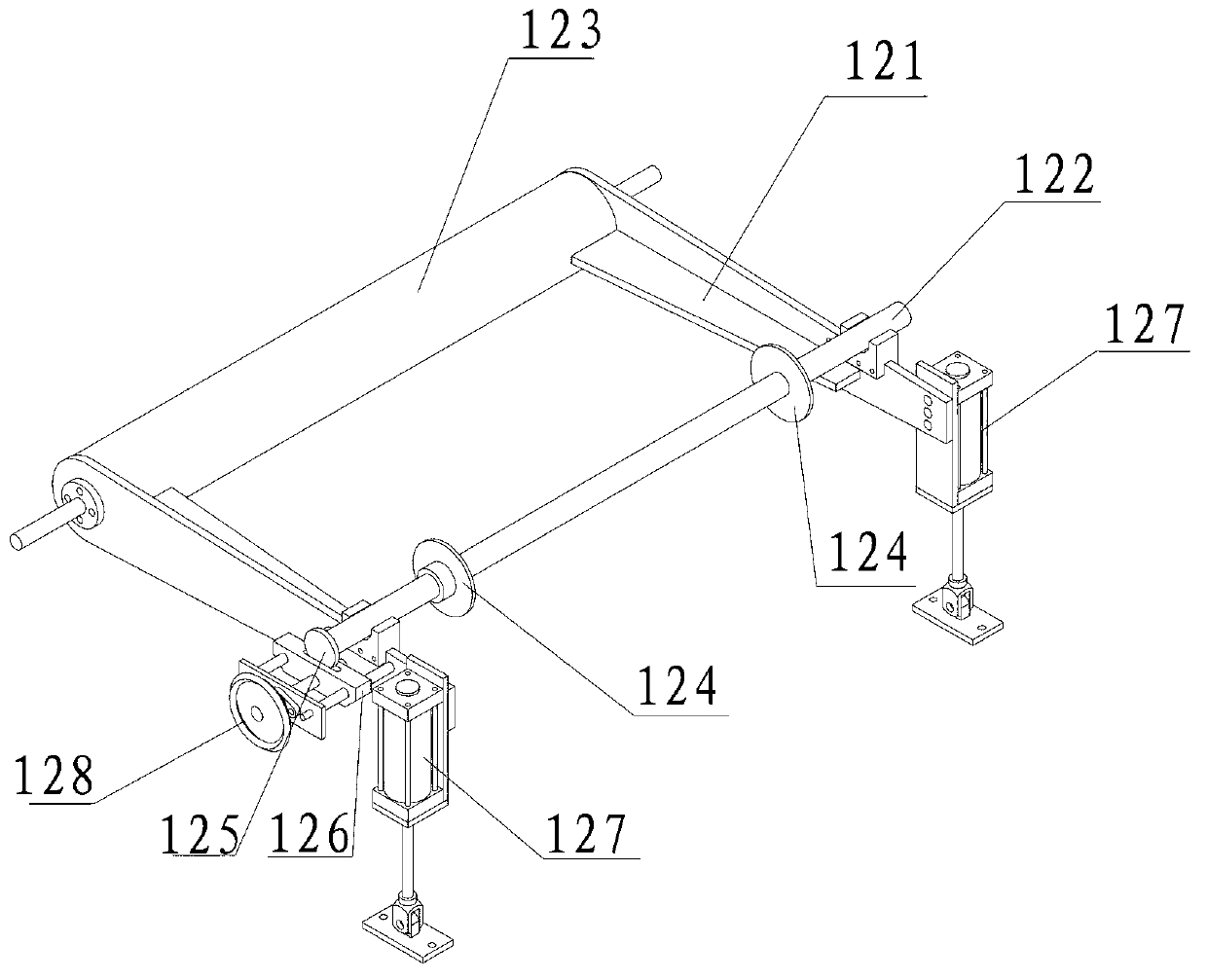

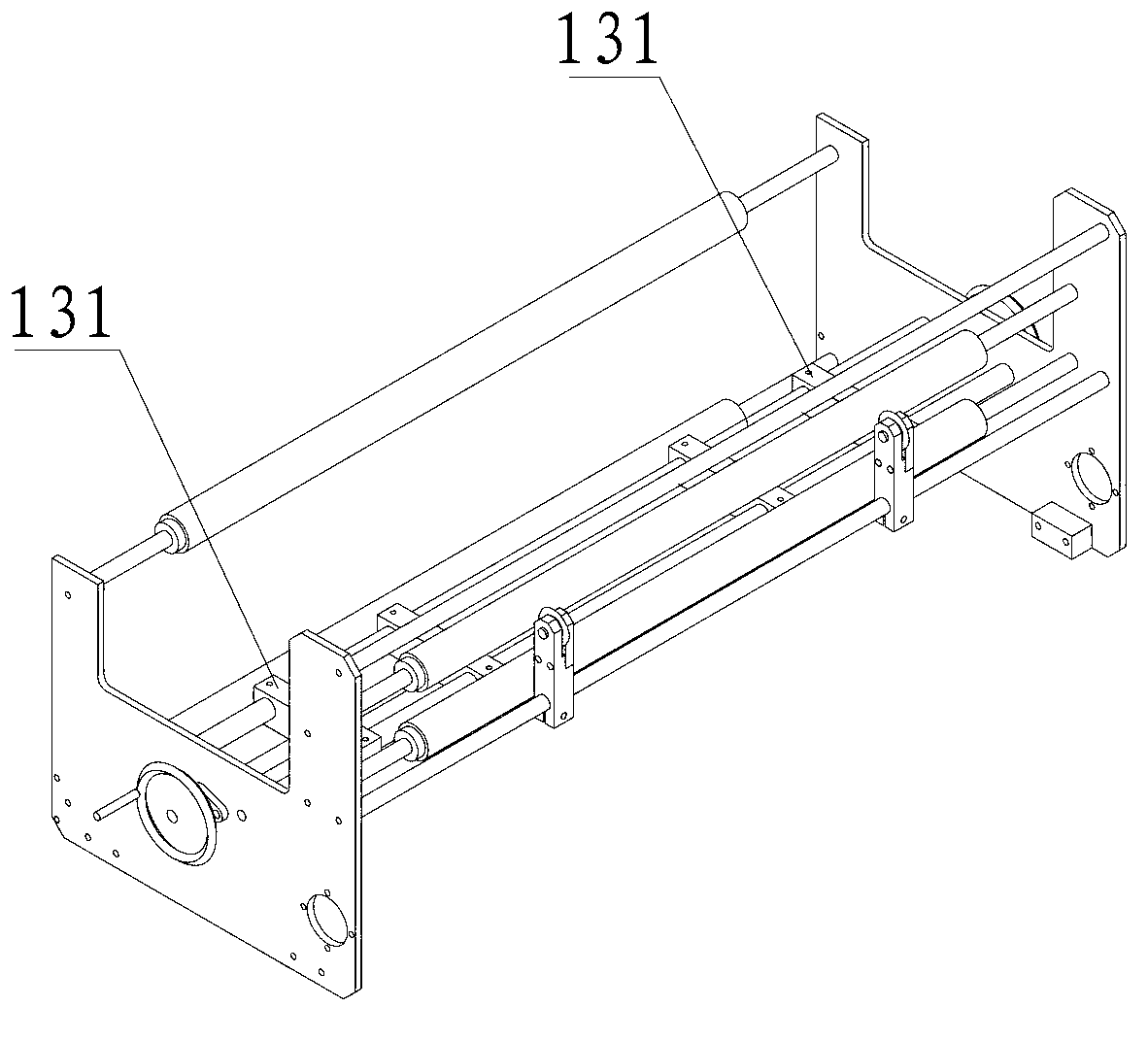

Multipurpose spreading machine with flattening and cloth-pressing functions

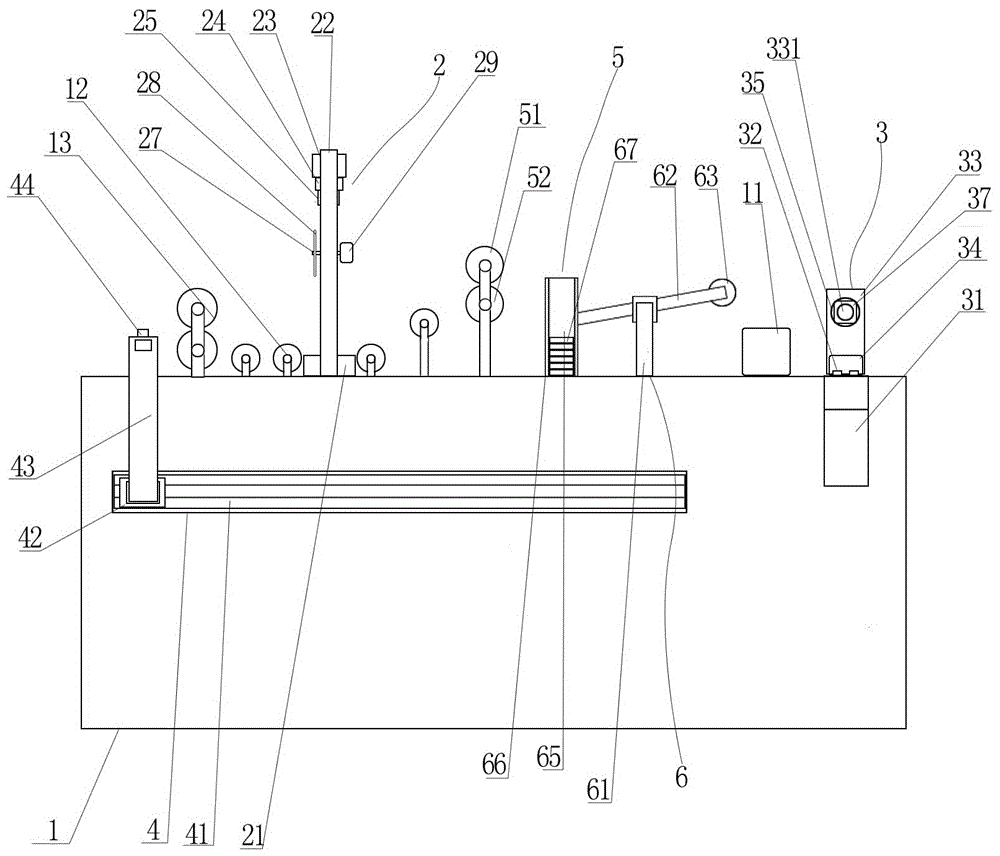

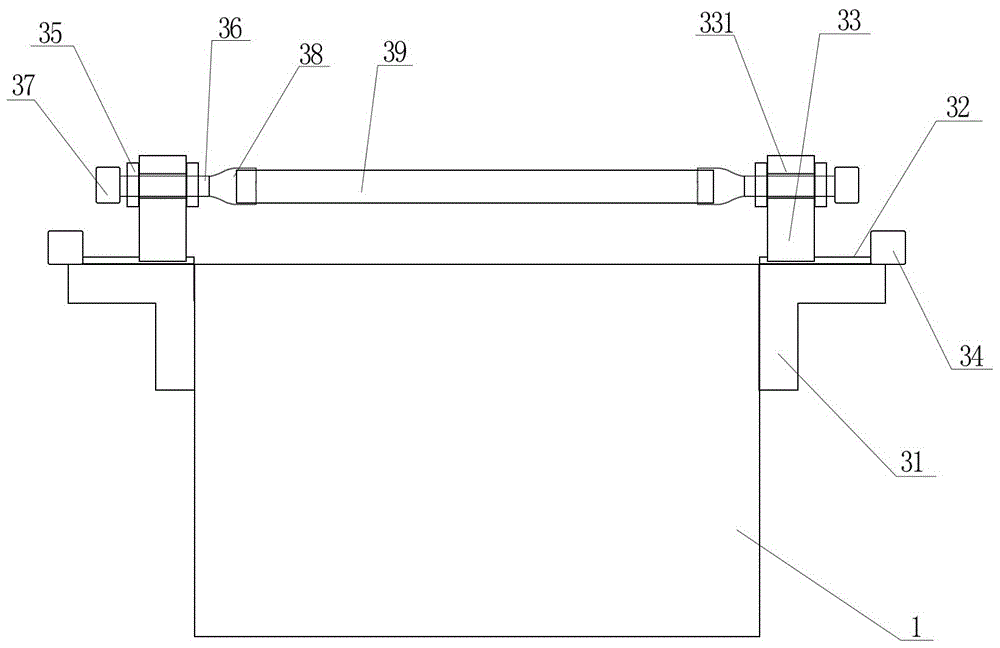

The invention relates to a multipurpose spreading machine with flattening and cloth-pressing functions. The multipurpose spreading machine includes a rack (1). The multipurpose spreading machine is characterized in that two sides of a spreading platform (2) are respectively provided with a side slide rail (3), a door type structure movable spreading frame (4) is arranged on the side slide rail (3), a bottom side of the rack (1) is provided with a reciprocating driving device along the side slide rail (3), one side middle part of the movable spreading frame (4) is provided with a first-stage scroll laying position (10), the upper part of the movable spreading frame (4) is provided with more than one upper scroll laying positions (11), electromagnetic pressurizing devices (19) are mounted on the inner sides of initial fixed mounts (18), and the lifting ends of the electromagnetic pressurizing devices (19) are equipped with cloth-pressing rods (20). The multipurpose spreading machine provided by the invention has a high degree of automation, can pull open a coiled cloth material and spread it on the spreading platform, the uncoiled cloth material does not deviate or wrinkle, also a plurality of cloth rolls can be operated simultaneously each time to release layers of cloth, and the spreading efficiency is greatly improved.

