Patents

Literature

304results about How to "Avoid crush damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

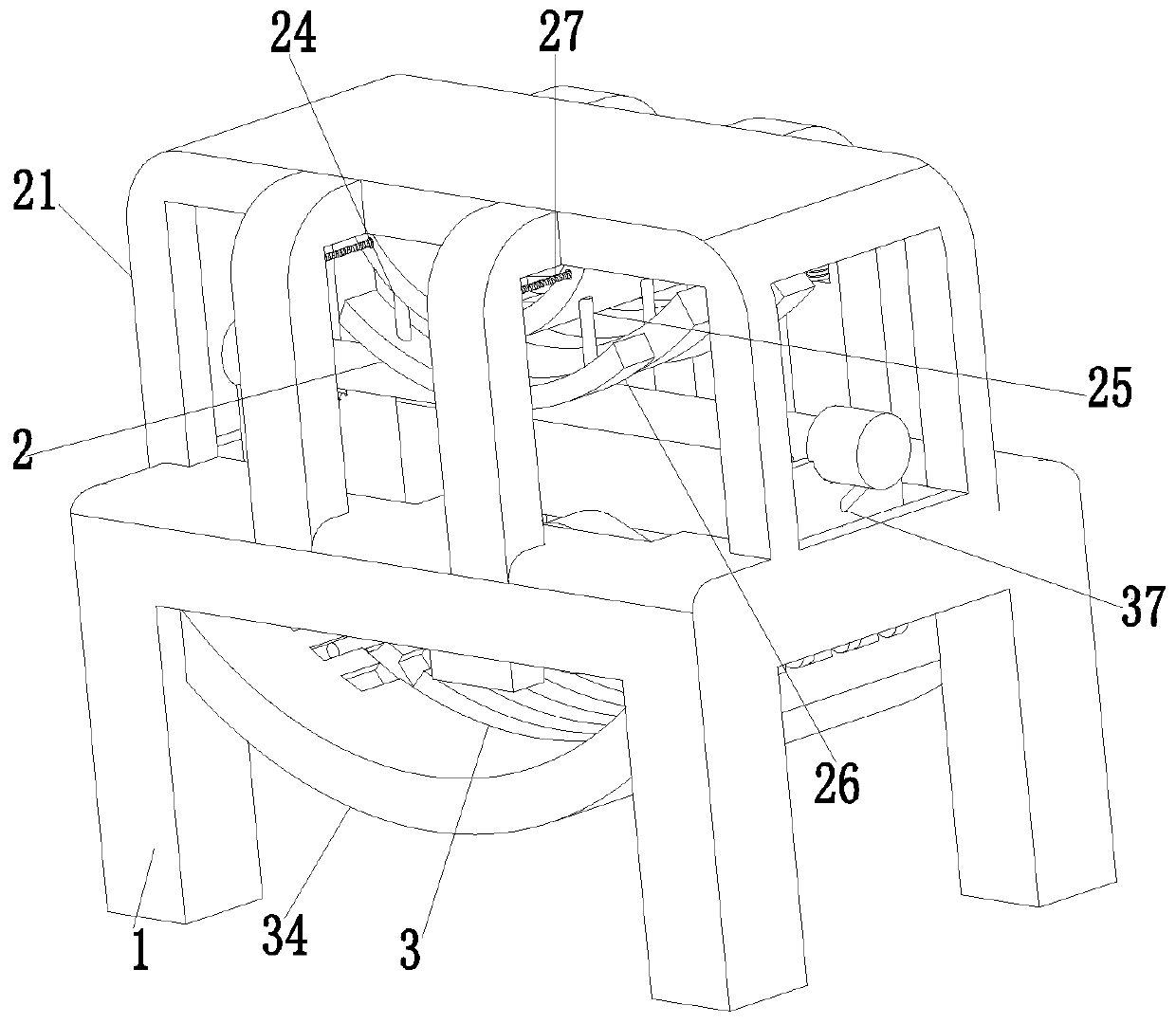

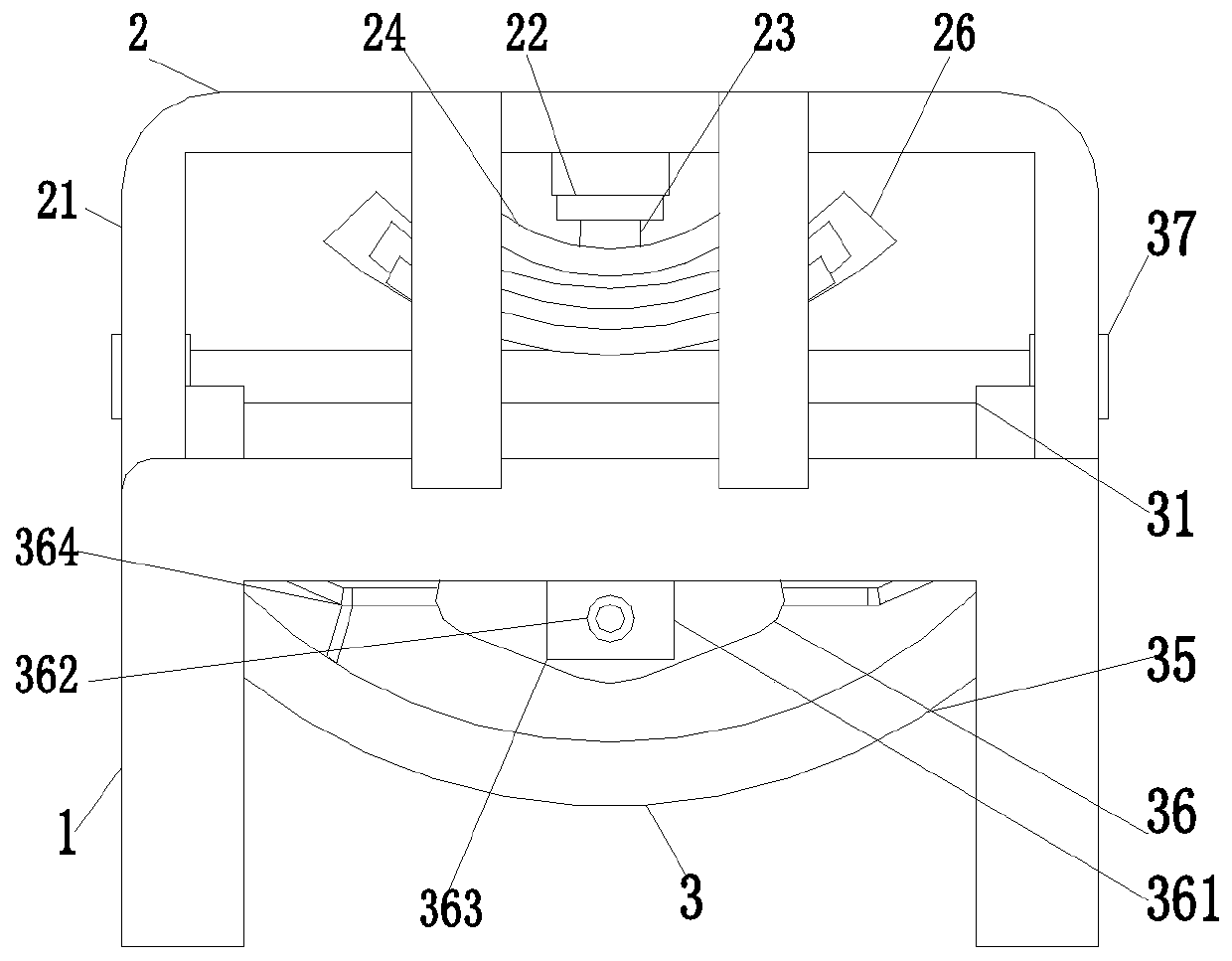

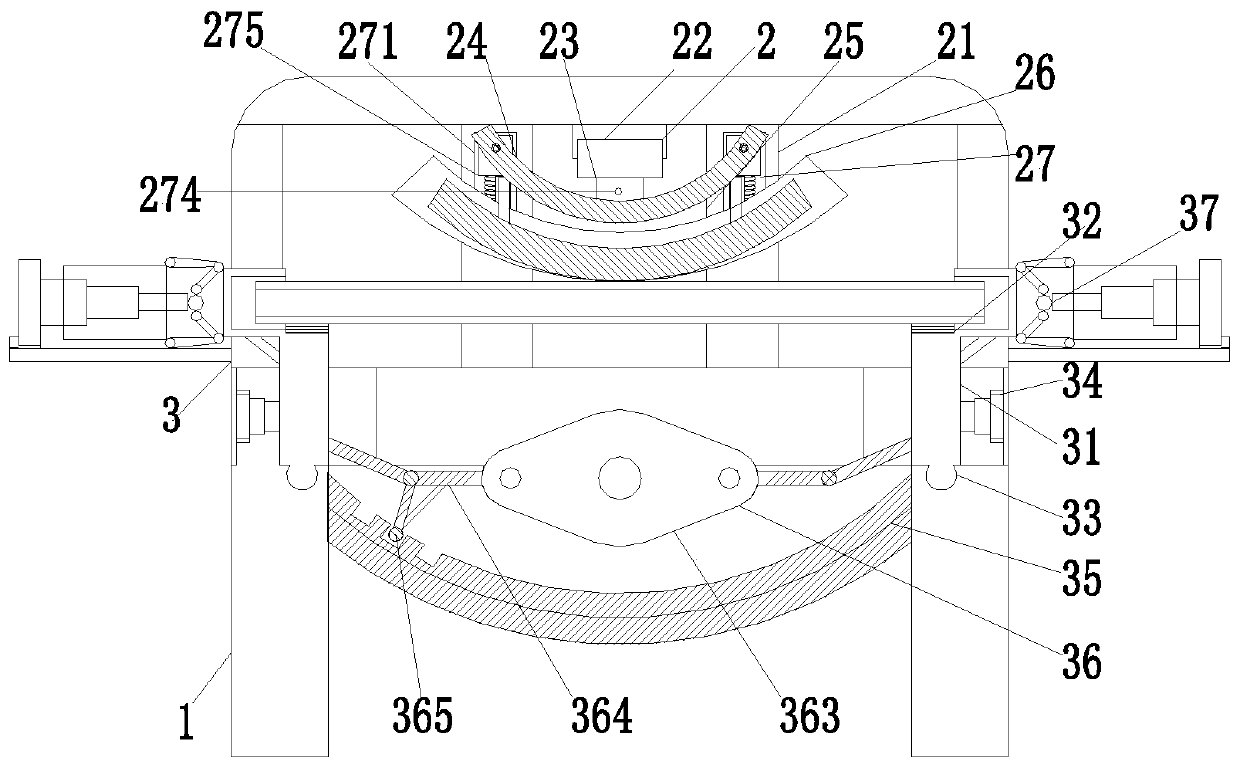

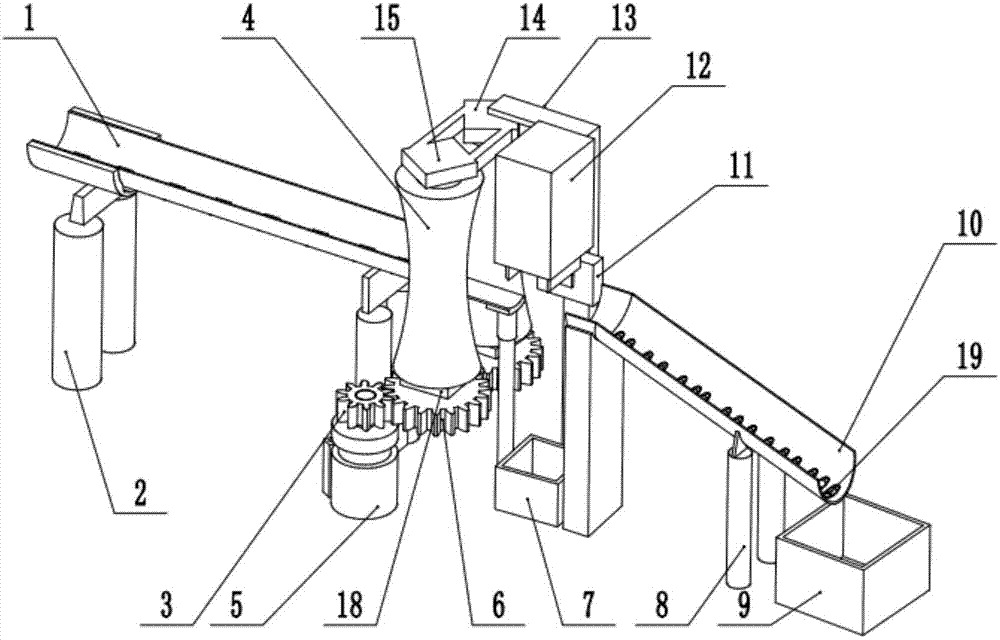

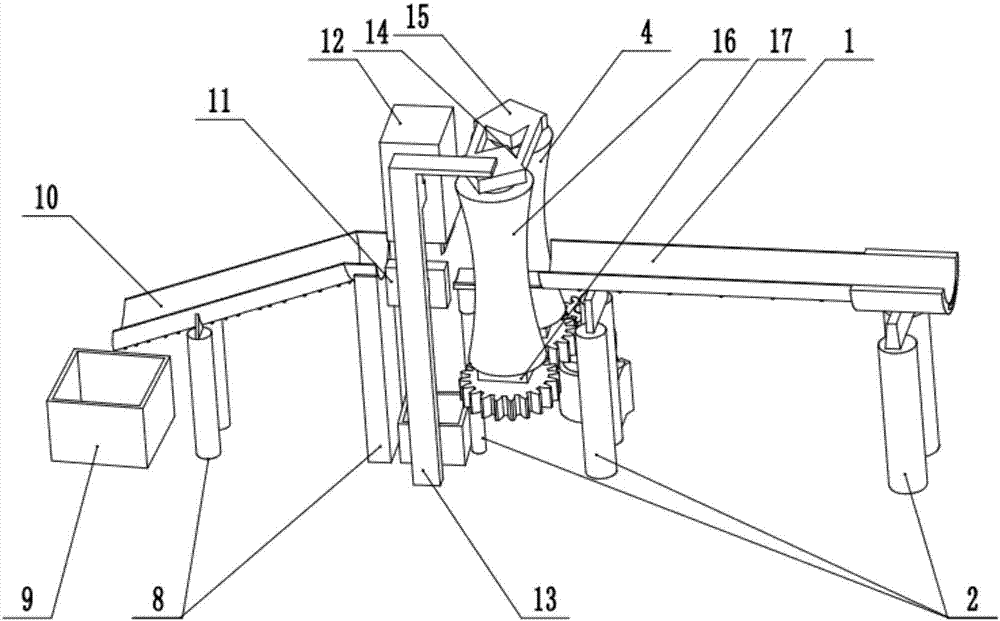

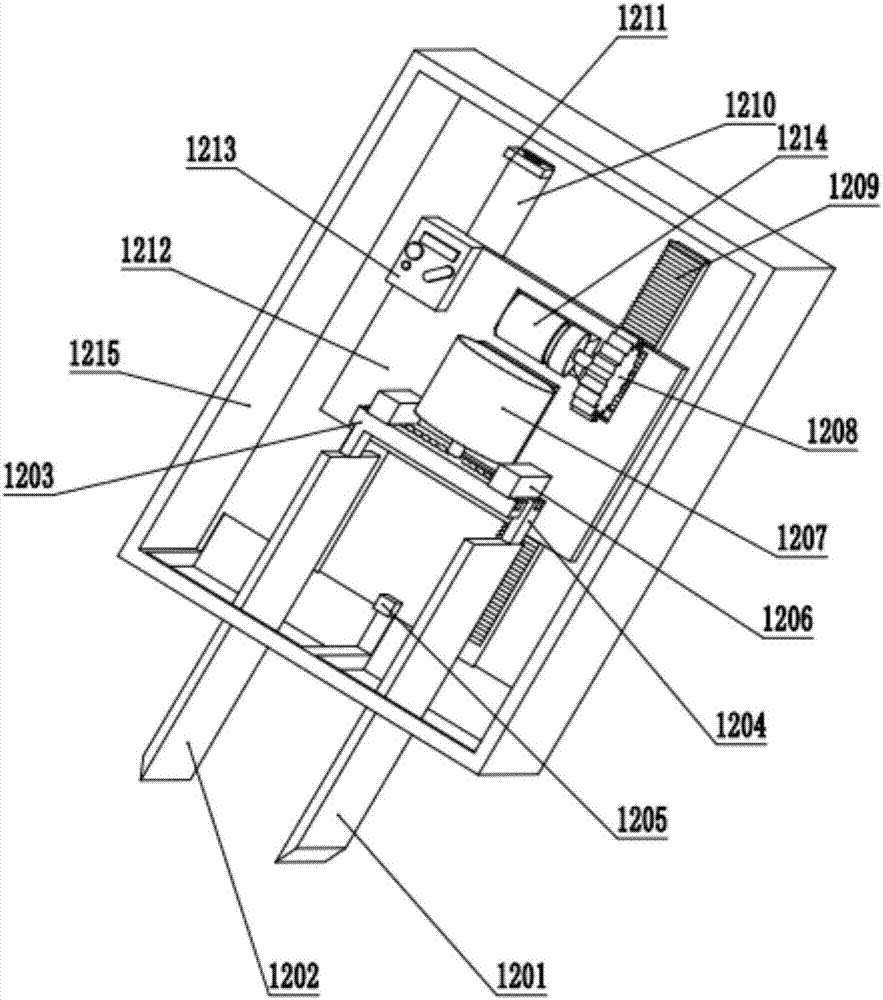

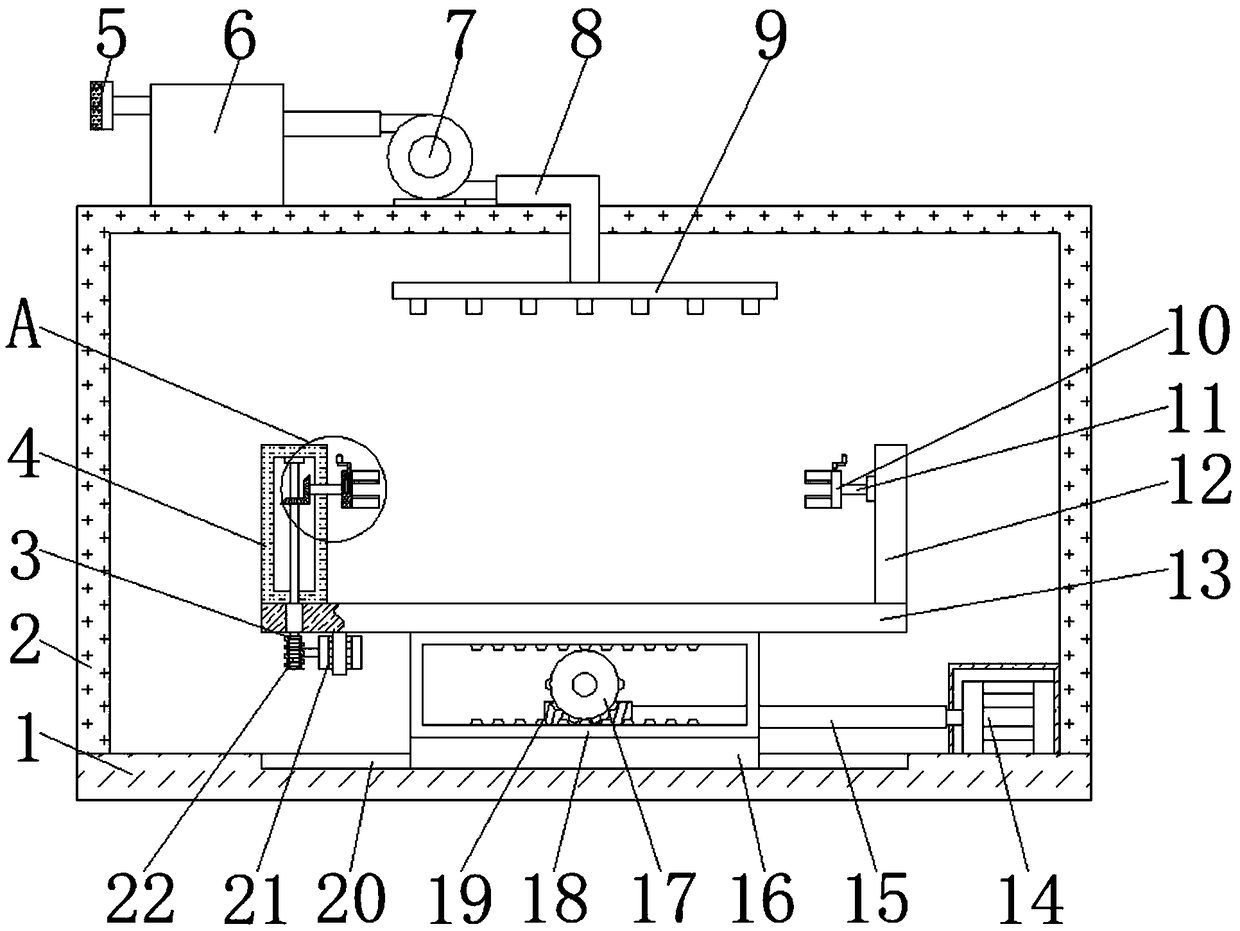

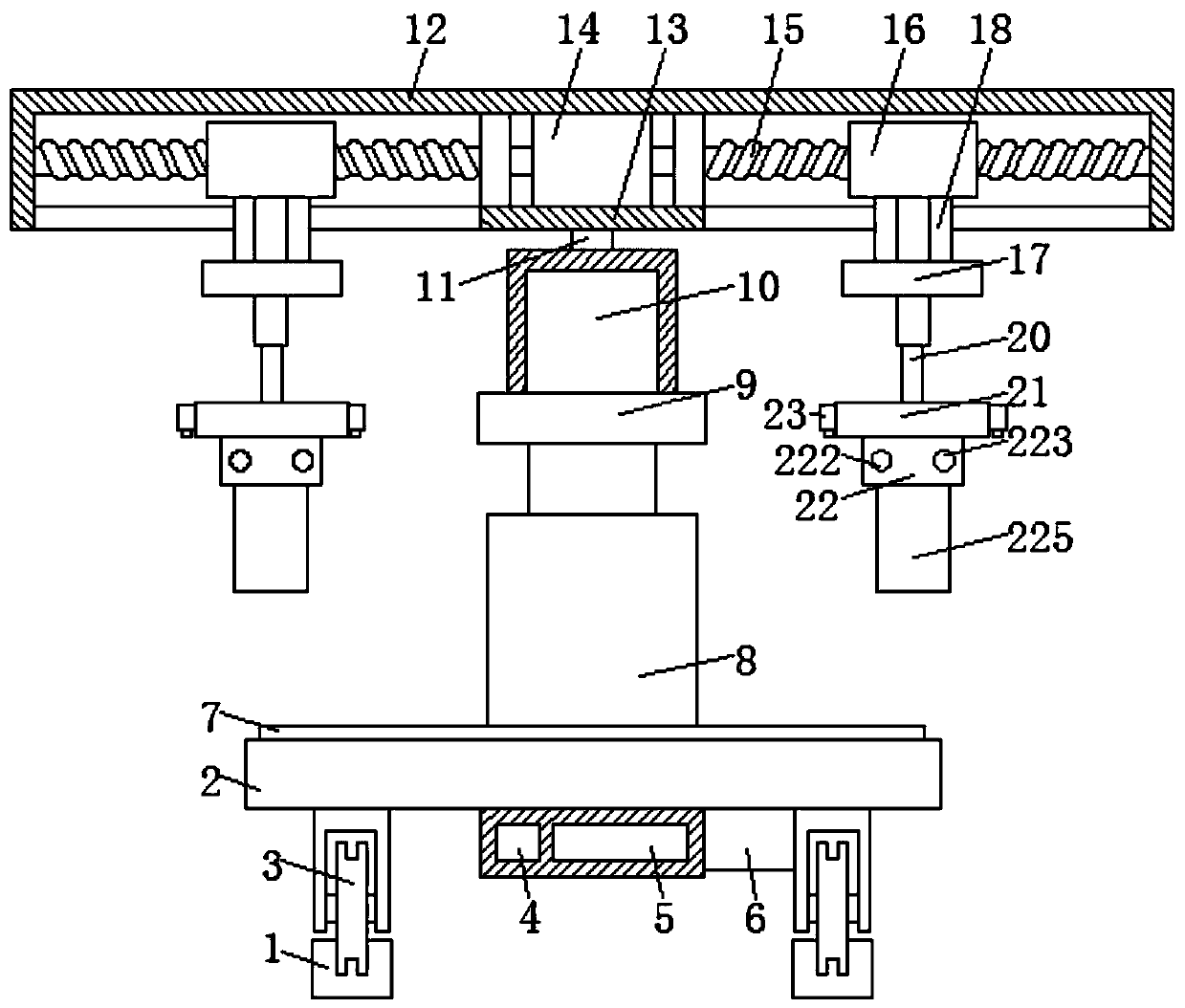

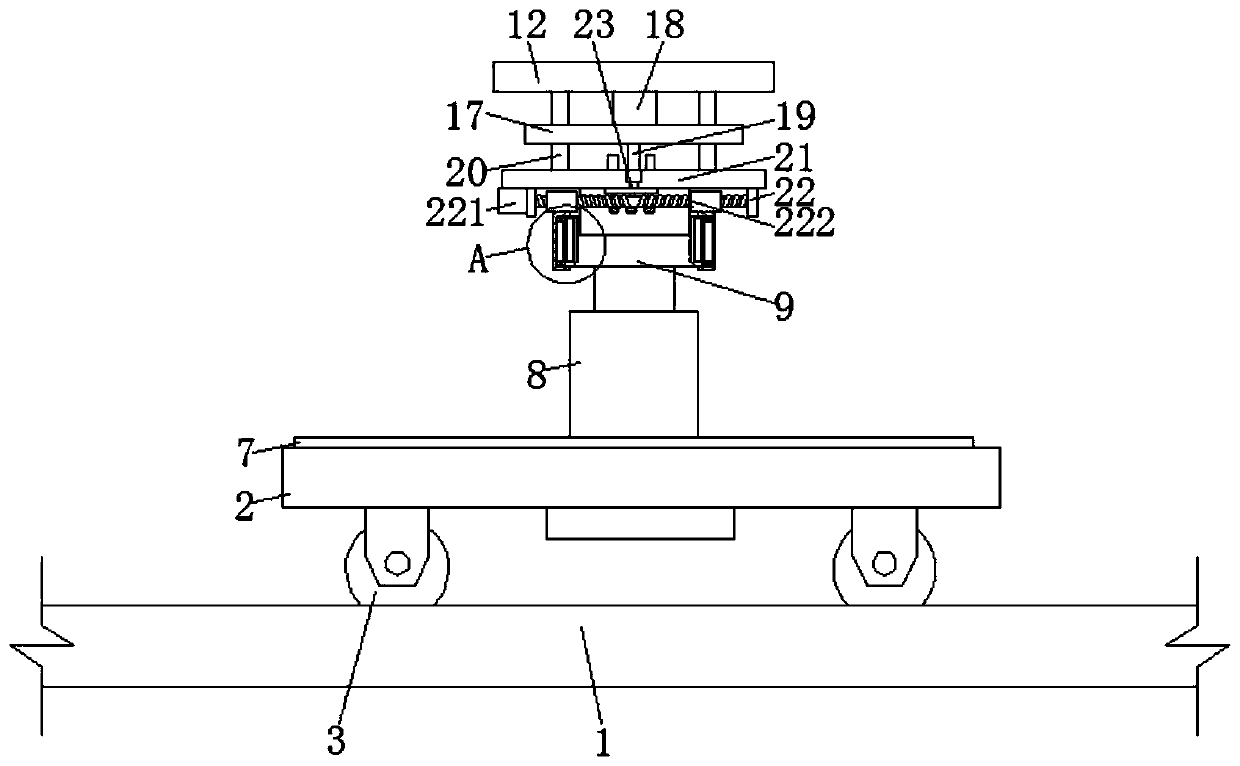

Bending machine for steel structure metal pipe fitting

ActiveCN111482495AAvoid easy crackingQuality improvementMetal-working feeding devicesPositioning devicesPress brakeClassical mechanics

