Patents

Literature

165results about How to "Avoid conducting electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical devices and anti-scarring agents

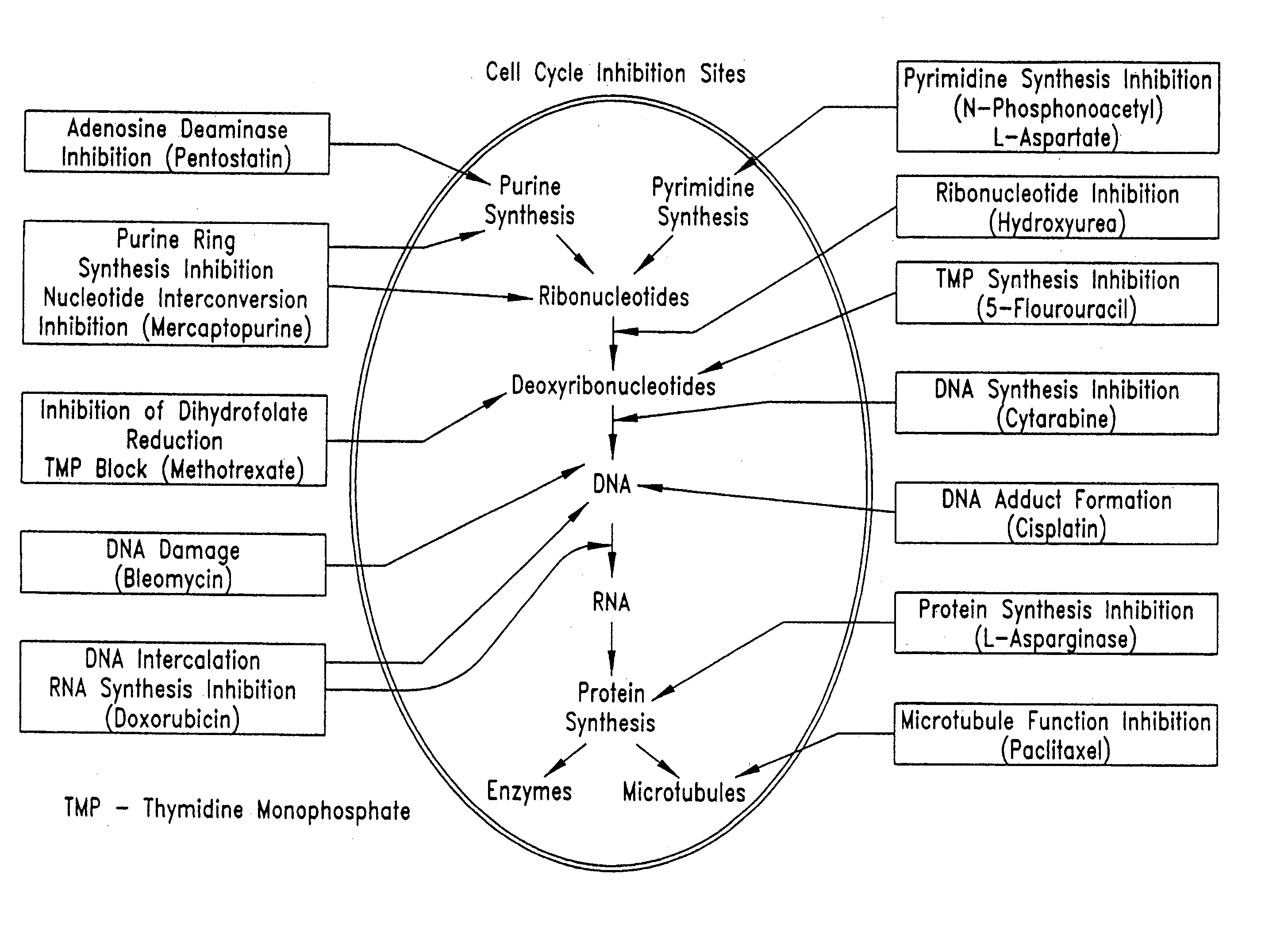

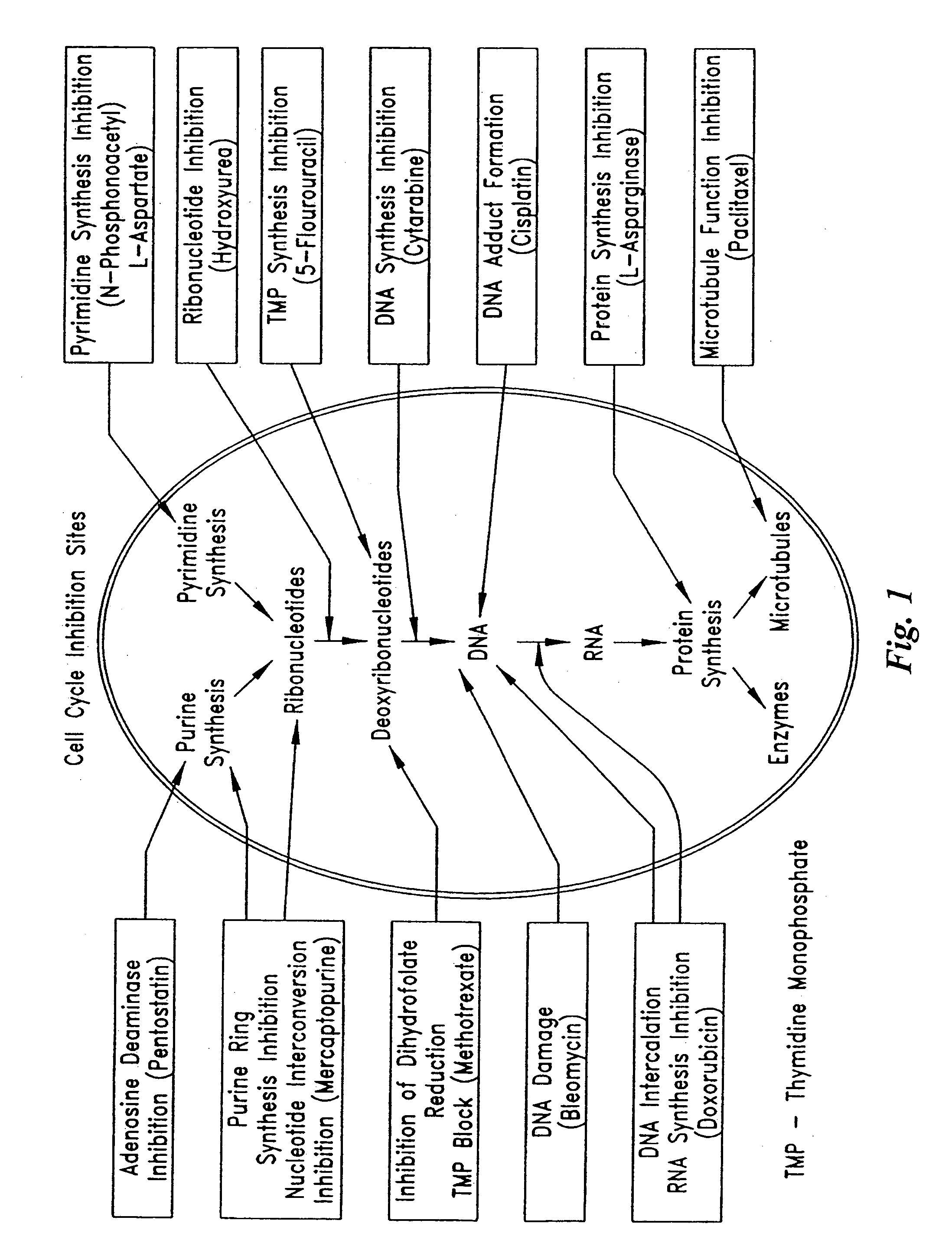

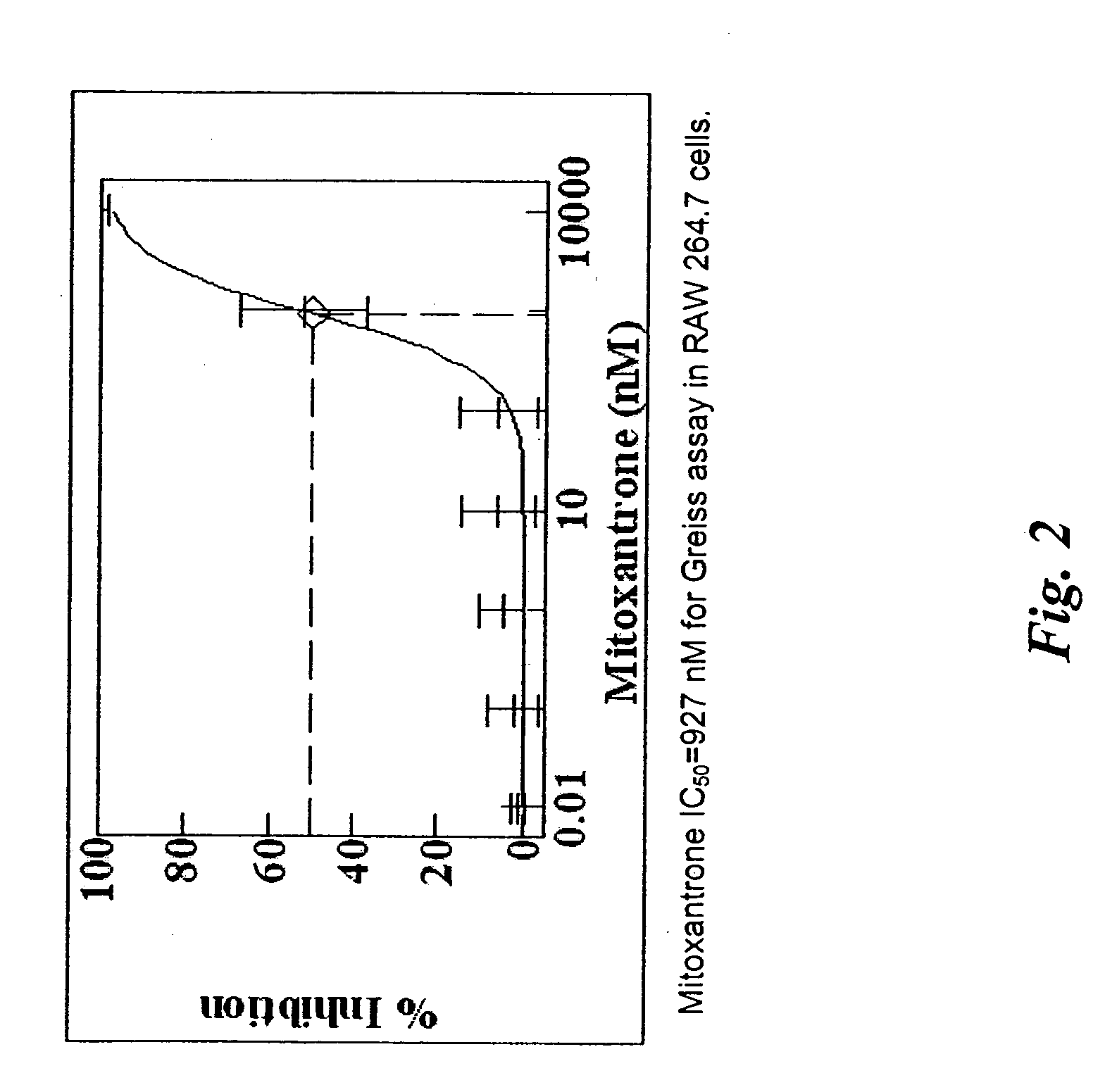

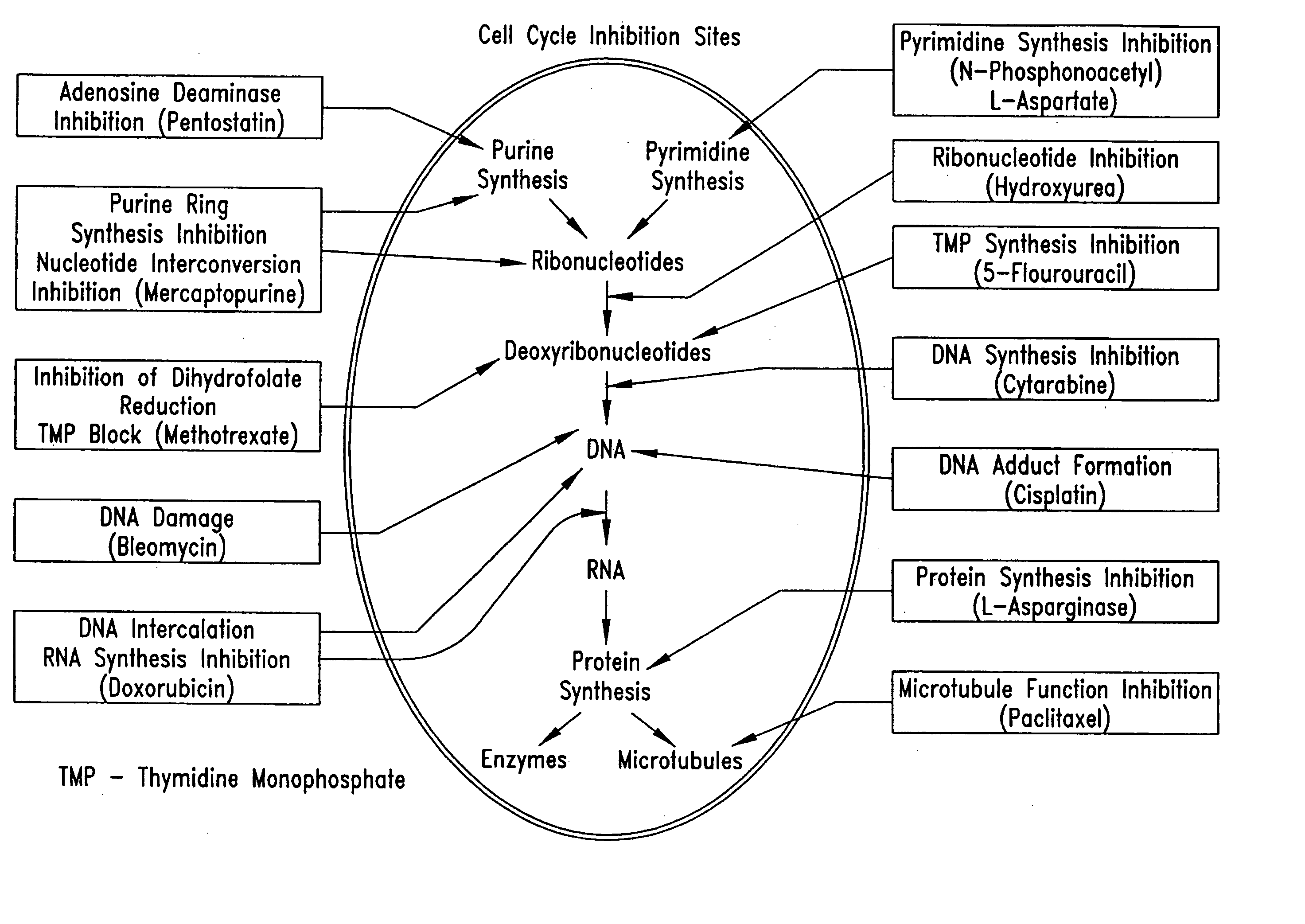

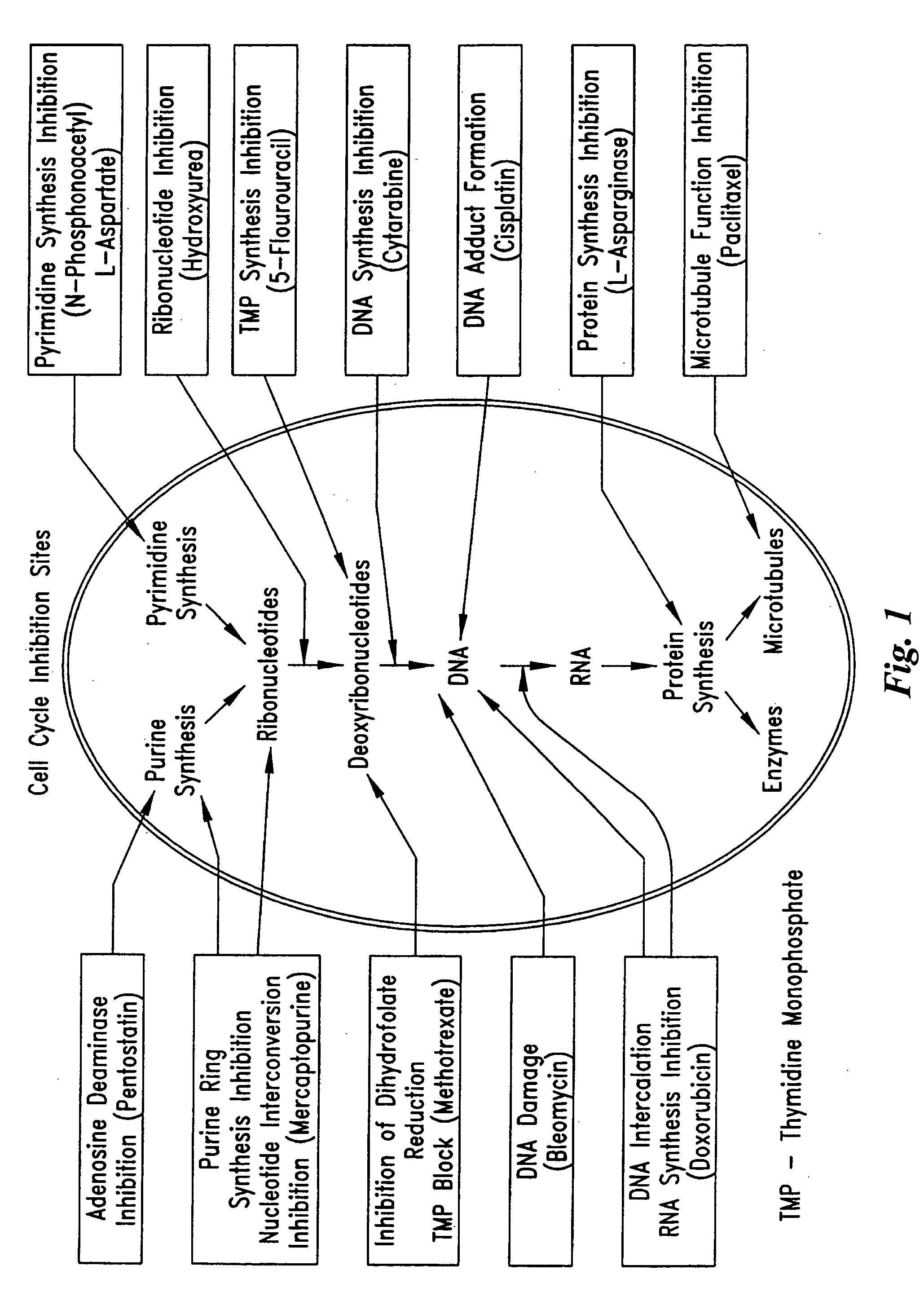

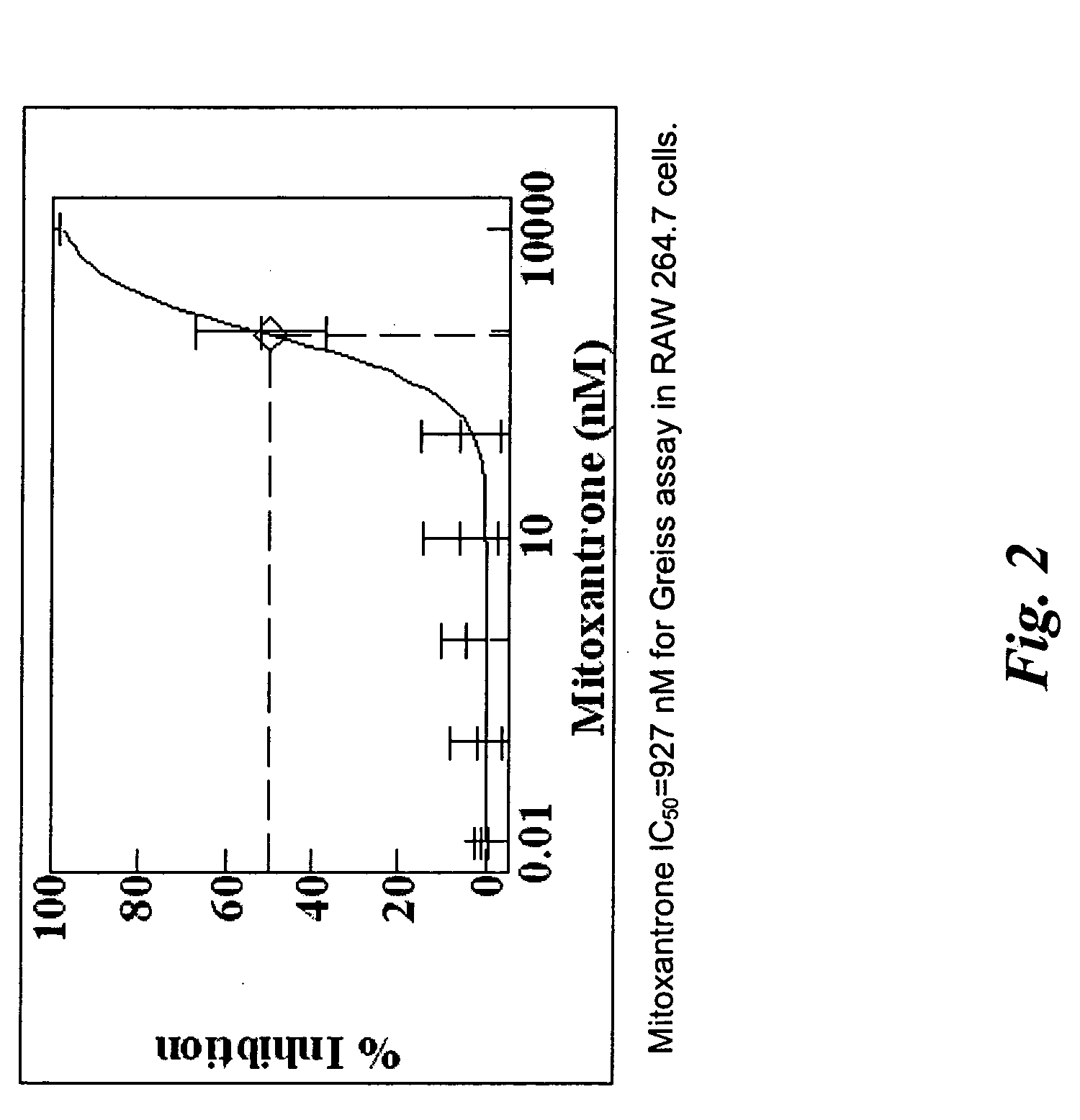

InactiveUS20050209664A1Prevent scar tissue overgrowthImprove conductivitySurgeryImplantable neurostimulatorsCell Cycle InhibitionElectrical devices

Electrical devices (e.g., cardiac rhythm management and neurostimulation devices) for contact with tissue are used in combination with an anti-scarring agent (e.g., a cell cycle inhibitor) in order to inhibit scarring that may otherwise occur when the devices are implanted within an animal.

Owner:ANGIOTECH INT AG (CH)

Electrical devices and anti-scarring agents

InactiveUS20050149157A1Reduce fibrosisReduce gliosisPeptide/protein ingredientsAntipyreticCell Cycle InhibitionElectrical devices

Owner:ANGIOTECH INT AG (CH)

Coating for one or more display areas on a glass or glass-ceramic plate, process for producing said coating, and uses thereof

ActiveUS20100219176A1High surface resistancePrevent electrical conductivityDoors for stoves/rangesDomestic stoves or rangesSol-gelMedicine

The transparent coating for one or more display areas of a glass or glass-ceramic plate is made by a process using a sol-gel paint containing alkyl silicates as binding agents. The transparent coating is provided on areas of the glass or glass-ceramic plate that have been left uncoated by a color-imparting opaque coating and is formed by applying the sol-gel paint to the areas left open and then thermally treating the sol-gel paint so as to cross-link reactive groups of the alkyl silicates. The coating has organic, non-hydrolyzable groups bound directly to silicon. A process for making the coating and the uses of the coated glass or glass-ceramic plate are part of the invention.

