Circuit board printing method for preventing carbon oil leakage short circuit and circuit board

A technology of circuit board and carbon oil, which is applied to printed circuit parts, electrical connection printed components, secondary treatment of printed circuits, etc., and can solve problems such as conductive short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0019] Such as figure 1 Shown, the present invention provides a kind of circuit board printing method that prevents carbon oil seepage short circuit, described circuit board includes the adjacent welding pad of pre-printed carbon oil, prevents the circuit board printing method of carbon oil oil seepage short circuit comprising Follow the steps below:

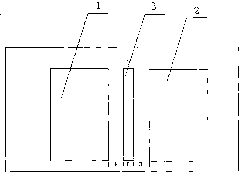

[0020] Step 100: setting up an isolation bridge, that is, an isolation bridge for isolating carbon oil is provided between adjacent pads of pre-printed carbon oil, and the isolation bridge prevents the pads from printing carbon oil and exuding carbon oil to conduct electricity. During the use of the circuit board, carbon oil will usually seep out of the pads printed with carbon oil, and the seepage of carbon oil will usually lead to a conductive short circuit between adjacent pads.

[0021] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com