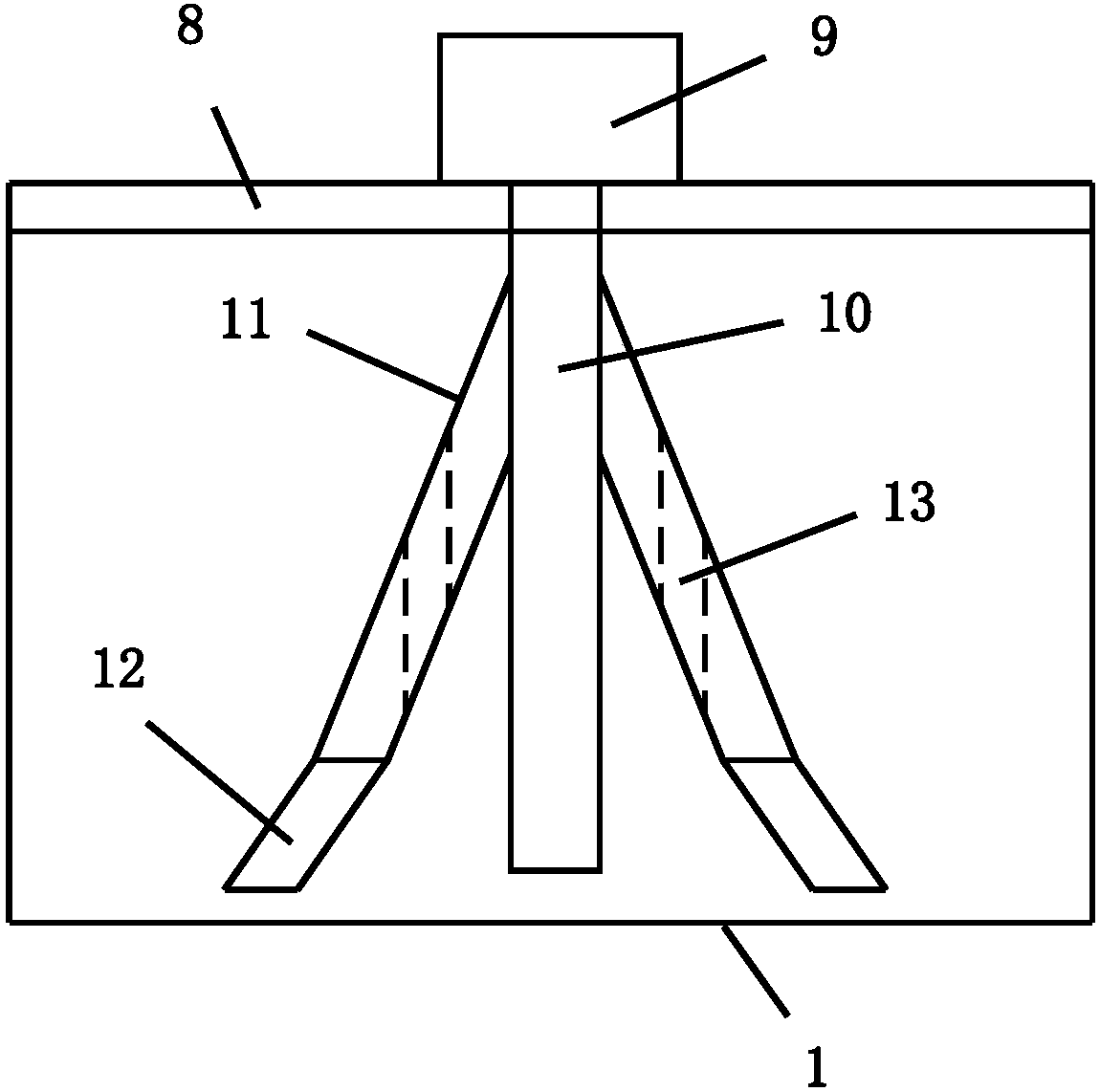

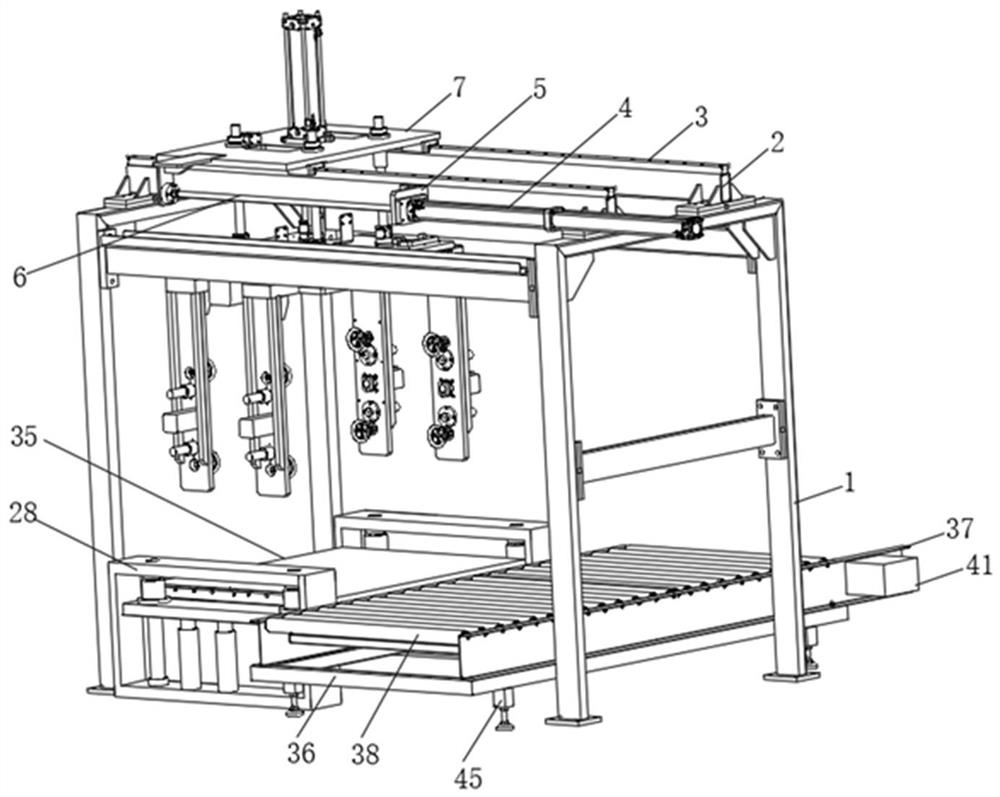

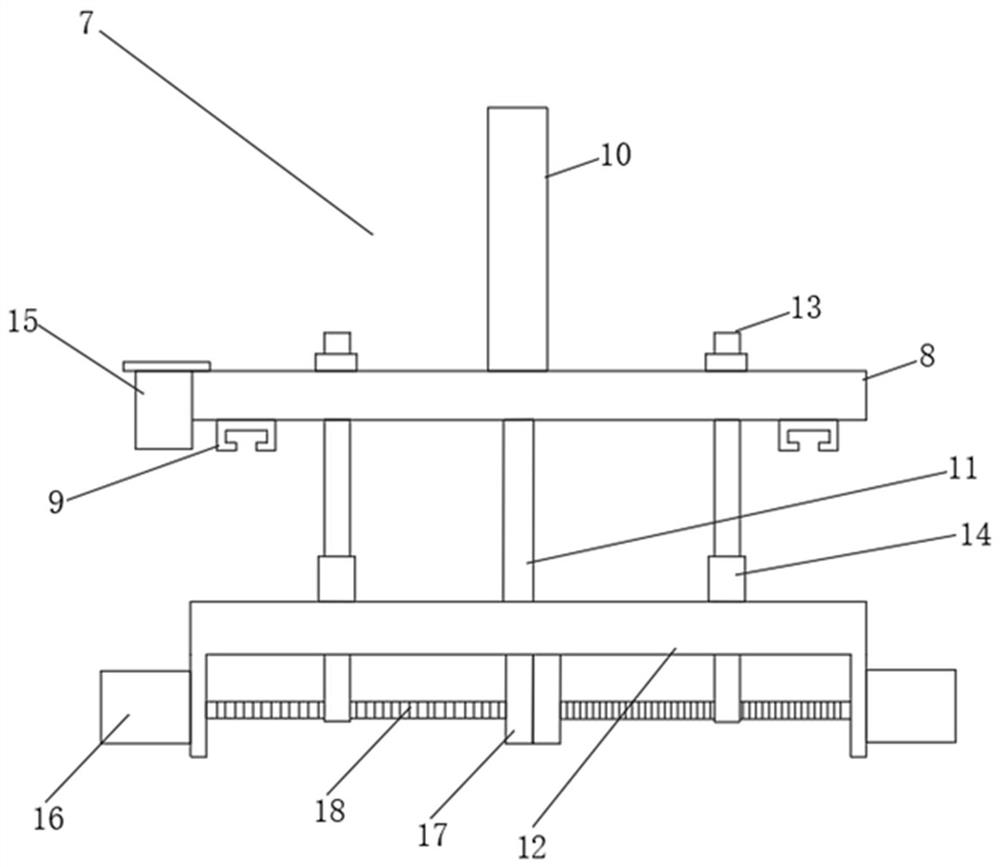

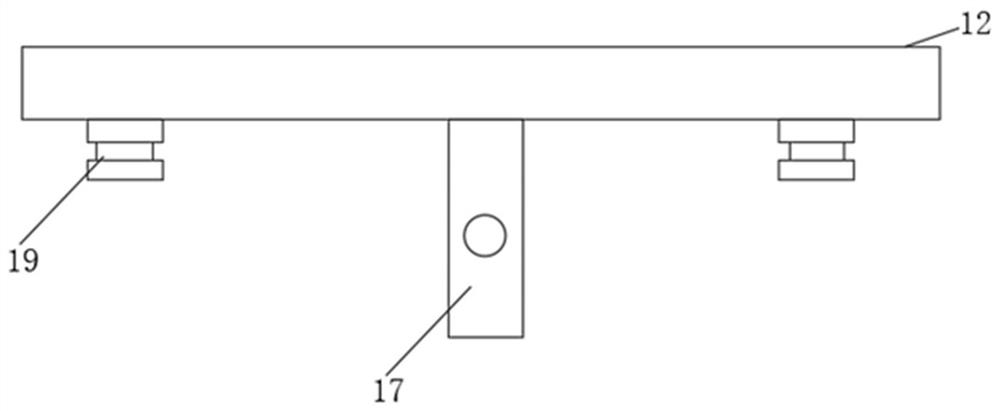

The invention relates to a bending machine for a steel structure metal pipe fitting. The bending machine comprises a supporting frame, a bending device and a clamping device, the supporting frame is of a U-shaped structure, the bending device is installed above the supporting frame, the clamping device is arranged below the bending device, and the clamping device is installed on the supporting frame. The bending machine for the steel structure metal pipe fitting can solve the problem that when an existing bending machine for a metal pipe fitting bends the metal pipe fitting, graded extrusion bending of the metal pipe fitting cannot be achieved, so that a straight pipe poor in bendability is prone to cracking and even the problem of breaking occurs during bending, the qualified rate of a finished bent pipe is affected, and the problem that when the existing bending machine clamps and fixes the metal pipe fitting, the clamping mechanism cannot be correspondingly adjusted along with position change of pipe fitting deformation, damage to a formed bent pipe is caused, the quality of the formed bent pipe is affected, metal pipe fittings with different diameters cannot be clamped and fixed, the formed bent pipe is unique in shape and single in diameter, and the use range is limited are solved.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