Owner:SCHOTT AG

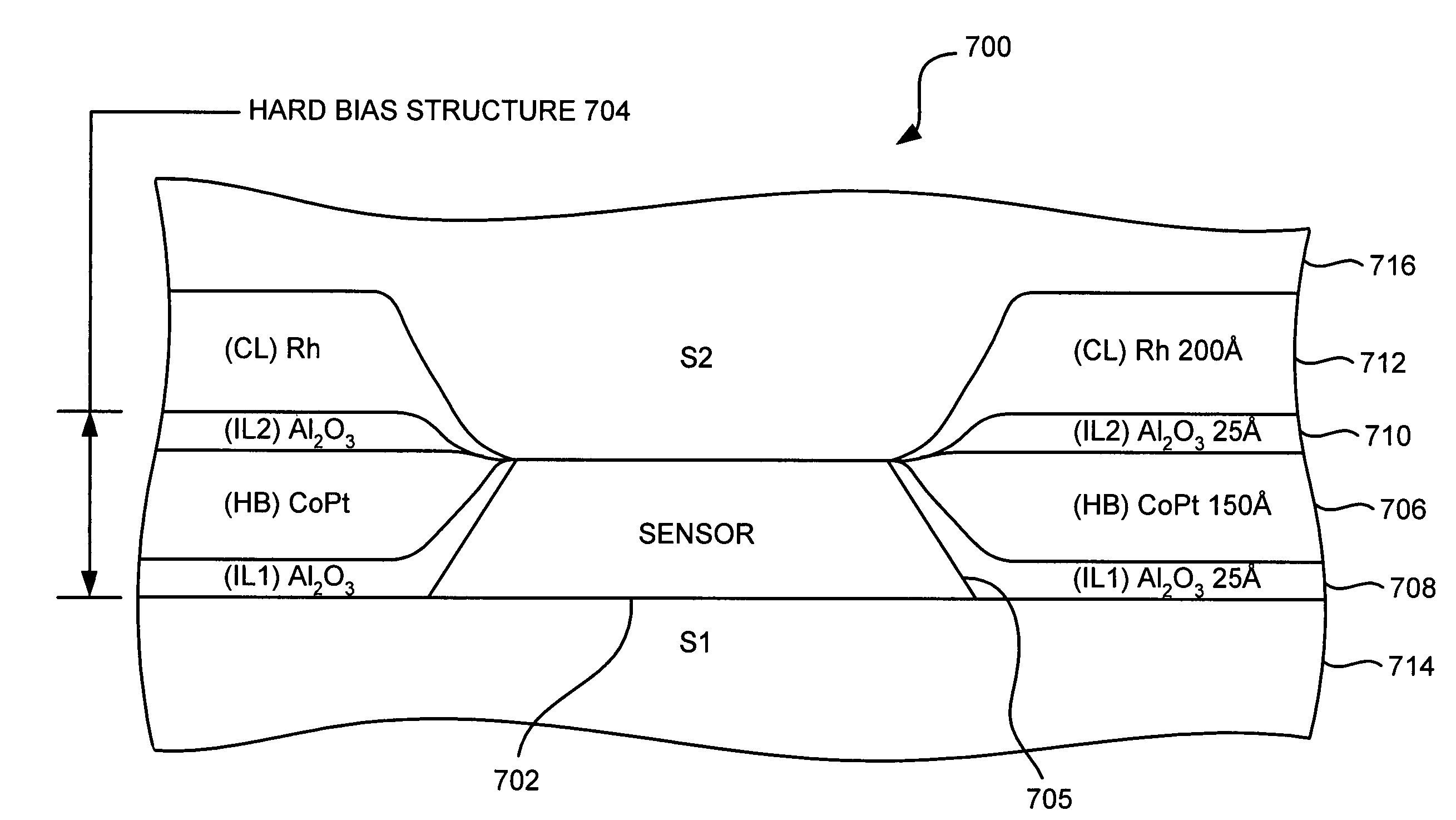

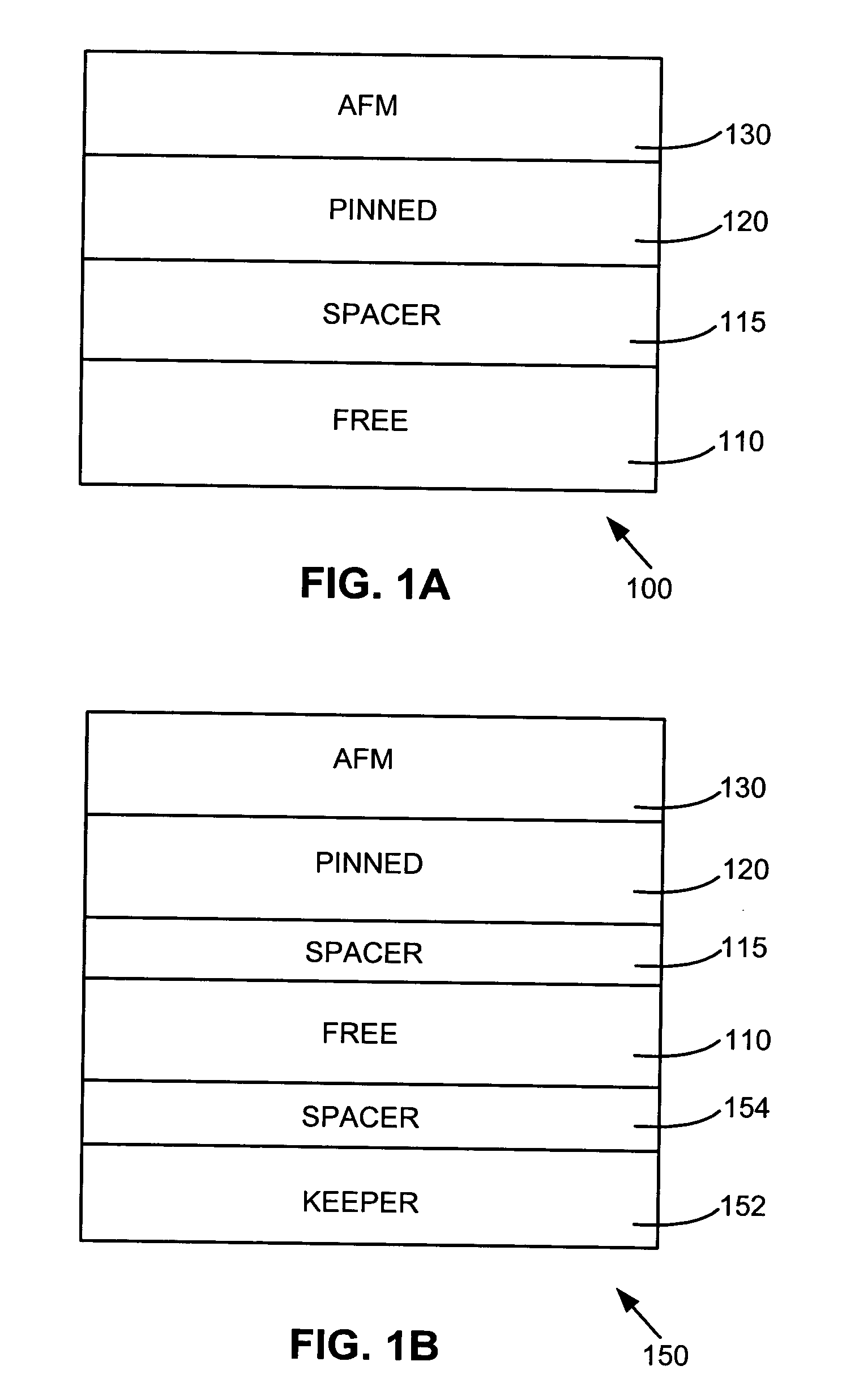

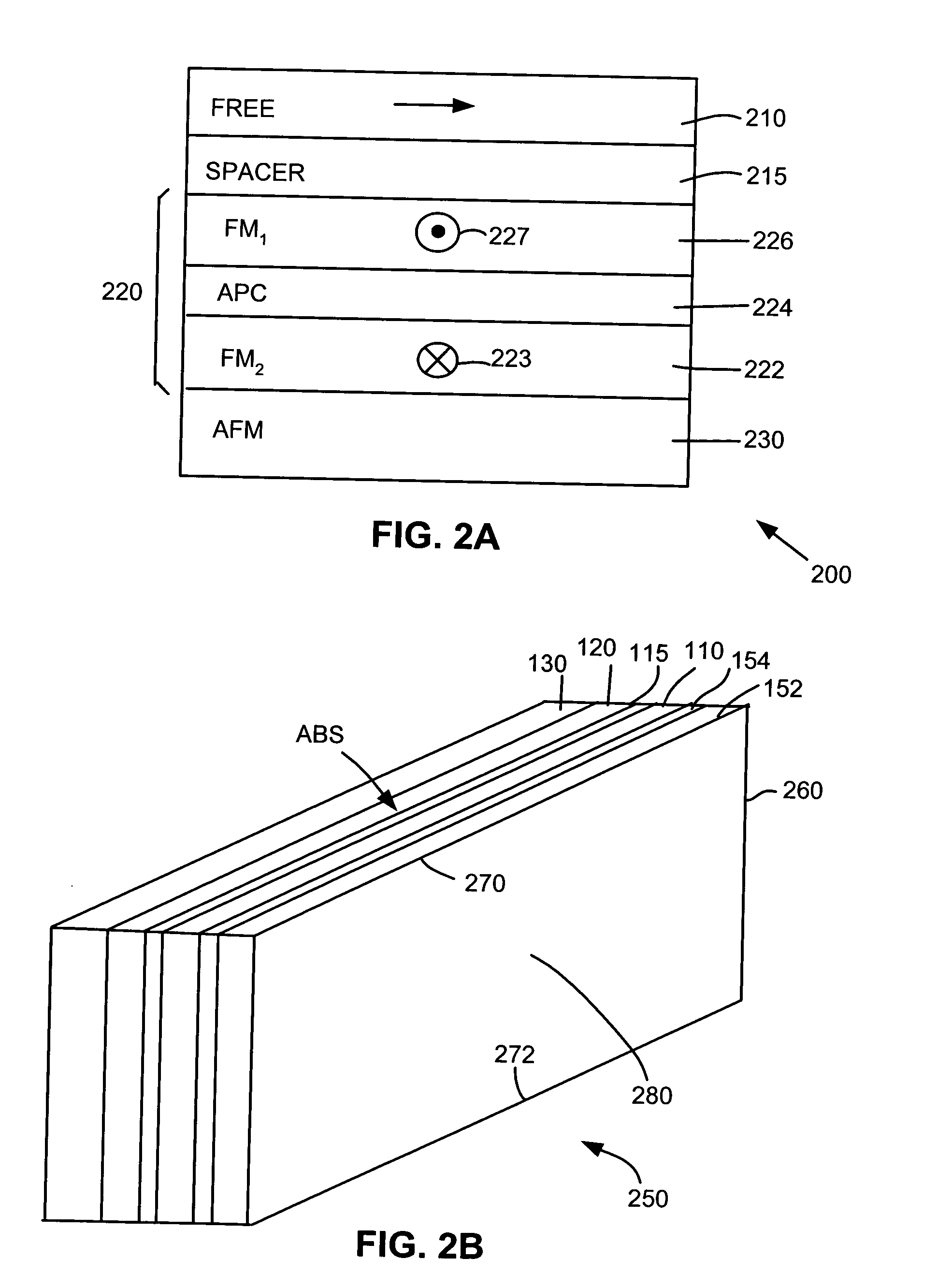

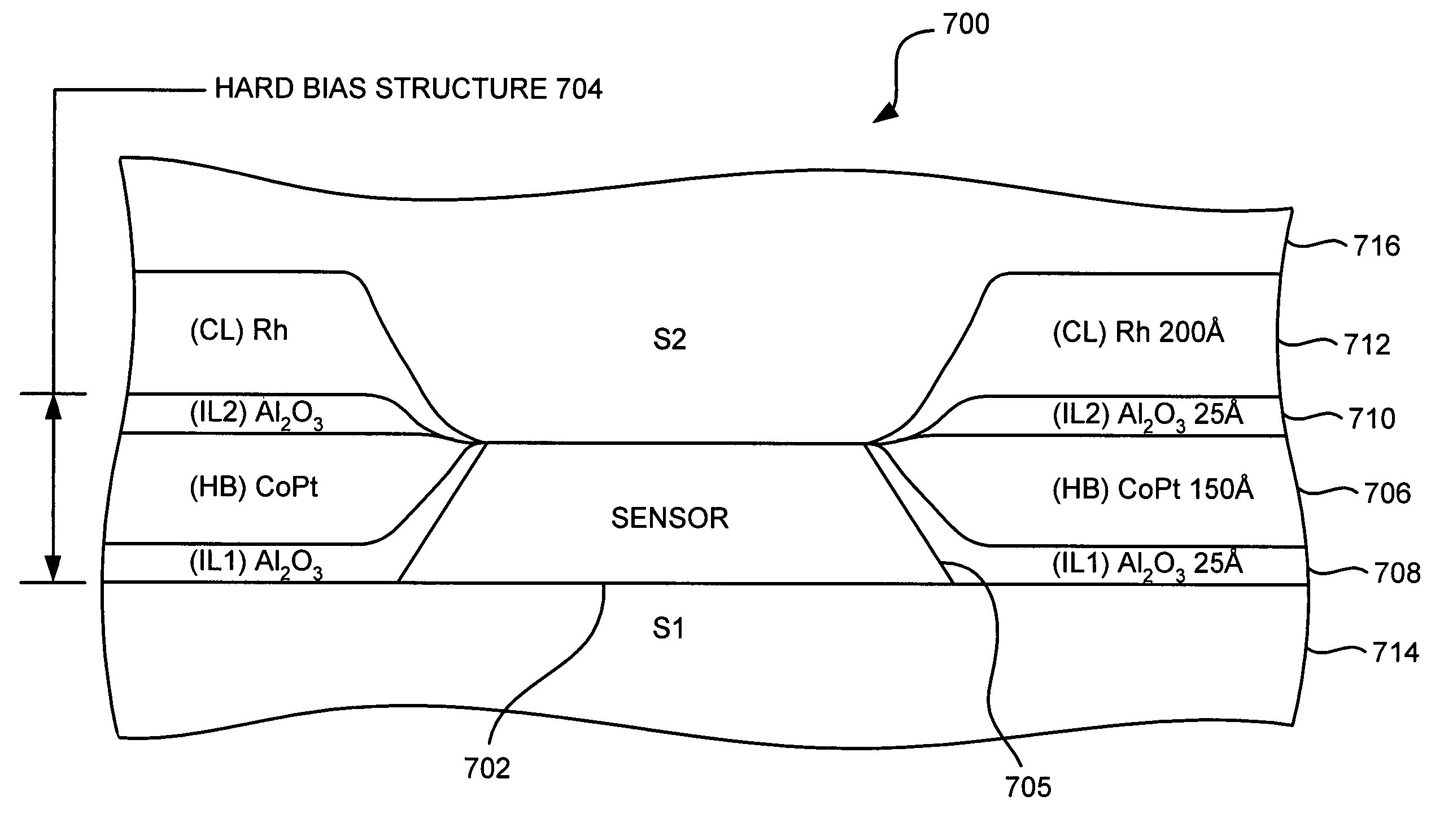

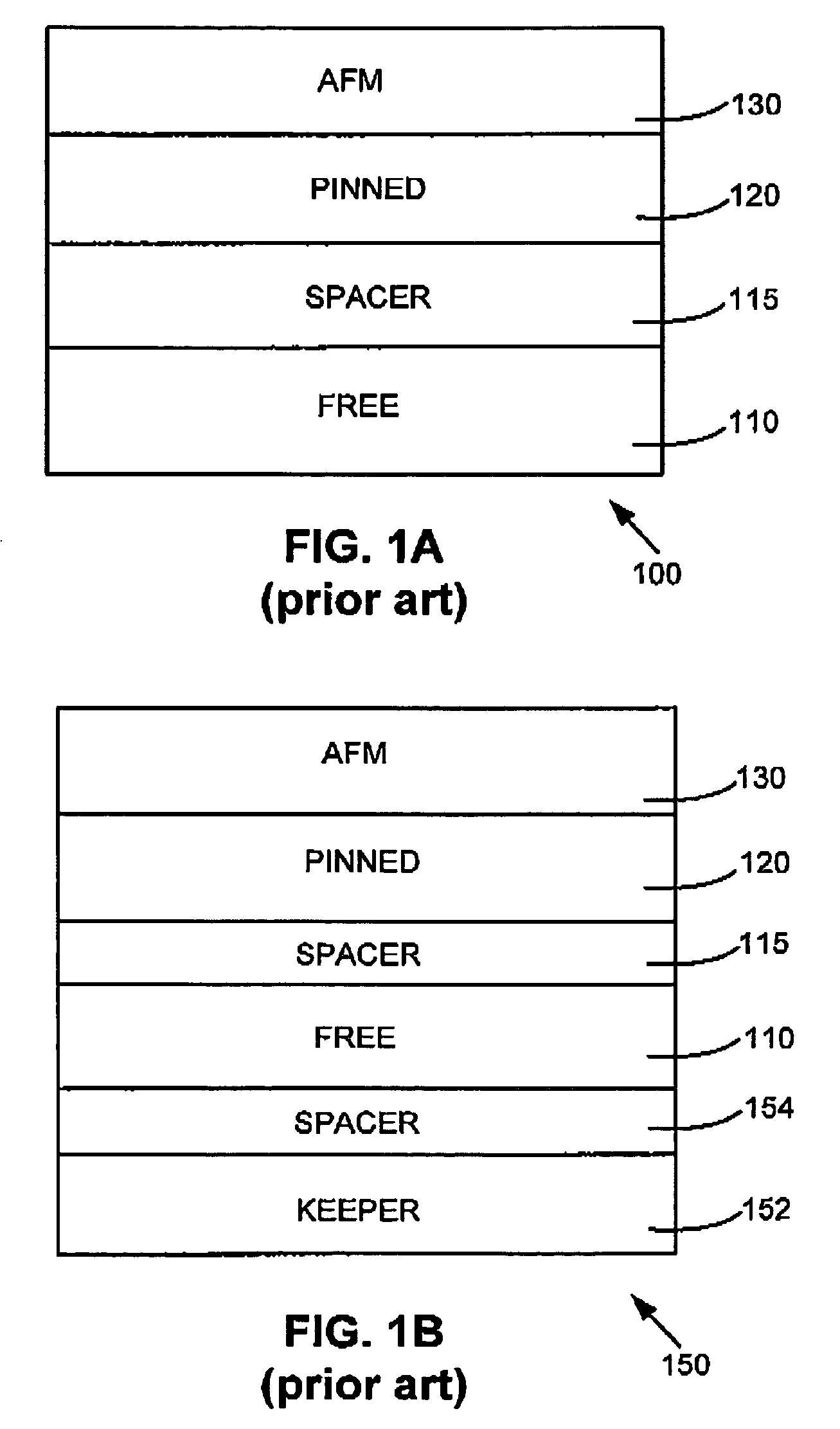

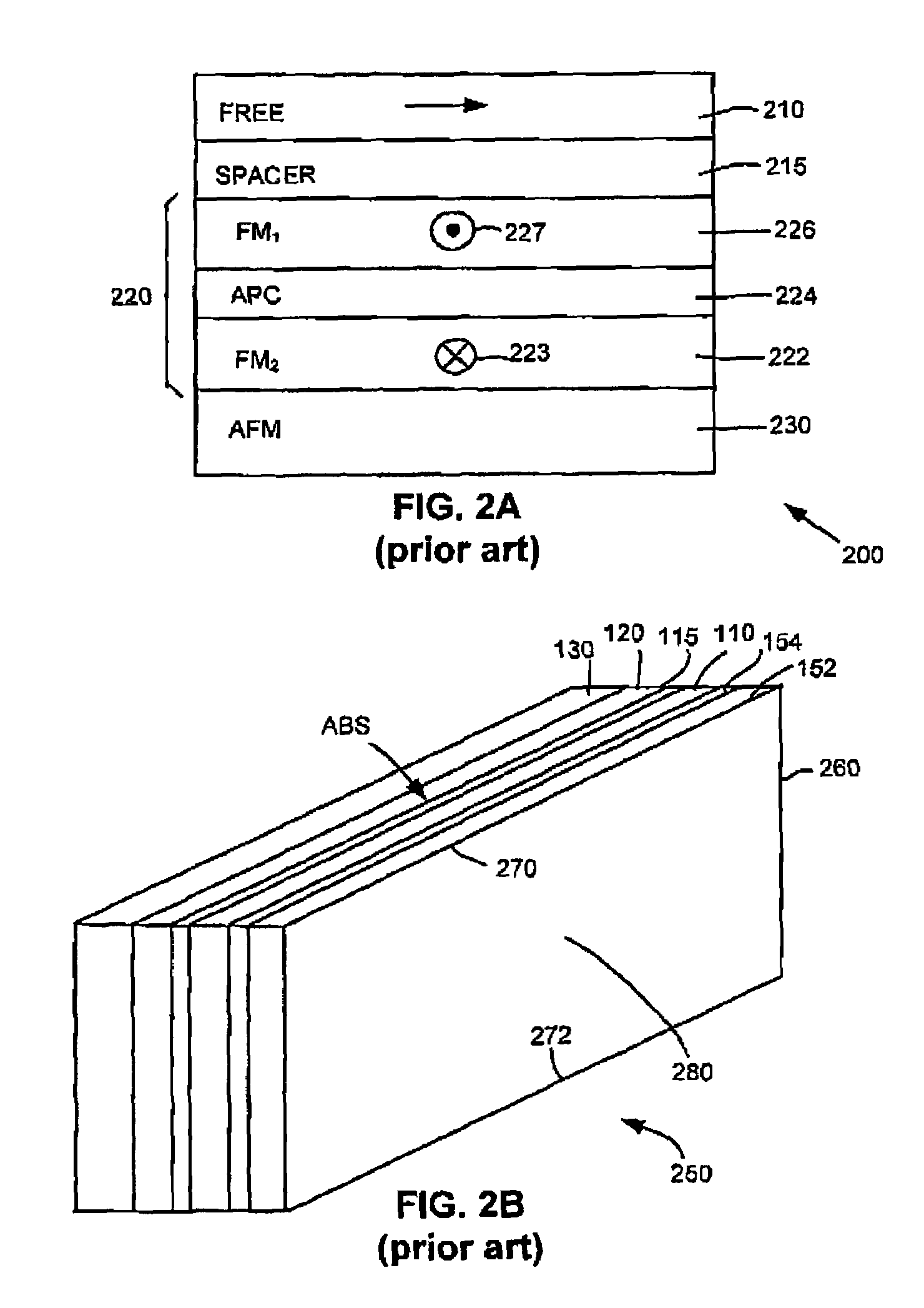

Structure providing enhanced self-pinning for CPP GMR and tunnel valve heads

InactiveUS20050018365A1Easy to fixAvoid conducting electricityRecord information storageManufacture of flux-sensitive headsCouplingVALVE PORT

A magnetic head having improved self-pinning. The head includes a sensor having an antiparallel (AP) pinned layer structure, where the AP pinned layer structure includes at least two pinned layers having magnetic moments that are self-pinned antiparallel to each other, the pinned layers being separated by an AP coupling layer. A pair of compression layers are positioned towards opposite track edges of the sensor. The compression layers provide compressive stress to the sensor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Structure providing enhanced self-pinning for CPP GMR and tunnel valve heads

InactiveUS7330339B2Easy to fixAvoid conducting electricityGalvano-magnetic devicesSolid-state devicesCouplingMagnetic moment

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

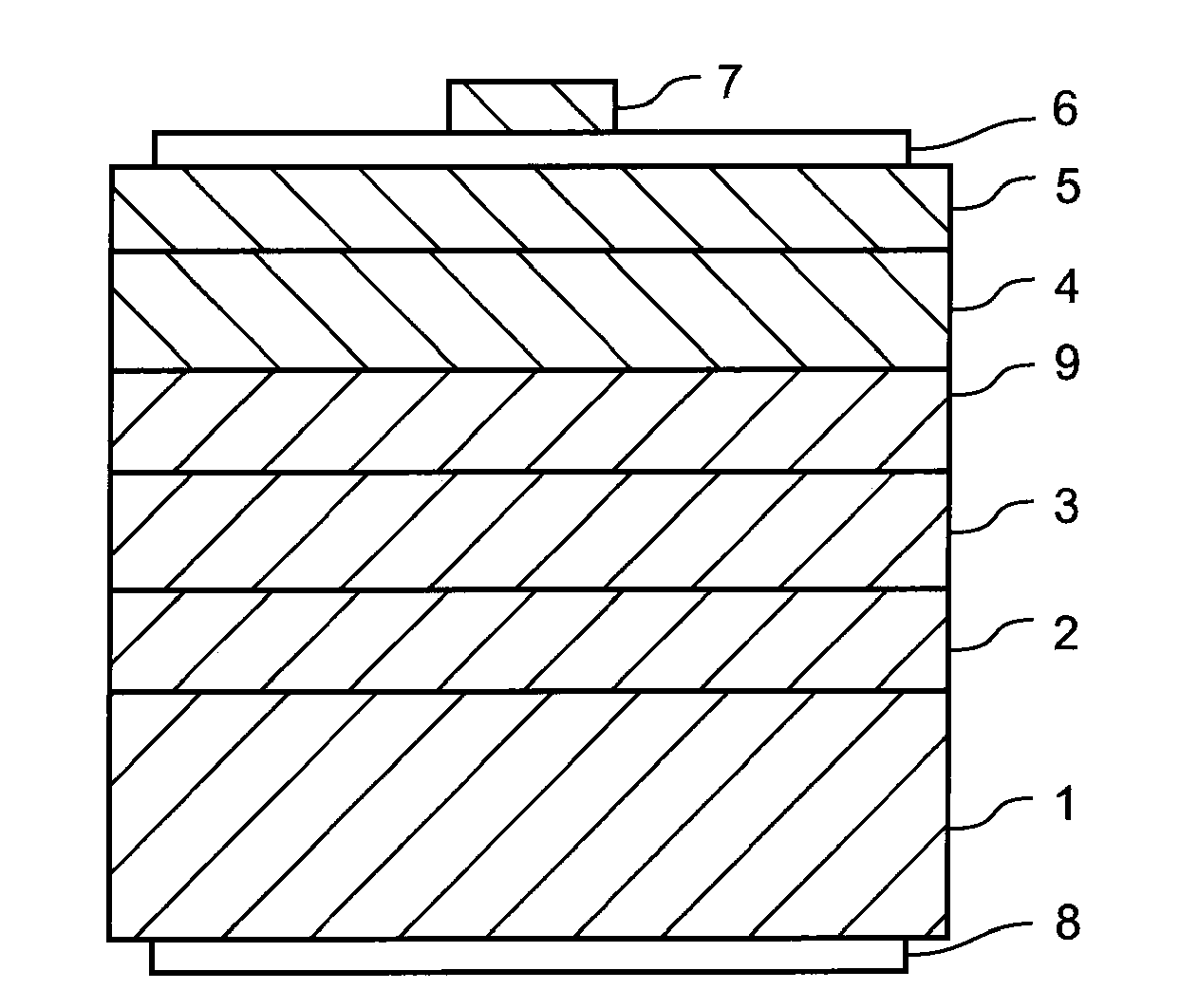

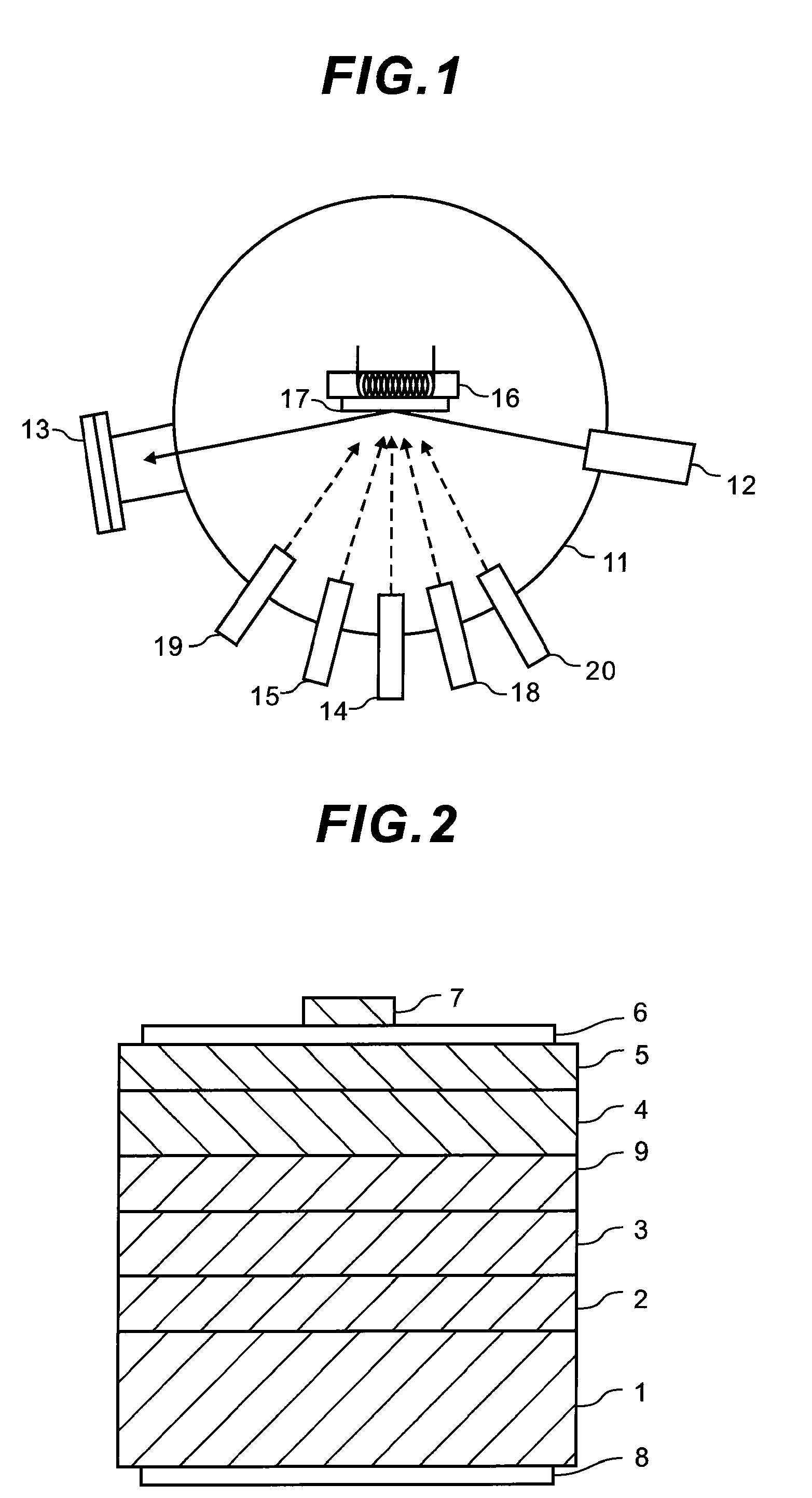

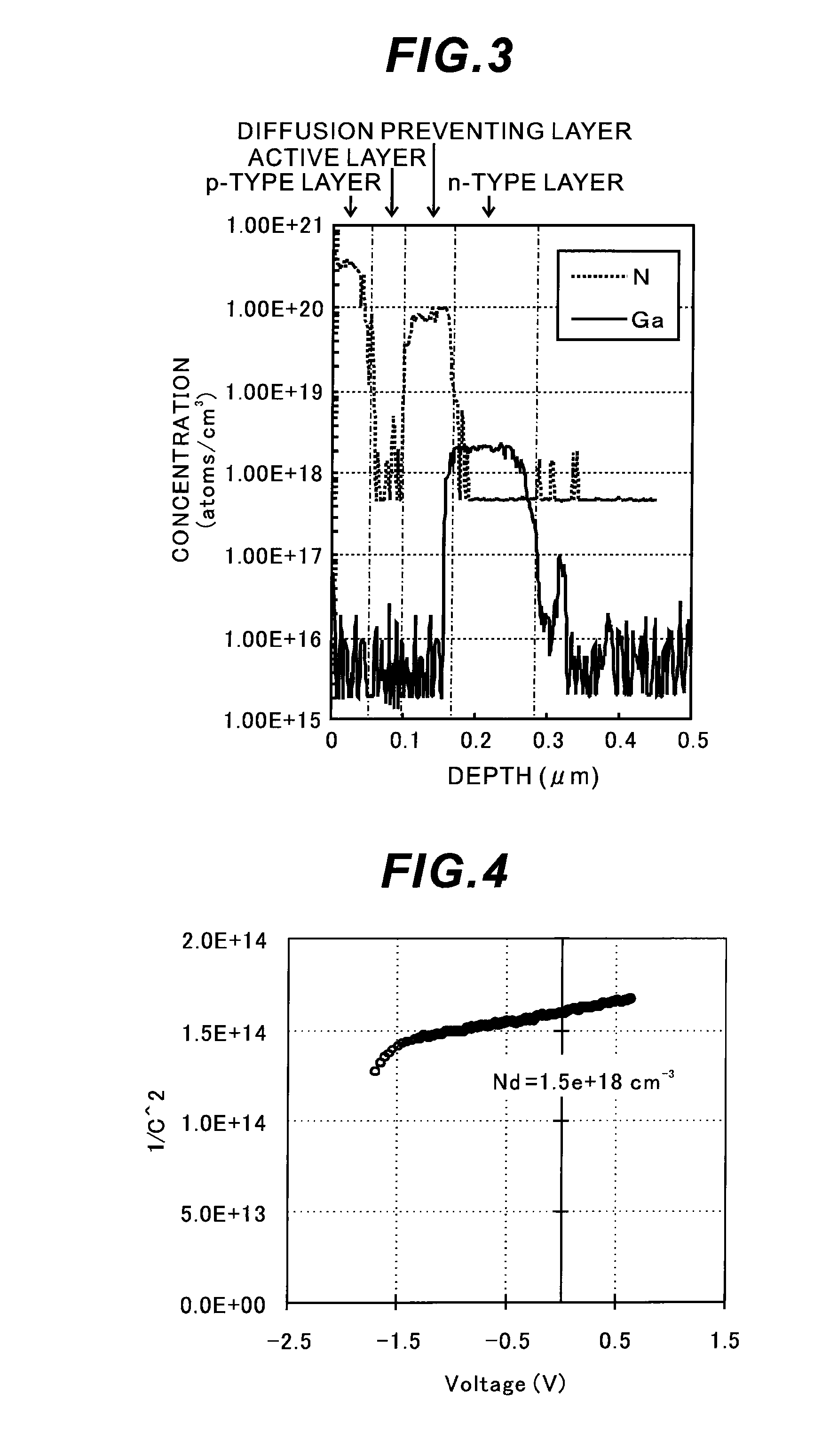

Zinc oxide based compound semiconductor device

InactiveUS20110089418A1Quality improvementAvoid conducting electricitySemiconductor/solid-state device manufacturingSemiconductor devicesDopantNitrogen

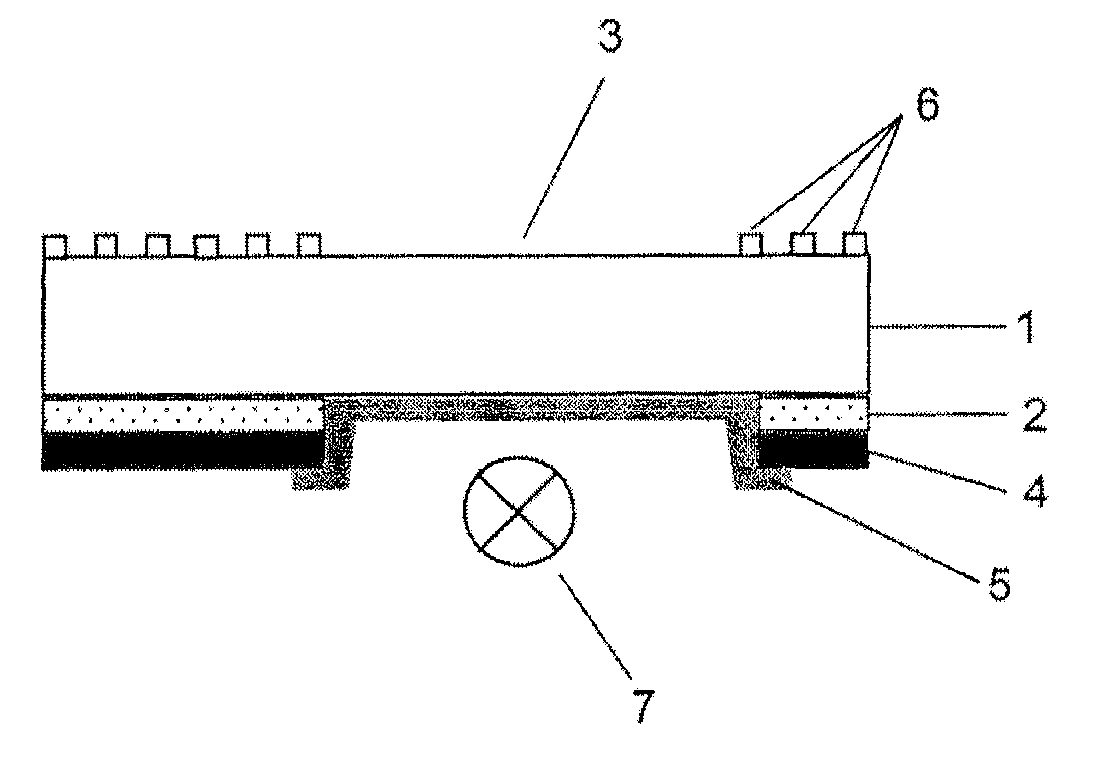

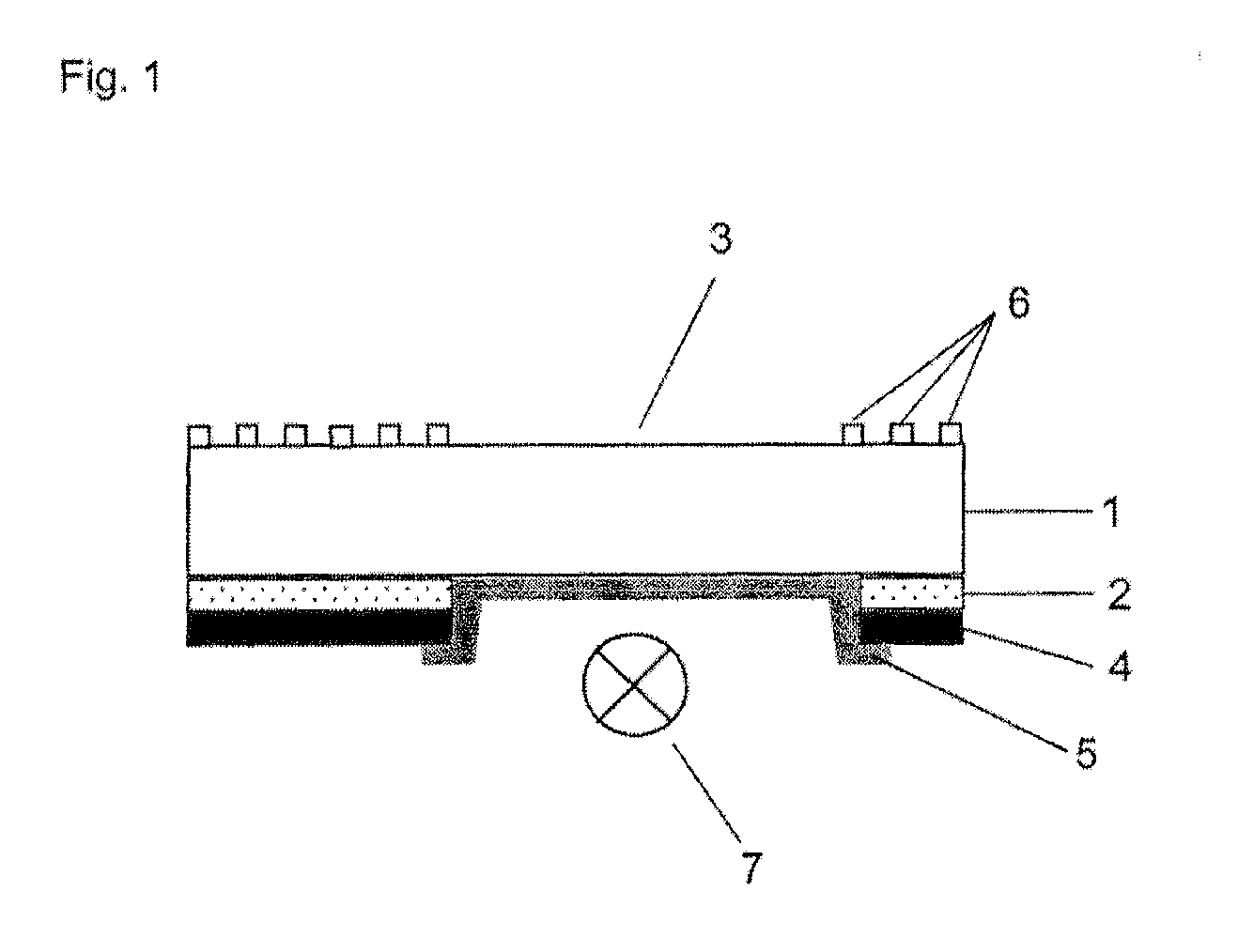

In a ZnO based compound semiconductor device, nitrogen (N) doped (Mg)ZnO:N layer is inserted as a diffusion barrier layer 9 between a ZnO based n-type layer 3 to which n-type dopants are doped and an active layer 4 or a p-type layer 5. The diffusion barrier layer 9 prevents diffusion of the n-type dopants to the active layer 4 or the p-type layer 5. Crystalline quality of the active layer 4 of the ZnO based compound semiconductor device is not deteriorated by the diffusion of the n-type dopants.

