Patents

Literature

70results about How to "Guaranteed rate performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery gradient core shell cathode material and synthetic method thereof

ActiveCN103236537AGuaranteed cycle performanceGuaranteed rate performanceCell electrodesNickel compoundsElectrical batteryPhysical chemistry

The invention provides a lithium ion battery gradient core shell cathode material and synthetic method thereof, and relates to a lithium ion battery cathode material and synthetic method thereof. The lithium ion battery gradient core shell cathode material provided by the present invention may have two kinds of core shell structures as follows: a two-layer structure: a ternary material is used as a core material, and a binary material or a unitary material is casing material, and the ternary material external layer is covered by the binary material or the unitary material; three-layer structure: the ternary material is used as a core material, and the binary material and the unitary material are casing materials, and the ternary material external layer is covered with the binary material, and the binary material is covered with the unitary material. The synthetic method includes: employing a coprecipitation method for obtaining a precursor, and then adding lithium source, calcining and coating to obtain the ternary gradient core shell material. Under the prerequisite that the structure stability of the material is kept, the cost is reduced, and the gram capacity of the material is improved, and the material circulating performance and rate capability of the material are improved, and the safety performance and low temperature performance of the ternary cathode material are increased, and the preparation technology is optimized and improved.

Owner:HARBIN INST OF TECH

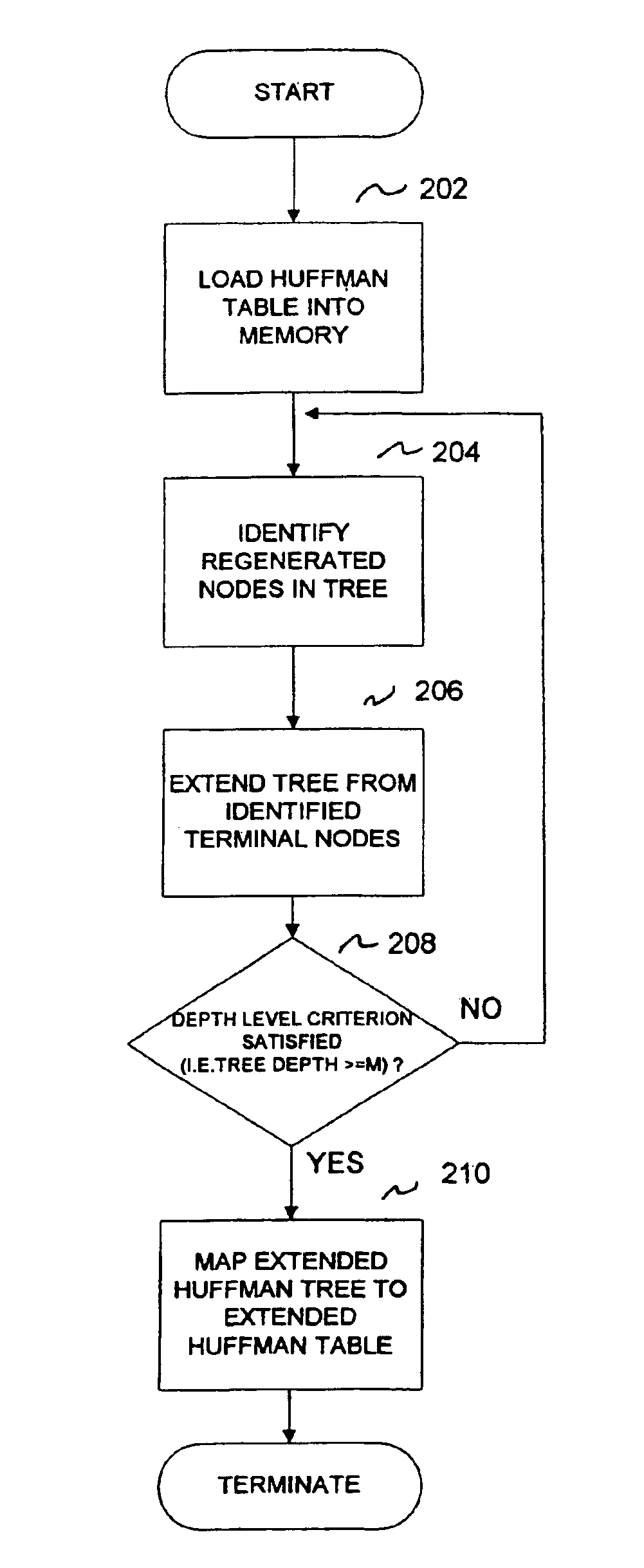

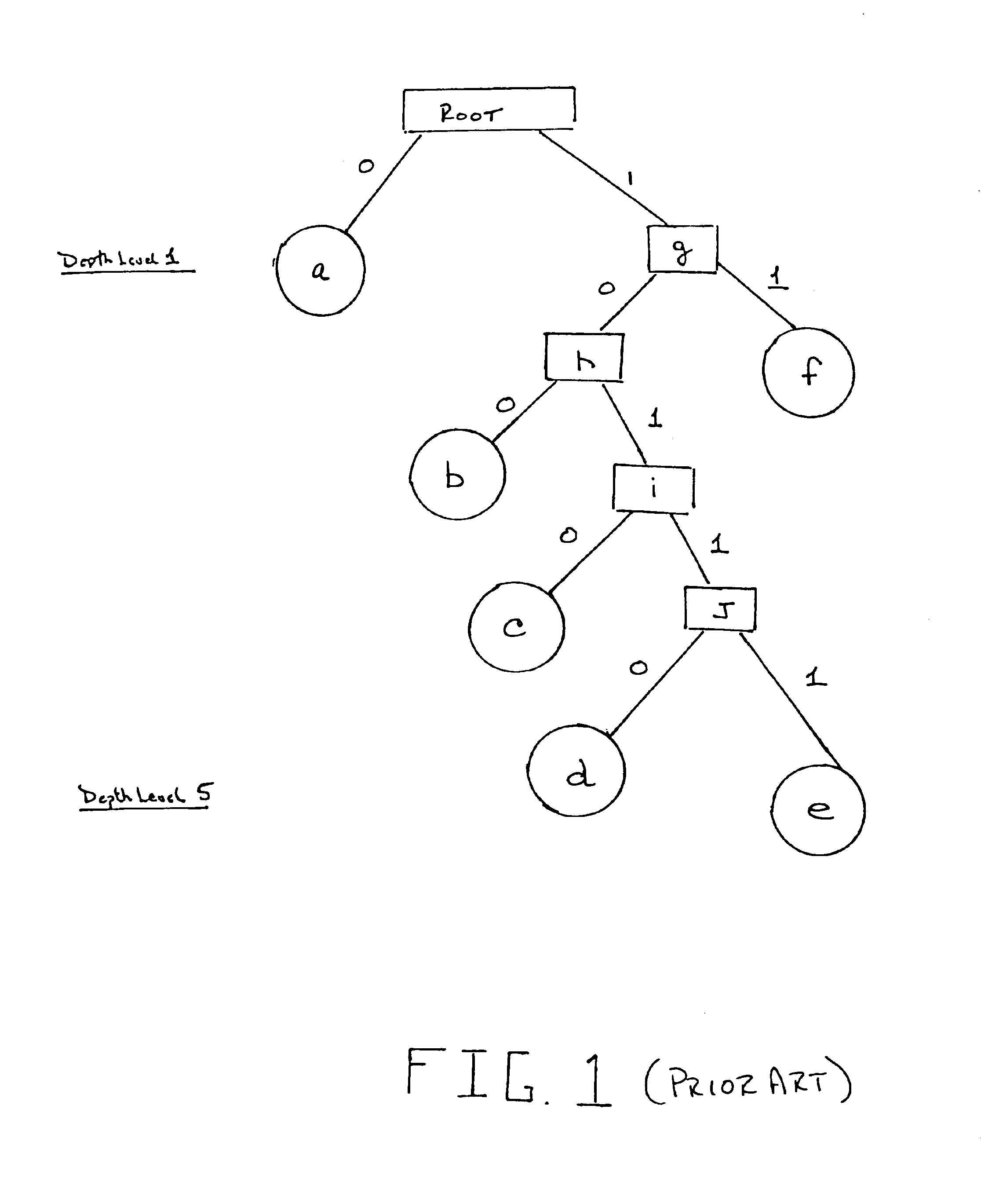

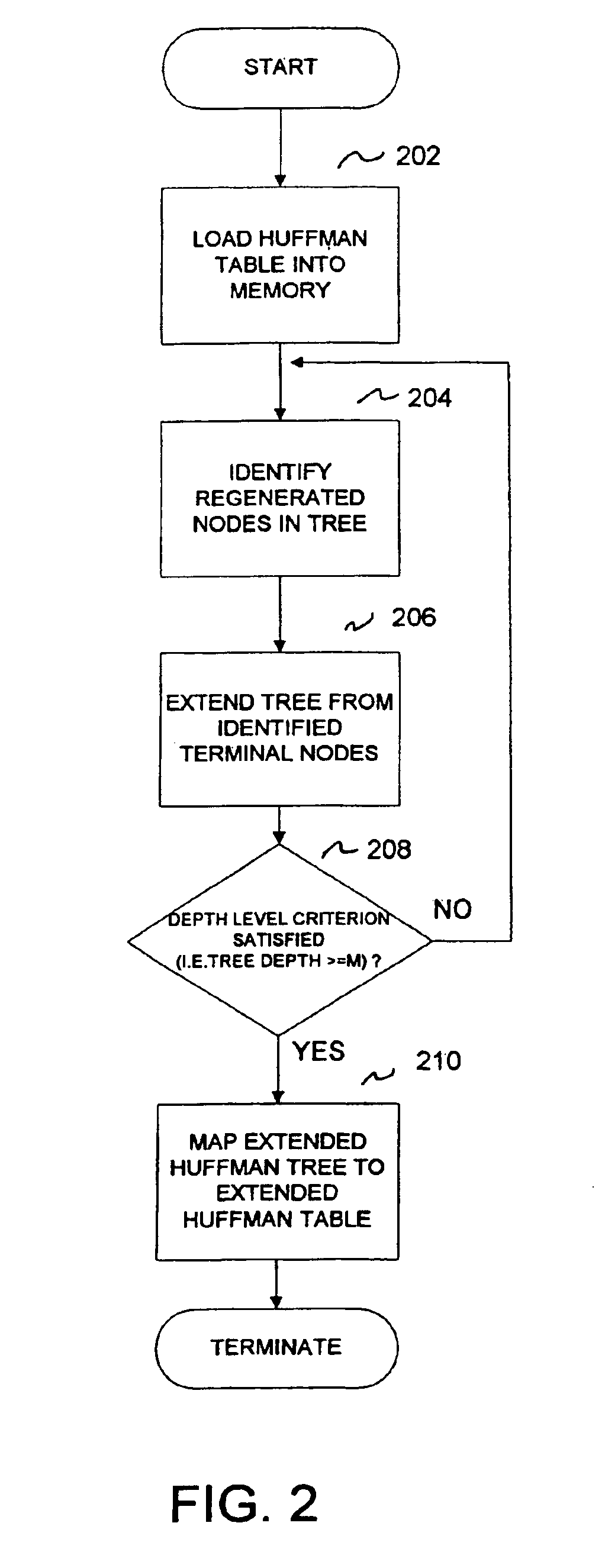

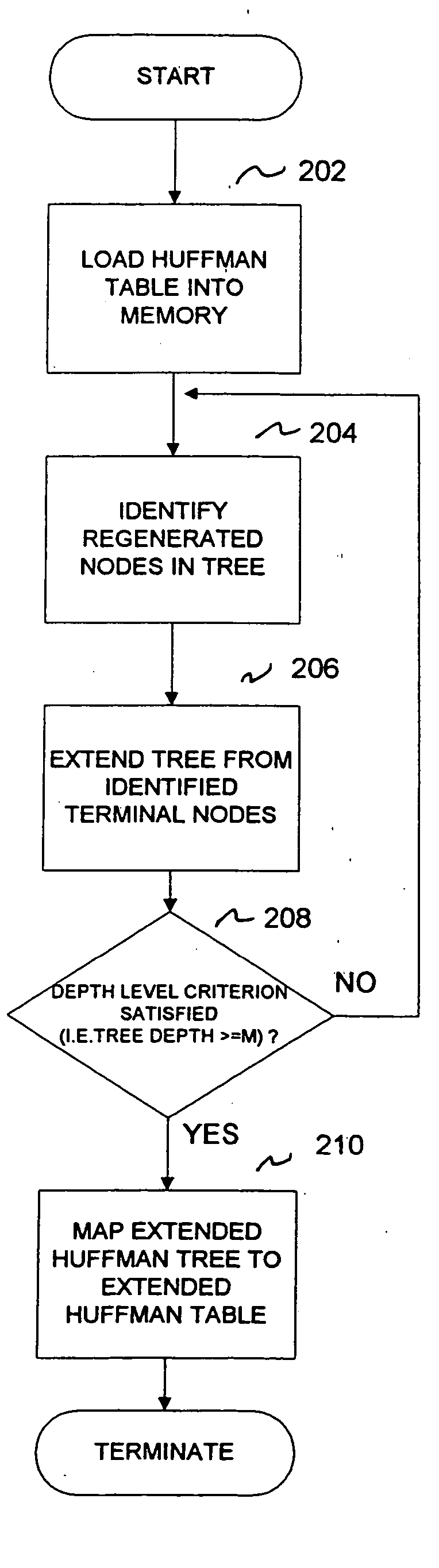

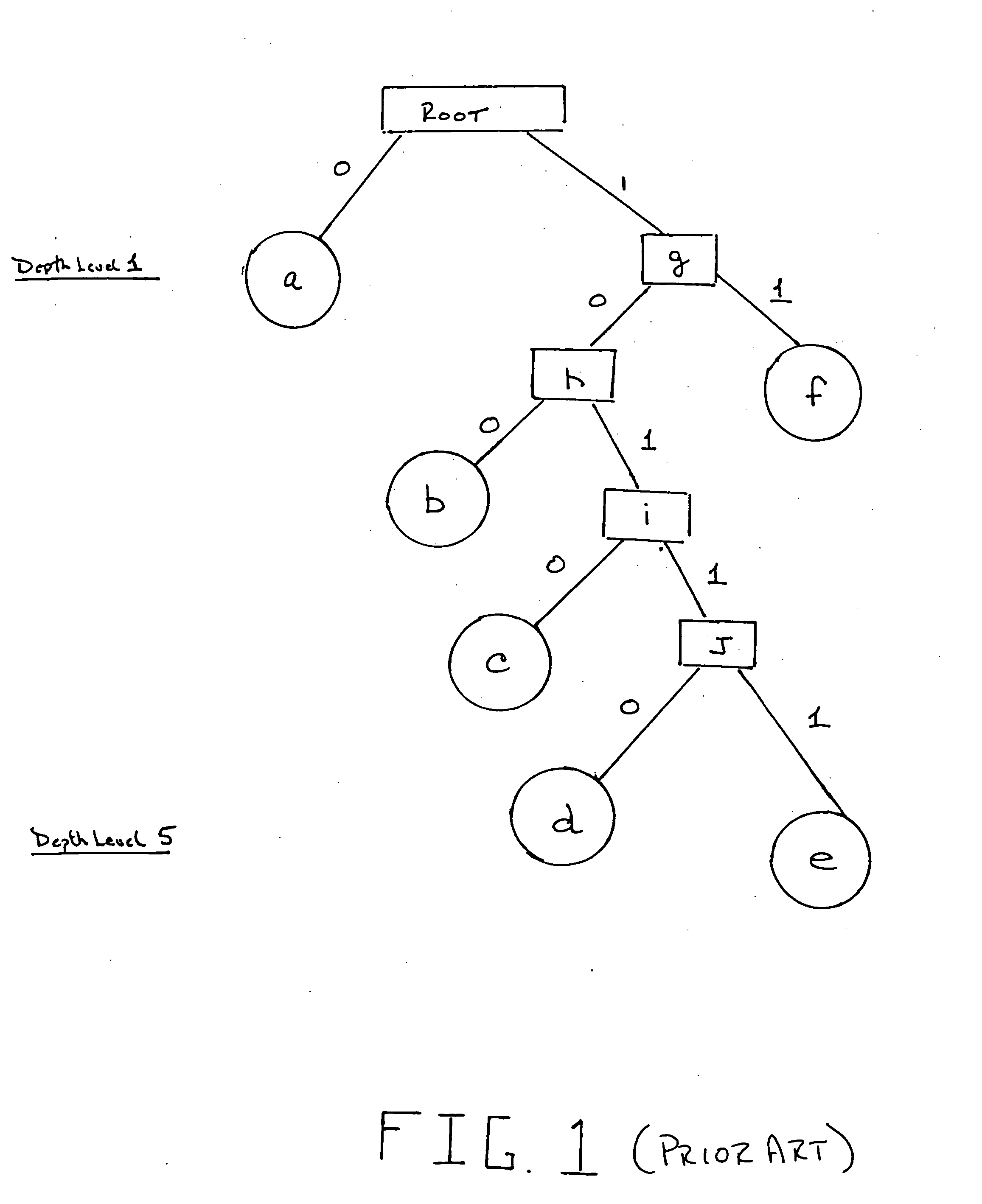

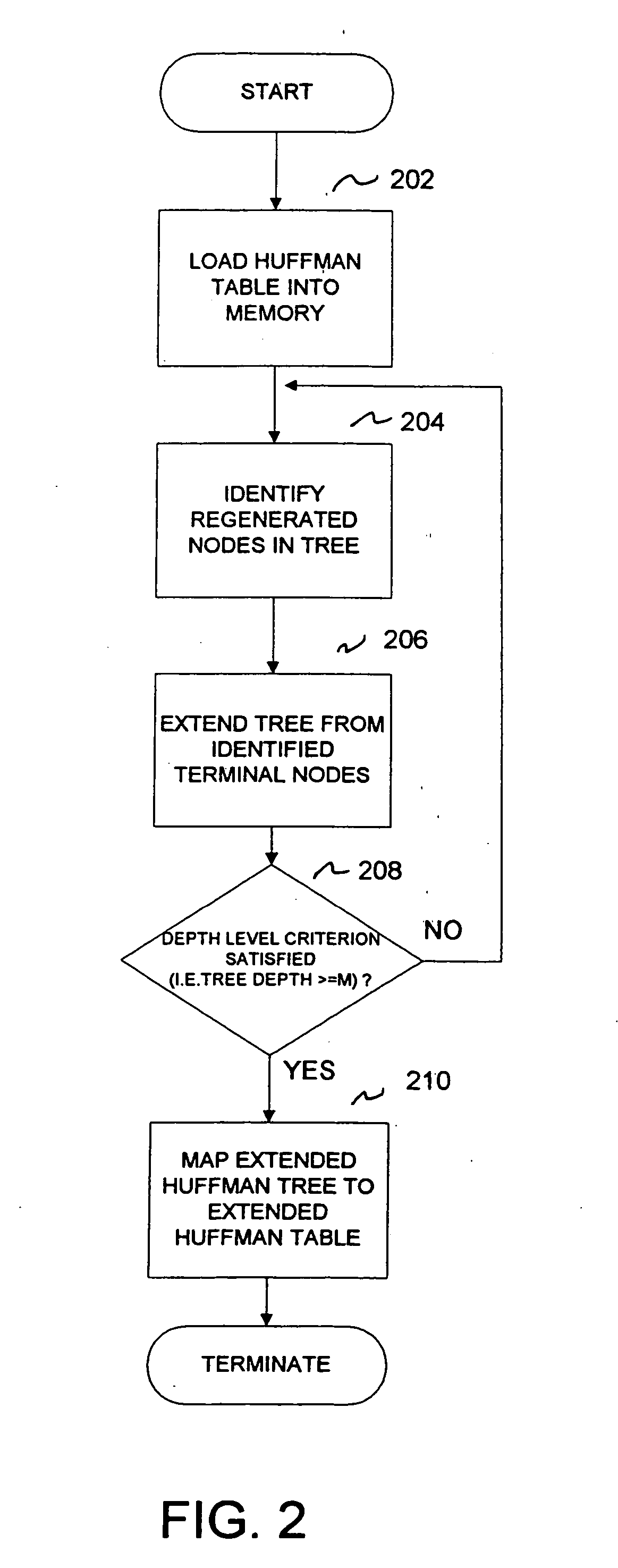

Adaptive variable length decoding method

InactiveUS7043088B2Guaranteed rate performanceCode conversionCharacter and pattern recognitionDecoding methodsHardware architecture

A method is disclosed for decoding multiple-coded symbols from a coded input symbol stream in a single clock cycle. The method constructs an original Huffman look-up table by extending the associated Huffman tree to decode multiple symbols in one clock cycle in a first embodiment and decodes multiple DCT coefficient symbols in an alternate embodiment. An advantage of the method is that the depth of the new Huffman tree is adjustable thereby making the method easily adaptable to various hardware architectures. A further advantage of the present invention is that the decoding process speed is significantly increased while the size of the lookup table is nominally increased.