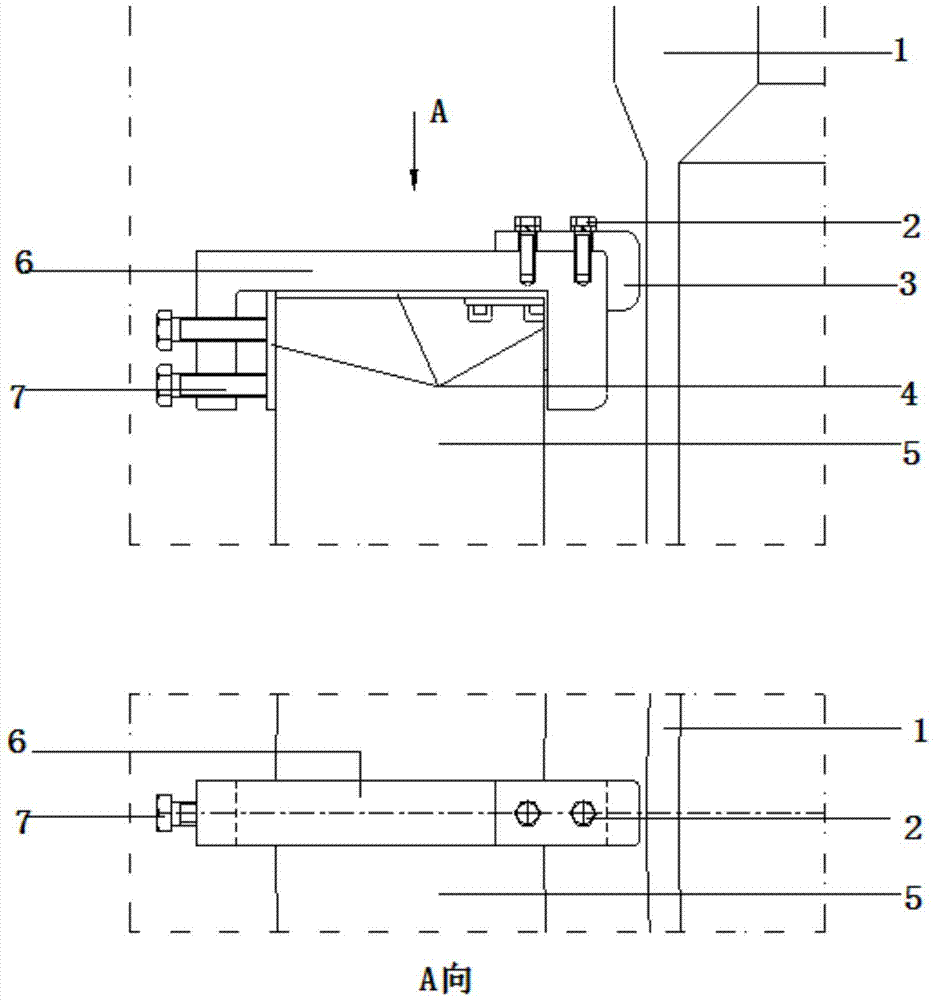

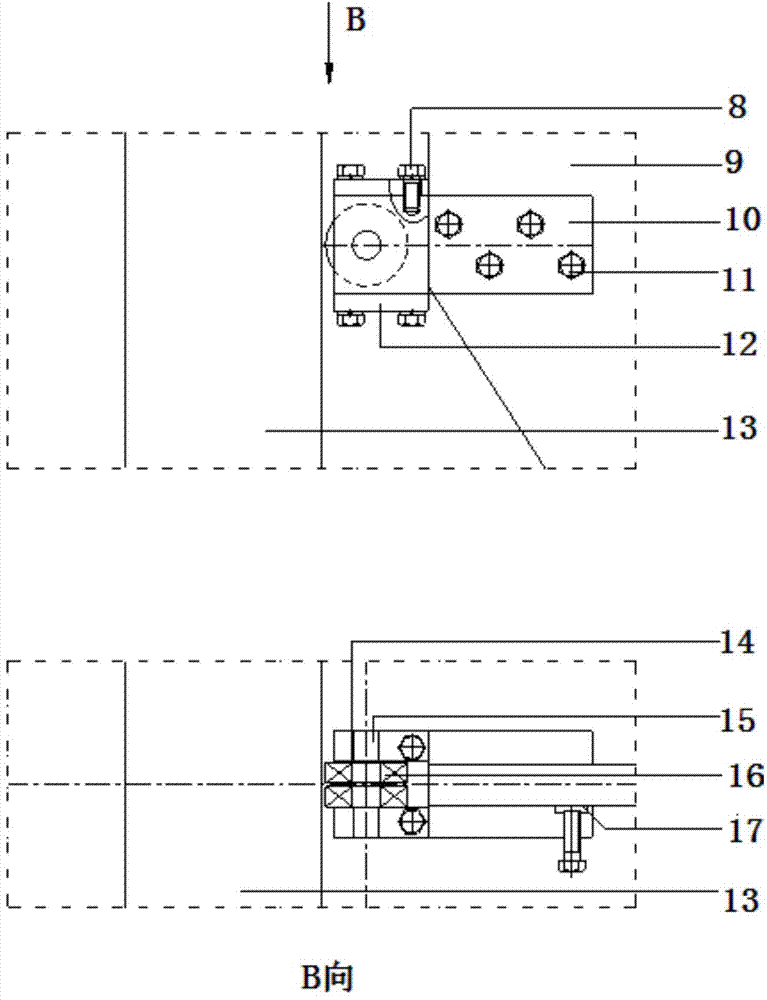

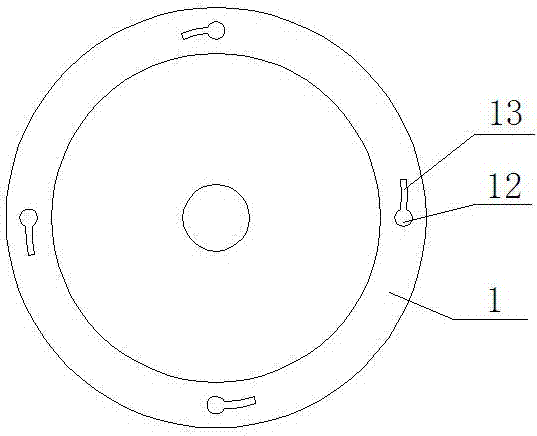

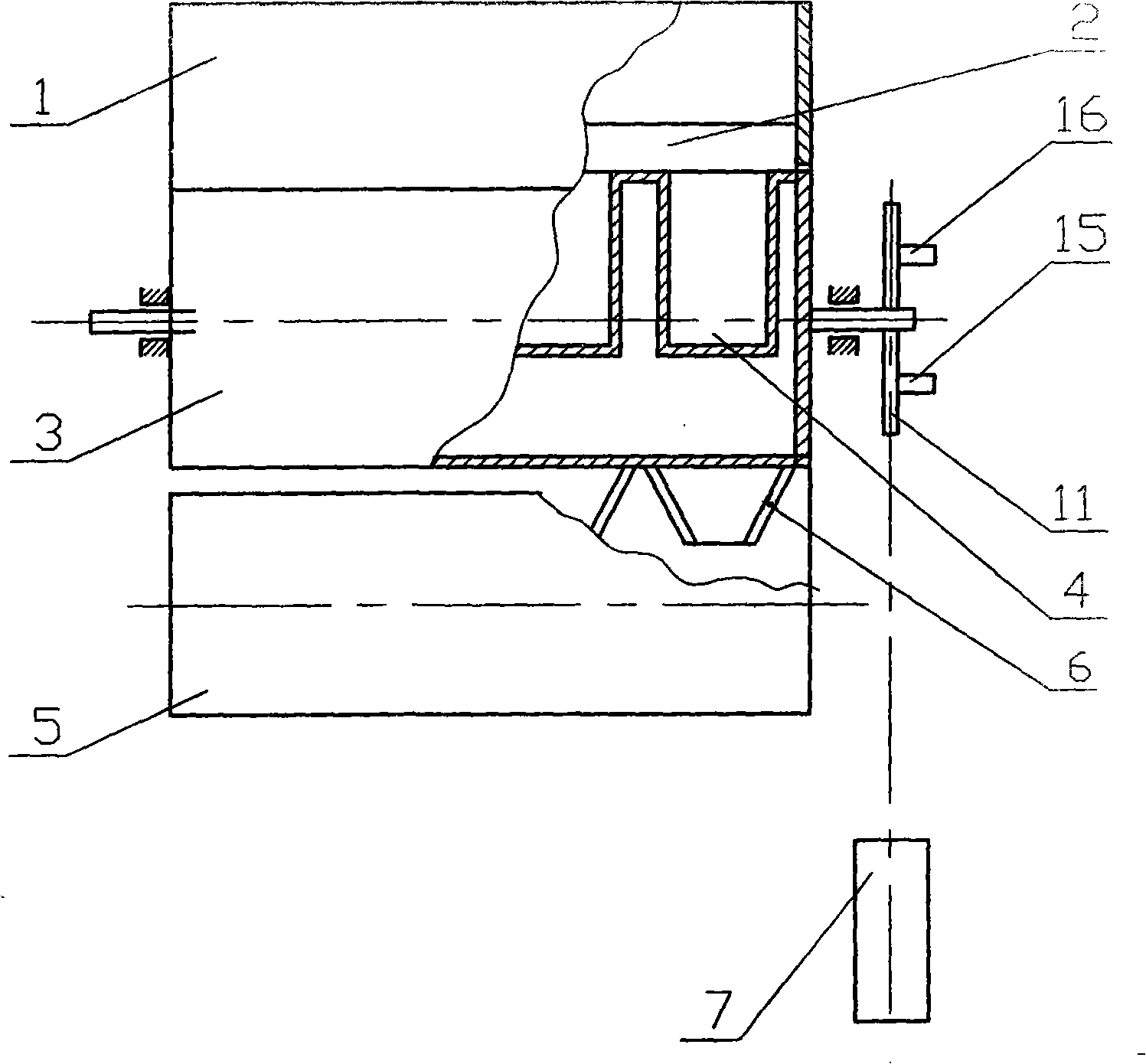

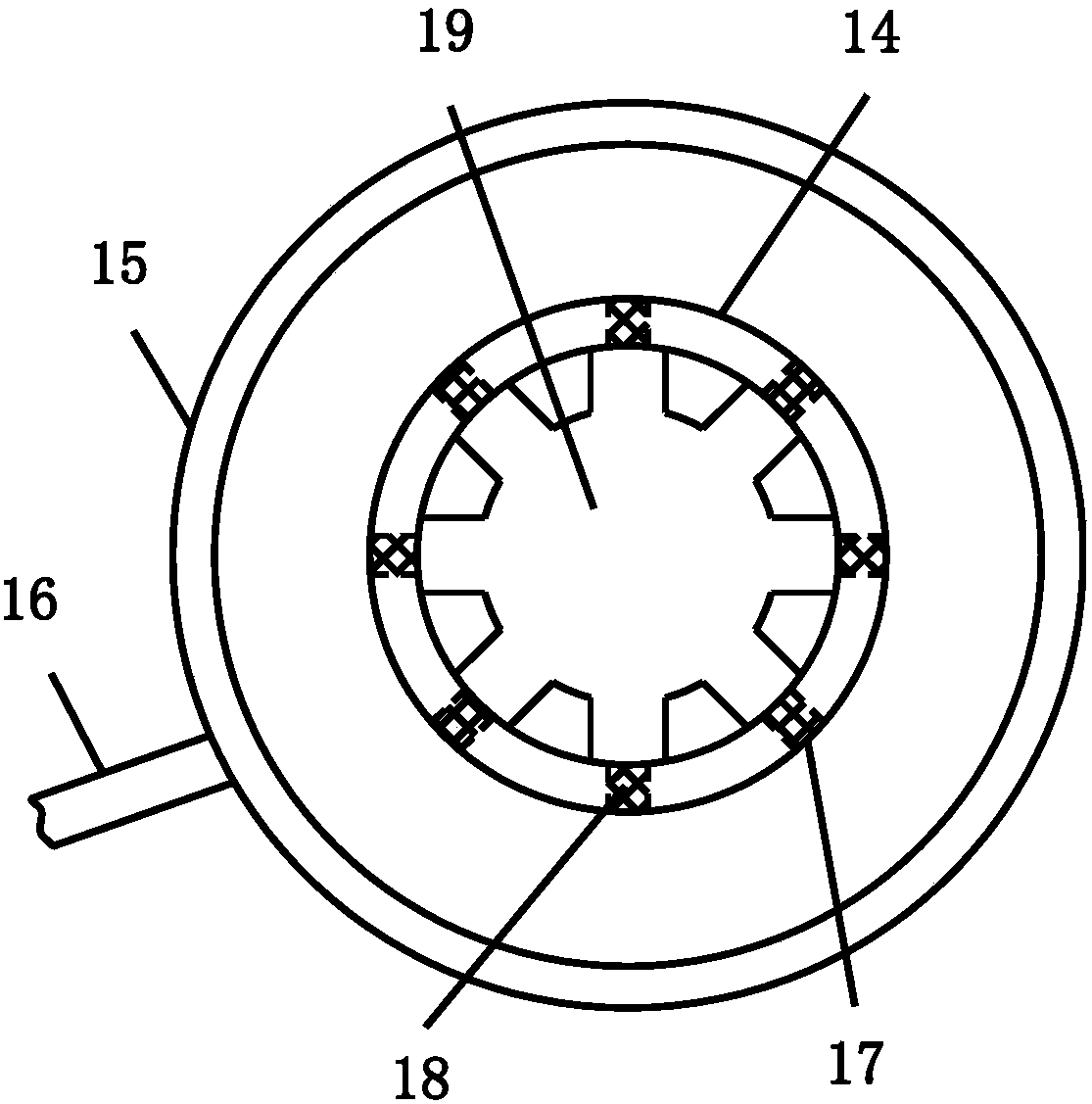

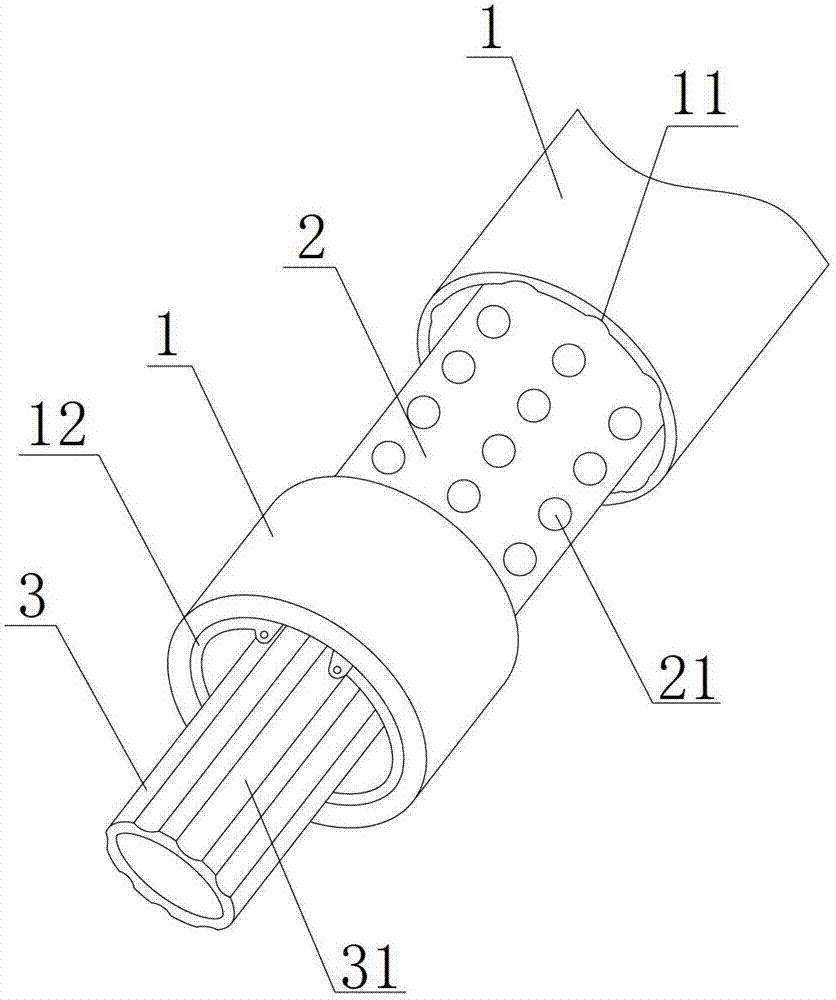

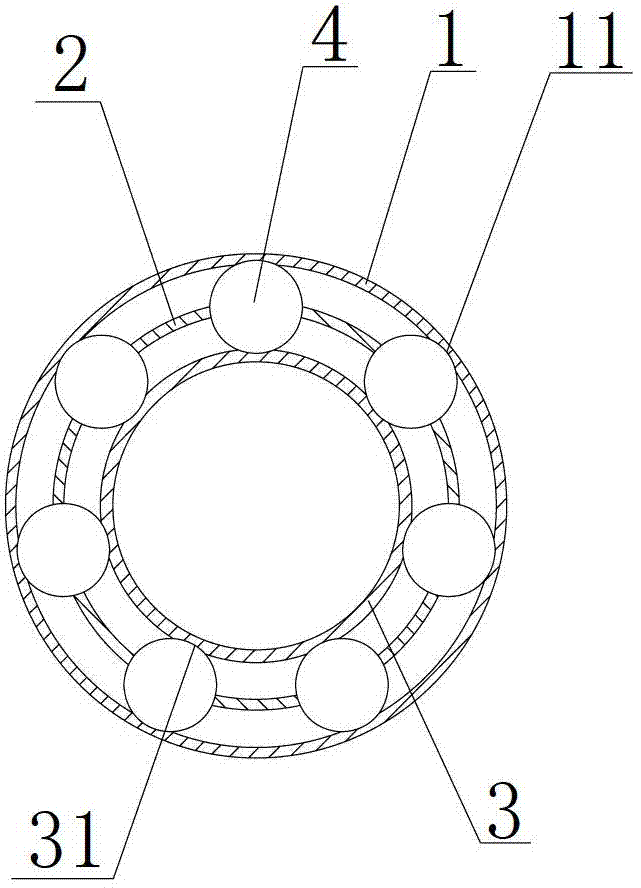

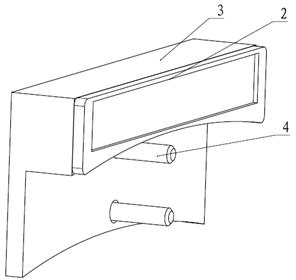

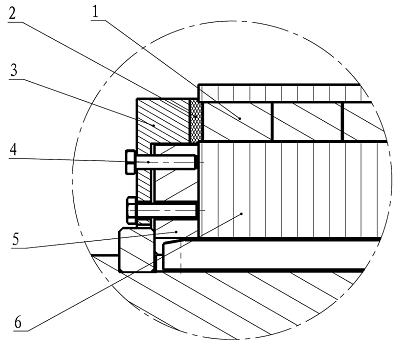

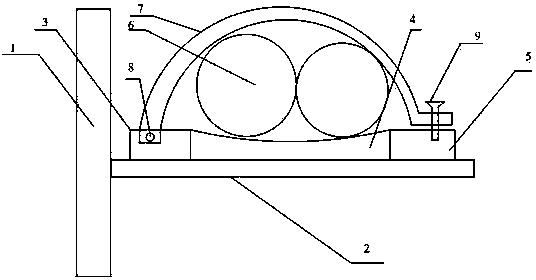

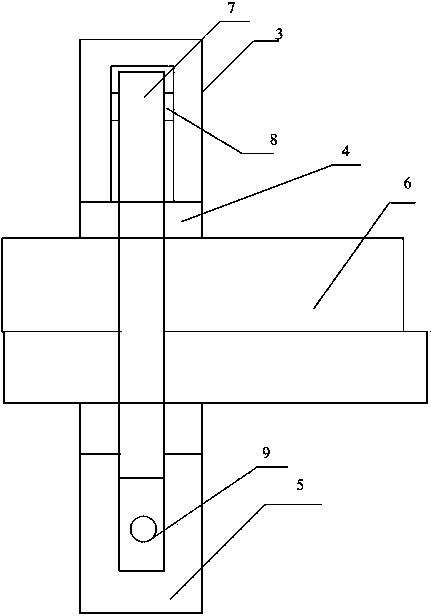

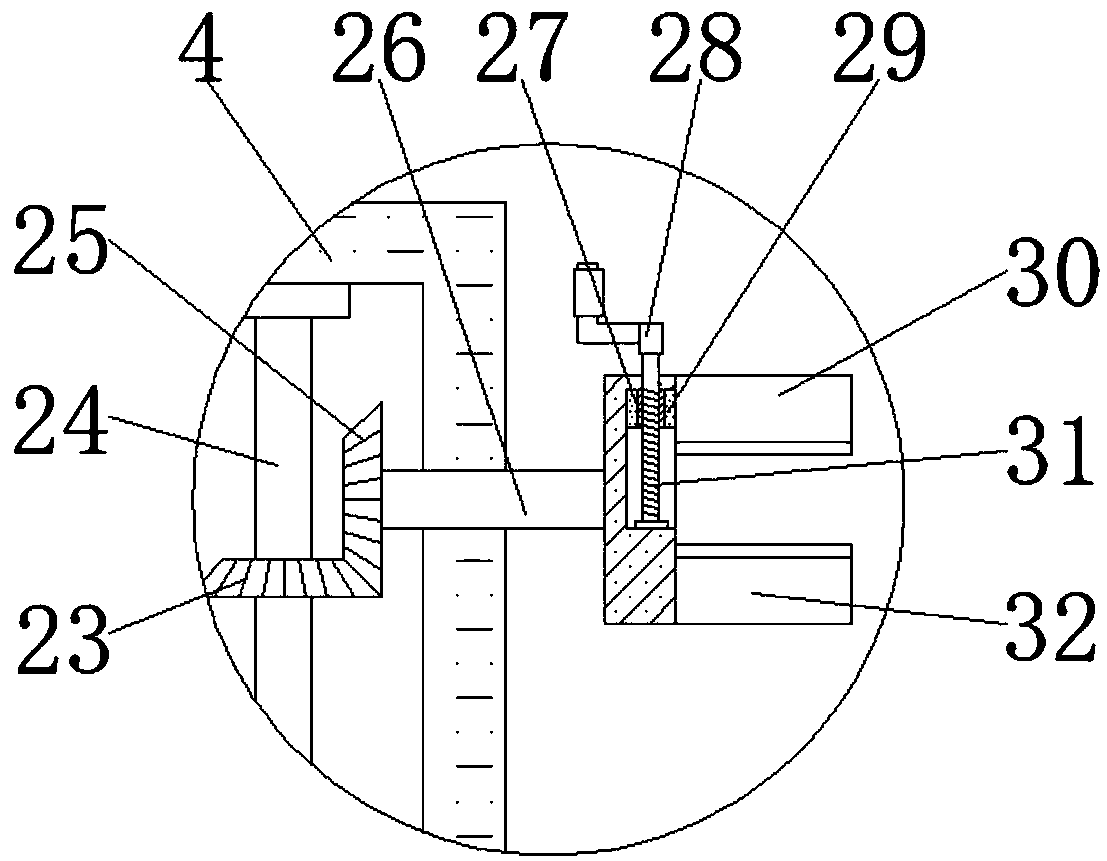

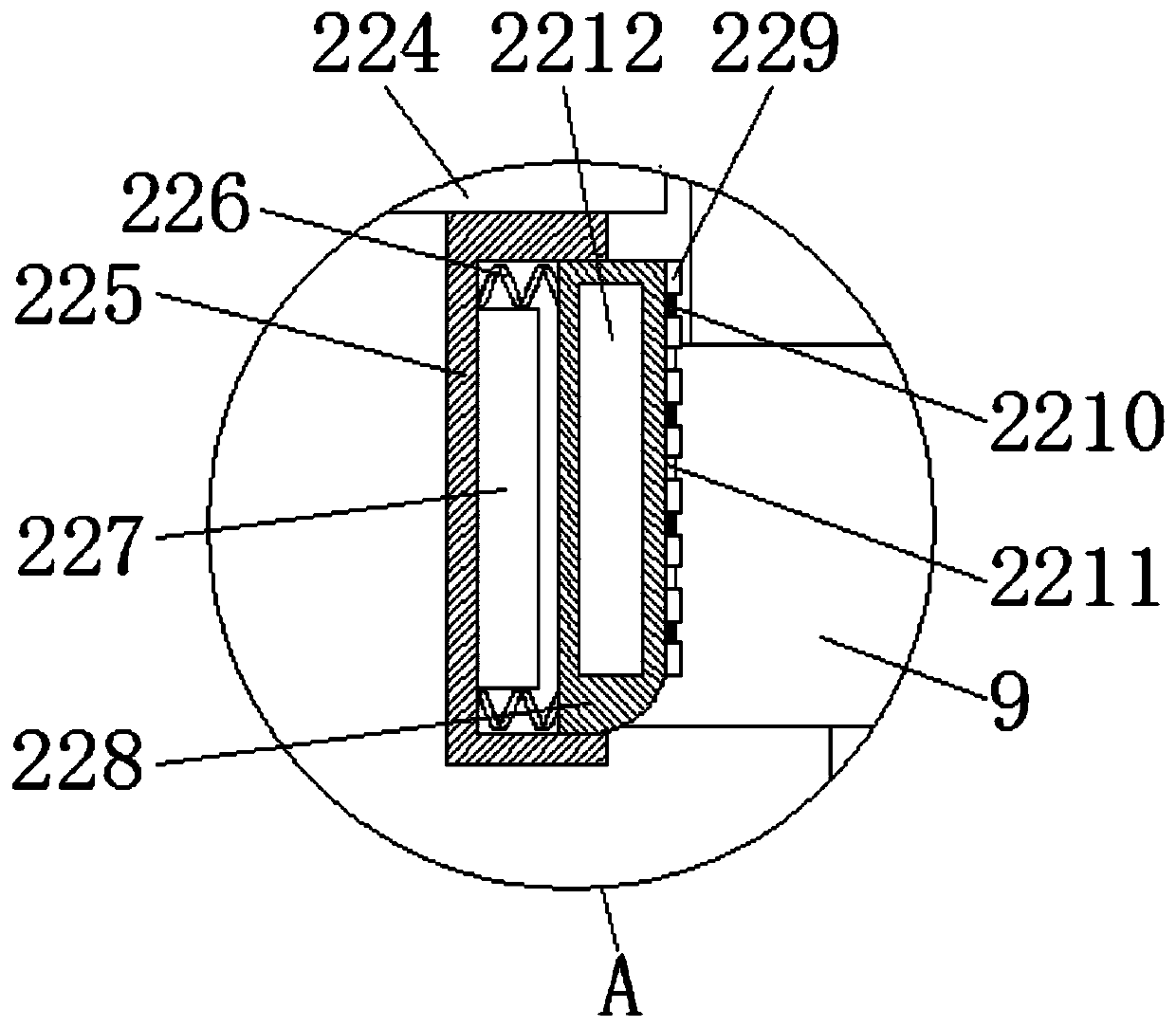

Centering device for hoisting shell of reactor core of high-temperature gas cooled reactor

ActiveCN103879887AAvoid bumpingAvoid crush damageNuclear energy generationSafety gearReactor pressure vesselCage device

The invention relates to a centering device for hoisting a shell of a reactor core of a high-temperature gas cooled reactor. The device comprises a top centering caging device and a bottom centering caging device. The top centering caging device is fixed on a primary flange of a reactor pressure vessel and the bottom centering caging device is fixed on a radial rib plate of the shell of reactor core in a supporting manner. While the shell of the reactor core is hoisted into the reactor pressure vessel, the top centering caging device can ensure that the outer wall of the shell of reactor core and the inner wall of the primary flange of the reactor pressure vessel can be within a minimum safe distance, and a bracket of the shell of reactor core and the inner wall of the reactor pressure vessel can be within a minimum safe distance. The bottom centering caging device adopts a bearing rolling structure, so that sliding friction and impact between the inner wall of the reactor pressure vessel and the shell of reactor core during hoisting can be prevented. All of the centering devices can be removed after finishing the hoisting of the shell of the reactor core. The novel centering device provided by the invention provides the safe and reliable guarantee for the large commercial high-temperature gas cooled reactor hoisting process.

Owner:TSINGHUA UNIV

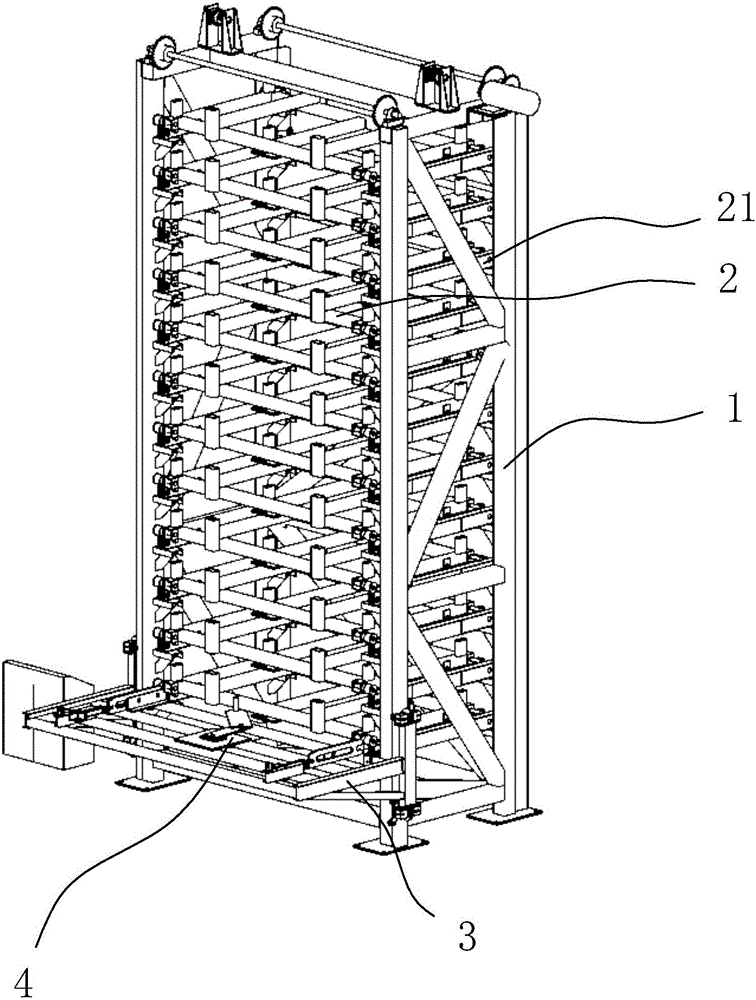

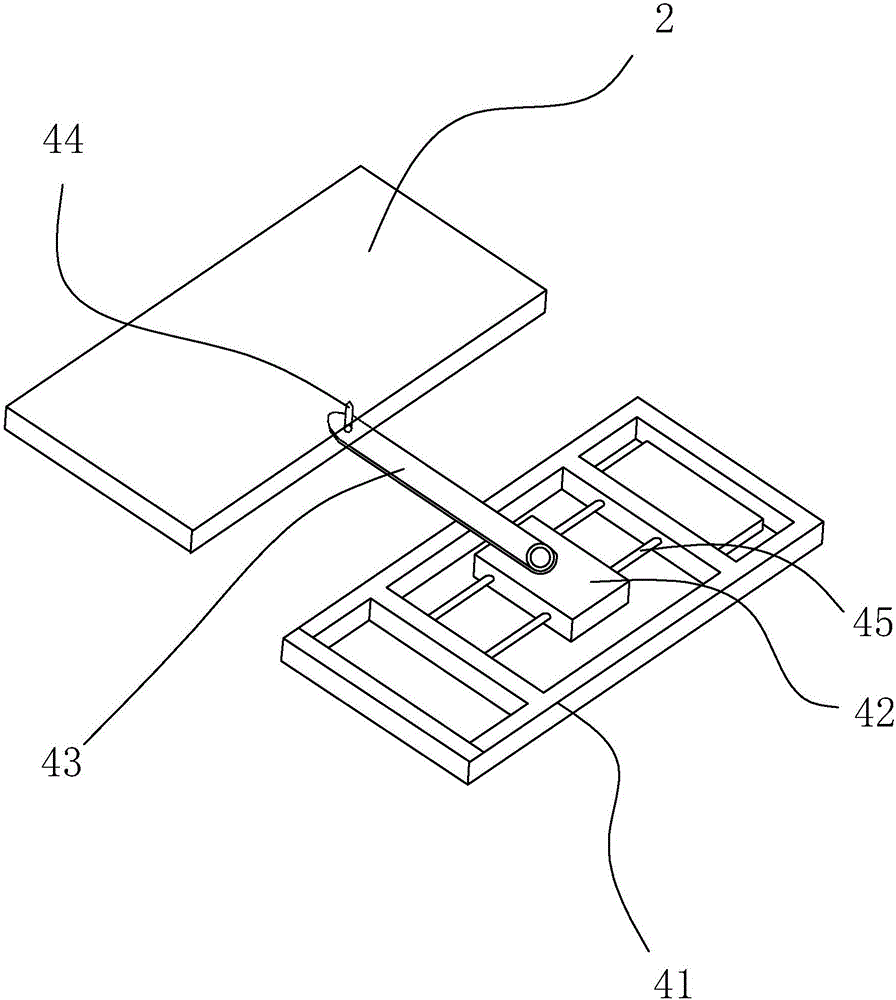

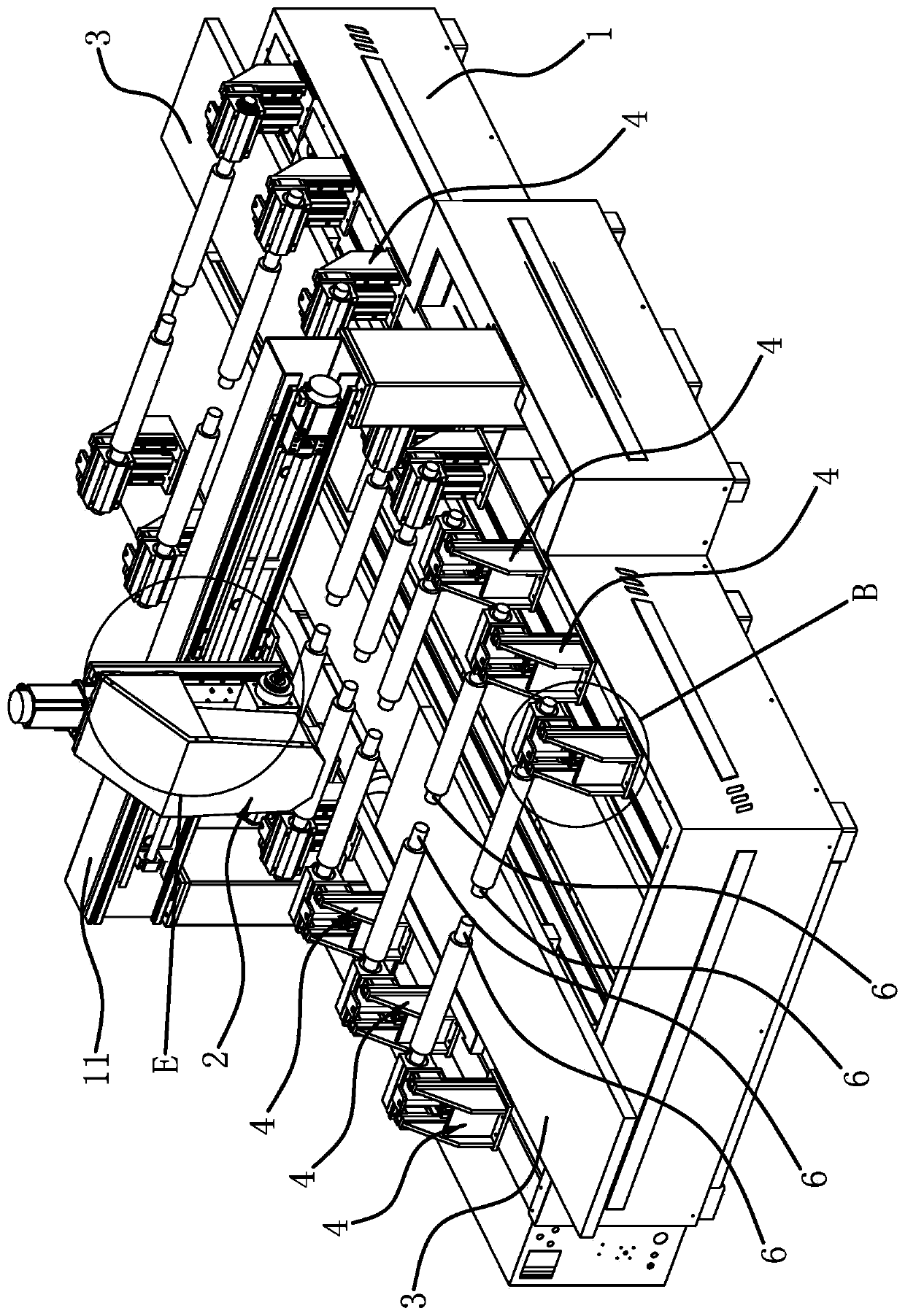

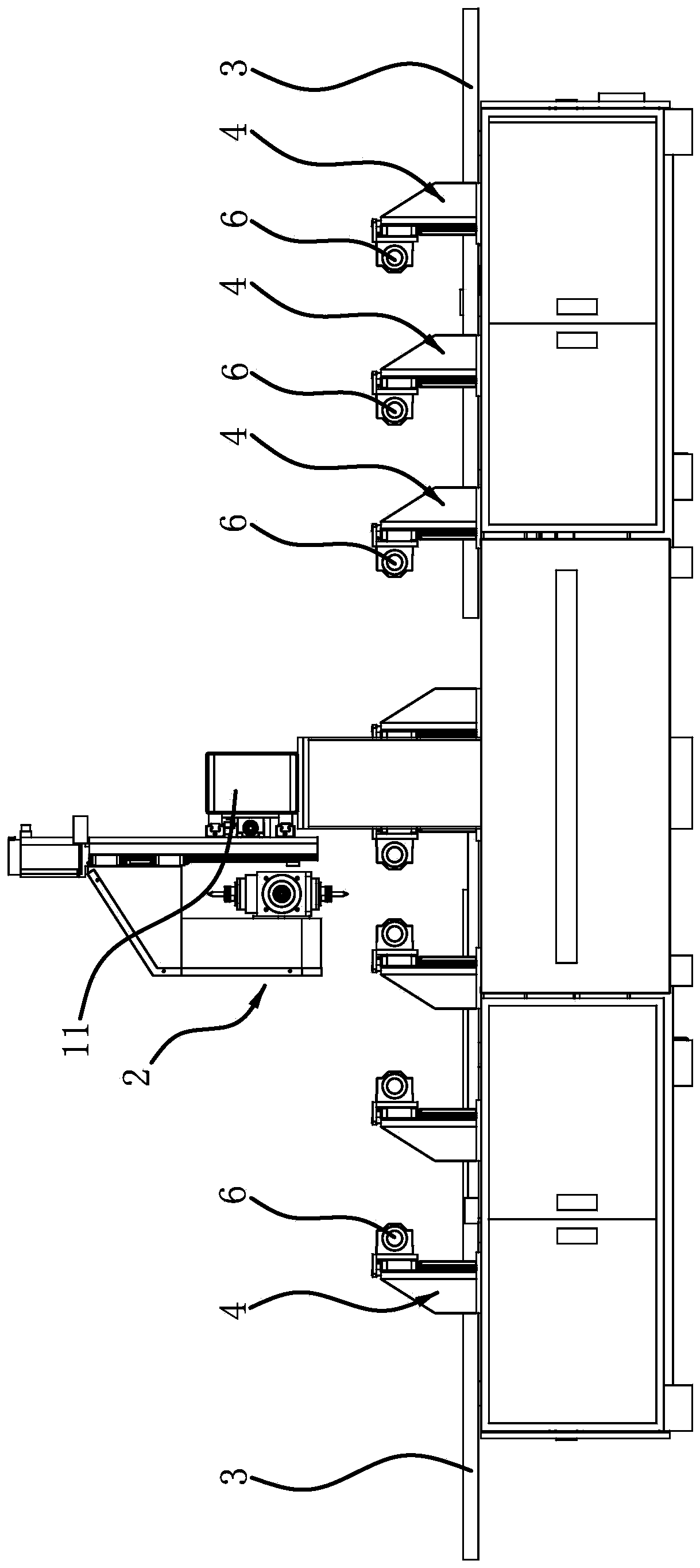

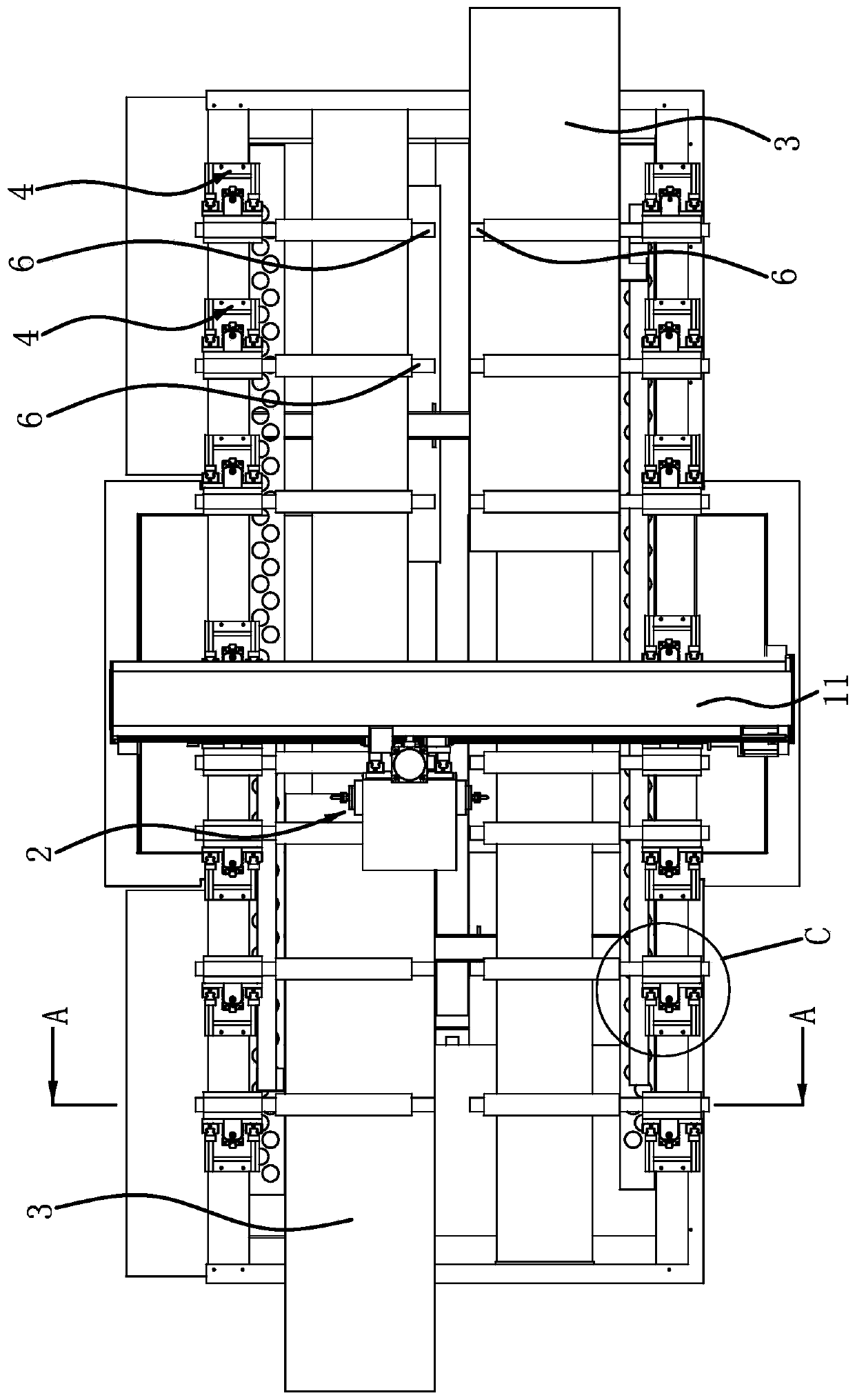

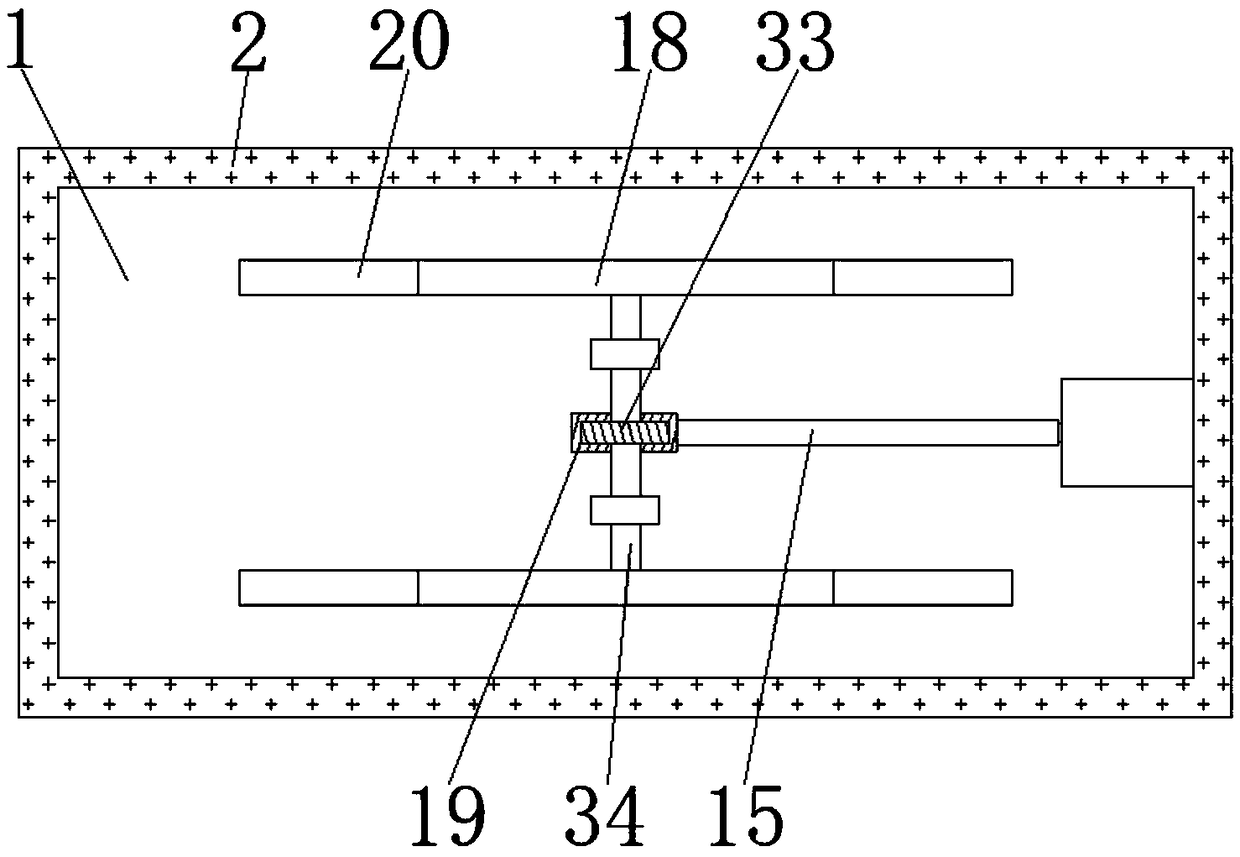

Automatic storage warehouse equipment

InactiveCN106005862AImprove work efficiencyAvoid crush damageStorage devicesStorage garageElectrical and Electronics engineering

The invention discloses automatic storage warehouse equipment. The automatic storage warehouse equipment comprises a storage rack vertically placed, and multiple carrying cars arranged in the storage rack in parallel from top to bottom at intervals; multiple translation rails positioned on two sides of the carrying cars are arranged in the storage rack; a lifting carrier capable of moving up and down along the storage rack is arranged on the outer side of the storage rack; and a storage device is mounted on the lifting carrier, and can drag the carrying cars to slide onto the lifting carrier along the translation rails. The automatic storage warehouse equipment can place goods on the carrying cars in the storage rack in a layered manner through the lifting carrier and the storage device on the lifting carrier, precisely takes the goods on the carrying cars in corresponding layers through the lifting carrier and the storage device when the goods need to be taken, can prevent the extrusion damage of the goods by the goods accumulation when effectively improving the goods storage efficiency, and is applied to the automatic storage warehouse field.

