High-density interconnection integrated circuit board manufacturing method

An integrated circuit board, high-density interconnection technology, applied in the directions of printed circuit manufacturing, printed circuit, printed circuit secondary processing, etc., can solve the problems of many production process links, high production cost, insufficient safety and reliability, etc. Achieve the effect of enhancing electroplating uniformity, improving production efficiency and production quality, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

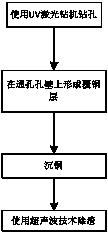

[0019] Such as figure 1 Shown, a kind of high-density interconnection integrated circuit board fabrication method, it comprises the following steps:

[0020] S1: Use a UV laser drill to drill through holes in the product area on the circuit board according to the design requirements, and drill test holes in the edge area of the board outside the product area;

[0021] S2: Use ordinary electroplating and micro-hole electroplating technology to form a copper clad layer on the plate surface, the wall of the via hole and the wall of the test hole, and fill the via hole and the test hole with resin after copper cladding;

[0022] S3: Carry out sinking copper treatment to plate;

[0023] S4: Use ultrasonic technology to remove slag from the board.

[0024] The stated test hole diameter is the same as the smallest via hole diameter in the product area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com