Owner:WSOU INVESTMENTS LLC

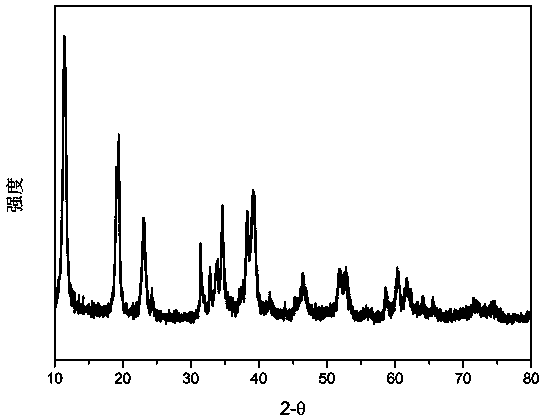

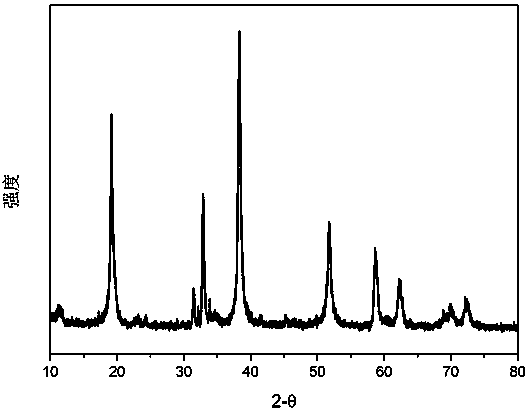

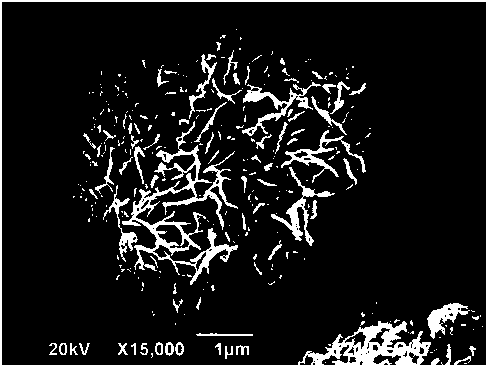

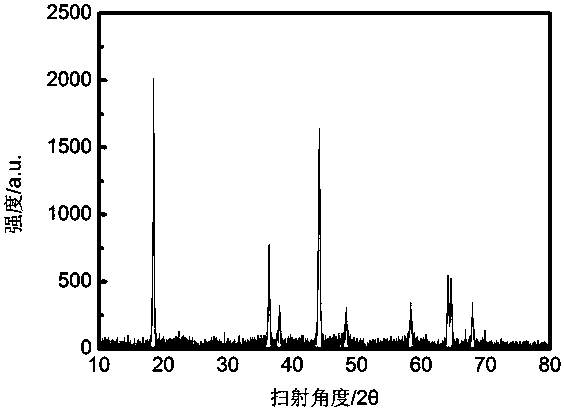

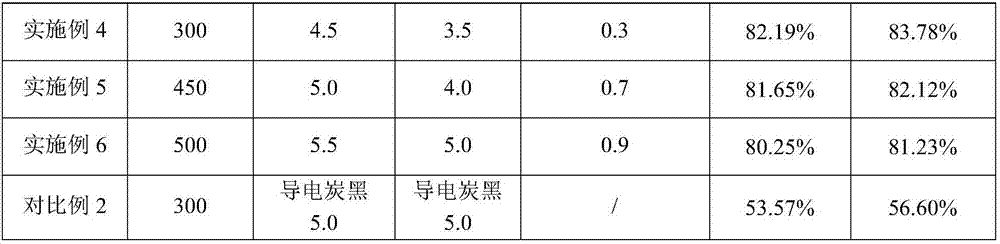

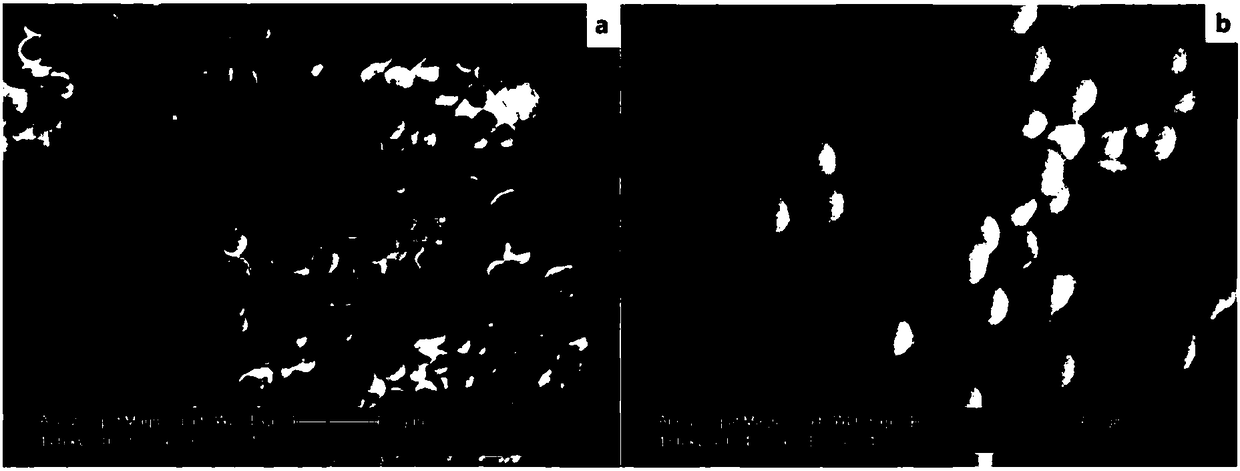

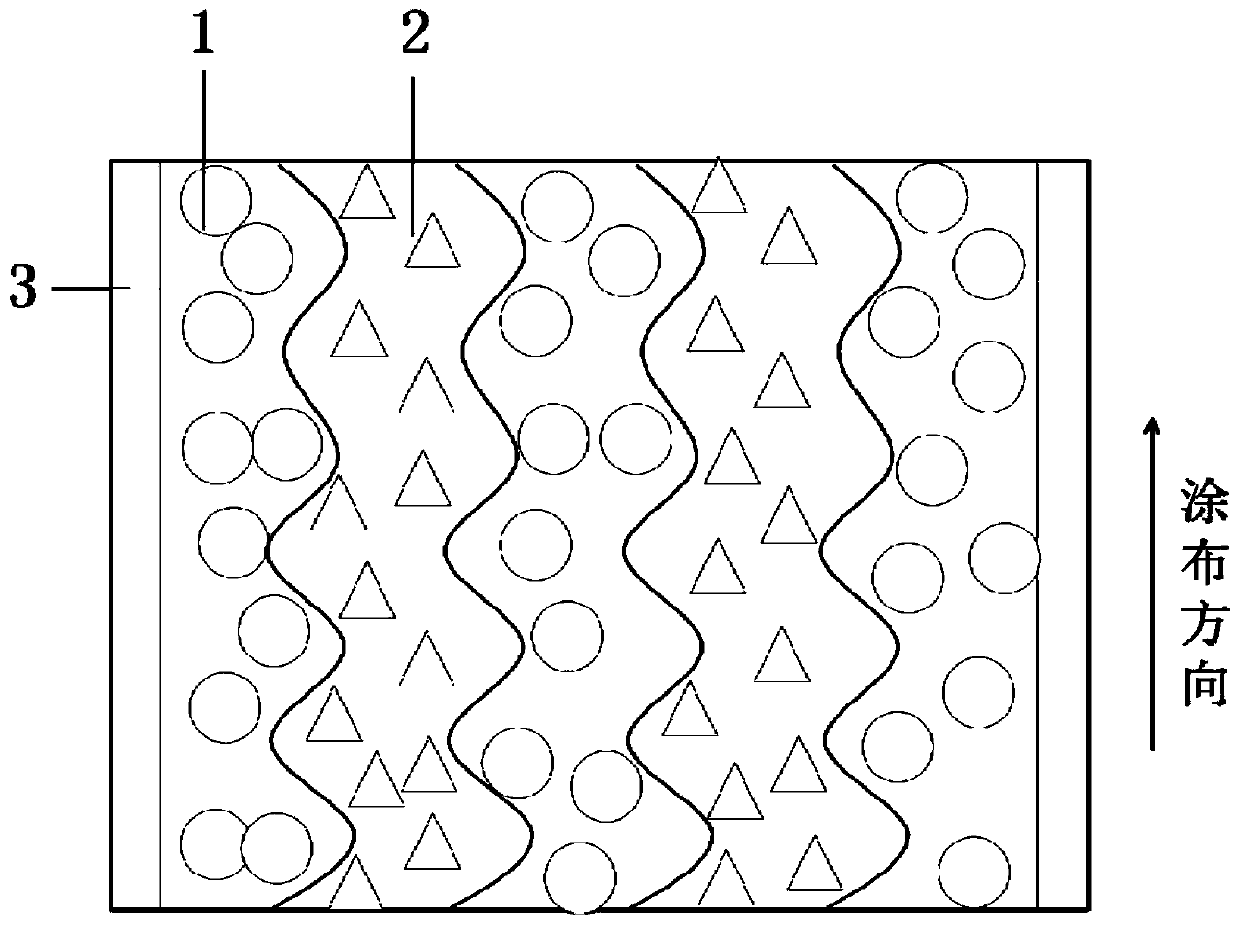

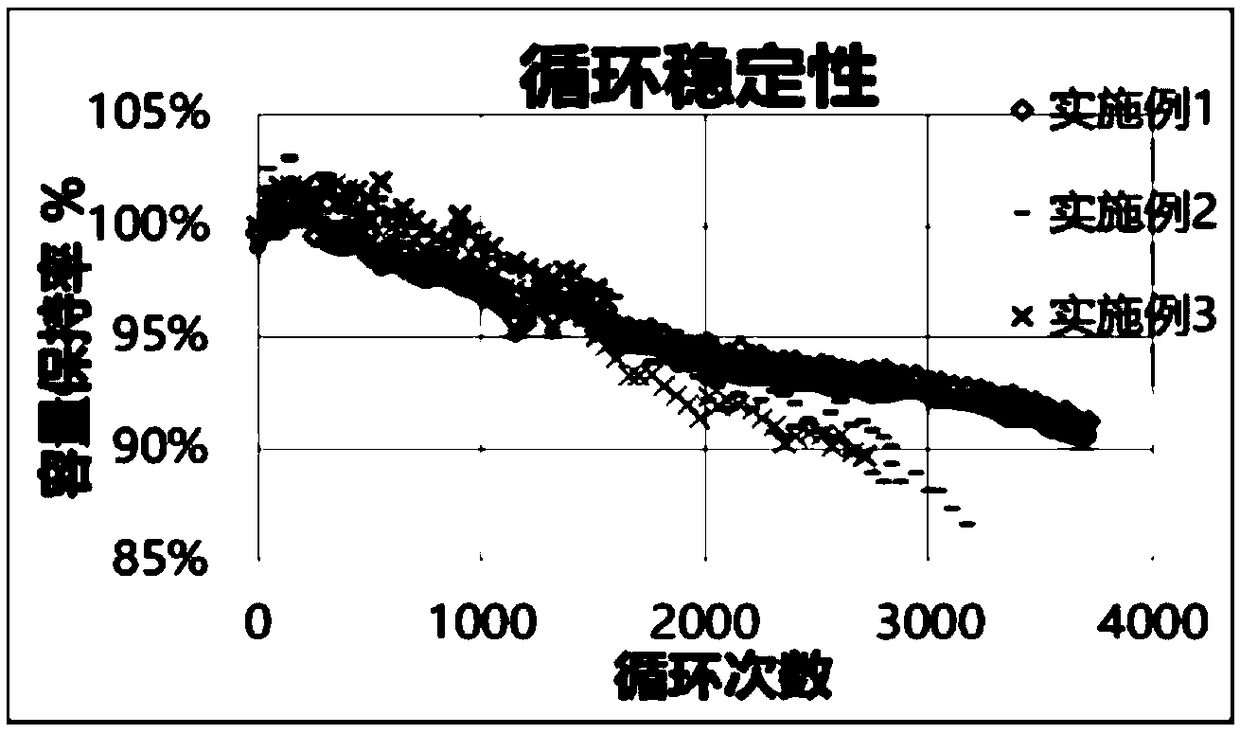

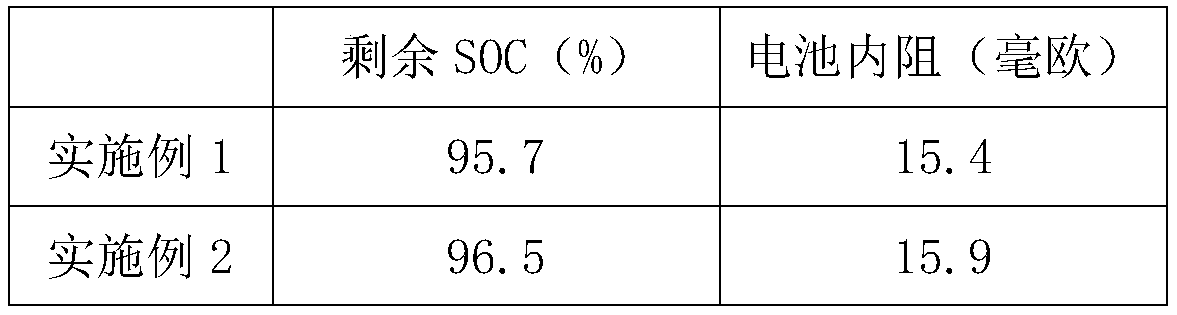

Core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

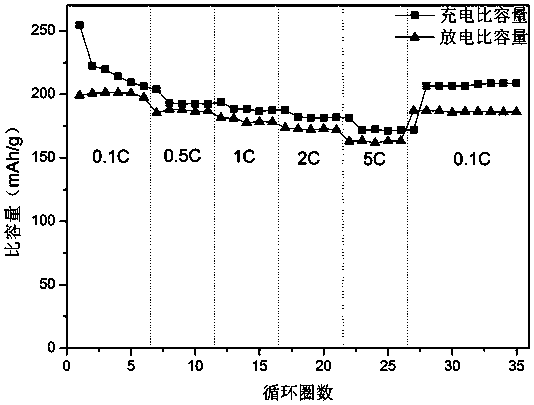

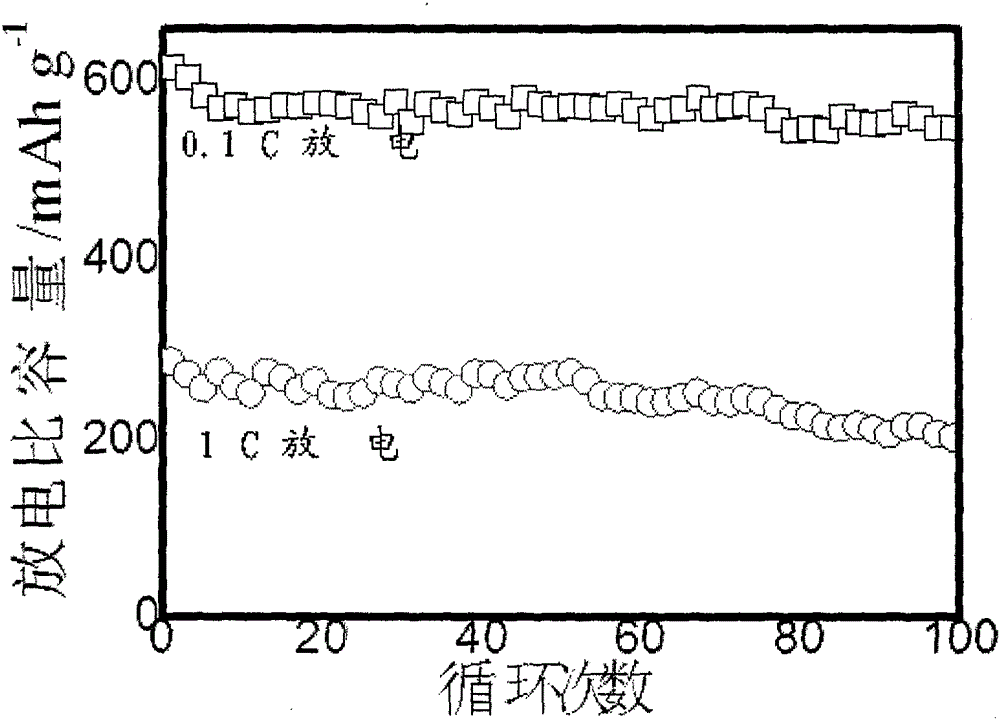

ActiveCN108793268AIncrease capacityShortened diffusion channelCell electrodesSecondary cellsHydroxideSpecific discharge

The invention discloses a core-shell structure gradient nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode materialprecursor is core-shell structure particles with the average particle size of 4-12 [mu]m, wherein an inner core is hydroxide precipitates of nickel, cobalt and manganese, a shell layer is carbonate precipitates of nickel, cobalt and manganese, the nickel content decreases gradually from the center of the core-shell structure particles to the surface of the shell layer, the manganese content increases gradually from the center of the core-shell structure particles to the surface of the shell layer, and the cobalt content is distributed evenly between the center of the core-shell structure particles and the shell layer. The invention also discloses the preparation method of the ternary positive electrode material precursor. A ternary positive electrode material obtained after the ternary positive electrode material precursor is mixed with lithium and calcined is assembled into a battery, at 0.1 C, the first discharge capacity can reach 198 mAh / g and still keeps at 182 mAh / g after the battery is circulated for 100 cycles, and the specific discharge capacity can reach 176.3 mAh / g at 5 C. The method is simple in process, low in cost and suitable for industrialized production.

Owner:ZHUJI PAWA NEW ENERGY

Core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor and preparation method thereof

ActiveCN108878818AGuaranteed charge and discharge capacityGuaranteed rate performanceSecondary cellsPositive electrodesLithiumManganese

The invention discloses a core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor and a preparation method thereof. The ternary positive electrode material precursoris a core-shell structure particle with an average particle diameter of 5-12 [mu]m. The chemical formula of a core is Ni<x>Co<y>Mn<1-x-y>(OH)<2>, wherein <x> is greater than or equal to 0.6 and is less than or equal to 0.9, <y> is greater than or equal to 0.1 and is less than or equal to 0.4, and <1-x-y> is greater than or equal to 0. The chemical formula of a shell is Ni<x>Co<y>Mn<1-x-y>CO<3>, wherein <x> is greater than or equal to 0.4 and is less than or equal to 0.7, <y> is greater than or equal to 0.1 and is less than or equal to 0.4, and <1-x-y> is greater than 0. A ternary positive electrode material made by lithium mixing and sintering of the core-shell structure nickel-cobalt-manganese ternary positive electrode material precursor is assembled into a battery, and excellent electrochemical performance is exhibited. The preparation method is simple in process, low in cost and suitable for industrial production.