Owner:STANLEY ELECTRIC CO LTD

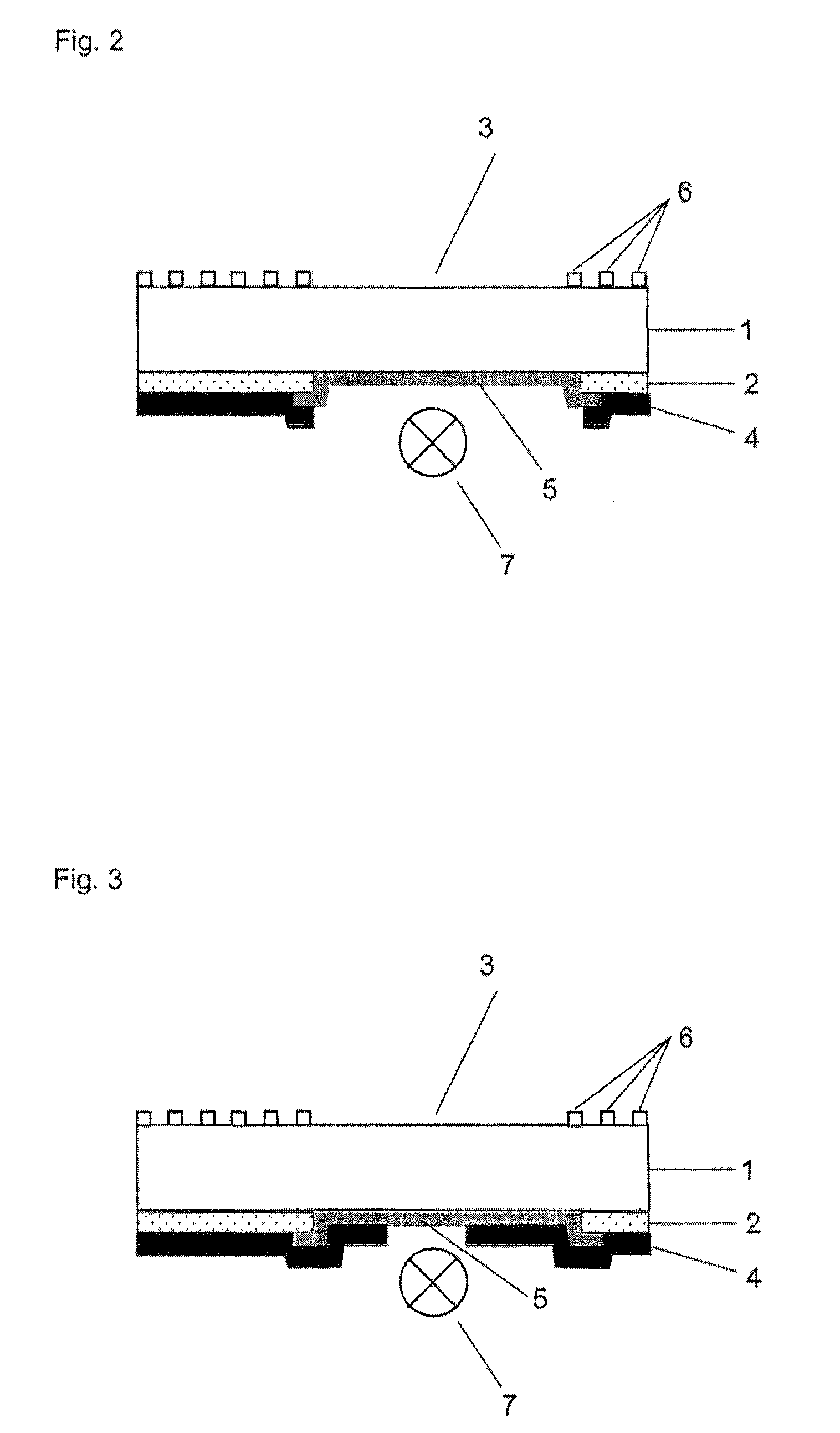

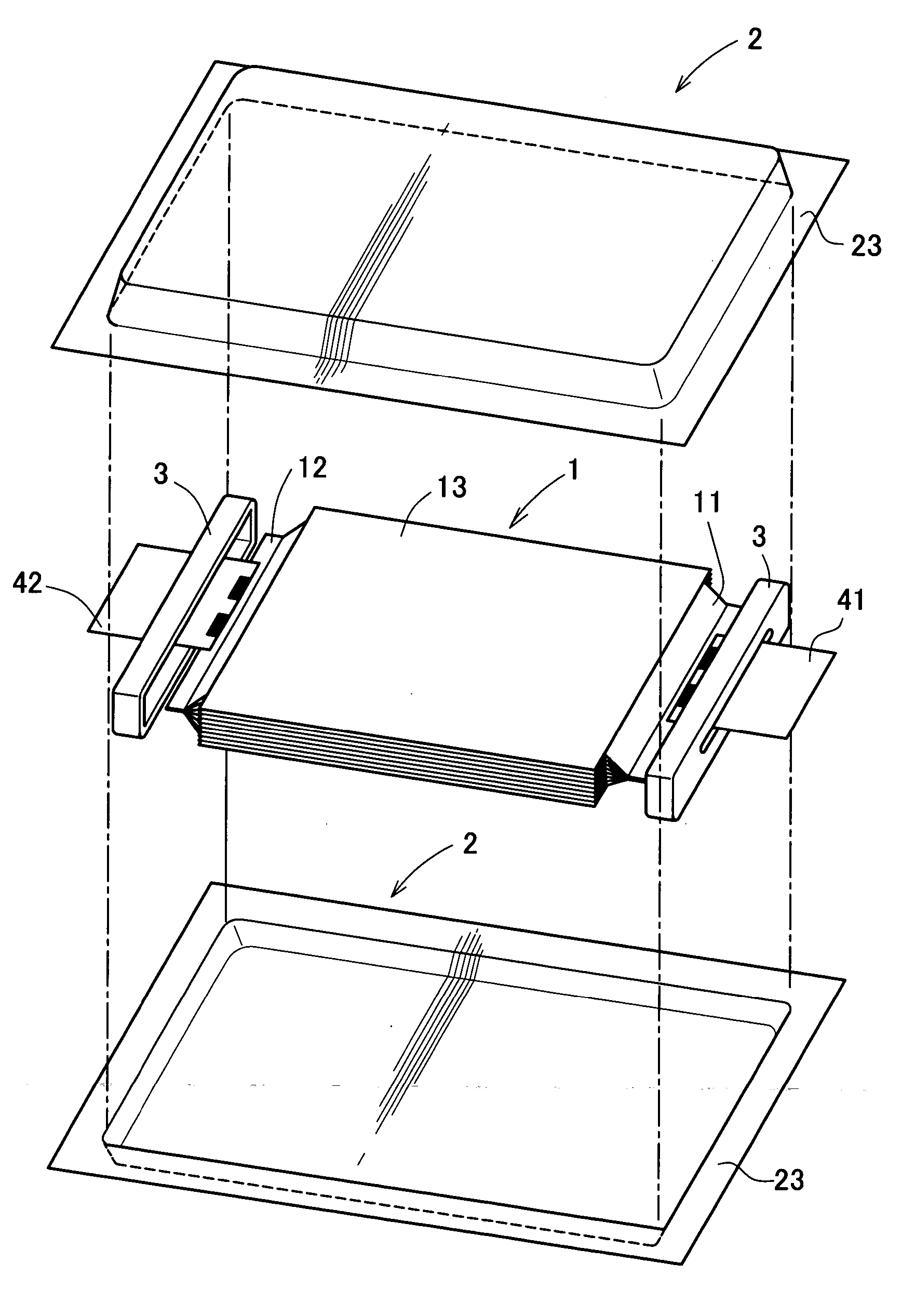

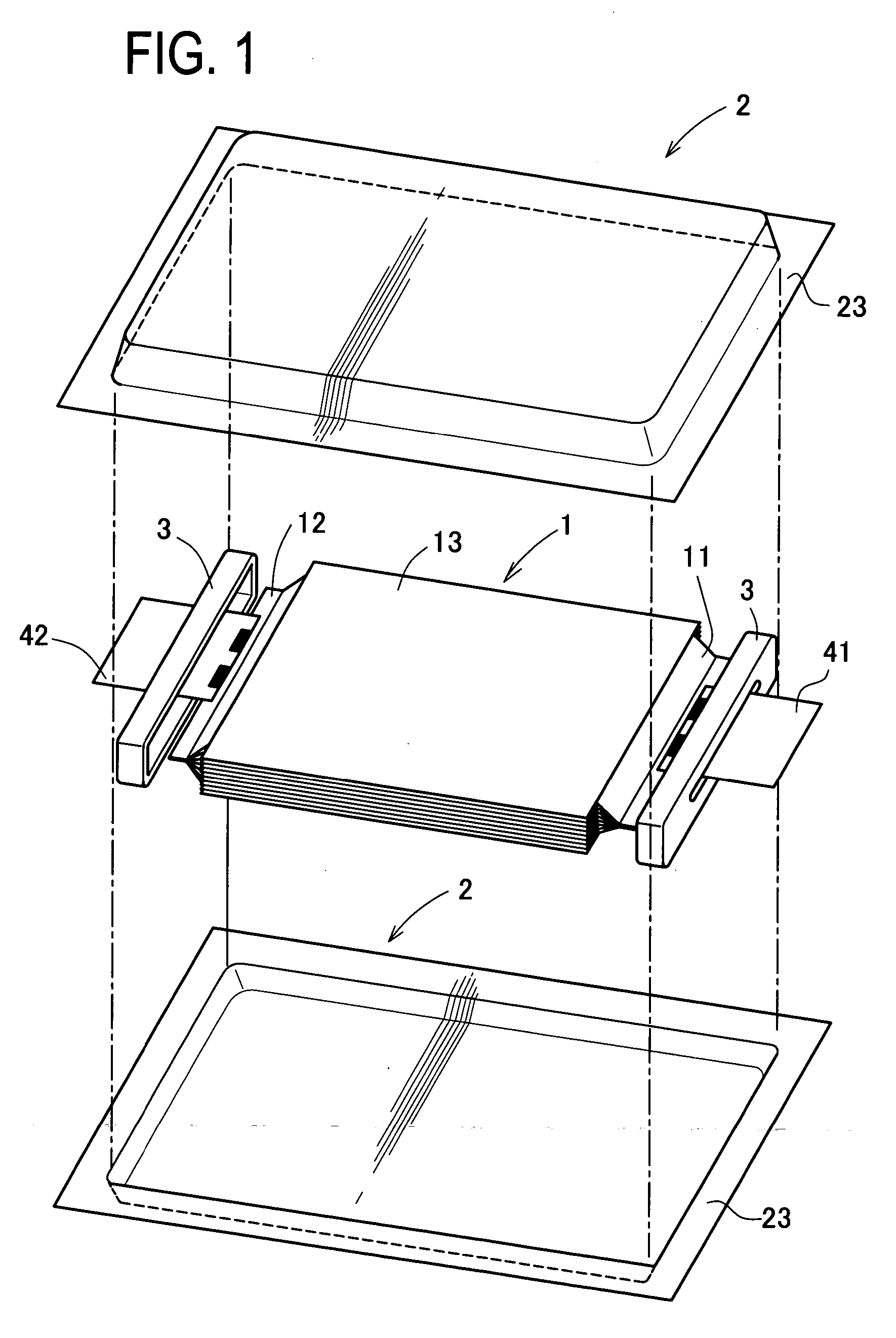

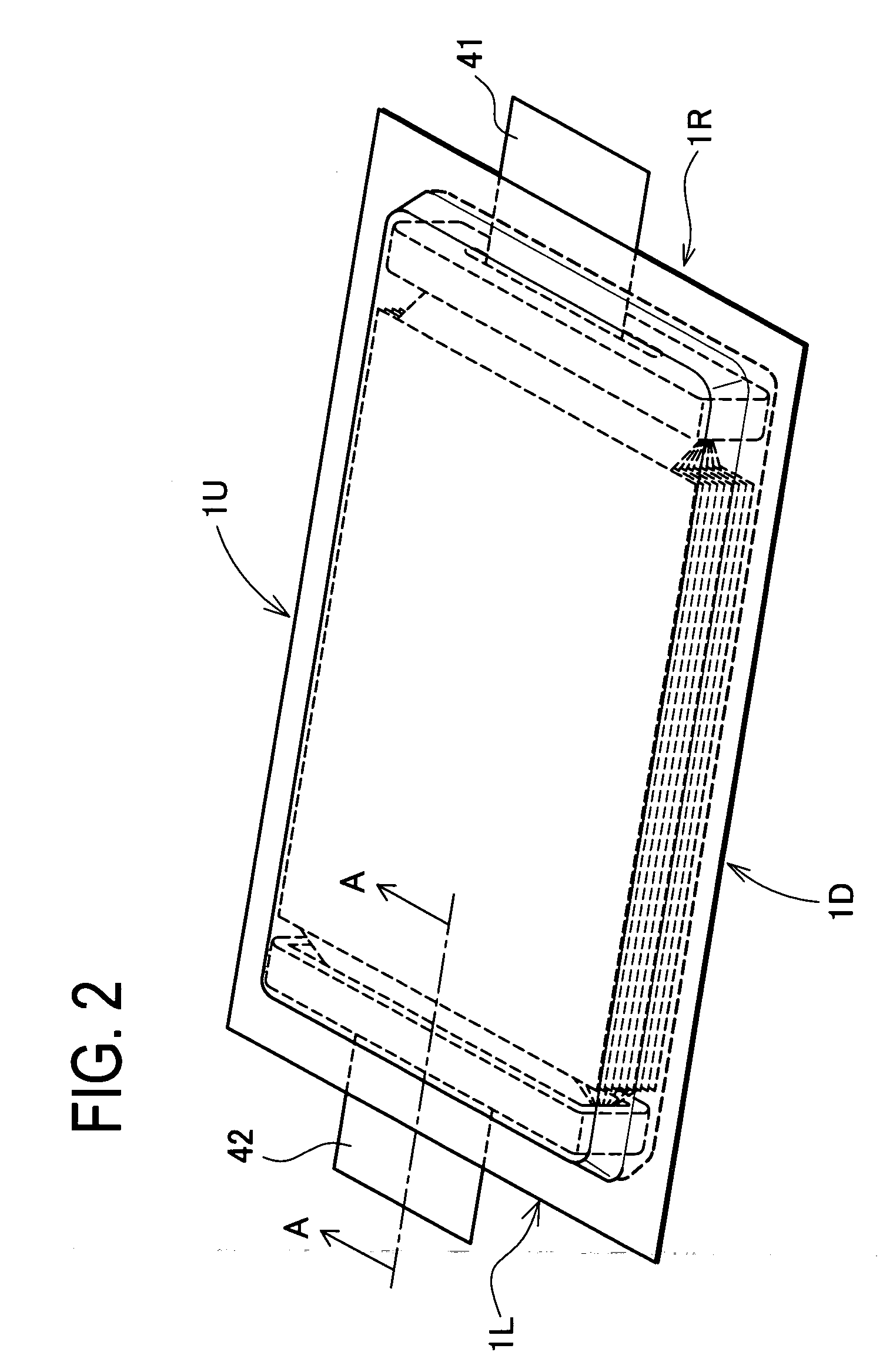

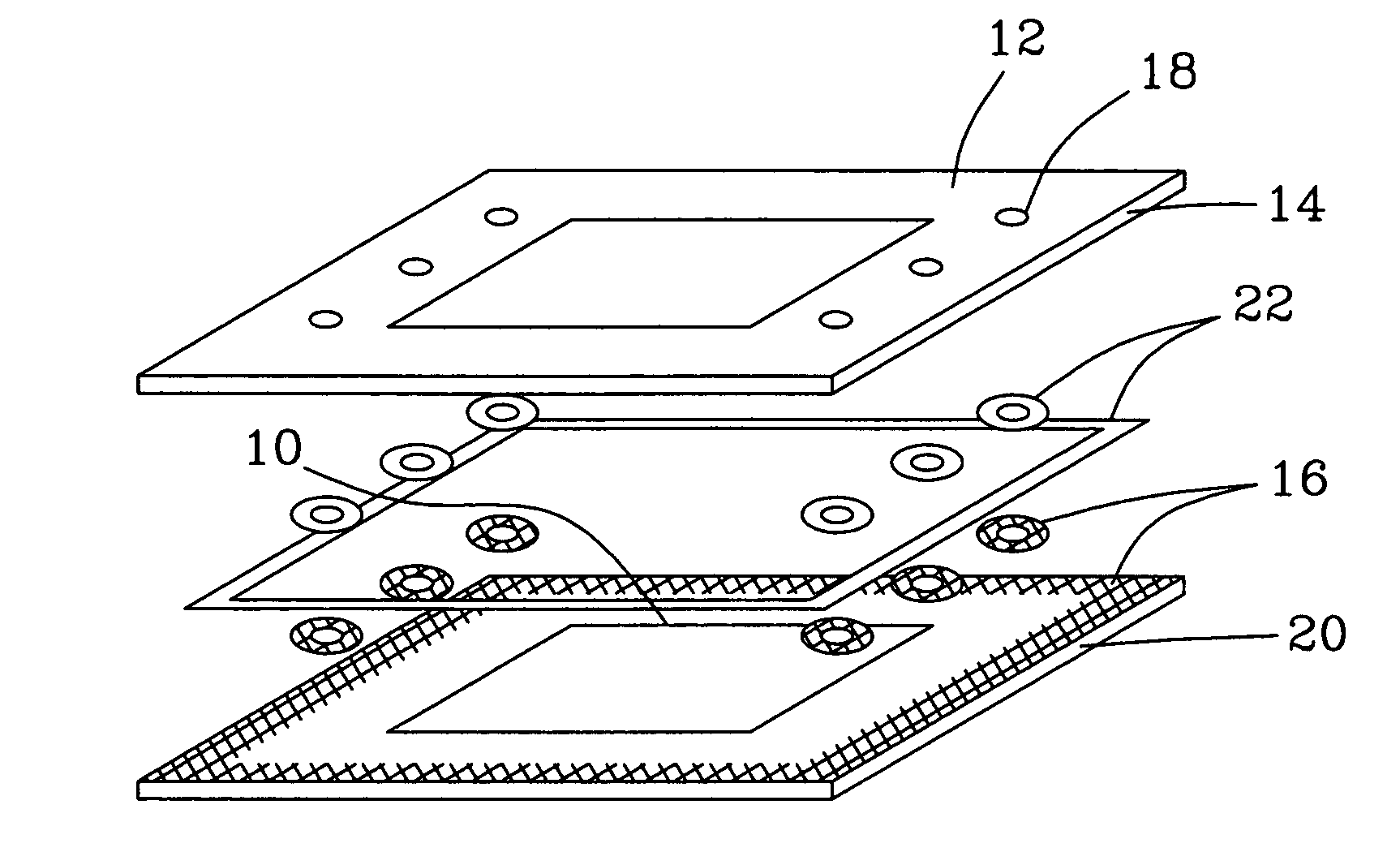

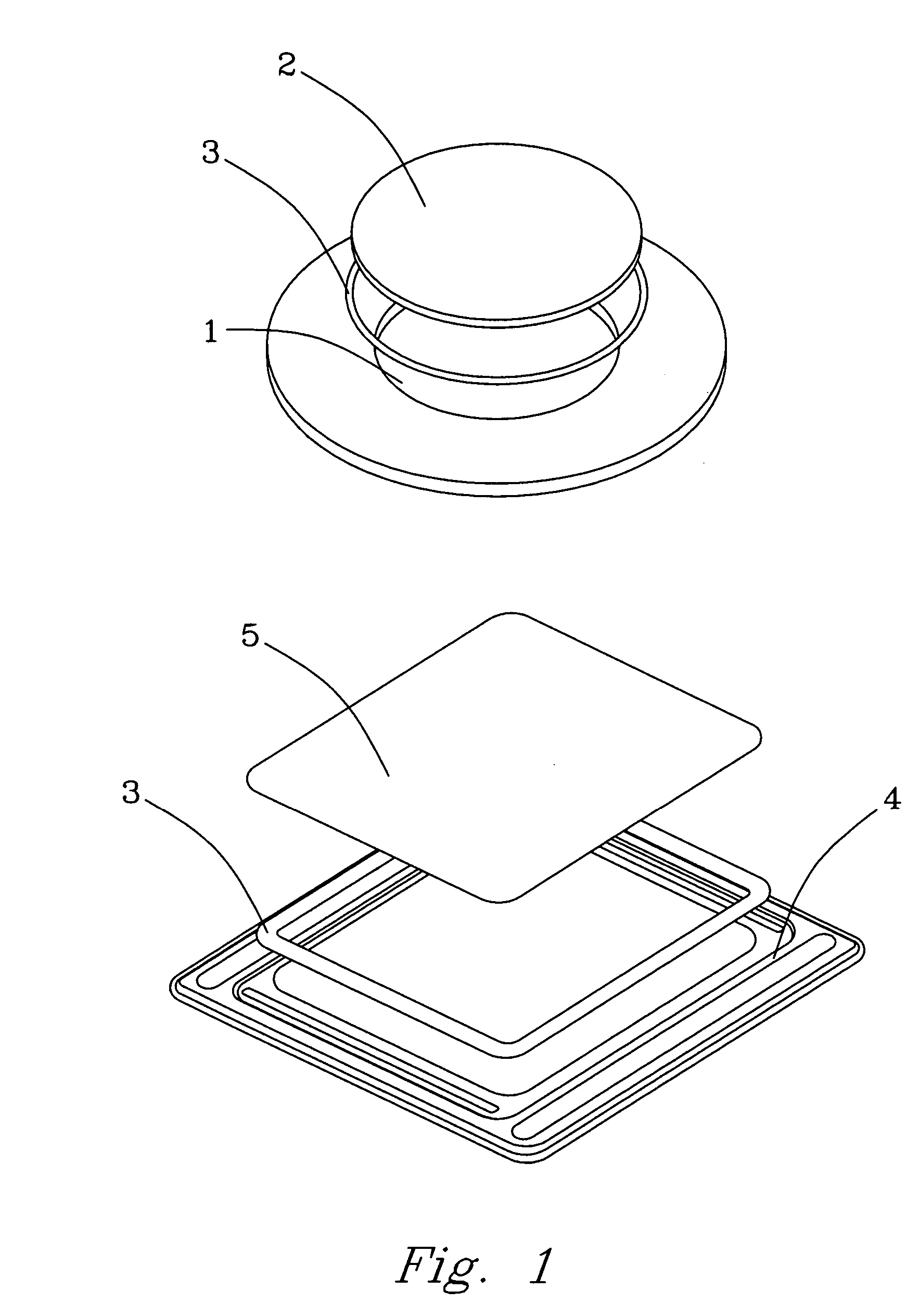

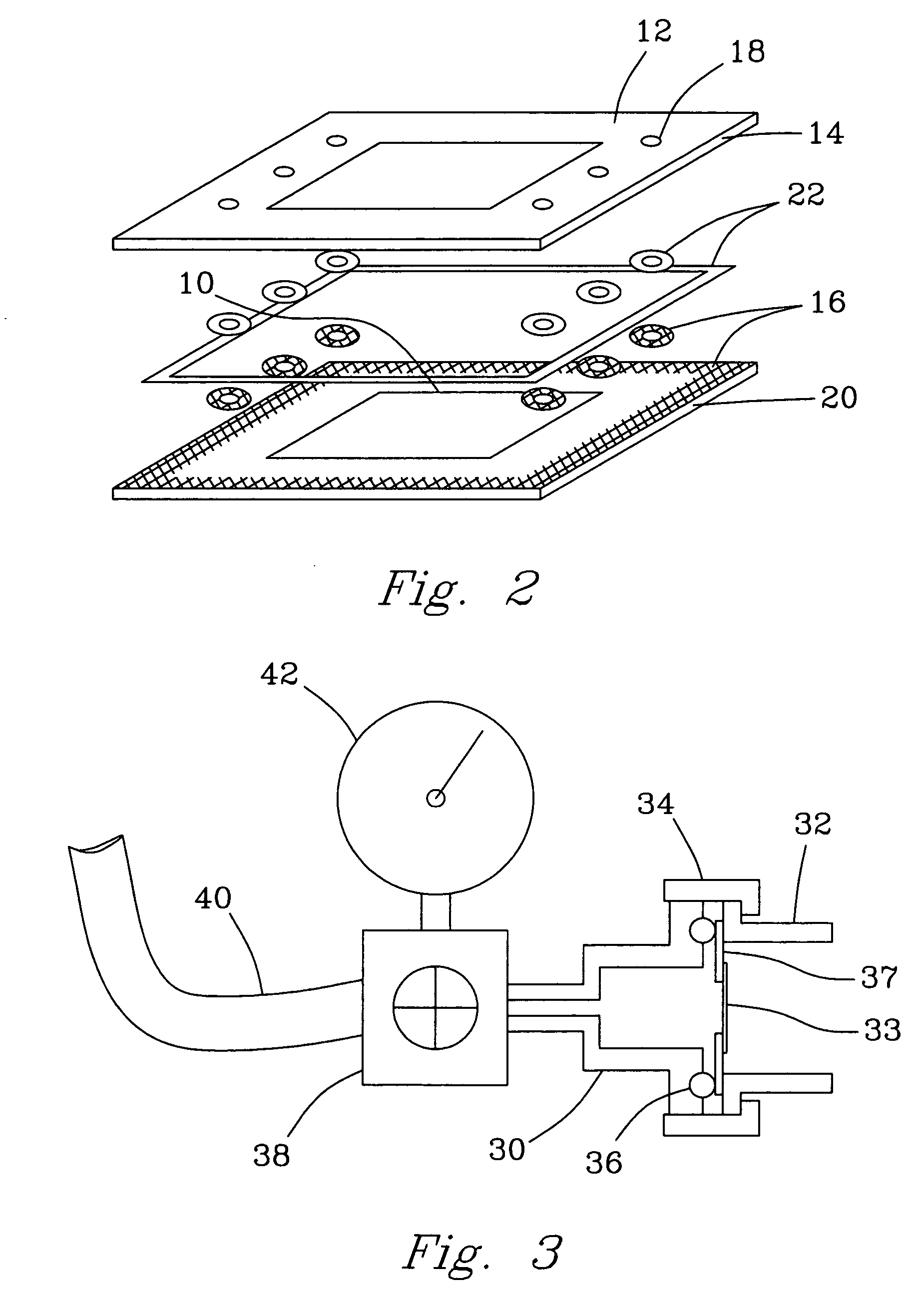

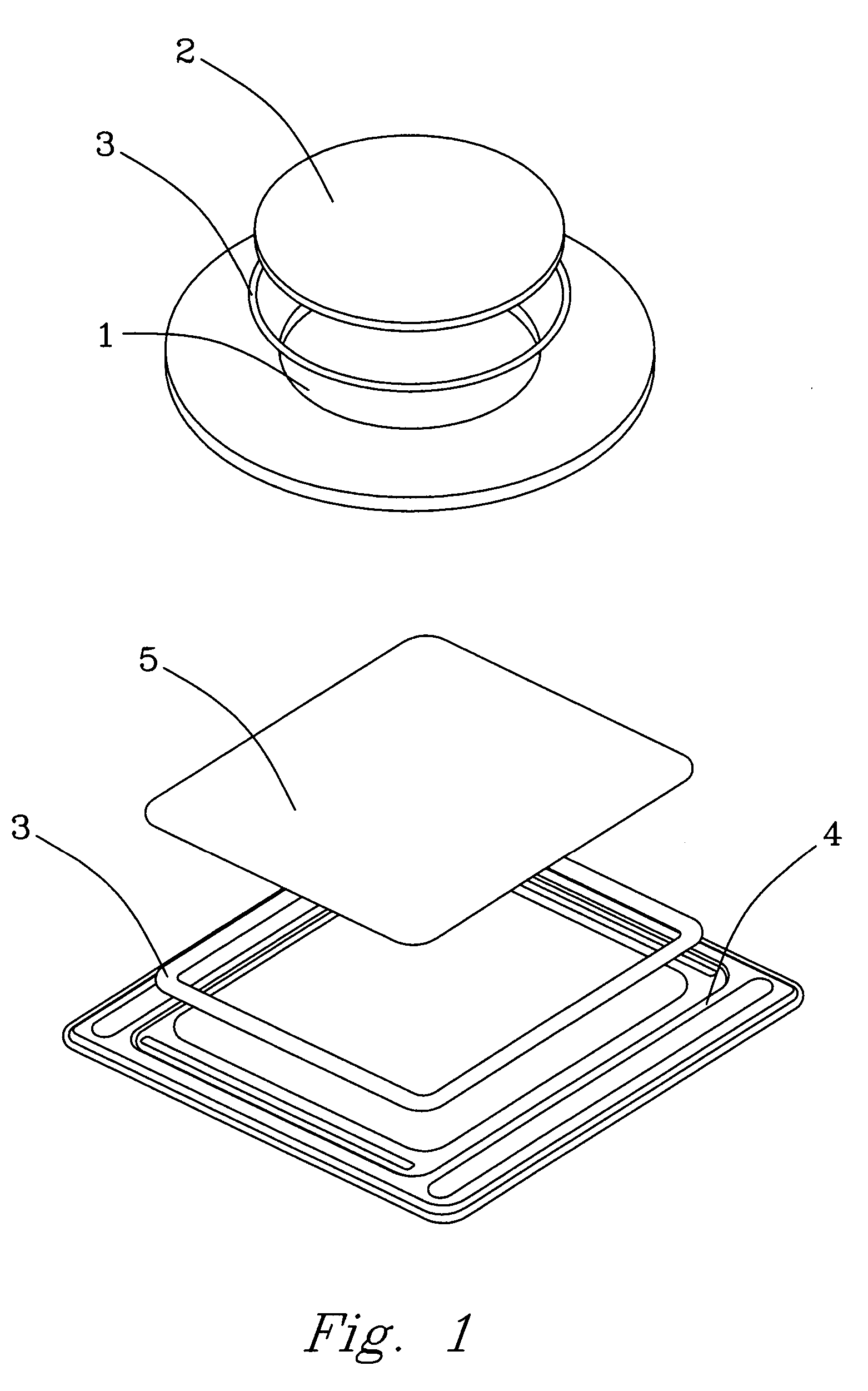

Laminate Type Secondary Battery and Battery Pack Thereof

InactiveUS20070231685A1Avoid fatigue failureAvoid it happening againFinal product manufactureSmall-sized flat cells/batteriesInternal pressureBattery pack

An electrode terminal 42 is connected to a current collector part 12 of electrodes through a deformation restricting member 3. Between laminate seals 2 and 2, a space 15 is formed above and below the current collector part 12. The deformation restricting member 3 is placed close to the inner wall peripheral portion of an outer package including sealing parts 23, thereby forming a deformation-restricting part 22 to restrict the inward deformation of the laminated films 2. In a section extending from the inside end of the deformation restricting member 3 to a battery element 1, the laminated films 2 face the space 15 to allow the deformation of the laminated films 2 in response to the change of internal pressure. At the decrease of internal pressure, the contraction of the laminated films 2 can be localized in the deformation-allowing part 21, thereby reducing the bending stress on an end portion of the sealing parts 23. Thus, the laminate type secondary battery and the battery pack thereof can be provided with the effect that the concentration of stress on the bonded part of the laminated films can be suppressed even when the expansion and contraction of the laminated films are repeated in response to the change of internal pressure of the laminated films bonded to hermetically accommodate the battery element.

Owner:TOYOTA JIDOSHA KK

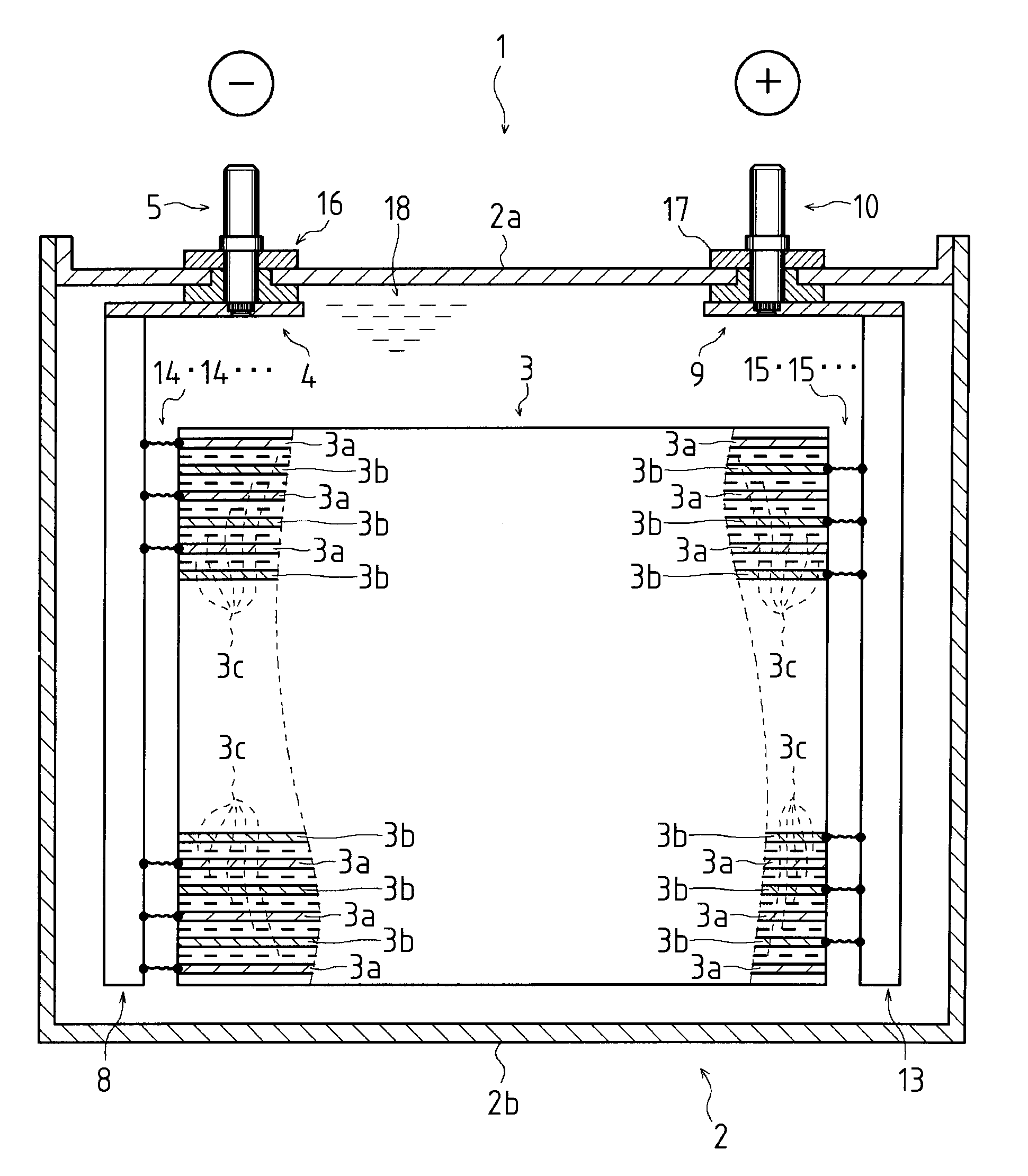

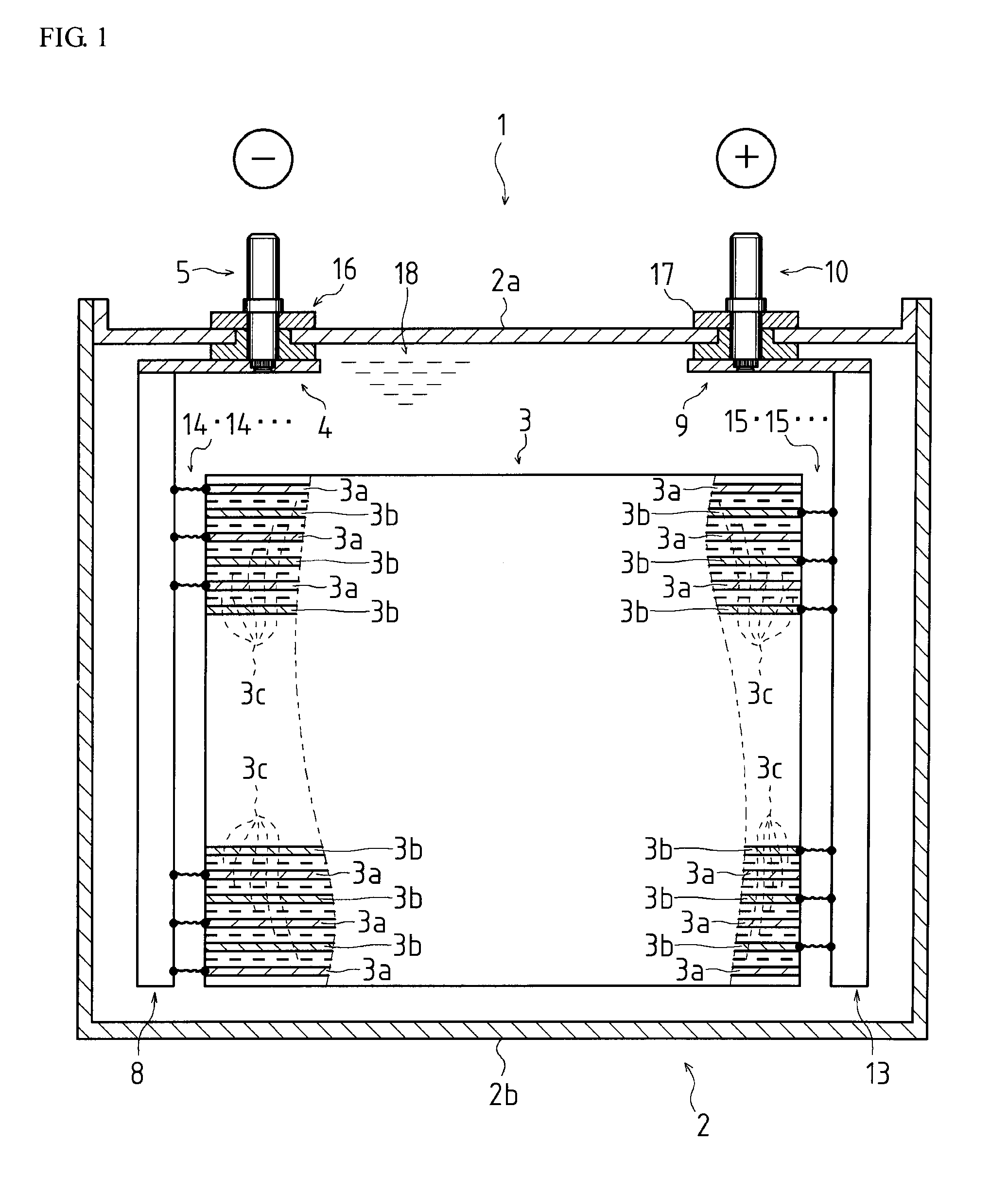

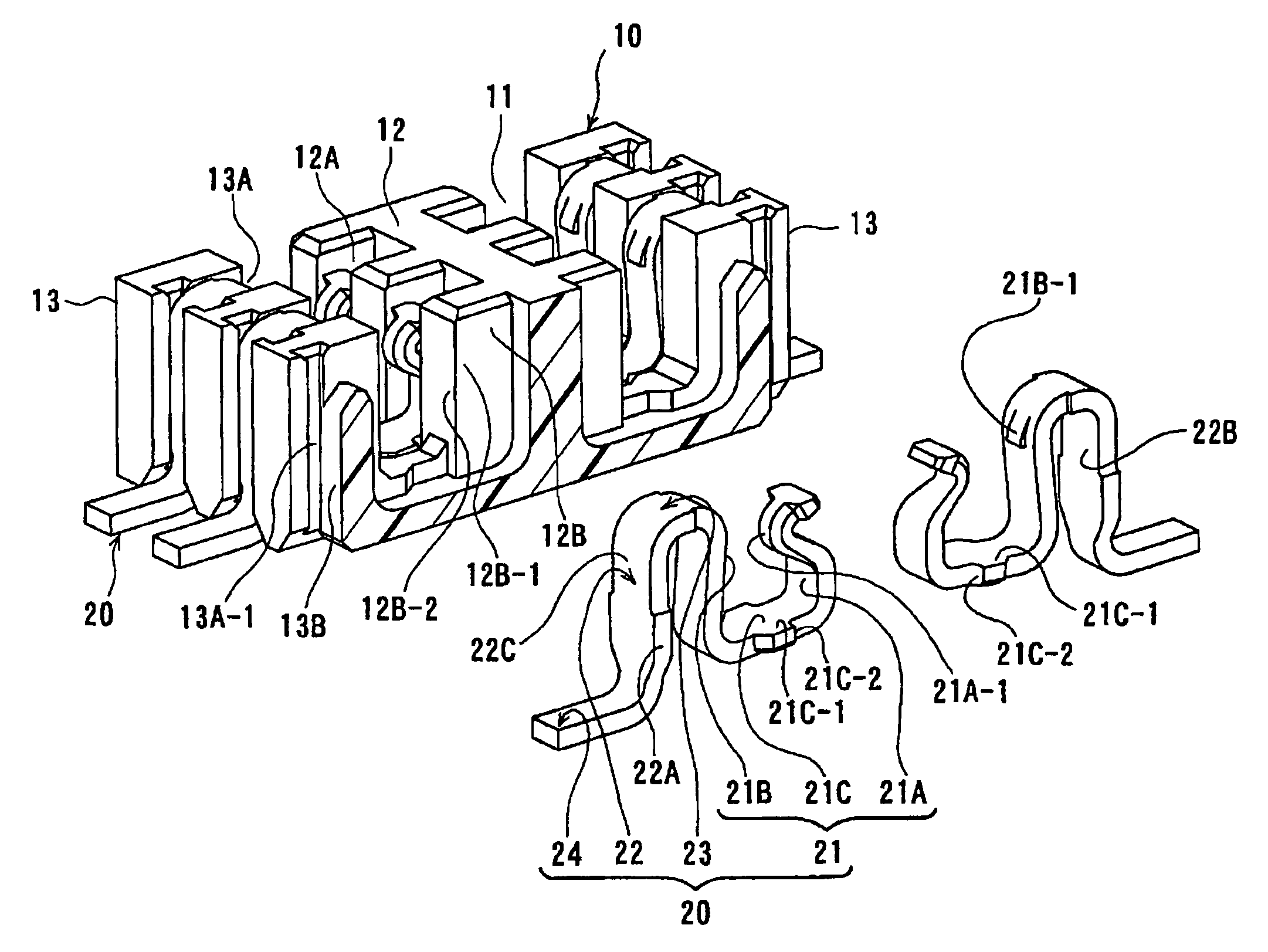

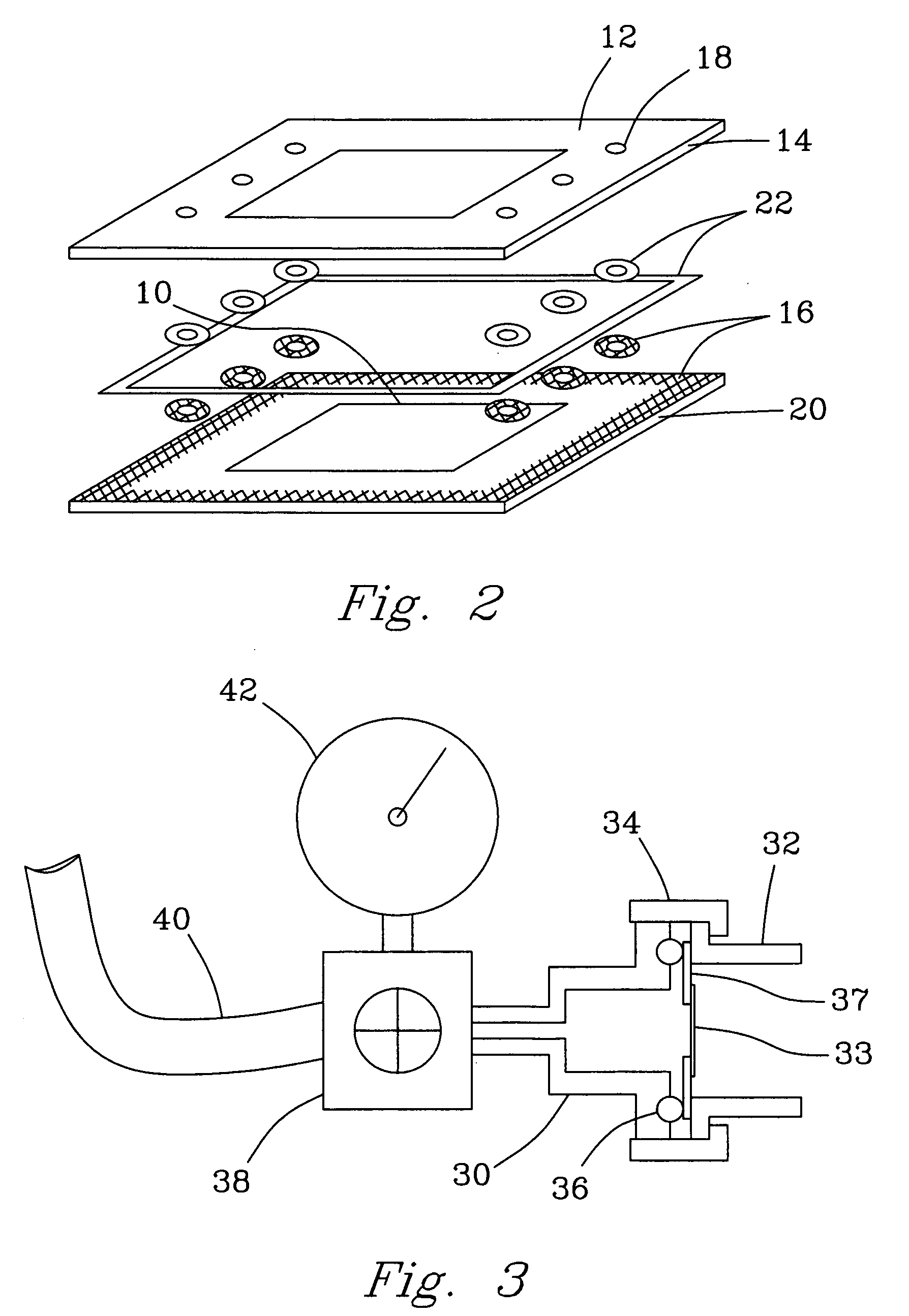

Terminal unit and method of manufacturing the same

ActiveUS20100092858A1Avoid conducting electricityAvoid changeSmall-sized cells cases/jacketsPrimary cellsEngineeringTerminal unit

The first aspect of the present invention is a terminal unit which contains an electrode part disposed in a case, for connecting with an electrode body and a terminal part having a rod shape with a first end and a second end, the first end for fixing to the electrode part, and the second end extending outside of the case. In one embodiment of the first aspect of the invention, the electrode part includes an insert hole into which the terminal part is inserted, the terminal part comprises an insert portion having an insert portion having a larger diameter than that of the hole and formed at the first end and a tip portion having a smaller diameter than that of the hole and formed at the nearer side of the first end than the insert portion. And, the clinch portion is press fitted into the insert hole, thereby fixing the terminal part to the electrode part. According to the present invention, the varying of electric conductivity in the terminal unit is prevented.

