A cut rolled stem processing procedure

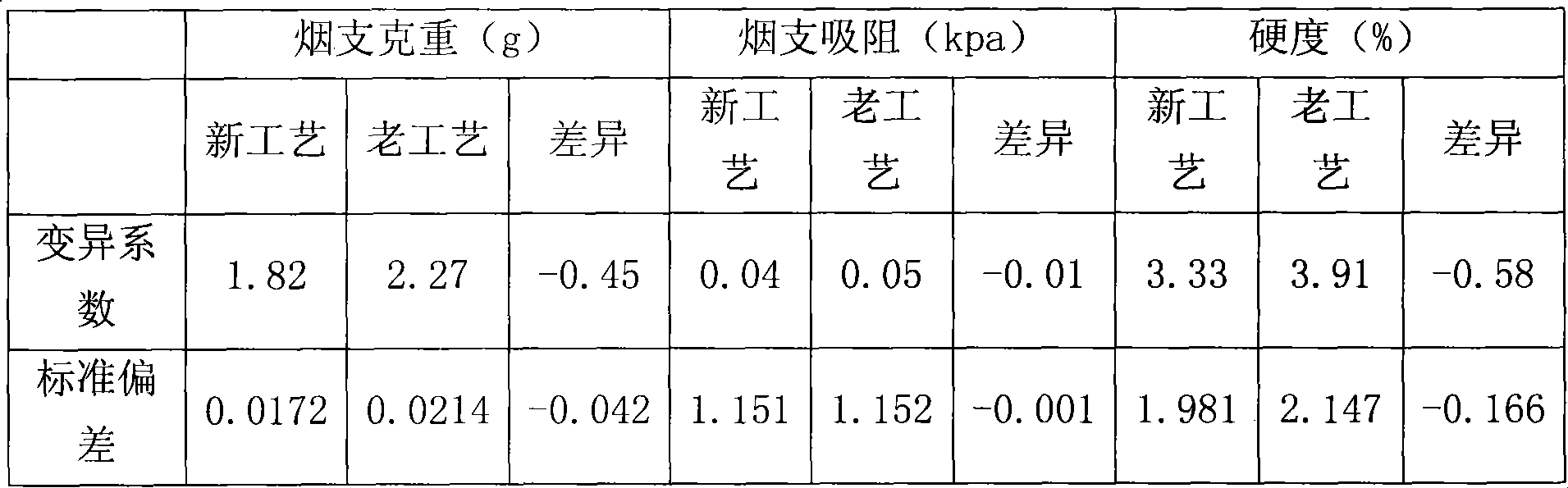

A processing technology and cut stem technology, which is applied in the field of cut stem processing technology, can solve the problems affecting the quality of cigarettes, use restrictions, and the impact is particularly obvious, and achieve the effects of small quality fluctuations, improved quality stability, and increased use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The cut stem processing technology of the present invention will be described in detail below in conjunction with the embodiments.

[0014] A cut stem processing technology of the present invention includes the following process: increasing temperature and humidifying tobacco stems: cutting stems; increasing temperature of cut stems; expanding cut stems; cutting cut stems; and storing cabinets. The specific method is as follows:

[0015] (1) Using tobacco stem warming and humidifying equipment to increase the temperature of the tobacco stem from normal temperature to 60°C, and increase the moisture content of the tobacco stem from 33% to 34-40%;

[0016] (2) using a stem cutter to cut the heated and humidified tobacco stems into stalks with a thickness of 0.12 to 0.3 mm;

[0017] (3) Using cut stem warming equipment to heat the cut stem slices to 70-90°C;

[0018] (4) At a high temperature of 150°C-170°C, the stem slices are dehydrated quickly and the volume is increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com