Owner:ZHUJI PAWA NEW ENERGY

High-nickel core-shell structure gradient nickel-cobalt-manganese ternary cathode material and preparation method thereof

ActiveCN109273701AAvoid damageGuaranteed cycleSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

A high-nickel core-shell structure gradient nickel-cobalt-manganese ternary cathode material and a preparation method thereof, wherein the ternary cathode material is LiNixCoyMn (1- X- Y) O2, wherein,0.70 <= x <= 0. 85, 0.05 <= y<= 0. 20, 1-X-Y > 0, which is composed of high nickel initial nucleus, middle layer and shell; The nickel element distributes uniformly in the high nickel initial nucleusand gradually decreases from the middle layer to the crust, the cobalt element distributes uniformly in the high nickel initial nucleus, the middle layer and the crust, and the manganese element increases gradually from the middle layer to the crust. The invention also discloses a preparation method of the ternary cathode material. The ternary cathode material prepared by the invention is assembled into a battery, which has high discharge specific capacity and good cycle and rate performance. The method of the invention is simple in process and low in cost, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

Three-dimensional network water-based composite binder and application thereof in lithium ion battery

ActiveCN111180733AGuaranteed bonding effectGuaranteed cycle performanceNegative electrodesSecondary cellsElectrical batteryCross linker

The invention provides a three-dimensional network water-based composite binder, which is prepared from the following components in percentage by weight: 5 to 50 percent of water-based polymer emulsion, 94.5 to 50 percent of water-soluble polymer and 0.5 to 10 percent of cross-linking agent. The three-dimensional network water-based composite binder is prepared by crosslinking the water-based polymer emulsion and the water-soluble polymer by a crosslinking agent to form a three-dimensional network molecular structure, wherein the water-based polymer emulsion is a water-based polyurethane emulsion or a vinyl acetate water-based copolymer emulsion. The invention also provides a negative electrode prepared from the three-dimensional network water-based composite binder and a lithium ion battery containing the negative electrode. The water-soluble polymer has relatively strong bonding force on the negative electrode material; the water-based polymer emulsion endows the polymer binder witha certain elasticity, and the cross-linking agent endows the binder with a three-dimensional molecular network structure, so that the toughness of the binder is enhanced, the damage of the volume change of active substances to an electrode plate structure in the charging and discharging process of the battery can be buffered, and the cycling stability of the lithium ion battery is maintained.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

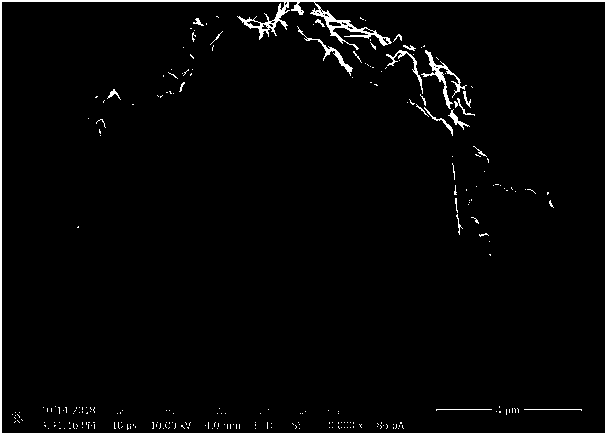

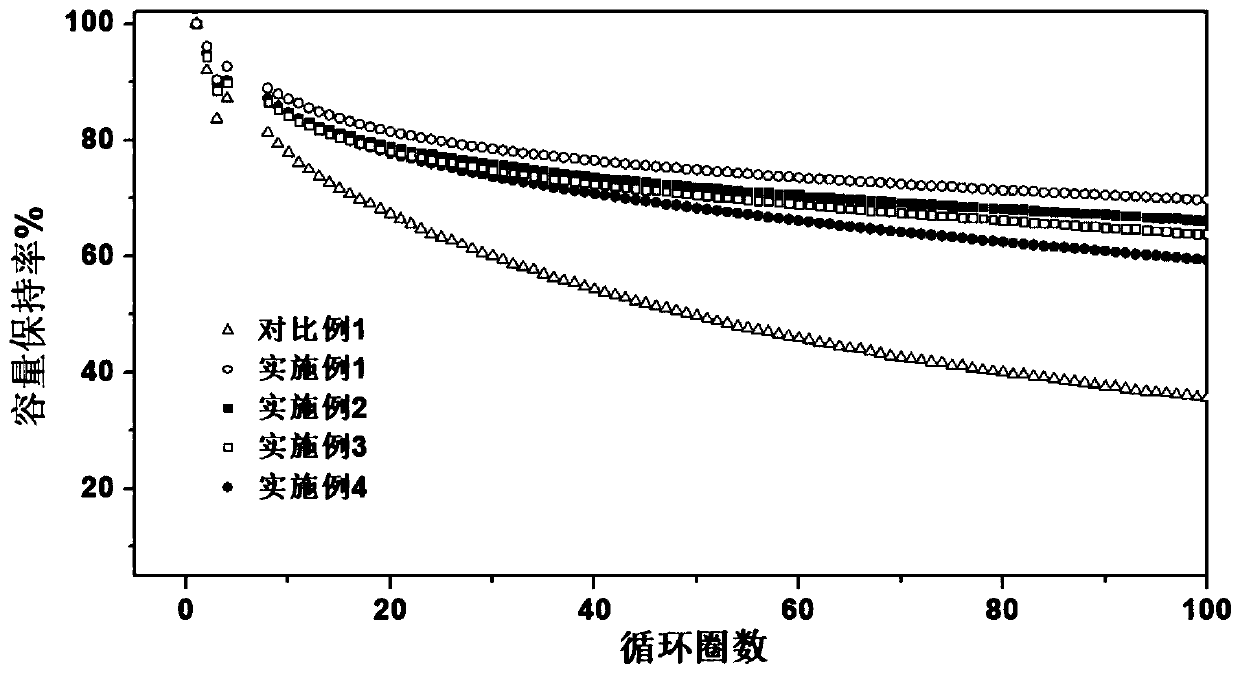

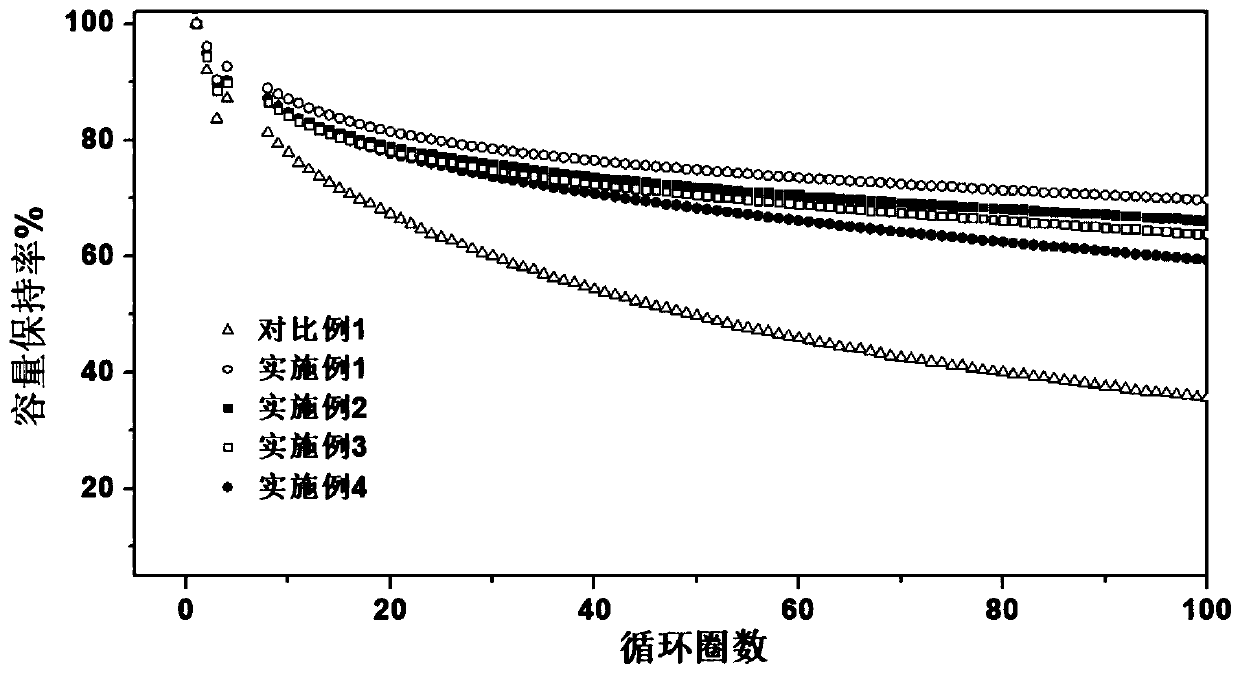

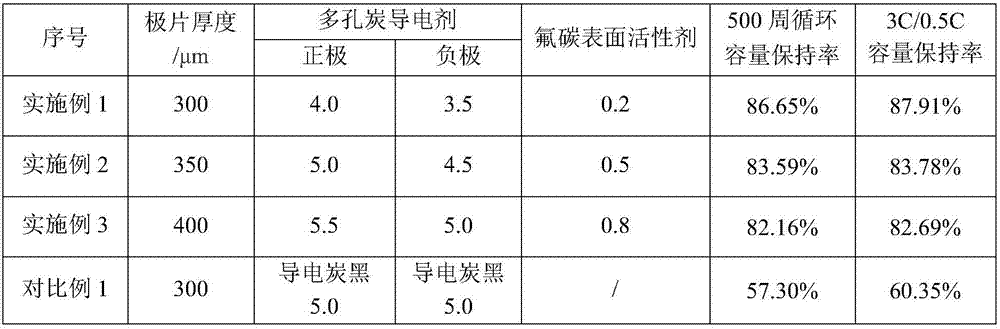

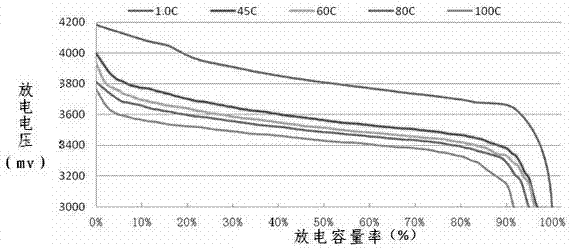

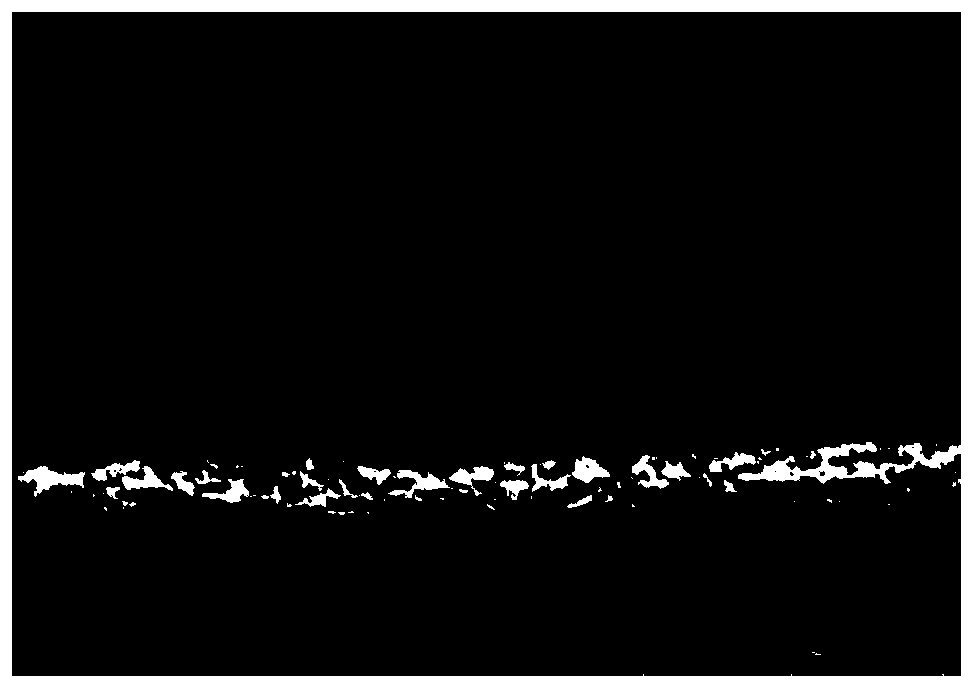

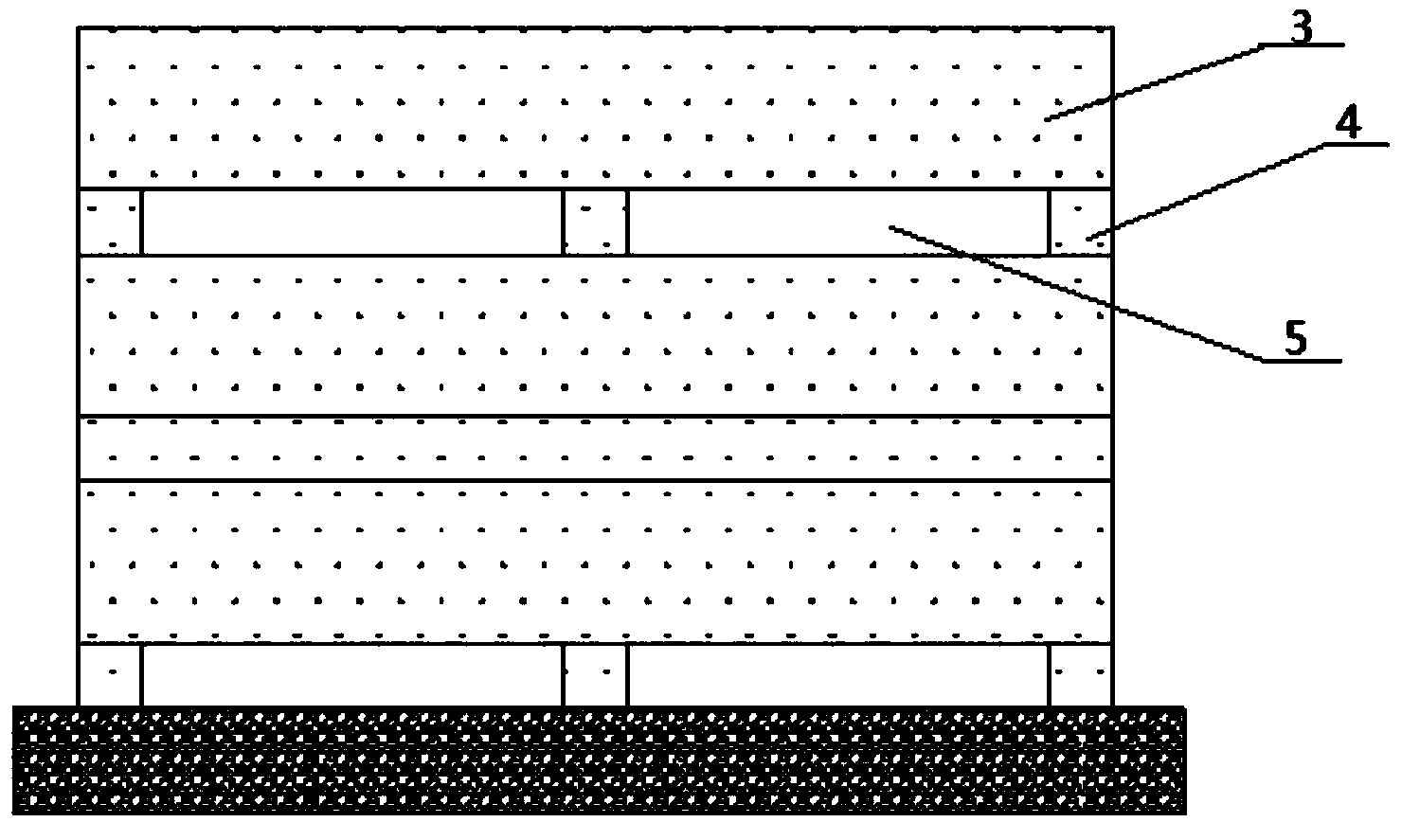

Preparation method of thick electrode with excellent electrochemical performance and lithium ion battery

InactiveCN107093701AReduce surface tensionEnhanced absorption and retention propertiesSecondary cellsElectrode collector coatingCurrent collectorPorous channel

The invention discloses a thick electrode with excellent electrochemical performance. An electrode thickness of the thick electrode is larger than 300mu m. The thick electrode comprises an anode thick electrode body and a cathode thick electrode body, wherein the anode thick electrode body comprises an anode current collector, an anode active material, an anode binder, a porous carbon conductive agent and a fluorocarbon surfactant; the cathode thick electrode body comprises a cathode current collector, a cathode active material, a cathode binder, a porous carbon conductive agent and a thickener; the porous carbon conductive agent has rich porous channels, can obviously absorb and keep electrolyte and solves the problems that thick electrode electrolyte has poor wettability, active material utilization is insufficient, and the like; the fluorocarbon surfactant can reduce surface tension of anode slurry, improve a coating effect of the slurry on the current collectors and meanwhile improve absorbing and keeping ability of an anode piece to the electrolyte. By means of the technical characteristics, the anode thick electrode body and the cathode thick electrode body with excellent conducting performance can be prepared out, so that a high energy density lithium ion battery with excellent electrochemical performance can be obtained.

Owner:上海汇平新能源有限公司

Preparation method of high-rate lithium ion battery

InactiveCN107086287AImprove conductivityImproved magnification performanceCell seperators/membranes/diaphragms/spacersFinal product manufactureCarbon layerPorosity

A preparation method of a high-rate lithium ion battery is used for manufacturing of lithium ion batteries and comprises the following steps: reeling prepared positive plate, negative plate and polyolefin diaphragm to form a battery cell, pre-packaging the battery cell with a shell, vacuum-drying, injecting an electrolyte, standing, forming, packaging and capacity-grading so as to obtain a lithium ion battery. By coating single and double surfaces of the positive plate with a conductive carbon layer, electronic conductivity and ion pass rate are enhanced, battery interlayer polarity is reduced, and then internal resistance of battery is reduced and high rate performance of batter are raised. By coating the edge cutting end of the plate with an anti-burr layer, short circuit or micro short circuit which might be caused by burr on the edge of the plate is prevented, self discharge rate is reduced, and safety performance of the battery is enhanced. By the use of the diaphragm with low porosity and under the precondition of guaranteeing high rate performance, self discharge rate and cost of the battery are reduced.

