Baking device for curing SMD LED glue and method thereof

A baking device and glue curing technology, applied in the field of LED baking, can solve the problems of fluorescent powder precipitation and inconsistent distribution, high labor intensity of technicians, inflexible and inconvenient use, etc., to improve energy utilization and luminous flux , Good effect of color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

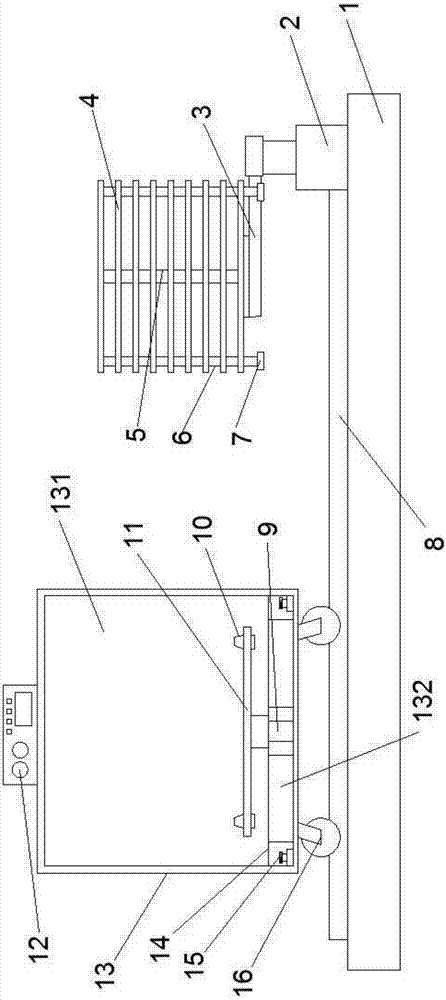

[0024] refer to figure 1 , an LED baking device, including a workbench 1, an oven body 13 and a feeding assembly, the workbench 1 is provided with a guide rail 8 and a feeding assembly, the four corners below the oven body 13 are provided with pulleys 16, the The pulley 16 cooperates with the guide rail 8, and the inside of the oven is provided with a motor 9, the output shaft of the motor 9 is fixedly connected with the center hole of the bottom 11 of the square fixed plate, and four corners of the square fixed plate 11 are symmetrically arranged with four A claw 10, a baking frame is provided on the feeding assembly, and a block 7 is provided at the bottom of the baking frame, and the block 7 is used in conjunction with the claw 10.

[0025] The baking frame includes a central column 5, at least two layers of baking trays 4 and pillars 6, the baking tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com