Owner:TOYOTA JIDOSHA KK

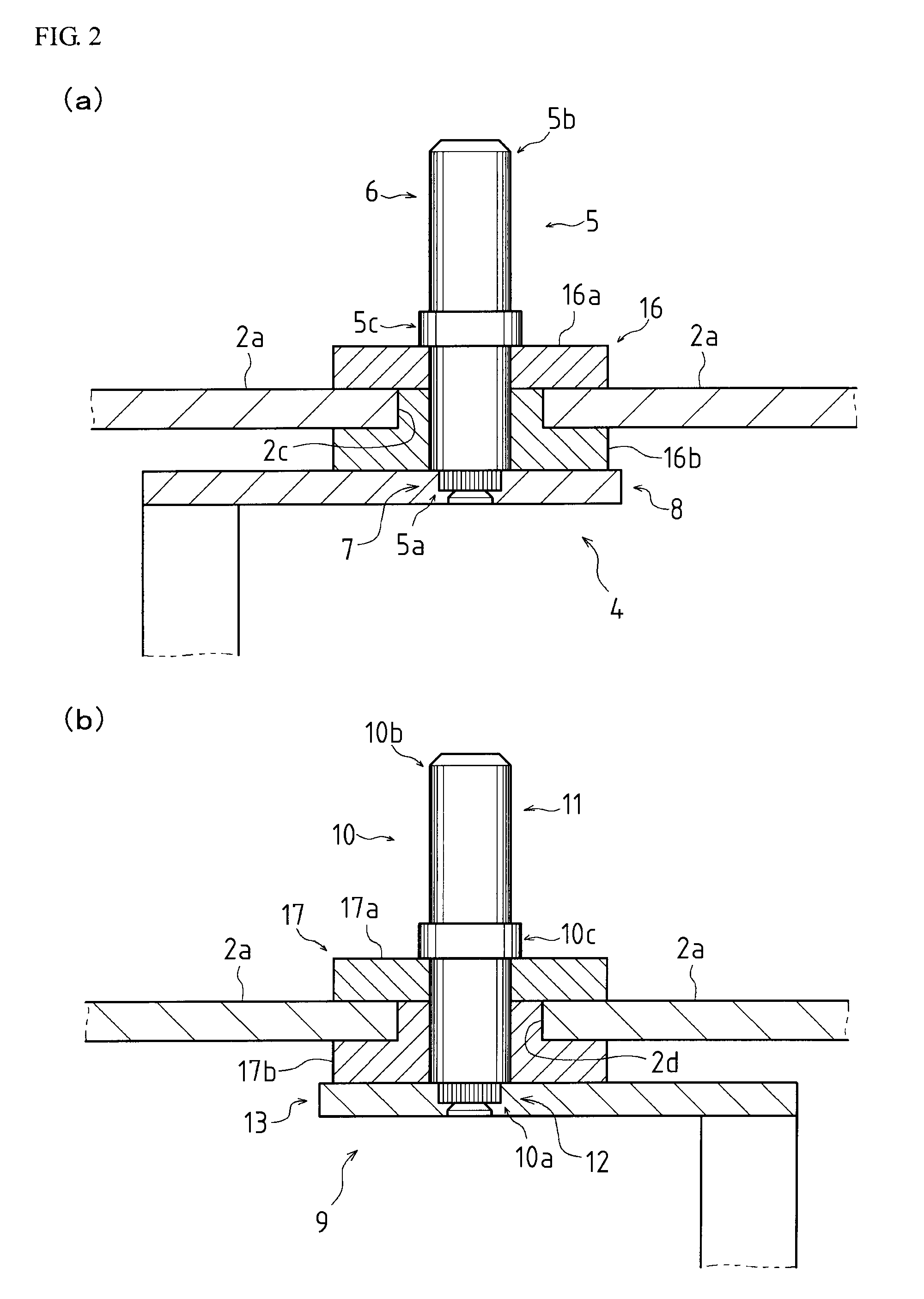

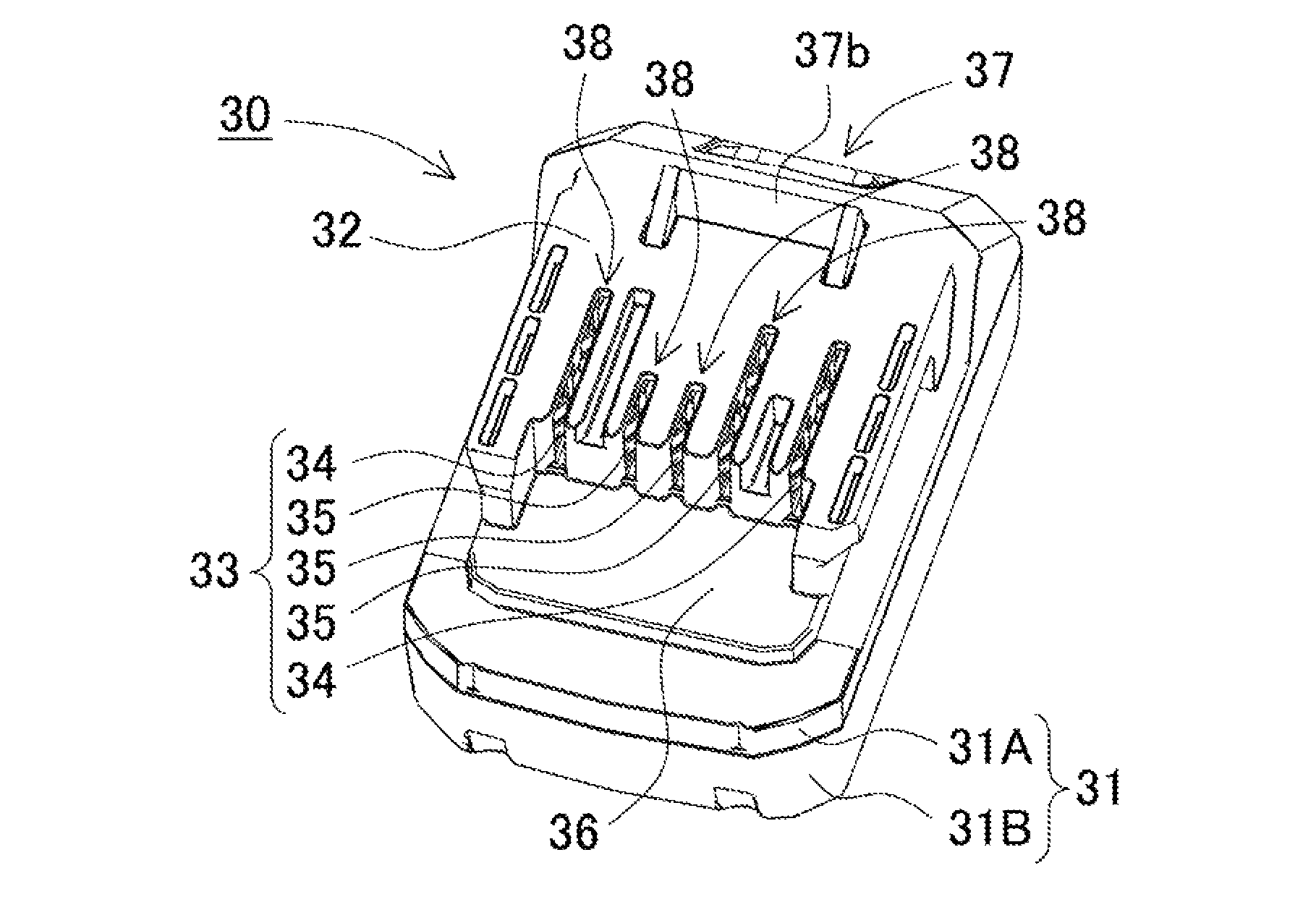

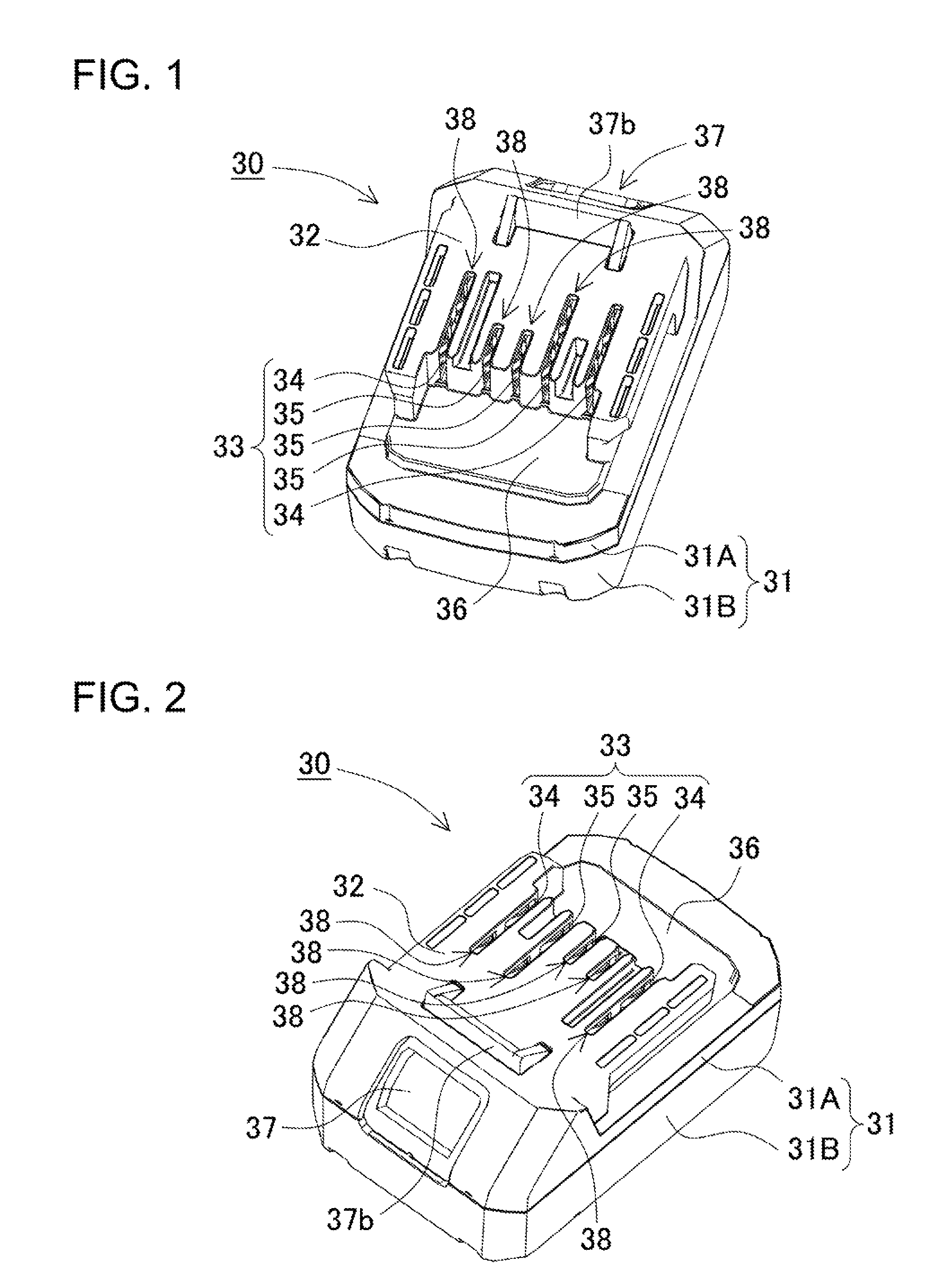

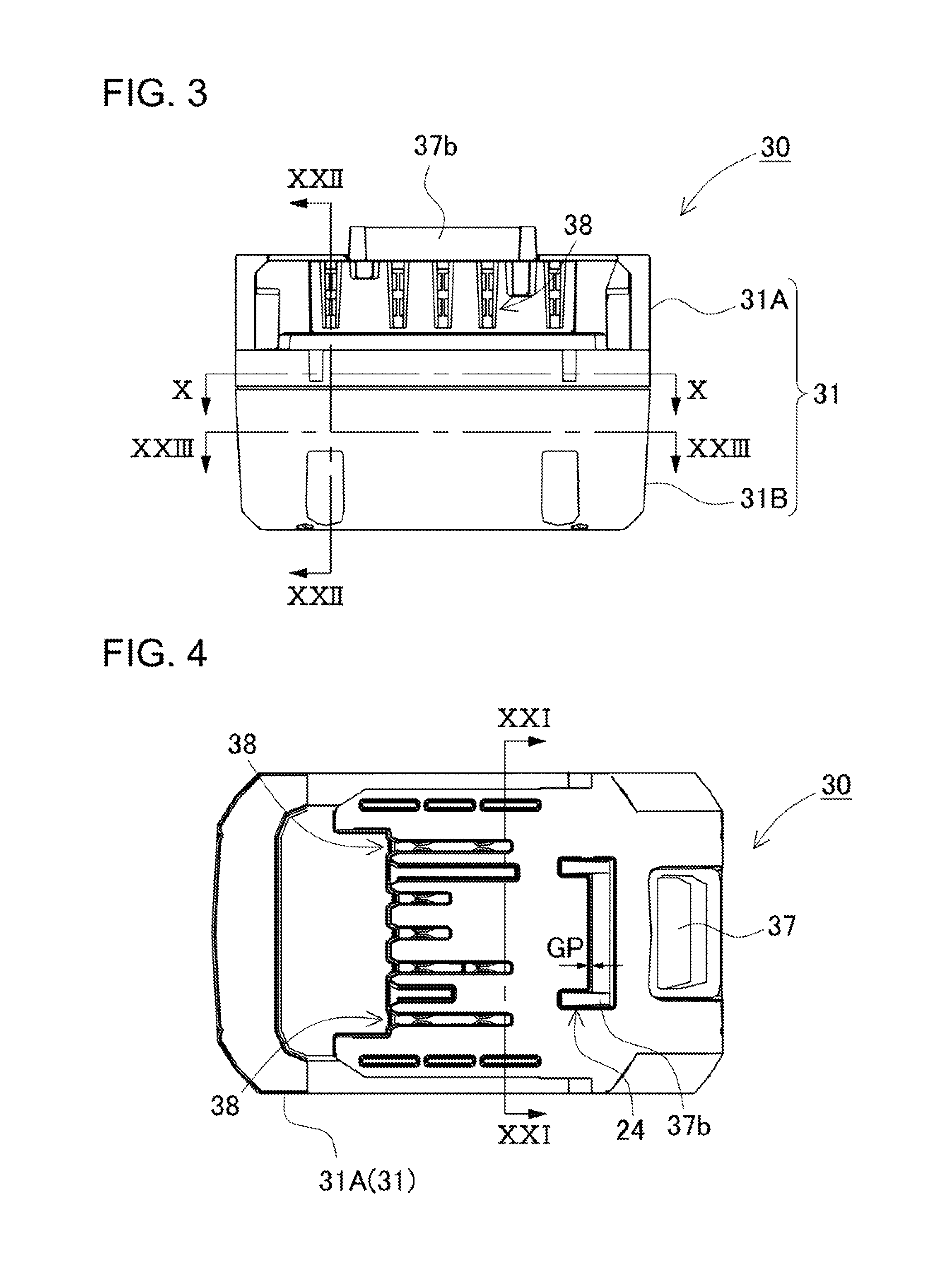

Battery pack having waterproof structure

ActiveUS8741461B2Avoid conducting electricityAvoid flowSmall-sized cells cases/jacketsSecondary cells servicing/maintenanceRechargeable cellBattery pack

A battery pack includes terminals (33) and a lock hook (37b). The terminals (33) are fastened onto a circuit board (74) and connected to rechargeable batteries (39). The terminals are exposed externally of a casing (31). The hook (37b) protrudes from a surface of the casing (31), and holds the battery pack on a charger (100). A hook opening window (24) is open in one of the surfaces of the casing. The hook (37b) can protrude from the surface of the casing (31). A drain hole (28) is open in another surface of the casing. A partition rib (25) is arranged between a path and an electronic circuit. The path is separated from the circuit. The path extends inside the casing (31) from the window (24). The circuit is mounted on the board (74). The window (24) communicates with the hole (28) through the path.

Owner:PANASONIC ENERGY CO LTD +1

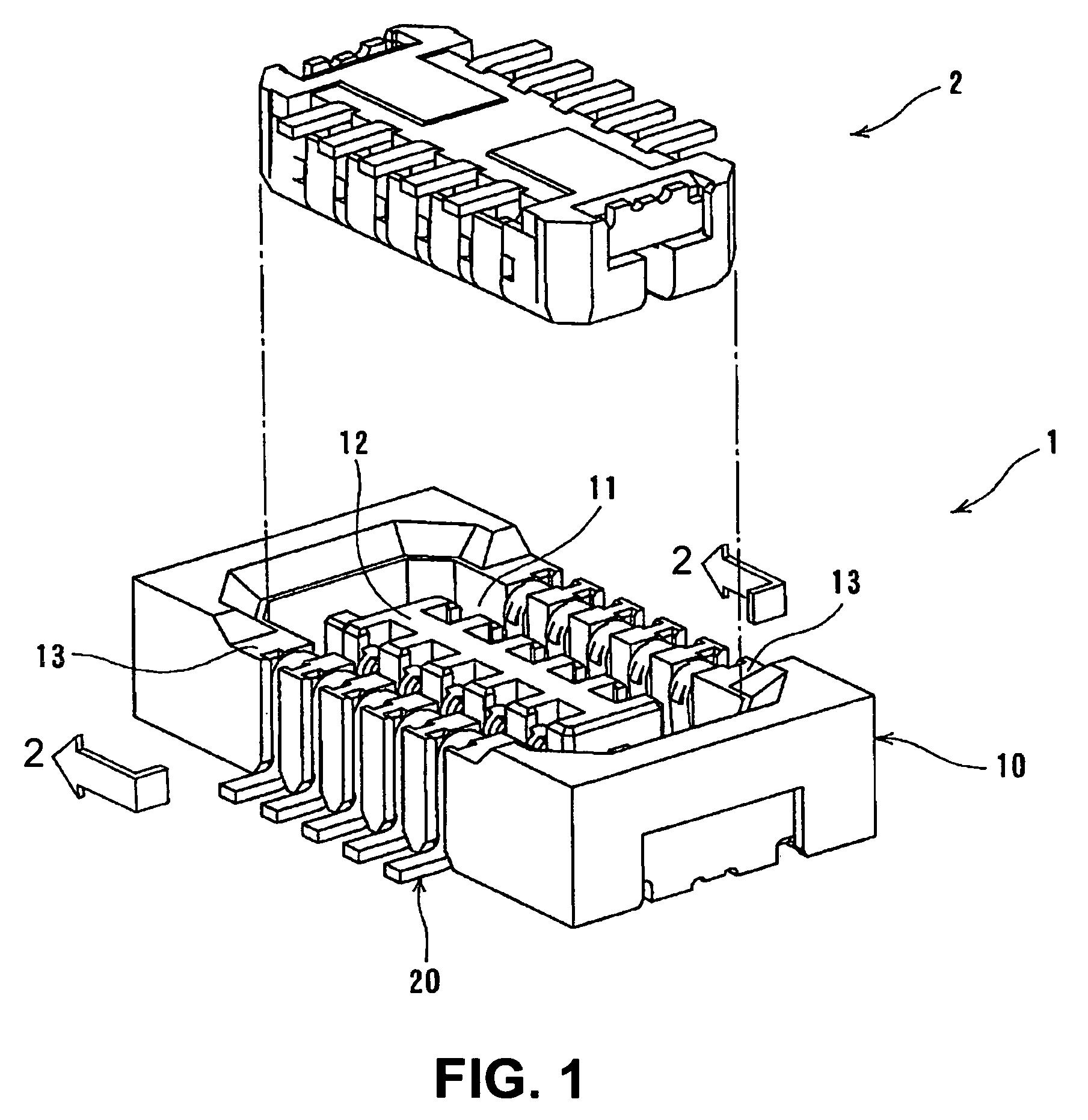

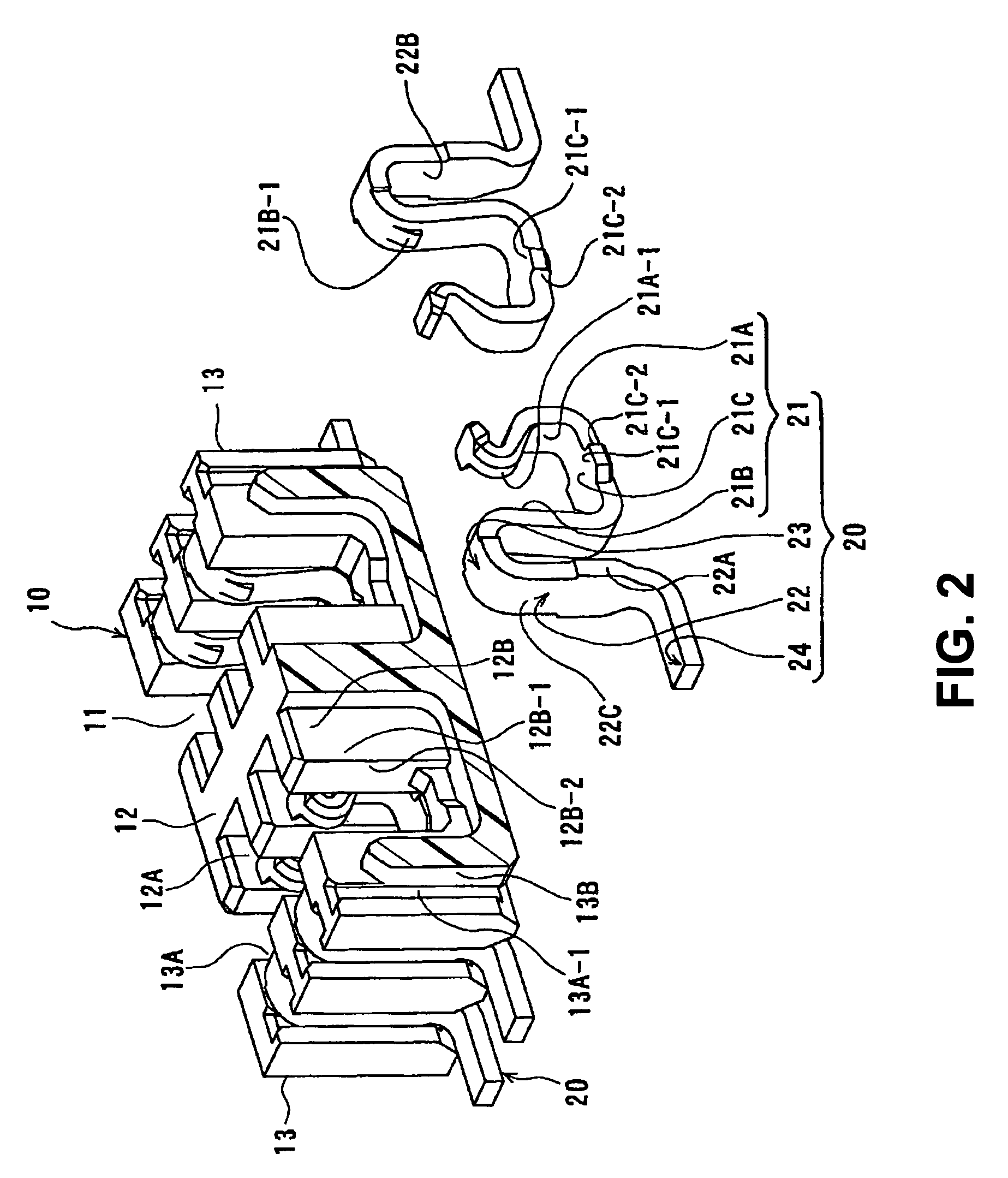

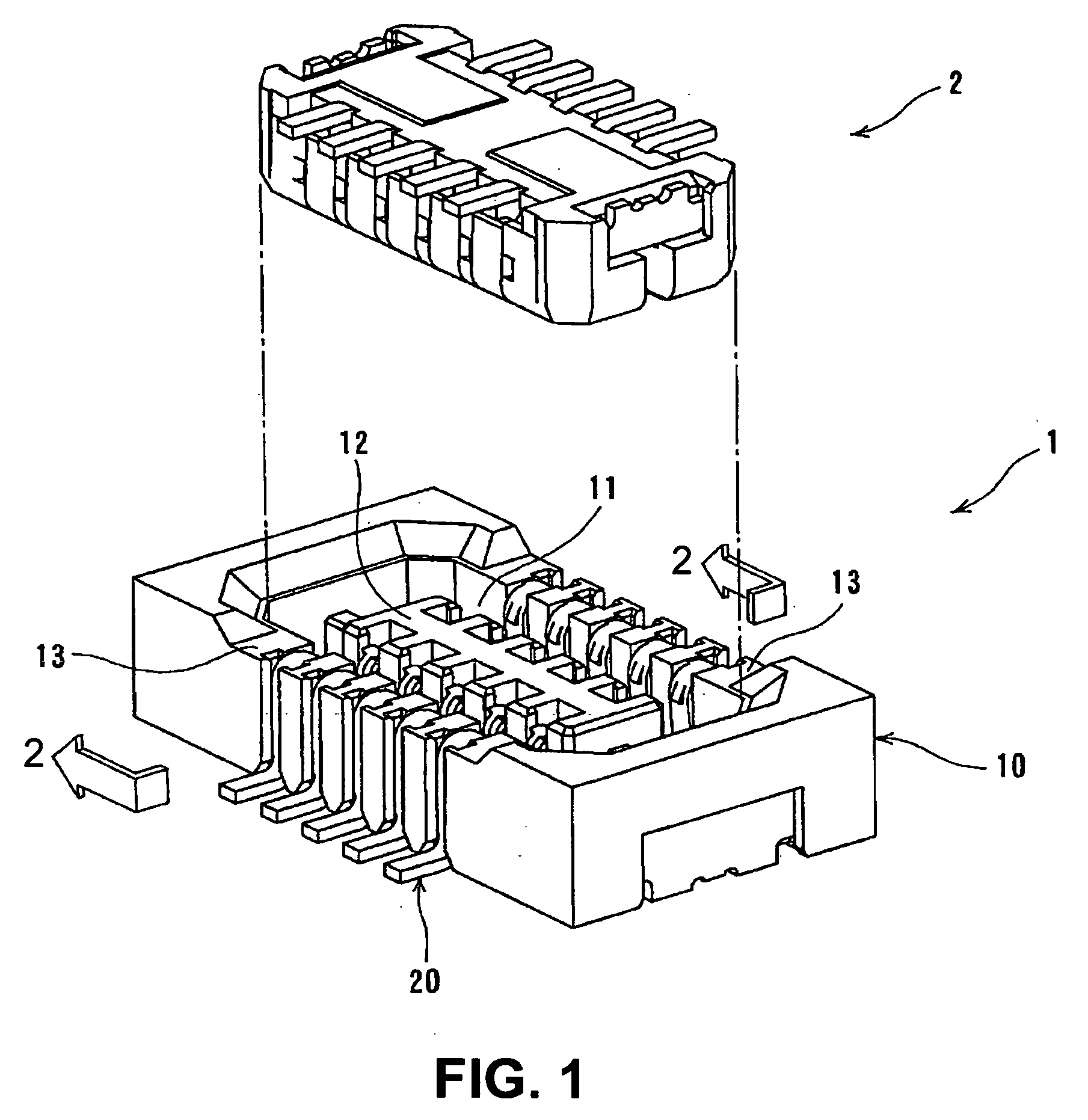

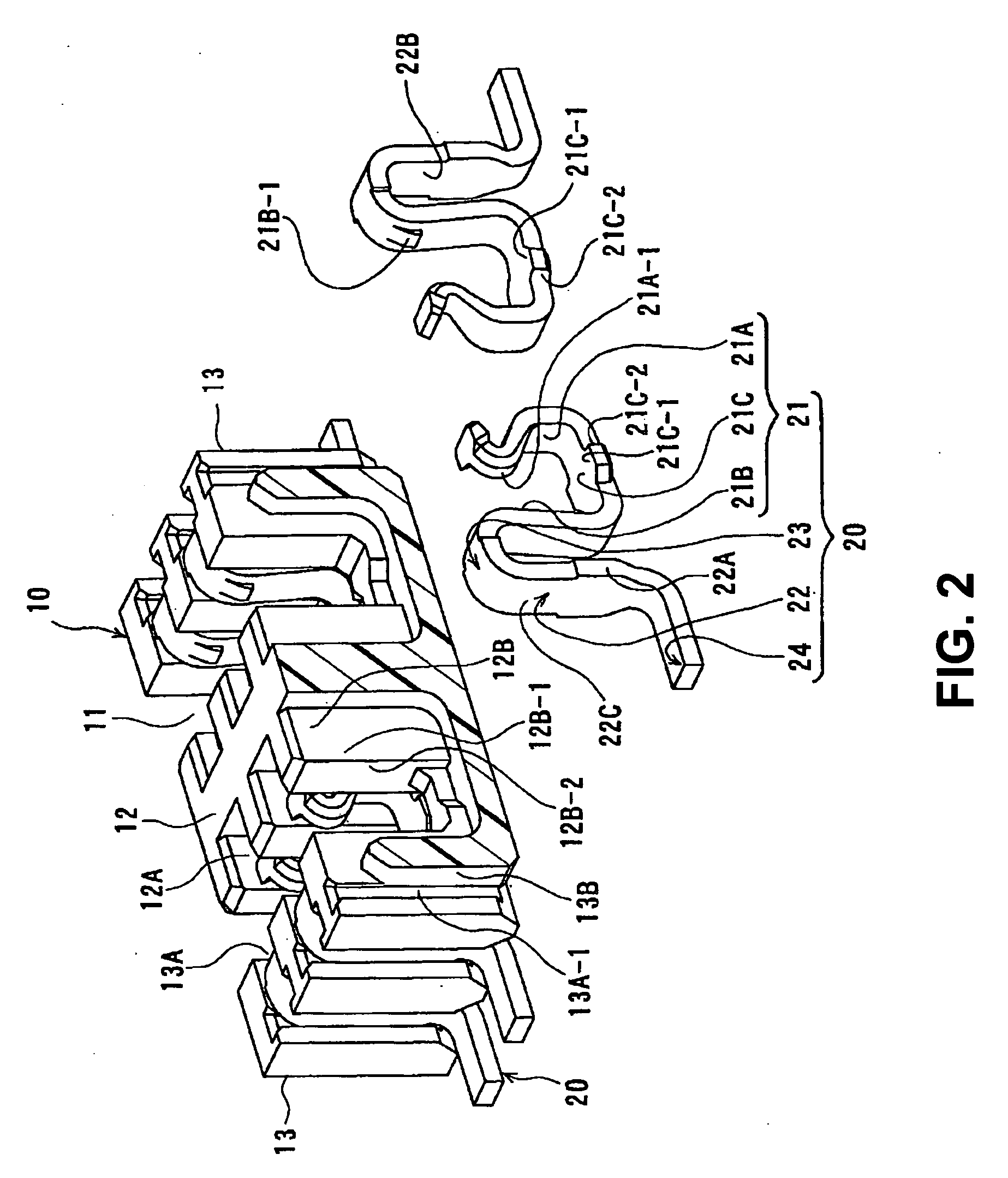

Electrical connector with regulating portion for regulating elastic deformation of terminal

ActiveUS7748993B2Add dimensionIncrease the areaCoupling contact membersPrinted circuitsMating connectionEdge surface

A connector to be connected to a mating connector includes a housing having a receptacle recess portion for receiving the mating connector, and a terminal retained in the housing. The housing includes a containing groove extending in a connecting direction for containing a fitting portion of the terminal. The fitting portion of the terminal includes an engaging portion at a side end edge thereof. The containing groove includes a regulating wall portion extending in the connecting direction and located inner side than a position of an edge surface of the engaging portion at the containing groove. The regulating wall portion includes a regulating surface extending in the connecting direction and a width direction of the terminal. When the mating connector is extracted, the regulating surface regulates an elastic deformation of the fitting portion by abutting against and engaging with the engaging portion.

