Patents

Literature

38results about How to "Improve plating uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

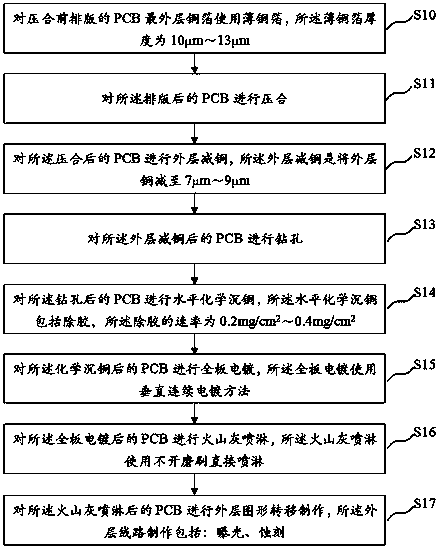

PCB circuit manufacturing method and PCB

InactiveCN110213895AAvoid over etchingMeet production needsInsulating substrate metal adhesion improvementInsulating layers/substrates workingEtchingDirect imaging

The invention discloses a PCB circuit manufacturing method and a PCB. The method comprises the following steps: using a thin copper foil with the diameter of 10 to 13 microns as the outermost layer ofcopper foil of a type setting PCB, then laminating, reducing the copper on the outer layer to be 7 to 9 microns after laminating, then carrying out hole drilling and low-speed chemical adhesive cleaning, using vertically continuous electroplating manufacturing in later electroplating working procedure, controlling the thickness of copper on the inner wall of the hole to be 15 to 20 microns and the thickness of copper on the surface to be 24 to 30 microns, then carrying out surface roughening in a cinerite spraying mode for turning off a polishing brush, then using a laser direct imaging exposure machine for exposure in the manufacturing process of an outer circuit, carrying out developing and etching by using a low-pressure and high-speed mode, and presetting 10% to 20% of a circuit compensating value in advance. The problems, such as a great number of too thin and too wide lines, excessive etching, under developing, short circuits and open circuits existing in the circuit manufacturing process, of the PCB product with fine circuits (for example, the ratio of line width to line gap is smaller than or equal to 2 mil / 2 mill) can be solved.