Owner:湖北猛狮新能源科技有限公司

Method for preparing three-dimensional ordered porous material

InactiveCN108538617AEvenly distributedFully contactedMaterial nanotechnologyHybrid capacitor electrodesMicrosphereSupercapacitor

The application discloses a method for preparing a three-dimensional ordered porous material. The method comprises: a conductive material is deposited on a template; and the template is removed to obtain a three-dimensional ordered porous material. The template is a micro / nano microsphere assembled to the substrate. The prepared three-dimensional porous electrode material has the ordered height and adjustable dimension and can be applied to energy storage devices such as a lithium ion battery, a supercapacitor and a metal air battery. The prepared three-dimensional ordered porous electrode hasthe unique performance in terms of flexible device and the has the broad application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

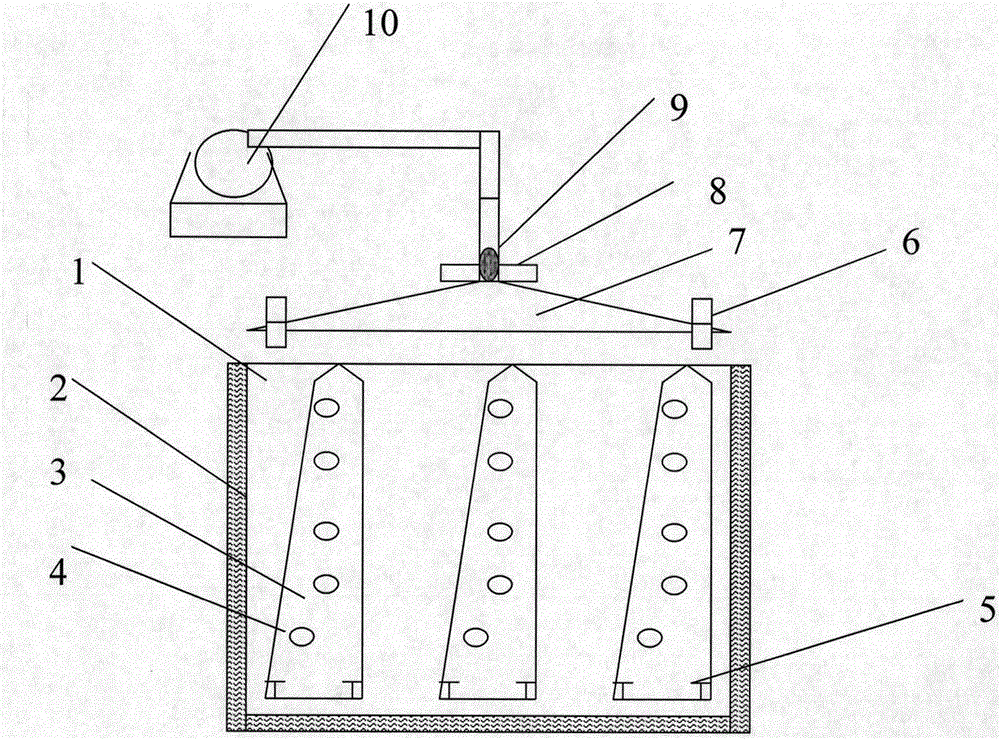

Preparation device and production method for sulfur electrode material

The invention relates to a preparation device and a production method for a sulfur electrode material. The sulfur electrode material preparation device comprises a mixer, a sulfur storage device, a heating system and a vacuum system, wherein the sulfur storage device is as high as the mixer body; a porous stainless steel tube is a trapezoidal stainless tube which is wide in bottom and narrow in top; holes which are 1-20 microns in hole diameter and 2-10 / square centimeters in hole count are symmetrically distributed in the surface of the stainless steel tube; the electrode material is a porous oxide electrode material dispersed with elemental sulfur; particles of the porous oxide electrode material are 10-500 nm; the porous oxide electrode material is one of hollow vanadium pentoxide nano powder, hollow nickel-cobalt-manganese-lithium oxide nano powder, hollow lithium manganate nano powder and hollow nickel-cobalt-lithium oxide nano powder; elemental sulfur accounts for 20-70% (in mass fraction) of the sulfur electrode material; 1-20% (in mass fraction) conductive polymer coats on the surface layer of the sulfur electrode material; the conductive polymer is one of polypyrrole, polyaniline, polythiophene and polyacrylonitrile. While being applied to a positive electrode of a lithium sulfur battery, the composite material has a high specific capacity and excellent circulating performance, and has a good application prospect in the battery field.

Owner:CHINA JILIANG UNIV

Lithium-sulfur battery separator membrane as well as preparation method and application thereof

ActiveCN110492045AInhibition of the shuttle effectImprove ionic conductivityLi-accumulatorsCell component detailsChemistryCyclic process

The invention discloses a lithium-sulfur battery separator membrane as well as a preparation method and application thereof, and belongs to the technical field of battery separator membranes. The lithium-sulfur battery separator membrane comprises a base membrane and a functional layer with which the base membrane is coated, wherein the functional layer comprises a functional material and an auxiliary agent, and the functional material comprises a layered sulfide, a conductive carbon material and nano cellulose. By adopting the technical scheme provided by the invention, the shuttle effect caused by lithium polysulfide in the cycle process of the lithium-sulfur battery can be effectively inhibited, and the capacity retention ratio, the electronic conductivity and the cycle effect of the lithium-sulfur battery are improved.

Owner:安徽金力新能源有限公司

Positive pole piece and preparation method thereof, lithium ion battery containing positive pole piece and application of lithium ion battery

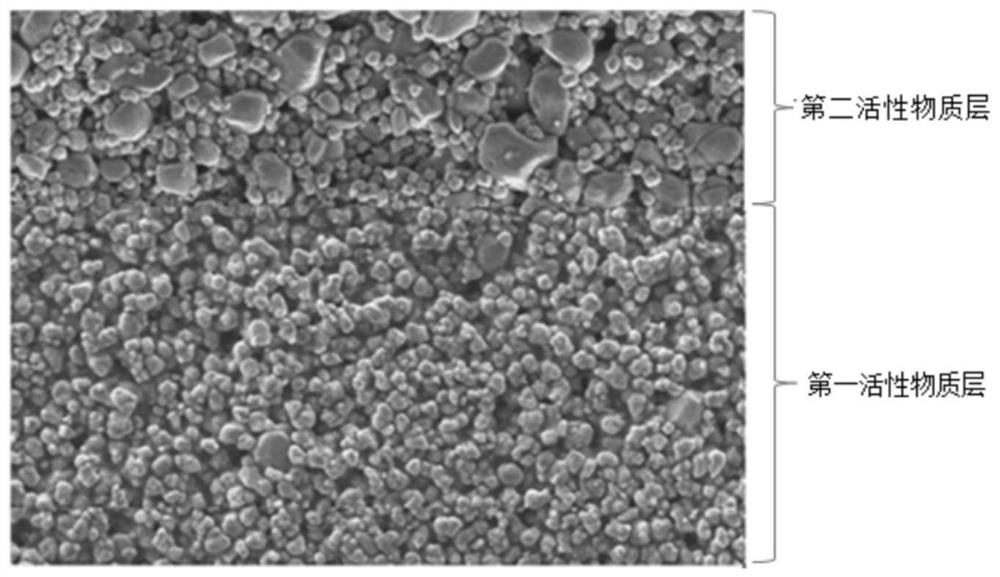

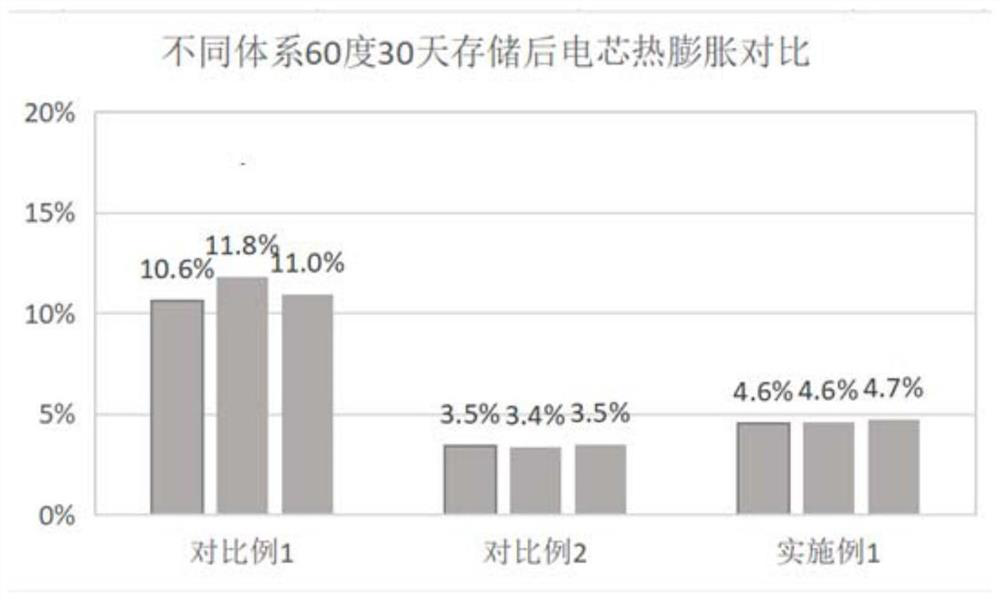

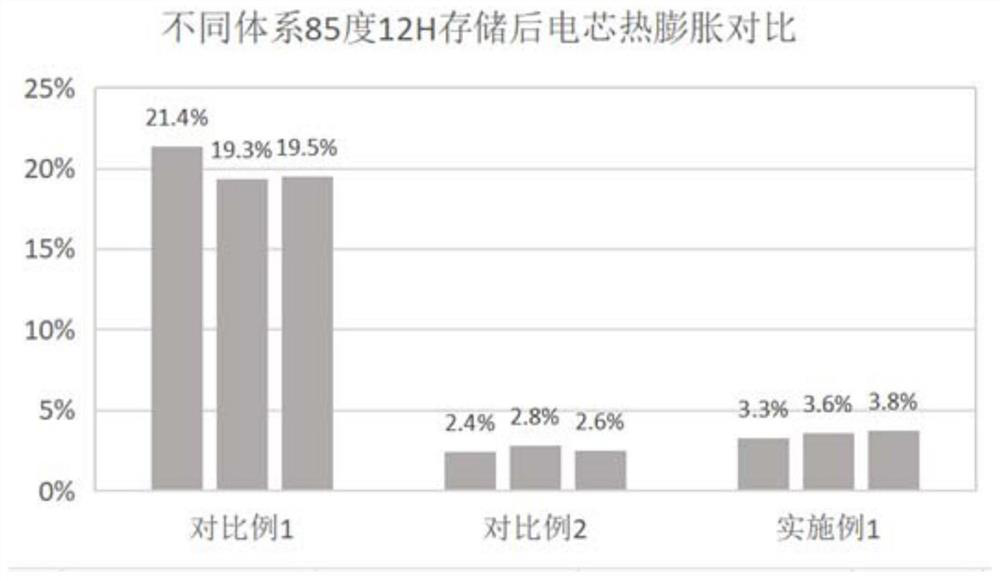

ActiveCN111864179ALower impedanceImprove high temperature stabilitySecondary cellsPositive electrodesPhysical chemistryPole piece

The invention provides a positive pole piece and a preparation method thereof, a lithium ion battery containing the positive pole piece and application of the lithium ion battery. The positive pole piece comprises a current collector, a first active substance layer and a second active substance layer which are sequentially stacked, and lithium cobalt oxide particles in the second active substancelayer comprise lithium cobalt oxide particles with first particle sizes and lithium cobalt oxide particles with second particle sizes, wherein the D50 of the lithium cobalt oxide particles with the first particle size is 5-8 [mu]m; and the D50 of the lithium cobalt oxide particles with the second particle size is 12 [mu]m-16 [mu]m. By adopting the structure, the high-temperature storage performance and the power performance after high-temperature storage of the battery are greatly improved while the power performance of the battery is not lost, and the power performance and the high-temperature storage performance of the unmanned aerial vehicle battery are well considered.

Owner:东莞维科电池有限公司

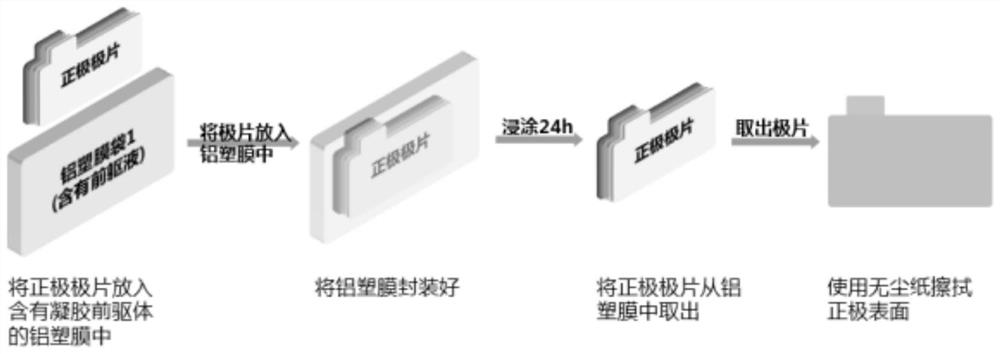

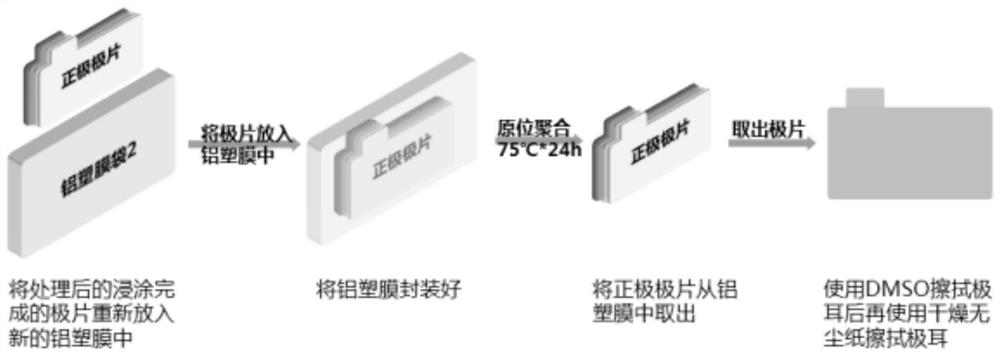

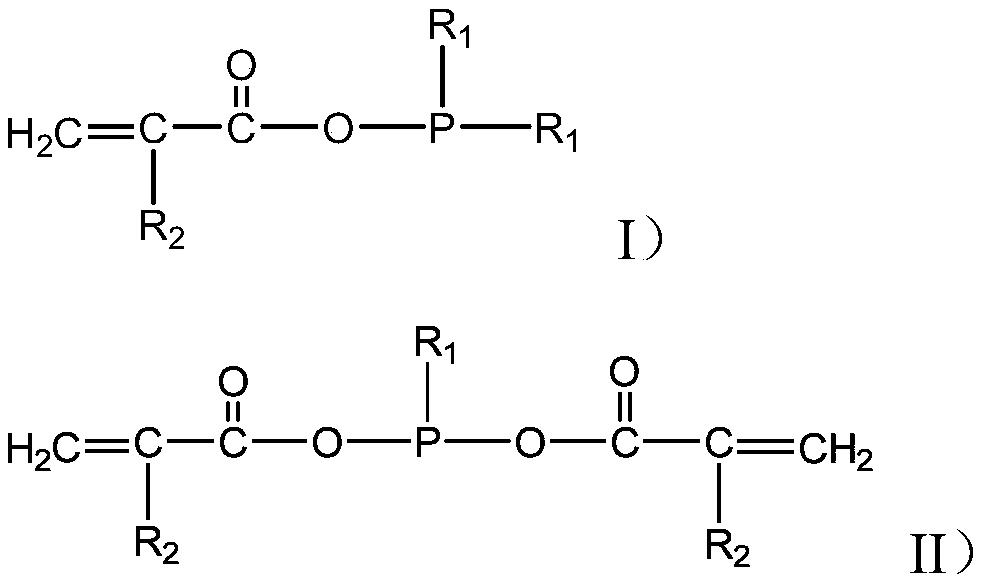

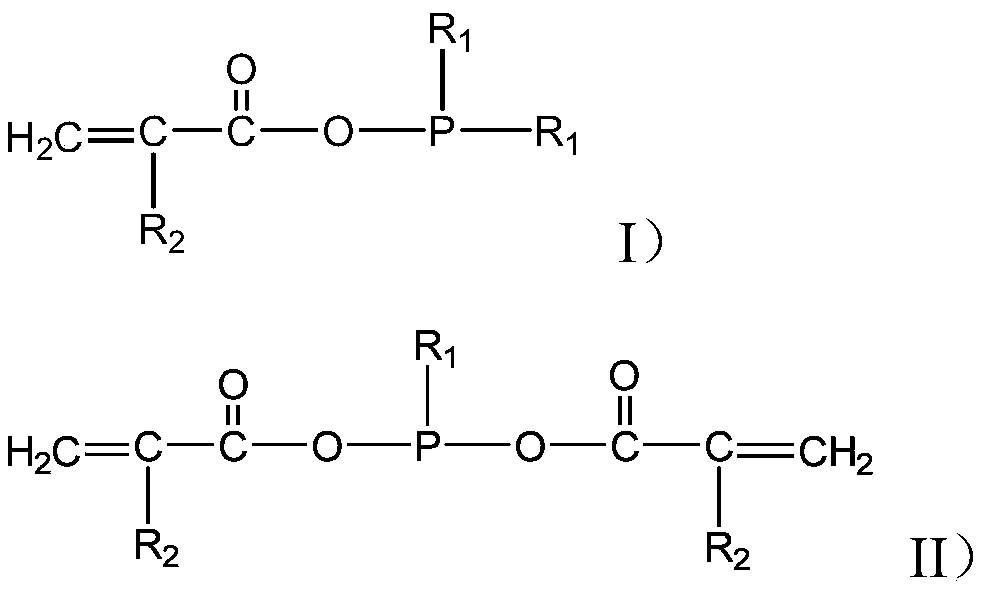

Gel electrolyte precursor and application thereof

ActiveCN112133961AImprove securityReduce decreaseSolid electrolytesCell electrodesElectrolytic agentIn situ polymerization

The invention relates to a gel electrolyte precursor and application thereof. The gel electrolyte precursor comprises a gel skeleton monomer, a flexible additive, a polymerization initiator and a lithium salt. The gel skeleton monomer comprises an acrylonitrile monomer. An elastic porous gel electrolyte can be obtained by mixing the gel electrolyte precursor with an electrolyte, and carrying out in-situ polymerization gelatinization and baking. A semi-solid battery assembled by the gel electrolyte can absorb electrolyte in the battery and reduce the existence of free electrolyte in the battery, and meanwhile, the absorbed electrolyte and the elastic porous state gel electrolyte form a new gel electrolyte, so that the electrolyte is ensured to have high conductivity, and the electrical property of the battery is ensured; and meanwhile, the use amount of the electrolyte is reduced, and an acrylonitrile polymer formed by the acrylonitrile monomer in the in-situ polymerization and gelatinization process has good flame retardant property and high voltage resistance, so that the purpose of improving the safety performance of the battery is achieved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

