One-way ventilation electronic cigarette atomization core

An electronic cigarette, one-way ventilation valve technology, applied in the direction of tobacco, smoker's products, applications, etc., can solve the problems of contamination of the atomizing core, the air intake hole cannot be closed, the entry of external dirt, etc., to overcome liquid leakage, The effect of preventing dirt from falling into the inside of the atomizing core and avoiding seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

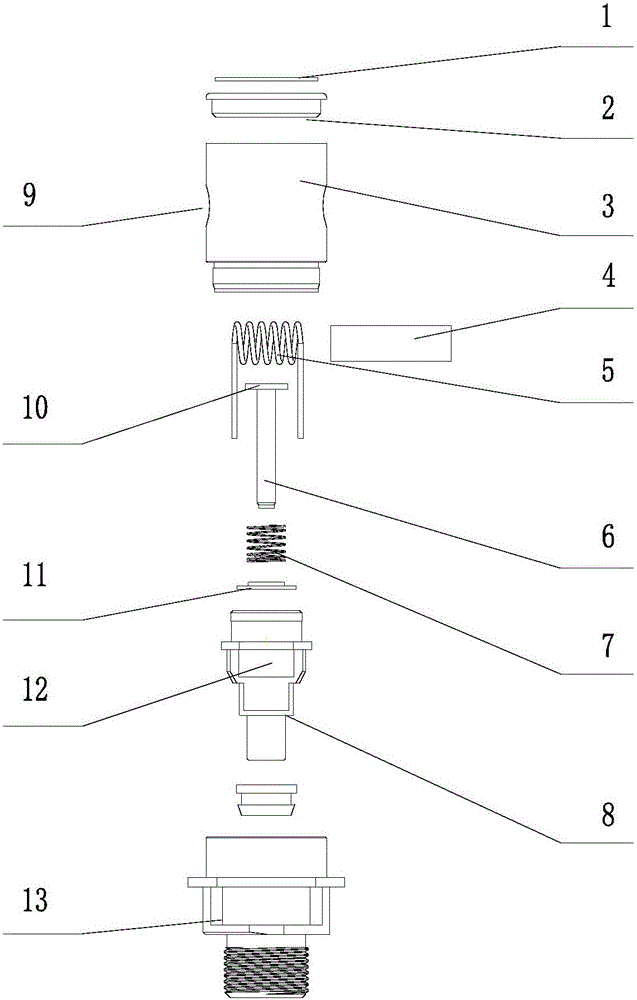

[0029] Such as figure 1 As shown, it is a three-dimensional disassembled structural diagram of the one-way ventilation electronic smog atomizing core of this embodiment. The atomizing core outer cylinder 3 of this embodiment is connected with the atomizing core conductive connecting column to form the atomizing core body. Wherein, two symmetrical liquid inlet holes 9 are opened on the tube wall surface of the atomizing core outer cylinder 3, and inside the atomizing core outer cylinder corresponding to the positions of the liquid inlet holes 9, a heating wire wound in a spiral shape is arranged laterally. 5. The helix of the heating wire 5 is pierced with a liquid-conducting cotton 4, and the two electrode connections of the heating wire 5 are respectively connected to the two electrodes of the conductive connecting column. The top of the atomizing core outer cylinder 3 is the atomizing core air outlet, and is provided with an annular cover 2 and a filter screen 1 . The ring...