Owner:GUANGZHOU GOLRI AUTOMATIC PARKING

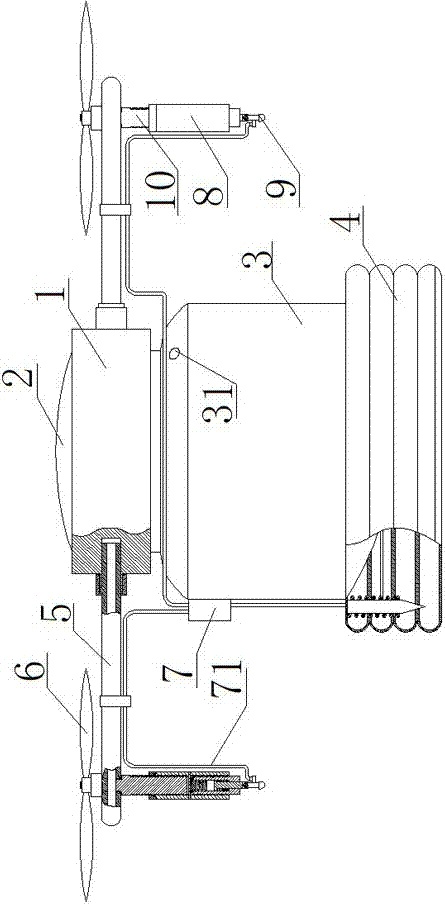

Unmanned aerial vehicle for plant protection

PendingCN106986010AAvoid damageAvoid crush damageAircraft componentsLiquid spraying apparatusMarine engineeringUncrewed vehicle

The invention relates to an unmanned aerial vehicle for plant protection. The unmanned aerial vehicle for plant protection comprises a center disk, a maintenance end cover and a medicine box, wherein the maintenance end cover and the medicine box are arranged on the center disk; a plurality of mounting holes for being matched with vehicle arms are formed in the center disk; motors and rotors which are connected with rotating shafts of the motors and arranged on the upper portions of the vehicle arms are arranged at the ends of the vehicle arms; a control device is arranged in the center disk and is in signal connection with the motors; the positions, on the lower portions of the rotors, of the bottoms of the vehicle arms are detachably connected with hanging rods connected with nozzles through sleeves; the nozzles communicate with the bottom of the medicine box through a medicine pipe equipped with a medicine pump; buffer gaskets are integrally arranged at the bottom of the medicine box; a limiting nail is fixedly arranged in the position, where the inner walls of the buffer gaskets make contact with the medicine box, of the bottom of the medicine box; the limiting nail is sleeved with a damping spring, and the sharp portion of the limiting nail is arranged downward; and one end of the damping spring is fixedly connected with the medicine box, and the other end of the damping spring is located on the upper portion of the sharp portion of the limiting nail. According to the unmanned aerial vehicle for plant protection, the structure is simple, the design is ingenious, vibration impact in the falling process of the unmanned aerial vehicle can be effectively buffered, and damage to the unmanned aerial vehicle structure is prevented.

Owner:西华九翔无人机产业园运营有限公司 +1

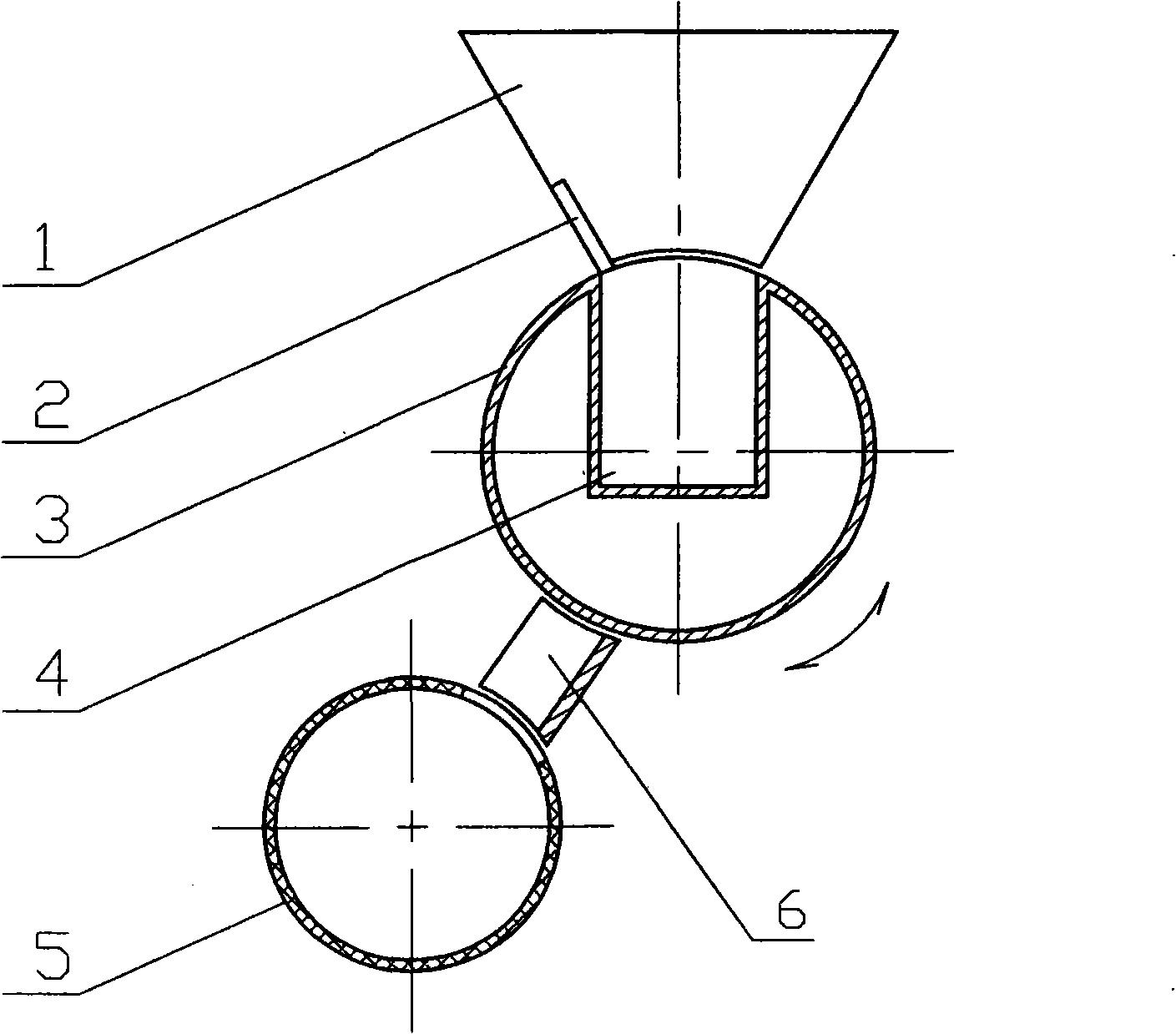

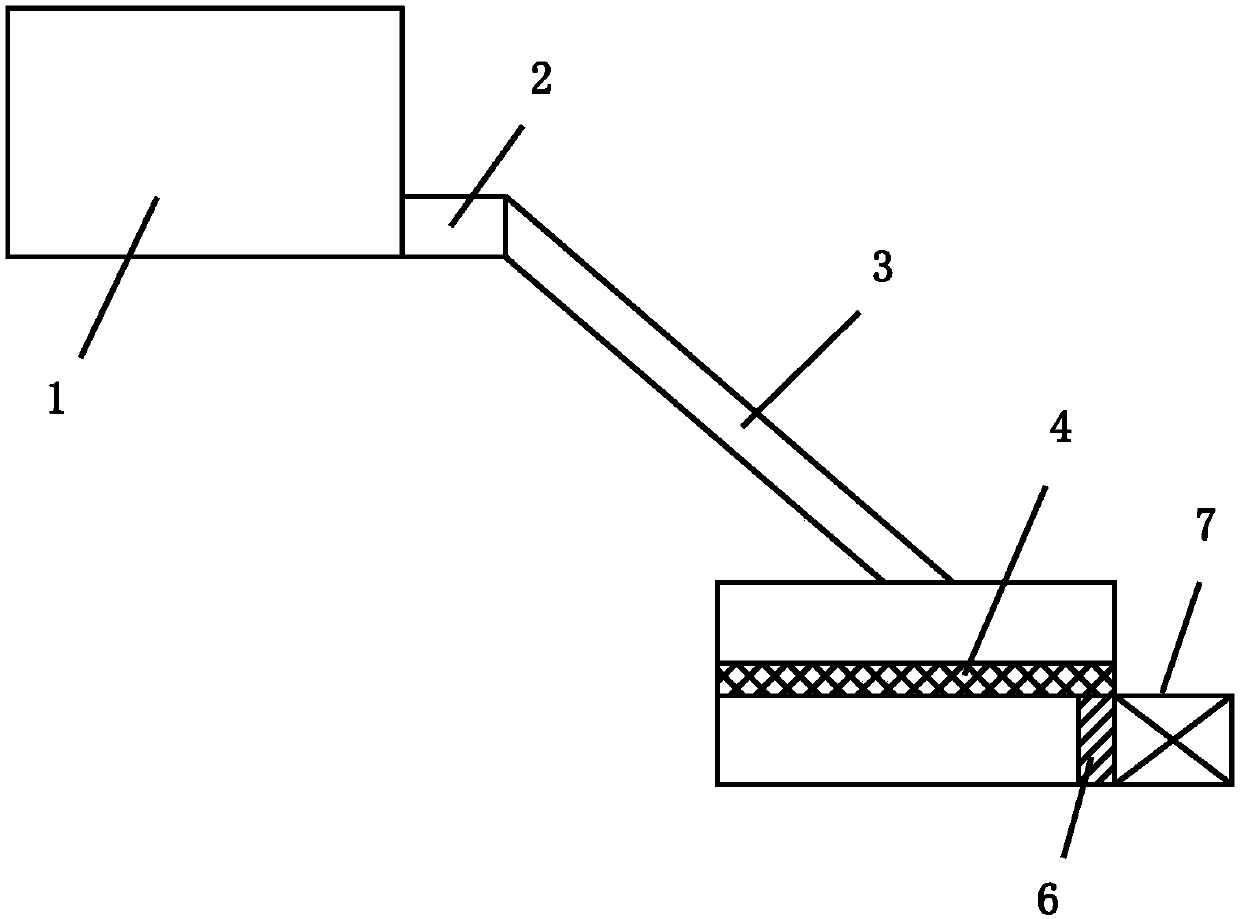

Scallop seed automatic allocation cage loading device

InactiveCN101336617ARealize automatic packagingPrevent crush damageClimate change adaptationPisciculture and aquariaBristleEngineering

The invention relates to an automatic distribution / cage loading machine for scallop seedlings. The machine comprises a cylindrical distributing roller (3) arranged on a machine frame, a plurality of holes formed in parallel on the cylindrical surface of the distributing roller (3), and distributing boxes (4) respectively arranged inside the holes. A plurality of discharge passages are formed by a plurality of discharge partitions (6) fixed on the machine frame below a feed hopper (1). The upper ends of the discharge passages are corresponding to the positions of the distributing boxes (4) and the lower ends thereof are positioned corresponding to the opening of each cultivation space of a scallop cage (5). The distributing roller drives the distributing boxes to rotate forwards or reversely at the predetermined angles, thereby realizing the automatic separate loading of the scallop seedlings. The automatic distribution / cage loading machine has the advantages of improved labor environment, high production efficiency and accurate distribution amount. Additionally, the automatic distribution / cage loading machine adopts the brush with flexible bristles to prevent the scallop seedlings from being crushed and damaged and thereby ensuring the safe loading of the scallop seedlings.

Owner:侯旭初

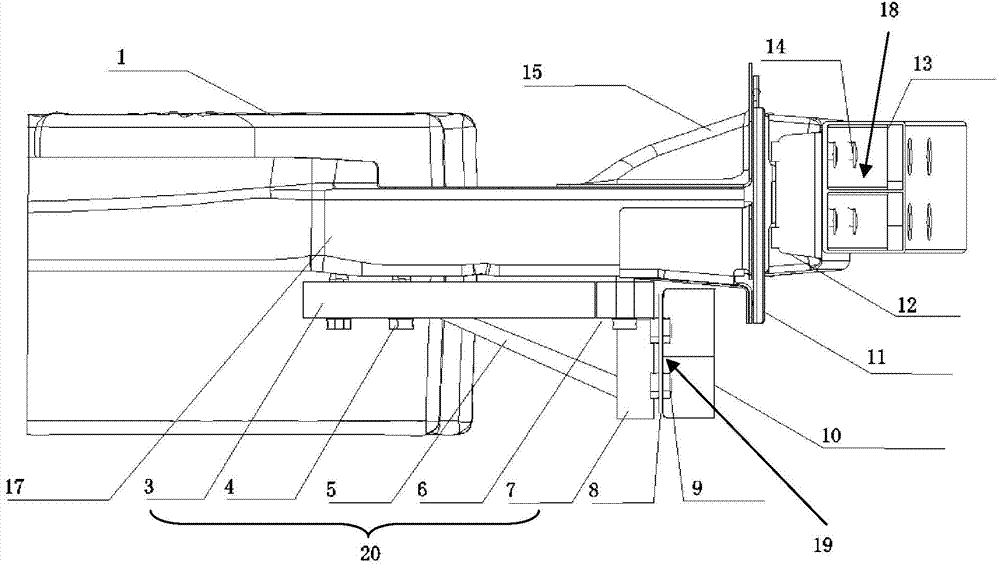

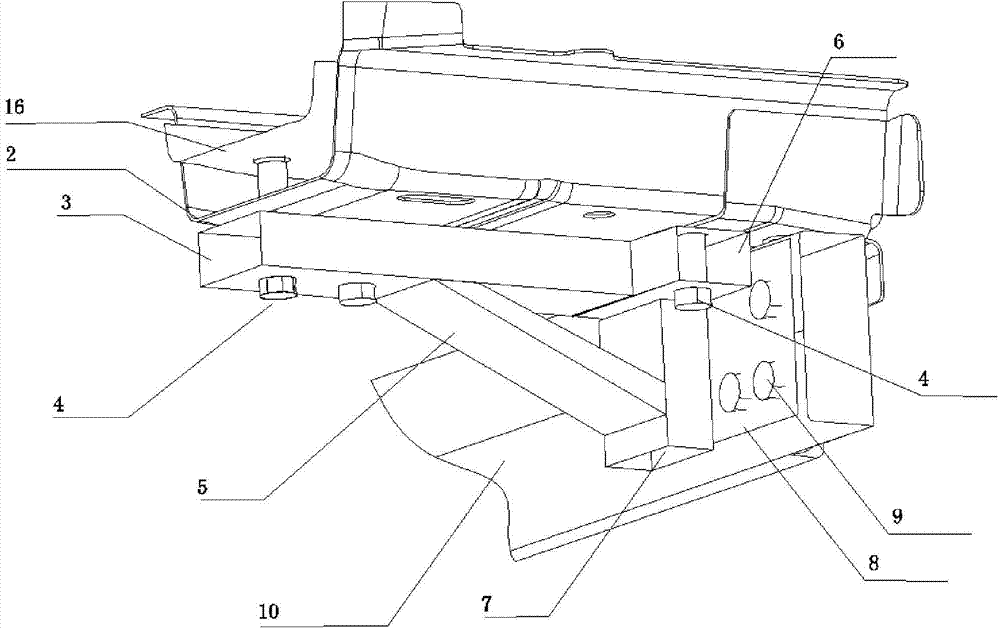

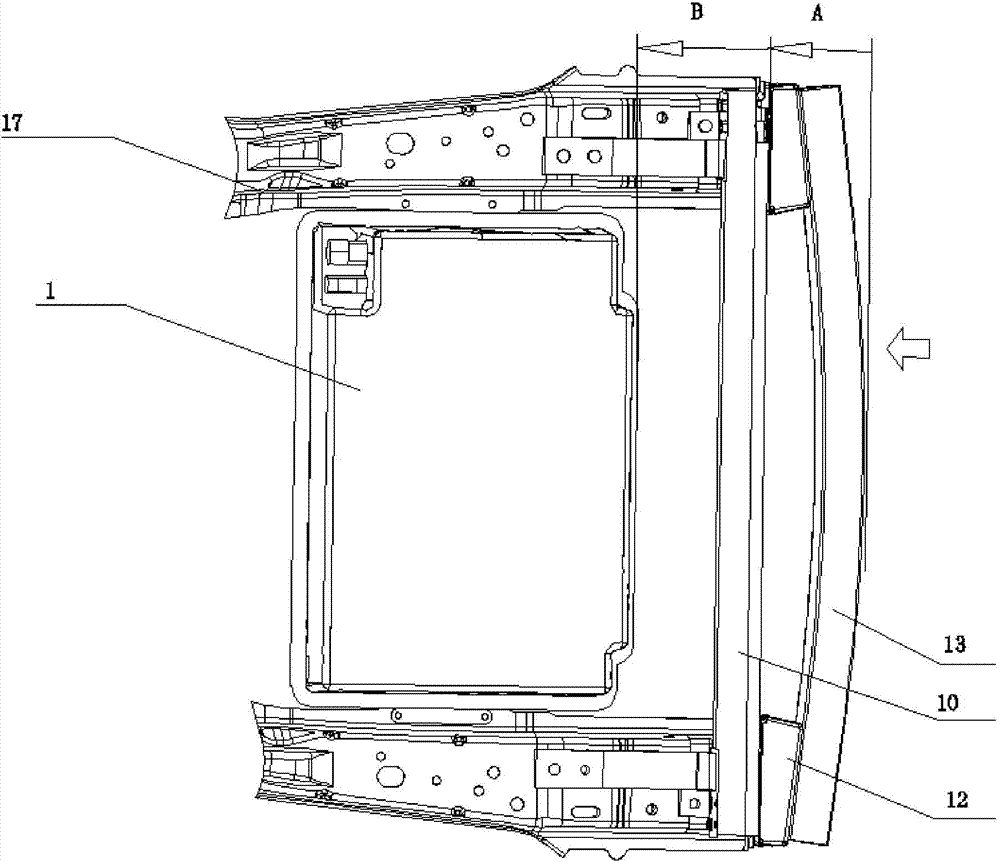

Impact protection structure for battery pack and automobile

The invention relates to the field of automobiles and provides an impact protection structure for a battery pack and an automobile. The impact protection structure comprises a battery pack storage space used for placing a battery pack and two longitudinal protection beams located on two outer sides of the battery pack storage space in the transverse direction, wherein the longitudinal protection beams extend in the longitudinal direction of the battery pack storage space and exceed the longitudinal outer end of the battery pack storage space; a primary anti-collision mechanism located on the outer side of the longitudinal outer end of the battery pack storage space is mounted on the longitudinal protection beams; a secondary anti-collision mechanism located between the primary anti-collision mechanism and the battery pack storage space is further mounted on the longitudinal protection beams. The automobile comprises the impact protection structure for the battery pack. The impact protection structure for the battery pack can better absorb energy after being collided to better protect the battery pack and to effectively reduce breakage of the battery pack, caused by squeezing deformation, or the probability of squeezing to damage peripheral components.

Owner:GREAT WALL MOTOR CO LTD

Automatic film pasting equipment for surface of semiconductor wafer

InactiveCN112397421APrevent movementReal-time monitoring of force strengthSemiconductor/solid-state device manufacturingWaferEngineering

The invention relates to the technical field of wafer processing equipment, in particular to automatic film pasting equipment for the surface of a semiconductor wafer, which can effectively save the physical strength and time during manual film pasting operation and improve the film pasting work efficiency by performing automatic film pasting treatment on a semiconductor wafer; meanwhile, the bubble removal effect between a film and the wafer is improved, the bubble residuals are avoided, and the effect is effectively improved. According to the wafer protection device, the stress intensity ofthe wafer is monitored in real time, so that the wafer can be conveniently protected, the wafer is prevented from being extruded and damaged, and the practicability and reliability are improved; the equipment comprises a base, a circular adsorption bin, a rubber pad and a first arc-shaped plate; a transverse pushing device is arranged at the top of the base, a pressure detection device is arrangedon the left side of the transverse pushing device, the circular adsorption bin is installed on the pressure detection device, and the rubber pad is installed at the top of the circular adsorption bin; multiple groups of conical holes are uniformly formed in the outer side of the top of the rubber pad; and the bottoms of the multiple sets of conical holes communicate with the interior of the circular adsorption bin.

Owner:太仓联科工业设计有限公司

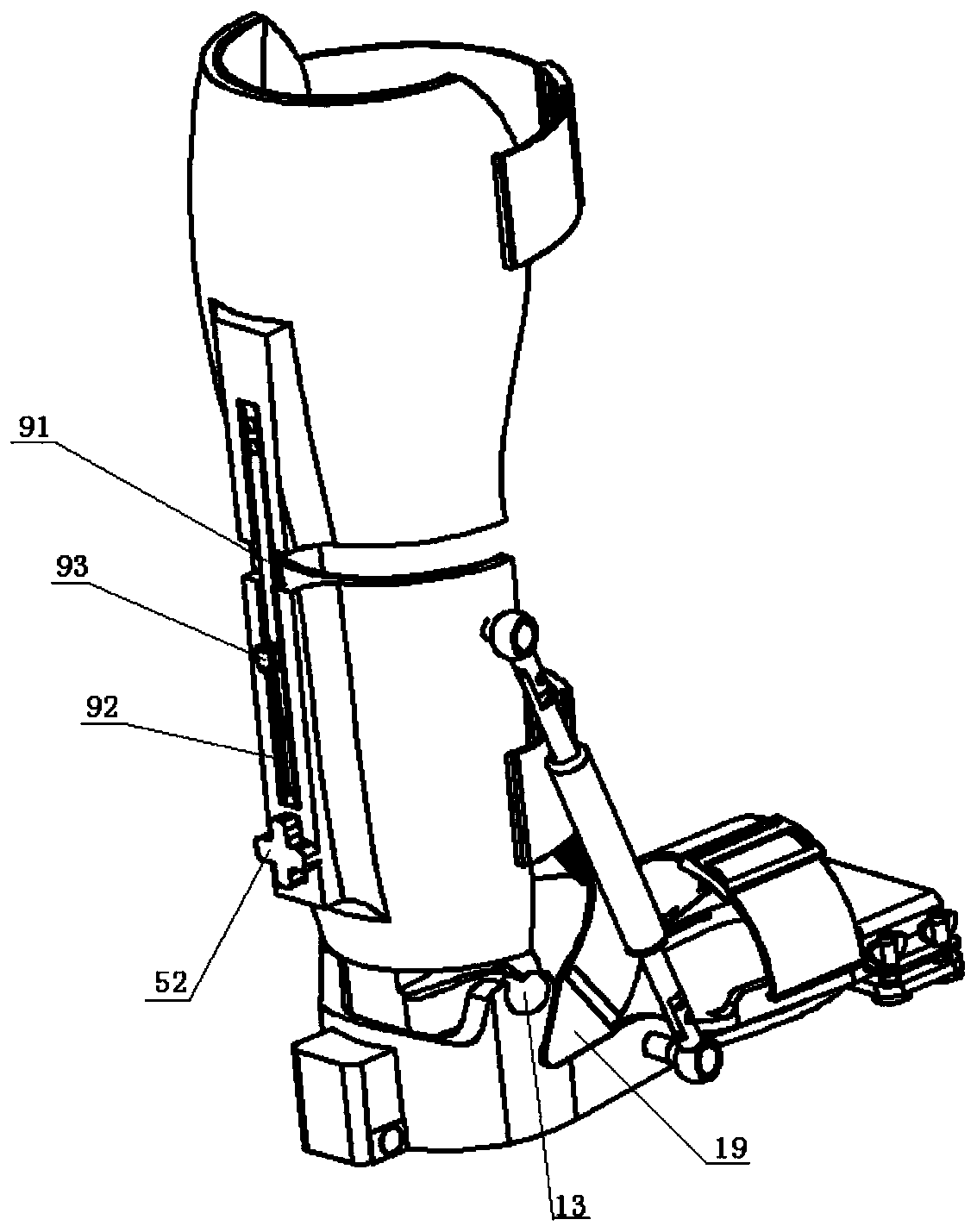

Lower limb spasm mode comprehensive rehabilitation device based on kinesitherapy

ActiveCN110575303AOptimize the treatment programLarge therapeutic benefitElectrotherapyChiropractic devicesPatient treatmentElectric heating

The invention discloses a lower limb spasm mode comprehensive rehabilitation device based on kinesitherapy. The lower limb spasm mode comprehensive rehabilitation device comprises shank protecting equipment, planta pedis protecting equipment and an angle adjusting mechanism for adjusting the included angle between the shank protecting equipment and the planta pedis protecting equipment, the angleadjusting mechanism comprises a drawing adjusting mechanism and an enstrophe / exstrophy adjusting mechanism, and the drawing adjusting mechanism and the enstrophe / exstrophy adjusting mechanism jointlydrive ankle joints of a patient to conduct motion in the four directions of plantar flexion, dorsiflexion, enstrophe and exstrophy. The lower limb spasm mode comprehensive rehabilitation device further comprises electrode patches and an electric heating heat-preservation layer, and thus affected limbs can be subjected to muscle electrical stimulation therapy and thermal therapy. According to the treatment demands of the patients, the three device bodies can be separately used or mutually combined to be used, and personalized treatment can be achieved. After being mutually combined, three treatment methods are synergistic, the treatment effect can be improved to the greatest extent, the effective rate of preventing and treating spasm is increased, the illness condition is relieved in the shortest time, and the treating strength and effect which cannot be achieved when a rehabilitation therapist conducts drawing hand or when the three treatments modes are separately used are provided.

Owner:XUANWU HOSPITAL OF CAPITAL UNIV OF MEDICAL SCI

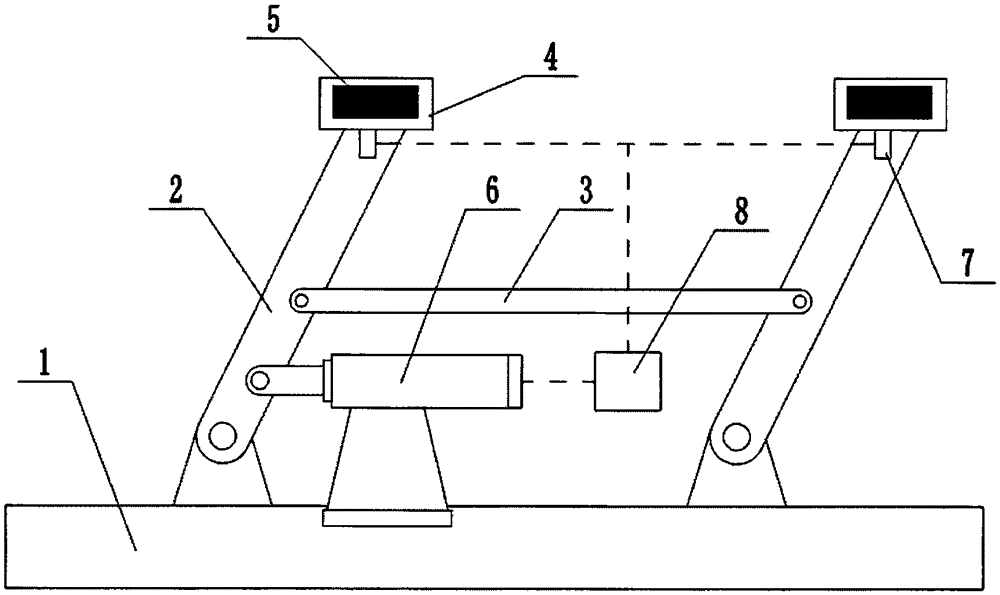

Transfer mechanism of vehicle frame

The invention relates to a transfer mechanism of a vehicle frame. The transfer mechanism includes a base and a parallelogram swing mechanism arranged on the base; the parallelogram swing mechanism includes two swing rods which are arranged in parallel; one of the swing rods is driven by an oil cylinder; a connection rod is connected between the two swing rods; the upper end of each swing rod is provided with a support block, the support block is embedded in an electromagnet, a pressure sensor is arranged on a support surface of the support block, the pressure sensor is connected to a controller of the oil cylinder; and the controller controls the drive speed of the oil cylinder according to an induction signal of the pressure sensor.

