Patents

Literature

194results about How to "Low self-discharge rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

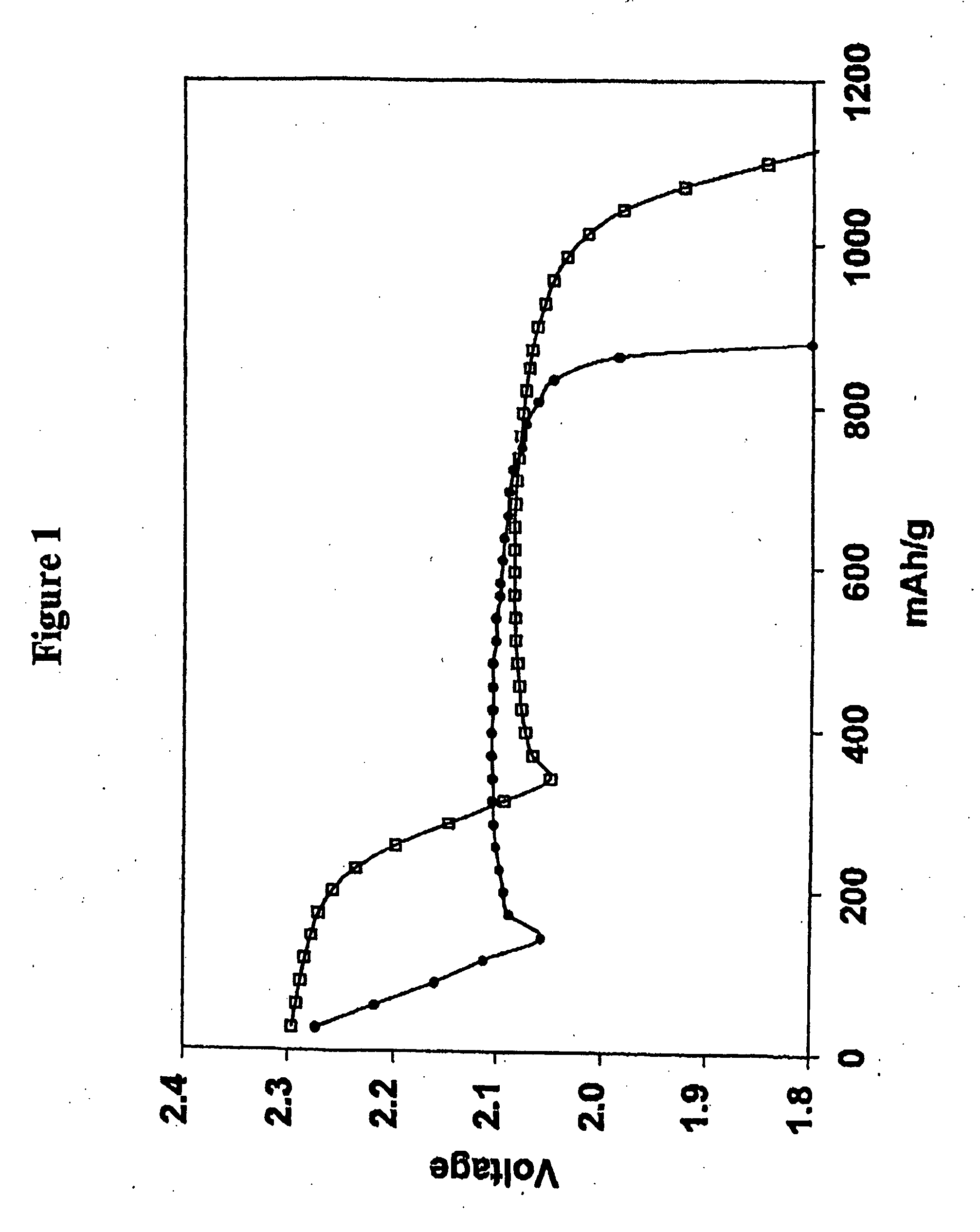

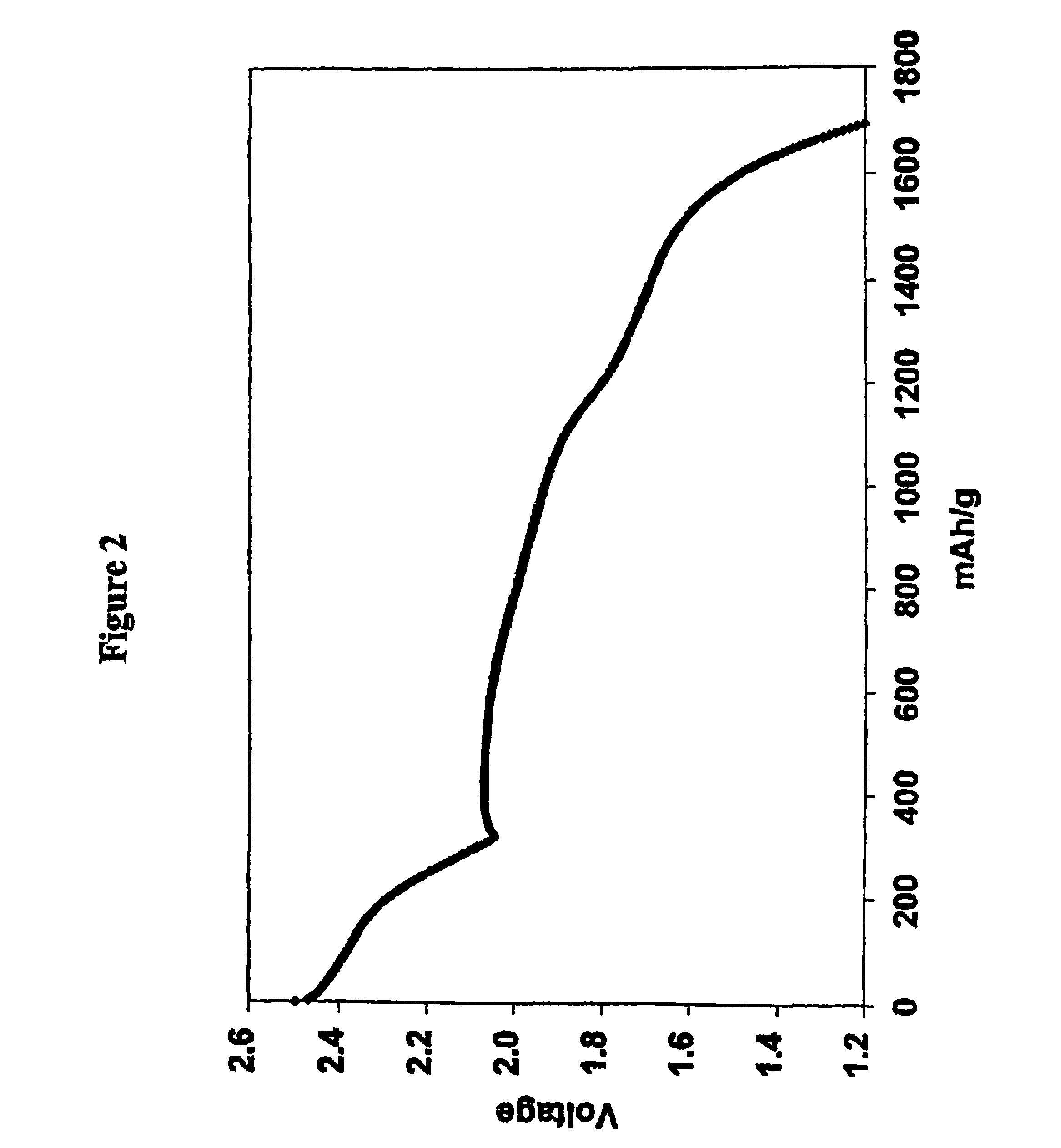

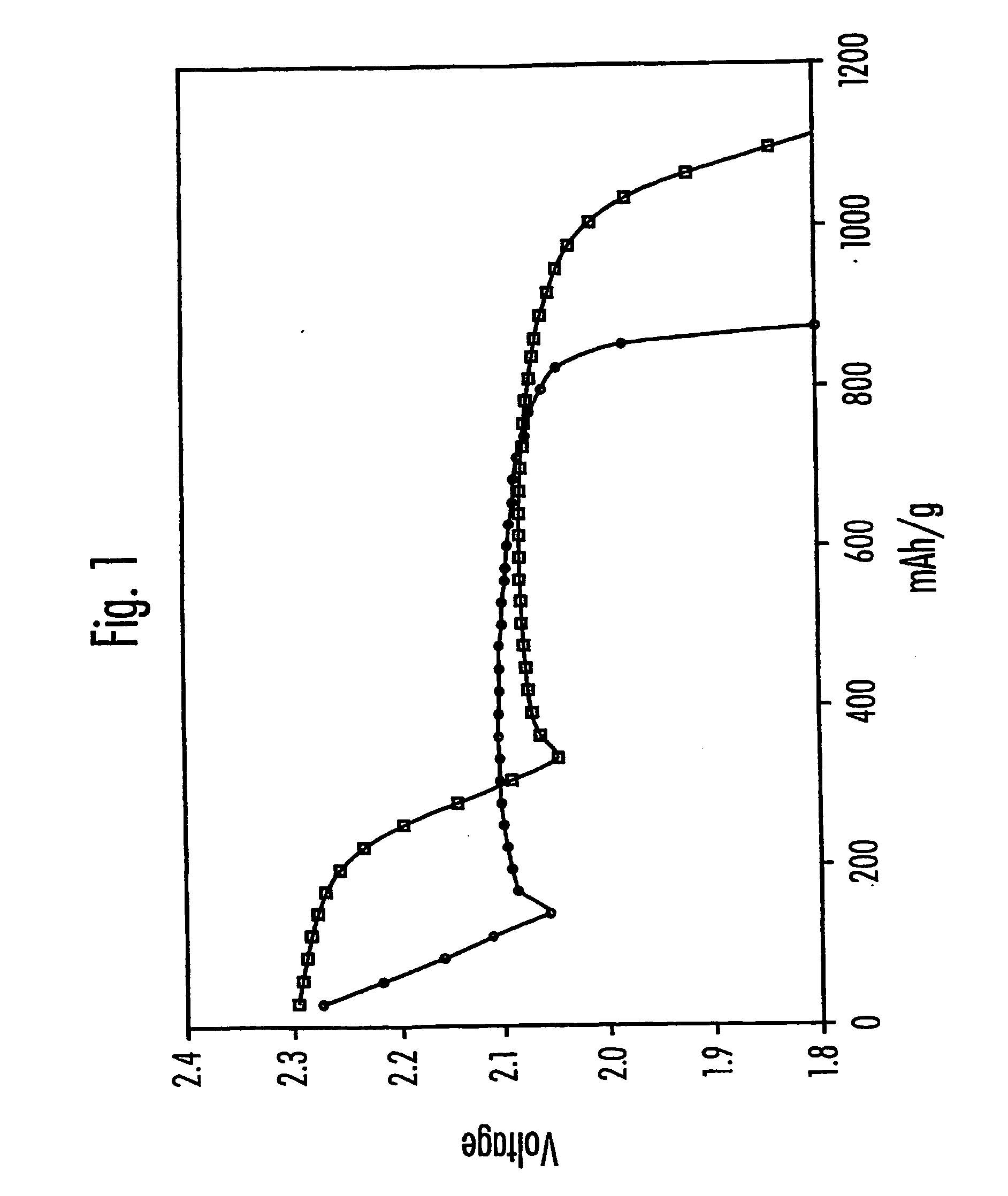

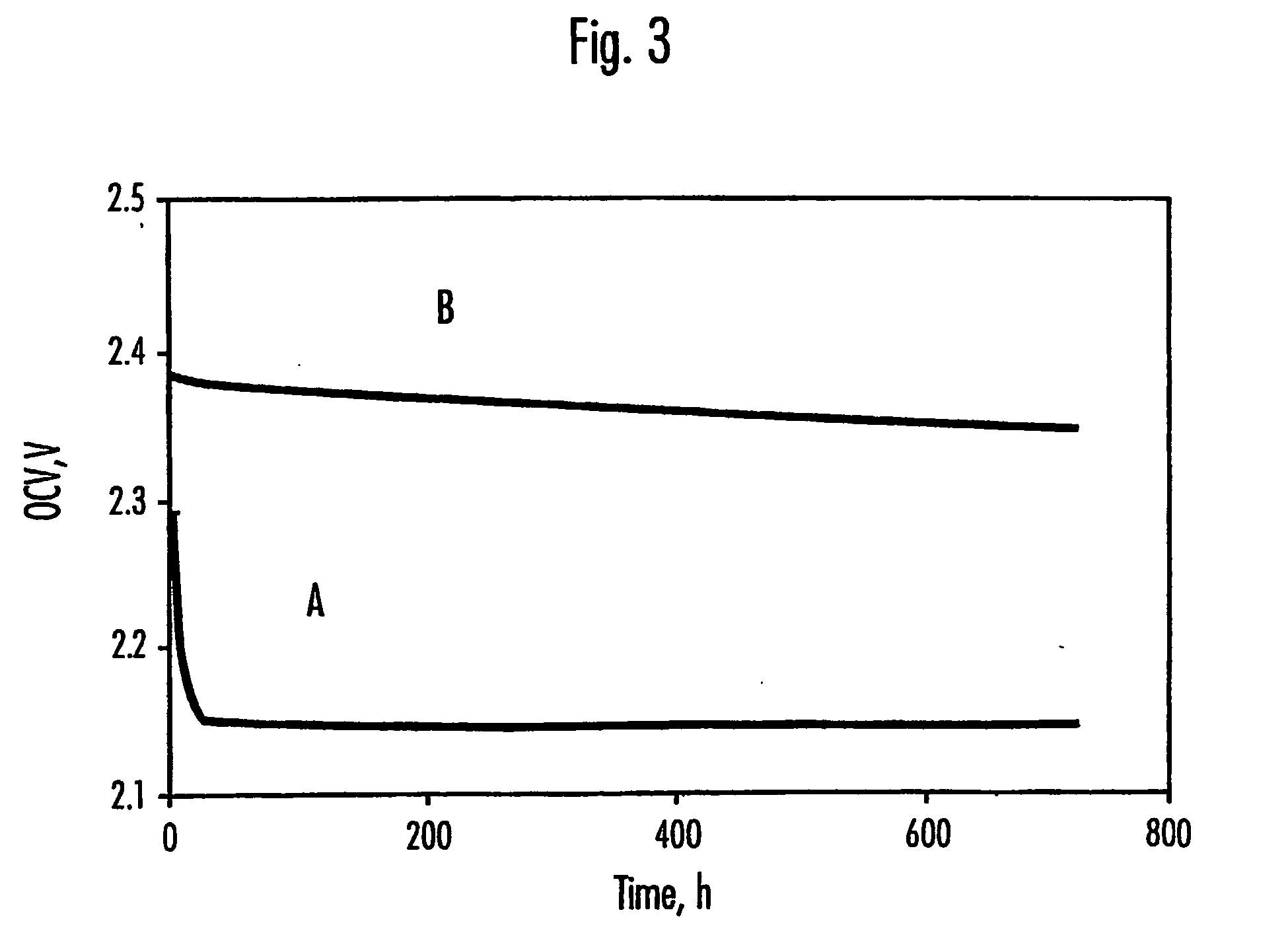

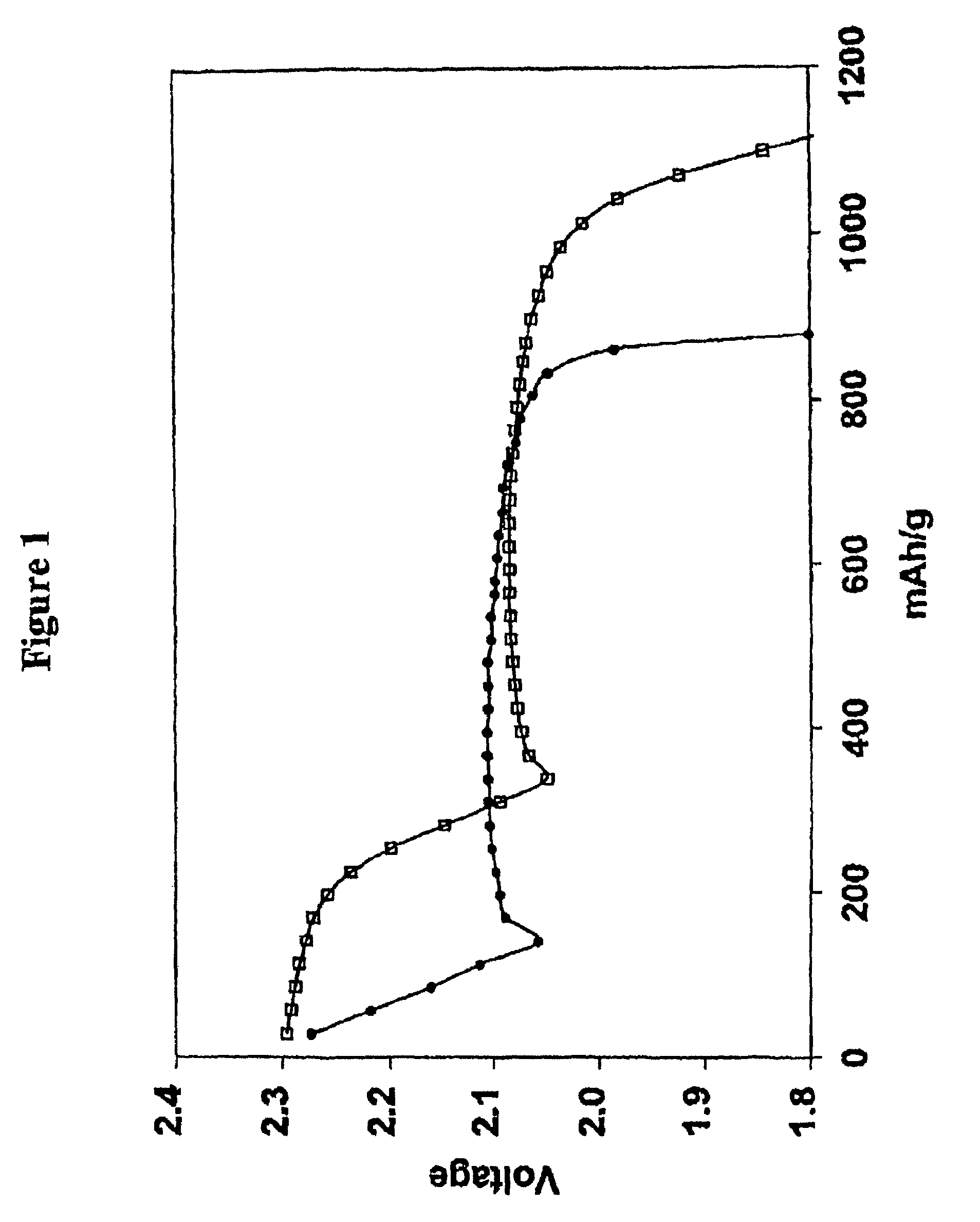

Methods of charging lithium sulfur cells

ActiveUS20050156575A1Reduce the probability of reactionLow self-discharge rateCell electrodesPrimary cellsLithium–sulfur batteryLithium sulfur

Owner:SION POWER CORP

Solid electrolyte material manufacturable by polymer processing methods

ActiveUS8268197B2Improve Li-based batteriesIncrease energy densityConductive materialSolid electrolyte cellsPolymer electrolytesHigh energy

The present invention relates generally to electrolyte materials. According to an embodiment, the present invention provides for a solid polymer electrolyte material that is ionically conductive, mechanically robust, and can be formed into desirable shapes using conventional polymer processing methods. An exemplary polymer electrolyte material has an elastic modulus in excess of 1×106 Pa at 90 degrees C. and is characterized by an ionic conductivity of at least 1×10−5 Scm-1 at 90 degrees C. An exemplary material can be characterized by a two domain or three domain material system. An exemplary material can include material components made of diblock polymers or triblock polymers. Many uses are contemplated for the solid polymer electrolyte materials. For example, the present invention can be applied to improve Li-based batteries by means of enabling higher energy density, better thermal and environmental stability, lower rates of self-discharge, enhanced safety, lower manufacturing costs, and novel form factors.

