Bamboo material grading method and system

A grading method and bamboo technology, applied in the field of bamboo grading methods and systems, can solve the problems of unreachable engineering composite materials, variability, performance fluctuations, etc., reduce cracking and warping deformation, high precision and accuracy, reduce The effect of volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The mechanical properties mentioned below may refer to elastic modulus, compressive strength, tensile strength and the like.

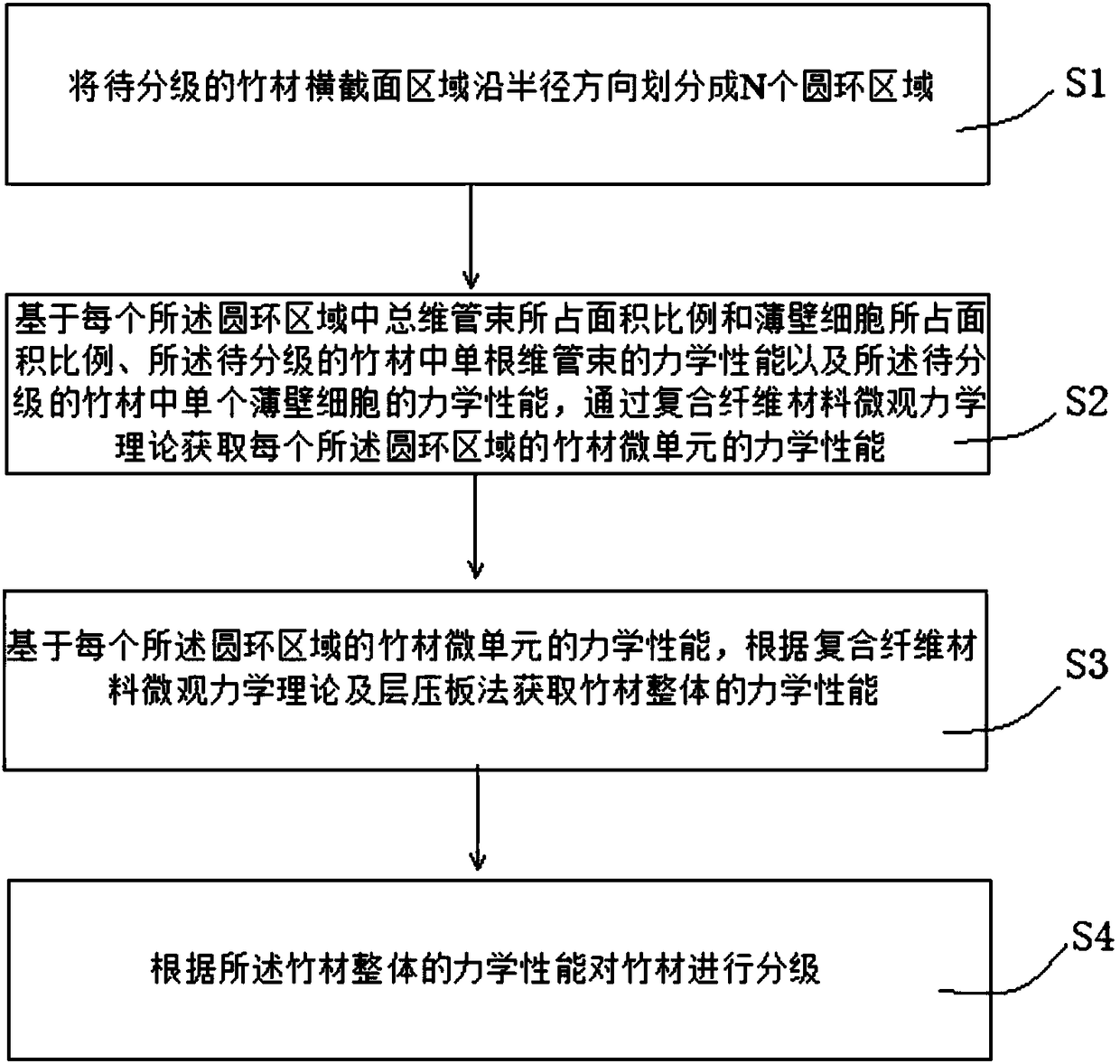

[0060] A kind of bamboo classification method that the embodiment of the present invention provides, refer to figure 1 , including the following steps:

[0061] (1) Taking four-year-old round bamboo as an example, the cross-section of moso bamboo is generally circular or oval. Record the collection location, collection time, collection quantity, collection person, bamboo age, diameter at breast height, length, diameter, etc. of the bamboo.

