Preparation method of high-rate lithium ion battery

A lithium-ion battery, high-rate technology, which is used in the manufacture of electrolyte batteries, battery electrodes, battery pack components, etc. The effect of improving electronic conductivity and ion passing rate, preventing short circuit or micro-short circuit, improving rate performance and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

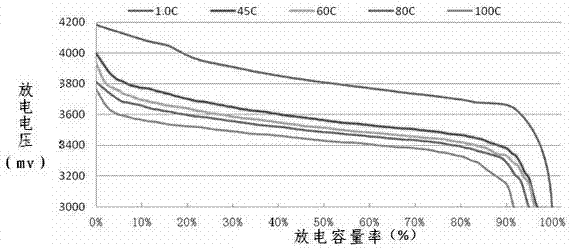

Image

Examples

Embodiment 1

[0033] Evenly mix 92% lithium cobalt oxide, 4% conductive carbon black SP-Li, and 4% polyvinylidene fluoride PVDF to make positive electrode dry powder, and then set the mass ratio as positive electrode dry powder: N-methylpyrrolidone = 1: The positive electrode dry powder of 1.0 is uniformly mixed with N-methylpyrrolidone to prepare a positive electrode slurry; use a coating machine to coat the positive electrode slurry on a carbon-coated aluminum foil, and dry to obtain a positive electrode sheet; then use the coating machine on the The front and back surfaces of the positive pole piece are coated with 2.0um conductive glue, and the positive pole piece is obtained by drying, rolling, and slitting. The mass ratio of conductive carbon black SP-Li and polyvinylidene fluoride PVDF in the conductive glue is It is conductive carbon black SP-Li: polyvinylidene fluoride PVDF=49:1, and the amount of solvent is 90% of the total weight of the conductive glue; use a spraying equipment to...

Embodiment 2

[0035]The mass percentage is 90% lithium iron phosphate, 5% carbon nanotube CNTS, and 5% polyvinylidene fluoride PVDF are evenly mixed to make positive electrode dry powder, and then the mass ratio is positive electrode dry powder: N-methylpyrrolidone=1: The positive electrode dry powder of 1.7 is uniformly mixed with N-methylpyrrolidone to prepare a positive electrode slurry; use a coating machine to coat the positive electrode slurry on a carbon-coated aluminum foil, and dry to obtain a positive electrode sheet; then use a coating machine to coat the positive electrode sheet Coating 3.0um conductive glue on the positive and negative surfaces of the conductive glue, drying, rolling, and slitting to obtain the positive electrode roll material. The mass ratio of conductive carbon black SP-Li and polyvinylidene fluoride PVDF in the conductive glue is conductive Carbon black SP-Li: polyvinylidene fluoride PVDF=32.3:1, the amount of solvent is 95% of the total weight of the conduct...

Embodiment 3

[0037] Evenly mix 95% lithium cobaltate, 3% graphene, and 2% polyvinylidene fluoride PVDF to make positive electrode dry powder, and then make the mass ratio lithium cobaltate:N-methylpyrrolidone=1: 1.5 Lithium cobaltate and N-methylpyrrolidone are uniformly mixed to prepare a positive electrode slurry; use a coating machine to coat the positive electrode slurry on carbon-coated aluminum foil, and dry to obtain a positive electrode sheet; then use a coating machine to coat the positive electrode sheet Coating 5.0um conductive glue on the positive and negative surfaces of the conductive glue, drying, rolling, and slitting to obtain the positive electrode roll material, the mass ratio of carbon nanotubes CNTS and polyvinylidene fluoride PVDF in the conductive glue is carbon nanotube CNTS: polyvinylidene fluoride PVDF=49:1, the amount of N-methylpyrrolidone is 92% of the total weight of the conductive glue; use a spraying equipment to coat a layer of ceramic coating on the cut end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com