Owner:RGT UNIV OF CALIFORNIA +1

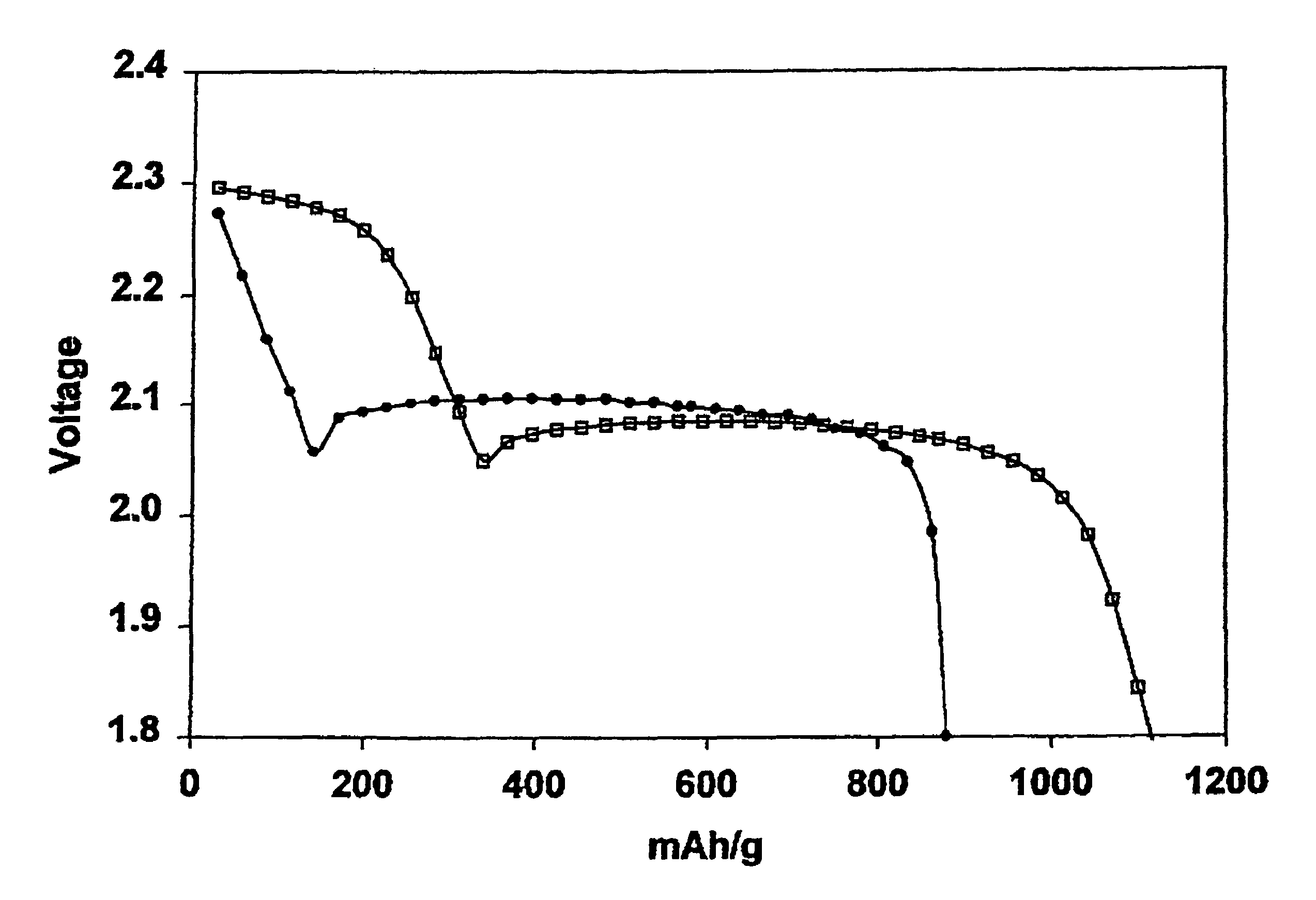

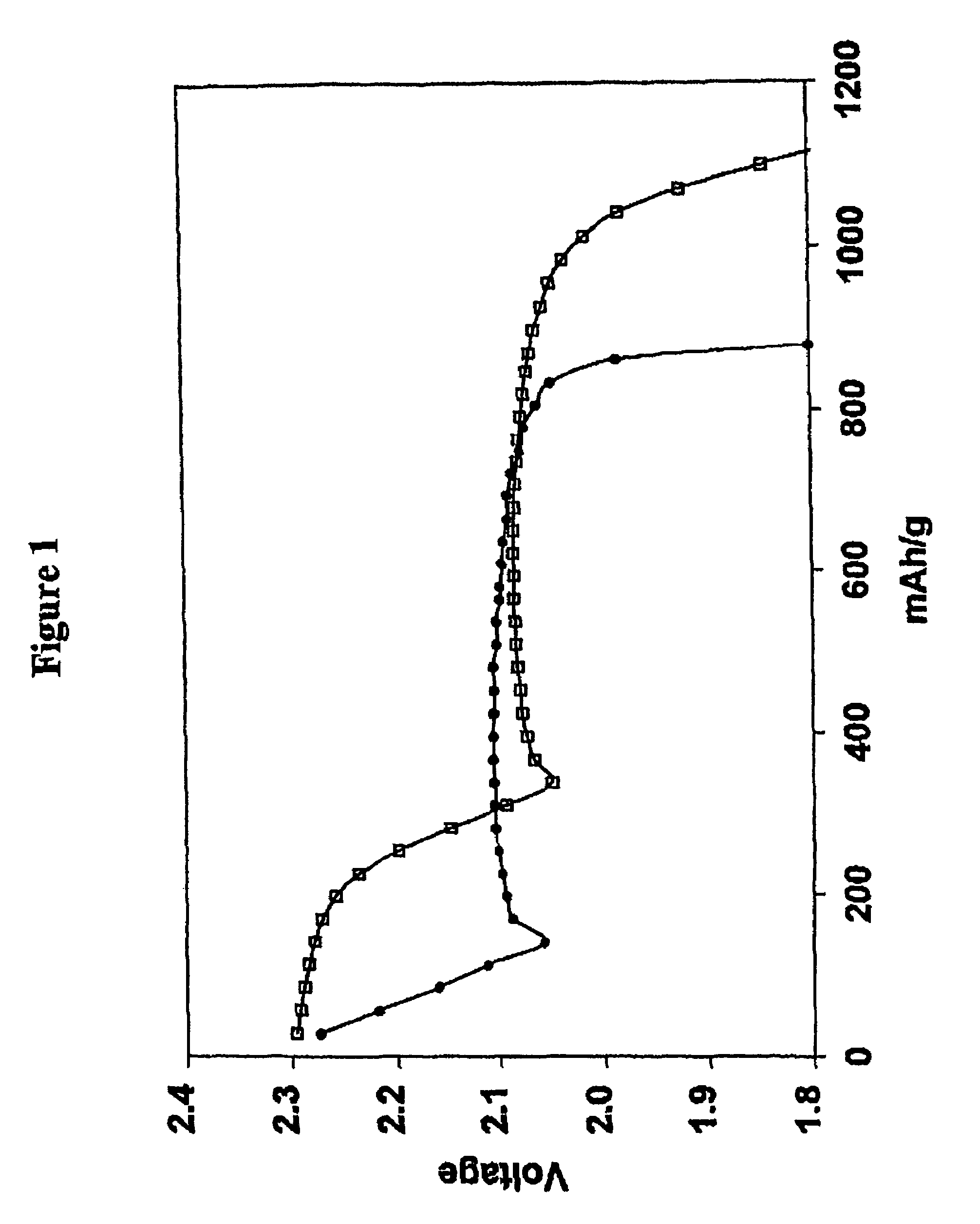

Electrolytes for lithium sulfur cells

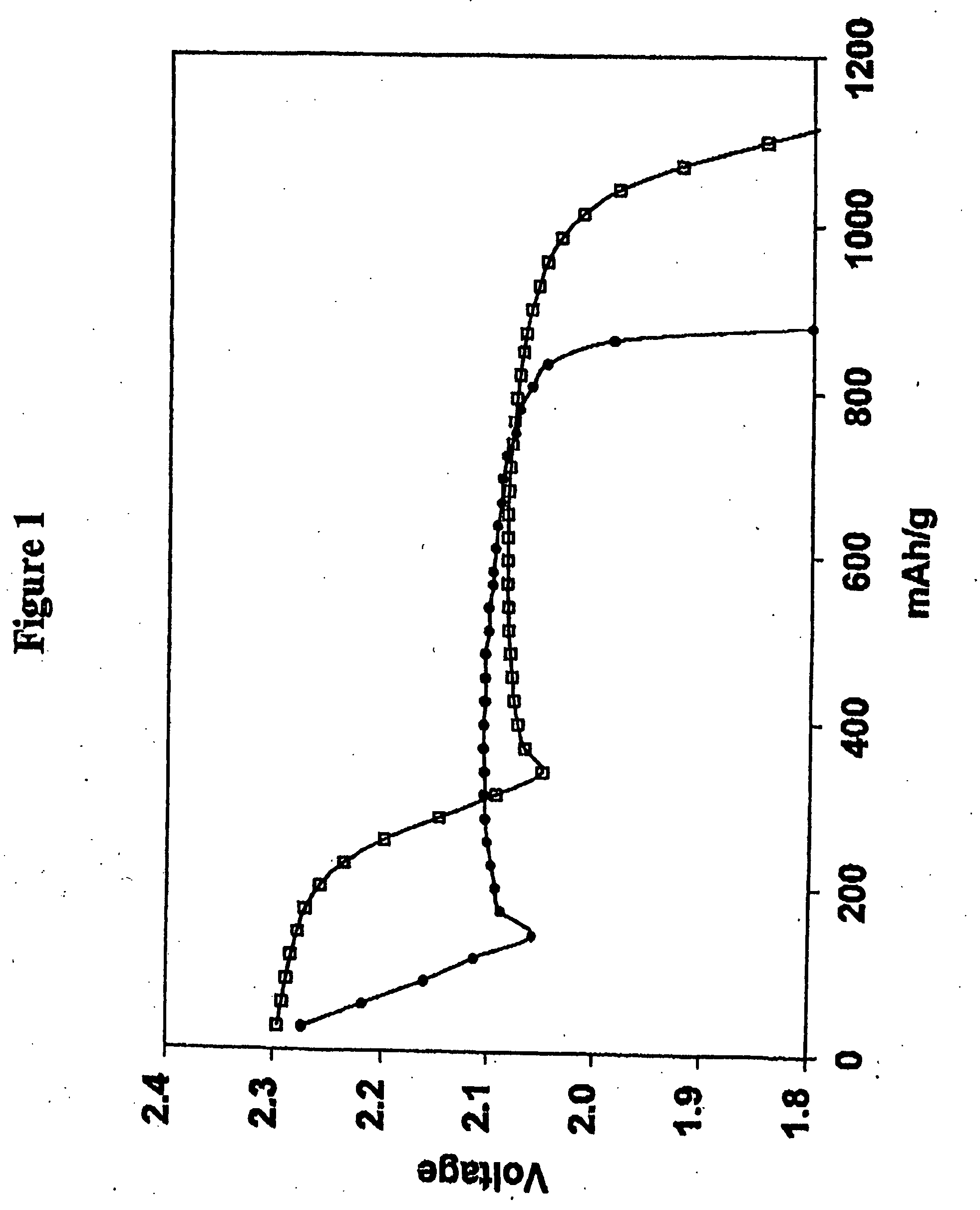

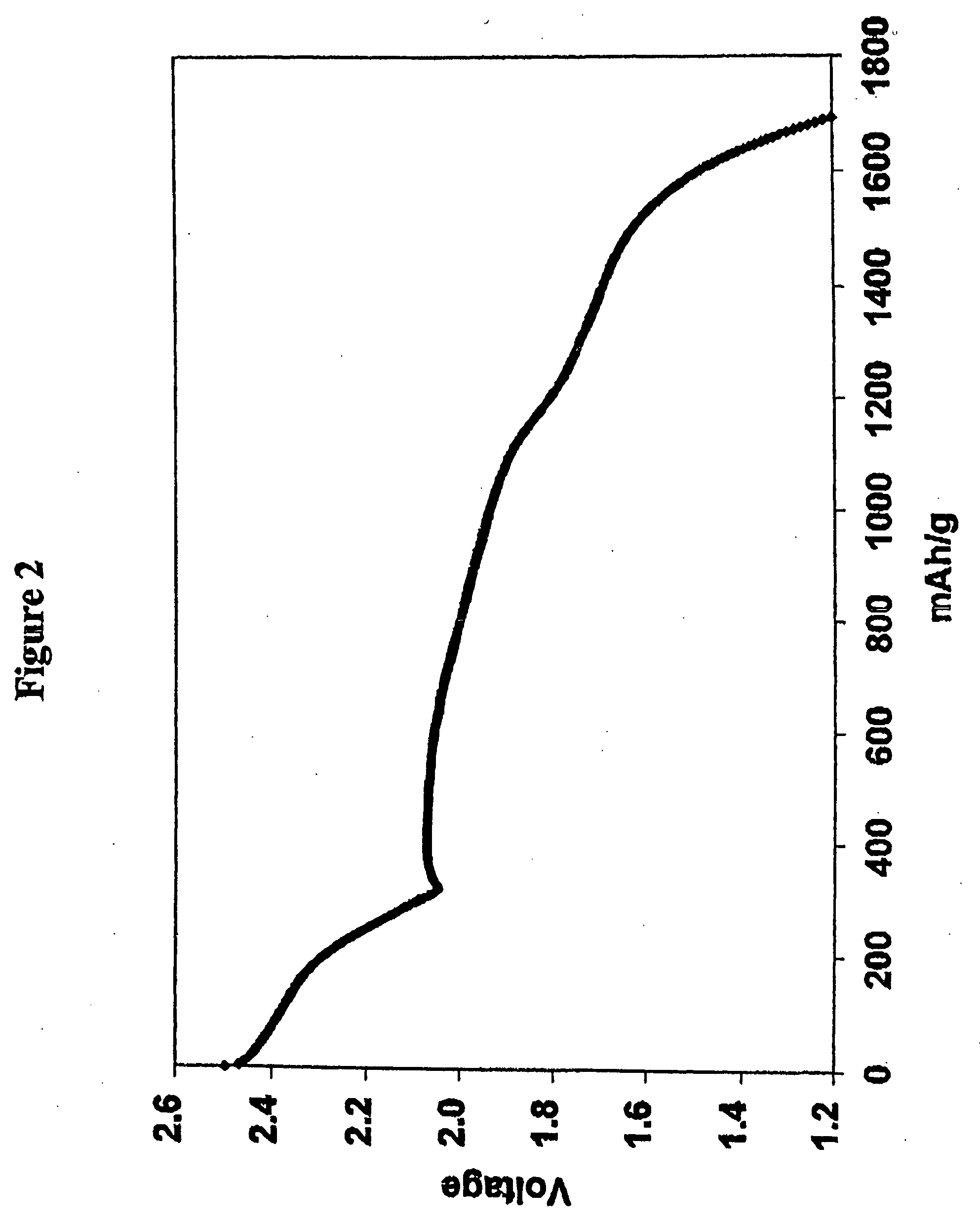

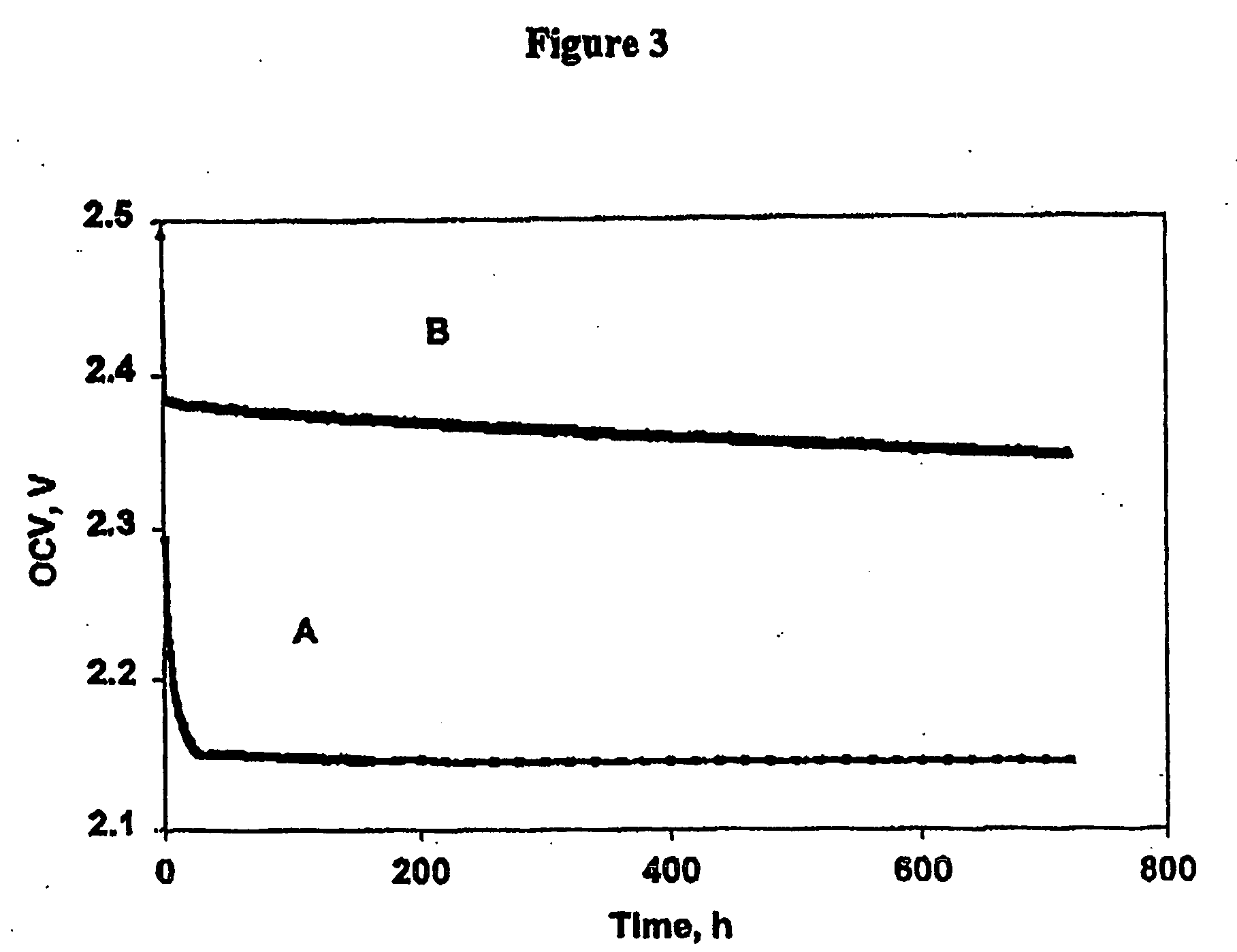

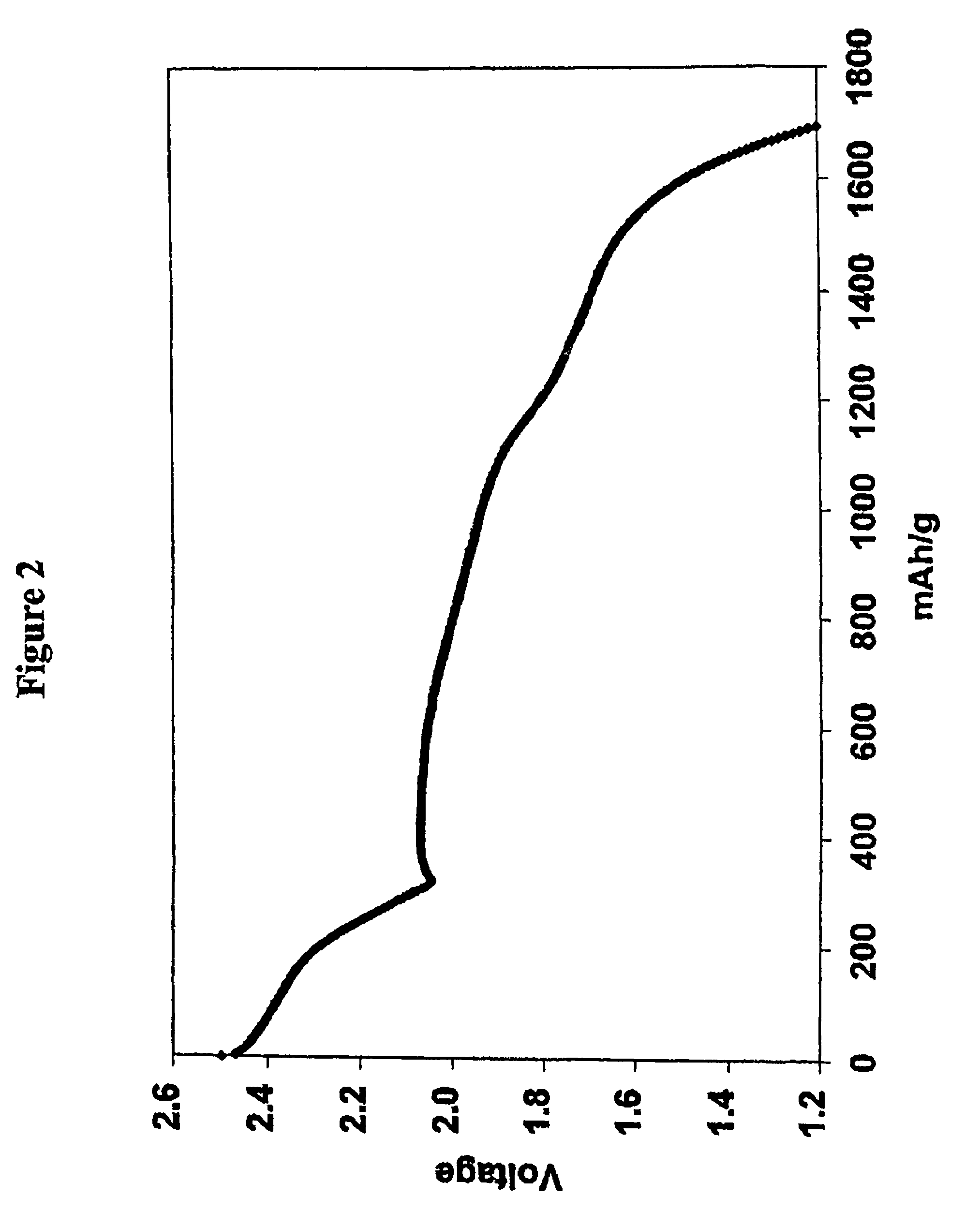

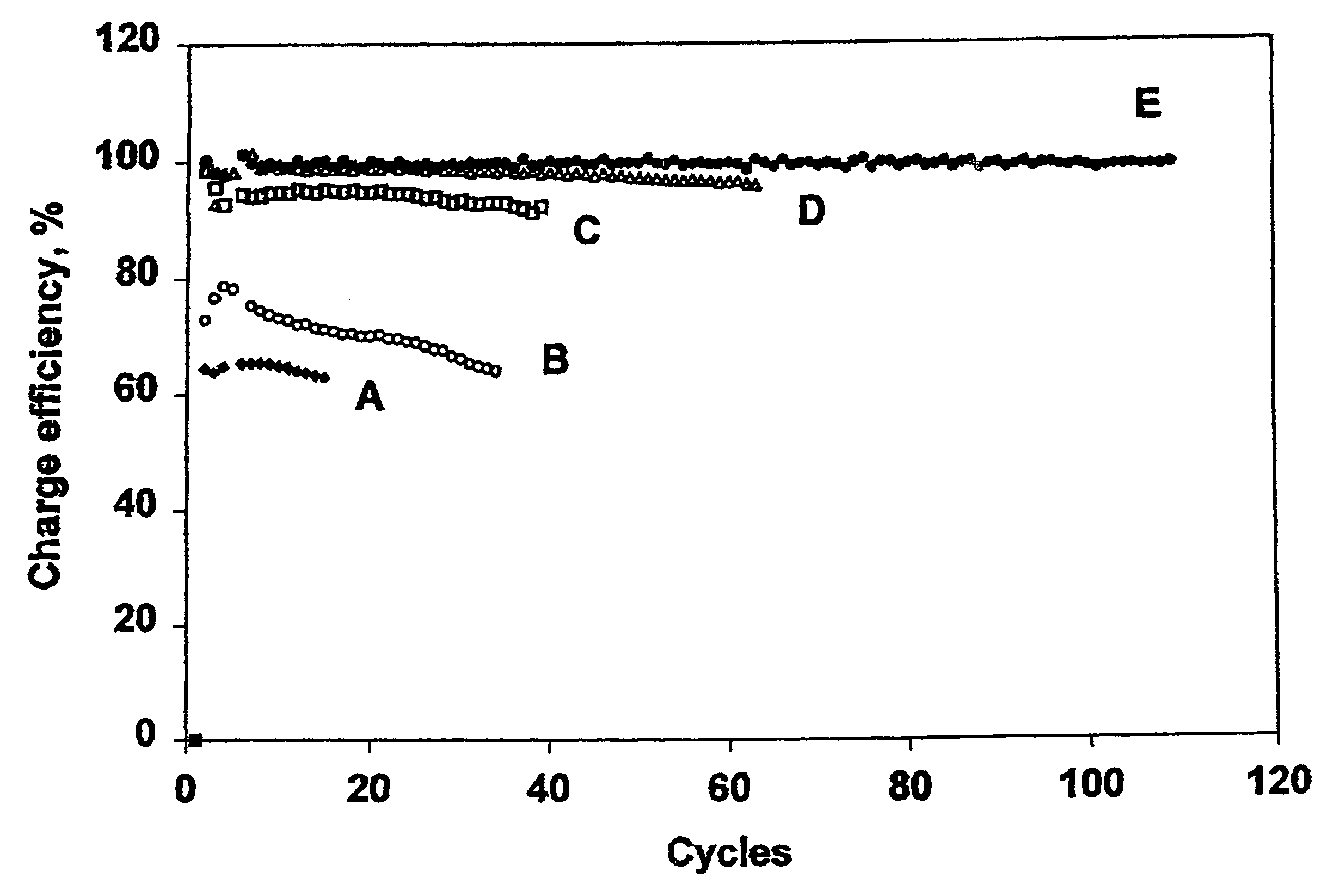

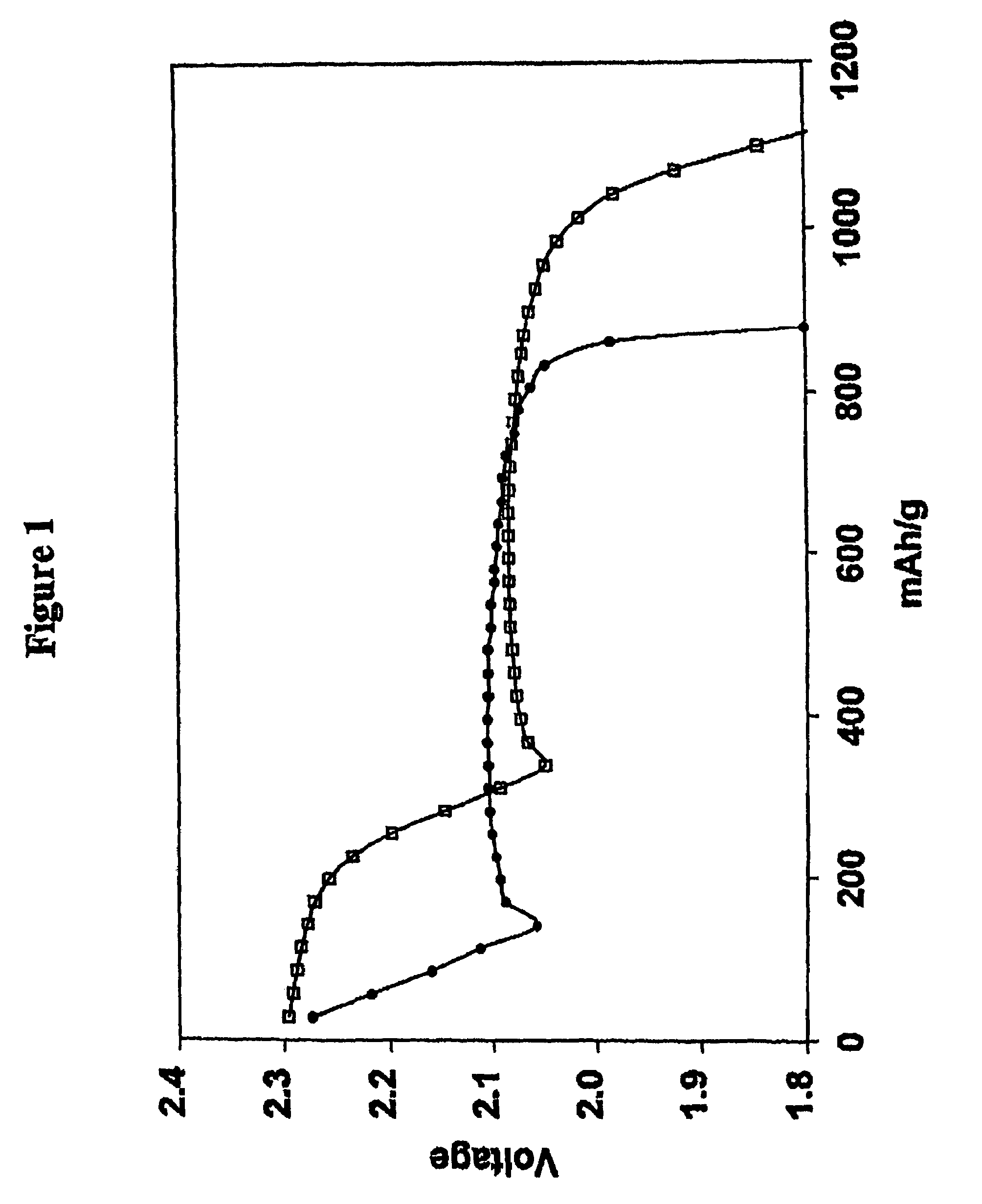

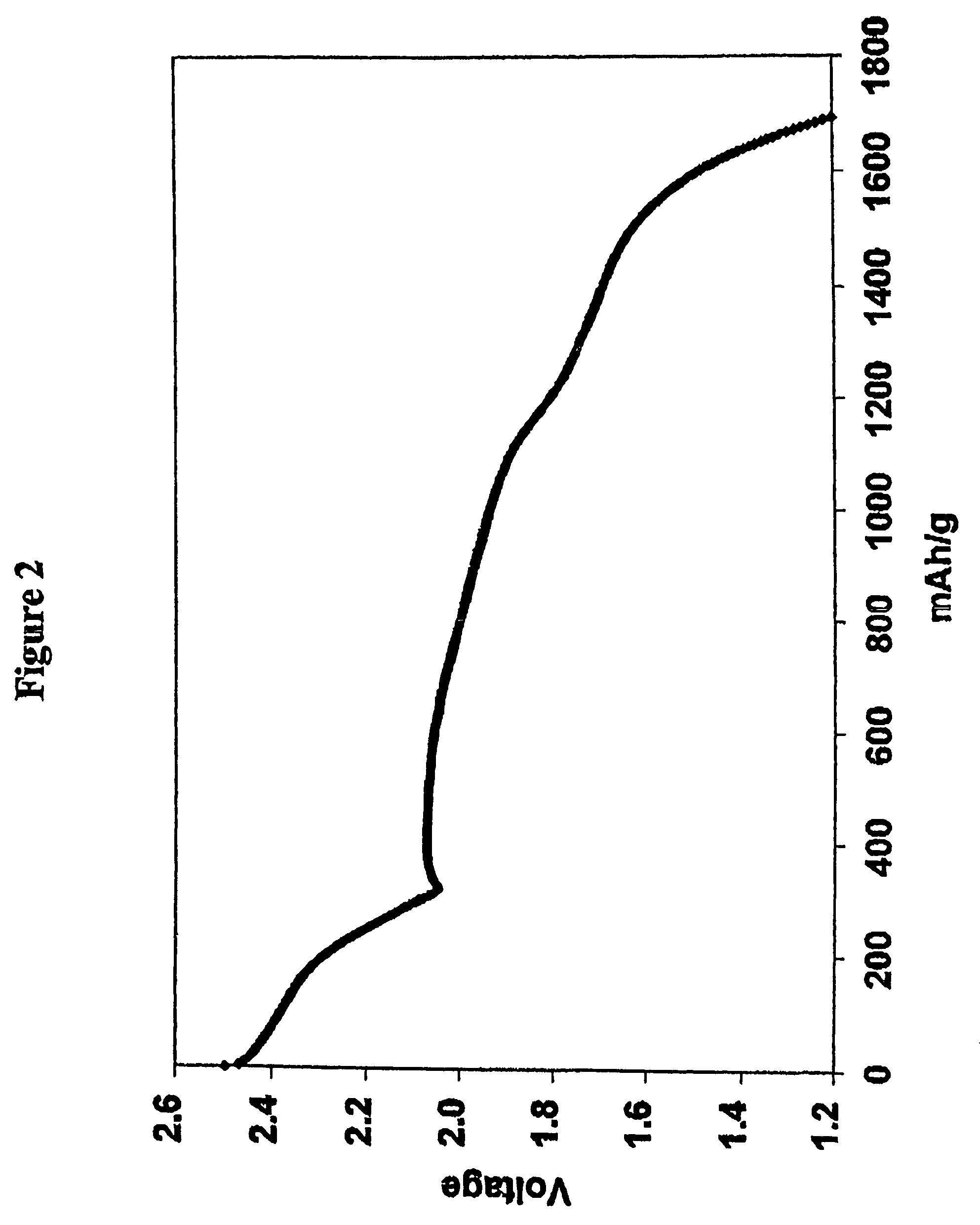

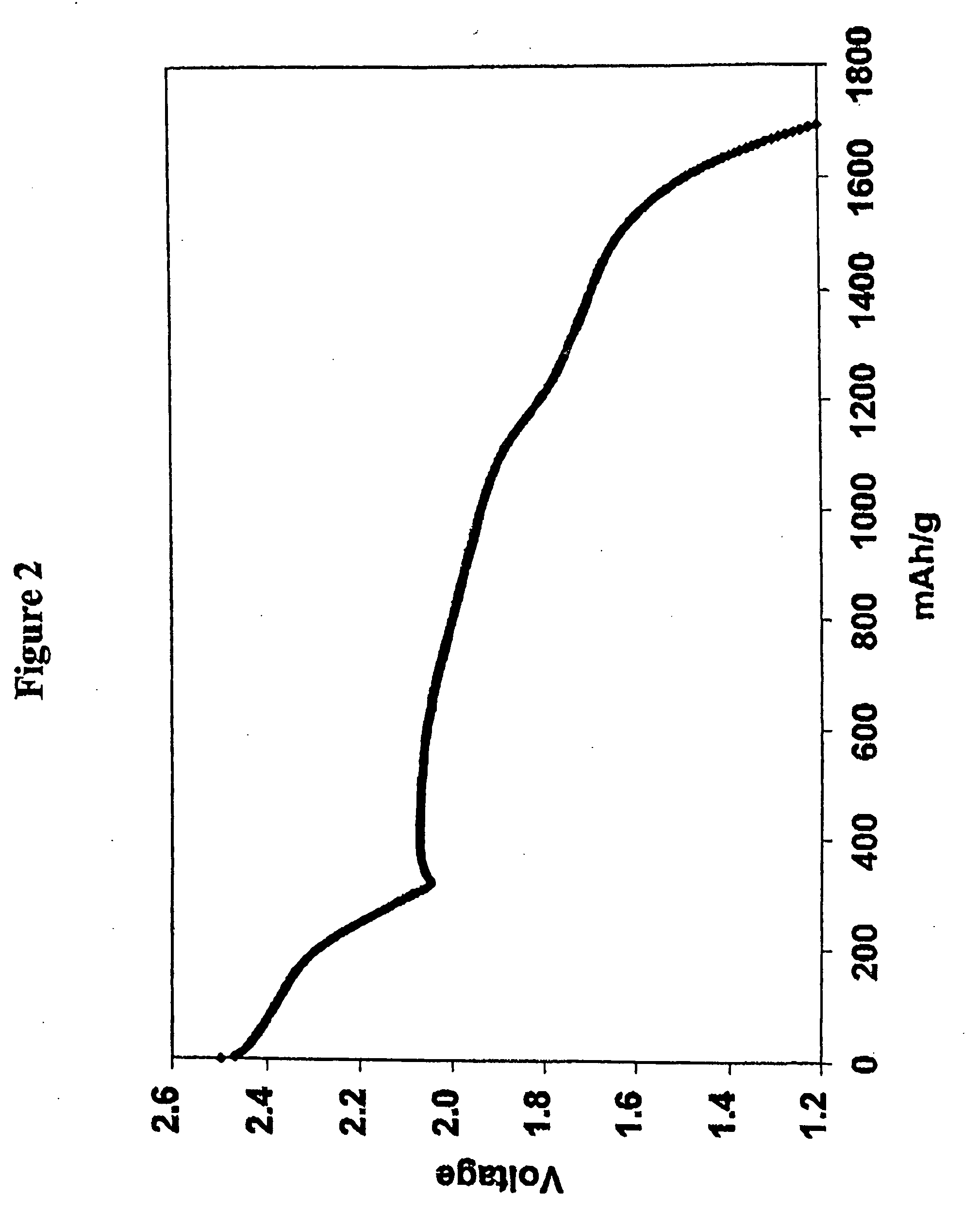

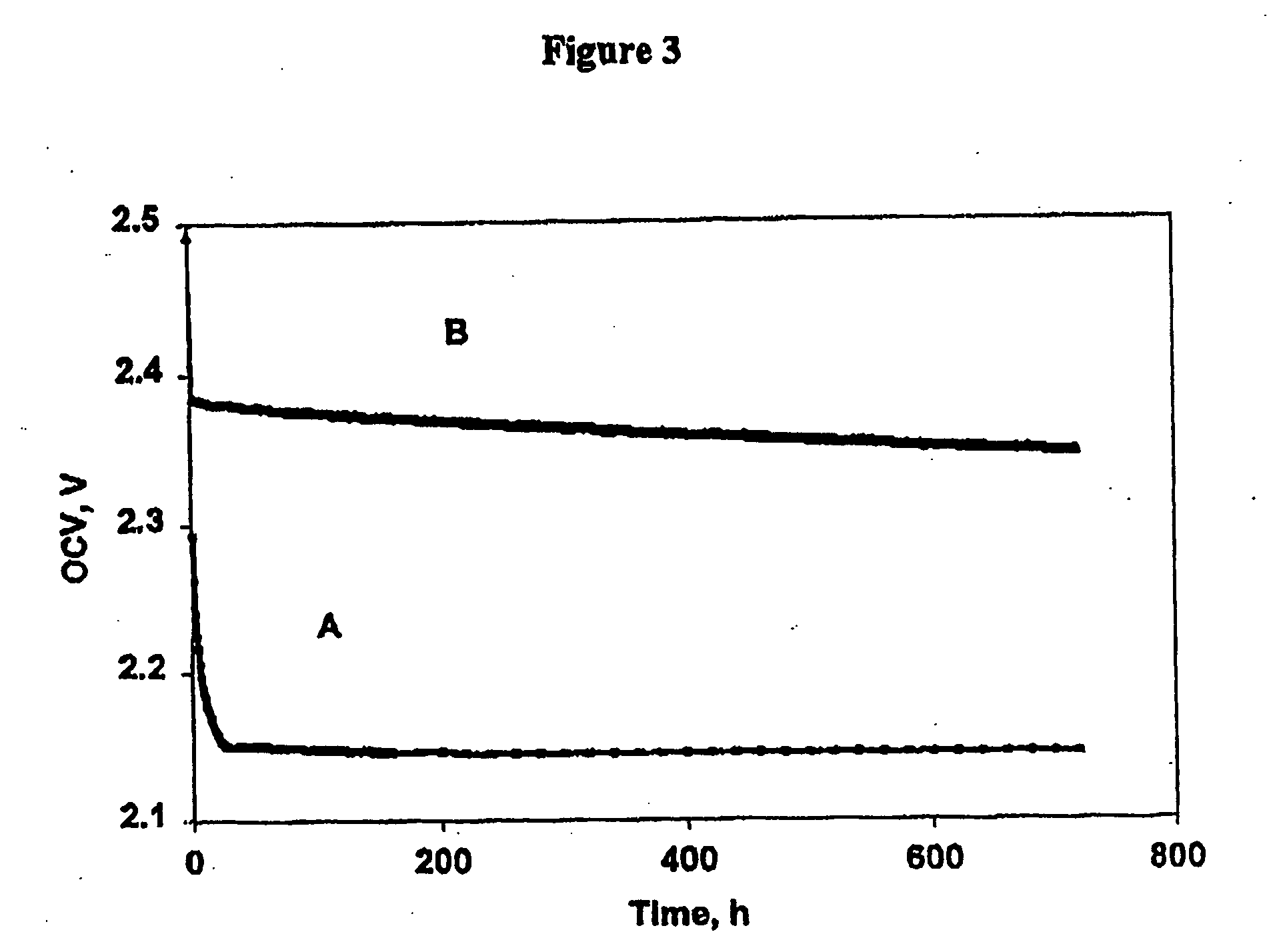

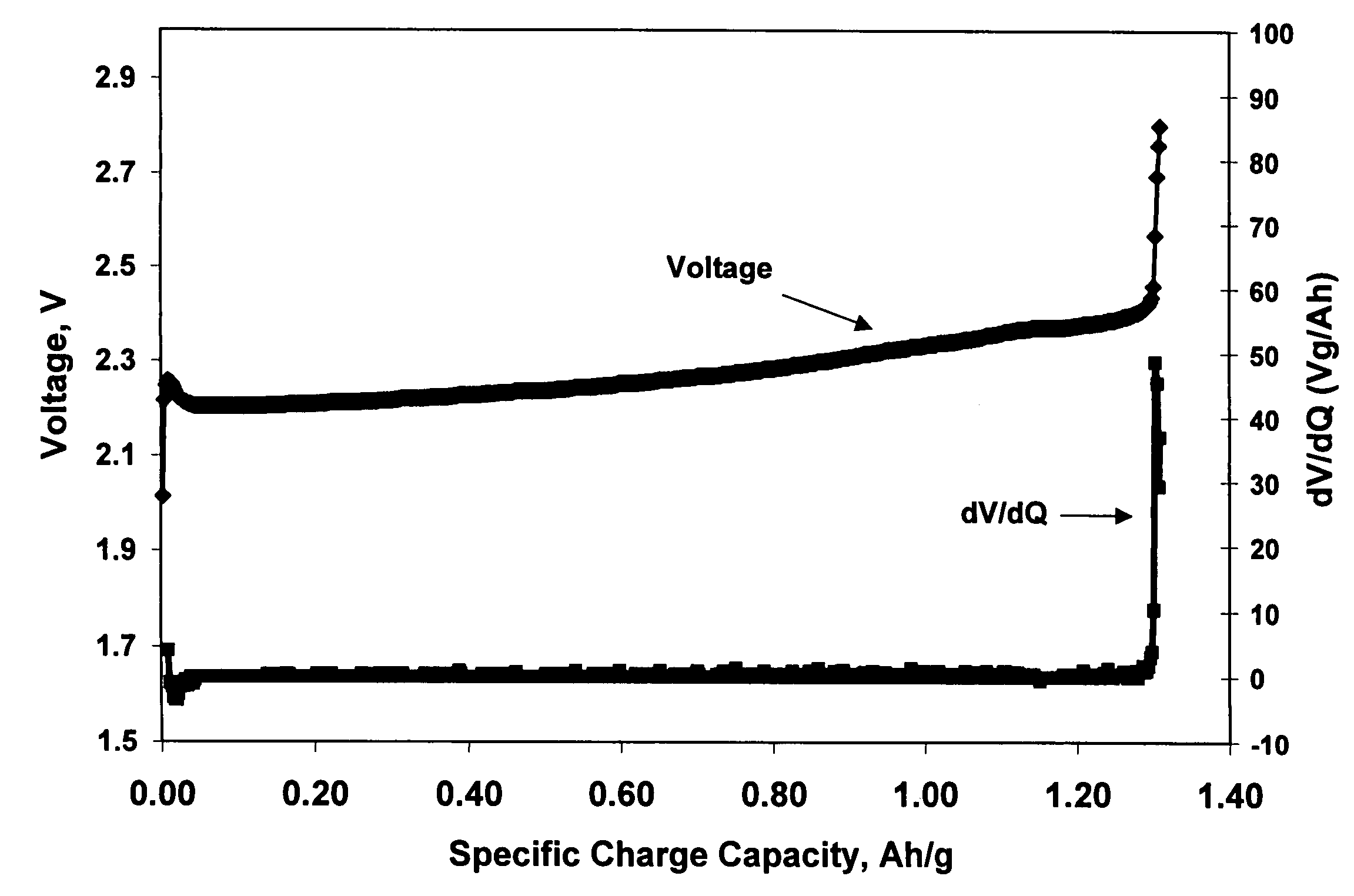

