Lithium ion battery and preparation method thereof

A lithium-ion battery and cell technology, applied in the field of lithium-ion batteries and their preparation, can solve the problems of low energy density of lithium-ion batteries, difficulty in meeting high-rate discharge, high-voltage and high-energy requirements, etc., to prevent precipitation and improve Magnification rate and energy density, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also relates to the preparation method of above-mentioned lithium ion battery, comprises the following steps:

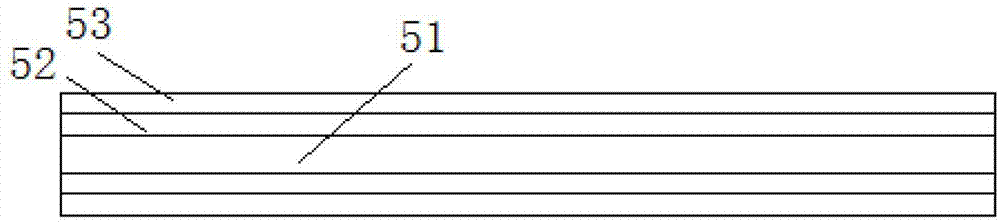

[0070] 1), prefabricated positive electrode sheet, separator and negative electrode sheet; when preparing the positive electrode sheet, the coating surface density of the positive electrode material layer on the positive electrode sheet is 25mg / cm 2 ~36mg / cm 2 ; When preparing the negative electrode sheet, the coating area density of the negative electrode material layer coated on the negative electrode sheet is less than or equal to 36mg / cm 2 ; and the ratio of the reversible capacity of the positive electrode to the reversible capacity of the negative electrode is set to 1.2:1~1.5:1;

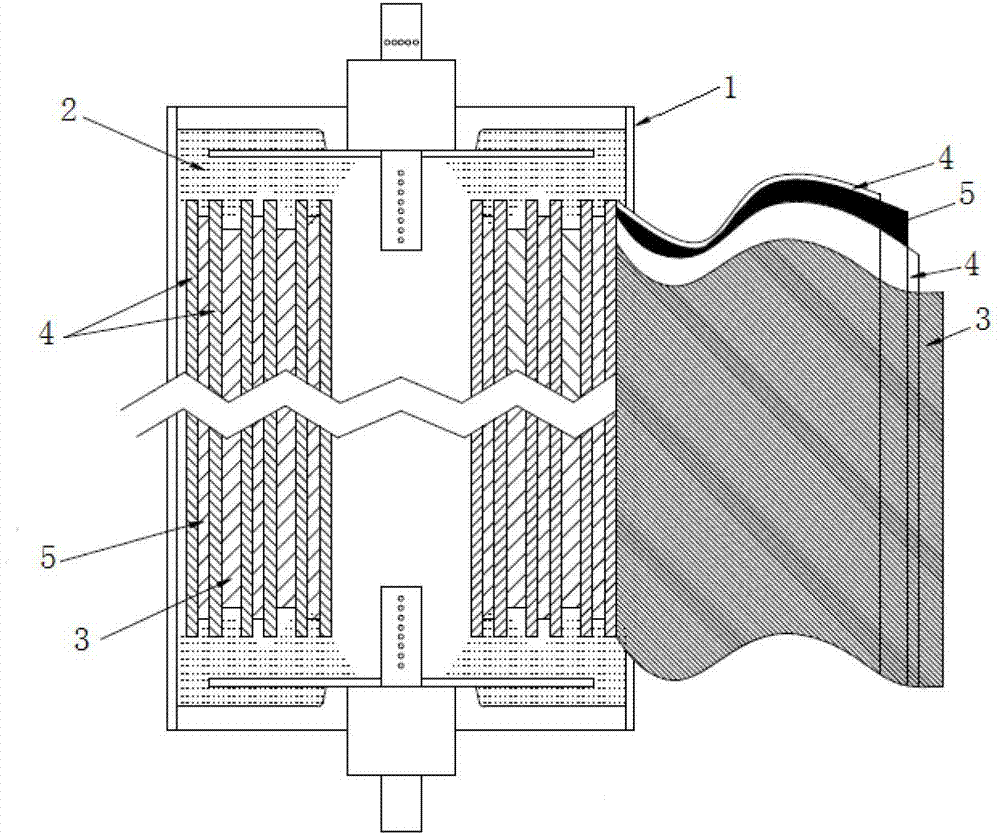

[0071] 2) According to the order of positive electrode sheet, diaphragm, negative electrode sheet and diaphragm, the cell is stacked and wound, and then the insulating tape is wrapped on the outside of the cell, and the cell is put into the casing and in...

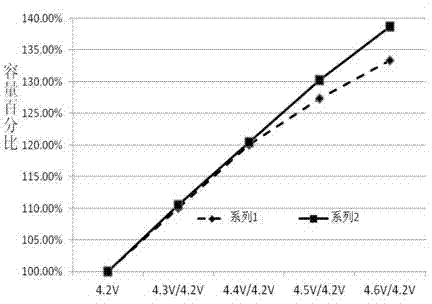

Embodiment 1

[0093] This embodiment provides a lithium-ion battery, including a casing, an electric core disposed in the casing, and an electrolyte solution. The electric core includes a positive electrode, a negative electrode, and a separator for isolating the positive and negative electrodes. A positive electrode material layer on the surface of the sheet, the negative electrode includes a negative electrode sheet and a negative electrode material layer coated on the surface of the negative electrode sheet, and the coating surface density of the positive electrode material layer is 36 mg / cm 2 , the coating surface density of the negative electrode material layer is 12 mg / cm 2 , and the ratio of the reversible capacity of the positive electrode to the reversible capacity of the negative electrode is 1.32:1.

[0094] In this embodiment, the positive electrode material layer contains 94% by mass of the positive electrode material, and the negative electrode material layer contains 92% by m...

Embodiment 2

[0118] This embodiment provides a lithium-ion battery, including a casing, an electric core disposed in the casing, and an electrolyte solution. The electric core includes a positive electrode, a negative electrode, and a separator for isolating the positive and negative electrodes. A positive electrode material layer on the surface of the sheet, the negative electrode includes a negative electrode sheet and a negative electrode material layer coated on the surface of the negative electrode sheet, and the double-sided coating surface density of the positive electrode material layer is 25mg / cm 2 , the coating surface density of the negative electrode material layer is 8 mg / cm 2 , and the ratio of the reversible capacity of the positive electrode to the reversible capacity of the negative electrode is 1.2:1.

[0119] In this embodiment, the positive electrode material layer contains 90% by mass of the positive electrode material, and the negative electrode material layer contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating surface density | aaaaa | aaaaa |

| Coating surface density | aaaaa | aaaaa |

| Coating surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com