Hanging type insulating device of wet electric precipitator insulating box

A technology for electrostatic precipitators and insulating devices, which is applied in the field of hanging insulating devices for wet electrostatic precipitator insulation boxes, which can solve problems such as inconvenient installation and maintenance, increased costs, cost of construction and operation, and high frequency of failures, so as to improve the safety of use Performance and operating costs, improved recycling rate, stable and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

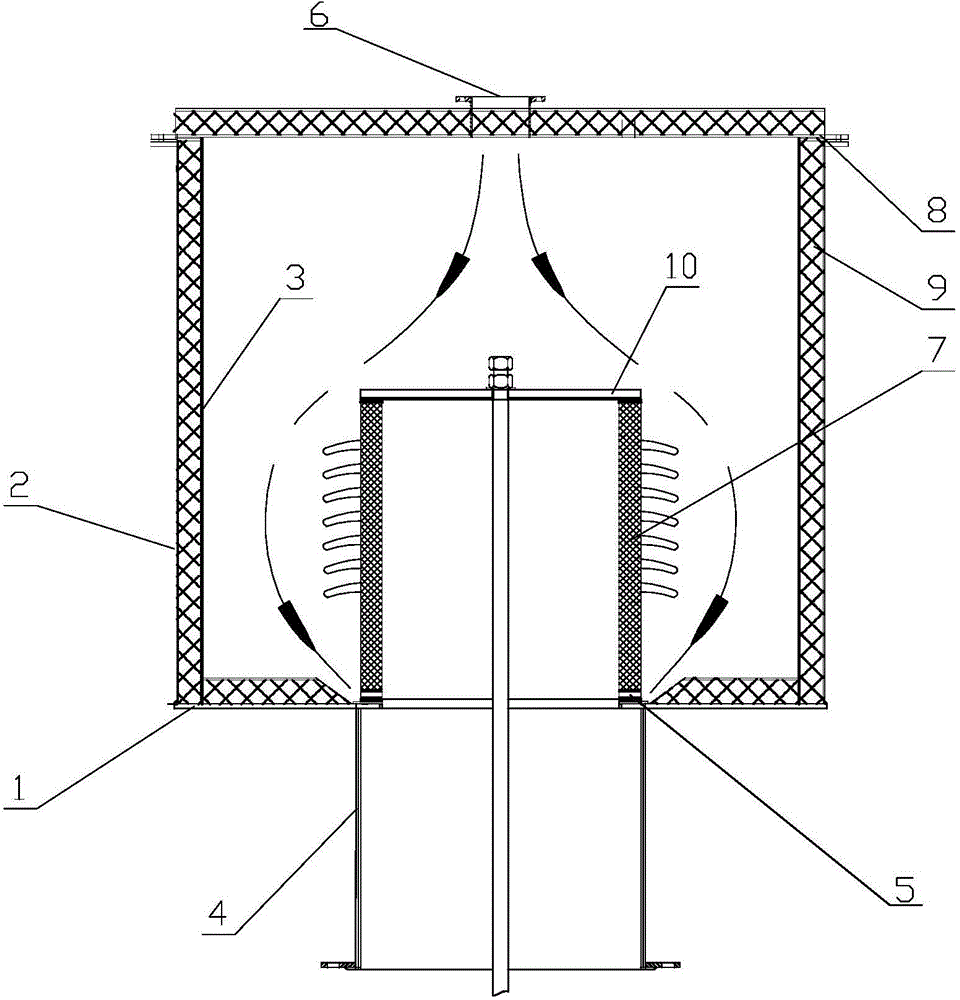

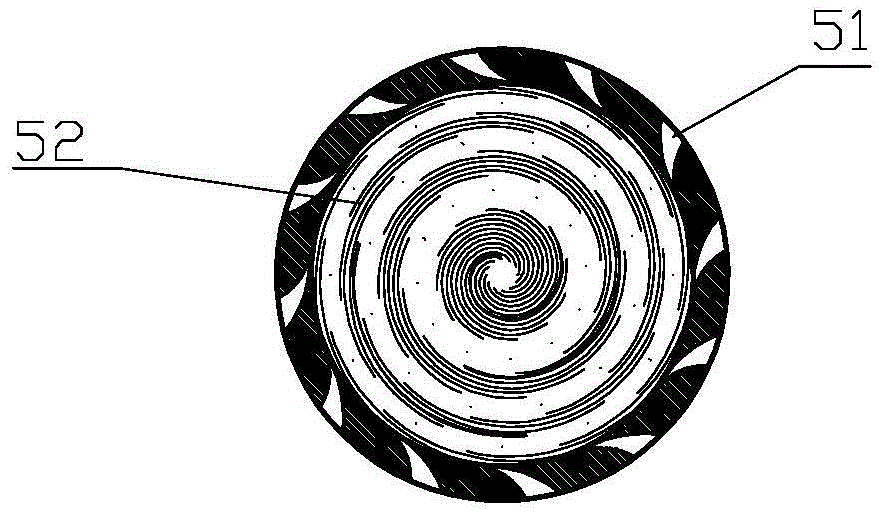

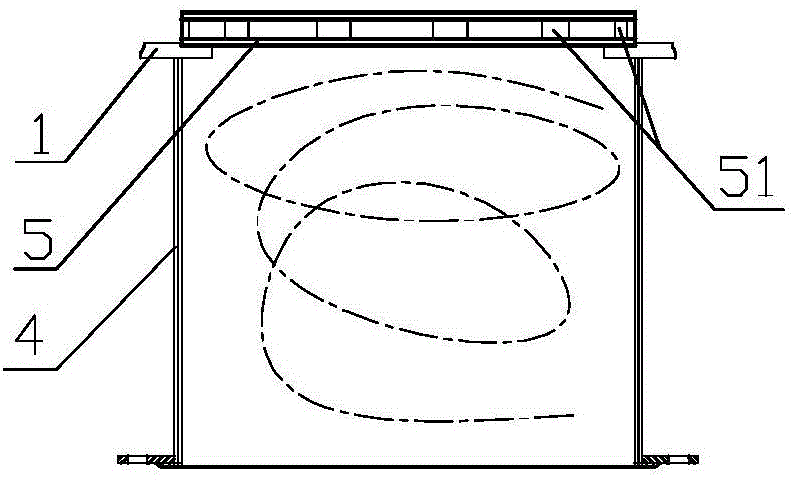

[0035] Such as Figure 1 to Figure 3 A suspension type insulating device for an insulating box of a wet electrostatic precipitator is shown, which includes an insulating cover, an insulating box base 4, a cyclone disk 5, an insulator 7 and a hanging rod. A hanging rod is arranged on the gland 10 of the insulator 7 . The insulating cover is arranged on the insulating box seat 4 through the chassis flange 1 .

[0036] Such as figure 1 As shown, the wall of the insulating cover is composed of an outer shell 2, an aluminum silicate fiber felt 9 and an inner shell 3, and the aluminum silicate fiber felt 9 is sandwiched between the outer shell 2 and the inner shell 3 Between, the outer casing 2 and the inner casing 3 are made of anti-corrosion metal plate material. A tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com