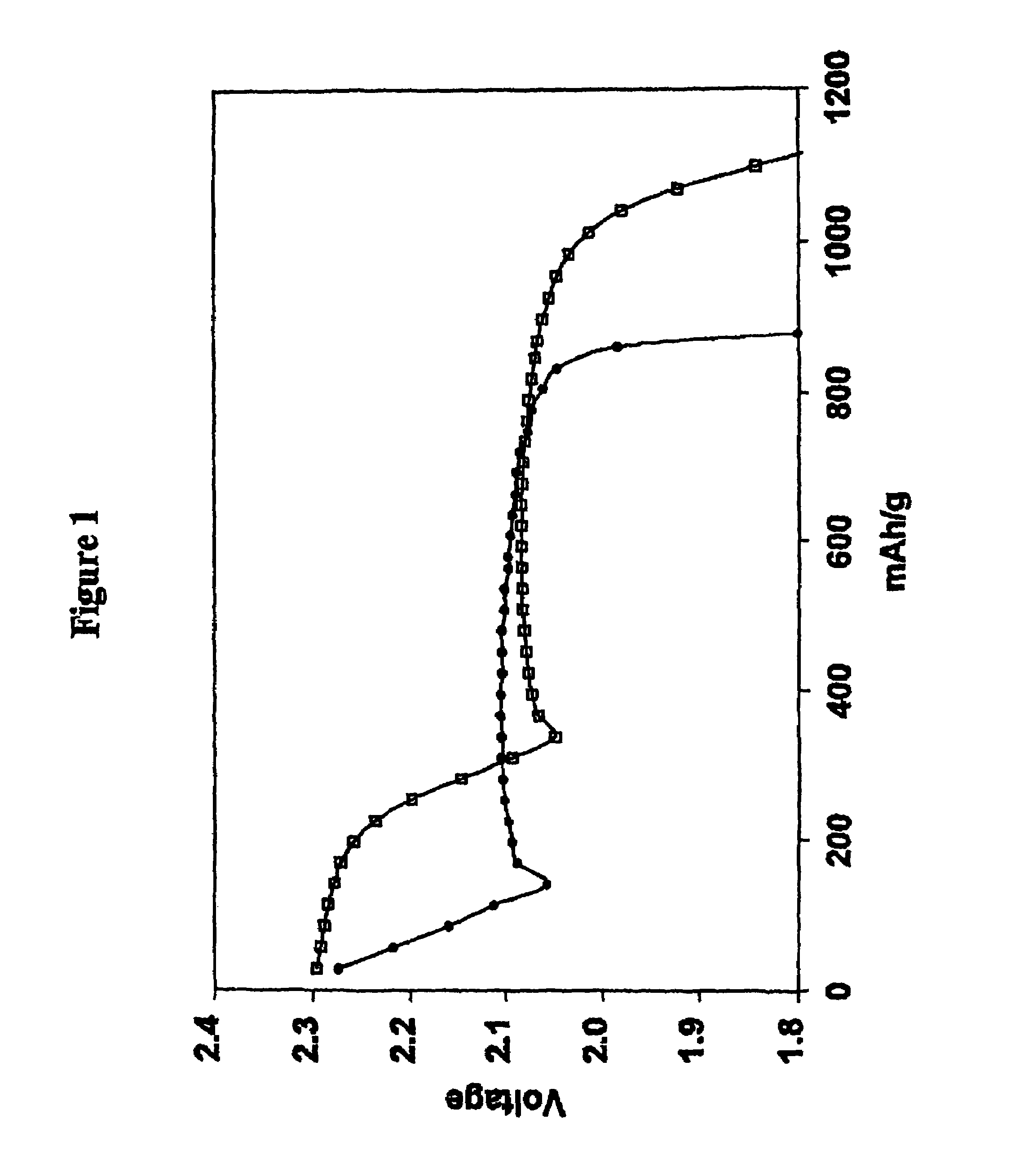

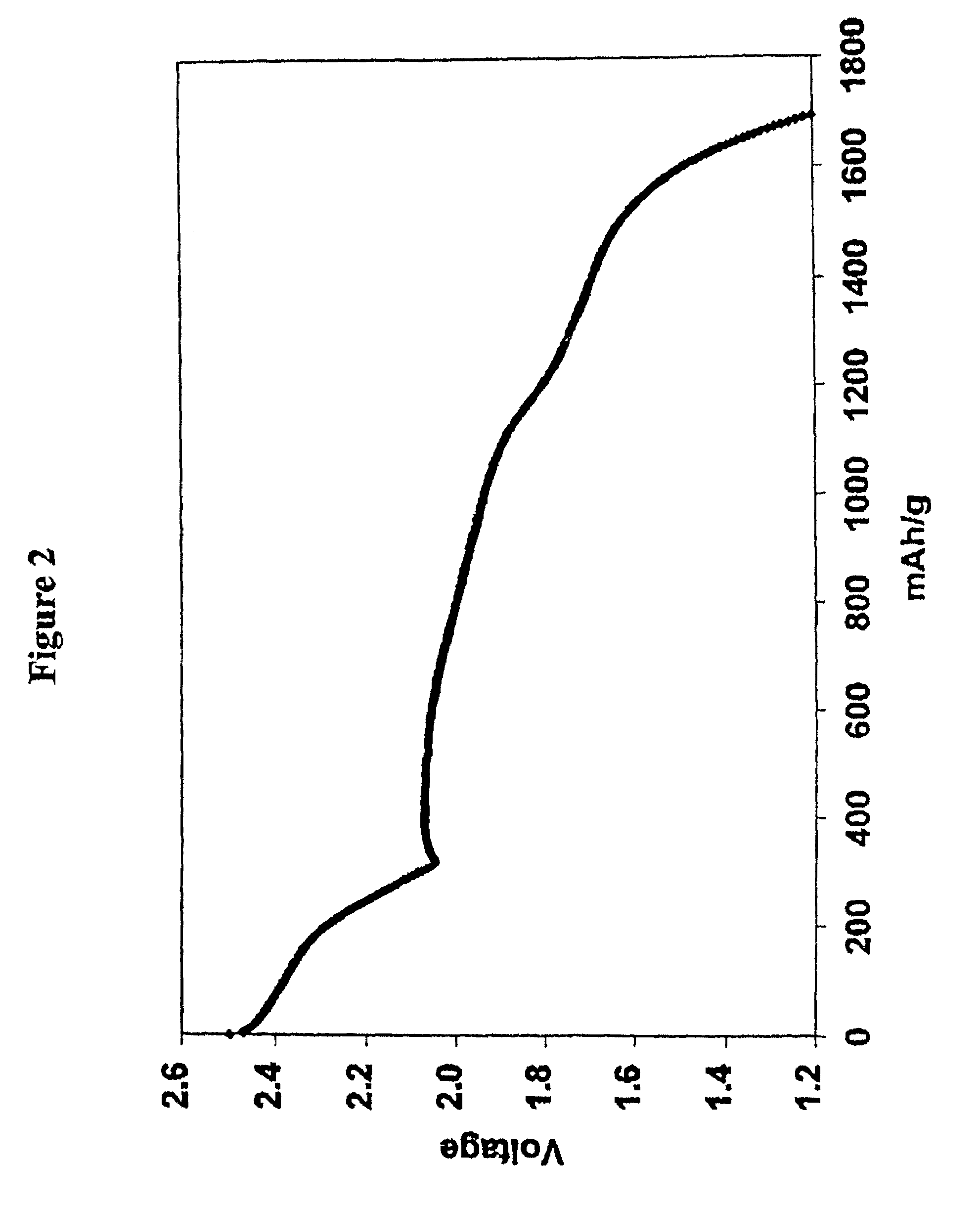

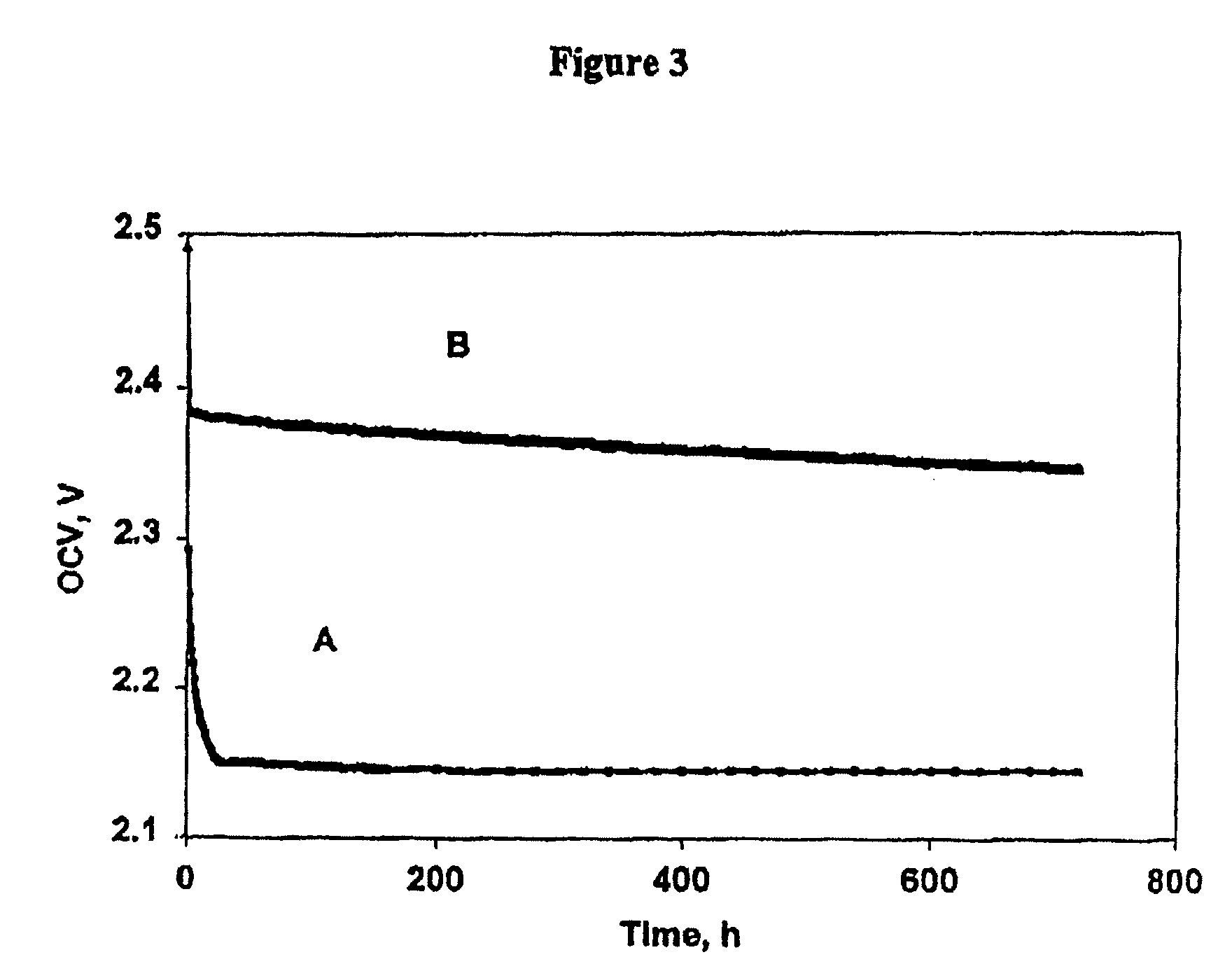

ActiveUS7358012B2Reduce the probability of reactionLow self-discharge rateFinal product manufactureOrganic electrolyte cellsLithium sulfurCharge discharge

Disclosed is an electrochemical cell comprising a lithium anode and a sulfur-containing cathode and a non-aqueous electrolyte. The cell exhibits high utilization of the electroactive sulfur-containing material of the cathode and a high charge-discharge efficiency.

