Heat exchanger fin, heat exchanger, condensers, and evaporators

a heat exchanger and fin technology, applied in the direction of indirect heat exchangers, refrigeration components, light and heating apparatus, etc., can solve problems such as deterioration of heat transfer rate, and achieve the effect of preventing the generation of bypass flow and improving heat transfer ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0144] Hereinafter, Examples related to the present invention and Comparative Examples which deviate from the gist of the present invention will be explained.

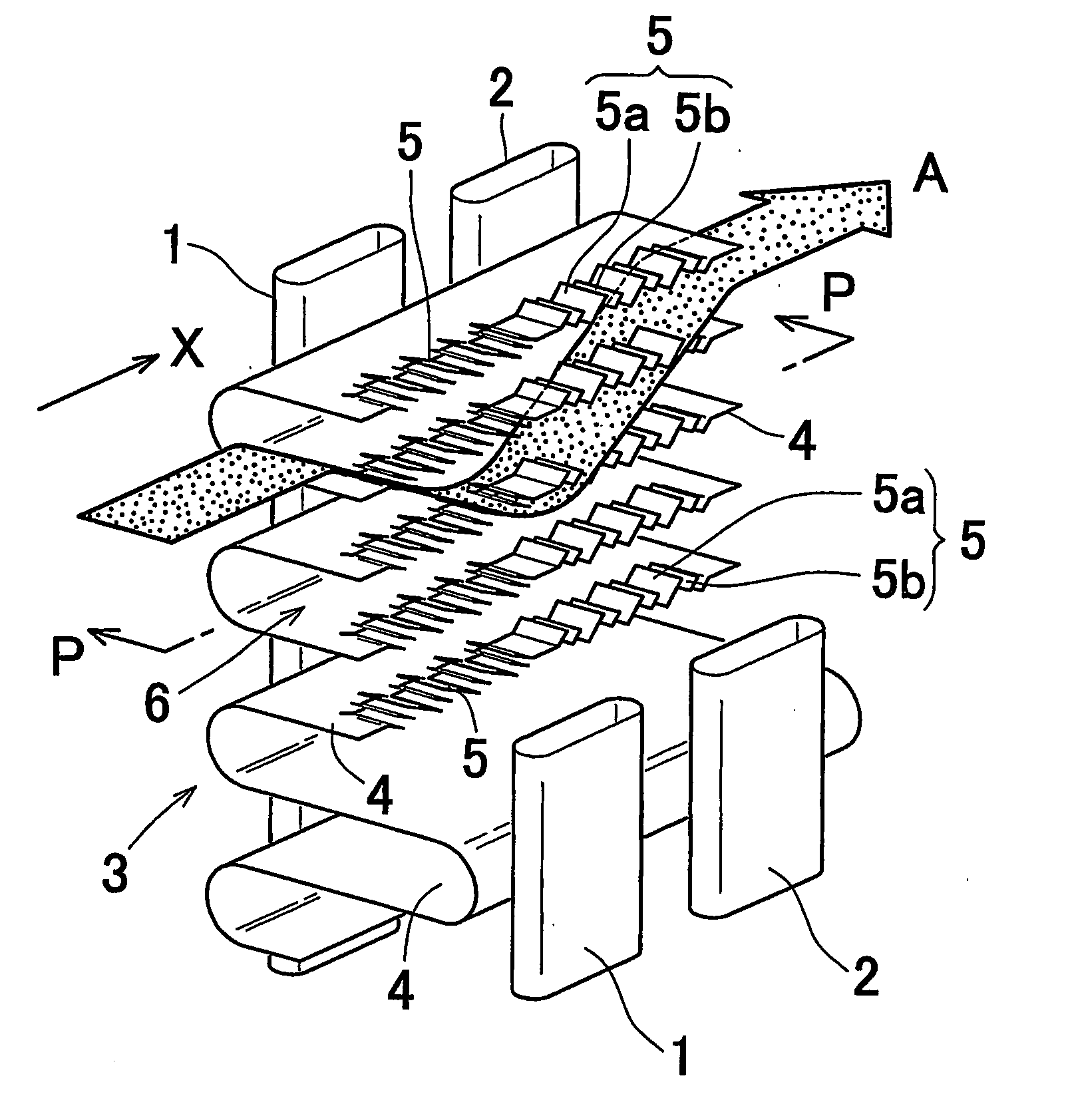

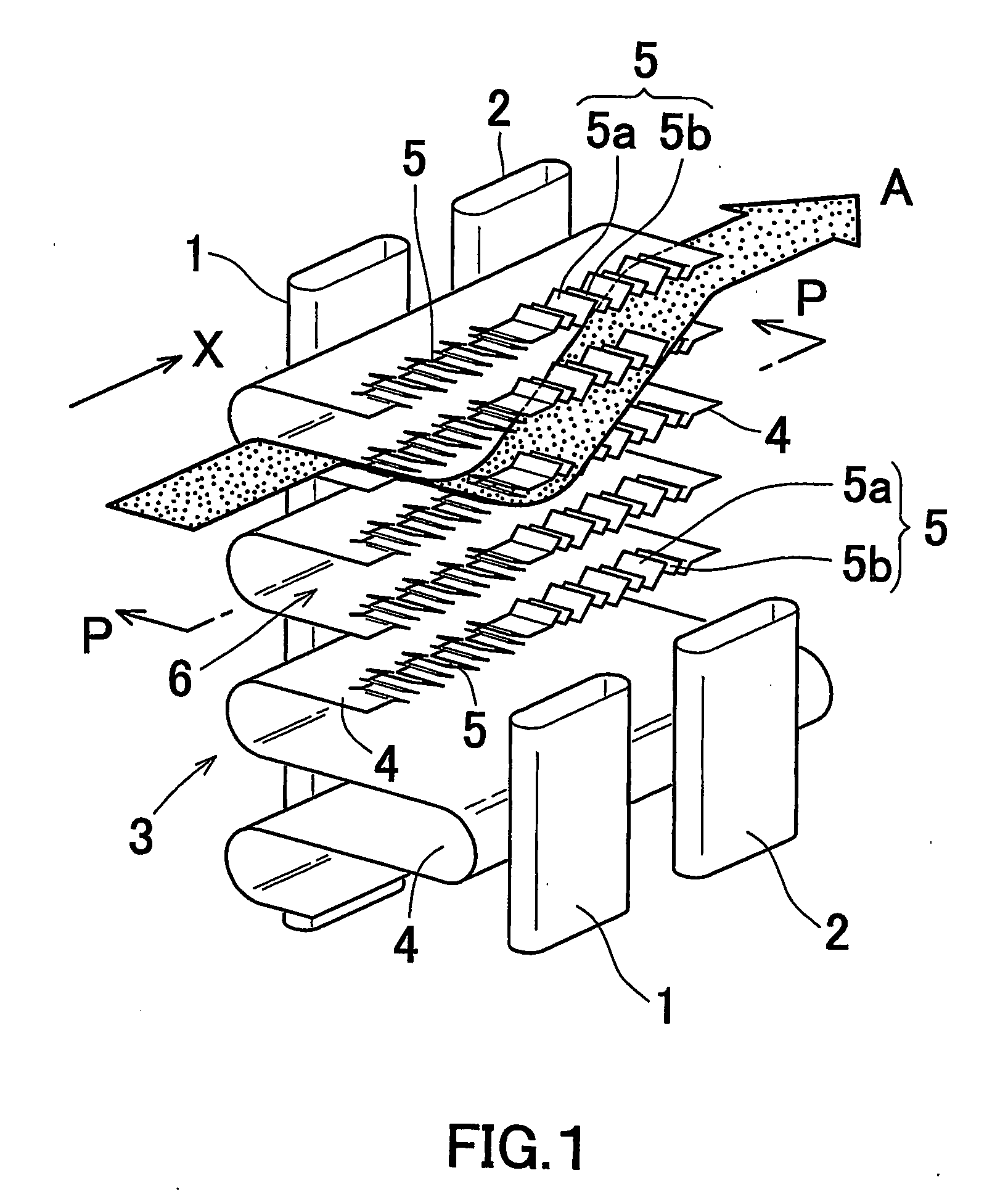

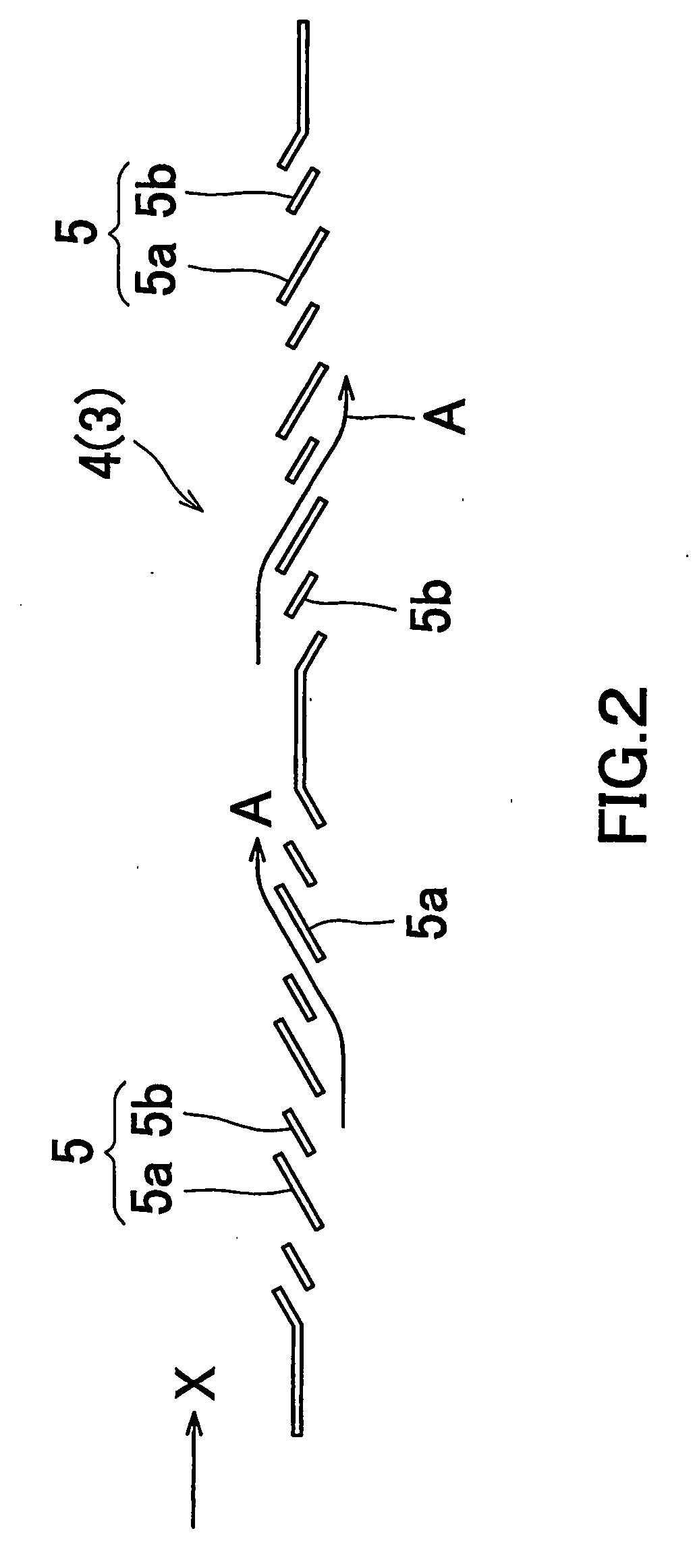

[0145] In accordance with the aforementioned embodiment, evaporators for car air-conditioners in which corrugated fins with different kinds of louvers were arranged between the adjacent flat heat exchanging tubes were examined.

examples 1 to 5

[0146]