Owner:深圳市鼎盛电路技术有限公司

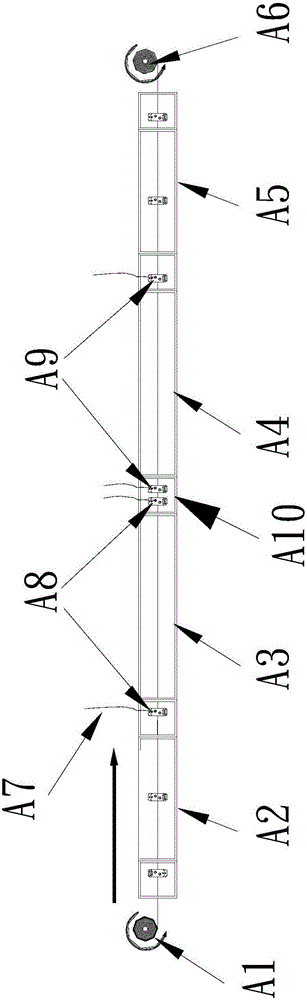

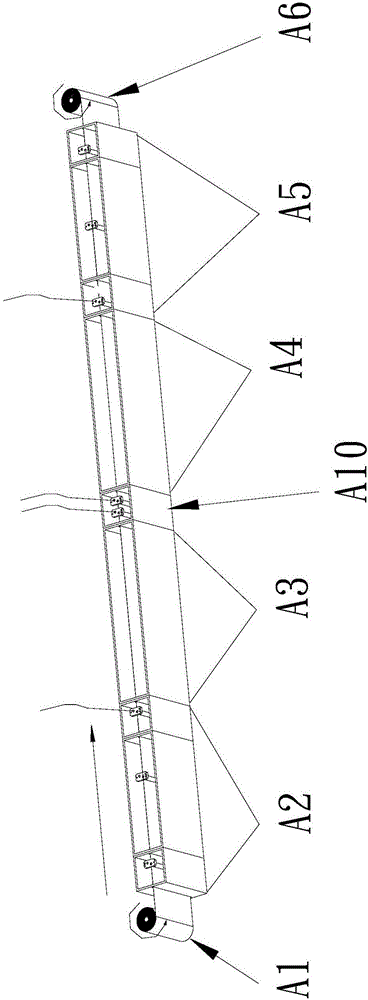

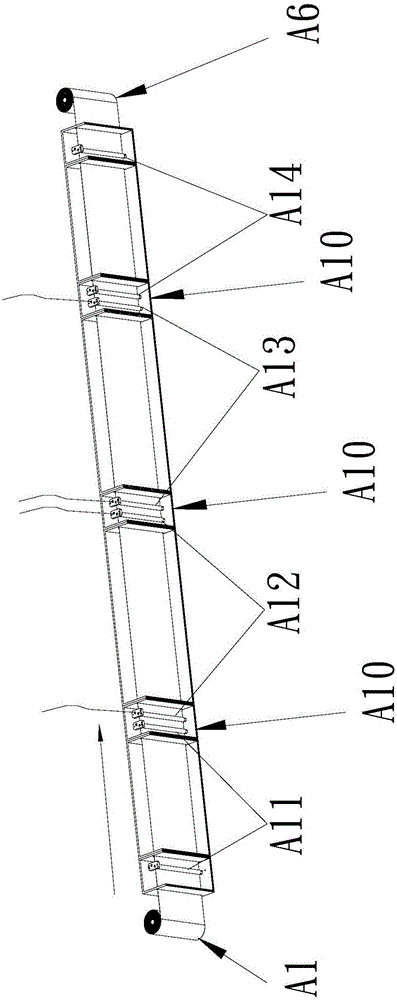

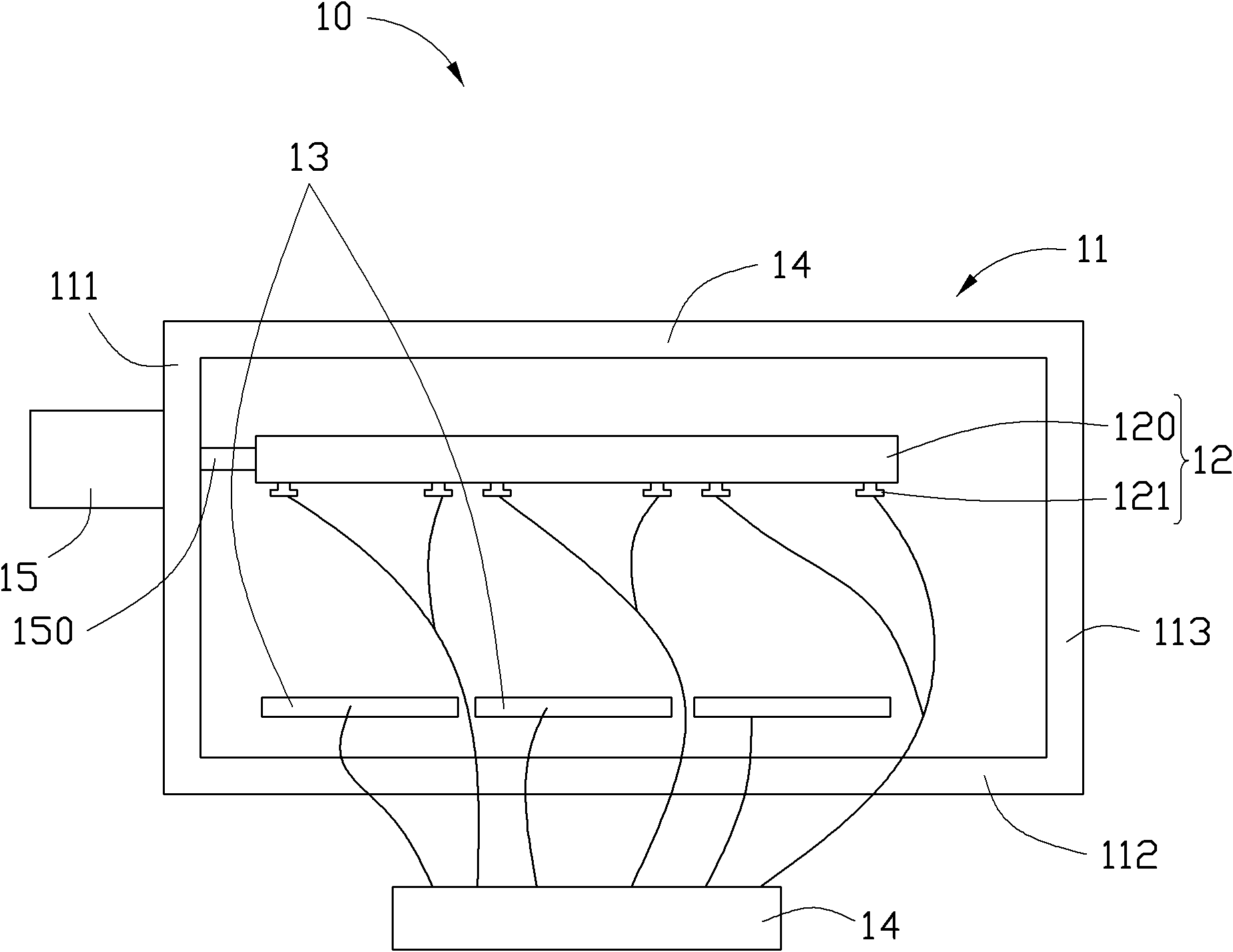

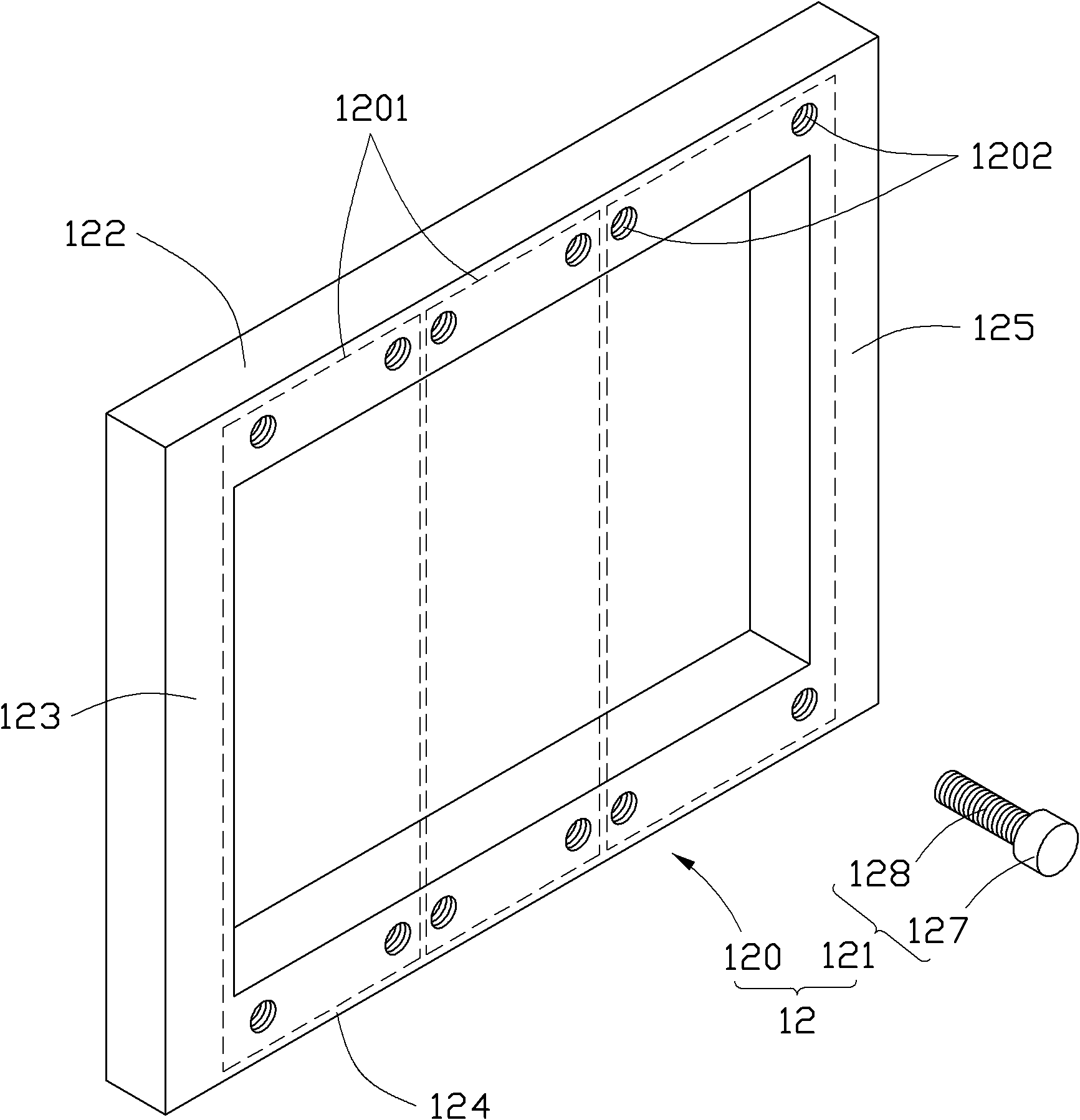

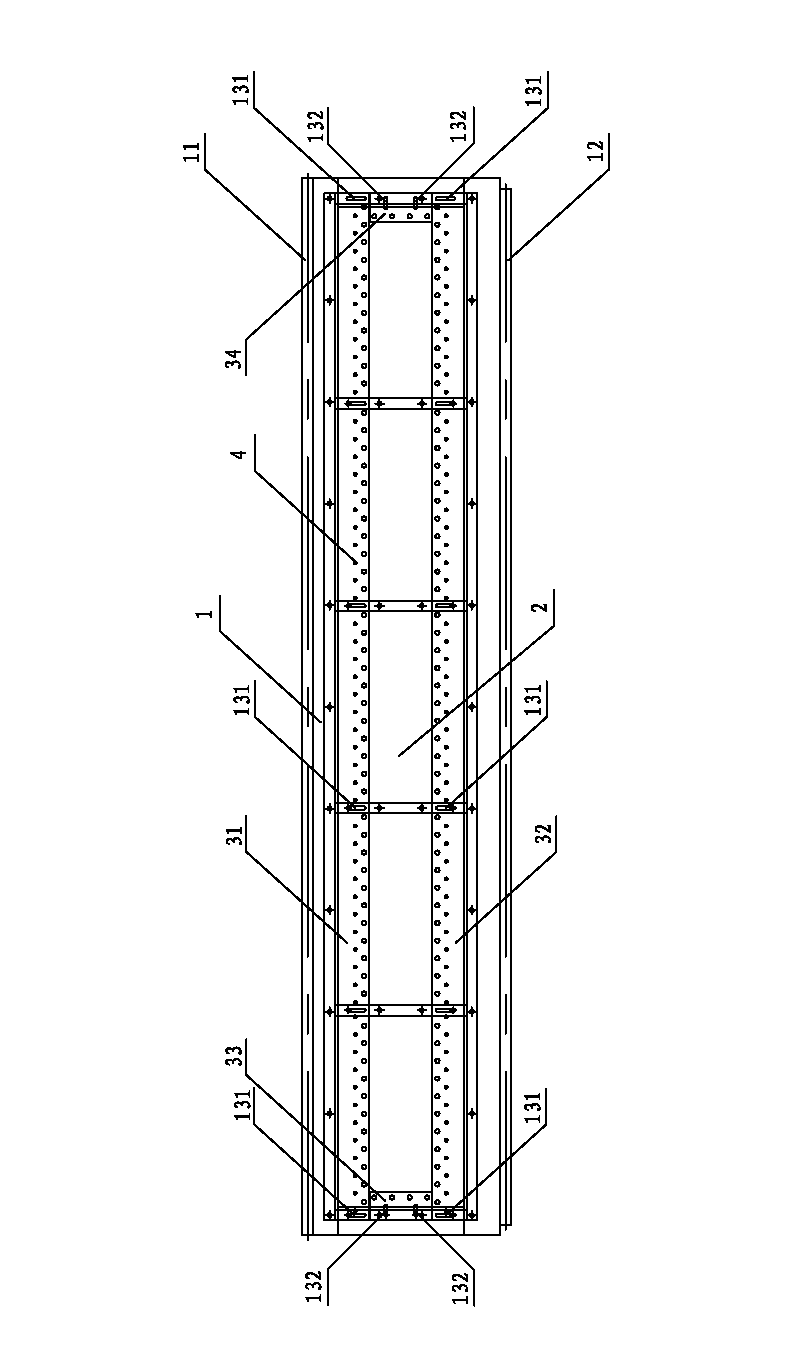

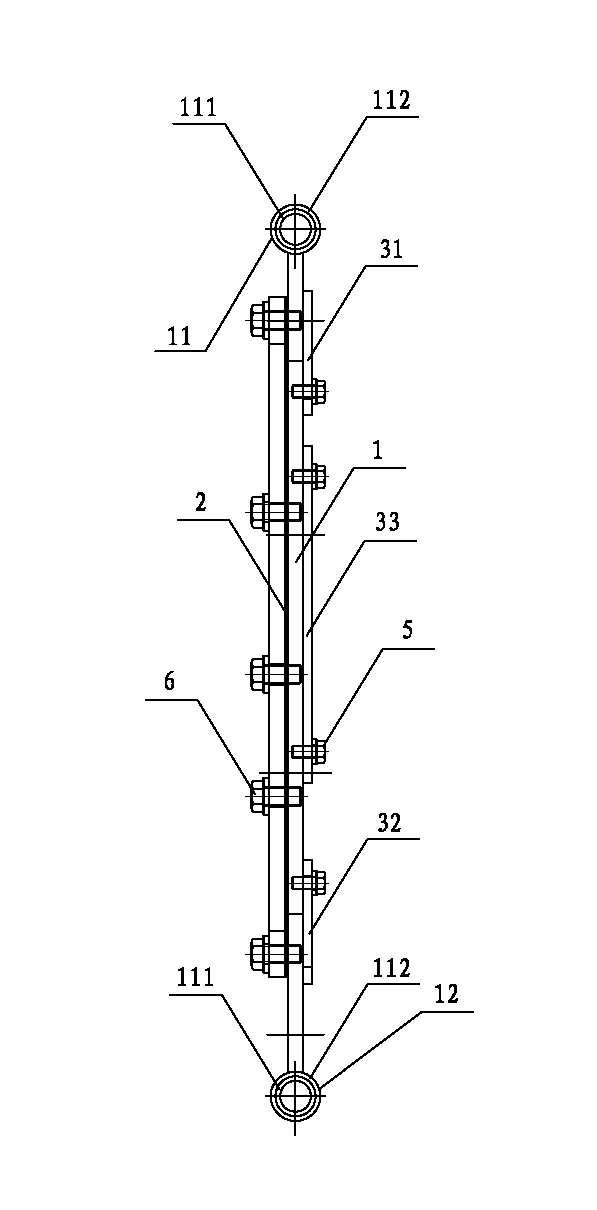

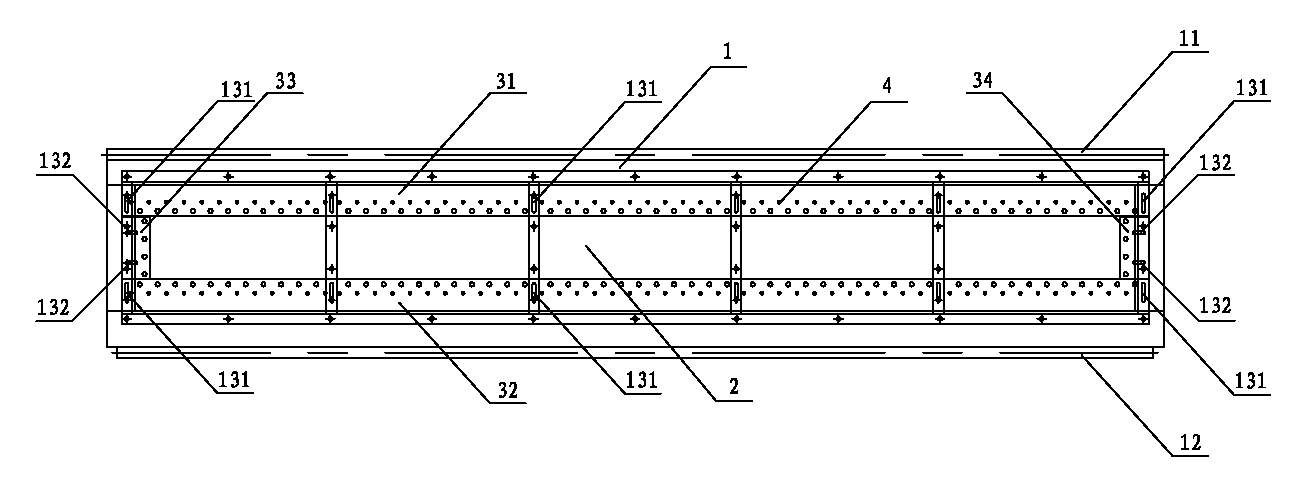

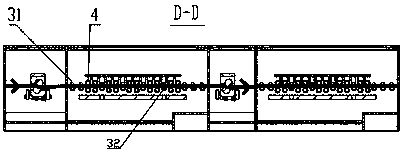

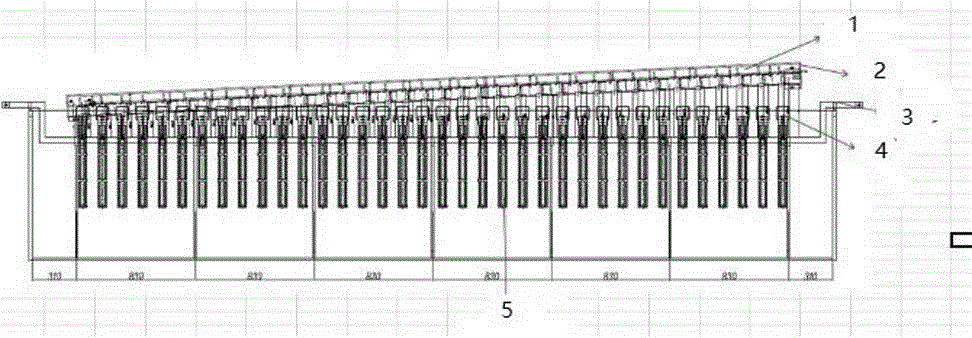

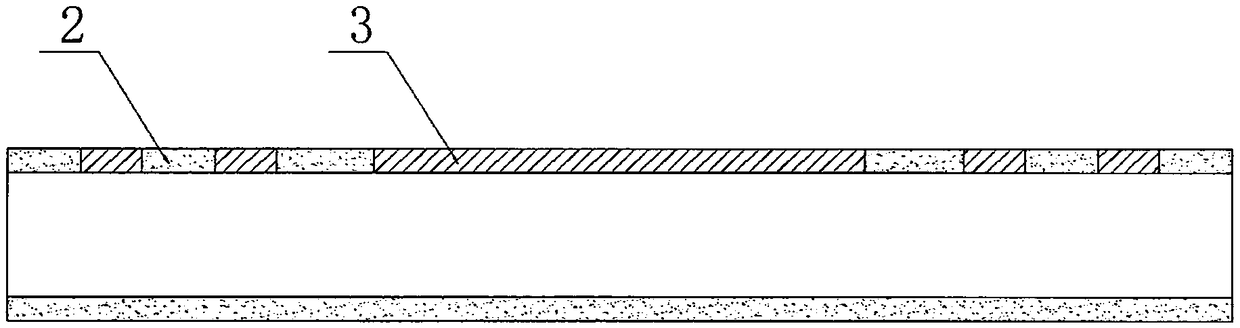

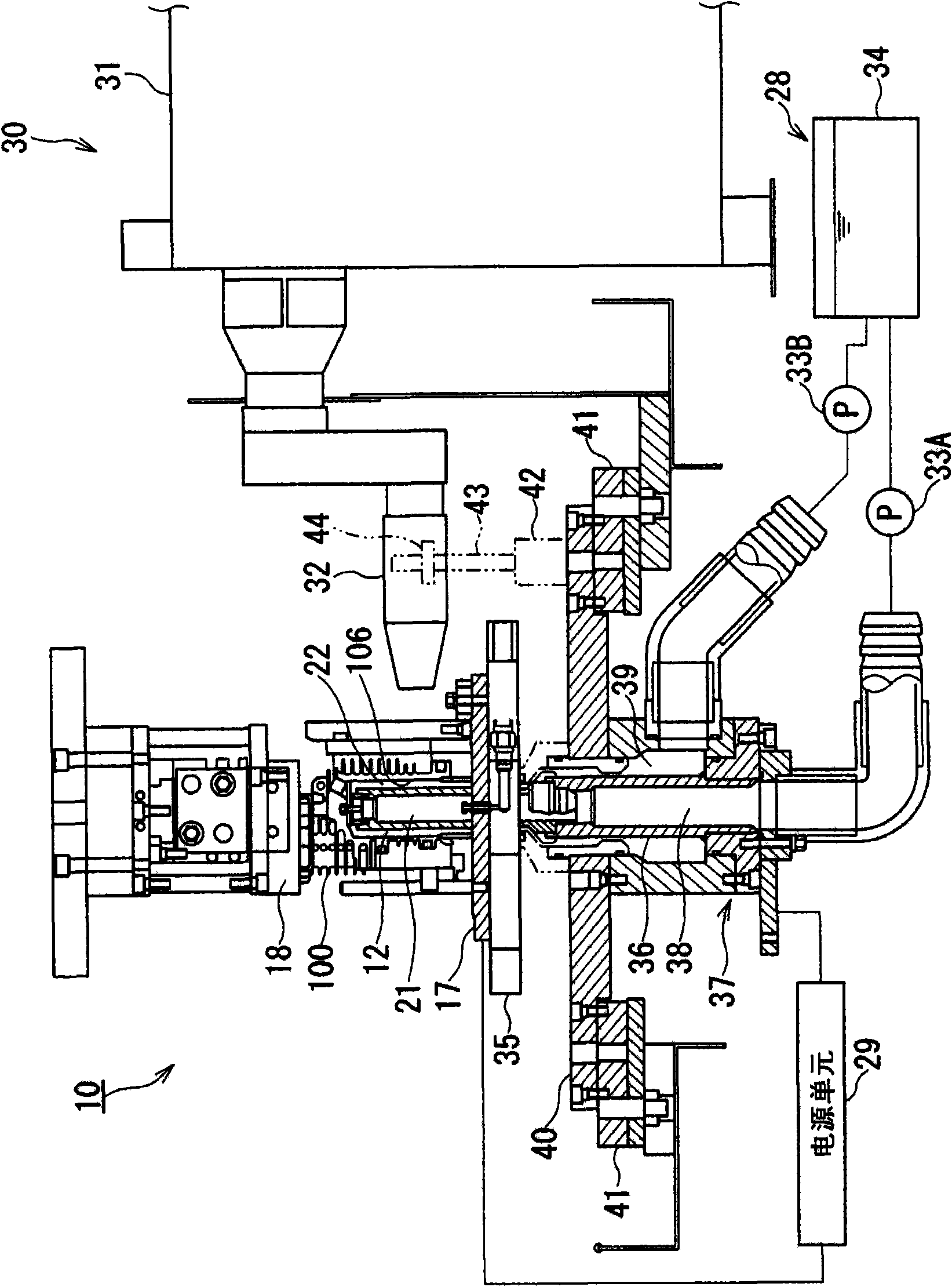

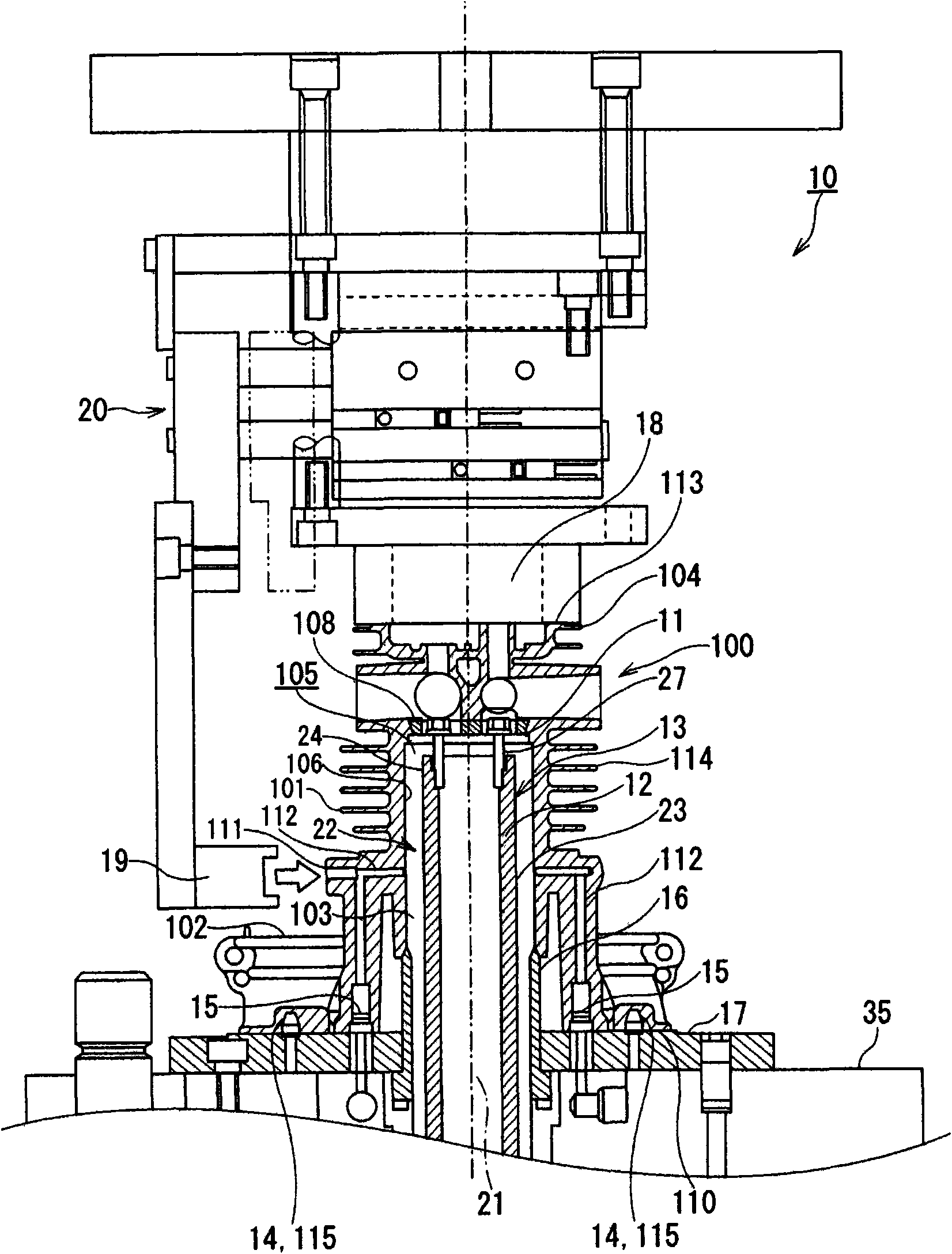

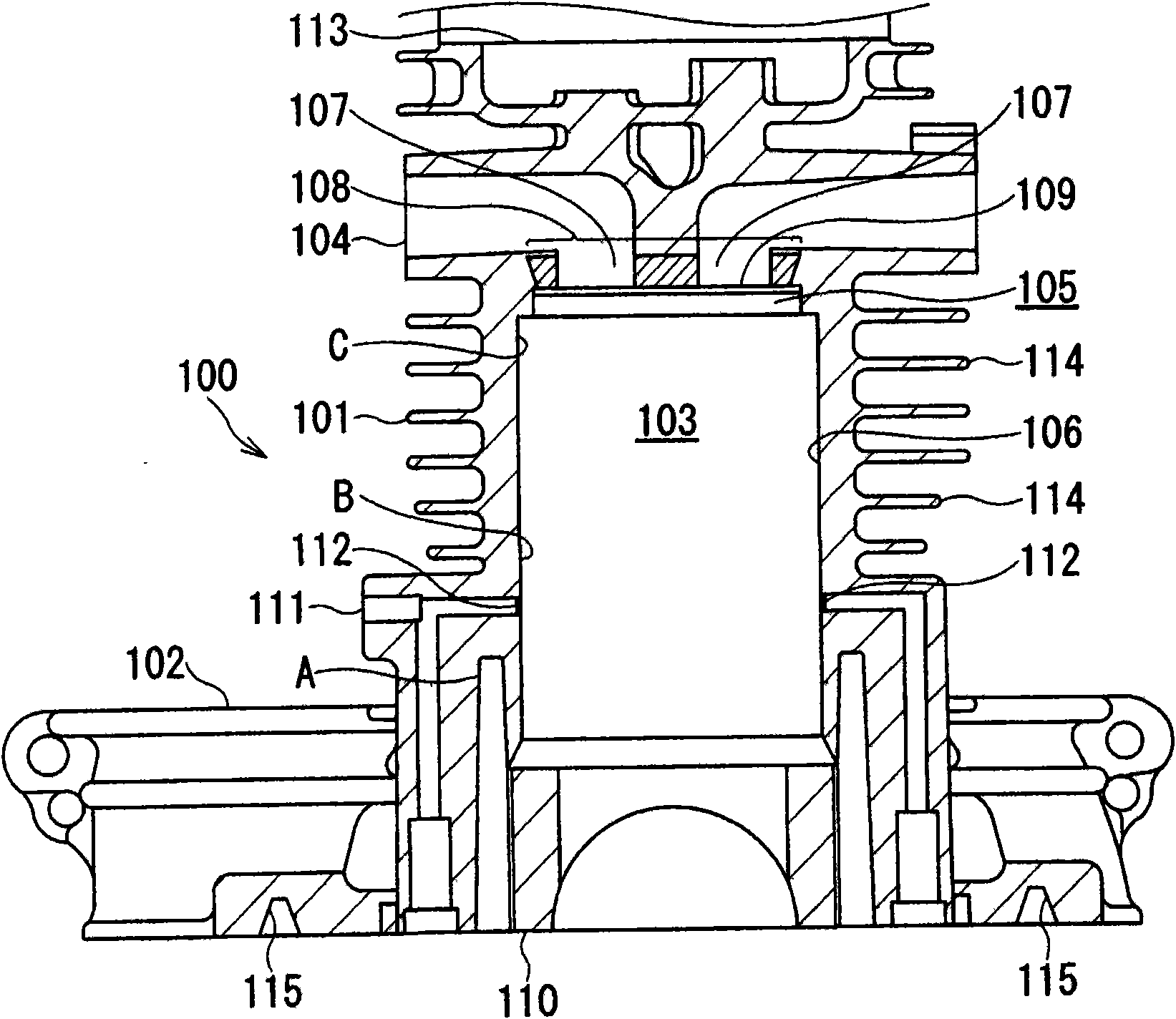

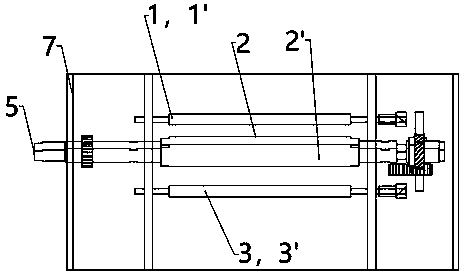

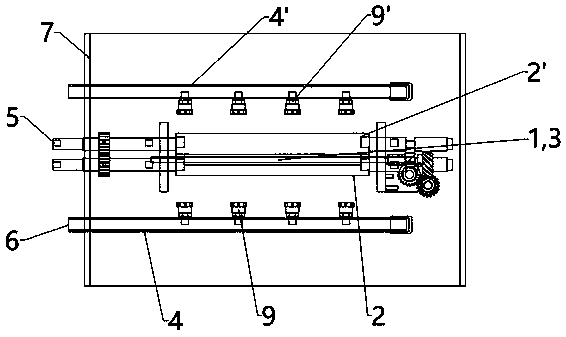

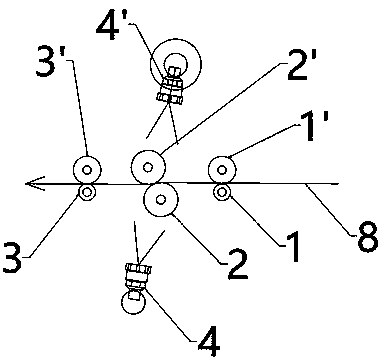

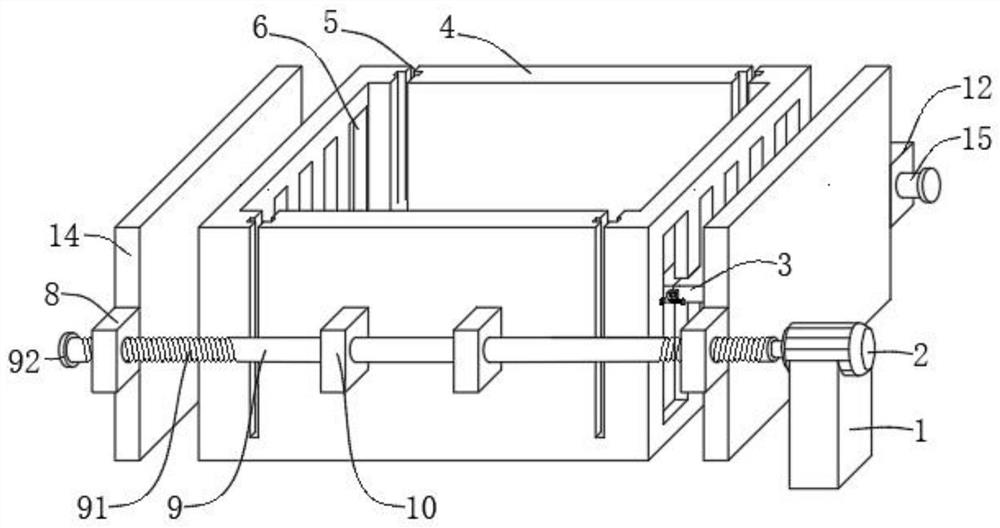

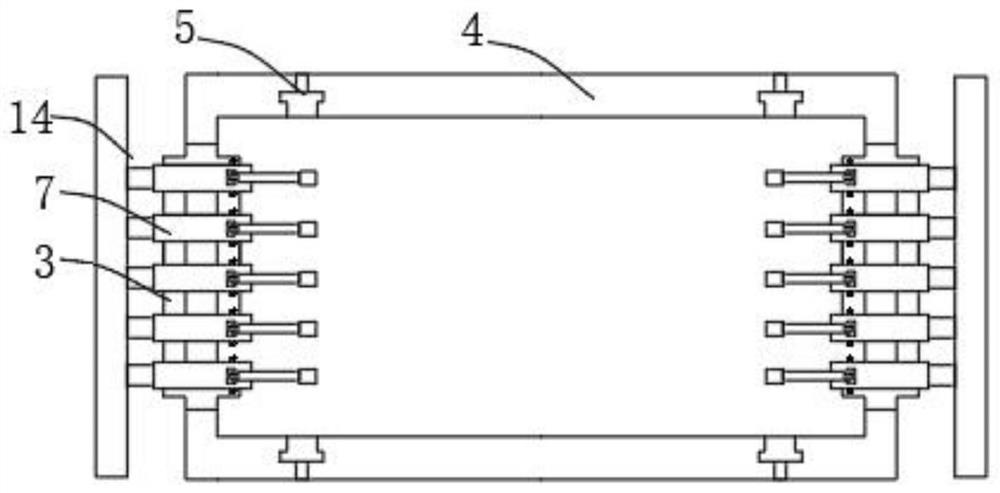

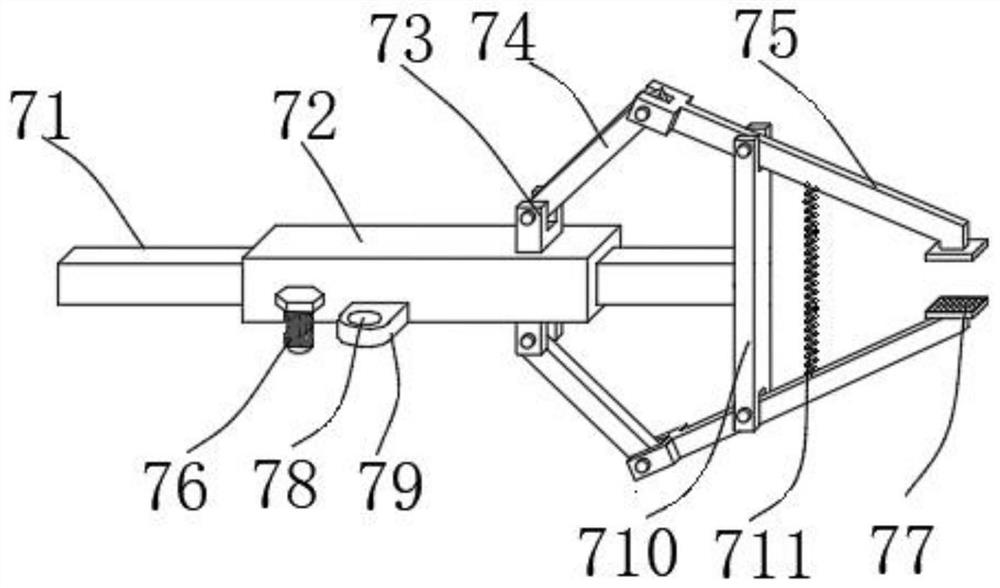

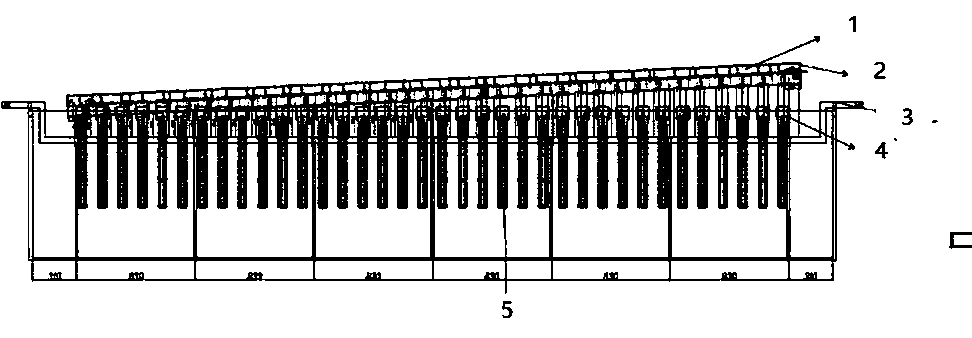

Electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment

ActiveCN106087028AGood electrical contactImprove plating uniformityCellsContacting devicesElectricityStructural reliability

The invention discloses electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment. The electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment is composed of an unreeling machine, a front treatment section, an electroplating section, a rear treatment section and a reeling machine, wherein the electroplating section is provided with an electroplating cylinder, a plurality of cathode clamps, a clamp drive control