Owner:JIHUA 3506 TEXTILE & APPL

Fishing shoe rubber, anti-skid fishing shoes and preparation method of fishing shoe rubber

InactiveCN104479177AImprove wear resistanceImprove aging resistanceFootwearVulcanizationPolyethylene glycol

The invention discloses fishing shoe rubber, anti-skid fishing shoes and a preparation method of the fishing shoe rubber. The fishing shoe rubber is prepared from the following components in parts by weight: 15-20 parts of standard rubber, 10-15 parts of butadiene rubber, 10-15 parts of butyronitrile, 10-15 parts of white carbon black, 25-30 parts of activated calcium carbonate, 2-2.5 parts of petroleum resin, 1-1.5 parts of tackifying resin, 3-5 parts of dioctyl oxalate, 1-1.5 parts of an anti-aging agent, 0.3-0.5 part of stearic acid, 1-1.5 parts of polyethylene glycol, 2-3 parts of zinc oxide, 0.5-0.6 part of a vulcanization accelerator MBTS, 0.1-0.2 part of a vulcanization accelerator MBT, 0.04-0.05 part of a TS-80 accelerator and 0.7-0.8 part of insoluble sulfur powder. The components of the fishing shoe rubber are reasonably proportioned, so that the shoe rubber has good abrasive resistance, ageing resistance and oil resistance; and the service life of the fishing shoes is prolonged.