Owner:HIROSE ELECTRIC GROUP

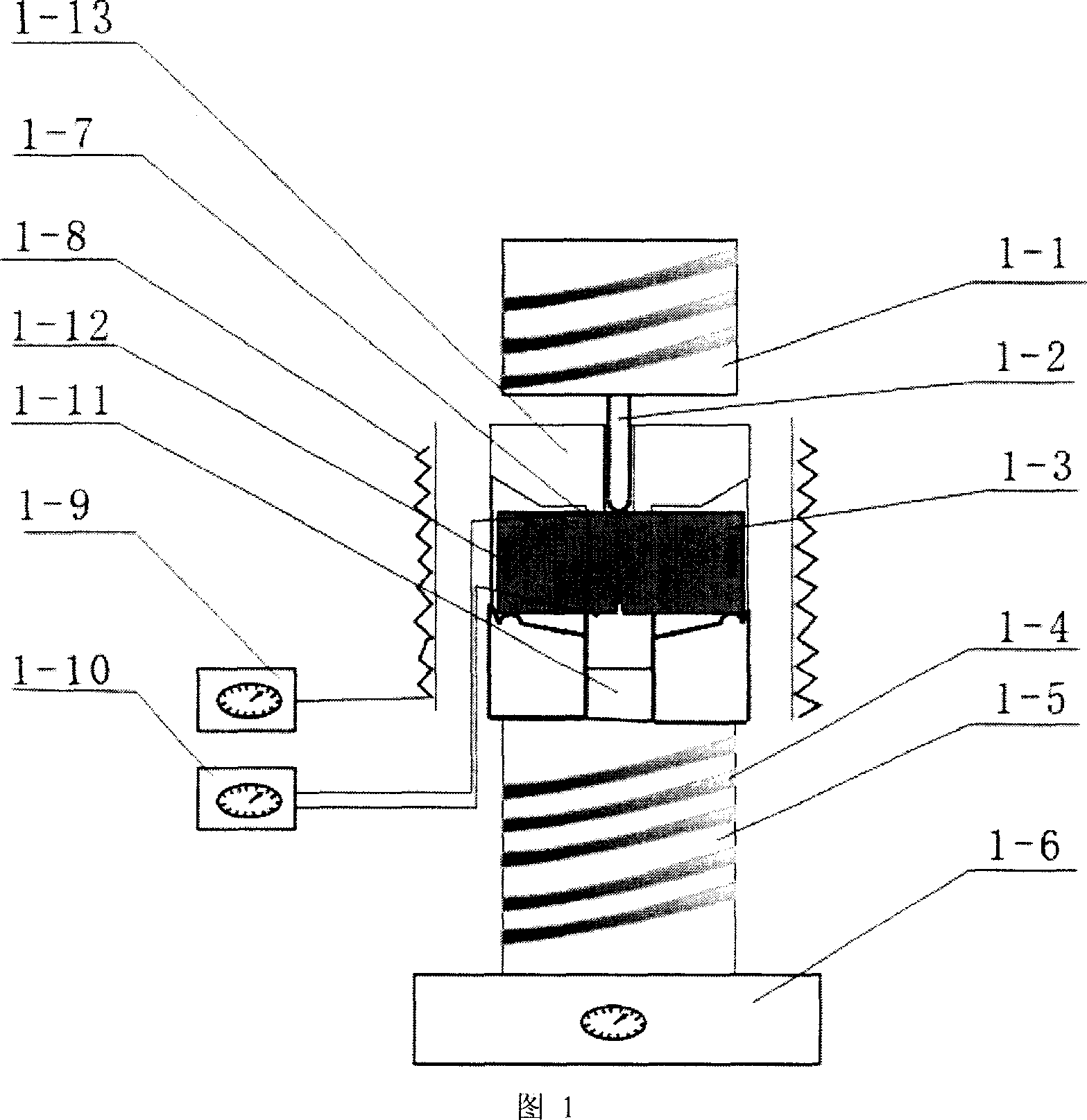

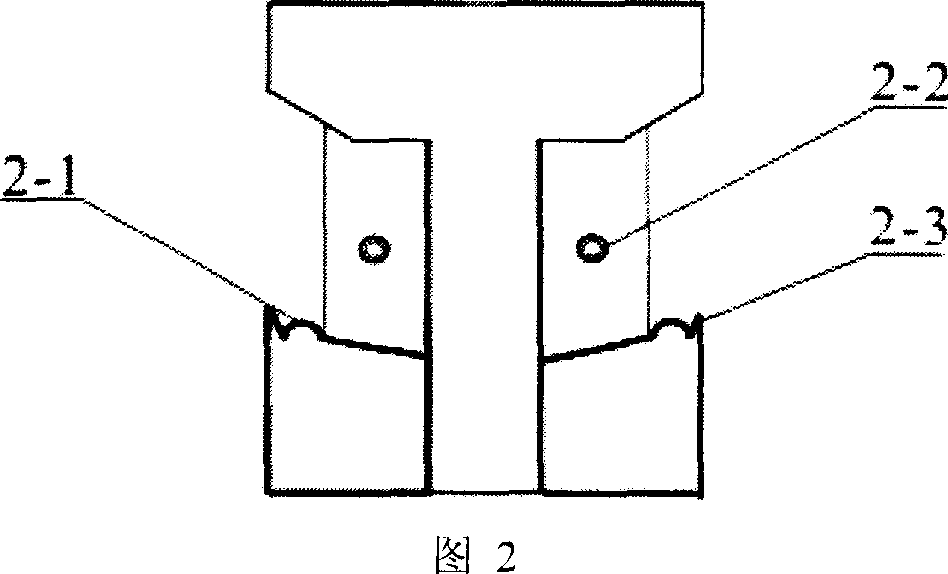

Method and device for three-point bending mechanical property test of small-sized sheet sample

InactiveCN1920521AAvoid conducting electricityAvoid Interfering with Acquisition SignalsMaterial strength using steady bending forcesHeating systemControl mode

The invention relates to a method for testing the curvature physical property at three points of small sheet sample, wherein said method comprises: arranging preformed sheet sample with micro cracked surface deposit on the sample table; using force control method, to contact the compress head with the upper surface of sample; entering into testing conditions, to avoid high load at contact moment; connecting two electrodes of said sheet sample with voltage collecting system, and increasing load stepped, recording the maximum load, and detecting the voltage change at the crack moment of said micro crack, and converting the voltage and time data into the relationship between speed and time. Said device is formed by three-point curvature sample table, sample table support system, cooling system, heating system, loading system, and testing system. The invention can directly mount small sheet sample on the tester, to process three-point curvature test and process critical stress strength factor test of preformed micro cracked sample.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

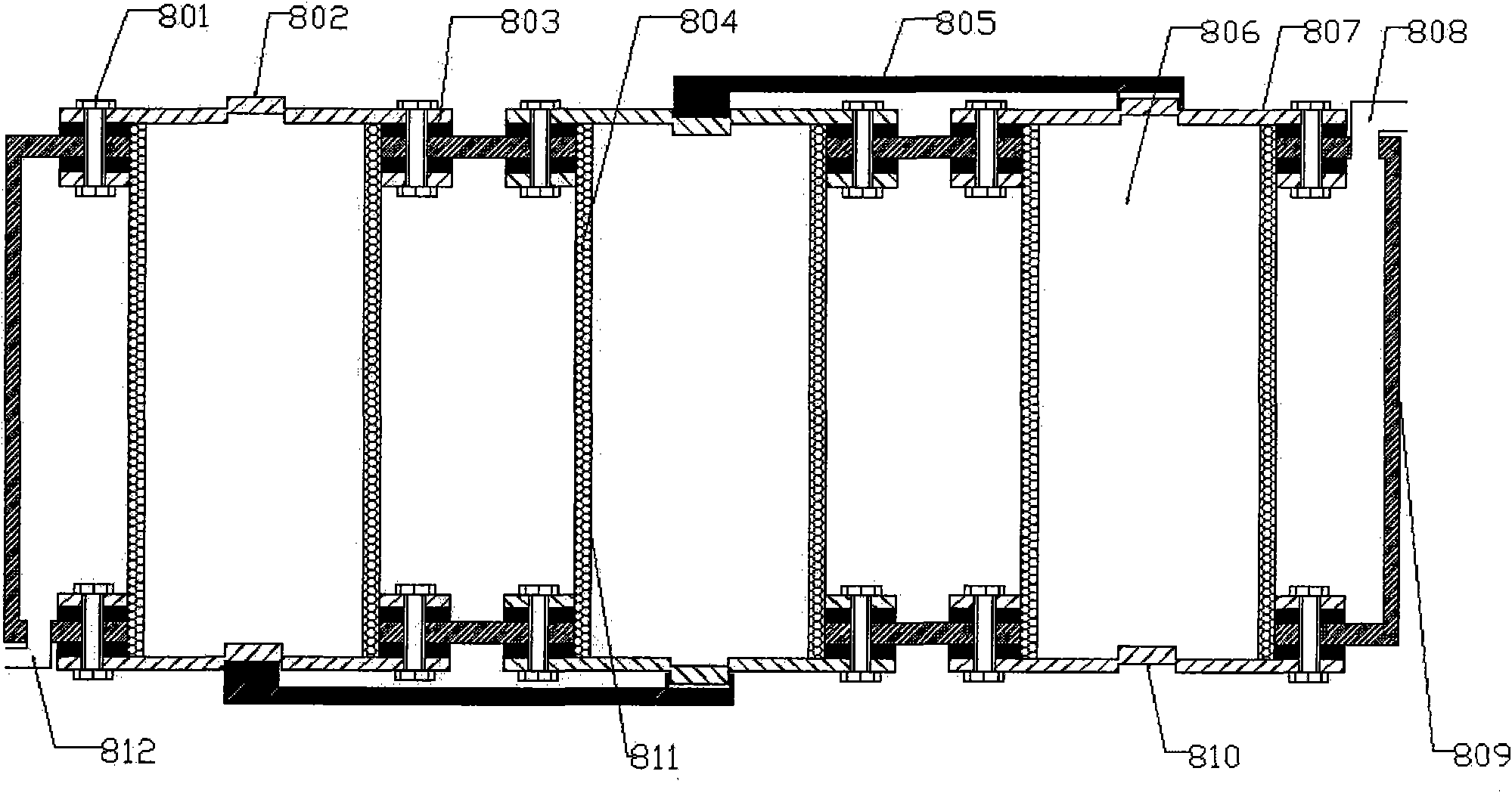

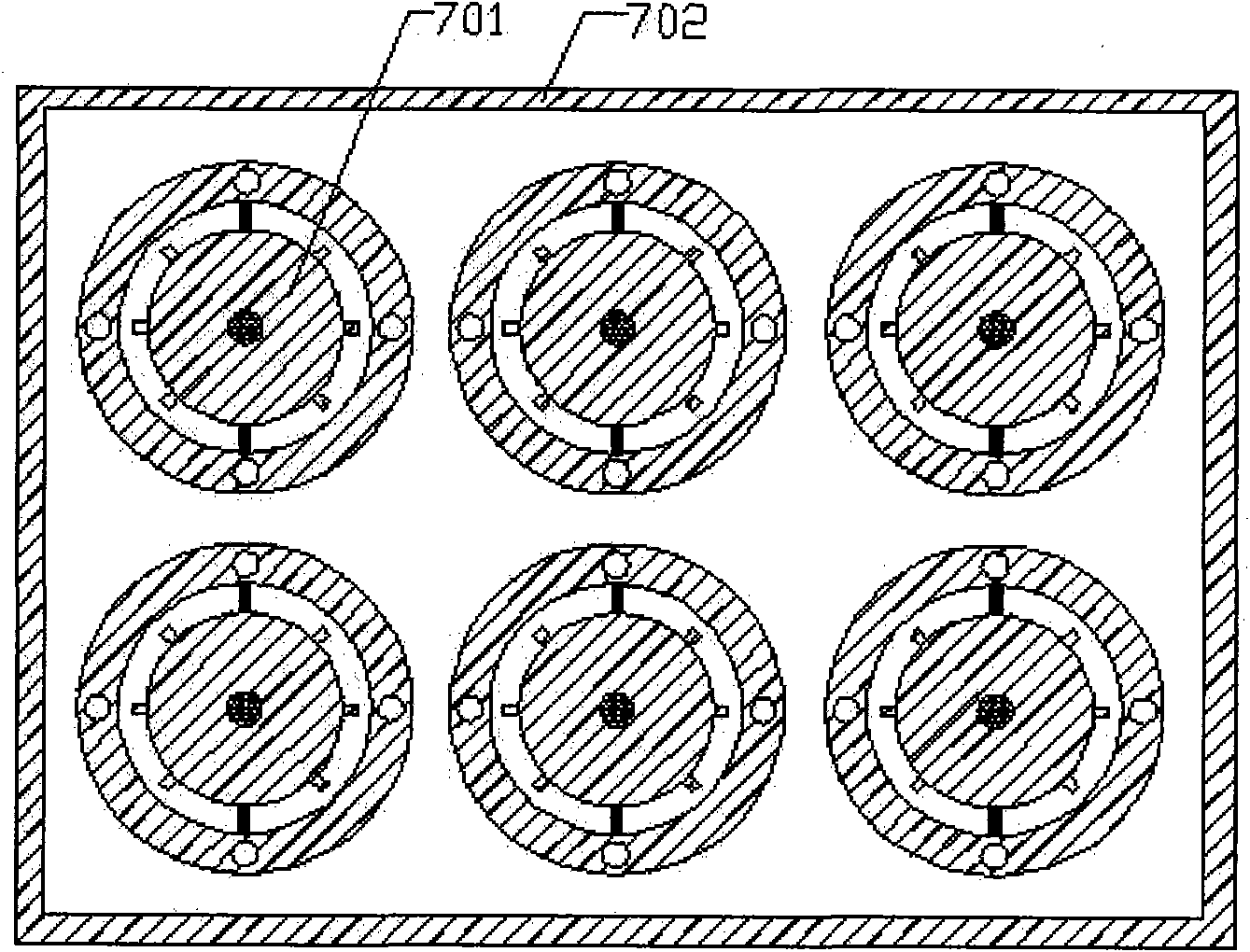

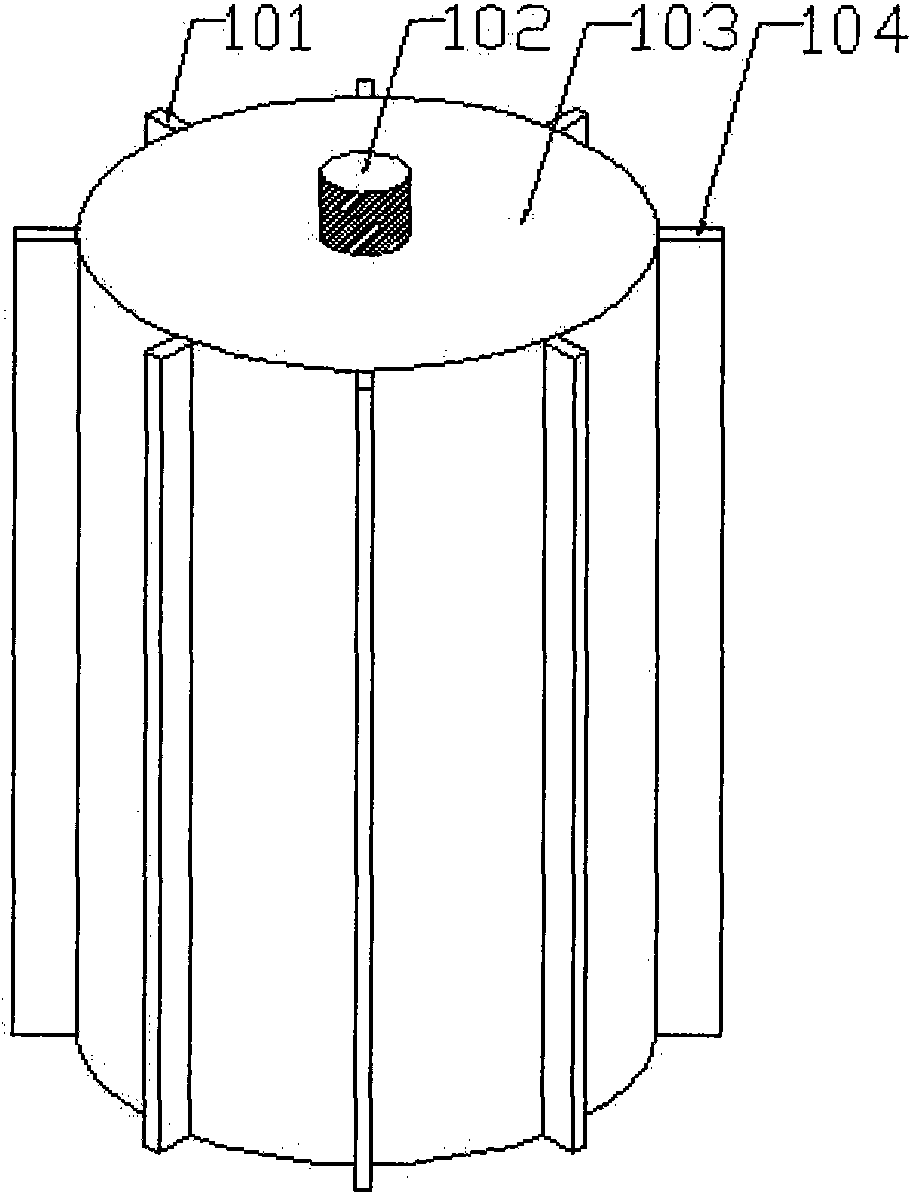

Recycling high-efficiency heat-radiating battery device for electric vehicle

InactiveCN101609901AIncrease heat transfer rateAvoid conducting electricitySmall-sized cells cases/jacketsBattery isolationPhase-change materialEngineering

The invention discloses a recycling high-efficiency heat-radiating battery device for electric vehicles. A plurality of symmetrically distributed single battery modules which are formed by sleeving single batteries into battery shells are arranged in a battery module box, phase change material is filled between the single batteries and the battery shells, gaskets are respectively arranged among the battery module box, flanges and the connecting parts of the single battery modules, the flanges and the single battery modules are fixedly connected with the battery module box by screws, both sides of the battery module box are respectively provided with a cooling liquid inlet and a cooling liquid outlet, liquid which flows from the cooling liquid inlet and the cooling liquid outlet is normal-temperature water in the battery module box, both ends of an electrode connecting pole are respectively connected with a battery anode and a battery cathode. The recycling high-efficiency heat-radiating battery device not only can effectively reduce the temperature of the whole battery device of an electric vehicle battery in a harsh thermal environment, but also can satisfy the temperature distribution balance among single batteries, is easy to recycle to achieve an optimal running condition, reduce cost and enhance economical efficiency.

Owner:GUANGDONG UNIV OF TECH

High strength insulating metal-to-ceramic joints for solid oxide fuel cells and other high temperature applications and method of making

InactiveUS20060060633A1Avoid conducting electricityImprove fracture toughnessCooking-vessel materialsSpectrometer detectorsFuel cellsHigh intensity

A seal formed between a metal part and a second part that will remain gas tight in high temperature operating environments which experience frequent thermal cycling, which is particularly useful as an insulating joint in solid oxide fuel cells. A first metal part is attached to an reinforcing material. A glass forming material in the positioned in between the first metal part and the second part, and a seal is formed between the first metal part and the second part by heating the glass to a temperature suitable to melt the glass forming materials. The glass encapsulates and bonds at least a portion of the reinforcing material, thereby adding tremendous strength to the overall seal. A ceramic material may be added to the glass forming materials, to assist in forming an insulating barrier between the first metal part and the second part and to regulating the viscosity of the glass during the heating step.

Owner:BATTELLE MEMORIAL INST

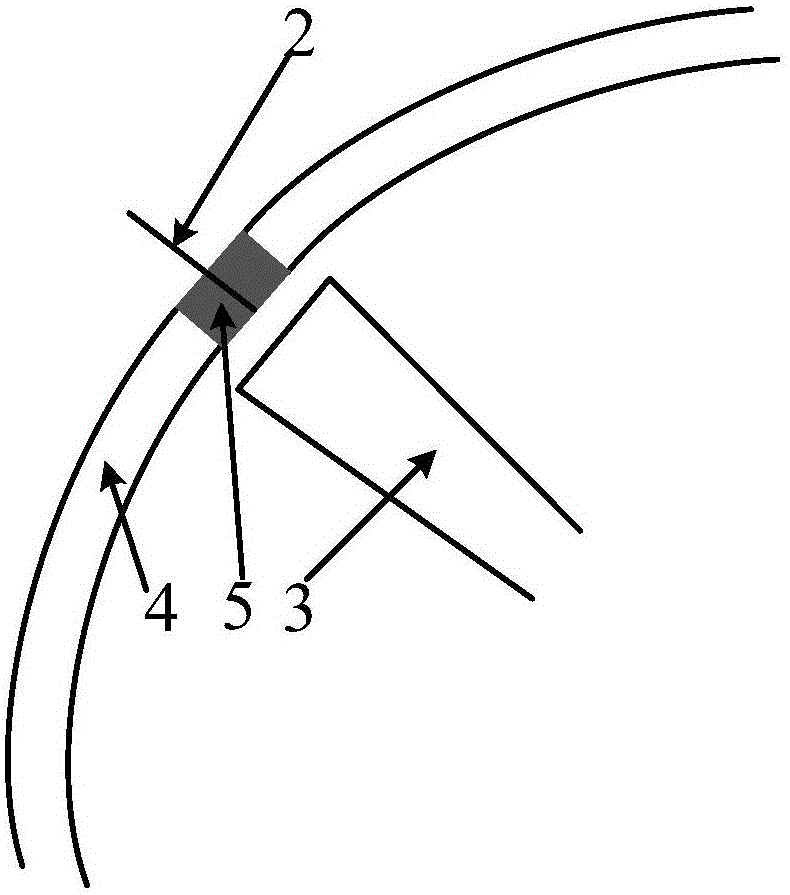

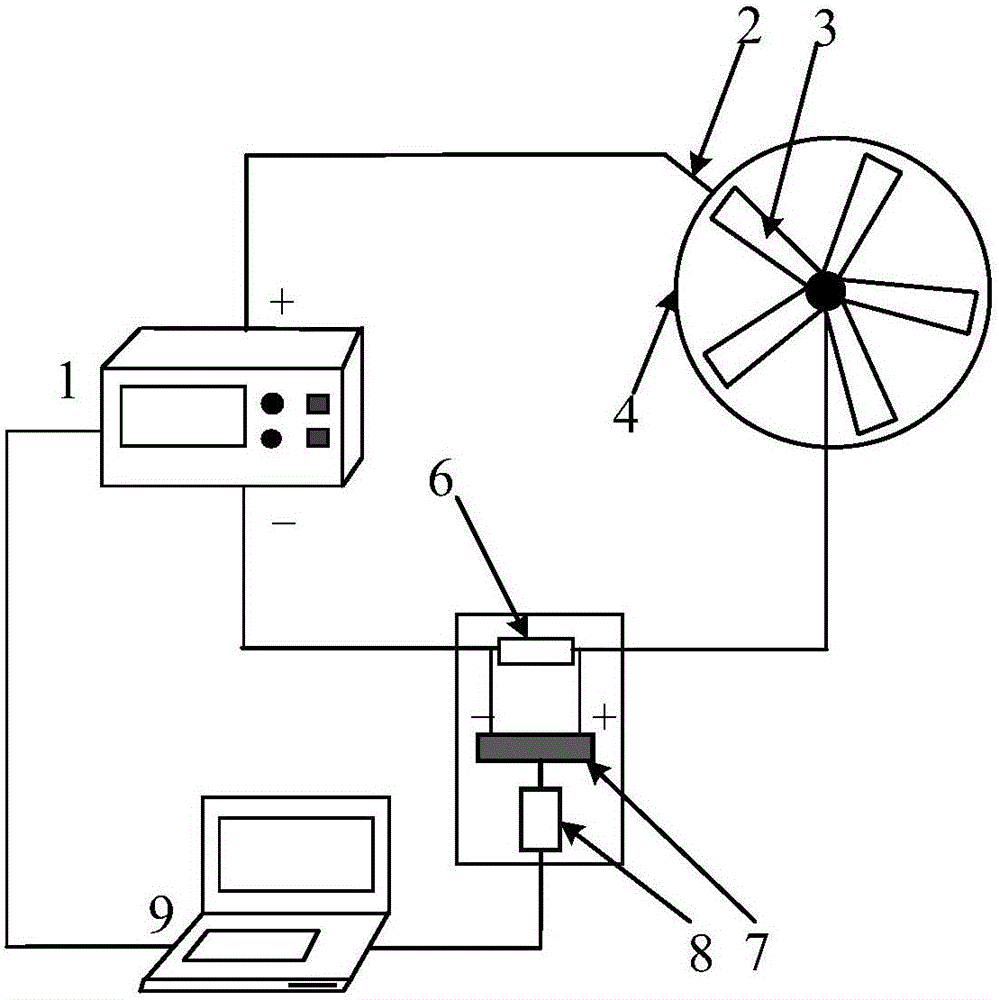

Blade tip gap measuring system and method based on AC discharging

The invention discloses a blade tip gap measuring system based on AC discharging. The blade tip gap measuring system comprises an AC numerical control adjustable exciter, a discharging probe, a current measurement conversion module, and a data processing module. One end of the discharging probe is flush with the inner wall of a casing. The other end of the discharging probe is exposed outside the casing. The part, inserted into the casing, of the discharging probe is wrapped in an insulated layer. The high-voltage end of the AC numerical control adjustable exciter is connected with the discharging probe. The cathode of the AC numerical control adjustable exciter is connected with the center of a rotor blade via the current measurement conversion module. The current measurement conversion module is connected with the control end of the AC numerical control adjustable exciter via the data processing module and is used for controlling the amplitude and the output of the output voltage of the AC numerical control adjustable exciter. A measuring method comprises drawing a relation curve between discharging initial voltage and blade tip gaps, measuring the discharging initial voltage of a rotor blade to be measured, finding out a corresponding blade tip gap value according to the relation curve, namely the blade tip gap of the rotor to be measured. The blade tip gap measuring system is good in practicality, convenient to install and use, simple in operation, short in voltage regulation time, and high in efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

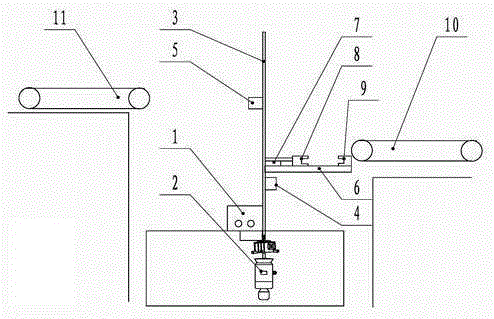

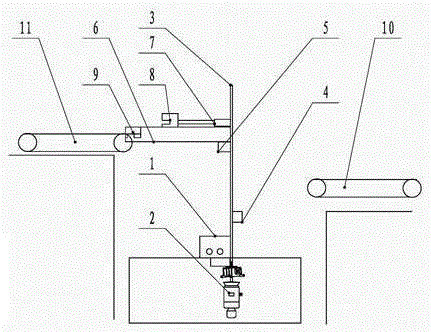

Lifting conveying device

The invention provides a lifting conveying device. The lifting conveying device comprises a controller, a lifting mechanism and a clamping transmission mechanism. The lifting mechanism comprises a driving motor and a screw-nut pair connected with the driving motor, wherein a lead screw is movably connected with a horizontal plate through a nut; a first clamping plate rotationally connected with the front end of the horizontal plate and a groove for containing the first clamping plate are arranged at the front end of the horizontal plate, and a second clamping plate opposite to the first clamping plate is arranged at the rear end of the horizontal plate; the first clamping plate and the second clamping plate are connected with the nut on the lead screw through the clamping transmission mechanism; a first sensor and a second sensor are arranged at the upper and lower ends of the lead screw respectively; the controller is arranged in a control box, and an operation panel is arranged on the surface of the control box. The driving motor, the clamping transmission mechanism and the two sensors are electrically connected with the controller. The requirements of front and back machining equipment for the height of the conveying device are both met through the lifting mechanism and the clamping transmission mechanism, and an electronic element is stably transferred from the front machining equipment to the back machining equipment.

Owner:SUZHOU YUANSHUO PRECISION MOLD

High strength insulating metal-to-metal joints for solid oxide fuel cells and other high temperature applications and method of making

InactiveUS20060063057A1Sufficient fluidityDurable bondCooking-vessel materialsFinal product manufactureOperating environmentOxide

A seal formed between a metal part and a second part that will remain gas tight in high temperature operating environments which experience frequent thermal cycling, which is particularly useful as an insulating joint in solid oxide fuel cells. A first metal part is attached to a reinforcing material. A glass forming material in the positioned in between the first metal part and the second part, and a seal is formed between the first metal part and the second part by heating the glass to a temperature suitable to melt the glass forming materials. The glass encapsulates and bonds at least a portion of the reinforcing material, thereby adding tremendous strength to the overall seal. A ceramic material may be added to the glass forming materials, to assist in forming an insulating barrier between the first metal part and the second part and to regulating the viscosity of the glass during the heating step.

Owner:BATTELLE MEMORIAL INST

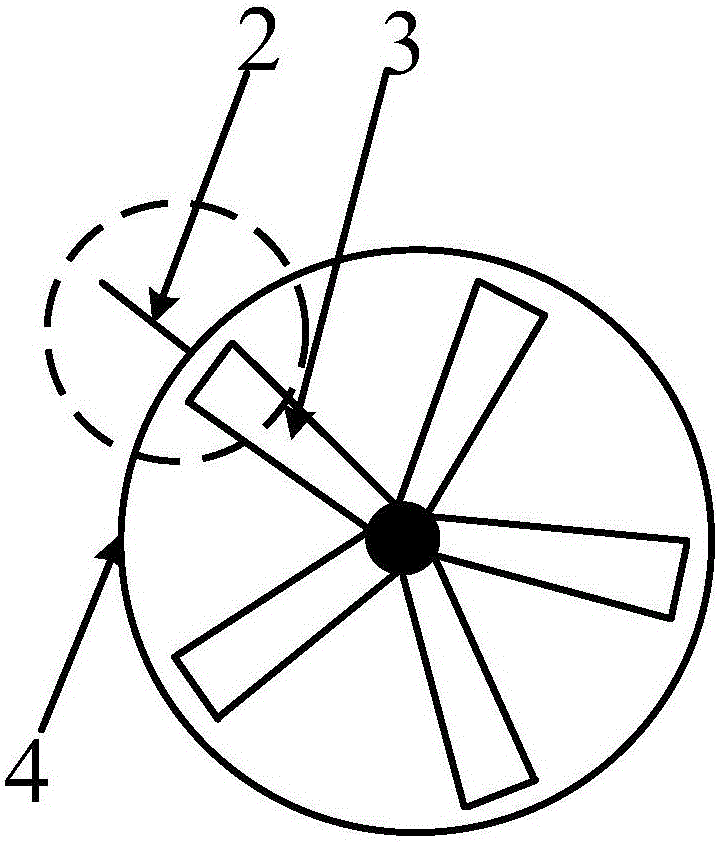

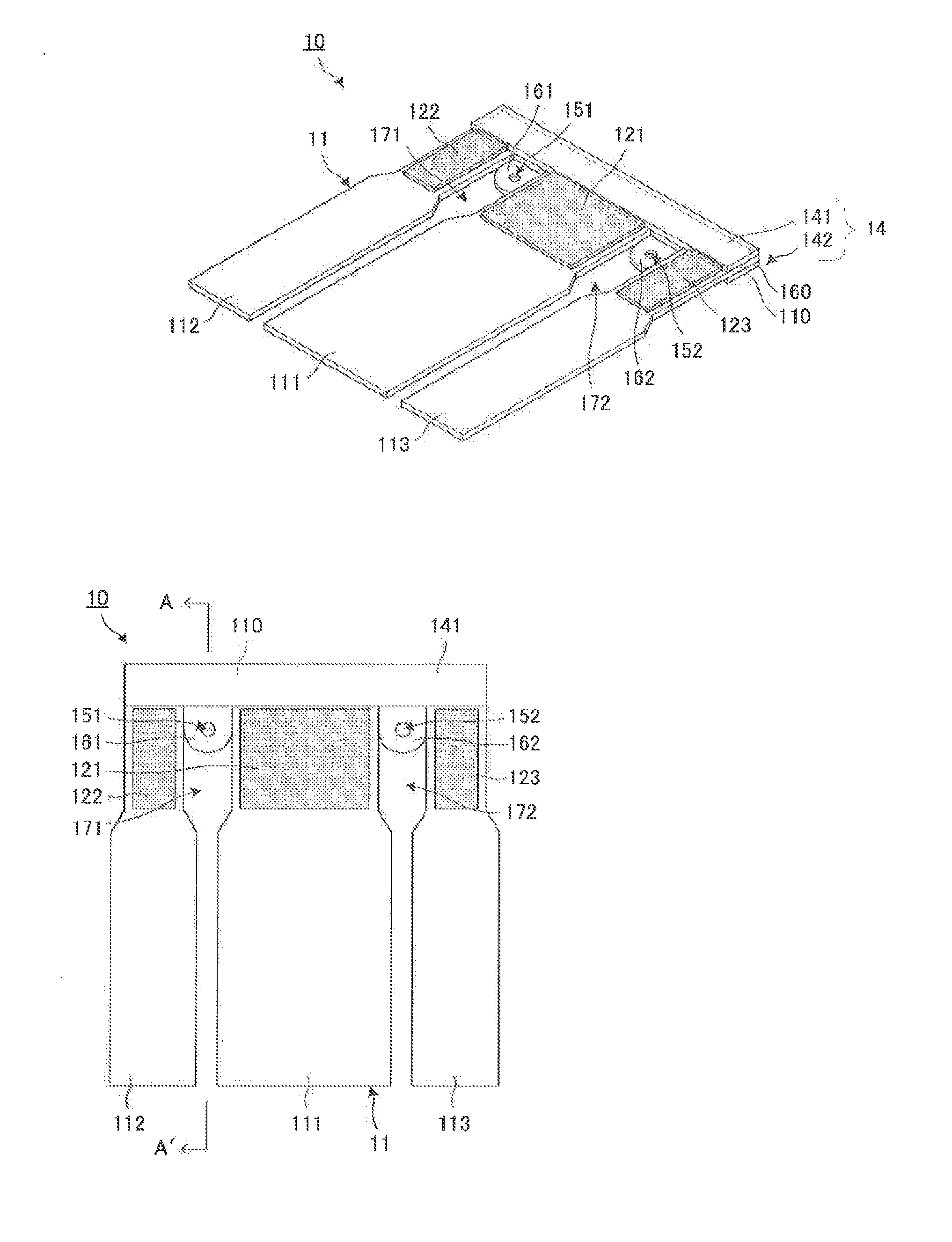

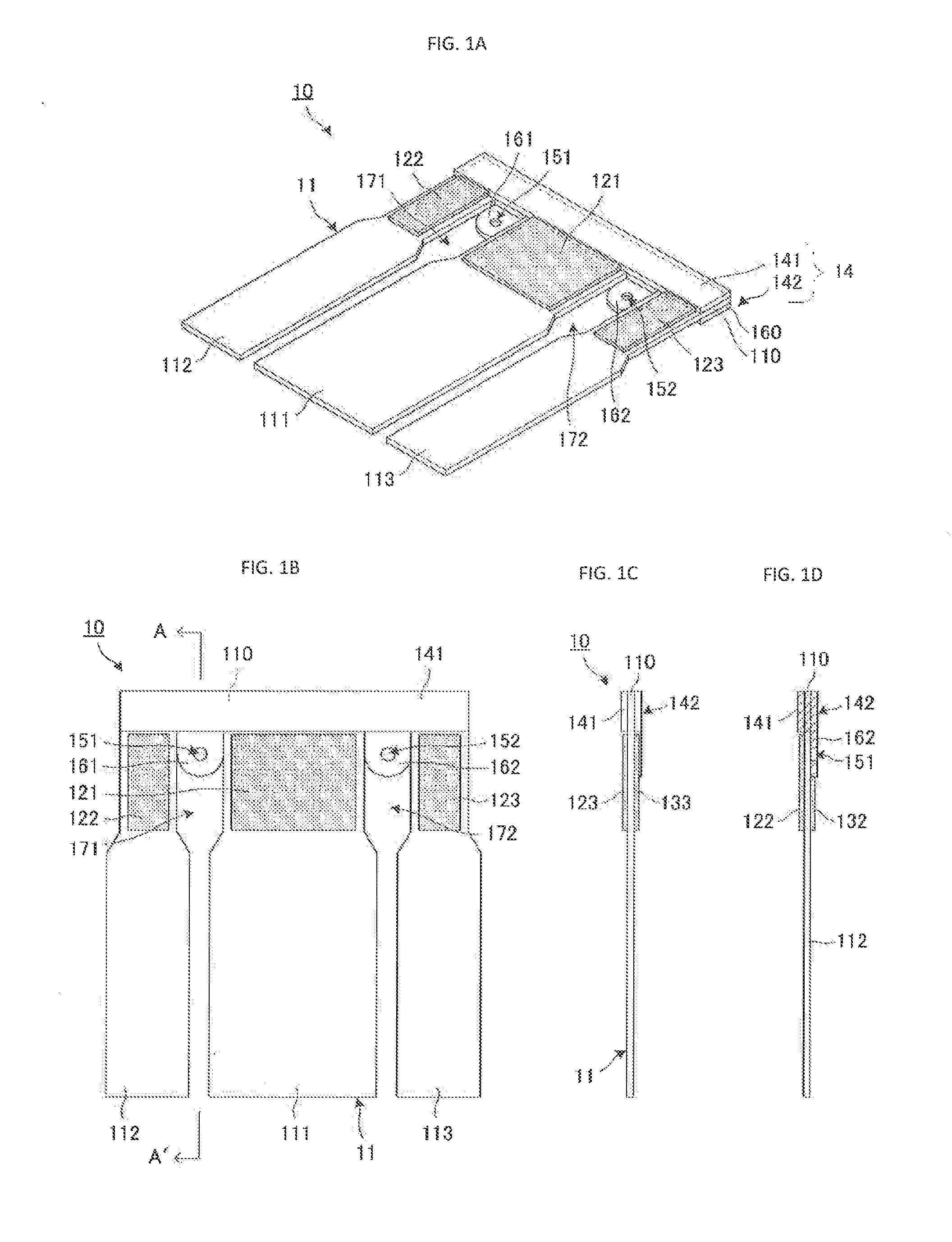

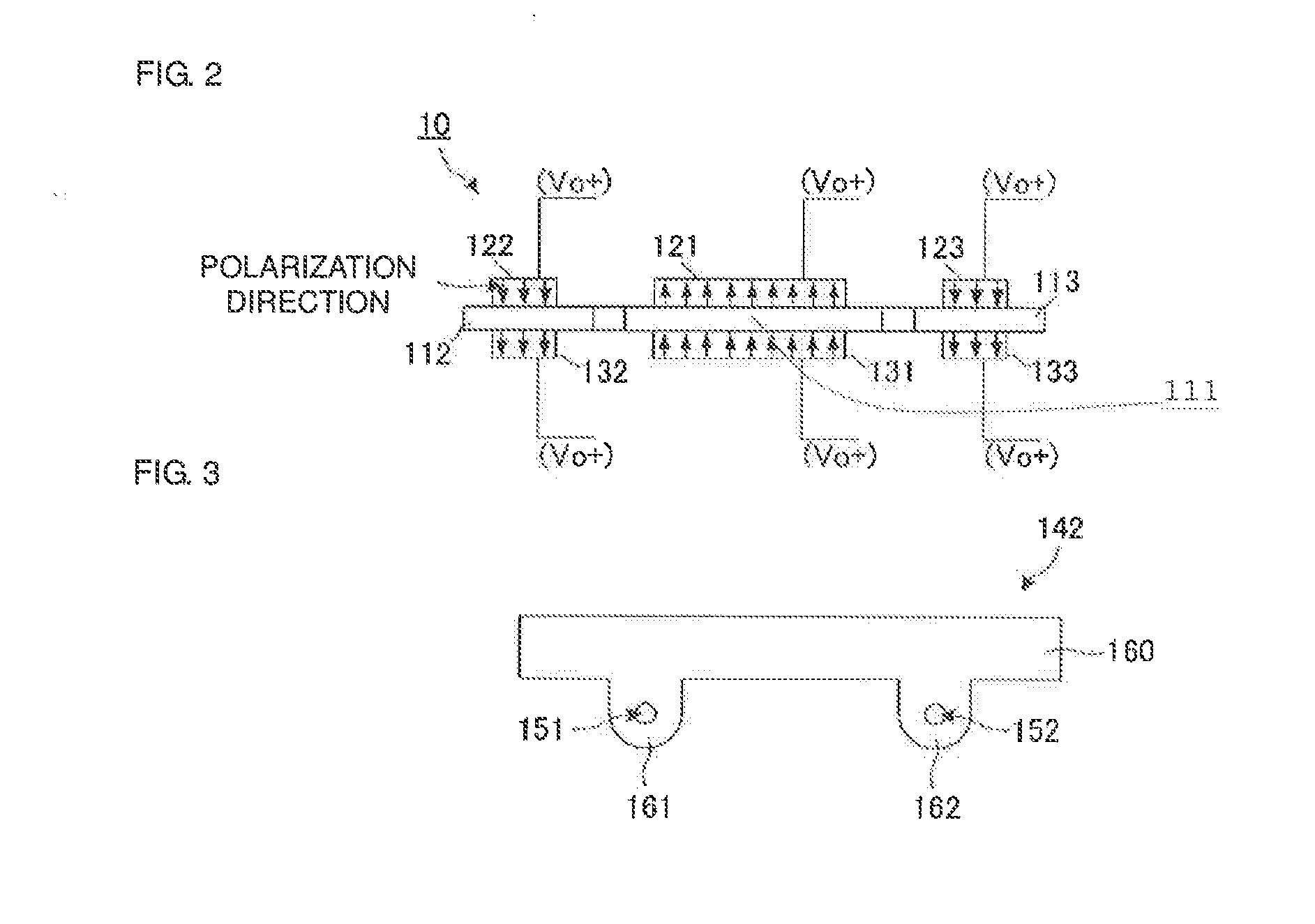

Piezoelectric fan

InactiveUS20150023819A1Reliably obtainedAvoid conducting electricitySemiconductor/solid-state device detailsSolid-state devicesPiezoelectric fanEngineering

A piezoelectric fan in which vibration of blades is unaffected by external noise includes a vibrating plate including blades and a base. First piezoelectric elements are attached to a side of a first blade adjacent to the base. Second piezoelectric elements are attached to a side of a second blade adjacent to the base. Third piezoelectric elements are attached to a side of a third blade adjacent to the base. A holder includes a supporting body and a holding member that sandwich the base therebetween. The holding member has a supporting portion and main-body fixing portions including respective main-body fixing holes. The main-body fixing portions extend from the supporting portion.