device, a positive plate and a power source system; the clamp drive control device can drive the cathode clamps to be opened before entering the incoming end position, closed when moving from the incoming end position to the outgoing end position, and opened after leaving from the outgoing end position; the power source system is provided with a direct current power source, a cathode conductive mechanism and a positive wire; and the cathode clamps are electrically connected with the cathode of the direct current power source through the cathode conductive mechanism when moving from the incoming end position to the outgoing end position. The electroplating clip conductive type reel-to-reel vertical continuous electroplating equipment has the advantages of being high in electroplating uniformity, wide in application range of electroplated flexible circuit boards, small in occupied space, capable of electroplating the electroplated flexible circuit boards smaller in thickness, high in working safety and high in structural reliability, and the electroplated boards are not likely to have an electroplating layering phenomenon.

Owner:GREAT CHIEFTAIN ELECTRONICS MACHINERY

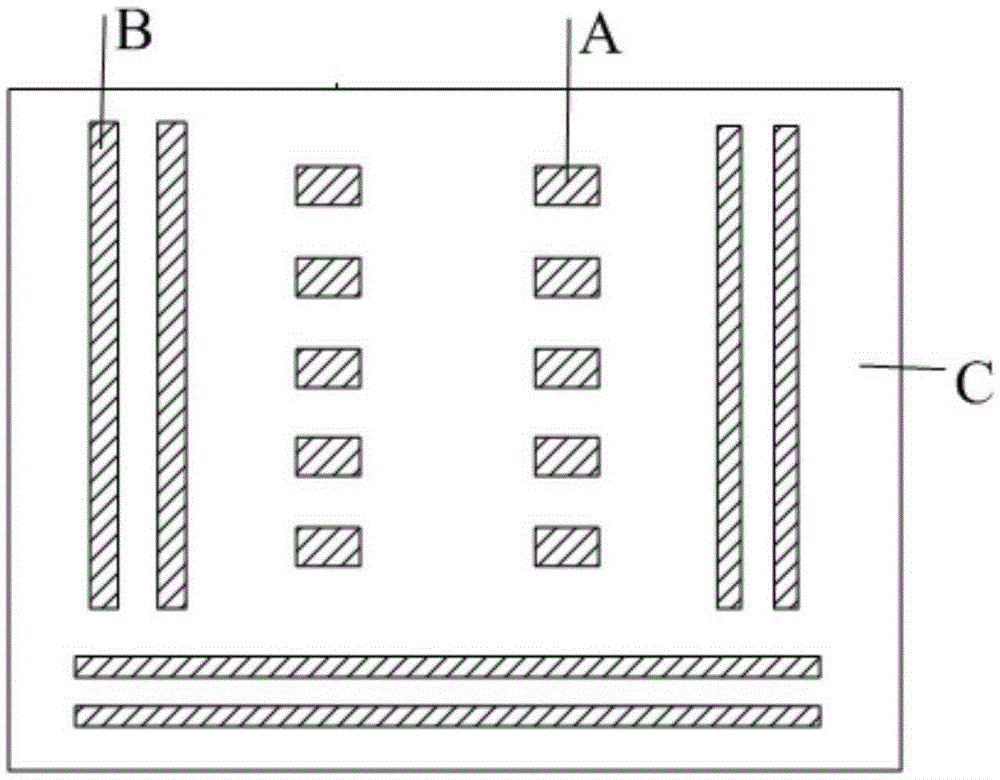

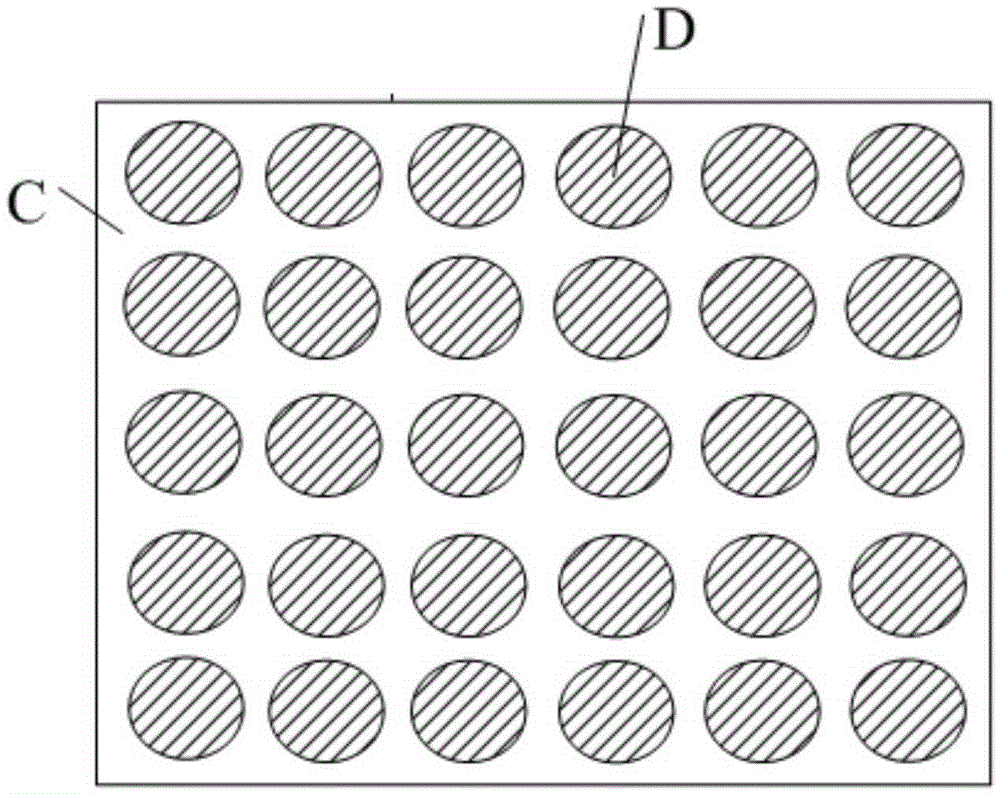

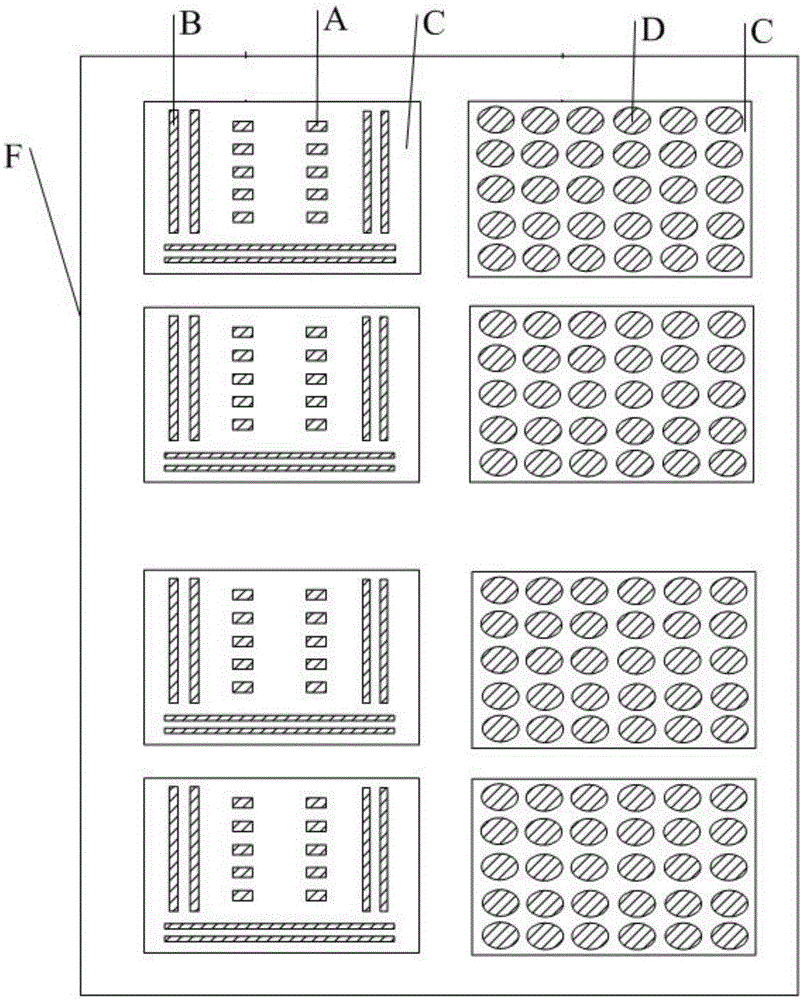

Method for improving electroplating uniformity of package substrate

InactiveCN105401189ASolve the phenomenon of poor plating uniformityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringCopper

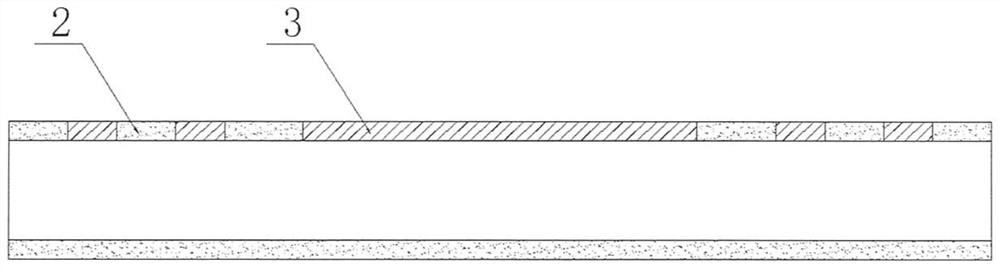

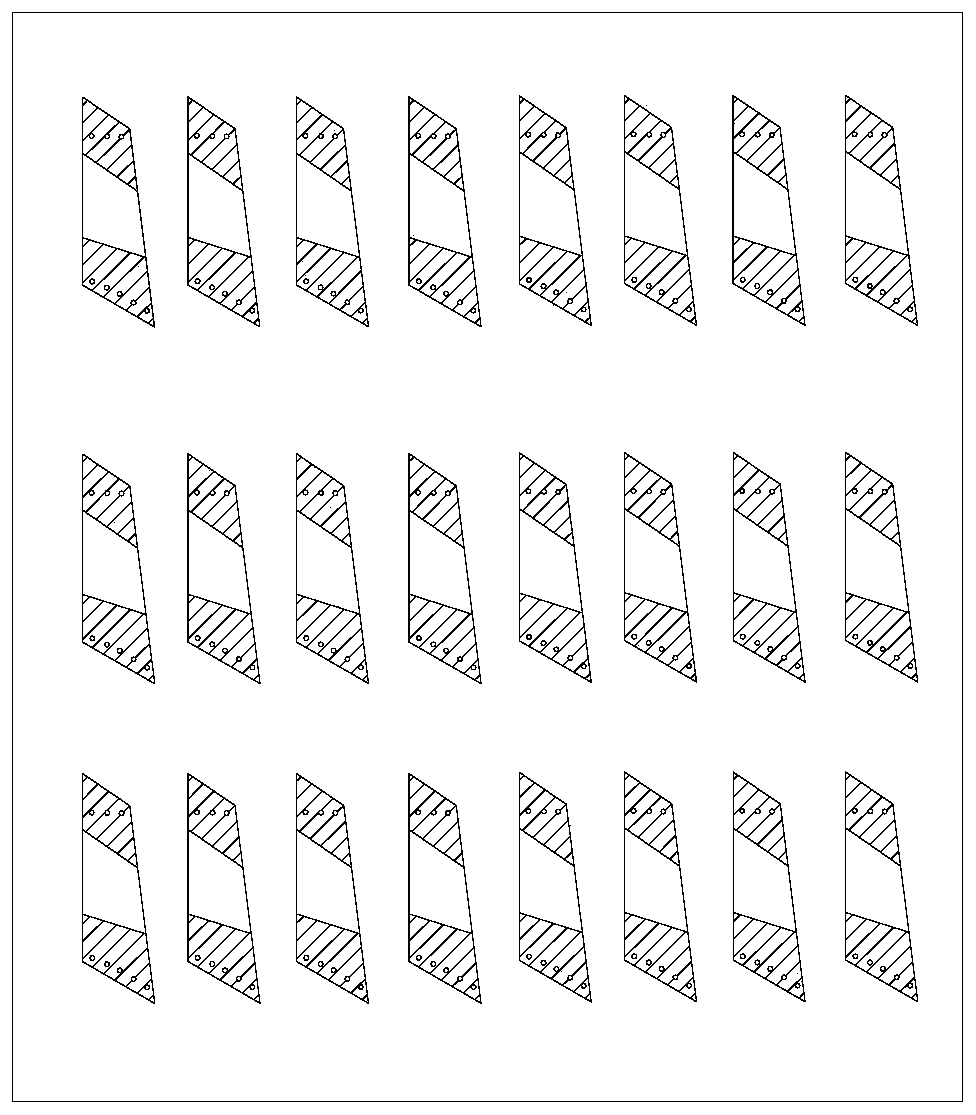

The invention relates to a method for improving the electroplating uniformity of a package substrate. The method comprises the following steps that (1), a top layer graph of a unit plate comprises a chip binding bonding pad and a fine circuit, and the base material area, except for the chip binding bonding pad and the fine circuit, of the unit plate is a copper-free area; (2), a bottom layer graph of the unit plate comprises a ball-mounting package bonding pad, and the base material area, except for the ball-mounting package bonding pad, of the unit plat is a copper-free area; (3), plate splicing is performed, particularly, the analysis result of the graph structures of the top layer and the bottom layer of the unit plate shows that the designed graph of the top layer of the unit plate is sparser than the graph of the bottom layer, namely the copper content of the graph of the top layer of the unit plate is smaller than that of the graph of the bottom layer, and during plate splicing, multiple unit plates are arranged on a production plate, and the adjacent unit plates on the left and right sides are arranged in a mirroring mode; and (4) an electroplating process is conducted. The phenomenon of poor electroplating uniformity is solved through the method of changing spliced plates, and the electroplating uniformity of the package substrate is improved.

Owner:NAT CENT FOR ADVANCED PACKAGING

Electroplating apparatus and electroplating method thereof

The invention relates to an electroplating apparatus, which is provided for electroplating a substrate comprising a plurality of areas requiring electroplating, wherein the areas requiring electroplating are electrically insulated. The electroplating apparatus comprises an electroplating bath, a cathode fixation structure, a plurality of anodes and a voltage controller. The cathode fixation structure comprises an installation frame and a plurality of electrical conductivity fixation components. The electrical conductivity fixation components are provided for installing the substrate on the installation frame, and conducting current to the substrate. Each electroplating-required area of the substrate is provided with at least an electrical conductivity fixation component. Each anode is corresponding to an electroplating-required area of the substrate arranged on the installation frame. The voltage controller forms electrical connections with a plurality of the anodes and a plurality of the electrical conductivity fixation components. The voltage controller is provided for controlling the electrifying status of each anode and at least an electrical conductivity fixation component arranged on the electroplating-required area corresponding to the anode so as to control the voltage between each anode and the electroplating-required area corresponding to the anode. The technical scheme further provides an electroplating method for using the electroplating apparatus.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

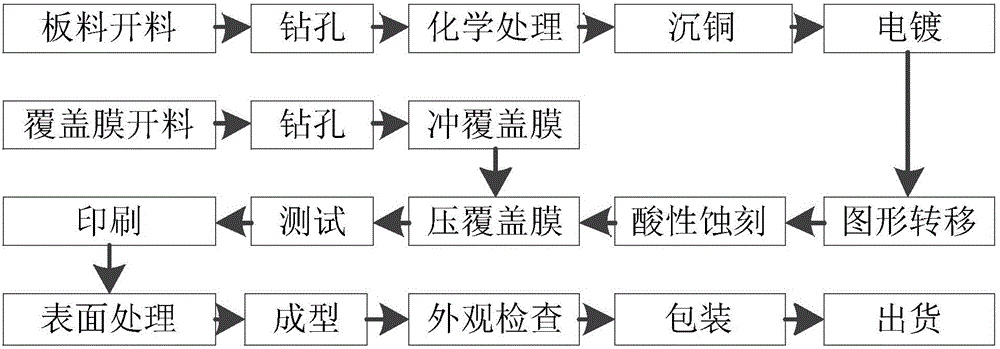

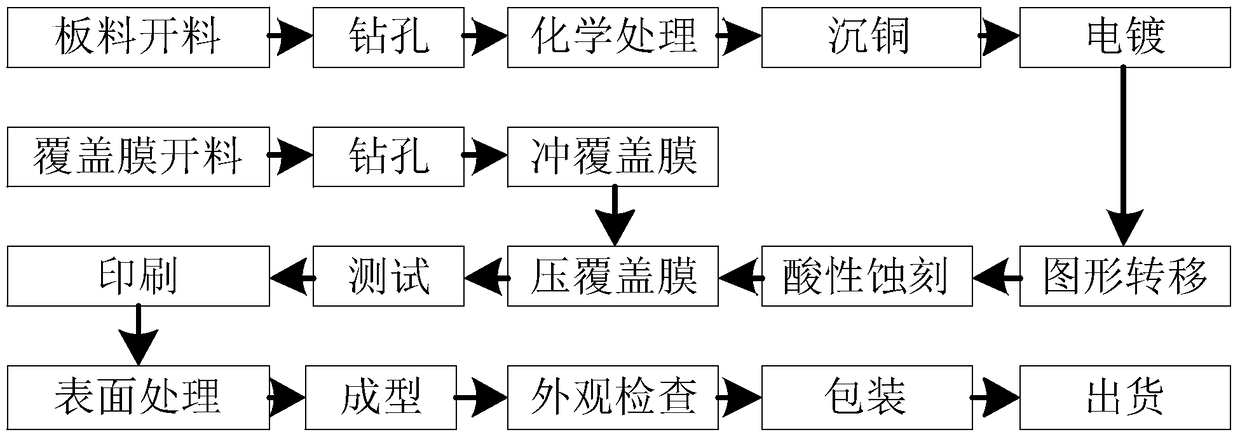

Method for producing double-surface thick copper flexible working board

The invention provides a method for producing a double-surface thick copper flexible working board. The invention is characterized by comprising the steps of a first step, drilling; a second step, chemical treatment; a third step, copper deposition; a fourth step, electroplating; a fifth step, pattern transferring; a sixth step, acid etching; a seventh step, covering film pressure-overlying, wherein the seventh step comprises procedures of A, treating a copper surface by means of a copper surface coarsening solution for etching the copper surface to a coarse surface and forming a honeycomb-shaped surface, B, in performing covering film pressure-overlying, utilizing silicone rubber with hardness of 45+ / -5 DEG C and temperature resistance of 250 DEG C above and below the substrate as accessories for ensuring high pressure overlaying effect of the covering film, and C, at a press jointing temperature of 190-200 DEG C and a press jointing pressure of 10-15Kg / m<2>, performing press jointing for 2-4 minutes, thereby jointing the substrate with the covering film for obtaining the working board. Because the technical solution is used, the method for producing the double-surface thick copper flexible working board has advantages of simple process, low cost, high drilling quality, and electroplating uniformity. The method further prevents the problems of bubbles on the covering film, filling glue insufficiency, thermal shock and laying in a reflow soldering test.

Owner:恩达电路(深圳)有限公司

Anode shielding used for increasing electroplating uniformity

InactiveCN102021637AImprove plating uniformityUniform thicknessElectrolysis componentsEngineeringElectroplating

The invention belongs to the field of the anode shielding for electroplating and particularly relates to an anode shielding used for increasing the electroplating uniformity. The anode shielding contains an anode shielding frame and an anode shielding cloth which can be fixed on the anode shielding frame in a detachable manner, wherein the internal frame of the anode shielding frame is completely covered with the anode shielding cloth. The anode shielding also contains four flat plates with through holes, wherein the flat plates are fixed at the upper, lower, left and right edges of the anode shielding cloth respectively. The anode shielding provided by the invention uses the flat plates which are fixed on the anode shielding frame and have the through holes, to adjust the density of power lines around a PCB and ensure that the surface coating of the PCB is uniform in thickness; and the anode shielding provided by the invention has simple structure, and the flat plates with the through holes on the anode shielding can be changed according to the specific situation.

Owner:东莞市宏德电子设备有限公司

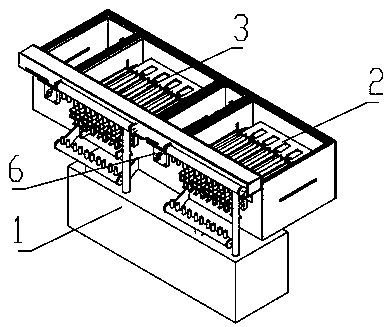

Horizontal continuous electroplating device and preparation method thereof

PendingCN108624943AStrong piercing abilityQuality improvementElectrolysis componentsPrinted circuit manufactureCopper platingElectroplating

The invention provides a horizontal continuous electroplating device. The device comprises an electroplating tank containing a copper plating liquor, upper anode electroplating spray pipes, lower anode electroplating spray pipes, upper conveying rollers, lower conveying rollers and cathode copper conductive rolling wheels; the upper anode electroplating spray pipes and the lower anode electroplating spray pipes are immersed in the electroplating tank containing the copper plating liquor and are used for spraying the liquor to a plating part; the upper conveying rollers and the lower conveyingrollers are used for horizontally conveying the plating plate; the cathode copper conductive rolling wheels are positioned on a horizontal conveying frame and are arranged above and below the platingplate; and each anode electroplating spray pipe is of a tubular structure made of a titanium material. The horizontal continuous electroplating device has the advantages that the perforating capability is high, moreover, the problems of plate edge lotus leaves, white spots and pinholes in the prior art are effectively solved, and the quality of a plated part product is effectively improved.

Owner:捷成微系统(惠州)股份有限公司

Automatic copper ball adding device

The invention discloses an automatic copper ball adding device. The automatic copper ball adding device sequentially comprises an adding box, inductors and a plurality of titanium basket from top to bottom. A temporary storage box is arranged at one end of the adding box. Ball feed channels corresponding to the titanium baskets are arranged on the adding box, and a lifting structure is arranged at one end of the adding box. By adoption of the automatic copper ball adding device, manual copper ball adding is changed into automatic copper ball adding, and intermittent production is changed into continuous production.

Owner:HUIZHOU JUNYA DIGITAL TECH CO LTD

Circuit board electroplating process method

ActiveCN109496080AImprove plating uniformityMeet design needsComputer designed circuitsEtchingThinning

The invention relates to a circuit board electroplating process method, which comprises the following steps: 1, a metal substrate is taken; 2, a first circuit layer is electroplated on the metal substrate; 3, an ABF film is pressed on the front surface of the metal substrate, and thermal curing operation is conducted to enable the first metal layer to be coated in the cured ABF film; 4, thinning is carried out to enable the first metal layer to expose the ABF film; 5, electroplating on the front surface of the metal substrate is carried out to form a second circuit layer, and electroplating onthe back surface of the metal substrate is carried out to form a compensation circuit layer; 7, the remaining photoresistive film is removed; and 8, window etching is carried out. According to the circuit board electroplating process method disclosed in the invention, the front electroplating thickness is optimized through a method of designing a compensation area on the back surface of a carrierplate, and the whole circuit electroplating uniformity is improved.