Owner:SION POWER CORP

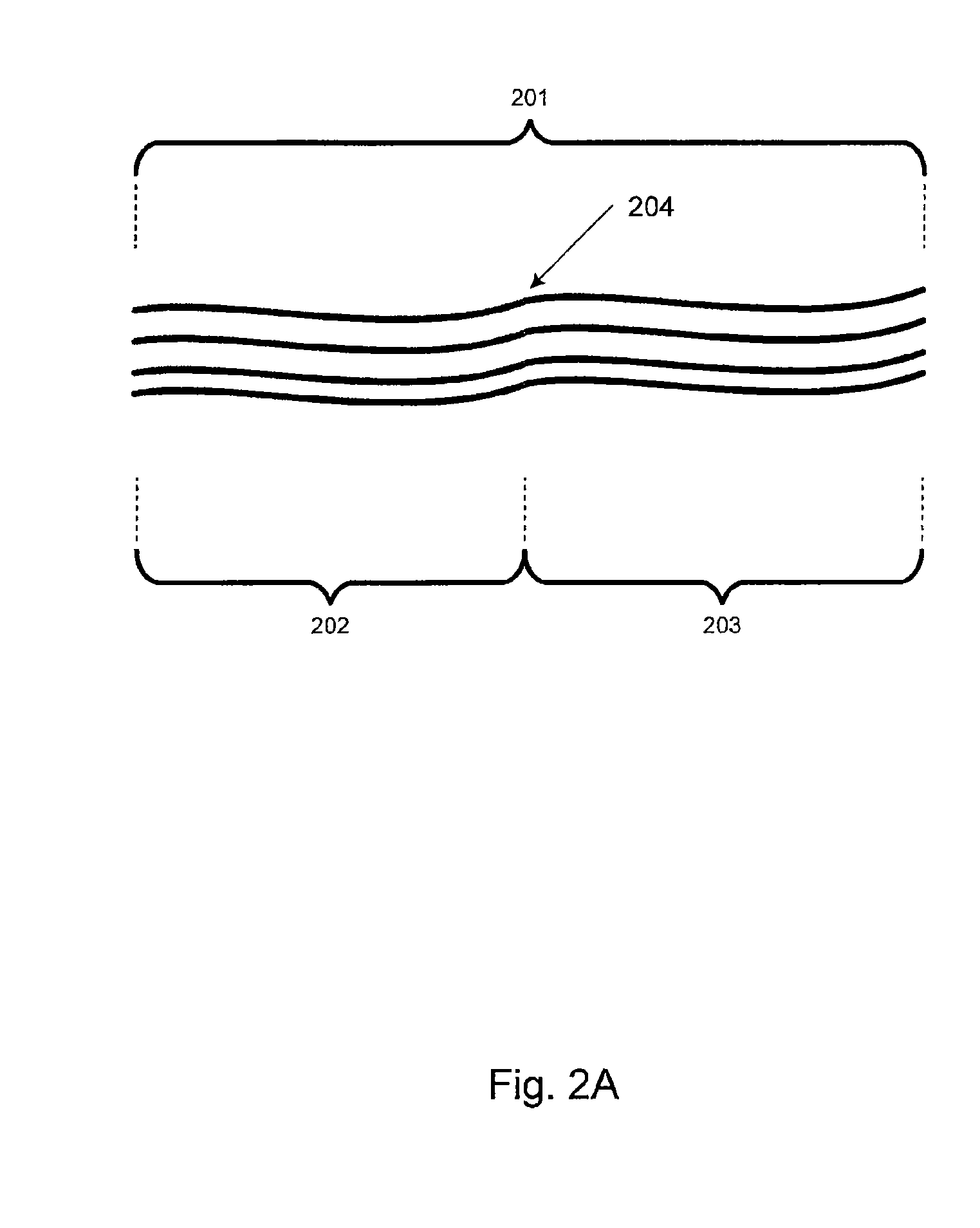

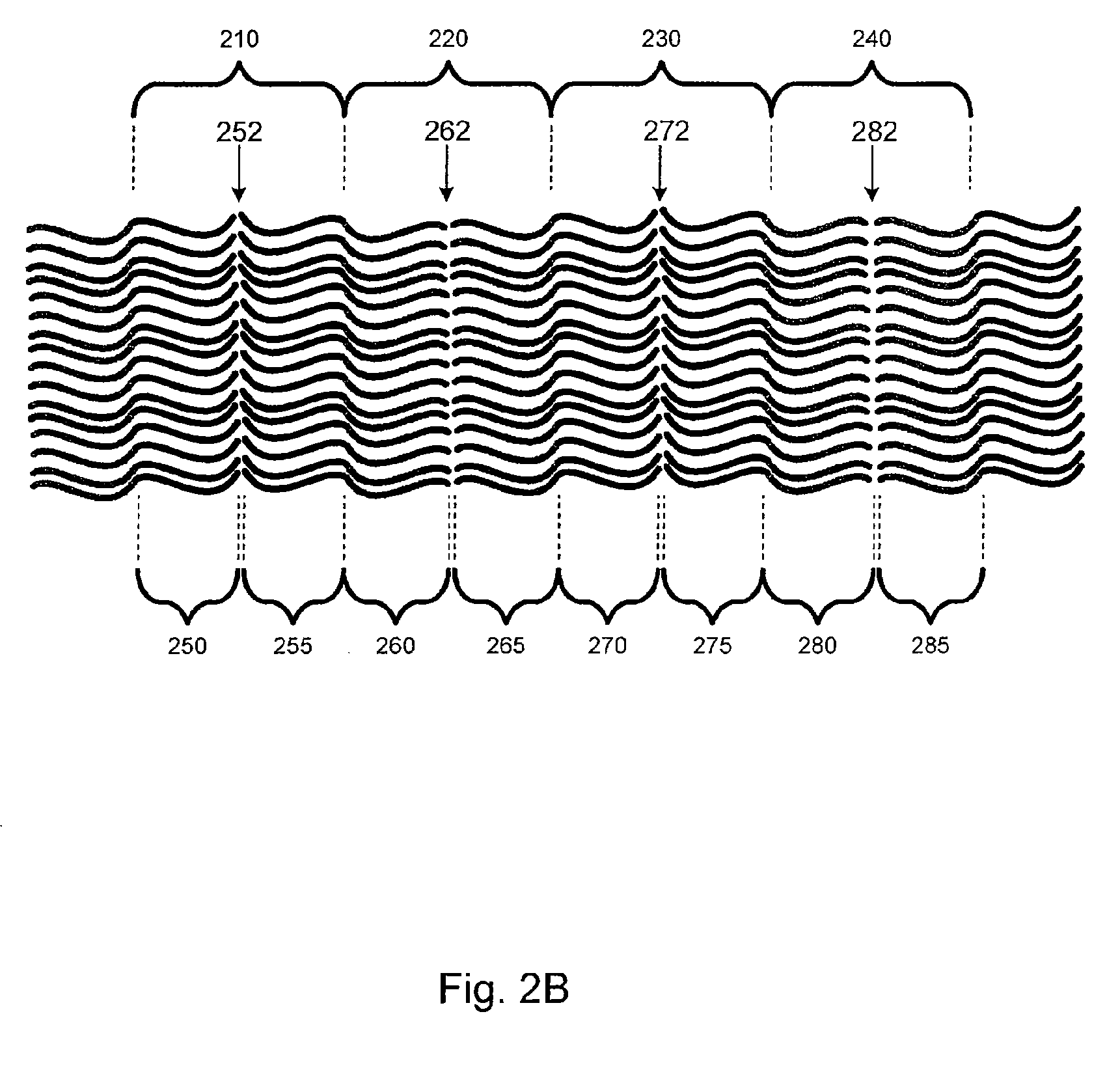

Methods of charging lithium sulfur cells

ActiveUS7019494B2Reduce the probability of reactionLow self-discharge rateCell electrodesPrimary cellsLithium–sulfur batteryLithium sulfur

Owner:SION POWER CORP

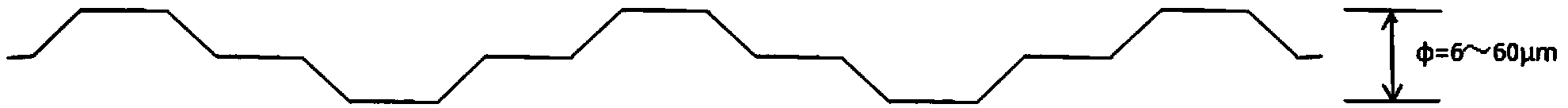

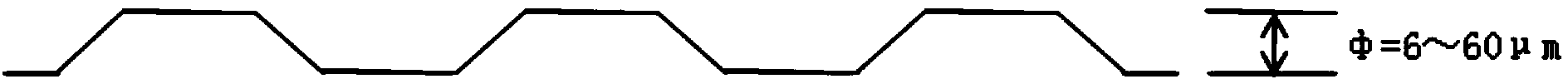

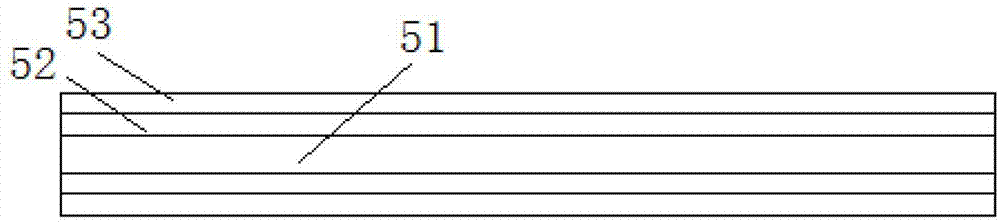

Lithium battery and preparation method thereof

ActiveCN103730683AIncrease energy densitySave spaceFinal product manufactureElectrode carriers/collectorsConvex structureMetal foil

The invention discloses a lithium battery. The lithium battery comprises a positive plate, a negative current collecting substrate, an isolating membrane and an electrolyte, wherein the isolating membrane and the electrolyte are arranged between the positive plate and the negative current collecting substrate; the positive plate comprises a positive current collecting body, a positive diaphragm and a positive polar lug, the positive diaphragm is attached to the positive current collecting body and contains a positive active material, and the positive polar lug is welded on the positive current collecting body; the negative current collecting substrate is made of a metal foil or a metal mesh with a thickness of 6-25 mu m, is 6-60 mu m in thickness and has a plane or concave-convex structure; and the electrolyte contains a lithium salt and a solvent, the lithium salt is lithium hexafluorophosphate, and the concentration of the lithium salt in the electrolyte is 1.5-7mol / L. The lithium battery disclosed by the invention has the characteristics of high power, high energy and low self-discharge rate. Meanwhile, the invention also discloses a preparation method and applications of the lithium battery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Electrolytes for lithium sulfur cells

ActiveUS20050147886A1Low self-discharge rateImprove overall utilizationFinal product manufactureOrganic electrolyte cellsLithium sulfurCharge discharge

Disclosed is an electrochemical cell comprising a lithium anode and a sulfur-containing cathode and a non-aqueous electrolyte. The cell exhibits high utilization of the electroactive sulfur-containing material of the cathode and a high charge-discharge efficiency.

Owner:SION POWER CORP

Methods of charging lithium sulfur cells

ActiveUS7646171B2Reduce the probability of reactionLow self-discharge rateCell electrodesMaterial analysis by electric/magnetic meansLithium–sulfur batteryLithium sulfur

Owner:SION POWER CORP

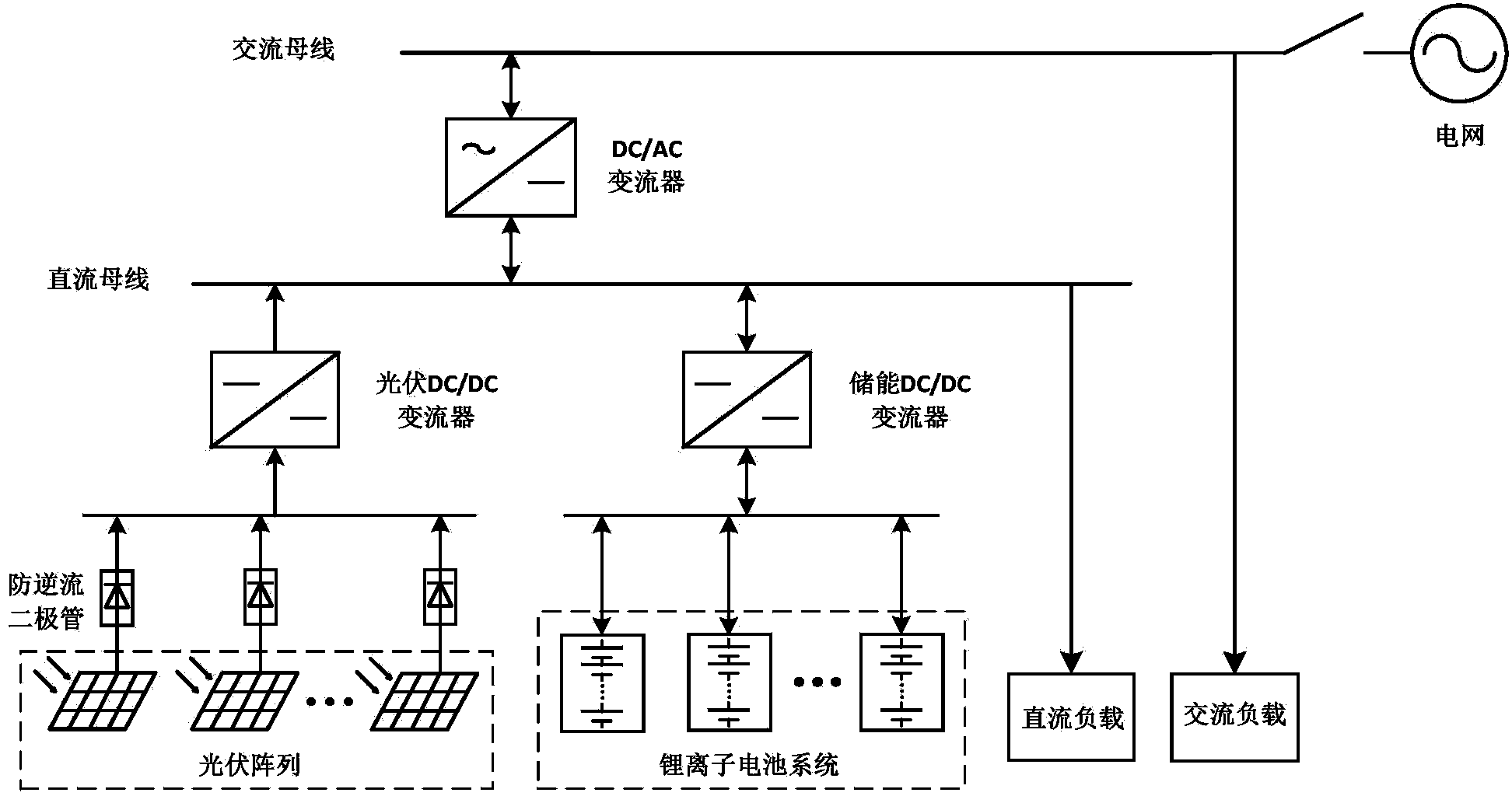

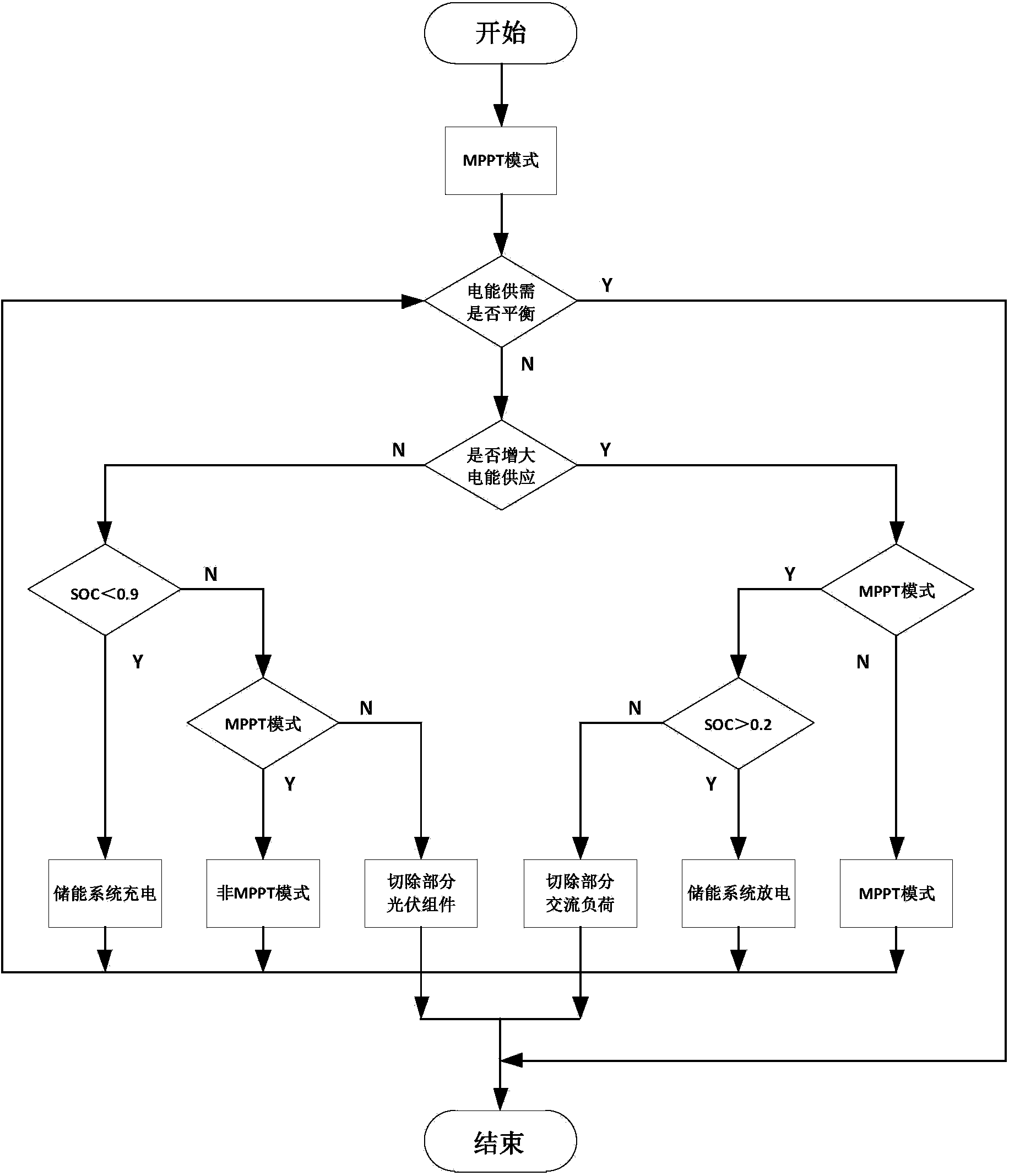

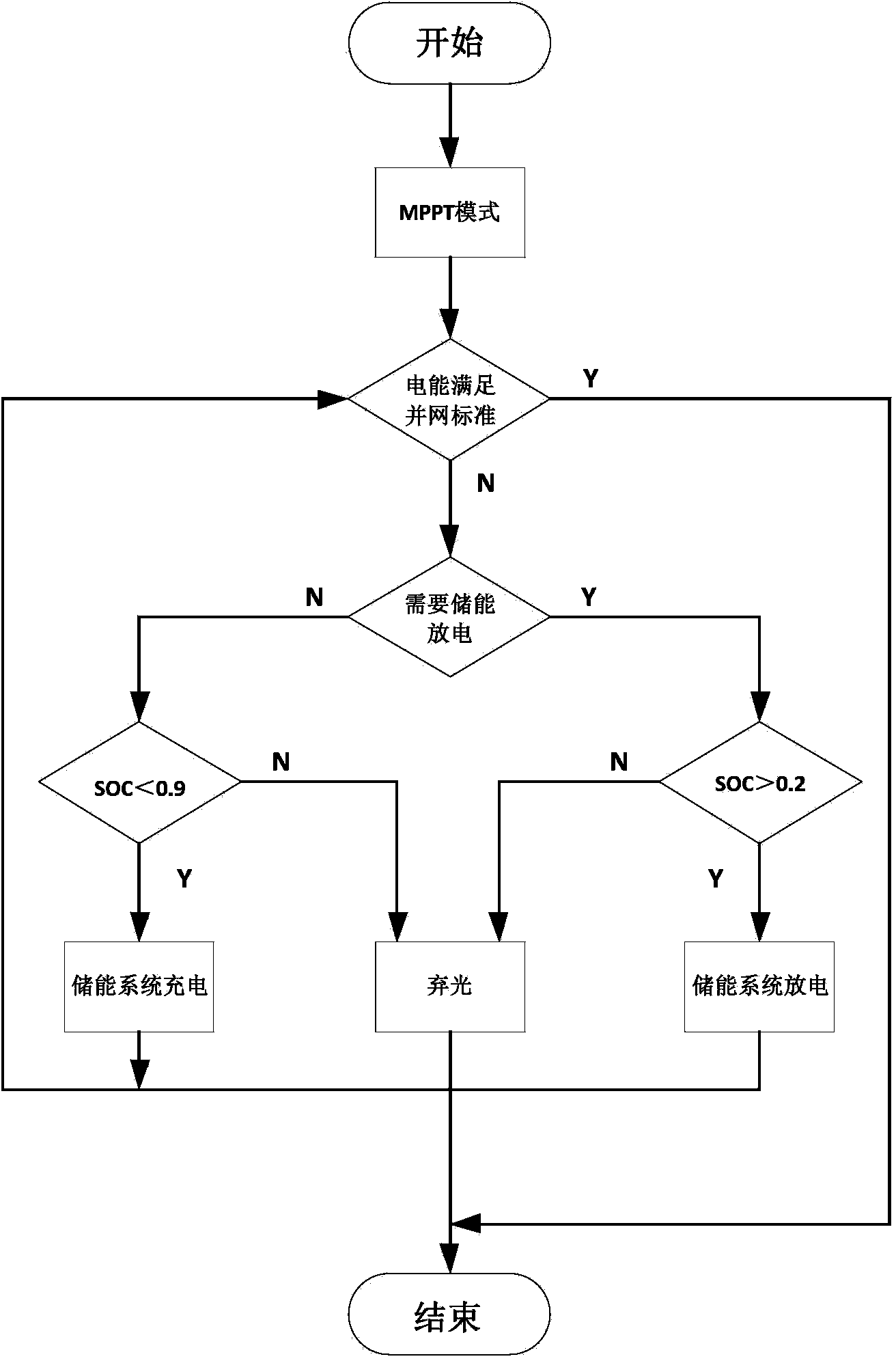

Off-grid and grid-connected operation light and storage joint power supply system

ActiveCN104052082AReduce output voltagePrevent backfeedSingle network parallel feeding arrangementsEnergy storagePower gridOperation mode

The invention provides an off-grid and grid-connected operation light and storage joint power supply system which comprises a DC / AC converter for connecting a direct current bus and an alternating current bus. The alternating current bus is connected with a power grid. The alternating current bus and the direct current bus are connected with an alternating current load and a direct current load respectively. The direct current bus is connected with a photovoltaic array and a battery system through a photovoltaic DC / DC converter and an energy storage DC / DC converter respectively. According to the off-grid and grid-connected operation light and storage joint power supply system, control strategies of the off-grid and grid-connected operation light and storage joint power supply system are provided and include the off-grid state operation control strategy and the grid-connected state operation control strategy. By means of the system and a method, the defects that an existing photovoltaic power supply system is instable in power supply quality, poor in schedulability, single in operation mode, low in energy conversion efficiency and the like are overcome.

Owner:STATE GRID CORP OF CHINA +2

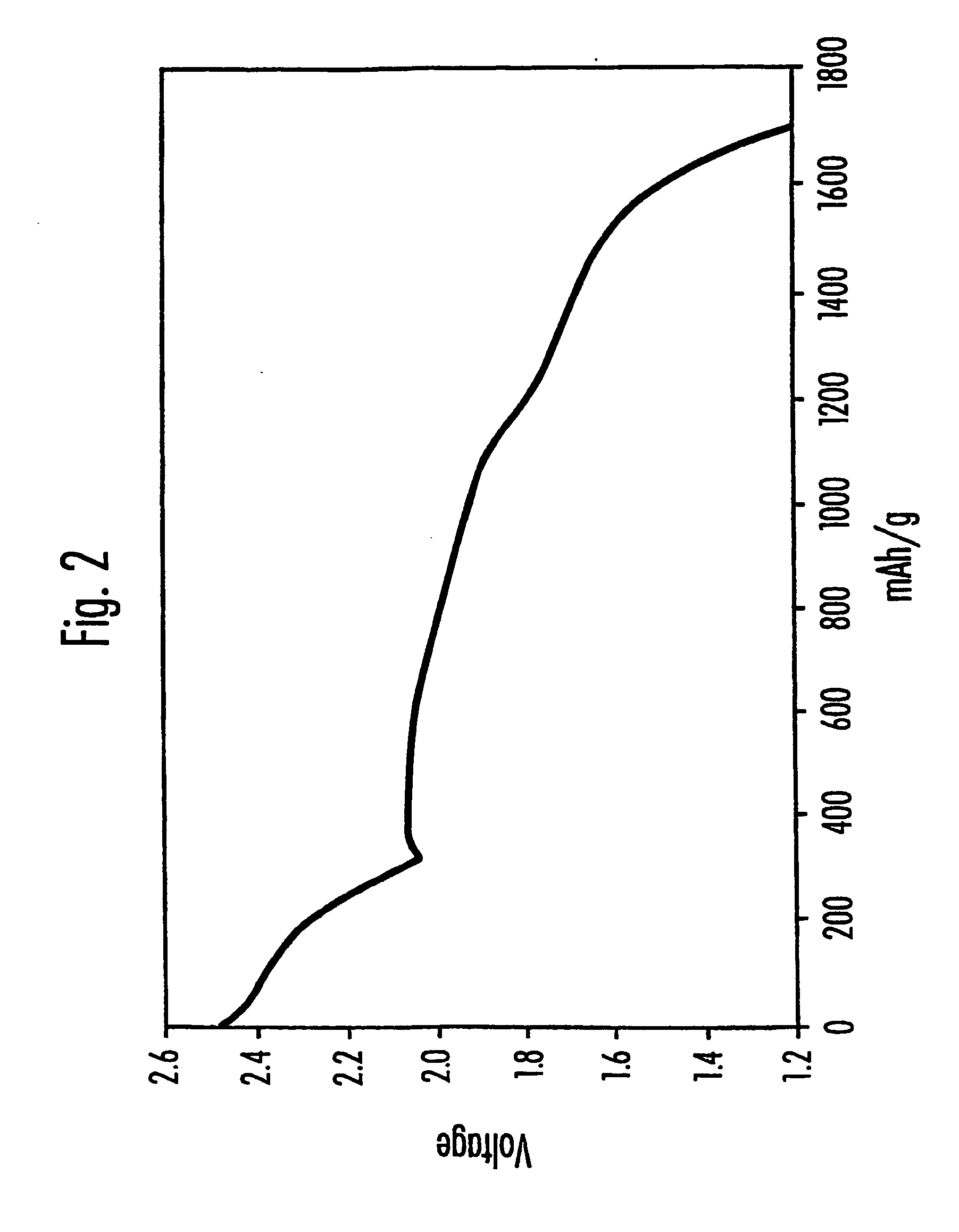

Electrolytes for lithium sulfur cells

InactiveUS20070082264A1Reduce the probability of reactionLow self-discharge rateFinal product manufactureOrganic electrolyte cellsLithium sulfurElectrochemical cell

Disclosed is an electrochemical cell comprising a lithium anode and a sulfur-containing cathode and a non-aqueous electrolyte. The cell exhibits high utilization of the electroactive sulfur-containing material of the cathode and a high charge-dis-charge efficiency.