Owner:MURATA MFG CO LTD

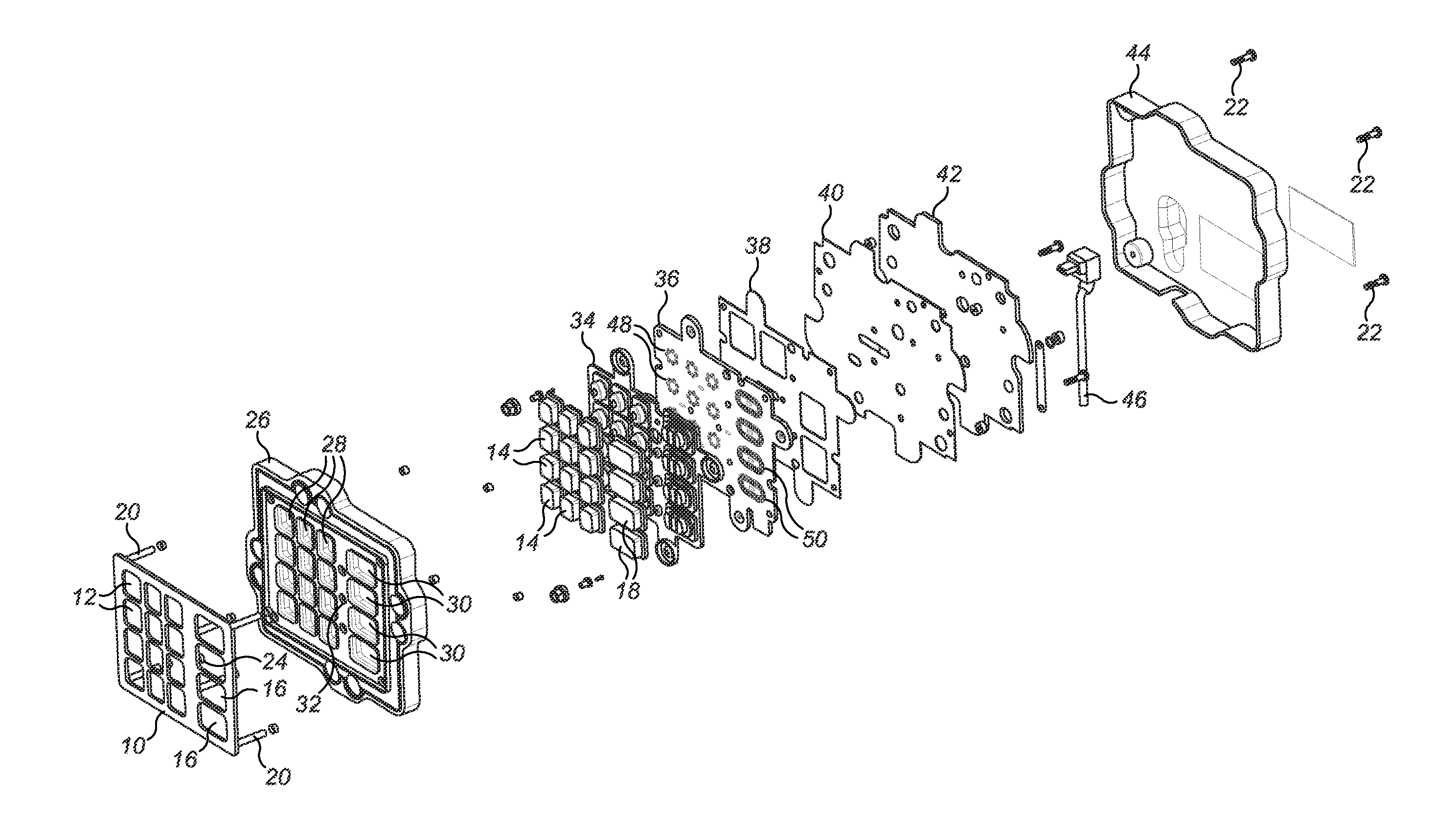

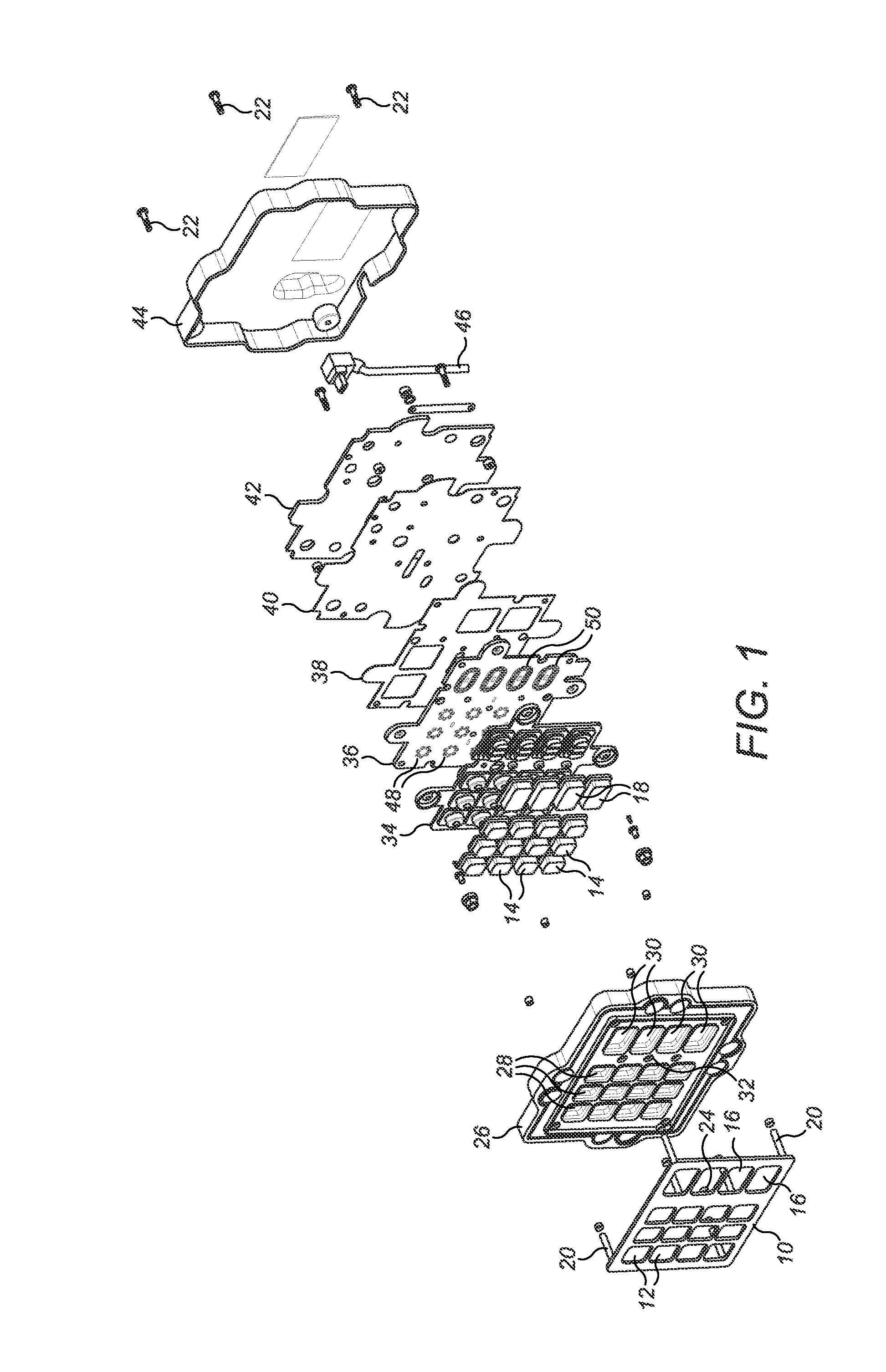

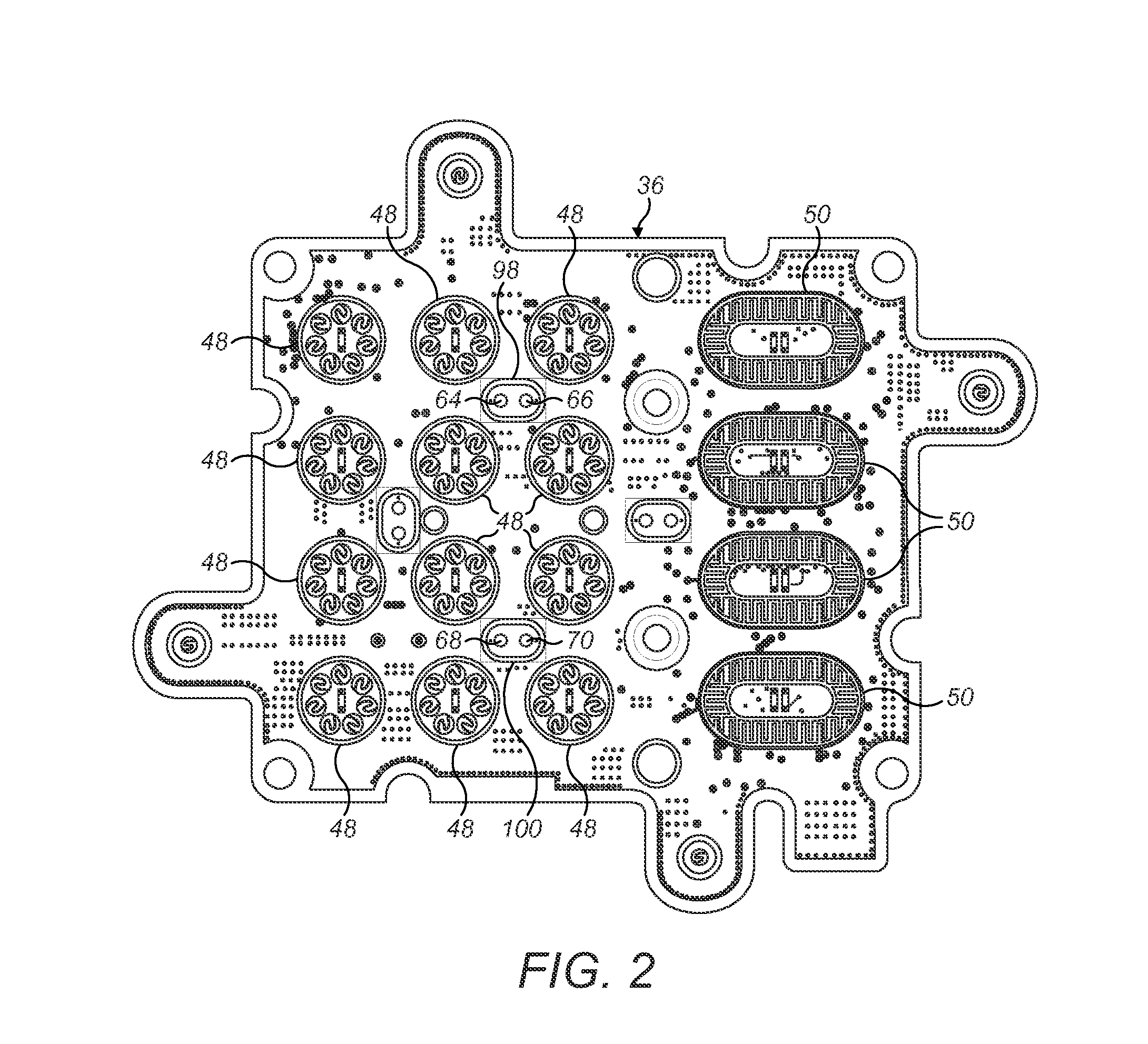

Keypad Device

InactiveUS20140041060A1Avoid conducting electricityError detection/correctionVolume/mass flow measurementElectrical resistance and conductanceElectricity

An example tamper detection mechanism may include an electrical pathway having a closed conductive configuration and being openable to prevent electrical conduction along the electrical pathway, and may further include detection circuitry connected to the electrical pathway and configured to detect a change in the resistance of the electrical pathway. The electrical pathway includes a pair of conductive pads electrically isolated from one another, and also includes a connector which in the closed conductive configuration contacts both conductive pads to form an electrical connection therebetween. The connector is moveable away from the pads to open the electrical connection for tamper detection. The connector has a resistor of predefined resistance which in the closed conductive configuration is included in the electrical pathway. The detection circuitry can distinguish, on the basis of the resistance of the electrical pathway, between connection of the pads by the connector and shorting between the two pads.

Owner:KEY INNOVATIONS

Circuit board printing method for preventing carbon oil leakage short circuit and circuit board

InactiveCN101827499APrevent seepageAvoid conducting electricityPrinted circuit secondary treatmentElectrical connection printed elementsEngineeringSoldering

The invention relates to a circuit board printing method for preventing carbon oil leakage short circuit. The circuit board comprises adjacent soldering-pans pre-printed with carbon oil. The circuit board printing method for preventing the carbon oil leakage short circuit comprises the following steps of: arranging solder bridges: arranging isolation bridges for isolating the carbon oil between the adjacent soldering-pans pre-printed with the carbon oil, wherein the isolation bridges prevent the soldering-pans printed with the carbon oil from leaking the carbon oil and generating short circuit; baking the circuit board: after making a circuit board pattern, baking the circuit board; and printing the carbon oil: printing the carbon oil on the soldering-pans of the circuit board required to be printed with the carbon oil. The circuit board printed by the circuit board printing method for preventing the carbon oil leakage short circuit cannot generate conducting short circuit due to carbon oil leakage in the using process.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

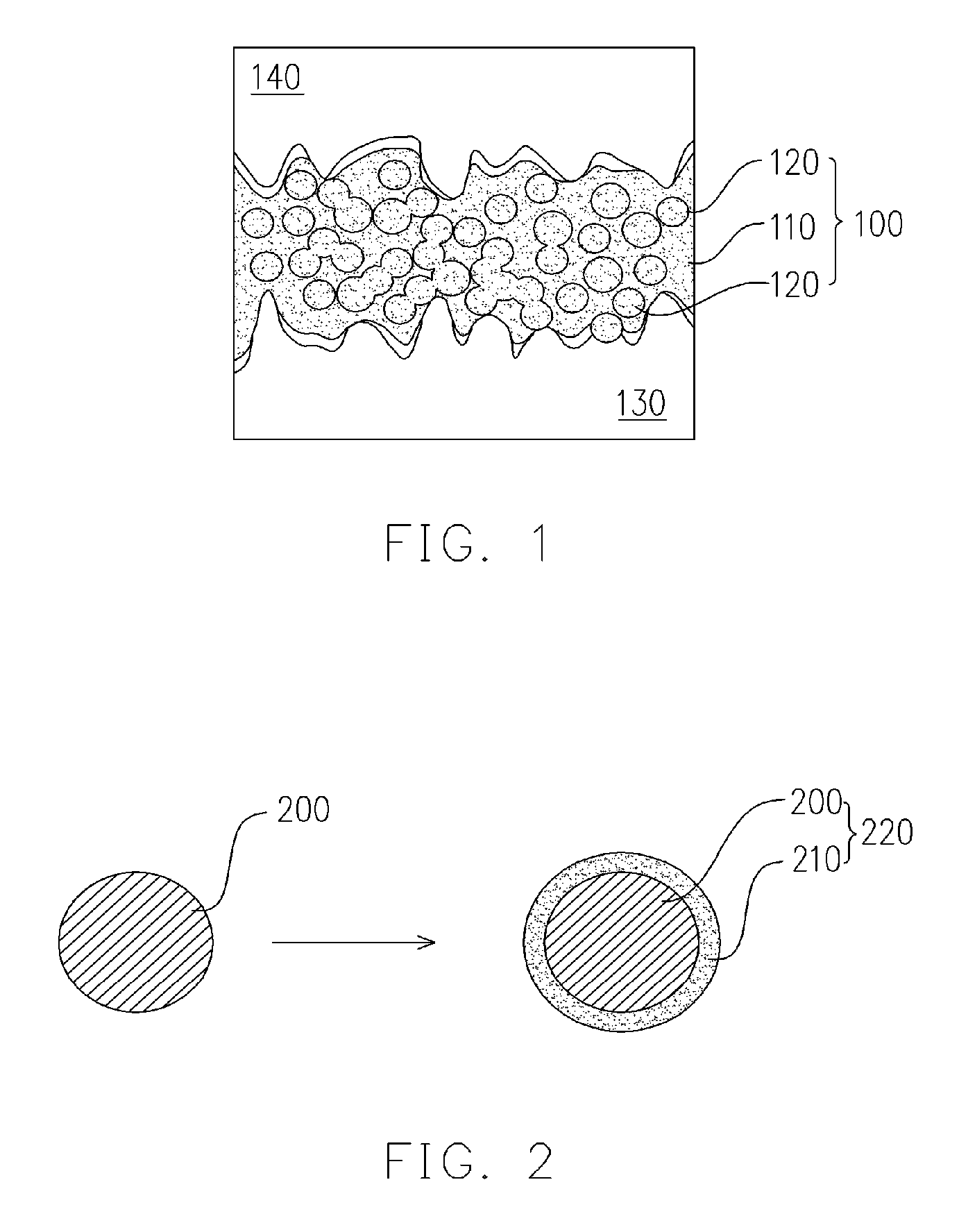

Micro-capsule film ceramic solid electrolyte for power lithium battery and preparation method

ActiveCN108134132AGood effectOvercoming instability flawsSolid electrolytesSecondary cellsRadio frequency magnetron sputteringNanoceramic

The invention discloses micro-capsule film ceramic solid electrolyte for a power lithium battery and a preparation method. The preparation method comprises the following steps: grinding lithium-ceramic electrolyte into a nano grade, preparing composite gel of silicon dioxide hydrogel and polyoxyethylene, putting the nano-grade ceramic electrolyte into the composite gel, performing spraying dryingso as to obtain microcapsules in which the nano-grade ceramic electrolyte is wrapped by gel, and further depositing the microcapsules according to a radio frequency magnetron sputtering method, thereby forming uniform and dense film solid electrolyte. By adopting the catalyst, the surfaces of nano-grade ceramic electrolyte micro particles are wrapped by the composite gel of silicon dioxide hydrogel and polyoxyethylene, the defect that ion channels are not stable when a ceramic film is subjected to temperature impact is overcome; in addition, the ceramic electrolyte is wrapped by the compositegel to form capsules, so that metal ions in the electrolyte are prevented from being reduced by a metal lithium, and electron conductivity can be effectively prevented. In addition, a solid electrolyte film made of the electrolyte is good in mechanical property and applicable to continuous on-scale preparation.

Owner:中瑞丸达机电科技(北京)有限公司

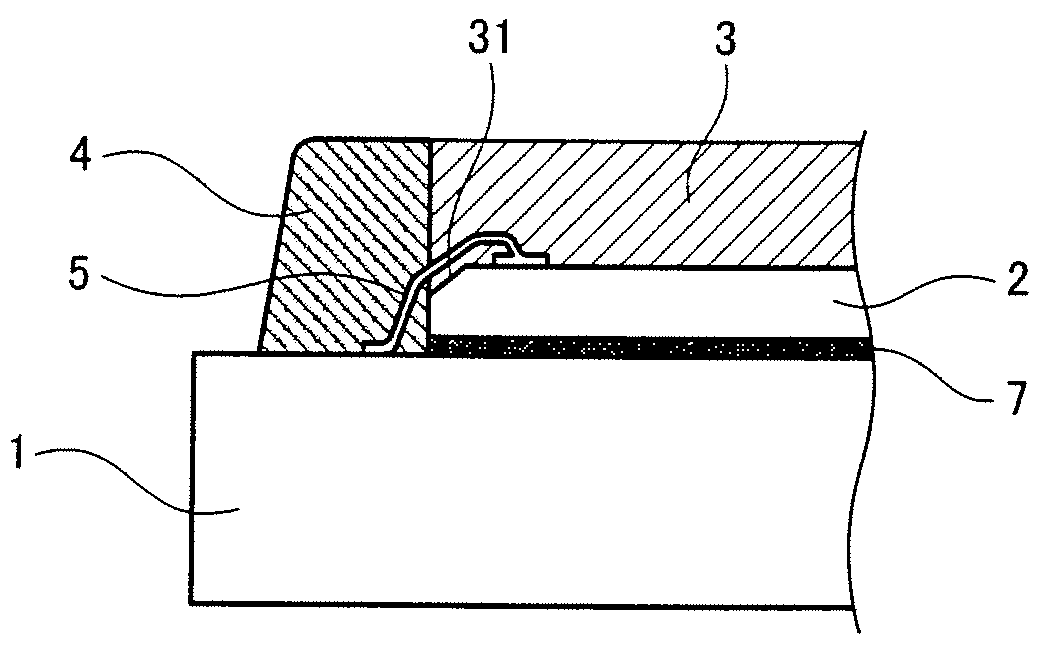

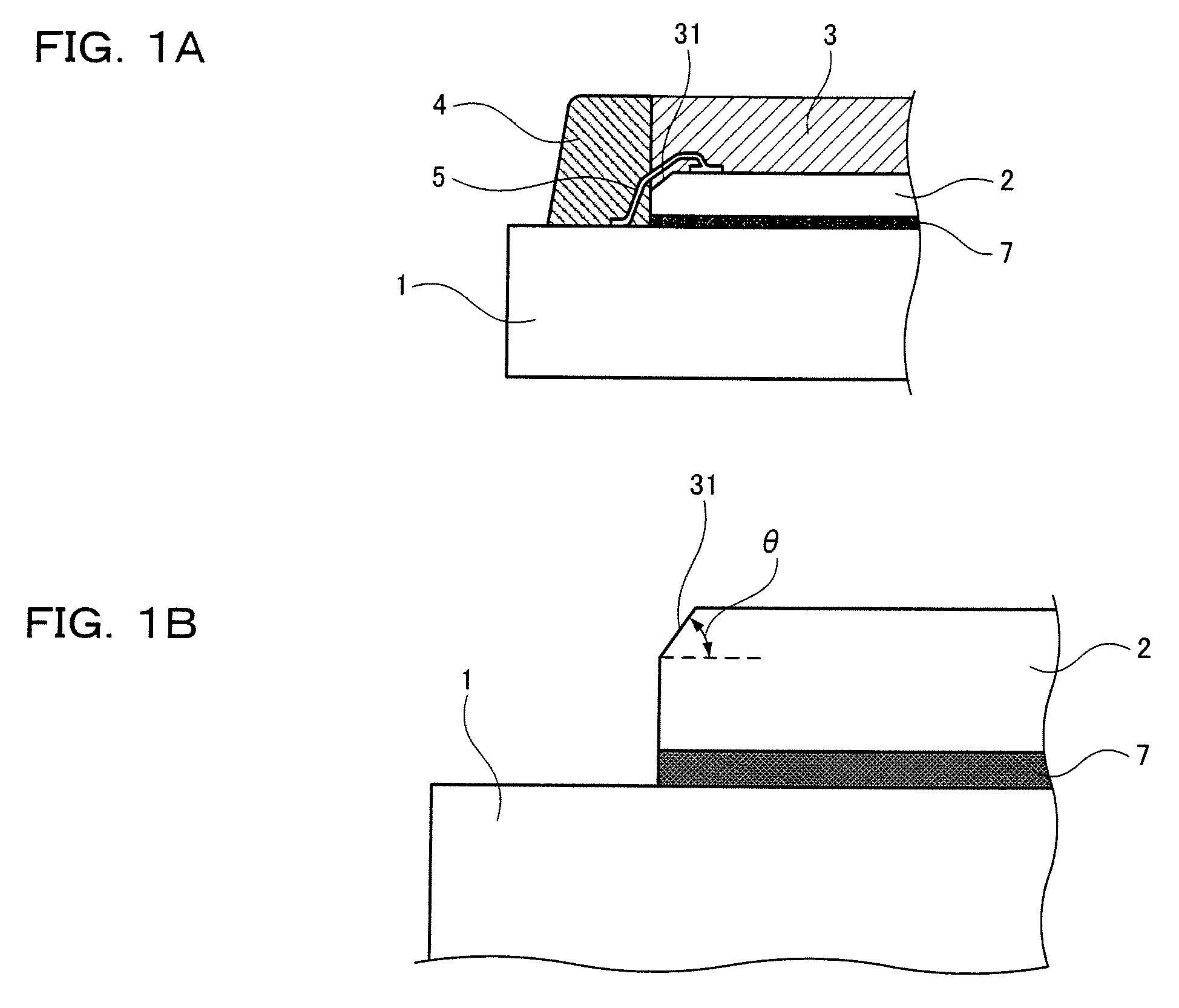

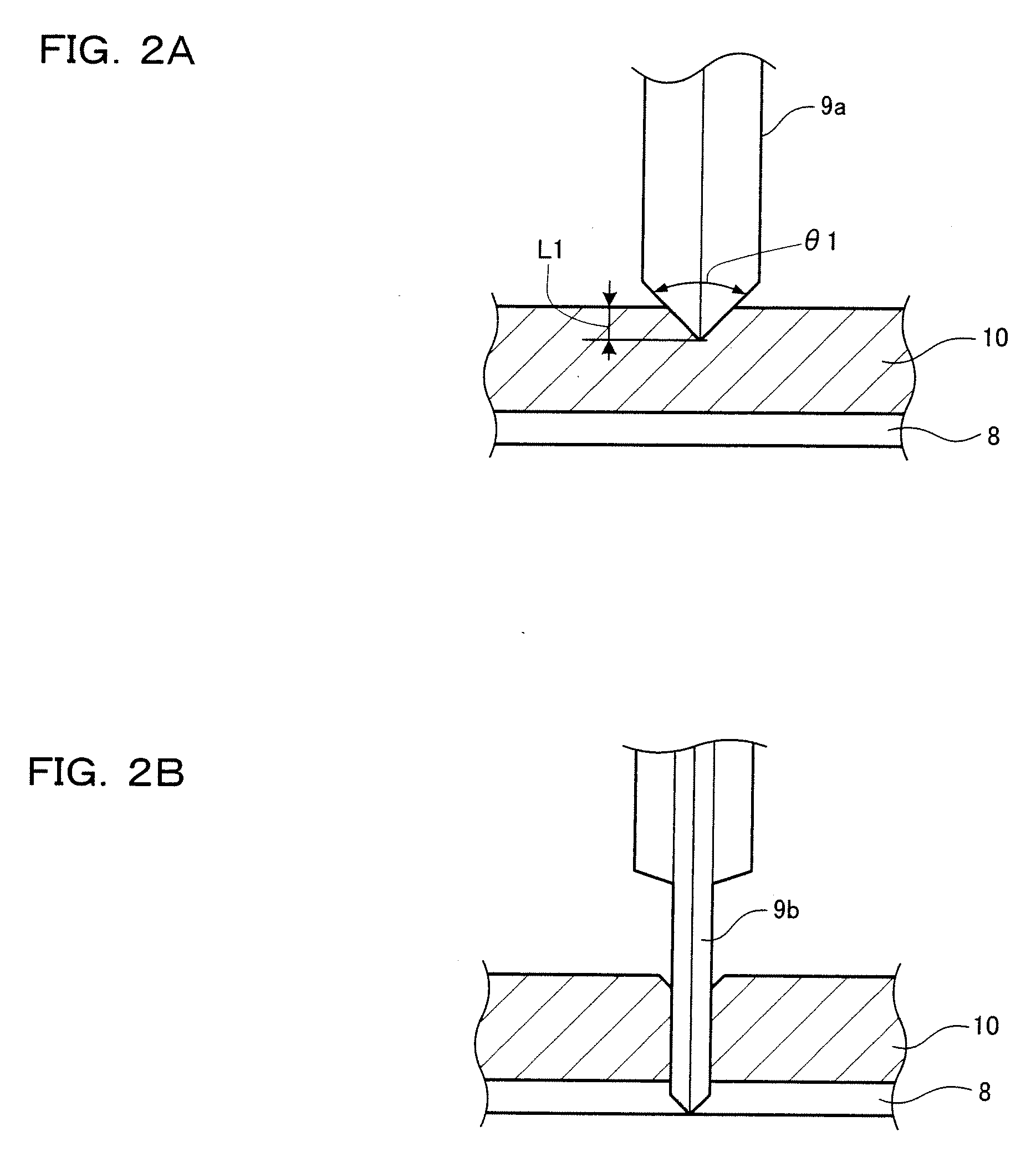

Electronic component and resin packaging method for electronic component

ActiveUS20090278265A1Reduce accumulationMeet the height limit requirementsLayered productsSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component, in which the outer perimeter portion of a component (2) is surrounded with a first sealing resin (4), a second sealing resin (3) is filled within the periphery of the first sealing resin (4), the component (2) and a board (1) are electrically connected by a wire (5), the edge, in the vicinity of which the wire (5) passes, of the outer perimeter edge portions of the component (2) is formed to be a chamfered oblique surface (31), and the wire (5) is provided to extend to the board (1) along the oblique surface (31). By this means, the overall height of the electronic component can be kept low.

