Electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment

A vertical continuous electroplating, roll-to-roll technology, applied in the direction of current conduction device, cleaning/polishing of conductive pattern, electrode, etc. Ground space, ensure good conductive contact, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

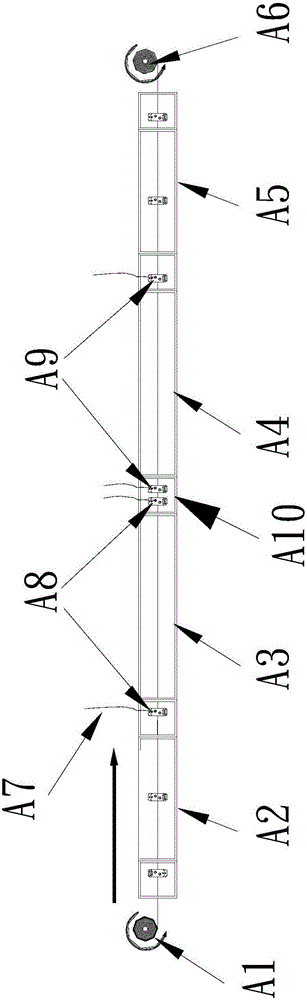

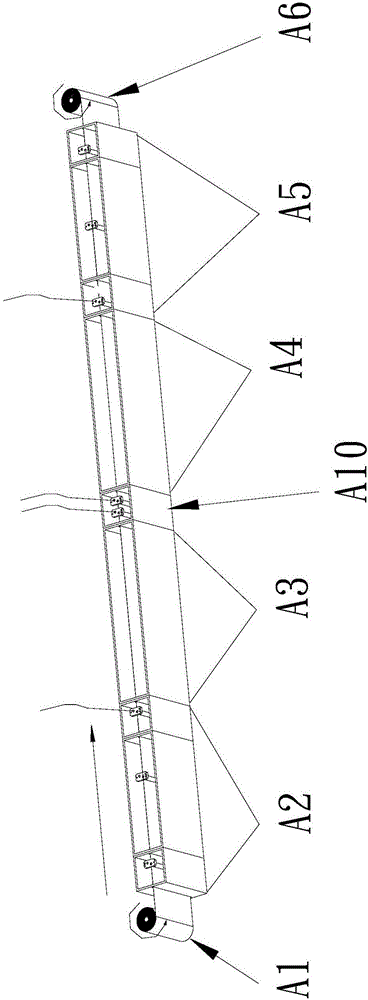

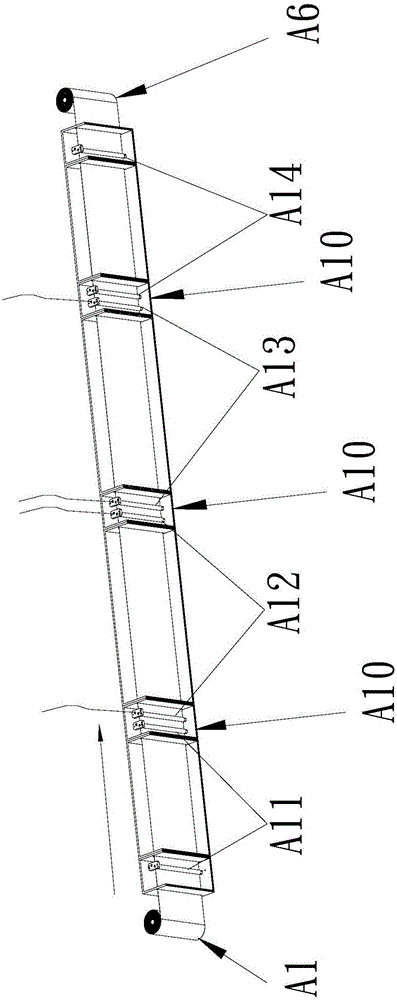

[0067] like Figure 5 to Figure 23 As shown, the electroplating clip conductive roll-to-roll vertical continuous electroplating equipment of the present invention is composed of an unwinder 1 , a pre-processing section 2 , an electroplating section 3 , a post-processing section 4 and a winding machine 5 . Wherein, the pre-treatment section 2, the electroplating section 3 and the post-treatment section 4 are all installed between the unwinder 1 and the winder 5 and arranged in sequence according to the direction from the unwinder 1 to the winder 5. The electroplated flexible circuit board FPC is released by the unwinder 1 and rewound into a roll by the winder 5, and the electroplated flexible circuit board FPC moving from the unwinder 1 to the winder 5 is released by the unwinder 1 and the winder. The machine 5 is tensioned in a plane, and the pre-treatment section 2, the electroplating section 3 and the post-processing section 4 sequentially perform electroplating pre-treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com