Owner:SION POWER CORP

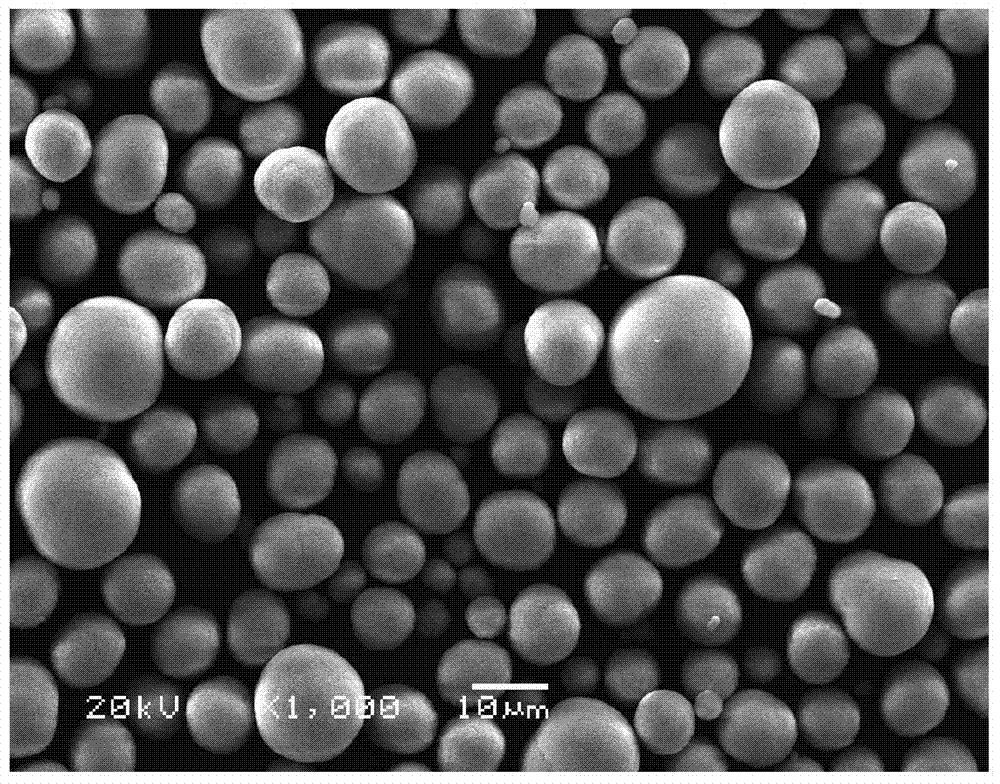

Lithium ionic cell positive plate made from ternary material and production method thereof

ActiveCN101504978AAffect performanceImprove uniformityElectrode manufacturing processesElectrode carriers/collectorsOrganic solventEngineering

The invention provides a lithium ion battery positive plate made from a ternary material and a method for preparing the same, which relate to a lithium ion battery. The lithium ion battery positive plate made from the ternary material is provided with a current collector, both the right side and the back side of the current collector are coated with a conductive layer respectively, and the conductive layer comprises the following components by mass percentage: 1 to 5 percent of conductive agent, 3 to 5 percent of binder, and the balance of anode active substances. The method comprises the following steps: stirring the binder with an organic solvent until the white binder is dissolved completely to obtain a transparent colloidal binder, standing the transparent colloidal binder, adding the conductive agent into the transparent colloidal binder, and stirring the mixture to obtain conductive gel; adding the anode active substances into the conductive gel, and stirring the mixture to obtain slurry; stirring the slurry, adjusting the viscosity, and sieving the slurry for standby; performing corrosion treatment on the current collector with an alkali liquor first, and then washing and drying the current collector; and coating the sieved slurry on the right side and the back side of the current collector evenly, drying the current collector to finish the coating so as to obtain the lithium ion battery positive plate made from the ternary material.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

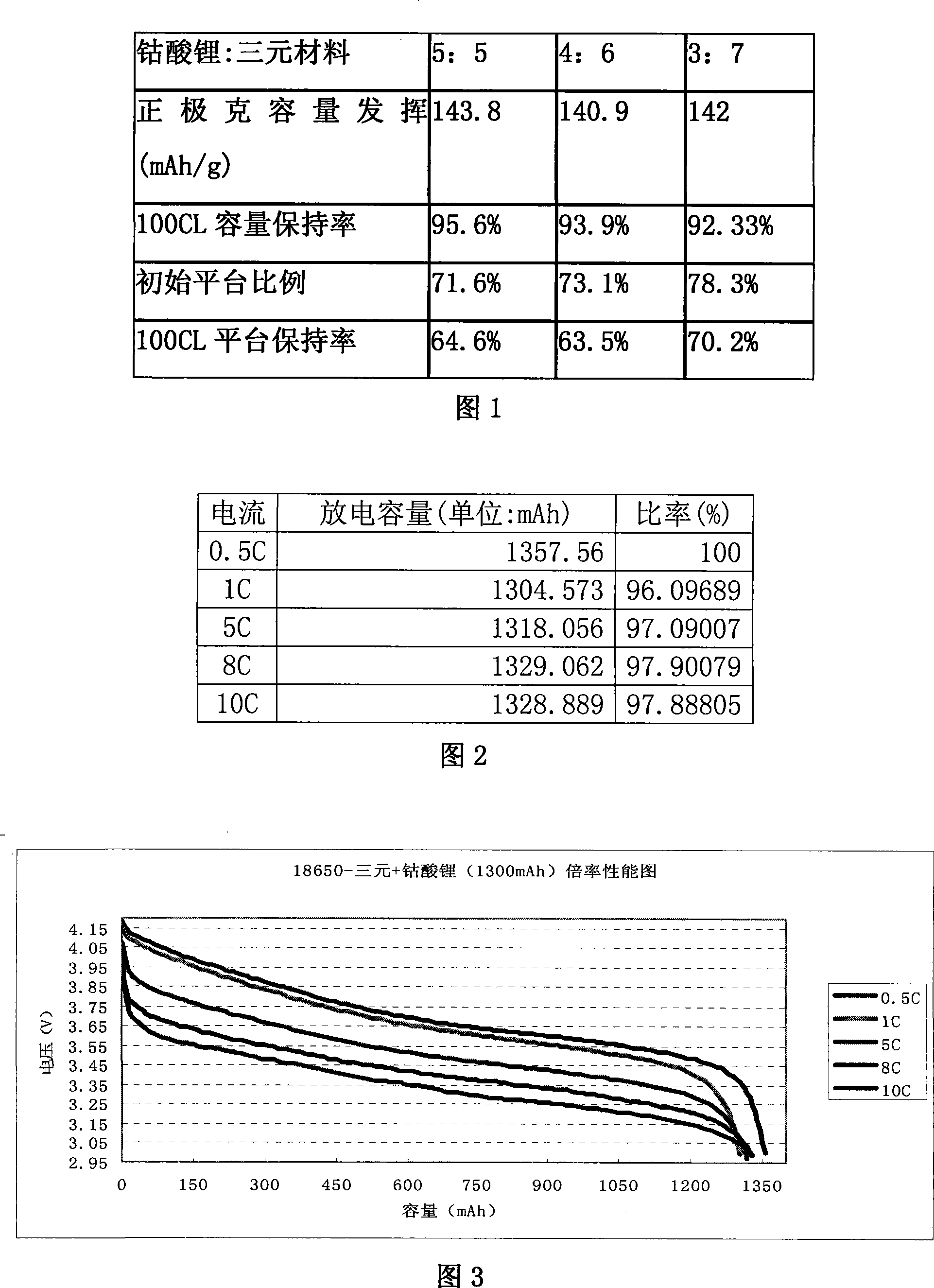

Lithium cell anode active substance, anode dressing and its preparing method

InactiveCN101071859AHigh platform capacityImprove electrical conductivityElectrode manufacturing processesBall millAdhesive

The invention is a lithium battery anode active matter, and anode dressing and the preparing method thereof. And the anode active matter comprises trinary material LiNixCoyMn1-x-yO2 and lithium cobaltate; the anode dressing comprises anode active matter, graphite conductive agent, charcoal black conductive agent, and adhesive; and the preparing method comprises: 1. ball-milling: a. ball-milling the trinary material, lithium cobaltate and graphite conductive agent in proportion; b. after a, adding the charcoal black conductive agent into ball-mill tank in proportion; and blending: a. taking the adhesive in proportion and blending with organic solvent, and when blending until no bubbles, stilling and serving; b. adding mixed material and other additives to colloid and blending thickly; and c. filtering for coating.

Owner:SHENZHEN B&K TECH

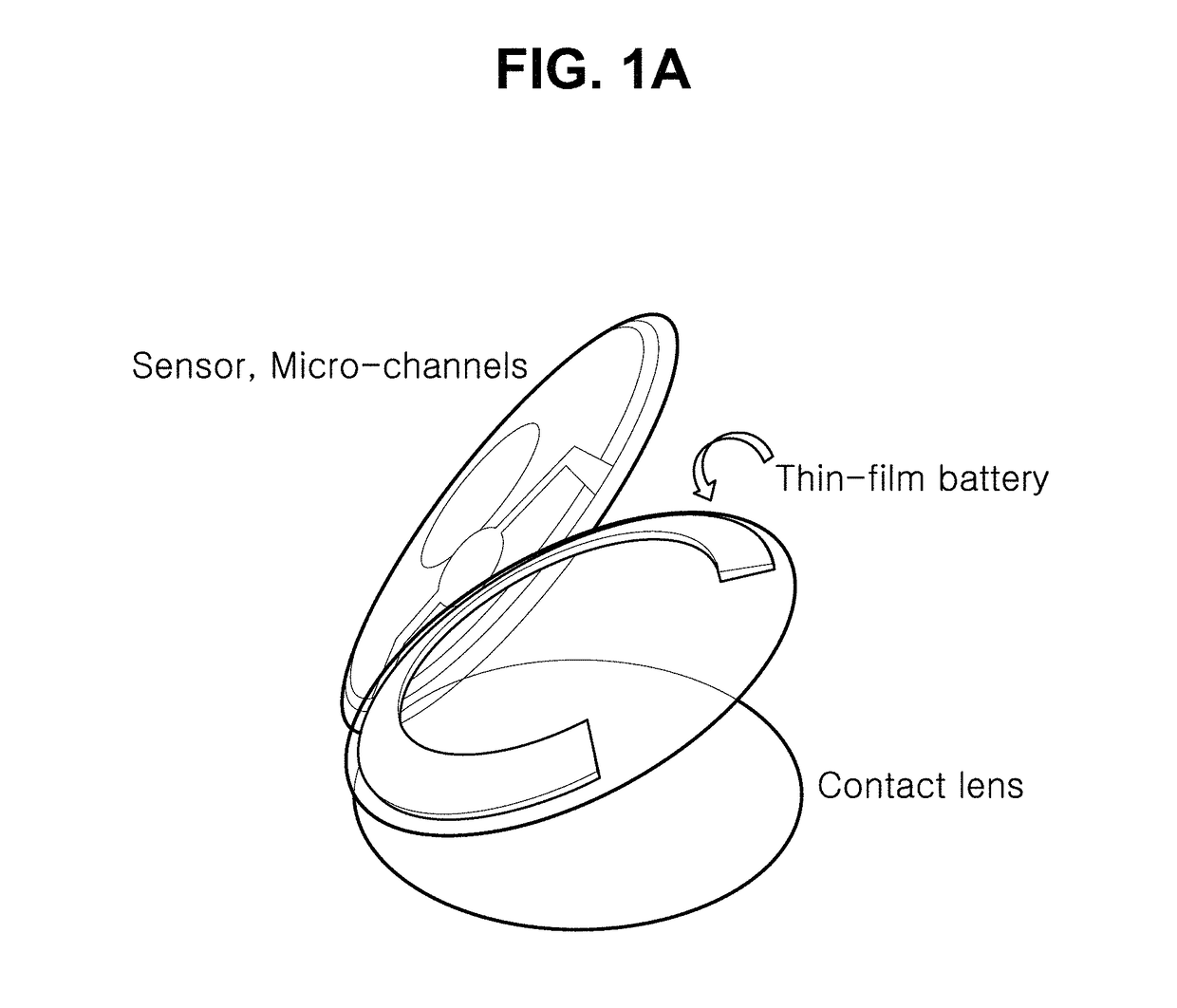

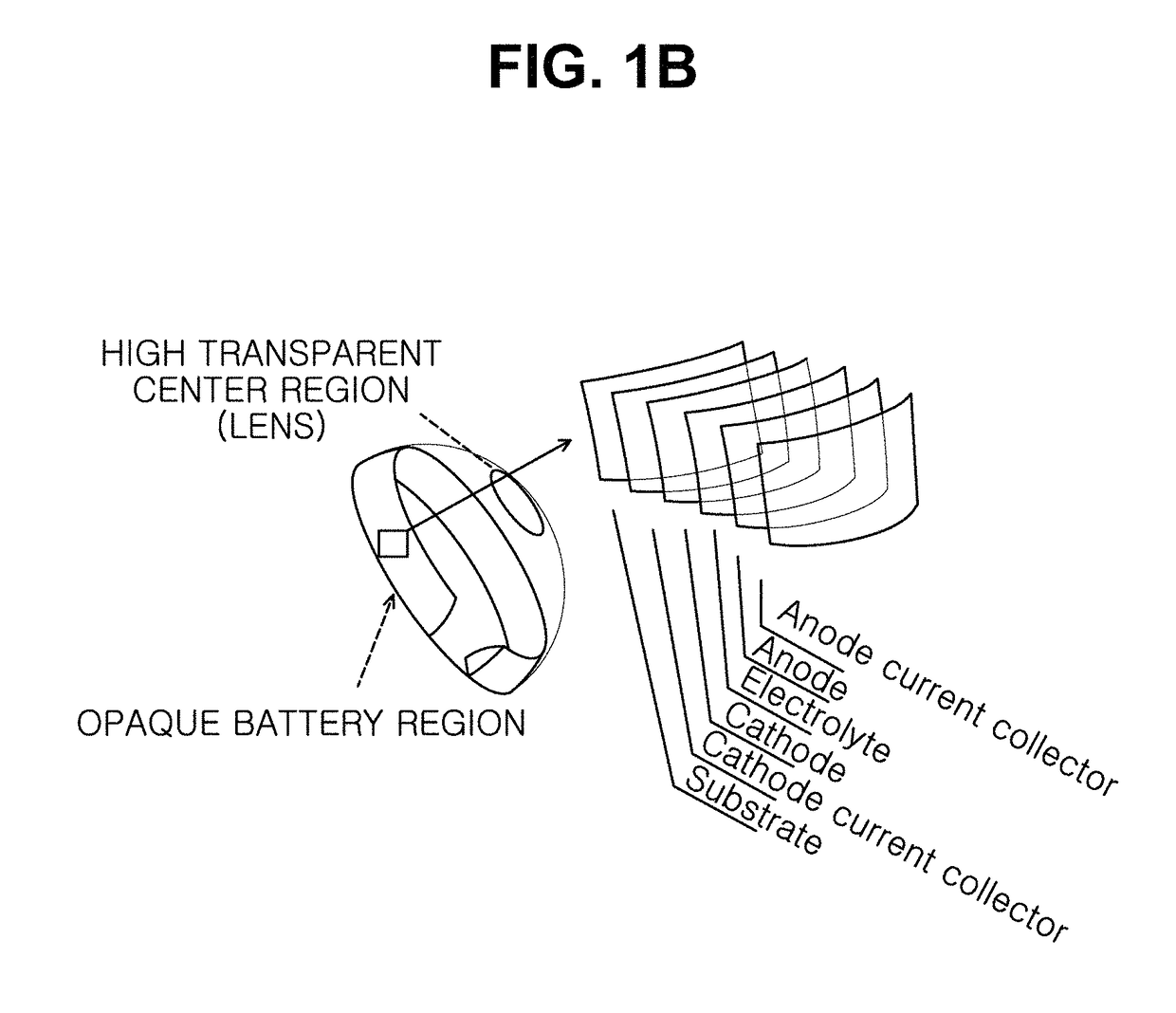

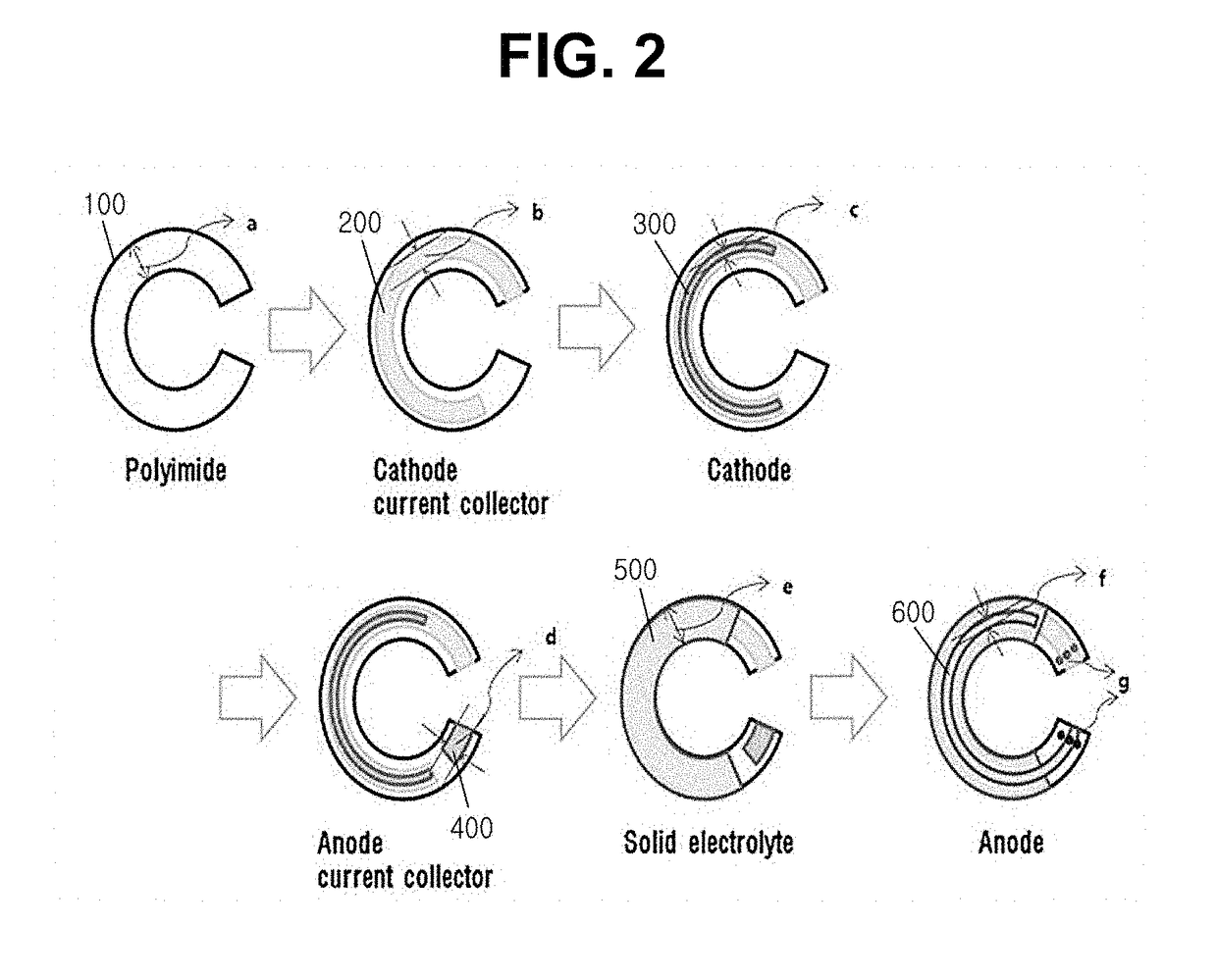

Smart wearable lens mounted with all-solid-state thin film secondary battery and method for manufacturing the same

PendingUS20190033618A1Low self-discharge ratePower supplyCircuit arrangementsFinal product manufactureElectrical batteryCurrent collector

Disclosed herein is a smart wearable lens mounted with an all-solid-state thin film secondary battery including a flexible substrate, a cathode current collector, a cathode, a solid electrolyte, an anode, and an anode current collector. The smart wearable lens mounted with the all-solid-state thin film secondary battery may be stably and continuously supplied with power and has a low self-discharge rate. In addition, the smart wearable lens may minimize aversion when humans are wearing the smart wearable lens and be suitably used for a curved lens, especially a micro-lens such as a contact lens.