Embodiment 2

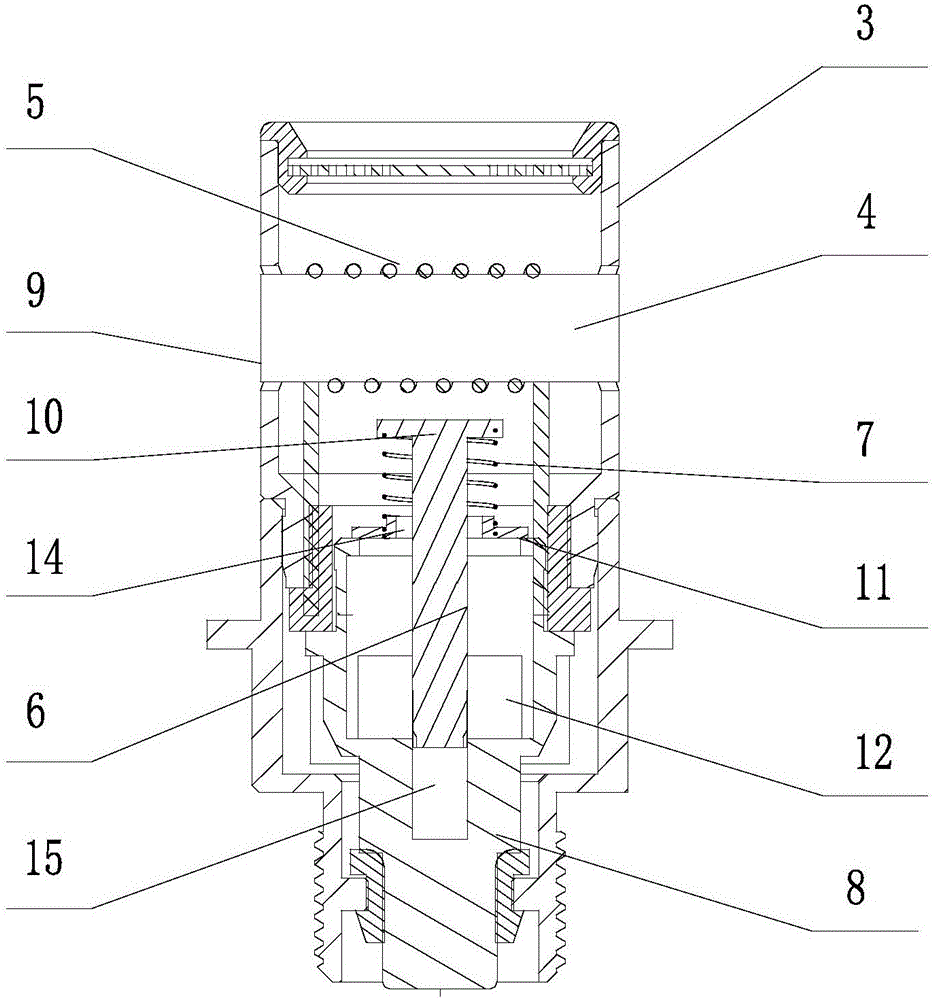

[0037] The difference between the present embodiment and embodiment 1 is the structure of the one-way ventilation valve, such as image 3 , Figure 4 As shown, the one-way ventilation valve is arranged on the upper end of the ventilation hole of the electrode rod 8 . In this embodiment, the one-way valve is composed of a valve ring 11 , a valve body 10 , a valve stem 6 , a spring 7 and a valve body frame 16 . Among them, the valve ring 11 is fixed and sealed on the upper end of the axial vent hole of the electrode rod 8, the valve ring 11 is provided with a central vent hole 14, and the valve body 10 is arranged on the upper side of the valve ring 11, and the diameter of the valve body 10 is smaller than the outer diameter of the valve ring 11. Greater than the diameter of the central vent hole 14, the central vent hole 14 can be completely covered.

[0038] Such as Figure 4 As shown, the valve stem 6 is connected to the upper end surface of the valve body 10, and a fixed ...

Embodiment 3

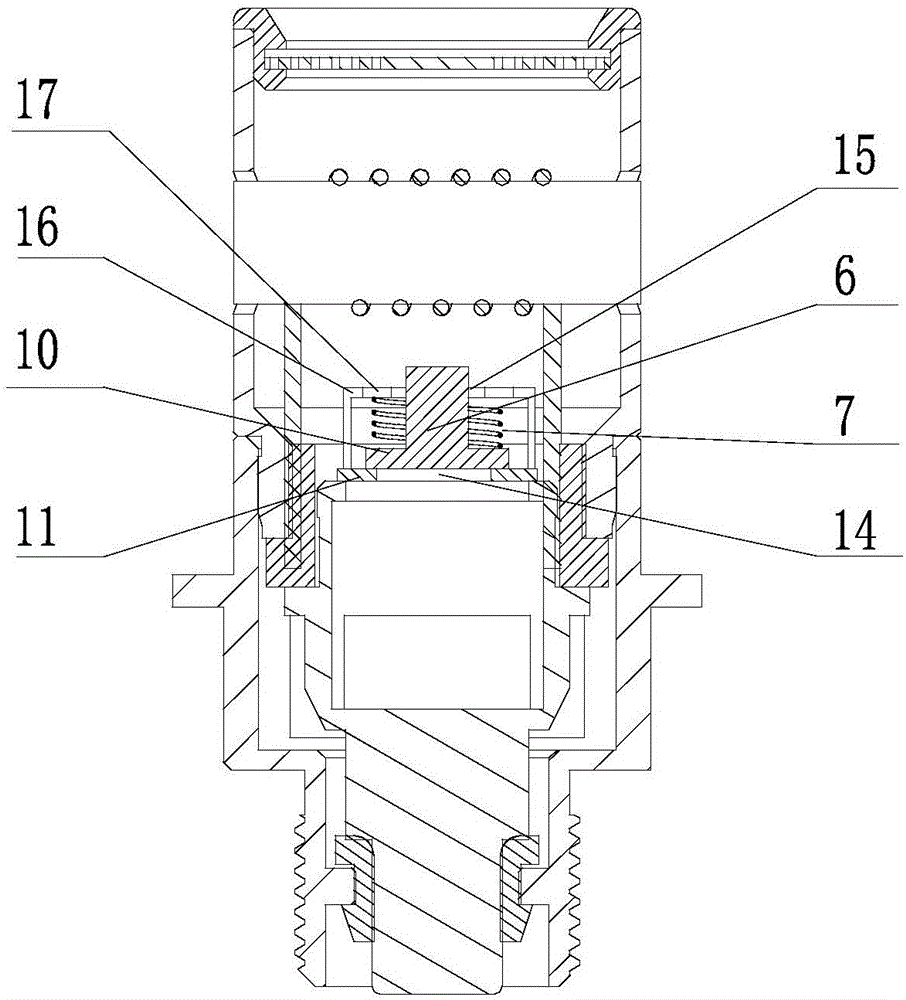

[0042] Such as Figure 5 As shown, it shows a combination structure of a one-way valve and an electrode rod 8 in this embodiment. The one-way valve includes a valve ring 11 , a valve body 10 , a valve stem 6 , a locking limit ring 19 and a spring 7 . The valve ring 11 is airtightly connected with the axial vent hole at the upper end of the electrode rod 8, the center of the valve ring 11 is provided with a valve stem limit hole 15, the center of the lower end surface of the valve body 10 is provided with a valve stem 6, and the valve stem 6 passes through the valve stem to limit the position. The hole 15 extends downwards, and the diameter of the valve stem limiting hole 15 is slightly larger than that of the valve stem 6, so that the valve stem 6 can slide axially and limit radial movement. At the same time, ring-cloth ventilation holes 18 are arranged around the valve stem limiting hole 15 of the valve ring 11 . The valve body 10 is arranged on the upper side of the valve r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com