Owner:PANASONIC CORP

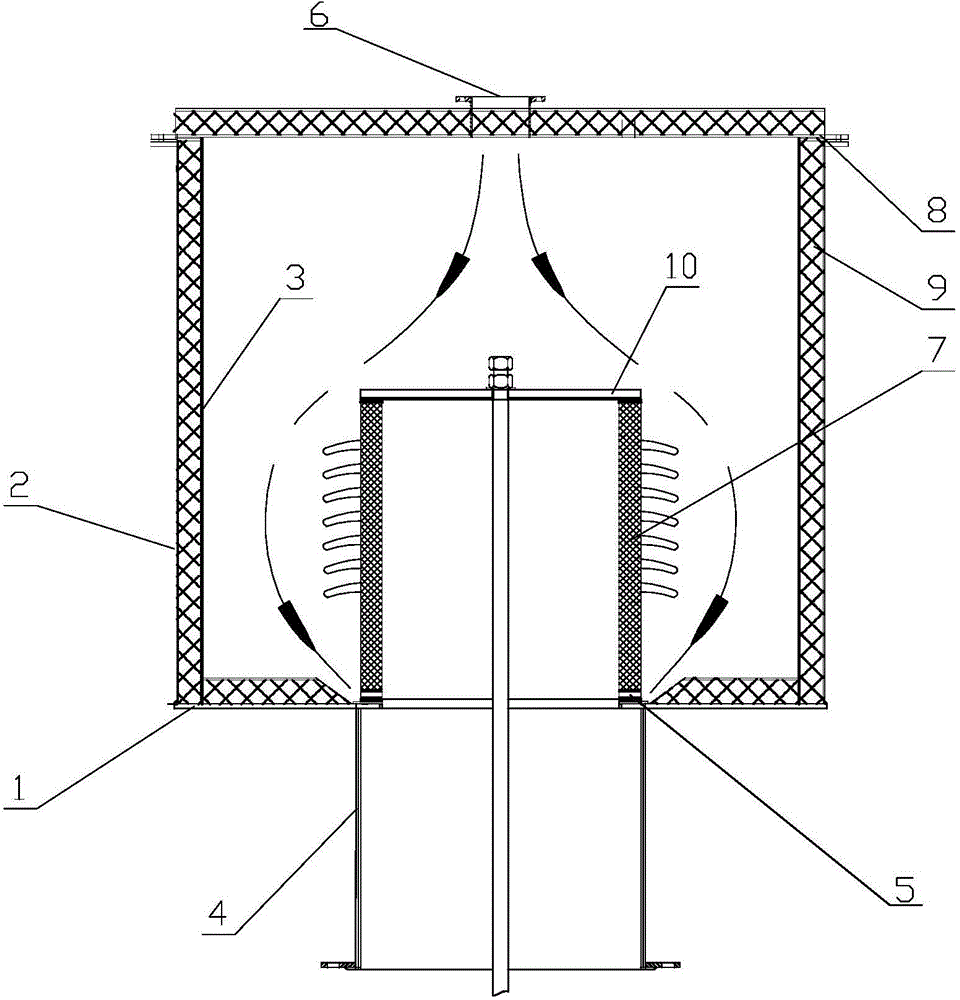

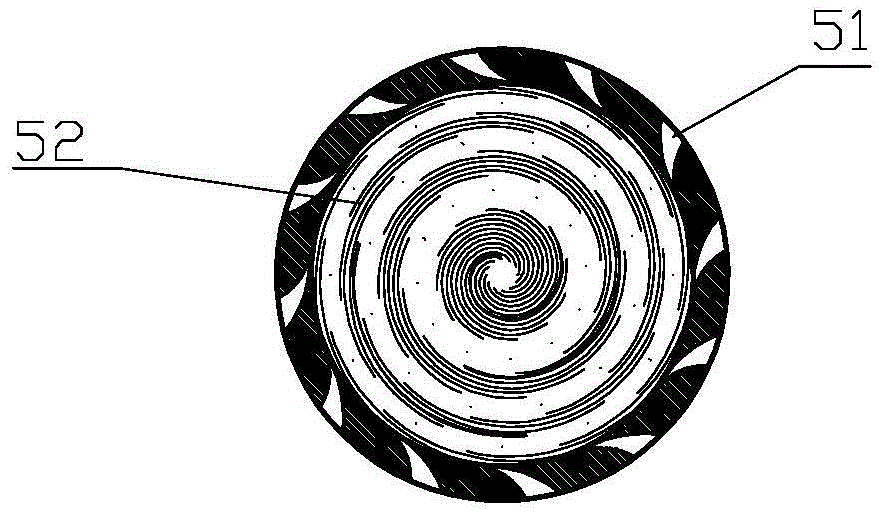

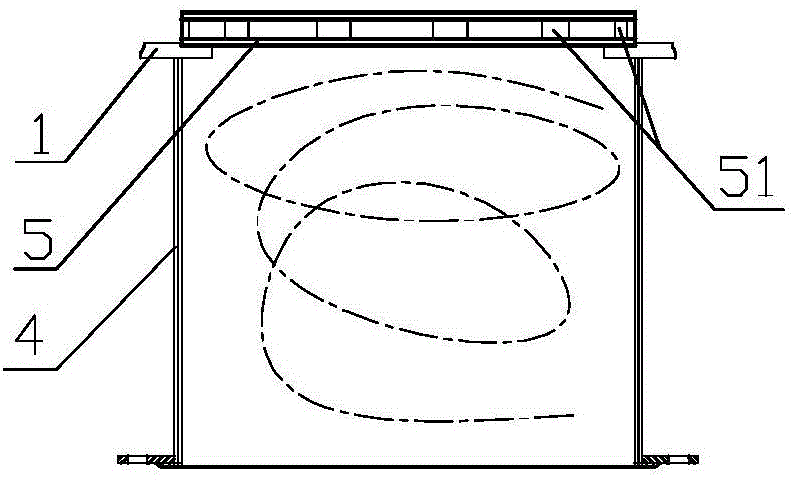

Hanging type insulating device of wet electric precipitator insulating box

ActiveCN104971825AImprove recycling ratesImprove surface smoothnessElectric supply techniquesCycloneElectricity

A hanging type insulating device of a wet electric precipitator insulating box comprises an insulating cover, an insulating box base, an insulator, a hanging rod and a cyclone disc. The insulating cover is arranged on the insulating box base through a bottom disc flange. A conical hole is formed in the center of a bottom plate of the insulating cover, and the large opening end of the conical hole faces upwards. The cyclone disc is a circular ring. A plurality of air flues are evenly distributed on the circumferential wall of the cyclone disc. The air flues are inclined air flues with the large outer ports and the smaller inner ports and are consistent in inclination direction. The cyclone disc is arranged in the conical hole of the bottom plate of the insulating cover, is coaxial with the bottom disc flange and is arranged at the upper end of the bottom disc flange. The insulator is placed at the upper portion of the cyclone disc. An air inlet is formed in the top of the insulating cover. After entering a cavity of the insulating cover through the air inlet, the hot air enters the insulating box base through the air flues on the cyclone disc, and a backspin cyclone curtain can be formed after hot air enters the insulating box base; partition is formed for an insulating box base inner cavity where wet smoke invades, the short circuit between the hanging rod with high-voltage electricity and the cavity of the insulating cover so that electric conduction can be avoided, and the short-circuit access among the hanging rod, a gland and the insulating box base is blocked.

Owner:SHANDONG GUOSHUN CONSTR GRP

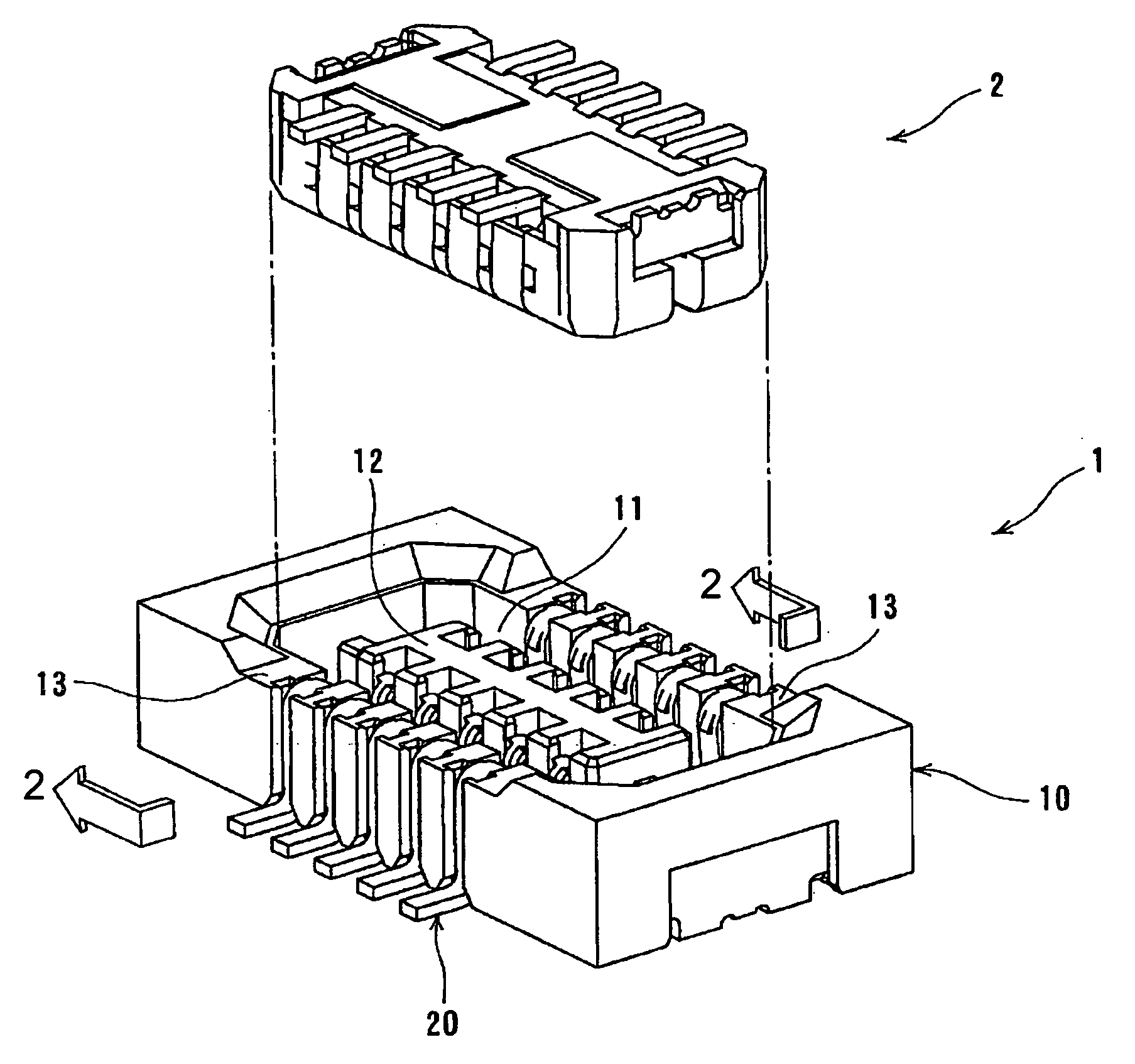

Electrical connector

ActiveUS20090221157A1Add dimensionIncrease the areaCoupling contact membersPrinted circuitsMating connectionEdge surface

A connector to be connected to a mating connector includes a housing having a receptacle recess portion for receiving the mating connector, and a terminal retained in the housing. The housing includes a containing groove extending in a connecting direction for containing a fitting portion of the terminal. The fitting portion of the terminal includes an engaging portion at a side end edge thereof. The containing groove includes a regulating wall portion extending in the connecting direction and located inner side than a position of an edge surface of the engaging portion at the containing groove. The regulating wall portion includes a regulating surface extending in the connecting direction and a width direction of the terminal. When the mating connector is extracted, the regulating surface regulates an elastic deformation of the fitting portion by abutting against and engaging with the engaging portion.

Owner:HIROSE ELECTRIC GROUP

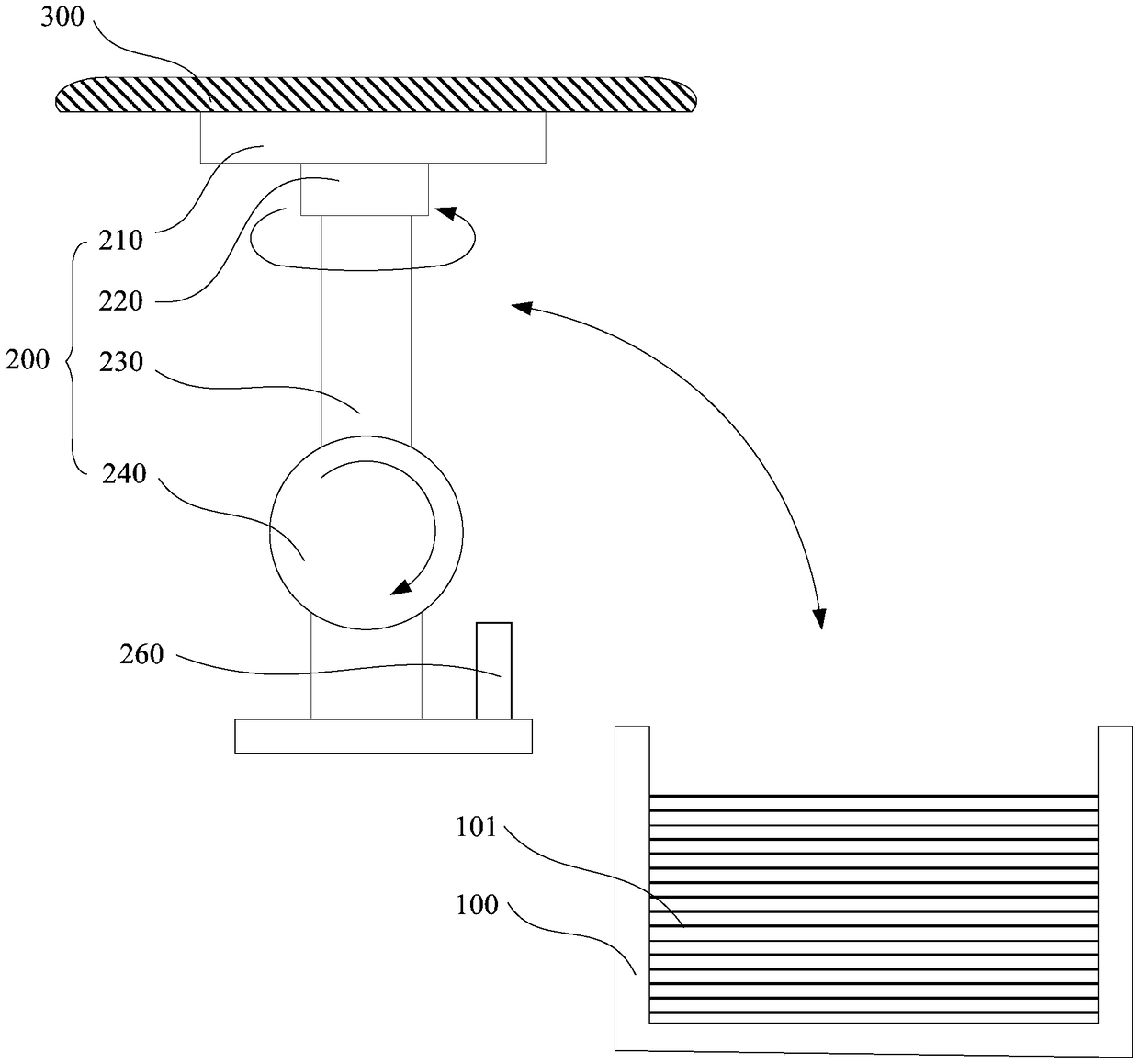

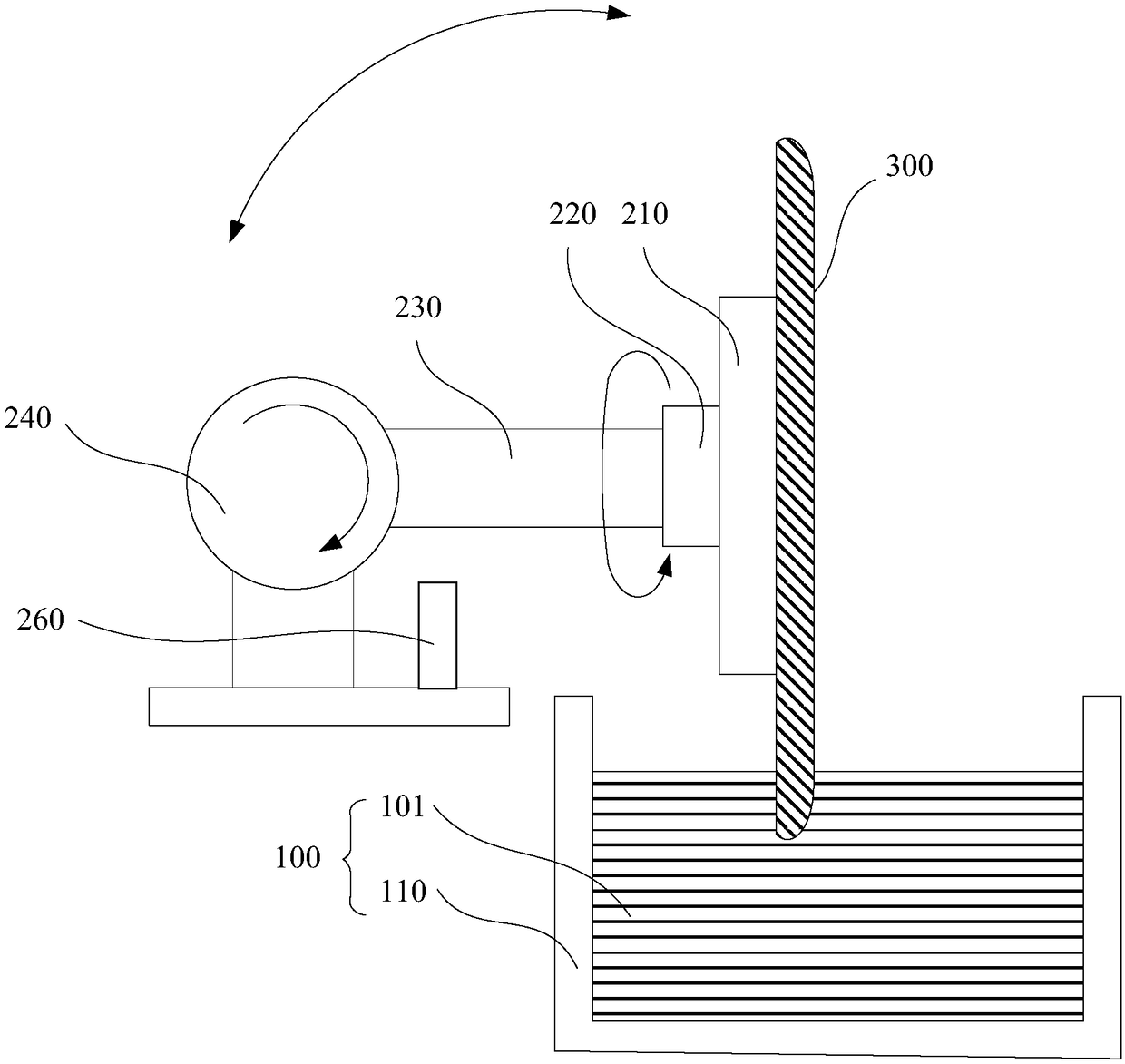

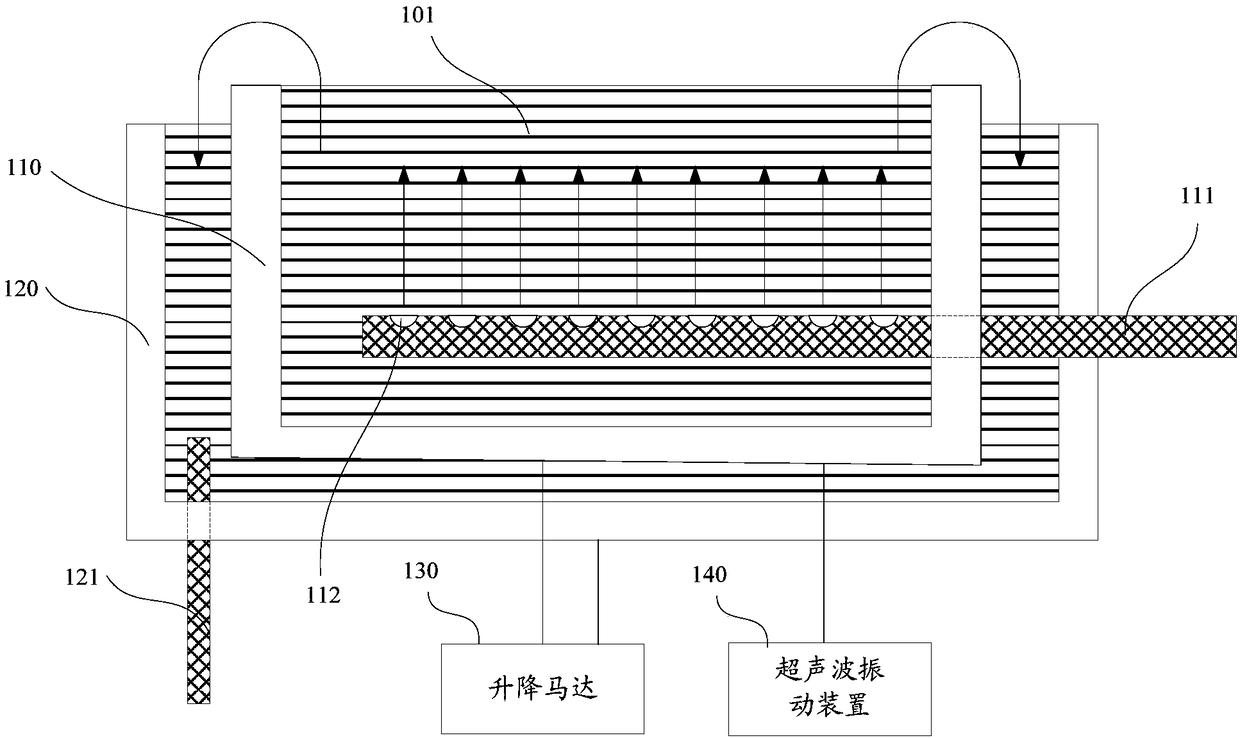

Wafer cleaning device

InactiveCN109411393AAvoid changing electrical propertiesAvoid conducting electricitySemiconductor/solid-state device manufacturingControllabilityElectrical and Electronics engineering

A wafer cleaning device comprises a cleaning groove and wafer fixing equipment, wherein a cleaning liquid is accommodated in the cleaning groove, the wafer fixing equipment is used for grabbing a wafer, the wafer is placed in the cleaning groove in a non-horizontal state, the wafer fixing equipment is used for immersing at least one part of the wafer in the cleaning liquid in a cleaning state anddriving the wafer to rotate. With the wafer cleaning device provided by the scheme, the wafer edge cleaning controllability and cleanness can be improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

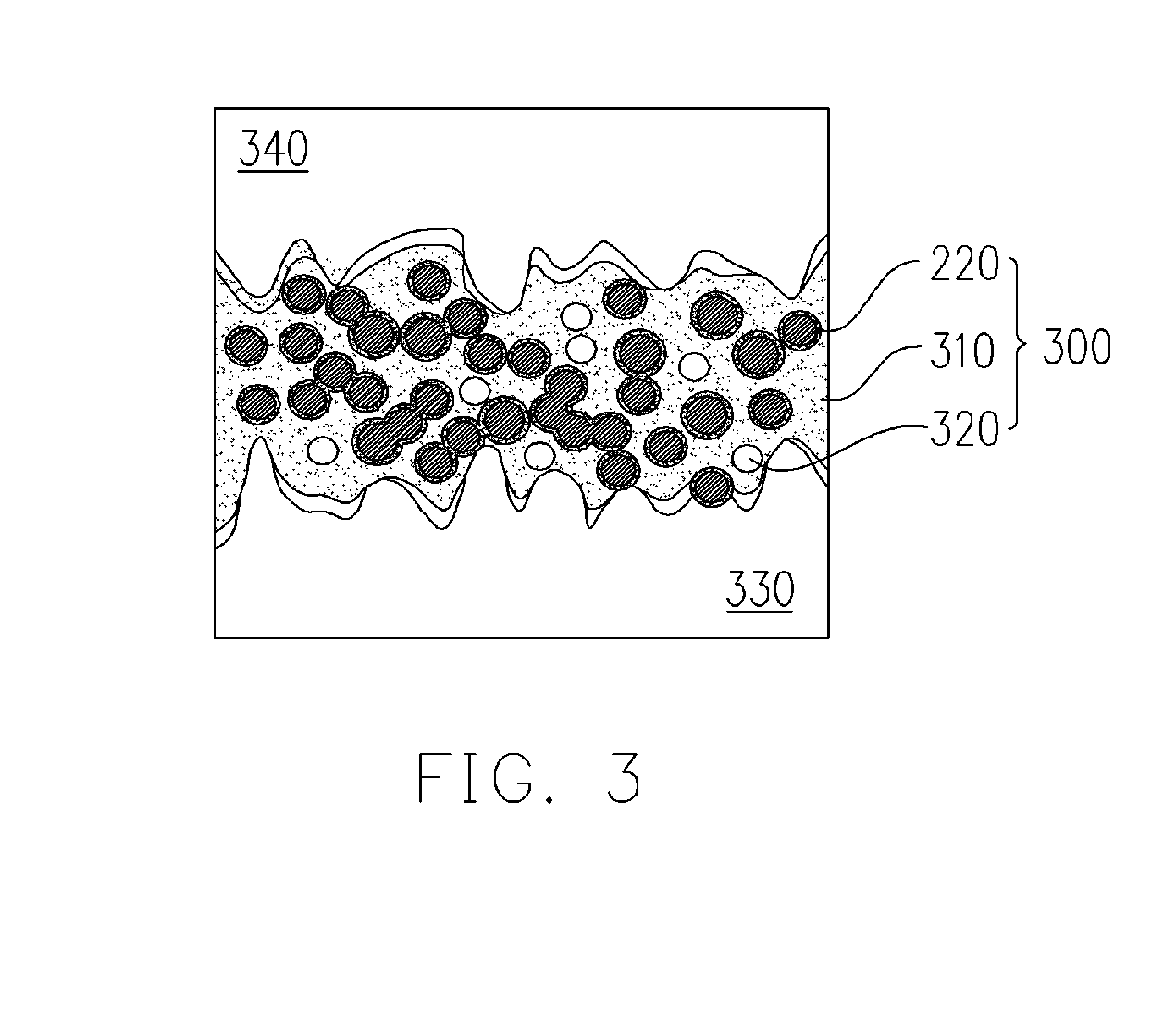

Thermal interface material and filler used therein

InactiveUS20060199878A1High dielectric strengthReduce electrical conductivitySemiconductor/solid-state device detailsSynthetic resin layered productsMaterials scienceElectrically conductive

A filler used in thermal interface materials (TIMs) is disclosed. The filler is composed of a plurality of electrically conductive particles, on which a non-electrically conductive films is formed for preventing the electrically conductive particles from electrical conducting with each other. The present invention also provides a thermal interface material (TIM) including the above-mentioned filler.

Owner:COMPAL ELECTRONICS INC

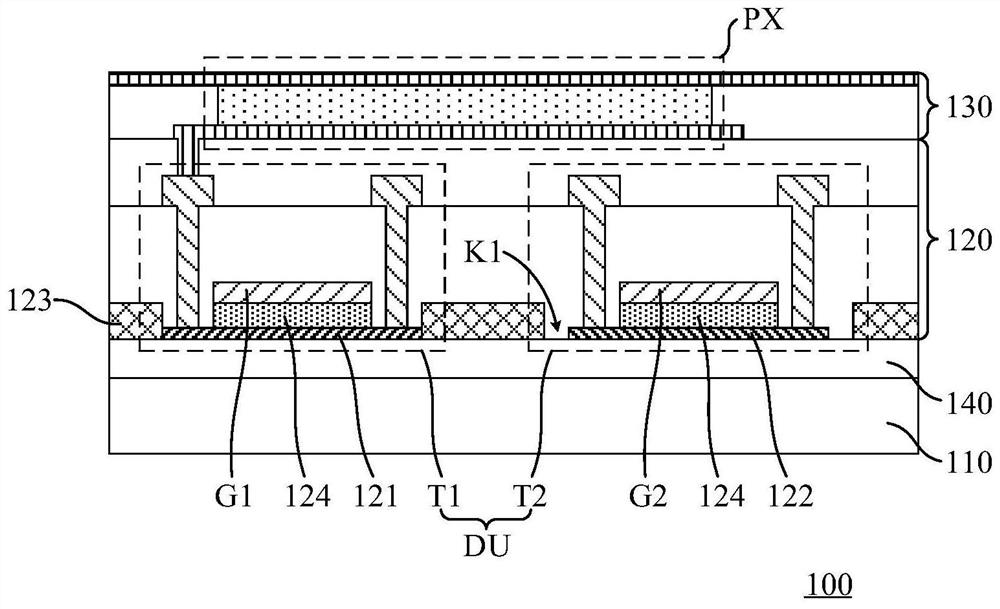

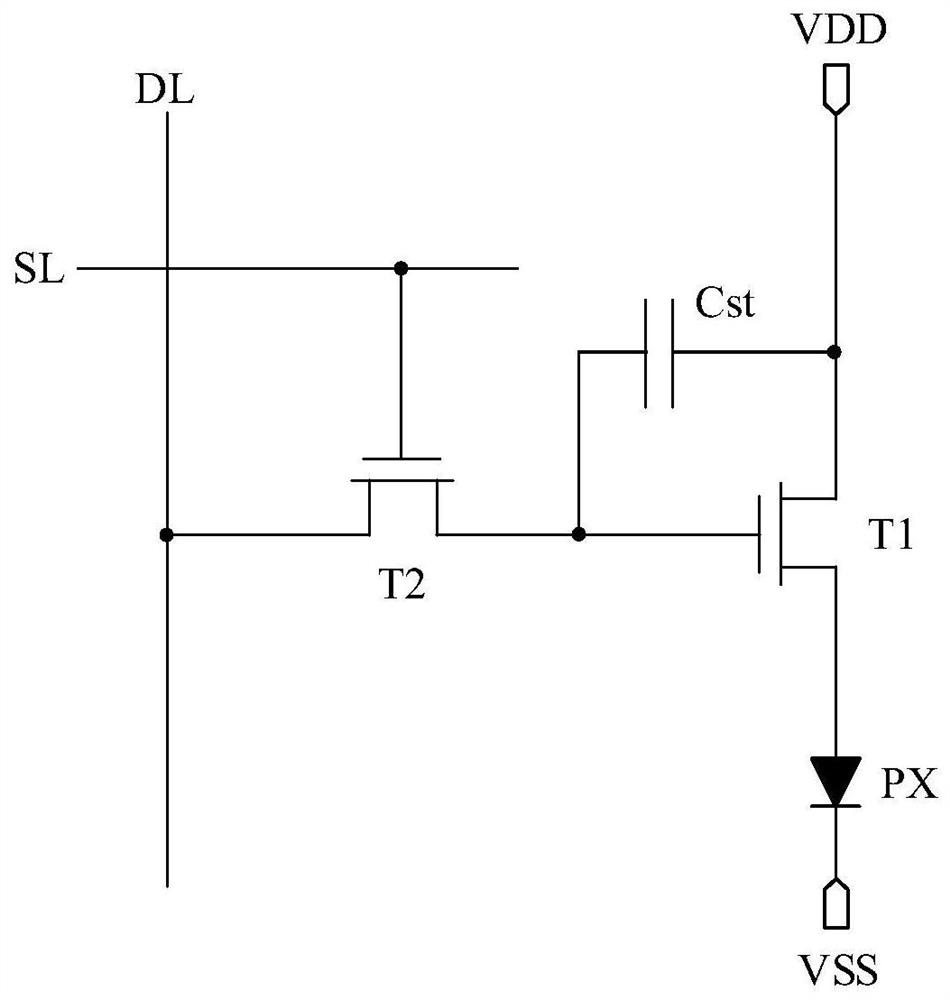

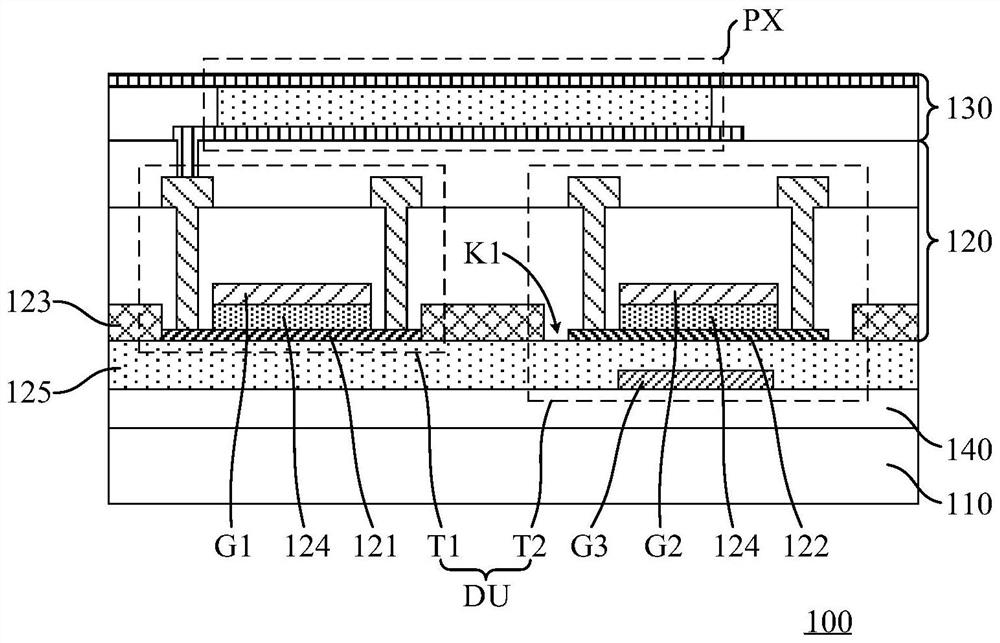

Display panel, manufacturing method thereof and display device

ActiveCN111710685AHigh activityGuaranteed stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsDisplay device

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel includes a substrate and a driving array layer; the driving array layer comprises a silicon transistor and an oxide transistor; the silicon transistor comprises a silicon active layer and a first grid electrode; the oxide transistor comprises an oxide active layer and a second grid electrode; the silicon active layer and the oxide active layer are arranged on the same layer; the driving array layer further comprises a silicon nitride gate insulating layer and a first silicon oxide gate insulating layer; at least one of the silicon nitride gate insulating layer and the first silicon oxide gate insulating layer is positioned on the surface, far away from the substrate, of the silicon active layer; the silicon nitride gate insulating layer comprises a first opening; the orthographic projection of the first opening on the substrate covers the orthographic projection of the oxideactive layer on the substrate; and the first silicon oxide gate insulating layer is further located on the surface, away from the substrate, of the oxide active layer. According to the display panel provided by the embodiment of the invention, the manufacturing difficulty of the display panel comprising two kinds of semiconductor material transistors is reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Socket and socket assembly

InactiveCN103700990AAvoid connectionAvoid conducting electricityCoupling device detailsTwo-part coupling devicesEngineeringElectric shock

The invention relates to a socket, which comprises a socket body, connectors and a rotating part. The socket body is of a hollow structure. The socket body is provided with a first side surface and a second side surface, wherein the first side surface is in parallel with the second side surface. The connectors are held in the socket body. The connectors are fixedly arranged on the first side surface. The rotating part is arranged on the second side surface. The rotating part can rotate relative to the connectors. A plurality of jacks are formed in the rotating part. The invention additionally provides a socket assembly using the socket. The socket assembly comprises a plug. The plug comprises a plug body and pins. Through holes are formed in the plug body. One ends of the pins are arranged in the plug body. The other ends of the pins are arranged in the through holes in a penetrating way and are partially arranged outside the socket body. After the plug is inserted into the socket and the plug is not turned, the projections of the jacks in the rotating part of the socket on the first side surface are isolated from the connectors, so that the pins are prevented from being connected with the connectors and getting electrified and electric shocks caused by reasons such as user negligence during use are prevented.