Owner:KOREA INST OF SCI & TECH

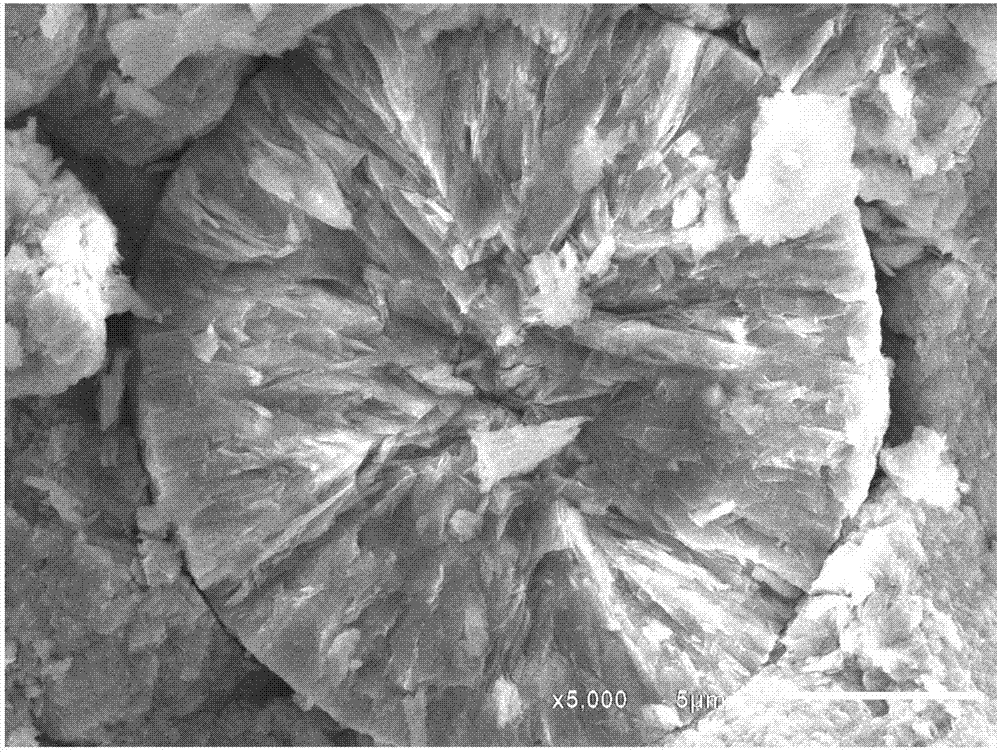

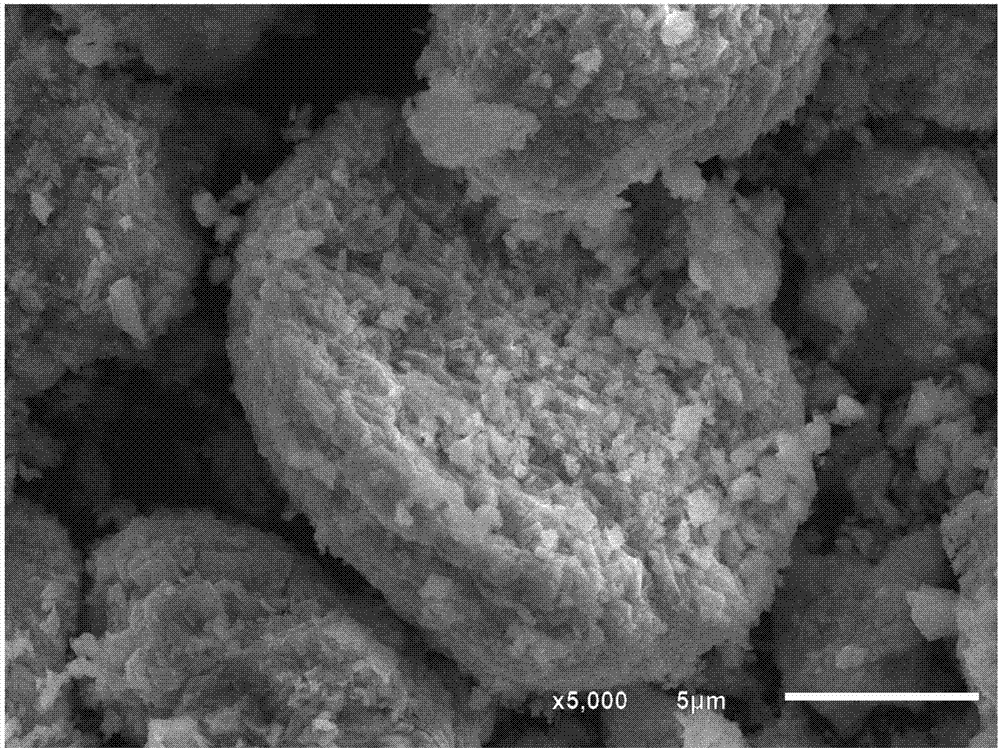

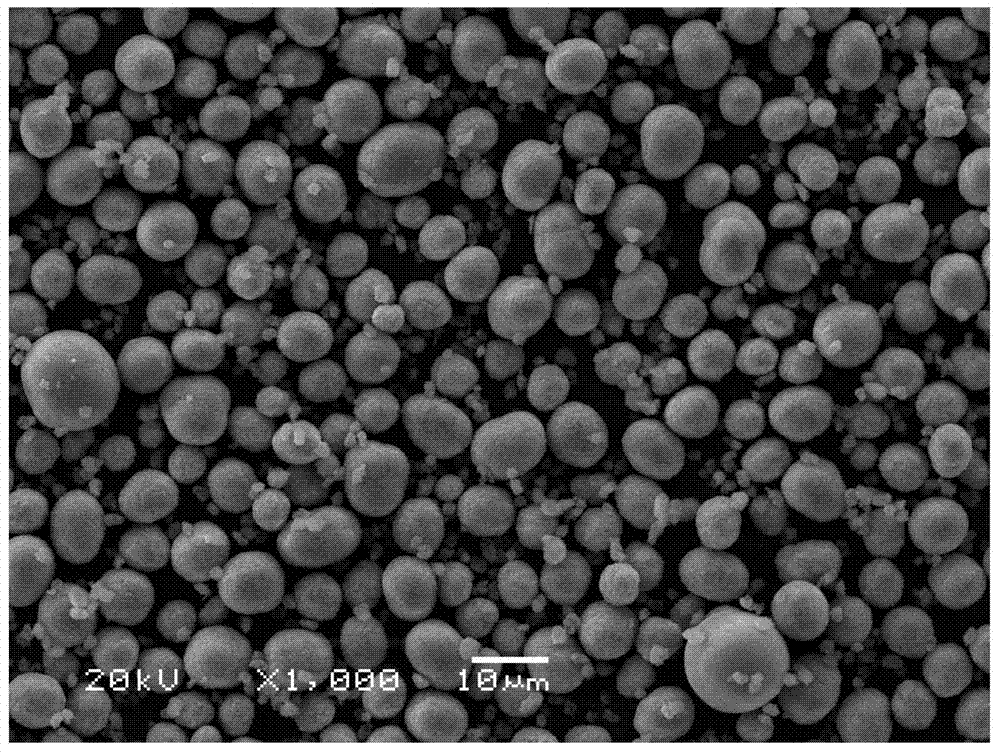

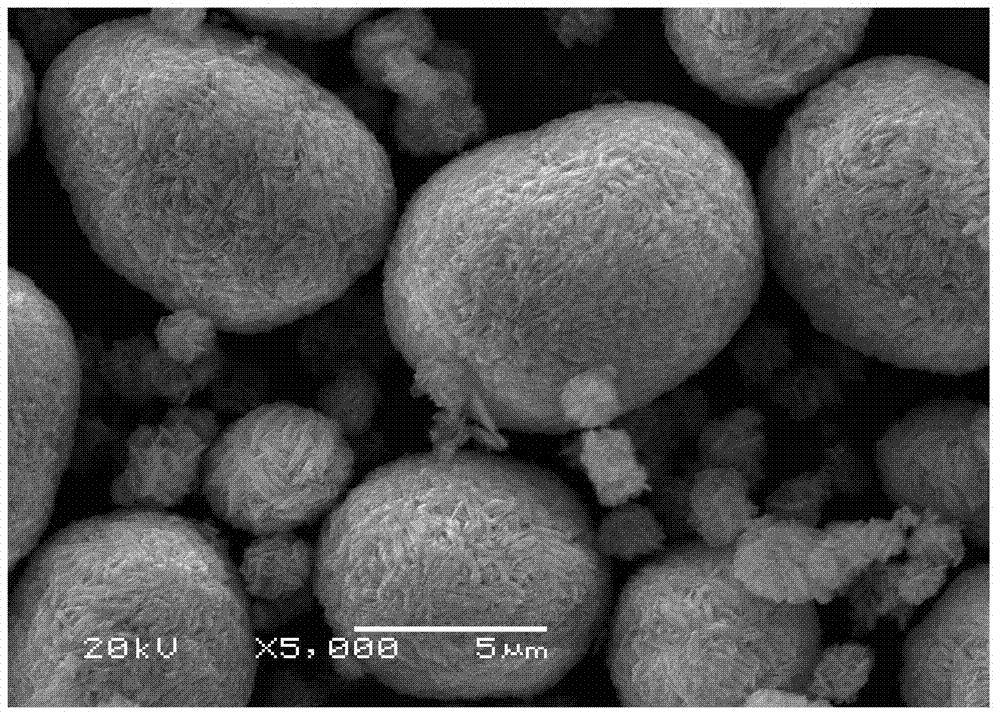

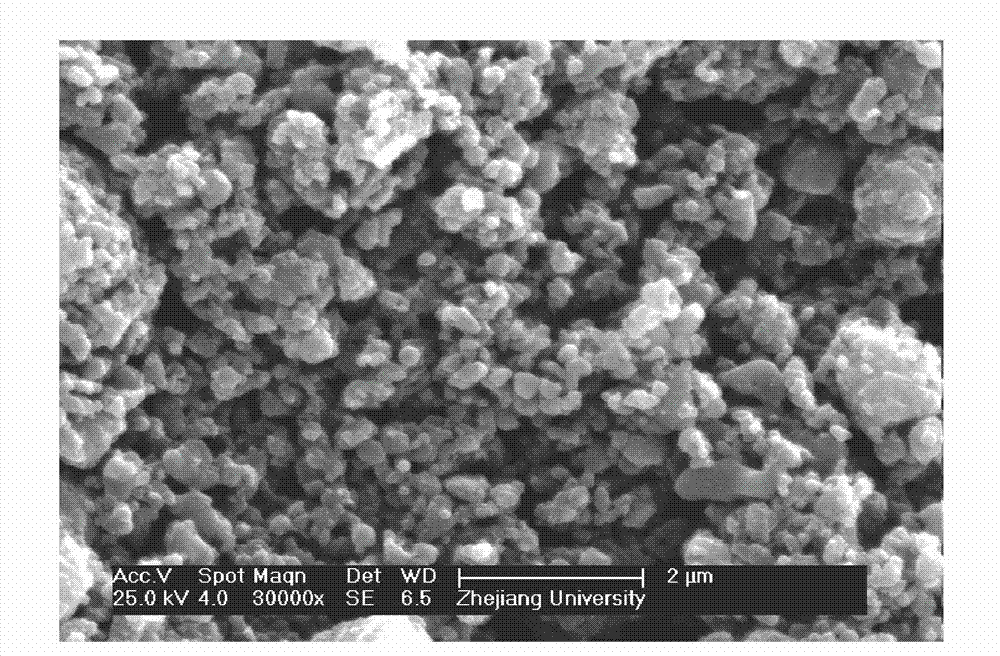

Lithium nickel cobalt manganese oxide material precursor and preparation method thereof and lithium-ion battery prepared from precursor

ActiveCN107324405AEvenly distributed sedimentHigh tap densityCell electrodesSecondary cellsHeat stabilityDischarge rate

The invention relates to a lithium nickel cobalt manganese oxide material precursor and a preparation method thereof and a lithium-ion battery prepared from the precursor. The lithium nickel cobalt manganese oxide material precursor is in a spherical form, primary particles are in the shape of emissive strips and the chemical formula is Ni(1-x-y)Co<x>Mn<y>(OH)<2>, wherein x is smaller than 0.2 and greater than 0 and y is smaller than 0.2 and greater than 0, the tap density is 1.6-1.9g / cm<3>, the median particle size D50 is 6-18 microns and the average pore size is 14-18nm. The preparation method of the lithium nickel cobalt manganese oxide material precursor is improved on the basis of a traditional one-step method, and the precursor prepared through the method has the characteristics of a precursor product under a single anti-oxidation condition and also has the characteristics of a precursor product under a single oxidation condition; and a ternary positive electrode material prepared from the precursor has the advantages of high capacity and high cycle performance, and also has the advantages of high compaction density, good heat stability and low self-discharge rate.

Owner:JINCHI ENERGY MATERIALS CO LTD

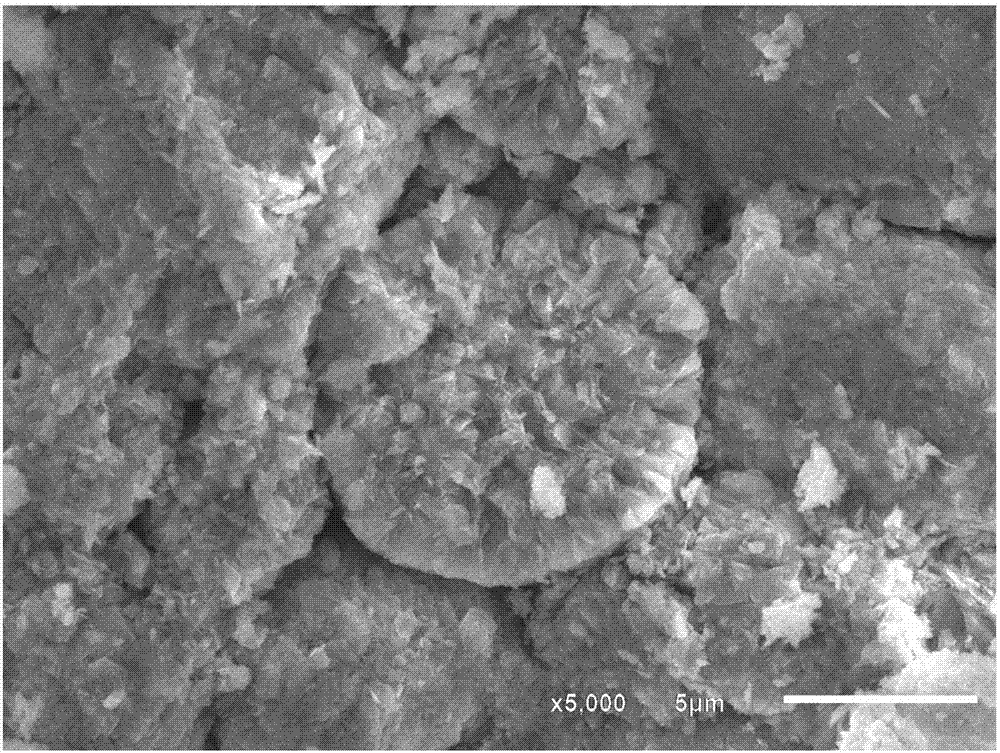

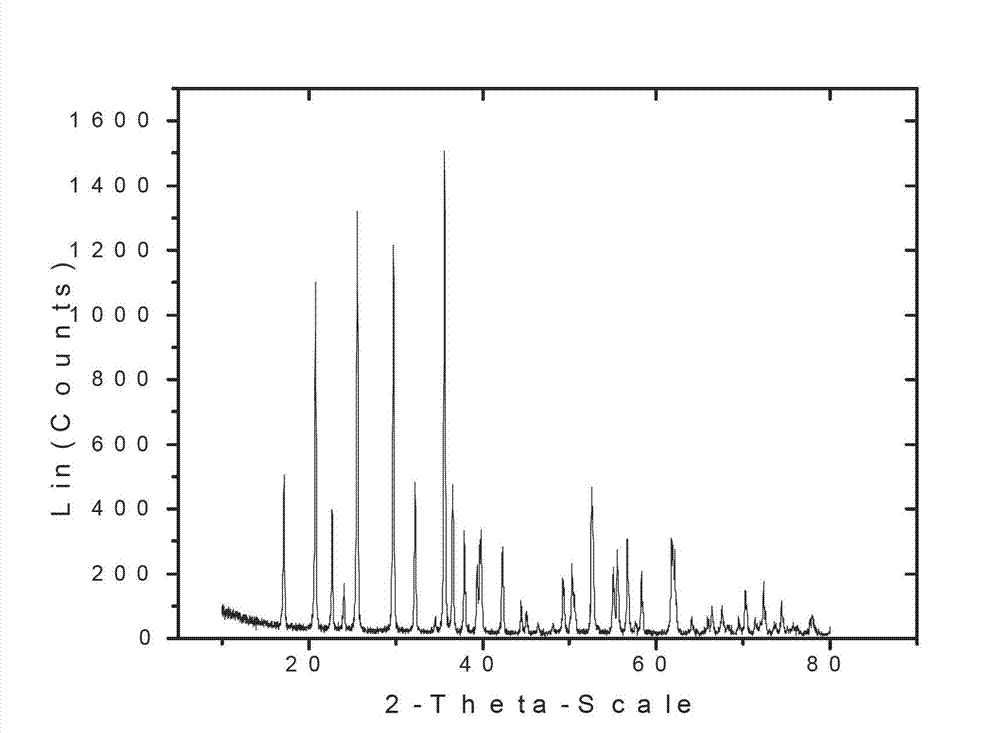

Precursor nickel-cobalt-manganese hydroxide of ternary material used for lithium batteries and preparing method thereof

ActiveCN104201368AIncrease compaction densityImprove thermal stabilityCell electrodesSecondary cellsManganeseDischarge rate

The invention relates to a precursor nickel-cobalt-manganese hydroxide of a ternary material used for lithium batteries and a preparing method thereof. The nickel-cobalt-manganese hydroxide is characterized in that: the general chemical formula of the nickel-cobalt-manganese hydroxide is NixCoyMnz(OH)2, wherein the sum of the x, the y and the z is 1, the x is less than 1 and more than 0, the y is less than 1 and more than 0 and the z is less than 1 and more than 0. The ternary material prepared from the nickel-cobalt-manganese hydroxide is high in compaction density, good in cyclic performance, high in thermal stability and low in self-discharge and has good comprehensive performance. The preparing method introduces a single-kettle batch production mode into a continuous production mode. A product with wide particle size distribution and more small particles is prepared by continuous production. Based on the product of the continuous production, batch production is utilized, the production process is free of generation of new small particles, only original small particles grow to be more compact, other larger particles grow at the same time, and the finished product is still wide in particle size distribution.

Owner:宁夏中色金辉新能源有限公司

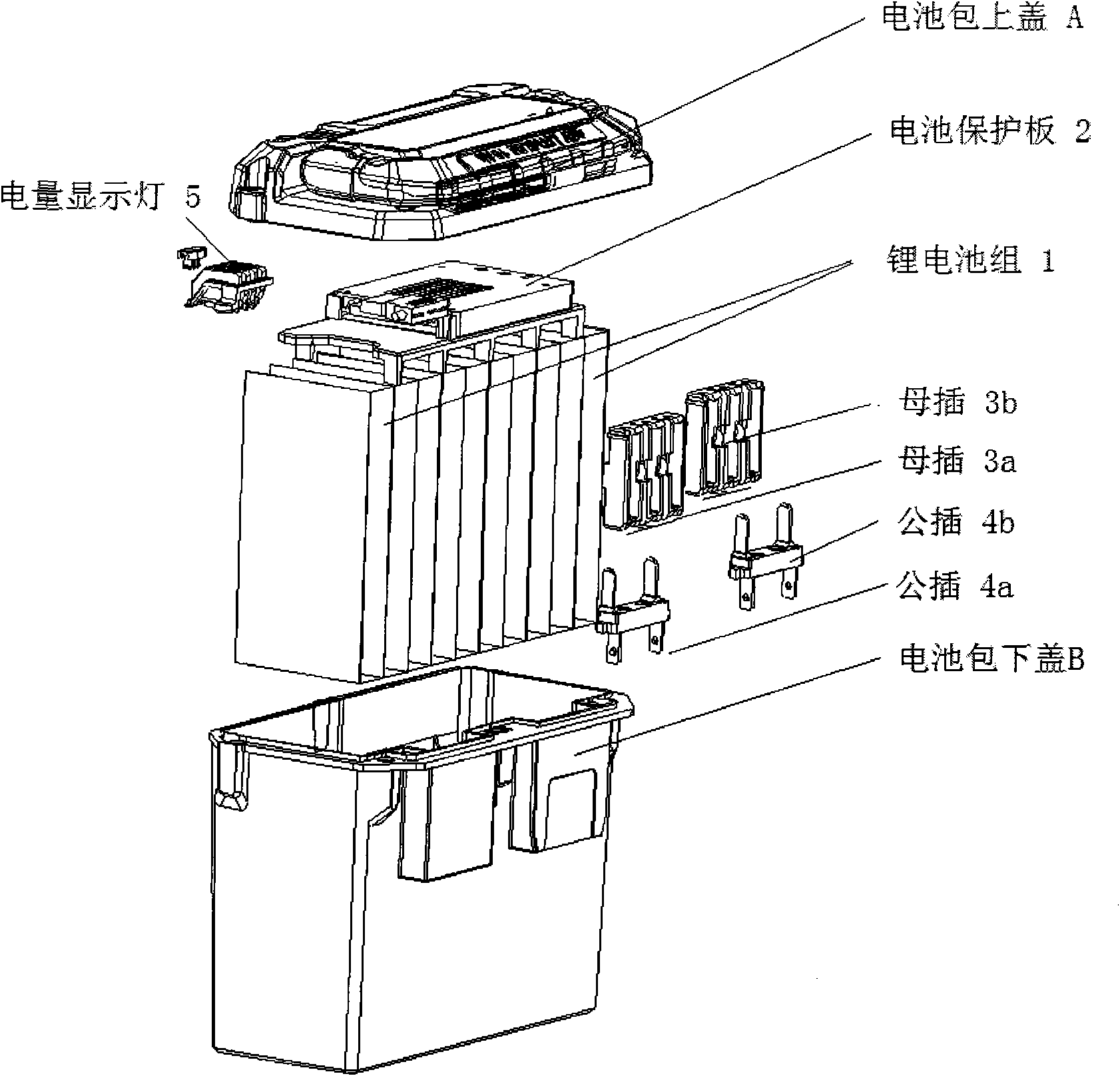

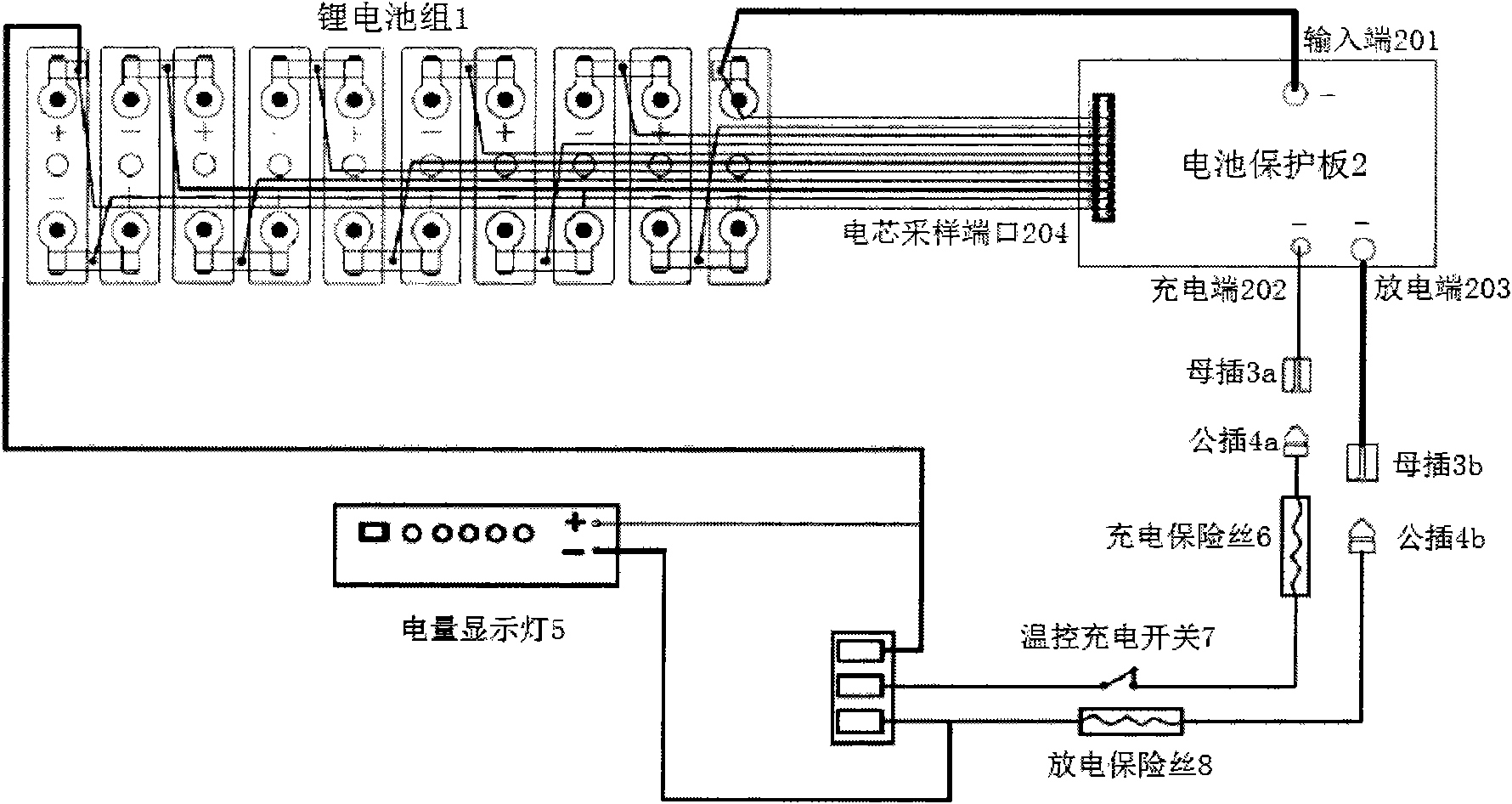

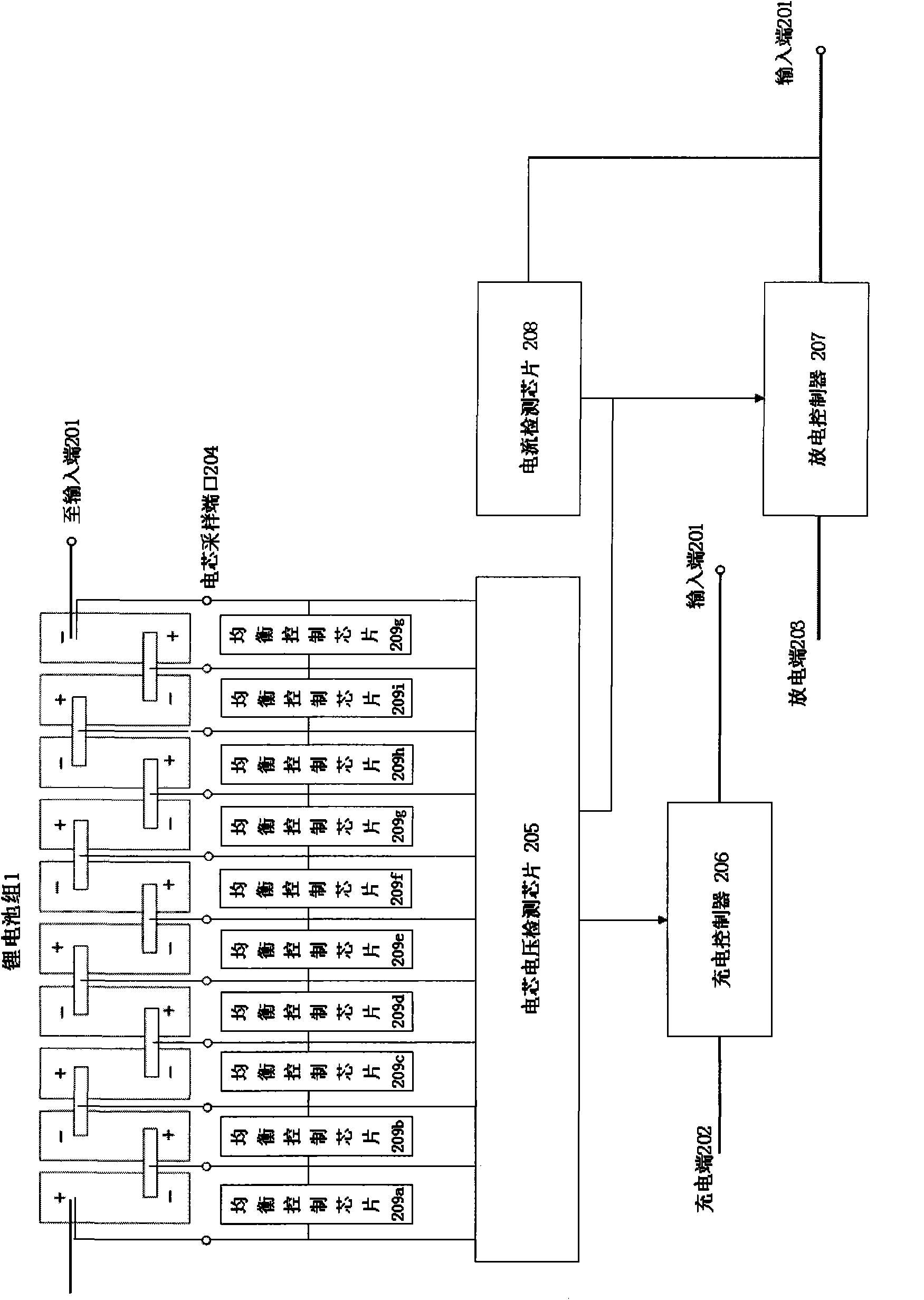

High-capacity lithium battery pack

InactiveCN102208696AReduce volumeImprove cycle lifeBatteries circuit arrangementsElectrical testingHigh energyElectrical battery

The invention relates to a high-capacity lithium battery pack, which is provided with a lithium battery pack (1), a charging interface, a discharging interface, a battery protection plate (2), an electric quantity indicating lamp (5), a charging fuse (6), a temperature control charging switch (7) and a discharging fuse (8), wherein the lithium battery pack (1) is formed by connecting a plurality of single battery cells in series; the charging interface and the discharging interface consist of female plugs (3a, 3b) and male plugs (4a, 4b); and the battery protection plate (2) is used for over charge, over discharge and over current protection and battery cell voltage balance of the lithium battery pack (1). Because the high-capacity lithium battery pack is adopted in the lithium battery pack, the lithium battery pack has the advantages of small volume, light weight, portability, easiness for carrying, high power capacity, high-energy density, high efficiency, high bearing capacity, long cycle life, low self-discharge rate, no memory effect, no pollution, excellent constant-voltage source performance and the like; and through the battery protection plate, adverse conditions of over charge, over discharge, over current, over high voltage of the single battery cells and the like are effectively prevented, the quality of the lithium battery pack is remarkably improved, and the lithium battery pack has the advantages of stable performance and long life.

