Method for evaluating effectiveness of glass fiber coating and application thereof

An effective and coating technology, applied in the field of testing, can solve the problems of lack of glass fiber yarn and the effectiveness of sizing agents, and achieve the effects of stable testing results, enhanced monitoring, and rapid identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

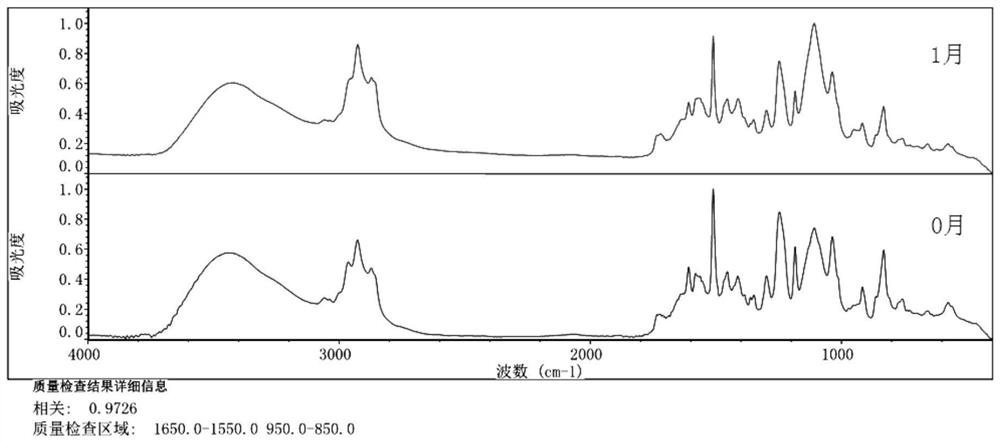

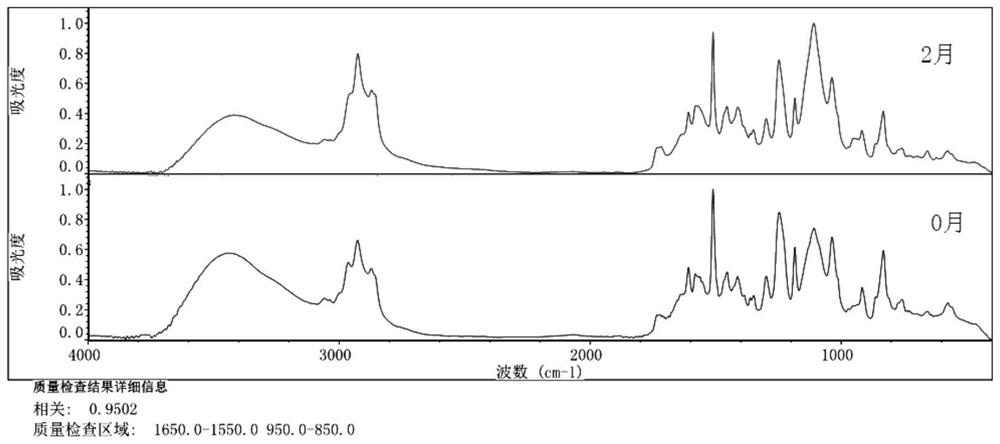

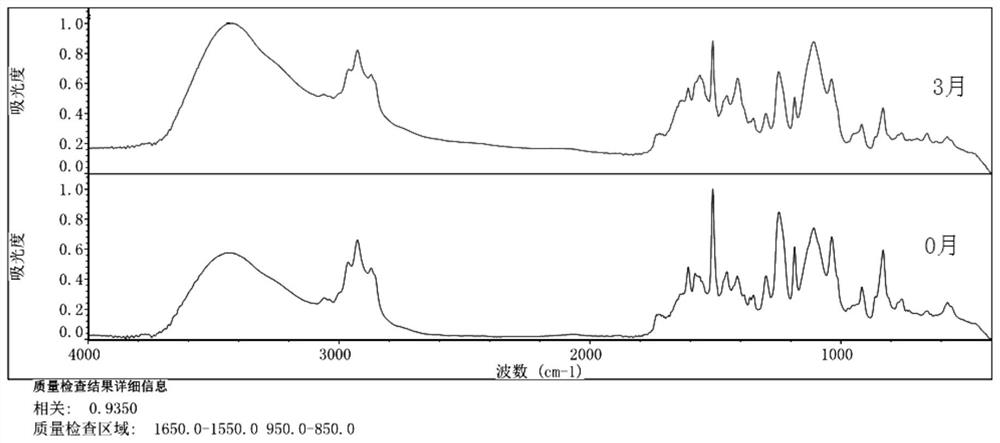

[0039] In this embodiment, the infiltrant solution left open for 0-4 months is used for detection. Specifically, the solution of the finished sizing agent used in this embodiment is the water-based epoxy emulsion wetting agent BG7 (3178) produced by Nanjing Glass Fiber Research and Design Institute Co., Ltd., and the solution of the finished sizing agent has a solid content of about 5%. dilute solution.

[0040] Specifically, the finished infiltrant solutions that have been placed for different times are directly injected into the liquid pool for infrared detection, and infrared detection is performed to obtain infrared spectra of the infiltrant solutions at different open storage times. The detection instrument of infrared detection in the present embodiment is Thermo Scientific TM Nicolet TM For the iS20 FTIR spectrometer, the liquid pool used in the detection instrument is a detachable liquid pool with an optical path of 0.1mm, and the window of the detachable liquid po...

Embodiment 2

[0048] In this embodiment, the glass fiber that has been infiltrated with the same proportion of wetting agent solution as in Embodiment 1 and sealed and stored for a period of time is used for infrared detection. The specific process is:

[0049] Get 20g of glass fiber and join in the Soxhlet extractor, add 300mL of acetone in the Soxhlet extractor to extract and obtain the extract; directly inject the extract into the same infrared detection instrument in Example 1 to detect and obtain the infrared spectrum.

[0050] In this example, the glass fibers whose sealed storage time reaches 0.5 years, 1 year, 2 years, 2.5 years, 3 years and 4 years are respectively obtained, and the infrared spectrum of the sizing agent of 0 months in Example 1 is used as the standard spectrum. Obtain the ratio of the S1 / S2 of each graph according to the mode of embodiment 1, take the standard graph as a reference, and then obtain the epoxy retention rate and the 930cm -1 ~880cm -1 The correlati...

Embodiment 3

[0057] In this example, the same infiltrant solution was repeatedly injected into the liquid pool for infrared detection for three times for detection, and the infrared spectrum obtained for the first time was used as the standard spectrum to obtain the infrared spectrum obtained from the three detections and the infrared spectrum obtained from the first detection. The full-spectrum correlation coefficient and epoxy retention rate of the test results are shown in Table 3.

[0058] table 3

[0059] full spectrum correlation coefficient Epoxy Retention the first time 1 100% the second time 0.9921 99.96% the third time 0.9950 100%

[0060] It can be known from the test results in Table 3 that the consistency of the test results of the present application reaches more than 99%, and the test results are accurate and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com