Owner:刘中华

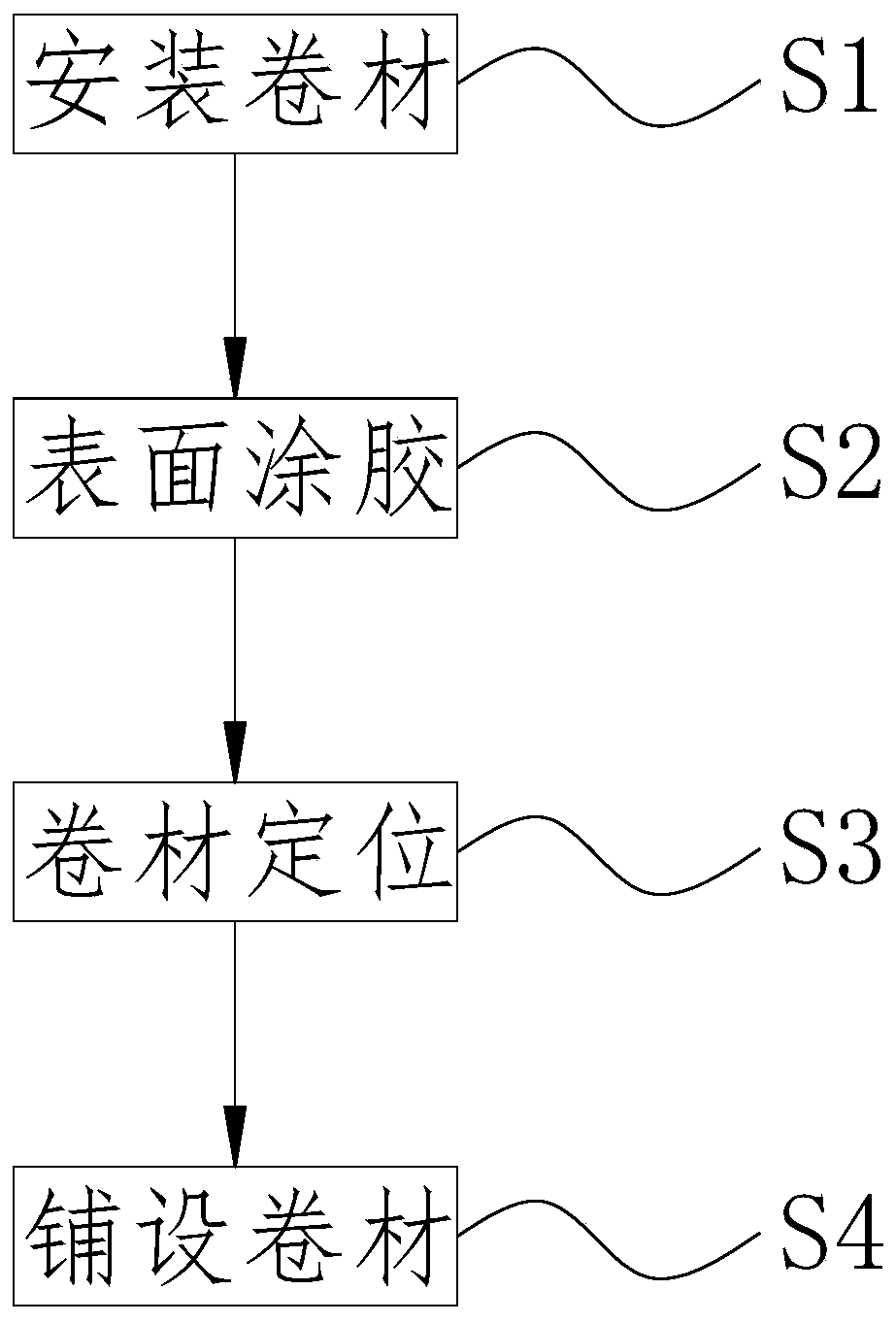

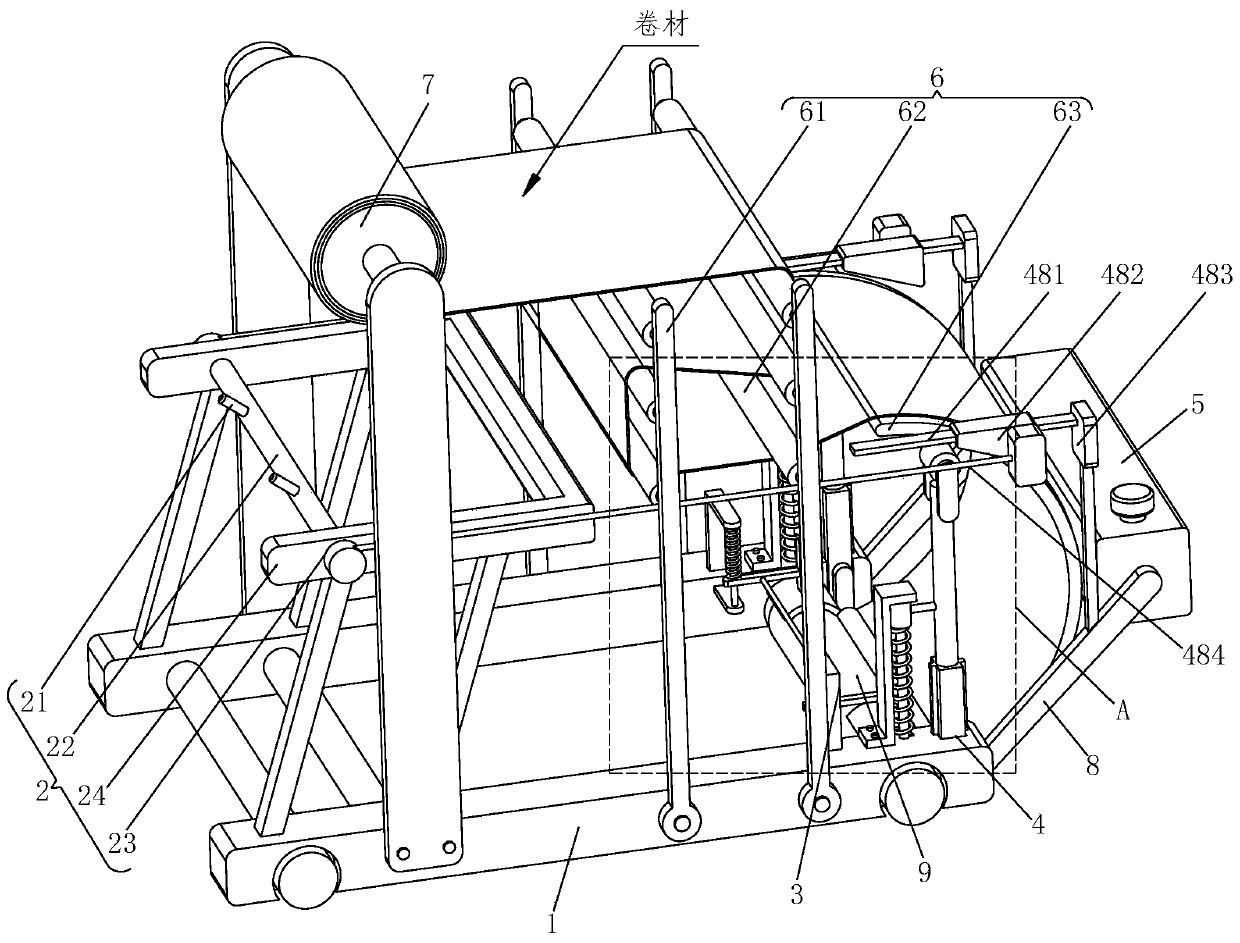

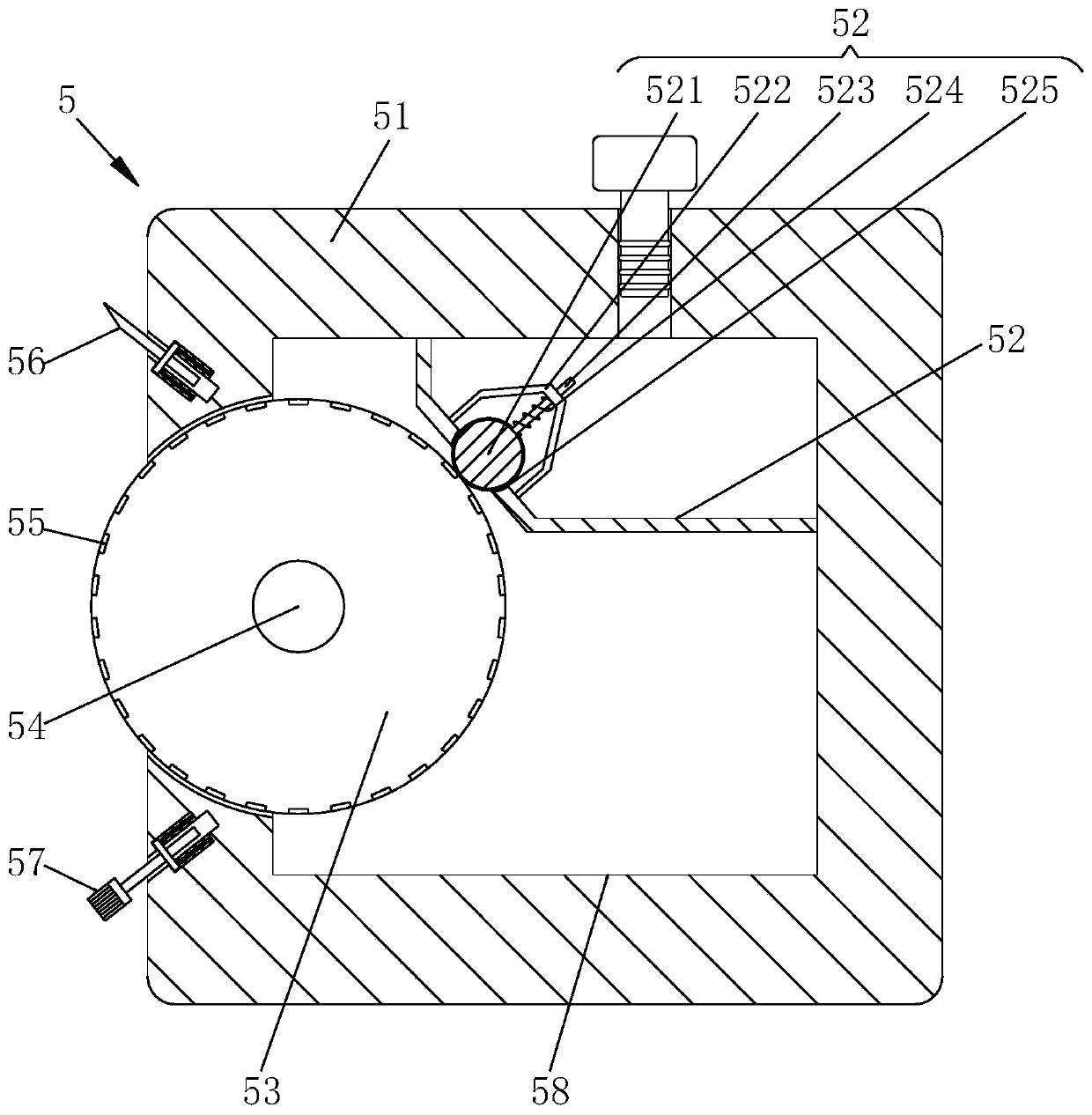

Waterproof coiled material laying construction method

The invention relates to a waterproof coiled material laying construction method. The waterproof coiled material laying construction method comprises a fixed base, a supporting assembly, a clamping mechanism, a positioning mechanism, a gluing mechanism, a bearing mechanism, a mounting roller, fixed plates and a fixed roller, the mounting roller is mounted above the fixed base through a first supporting plate, and the bearing mechanism is arranged above the fixed base and located on the right side of the mounting roller, the supporting assembly is arranged on the lower left portion of the mounting roller, the fixed roller is mounted on the inner side wall of the right end of the fixed base, the clamping mechanism is arranged over the fixed roller, the positioning mechanism is arranged on the right side of the clamping mechanism, the fixed plates are welded to the outer wall of the right end of the fixed base, the gluing mechanism is arranged at the upper end of the fixed plates, and thetwo side walls of a gluing shell are installed on the top side walls of the two fixed plates correspondingly. According to the waterproof coiled material laying construction method, the uniformity ofglue coating is effectively guaranteed, waste of glue is avoided, and meanwhile the tightness between a waterproof coiled material and a laid road surface is effectively guaranteed in the laying process.