Owner:CHANGZHOU GLOBE CO LTD

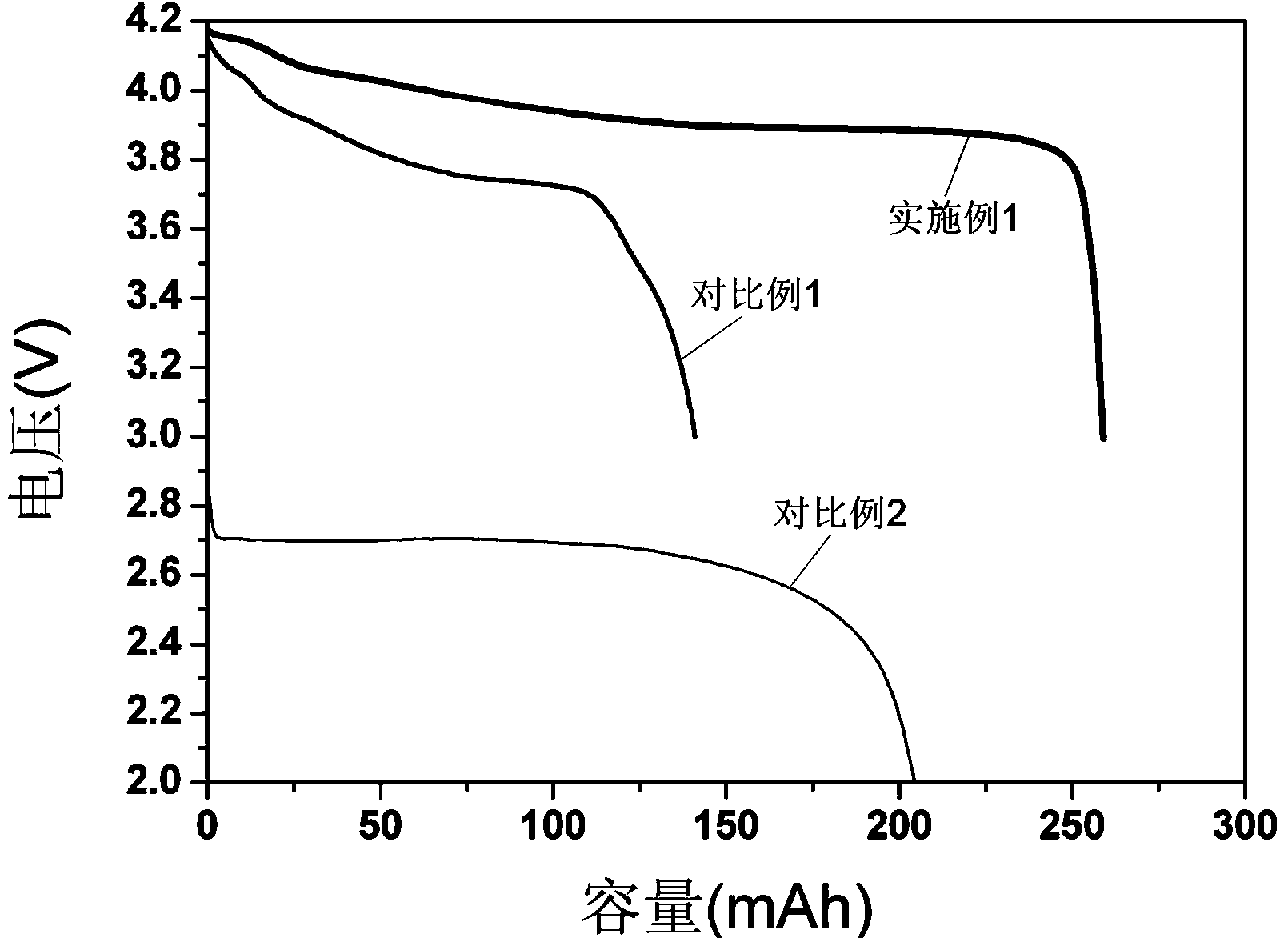

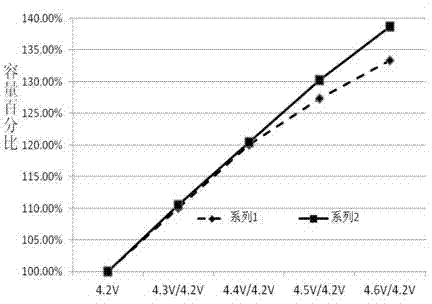

Lithium ion battery and preparation method thereof

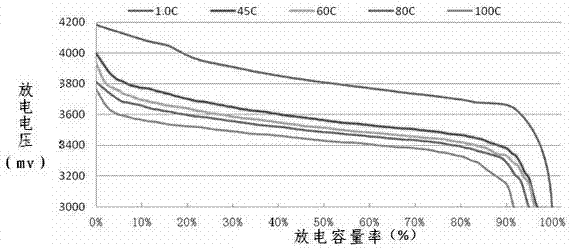

ActiveCN103094609AImprove securityIncrease specific energyFinal product manufactureNon-aqueous electrolyte accumulator electrodesHigh energyDischarge rate

The invention relates to a lithium ion battery comprising a shell, an electric core arranged inside the shell and electrolyte, wherein the electric core comprises a positive electrode, a negative electrode, and a membrane for separating the positive electrode from the positive electrode; the positive electrode comprises a positive electrode piece and a positive electrode material layer coated on the surface of the positive electrode piece; the negative electrode comprises a negative electrode piece and a negative electrode material layer coated on the surface of the negative electrode piece; the density of the coating face of the positive electrode material layer is 25-36mg / cm<2>; the density of the coating face of the negative electrode material layer is less than or equal to 36mg / cm<2>; and a ratio of the reversible capacity of the positive electrode to the reversible capacity of the negative electrode is (1.2:1)-(1.5:1). The negative electrode comprises the negative electrode piece, a negative electrode inner coating coated on the surface of the negative electrode piece, and a negative electrode outer coating coated on the surface of the negative electrode inner coating. The lithium ion battery has high multiplying power, high working voltage, high energy density, and low self discharge rate. The invention simultaneously provides a preparation method of the lithium ion battery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

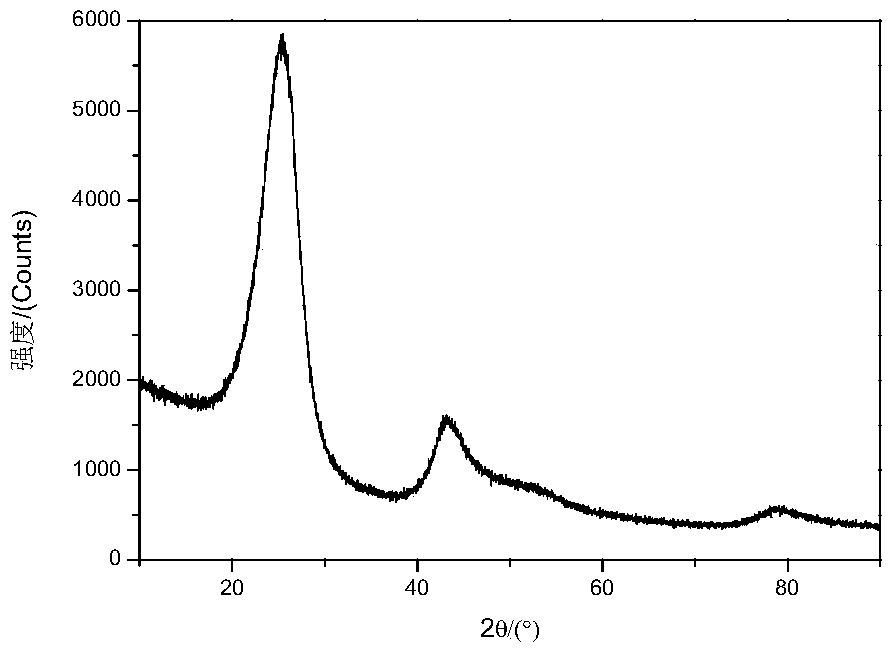

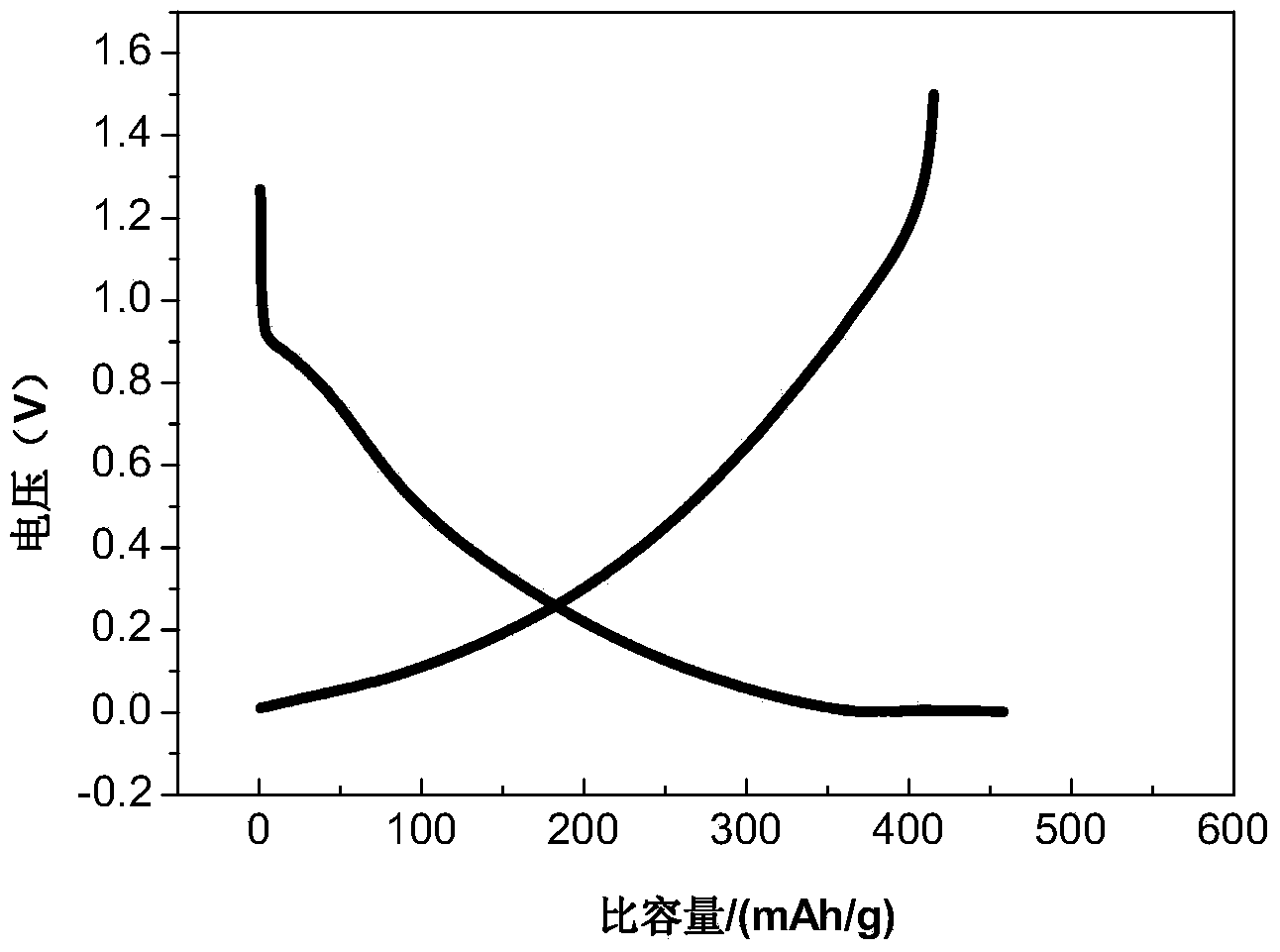

Soft carbon anode material for lithium-ion power and energy storage battery as well as preparation method and application of soft carbon anode material

ActiveCN104269555AIncrease energy densityLarge capacityCell electrodesSecondary cellsPorosityMicrosphere

The invention provides a soft carbon anode material for a lithium-ion power and energy storage battery as well as a preparation method and application of the soft carbon anode material. According to the preparation method, a low-concentration purifying reagent and a mesophase carbon microsphere precursor are stirred and mixed, so as to enable the low-concentration purifying reagent to react with impurities to generate water-soluble substances, and the water-soluble substances are washed by purified water, so that the impurity content is reduced, the product purity is improved, the carbon content is greater than 99.3%, and the self-discharge rate is obviously reduced; through low-temperature carbonization, and through surface activation modification of a material by a lithium-containing compound and / or an activating reagent, a dense film similar to an SEI (solid electrolyte interface) component is formed on the surface of the material, which facilitates the reduction of L<i+> consumed in the SEI film forming process during the charging and discharging process of the battery, thereby improving the initial coulombic efficiency and improving the cycle performance; the porosity is increased, lithium intercalating and de-intercalating active sites are increased, the capacity of the material is increased, and thus the energy density of the whole battery is increased.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Preparation method of high-rate lithium ion battery

InactiveCN107086287AImprove conductivityImproved magnification performanceCell seperators/membranes/diaphragms/spacersFinal product manufactureCarbon layerPorosity

A preparation method of a high-rate lithium ion battery is used for manufacturing of lithium ion batteries and comprises the following steps: reeling prepared positive plate, negative plate and polyolefin diaphragm to form a battery cell, pre-packaging the battery cell with a shell, vacuum-drying, injecting an electrolyte, standing, forming, packaging and capacity-grading so as to obtain a lithium ion battery. By coating single and double surfaces of the positive plate with a conductive carbon layer, electronic conductivity and ion pass rate are enhanced, battery interlayer polarity is reduced, and then internal resistance of battery is reduced and high rate performance of batter are raised. By coating the edge cutting end of the plate with an anti-burr layer, short circuit or micro short circuit which might be caused by burr on the edge of the plate is prevented, self discharge rate is reduced, and safety performance of the battery is enhanced. By the use of the diaphragm with low porosity and under the precondition of guaranteeing high rate performance, self discharge rate and cost of the battery are reduced.

Owner:湖北猛狮新能源科技有限公司

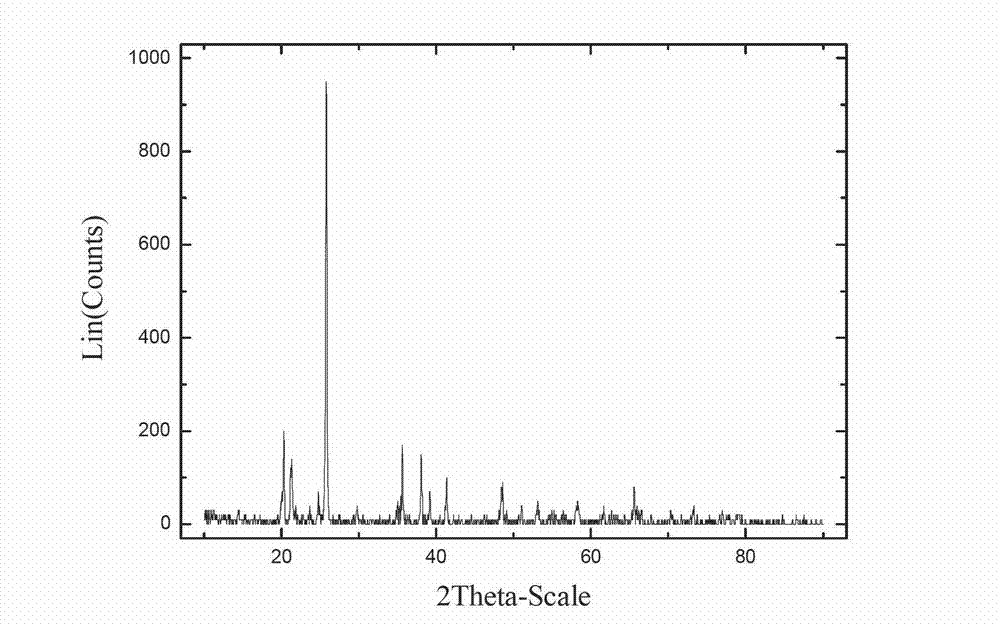

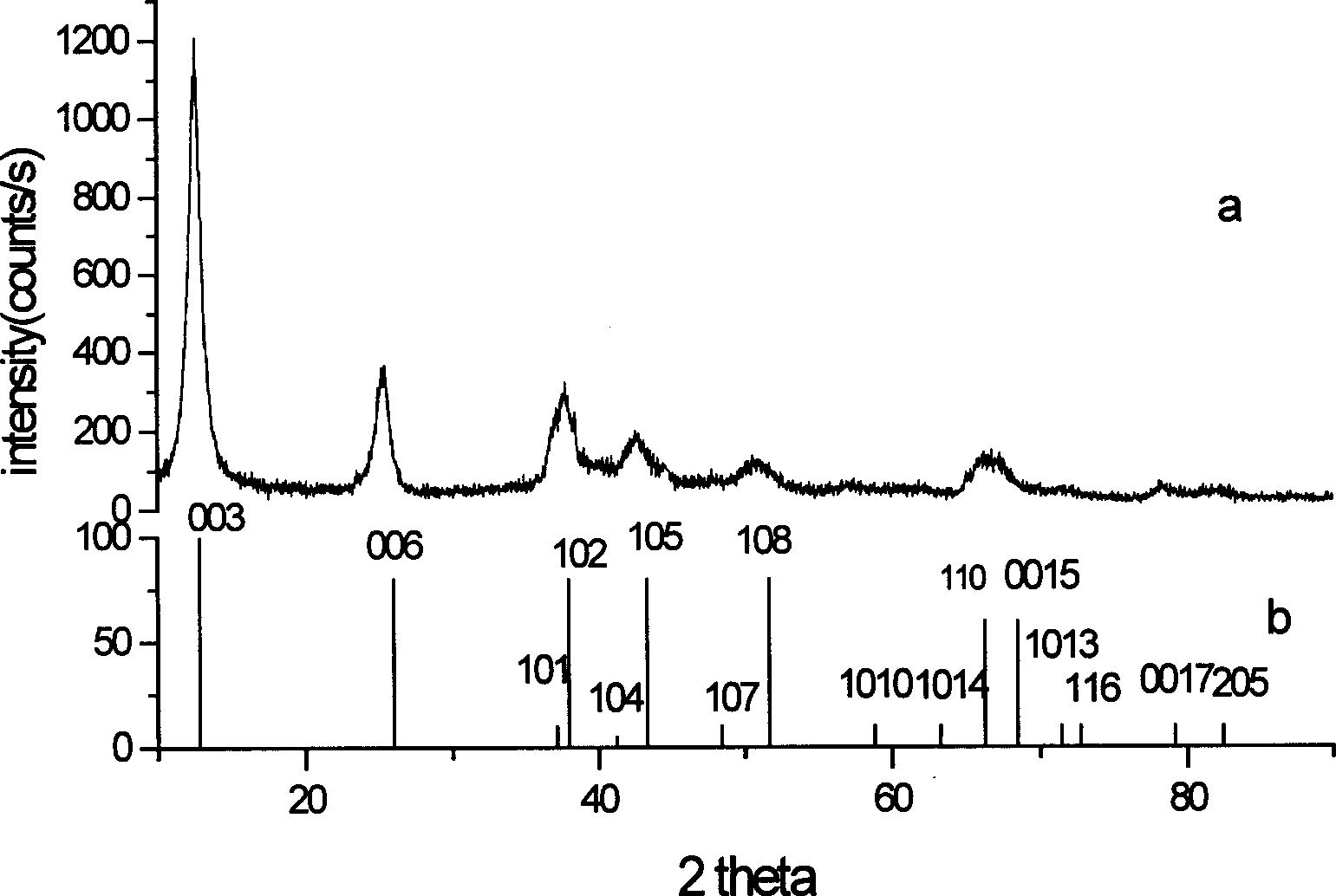

Novel process for preparing battery-grade iron phosphate material by using iron hydroxide

InactiveCN102897739ALow self-discharge rateReduced processing performancePhosphorus compoundsPhosphoric acidIndustrial scale

The invention discloses a novel process for preparing a low-cost battery-grade iron phosphate material by using iron hydroxide. The process comprises the following steps: mixing a zero-valent iron source and corrosive acid in a molar ratio, and adding a certain amount of primary water and ammonia water; stirring to react for 0 to 24 hours, and slowly adding hydrogen peroxide until the iron source disappears and the solution turns to orange; adding surfactant which is 1 to 5 percent that of the mass of the iron source into the solution; adding a reagent containing phosphate radicals into the solution according to a certain molar ratio of iron element to phosphor element under a stirring condition to obtain iron phosphate precipitate; filtering and washing the product 3 to 5 times with the primary water which is 3 to 7 times the weight of the iron phosphate; drying in vacuum for 4 to 12 hours at 50 and 80 DEG C to obtain FePO4.2H2O. The process for preparing battery grade iron phosphate is simple and easy to carry out and low in cost; and the prepared product has good product crystal structure, few impurities and uniform granularity and is suitable for industrial scale production; moreover, the lithium iron phosphate prepared by the process has high specific capacity, low self-discharge, high tap density, stable product performance and good processing performance.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

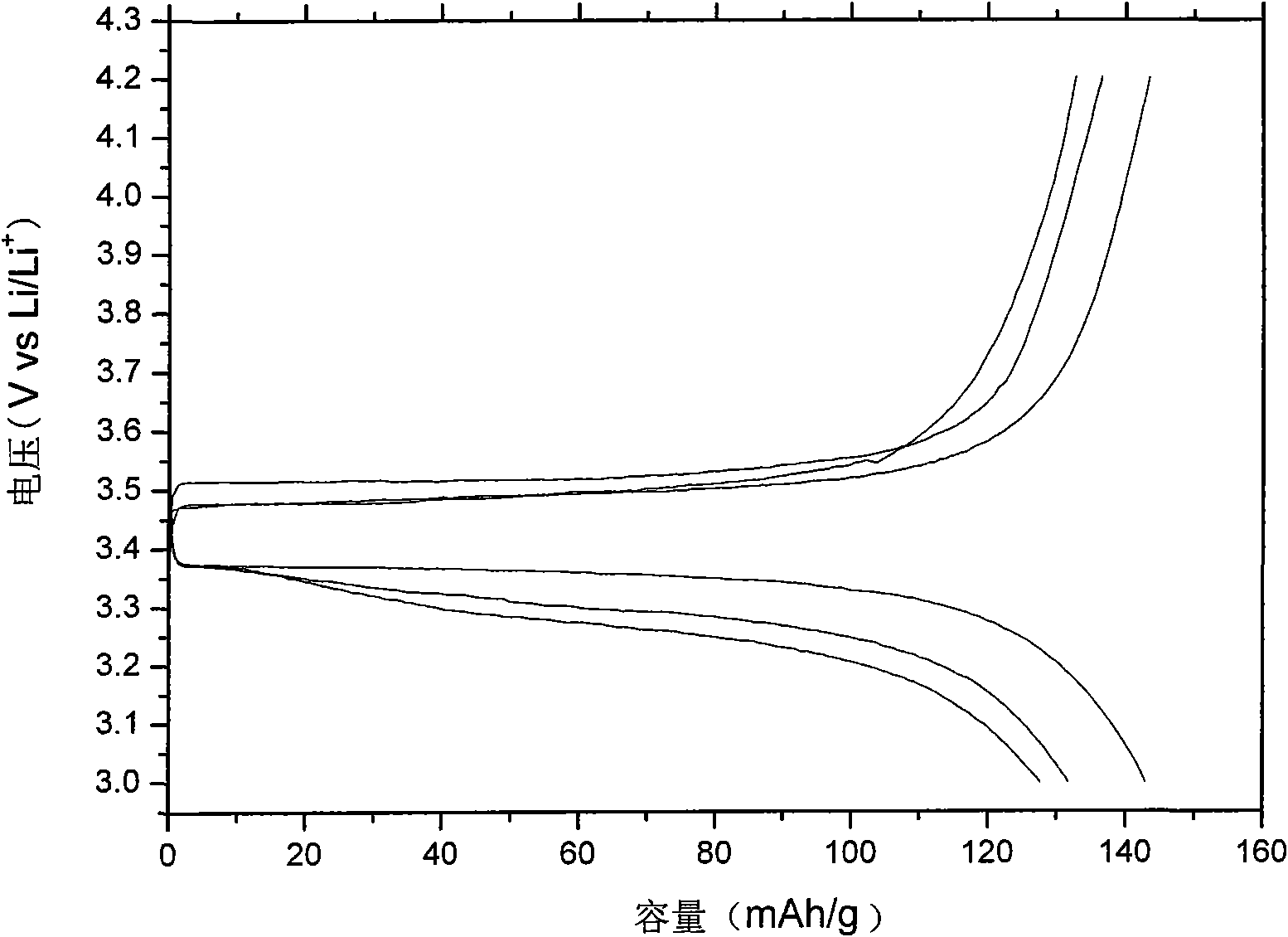

High performance lithium ion secondary battery and manufacture method

InactiveCN101145610ALong cycle lifeLow self-discharge rateElectrode manufacturing processesSecondary cellsWater soluble polymersSolvent

The invention discloses a high-performance lithium ion secondary battery. The active substance of the anode of the battery is lithium-containing compound oxide of the chemical formula: LiFe(1-y)MyPO4, wherein M is one element selected from Co, Ni, Mn, Al, S, Ca, K, Na, Mo and Cr, y is more than 0 but less than or equal to 0.75. A water-soluble polymer is used as an adhesive. The anode of the inventive lithium ion secondary battery is prepared by mixing LiFe(1-y)MyPO4 compound with the water-soluble polymer at a given weight ratio, adding a conductive substrate and water as an solvent, mixing, stirring and filtering to obtain a homogenous slurry, coating the flurry on the surface of an aluminum foil, drying at 55-150 DEG C to obtain an anode piece, winding together with a cathode piece, assembling, infusing, standing, pre-charging with a 0.01C-0.65C current, standing again, and fractioning volumes. The inventive high-performance lithium ion secondary battery has the advantages of good property of high-current charge and discharge, long cycle life, high safety, environmental friendliness, and low cost.

