Recycling high-efficiency heat-radiating battery device for electric vehicle

A technology for battery devices and electric vehicles, applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as battery temperature rise, battery violent combustion, battery performance degradation, etc., to prolong battery life and facilitate recycling , Improving the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

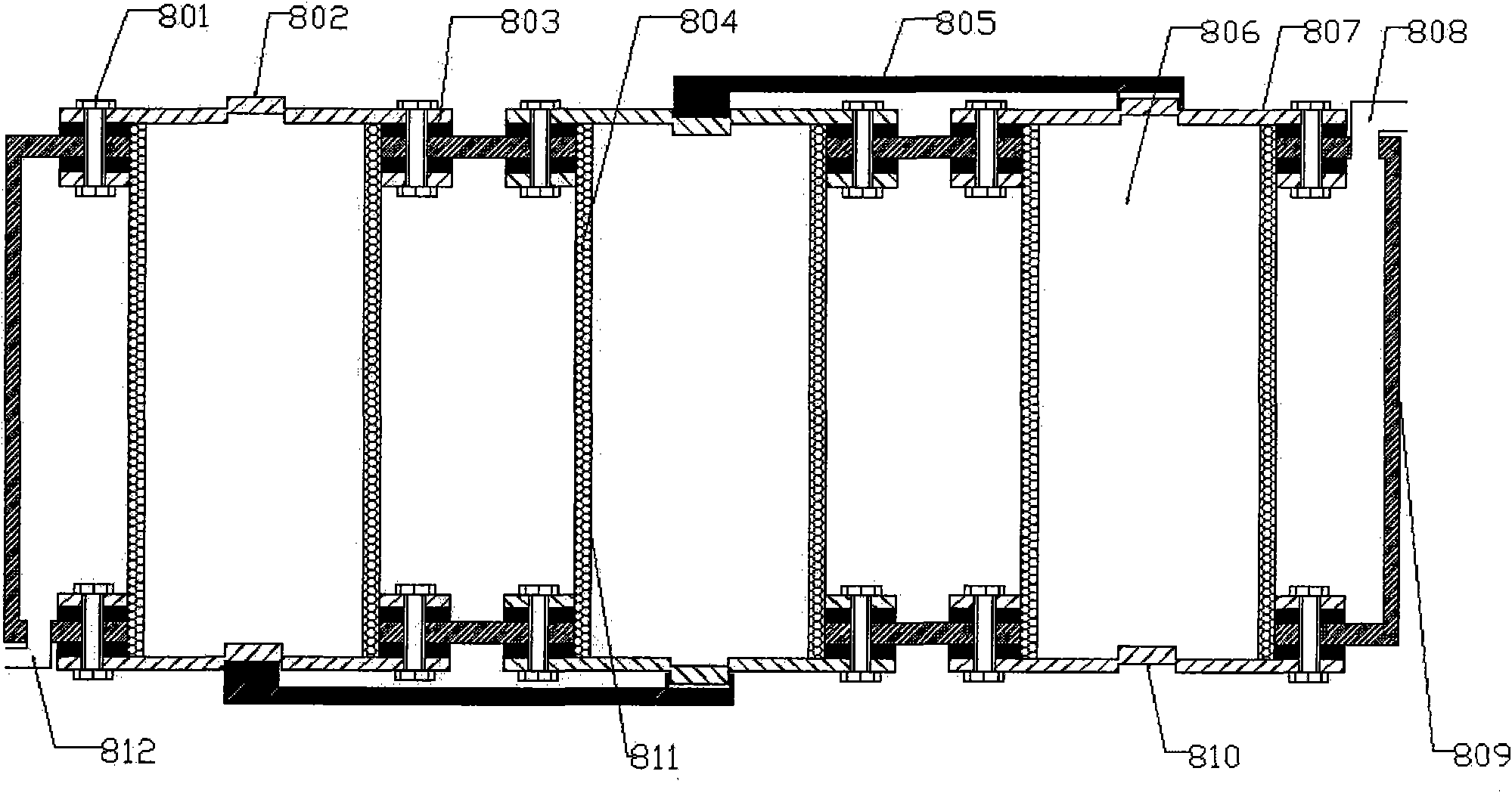

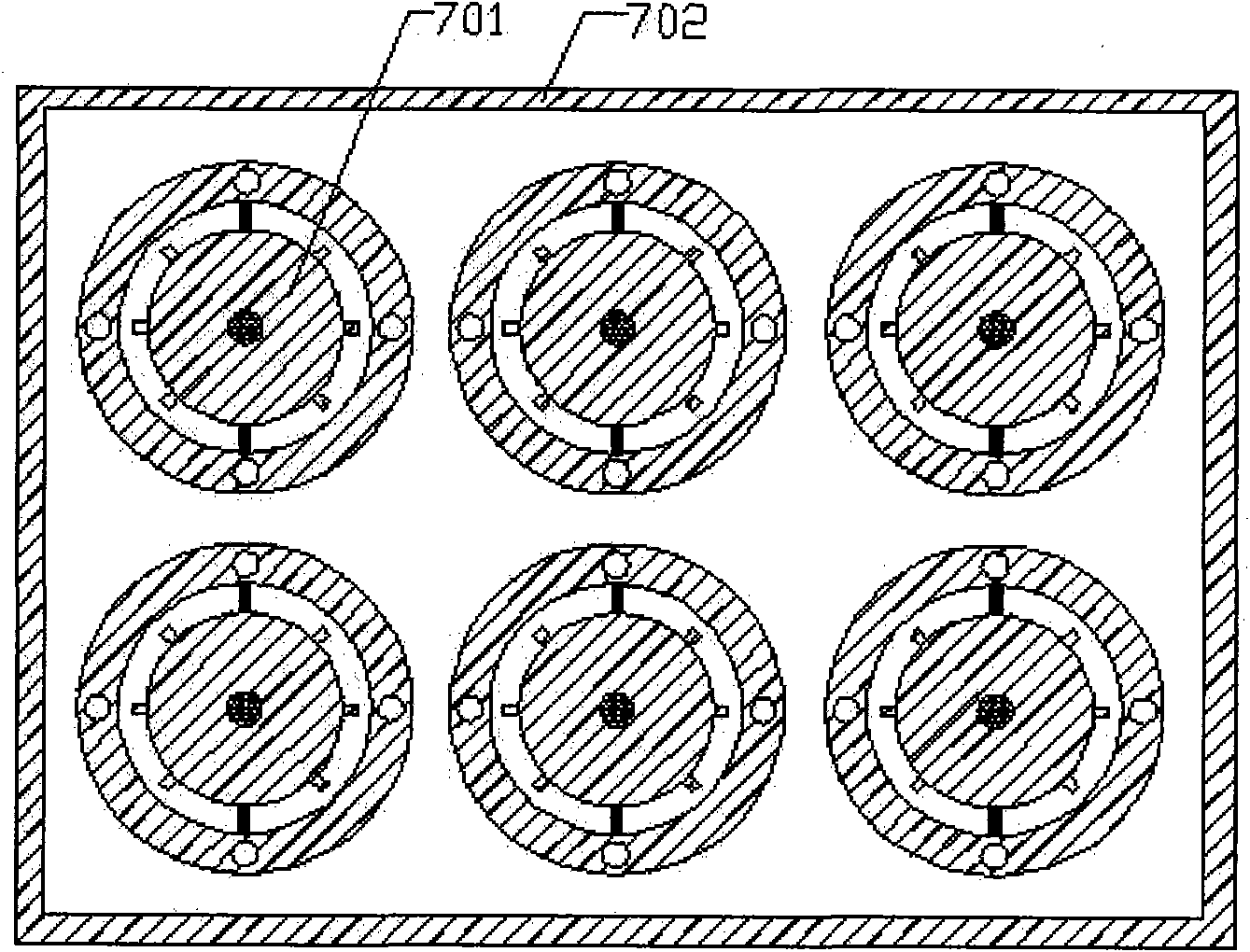

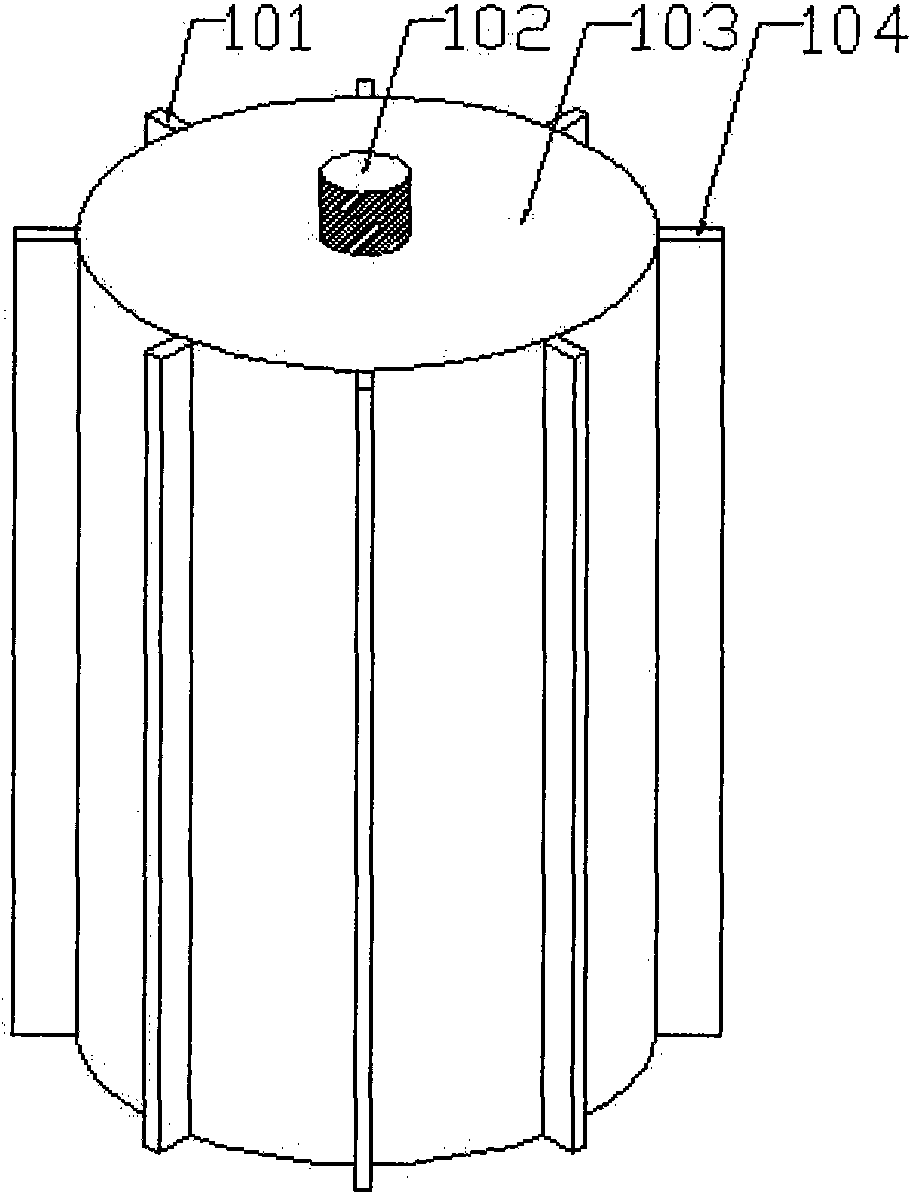

[0029] A recycling high-efficiency heat-dissipating electric vehicle battery device of the present invention, the battery device is installed in the battery module box 809 with a number of symmetrically arranged single battery modules 701 formed by inserting the single battery 806 into the battery housing 811 The phase change material 804 is filled between the single battery 806 and the battery case 811, and the gasket 803, the flange 807 and the single battery module 701 are respectively installed between the battery module box 809 and the connection parts of the flange 807 and the single battery module 701 Connect and fix the battery module box 809 with screws 801; there are cooling liquid inlets 812 and cooling liquid outlets 808 on both sides of the battery module box 809, and the liquid flowing through the cooling liquid inlet 812 to the cooling liquid outlet 808 in the battery module box 809 is at room temperature. water; the two ends of the electrode connection column 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com