Foldable steel dam bottom shaft watertight structure

A bottom shaft and water-stop technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as difficult sealing, difficult sealing, and aesthetic impact, and achieve good sealing, high reliability, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

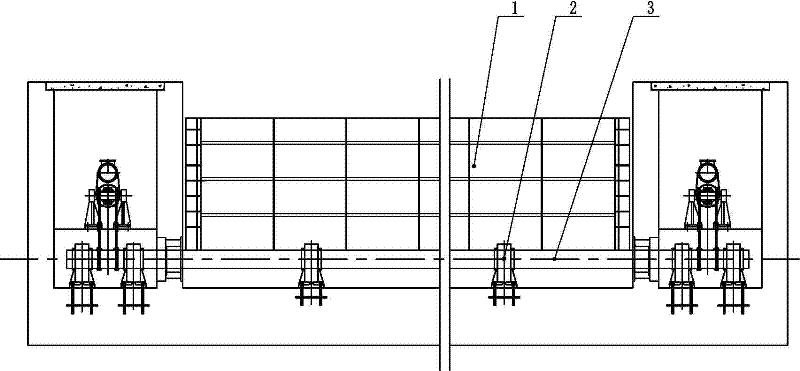

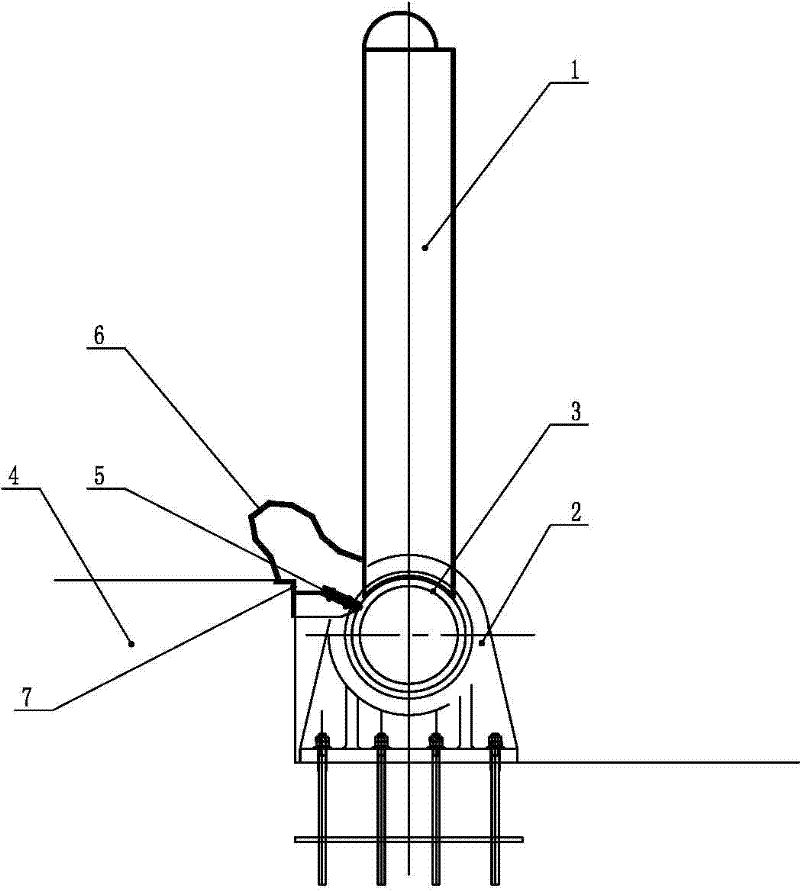

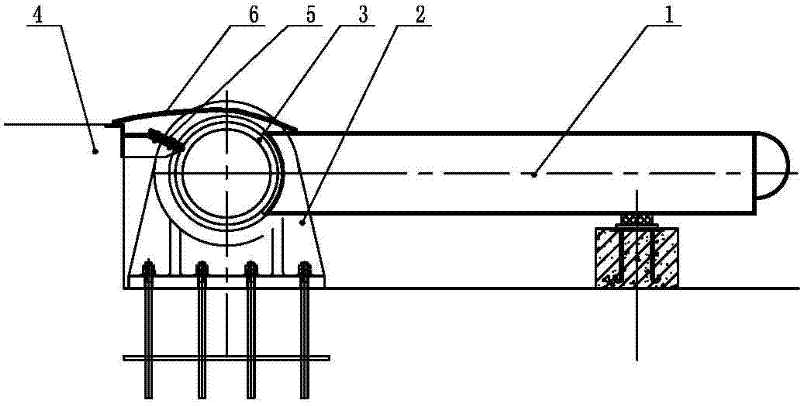

[0020] Such as figure 1 As shown in -6, it is a foldable steel dam bottom shaft water-stop structure. The bottom shaft 3 is fixed on the bottom of the door leaf 1, and the bottom shaft 3 is fixed on the concrete foundation 4 through the hinge seat 2. The door leaf 1 and the concrete foundation 4 There is a sealing and water-stopping part 6 between them. The sealing and water-stopping part 6 includes a chain plate assembly corresponding to the two ends of the door leaf. The two chain plate assemblies are connected through a soft rubber belt 601, and the upper end of the soft rubber belt 601 is The pressing plate 604 is fixed on the door leaf 1, so that the upper end of the soft rubber belt 601 is sealed and connected with the door leaf 1. On the concrete foundation 4 and the corresponding position of the soft rubber belt is provided with a sealing embedded part 7, and the lower end of the soft rubber belt 601 passes through the lower pressing plate. 607 is fixed on the sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com