Owner:SHENZHEN YILI ENERGY

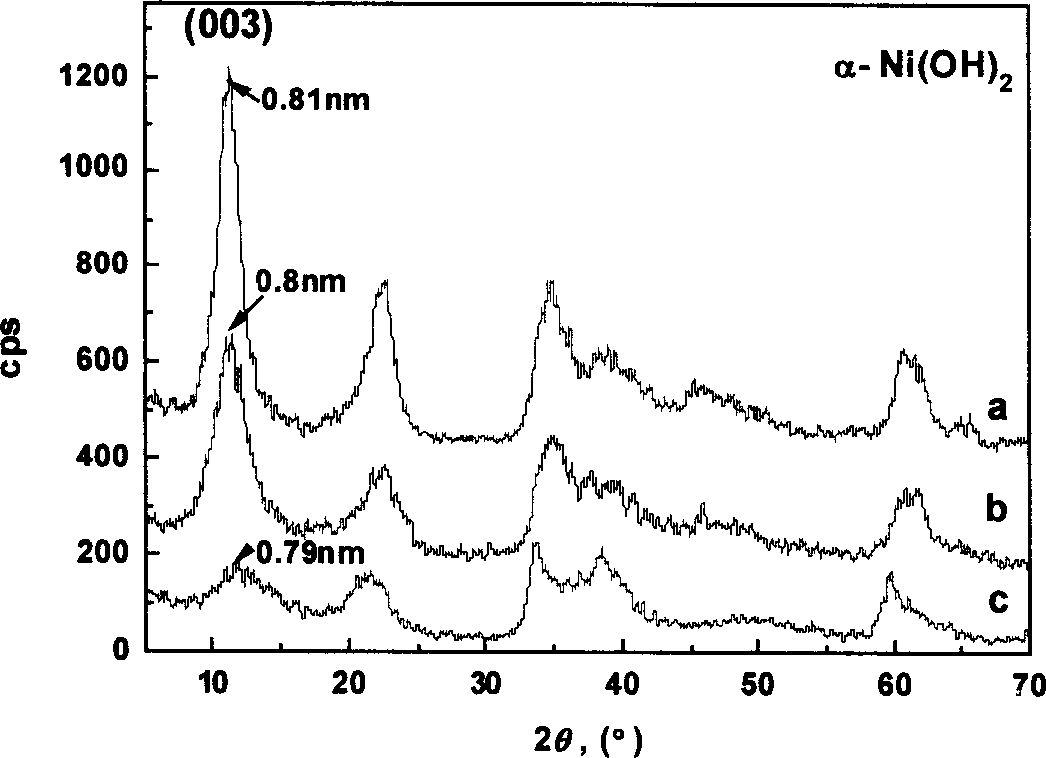

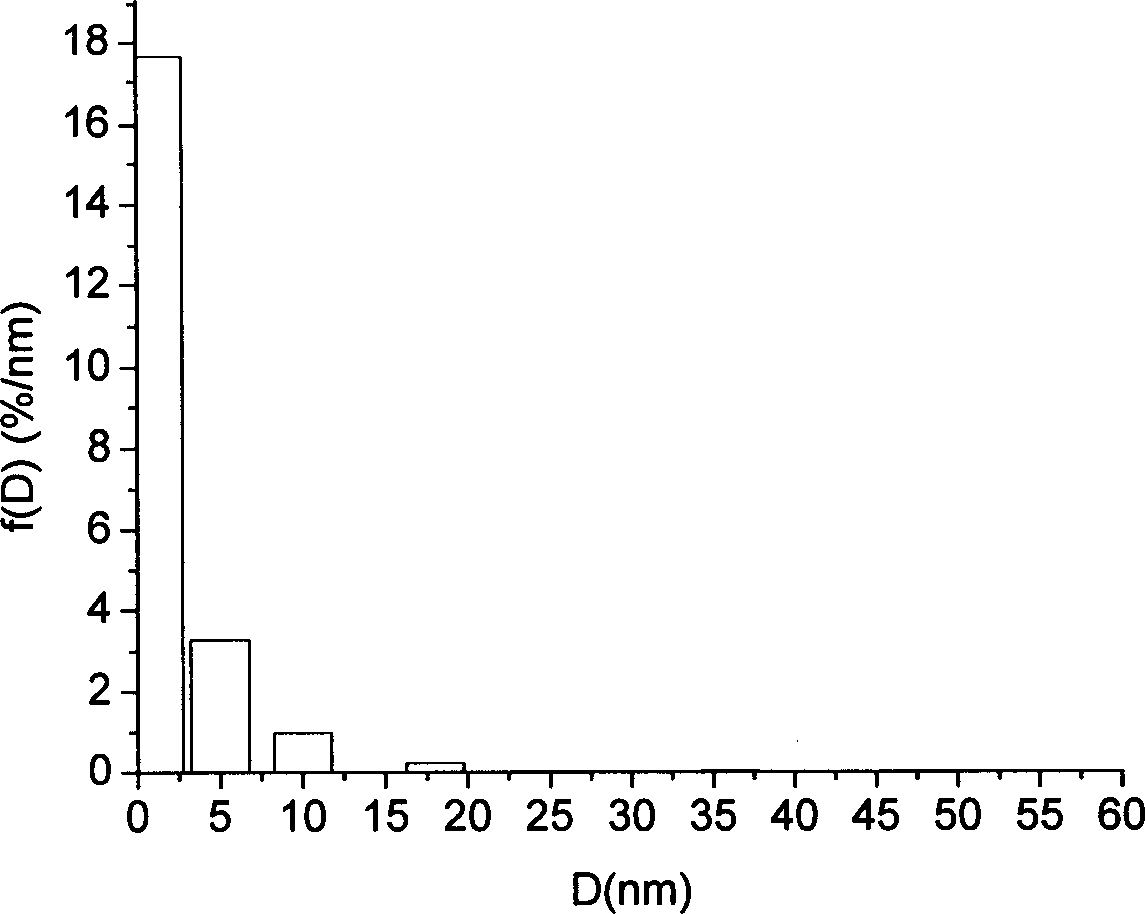

Nanometer alpha-nickel hydroxide and its prepn

InactiveCN1772629AImprove conductivityImprove proton conductivityNickel oxides/hydroxidesPotassium hydroxideUltrasonic dispersion

The present invention provides one kind of nanometer alpha-nickel hydroxide and its preparation process. The preparation process adopts bivalent nickel slat as main material, and includes the steps of: adding doping metal salt to compound reaction solution, compounding precipitant solution with potassium hydroxide or sodium hydroxide, adding the precipitant solution to the reaction solution under stirring and ultrasonic dispersing to obtain nickel hydroxide, washing and drying to constant weight. Thus prepared nanometer alpha-nickel hydroxide has small and homogeneous particle size, great specific surface area, high heat stability, stability in alkali medium, high specific discharge capacity, and other features, and may be used as the positive pole material in secondary alkali ZnNi cell, H-Ni cell and FeNi cell.

Owner:SOUTH CHINA UNIV OF TECH

Electrolyte used for ion state mixed crystal salt storage battery

ActiveCN102881949AAvoid pollutionAvoid polluting emissionsLead-acid accumulatorsStrong acidsDistilled water

The invention discloses an electrolyte used for an ion state mixed crystal salt storage battery. The electrolyte comprises the following components in percentage by weight: 52-80% of hydrosulphate, 0.1-8% of corrosion inhibitor, 0.4-3% of antiager, 3-12% of strong acid salt agent, 0.1-10% of ester ion concentration control agent, 1-13% of lead-acid storage battery activating agent, 1-10% of chemically pure sulfuric acid of which the concentration is larger than or equal to 98%, and the balance of distilled water. The electrolyte disclosed by the invention has the advantages that the environment pollution caused by sulfuric acid in the electrolyte of the existing lead-acid storage battery is effectively avoided, a system is enabled to have stable and mild reactivity, the stable electrochemical performance of the storage battery is improved, the high and low ambient temperature adaptability is strong, the effective discharge capacity and the self discharge rate are small, and the service life of the battery can be effectively prolonged.

Owner:北京艾塔文商贸有限责任公司

Compound nylon diaphragm, and manufacturing method

InactiveCN1917255AHigh moisture absorptionStrong hydrophilic liquid retention performanceCell component detailsNon-woven fabricsNickel cadmiumHot melt

The diaphragm is a hot melted and rolled product from non-woven fabrics of nylon backing material in one, two or three layers. In total weight of raw fiber, nylon fiber is in 40-60 wt%, and hot melted composite fiber with dual constituents in low melting point is in 40-60 wt%; or, nylon fiber is in 40-60 wt%, hot melted composite fiber with dual constituents in low melting point is in 30-45 wt%, superfine vinylon fiber is in 10-15 wt%. The method includes steps: using different techniques prepares non-woven fabrics of nylon backing material in different structures; using hot rolling machine with three rollers rolls non-woven fabrics of nylon backing material in one, two or three layers. Features are: simple method, small investment easy of obtaining materials and low cost. The diaphragm is accorded with requirements of nickel cadmium SC cell: high capacitance 1500man-2000man, and discharging in 10C-15C high multiplying factors.

Owner:CHANGZHOU KANGJIE SPECIAL NON WOVEN FABRICS CO LTD

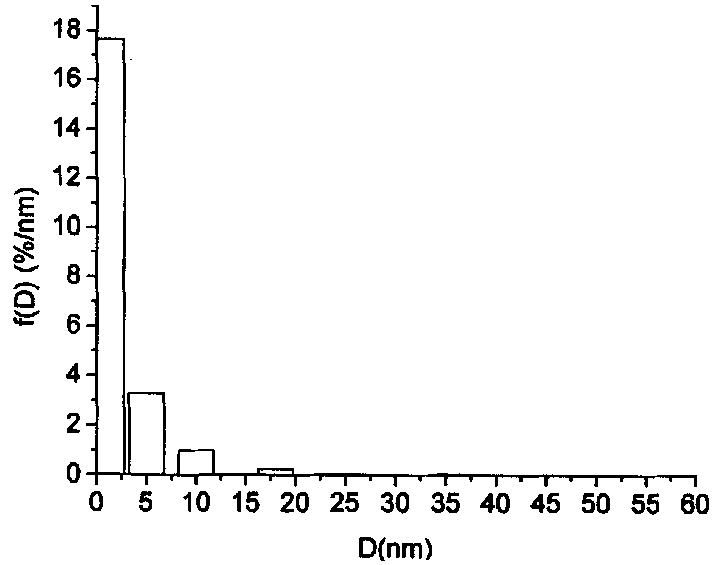

Nano grade nickel oxyhydroxide and process for preparing same

InactiveCN1433970ASmall and uniform particle sizeFully dispersed evenly dispersedCell electrodesNickel carbonylsPrimary cellPrimary battery

The present invention relates to the field of cell material, in particular, it relates to a method for preparing positive material nickel oxyhydroxide for zinc-nickel primary cell, zinc-nickel secondary cell and other cells using compound of nickel as active matter, such as cadmium-nickel cell, metal hydride nickel cell and Hawkins cell and nano grade nickel oxyhydroxide prepared by said method. The nano nickel oxyhydroxide is prepared by using nickeous salt as raw material, using sodium hypochlorite as oxidant; adopting precipitation reaction and oxidation reaction simultaneously in alkalineaqueous solution and adopting ultrasonic wave to make oscillation dispersion in the course of reaction. Said invented product is fine and uniform in grain size, large in specific surface area, high in initial discharge specific value, low in self-discharge rate and stable in electric performance.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for lithium ion battery negative pole slurry

The invention discloses a preparation method for a lithium ion battery negative pole slurry. The preparation method comprises the following steps: adding solid raw materials comprising, by mass, 90 to 95% of powdered carbon, 1 to 3% of a conductive agent, 1 to 4% of a binder LA133 and 1 to 3% of SBR into deionized water in an environment with a temperature of 15 to 35 DEG C, wherein a mass ratio of the solid raw materials to the deionized water is 1:1; carrying out vacuum-pumping and then stirring in a stirrer for 5.1 to 9.4 h so as to obtain a mixture A; and adding NMP accounting for 0.5 to 1% of the mass of the mixture A 1 to 2 h before discharging of the mixture A and carrying out filtration so as to obtain the negative pole slurry. According to the invention, since a CMC glue solution does not need to be prepared in advance, preparation time for the slurry is shortened, the problem of dusting of a negative pole piece is overcome, and thus, self-discharge of a battery is mitigated, and influence on the service life of the battery resulting from introduction of sodions by CMC is avoided.

Owner:JIANGSU LITIAN NEW ENERGY TECH

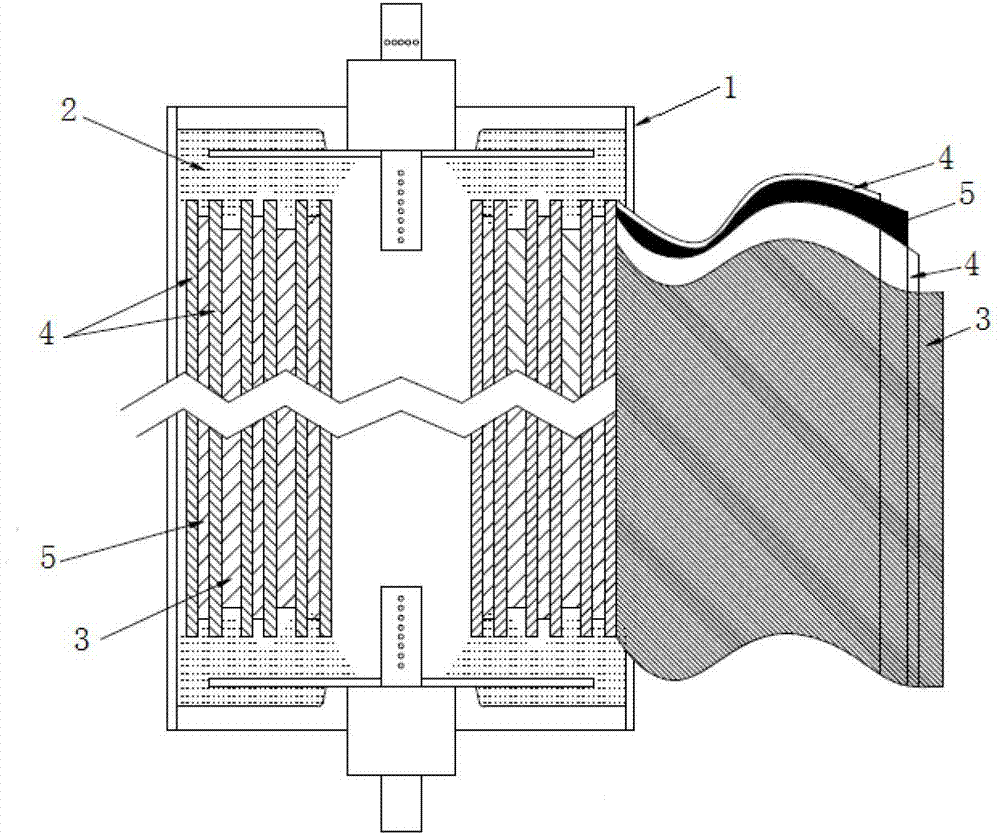

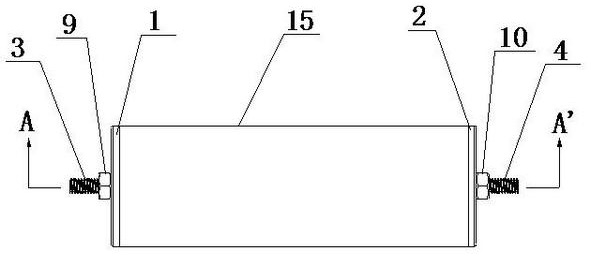

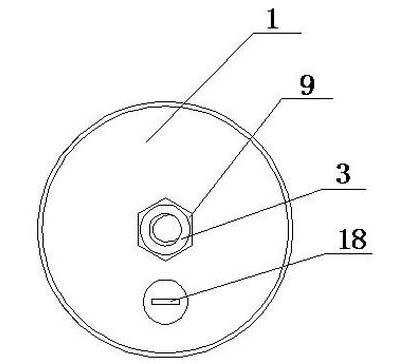

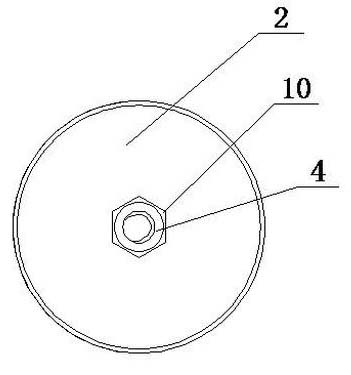

Lithium battery and assembling method thereof

InactiveCN102064339AEasy to useImprove practicalityFinal product manufactureCell component detailsPower flowElectrical battery

The embodiment of the invention discloses a lithium battery which comprises a shell, wherein both ends of the shell are open to form two opening ends; one opening end is connected and matched with an anode cover board; the other opening end is connected and matched with a cathode cover board; a battery pole rod body is coated in the shell; the winding initial position of the battery pole rod body is connected with a middle bracket tube; the middle bracket tube runs through the battery pole rod body; the anode of the battery pole rod body is connected with the anode cover board through one end of the middle bracket tube to form an anode end of the lithium battery; and the cathode of the battery pole rod body is connected with the cathode cover board through the other end of the middle bracket tube to form a cathode end of the lithium battery. The embodiment of the invention also discloses an assembling method of the lithium battery. The lithium battery is in a stud structure and has a low self-discharge rate, strong current conveyance capacity and high battery comprehensive performance. Moreover, the lithium battery has a simple assembling process, a simple manufacturing process and a low cost.

Owner:王正伟

Electrolytes for lithium sulfur cells

ActiveUS8828610B2Reduce the probability of reactionLow self-discharge ratePrimary cell to battery groupingOrganic electrolyte cellsLithium–sulfur batteryLithium sulfur

Disclosed is an additive for an electrochemical cell wherein the additive includes an N—O bond. The additive is most preferably included in a nonaqueous electrolyte of the cell. Also disclosed are cells and batteries including the additive, and methods of charging the batteries and cells. An electrochemical cell including the additive preferably has an anode that includes lithium and a cathode including an electroactive sulfur-containing material.

Owner:SION POWER CORP

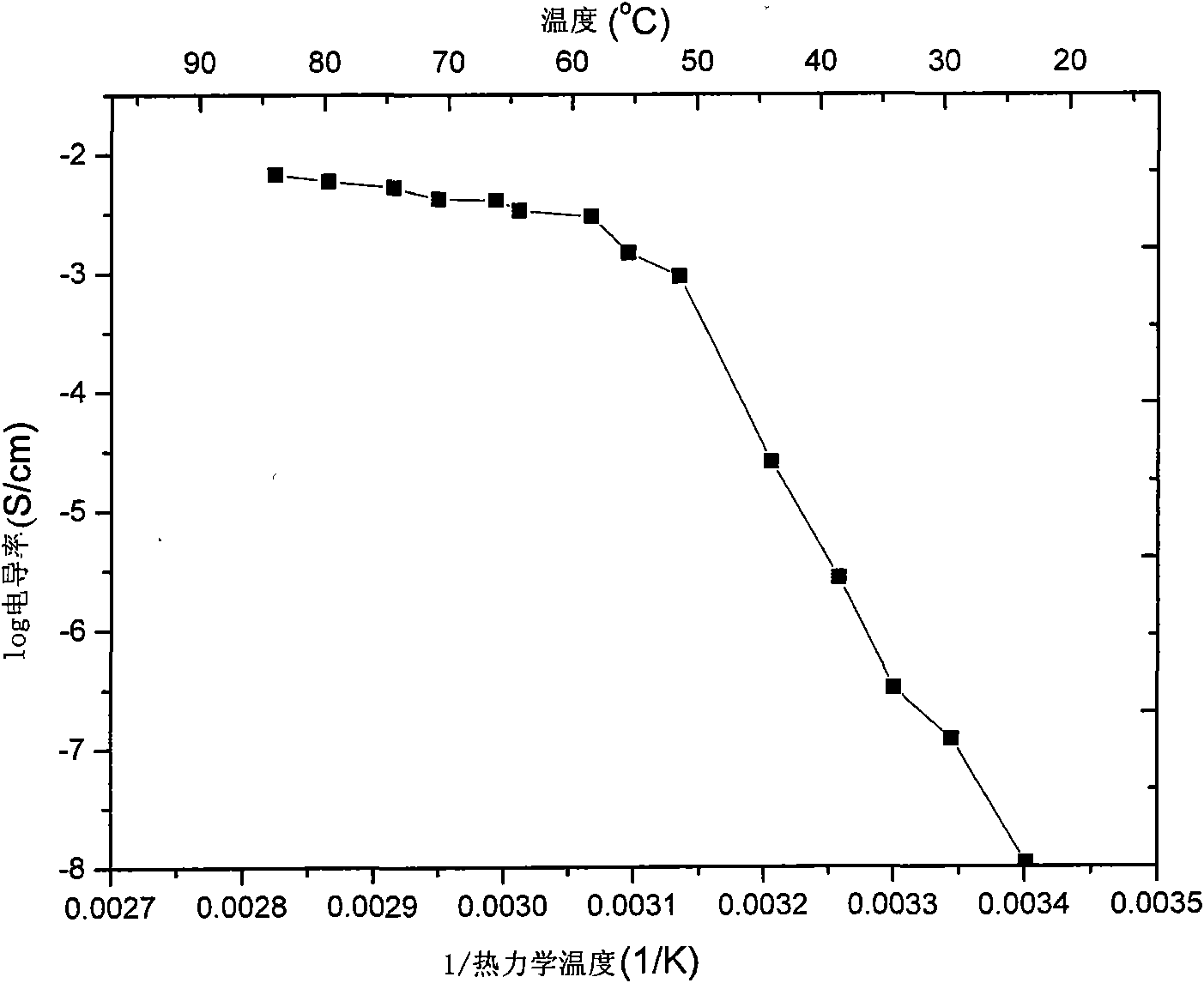

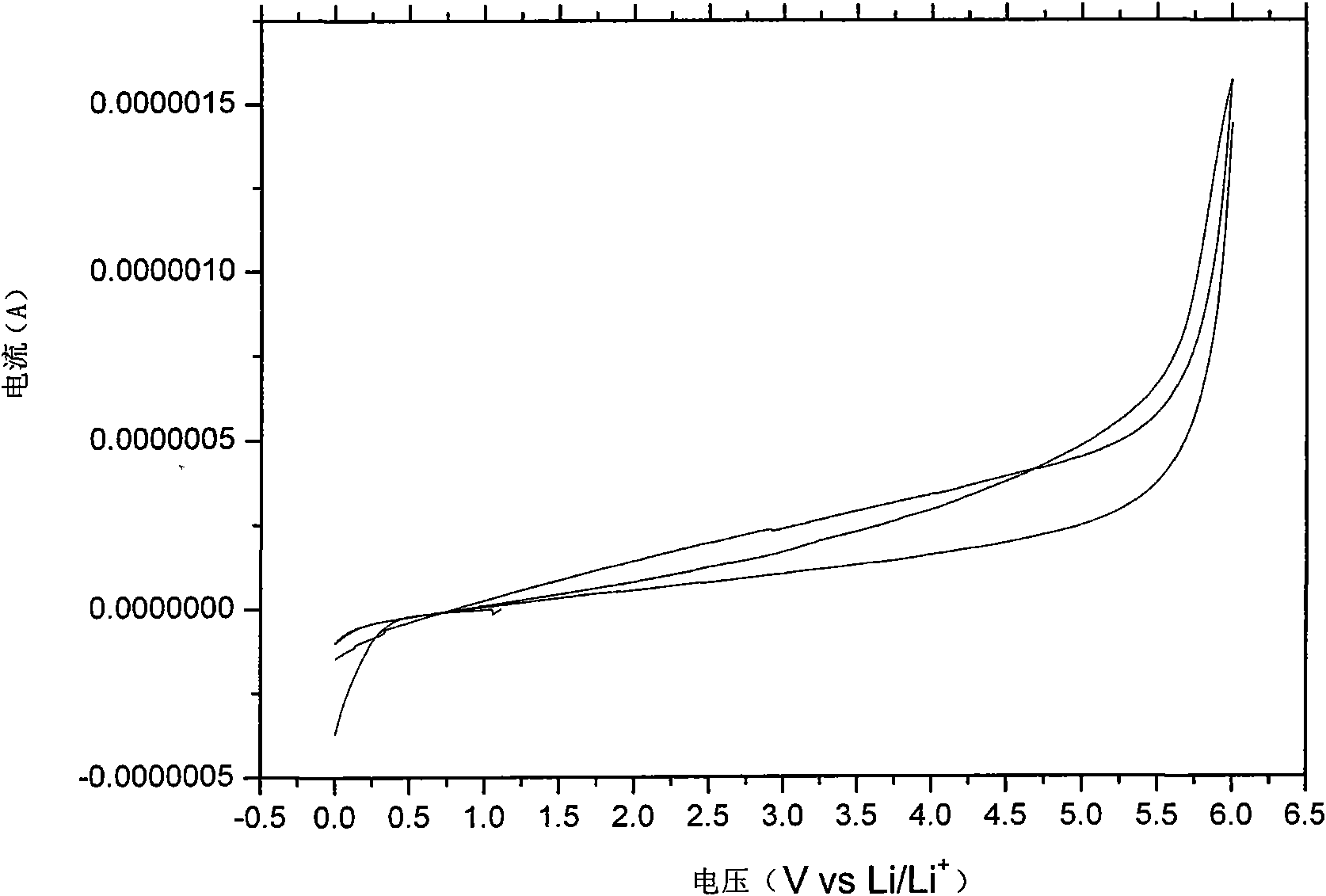

Phase variation electrolyte as well as preparation method and application thereof

The invention provides a phase variation lithium ion electrolyte comprising the following components of lithium salts and organic compounds containing acid amide functional groups. The invention also provides a preparation method of the electrolyte, comprising the following steps: a. mixing the lithium salts and the organic compounds containing acid amide functional groups; b. heating the mixture and melting the mixture to obtain transparency liquid; and c. cooling the transparency liquid to obtain the electrolyte, wherein the steps a, b and c are operated in dry environments. The phase variation lithium ion electrolyte is applied to chargeable and dischargeable lithium batteries. In addition, the invention also provides a chargeable and dischargeable lithium battery comprising the electrolyte. The electrolyte has lower electrical conductivity and higher thermal and chemical stability when being a solid under the condition that the temperature is lower than a phase variation temperature and has higher electrical conductivity when being liquid under the condition that the temperature is higher than the phase variation temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Nano-range nickel gamma-hydroxy oxide and preparing process thereof

A nano-class gamma-nickel hydroxyoxide is prepared through dissolving Ni salt in water, mixing with surfactant and Co (or Zn or Cd) salt, adding dropwise to the alkaline aqueous solution of oxidant, and oxidizing reaction while strong ultrasonic dispersing. Its advantages are low granularity, high specific surface area, high discharge cavacity, low self-discharge rate, high bulk density and high electric stability. It can be used as positive electrode of Zn-Ni battery.

Owner:SOUTH CHINA UNIV OF TECH

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com