Owner:盘达建设工程集团有限公司

Skin-friendly and environment-friendly polyurethane synthetic leather for earphone sleeve and preparing method of leather

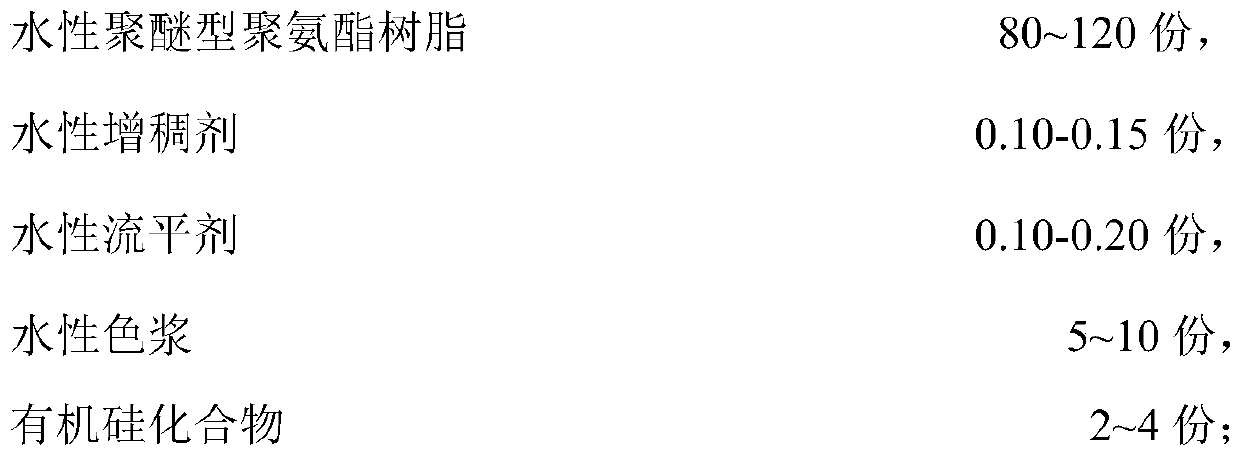

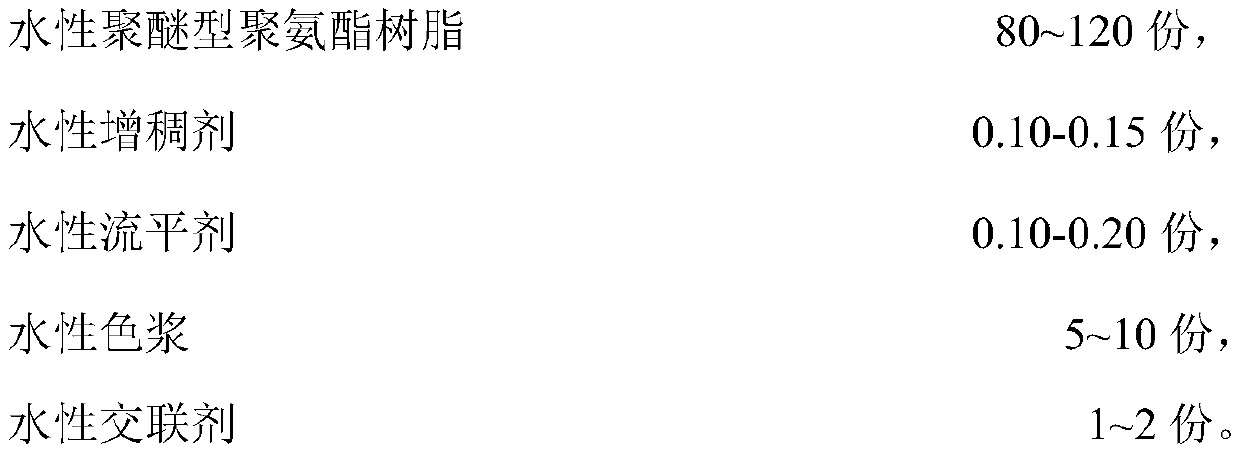

InactiveCN110541312APromote environmental protectionReduce usageGrip property fibresCoatingsSurface layerSolvent free

The invention discloses skin-friendly and environment-friendly polyurethane synthetic leather for an earphone sleeve and a preparing method of the leather. The leather sequentially comprises a dry-method surface layer, a middle layer, a foaming layer and a base cloth layer from outside to inside. The dry-method surface layer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts of waterborne color paste and 2-4 parts of an organic silicon compound. The middlelayer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts ofwaterborne color paste and 1-2 parts of a waterborne crosslinking agent. By means of the waterborne solvent-free process, the finished product can be controlled to be free of DMF, environmentally friendly and healthy; the prepared polyurethane synthetic leather is long in service life, excellent in hydrolysis resistance, soft in surface touch and plump in texture.

