Self-propelled pineapple harvesting machine

A self-propelled, pineapple technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inconvenient popularization and utilization, unsuitable shape, easy to get stuck in farmland, etc., and achieve low maintenance cost and low cost , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention.

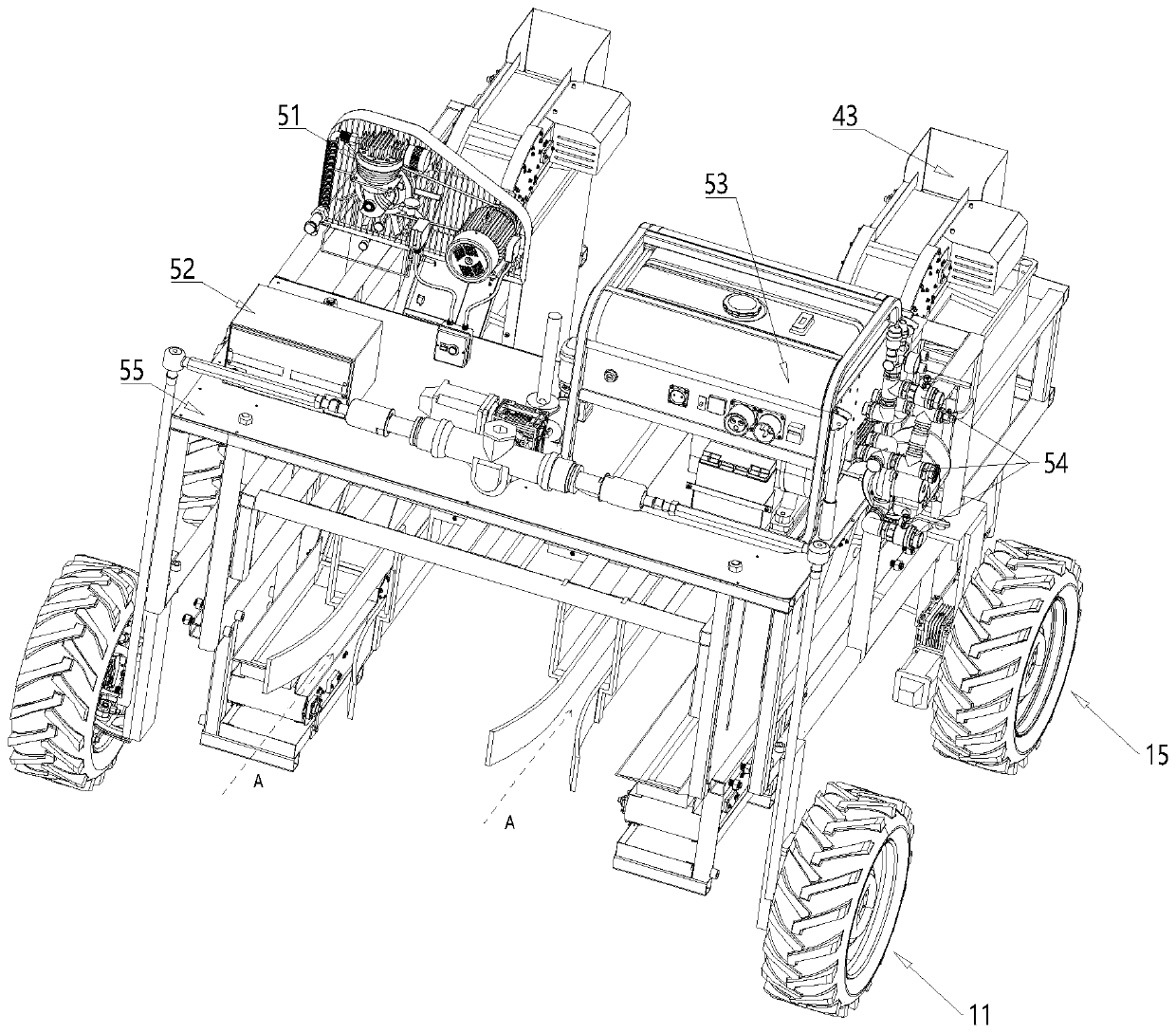

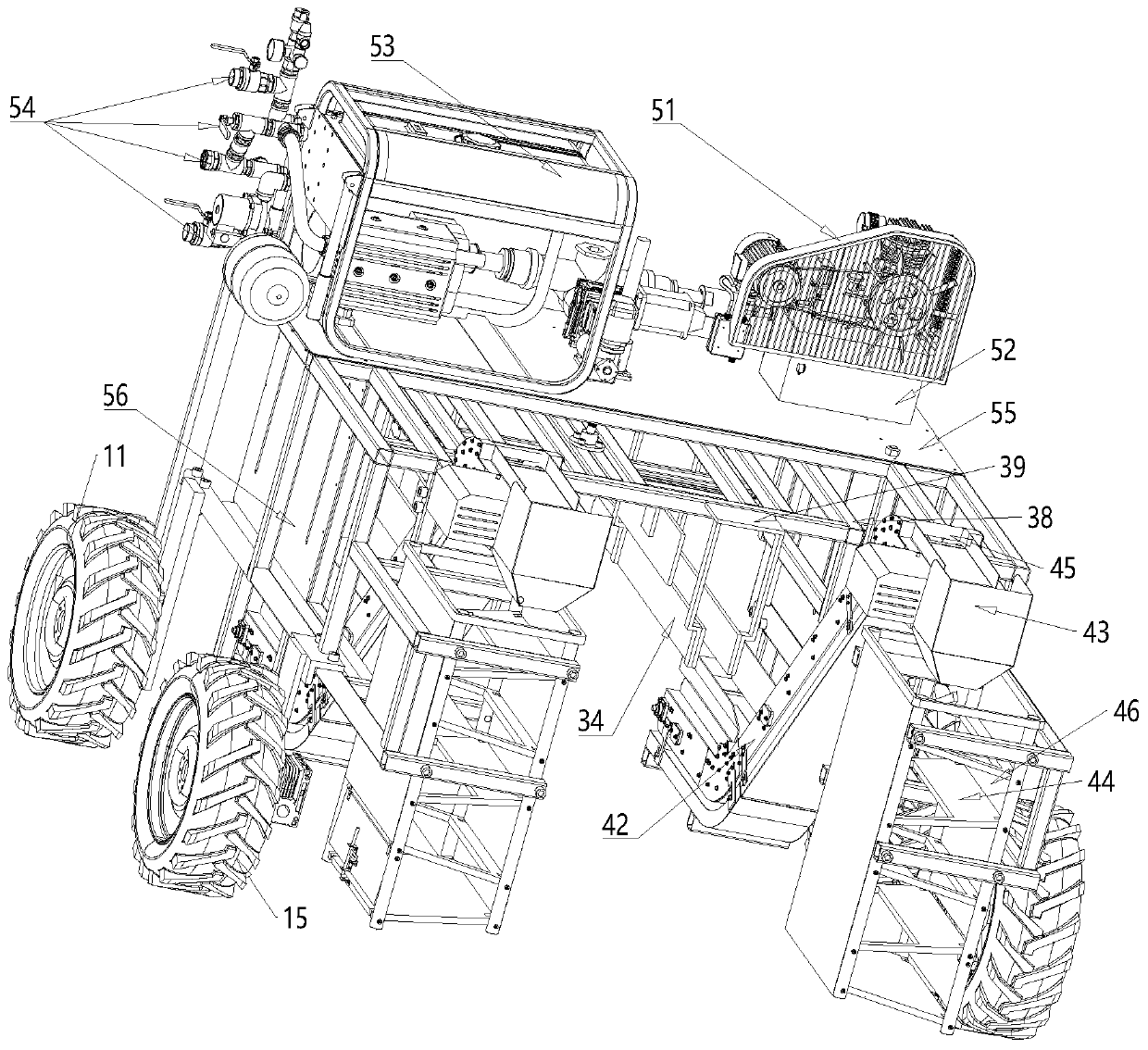