Owner:无锡市友佳车辆配件厂

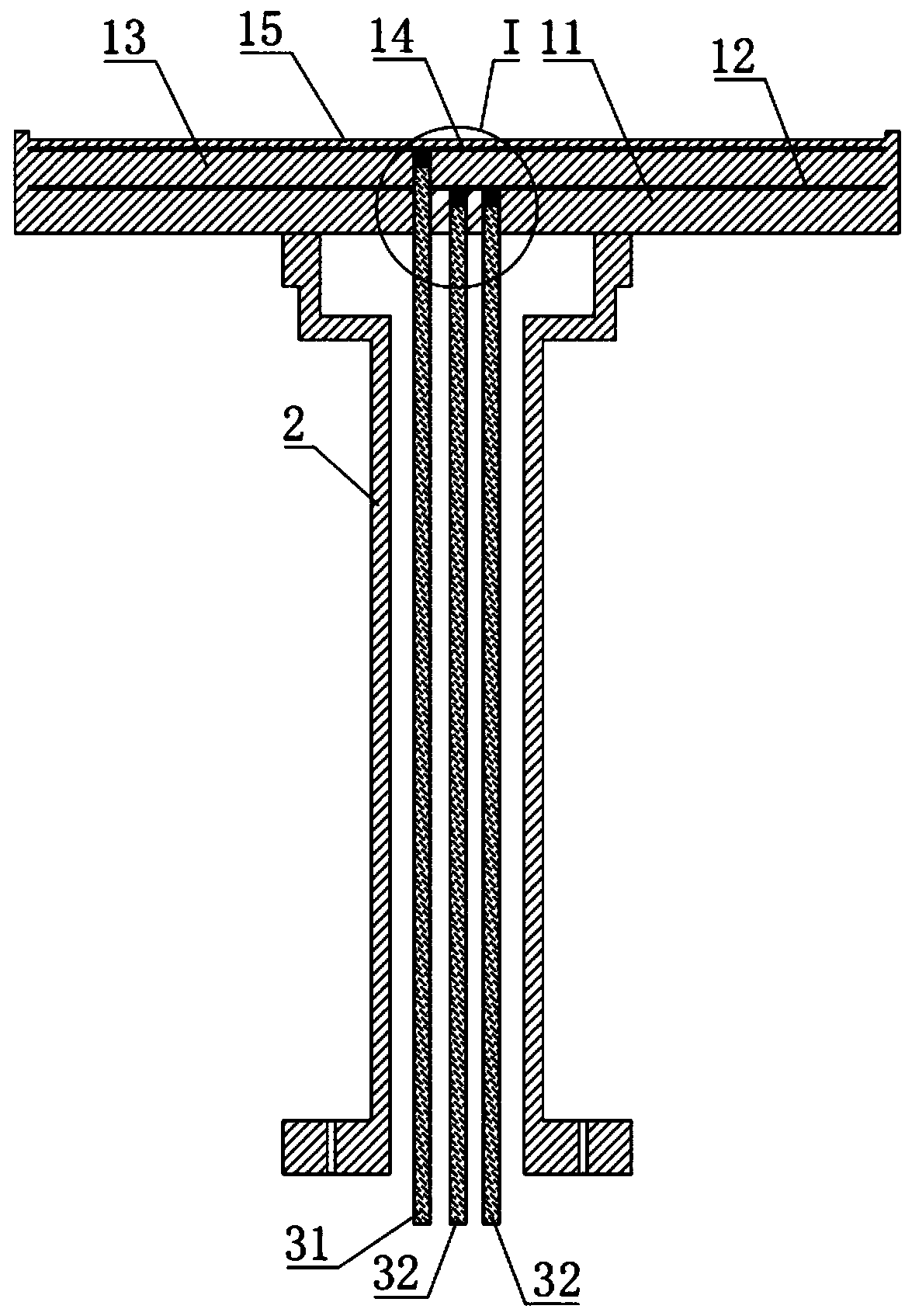

Cover plate glass platinum channel thermocouple device and manufacturing method thereof

ActiveCN106698892ASo as not to damageNot subject to bending and twistingGlass furnace apparatusForeign matterThermal expansion

The invention discloses a cover plate glass platinum channel thermocouple device and a manufacturing method thereof. A thermocouple is extended and straightened and then is subjected to double-layer cladding, so the fact that the surface of the thermocouple is not corroded by harmful foreign matters is guaranteed, bending and distortion of the thermocouple in the cladding process can be effectively avoided, and the strength reduction of the thermocouple caused by bending and distortion of the thermocouple which is collided by external force is avoided; a mould with the structure the same as that of the cladded thermocouple is put into a thermocouple mounting hole, the lower half part in the thermocouple mounting hole is poured, and the mould is taken out after the lower half part pouring layer is coagulated; the cladded thermocouple is put on the lower half pouring layer in the thermocouple mounting hole, so the fact that the thermocouple is not damaged by extrusion is guaranteed, and the bending and distortion of the thermocouple in the pouring process is avoided; the cover plate glass platinum channel thermocouple device is fixed, stable and insusceptible to deformation through once pouring and fixing, and the extrusion force, generated by thermal expansion, of the platinum channel is counteracted by the cladding layer cladding the thermocouple.

Owner:陕西彩虹电子玻璃有限公司

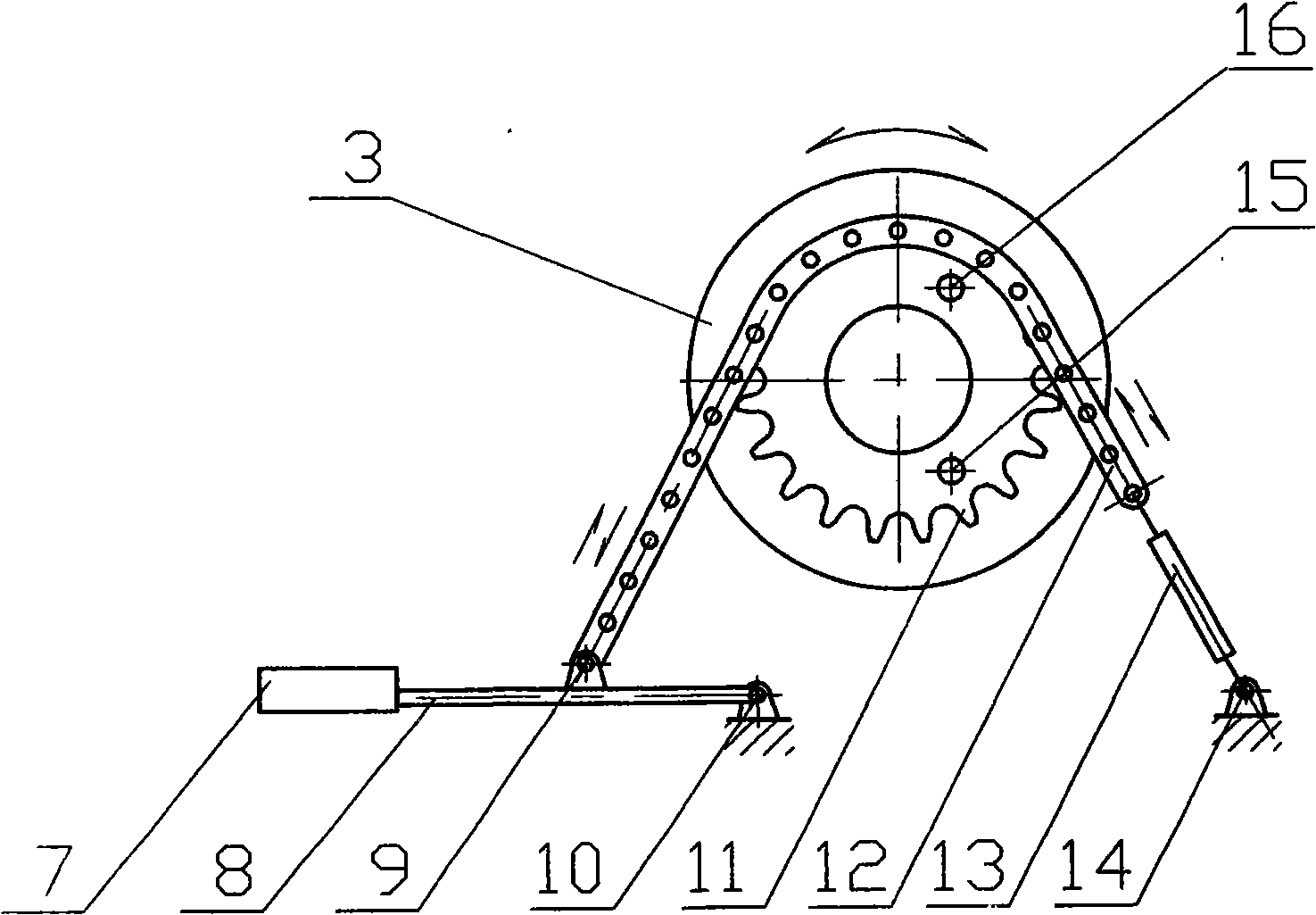

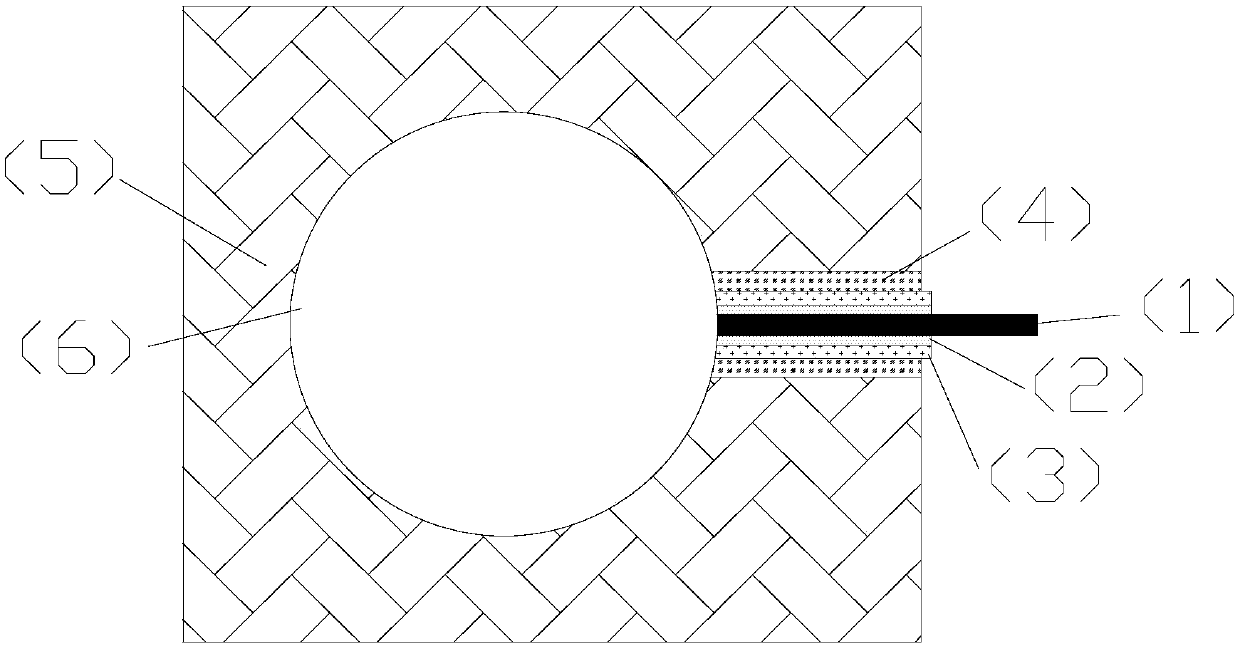

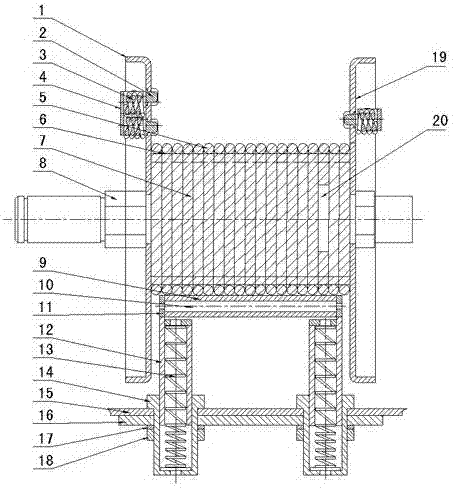

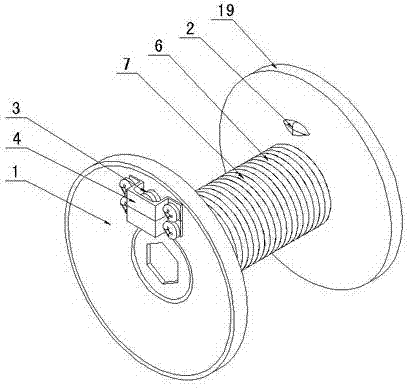

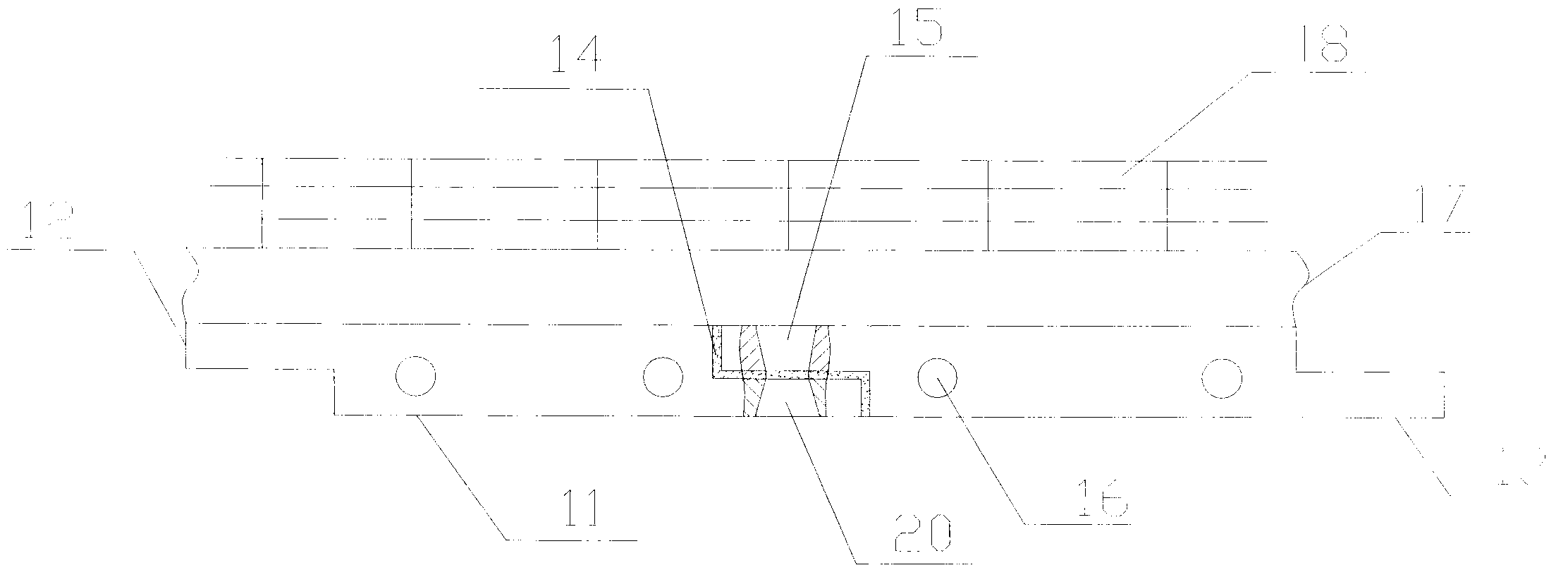

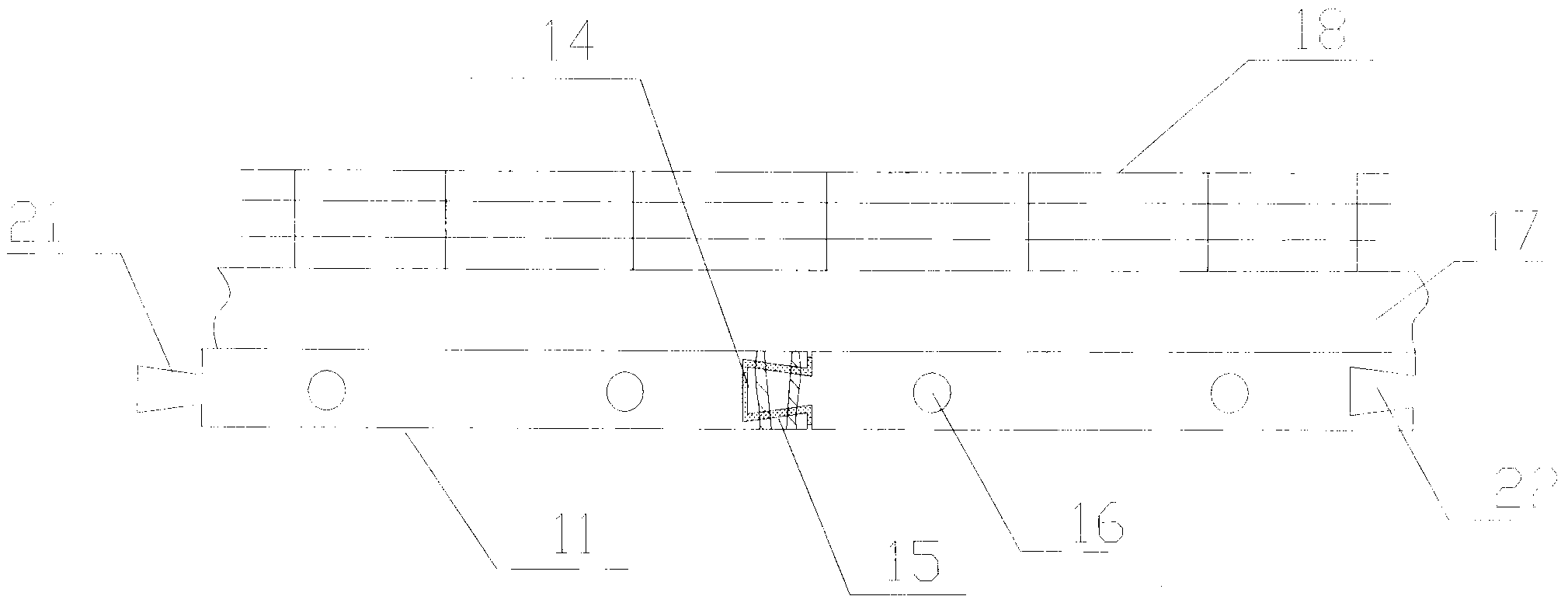

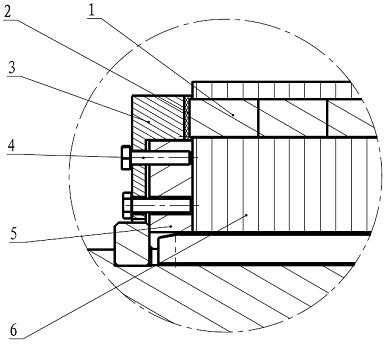

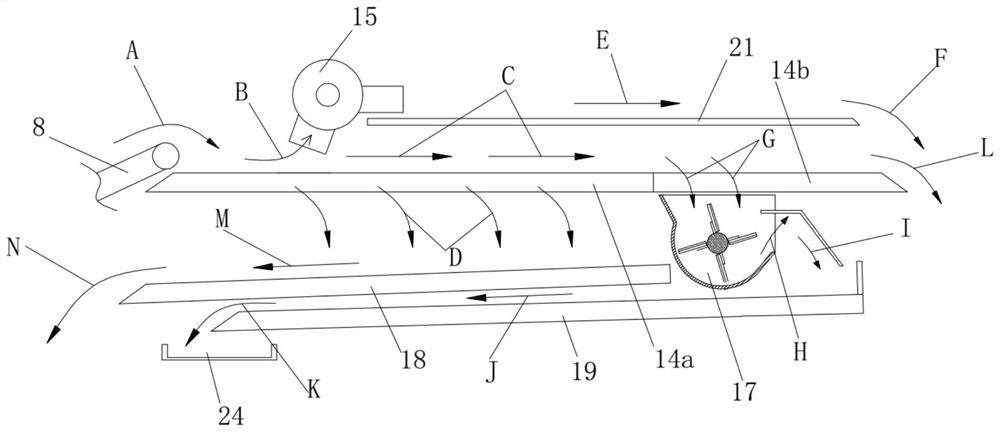

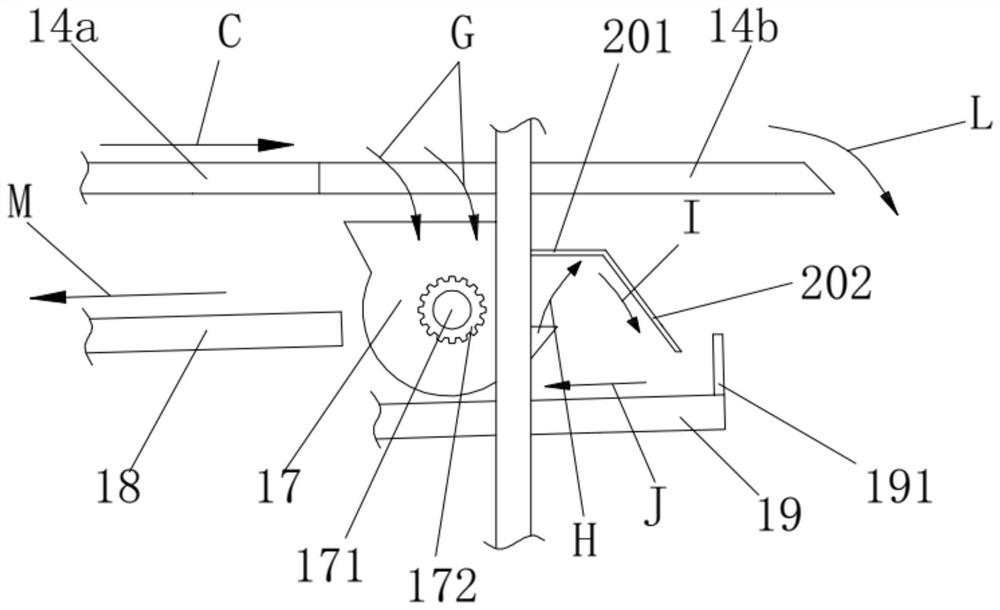

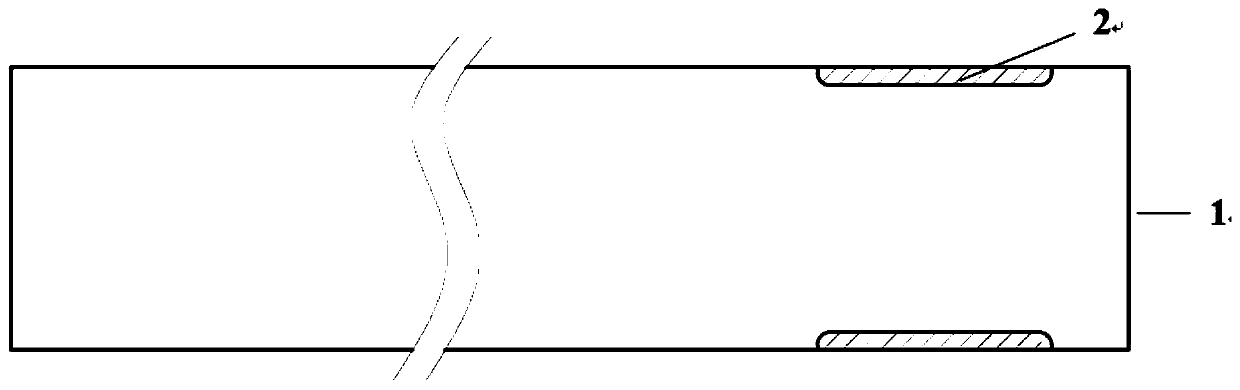

Automatic reversing winding displacement device for rope drum of steel wire rope

The invention discloses an automatic reversing winding displacement device for a rope drum of a steel wire rope. The automatic reversing winding displacement device comprises a rope drum (7) arranged on a rotating shaft (8) and a wire pressing mechanism which is fixed to a housing (15), wherein at least one layer of steel wire rope winding displacement guiding mechanism is arranged on left and right lateral plates (1 and 19) of the rope drum (7); the steel wire rope winding displacement guiding mechanisms on the left and right lateral plates (1 and 19) are arranged in a crossed mode at a steel wire rope conversion winding layer, and comprise steel wire rope guide blocks (2), thrust springs (3) and guide bases (4); the steel wire rope guide blocks (2) are arranged on T-shaped mounting holes of the left and right lateral plates (1 and 19); the guide bases (4) are fixed on the left and right lateral plates (1 and 19); and the thrust springs (3) are arranged between ends of the steel wire rope guide blocks (2) and the guide bases (4). Due to the adoption of the structure, the automatic reversing winding displacement device has the advantages of simple and reasonable structure, convenience in installation and use, safe and reliable reversing, compact and regular arrangement, long service life and the like.