Owner:HUIZHOU KELIN ELECTRICAL APPLIANCE

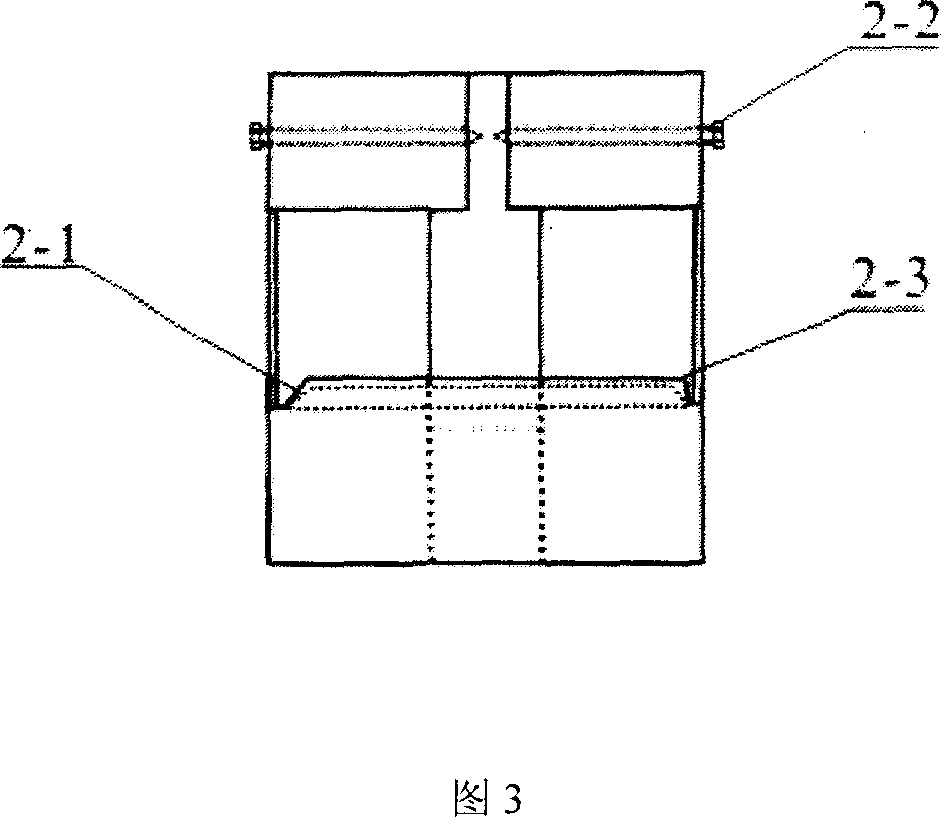

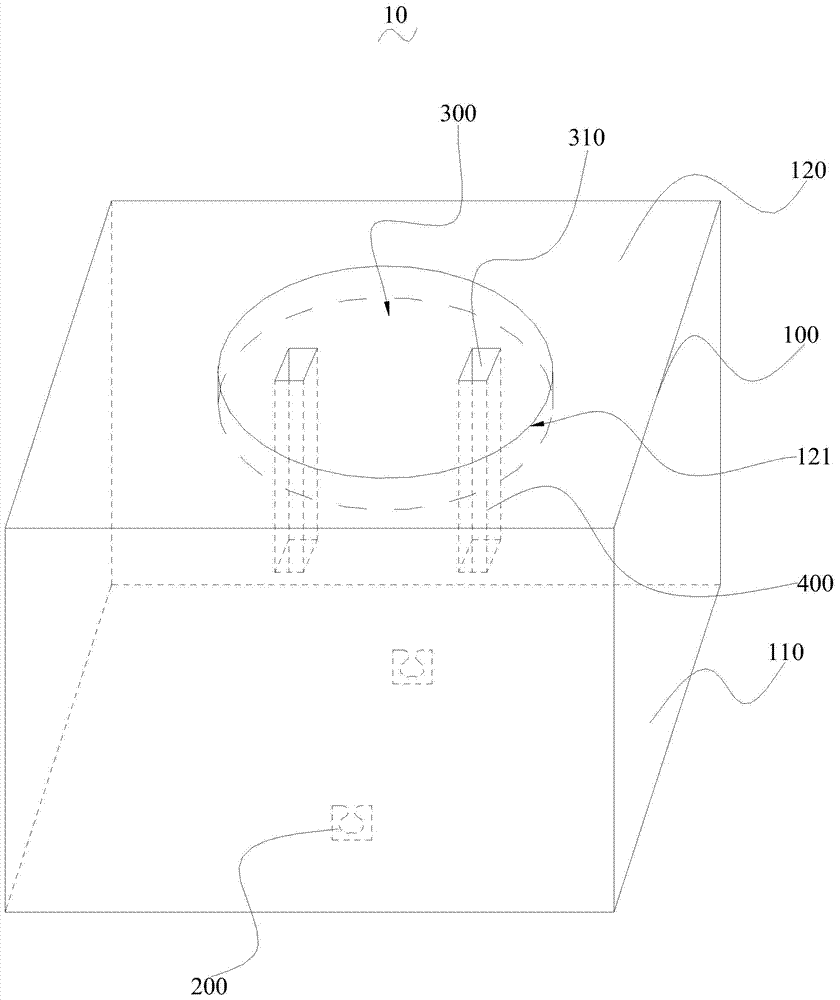

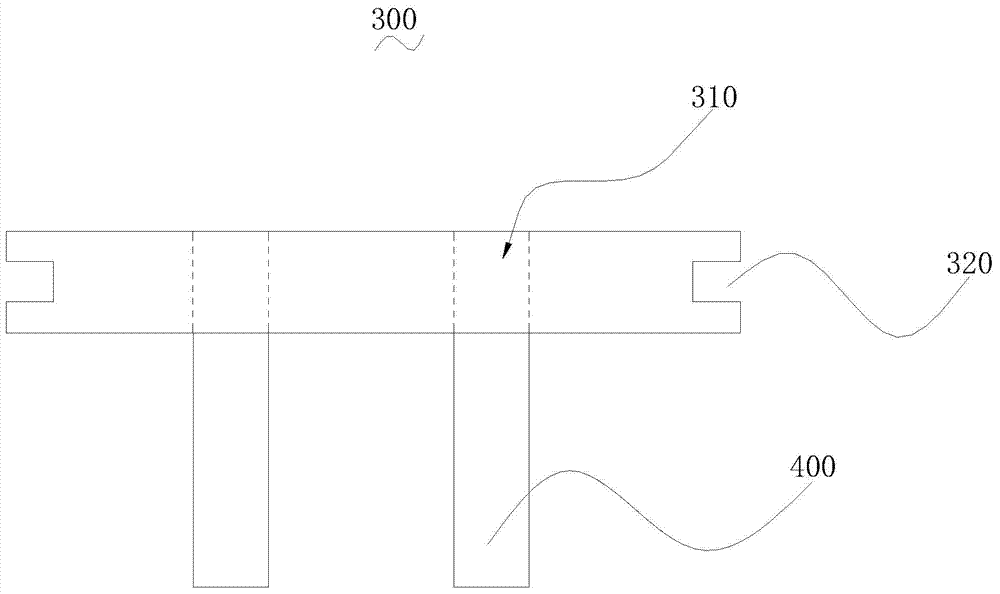

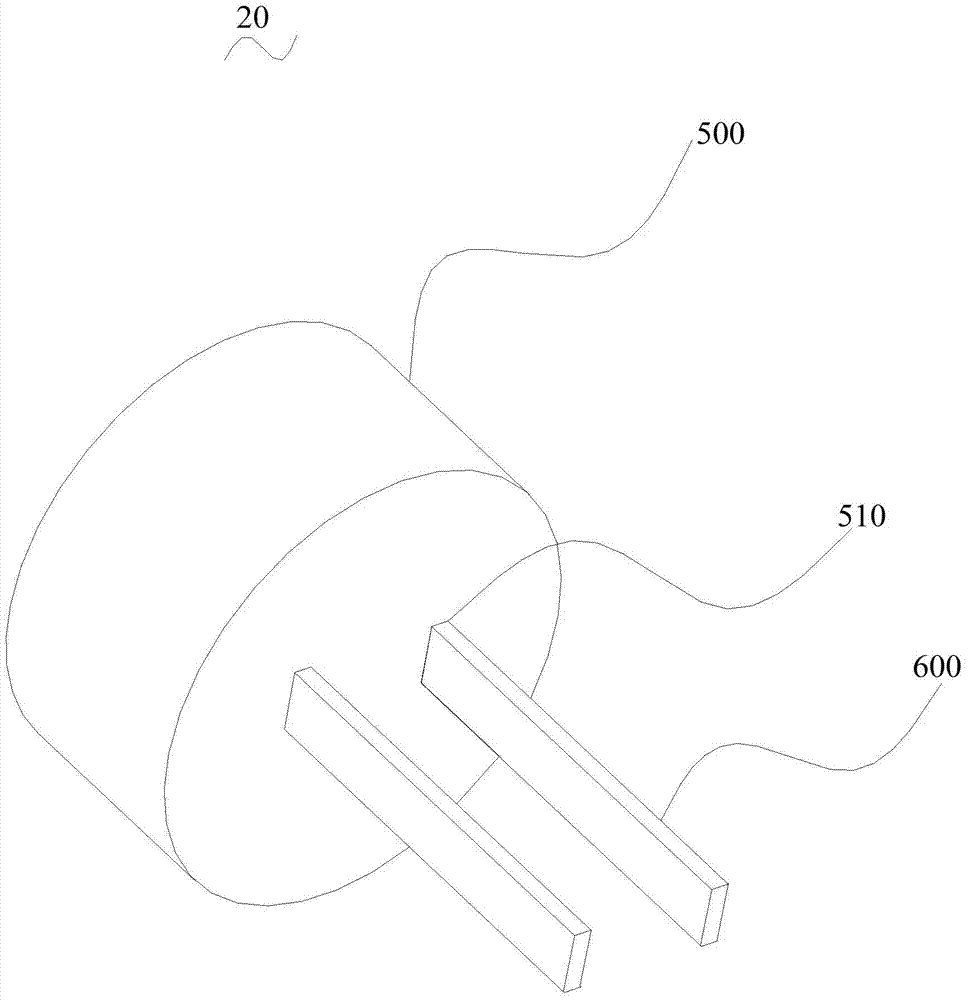

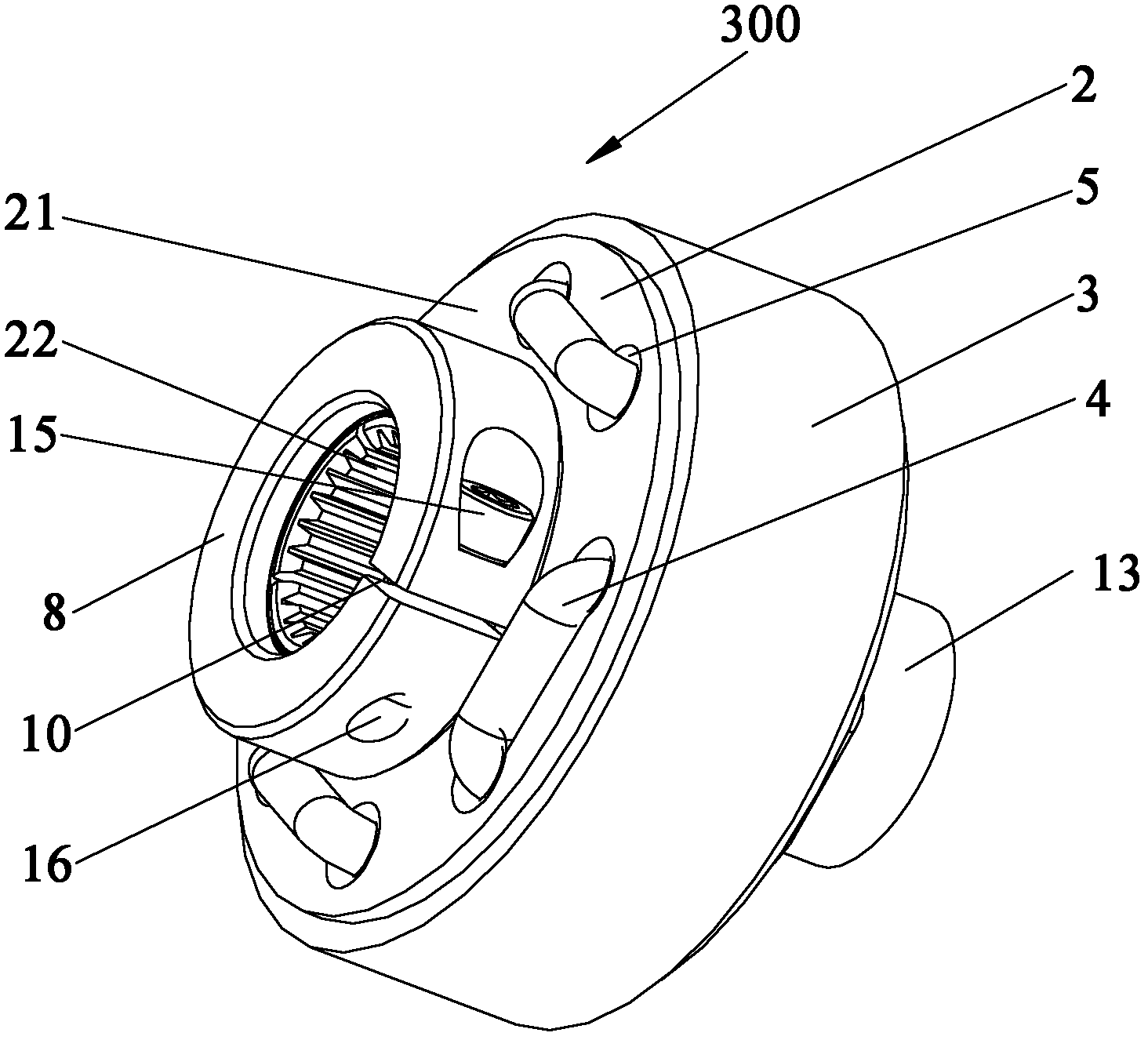

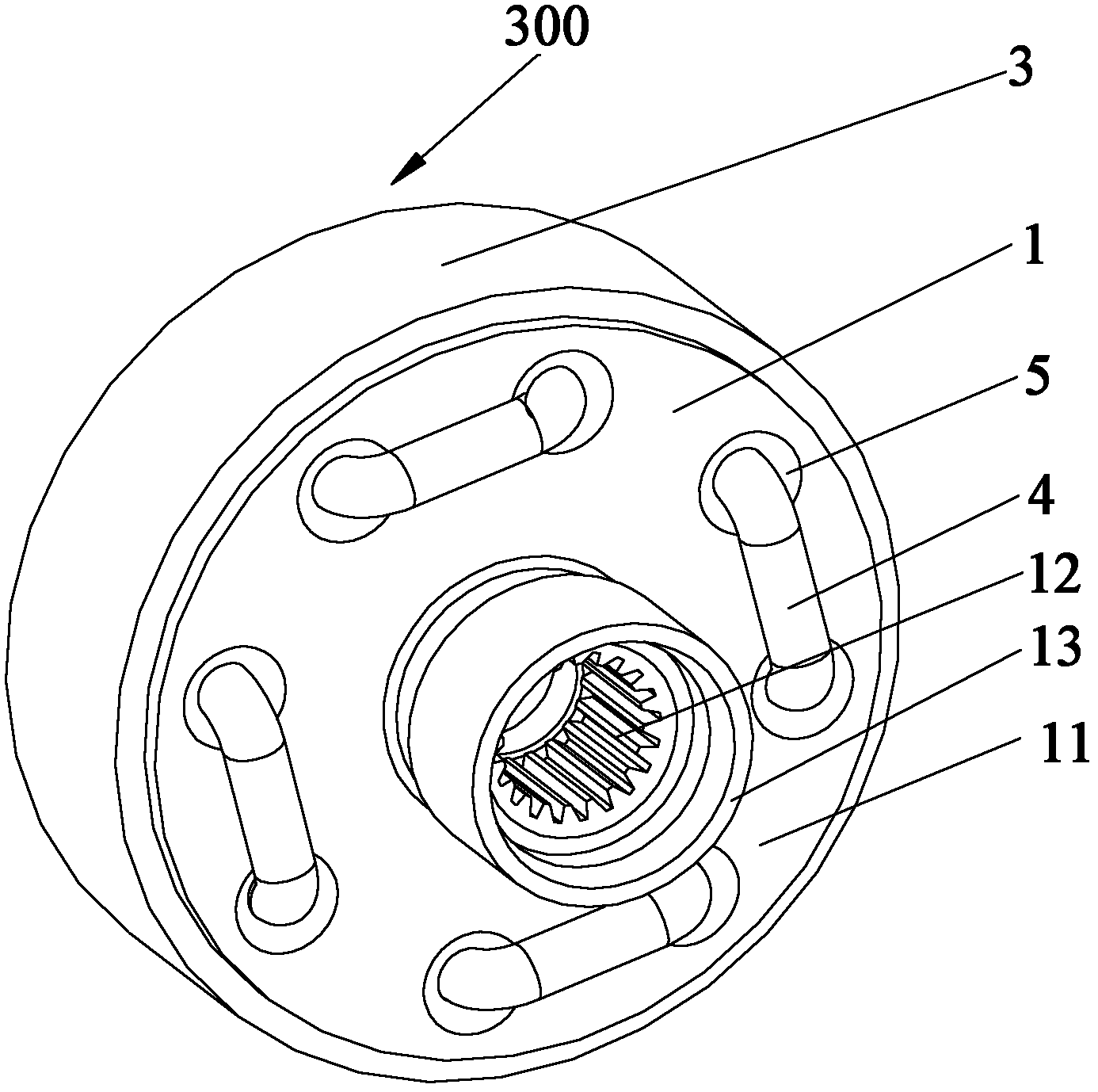

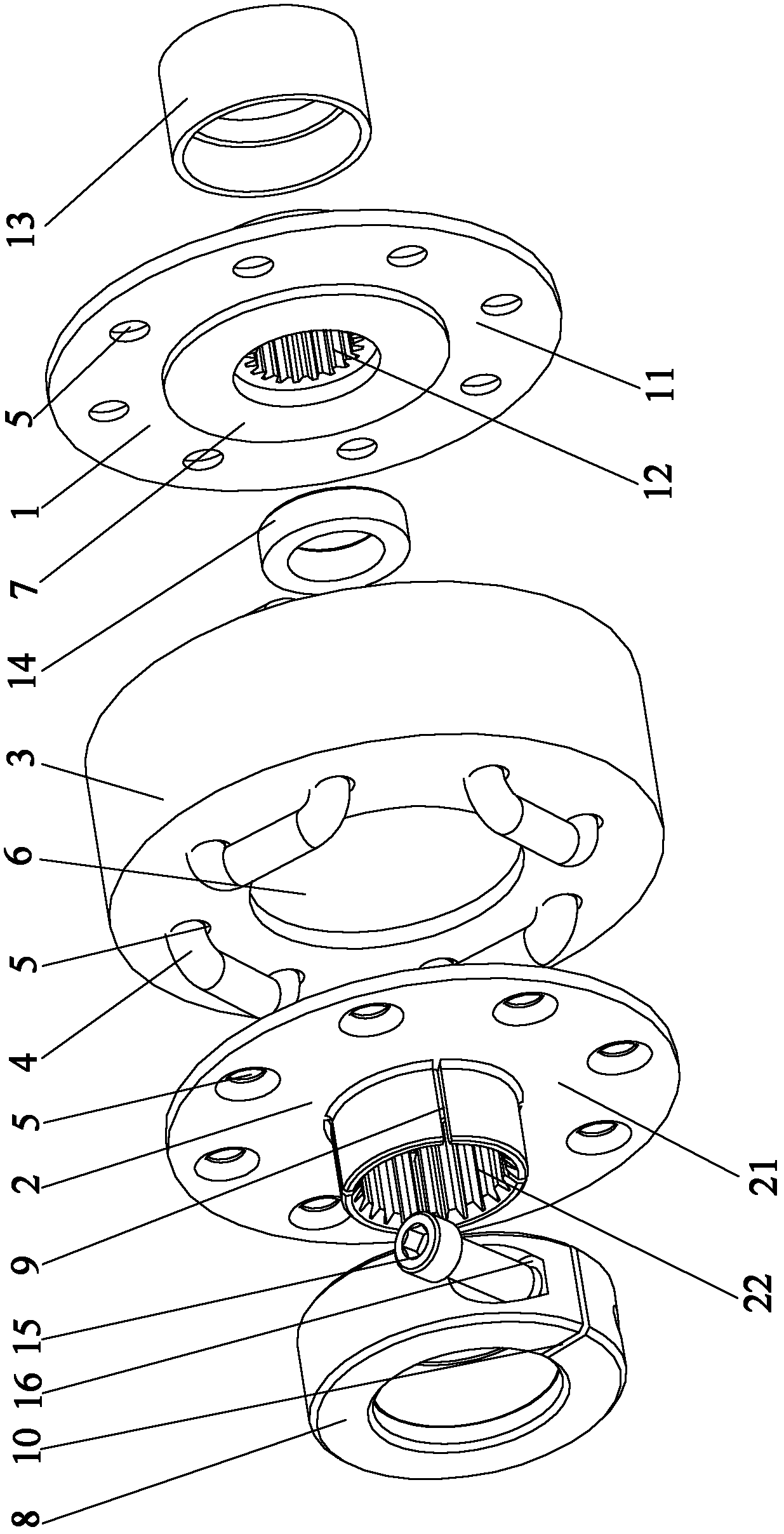

Coupling and connecting structure of electric vehicle

ActiveCN102966674AAvoid conducting electricityAvoid passingCouplings for rigid shaftsInsulating bodiesCouplingReducer

The invention discloses a coupling (300). The coupling (300) comprises an input part (1) and an output part (2), wherein the coupling (300) further comprises an insulating part (3) which is coaxially and fixedly arranged between the input part (1) and the output part (2). The invention further discloses a connecting structure for a motor and speed reducer or the motor and a transmission of an electric vehicle. The coupling has an insulating function, can prevent the electric conduction between an input shaft and an output shaft, and has higher safety.

Owner:BEIQI FOTON MOTOR CO LTD

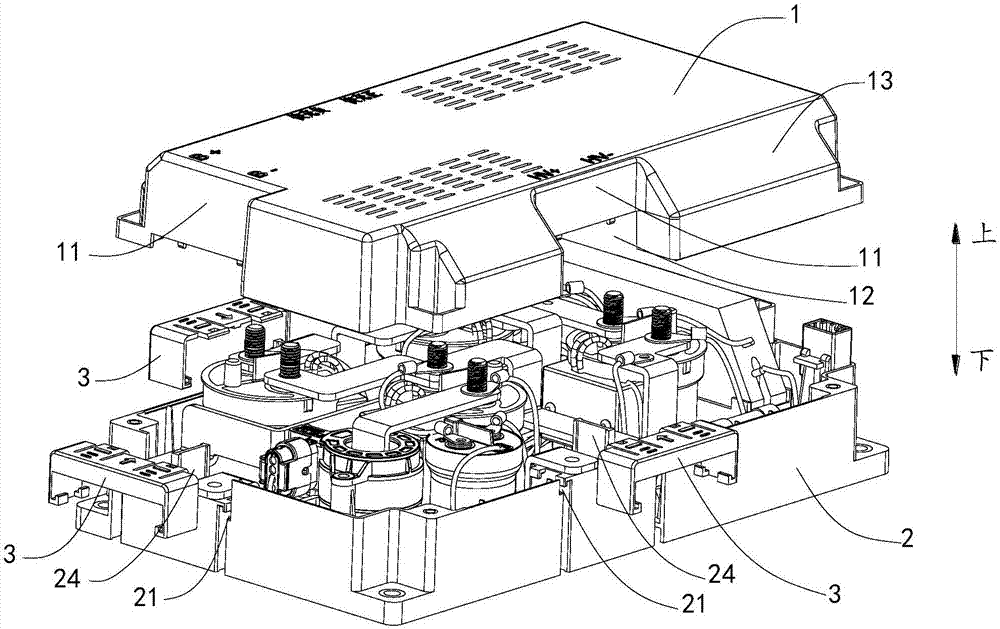

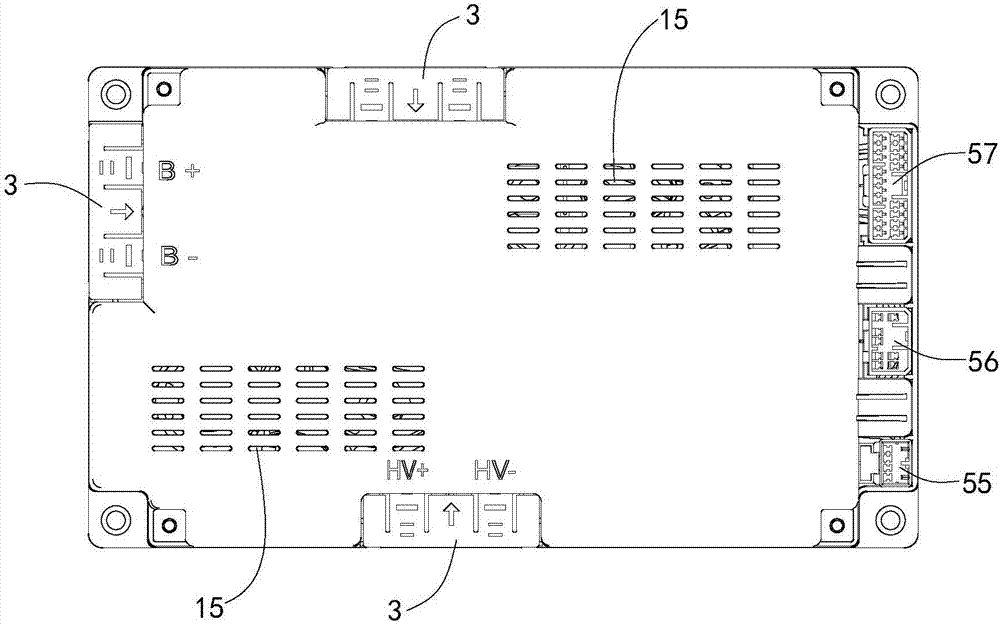

Integrated high-voltage electrical box for battery system

ActiveCN107403971AImprove compatibilityImprove securityCells structural combinationElectrical batteryEngineering

The invention relates to an integrated high-voltage electrical box for a battery system. The integrated high-voltage electrical box comprises an upper cover and a casing, wherein the upper cover covers the casing and is detachably connected with the casing; a high-voltage component, a positive and negative electrode input copper bar and two positive and negative electrode output copper bars are mounted in the casing, one end of the positive and negative electrode input copper bar and one end of each of the two positive and negative electrode output copper bars are connected with the high-voltage component, and the other end of the positive and negative electrode input copper bar and the other end of each of the two positive and negative electrode output copper bars are located in the upper side edge position of the casing; a plugging structure which is used for enabling the other ends of the two positive and negative electrode output copper bars and the other end of the positive and negative electrode input copper bar to be safely exposed is arranged on the peripheral side of the upper cover. One input end and two output ends are arranged on a battery case, so that the electrical box has higher compatibility and can adapt to different project demands; the high-voltage component is mounted on the casing, so that the electrical elements are high in integration degree, high in space utilization rate and flexible and convenient to maintain; the plugging structure is arranged on the upper cover, and the high voltage input and output safety of the electrical box is improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

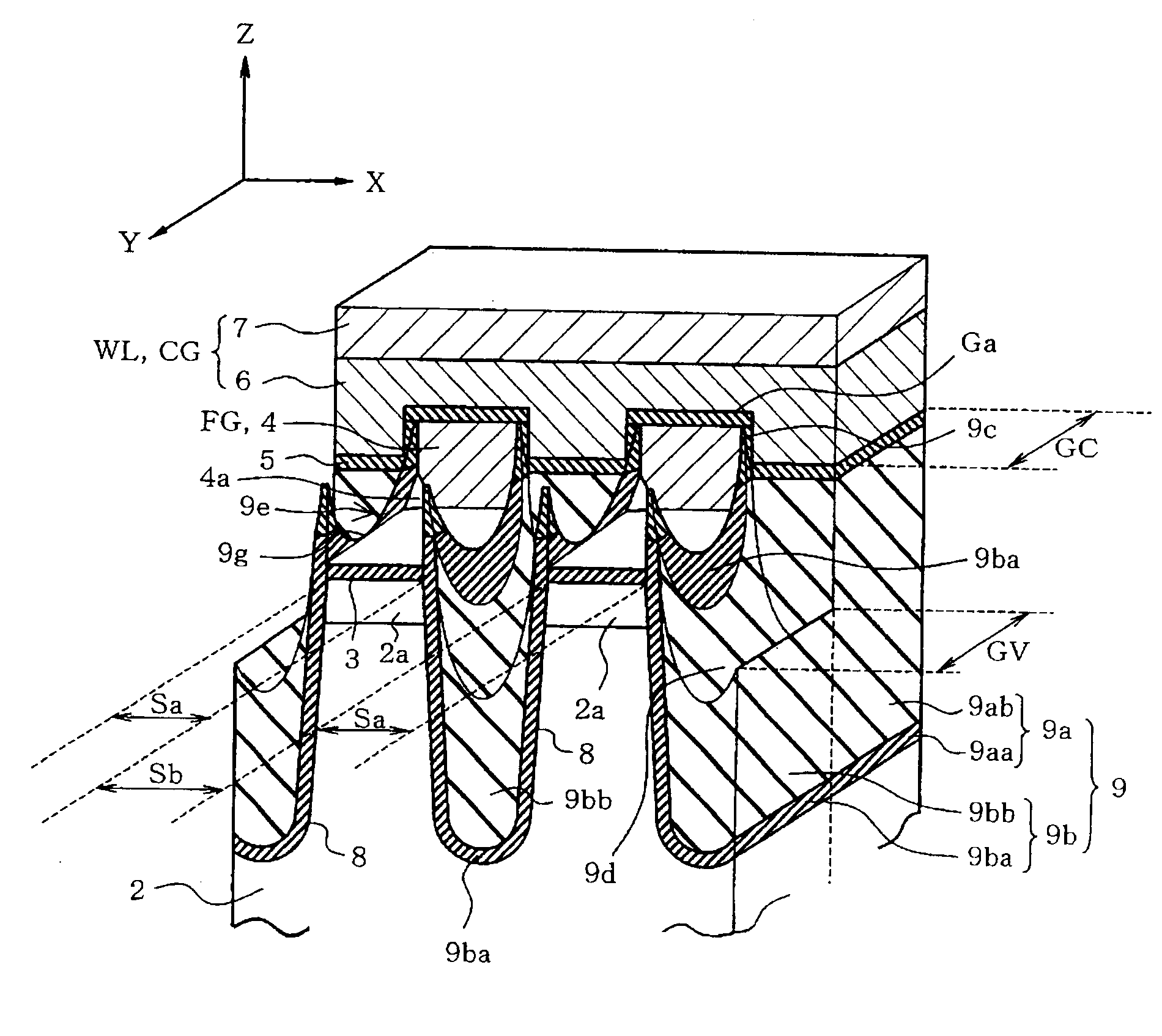

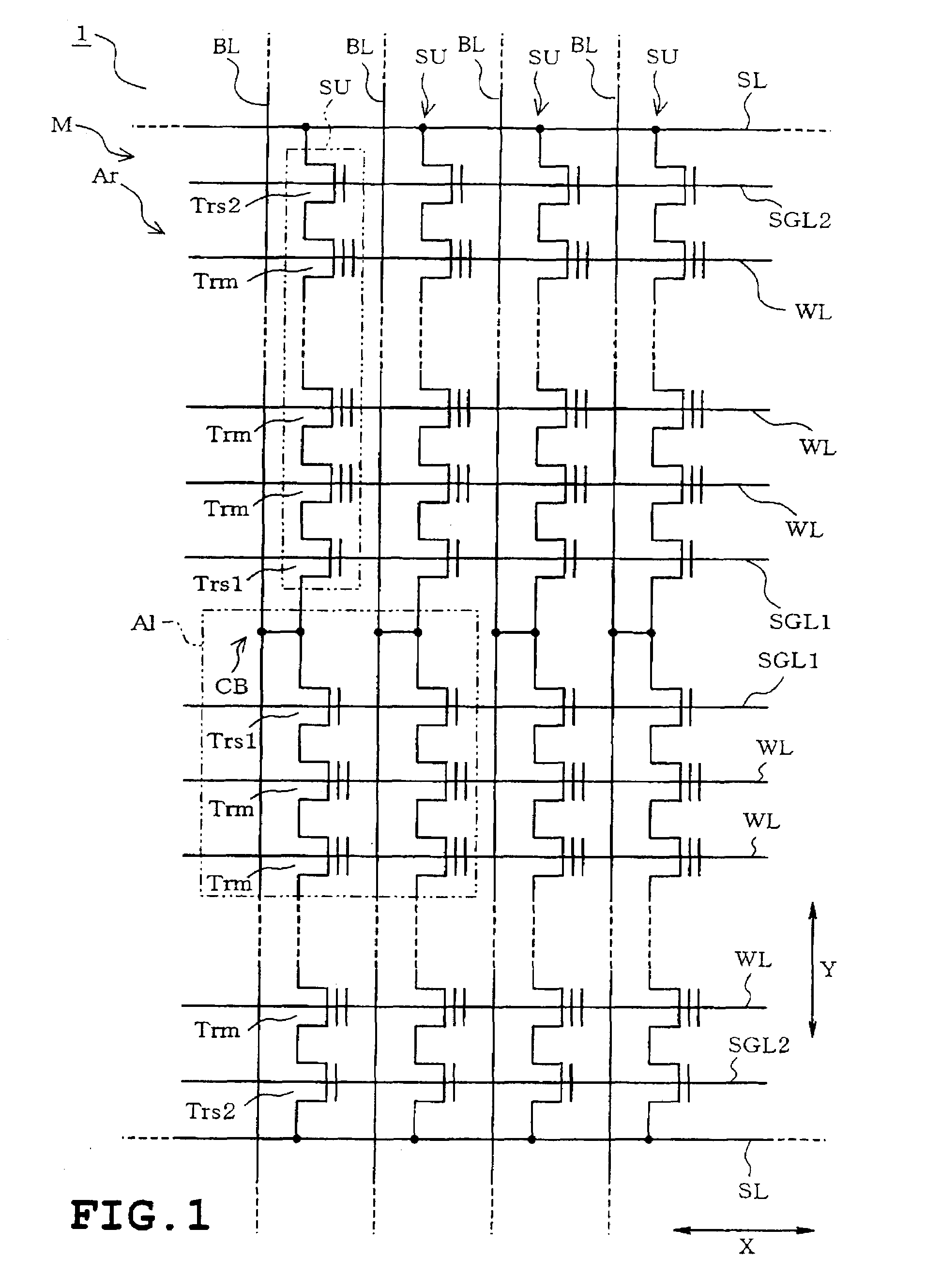

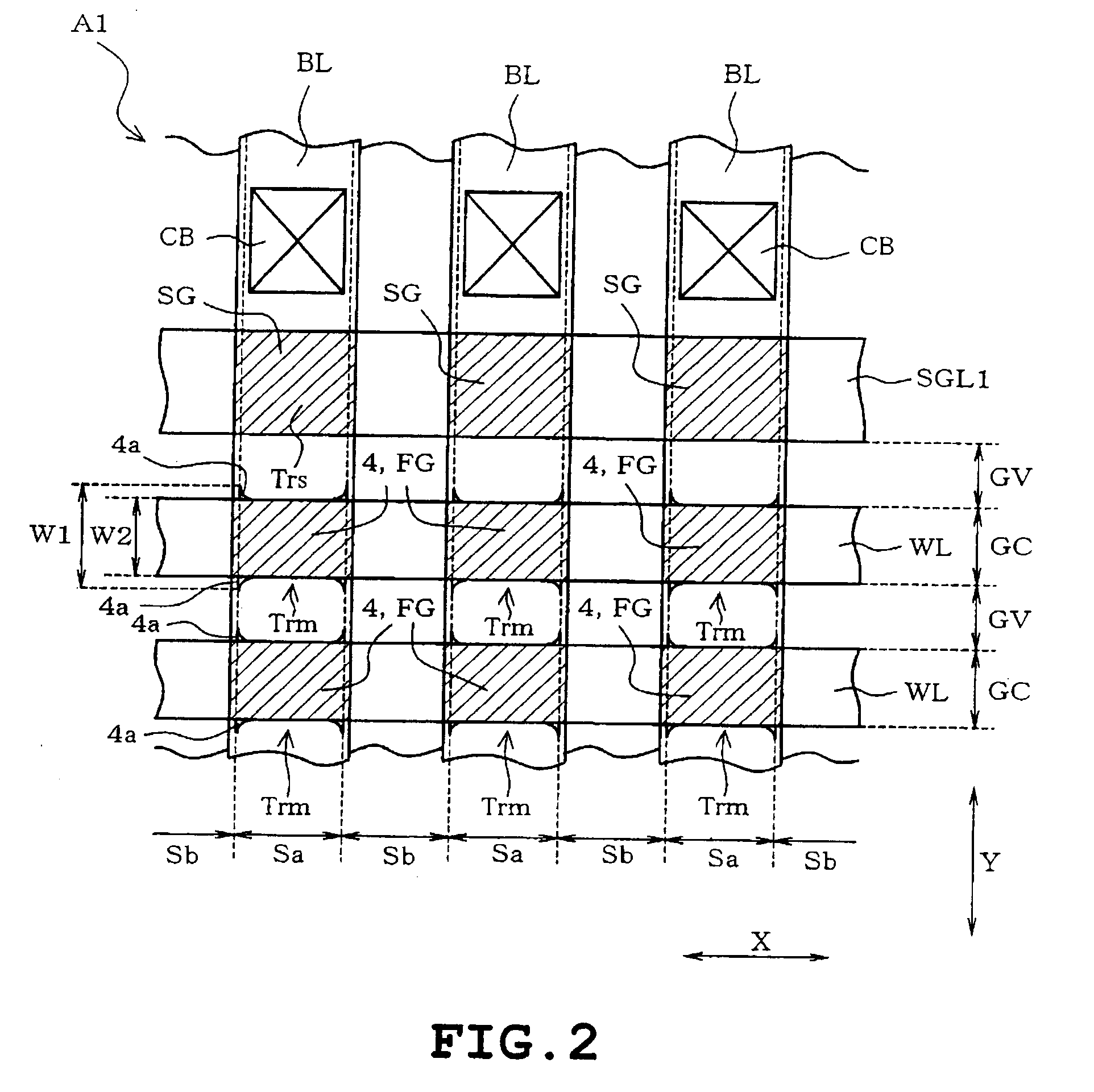

Semiconductor device and method of fabricating the same

InactiveUS20080315283A1Avoid conducting electricityTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device includes a semiconductor substrate having a plurality of element regions and a plurality of element isolation regions in a first direction, a plurality of floating gate electrodes formed via a gate insulating film on the respective element regions, an intergate insulating film formed on the floating gate electrodes, a plurality of control gate electrodes formed on the intergate insulating film so as to extend over the adjacent floating gate electrodes, and an element isolation insulating film formed in the element isolation region and having an upper end located higher than the upper surface of the gate insulating film, the element isolation insulating film including a part formed between the control gate electrodes so that the central sidewall of the element isolation insulating film is located lower than the end of the sidewall of the element isolation insulating film.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com