Owner:JCET GROUP CO LTD

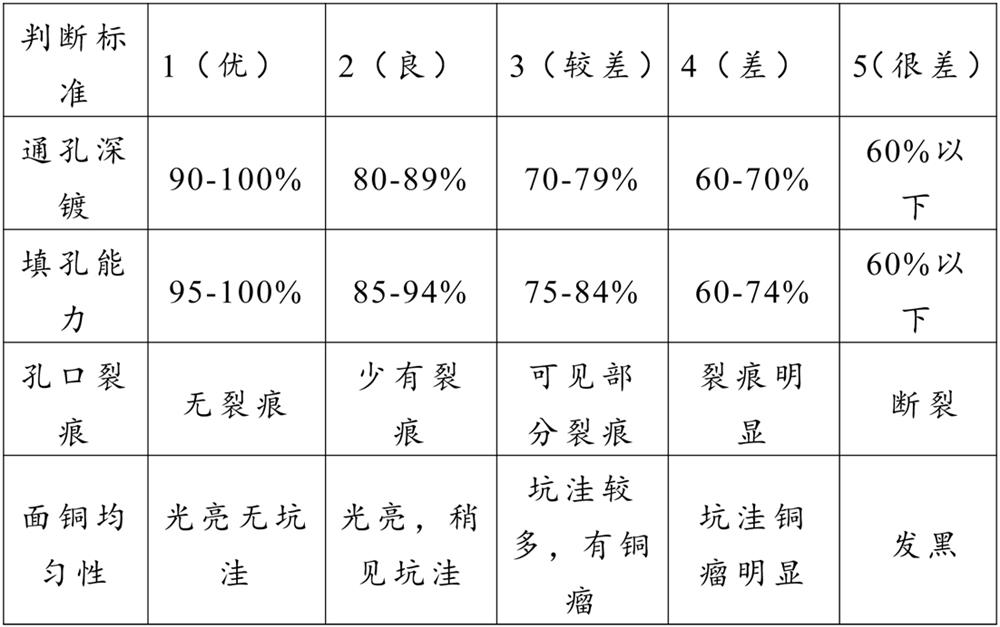

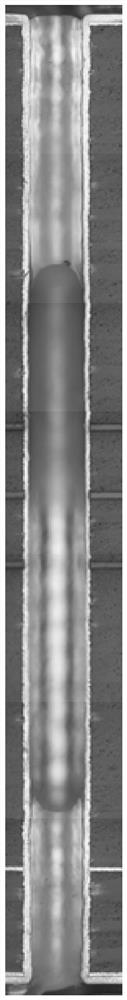

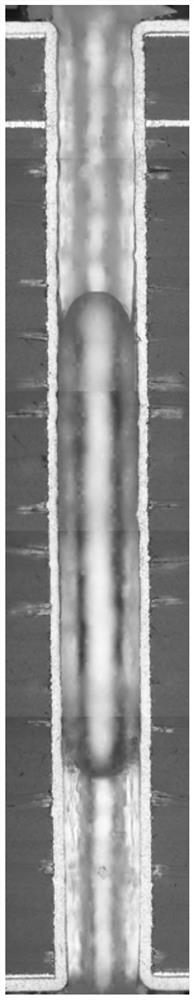

Copper electroplating formula for pulse through hole filling and electroplating process thereof

InactiveCN114351195AReduce concentration polarizationIncrease deposition ratePrinted element electric connection formationElectroplatingCopper salt

The invention discloses an electrocoppering formula for pulse through hole filling and an electroplating process thereof. The electrocoppering formula comprises, by mass concentration, 60-90 g / L of copper salt, 150-200 g / L of concentrated sulfuric acid, 30-90 mg / L of an inhibitor, 10-30 mg / L of a leveling auxiliary agent, 1-8 g / L of an accelerator, 20-60 mg / L of a positioning agent, 15-45 mg / L of a dispersing agent and 15-45 mg / L of a brightening agent. The solution provided by the invention ensures that the orifice of the through hole is not broken, for a plate with the thickness-diameter ratio of more than 15: 1, the deep plating capacity is more than 95%, the thickest thickness of the hole filling plate can be more than 3.5 mm, and the hole filling rate is kept more than 95%.

Owner:SHENZHEN CHENGGONG CHEM

Copper plating additive suitable for printed circuit board and copper electroplating solution

The invention relates to the field of copper plating additives, and particularly discloses a copper plating additive suitable for a printed circuit board and a copper electroplating solution. The copper plating additive comprises the following components according to the concentration ratio: 1-50 mg / L of brightening agent, 1-100 mg / L of leveling agent, 0.5-50 g / L of wetting agent and the balance pure water. The copper electroplating solution comprises the following components according to the concentration ratio: 180-250g / L of sulfuric acid, 50-80g / L of copper sulfate pentahydrate, 40-120ppm of chloride ions, 10-50ml / L of coppering additive and the balance pure water. According to the copper plating additive, the uniformity of a plating layer and the deep plating capacity of a plating solution can be effectively improved, the deep plating capacity TP of a through hole with the aspect ratio being 8 can reach 92.4%, the deep plating capacity TP of a through hole with the aspect ratio being 12 can reach 83.3%, and the electroplating uniformity COV of the printed circuit board can reach 9.5%.

Owner:珠海松柏科技有限公司 +2

A kind of circuit board electroplating process method

ActiveCN109496080BImprove plating uniformityMeet design needsComputer designed circuitsEtchingEngineering

The invention relates to a circuit board electroplating process, which comprises the following steps: step 1, taking a metal substrate; step 2, electroplating the first circuit layer on the front of the metal substrate; step 3, pressing an ABF film on the front of the metal substrate, and heat Curing operation, so that the first metal layer is coated in the cured ABF film; step 4, thinning the first metal layer to expose the ABF film; step 5, electroplating on the front of the metal substrate to form the second circuit layer, and on the back of the metal substrate Electroplating forms a compensation circuit layer; Step 7, removing the remaining photoresist film; Step 8, window etching; a circuit board electroplating process method of the present invention, which optimizes the thickness of the front electroplating by designing the compensation area on the back of the carrier board, and improves the overall layout of the circuit. Uniformity of plating.

Owner:JCET GROUP CO LTD

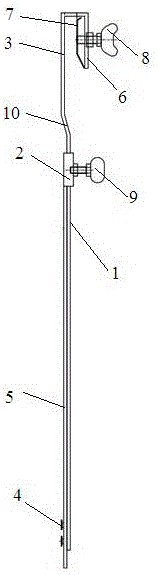

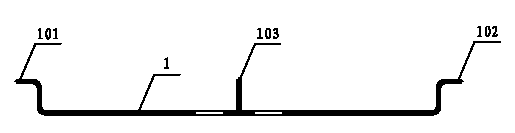

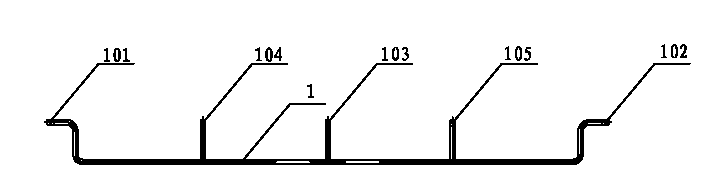

Accompany-plating edge strip for improving electroplating uniformity

InactiveCN105887173AImprove plating uniformityImprove uniformityElectrolysis componentsEngineeringElectroplating

The invention belongs to the technical field of electroplating, and relates to an accompany-plating edge strip for improving electroplating uniformity. The accompany-plating edge strip is characterized by comprising a main edge strip body and an auxiliary edge strip body. A hook is arranged at the upper end of the main edge strip body. A first fixed rotary knob is installed on the hook. A sliding sleeve is arranged at the upper end of the auxiliary edge strip body. The sliding sleeve is arranged on the main edge strip in a sleeving mode and can move along the main edge strip. The sliding sleeve is provided with a second fixed rotary knob. The hook is provided with a convoluted portion. The convoluted portion is provided with a first fixed rotary knob and further connected with a leaf spring which is bent in the convoluted portion. The threaded end of the first fixed rotary knob abuts against the leaf spring. The accompany-plating edge strip can be rapidly fixed to electroplating equipment, the electroplating current densities of all areas are improved, and electroplating uniformity is improved.

Owner:共青城超群科技协同创新股份有限公司

Pre-plating method and surface processing device

InactiveCN101613866APre-plating optimizationGood adhesionElectrolysis componentsReaction temperatureEngineering

In a method of pre-plating surface of the object to be processed by using a surface processing device provided with electrodes, the electrode is located to face to the surface to be processed; the treatment fluid is led between the electrode and the surface of the object to be processed so that the electrode and the surface of the object to be processed are conducted; in the process of pre-plating, the hot air is blown to the object to be processed to the external part, and the surface of the object to be processed is heated to the reaction temperature for pre-plating.

Owner:SUZUKI MOTOR CORP

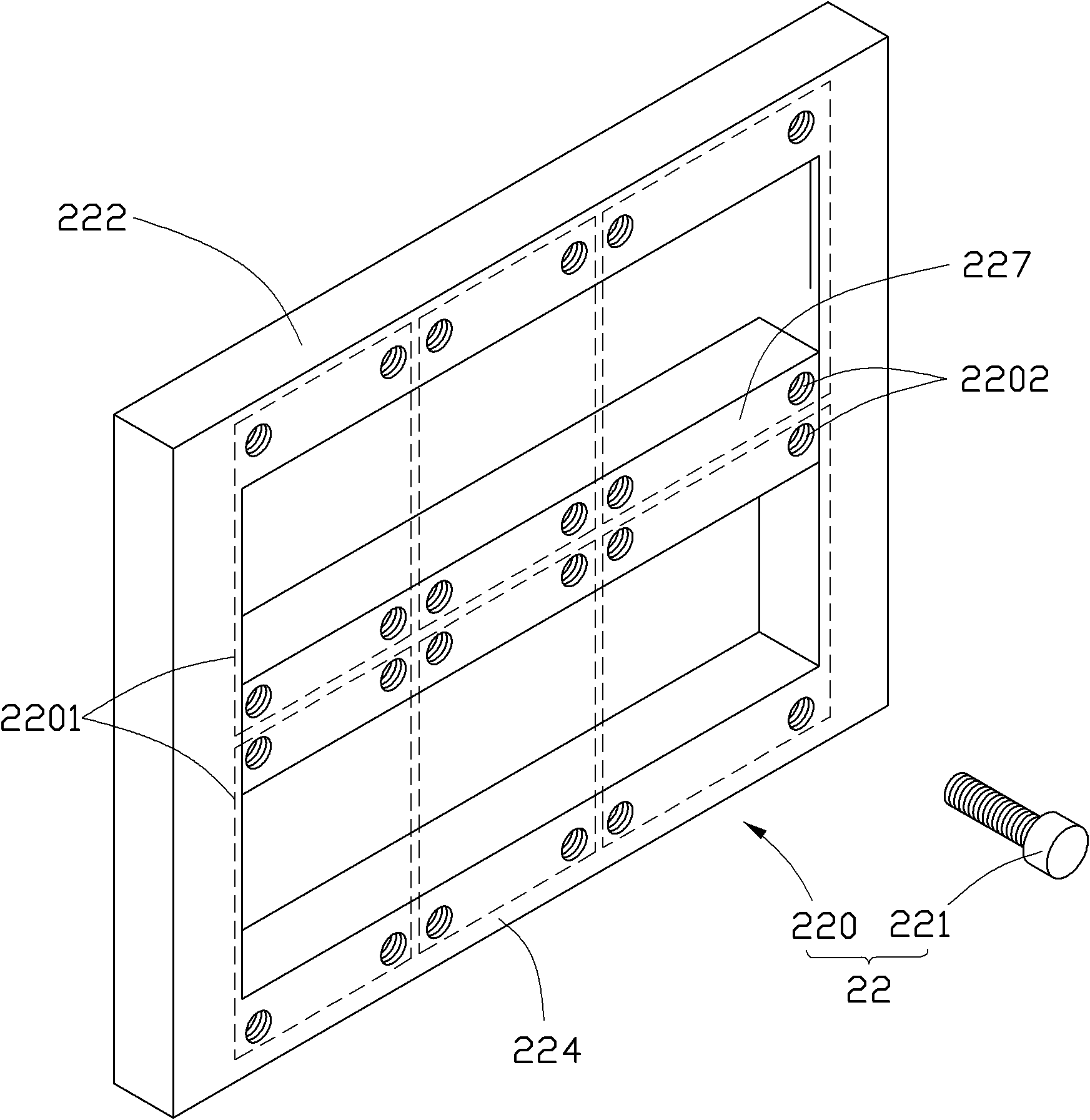

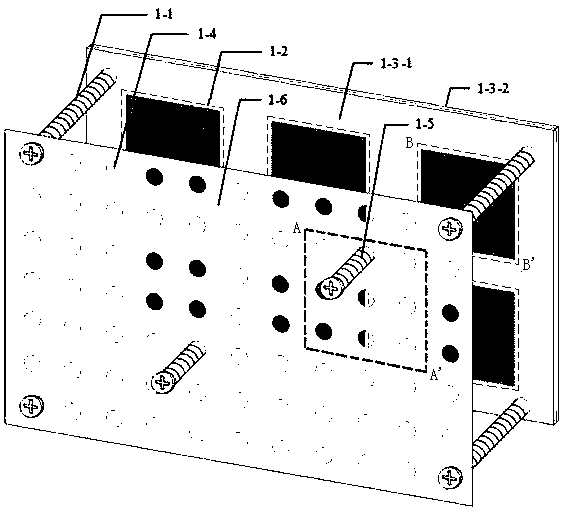

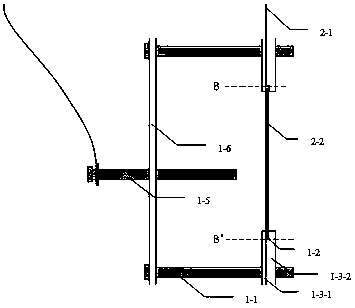

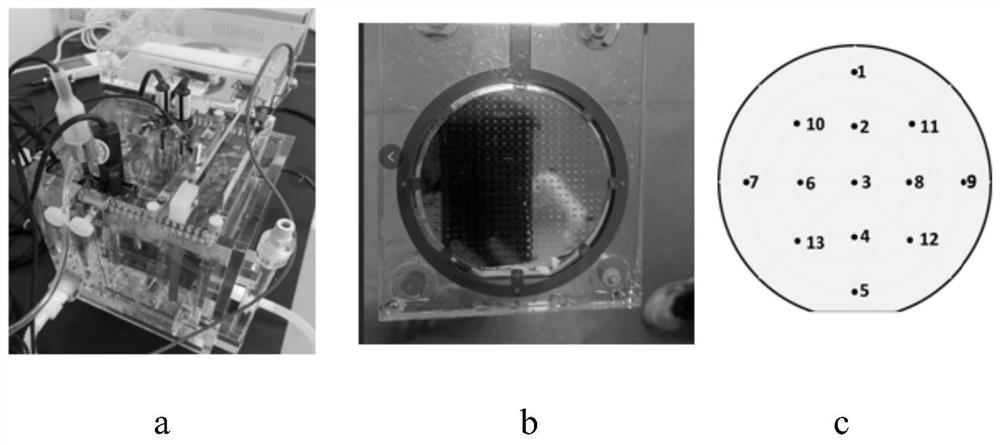

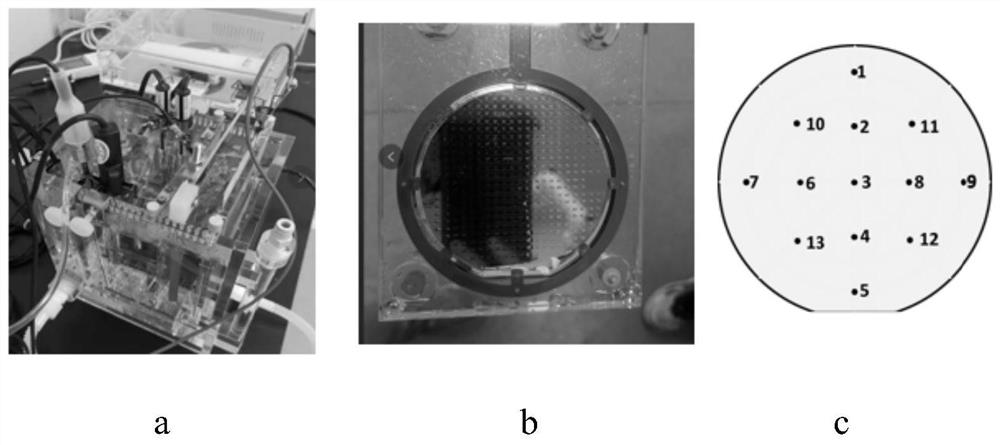

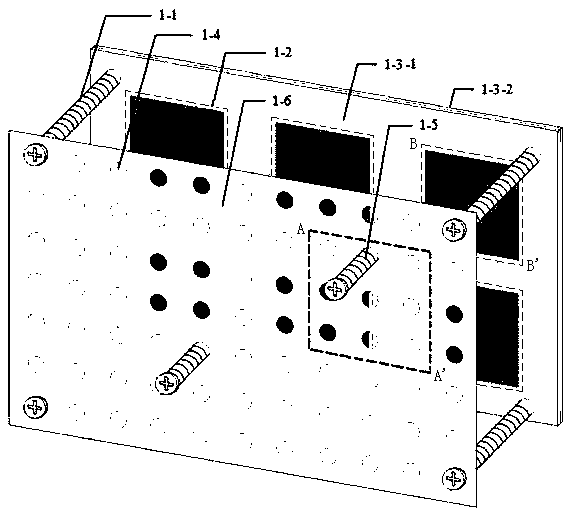

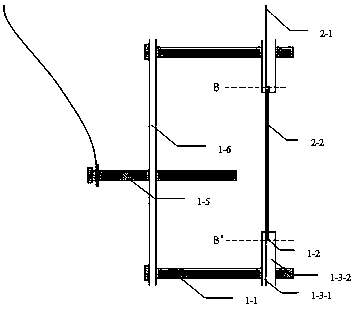

Clamping device suitable for multi-substrate high precision electroplating

The invention discloses a clamping device suitable for multi-substrate high precision electroplating, relates to a device for clamping a plurality of different substrates for high precision electroplating, and aims to improve the problems that an existing device is complicated in structure, relatively high in cost, low in universality, low in work efficiency, relatively poor in electroplating uniformity of a product and the like. The technical key point is follows: the clamping device comprises a substrate cover (1-3-1), a substrate bottom plate (1-3-2), an anode positioning plate (1-6) and anauxiliary anode probe (1-5); a plurality of rectangular slots (1-2) are formed in the substrate bottom plate (1-3-2); rectangular through holes are formed in positions, corresponding to the rectangular slots (1-2), of the substrate cover (1-3-1); the anode positioning plate (1-6), the substrate cover (1-3-1) and the substrate bottom plate (1-3-2) are fixedly connected through fixed bolts (1-1); screw holes (1-4) are distributed in an array in the anode positioning plate (1-6); and the auxiliary anode probe (1-5) is arranged in a screw position in the anode positioning plate (1-6).