Owner:贾新天

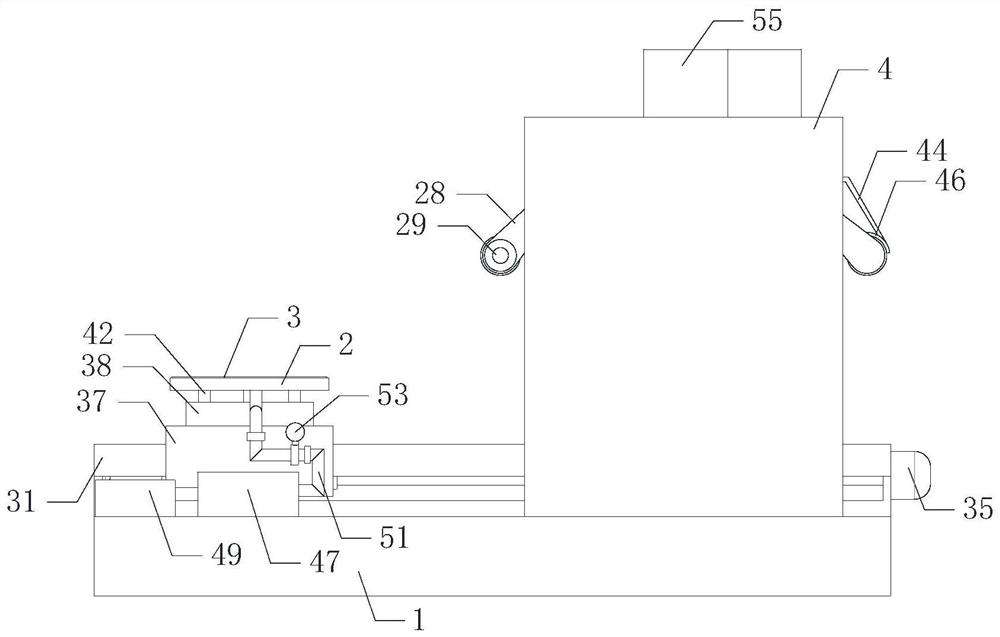

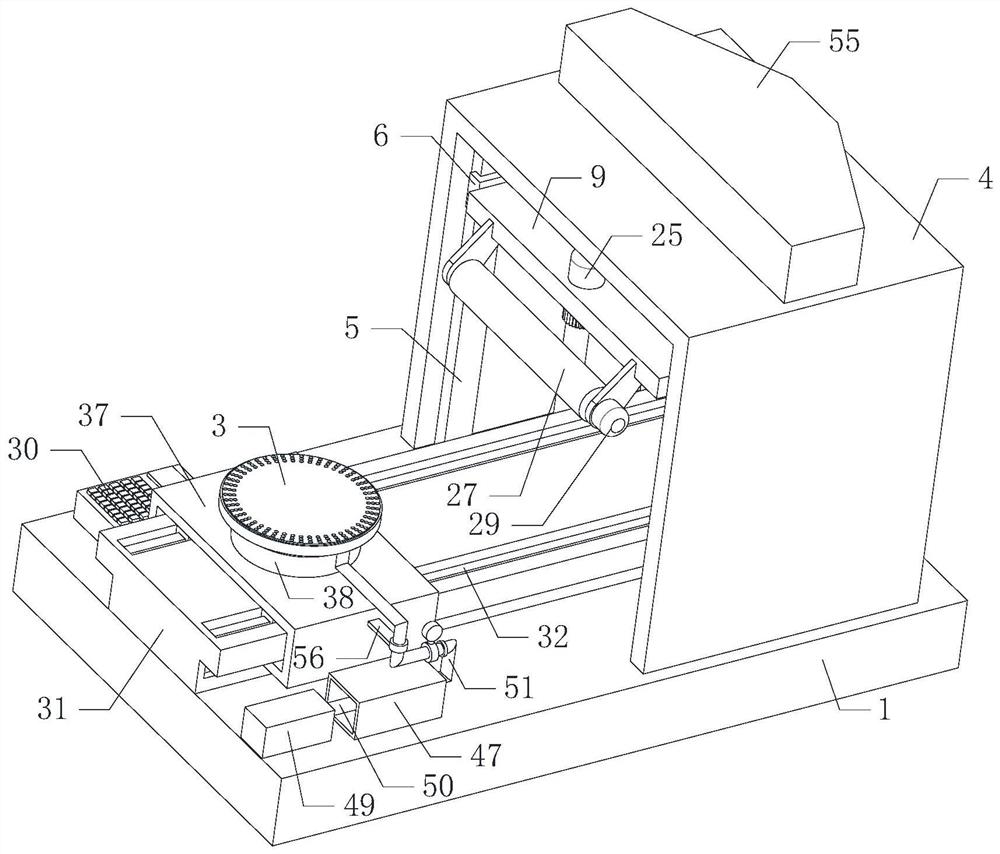

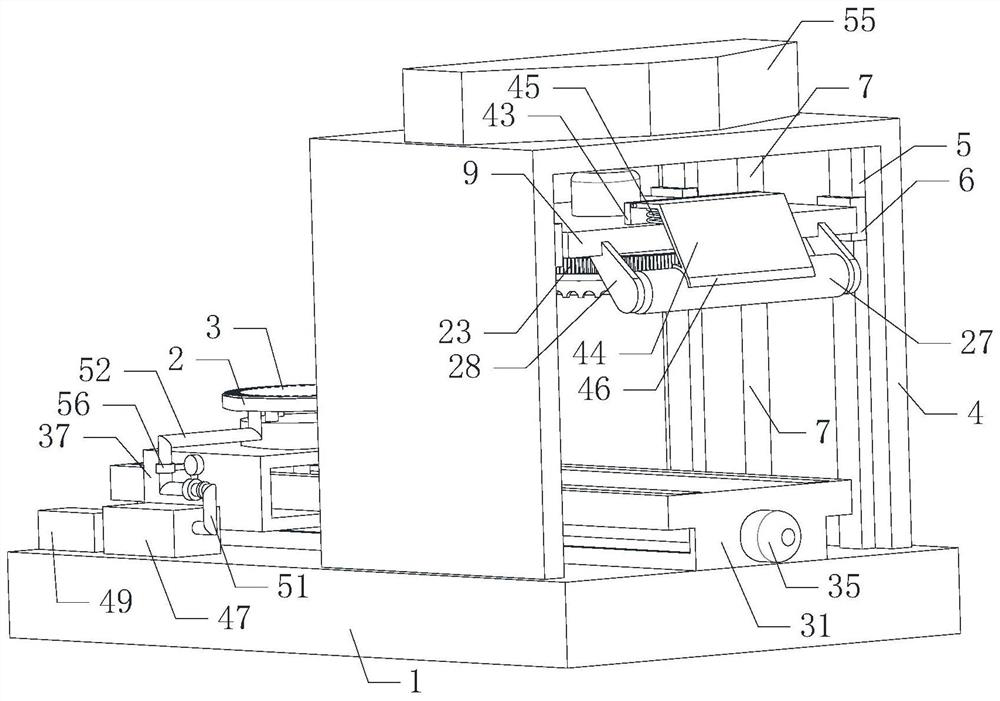

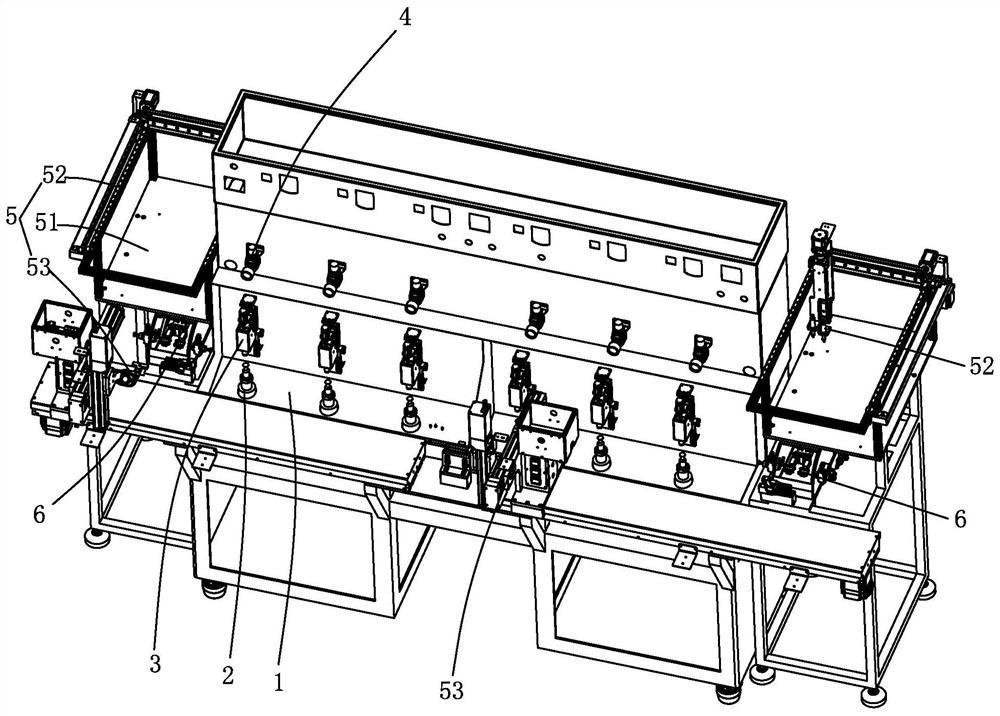

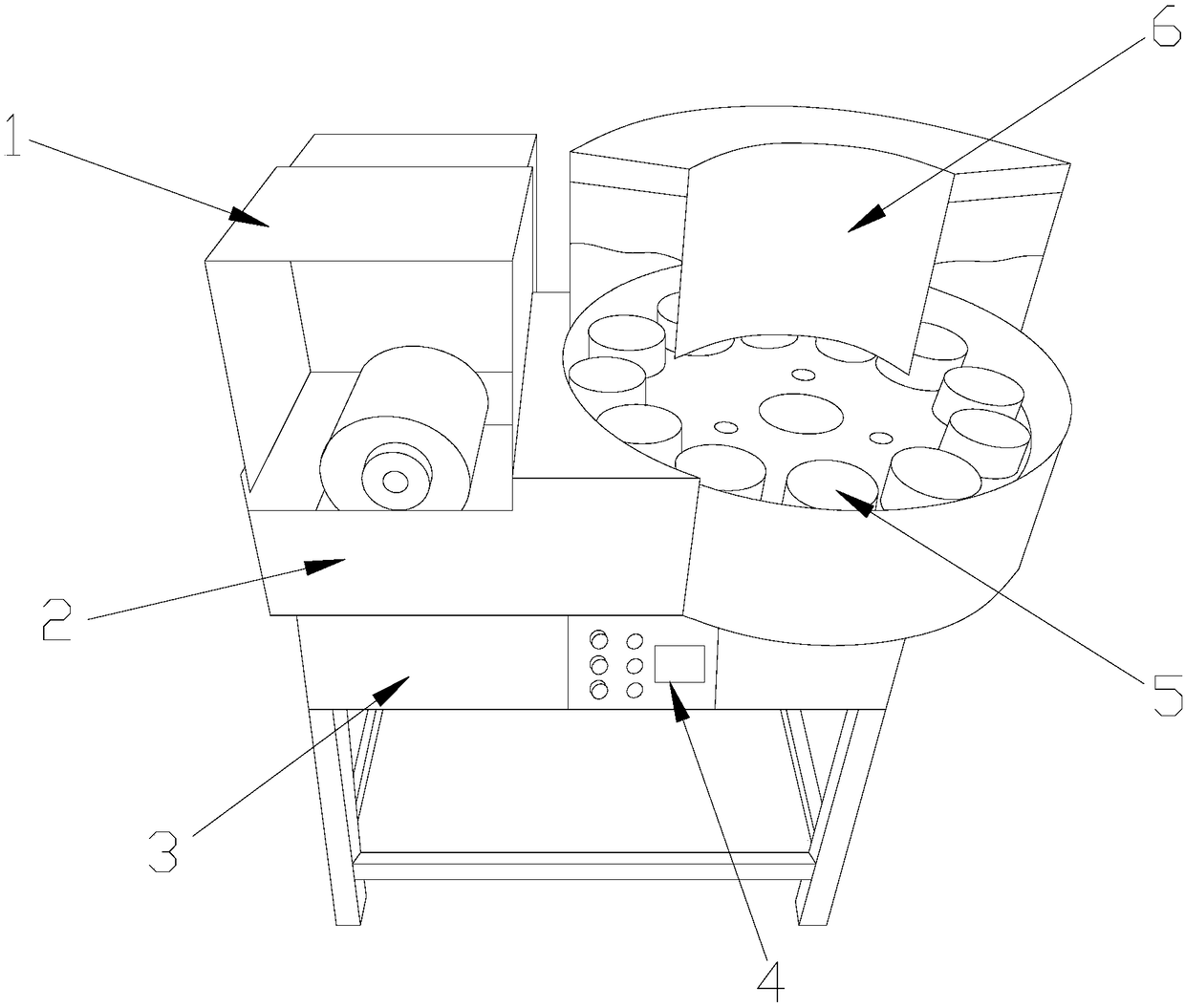

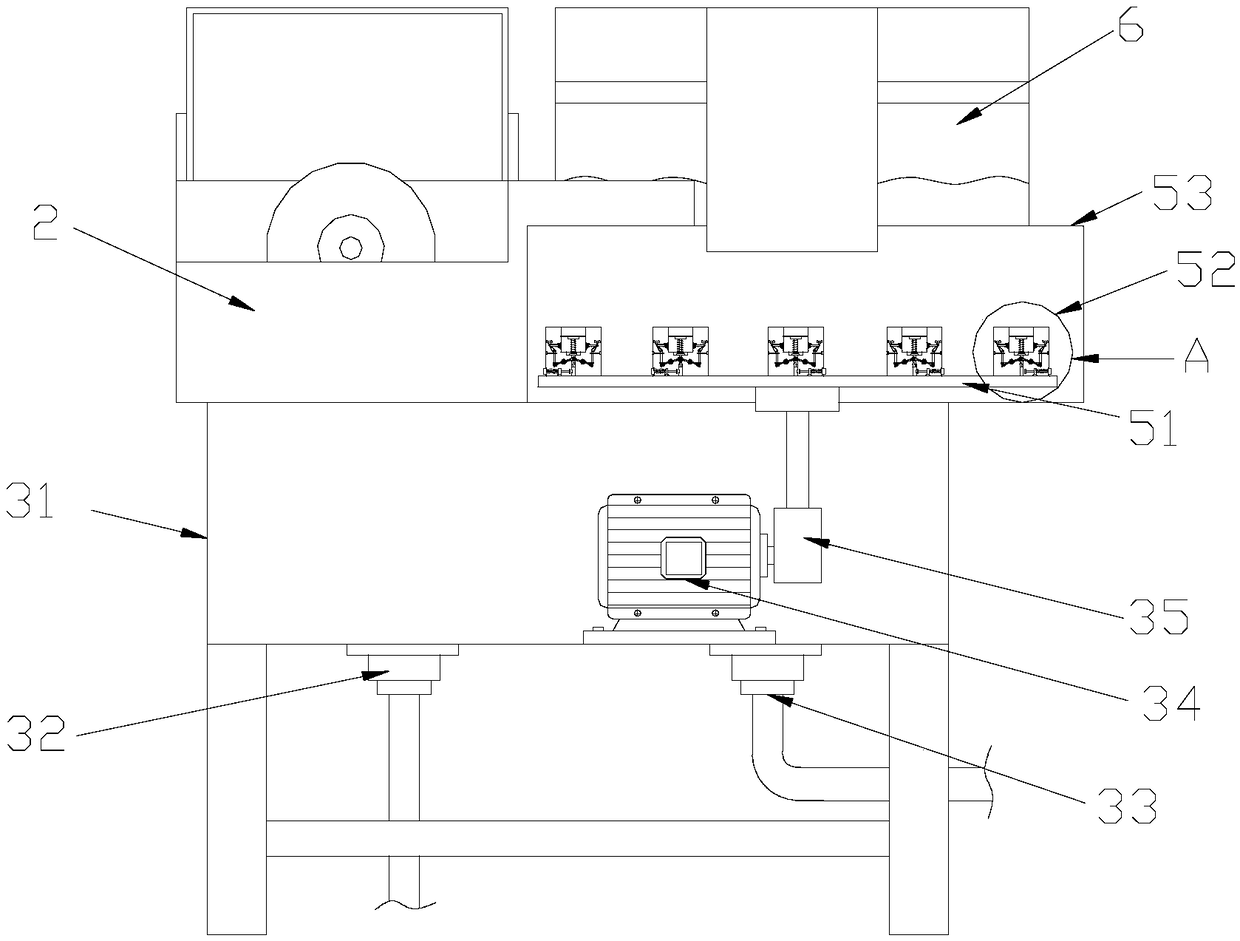

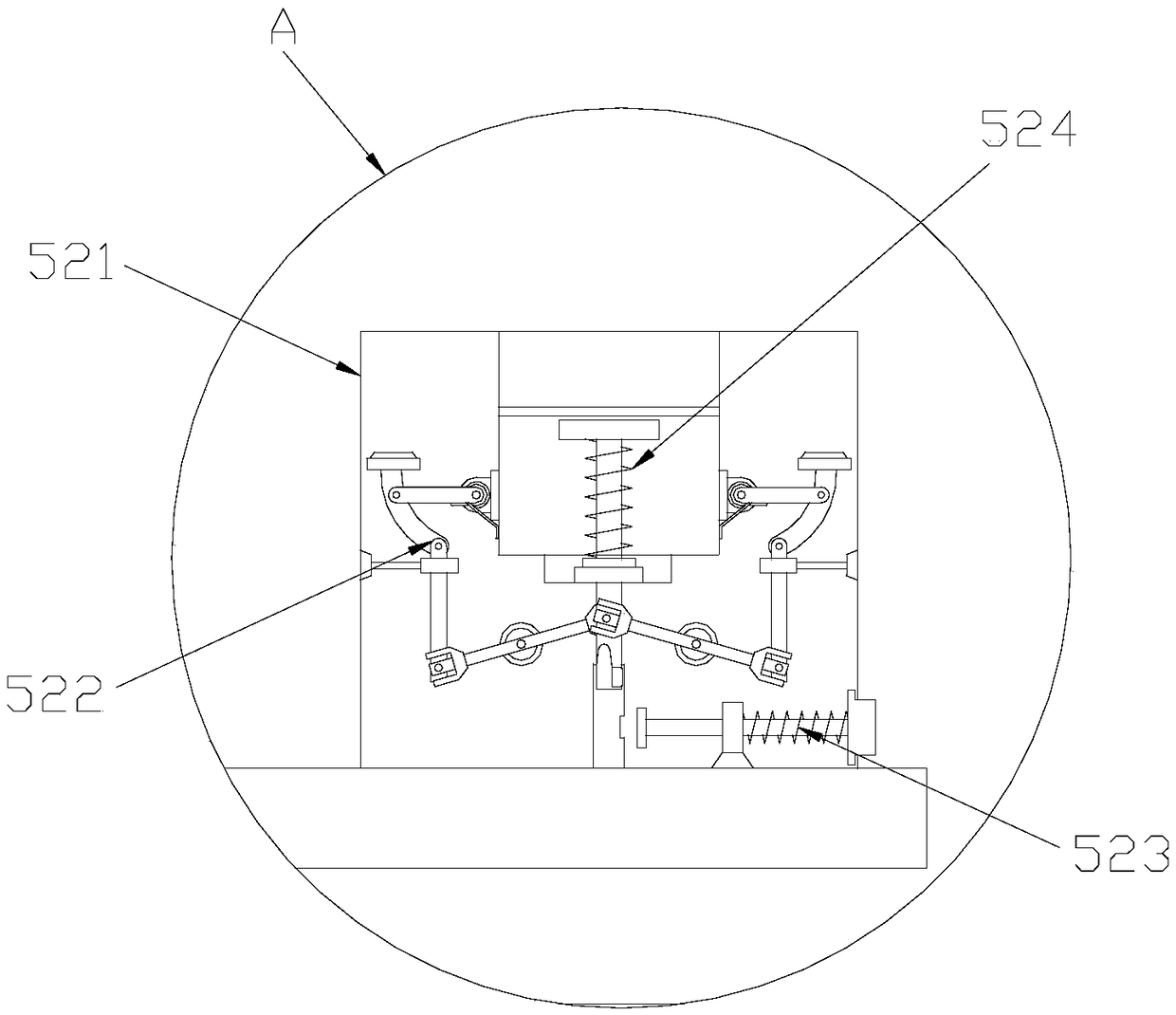

Full-automatic lens producing and processing equipment

ActiveCN113134765AAvoid crush damageImprove automationGrinding carriagesOptical surface grinding machinesOphthalmologyEngineering

The invention provides full-automatic lens production and processing equipment, which comprises a grinding device used for grinding a lens and a swinging device used for driving the lens to be ground; the swinging device comprises a swinging mechanism, a lifting mechanism and a pressing mechanism; and the pressing mechanism comprises a connecting base, a lens suction set and a lens jacking set. During use, the lens is sucked through the lens suction set, the lens sucked by the lens suction set descends to the position of the grinding device through the lifting mechanism, then the lens on the lens suction set is driven by the lens jacking set to press the grinding device so as to abut against the grinding device, and the lens is driven by the swing mechanism to swing along the grinding device so as to be processed. According to the full-automatic lens producing and processing equipment provided by the invention, the lens can be firstly sucked, the lens is descended to the grinding position for grinding, automation is improved, the lens does not need to be manually placed, the lens is firstly descended through the lifting mechanism, then the lens is pressed to the grinding device through the lens jacking set, the buffering protection effect is achieved, and the lens can be prevented from being pressed, exploded and damaged.

Owner:中山市光维智能科技有限公司

Linseed dehulling process

ActiveCN107715949AImproved peeling processAchieve epidermal detachmentGas current separationFatty-oils/fats productionDry iceEngineering

The invention discloses a linseed dehulling process. The linseed dehulling process comprises the following steps that A, linseeds are put into a wok, heated to 100-105 DEG C and evenly mixed for 20 min; B, the wok is connected to a dehulling mechanism through a delivery pipe, the linseeds are conveyed to the dehulling mechanism through the delivery pipe, and the linseeds are subjected to dehullingtreatment through the dehulling mechanism and are cooled through dry ice in the treatment process; C, a vibrating screen is arranged below the dehulling mechanism, a heating wire is arranged in the vibrating screen, a filter screen is arranged below the vibrating screen, and the outer side of the filter screen is connected with a negative-pressure fan; the linseeds fall onto the vibrating screenafter being treated through the dehulling mechanism, the vibrating screen is heated to 70-80 DEG C, linseed kernels and linseed hulls are separated, the linseed kernels are retained on the vibrating screen, and the linseed hulls pass through the vibrating screen under the suction action of the negative-pressure fan and are finally gathered onto the filter screen. Through the linseed dehulling process, the defects in the prior art can be overcome, and the separation degree of linseed hulls and kernels is further improved.

Owner:宁夏君星坊食品科技有限公司

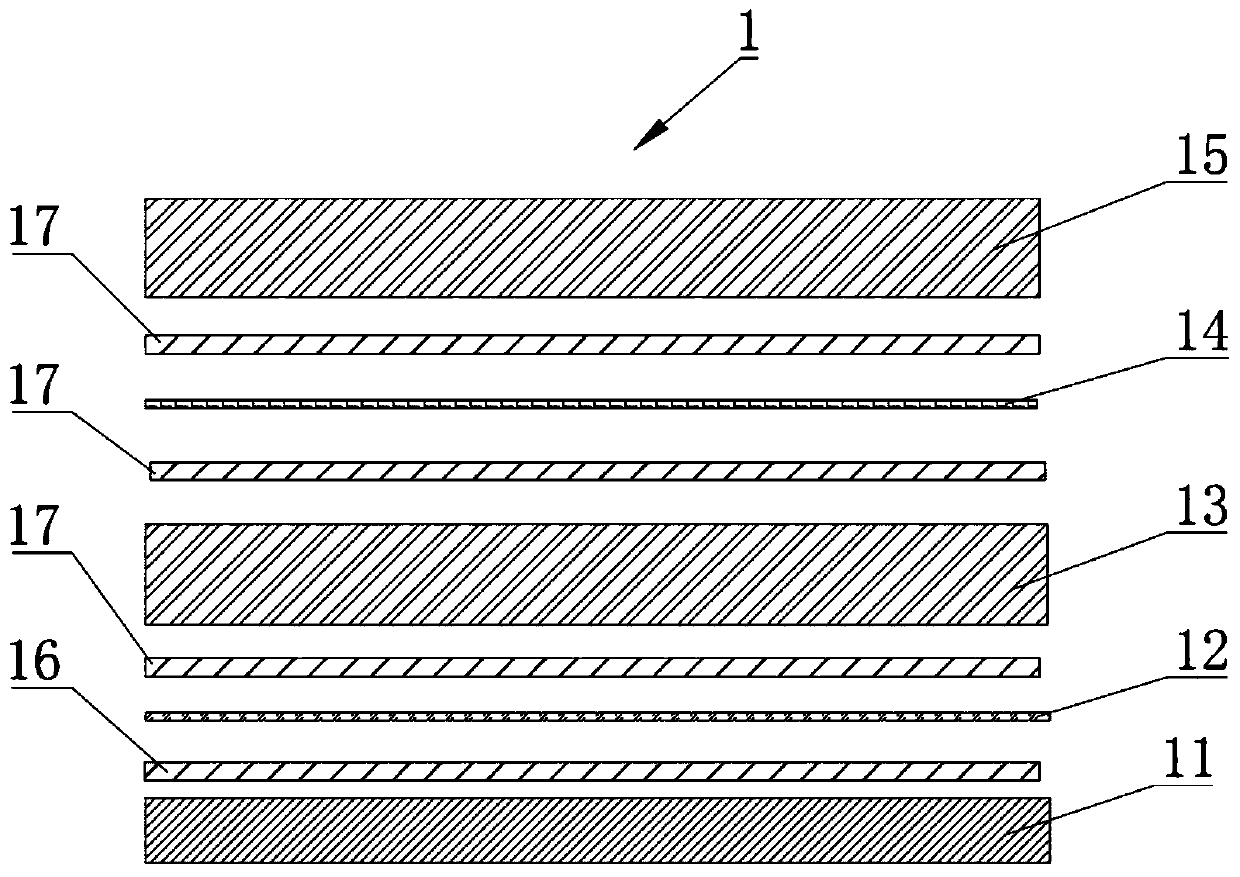

Chemical vapor deposition equipment, ceramic heating disc and preparation method of ceramic heating disc

PendingCN110230043AEasy to set upEasy to operateChemical vapor deposition coatingEtchingHeat conducting

The invention provides chemical vapor deposition equipment, a ceramic heating disc and a preparation method of the ceramic heating disc. The ceramic heating disc comprises a heating disc body and a ceramic tube, wherein the heating disc body comprises a first aluminum nitride ceramic base plate, a heating sheet, and a second aluminum nitride ceramic base plate which are sequentially stacked from bottom to top; each layer is bonded by heat-conducting ceramic slurry, and the heating disc is subjected to sintering to form a whole; and the heat conductivity of an obtained first ceramic body is lower than that of a second ceramic body. The chemical vapor deposition equipment comprises the ceramic heating disc. The preparation method of the ceramic heating disc comprises the following steps thatthe first aluminum nitride ceramic base plate, the heating sheet, the second aluminum nitride ceramic base plate, an electrode plate and a third aluminum nitride ceramic base plate are bonded throughthe ceramic slurry in sequence, and the heating plate body is obtained through hot-pressing sintering. According to the chemical vapor deposition equipment, the ceramic heating disc and the preparation method, most of heat generated by the heating sheet is transferred upwards, so that the whole resistance arrangement of the heating disc is more simple and easy to operate, interference factors canbe reduced, and the temperature can be better controlled in the wafer etching or deposition process.

Owner:SUZHOU KEY MATERIALS TECH

Bottle body cleaning device for cosmetic production

InactiveCN108746130AAvoid crush damageEnsure safetyHollow article cleaningBottleBiomedical engineering

The invention discloses a bottle body cleaning device for cosmetic production. The bottle body cleaning device comprises a cleaning protection cover, a hairbrush cleaning mechanism, a cleaning equipment support, an electrical controller, a bottle body rotating device and a bottle body spray-washing structure. The bottle body cleaning device is provided with a bottle body fixator, and a cosmetic bottle body can be fixed well when being placed on the device. Even if the bottle body enters the bottle body spray-washing structure to be cleaned after a cleaning solution is applied to the outer surface of the bottle body, no slippage can occur. The phenomenon that the bottle body is squeezed and damaged or the cleaning device is damaged due to the cosmetic bottle body slips down is avoided, andthe safety of working of the cleaning device is ensured.

Owner:湖州御筵科技有限公司

Linear bearing

ActiveCN102767567AExtended service lifeAvoid the phenomenon of stop scrollingLinear bearingsStopped workEngineering

The invention provides a linear bearing, aiming at solving the problem that the linear bearings in the prior art always stop working due to friction existing among balls. The linear bearing comprises an inner ring, a retainer and an outer ring which are sleeved together from inside to outside in sequence. The linear bearing also comprises a plurality of balls arranged on the retainer in a rolling manner, wherein the balls are in contact with the inner ring and the outer ring and are arranged at intervals. The linear bearing has the following beneficial effects that the balls arranged closely in the prior art are dispersed, so that the balls are separated reasonably and effectively, the independent operation capacity of each ball is increased, the operation of the linear bearing is not affected, and the service life of the linear bearing is simultaneously prolonged. Therefore, the linear bearing has good practicability.