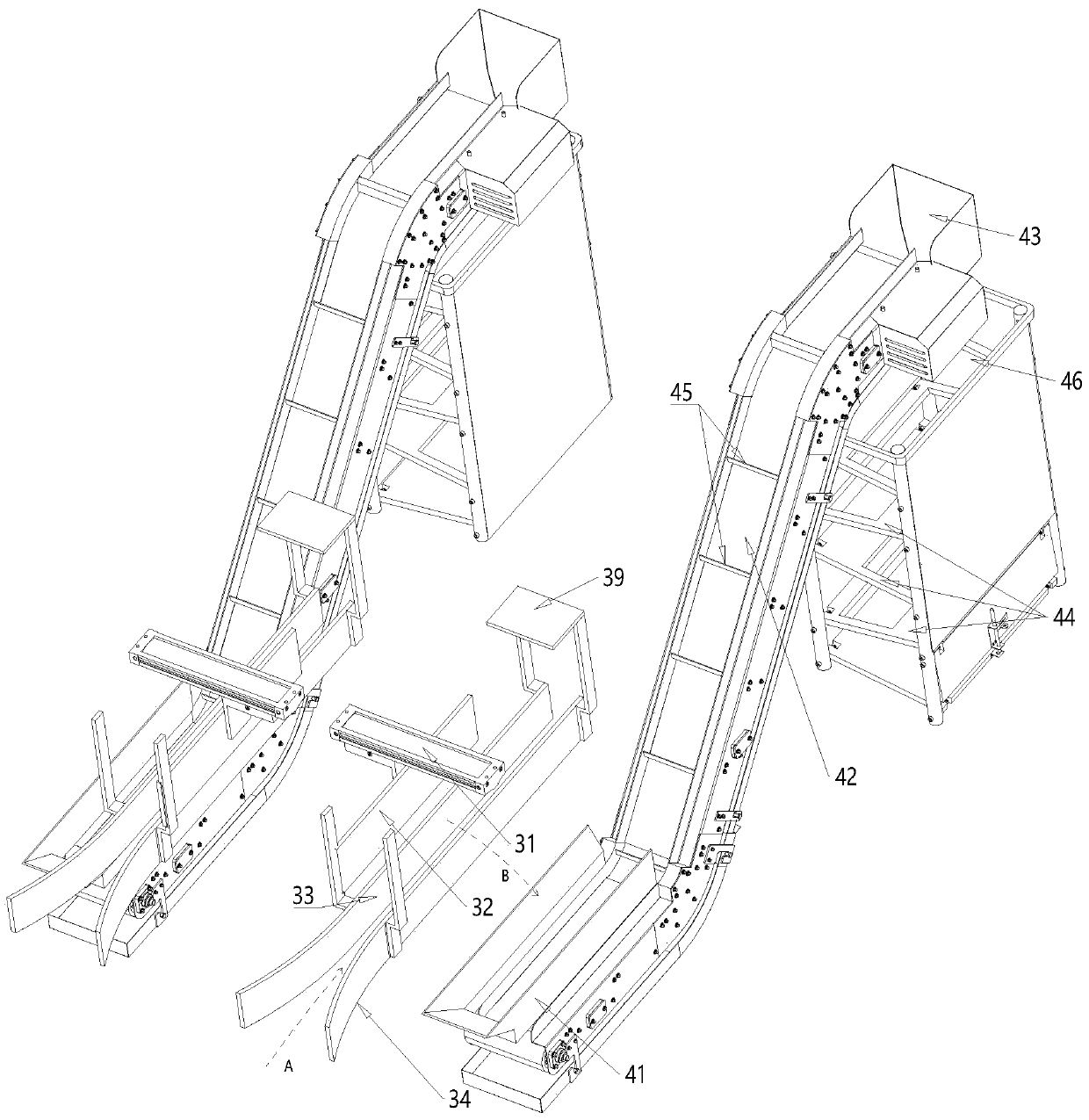

[0030] The rest are not detailed as figure 1 , figure 2 Shown is the overall structure schematic diagram of the present invention; The present invention can be divided into three parts of traveling mechanism, picking mechanism, collecting mechanism. Three parts are all installed and work together by frame 38;

[0031] Wherein walking part comprises: as the front wheel 11 of steering wheel and relevant part; As the trailing wheel 15 of drive wheel and relevant part, power part.

[0032] Relevant part reference of front wheel 11 of steering wheel Figure 5 , including front wheel 11, receiving cup 16, connecting rod 17, steering gear assembly 18, motor 13, speed reducer 14. The output shaft of motor 13 outputs torque to steering gear assembly 18 through speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com