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

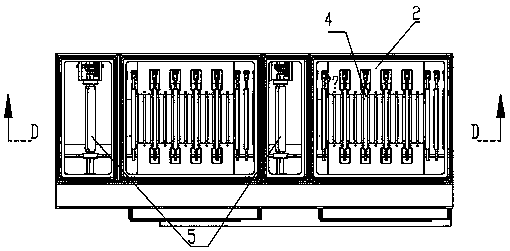

Plating bath cathode wheel spraying-configured electric conduction device

PendingCN108642549AOvercome the scratching problemOvercome efficiencyCurrent conducting devicesElectrodesWater blockElectroplating

The invention provides a plating bath cathode wheel spraying-configured electric conduction device which comprises a plating bath body. A set of upper and lower fluctuation electric conduction wheelsforming a fluctuation type wavy plating path are arranged in the plating bath body. First-grade upper and lower water blocking wheels are arranged on the left sides and the right sides of the upper and lower fluctuation electric conduction wheels correspondingly. An upper spraying pipe is arranged on the upper side of the upper fluctuation electric conduction wheel, and a lower spraying pipe is arranged on the lower side of the lower fluctuation electric conduction wheel. The upper spraying pipe and the lower spraying pipe are located on the corresponding positions of the outer sides of the upper fluctuation electric conduction wheel and the lower fluctuation electric conduction wheels and are used for spraying electric conduction liquid to the corresponding fluctuation electric conductionwheels. Gaps for a to-be-plated plating plate to pass through are formed between the corresponding upper wheels and lower wheels of the two sets of upper and lower water blocking wheels and one set of upper and lower fluctuation electric conduction wheels. The plating path of the to-be-plated plating plate is a fluctuation type wavy path. The plating bath cathode wheel spraying-configured electric conduction device has the beneficial effects that the electric conduction performance is good, and plating uniformity and plating current stability are good.

Owner:捷成微系统(惠州)股份有限公司

Production method of double-sided thick copper flexible working board

The invention provides a method for producing a double-surface thick copper flexible working board. The invention is characterized by comprising the steps of a first step, drilling; a second step, chemical treatment; a third step, copper deposition; a fourth step, electroplating; a fifth step, pattern transferring; a sixth step, acid etching; a seventh step, covering film pressure-overlying, wherein the seventh step comprises procedures of A, treating a copper surface by means of a copper surface coarsening solution for etching the copper surface to a coarse surface and forming a honeycomb-shaped surface, B, in performing covering film pressure-overlying, utilizing silicone rubber with hardness of 45+ / -5 DEG C and temperature resistance of 250 DEG C above and below the substrate as accessories for ensuring high pressure overlaying effect of the covering film, and C, at a press jointing temperature of 190-200 DEG C and a press jointing pressure of 10-15Kg / m<2>, performing press jointing for 2-4 minutes, thereby jointing the substrate with the covering film for obtaining the working board. Because the technical solution is used, the method for producing the double-surface thick copper flexible working board has advantages of simple process, low cost, high drilling quality, and electroplating uniformity. The method further prevents the problems of bubbles on the covering film, filling glue insufficiency, thermal shock and laying in a reflow soldering test.

Owner:恩达电路(深圳)有限公司

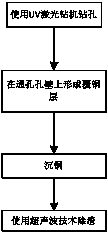

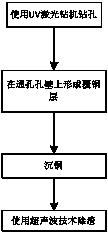

A kind of high-density interconnection integrated circuit board manufacturing method

ActiveCN104144571BEfficient removalImprove reliabilityConductive pattern polishing/cleaningPrinted element electric connection formationUv laserHigh density

The present invention discloses a method for manufacturing a high-density interconnected integrated circuit board, which comprises the following steps: S1: use a UV laser drill to drill through holes in a product area on a circuit board according to design requirements, and drill through holes in a board outside the product area of the board Drill test holes in the edge area; S2: Use ordinary electroplating and micro-hole electroplating technology to form a copper cladding layer on the board surface, via hole wall and test hole wall, and use resin to fill the via hole and test after copper cladding. hole; S3: copper immersion treatment is performed on the plate. S4: Use ultrasonic technology to remove glue residue on the board. The invention provides a method for manufacturing a high-density interconnected integrated circuit board with high safety, reliability and high production efficiency.

Owner:四川深北电路科技有限公司

Anode for improving electroplating uniformity

InactiveCN102021638BImprove plating uniformityImprove uniformityElectrodesPotential differenceEngineering

Owner:东莞市宏德电子设备有限公司

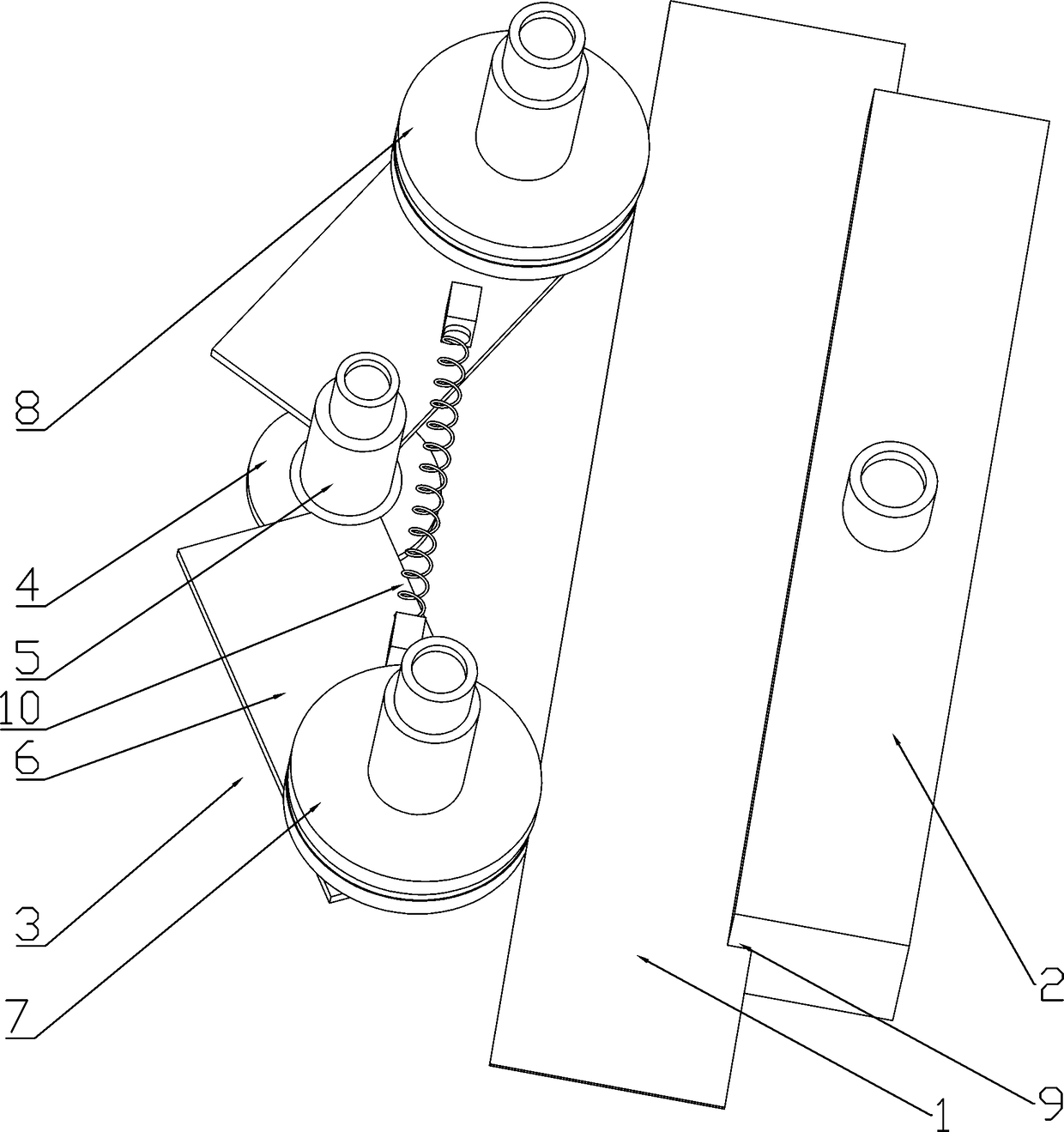

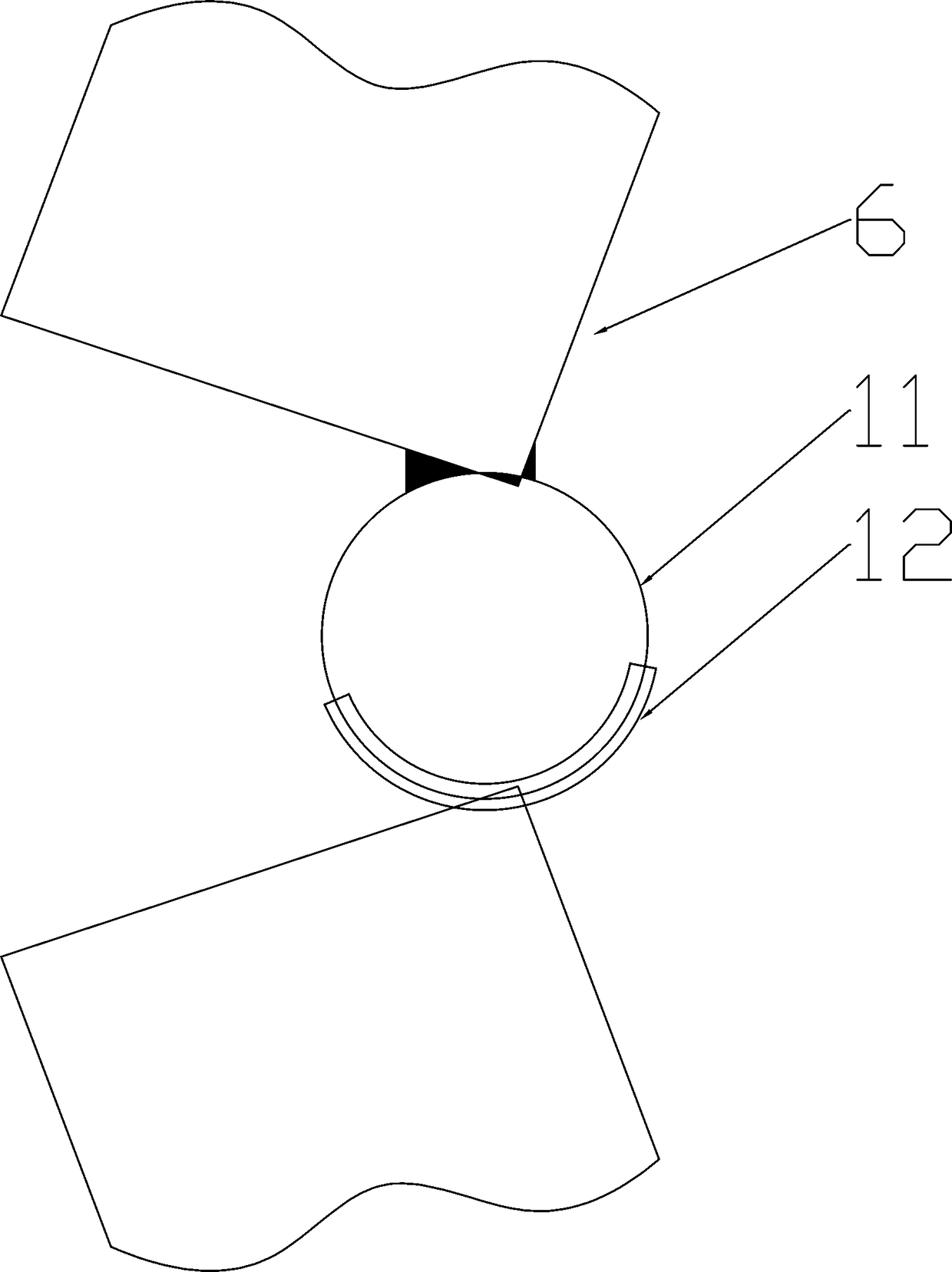

Photoelectric coupler lead frame limiting support

InactiveCN108987366APrevent derailmentAvoid crush damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringSlide plate

A photoelectric coupler lead frame limiting support comprises a positioning sliding plate arranged on one side of a lead frame of a photoelectric coupler, and an adjustable sliding mechanism arrangedon the other side of the lead frame of the photoelectric coupler, wherein the adjustable sliding mechanism comprises a fixed base; a rotating shaft arranged on the fixed base, and two positioning plates hinged to a rotating shaft and connected with each other through springs. A first rotating wheel and a second rotating wheel are symmetrically arranged on the two positioning plates respectively, positioning sliding grooves are formed in the first rotating wheel, the second rotating wheel and the positioning sliding plate. According to the photoelectric coupler lead frame limiting support, a flexible positioning conductive device is provided by the arrangement of an adjustable sliding mechanism, so that the good conductive performance is guaranteed.

Owner:徐百灵

High-density interconnection integrated circuit board manufacturing method

ActiveCN104144571AEfficient removalImprove reliabilityConductive pattern polishing/cleaningPrinted element electric connection formationUv laserHigh density

The invention discloses a high-density interconnection integrated circuit board manufacturing method which comprises the following steps that S1, a UV laser drilling machine is used to drill a via hole in the product area on a circuit board according to the design requirement, and a test hole is drilled in the board edge area outside the board product area; S2, a copper covering layer is formed on the board surface, the via hole wall and the test hole wall through a common electroplate drawing micropore electroplate technology, and the via hole and the test hole are filled with resin after copper covering is conducted; S3, electroless plating copper treatment is conducted on the board; S4, desmear treatment is conducted on the board through an ultrasonic technology. The high-density interconnection integrated circuit board manufacturing method is high in safety and reliability and high in production efficiency.

Owner:四川深北电路科技有限公司

Electric-corrosion-resisting compound electroplating liquid for scaffold

InactiveCN106011952AEasy to prepareElectroplating process is easy to implementElectrolytic coatingsCerium nitrateSodium Bentonite

The invention discloses an electric-corrosion-resisting compound electroplating liquid for a scaffold. The compound electroplating liquid is prepared from, by weight, 6.8-9 parts of aniline, 0.1-0.2 part of ammonium persulfate, 50-60 parts of boric acid, 1.5-2 parts of EDTA, 220-250 parts of nickel sulfate, 40-50 parts of nickel chloride, 0.2-0.3 part of polyethylene glycol 8000, 50-60 parts of teflon emulsion, 3-4 parts of a cationic surfactant FC134, 2.5-3 parts of lanthanum nitrate, 2.3-2.6 parts of cerium nitrate, 4-5 parts of barium sulfate, 2.8-3.5 parts of bentonite, a proper amount of ethyl alcohol and a proper amount of deionized water. According to the prepared electroplating liquid, the preparation method is simple, the electroplating process is easy to implement, the electroplating uniformity is good, an electroplating layer is smooth and uniform, stability and density are high, corrosion resistance, rust resistance and other properties are improved, and the electroplating liquid is worthy of popularization.