Owner:ANHUI ANLI MATERIAL TECH

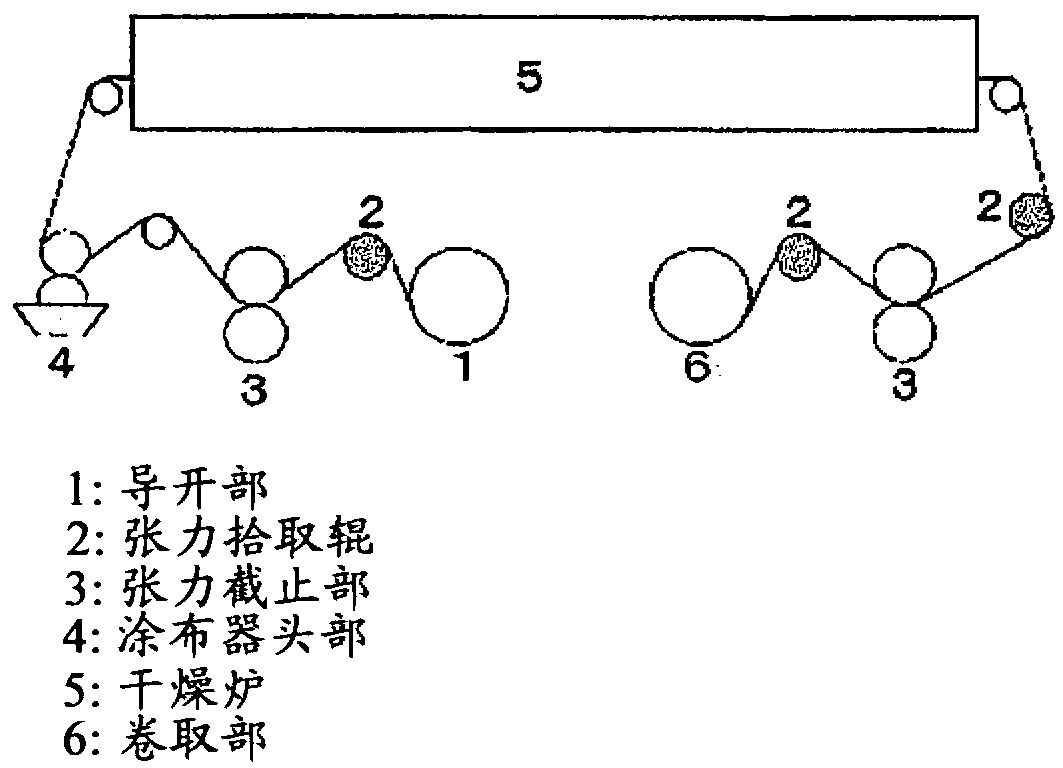

Laminate porous film manufacturing method

InactiveCN103314044ANo creasesCoating stabilitySynthetic resin layered productsPretreated surfacesComposite materialPorous film

Provided is a manufacturing method of a laminate porous film which is not prone to wrinkling and which comprises a covering layer laminated on at least one surface of a polyolephin resin porous film. This manufacturing method of a laminate porous film comprising a covering layer laminated on at least one surface of a polyolephin resin porous film is characterized by the tension (Ta) of the film in the drying step being less than or equal to 40N / m.