TABLE 1Lwl (mm)Lws (mm)Lws / LwlFp (mm)La (°)Example 11.10.1670.1521.326Example 21.00.3330.3331.326Example 31.00.500.501.326Example 40.850.5830.6861.326Example 50.850.650.7651.326Comparative0.750.751.01.326Example 1

Lwl: width of wide louver (mm)

Lws: width of narrow louver (mm)

Lws / Lwl: louver width ratio

Fp: fin pitch (mm)

La: louver angle (°)

[0147] In Table 1, the evaporator of Example 1 was provided with corrugated fins having a plurality of louver fins each including wide louvers and narrow louvers arranged alternatively. The louver width Lwl of the wide louver was 1.1 mm, the louver width Lws of the narrow louver was 0.167 mm, the louver angle La was 26°, the fin pitch Fp was 1.3 mm and the louver width ratio Lws / Lwl was 0.152.

[0148] In the evaporator of Example 2, the louver width Lwl of the wide louver was set to 1.0 mm, and the louver width Lws of the narrow louver was set to 0.333 mm. The remaining dimensions were set to the same as those in Example 1. The louver widt...

examples 6 , 7

Examples 6, 7

[0157]

TABLE 2Lwl (mm)Lws (mm)Lws / LwlFp (mm)La (°)Example 61.00.3330.3331.328Example 71.00.500.501.328Comparative0.750.751.01.328Example 2

Lwl: width of wide louver (mm)

Lws: width of narrow louver (mm)

Lws / Lwl: louver width ratio

Fp: fin pitch (mm)

La: louver angle (°)

[0158] As shown in Table 2, the evaporator of Example 6 was prepared in the same manner as the aforementioned Example 2 except that the louver angle La was set to 28°.

[0159] The evaporator of Example 7 was prepared in the same manner as the aforementioned Example 3 except that the louver angle La was set to 28°.

[0160] The evaporator of Comparative Example 2 was prepared in the same manner as the aforementioned Comparative Example 1 except that the louver angle La was set to 28°.

[0161] Regarding the aforementioned evaporators, each heat transfer rate with respect to the front wind velocity was measured by computer simulation. The results are shown in the graph of FIG. 6.

[0162] As will be apparent from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com