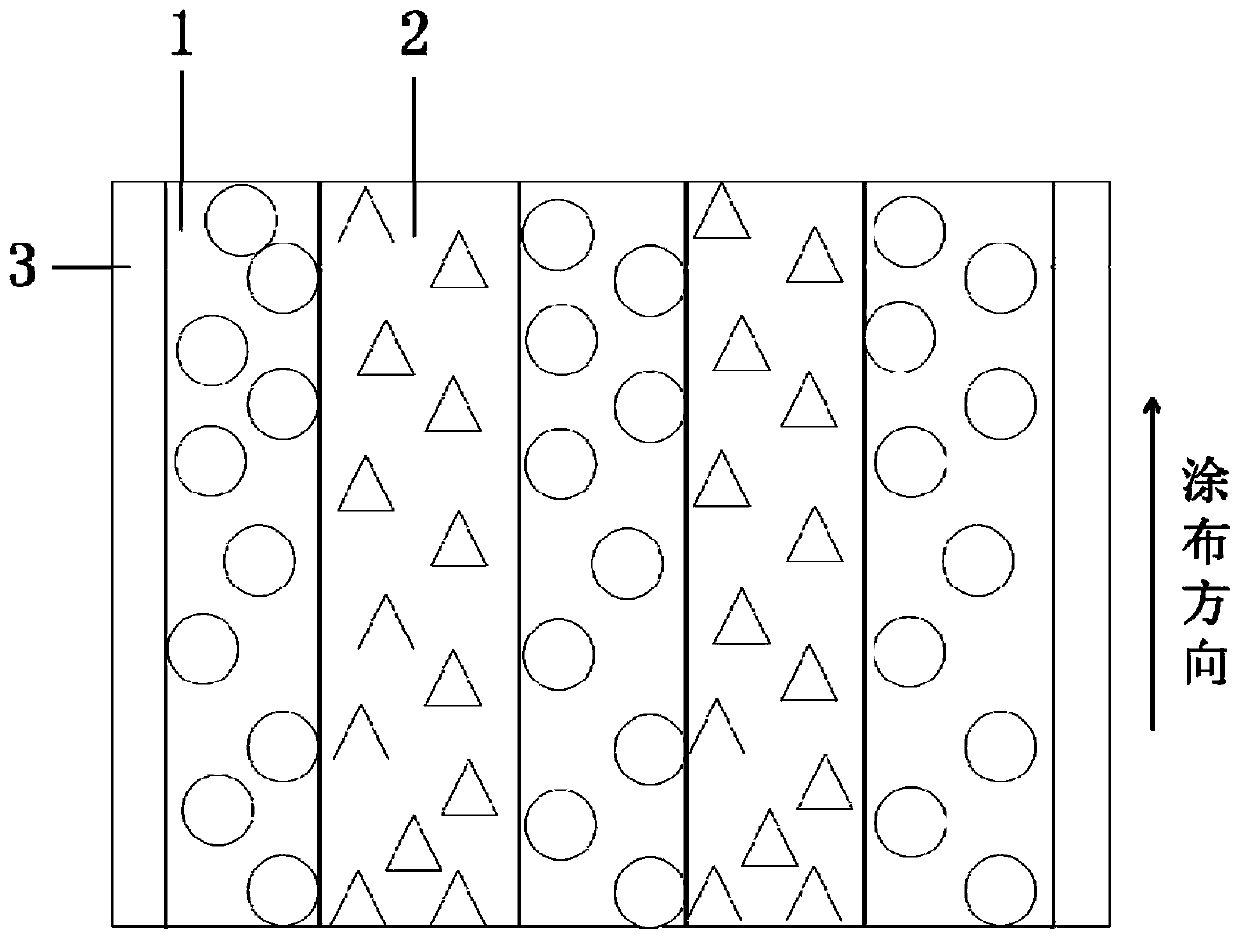

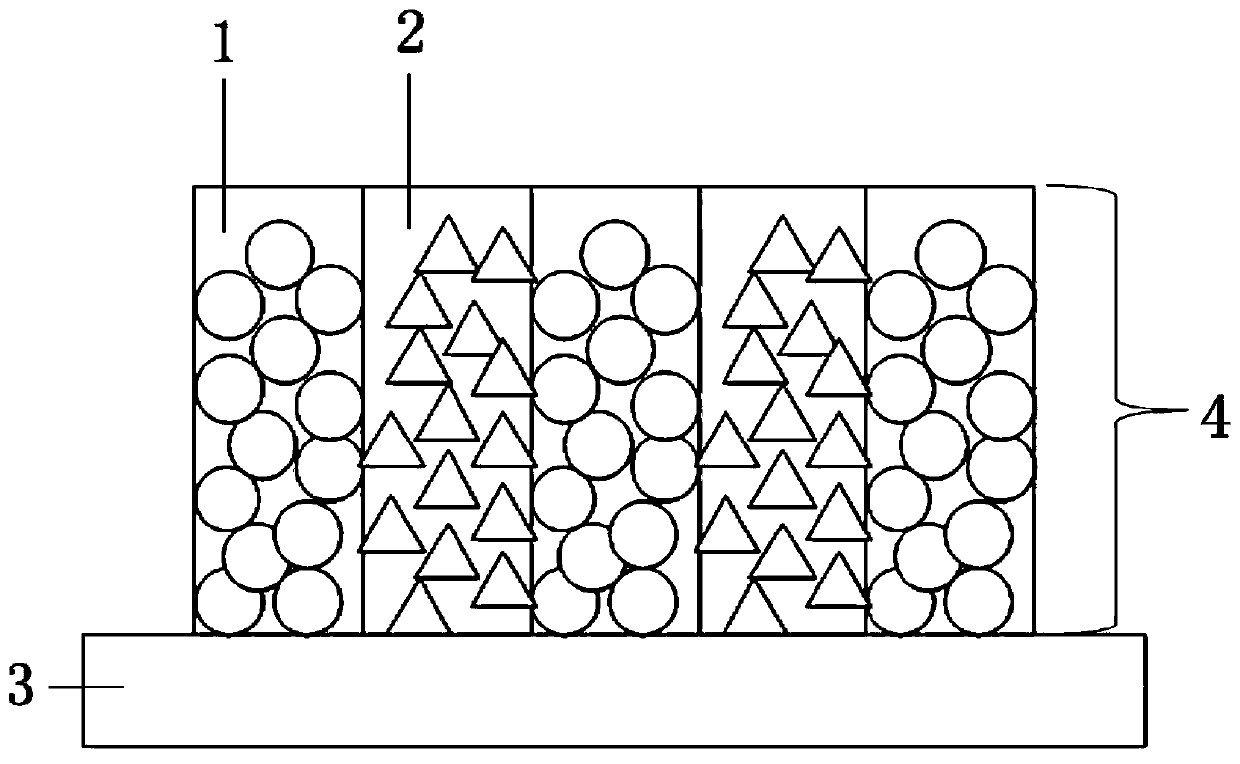

Negative pole piece of lithium ion battery, preparation method of negative plate and lithium ion battery

PendingCN110233240AEasy to prepareIncrease production capacityNegative electrodesSecondary cellsAluminium-ion batteryElectrical battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a negative pole piece of a lithium ion battery. The negative pole piece of the lithium ion battery comprises a negative current collector and a negative material layer arranged on the negative current collector, wherein the negative electrode material layer is composed of carbon material strips and silicon-based material strips which are sequentially and alternately distributed from left to right, namely, the carbon material strip-the silicon-based material strip-the carbon material strip-the silicon-based material strip-the carbon material strip. According to the negative pole piece of the lithium ion battery, the energy density of the battery is effectively improved, and the battery has excellent capacity retention rate and rate performance in the cycling process.

Owner:SHENZHEN UTILITY POWER SOURCE CO LTD

Adaptive variable length decoding method

InactiveUS20050008238A1Guaranteed rate performanceCode conversionCharacter and pattern recognitionDecoding methodsHardware architecture

A method is disclosed for decoding multiple-coded symbols from a coded input symbol stream in a single clock cycle. The method constructs an original Huffman look-up table by extending the associated Huffman tree to decode multiple symbols in one clock cycle in a first embodiment and decodes multiple DCT coefficient symbols in an alternate embodiment. An advantage of the method is that the depth of the new Huffman tree is adjustable thereby making the method easily adaptable to various hardware architectures. A further advantage of the present invention is that the decoding process speed is significantly increased while the size of the lookup table is nominally increased.

Owner:WSOU INVESTMENTS LLC

Composite solid electrolyte membrane, and preparation method and application thereof

PendingCN109818053AImprove flexibilityHigh strengthLi-accumulatorsCyclohexanoneSolid state electrolyte

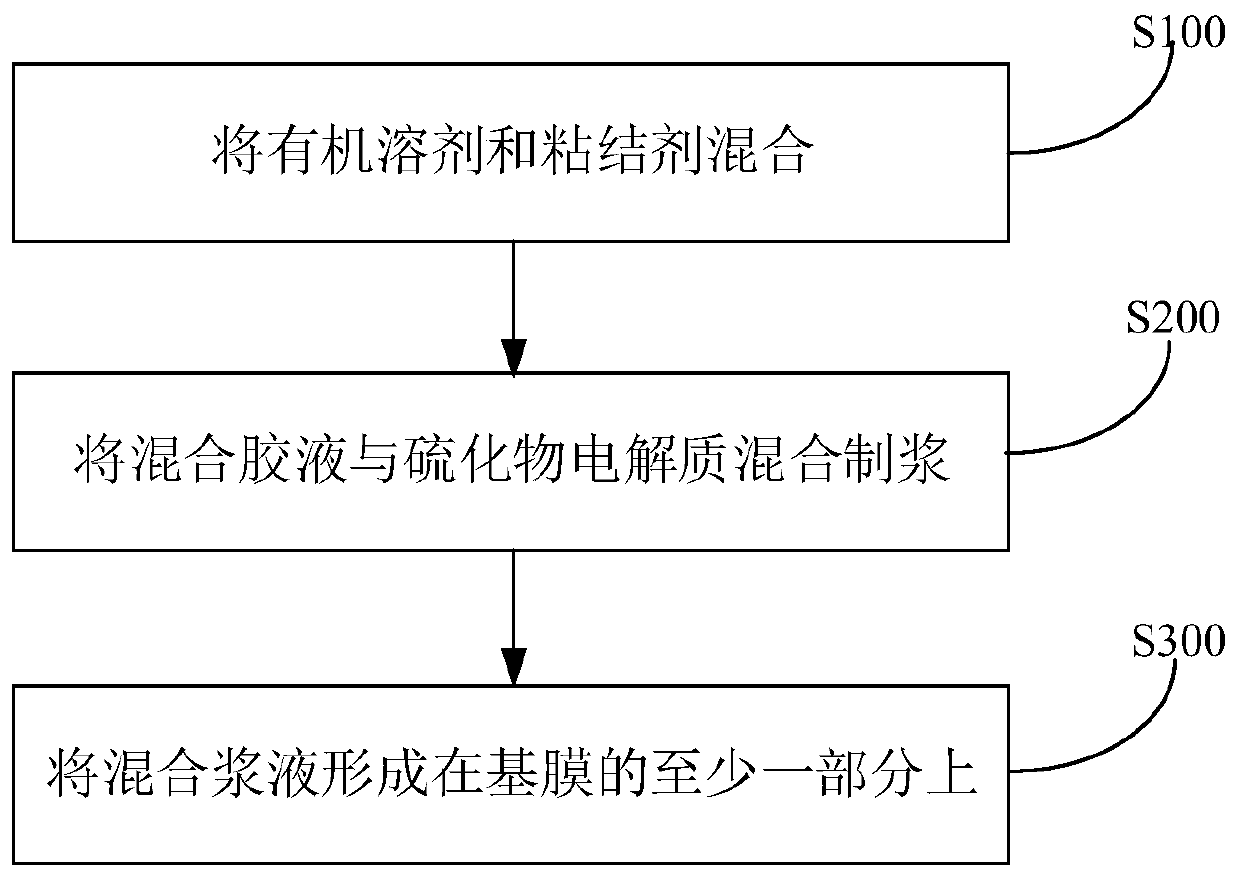

The invention discloses a composite solid electrolyte membrane as well as a preparation method and application thereof. The preparation method of the composite solid electrolyte membrane comprises thefollowing steps: (1) mixing an organic solvent and a binder to obtain a mixed glue solution; (2) mixing the mixed glue solution with sulfide electrolyte to prepare slurry so as to obtain mixed slurry; and (3) forming the mixed slurry on at least one part of the base membrane to obtain the composite solid electrolyte membrane. In the step (1), the organic solvent is selected from at least one of dichloromethane, tetrahydrofuran, n-hexane, n-heptane, methylbenzene, 2,4-dimethyl-3-pentanone, chlorobenzene, xylene, anisole, cyclohexanone, and 1,3,5-trimethylbenzene, n-decane and methyl formamide.The composite solid electrolyte membrane obtained by the method disclosed by the invention has the advantages of good flexibility, high strength, good toughness, high ionic conductivity and good thermal stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of high-safety performance lithium-ion battery

ActiveCN106684436AImprove thermal stabilityHigh mechanical strengthCell electrodesFinal product manufactureEnvironmental resistanceSlurry

The invention discloses a preparation method of a high-safety performance lithium-ion battery. The method comprises the following steps of adopting zinc oxide-coated lithium cobalt oxide as a positive electrode material, mixing the positive electrode material, a conductive agent, a binder and deionized water into slurry and coating a current collector to prepare a positive plate; adopting lithium titanate coated with a mixture of titanium oxide and silicon oxide as a negative electrode material and then mixing the negative electrode material, the binder, the conductive agent and the deionized water into slurry and coating the current collector to prepare a negative plate; adopting a prepared zirconia-reinforced aluminum oxide porous ceramic membrane as the membrane; and finally assembling the lithium-ion battery. The battery prepared by the method is good in high temperature resistance, excellent in cycling stability, high in energy density, safe and environment-friendly.

Owner:湖南聚和源科技有限公司

Five-element lithium ion battery positive electrode material, preparation method and lithium battery prepared from five-element lithium ion battery positive electrode material

ActiveCN111668475AStrong structural stabilityImproved magnification performanceCell electrodesSecondary cellsChemical physicsPhysical chemistry

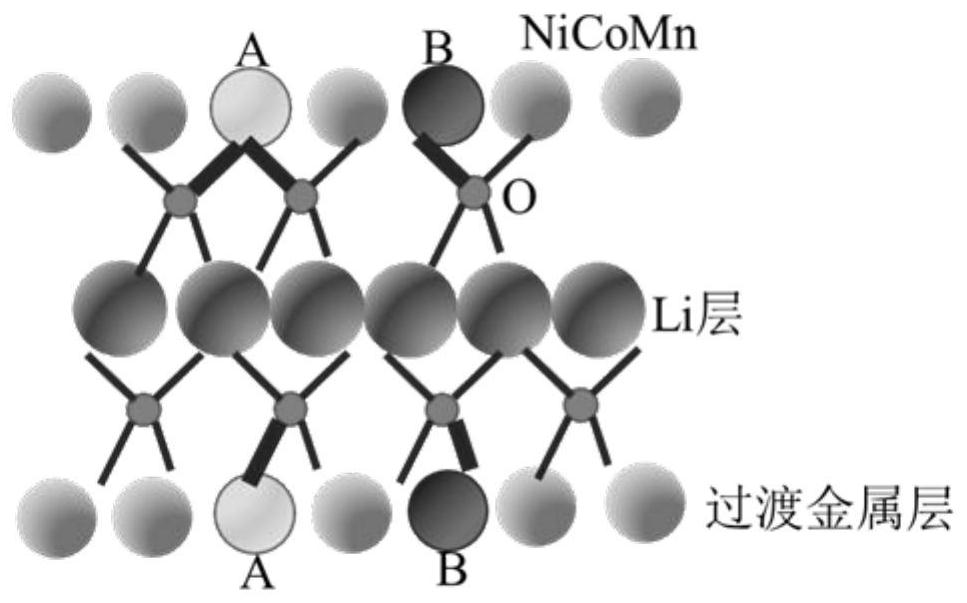

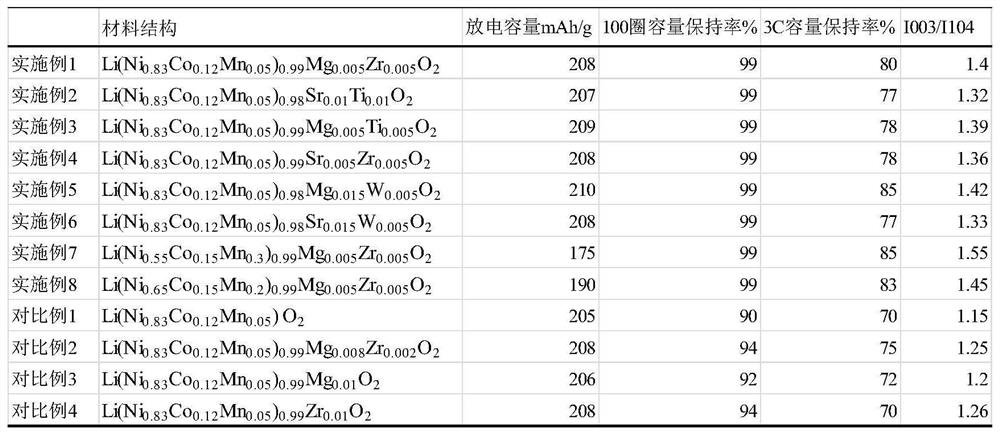

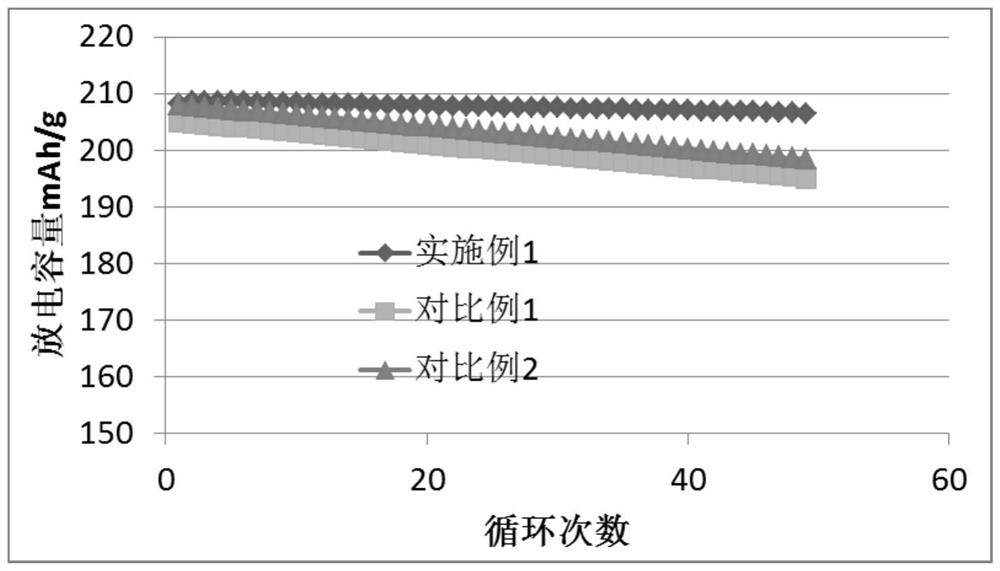

The invention discloses a five-element lithium ion battery positive electrode material with an equivalent valence ratio, high stability and long cycle, a preparation method and a lithium battery prepared from the five-element lithium ion battery positive electrode material. The five-element positive electrode material has the following structure: Li(NiCoMn)xAyBzO2, wherein x is greater than or equal to 0.98, the element A comprises one of Mg and Sr, the element B is one of Zr, Ti and W, and the ratio of the element A to the element B needs to meet the following equation: (3-A valence)*y=(B valence-3)*z, and x+y+z=1. Compared with traditional ternary and other non-equal-proportion system materials, the five-element lithium ion battery positive electrode material has higher structural stability, and the cycle performance is obviously improved; and material defects are few, Li / Ni mixed arrangement is low, and the rate capability is more excellent.