Owner:江苏九州传动科技有限公司

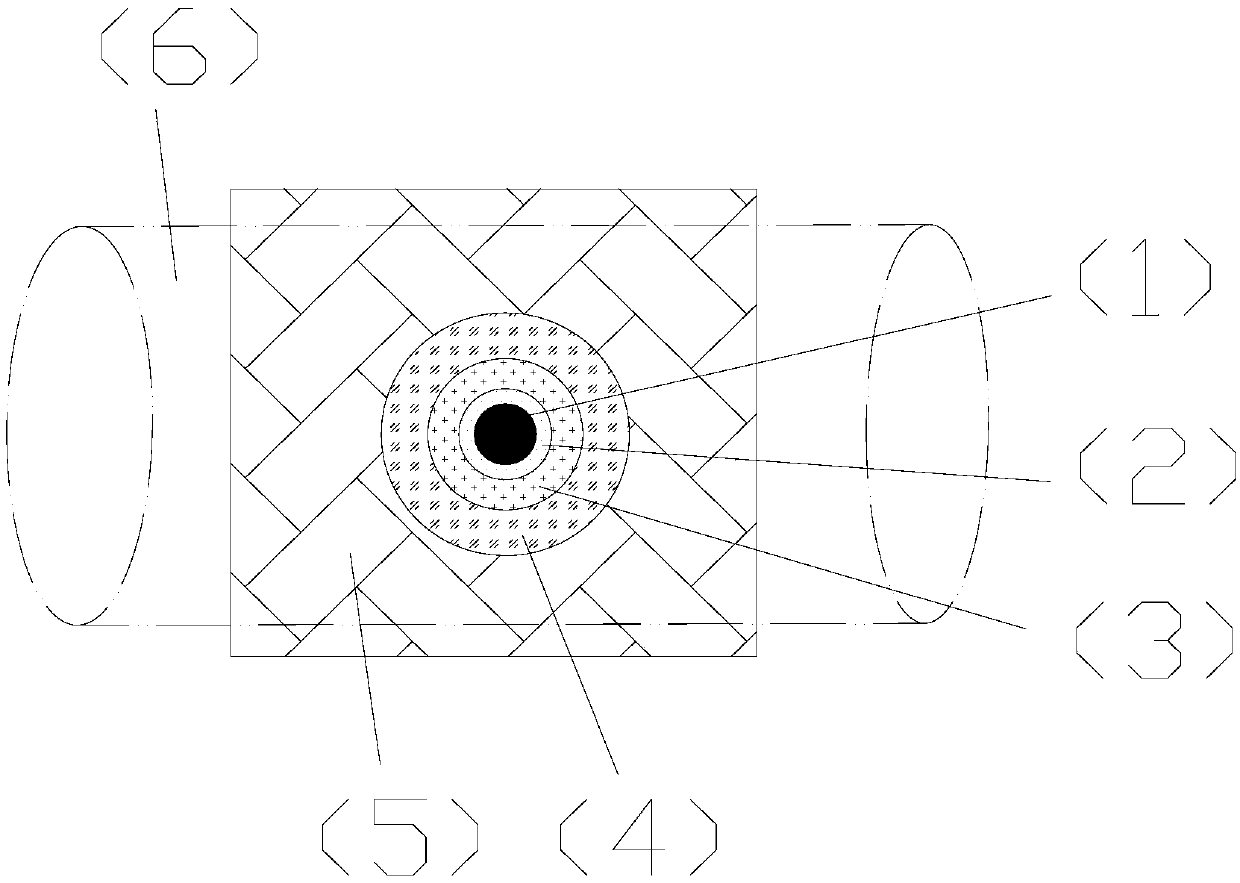

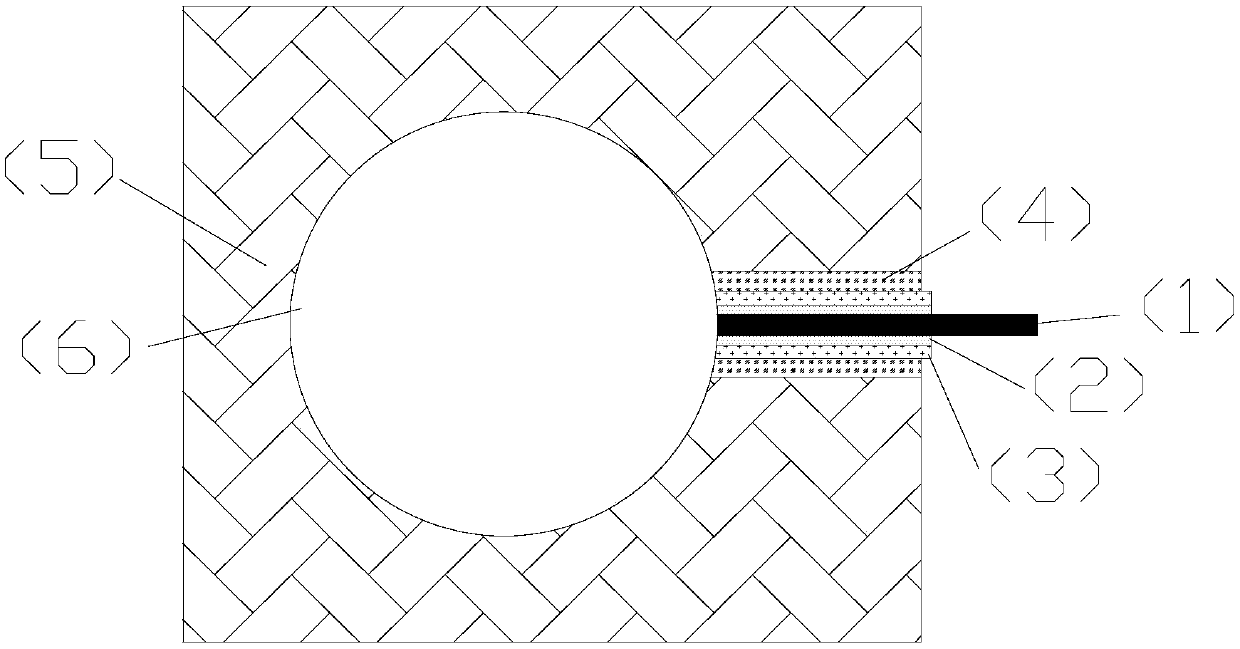

Pavement slab

InactiveCN103103903AAvoid crush damageImprove enduranceSingle unit pavingsPaving gutters/kerbsRoad surfaceEngineering

The invention discloses a pavement slab. The pavement slab comprises a base layer and a protective layer which is covered on the base layer, wherein the base layer is formed by combining a plurality of supporting plates in the same plane; connecting pieces matched with each other are arranged on at least one group of corresponding sides of the supporting plates; and two adjacent supporting plates are fixedly connected with each other. The pavement slab is laid on the road, and the pavement bearing capacity is improved; the pressure acting on the pavement slab can be uniformly dispersed through the pavement slab, the phenomenon that the ground is extruded to be damaged due to the stress at a single position is avoided, and the using cost is reduced; the hardness of the pavement is improved, and the horizontal driving vehicle speed is improved; and moreover, because the pavement slab comprises the base layer and the protective layer, the protective layer has the function of effectively preventing the base layer from being damaged, and the using cost of the base layer plate is reduced.

Owner:江苏广卫建设有限公司

Magnetic steel end fastening structure of permanent magnet motor rotor

InactiveCN102611228AAvoid crush damagePrevent looseningMagnetic circuit rotating partsPermanent magnet motorThermal expansion

The invention provides a magnetic steel end fastening structure of a permanent magnet motor rotor. The structure comprises magnetic steel, a thermal expansion glass felt, a stainless steel pressure plate, a stainless steel fastener, a rotor core pressure ring and a rotor core, wherein the magnetic steel is axially divided into multiple sections which are inserted into the magnetic steel slots of the rotor core; the rotor core pressure ring is compacted on the end surface of the rotor core; the stainless steel pressure plate is compacted on the magnetic steel and the rotor core pressure ring and connected with the rotor core pressure ring through the stainless steel fastener; and the thermal expansion glass felt is located between the stainless steel pressure plate and the magnetic steel. In the invention, the axial thickness is freely adjusted by use of the high expansion rate of the thermal expansion glass felt so as to realize flexible fixation of the magnetic steel and solve the problems caused by the manufacturing error. Moreover, since each pole is provided with an independent fastening device, the technological tool is not needed, the manufacturing process is facilitated, and the loosening of the magnetic steel caused by dismantling the tool is avoided.

Owner:SINOPAL (QINGDAO) ELECTRIC CO LTD

Sugarcane dissection device

The invention discloses a sugarcane dissection device and belongs to the field of food processing machineries. In specific, a roller is adopted for feeding, a photoelectric sensor is utilized to measure the length of a nodal bud, and a cutter automatically adjusts the spaces to cut off a sugarcane to reasonably cut the sugarcane into sections; and a photoelectronic device has a plurality of modes and can precisely cut the sugarcane with different colors and different states into sections after being mounted with a light-projector and an optical receiver with different colors. The sugarcane dissection device has the advantages of high efficiency and precision and low noise during working. According to the sugarcane sectioned by the sugarcane dissection device, the nodal bud and pulp are separated and placed separately, the pulp is not damaged due to extrusion, is attractive in appearance, excellent in taste and convenient to eat and utilize, and the nodal bud can be conveniently planted.

Owner:威海神舟信息技术研究院有限公司

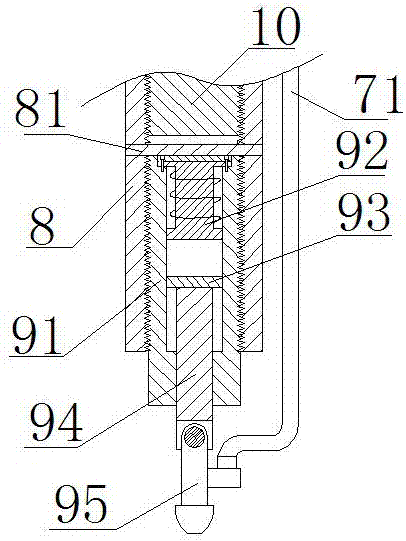

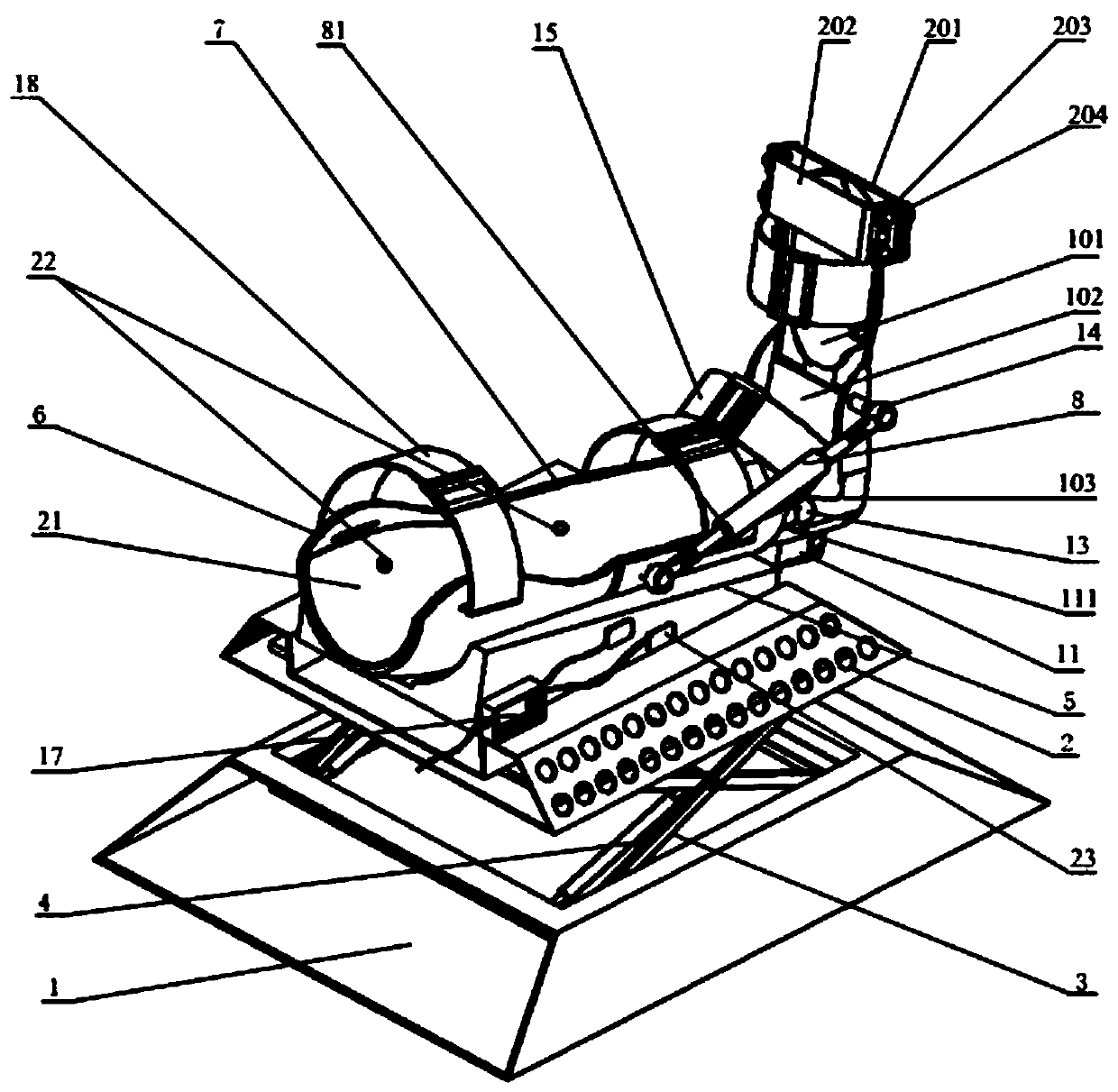

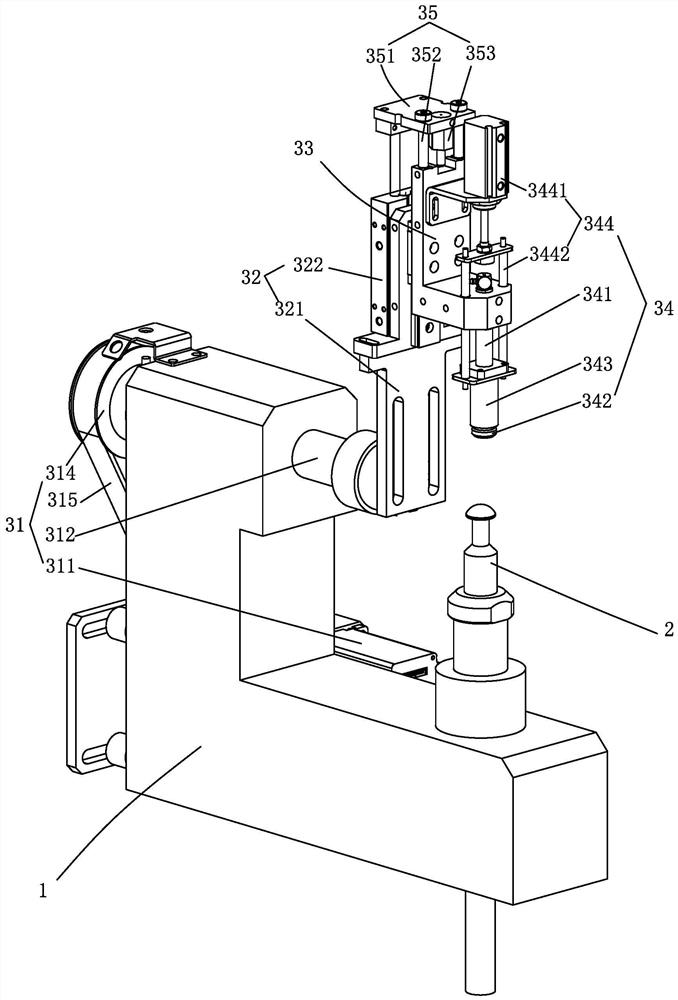

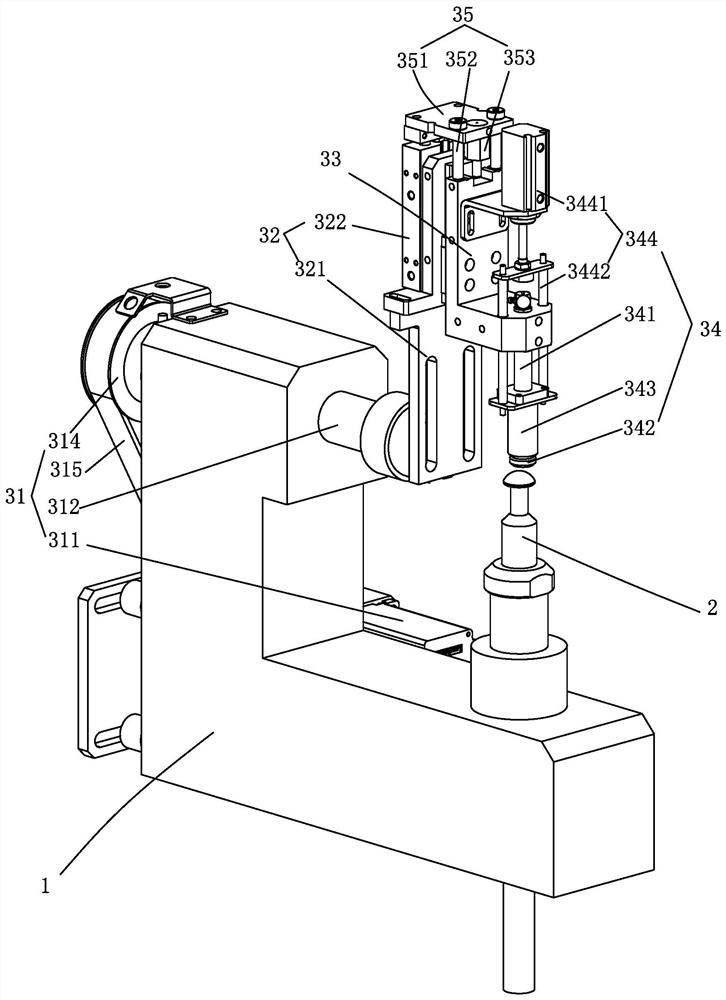

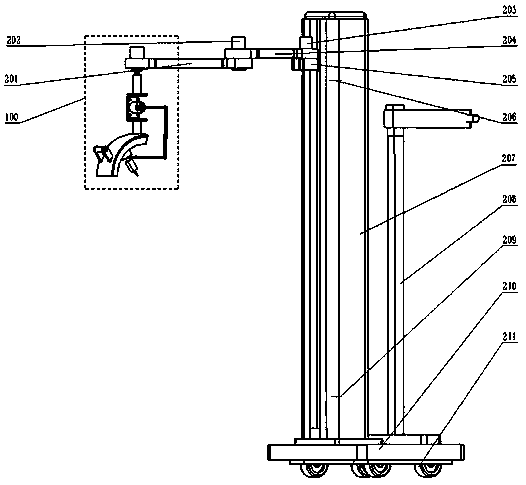

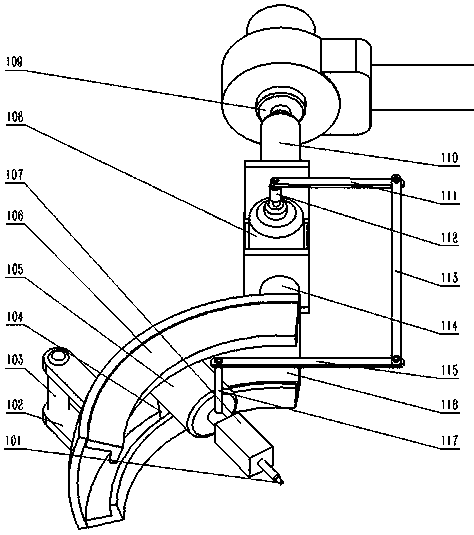

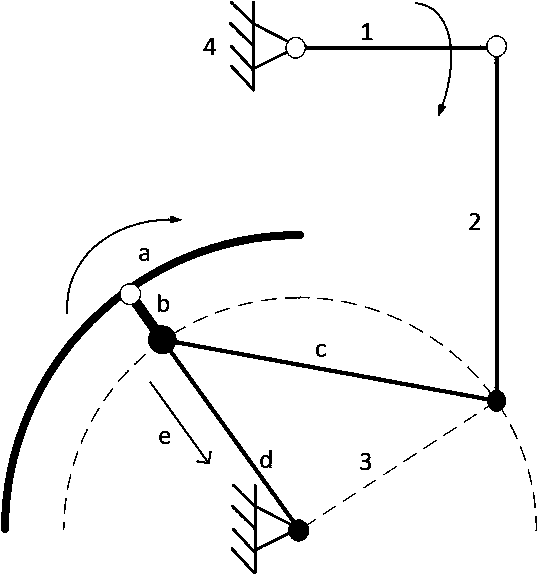

Fixed-point puncture device and robot using the fixed-point puncture device

PendingCN110623714AHigh positioning accuracyExpand the scope of workDiagnosticsSurgical needlesPhysical medicine and rehabilitationMedical robot

The invention discloses a fixed-point puncture device and a robot using the fixed-point puncture device, and relates to the field of medical robots. The robot mainly comprises a fixed-point puncture device, an SCARA type mechanical arm, a driving motor and a base. The SCARA type mechanical arm can meet the requirements of high positioning precision and large working range of a medical robot, the fixed-point puncture device can realize the fixed-point variable-angle movement of a puncture needle, and the fixed-point puncture device and the SCARA type mechanical arm can realize the posture adjustment and control of the puncture needle. The driving force of the fixed point puncture device is provided by the driving motor, and each rotary joint of the robot is driven and braked by the drivingmotor, so that it is convenient for the robot to conveniently adjust the posture and keep the current state. The invention designs the fixed-point puncture device and the robot using the fixed-point puncture device to assist a doctor in the fixed-point puncture diagnosis, thus making up for the defects of manual puncture and improving the stability of puncture and the success rate of diagnosis.

Owner:UNIV OF JINAN

Positioning structure of carpentry machining center

ActiveCN111391038AImprove positional stabilityThere will be no phenomenon of uneven forceMulti-purpose machinesProfiling/shaping machinesMachineCarpentry

The invention provides a positioning structure of a carpentry machining center and belongs to the technical field of machining equipment. The problem that the positioning stability of irregular-shapedworkpieces by an existing carpentry machining center is poor is solved. The carpentry machining center of the positioning structure comprises a machine frame and a transverse beam which is fixed to the machine frame; a machining assembly is disposed on the transverse beam; and a machining platform is slideably disposed on the machine frame in the horizontal direction. The positioning structure comprises a plurality of installing seats which are arranged on the machine frame; positioning pressure rollers are horizontally disposed on the installing seats correspondingly; the plurality of installing seats are arranged in two rows; lifting seats are slideably connected to the installing seats in the vertical direction correspondingly; one ends of the positioning pressure rollers are connectedto the lifting seats, and the other ends of the two rows of positioning pressure rollers face the inner side of the machine frame; when the lifting seats ascend, the other ends of the two rows of positioning pressure rollers can be located above the machining platform; and each installing seat is provided with a driving part. The positioning stability of the irregular-shaped workpieces by the carpentry machining center is higher.

Owner:吴善旺

Hoop type cable duct cable support

InactiveCN104052009APrevent fallingAvoid crush damageCable installations on groundPipe supportsSurface mountingCushion

The invention discloses a hoop type cable duct cable support which comprises a wall-attached stand column installed on the side wall of a cable duct. A transverse supporting column which is placed transversely is connected with the wall-attached stand column. The axis of the transverse supporting column is perpendicular to that of the wall-attached stand column. A hinged block, a rubber soft cushion block and a positioning block are installed on the upper surface of the transverse supporting column. The rubber soft cushion block is located between the hinged block and the positioning block. The hinged block is close to the wall-attached stand column. The positioning block is away from the wall-attached stand column. A groove A is formed in the upper end face of the hinged block. The hoop type cable duct cable support further comprises an arc-shaped plate. One end of the arc-shaped plate is inserted into the groove A, the end, inserted into the groove A, of the arc-shaped plate is connected with the inner wall of the groove A through a rotating shaft, the other end of the arc-shaped plate is connected with the positioning block through a positioning screw, and the arc-shaped plate protrudes upwards. The hoop type cable duct cable support has the advantages that the hoop type cable duct cable support is simple in structure, low in cost and convenient to operate, and construction time is shortened; multiple large-caliber cables are placed on the transverse supporting column in each unit length, and therefore the cables are prevented from rolling down, and the cables are prevented from extrusion damage.

Owner:STATE GRID SICHUAN ELECTRIC POWER

Wooden cabinet transfer equipment

PendingCN112141873AEasy to moveReduce the adverse effects of inertiaConveyorsBase supporting structuresElectric machineryEngineering

The invention relates to the technical field of transfer equipment, in particular to wooden cabinet transfer equipment. The wooden cabinet transfer equipment comprises a support frame, a moving assembly, a lifting plate, a clamping assembly and a lifting assembly. Lead screws are driven by corresponding first motors to rotate, a nut moves on the lead screws, a connecting plate is driven by the nutto move in the direction of the lead screws, so as to drive two clamping plates to move, the clamping plates at two ends of the lifting plate are driven by the two first motors to correspondingly move, so as to clamp a wooden cabinet, and the two first motors are used for driving, so that accurate control for clamping operation of the wooden cabinet is increased, control for the clamping force can be improved, the wooden cabinet is clamped more firmly by the wooden cabinet transfer equipment, the safety of subsequent transfer operation is improved, and the wooden cabinet can be prevented frombeing extruded and damaged in the operation process.