Owner:MITSUBISHI PLASTICS INC

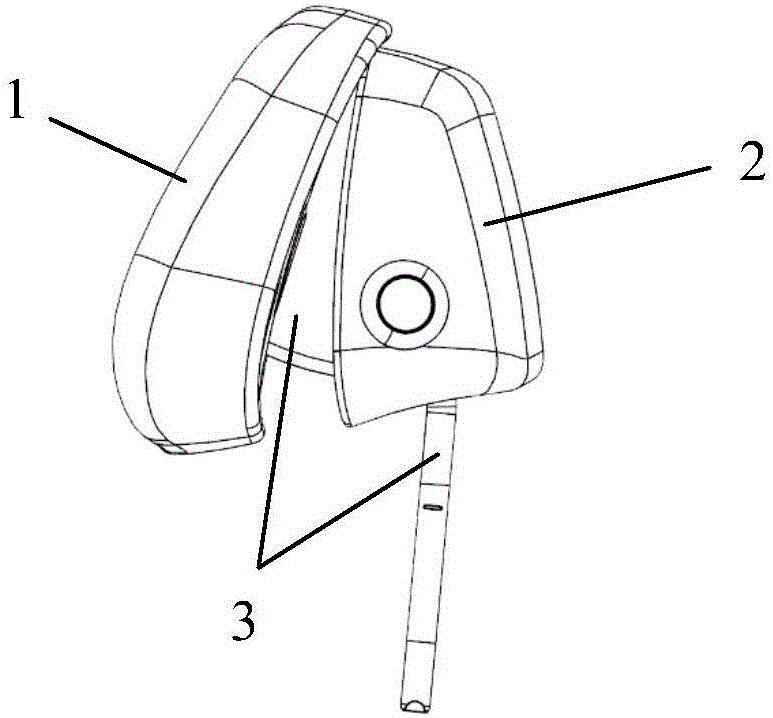

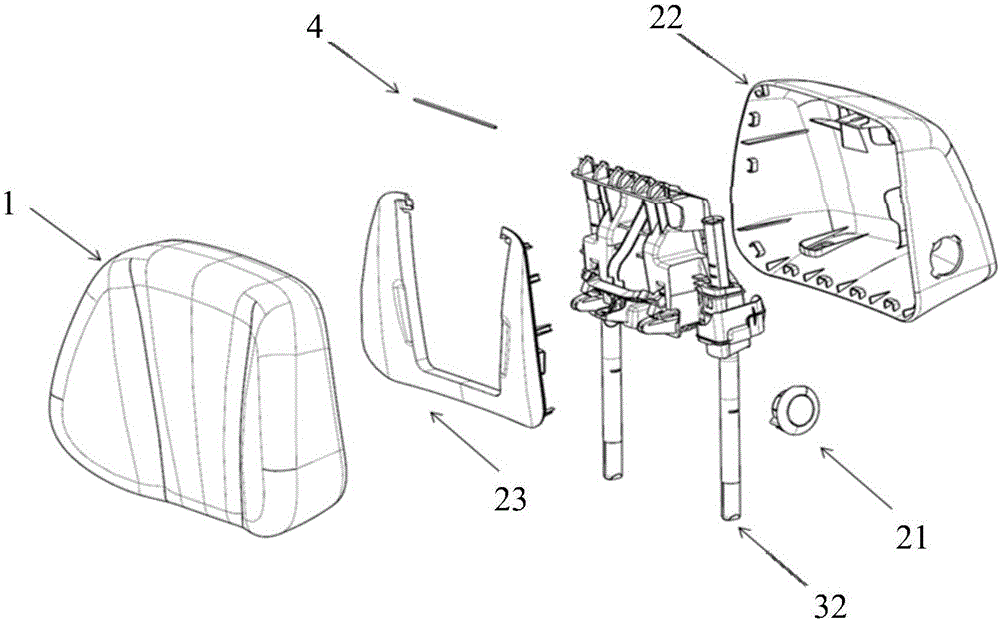

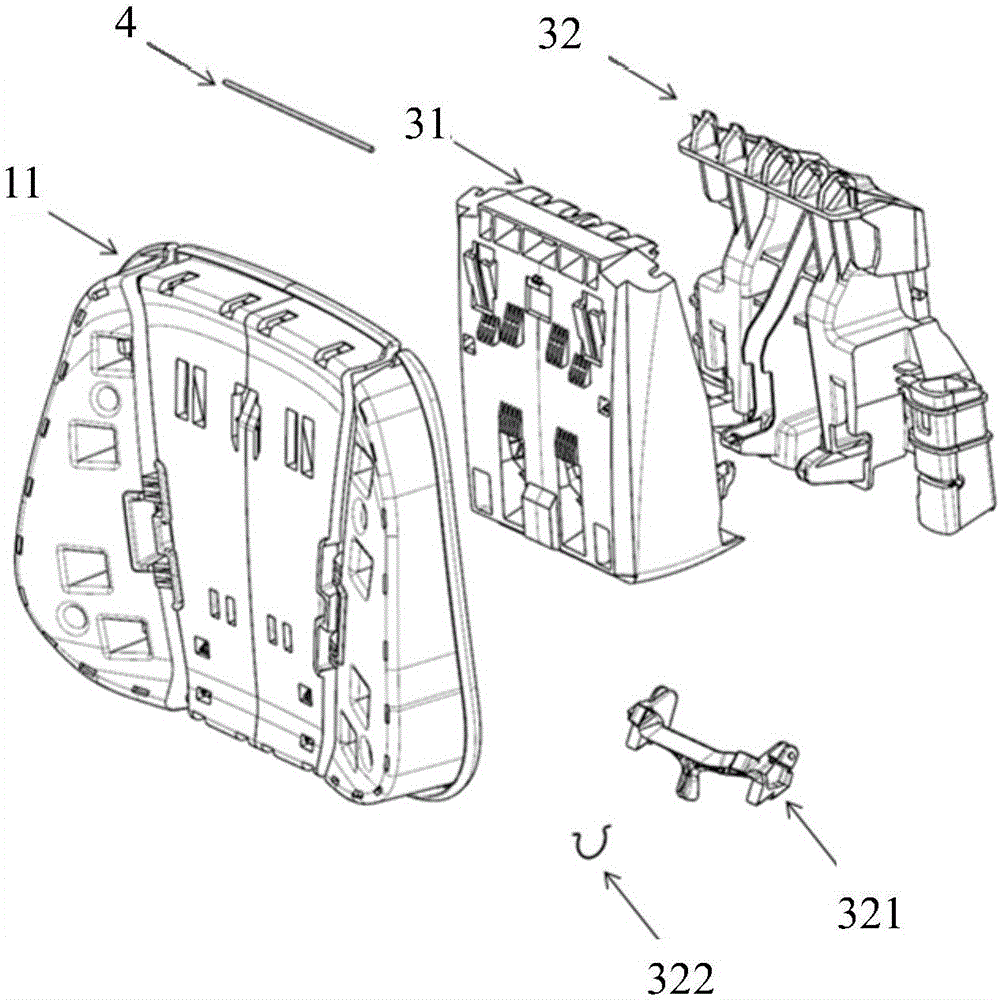

Automobile seat headrest

The invention discloses a car seat headrest, which comprises a front cover assembly, a rear cover assembly and a connection assembly, the connection assembly is used to connect the front cover assembly and the rear cover assembly; The connection assembly includes a turning body and a base, the turning body is installed in the front cover assembly, the base is installed in the rear cover assembly, the turning body and the top of the base Connected by a rotating shaft, the overturning body is provided with a plurality of locking teeth, and the base is equipped with pawls, and when the turning body rotates around the rotating shaft, the pawls cooperate with the plurality of locking teeth It is used to lock the turning body on multiple locking positions. Since the headrest can be locked at multiple card positions when the headrest is flipped back and forth, the angle and range of the flip adjustment are stable. In addition, because the headrest is divided into three parts, the front cover assembly, the rear cover assembly and the connection assembly, when the headrest is turned back and forth, no uncontrollable wrinkles will appear.

Owner:SAIC GENERAL MOTORS +1

Preparation method of anti-fog transparent silicone rubber film for rearview mirror of automobile

ActiveCN104212377AHigh transparencyIncrease elasticityFilm/foil adhesivesPolymer scienceTransmittance

The invention discloses a preparation method of an anti-fog transparent silicone rubber film for a rearview mirror of an automobile. The preparation method is characterized by comprising the following steps: coating one face of silicon rubber with an organosilicone pressure sensitive adhesive Q2-7735, then baking the organosilicone pressure sensitive adhesive Q2-7735 at a temperature of 180 DEG C for 30s to ensure that the organosilicone pressure sensitive adhesive Q2-7735 is cured, covering with a transparent PVC film; and spraying a polyether silane waterproof agent on the other face of the silicon rubber, and then baking the polyether silane waterproof agent at a temperature of 150 DEG C for 30-60min to ensure that polyether silane and hydroxyl on the surface of the silicon rubber generate a condensation reaction to obtain the anti-fog transparent silicone rubber film for the rearview mirror of the automobile. The silicon rubber provided by the invention is high in transparency and is pasted on a mirror surface without influencing light rays or causing distortion due to the fact that the light transmittance is greater than 98 percent. The silicon rubber is good in rebound resilience and can resist against tearing, hot and cold impaction, heat, radiation and ageing.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

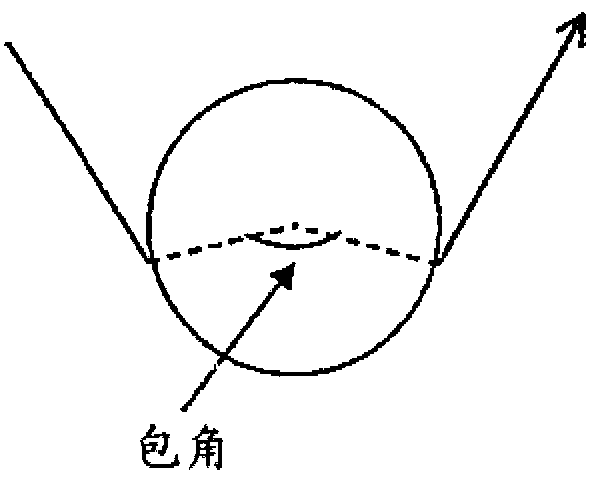

Frame automatic film pasting device and film pasting method thereof

InactiveCN106672305AEliminate inaccurate positioningNo creasesPackagingEngineeringFilm-coated tablet

The invention discloses a frame automatic film pasting device and a film pasting method thereof. The frame automatic film pasting device comprises a frame automatic locating device, a film pasting mechanism and a film coating mechanism. The frame automatic locating device fixes a frame to be subjected to film pasting to a jig plate. The film pasting mechanism is used for pasting a protective film to the peripheral outer side wall of the frame to be subjected to film pasting. The film coating mechanism pastes the protective film exposed on the peripheral outer side wall of the frame to be subjected to film pasting to the position, uncoated with a film, of the frame to be subjected to film pasting. The frame automatic film pasting device is simple in structure and easy to operate, film pasting can be carried out on non-plane products, that is, film pasting can be carried out on articles with corners, and applicability is good.

Owner:HEFEI BYAT AUTOMATIC TECH CO LTD

Crease-free picture frame screen with hidden spring

The invention discloses a crease-free picture frame screen with a hidden spring belonging to the technical field of projection display. The picture frame screen comprises a frame and a screen, wherein the screen is arranged on the surface of the frame; support rods are arranged at the periphery of the screen and run through the overall edge length of the screen; a plurality of elastic parts are evenly distributed on the support rods; one end of each elastic part is connected with the corresponding support rod and the other end is connected with the frame; and a picture frame is also arranged at the periphery of the frame, wraps the periphery of the screen and the elastic parts, and is arranged on the frame in a clamping manner. The crease-free picture frame screen has the beneficial effects that the support rods are arranged at the periphery of the screen, and the elasticity of the elastic parts is evenly dispersed to the periphery of the screen, so that the curtain has constant, lasting and uniform tension and is kept in a flat state for a long period of time; no crease appears in the screen surface; an image can be displayed under an ultra-short focus projection in an undistorted manner; the front surface and the rear surface of the screen are clean and tidy in structure; and the elastic parts or other point bulges are not exposed, so that a user can be prevented from being scratched.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Double-sided adhesive film and manufacturing method thereof

The invention provides a double-sided adhesive film and a manufacturing method thereof, wherein a transparent substrate can be attached to easily form a display panel. Meanwhile, the generation of bubbles, wrinkles and the like is less likely to occur. The double-sided adhesive film is used for the adhesion of a plurality of transparent substrates to form a display panel. The double-sided adhesive film is characterized by comprising a releasable film, and a laminated body formed on the releasable film and provided with a first adhesive layer and a decorative layer. When the transparent substrates are attached together by means of the double-sided adhesive film to form the display panel, the decorative layer is arranged on the laminated body in such a manner that the other part of the display panel, except a display part, is covered by the decorative layer.