Owner:WANHUA CHEM GRP CO LTD

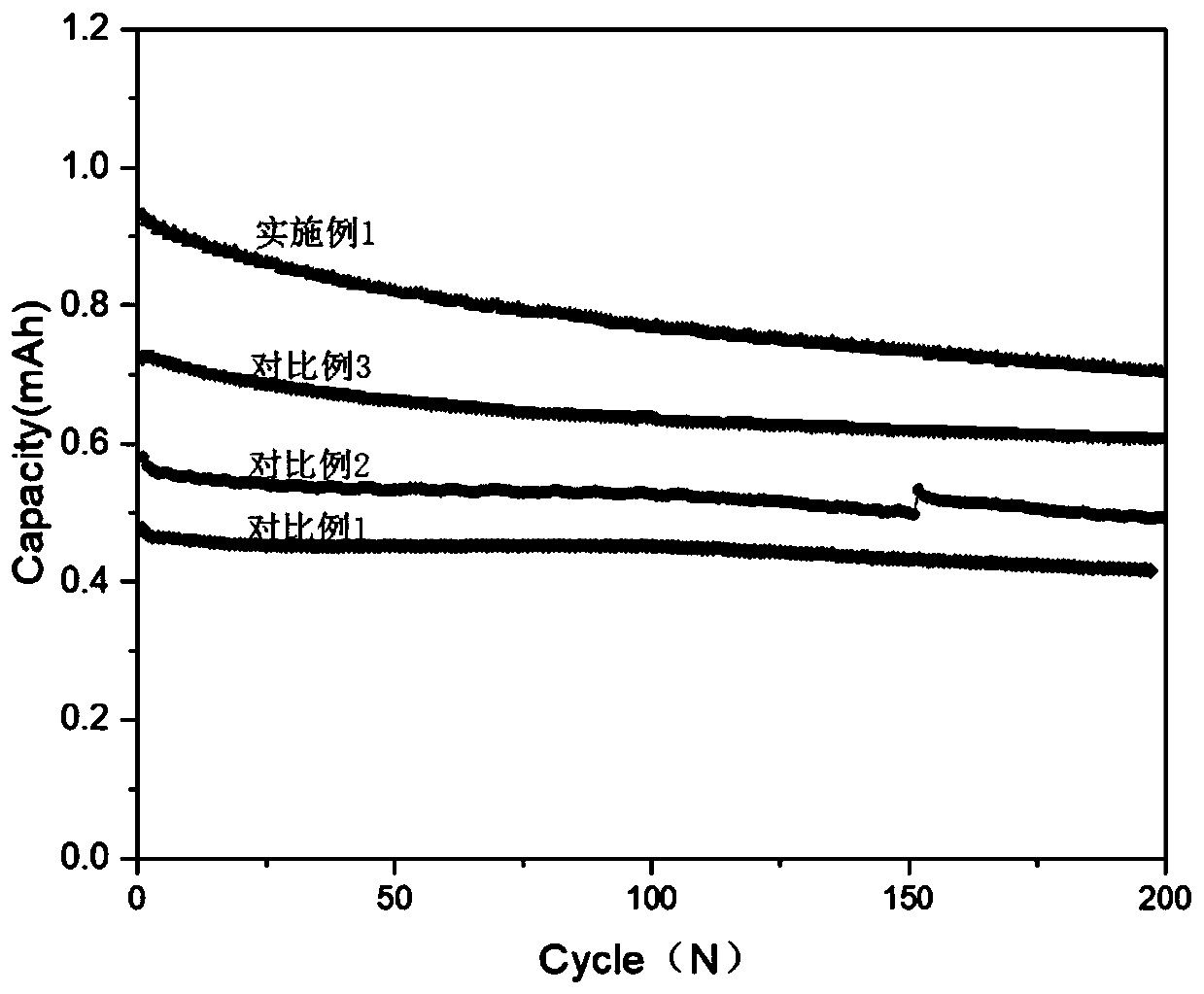

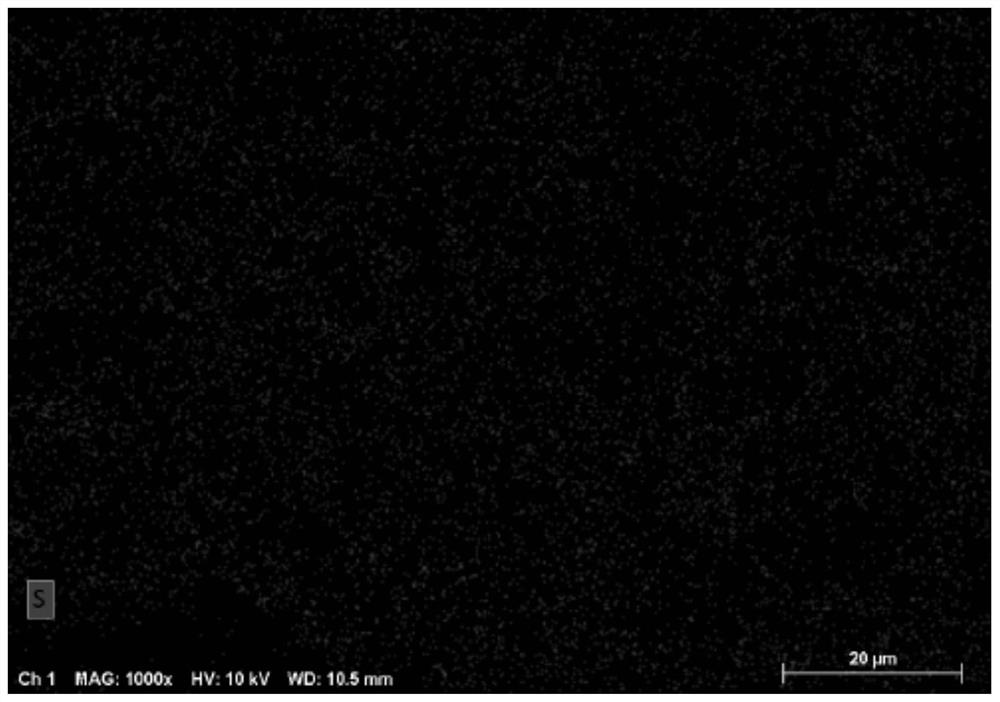

Preparation method of metal-clad S/Ni-Co-Mn-Li oxide electrode material

InactiveCN105304871ASimple processEasy to operatePositive electrodesNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur

The invention relates to a preparation method of a metal-clad S / Ni-Co-Mn-Li oxide electrode material. The metal-coated S / Ni-Co-Mn-Li oxide electrode material is obtained through mechanically milling and mixing S / Ni-Co-Mn-Li oxide and then carrying out metal oxide deposition, diol reduction and drying; the mass of S accounts for 65 to 90 percent of the total mass of the electrode material, the mass of the Ni-Co-Mn-Li oxide accounts for 3 to 20 percent of the total mass of the electrode material, and the mass of clad metal accounts for 7 to 15 percent of the total mass of the electrode material; metal is one or two of Cu, Ag, W and Au; very good specific capacity, excellent multiplying power and excellent circulating performance are obtained when the electrode material is used for a positive electrode of a Li-S battery; the preparation method has a very good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

Electrolyte for over 4.2V high-voltage system battery

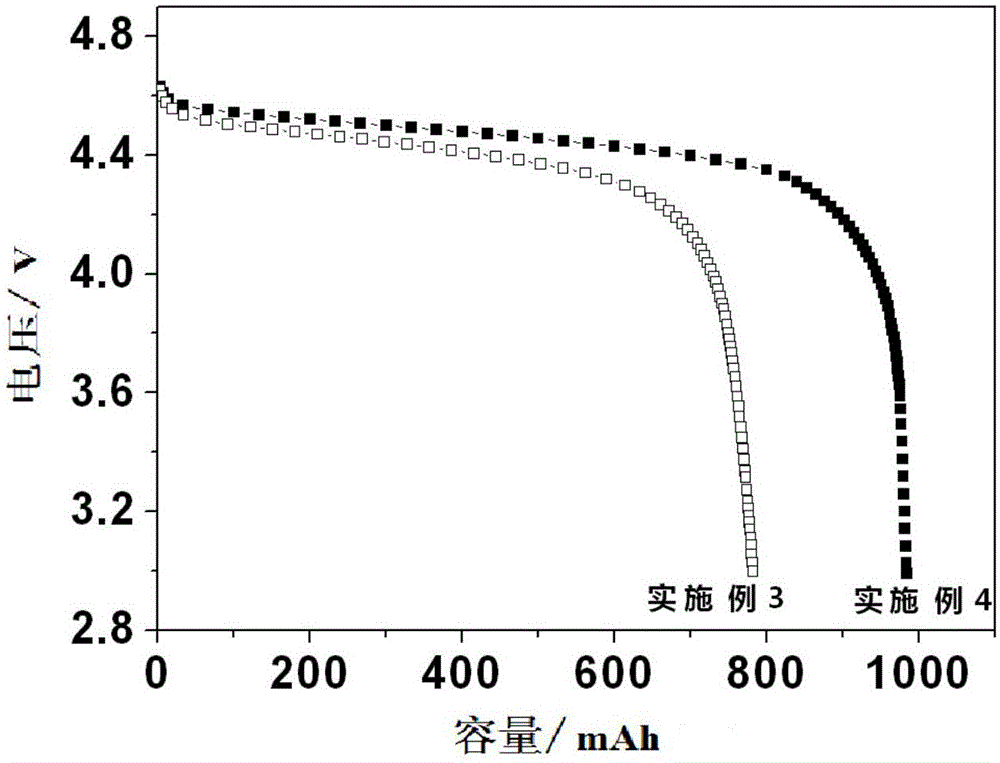

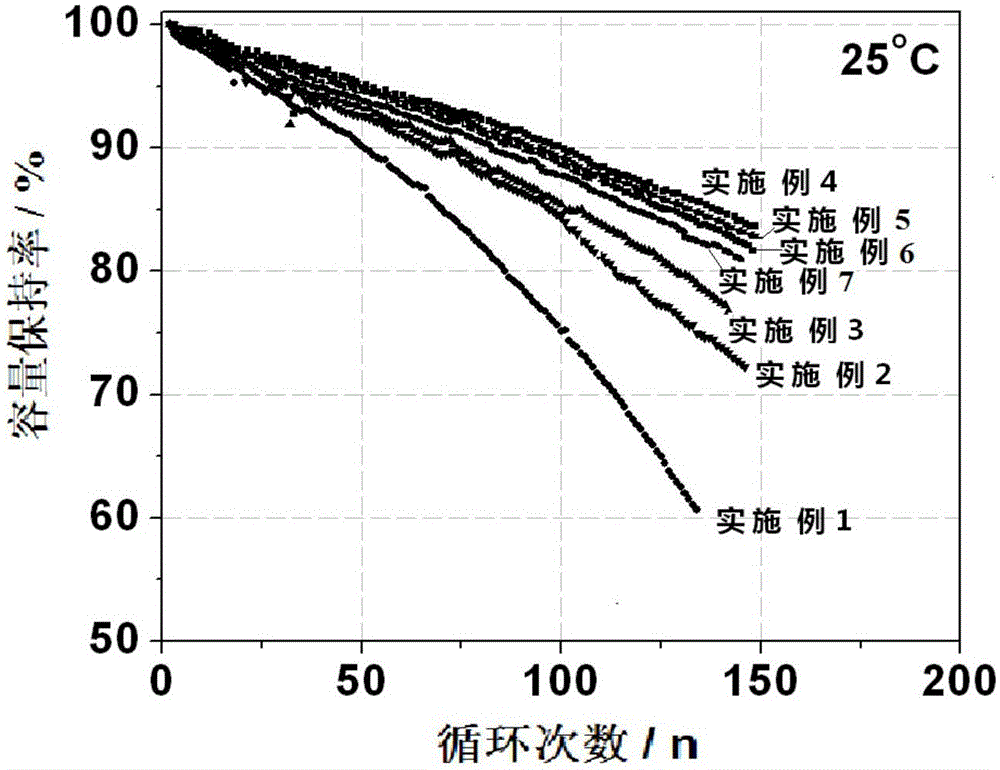

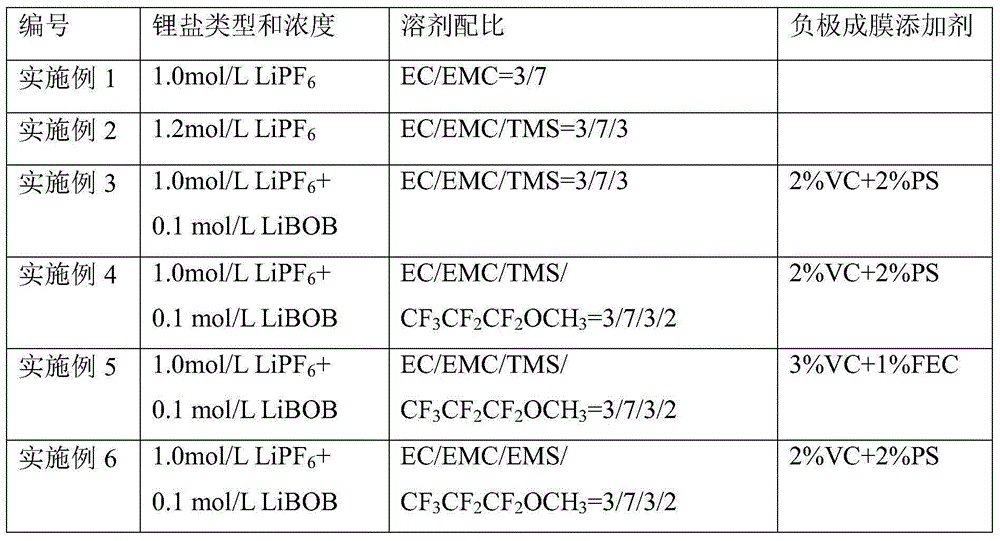

InactiveCN106450449ALow viscosityReduced rate performanceSecondary cellsOrganic electrolytesLithiumOrganic solvent

The invention discloses an electrolyte for an over 4.2V high-voltage system battery. The electrolyte comprises a non-aqueous organic solvent, a lithium salt and a sulfone solvent, wherein the electrolyte is characterized in that an electrolyte system also comprises a fluoroether solvent and a film-forming additive. An oxidative decomposition-resistant window of the electrolyte system can be obviously improved by addition of the sulfone solvent; and the electrolyte can meet use of the over 4.2V high-voltage system battery. However, the viscosity of the electrolyte system is improved by addition of the sulfone solvent, so that the conductivity of the system is reduced. Meanwhile, the performance of the battery is reduced due to the fact that the sulfone solvent cannot easily form a film on a negative electrode, so that the same a fluoroether solvent capable of resisting high-voltage decomposition is introduced into the electrolyte system to reduce the viscosity of the system; the conductivity is ensured within a reasonable range; and the film-forming additive is added, and excellent cycle performance of the high-voltage system battery is ensured.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