Owner:王世群

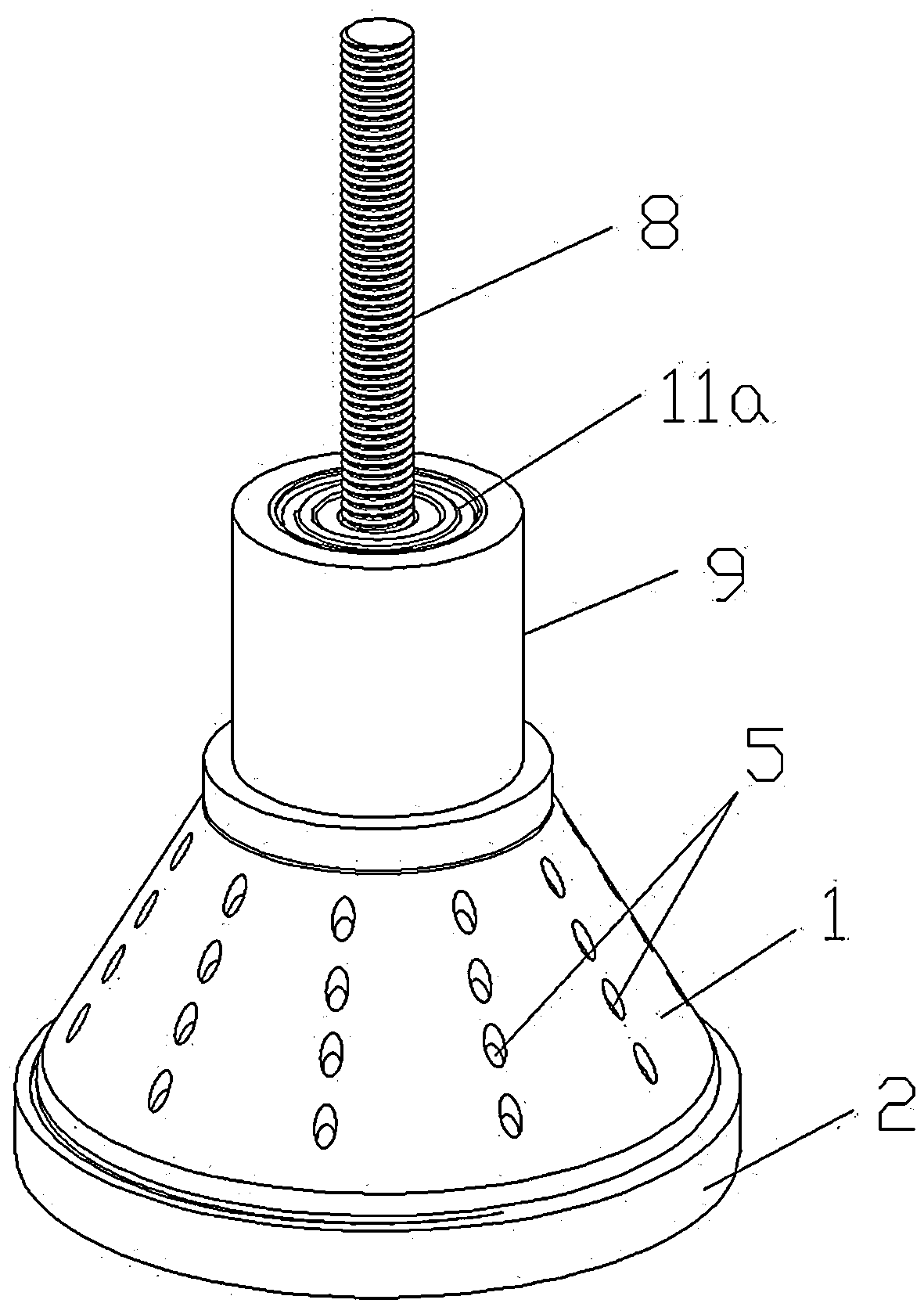

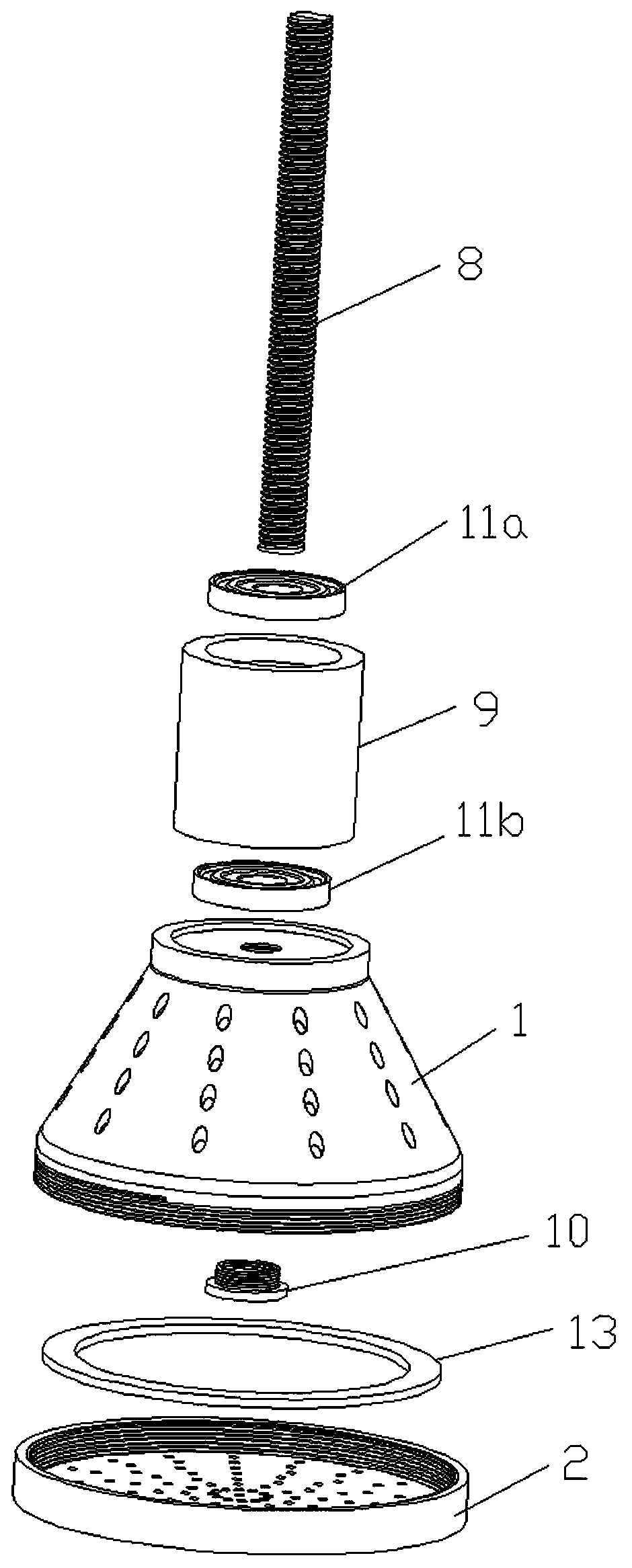

A fixture for photovoltaic cell electroplating

ActiveCN112458509BPracticalImprove work efficiencyElectrolysis componentsFinal product manufactureCircular discElectrical battery

The invention discloses a fixture for photovoltaic cell electroplating, which includes a flower basket and a motor. The peripheral side of the motor is fixedly connected to a fixing seat, the output shaft of the motor is fixedly connected to one end of a rotating shaft, and the end of the rotating shaft away from the motor is fixedly connected to a limiting disk. , the rotating shaft is provided with an external thread on the peripheral side near the end, and is screwed to the inside of the first fixed block, the first fixed block is fixedly installed on one side of the movable plate, and the other side of the movable plate is fixedly connected to the second fixed block. block, the inside of the second fixed block is slidably connected with a slide bar, and the middle part of the rotating shaft and the slide bar is connected to the limit seat, and the limit seat is fixedly installed on the outside of the flower basket. The chute, the inner side of the chute is slidably connected to the slider, and the clamping block is used to clamp and fix the surface, which is conducive to improving the uniformity of electroplating, so that the clamping force is evenly distributed on the surface of the silicon wafer, and the silicon wafer is prevented from being damaged by the clamp. Fragments, hidden cracks.

Owner:SUZHOU SUNWELL NEW ENERGY CO LTD

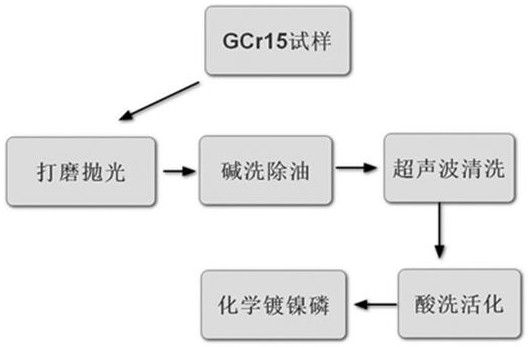

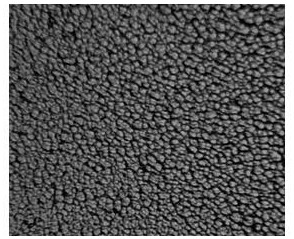

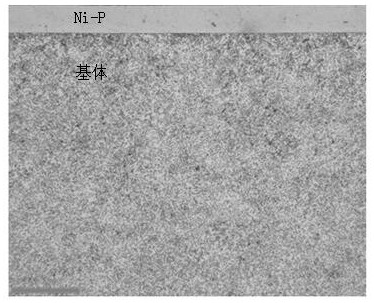

Chemical nickel plating process for bearing steel

PendingCN114807917ASimple compositionEasy to prepareLiquid/solution decomposition chemical coatingSodium Hypophosphite MonohydrateSodium phosphates

A chemical nickel plating process for bearing steel is characterized in that the pretreated bearing steel is placed in a chemical nickel plating solution with the temperature of 80-90 DEG C and the pH value of 4-6 for plating, the chemical nickel plating solution comprises 20-30 g / L of nickel sulfate, 20-30 g / L of sodium hypophosphite, 10-30 ml / L of lactic acid and 5-10 g / L of citric acid, and the thickness of a plating layer is 5-30 microns. According to the design, the raw material composition and the preparation process are simple, the plating uniformity is high, the plating speed is high, the hardness is high, and the method is suitable for large-scale production.

Owner:WUHAN TEXTILE UNIV

A copper ball automatic adding device

The invention discloses an automatic copper ball adding device. The automatic copper ball adding device sequentially comprises an adding box, inductors and a plurality of titanium basket from top to bottom. A temporary storage box is arranged at one end of the adding box. Ball feed channels corresponding to the titanium baskets are arranged on the adding box, and a lifting structure is arranged at one end of the adding box. By adoption of the automatic copper ball adding device, manual copper ball adding is changed into automatic copper ball adding, and intermittent production is changed into continuous production.

Owner:HUIZHOU JUNYA DIGITAL TECH CO LTD

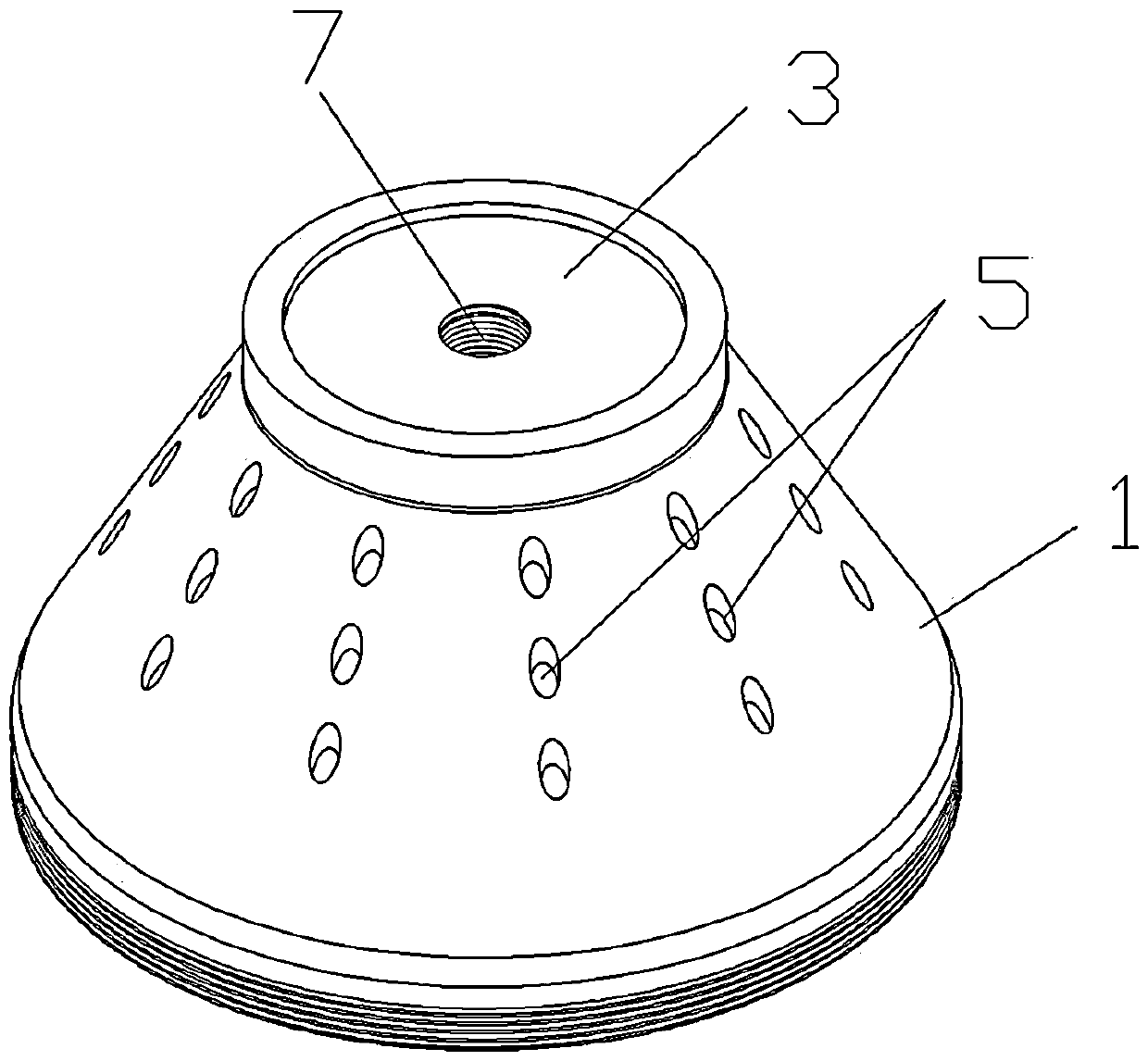

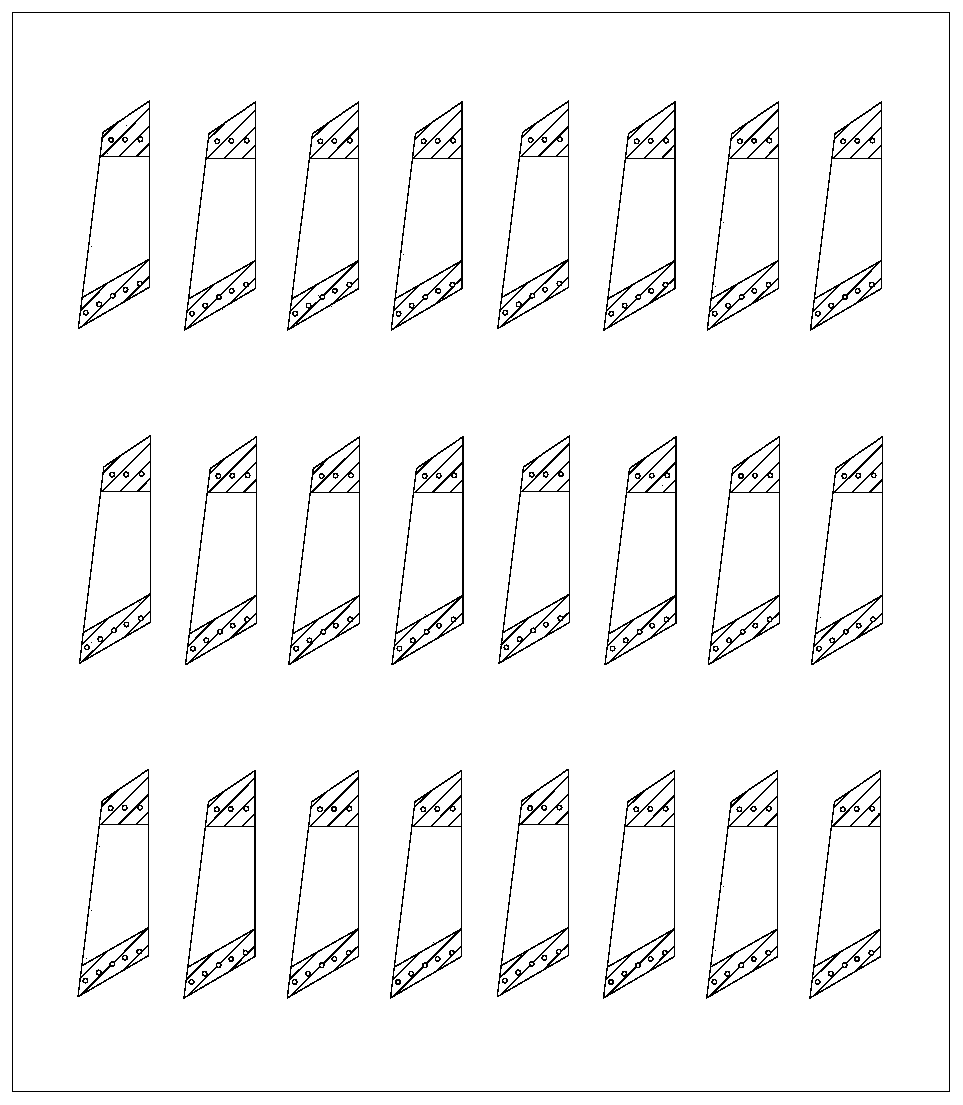

A cathode device for batch electroplating metal heat sink elements

ActiveCN108385154BElectroplating to achieveMeet electroplating requirementsElectrodesEngineeringHeat sink