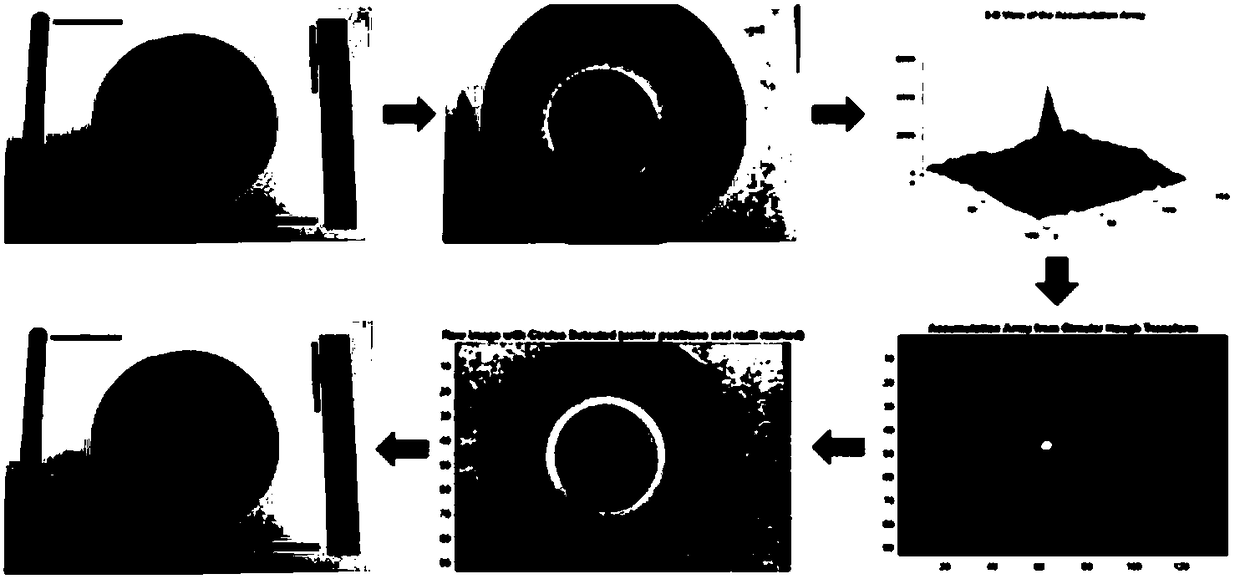

[0062] (2) Place a standard scale 7 around the end cross-section of the bamboo for calibration, use a high-definition camera to collect the images of the end cross-section of the scale 7 and the bamboo, and collect the overall feature image in the length direction at the same time. Input it to the image processing device for image processing, process all the collected images in grayscale, and adjust the co...

Embodiment 2

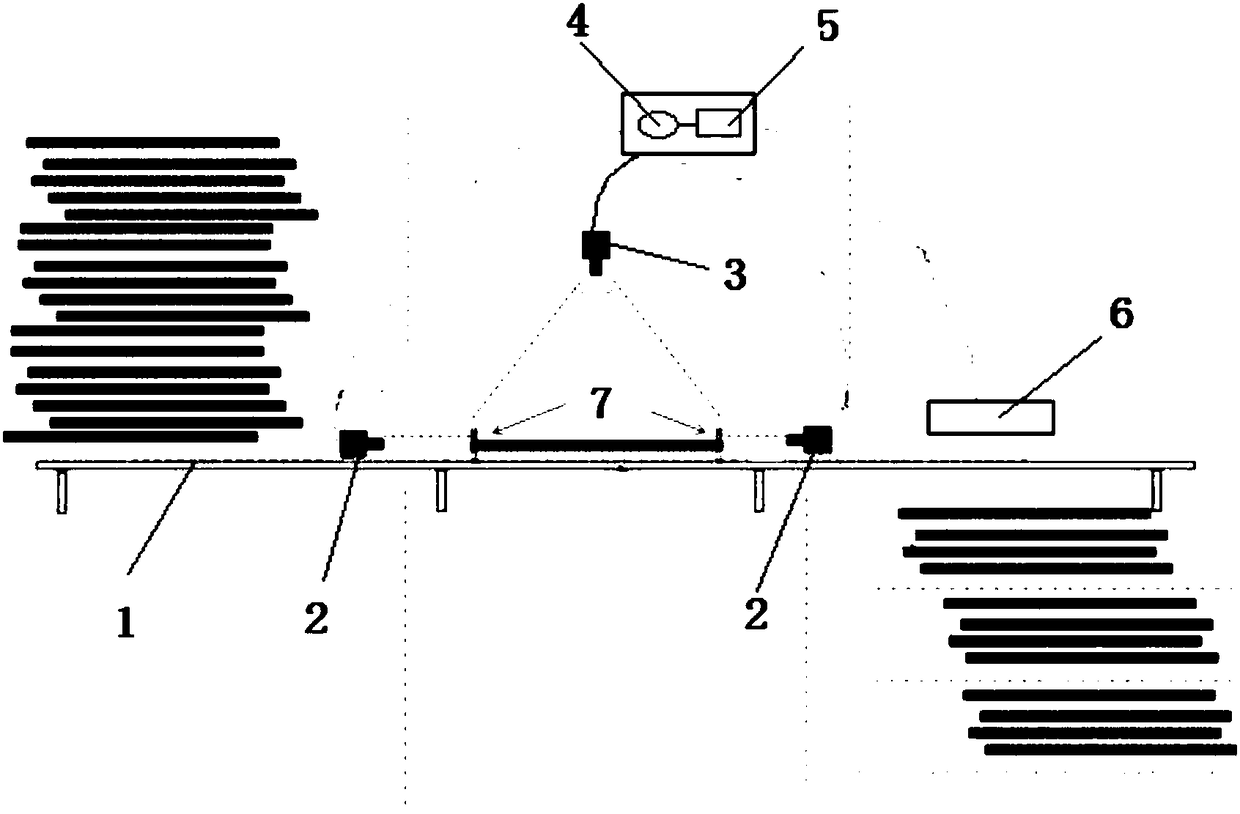

[0091] What the embodiment of the present invention provides is a kind of bamboo classification system, refer to figure 2 ,include:

[0092] Feeding unit 1, conveying bamboo to the image acquisition area through a conveyor belt;

[0093]The first image acquisition unit 2 is used to collect the cross-sectional area image of the bamboo and set the standard scale image around the cross-sectional area of the bamboo;

[0094] The second image acquisition unit 3 is used to collect the overall image of the bamboo to be graded in the length direction, and identify the length of the bamboo section and the number of bamboo nodes of the bamboo;

[0095] The image processing unit 4 divides the bamboo cross-sectional area to be classified into N ring areas along the radial direction, obtains the diameter of each ring area according to the standard scale calibration method, and according to each ring area diameter, obtain the outer diameter of the bamboo cross-sectional area, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com