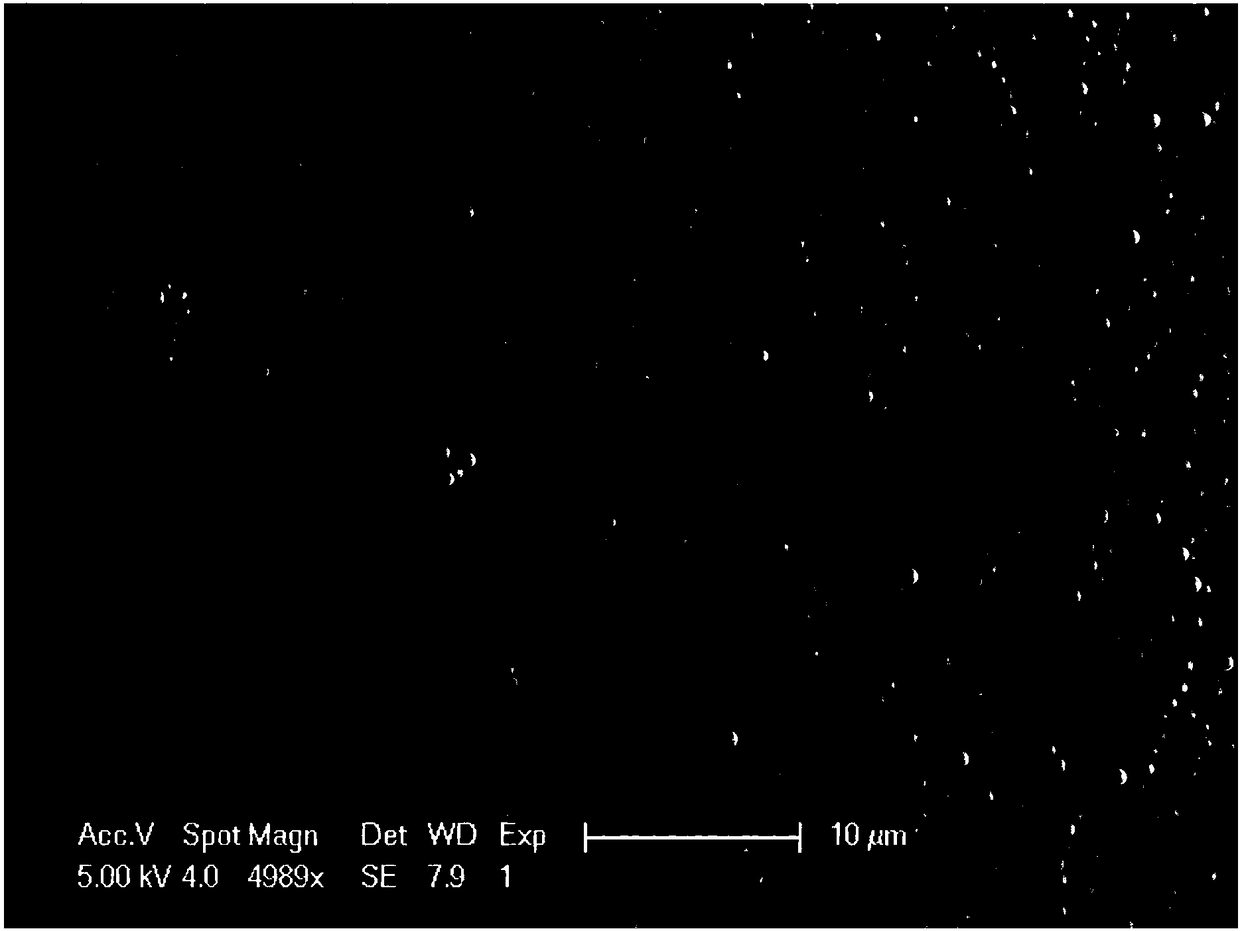

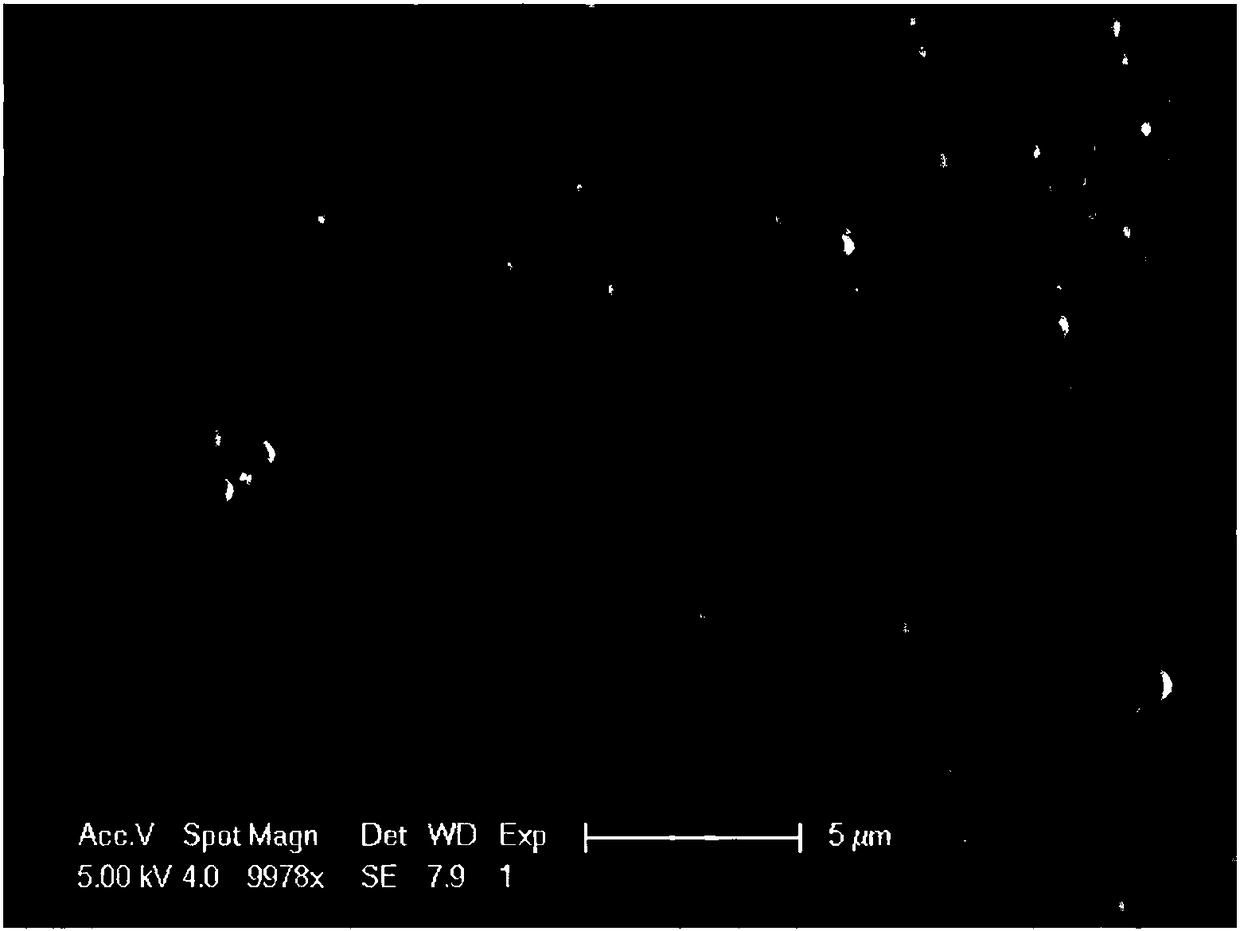

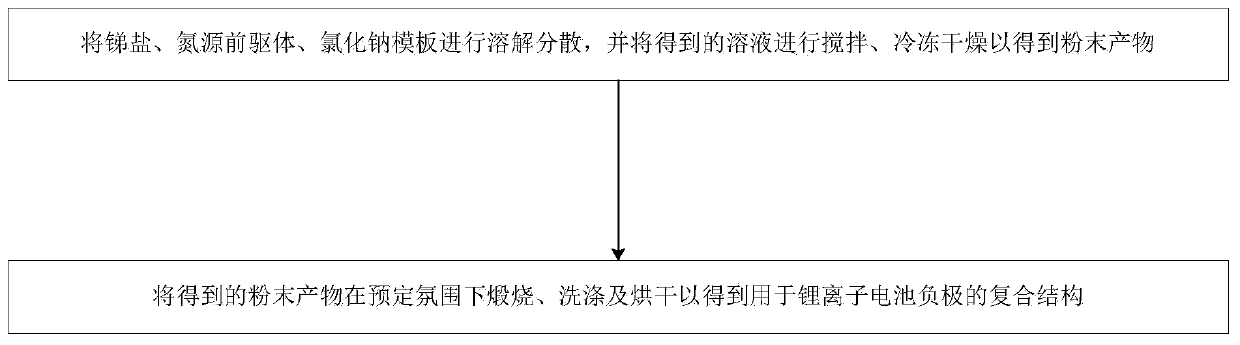

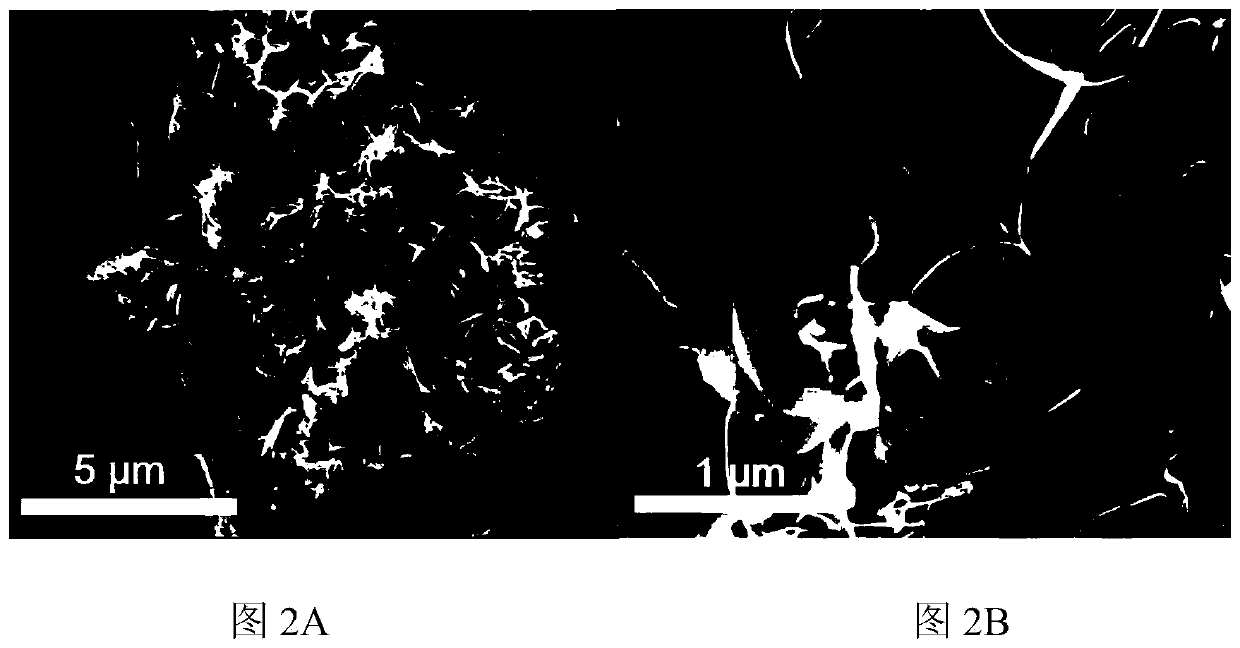

Composite structure for lithium ion battery cathode and preparation method thereof

ActiveCN110061215AGuaranteed stabilityGuaranteed rate performanceMaterial nanotechnologyCell electrodesNanoparticles dispersionNitrogen doped

The invention belongs to lithium ion battery technical field, and discloses a composite structure for lithium ion battery cathode and a preparation method thereof. The composite structure comprises nano particles and carbon nano sheets, wherein the nano particles are dispersed on the carbon nano sheets, and a core-shell structure is provided. The carbon nano sheets are three-dimensional porous nitrogen-doped carbon nano sheets. The nano particles comprise antimony oxide shells and antimony cores disposed in the antimony oxide shells, wherein the antimony cores and the antimony oxide shells arebuffer layers mutually for each other. The antimony cores and the antimony oxide shell layers are buffer layers, and are cooperated with lithium storage to relieve volume expansion effect. The three-dimensional porous nitrogen-doped carbon nano sheets used as a substrate for loading the nano particles and a conductive framework, so that the stability and the rate capability of the composite structure are further ensured, more lithium storage active sites are provided by nitrogen doping, the conductivity of the composite structure is increased, and the long-cycle stability of the material is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

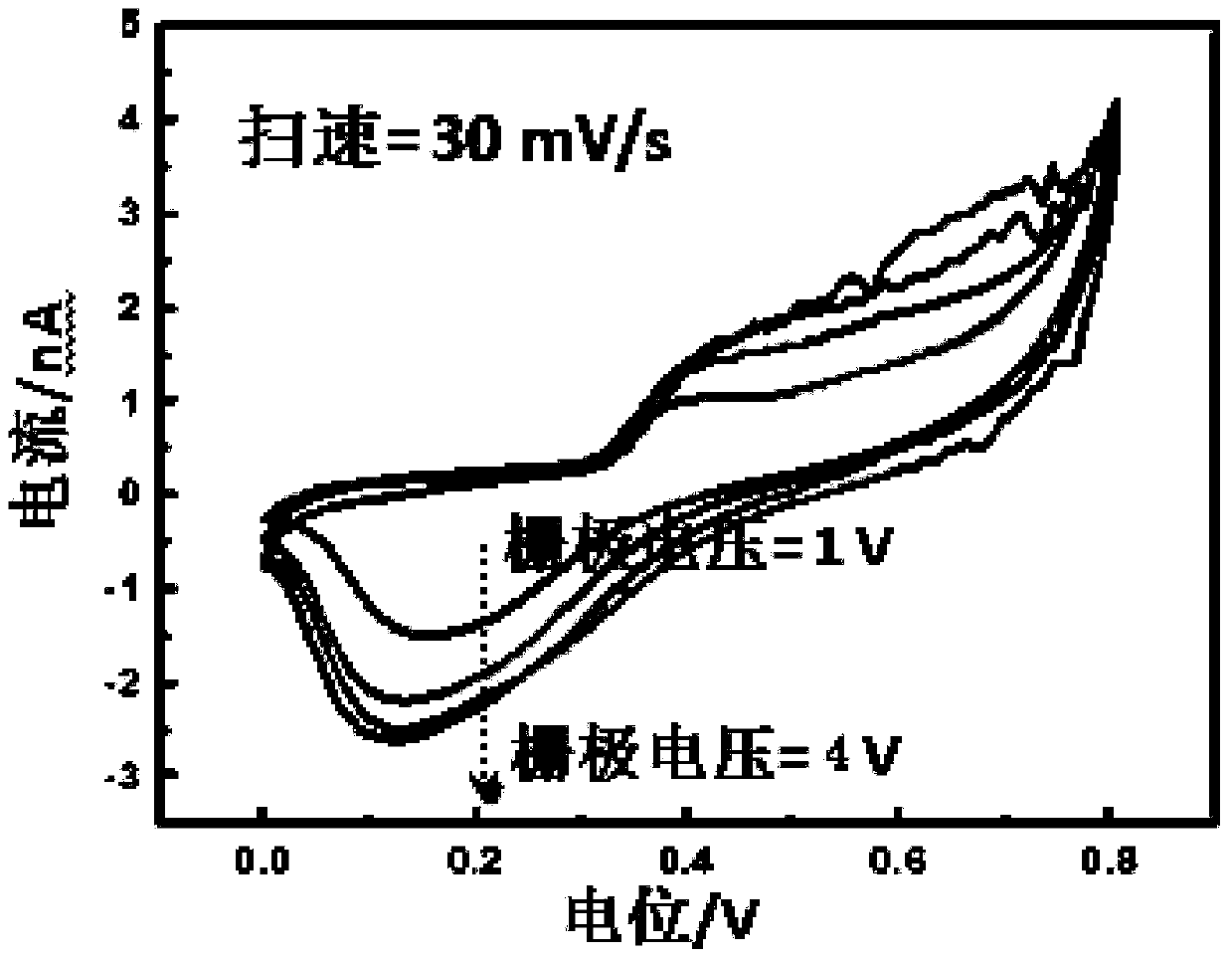

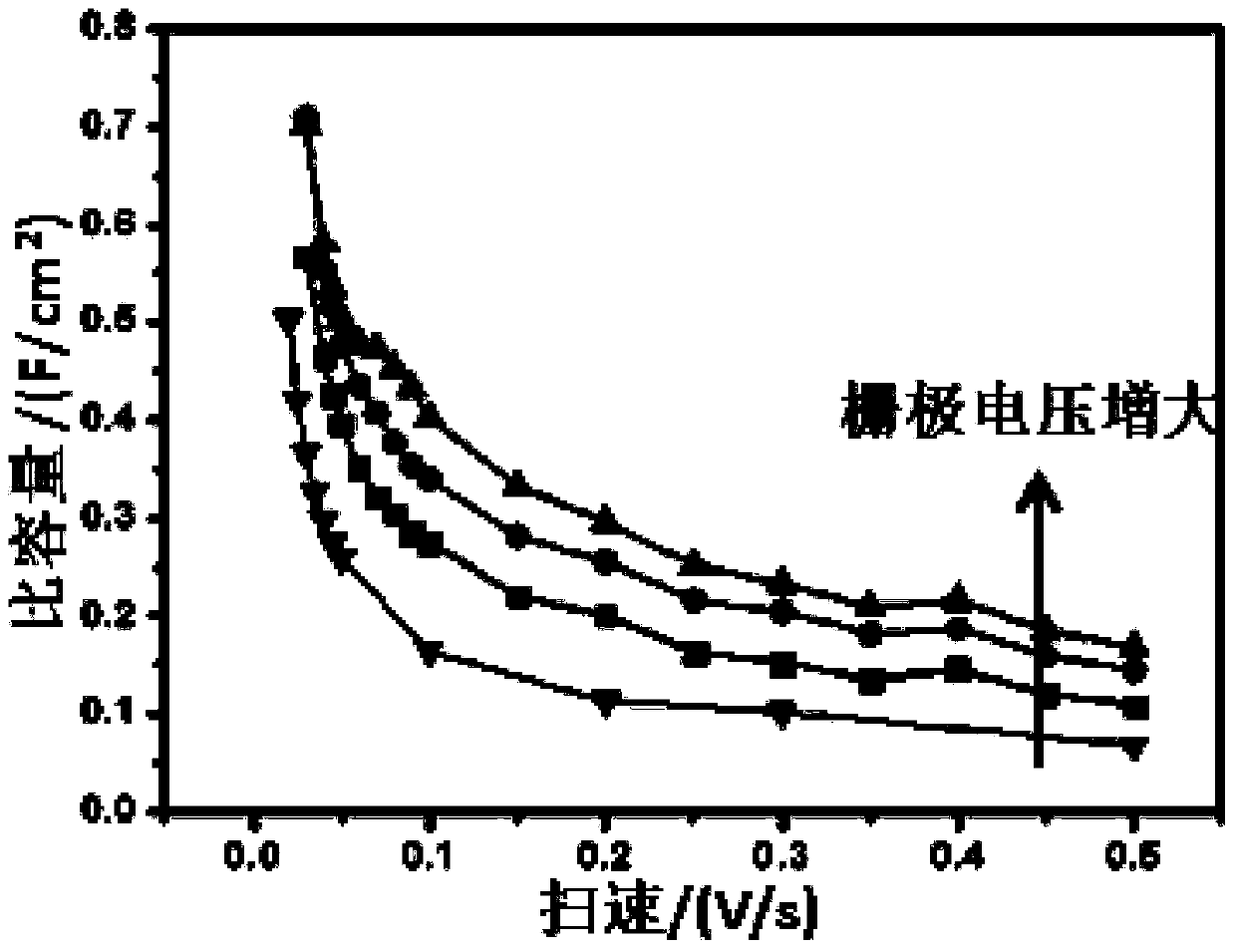

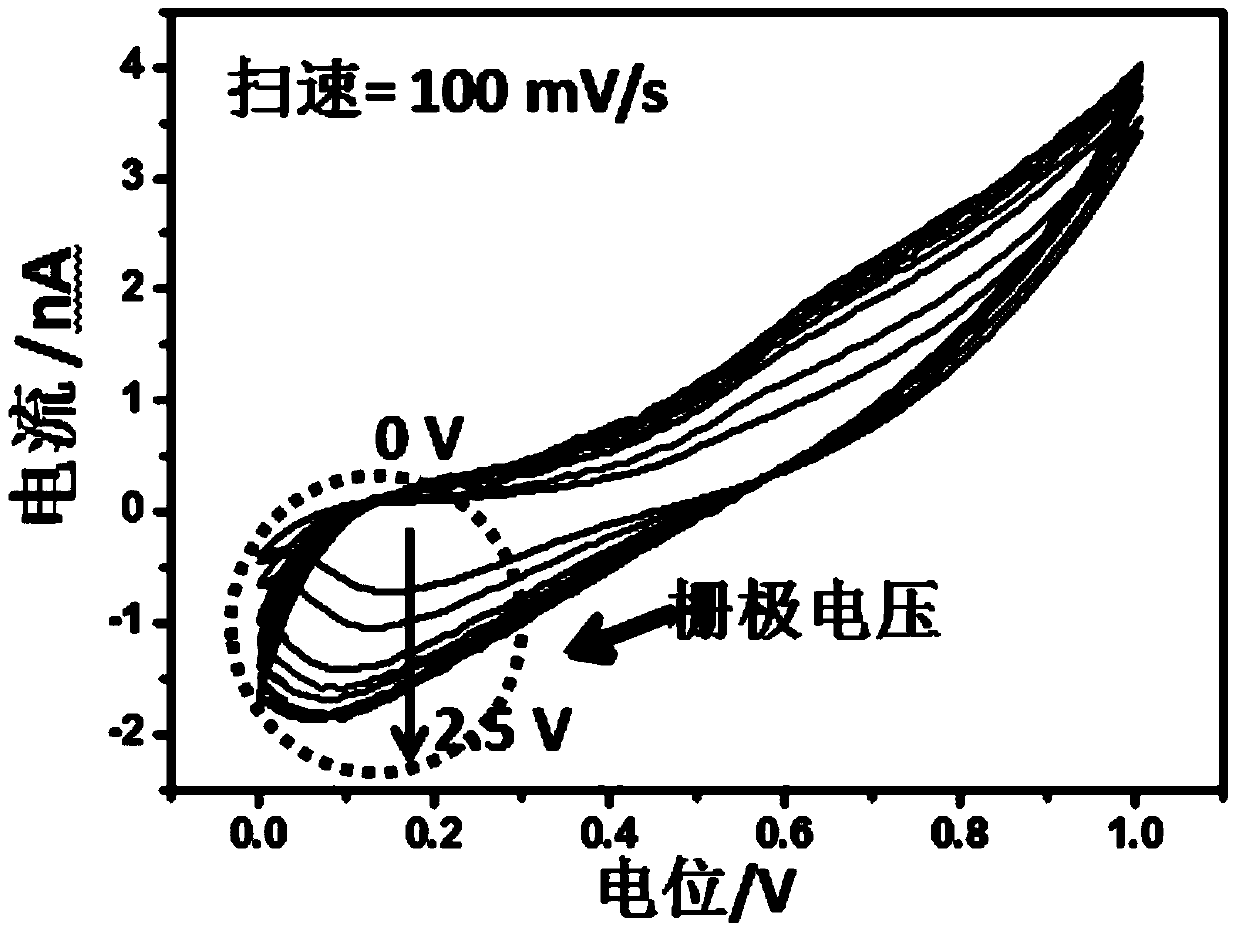

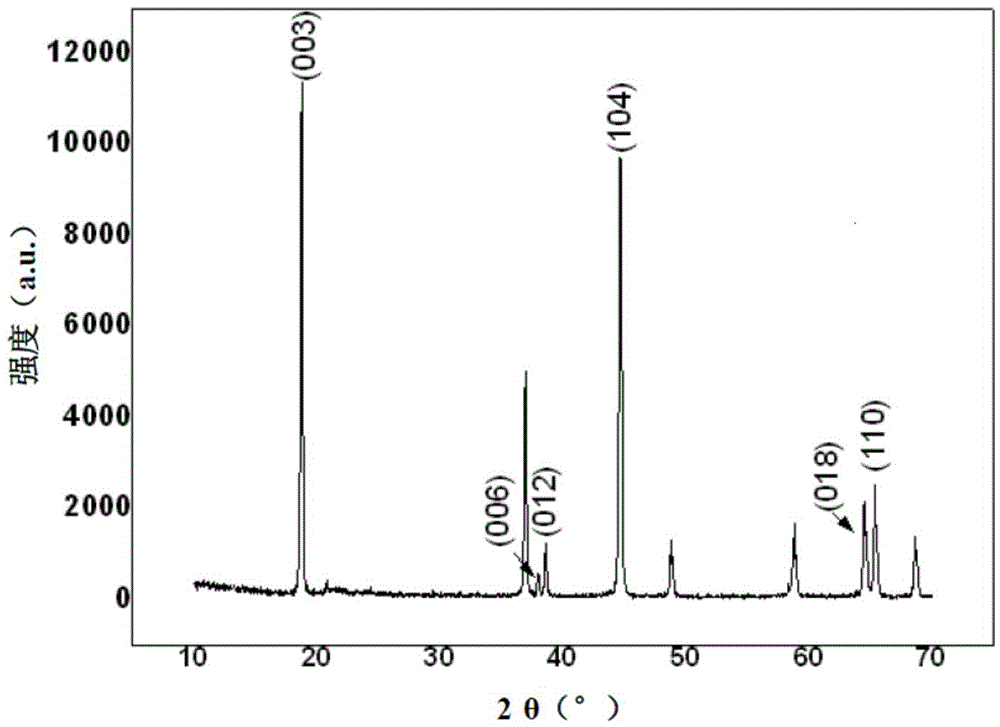

Manufacturing method of field-effect regulated supercapacitor

ActiveCN104217863AIncrease energy densityThe strength of the applied electric field is easy to adjustHybrid/EDL manufactureResistSupercapacitor

The invention discloses a manufacturing method of a field-effect regulated supercapacitor. The manufacturing method includes the steps of depositing a layer of dielectric material on a substrate; spreading electrode material on the dielectric material; coating the dielectric material and trenches with resist to obtain a source, a drain and an electrode of the supercapacitor; coating the source and the drain with photoresist; performing overall packaging with polydimethylsiloxane, and pouring in electrolyte to obtain the field-effect regulated supercapacitor. A concept to increase energy density of the supercapacitor is provided, namely carrier distribution and conductivity of material are changed via additional field effect so that an energy storage device is optimized; under regulating action of a gate electric field, the capacity of the supercapacitor is averagely increased by three times to five times, and original rate performance is retained.

