Lithium nickel cobalt manganese oxide material precursor and preparation method thereof and lithium-ion battery prepared from precursor

A technology of nickel cobalt lithium manganate and precursor, which is applied in the field of nickel cobalt lithium manganate material precursor and its preparation, and the field of lithium ion battery materials, can solve the problem that the diffusion path of lithium ions is too long, hinder the diffusion of lithium ions, and the energy density of materials Low problems, to achieve the effect of improving capacity and cycle performance, increasing convenience, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

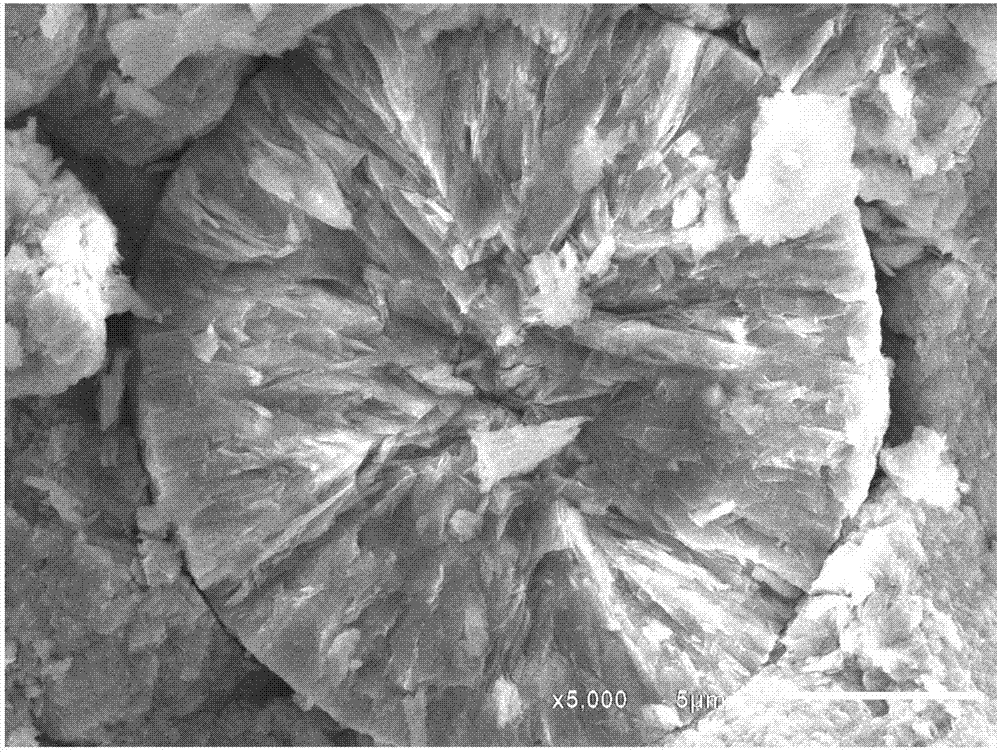

[0036] A kind of nickel cobalt manganate lithium material precursor of the present invention, its scanning electron microscope figure (SEM) such as figure 1 As shown, the porosity data as Figure 4 , as can be seen from the figure, the internal primary particles are emissive strips, the particle growth mode is emissive form, and the degree of bonding is neither dense nor loose; the precursor of the nickel cobalt lithium manganese oxide material is spherical, and the chemical molecular formula is Ni 0.8 co 0.1 mn 0.1 (OH) 2 , the tap density is 1.83g / cm 3 , granularity D 50 It is 9.5μm, and the average pore diameter is 16.5345nm.

[0037] The preparation method of the nickel cobalt lithium manganese oxide material precursor of the present embodiment comprises the following steps:

[0038] (1) Nickel sulfate, cobalt sulfate and manganese sulfate are respectively dissolved in deionized water to be mixed with mixed salt solution A; The molar ratio of the elements is 8:1:1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com