Owner:TOPPAN TDK LABEL CO LTD

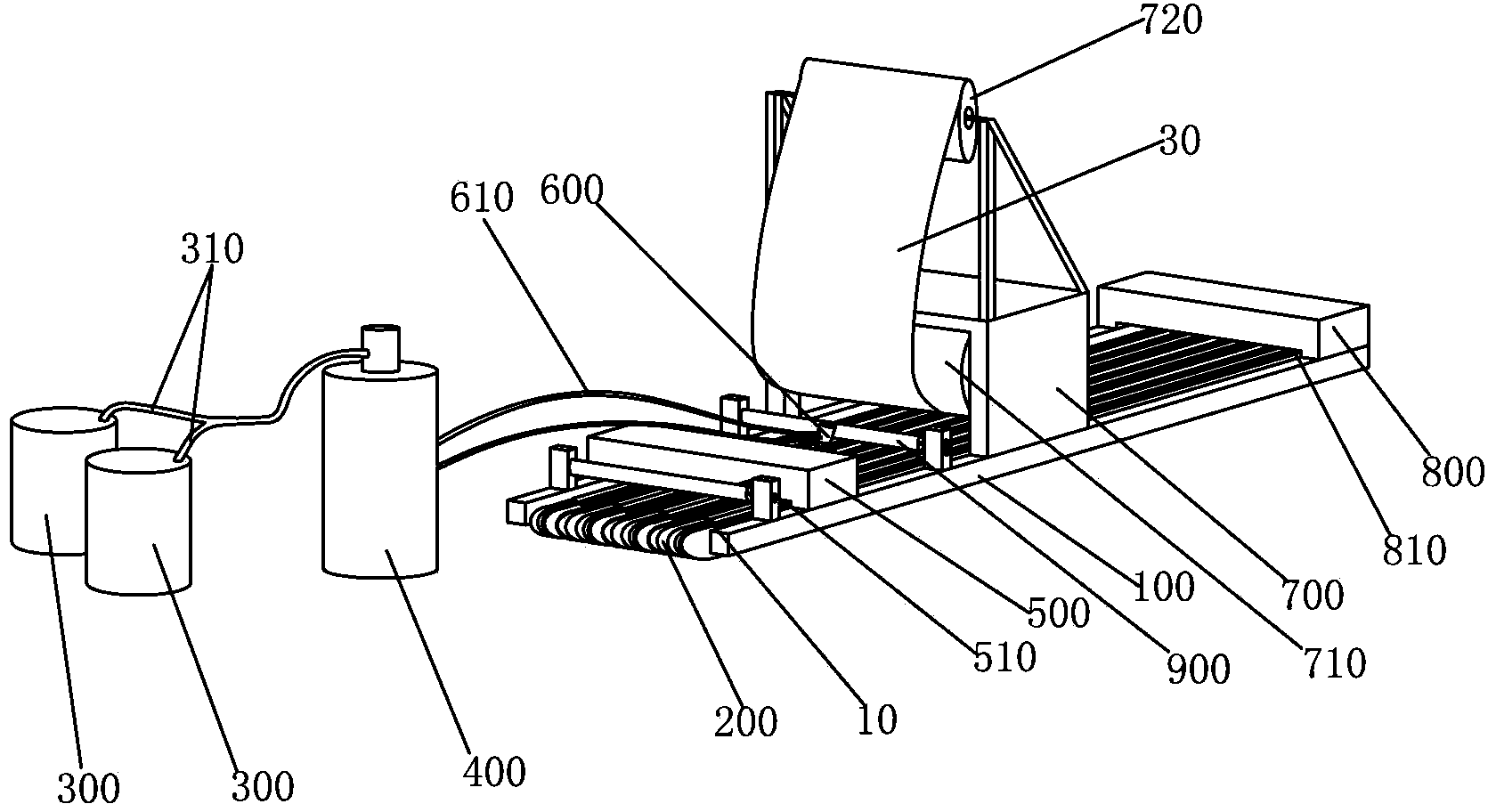

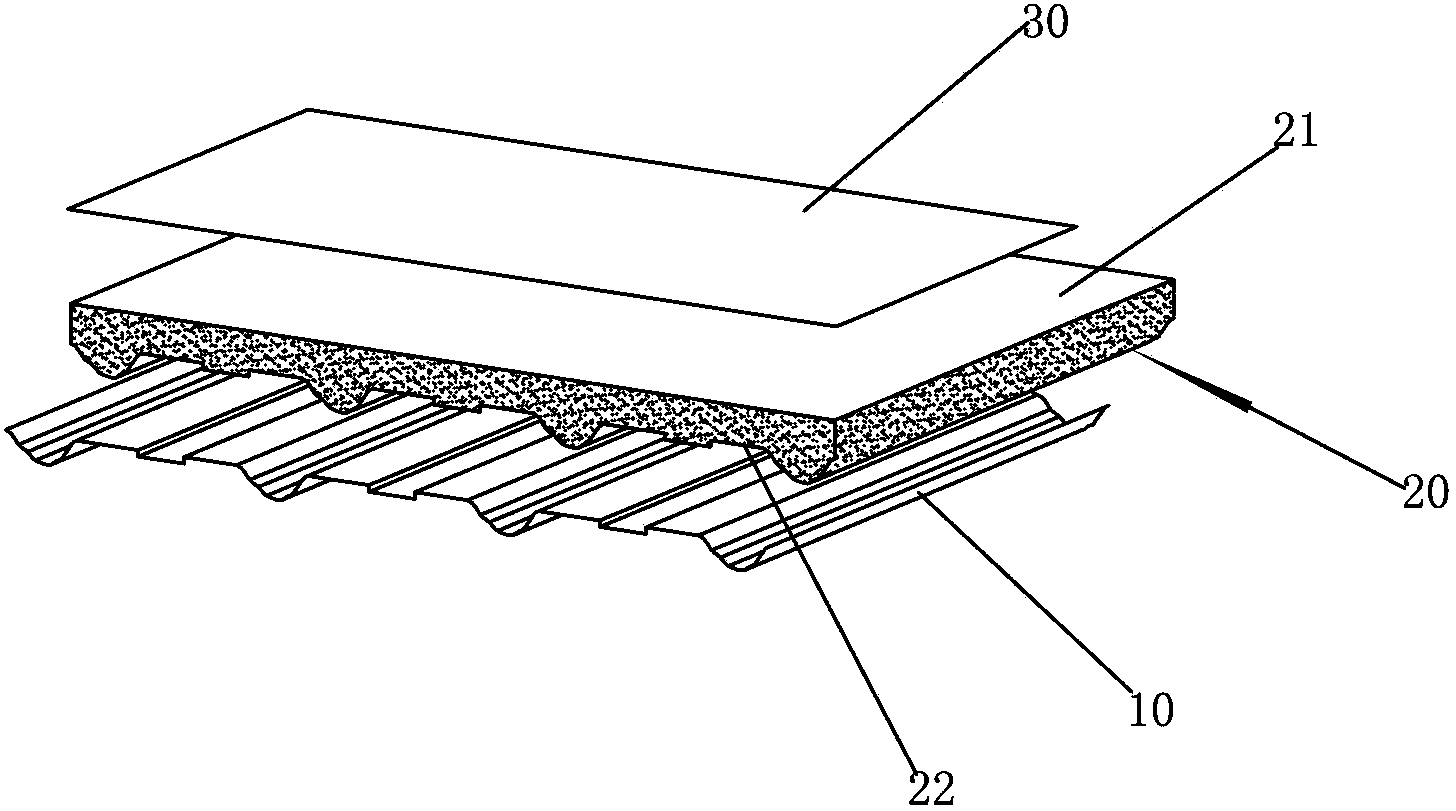

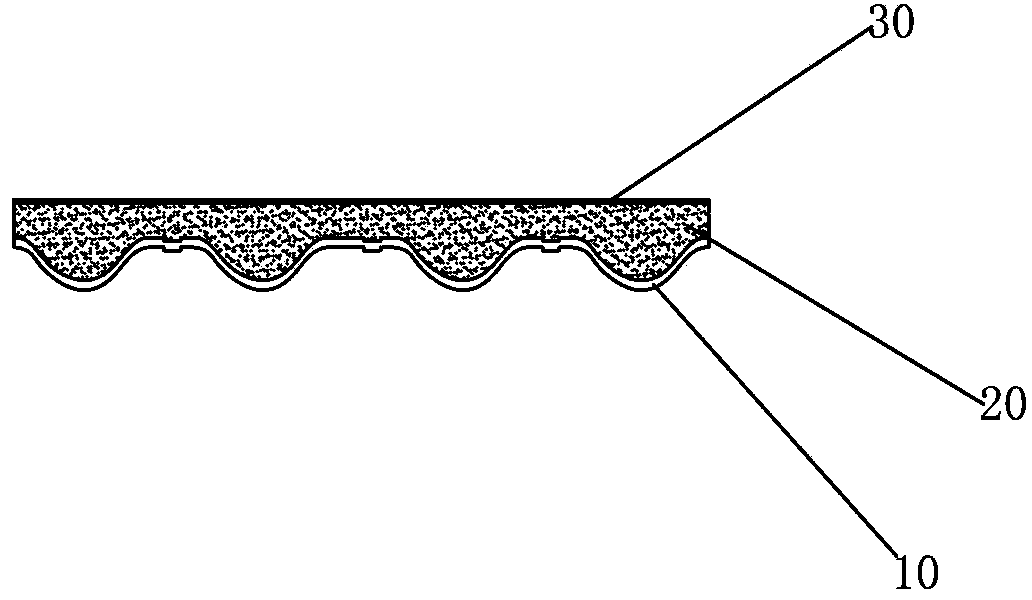

Production technology and equipment for thermal insulating and flame-retardant wall

The invention discloses a production technology and equipment for thermal insulating and flame-retardant wall. The production technology includes: step 10, heating polyisocyanate and polyether respectively to 39-41DEG C; step 20, mixing the polyisocyanate and polyether in a volume ratio of 1:1.1-1.6, and conducting stirring to obtain a foaming agent; step 30, heating a substrate profile to 39-41DEG C; step 40, jetting the foaming agent evenly onto the substrate profile surface to form a foaming layer; step 50, sticking a flame-retardant layer on the foaming layer to obtain a semi-finished product; and step 60, drying the semi-finished product to obtain a finished product. The obtained foaming agent has a short foaming time, which is shorter than the foaming time under room temperature by at least over one time. The rate of finished products is high, and the yield is increased by over 50% compared with the circumstance of not heating the substrate profile. At the same time, the whole production process is simple, and the production equipment is not complex, so that the process and the equipment are suitable for mass production, and the production efficiency is high.

Owner:PUTIAN CHENGXIANG JIN XIN LIGHT STEEL COLOR PLATECO

Spinning flange ring and forming technology thereof

ActiveCN105889744AImprove mechanical propertiesNo crackInternal combustion piston enginesConstructions elementsPunchingEngineering

The invention belongs to the technical field of automobile accessories, and particularly relates to a spinning flange ring and a forming technology thereof. The spinning flange ring comprises a flange ring body and a central inner hole. The inner wall of the flange ring body is of a groove structure. The ring body with the outer wall smoothly protruding surrounds the central inner hole. The spinning flange ring is manufactured through the first step of feeding, the second step of punching, the third step of inclination pressing, the fourth step of spinning forming, the fifth step of punching, the sixth step of inner circle turning, and the seventh step of outer circle turning and small hole drilling. The flange ring is manufactured through the spinning technology, the shape of a blank is preprocessed, part of the outer edge of the blank is pressed down, positioning is achieved through the central hole, and no cracks or wrinkles can appear in the spinning process; meanwhile, by means of the spinning technology, the product is good in plastic performance and longer in service life.

Owner:ZHEJIANG DONGXING AUTO PARTS

Drying and fold removal integrated machine for spinning

InactiveCN109594275AImprove drying efficiencyEasy to useMechanical cleaningPressure cleaningProcess engineering

The invention discloses a drying and fold removal integrated machine for spinning. The drying and fold removal integrated machine for spinning comprises a machine body, wherein partition boards are fixedly connected with two sides in the machine body; fixed blocks are fixedly connected with the top and the bottom of the right side of an inner cavity of the machine body; air outlet holes are formedin the surfaces of the fixed blocks; heating wires are fixedly connected into the fixed blocks; a storage battery, a heating box, a fan and a control panel are fixedly connected with the top of the machine body from left to right in sequence. By cooperative use of the storage battery, the heating box, the fan, the control panel, an air outlet pipe, the heating wires, a heater, steam outlet pipes,first electric telescopic rods, a bracket, a steam press wheel and steam outlet holes, the drying and fold removal integrated machine for spinning is convenient to use, has high drying efficiency, and can remove folds on the surface of the fabric during fabric processing, folds cannot appear on the surface of the fabric, following processing of the fabric cannot be affected, demands of people canbe met, and the machine is convenient to use.

Owner:管洪化