Owner:WUHAN UNIV OF TECH

Surface-doped rich lithium cathode material and preparation method thereof

ActiveCN104538622ALess side effectsGuaranteed rate performanceCell electrodesElectrolytic agentPhysical chemistry

The invention relates to a surface-doped rich lithium cathode material and a preparation method thereof. The xLi2MnO3. (1-x)Li(Ni0.5Mn0.5)O2 is used as a matrix, the surface layer of the matrix is doped with Rh3+, and the surface layer doped with the Rh3+ can be represented by xLi2MnO3. (1-x)LiNinMnmRh1-m-n O2, wherein 0<x<1, 0<n<=0.5, and m<=0.5. By adopting the surface doping mode, the side reaction between a cathode material and electrolyte is lowered, and therefore the rate capacity of the cathode material is guaranteed, and the cycle performance of the cathode material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Electrolyte raw material composition, electrolyte, lithium ion secondary battery and preparation method thereof

ActiveCN111430780AGuaranteed cycle performanceGuaranteed rate performanceSecondary cellsOrganic electrolytesElectrolytic agentOrganic Ester

The invention provides a gel electrolyte raw material composition for a lithium ion battery. The composition comprises a non-aqueous organic solvent, an electrolyte lithium salt, an additive inorganicacid organic ester and / or nitrile and acrylate. The invention provides a gel electrolyte for the lithium ion battery. The electrolyte is obtained by mixing the composition provided by the invention with a thermal initiator and then carrying ouit polymerizing. The invention provides the lithium ion secondary battery and a preparation method thereof; and the battery comprises a pole core and an electrolyte, wherein the pole core and the electrolyte are sealed in a battery housing, the pole core comprises a positive plate, a negative plate and a diaphragm, and the electrolyte is the electrolyteprovided by the invention. The gel electrolyte provided by the invention can greatly improve the safety and durability of the lithium ion battery.

Owner:FARASIS TECH (GANZHOU) CO LTD

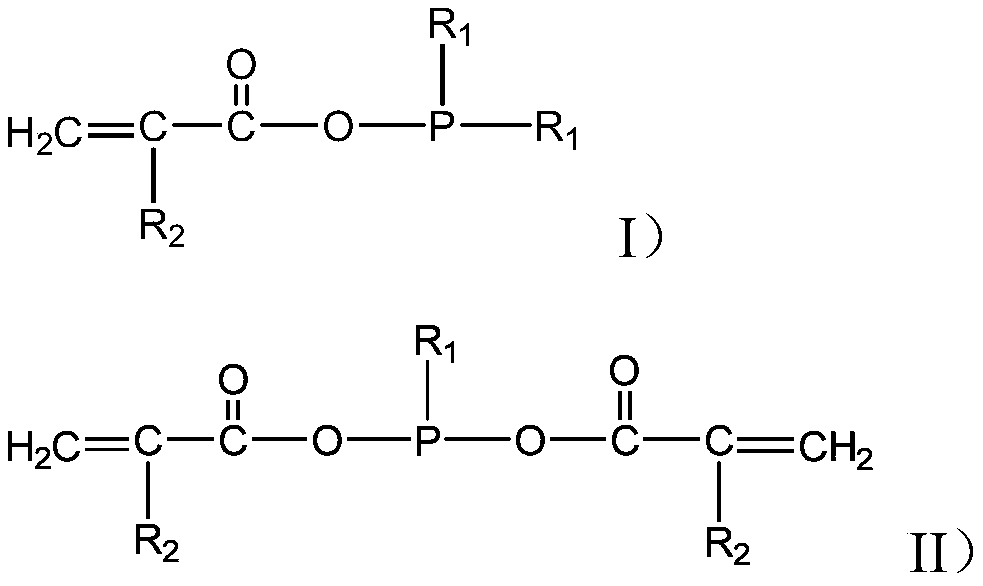

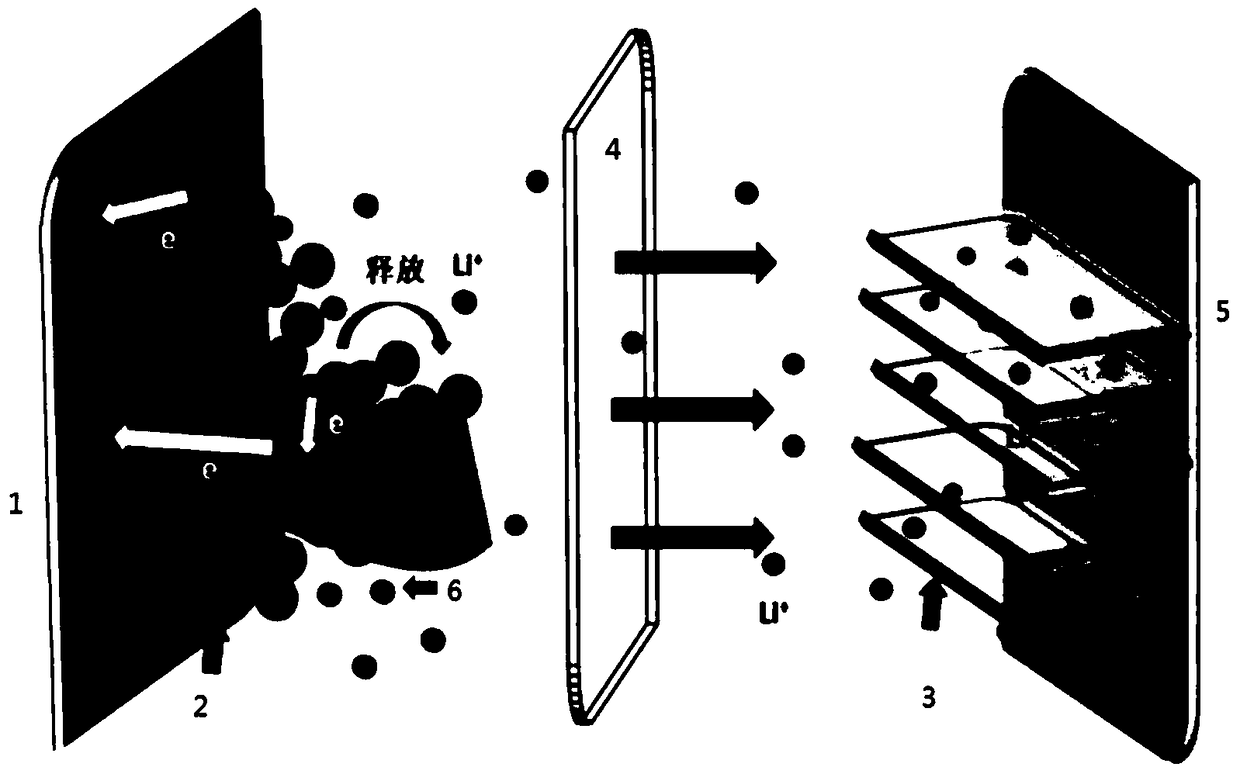

A lithium ion battery and a preparation method thereof

InactiveCN109088059AHigh electron mobilityReduce bloatFinal product manufactureCell electrodesHigh rateElectrical battery

A fast charge and highly stable lithium ion battery is provided. As the positive electrode of the battery uses reduced graphene (rGO) with high conductivity and high specific surface area as conductive material, the system has excellent electron mobility; LiFePO4 with high structural stability is used as active material, so the space structure of the positive electrode material does not collapse even under the condition of high rate charging; the negative electrode active material adopts the carbon material with high-layer spacing, which ensures that lithium ions can be rapidly intercalated and desintercalated under the condition of high rate charge and discharge and the expansion between the material layer is reduced during the lithium ion entering and leaving process. The use of the positive electrode and the negative electrode makes the battery cycle performance improved, the service life is prolonged, and the lithium ion battery can be charged quickly in a few minutes; the servicecharacteristic of the lithium ion battery with fast and long effect is realized, and the problem that the charging speed of the lithium ion battery is too slow and the cycle life is short in the priorart is solved.

Owner:桑顿新能源科技(长沙)有限公司

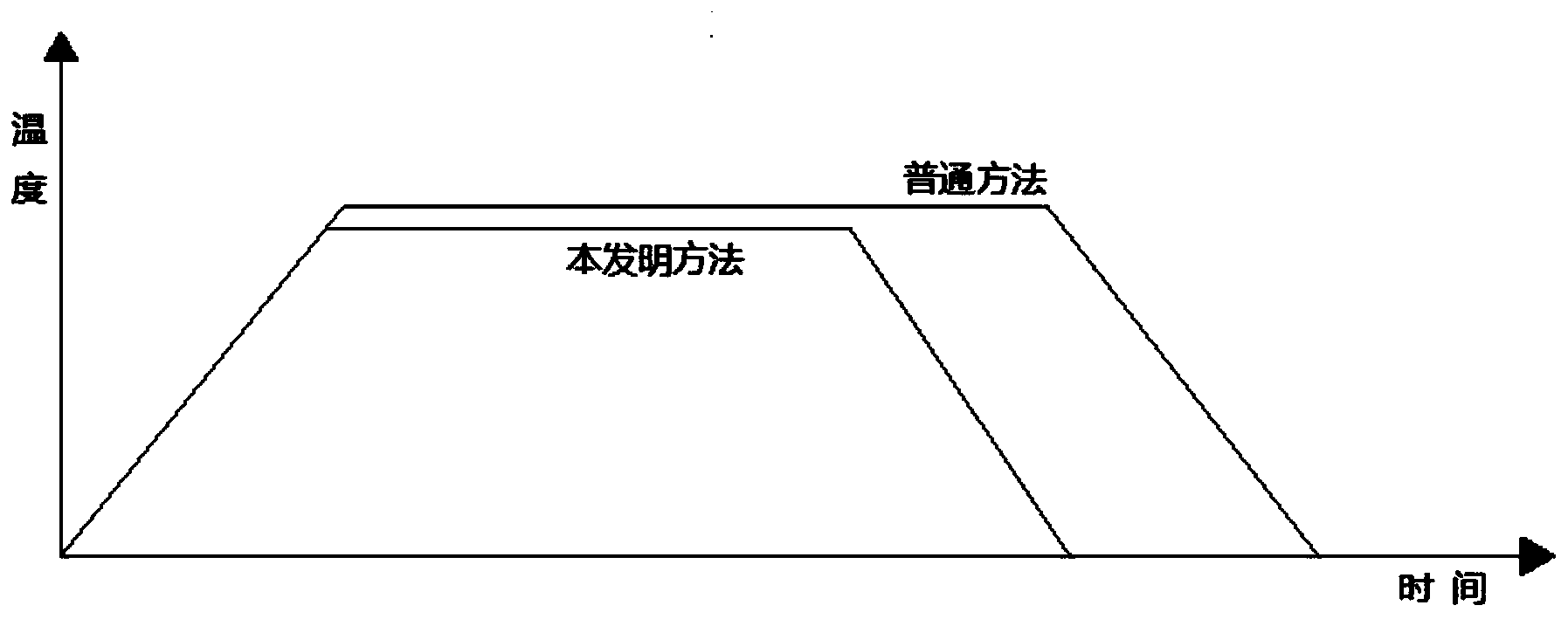

Formation method for prolonging storage time of lithium ion battery

ActiveCN109786875AReduce self-discharge phenomenonExtended storage lifeFinal product manufactureSecondary cells charging/dischargingLithium iron phosphateMass ratio

The invention provides a formation method for prolonging storage time of a lithium ion battery. A positive active material in the lithium ion battery is mainly composed of lithium iron phosphate; an electrolyte of the lithium ion battery comprises an additive composed of fluoroethylene carbonate (FEC) and NaF, wherein the FEC accounts for 0.5-1.5% of the electrolyte and the NAF accounts for 0.001-0.02% of the electrolyte according to the total mass ratio of the electrolyte. According to the formation method, a current, a voltage and formation time are controlled to form a stable SEI film, so that the battery performance deterioration caused by over-discharge due to self-discharge in a storage process of the battery is avoided.

Owner:HANGZHOU DOLAY ELECTRONICS TECH +1

Method for determining infiltration state of lithium ion battery electrolyte

InactiveCN110148793AGuaranteed cycleGuaranteed rate performanceFinal product manufactureSurface/boundary effectPhysical chemistryPole piece

The invention discloses a method for determining infiltration state of a lithium ion battery electrolyte. The method comprises the steps of: (1) preparing a colored impregnating compound, adding the colored impregnating compound into an electrolyte, and performing uniform mixing to obtain the colored electrolyte; and (2) injecting the colored electrolyte into a battery to dismount the battery while completing primary electrolyte injection, formation and secondary electrolyte injection, determining the infiltration state of the electrolyte by determining whether the color region distribution ona diaphragm and a pole piece is uniform or not to regulate the primary electrolyte injection amount, the second electrolyte injection amount and the formation process. Compared to a traditional method, the method has the advantages that the electrolyte infiltration state is confirmed by distinguishing the color region distribution on the diaphragm and the pole piece, and the impregnating compoundis not easy to volatilize, so that the electrolyte can be observed carefully for a long time. The method can conveniently, quickly and visually distinguish the electrolyte infiltration state, improves the consistency in the production process of the battery, and ensures the cycle and rate capability of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for producing lithium manganate

ActiveCN103466714AIncrease contact surfaceEliminate or reduce burning refractoriesCell electrodesManganates/permanganatesElectrolysisAdhesive

The invention provides a method for producing lithium manganate. The method comprises the following steps of: mixing electrolytic manganese dioxide and a lithium-containing compound by adopting a dry method, wherein a molar ratio of Mn:Li is 2:1.08; heating the mixed raw materials to the temperature of 550-650 DEG C, and keeping the temperature for 1-2 hours; adding an adhesive into the pre-sintered materials, pressing the materials into blocks by using a roller press, cutting the blocks into the required size according to the size of a burning plate, thus obtaining material blocks to be burned; stacking the blocks on the burning plate, sintering the blocks in a calcining kiln, wherein the sintering temperature is 750-850 DEG C; keeping the temperature for 3-5 hours, naturally reducing the temperature, and finishing the sintering process; and finally, crushing the blocks by adopting a rolling machine, thus obtaining a finished product. The lithium manganate material is pressed and sintered, relevant parameters in the preparation process are optimized, the sintering time of the lithium manganate is shortened, lithium volatilization in the sintering process is reduced, the resources and material cost are saved, and the yield is increased.

Owner:WUXI JEWEL POWER & MATERIALS

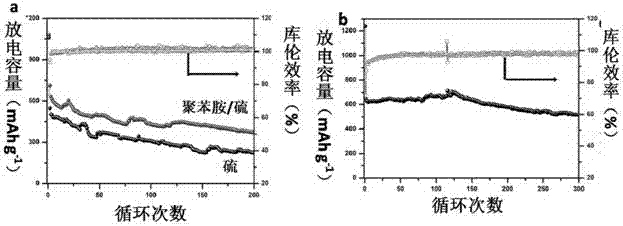

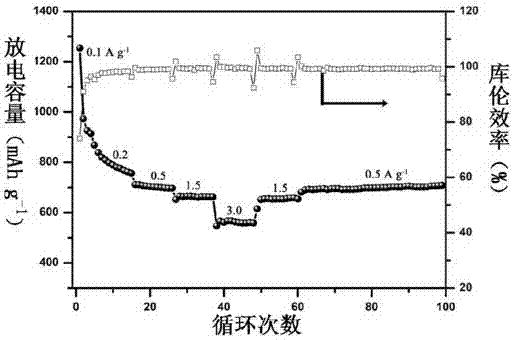

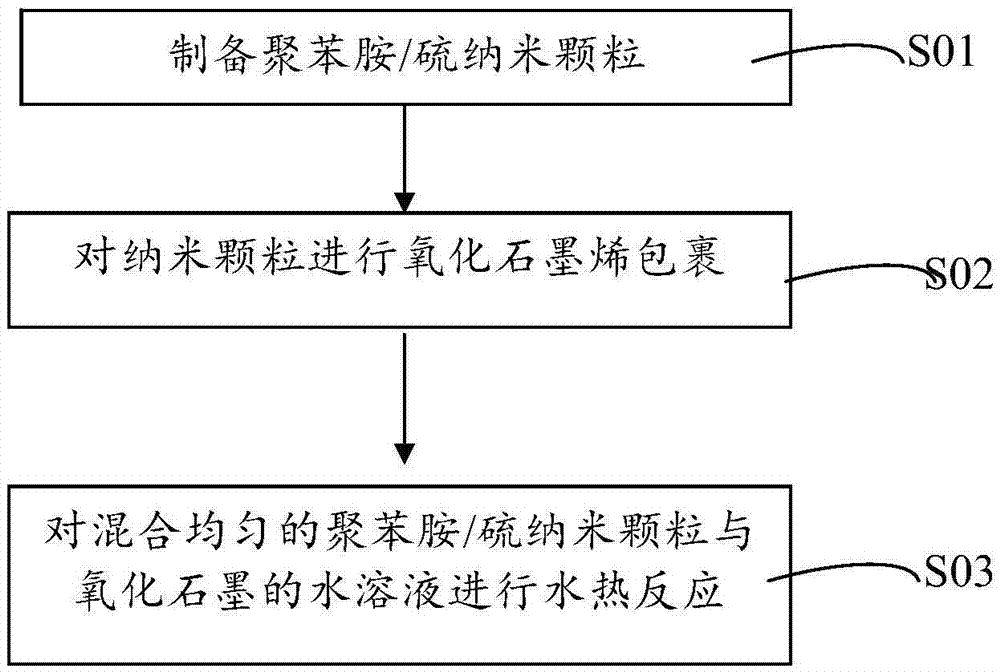

Graphene/polyaniline/sulfur composite cathode material and preparation method thereof, lithium sulfur battery

ActiveCN105449179AEnsure structural stabilityHigh lithium storage capacityCell electrodesSecondary cellsMaterials preparationComposite cathode

The invention provides a graphene / polyaniline / sulfur composite material and a preparation method thereof, a lithium sulfur battery cathode and a lithium sulfur battery. The graphene / polyaniline / sulfur composite material takes polyaniline / sulfur nano-particles as base bodies and packages and reduces graphene nanosheets in situ. The graphene / polyaniline / sulfur composite cathode material preparation method comprises preparing polyaniline / sulfur nano-particles, carrying out oxidation grapheme package to the polyaniline / sulfur nano-particles, carrying out water heat treatment to the packaged material. The lithium sulfur battery cathode and the lithium sulfur battery all contain the graphene packaged polyaniline / sulfur composite cathode material which endows good cycle performance and rate capability to the lithium sulfur battery. The graphene / polyaniline / sulfur composite cathode material has excellent conductivity and structure stability, is simple in preparation method and is suitable for industrial production.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method of electrode plate, electrode plate and secondary battery

PendingCN114203969AGuaranteed capacityGuaranteed rate performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batterySlurry

The invention provides a preparation method of an electrode plate, the electrode plate and a secondary battery, and the preparation method comprises the following steps: S1, mixing and dispersing an electrode active material, a binder, a conductive agent and a solvent to prepare slurry with the solid content of 30-90%; s2, concentrated solvent removal is conducted on the slurry obtained in the step S1, and powder with the solid content being 90% or above is obtained; and S3, pressing the powder obtained in the step S2 to at least one surface of a current collector through dry-method compounding equipment to obtain the electrode plate. Compared with the prior art, the preparation method provided by the invention adopts a dry-wet combined process to prepare the thick electrode, ensures that the slurry is uniformly dispersed on the current collector, and greatly reduces the transmission difference between electrons and ions, thereby ensuring the capacity and rate capability of the battery.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com