Sealed pipe quick-assembling structure and assembly tool thereof

A technology for sealing pipes and pipes, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., and can solve problems such as unbalanced locking torque, leakage, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring to appendix 9 and accompanying drawing 9-a, the old-fashioned hoop consists of two hoop inner chute snap rings 10-1, one side in the radial direction is the hoop shaft 10-3, and the two hoop inner chute snap rings 10 -1 When the pipe chuck is clamped, the clamp lock nut 10-2 of the clamp lock bolt 10-4 is locked, and the clamped pipe chuck is compressed and sealed, and the clamp lock nut 10- 2 is too loose, the axial gap between the chute ring 10-1 in the hoop and the chute on the side of the hoop lock bolt 10-4 increases, on the contrary, when the hoop lock nut 10-2 is too tight , the axial clearance between the inner chute of the clamp 10-1 and one side of the chute of the clamp shaft 10-3 may increase, and the assembly of the old-fashioned clamp structure is difficult to meet the requirement of locking torque balance, and there are more chances of leakage .

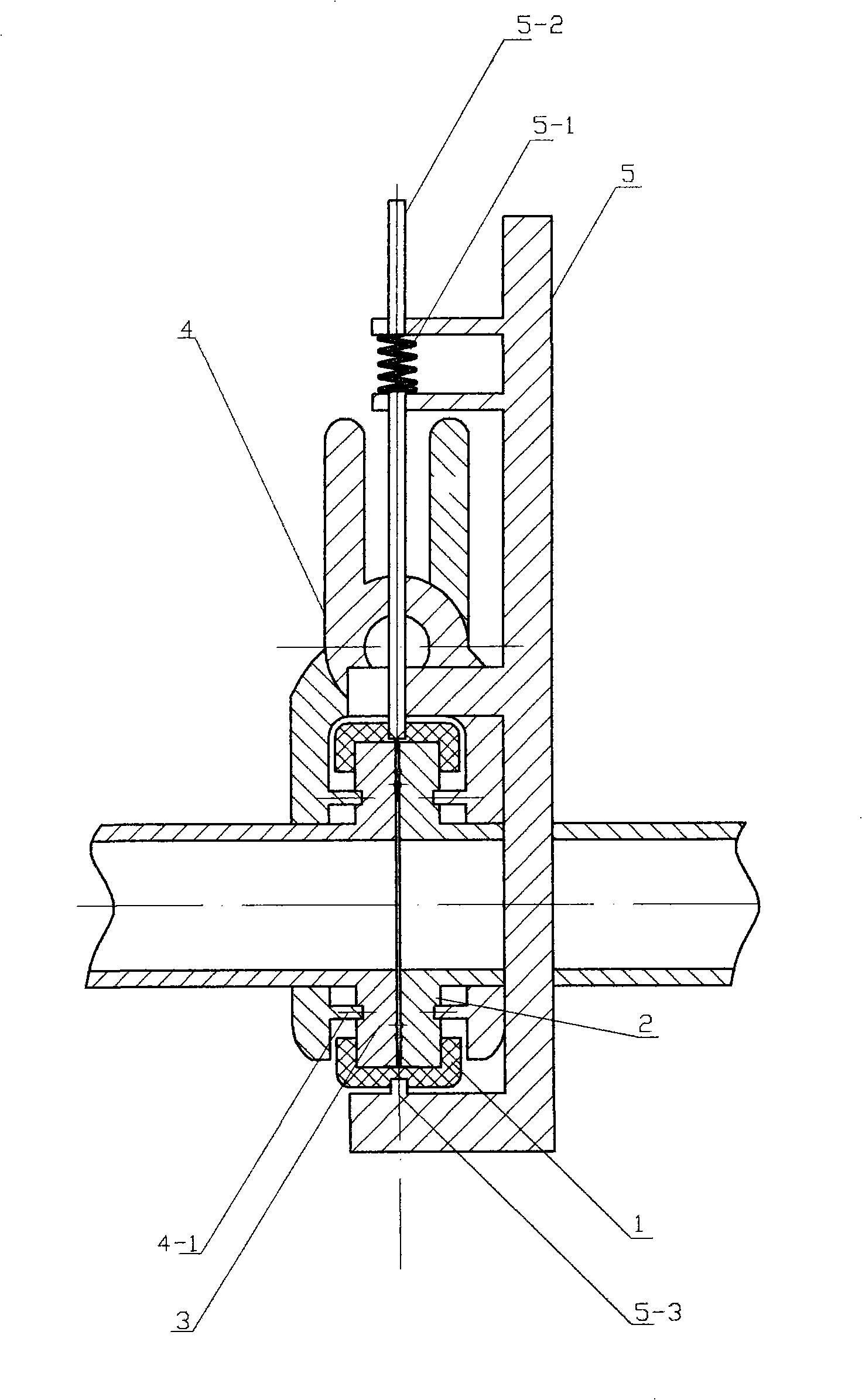

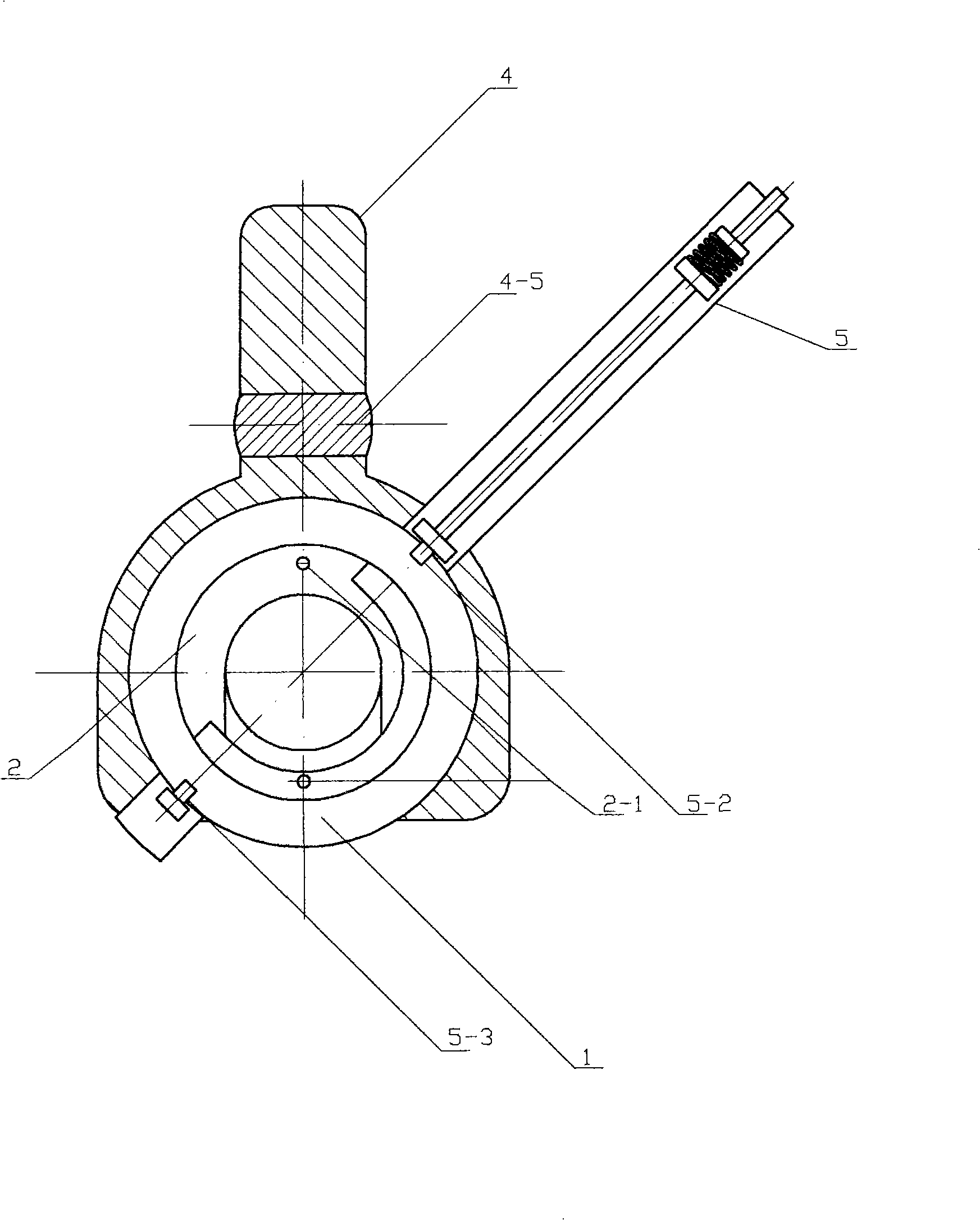

[0027] refer to Figure 8 The clamp chuck locking structure view, the pipeline chuck 2, the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com