Thermoplastic elastomer door seal easy to weld and preparation method thereof

The invention relates to a thermoplastic elastomer door seal easy to weld. The door seal is prepared from, by weight, 40-55 parts of SEBS elastomers, 5-15 parts of tackifying resin, 10-15 parts of filler, 5-15 parts of processing oil, 10-15 parts of polypropylene, 1-2 parts of lubricating agent, 0.1-1 part of pigment, 0.1-0.5 part of antibacterial and antifungal agent, 0.1-0.5 part of antioxidant and 0.1-0.5 part of ultraviolet light absorber. The invention further provides a preparation method of the thermoplastic elastomer door seal. The thermoplastic elastomer door seal easy to weld is high in welding strength and good in rebound elasticity, still keeps the good elasticity in the low-temperature application environment such as refrigerators and other refrigeration appliances, prevents a flash seam from being produced, can better close the gap between a door body and a box body, reduces electric appliance energy consumption and makes a contribution to further energy conservation of the refrigeration appliances.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

Seamless paper pipe production line

InactiveCN102950818AExcellent overall performanceReduce wastePaper/cardboard wound articlesPaper sheetCopper foil

The invention discloses a seamless paper pipe production line, which comprises paper processing equipment, a paper sizing device, a paper pipe covering pipe, a paper pipe waxing device and a paper pipe calendaring device. At first, the paper processing equipment processes paper so that the two sides of the paper become thin, the surface flatness and hardness of the paper can be improved, and then, the paper is chopped into be in a proper dimension for standby; and the paper sizing device sizes the surface of one side of the paper, the sized paper is covered on the peripheral surface of the outer side of a paper pipe through the paper pipe covering device, the edge parts of the two sides of the paper, which become thin, are clung with each other, and in this way, a seamless paper pipe can be formed. After the paper pipe waxing device waxes on the peripheral surface of the outer side of the seamless paper pipe, the seamless paper pipe becomes smooth; and the seamless paper pipe is subjected to calendaring by the paper pipe calendaring machine, so that the seamless paper pipe has good straightness and cylindricity. When the seamless paper pipe is used for winding a thin film, a copper foil and other thinner materials, the materials can not be wrinkled, so that the waste caused by the damaged materials can be greatly reduced.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

Environment-friendly wear-resisting semi-rigid heat-shrinkable tube for protecting car metal pipeline and preparation method thereof

InactiveCN104788776AAct as stressPlay a protective effectPipe protection against damage/wearLow-density polyethyleneAntioxidant

The invention discloses an environment-friendly wear-resisting semi-rigid heat-shrinkable tube for protecting a car metal pipeline and a preparation method thereof. The heat-shrinkable tube is mainly prepared from the following ingredients in parts by weight: 50-75 parts of low-density polyethylene, 25-50 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of an inorganic filler, 1.5-2.0 parts of an antioxidant, 1.0-2.0 parts of a lubricant and 3-6 parts of carbon black masterbatch. The preparation method comprises the following steps: granulation, extrusion, irradiation and expansion with a two-step mixing method. The heat-shrinkable tube has good adhesive strength with the car pipeline, the phenomena of separation from the pipeline and pleating of the heat-shrinkable tube cannot occur in the bending operation, and the sealing is ensured. Meanwhile, the environment-friendly wear-resisting semi-rigid heat-shrinkable tube has the characteristics of being easy and convenient to mount, high in performance cost ratio, safe and durable and can effectively prolong the service life of the car pipeline and reduce the potential safety hazards of vehicles during use.

Owner:大连联合高分子材料有限公司

Automatic film pasting equipment

Owner:TIANJIN KUNHAO PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com