Owner:萧县八宝畜禽养殖农民专业合作社

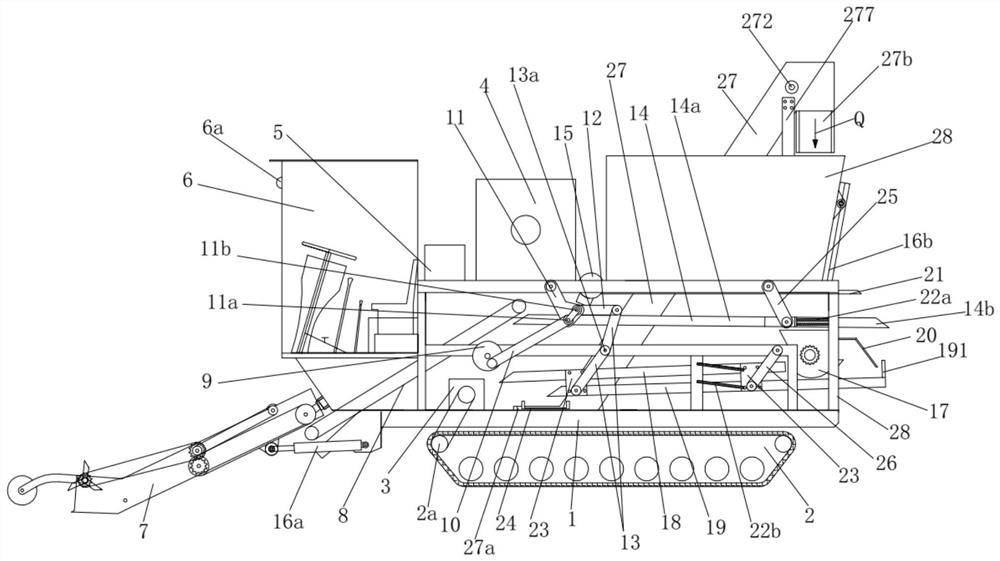

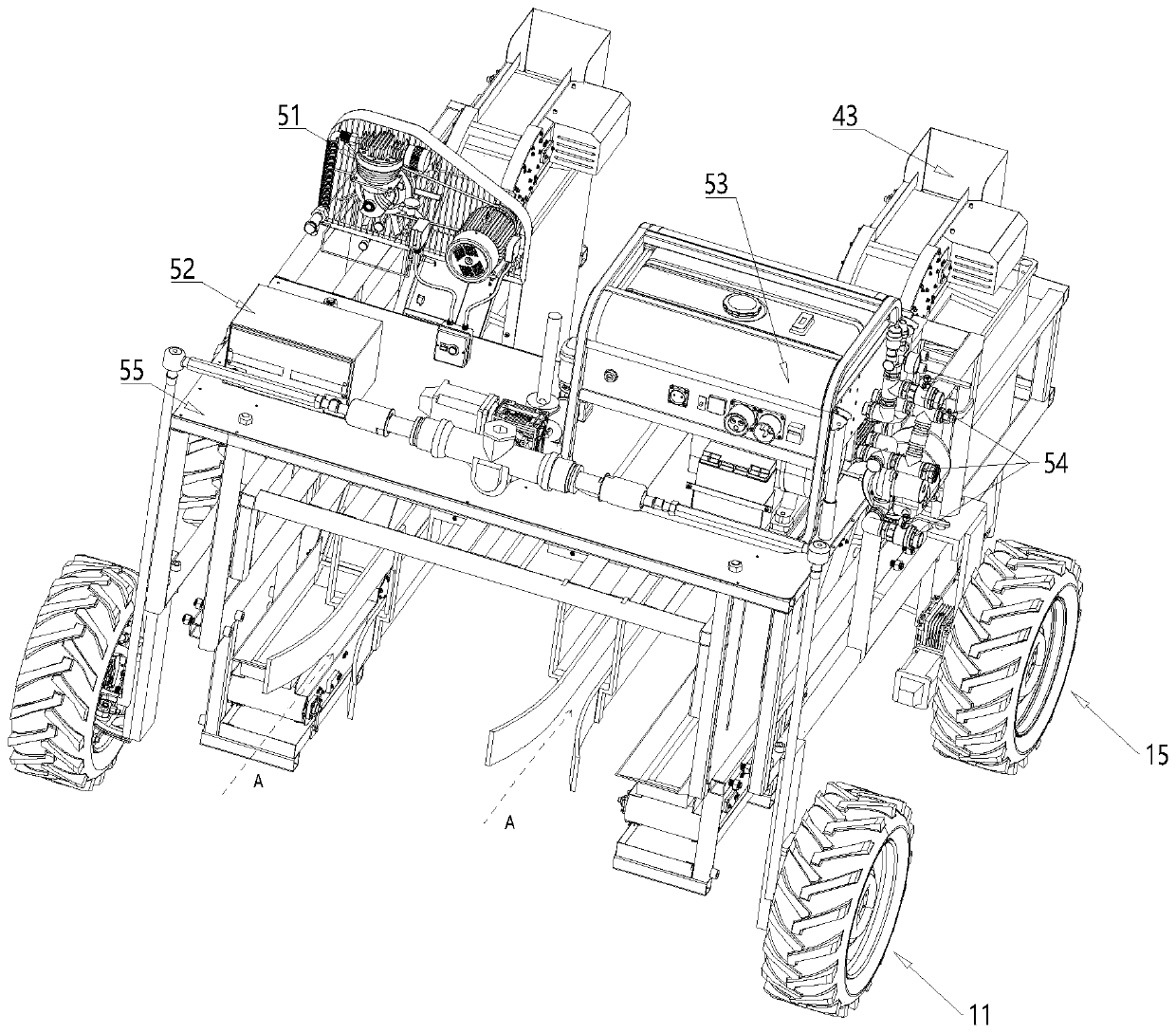

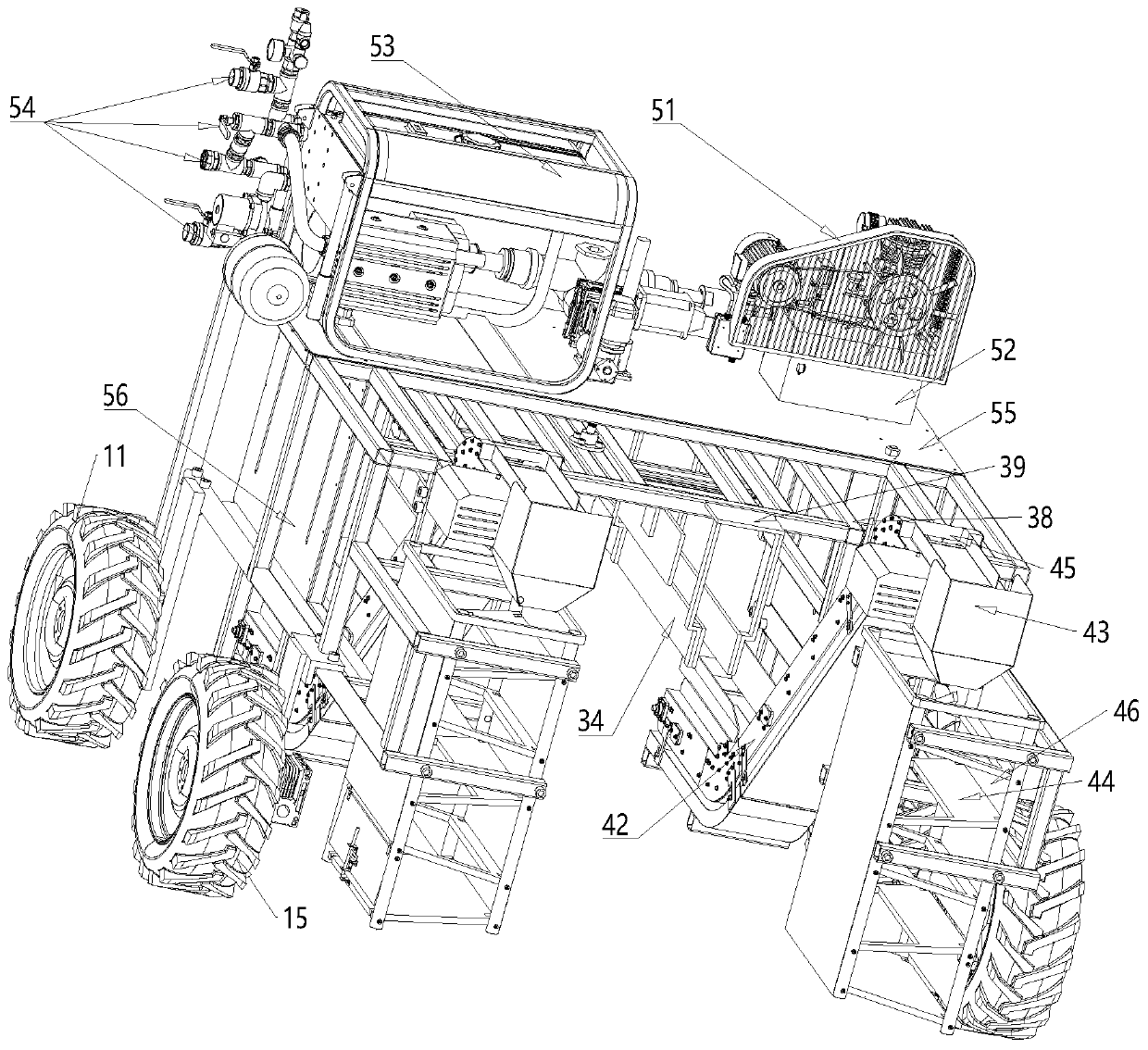

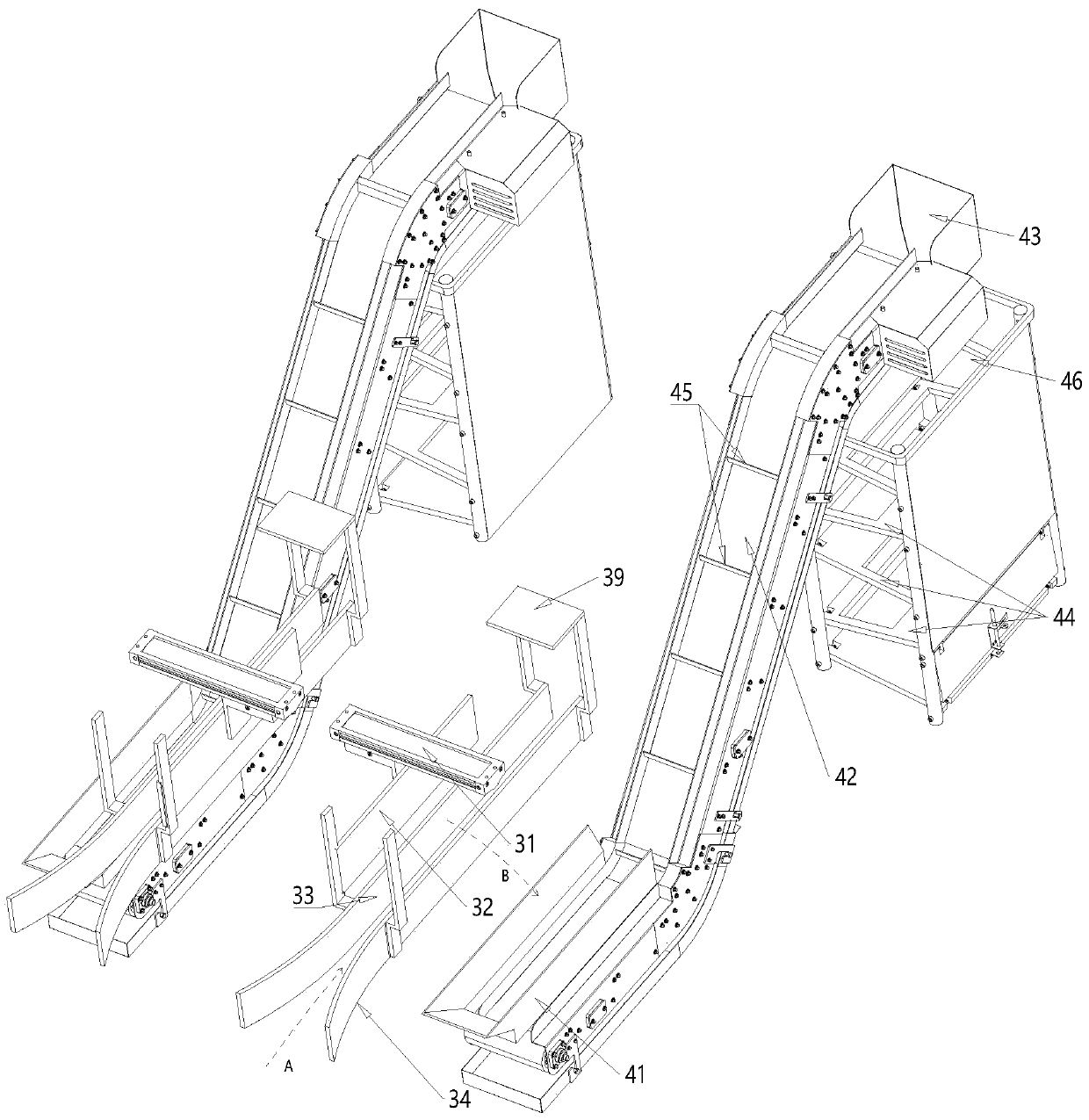

Crawler-type harvester for cyperus esculentus

PendingCN111742687AImprove adaptabilityHigh yieldDiggersEndless track vehiclesAgricultural engineeringAgricultural science

The invention relates to a crawler-type harvester for cyperus esculentus. According to the technical scheme, a soil crushing and feeding device driven by an engine, a lifting and conveying device, anupper layer vibrating screen, an auger-type soil throwing and crushing device, a lower layer vibrating screen, a horizontal conveying vibrating screen and a material receiving and lifting mechanism are arranged on a frame; a feeding end of the soil crushing and feeding device is connected with a feeding end of the lifting and conveying device; a discharge end of the lifting and conveying device isconnected with a feeding end of the upper layer vibrating screen; a discharge end of the lower layer vibrating screen is connected with a feeding end of the horizontal conveying vibrating screen; a discharge end of the horizontal conveying vibrating screen is connected with a feeding hole of the material receiving and lifting mechanism; a discharge hole of the material receiving and lifting mechanism is connected with a feeding hole of the upper part of a harvesting box; and a travelling mechanism is a travelling crawler arranged at two sides of a chassis. The crawler-type harvester has a wide application range, integrates multiple functions of excavating and soil crushing, root crushing, separating, screening and recycling, is suitable for high-efficiency harvesting of the cyperus esculentus, is easy to move, and has a great popularization prospect.

Owner:新乡地隆药业机械有限公司

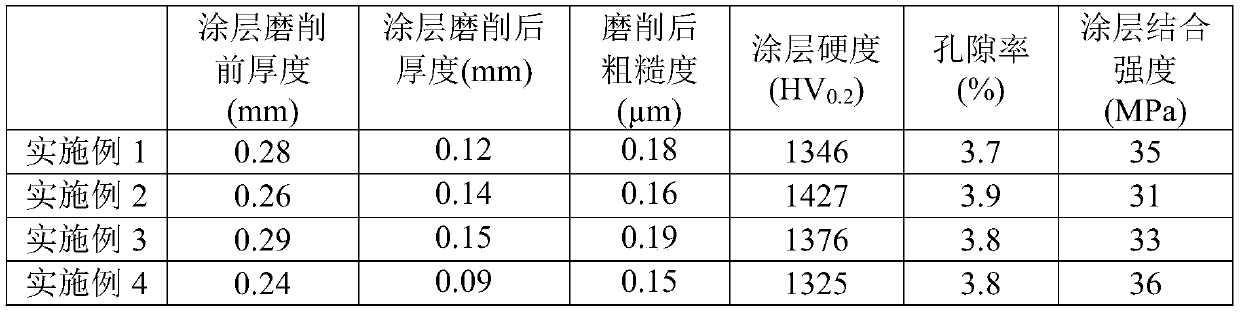

Surface treatment method for power transmission shaft of speed reducer and coating

InactiveCN110952060AGuaranteed uniformityMaximum wear and friction protectionMolten spray coatingReduction driveSand blasting

The invention discloses a surface treatment method for a power transmission shaft of a speed reducer and a coating, and relates to the technical field of material surface treatment. The method comprises the steps: a to-be-sprayed area on the surface of the power transmission shaft of the speed reducer is machined to form a groove; then, the surface in the groove is activated and roughened througha sand blasting method; and then, a wear-resisting and friction-reducing coating is formed in the groove through direct spraying, wherein the speed reducer power transmission shaft is an input shaft or an output shaft. The groove is formed in the surface of the power transmission shaft of the speed reducer, the groove is used for restraining the coating deposited in the groove subsequently, and the groove structure can further prevent the coating from being extruded and damaged when the coating is subjected to grinding machining and oil seal sealing is installed in an interference mode in theaxial direction. According to the surface treatment method, the wear-resistant and friction-reducing coating can be formed through direct spraying in the groove and a bonding layer does not need to bearranged; an oxide skin of the surface to be sprayed is removed through surface sand blasting pretreatment so as to improve the surface activity and the surface roughness, and therefore, the bondingstrength between the coating and the groove is improved.

Owner:GUANGDONG INST OF NEW MATERIALS

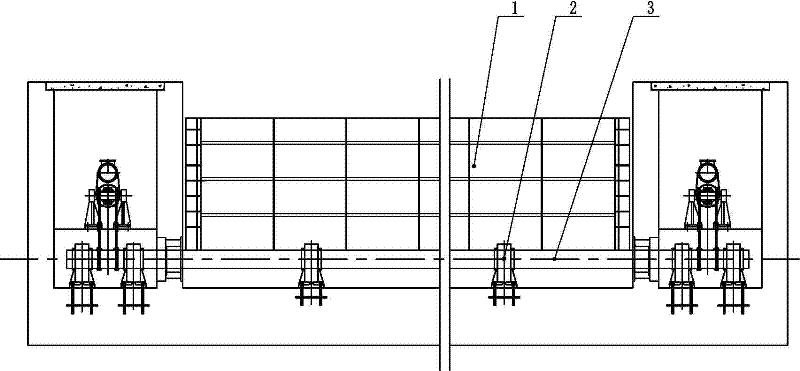

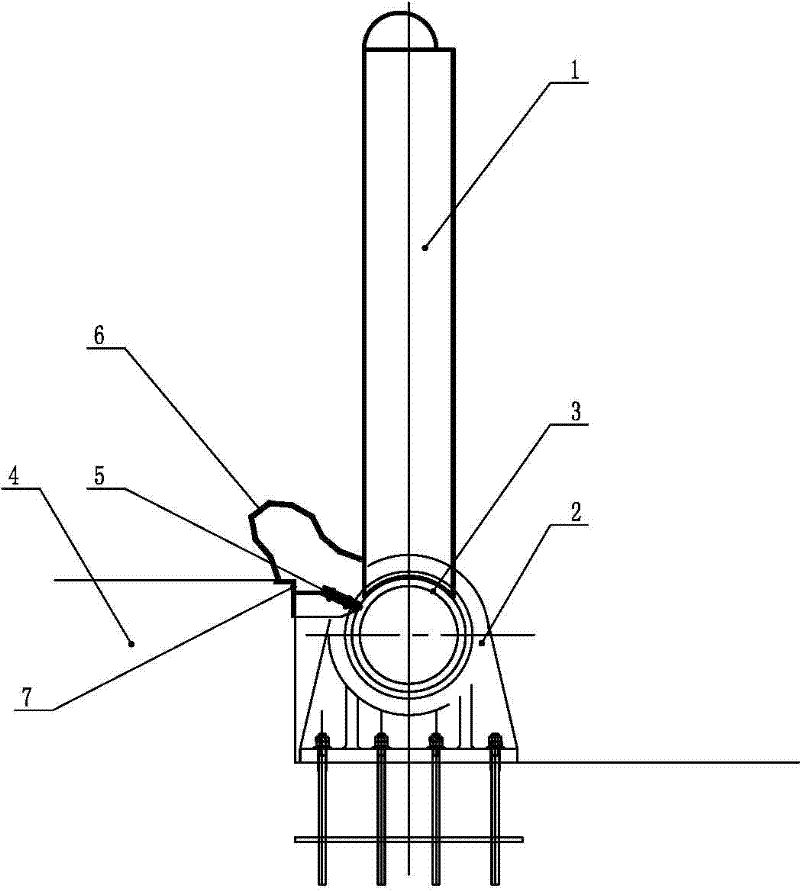

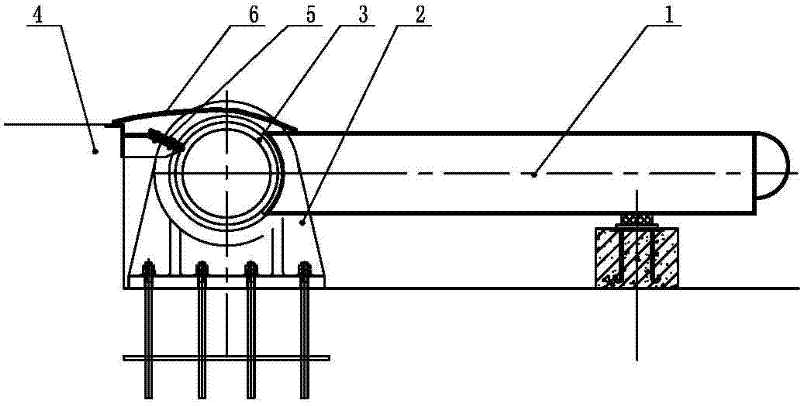

Foldable steel dam bottom shaft watertight structure

The invention discloses a foldable steel dam bottom shaft watertight structure in the technical field of steel dam gates. The foldable steel dam bottom shaft watertight structure includes a bottom shaft fixed at the bottom of a gate leaf, wherein the bottom shaft is fixed on a concrete foundation through a hinged support; a water sealing element is arranged between the gate leaf and the concrete foundation; the water sealing element includes link plate assemblies corresponding to the two ends of the gate leaf; the two link plate assemblies are connected through a rubber band; the upper end of the rubber band is hermetically connected with the gate leaf, and the lower end of the rubber band is hermetically connected with the concrete foundation; the two ends of the rubber band extend out of the link plate assemblies; and each link plate assembly includes a plurality of link plates that are sequentially hinged. The rubber band can be folded and sealed at will and can be reliably supported by adopting the link plate assemblies at the two ends thereof, as a result, the two ends of the rubber band can be permanently attached onto the gate wall during the rotation of the gate leaf, and water leakage is avoided; the device is satisfactorily sealed and highly reliable to use, and has a simple structure; and the foldable steel dam bottom shaft watertight structure adopts the link plates for sealing by changing the functions of the link plates, so as to achieve an unexpected effect.

Owner:YANGZHOU CHUMEN ELECTROMECHANICAL DEVICES MFG

Self-propelled pineapple harvesting machine

The invention discloses a self-propelled pineapple harvesting machine. The self-propelled pineapple harvesting machine comprises a walking mechanism, a picking mechanism and a collecting mechanism; the picking mechanism comprises a push plate, a side baffle and a lifter; the side baffle is used for controlling the direction of fruits and stems entering the picking mechanism, and the push plate moves in the preset direction and is matched with the side baffle to separate the fruits from the stems; and the lifter is used for changing the height of the picking mechanism to be matched with pineapple plants with different plant heights. Picked pineapples are conveyed into a collecting frame through a conveying belt, and multiple buffer plates are arranged in the frame to prevent injury caused by mutual extrusion. Tires with specific lines are used on the walking mechanism, and the machine is effectively prevented from being caught in a farmland. The self-propelled pineapple harvesting machine does not depend on a microcomputer and related electronic equipment, and is high in reliability and low in maintenance cost. The self-propelled pineapple harvesting machine is high in mechanizationdegree, convenient to operate, low in cost and high in picking efficiency, and the time and labor are saved.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Efficient paint spraying and drying device for bamboo wood board producing and machining

InactiveCN108704815ADry evenlyImprove yield ratePretreated surfacesCoatingsAgricultural engineeringBevel gear

The invention discloses an efficient paint spraying and drying device for bamboo wood board producing and machining. The efficient paint spraying and drying device comprises a fixing base. A drying box is fixedly connected to the top of the fixing base. The left side of the top of the drying box is fixedly connected with an air heating box. The right side of the air heating box communicates with adraught fan through a through pipe. Through cooperative usage of a first worm, a first fixing column, a movable base, a first motor, a first transmission rod, a special-shaped gear, a gear plate frame, a second worm, a second motor, a first gear, a first bevel gear, a second transmission rod, a second bevel gear, a second rotation rod, a second gear and a third transmission rod, the effect of automatic overturning during bamboo wood board drying is achieved, bamboo wood boards can be evenly dried, the drying efficiency is greatly improved, and accordingly the work efficiency of a user is improved; and the yield of the bamboo wood boards is increased, accordingly, the practicability of the paint spraying and drying device is greatly improved, and the efficient paint spraying and drying device is suitable for usage and popularization.

Owner:安吉华祥竹木工艺品厂

Carrying industrial robot

InactiveCN110271863AAchieve automatic handlingImprove handling efficiencyConveyor partsElectricityElectric drive

The invention relates to the technical field of robots, and discloses a carrying industrial robot. The carrying industrial robot comprises a rail and a base; an electric-driven guide wheel is arranged at the bottom of the base, and is movably sleeved with the rail; and a controller is arranged in an equipment box at the middle part of the bottom end of the base. In the carrying industrial robot, a second motor is started to drive two clamping jaws to relatively move to clamp objects; when the clamped objects contain ferrous magnetic absorption materials, a power supply device is used for supplying electricity to electromagnets in the clamping jaws, and magnetism of the electromagnets is used for absorbing the objects to be clamped; meanwhile, the device can drive a sucker to descend through startup of a hydraulic rod, and a sucker is used for vacuumizing absorption of the tops of the objects, so that the object clamping stability is improved; and the device is provided with multiple clamping modes, improves the object carrying range and the clamping stability, and prevents the damage condition of the objects due to loose falling of the objects.

Owner:莫庆锋

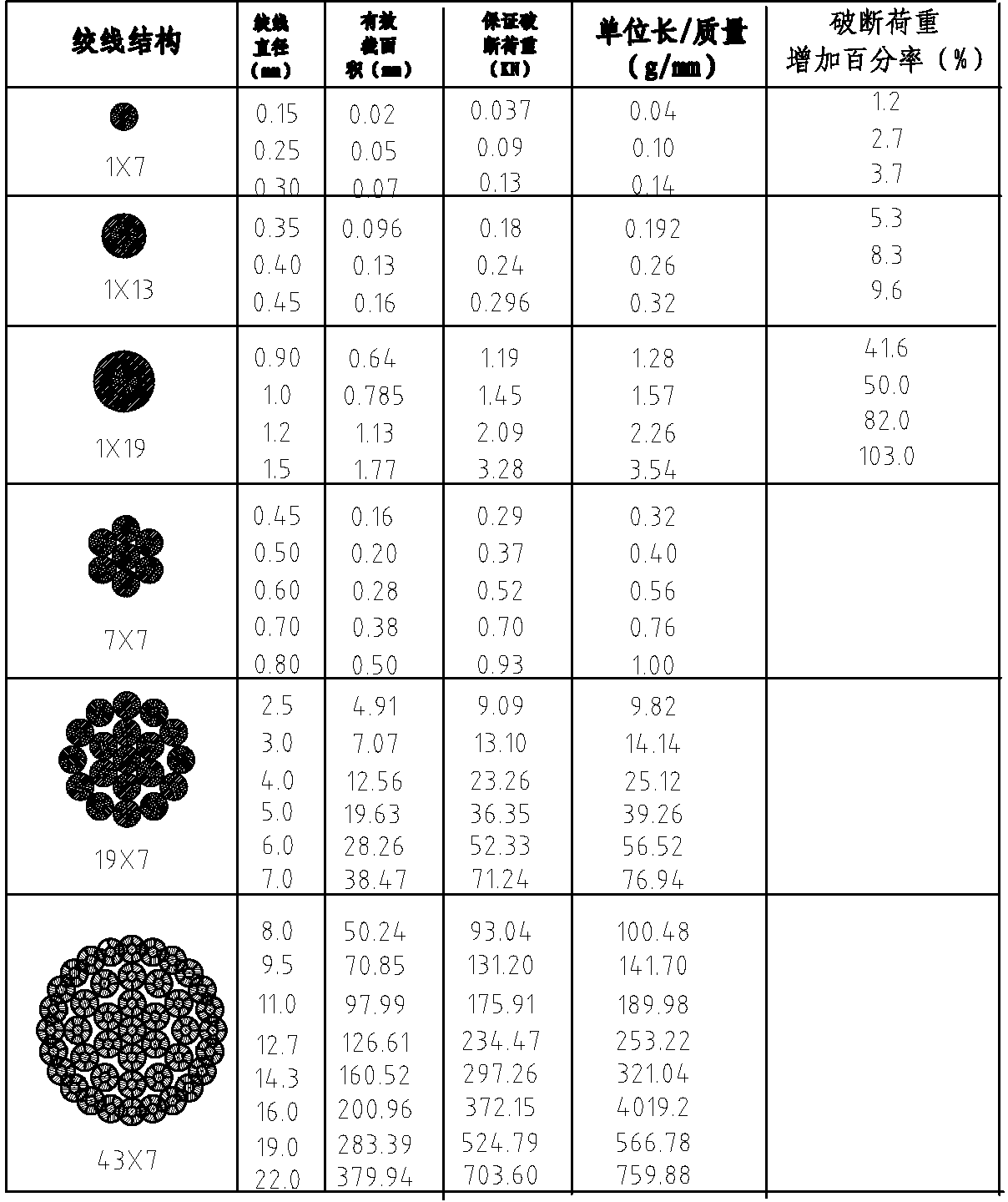

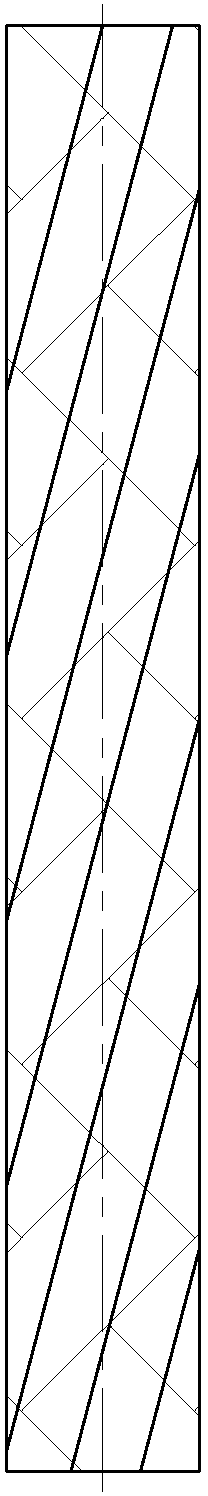

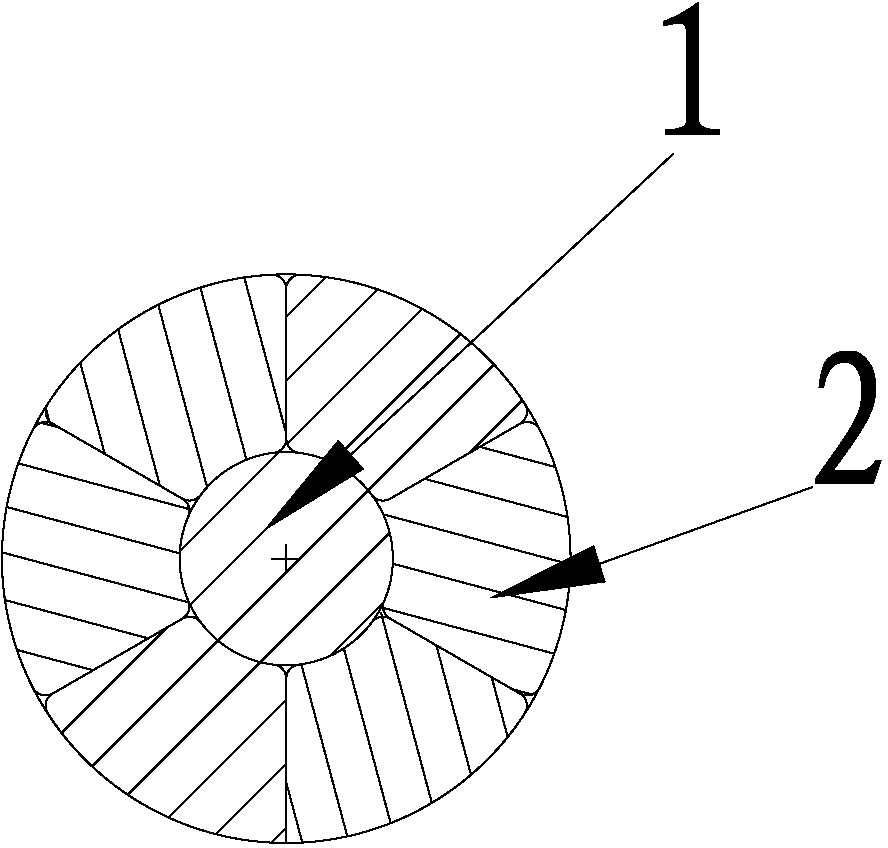

High-strength composite stranded wire with trapezoidal section and one-step preparation method thereof

The invention discloses a high-strength composite stranded wire with a trapezoidal section and a one-step preparation method thereof. The high-strength composite stranded wire is formed by stranding at least one composite core wire, and is characterized in that the composite core wire consists of a cylindrical core wire, and a plurality of trapezoidal stranded wires surrounding the cylindrical core wire and having trapezoidal sections; the surface of each trapezoidal stranded wire is wound with a layer of unidirectional or bidirectional fiber; the trapezoidal stranded wires surround the cylindrical core wire for stranding, with the stranding angle of 6-12 degrees and the pitch of 120-180mm; the cylindrical core wire is formed by sticking a plurality of carbon fibers through a cylindrical hole mould; and each trapezoidal stranded wire is formed by sticking a plurality of carbon fibers through a trapezoidal hole mould. The high-strength composite stranded wire has the advantages of large effective section area and high bearing capability.

Owner:南京诺尔泰复合材料设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com