The invention discloses a cathode device for batch plating of metal heat sink components. The cathode device comprises a loading cover and a loading tray. The loading cover is in a circular truncatedcone shape. A conducting plate is arranged on the top face of the loading cover. A conducting ring is arranged on the bottom edge of the loading cover. The cover wall of the loading cover is providedwith an electroplating solution through hole array. A set wire leads are inlaid in the cover wall of the loading cover. The top ends of the metal leads are connected with the conducting plate, and thebottom end of the metal leads are connected with the conducting ring. The loading tray is connected with the bottom of the loading cover in a screw-thread fit mode to form a loading cavity used for containing the metal heat sink components. The loading tray is provided with a set of electroplating solution flow holes. A screw hole is formed in the center of the conducting plate. The top of the loading cover is provided with a mounting hole concentric with the screw hole. A conducting post is arranged in the mounting hole in a penetration mode and used for being in threaded connection with a cathode connector of electroplating equipment. Through the cathode device, there is no need to clamp the metal heat sink components, and an electroplating solution flows into and out of the loading cavity to achieve electroplating. The cathode device is simple in structure, convenient to install, good in stability, high in electroplating uniformity and capable of meeting the requirements for electroplating of the metal heat sink components.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

Circuit board electroplating method

InactiveCN110351957APlating parameters consistentGood plating uniformityPrinted circuit manufactureEngineeringElectroplating

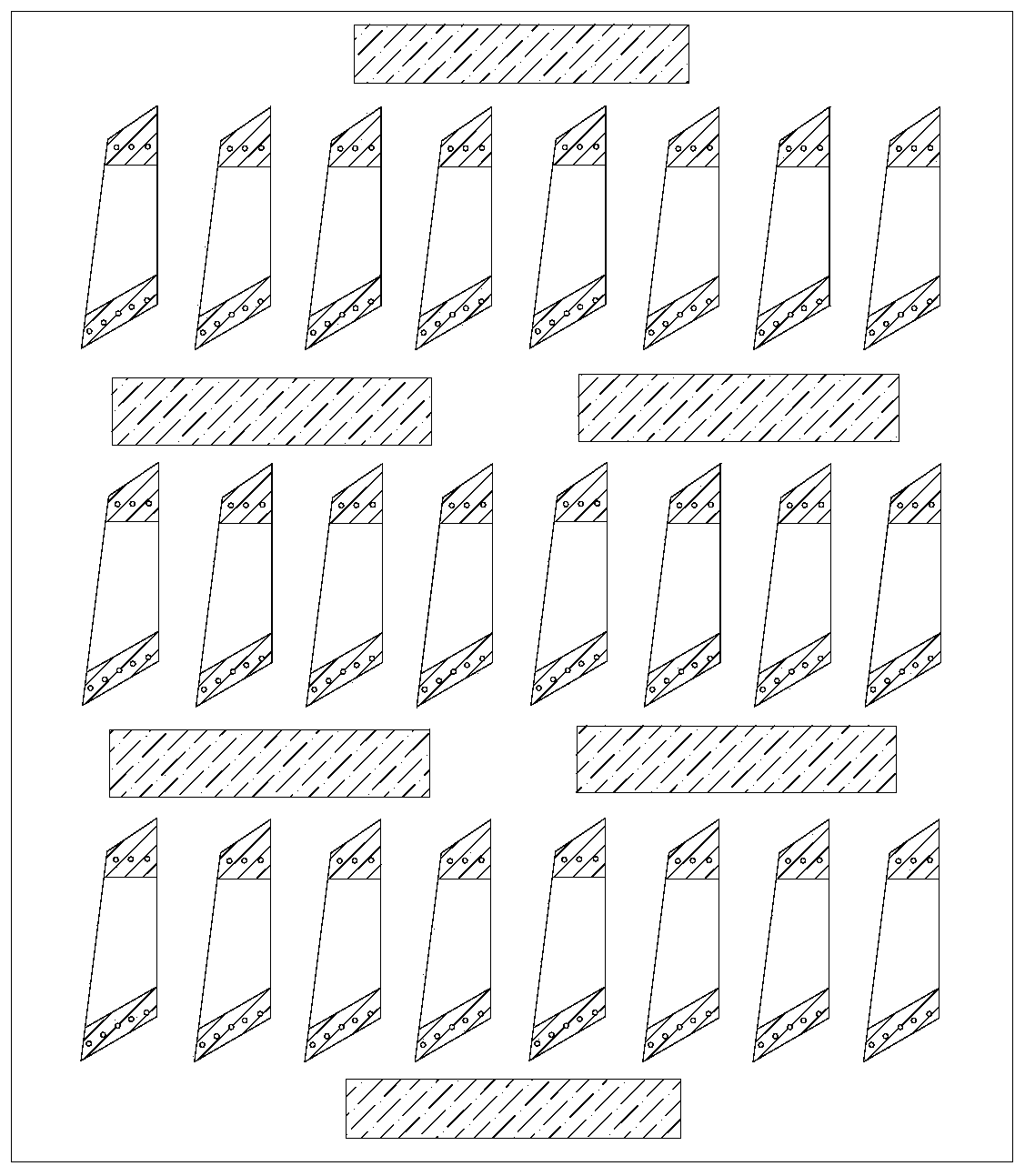

The invention discloses a circuit board electroplating method. The circuit board electroplating method comprises steps that a front selective plating region and a back selective plating region of a single product are separately obtained; when the areas of the front selective plating region and the back selective plating region are different, a raw material for making the single product is subjected to selective plating region arrangement, the front selective plating regions of adjacent two single products located in the same row are respectively located on two sides of the raw material, and the total areas of the selective plating regions of the two sides of the raw material are the same, and the raw material is electroplated according to selective plating region arrangement. The circuit board electroplating method is advantaged in that the area of non-selective plating regions of the raw material is not needed, plating parameters on the two sides of the raw material are the same, plating uniformity is good, and plating cost can be saved.

Owner:SHENZHEN SUNWAY COMM

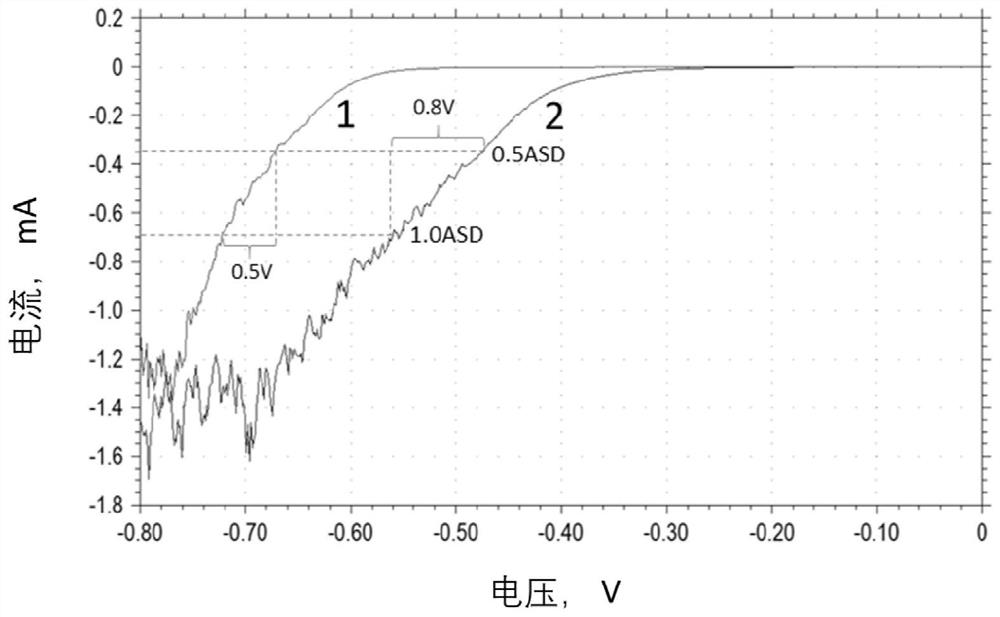

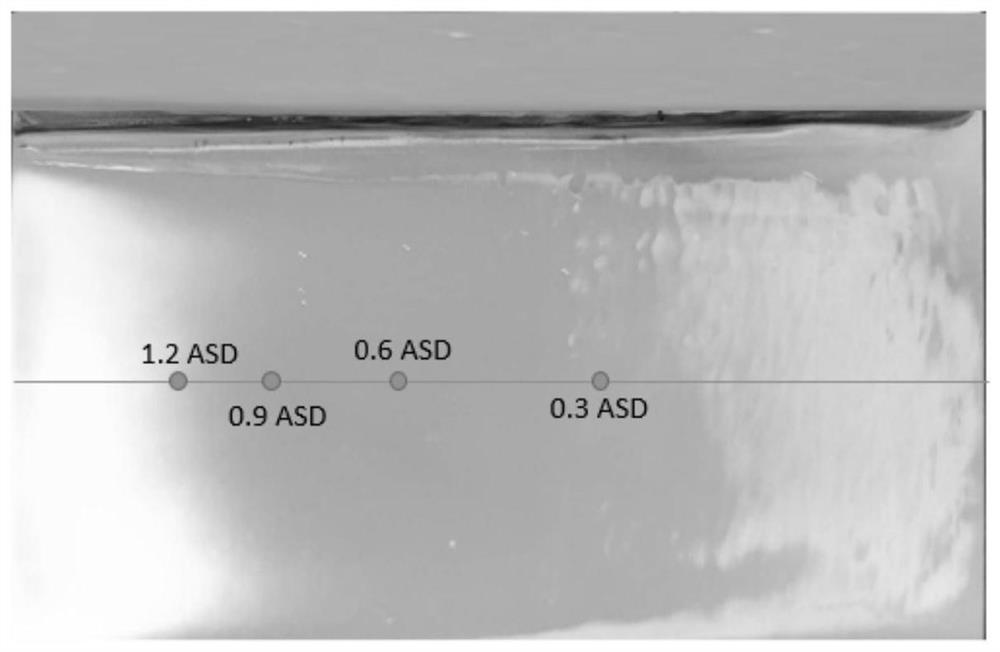

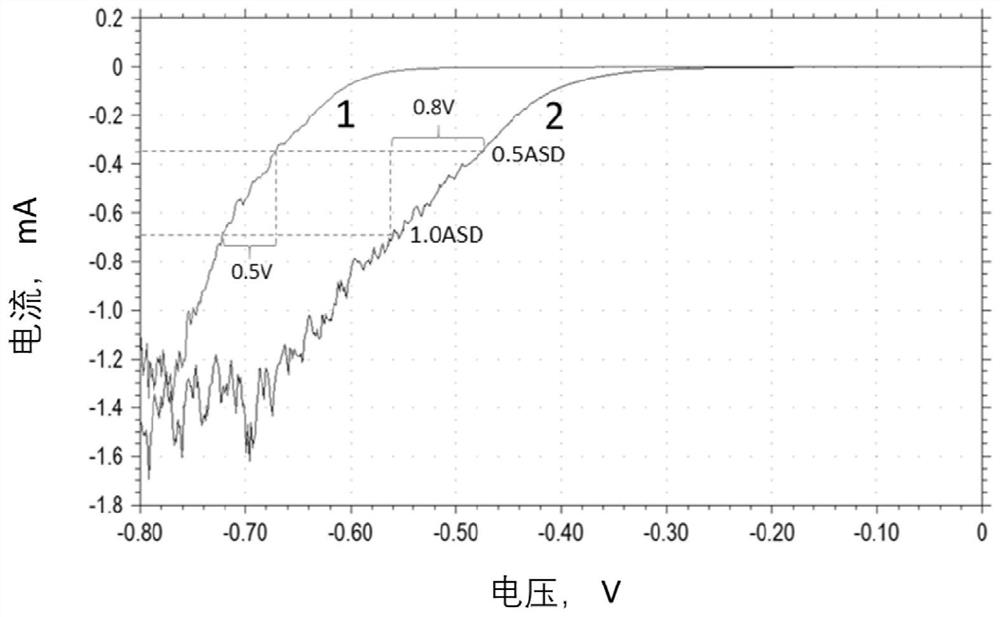

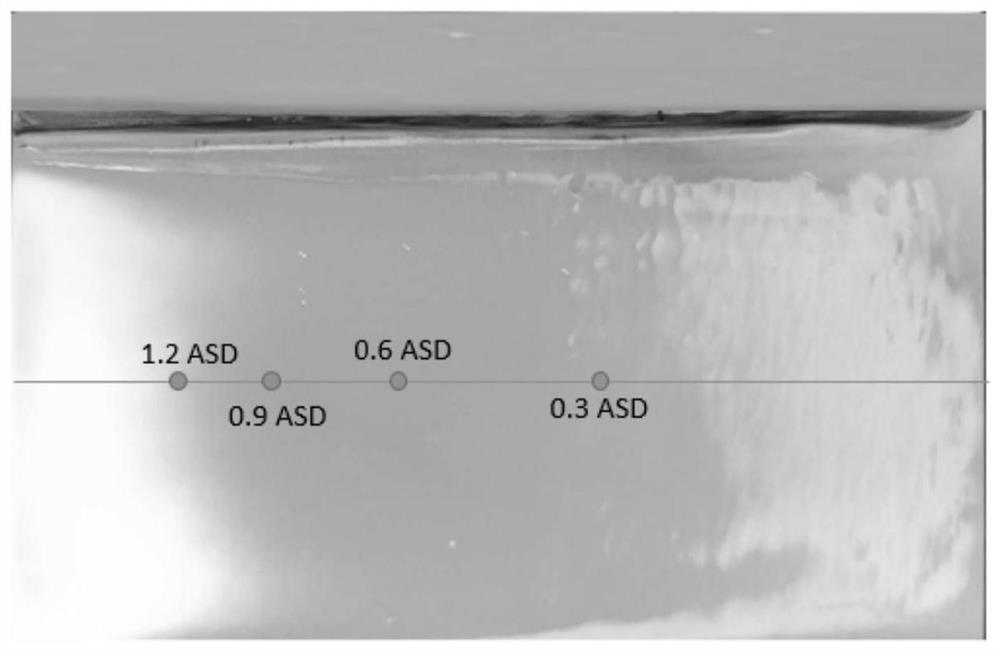

Electrochemical methods for predicting electroplating uniformity of electroplating baths, methods and applications for screening electroplating baths

ActiveCN113960148BPredicting Plating UniformityPrediction and judgment of plating uniformityCellsMaterial electrochemical variablesCyanidePotential difference

The invention relates to the field of leveling prediction of electroplating gold, and discloses an electrochemical method for predicting the electroplating uniformity of an electroplating solution, a method for screening the electroplating solution and its application. Electrochemical method comprises: apply voltage U to carry out electroplating on the electroplating pond that electroplating solution is housed; Change described voltage U, and measure corresponding electroplating current intensity I, draw the variation curve of electroplating current intensity I to described voltage U; Through the change curve, the absolute value of the potential difference between at least two current density values set for the electroplating solution is calculated, which is used to predict the electroplating uniformity of the electroplating solution through electroplating. Therefore, the plating uniformity of the electroplating solution is effectively judged and the time is short, especially the electroplating uniformity of the cyanide-free gold plating solution for wafer gold plating. It is also effective for adsorbing additives that do not have strong convection dependence on the electrode surface.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV +1

Electrochemical method for predicting electroplating uniformity of electroplating liquid, method for screening electroplating liquid and application

ActiveCN113960148APredicting Plating UniformityPrediction and judgment of plating uniformityCellsMaterial electrochemical variablesCyanidePotential difference

The invention relates to the field of gold electroplating levelness prediction, and discloses an electrochemical method for predicting electroplating uniformity of electroplating liquid, a method for screening the electroplating liquid and application. The electrochemical method comprises the following steps: applying voltage U to an electroplating pool filled with electroplating liquid for electroplating; changing the voltage U, measuring the corresponding electroplating current intensity I, and drawing a changing curve of the electroplating current intensity I to the voltage U; and according to the change curve, calculating an absolute value of a potential difference between at least two current density values set for the electroplating liquid, and using the absolute value to predict the electroplating uniformity of the electroplating liquid for electroplating. Therefore, the electroplating uniformity of the electroplating liquid is effectively judged, and the time is short, especially the electroplating uniformity of the cyanide-free gold plating liquid for wafer gold plating. And the method is also effective for adsorbing an additive which does not have strong convection dependence on the surface of the electrode.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV +1

A clamping device suitable for multi-substrate high-precision electroplating

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com