Centering device for hoisting shell of reactor core of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and centering device technology, which is applied in safety devices, greenhouse gas reduction, transportation and packaging, and can solve problems such as large area, heavy core shell weight, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

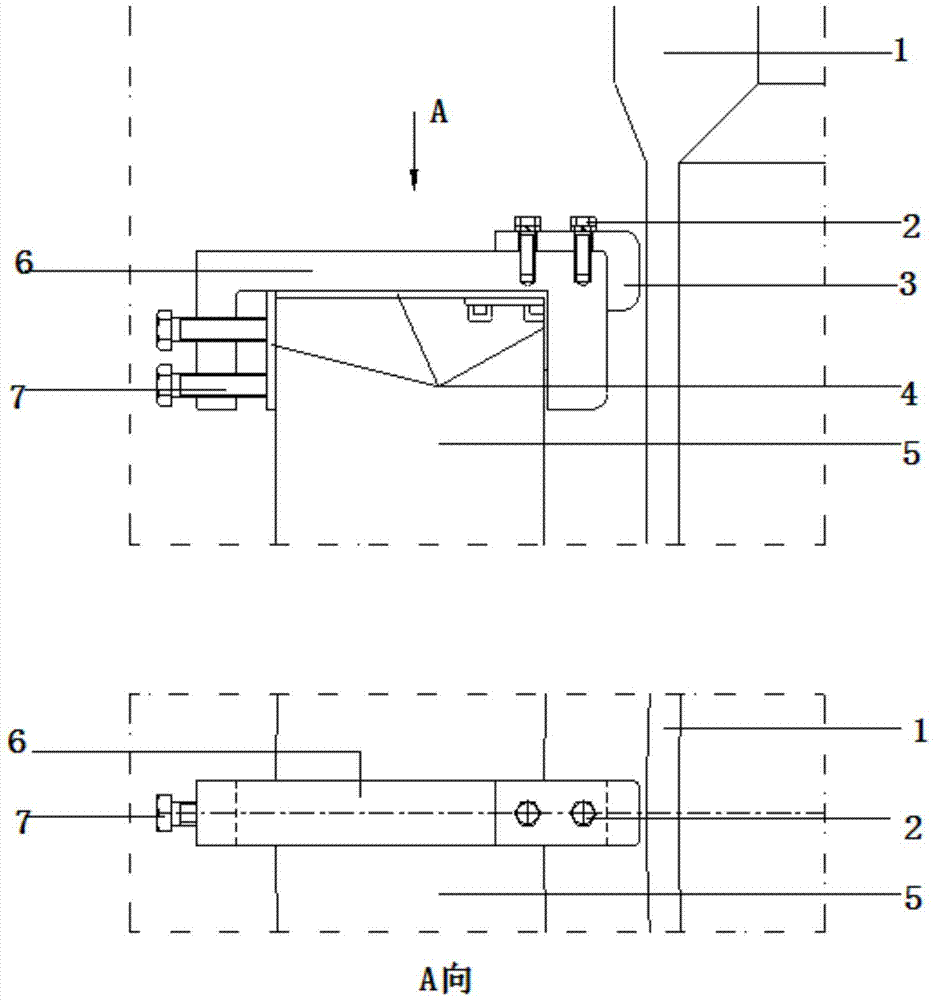

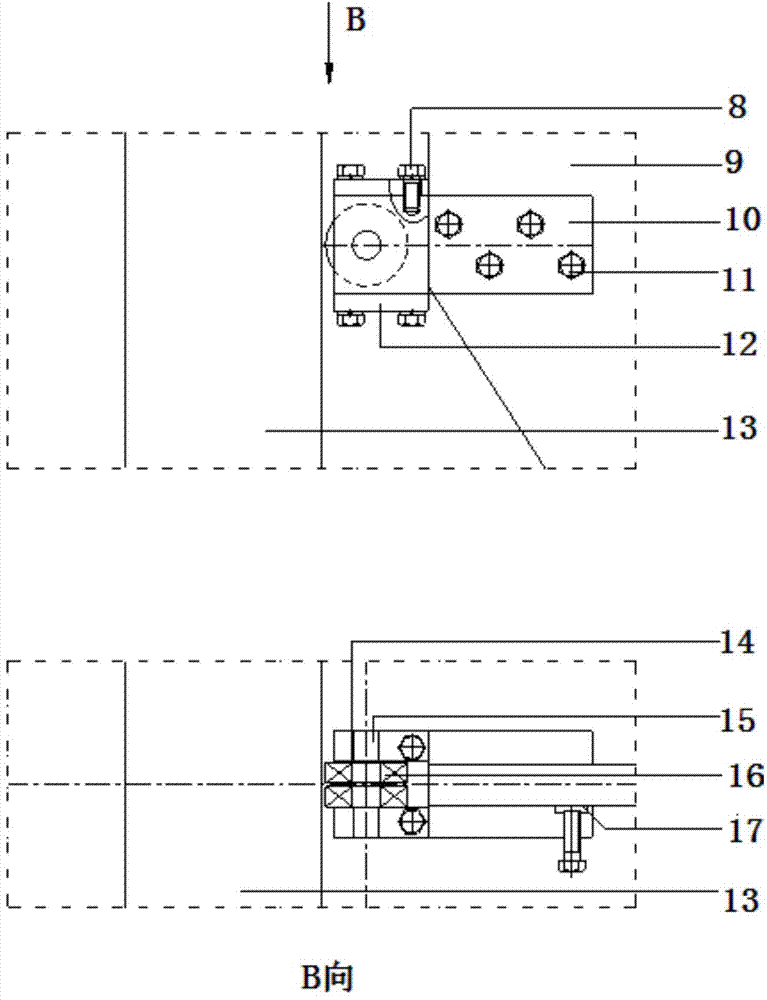

[0015] see figure 1 , The present invention provides a high temperature gas-cooled reactor core casing hoisting and centering device, which includes several top centering and limiting devices. The top centering limiting device includes adjusting block fastening screw 2, adjusting block 3, reactor pressure vessel main flange protection gasket 4, centering block fastening screw 7 and centering block 6. The centering limit block 6 is in concave shape, which is clamped by the fastening screw 7 of the centering limit block so as to be buckled on the main flange 5 of the pressure vessel; the adjustment block 3 is L-shaped, and the screw is fastened by the adjustment block ) is firmly connected to the centering limit block 6. The top centering limit device is clamped on the main flange 5 of the reactor pressure vessel through the centering limit block fastening screw 7, and the contact surface between the top centering limit device and the main flange 5 of the reactor pressure vesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com